Gambro Prismaflex User training

Prismaflex Machine

Prismaflex Schematic

Communication Unit

• Give a general indication of

operating conditions.

• Status Lights

– Green Indicates all parameters

are normal during treatment

–YellowIndicates advisory or

caution alarm

–RedIndicates highest priority

alarm and needs immediate

intervention.

Interactive display is your command center.

It provides screens to guide you through the

functionalities of the machine. The contents of the

display depend on the software mode and

operations at the moment.

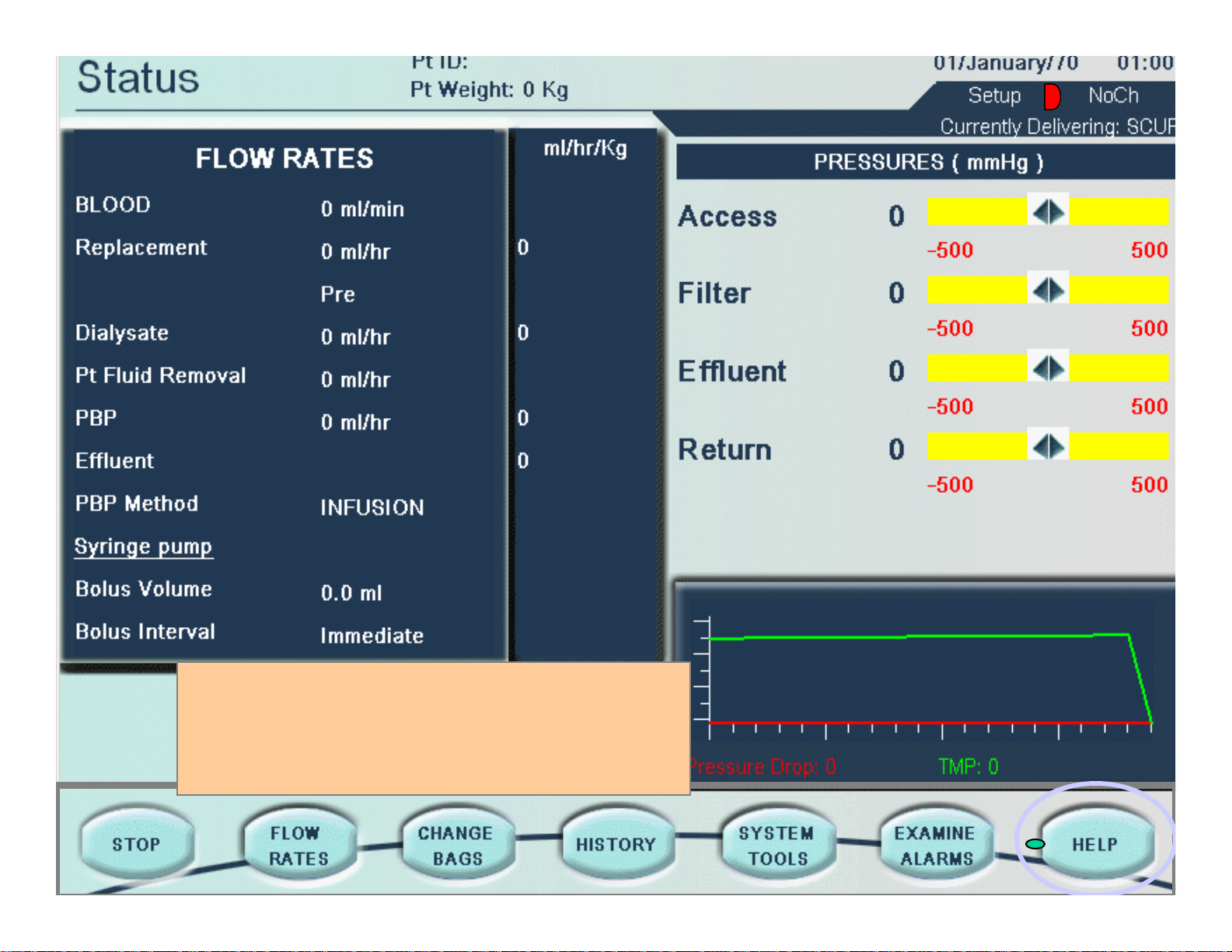

The status screen is the main operating

screen while a treatment is underway. You

can see pressure conditions in the set and

the flow rate settings at a glance.

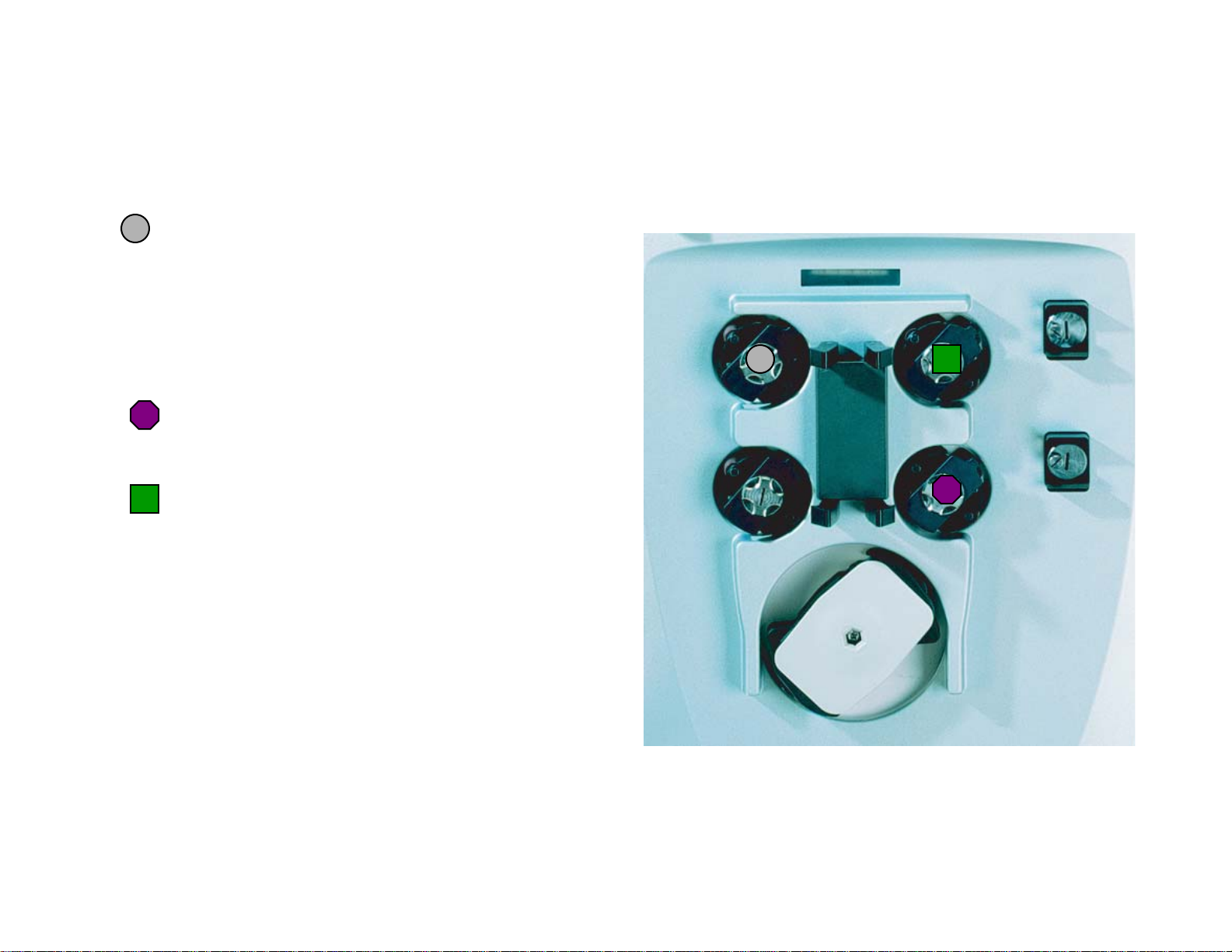

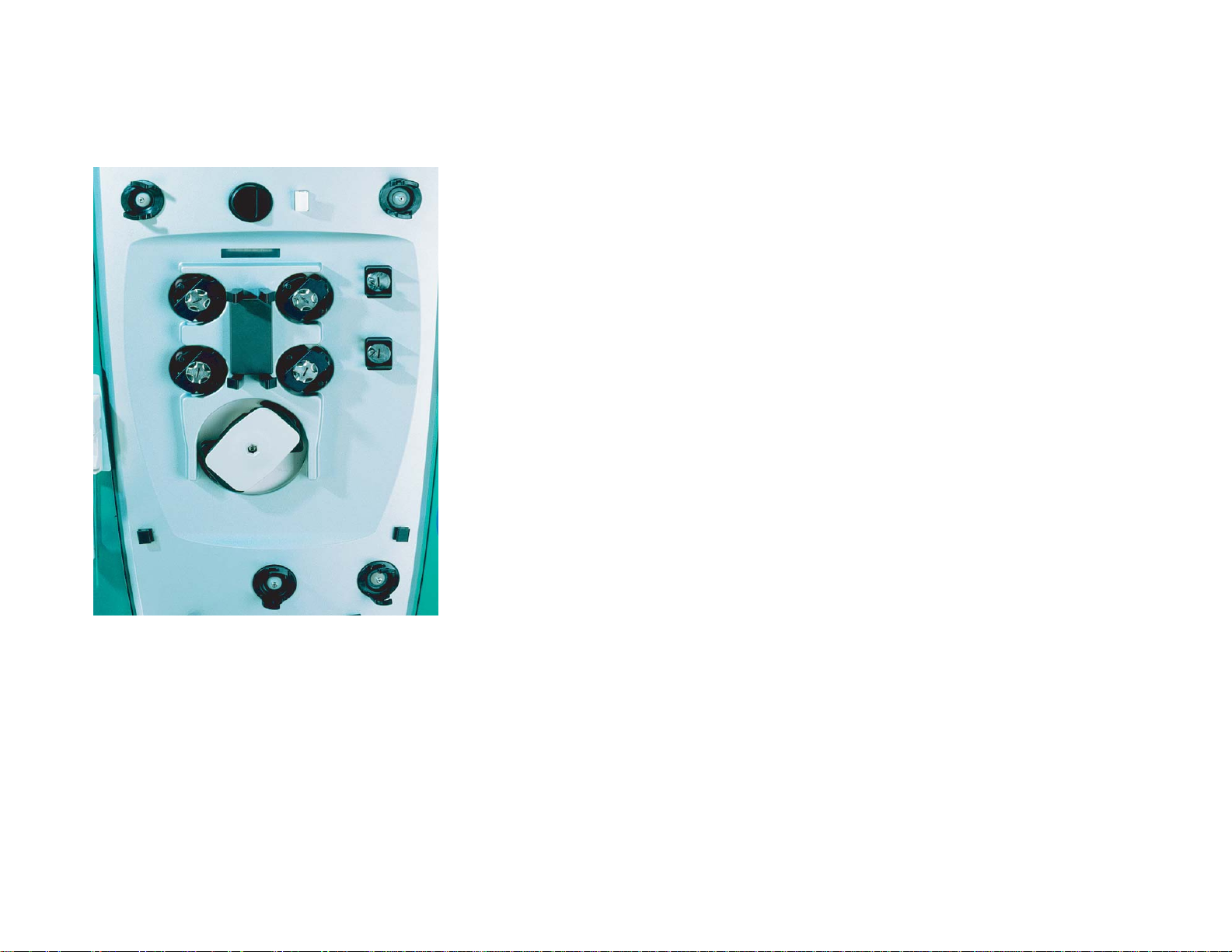

Flow Control Unit

Control Unit

Effluent pump: Pumps ultrafiltrate/dialysate.

Automatically controls the ultrafiltration rate

in the filter, based on the current patient fluid

removal, pre-blood pump, replacement and

dialysate pump rates. Max flow: 10,000ml/hr

Pumps replacement solution into the blood

flowpath. Max flow: 8000ml/hr

Pumps dialysate into the fluid compartment of

the filter. Max flow:

8000ml/hr.

Pinch Valves:

Mechanisms that hold the pinch valve

segments of the Prismaflex Set. The valves

open/close automatically and allow pre and

post filter options for infusing replacement

solution.

Flow Control Unit

Blood pump

Occlusive, peristaltic pump that conveys

blood through the blood flowpath of the

set and back to the patient. Blood

source may be directly from patient, or

from a device, such as an ECMO

machine. Flow rate up to 450ml/min.

Pre-blood pump (PBP)

Can be used to deliver a sterile infusion

solution into the blood access line

before the blood pump. May be used for

anticoagulation strategies or for predilution. Max flow rate: 8000ml/hr.

Prismaflex does not allow the PBP rate

to exceed the blood flow rate.

Control Unit

Scale hook assembly

Slide-out bar tray and removable

carrying bar for hanging/removing

fluid bags. Rotate the handle of the

carrying bar downwards, then push

the bar tray into the scale to close it.

Scales

Effluent

Pre-blood pump (PBP)

Dialysate

Replacement

Precision scales independently

monitor the weight of each bag and

control ultrafiltration and patient fluid

removal.

Tubing guides

Secure the lines of the set in position

on the control unit. The guide color

matches the color of the set line it

holds.

Flow Control

Pressure sensor housing

Access

Filter

Effluent

Unused (for future therapies)

Each pressure sensor housing holds the

corresponding pressure pod of the Prismaflex

Set and provides a connection between the pod

and an internal pressure sensor. This provides

non-invasive pressure monitoring of the access

line, filter, and effluent line. There are no airblood interfaces.

Control Unit

Syringe pump assembly

Delivers anticoagulant or other solution into the blood

flowpath via a syringe. Delivery can be continuous or

in boluses (See Prismaflex Operator Manual for

specification).

Syringe pump control panel

UP and DOWN buttons on the machine allow you to

install or remove a syringe.

Bar code reader

Each type of Prismaflex Set has its own range of

alarm limits and flow rate possibilities. When a set is

loaded, the bar code reader automatically scans the

identification code. The control unit then accesses the

correct operating ranges and priming sequence. This

is an important, proactive safety feature.

Control Unit

Cartridge carrier

Houses the cartridge of the

Prismaflex Set and moves inward

to automatically load the set into

the pumps raceways.

Blood leak detector (BLD)

Continuously monitors the effluent

line for the presence of red blood

cells.

Discharger ring guide

Holds the discharger ring, located

on the effluent line of the

Prismaflex Set. Provides an

electrical ground and minimizes

electrical interference with other

ICU devices.

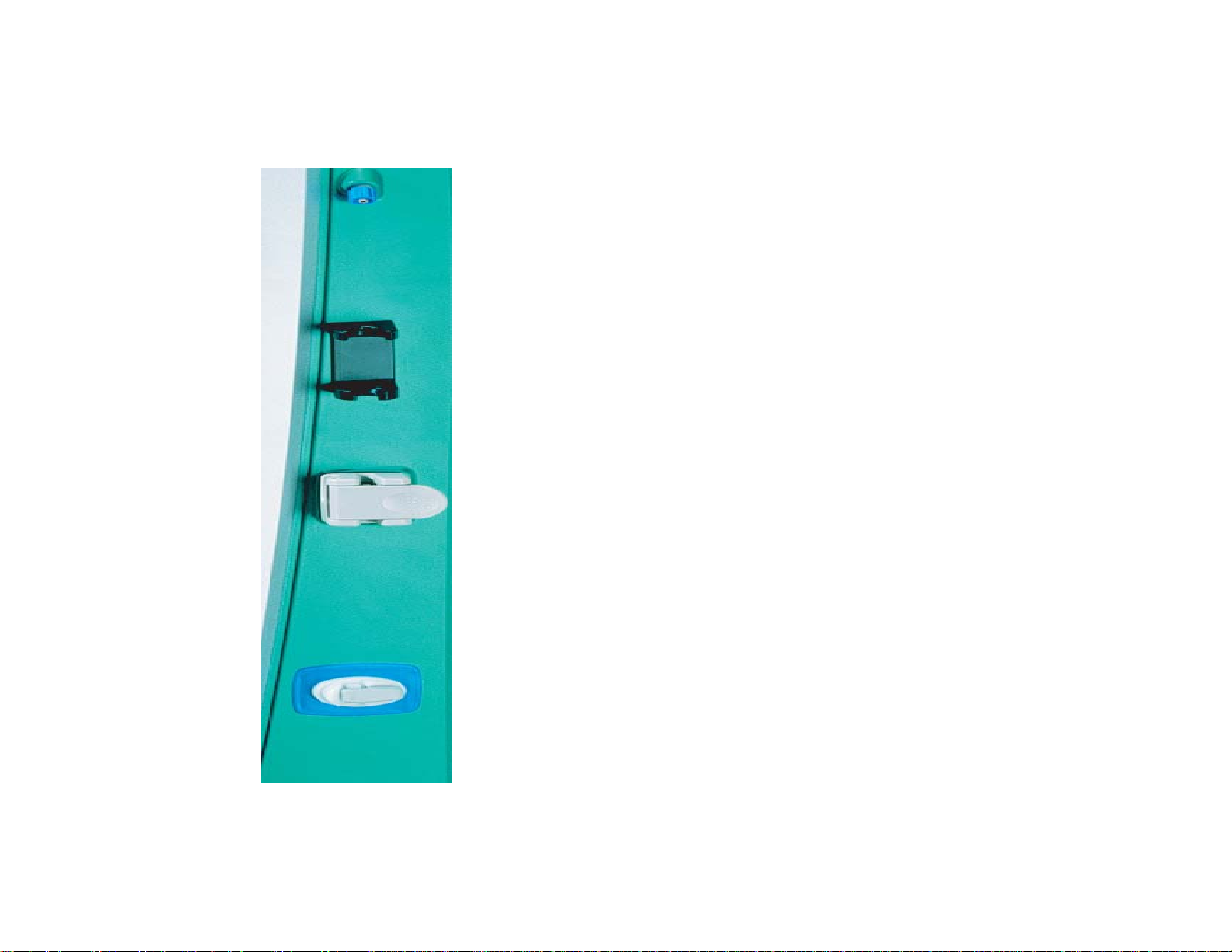

Control Unit

Return pressure port

Provides a connection between an internal pressure

sensor and the monitor line of the set’s deaeration

chamber. Non-invasive pressure monitoring of the

deaeration chamber and return line is provided. A

fluid barrier in the monitor line protects the interior

of the control unit form accidental fluid entry.

Deaeration chamber holder

Secures the deaeration chamber, which is located

on the return line of the Prismaflex Set.

Ultrasonic air bubble detector (UABD)

Continuously monitors the return line for air

bubbles. Within the housing are also a tubing

detection switch and a blood sensor. These sensors

provide additional monitoring of return line

conditions while you are setting up for treatment.

Return line clamp

This occlusive safety clamp closes if any condition

of possible patient hazard is detected. The clamp

prevents blood and/or air from passing to the

patient. A tubing detection switch is also in the

clamp housing, allowing Prismaflex to notify you if

the return line is not correctly installed in the clamp.

Sets, Therapies and Bags

SAMPLE SITES

•Effluent line

•Access line before the blood pump

•Access line (filter) after the blood pump

•Return line before the blood warmer

connectors and deaeration chamber.

Sample sites are color-coded ports with a

latex free plug that allows needle entry. You

can use these to obtain fluid or blood

samples, or to remove trapped air.

BLOOD WARMER CONNECTOR

This luer-lock connector allows you to attach a

disposable set for a blood warmer. The

connection is made to the return line before

the deaeration chamber. The warmer set must

be connected during Setup procedures—it is

automatically primed along with the

Prismaflex Set.

Sets, Therapies and Bags

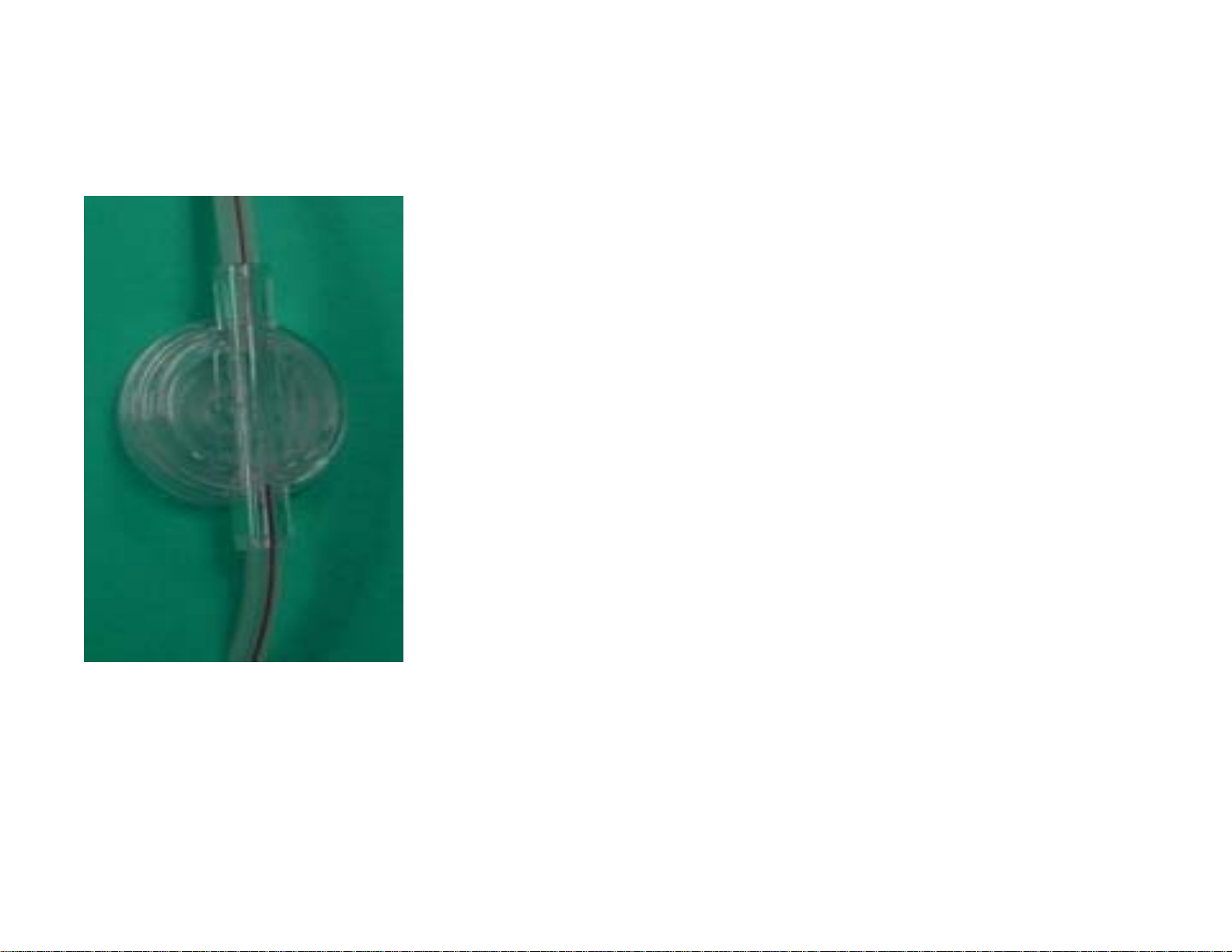

DEAERATION CHAMBER

Manages air

Bottom to tope blood flow in the set promotes continuous

elimination of air. In the return line, the dearation chamber provides

a unique conveyance path that works like a vortex to propel all air

out of the blood. Post-filter replacement solution is added into the

deaeration chamber on top of the blood. Using a minimum of 200

to 500 ml/hr of post filter replacement will prevent air/blood

interface. This is recommended to minimize clotting and foaming

into deaeration chamber.

Semi-automated fluid level adjustment

Arrow keys on a special screen allow you to easily adjust the fluid

level up or down in the chamber.

DEAERATION CHAMBER MONITOR LINE

Connects the deaeration chamber to an internal pressure sensor,

enabling return pressure monitoring and removal of air from the

chamber, if needed. A fluid barrier at the end of the line protects the

interior of the control unit form accidental blood/fluid entry.

Tightening the connections is part of your usual setup and

treatment management duties.

Sets, Therapies and Bags

PRESSURE PODS

Effluent

Access

Filter

These integral pressure monitoring

components connect with pressure

sensors inside the machine. A

diaphragm in the pod moves according

to the pressure exerted by the fluid

flowing in the line. The internal pressure

sensor converts this motion to a

pressure reading…

When treatment begins, access pressure

is sensed to establish the type of blood

source (negative or positive pressure).

Software then activates the correct

access pressure monitoring range.

Sets, Therapies and Bags

Discharger ring

This component on the effluent line

installs in the ring guide on the control

unit. Provides an electrical ground and

minimizes electrical interference with other

ICU devices.

Spike/Luer lock connector

Located at the tip of each solution line,

you may use either the spike or the luer

lock to connect to the fluid bags. If you’re

using the luer lock, you need to remove

the spike.

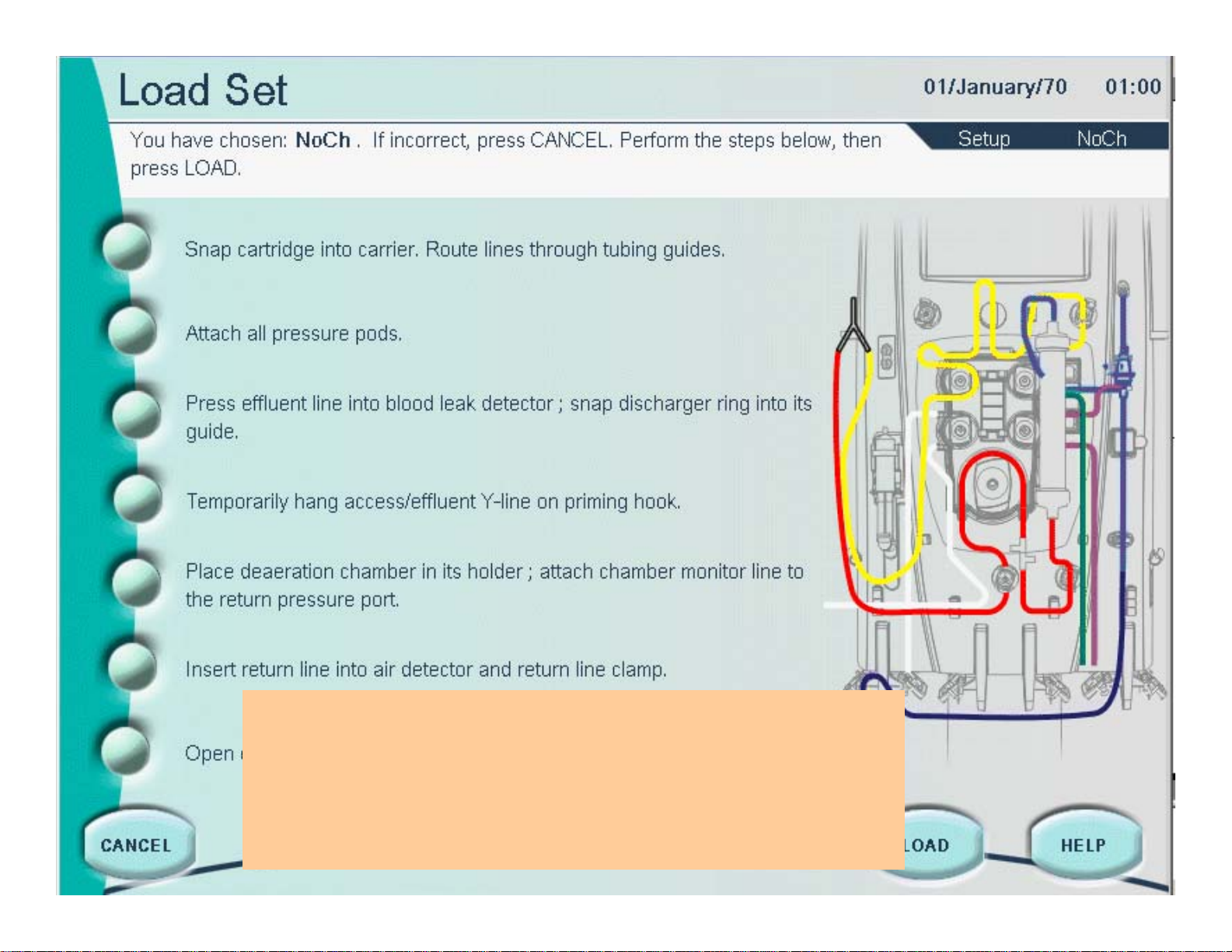

Loading...

Loading...