Prismaflex

®

Service Manual

For use with software version 7.xx

Manufacturer:

Gambro Lundia AB

Box 10101, Magistratsvägen 16, SE-220 10 Lund, Sweden

Tel: +46-46-16 90 00, Fax: +46-46-16 96 96

www.gambro.com

Questions or comments about this publication can be directed to your local representative or to the manufacturer.

Order number:

G5005209

Copyright:

© 2005–2012 Gambro Lundia AB

Gambro, Prismaflex, Adsorba, Prismaflo, Prismacomfort, Prismatherm, MARSFLUX, diaFLUX, diaMARS, X-MARS,

septeX, oXiris, Hospal and MARS are trademarks belonging to the Gambro Group.

G5005209

Program version 7.xx

This page is intentionally left blank

Program version 7.xx

G5005209

Prismaflex®Service Manual

1. Before you get started

2. Installation Guide

3. Technical Description

4. Function Check

5. Alarms and Troubleshooting

6. Maintenance

7. Schematics

8. Specifications

9. Equations

G5005209

Program version 7.xx

Contents

1. Before you get started

AboutthisManual ...............................................

KeywordsUsedinthisManual .....................................

Complaint .....................................................

Responsibility and Disclaimer . .....................................

Safety Definitions ...............................................

Maintenance ...................................................

CompetenceofServiceEngineers ...................................

TechnicalSupport ...............................................

Symbols ......................................................

ElectricalSafety ..............................................

Instructionsandwarnings .......................................

Information .................................................

Communication ..............................................

Environmental ...............................................

Transportationandstorage ......................................

Solutions ...................................................

CertificationMarks ............................................

Disposal ......................................................

DisposalofDiscardedEquipment .................................

2. Installation Guide

1:2

1:2

1:3

1:3

1:4

1:5

1:5

1:5

1:6

1:6

1:6

1:7

1:8

1:8

1:8

1:9

1:10

1:10

1:10

AboutthisChapter .................................................

Installation .......................................................

Contents of Prismaflex

Electrical Requirement

Electromagnetic Envir

®

s ...........................................

onmentRequirements ...........................

olUnitShippingCarton ...................

Contr

SpaceRequirements .............................................

Unpacking and Assem

bly .........................................

Unpacking ..................................................

Connect Power Co

Install Scal

eCarryingBars ......................................

Attachment

Change of S

®

Prismafl

Electr

Insta

pdate .......................................................

SW u

libratethedisplay ................................................

Ca

3. Technical Description

ex

icalSafetyInspection .....................................

llationTest ..............................................

rd ...........................................

ofcautionlabel .....................................

yringeClip ........................................

ControlUnitCalibrations .............................

Prismaflex®ControlUnit ............................................

®

Prismaflex

Prismaflex

ControlUnitFunctions ..................................

®

ControlUnitComponents ...............................

FrontPanelComponents ..........................................

RearPanelComponents ...........................................

InteriorComponents .............................................

Interior—Door(Closedhatch) ................................

Interior—Door(Openedhatch) ...............................

2:2

2:3

2:3

2:4

2:4

2:4

2:4

2:4

2:5

2:6

2:6

2:7

2:7

2:8

2:8

2:11

2:12

3:2

3:2

3:3

3:3

3:14

3:16

3:16

3:16

Program version 7.xx

G5005209

Interior—Front1 ..........................................

Interior—Front2 ..........................................

Interior—Front3 ..........................................

Interior—Front4 ..........................................

ElectricalDescription ...............................................

InternalConnections .............................................

Modules ......................................................

PowerSupply ................................................

CarrierBoard ................................................

ControlCPU .................................................

ProtectiveCPUboard ..........................................

ARPSboard .................................................

PIBboard ...................................................

Alarmlightmodule ...........................................

LVDSinterfaceboard ..........................................

ExternalRS232board ..........................................

ExternalEthernetboard ........................................

ExternalRemoteAlarmConnector ................................

Fluidpumps .................................................

Bloodpump .................................................

Syringepump ................................................

Loader .....................................................

Scales ......................................................

ABDassembly ...............................................

Signals .....................................................

3:18

3:20

3:22

3:24

3:28

3:28

3:31

3:33

3:34

3:35

3:36

3:38

3:40

3:41

3:41

3:41

3:41

3:42

3:42

3:42

3:43

3:43

3:43

3:44

3:45

4. Function Check

AboutthisChapter .................................................

Main-controlledComponents ......................................

Self–tests ........................................................

Operating System Initialization .....................................

Initialization Test ................................................

PrimeSelf-test ..................................................

Pre-Prime ...................................................

Post-Prime ..................................................

PeriodicSelf-test ................................................

AlarmMonitoringDuringthePeriodicSelf-Test ......................

TechnicalScreens ..................................................

FirstTechnicalScreen ............................................

SecondTechnicalScreen ..........................................

ThirdTechnicalScreen ...........................................

FourthTechnicalScreen ..........................................

FifthTechnicalScreen ............................................

SixthTechnicalScreen ...........................................

5. Alarms and Troubleshooting

4:2

4:3

4:4

4:4

4:5

4:8

4:8

4:13

4:21

4:23

4:24

4:24

4:29

32

4:

:35

4

4:36

4:37

G5005209

Program version 7.xx

Aboutthischapter .................................................

WarningAlarms ...................................................

®

Prismaflex

ControlUnitActions ...................................

OperatorResponse ..............................................

OverriddenWarningAlarms .......................................

MalfunctionAlarms ................................................

5:2

5:3

5:3

5:3

5:4

5:5

Prismaflex®ControlUnitActions ...................................

OperatorResponse ..............................................

OverriddenMalfunctionAlarms ....................................

CautionAlarms ...................................................

®

Prismaflex

ControlUnitActions ...................................

OperatorResponse ..............................................

AdvisoryAlarms ..................................................

®

Prismaflex

ControlUnitActions ...................................

OperatorResponse ..............................................

OverriddenAdvisoryAlarms .......................................

Alarm Priorities . . .................................................

AlarmPriorityList ..............................................

Troubleshooting ...................................................

AbouttheTroubleshootingChapter ..................................

WarningAlarms ...................................................

CautionAlarms ...................................................

AdvisoryAlarms ..................................................

MalfunctionAlarms ................................................

Miscellaneous ....................................................

PowerFailure .....................................................

6. Maintenance

5:5

5:5

5:6

5:7

5:7

5:7

5:8

5:8

5:8

5:8

5:9

5:9

5:14

5:14

5:15

5:39

5:48

5:66

5:97

5:101

AboutthisChapter .................................................

ElectricalSafetyInspection ..........................................

General .......................................................

Visualinspection .............................................

PET-ProtectiveEarthTest ......................................

Note: ....................................................

Testequipment ............................................

Test .....................................................

CheckofConductivityClip .....................................

Testequipment ............................................

Test .....................................................

ELT/PLT ...................................................

Testequipment ............................................

General conditions for ELT / PLT ..............................

ELT-EarthLeakageCurrentTest ..............................

PLT-PatientLeakageCurrentTest .............................

Test .....................................................

RecordofElectricalSafetyInspection ................................

Visualinspection ...........................................

Remarks: .................................................

ConductivityClipTest .......................................

PET-ProtectiveEarthTest ...................................

ELT-EarthLekageCurrentTest ...............................

PLT-PatientLeakageCurrentTest ..............................

ComponentreplacementwithneededESI .............................

PreventiveMaintenance .............................................

ToolsNeeded ..................................................

WorkingTime ..................................................

®

Prismaflex

PMKit ..............................................

VisualInspectionandCleaning .....................................

ComponentReplacement ..........................................

6:3

6:4

6:4

6:5

6:5

6:5

6:5

6:5

6:6

6:6

6:6

6:6

6:6

6:6

6:6

6:7

6:8

6:9

6:

:9

6

6:9

6:9

6:10

6:10

6:12

6:13

6:13

6:14

6:14

6:15

6:17

9

Program version 7.xx

G5005209

PowerSupplyCheck .............................................

ExchangeofLeadBatteriesforBatteryBackup ......................

ServiceMode-CheckoutusingServiceDiagnoseMode ..................

ServiceScreens ...................................................

Service-DiagnoseScreens ...........................................

DiagnoseScreen–PumpsDiagnose .................................

DiagnoseScreen–ScaleDiagnose ..................................

Diagnose Screen – Pressure Pod Reposition . . . .........................

DiagnoseScreen–AlarmsToneandLight ............................

DiagnoseScreen–AirDetector .....................................

DiagnoseScreen–SyringePump ...................................

DiagnoseScreen–ClampandPinchValves ...........................

DiagnoseScreen–BLD(BloodLeakDetector) .........................

DiagnoseScreen–Internal ........................................

DiagnoseScreen–Communication ..................................

DiagnoseScreen–PMtimerandDate ................................

DiagnoseScreen–CleanScreen ....................................

Diagnose Screen – SW Configuration ................................

DiagnoseScreen–2DBarcode .....................................

ServiceCalibrationScreens ..........................................

Calibration Screen – Language Configuration ..........................

CalibrationScreen–ScalesCalibration ...............................

Calibration Screen – Pressure Sensors Calib

Calibration Screen – Syringe Pump Calibra

Calibration Screen – Filter Clotti

Calibration Screen – Set Clock an

Calibration Screen – Screen Bri

Calibration Screen – Pitch an

Calibration Screen – Extern

Calibration Screen – Ther

Calibration Screen –

Calibration Screen

Calibration Scre

Calibration Scr

Calibration S

Calibration

Calibrati

Calibra

Calibr

Funct

alCheck ......................................................

Fin

onScreen–SupplementarySyringe ...........................

tion Screen – Settings Handling ...............................

ation Screen – Blood Warmer Configuration ......................

ionalTest ....................................................

en–SerialNumber ..................................

een–AirDetector ...................................

creen–IPSettings ....................................

Screen – Syringe Holder Configuration ......................

apy/Sets Configuration ........................

Anticoagulation Configuration .....................

–AnticoagulationSolutions .........................

ngLimits ............................

dDate ..............................

ghtnessCalibration ......................

dVolume ...............................

alCommunicationInterface ..................

ration .......................

tion .........................

6:20

6:20

6:21

6:22

6:24

6:26

6:28

6:30

6:32

6:34

6:36

6:41

6:43

6:44

6:45

6:53

6:55

6:56

6:57

6:58

6:60

6:61

6:64

6:66

6:68

6:69

6:70

6:71

6:72

6:73

6:76

6:78

6:84

6:85

6:86

6:87

6:88

6:90

6:92

6:94

6:97

G5005209

Program version 7.xx

7. Schematics

8. Specifications

Performance ......................................................

FlowRatesandAccuracy .........................................

BloodFlowRate .............................................

AutomaticBloodReturnVolume .................................

ReplacementSolution/FluidFlowRate .............................

DialysateFlowRate ...........................................

PBPSolutionRate ............................................

Patient Fluid Removal Performance / Patient Plasma Loss Performance . . . .

8:3

8:3

8:3

8:3

8:3

8:3

8:4

8:4

EffluentFlowRate ............................................

Syringe Settings ................................................

Systemic, Prismaflexsyringepumpanticoagulationmethod .............

Citrate – Calcium, PrismaflexSyringePumpanticoagulationmethod ......

TPESettings ...................................................

Pressuresensorrange,accuracyandalarmlimits ........................

Access .....................................................

Return .....................................................

Filter ......................................................

Effluent ....................................................

Patientsafety ...................................................

AirBubbleDetector ...........................................

BloodLeakDetector ...........................................

Alarmsignals .....................................................

Audible .......................................................

Soundpressurelevels ..........................................

Characteristics ...............................................

Visual ........................................................

PhysicalData .....................................................

Weight,dimensions,etc. ..........................................

ScalesCharacteristics ............................................

ScaleWeightRange ...........................................

Scaleaccuracy: ...............................................

Power ........................................................

Linepower ..................................................

Batterybackup ...............................................

Externalcommunication ..........................................

Environmentaldata ................................................

Operation .....................................................

Transportation and Stora

ge ........................................

Noiselevel ....................................................

Vibrationlevels .................................................

Fluid spillage . . .................................................

Cleanability . . . .................................................

Electromagne

Electrical S

AC Leakage

Defibril

Radio F

romagnetic Compatibility .....................................

Elect

entialEqualization ............................................

Pot

ntinuousOperation ............................................

Co

onformitytoInternationalRules ......................................

C

ticEmissionsandImmunity .............................

afety ...................................................

Current .............................................

lation-proofAppliedPart ....................................

requencyInterference ......................................

Medical Device Classification ........................................

®

Prismaflex

DisposableSets ..........................................

CRRTDisposableSets ..............................................

Low flowsets ..................................................

Priming parameters and Blood flowrates ...........................

Patient fluid removal and Patient fluidloss/gainlimit ..................

Solution flowrates ............................................

Return Blood and Recirculation flowrates ..........................

High flowsets ..................................................

Priming parameters and Blood flowrates ...........................

Patient fluid removal and Patient fluidloss/gainlimit ..................

8:4

8:5

8:5

8:6

8:6

8:6

8:6

8:7

8:7

8:9

8:9

8:9

8:9

8:10

8:10

8:10

8:10

8:10

8:11

8:11

8:11

8:11

8:11

8:11

8:11

8:12

8:12

8:13

8:13

8:13

8:13

8:14

8:14

8:14

8:14

8:19

8:19

8:19

8:19

8:19

8:20

8:20

8:21

8:22

8:23

8:24

8:24

8:24

8:24

8:25

8:25

8:26

8:26

8:26

Program version 7.xx

G5005209

Solution flowrates ............................................

Return Blood and Recirculation flowrates ..........................

TPEDisposableSets ...............................................

Low flowsets ..................................................

Priming parameters and Blood flowrates ...........................

Return Blood and Recirculation flowrates ..........................

High flowsets ..................................................

Priming parameters and Blood flowrates ...........................

Return Blood and Recirculation flowrates ..........................

HPKits .........................................................

Priming parameters and Blood flowrates ..............................

Return Blood and Recirculation flowrates .............................

9. Equations

8:27

8:27

8:28

8:28

8:28

8:28

8:29

8:29

8:29

8:30

8:30

8:30

Blood pump flowrate ............................................

Filter pressure drop . . . ...........................................

Effluent flowrate ................................................

Transmembranepressure ..........................................

Totalpredilution ................................................

CRRTprescriptionindicators .......................................

Filtration Fraction ..........................................

Doses ...................................................

Patient fluidremoved .............................................

Accesstransmembranepressure ....................................

SoftwareCalculationsofTargetPatientPlasmaLoss .....................

FormulasusedinTPE ............................................

Patientplasmaloss ..............................................

PBP flowrate ..................................................

Syringe flowrate ................................................

9:2

9:2

9:2

9:3

9:3

9:3

9:3

9:4

9:5

9:5

9:5

9:6

9:6

9:7

9:7

G5005209

Program version 7.xx

This page is intentionally left blank

Program version 7.xx

G5005209

Chapter 1

Before you get started

AboutthisManual .....................................

KeywordsUsedinthisManual ...........................

Complaint ...........................................

Responsibility and Disclaimer . . ..........................

Safety Definitions .....................................

Maintenance .........................................

CompetenceofServiceEngineers .........................

TechnicalSupport .....................................

Symbols ............................................

ElectricalSafety ....................................

Instructionsandwarnings .............................

Information .......................................

Communication ....................................

Environmental .....................................

Transportationandstorage ............................

Solutions .........................................

CertificationMarks ..................................

Disposal ............................................

DisposalofDiscardedEquipment .......................

1:2

1:2

1:3

1:3

1:4

1:5

1:5

1:5

1:6

1:6

1:6

1:7

1:8

1:8

1:8

1:9

1:10

1:10

1:10

G5005209

Program version 7.xx

Prismaflex®Service Manual - Before you get started

1:1

About this Manual

This service manual provides the informationneededtoinstall

the Prismaflex control unit, to carry out maintenance, component

replacements and calibrations. It is a guidance on how to identify and

repair faults that may occur.

All available spare parts to be used for the Prismaflex control unit are

found in the illustrated Spare Parts List.

This service manual also provides a technical description of the

functionality of the Prismaflex control unit, including technical data.

Keywords Used in this Manual

Authorized service technicians

This term refers to Gambro trained and certified service technicians.

Filter

Depending on the therapy in use, Filter stands for either:

• Hemofilter/Dialyzer

• Plasmafilter

• Hemopurification cartridge

Manual

The term Manual refers to this Service Manual unless specified

differently.

Operator

In this manual, Operator designates appropriately trained and qualified

clinical staff who is in charge of t

he Prismaflex control unit. The

operator sets the prescribed values in accordance with the prescribed

treatment, responds to alarms, troubleshoots the Prismaflex control

unit, handles the bags, etc.

Once the training material is read

through and understood, the operator is approved to operate the

Prismaflex control unit. The operator works within one meter from the

front of the Prismaflex co

ntrol unit.

Responsible Organization

In this manual, Responsible Organization means a function or a person

who can identify, analyze, and control potential risks that could occur,

for example, when connecting the Prismaflex control unit to other

equipment or when making changes to the equipment connected to

the Prismaflex control unit.

1:2

Screens

The Prismaflex control unit displays different screens during operation.

Whenever a screen is referred t o in this manual, it is identified by its

title, e.

g. Enter Flow Settings screen or Status screen.

®

Prismaflex

Service Manual - Before you get started

G5005209

Program version 7.xx

Softkeys

Whenever a Softkey on the Prismaflex screen is referred to in this

manual, it is written in capital italic letters, e.g. NEW PATIENT or

CHANGE BAG.

Training Material

The operator's manual is the primary training material for staff who is

to operate the Prismaflex system. See section “Competence of Service

Engineers” on page 1:5, for information concerning the minimum level

of competence required for service engineers.

Complaint

If a c omplaint is raised it shall be communicated to the relevant Gambro

Sales Company. In order for the Sales Company to be able to determine

the relevance of a complaint, it is of vital importance that the deviation

is communicated to them as comprehensive as the issue requires.

Responsibility and Disclaimer

Gambro accepts responsibility for the safety, reliability, and

performance of this equipment only:

• If any modifications to the equipment have been authorized in

writing by Gambro and carried out by an authorized service

technician.

• If the electrical installation for powering the equipment complies

with all applicable local electrical codes and requirements

including, if applicable, IEC requirements.

• If the equipment is used in accordance with the Service Manual

and the Operator's Manual.

Gambro will provide, on request, a service manual which contains

all necessary circuit diagrams, calibration instructions, and service

information to enable authorized service technicians to repair those

parts of t his equipment which Gambro considers to be repairable.

Gambro does not accept any responsibility or liability for use of

accessories or disposables other than those specified in this manual

or if any specified accessory or disposable is not used in accordance

with this manual, online instructions and the Instructions for Use

accompanying those accessories and disposables.

Since Gambro has no control over service work which is not

performed by authorized service technicians, Gambro will in no way

be responsible or liable for any damages resulting from the operation

or performance of a ny device, or any i njury caused thereby, after repair

has been performed by any person other than an authorized service

technician of Gambro.

G5005209

Program version 7.xx

Prismaflex®Service Manual - Before you get started

1:3

Under no circumstances will Gambro be liable for any indirect,

incidental, special or consequential damages of any kind, its liability

being hereby limited solely to repair or replacement.

Safety Definitions

This manual uses the following s afety definitions :

WARNING

A warning alerts the reader about a situation which, if not avoided,

could result in an adverse reaction, injury or death.

WARNING

CAUTION

A caution alerts the reader about a situation which, if not avoided,

could result in minor or moderate injury to the user or patient or

damage to the equipment or other property.

CAUTION

Note: Notes are added to give more information.

1:4

Prismaflex

®

Service Manual - Before you get started

G5005209

Program version 7.xx

Maintenance

To ensure proper operation of the Prismaflex control unit, an authorized

service t echnician must perform a complete series of maintenance

procedures at regular intervals.

The maintenance and calibration information is provided in this

Service Manual, see Preventive Maintenance on page 6:13.

It is mandatory to perform at least one preventive maintenance once a

year or every 6000 hour. The rate of preventive maintenance might be

different due to variations of the operating environment.

Competence of Service Engineers

There is a certain minimum level of competence required for Service

Engineers who maintain and repair Gambro products, summarized

as follows.

A Service Engineer is considered authorized if he/she has:

1. Attended Prismaflex technical service course and has been given a

certificate stating that the technician has passed the course.

2. Access to the recommended test equipment and special tools

detailed in this Service Manual.

3. Access to the recommended Prismaflex control unit - Spare parts

List.

4. Access to and understanding of the Prismaflex control unit - Service

manual and the Prismaflex control unit - Operator's Manual.

In general, this policy implies that training will be carried out by

Gambro Lundia AB, while local markets are responsible for their own

service organization.

Technical Support

For technical support please contact your local Gambro Service

representative or visit the website.

G5005209

Program version 7.xx

Prismaflex®Service Manual - Before you get started

1:5

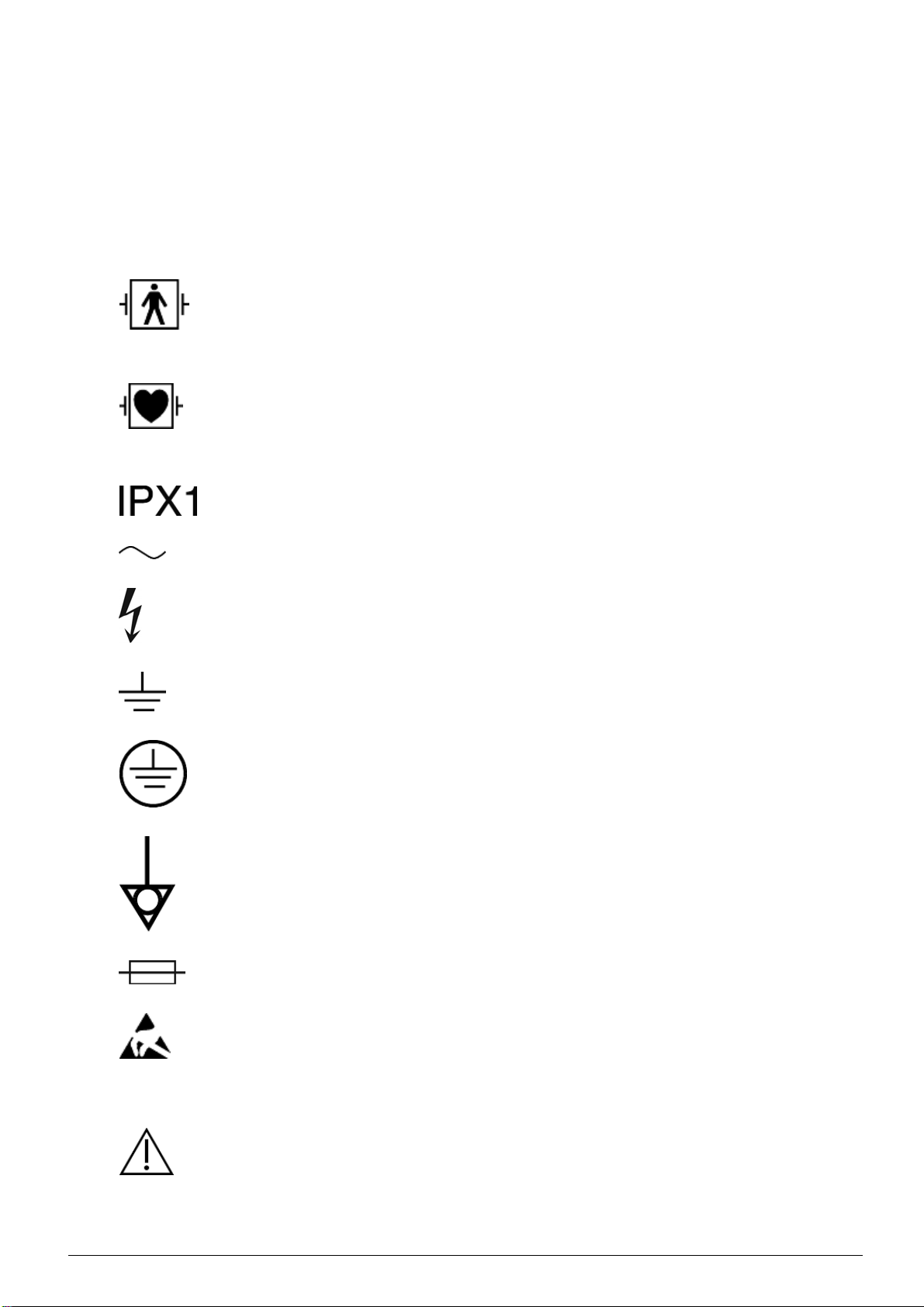

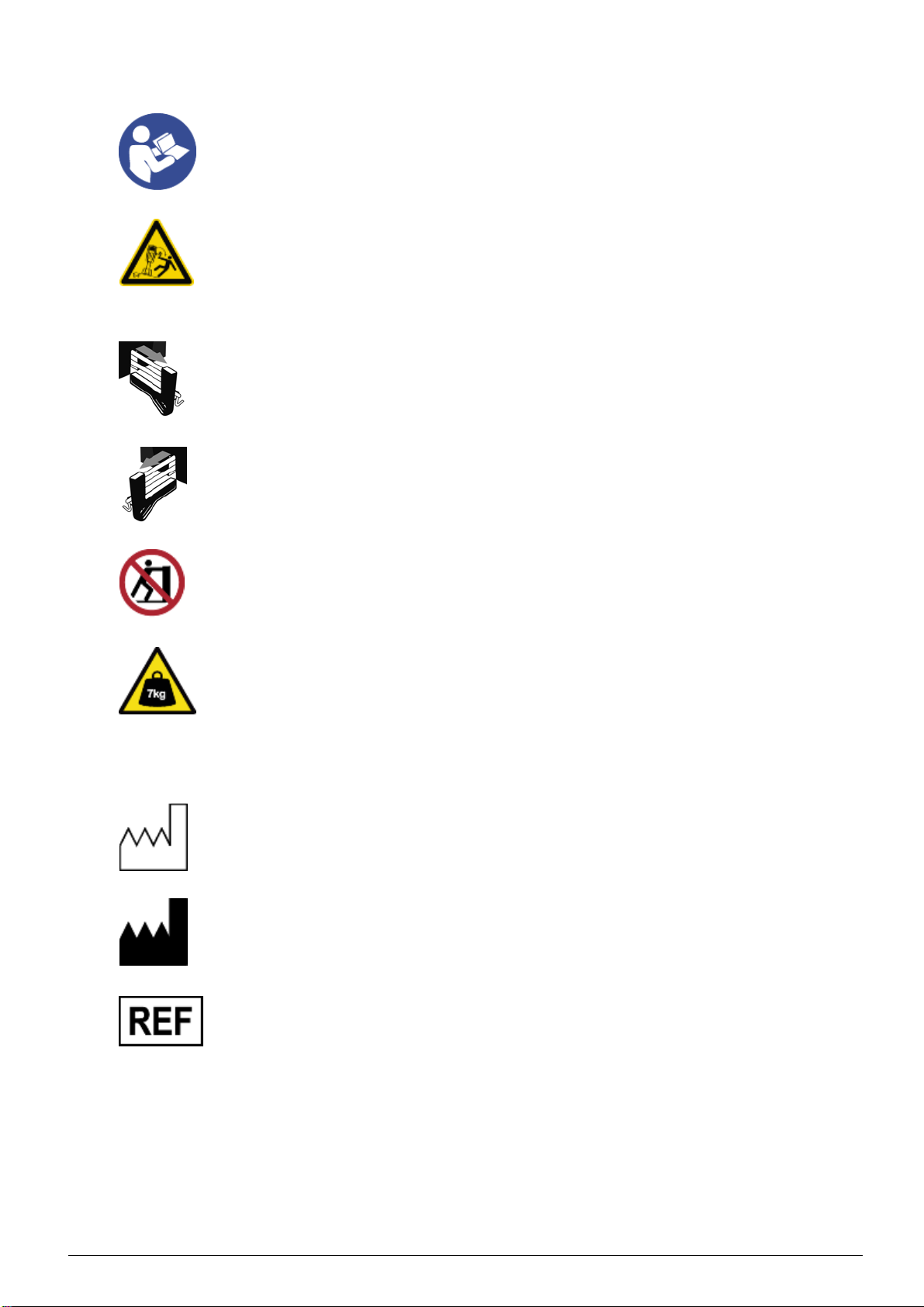

Symbols

If applicable, the following symbols appear on or near the serial

number label or other permanently affixed labels of this device. For

more information, see chapter 8: “Specifications” on page 8:2.

Electrical Safety

Equipment applied part is Type BF, defibrillation - proof per IEC

60601-1.

Note: TobesureofthePrismaflex control unit’s classification see type

label found at the back of the Prismaflex control unit.

Equipment applied part is Type CF, defibrillation-proof per IEC

60601-1.

Note: TobesureofthePrismaflex control unit’s classification see type

label found at the back of the Prismaflex control unit.

Device meets the “drip proof” classification requirements.

Device requires an alternating supply current.

Nearby high-voltage conductors could be hazardous if contacted.

This symbol is located near functional ground locations on this device.

This symbol is located near protective ground locations on this device.

This symbol identifies the point of connection of a potential

equalization conductor.

The terminal is c onnected to the chassis and should be connected to

corresponding terminals on other equipment in order to eliminate

potential differences.

Fuse.

Certain components within this equipment are sensitive to electrostatic

discharge.

1:6

Instructions a

nd warnings

Attention, consult accompanying documents.

®

Prismaflex

Service Manual - Before you get started

G5005209

Program version 7.xx

Read instructions before use.

This symbol warns against an incline of the Prismaflex control unit of

more than 5° from the floor.

Note: This warning label must be applied on the warmer holder before

use. It should be mounted on deliverance. The background color is

yellow.

Pull out scale completely before hanging bag.

Pull out scale completely before hanging bag.

Risk of tipping the Prismaflex control unit from pushing, leaning,

resting, etc. The colors are red, white, and black.

This symbol is applied on the stand if t he Prismaflex calibration weight

kit is stored inside. Calibration weights are to be removed before tilting

the Prismaflex control unit into horizontal position.

The color is black on a yellow background.

Information

Date of manufacture with year as four digits.

Manufacturer. The year of manufacture may be included in the symbol

expressed as four digits.

Catalog number.

G5005209

Program version 7.xx

Prismaflex®Service Manual - Before you get started

1:7

Serial number.

Communication

Ethernet port.

RS232 Serial Communication port.

Remote alarm connection.

Environmental

This symbol indicates that:

– since the equipment contains dangerous substances, it must be

recycled rather than disposed together with other municipal waste;

– the equipment was placed on the market after 13 August 2005.

The device contains toxic or hazardous substances or elements.

Recycle the cardboard.

Transportation and storage

Fragile – handle with care.

Keep dry.

The maximum stacking load permitted on the transport package is

100 kg.

This end up.

1:8

Prismaflex

®

Service Manual - Before you get started

G5005209

Program version 7.xx

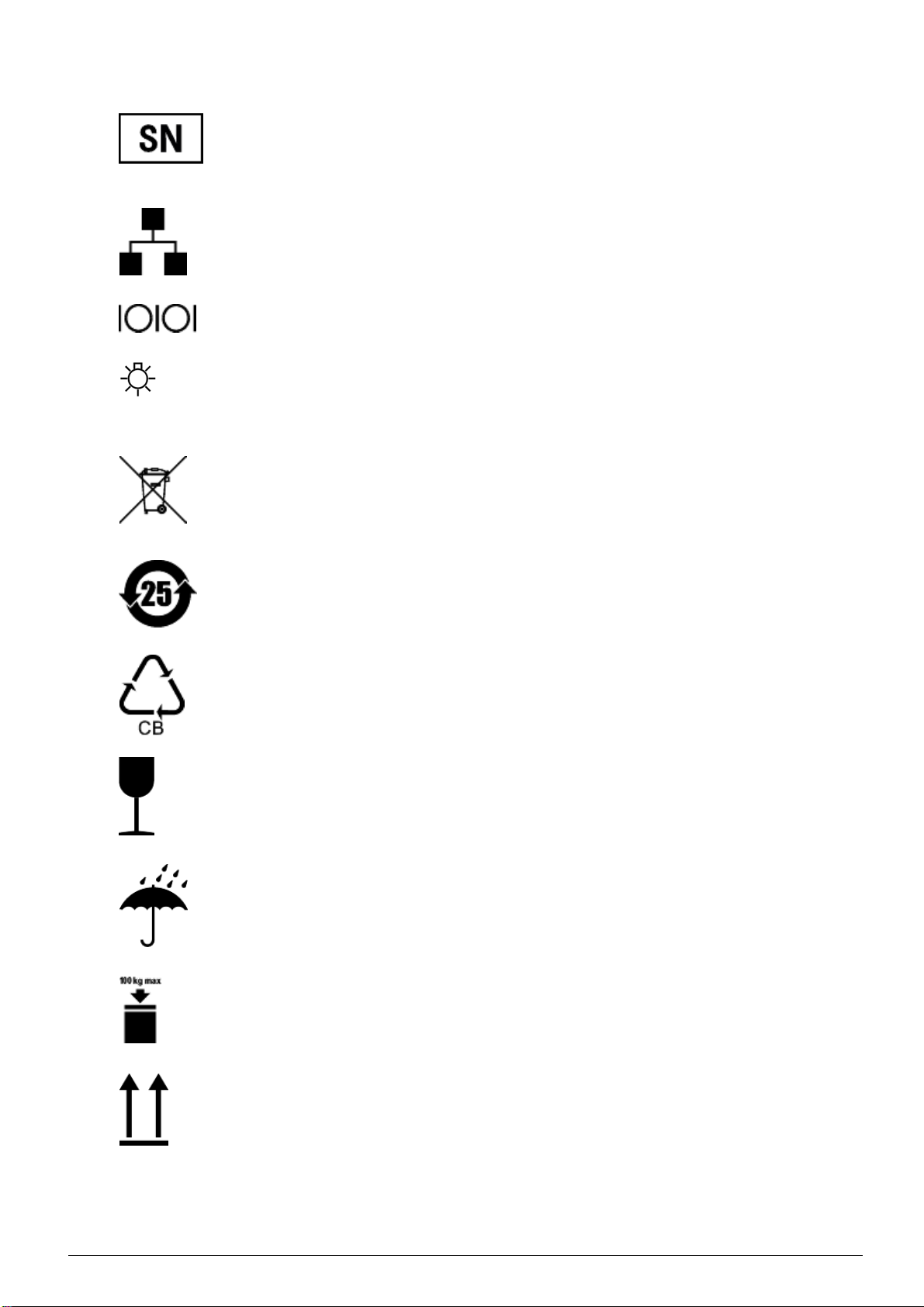

Atmospheric pressure limitation. Upper and lower limits are expressed

with numeric values in kPa.

Humidity limitation. Upper and lower limits are expressed with

numeric values in %.

Temperature limitation. Upper and lower limits are expressed with

numeric values in degrees Celsius or Fahrenheit.

Solutions

Circle sign; placed as colored symbol on effluent scale and in the

graphical user interface in screens related to effluent. On the disposable

set the symbol is a relief shape in the plastic cover indicating the

effluent pump.

Triangle sign; placed as colored symbol on PBP scale and in the

graphical user interface in screens related to PBP. On the disposable

set the symbol is a relief shape in the plastic cover indicating the PBP

pump.

Square sign; placed as colored symbol on dialysate scale and in

the graphical user interface in screens related to dialysate. On the

disposable set the symbol is a relief shape in the plastic cover indicating

the dialysate pump.

Octagon sign; placed as colored symbol on replacement scale and in

the graphical user interface in screens related to replacement. On

the disposable set the symbol is a re

lief shape in the plastic cover

indicating the replacement pump.

G5005209

Program version 7.xx

Prismaflex®Service Manual - Before you get started

1:9

Certification Marks

The CE-conformity mark indicates that the Prismaflex control unit

conforms to the requirements in the EC Council Directive 93/42/EEC

of 14 June, 1993 concerning medical devices. It also indicates that

the notified body British Standards Institution (BSI, No. 0086) has

approved the Quality Management System. The CE conformity mark

is only valid for the Prismaflex control unit. Disposables and any

accessories specified for use with the Prismaflex control unit are

marked with CE conformity marks in their own right.

The CSA (C-US) mark indicates that the Prismaflex control unit

conforms to the requirements related to safety of medical d evices for

the US and Canada. The “C” and the “US” adjacent to the CSA mark

indicate that the Prismaflex control unit has been evaluated to the

applicable ANSI/UL and CSA standards for use in the US and Canada.

The CCC mark indicates that the Prismaflex control unit conforms to

the safety requirements for China Compulsory Certification (CCC) as

described by the competent authority Certification and Accredi

tation

Administration of People's Republic of China (CNCA). The “S”

adjacent to the CCC mark indicates that safety requirements are met.

Disposal

The Prismaflex control unit shipping carton, foam packing, and

other packaging material should be disposed of according to local

regulations.

For the purpose of protecting the environment the Prismaflex control

unit must not be disposed with general domestic waste, but shall be

separately collected for dismantling and recovery. Where applicable

national regulations shall be applied. Consult your relevant Gambro

Sales Company for information.

Disposal of Discarded Equipment

Discarded electromedic

with municipal waste but must be collected separately in order to

guarantee ecologically correct disposal to prevent dispersion of

potential pollutant

Pay attention to the fact that some components of the Prismaflex control

unit (display, ba

tteries, circuit boards, etc.) may contain toxic

substances which, if released into the environment, pose a risk to the

health of living organisms and the environment itself.

al equipment must not be disposed together

s into the environment.

1:10

The Prismaflex control unit contains a lithium energy cell and

a lead-acid battery. The lithium energy cell is embedded in a

semiconduc

tor on the monitor circuit card assembly. When replacing

these components, follow local regulations for proper disposal.

®

Prismaflex

Service Manual - Before you get started

G5005209

Program version 7.xx

Chapter 2

Installation Guide

Contents

AboutthisChapter .......................................

Installation .............................................

®

Contents of Prismaflex

ElectricalRequirements .................................

ElectromagneticEnvironmentRequirements .................

SpaceRequirements ...................................

UnpackingandAssembly ...............................

Unpacking ........................................

ConnectPowerCord .................................

InstallScaleCarryingBars ............................

Attachmentofcautionlabel ...........................

ChangeofSyringeClip ..............................

®

Prismaflex

ElectricalSafetyInspection ...........................

InstallationTest ....................................

SWupdate .............................................

Calibratethedisplay ......................................

ControlUnitCalibrations ...................

ControlUnitShippingCarton .........

2:2

2:3

2:3

2:4

2:4

2:4

2:4

2:4

2:5

2:6

2:6

2:7

2:7

2:8

2:8

2:11

2:12

G5005209

Program version 7.xx

Installation Guide

2:1

About this Chapter

This chapter describes the installation procedure of the

Prismaflex control unit. The installation must be performed by an

authorized service technician.

2:2

Installation Guide

G5005209

Program version 7.xx

Installation

WARNING

Read these installation instructions before starting installation.

Read the Prismaflex Service Manual and perform the installation

test before first use.

All electrical installations must comply with all applicable local

electrical codes and manufacturer specifications.

The assembled Prismaflex control unit weighs approximately 78 kg

(172 lb). Use at least two people to lift it out of the shipping carton.

Handle the Prismaflex control unit carefully.

WARNING

Contents of Prismaflex®Control Unit Shipping Carton

Each Prismaflex control unit is pre-attached to a column and a base

with casters. The Prismaflex control unit comes packaged with the

following items:

• Installation kit:

- United States-style power cord, with retaining bracket

- Continental European-style power cord, with retaining bracket

-4screws

- 4 scale carrying bars

• 20 ml syringe clip

• Pump crank

• Caution stickers

• Potential equalization connector

• Prismaflex Operator’s manual on CD

G5005209

Program version 7.xx

Installation Guide

2:3

Electrical Requirements

The Prismaflex control unit operates from an electrical power source

that delivers the following:

• from 100 (–10%) Vac to 240 (+10%) Vac; from 45 Hz to 65 Hz

It is essential that the power socket is properly grounded and in good

condition. If there is any doubt regarding the condition of the power

cord, have the wiring checked by a qualified electrician.

Electromagnetic Environment Requirements

The Prismaflex control unit requires special precautions regarding

EMC and needs to be installed and put into service according to the

EMC information provided in the Operator’s Manual.

Space Requirements

The assembled Prismaflex control unit requires a minimum of 63 cm

× 63 cm (25 in × 25 in) of floor space. There must be enough space

around the Prismaflex control unit so that all fluid bags can hang freely

from the scale carrying bars.

Unpacking and Assembly

CAUTION

Be careful when you move the Prismaflex control unit, so that you

don't make it fall over.

CAUTION

Unpacking

1. Open the shipping carton. C

out of the carton and place it upright. Carefully remove the foam

packing and pay attention not to damaging the Prismaflex control

unit components. Dispo

and other packaging material according to local regulations.

2. Inspect all components, paying particular attention to the front

panel of the Prisma

flex control unit. If any damage has occurred,

immediately contact your local sales or service representative.

arefully lift the Prismaflex control unit

se of the shipping carton, foam packing,

2:4

Installation Guide

G5005209

Program version 7.xx

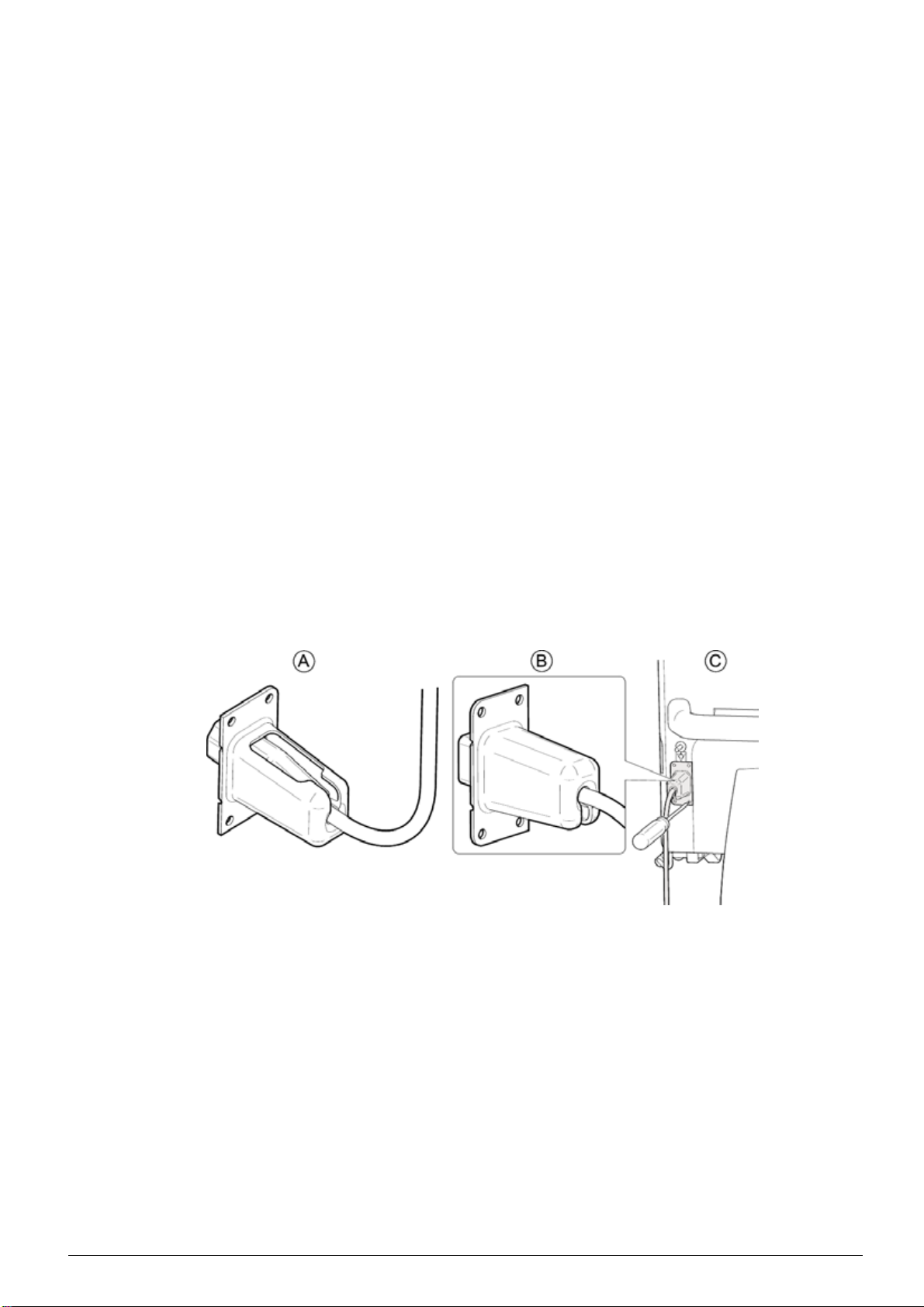

Connect Power Cord

Tool needed: Torx T-20

1. Select the appropriate power cord and cable support package.

Note: If the supplied power cord does not fit the wall socket, contact

an authorized electrician that can connect the power cord to the wall

socket.

2. Insert the power cord into the cable support, so that the cable

support fits tightly against the female connector of the power cord.

(A)

3. Turn the cable support by half a turn so that the cable support

guide is downward. (B)

4. Plug the power cord into the power cord socket on the rear panel

of the Prismaflex control unit.

5. Using the 4 screws provided, secure the cable support to the studs

on either side of the power cord socket. Tighten the screws using

the Torx T-20. (C)

6. The Prismaflex control unit has a connection on the rear panel

for a Potential Equalization Conductor. If require

d, connect the

Potential Equalization Conductor to the connector.

Figure 2:1 Connecting the Power Cord

G5005209

Program version 7.xx

Installation Guide

2:5

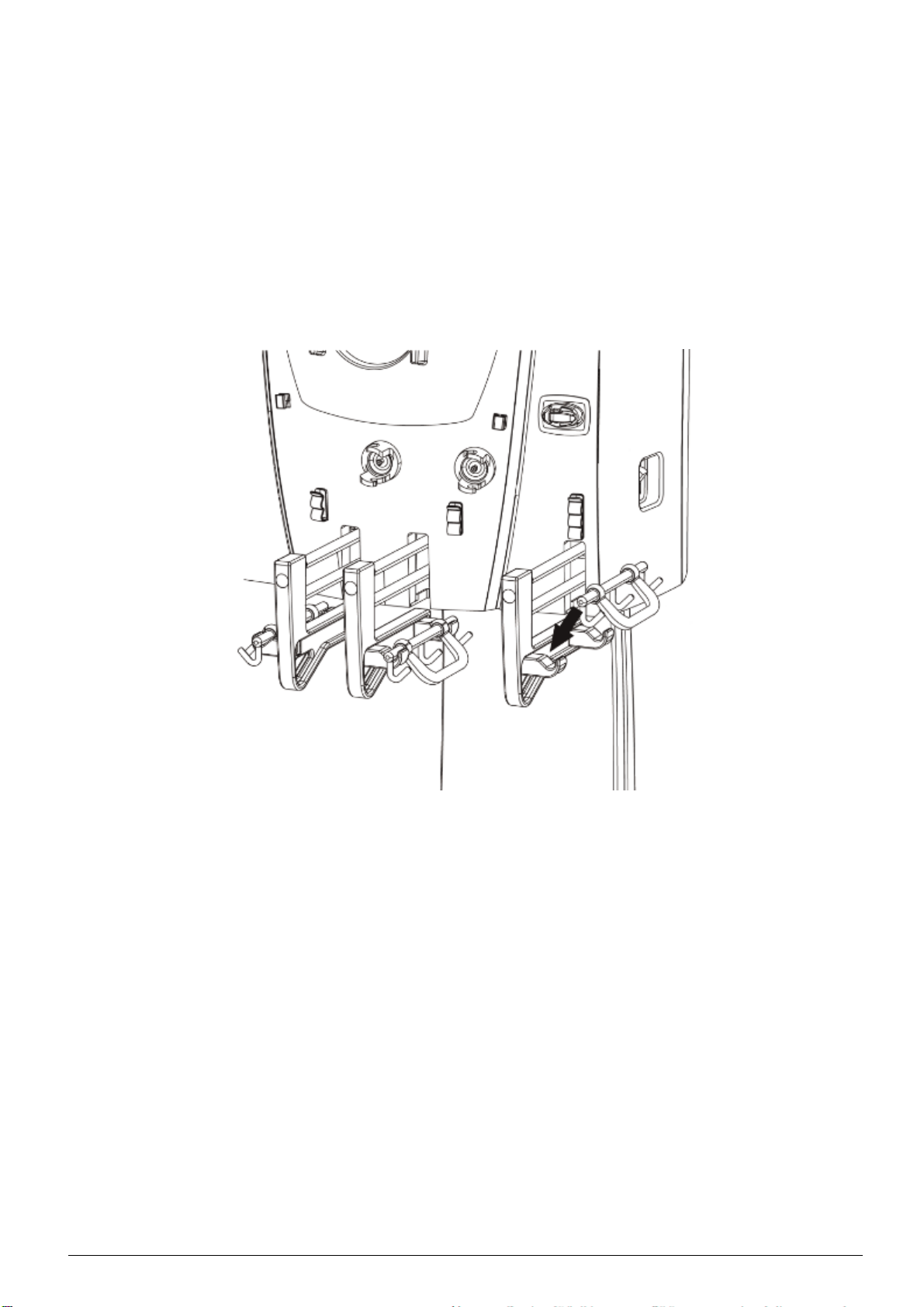

Install Scale Carrying Bars

Working one scale at a time, install the carrying bars into the bar trays

of the four scales.

1. Open the scale, place a carrying bar on the bar tray.

2. Rotate the carrying bar so that the handle is pointing toward the

floor; close the scale.

Note: Scale will not close properly unless the handle of the carrying

bar i s rotated toward the floor.

Figure 2:2 Placing the Carrying Bars on the Scales

Attachment of caution label

Tools needed: Cleaning Material

Perform the following steps to attach the caution labels to the front

panel:

1. CleantheareaofPrismaflex control unit where the stickers are to

be placed according to point 3 in Visual Inspection and Cleaning

on page 6:15.

2. Place the sticker next to the handle of the Effluent scale and the

Replacement scale.

Note: The pictures on the stickers are not identical. Blue area on sticker

is to be facing towards the Effluent scale and the Replacement scale.

2:6

Installation Guide

G5005209

Program version 7.xx

3. Check that all stickers are firmly attached to the surface of the

Prismaflex control unit.

4. Clean the surface on and around the stickers.

Change of Syringe Clip

Tools needed: Torx T-20

Perform the following steps to perform the change of the syringe clip:

1. Enter Service mode, Diagnose Screen - Syringe pump.

2. Using the syringe pump hard keys, move the plunger to its bottom

position.

3. Switch off the Prismaflex control unit.

4. Remove the Torx screw (T-20).

5. Slide the syringe plate down.

6. Slide in the new syringe plate.

7. Fasten the screw that holds the syringe plate.

8. Select the correct size of the syringe clip and perform a

configuration of the syringe holder, see Calibration Screen –

Syringe Holder Configuration on page 6:87.

®

Prismaflex

CAUTION

The installer is required to use an ESD (electro-static discharge)

Grounding Wrist strap during this procedure to avoid unintentional

damage to the electronic dev

Do not remove any cards or IC chips from their antistatic containers

until you are ready to inst

from a system, immediately place them in an antistatic bag or

container.

When handling cards or IC's, hold them by their edges. Avoid

touching the components and connector leads on the card. Avoid

touching the lead

Control Unit Calibrations

ices in the Prismaflex control unit.

all them. When removing cards or chips

sontheIC.

G5005209

Program version 7.xx

Do not slide cards or IC's over any surface. Avoid plastic, vinyl

and Styrofoam i

n your work area.

CAUTION

Before first use of the Prismaflex control unit, the operations below

must be per

formed in Service mode by an authorized service technician

and recorded in the Maintenance Log (attached to the inside wall of

the rear panel).

Installation Guide

2:7

Calibration instructions are provided in Service Calibration Screens on

page 6:58.

1. Plug the power cord into the wall socket and turn on the

Prismaflex control unit.

2. Verify all scales, calibrate if necessary.

3. Verify the syringe pump, calibrate if necessary.

4. Check all pressure sensors, calibrate if necessary.

5. Set the time and date.

6. In service mode, select CALIBRATE –

LANGUAGE CONFIGURATION and install the required language.

7. Configure therapies, disposable sets, a nticoagulation options, and

blood warmer, if applicable.

As default the Prismaflex control unit is enabled for CRRT. Default

filter set available is M60 and M100.

Electrical Safety Inspection

To ensure proper operation, an Electrical Safety Inspection (ESI)

of the Prismaflex control unit shall be performed. Inspection is

performed according to instructions found in section “Electrical Safety

Inspection” on page “6:4”. Test shall be documented in specificrecord

and stored for future reference.

Installation Test

Note: Read the Service’s Manual before performing the installation

test.

Before the first use of the Prismaflex control unit on a patient, the

installation test must be p

erformed with a Prismaflex CRRT set in

place on the Prismaflex control unit. The installation test verifies that

the Prismaflex control unit is properly installed. The test is performed

using saline solution a

s a substitute for priming solution and fluid bags,

and a container of water as a substitute for the patient. Successful

completion of the installation t est indicates that the Prismaflex control

unit i s functionin

g properly.

Supplies needed:

2:8

• Prismaflex CRRT set

• 4 fluid bags (saline solution) 1000 ml each

• 1 fluid conta

iner 1000 ml, filled with 500 ml tap water

• Catheter, 8F

Installation Guide

G5005209

Program version 7.xx

To perform the installation test, follow the steps below;

1. Turn on the Prismaflex control unit. The Prismaflex control unit

performs an initialization test to check the system electronics,

startup signal sounds twice and status lights (green, red and yellow)

are lit during the test.

2. Choose NEW PATIENT when the Choose Patient screen

appears and enter patient information.

3. Check that the SCUF, CVVH, CVVHD, CVVHDF softkeys

are available on the Choose Therapy screen. Choose the

CVVHDF therapy.

4. Choose NO ANTICOAGULATION as

Anticoagulation Method.

5. Follow the instructions on the screen to load and prime the set. Use

saline solution as a substitute to priming and dialysate solutions.

The Prismaflex control unit performs multiple self-tests during

the priming cycle.

6. When the prime and the prime test are completed, press

CONTINUE.The Enter Treatment Settings screen

appears. Set the Loss/Gain Limit to 140 ml/3h. Press

CONFIRM ALL.

7. The Enter Flow Settings screen appears. Set the f

ollowing

flow rates and press the CONFIRM ALL softkey.

Blood:

180 ml/min

PBP:

1100 ml/h

Dialysate:

1200 ml/h

Replacement:

1300 ml/h

Fluid Removal Rate:

200 ml/h

8. When the Review Prescription screen appears, verify the

above flow rates, then press CONTINUE.

9. When the Connect Patient screen ap

pears, place the access

and return lines preferably connected through an 8F catheter into

the container of water. Press CONTINUE.

10. The Verify Patient Connect

ion screen appears. Press

the START softkey, to enter Run mode.

Note: Because the installation test is performed with

water, the Warning:

Return Disconnection and

Advisory: Cannot Detect Return alarms could occur

after the Prismaflex control unit has entered Run mode. If either of

these alarms occu

r, press CONTINUE/OVERRIDE (depending on

active alarm) and continue with the test. The alarms will not affect the

outcome of the installation test.

G5005209

Program version 7.xx

11. Note the hour

and minute on the Status screen when the

Prismaflex control unit enters Run mode (this information can be

found in History screen, pressing EVENTS softkey).

12. Run the in

stallation test for at least 15 minutes.

Installation Guide

2:9

13. Place a clamp on the access line (red) below the cartridge.

The Warning: Access Pressure Extremely

Negative alarm should occur. Verify that the red light is flashing

and the audible alarm sounds with a high sound, 10 sound pulses

repeated approx. every 8 seconds.

14. Unclamp the access line and press the CONTINUE softkey

on the Warning screen. Verify that the alarm is cleared

(Warning screen leaves display, green light lit).

15. Check the Battery Backup function.

Note: Performed only if the Prismaflex control unit has Battery

Backup installed. See section “Third Technical Screen” on page

4:32, Power section. Otherwise continue with step 19.

Disconnect the power cord from the wall socket. The

Advisory: Main Power Lost alarm should occur. Verify

that the yellow light is permanently lit and the audible alarm

sounds with a low sound, 2 sound pulses repeated approx. every

21 seconds.

16. Press the OVERRIDE softkey. The Advisory screen leaves the

display, but remains in Examine Alarms. Yellow light is lit, th

e

Prismaflex control unit returns to the Status screen and the battery

icon, in the top right corner of the display, is l it.

17. Connect the power cord to the wall socket. Verify t

hat the battery

icon disappears and that the Prismaflex control unit continues

in run mode. Verify that the alarm is cleared from the Examine

Alarms (press SYSTEM TOOLS softkey and verify

that the

EXAMINE ALARMS softkey is not present) and green light lit.

18. Press the STOP softkey, then press the END TREATMENT softkey

and follow the instructions to unloa

dtheset.

19. In service mode, select Diagnose Screen – PM timer and Date.Set

and verify the PM timer.

20. Document the Prismaflex cont

rol unit configuration with either of

the following:

- Download the logging data of the simulated treatment (LOX

file) from the technical

data card, and attach it to the GFS

record, OR

- Download the logging data of the simulated treatment

(LOX file) from the

technical data card, and email it to

barcode@gambro.com, OR

2:10

- Take a photo of the barcode in Service mode according to

instruction

s in Service - Diagnose, 2D Barcode, and send it to

barcode@gambro.com

21. Exit Service mode.

Installation Guide

G5005209

Program version 7.xx

SW update

1. Check that the machine is switched off.

2. Open the cabinet using an 8 mm Hex key.

3. Swing open the bracket mounted with protective and PIB board

to access the PC-board.

4. Connect a PC keyboard to the PS2 connector on the PC 104 board.

5. Turn on the machine and insert the software upgrade CD into the

CD-player.

Note! Software 7.xx requires PC-104 board (PCM-9375) to work.

6. Switch the main switch to OFF to restart the machine, wait 5

seconds and switch it ON again to boot from the CD.

7. A list with different boot setups is displayed.

8. Press 1 on the PC keyboard to start the software download –

“Initiate all”.

9. A question appears; do you want to continue, press Y on the PC

keyboard.

10. When the software upgrade is complete a messa

ge “Press any key

to continue.” occurs.

11. Remove the software CD and PC keyboard.

12. Switch the main switch to OFF to rest

art the machine, wait 5

seconds and switch it ON again.

G5005209

Program version 7.xx

Installation Guide

2:11

Calibrate the display

1. Make sure that the Prismaflex control unit is switched OFF before

starting the procedure.

2. Open the back door using the 8 mm Hex tool.

3. Set the SW1 (Dip Switch 1), on the Carrier board, to the ON

position.

4. Turn on the Prismaflex control unit and follow the instructions

given on the screen.

5. Turn off the Prismaflex control unit when the message

Press STOP to convaliate the calibr. appears or

press SET(S).

6. Set the switch SW1 (Dip Switch 1), to the OFF position.

2:12

Installation Guide

G5005209

Program version 7.xx

Chapter 3

Technical Description

Contents

Prismaflex®ControlUnit ..................................

®

Prismaflex

Prismaflex

FrontPanelComponents ................................

RearPanelComponents .................................

InteriorComponents ...................................

ElectricalDescription .....................................

InternalConnections ...................................

Modules ............................................

PowerSupply ......................................

CarrierBoard ......................................

ControlCPU .......................................

ProtectiveCPUboard ................................

ARPSboard .......................................

PIBboard .........................................

Alarmlightmodule .................................

LVDSinterfaceboard ................................

ExternalRS232board ................................

ExternalEthernetboard ..............................

ExternalRemoteAlarmConnector ......................

Fluidpumps .......................................

Bloodpump .......................................

Syringepump ......................................

Loader ...........................................

Scales ............................................

ABDassembly .....................................

Signals ...........................................

ControlUnitFunctions ........................

®

ControlUnitComponents .....................

Interior—Door(Closedhatch) ......................

Interior—Door(Openedhatch) .....................

Interior—Front1 ................................

Interior—Front2 ................................

Interior—Front3 ................................

Interior—Front4 ................................

3:2

3:2

3:3

3:3

3:14

3:16

3:16

3:18

3:20

3:22

3:24

3:26

3:28

3:28

3:31

3:33

3:34

3:35

3:36

3:38

3:40

3:41

3:41

3:41

3:41

3:42

3:42

3:42

3:43

3:43

3:43

3:44

3:45

G5005209

Program version 7.xx

Technical Description 3:1

Prismaflex®Control Unit

The Prismaflex control unit is pre-attached to a column and a base with

casters. For installation see Installation Guide on page 2:1.

Prismaflex®Control Unit Functions

The Prismaflex control unit is a software-controlled device that

performs the following functions:

• Loads and primes the Prismaflex disposable set automatically.

• Pumps blood through the blood flowpath of the

Prismaflex disposable set.

• Delivers anticoagulant solution into the blood flowpath.

• Pumps sterile infusion solutions into the blood flowpath of the

Prismaflex disposable set, according to therapy in use.

• Pumps sterile dialysate into the fluid compartment of the filter in

CRRT therapies.

• Controls the patient fluid removal or plasma loss, according to

the therapy in use.

• Monitors the system and alerts the operator to abnormal situations

through alarms.

3:2 Technical Description

G5005209

Program version 7.xx

Prismaflex®Control Unit Components

The Prismaflex control unit components are divided into:

• Front Panel

• Rear Panel

• Interior Components

Front Panel Components

The front panel components of the Prismafl ex control unit are

illustrated and described in the following figures.

• Figure 3:1 on page 3:4 shows the pumps.

• Figure 3:2 on page 3:6 shows the pressure components.

• Figure 3:3 on page 3:8 shows sensors and clamps.

• Figure 3:4 on page 3:10 shows the scale components.

• Figure 3:5 on page 3:12 shows miscellaneous components.

G5005209

Program version 7.xx

Technical Description 3:3

Figure 3:1 Pumps

1. Dialysate/replacement 2 pump

CVVHD, CVVHDF: Pumps

dialysate solution into the fluid

compartment of the filter.

CVVH: If post-filt

er replacement delivery has been chosen and

replacement solution has been placed on the green scale, this pump

delivers replacement solution into the post-filter blood flowpath.

2. Replacem

ent pump

Pumps replacement solution/fluid into the blood flowpath.

CRRT: Rep

lacement solution can be delivered either pre- or

post-filter.

TPE: Re

3:4 Technical Description

placement fluid is always delivered 100% post filter.

G5005209

Program version 7.xx

3. Blood pump

Pumps blood through the blood flowpath of the Prismaflex disposable set.

4. Pre-blood pump (PBP)

If required, pumps a solution i nto the blood access line at a location

immediately after patient blood enters the line and before the blood

pump.

In “Citrate – Calcium, Prismaflex syringe pump” anticoagulation

the PBP is the pump infusing the citrate solution into the blood

access line.

5. Syringe pump assembly

The pump assembly holds the solution-filled syringe and controls

the rate of delivery. Delivery can be continuous or in boluses.

In “Systemic, Prismaflex syringe pump” anticoagulation method,

the syringe pump delivers anticoagulant into the blood flowpath.

In “Citrate – Calcium, Prismaflex syringe pump” anticoagulatio

method, the syringe pump delivers calcium solution into patient via

a separate central venous access.

6. Effluent pump

CRRT: Pumps ultrafiltrate/dialysate; a utomatically controls the

ultrafiltration rate, based on the operator-set patient fluid removal

rate, PBP, dialysate, replacement, and syri

nge flow rates (if

applicable).

TPE: Pumps removed plasma; automatic

ally controls the

plasmafiltration rate based only on the operator-set patient plasma

loss and replacement fluid rates. PBP and syringe flow rates are not

considered in the effluent pump rat

e.

7. Pump raceway

Tubing pathway within each peristaltic pump. The raceways accept

the pump segments of the Pr

ismaflex disposable set.

8. Rotor

Center component of each peristaltic pump that rotates during pump

operation. Holds t

wo rollers that occlude the pump segment in the

raceway. Occlusion moves the fluid in the pump segment forward

in discrete amounts and prevents backflow.

n

G5005209

Program version 7.xx

Technical Description 3:5

Figure 3:2 Pressure components

3:6 Technical Description

G5005209

Program version 7.xx

1. Return pressure port

Connects to the monitor line of the deaeration chamber on the

Prismaflex disposable set. A pressure sensor (transducer) located

behind the pressure port enables noninvasive pressure monitoring

of the return line and deaeration chamber. A fluid barrier at the

distal end of the monitor line protects the return pressure sensor

from accidental blood entry.

2. Effluent pressure pod

3. Deaeration chamber holder

Holds the deaeration chamber of the Prismaflex disposable set.

4. Filter pressure pod

5. Access pressure pod

6. Pressure sensor housings

Housings that hold the pressure pods of the Prismaflex disposable

set. A pressure sensor (transducer) is located behind each housing.

The sensors and pressure pods enable noninvasive pressure

monitoring of the access, filter, and effluent lines. There are no

air-blood interfaces.

7. Pressure pod (not used, for future therapy)

G5005209

Program version 7.xx

Technical Description 3:7

Figure 3:3 Sensors and clamps

3:8 Technical Description

G5005209

Program version 7.xx

1. Discharger ring guide

Holds the electrostatic discharger ring of the Prismaflex disposable

set. The main function of the discharger ring is to lower the voltage

potential in the blood/fluid path. As a result, artifacts on cardiac

monitors will be minimized.

Always install the discharger ring in its guide before connecting a

patient to the Prismaflex disposable set.

2. Air bubble detector (housing also has a tubing detection switch

and a patient blood sensor)

Ultrasonic transmission/detection device that continuously monitors

the return line for air bubbles. A Warning alarm occurs if a bubble

is detected.

Tubing detection switch (physically moves down when tubing is

installed).

Patient blood sensor (infrared sensor that detects if blood is in the

tubing).

3. Return lin e clamp (assembly also has a tubing detection switch)

Occlusive clamp that closes during all Warning and Malfunction

alarms, when power is off, and during some self-tests. Preve

nts

blood and/or air from passing to the patient.

For patient safety, a tubing detection switch is also located in the

return clamp assembly. The switch physically mo

ves down when

tubing is correctly installed under the clamp.

4. Pinch valves (upper and lower)

CVVH, CVVHDF: Upper pinch valve accepts tu

bing coming

from the dialysate/replacement 2 pump; lower pinch valve accepts

tubing coming from the replacement pump. The valves open/close

automatically to allow pre- and po

st-filter options for delivery of

replacement solution.

5. Bar code reader

The bar code reader that de

codes the bar code on the

Prismaflex disposable set during the set loading procedure. With

this information, Prismaflex software accesses the default alarm

limits, flow rate range

s, and priming sequence for the set that is

loaded.

6. Syringe control panel

Consists of UP an

d DOWN buttons that allow installation and

removal of the syringe. The buttons are activated/inactivated by

Prismaflex software, depending on operating conditions.

7. Blood lea

k detector

Continuously monitors the effluent line for the presence of red

blood cells, indicating a leak in the filter membrane. A warning

alarm oc

curs if red blood cells are detected.

G5005209

Program version 7.xx

Technical Description 3:9

Figure 3:4 Scale components

3:10 Technical Description

G5005209

Program version 7.xx

1. Dialysate scale (green square)

2. Replacement scale (purple octagon)

3. Scale carrying bar assembly

The bar tray on each scale holds a removable carrying bar with

three hooks. Using a table or other support, bags may be attached

to/removed from the hooks. After the carrying bar is replaced in

the bar tray, it m ust be rotated so the handle i s toward t he floor, so

the scale can be properly closed.

Various sizes of bags can be used, depending on the scale.

4. Effluent scale (yellow circle)

5. PBP scale (white triangle)

6. General scale Information

Independently monitor fluid bag/container weights. Weight is u

by Prismaflex software to precisely control solution flow rates and

patient fluid removal /plasma loss. An alarm sounds when the

PBP, dialysate and replacement solution bags/containers

are nearly

empty, or when the effluent bag is nearly full.

The operator pulls the bar tray of a scale out (away from) the control

unit to attach or remove bags/containers. When t

he tray is pulled

out, the scale is in “open” position; when the tray is completely

pushed in, the scale is in “closed” position. An alarm sounds if the

scale is open when operating conditions requ

ireittobeclosed.

sed

G5005209

Program version 7.xx

Technical Description 3:11

Figure 3:5 Miscellaneous components

3:12 Technical Description

G5005209

Program version 7.xx

1. Status light

Lights up to give a general indication of operating conditions.

Green constant light: Indicates that all monitored parameters are

normal during administration of the treatment (Run mode).

Yellow constant light: Indicates that an Advisory alarm has

occurred, or an alarm has been overridden. Immediate patient

safety is not compromised, but the operator should investigate (Run

mode).

Note: During modes in which a patient treatment is not in progress

(Setup, Standby, End, and Custom m ode), yellow indicates that

monitoring is active, and that all monitored parameters are normal.

Ye l l o w flashing light: Indicates that a Caution alarm has occurred.

Immediate patient safety is not compromised, but the operator

should investigate (Run mode).

Red flashing light: Indicates that a Warning or Malfunction alarm

has occurred because of a condition of possible patient hazard.

Immediate operator intervention is required (Run mode).

2. Tubing clips

Secure the blood lines going to the patient, i ncluding the PBP line.

Route tubing through clips closest to patient, according to color

coding.

3. Tubing guides

Hold the lines of the Prismaflex disposable set in correct position

on the control unit. The color of each tubing g

uide matches the

color of the line it holds.

4. Loader

Loads the Prismaflex disposable se

t.

5. Side hooks (left and right side)

Bags can be put on this hook.

6. Recessed handles (lef

tandrightside)

7. Display

Shows text and softkeys. Provides operating, alarm, and help

instructions. Pr

essing the softkeys allows the operator to change

settings, start and stop functions, and navigate between screens.

8. Upper clip

Supports th

e calcium infusion line when performing “Citrate –

Calcium, Prismaflex syringe pump” anticoagulation method.

Temporarily holds the return line during setup of hemopurification

sets.

G5005209

Program version 7.xx

Technical Description 3:13

Rear Panel Components

Figure 3:6 Prismaflex

control unit: Rear Panel

1. Speaker

Creates alarm sounds.

2. Fan

Provides continuous ventilation for the interior components of the

control unit.

3. Hour meter

Displays operating hours (cumulative time that power to the

Prismaflex control unit has been on).

3:14 Technical Description

G5005209

Program version 7.xx

4. Remote alarm connection

Connection for an optional remote alarm (for example installed in

a nursing station).

5. Buzzer (inside)

Transmits a continuous buzz if a power loss occurs.

6. Rear handle (bottom)

7. Power cord holder

8. Power cord socket

9. Connection for potential equalization conductor

Potential equalization terminal is connected to the monitor chassis.

It can be connected to corresponding terminals on other equipment

to eliminate potential differences. Do not use it for additional

protective grounding.

10. Power switch

11. Pump crank

12. Technical data card holder

You can copy history data to a technical data card.

13. Ethernet port

An IP addressable port for data exc

hange with a personal computer

or communication network. Network communication ability is only

intended for sending out data and will not receive data that changes

the settings in the Prisma flex c

ontrol unit.

14. RS232 serial communication port

For data exchange with a personal computer, communication

network or modem. Netwo

rk communication ability is only

intended for sending out data and will not receive data that changes

the settings in the Prisma flex control unit.

15. Rear handle (

top)

G5005209

Program version 7.xx

Technical Description 3:15

Interior Components

Only authorized service technicians have access to the interior of the

Prismaflex control unit and are allowed to perform service maintenance

on the Prismaflex control unit.

This section is divided into:

• Door

• Front

Interior — Door (Closed hatch)

3:16 Technical Description

G5005209

Program version 7.xx

1. Remote alarm board

For use with external alarms.

2. Power Supervision Board

Power Supervision board detects unintended switch off during

treatment.

3. RS 232 board

Enables external serial data communication with the

Prismaflex control unit.

4. Memory board

Prismaflex control unit interface for the technical data card.

5. Ethernet board

Enables external Ethernet communication with the

Prismaflex control unit.

6. PIB board

Peripheral Interface Board. Contains the circuitry and connections

for the UABD, venous clamp, BLD and the pinch valves.

7. Log book

Update the Prismaflex control unit log book when the service is

performed.

G5005209

Program version 7.xx

Technical Description 3:17

Interior — Door (Opened hatch)

3:18 Technical Description

G5005209

Program version 7.xx

1. Protective board

Controls the Protective system.

2. Power supply

Supplies DC voltage to the Prismaflex control unit.

3. RAM memory

Internal memory for the PC 104 board.

4. PC 104 board

Control system C PU.

5. Compact flash

Placed on backside of PC 104 board, stores the Prismaflex software.

6. Carrier board

Interface for the PC 104 board.

7. Hour meter

Counts the total running hours of the Prismaflex control unit. Not

only the treatment hours.

G5005209

Program version 7.xx

Technical Description 3:19

Interior — Front 1

3:20 Technical Description

G5005209

Program version 7.xx

1. PBP (Pre-blood pump)

A stepper motor runs the slave pump rotor which rotates the PBP

pump.

2. Blood pump

Runs the Blood pump rotor.

3. Syring pump assemb ly

Administrates the syringe fluids.

4. Replacement pump

A stepper motor runs the slave pump rotor which rotates the

replacement pump.

5. Dialysate pump

A stepper motor runs the slave pump rotor which rotates the

dialysate pump.

6. Effluent pump

A stepper motor runs the slave pump rotor which rotates the

Effluent pump

7. Loader board

Controls the loader stepper motor.

8. Loader stepper motor

Maneuvers the loader.

9. Micro switch

Detection for completely loaded Prismaflex d

isposable set.

G5005209

Program version 7.xx

Technical Description 3:21

Interior — Front 2

3:22 Technical Description

G5005209

Program version 7.xx

1. Access pressure sensor

2. Filter pressure sensor

Cable length 50 cm

3. Effluent pressure sensor

Cable length 100 cm

4. Return pressure port

5. Pressure sensor

Fifth pod. Not used, for future therapy. Cable length 70 cm

6. Blood Leak Detector BLD

Infrared blood leak detection (detects presence of red blood cells

in the effluent line).