Gambro AK10 User manual

CORA

\

À

E

,

-

Hemofiltration

Operator’s

for

BMM

HFM

hemofiltration

10-1

10-1

manual

AK-10

Systeh'

|

ir

à

4

ee

The

Introduction

The

AK-10

two

basic

Fluid

modified

variety

This

in

the

monitor

monitors

tem.

standard

amount

of

infusion

ment.

system

building

Monitor.

by

adding

of

needs

manual

The

describes

AK-10

system.

for

extracorporeal

the

blood

HFM

hemofiltration.

of

filtrate

solution

blocks,

The

and

circulation

10-1

drawn

AK-10

for

hemofiltration

the

Blood

system

or

treatment

is

given

can

interchanging

the

operation

The

BMM

circulation.

the

hemofiltration

It

controls

from

the

to

the

is

designed

Monitor

easily

be

expanded

monitors

techniques.

of

two

10-1

is

the

It

controls

in

the

extracorporeal

fluid

and

monitors

patient

patient

and

during

system

around

and

the

or

to

meet

a

of

the

monitors

standard

and

monitor

the

the

amount

the

treat-

blood

sys-

for

for

hemofiltration.

Contents

Introduction

Description

The

Blood

Monitor

The

Hemofiltration

Hemofiltration

Attaching

Starting

Priming

Initiating

Changing

Discontinuing

the

the

machine

and

hemofiltration

parameters

hemofiltration

Fluid

preparations

blood

and

fluid

rinsing

procedure

during

Monitor

lines

treatment

11

12

14

15

16

spetto;

Note:

operated

are

manual.

When

equipment

sured.

The

AK-10

by

familiar

unpacking,

is

hemofiltration

persons

with

the

check

damaged

trained

operation

in

equipment

proper

machine

hemotiltration

procedure

operation

for

damage.

may

given

cannot

only

and

in

be

who

this

If

be

as-

Alarms

Blood

Monitor

Hemofiltration

Error

alarms

Operator

Technical

Cleaning

Technical

Technical

data

data

alarms

action

error

BMM

HFM

Monitor

table

codes

10-1

10-1

alarms

17

18

19

20

21

24

25

26

27

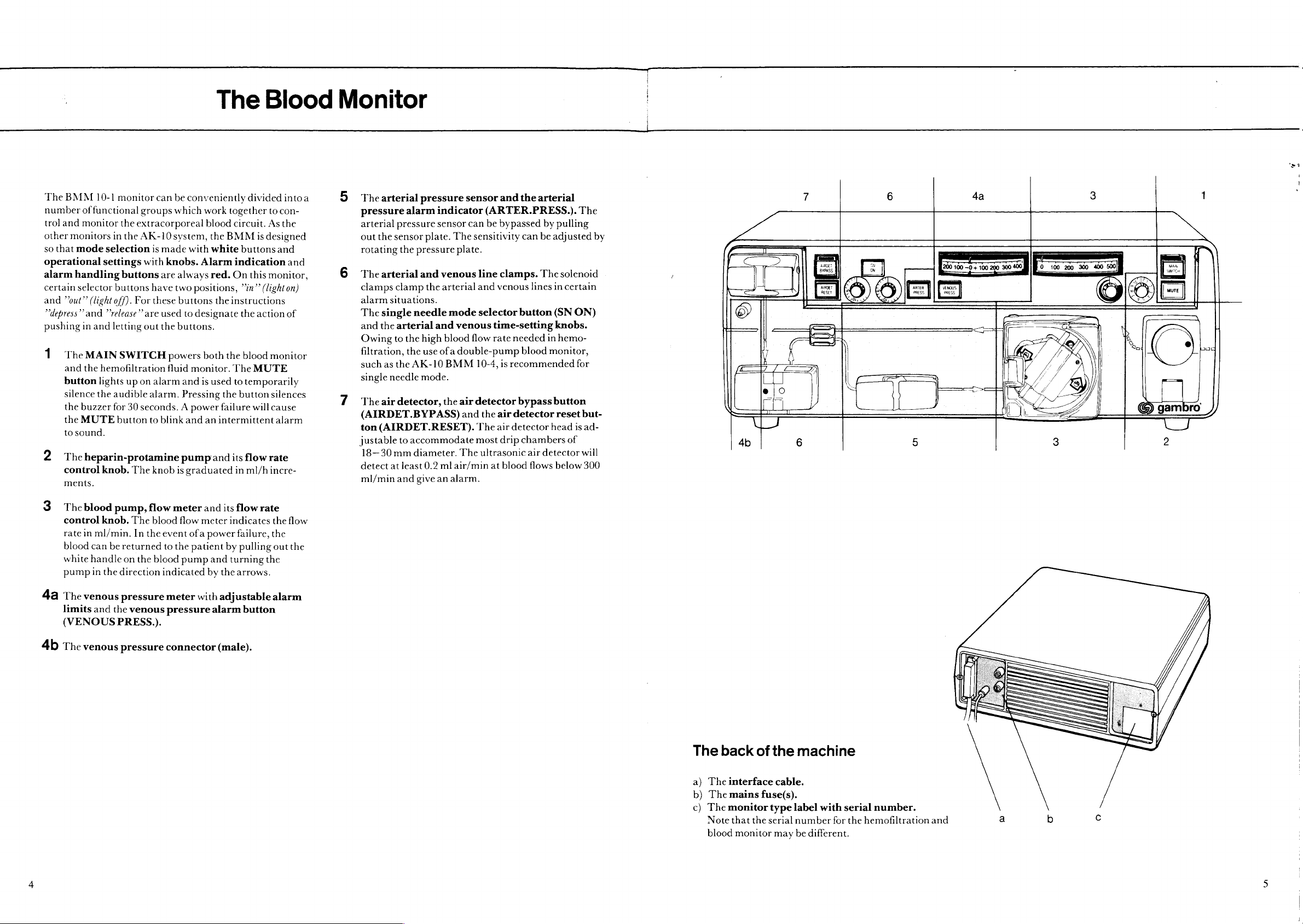

The

The

BMM

10-1

number

trol

other

so

operational

alarm

certain

and

“depress”

pushing

1.

2

of

functional

and

monitor

monitors

that

mode

handling

selector

“out”

(light

and

in

The

MAIN

and

the

button

silence

the

buzzer

the

MUTE

to

sound.

The

heparin-protamine

control

ments.

monitor

the

in

selection

settings

buttons

buttons

off).

“release”

and

letting

SWITCH

hemofiltration

lights

the

audible

for

button

knob.

can

be

groups

extracorporeal

the

AK-10

For

are

up

on

30

seconds. A power

The

is

made

with

are

have

these

used

out

the

alarm

alarm.

to

blink

knob

which

system,

knobs.

two

powers

fluid

conveniently

work

blood

the

with

white

Alarm

always

buttons.

is

red.

positions,

buttons

and

Pressing

pump

to

designate

both

monitor.

is

used

and

an

and

the

graduated

the

failure

intermittent

together

BMM

instructions

the

its

Blood

divided

to

circuit.

indication

On

The

to

in

As

isdesigned

buttons

“in”

the

blood

button

and

this

monitor,

(lighton)

action

monitor

MUTE

temporarily

silences

will

cause

alarm

flow

rate

ml/h

incre-

intoa

con-

the

and

of

Monitor

The

arterial

pressure

arterial

out

the

rotating

The

arterial

clamps

alarm

The

single

and

the

Owing

filtration,

such

as

single

The

air

(AIRDET.BYPASS)

ton

(AIRDET.RESET).

justable

18—30

detect

ml/min

pressure

alarm

pressure

sensor

the

pressure

and

clamp

situations.

needle

arterial

to

the

high

the

the

AK-10

needle

mode.

detector,

to

accommodate

mm

diameter.

at

least

and

give

indicator

sensor

plate.

The

venous

the

arterial

mode

and

blood

use

ofa

BMM

the air

0.2

ml

air/min

an

alarm.

sensor

and

(ARTER.PRESS.).

can

be

bypassed

sensitivity

plate.

line

clamps.

and

venous

selector

venous

double-pump

time-setting

flow

rate

10-4,

is

detector

and

the

air

The

air

most

drip

The

ultrasonic

at

blood

the

arterial

by

pulling

can

be

adjusted

The

lines

in

button

(SN

knobs.

needed

recommended

detector

detector

in

blood

monitor,

bypass

chambers

air

detector

flows

hemo-

button

reset

head

below

The

by

solenoid

certain

ON)

for

but-

is

ad-

of

will

300

AiRDEY

BYPASS

AIROET

RESET

ARTER

PRESS

VENOUS

PRESS

3

Theblood

control

rate

blood

white

pump

4a

The

limits

(VENOUS

4b

The

knob.

in

ml/min.

can

be

handle

in

the

venous

and

venous

pump,

flow

The

blood

In

the

returned

on

the

blood

direction

pressure

the

venous

PRESS.).

pressure

meter

flow

meter

event

ofa

to

the

patient

pump

indicated

meter

with

pressure

connector

and

its

flow

indicates

power

failure,

by

pulling

and

turning

by

the

arrows.

adjustable

alarm

(male).

rate

the

button

the

flow

the

out

the

alarm

The

a)

The

b)

The

c)

The

Note

blood

back

interface

mains

monitor

that

the

monitor

of

the

cable.

fuse(s).

type

serial

may

machine

label

with

number

be

for

different.

serial

number.

the

hemofiltration

and

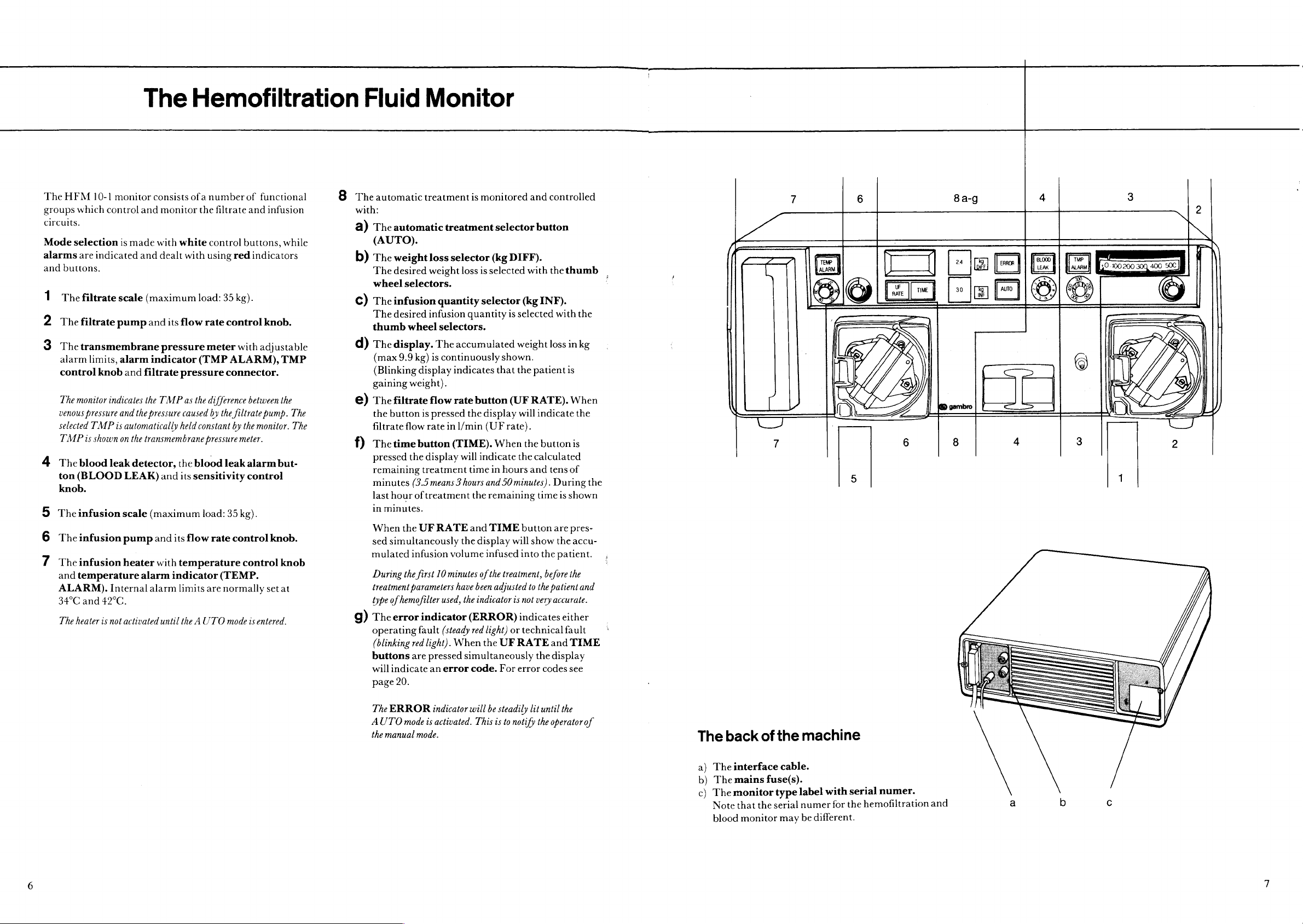

The

The

HFM

10-1

groups

circuits.

Mode

alarms

and

2

3

4

which

control

selection

are

indicated

buttons.

The

filtrate

Thefiltrate

Thetransmembrane

alarm

limits,

control

The

venous

selected

TMP

The

ton

knob.

The

The

The

and

ALARM).

34°C

The

knob

monitor

indicates

pressure

TMP

is

shown

blood

(BLOOD

infusion

infusion

infusion

temperature

and

42°C.

heater

is

monitor

scale

pump

alarm

and

is

on

leak

Internal

not

consists

and

is

made

with

and

dealt

(maximum

and

indicator

and

filtrate

the

TMP

the

pressure

automatically

the

transmembrane

detector,

LEAK)

scale

(maximum

pump

and

heater

with

alarm

alarm

activated

Hemofiltration

ofa

monitor

pressure

and

until

the

white

with

load:

its

flow

(TMP

pressure

as

the

caused

held

constant

the

blood

its

sensitivity

its

flow

temperature

indicator

limits

the

AUTO

number

control

using

rate

meter

difference

by

pressure

load:

rate

are

of

filtrate

and

buttons,

red

35

kg).

control

with

ALARM),

connector.

between

the

filtrate

by

the

meter.

leak

alarm

control

35kg).

control

control

(TEMP.

normally

mode

ts

functional

infusion

while

indicators

knob.

adjustable

TMP

the

pump.

The

monitor.

entered.

but-

knob.

knob

set

at

The

Fluid

8

The

with:

a)

b)

C)

d)

©)

f)

When

sed

mulated

During

treatment

type

Q)

The

operating

buttons

will

page

Monitor

automatic

The

(AUTO).

The

The

wheel

Theinfusion

The

thumb

The

(max

(Blinking

gaining

The

the

button

filtrate

The

pressed

remaining

minutes

last

hour

in

minutes.

simultaneously

of

(blinking

indicate

treatment

automatic

weight

desired

desired

display.

filtrate

time

error

20.

loss

weight

selectors.

infusion

wheel

9.9

kg)

display

weight).

flow

is

flow

rate

button

the

display

treatment

(3.5

of

treatment

the

UF

infusion

the

first 10

parameters

hemofilter

indicator

fault

red

light).

are

pressed

is

monitored

treatment

selector

loss

is

quantity

selectors.

The

is

continuously

pressed

in

means 3 hours

RATE

minutes

used,

selector

quantity

accumulated

indicates

rate

button

the

display

l/min

(TIME).

will

indicate

time

the

and

the

display

volume

of

have

been

the

indicator

(ERROR)

(steady

red

When

the

simultaneously

an

error

code.

selector

(kg

DIFF).

selected

(kg

is

selected

weight

shown.

that

the

(UF

will

(UF

rate).

When

the

in

hours

and

50

minutes).

remaining

TIME

button

will

infused

light)

into

the

treatment,

adjusted

is

indicates

or

UF

RATE

For

error

not

technical

and

controlled

button

with

the

INF).

with

loss

patient

RATE).

indicate

the

button

calculated

and

tens

During

time

is

are

show

the

the

patient.

before

to

the

patient

very

accurate.

either

and

the

display

codes

thumb

the

inkg

is

When

the

is

of

the

shown

pres-

accu-

the

and

fault

TIME

see

8a-g

—

;

ERROR

|

AUTO

|

(,

=

40

-100.200

309

400

500

The

AUTO

the

manual

ERROR

mode

indicator

is

activated.

mode.

will

This

be

steadily

is

to

notify

lit

the

until

the

operator

of

The

back

a)

Theinterface

b)

The

mains

monitor

The

c)

that

Note

blood

of

fuse(s).

the

monitor

the

cable.

label

type

serial

may

machine

with

for

numer

be

different.

numer.

serial

hemofiltration

the

and

Hemofiltration

First

check

that

the

mains

cables

are

failure

alarm

connected.

that

the

(BMM)

correctly

connected.

not

operate.

Setting

1

Hang

up

tion

for

2

Hang

up

Make

sure

to

contain

of

the

infusion

will

result

interface

and

placed.

cable

the

hemofiltration

An

alarm

Ifimproperly

up

container/bags

the

treatment

empty

that

the

selected

solution

on

container/bags

the

container/bags

quantity

connected

ifthe

between

will

connected

with

the

infusion

plus

the

to

power. A power

mains

cables

the

blood

fluid

monitor

result

if

the

sufficient

scale.

on

the

have

of

filtrate

patient’s

are

not

monitor

(HFM)

the

cable

monitors

infusion

filtrate

scale.

the

capacity

i.e.

the

weight

is

is

not

will

solu-

volume

loss.

preparations

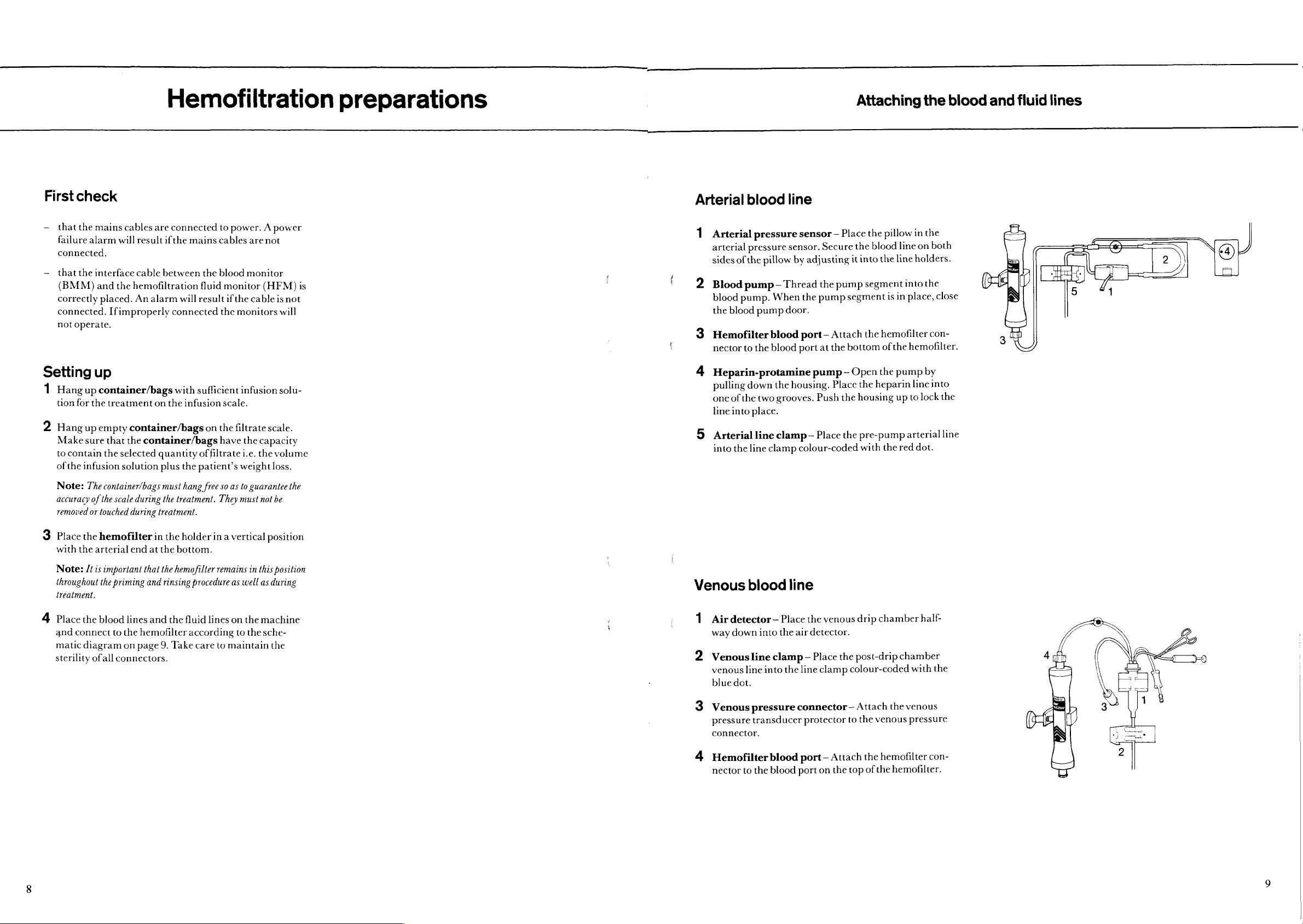

Arterial

1

Arterial

arterial

sides

2

Blood

blood

the

3

Hemofilter

nector

4

Heparin-protamine

pulling

one

line

5

Arterial

into

blood

pressure

of

the

pump-

pump.

blood

to

down

of

the

into

place.

the

line

line

pressure

sensor.

pillow

by

Thread

When

pump

door.

blood

the

blood

the

housing.

two

grooves.

line

clamp

clamp

sensor — Place

Secure

adjusting

the

the

pump

port-

port

at

pump — Open

Push

-—

Place

colour-coded

Attaching

the

it

into

pump

segment

segmentis

Attach

the

Place

bottom

the

the

housing

the

pre-pump

with

the

the

pillow

blood

the

hemofilter

of

the

heparin

the

in

line

on

line

holders.

into

in

place,

the

hemofilter.

pump

line

up

tolock

arterial

red

dot.

the

the

both

the

close

con-

by

into

the

blood

line

and

fluid

lines

Note:

The

accuracy

removed

Place

with

Note: / is

throughout

treatment.

Place

and

matic

sterility

of

or

touched

the

hemofilter

the

arterial

the

the

blood

connect

diagram

ofall

container/bags

the

scale

important

priming

lines

to

the

on

connectors.

must

during

the

during

treatment.

in

the

end

at

the

that

the

and

rinsing

and

hemofilter

page

9.

hang

free

treatment.

holder

bottom.

hemofilter

procedure

the

fluid

lines

according

Take

care

so

as

to

guarantee

They must

in a vertical

remains

to

not

in

this

as

well

as

on

the

machine

to

the

sche-

maintain

position

during

the

the

be

position

Venous

1

Air

detector - Place

way

2

Venousline

venous

blue

3

Venous

pressure

connector.

4

Hemofilter

nector

blood

down

line

dot.

pressure

to

line

into

the

air

clamp — Place

into

the

transducer

blood

the

blood

the

venous

detector.

line

clamp

drip

the

post-drip

colour-coded

chamber

connector — Attach

protector

port—

port

Attach

on

the

to

the

top

the

of

venous

hemofilter

the

half-

chamber

with

the

the

venous

pressure

con-

hemofilter.

Starting

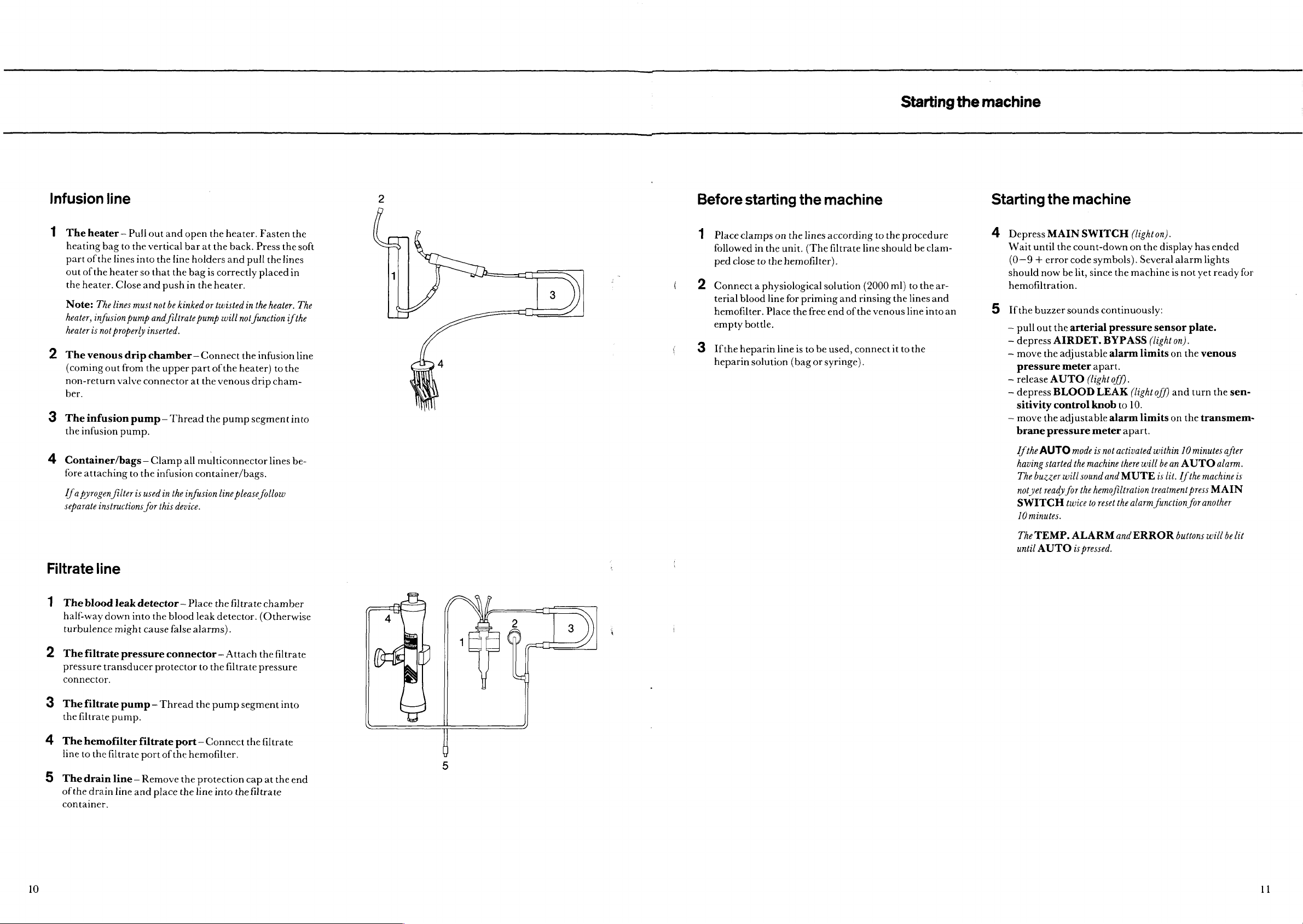

Infusion

1

Theheater - Pull

heating

part

out

the

Note:

heater,

heater

2

The

(coming

non-return

ber.

3

Theinfusion

the

line

bag

of

the

lines

of

the

heater

heater.

infusion

Close

The

lines

infusion

is

not

properly

venous

out

valve

out

and

to

the

vertical

into

the

line

so

that

the

and

push

must

not

be

kinked

pump

and

filtrate

inserted.

drip

chamber — Connect

from

the

upper

connector

pump-

Thread

pump.

open

the

bar

at

holders

bag

is

in

the

or

pump

part

of

at

the

the

heater.

the

back.

and

pull

correctly

heater.

twisted

in

will

not

the

the

heater)

venous

pump

Fasten

Press

the

the

lines

placed

the

heater.

function

infusion

to

the

drip

cham-

segment

the

soft

in

The

if

the

line

into

Before

starting

Place

clamps

followed

ped

Connect a physiological

terial

hemofilter.

empty

Ifthe

heparin

in

close

to

blood

bottle.

heparin

solution

the

Place

the

on

the

lines

unit.

(The

the

hemofilter).

line

for

priming

the

line

is

to

(bag

machine

according

solution

free

end

be

used,

or

syringe).

filtrate

line

(2000

and

rinsing

of

the

connect

to

the

procedure

should

ml)

the

venous

it

to

be

to

the

lines

line

the

clam-

ar-

and

into

an

the

machine

Starting

4

Depress

Wait

(0—9 + error

should

hemofiltration.

Ifthe

—

pull

—

depress

—

move

pressure

—

release

—

depress

sitivity

—

move

brane

the

MAIN

until

the

now

buzzer

out

the

AIRDET.

the

adjustable

AUTO

BLOOD

control

the

adjustable

pressure

machine

SWITCH

count-down

code

symbols).

be

lit,

since

sounds

arterial

meter

apart.

(light

LEAK

knob

meter

(light

on).

on

the

display

Several

the

machine

continuously:

pressure

BYPASS

alarm

sensor

(light

limits

off).

(light

off)

to

10.

alarm

limits

apart.

alarm

is

not

on).

on

the

and

on

the

has

ended

lights

yet

ready

plate.

venous

turn

the

transmem-

for

sen-

4

Container/bags — Clamp

fore

attaching

Lf a pyrogen

Separate

Filtrate

1

The

blood

half-way

turbulence

2

Thefiltrate

pressure

to

filter

instructions

line

leak

down

into

might

pressure

transducer

connector.

3

Thefiltrate

the

filtrate

4

Thehemofilter

line

to

5

The

drain

of

the

container.

pump - Thread

pump.

the

filtrate

line-

drain

line

all

multiconnector

the

is

used

for

infusion

this

container/bags.

in

the

infusion

device.

detector — Place

the

blood

leak

cause

false

alarms).

connector — Attach

protector

to

the

filtrate

port

Remove

and

port-

of

the

place

Connect

hemofilter.

the

protection

the

line

line

please

the

filtrate

detector.

the

filtrate

pump

segment

into

the

lines

follow

chamber

(Otherwise

the

filtrate

pressure

into

the

filtrate

cap

at

the

filtrate

be-

end

If

the

AUTO

having

The

buzzer

not

yet

SWITCH

10

minutes.

The

TEMP.

until

AUTO

mode

started

will

ready

for

twice

ALARM

is

not

activated

the

machine

sound

and

the

hemofiltration

to

reset

the

and

is

pressed.

within

there

will

be

an

MUTE

is

lit.

treatment

alarm function

ERROR

10

minutes

AUTO

If

the

machine

press

for

another

buttons

will

after

alarm.

MAIN

be

is

lit

10

11

Priming

General

For

priming

continue

rinsing

by

the

in

steps

cedure.

Check

1

Arterial

the

alarm

Blood,

the

clamp

2

Airdetector-—

AIRDET.

will

The

reactivate

off).

the

3

Venous

to

pressure.

VENOUS

buzzer

To

+200

4

Blood

until

will

and

the

turn

and

rinsing

with

the

of

other

hemofilters,

manufacturer

1--5

below

safety

pressure

arterial

buzzer

pressure

will

be

heparin,

sounds.

and

adjust

of

procedure

should

should

functions

sensor - Clamp

pillow.

activated:

infusion

To

the

Release

RESET

be

activated:

arterial

If

venous

simulate a decrease

reactivate

BLOOD

be

the

alarm,

the

and

the

necessary,

drip

pressure — Move

The

PRESS

sounds.

mmHg.

leak — Turn

activated:

arterial

depress

sensitivity

All

venous

alarm,

adjust

chamber

venous

(light

The

the

alarm,

the

LEAK

All

and

the

control

(light

pumps

arterial

pumps

venous

the

Gambro

on

this

page.

the

procedure

be

followed.

be

incorporated

The

arterial

ARTER.

and

filtrate

reactivate

sensor

plate

AARDET.

on).

The

stop,

solenoid

press

AIRDET.

the

fluid

using a syringe.

the

adjustable

and

an

increase

pressure

sensitivity

lights

BLOOD

on).

set

the

clamps

knob

alarm

All

and

alarm

up.

The

stop,

LEAK

pumps

venous

up

Fiber

For

recommended

The

into

the

line

PRESS.

pumps

the

alarm,

ifnecessary.

BYPASS

air

detector

the

buzzer

clamps

RESET

to

the

correct

of

will

limits

control

blood

the

buzzer

close.

button

two

degrees

and

Hemofilters

priming

instructions

this

pro-

just

before

pressure

(light

on).

stop

and

remove

(light

off);

alarm

sounds.

close*.

To

(light

levelin

alarm

limits

the

venous

be

activated:

stop,

the

clamps

close*.

at + 10

knob

down

leak

alarm

sounds

Jo

reactivate

and

(light

rinsing

and

the

and

procedure

Gambro®

Approximately

infusion

procedure

should

An

and

pass

circuit.

recommended

be

followed.

additional

prime

the

through

1

Remove

fusion

2

When

the

infusion

venous

3

Remove

pump

circuit.

4

Prime

air

from

gently

5

Unclamp

should

venous

6

Rinse

ml

of

7

Unclamp

again.

priming

8

Just

before

used

remove

cuit.

Adjust

chamber

(10

mm)

2000

rest

the

pump

500

at

with

tapping

not

and

priming

Rinse

Fiber

500

Ifa

of

membrane

any

drip

any

150

the

be

line

solution.

with a syringe

below

Hemofilters

ml

of

infusion

pyrogen

filter

by

the

ml

of

priming

the

system.

to

obstructing

to

rinse

ml

of

infusion

pump

and

chamber.

obstructing

ml/min

500

ml

of

blood

compartment

the

upper

the

filtrate

in

position

at

the

top

prime

the

solution.

the

venous

and

prime

the

2000

any

remaining

the

amount

the

solution

is

included

manufacturer

solution

At

least

half

the

filtrate

compartment.

clamps

and

prime

solution

clamp

the

clamps

to

rinse

and

priming

line

in

the

of

filtrate

line

ml

top

header

(the

filtrate

filtrate

the

hemofilter.

compartment

and

with

of

priming

air

of

fluid

until

of

the

solution

clamp

the

the

drip

is

used

to

in

the

for

priming

will

be

required

of

this

volume

and

start

the

infusion

has

been

infusion

and

start

prime

and

in

the

with

the

pump

pump)

the

remaining

solution

from

the

in

the

venous

level

is

chamber.

prime

the

infusion

hemofilter

and

line

and

rinsing

to

rinse

should

the

in-

circuit.

used,

stop

line

at

the

blood

the

blood

remove

hand.

segment

clamp

with

1000

filtrate

line

500

ml

has

been

blood

cir-

drip

at

least 1 cm

the

the

by

the

of

a

/A\

off).

9

5

Transmembrane

a)

b)

12

Move

the

decrease

sound.

Move

the

an

increase

sounds

and

To

reactivate

limits

at 0 and

knob

at

lower

in

TMP:

upper

100

pressure:

adjustable

TMP

adjustable

in

TMP:

the

filtrate

the

alarm,

200

mmHg.

mmHg.

TMP

TMP

(light

pump

set

alarm

on),

alarm

(lighi

stops.

the

adjustable

Set

the

(light

off).

*)

limit

the

limit

on),

the

TMP

Not

to

simulate

buzzer

to

simulate

buzzer

alarm

control

on

all

models

will

a

10

Turnoffthe

venous

Insert

pump

The

hemofilter

lines.

the

filtrate

and

unclamp

blood

is

now

pump

pump

the

ready

and

clamp

segment

infusion

for

use.

the

into

and

arterial

the

filtrate

filtrate

and

lines.

13

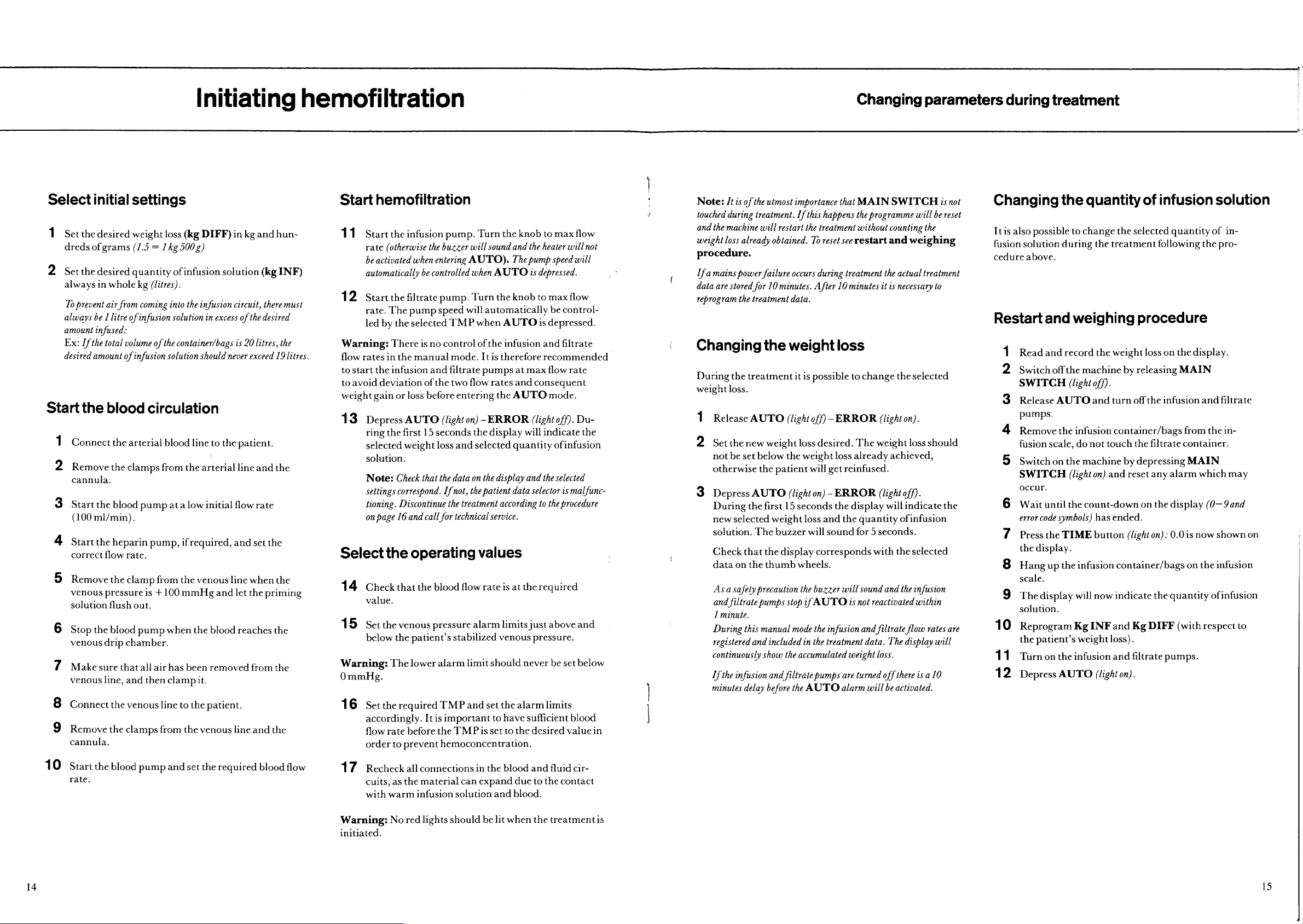

Initiating

Select

Start

initial

Set

the

dreds

of

Set

the

always

To

prevent

always

be 1 litre

amount

Ex:

If

the

desired

amount

the

Connect

Remove

cannula.

Start

(100

ml/min).

Start

correct

Remove

venous

solution

Stop

the

venous

Make

venous

Connect

Remove

cannula.

desired

grams

desired

in

whole

air

from

of

infused:

total

volume

of

blood

the

arterial

the

clamps

the

blood

the

heparin

flow

rate.

the

clamp

pressure

flush

blood

drip

chamber.

sure

that

line,

and

the

venous

the

clamps

settings

weight

quantity

loss

(1.5 = 1

kg

(litres).

coming

infusion

of

the

infusion

solution

(kg

kg

500g)

of

infusion

into

solution

container/bags

circulation

blood

from

the

pump

at a low

pump,

ifreguired,

from

the

is + 100

out.

pump

all

then

air

line

from

mmHg

when

has

clamp

to

the

DIFF)

the

infusion

in

should

line

arterial

initial

venous

the

been

it.

the

patient.

venous

in

solution

circuit,

excess

is

never

to

the

flow

and

line

and

let

blood

removed

line

kg

and

(kg

there

of

the

desired

20

litres,

exceed

patient.

line

and

rate

set

the

when

the

priming

reaches

from

and

hemofiltration

hun-

INF)

must

the

19

litres.

the

the

the

the

the

Start

11

12

Warning:

flow

to

to

weight

13

Select

14

15

Warning:

OmmHg.

16

hemofiltration

Start

the

infusion

rate

(otherwise

be

activated

automatically

Start

rate.

led

rates

start the

avoid

deviation

gain

Depress

ring

selected

solution.

Note:

settings

tioning.

on

page

Check

value.

Set

below

Set the

accordingly.

flow

order

when

the

filtrate

The

pump

by

the

selected

There

in

the

manual

infusion

or

loss

AUTO

the

first

weight

Check

correspond.

Discontinue

16

and

the

operating

that

the

venous

the

patient’s

The

lower

required

rate

before

to

prevent

pump.

Turn

the

buzzer

will

entering

be

controlled

is

no

and

of

the

before

(light

15

that

call

pump.

speed

will

TMP

control

mode.

filtrate

two

entering

on)

seconds

loss

and

the

data

If

not,

the

treatment

for

technical

AUTO).

when

Turn

when

of

flow

the

selected

on

the

values

the

blood

flow

pressure

alarm

TMP

It

is

the

alarm

stabilized

limit

and

important

TMP

hemoconcentration.

the

knob

sound

and

the

The

pump

AUTO

the

automatically

the

It

is

pumps

rates

the

-ERROR

display

is

knob

AUTO

infusion

therefore

at

max

and

consequent

AUTO

(light

will

quantity

the

display

and

patient

data

selector

according

service.

rate

is

at

the

limits

just

venous

should

set

to

is

set

the

have

to

alarm

the

pressure.

never

sufficient

desired

to

max

flow

heater

will

not

speed

will

depressed.

to

max

flow

be

control-

is

depressed.

and

filtrate

recommended

flowrate

mode.

off).

Du-

indicate

the

to

the

required

above

the

of

infusion

selected

is

malfunc-

procedure

and

be

set

below

limits

blood

valuein

|

Note:

It

is

of

touched

during

and

the

machine

weight

loss

already

procedure.

Ifa

mains

power

data

are

stored

reprogram

the

Changing

During

weight

1

2

3

the

treatment

loss.

Release

Setthenew

not

otherwise

Depress

During

new

solution.

Check

data

As a safety

and

1

During

registered

continuously

If

minutes

AUTO

be

set

the

selected

that

on

the

filtrate

minute.

this

the

infusion

delay

the

utmost

treatment.

will

restart

obtained.

failure

occurs

for

10

minutes.

treatment

the

data.

weight

(light

weight

below

the

the

patient

AUTO

The

and

(light

first

15

weight

buzzer

the

display

thumb

precaution

pumps

stop

manual

mode

included

show

the

and

filtrate

before

the

importance

If

this

happens

the

treatment

To

reset

during

After

it

is

possible

off) - ERROR

loss

desired.

weight

will

on)

seconds

loss

and

will

corresponds

wheels.

the

buzzer

if

AUTO

the

in

the

accumulated

pumps

AUTO

Changing

that

MAIN

the

without

see

restart

treatment

10

minutes

loss

to

change

The

loss

already

get

reinfused.

-ERROR

the

display

the

quantity

sound

for 5 seconds.

will

sound

is

not

infusion

treatment

and

weight

are

turned

alarm

data.

SWITCH

programme

counting

and

the

it

is

(light

weight

achieved,

(light

will

with

and

reactivated

filtrate

The

loss.

off

will

be

parameters

will

be

the

weighing

actual

treatment

necessary

the

of

the

the

there

activated.

to

selected

on).

loss

should

off).

indicate

infusion

selected

infusion

within

flow

rates

display

will

is a 10

is

not

reset

the

are

during

Changing

Itis

also

possible

fusion

solution

cedure

above.

Restart

一

N

©

AB.

a

©

M

O

9

10

11

12

and

Read

and

Switch

off

SWITCH

Release

pumps.

Remove

fusion

scale,

Switch

SWITCH

occur.

Wait

until

error

code

Press

the

the

display.

Hang

up

scale.

The

display

solution.

Reprogram

the

patient’s

Turnon

Depress

treatment

the

quantity

to

change

during

the

treatment

weighing

record

the

weight

the

machine

(light

off).

AUTO

the

on

symbols)

the

AUTO

infusion

do

the

machine

(light

the

count-down

TIME

the

infusion

will

Kg

weight

infusion

and

turn

container/bags

not

touch

on)

and

has

ended.

button

now

INF

and

loss).

and

(light

of

infusion

the

selected

quantity

following

procedure

loss

on

the

by

releasing

off

the

infusion

the

filtrate

by

depressing

reset

any

alarm

on

the

display

(light

on):

0.015

container/bags

indicate

on).

the

Kg

DIFF

filtrate

pumps.

quantity

(with

solution

of

the

pro-

display.

MAIN

and

from

the

container.

MAIN

which

(0—9and

now

shown

on

the

infusion

of

respect

in-

filtrate

in-

may

on

infusion

to

14

10

Start

rate.

the

blood

pump

and

set

the

required

blood

flow

17

Recheck

cuits,

with

warm

Warning:

No

initiated.

as

all

the

red

connections

material

infusion

lights

solution

should

can

in

the

expand

and

be

lit

blood

due

blood.

when

and

fluid

to

the

the

treatment

cir-

contact

is

15

Discontinuing

1

If

the

Note:

volume

2

heparin-protamine

the

pump

at

the

treatment.

When

the

desired

obtained,

by

-

~

—

—

has

Turn

and

filter.

Turn

line

Release

Move

pressure

Adjust

0mmHg.

Turn

the

following:

AUTO

the

buzzer

the

infusion

the

filtrate

The

treatment

been

off

clamp

off

leading

the

the

off

the

treatment

blinks

sounds

pump

is

attained.

the

filtrate

the

the

infusion

to

AUTO

alarm

meter

lower

the

blood

prescribed

weight

pump

considered

filtrate

the

venous

(light

limits

apart.

venous

loss

should

stops

stops.

pump.

line

pump

blinks)

on

pump.

pump

has

time

before

and

infusion

be

terminated.

finished,

pressure

when

Set

TMP

coming

and

clamp

drip

chamber.

-ERROR

the

transmembrane

been

volume

the

at

out

of

alarm

used,

stop

finishing

have

been

This

is

indicated

preset

infusion

100mmHg

the

hemo-

the

infusion

(light

on).

limit

to

the

hemofiltration

Return

7

8

10

11

12

13

14

15

16

the

blood

Clamp

remove

Connect

physiologic

Invert

blood.

Start

flow

circuit.

Clamp

quate

When

turned

venous

patient.

When

Release

ary

fluid

the

it

the

the

rate

the

emptying

the

to

line

the

tient,

depress

to

reset

to

be

started

Remove

lines.

pulling

Remove

out

arterial

from

the

arterial

solution.

hemofilter

blood

to

remove

venous

required

the

and

blood

MAIN

the

and

Disarm

the

the

infusion

blood

line

the

patient.

blood

to

facilitate

pump

and

the

blood

line

repeatedly

of

the

hemofilter.

amount

patient,

AIRDET.

immediately.

discard

stop

cannula

lines

SWITCH

programme

sensor

and

are

disconnected

BYPASS

the

hemofilter,

the

arterial

plate.

and

and

line

to

set

the

from

of

blood

the

blood

disconnect

(light

even

pressure

the

filtrate

the

cannula

at

least

100

ml

the

rinse-back

desired

off).

ifa

rinse-back

the

extracorporeal

to

facilitate

has

been

pump,

clamp

it

from

from

the

(light

on).

This

is

necess-

new

treatmentis

blood

lines

alarm

containers/bags.

and

of

of

ade-

re-

the

pa-

and

by

the

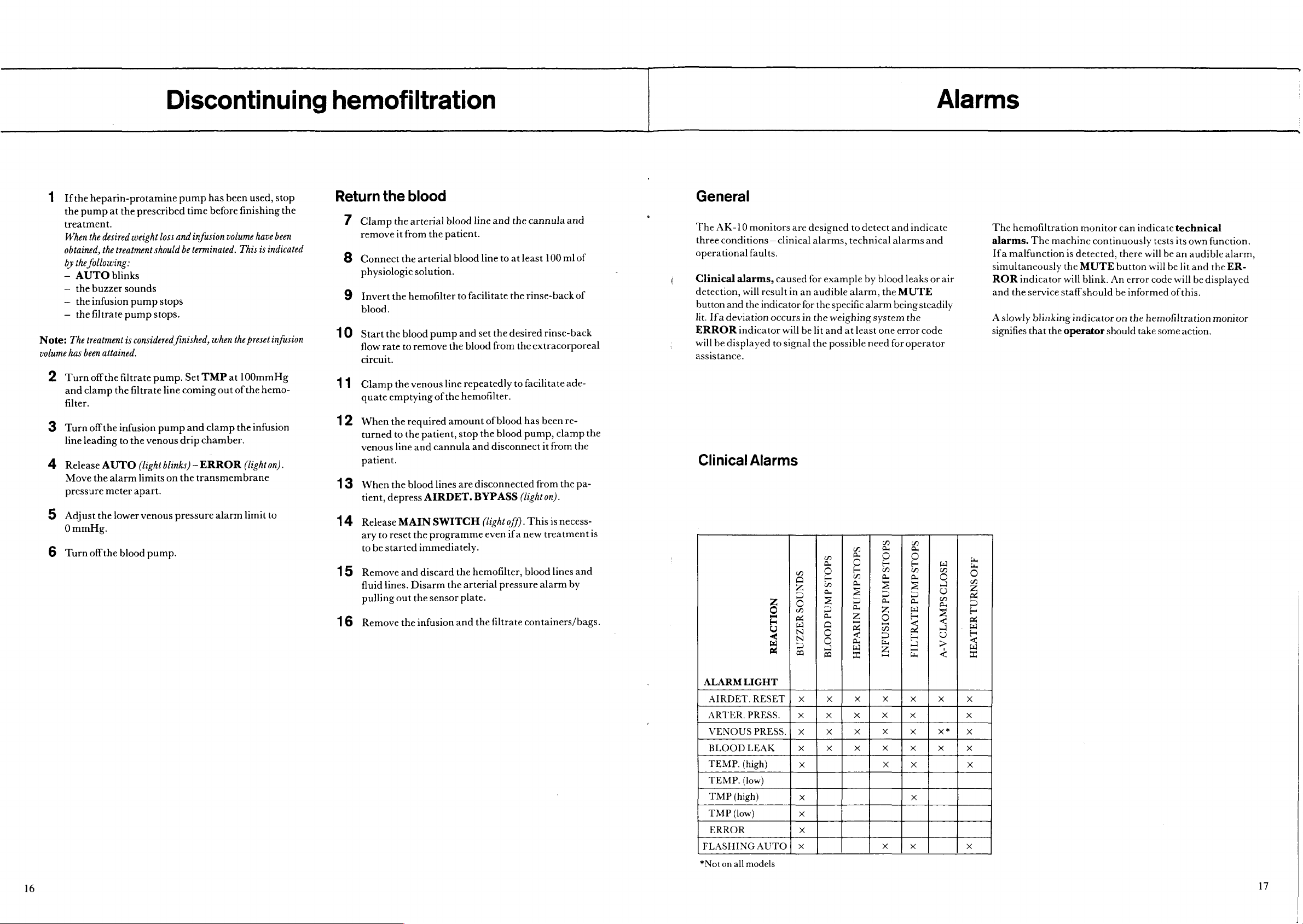

General

The

AK-10

three

operational

Clinical

detection,

button

lit.

Ifa

ERROR

will

be

assistance.

Clinical

monitors

conditions — clinical

faults.

alarms,

will

and

the

deviation

indicator

displayed

Alarms

are

designed

alarms,

caused

result

indicator

occurs

to

z

© の

= ~

бы

QINI|IS|ZIS

Zoe

in

an

for

in

will

be

signal

z

2

|o

N

m

for

audible

the

the

lit

the

A,

| a |

to

detect

and

technical

example

alarm,

specific

weighing

and

at

least

possible

£

O

の

A = = 中 の

la

=

|s|á|

と

> Z

A

ав

|}O | a

Al

m

m

alarms

by

blood

the

MUTE

alarm

being

system

one

error

need

for

(の

1515

E

2 | z | 2|

о

5

Se}

=

Alarms

indicate

and

leaks

or

air

steadily

the

code

operator

(の

E

回

O

a A

m

=

E a u

İzl

als

ol

圖

ee]

E

<

The

hemofiltration

alarms.

Ifa

malfunction

simultaneously

ROR

and

the

A

slowly

signifies

回

Z

č

>

E

E

<

le

x

The

machine

indicator

service

blinking

that

the

monitor

continuously

is

detected,

the

MUTE

will

blink.

staff

should

indicator

operator

can

there

button

An

error

be

informed

on

the

should

indicate

take

technical

tests

its

own

will

be

an

audible

will

be

lit

and

code

will

be

of

this.

hemofiltration

some

action.

function.

alarm,

the

ER-

displayed

monitor

16

ALARM

AIRDET.

ARTER.

VENOUS

BLOOD

TEMP.

TEMP.

TMP

TMP

ERROR

FLASHING

*Not

(high)

(low)

on

all

LIGHT

RESET | x

PRESS.

PRESS.|

LEAK

(high)

(low)

AUTO]

models

x x

x

x x x x x

x

x x x x

x

x x x x

x x | x

x x

x

x

x x x x

x

x x x

x*

x

x

x

17

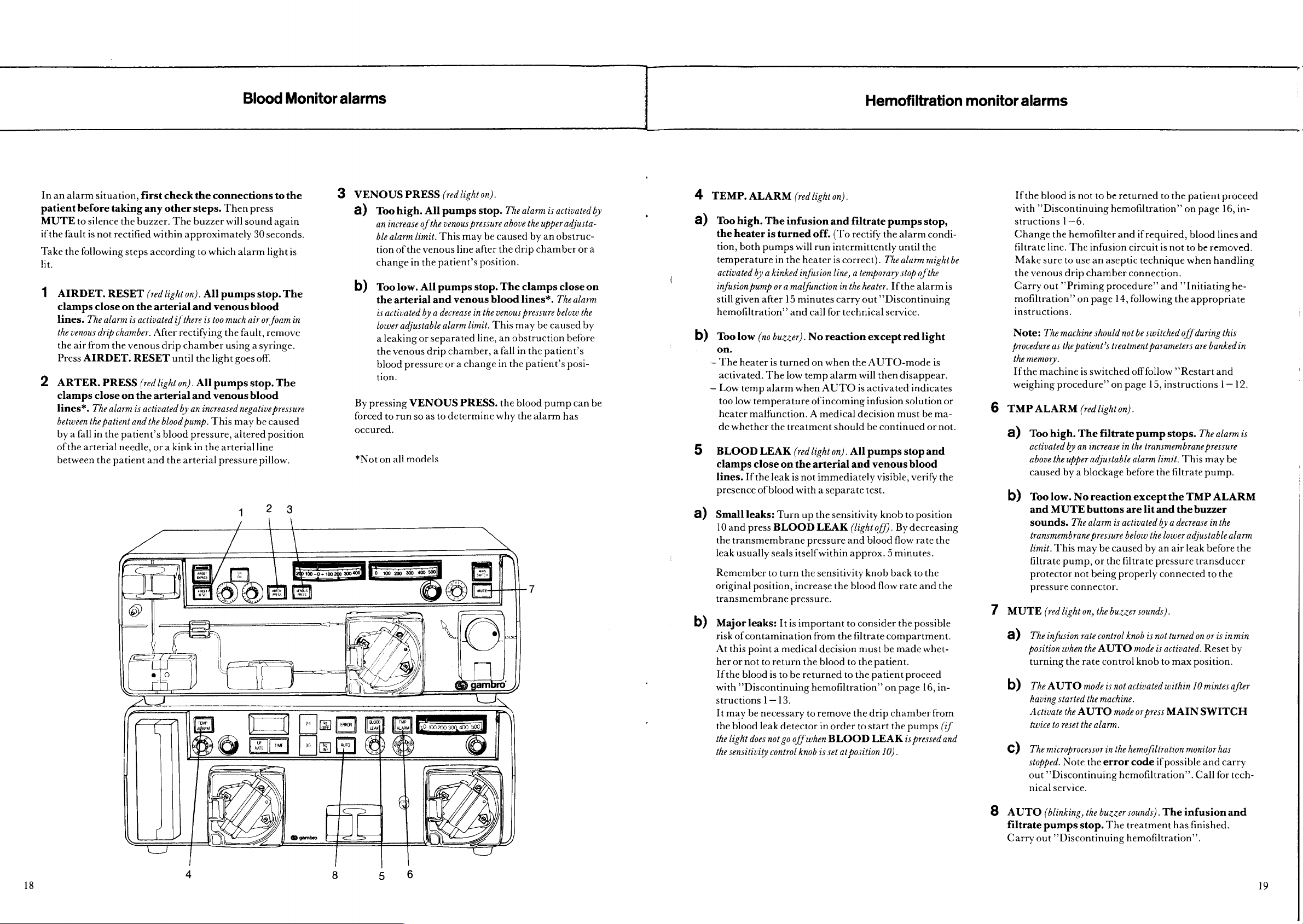

Blood

In

analarm

patient

MUTE

if

the

Take

lit.

1

AIRDET.

clamps

lines.

the

the

Press

2

ARTER.

clamps

lines*.

between

by a fall

of

between

before

to

silence

fault

is

the

following

The

venous

air

from

AIRDET.

the

the

arterial

situation,

taking

the

not

rectified

steps

RESET

close

on

alarm

is

drip

chamber.

the

venous

RESET

PRESS

close

on

The

alarm

patient

and

in

the

patient’s

needle,

the

patient

first

check

any

other

buzzer.

the

activated

the

is

The

within

according

(red

light

arterial

if

After

drip

until

(red

light

arterial

activated

the

blood

blood

or a kink

and

the

the

connections

steps.

Then

buzzer

will

approximately

to

which

on).

AU

pumps

and

venous

there

is

too

much

rectifying

chamber

on).

by

an

pump.

pressure,

arterial

the

using a syringe.

the light

All

pumps

and

venous

increased

This

in

the

arterial

pressure

press

sound

alarm

blood

air

fault,

goes

stop.

blood

negative

may

altered

to

again

30

seconds.

lightis

stop.

or

foam

remove

off.

The

pressure

be

caused

position

line

pillow.

Monitor

the

The

in

[en

alarms

3

VENOUS

a)

b)

By

pressing

forced

occured.

*Not

BLOOD

LEAK

E

2

]

©)

K 2

PRESS

Too

high.

an

increase

ble

alarm

tion

of

the

change

Toolow.

the

arterial

is

activated

lower

adjustable

a

leaking

the

venous

blood

pressure

tion.

VENOUS

to

run

on

all

models

る

(red

All

pumps

of

the

venous

limit.

This

venous

in

the

patient’s

All

pumps

and

venous

by a decrease

alarm

or

separated

drip

chamber, a fall

or a change

so

as

to

determine

light

on).

stop.

pressure

may

be

line

after the

position.

stop.

in

the

limit.

line,

PRESS.

The

above

caused

drip

The

blood

venous

This

may

an

obstruction

in

in

the

the

blood

why

the

alarm

is

activated

the

upper

by an

obstruc-

chamber

clamps

lines*.

pressure

The

below

be

caused

the

patient’s

patient’s

pump

alarm

by

adjusta-

ora

close on

alarm

the

by

before

posi-

can

be

has

4

TEMP.

a)

Too

high.

the

heater

tion,

both

temperature

activated

infusion

still

given

hemofiltration”

b)

Toolow

on.

~

The

heater

activated.

—

Low

temp

too

low

heater

de

whether

5

BLOODLEAK

clamps

lines.

presence

а)

Smallleaks:

10

and

the

transmembrane

leak

usually

Remember

original

transmembrane

b)

Major

risk of

At

this

her

or

Ifthe

with

"Discontinuing

structions

It

may

the

blood

the

light

the

sensitivity

ALARM

by a kinked

pump

after

(no

temperature

malfunction. A medical

close on

If

the

of

press

(red

light

The

infusion

is

turned

pumps

in

or a malfunction

buzzer).

is

The

alarm

the

leak

blood

Turn

BLOOD

off.

will

run

the

heater

infusion

15

minutes

and

call

No

turned

on

low

temp

when

of

treatment

(red

light

the

arterial

is

not

immediately

with a separate

up

the

LEAK

on).

and

(To

intermittently

is

line, a temporary

for

reaction

when

alarm

AUTO

incoming

should

on).

sensitivity

pressure

seals

itself

within

to

turn

the

sensitivity

position,

leaks:

contamination

point a medical

not

to

blood

be

necessary

leak

does

It

return

is

to

1—13.

detector

not

go

control

increase

pressure.

is

important

be

off

knob

the

from

decision

the

blood

returned

hemofiltration”

to

remove

in

order

when

BLOOD

is

set

Hemofiltration

filtrate

rectify

correct).

in

the

carry

technical

the

All

and

(light

and

approx. 5 minutes.

blood

to

the

filtrate

to

to

the

the

at

position

pumps

the

alarm

until

The

alarm

stop

heater.

If

the

out

""Discontinuing

service.

except

AUTO-mode

will

is

activated

infusion solution

decision

be

red

then

disappear.

must

continued

pumps

venous

visible,

test.

knob

off).

By

blood

flow

knob

back

flow

rate

consider

must

the

to

the

compartment.

be

made

patient.

patient

on

page

drip

chamber

start

the

LEAK

10).

stop,

condi-

the

might

of

the

alarm

is

light

is

indicates

or

be

ma-

or

not.

stop

and

blood

verify

the

to

position

decreasing

rate the

to

the

and

the

possible

whet-

proceed

16,

in-

from

pumps

is

(if

pressed and

monitor

be

alarms

Ifthe

blood

is

not

with ” Discontinuing

structions

Change

filtrate

Make

the

Carry

mofiltration”

instructions.

Note:

procedure

the

memory.

Ifthe

weighing

TMP

a)

Too

activated

above

caused

b)

Toolow.

and

filtrate

protector

pressure

MUTE

a)

position

turning

b)

having

Activate

twice

C)

The

stopped.

out

nical

1—6.

the

hemofilter

line.

The

sure

to

use

venous

drip

out’

Priming

The

machine

as

the

machine

procedure”

ALARM

high.

by

the

upper

by a blockage

chamber

on

patient’s

is

(red

The

an

No

MUTE

sounds.

transmembrane

limit.

This

buttons

The

may

pump,

not

connector.

(red

light

on,

The

infusion

The

AUTO

when

the

started

the

to

reset

rate

the

rate

mode

the

AUTO

the

microprocessor

Note

the

”Discontinuing

service.

to

be

returned

hemofiltration”

and

infusion

an

page

should

switched

circuit

aseptic

connection.

procedure”

14,

following

not

treatment

off

on

page

light

on).

filtrate

increase

in

the

adjustable

reaction

alarm

before

except

are

alarm

is

activated

pressure

being

below

be

caused

or

the

filtrate

properly

the

buzzer

control

knob

AUTO

machine.

alarm.

mode

control

is

not

activated

mode

in

the

hemofiltration

error

code

hemofiltration”.

to

the

patient

on

if

required,

technique

be

switched

parameters

follow ” Restart

15,

pump

transmembrane

the

lit

and

the

by

blood

is

not

to

when

and

’’

Initiating

the

appropriate

off

instructions 1 —

stops.

limit.

This

filtrate

the

TMP

the

by a decrease

lower

adjustable

an

air

leak

pressure

connected

sounds).

is

not

turned

is

activated.

knob

to

max

within

10

or

press

MAIN

monitor

if

possible

proceed

page

16,

in-

lines

and

be

removed.

handling

he-

during

this

are

banked

in

and

12.

The

alarm

is

pressure

may

be

pump.

ALARM

buzzer

in

the

alarm

before

the

transducer

to

the

on

or

is

in

min

Reset

by

position.

mintes

after

SWITCH

has

and

carry

Call

for

tech-

18

AUTO

filtrate

Carry

(blinking,

pumps

out

the

buzzer

stop.

The

treatment

”Discontinuing

hemofiltration”.

sounds).

The

has

infusion

finished.

and

19

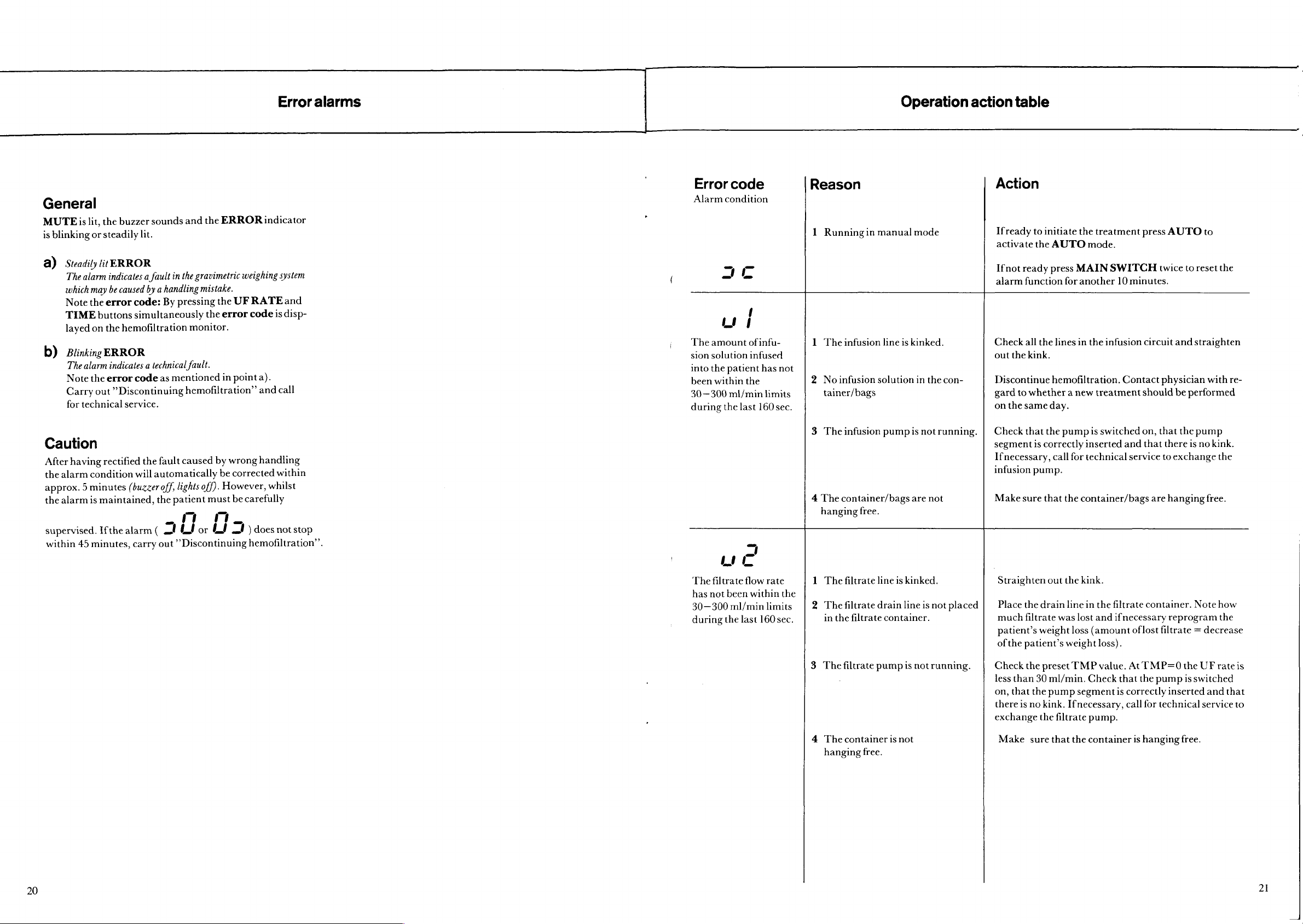

Error

General

MUTE

is

а)

b)

is

lit,

blinking

or

Steadily

The

alarm

which

may

Note

the

TIME

layed

on

Blinking

The

alarm

Note

the

Carry

for

technical

the

buzzer

sounds

steadily

lit

error

buttons

the

lit.

ERROR

indicates a fault

be

caused

by a handling

code:

By

simultaneously

hemofiltration

ERROR

indicates a technical

error

code

as

out

’Discontinuing

service.

and

the

ERROR

in

the

gravimetric

mistake.

pressing

mentioned

the

UF

the

error

monitor.

fault.

in

pointa).

hemofiltration”

indicator

weighing

RATE

code

is

and

system

call

and

disp-

alarms

Error

Alarm

The

amount

sion

solution

into

the

been

within

30—300

during

code

condition

г

> >

/

tl

of

infused

patient

the

ml/min

the

last

infu-

has

not

limits

160

sec.

Reason

1

Runningin

1

The

infusion

2

Noinfusion

tainer/bags

Operation

manual

solution

line

mode

is

kinked.

in

the

con-

action

Action

Ifready

activate

Ifnot

alarm

Check

out

the

Discontinue

gard

on

the

table

to

initiate

the

ready

function

all

the

kink.

to

whether a new treatment

same

the

treatment

AUTO

press

lines

hemofiltration.

day.

MAIN

for

another

in

mode.

the

infusion

SWITCH

press

10

minutes.

circuit

Contact

should

AUTO

twice

to

reset

and

straighten

physician

be

performed

to

with

the

re-

Caution

After

having

the

alarm

approx. 5 minutes

the

alarm

supervised.

within

rectified

condition

is

maintained,

Ifthe

45

minutes,

the

will

automatically

(buzzer

alarm

(

carry

fault

caused

off,

lights

off).

the

patient

LI

orli

out

”Discontinuing

by

wrong

be

corrected

However,

must

be

я } does

handling

within

whilst

carefully

not

stop

hemofiltration”,

The

has

not

30—300

during

=

Lit

filtrate

flow

been

ml/min

the

last

rate

within

limits

160

the

sec.

3

Theinfusion

4

The

container/bags

hanging

1

The

filtrate

2

The

filtrate

in

the

filtrate

3

The

filtrate

4

The

container

hanging

free.

line

drain

pump

free.

pump

is

not

are

is

kinked.

line

container.

is

not

is

not

running.

not

is

not

placed

running.

Check

that

the

segment

Ifnecessary,

infusion

Make

Straighten

Place

much

patient’s

of

Check

less

on,

there

exchange

Make

sure

the

filtrate

the

patient’s

the

than

that

is

no

sure

is

correctly

pump.

that

out

drain

weight

preset

30

the

pump

kink.

the

pump

call

for

the

container/bags

the

kink.

line

was

lost

loss

weight

TMP

ml/min.

segmentis

Ifnecessary,

filtrate

that

the

is

switched

inserted

technical

in

(amount

Check

pump.

container

and

the

filtrate

and

ifnecessary

loss).

value.

that

correctly

call

on,

that

service

are

container.

of

lost

At

TMP=0

the

pump

for

is

hanging

that

the

pump

there

is

no

kink.

to

exchange

hanging

reprogram

filtrate = decrease

the

is

inserted

technical

free.

the

free.

Note

how

the

UF

rate

switched

and

that

service

is

to

21

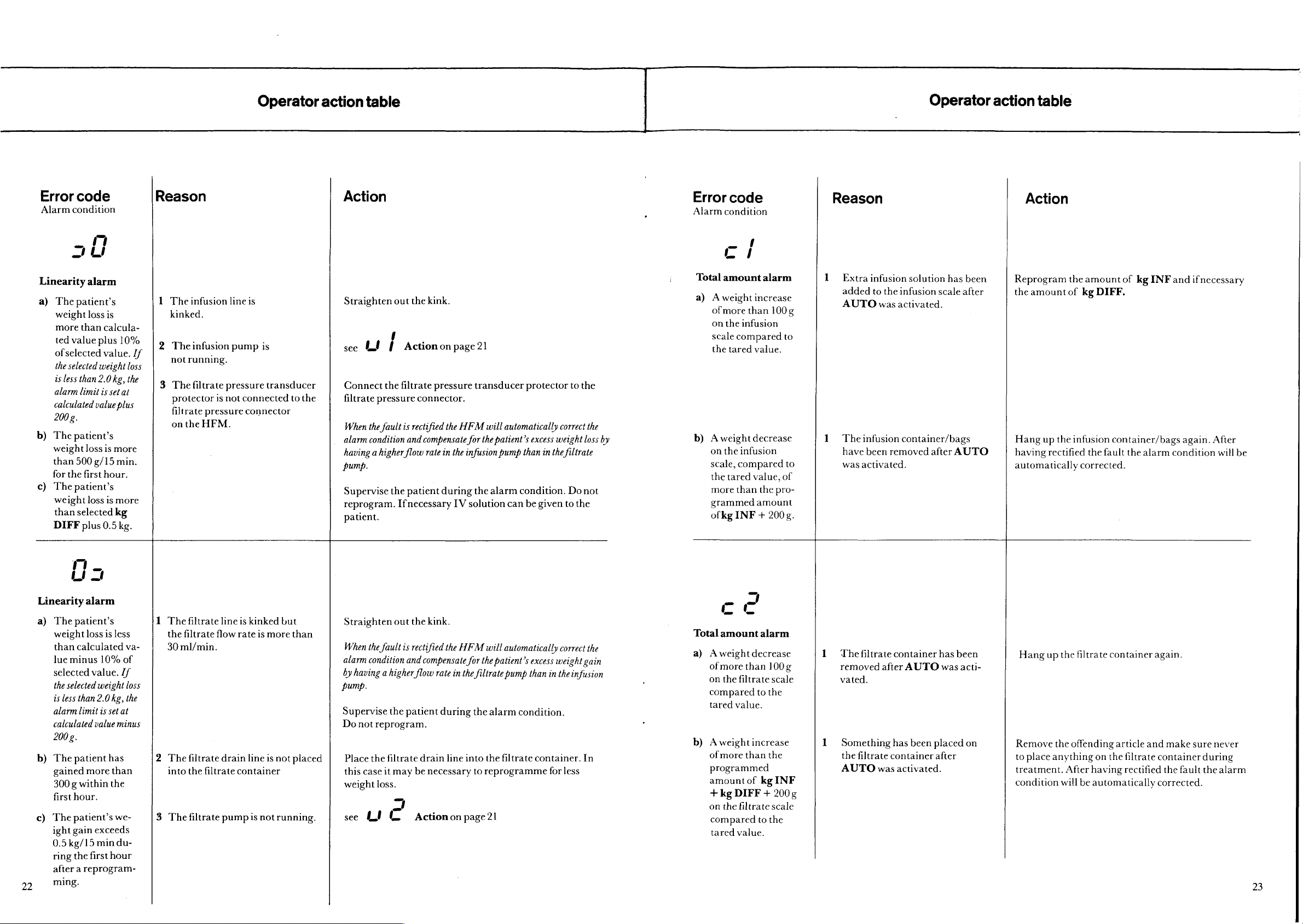

Operator

Jf

loss

the

Reason

1

The

kinked.

2

The

infusion

not

running.

3

The

protector

filtrate

onthe

infusion

filtrate

is

pressure

HFM.

line

is

pump

pressure

not

connected

connector

is

transducer

Error

Alarm

code

condition

a

„LI

Linearity

a)

The

patient’s

weight

more

ted

value

of

selected

the

selected

is

less

alarm

calculated

200

g.

b)

The

patient’s

weight

than

500 g/15 min.

for

the

c)

The

patient’s

weight

than

selected

DIFF

alarm

loss

than

plus

weight

than

2.0

limit

value

loss

first

loss

plus

门

is

calcula-

10%

value.

kg,

is

set at

plus

is

more

hour.

is

more

kg

0.5

kg.

to

the

action

Action

Straighten

see

Connect

filtrate

When

alarm

having a higher

pump.

Supervise

reprogram.

patient.

table

out

the

kink.

/

İLİ | Actionon

the

pressure

the

fault

condition

ㆍ

filtrate

pressure

connector.

is

rectified

and

compensate

flow

rate

the

patient

Ifnecessary

the

in

during

page

21

transducer

HFM

for

the

infusion

the

IV

solution

will

automatically

the

patient’s

pump

alarm

can

protector

correct

excess

weight

than

in

the

filtrate

condition.

be

given

to

to

Do

the

loss

not

the

the

by

Error

Alarm

code

condition

—

L

Total

amount

a) A weight

of

more

on

the

scale

compared

the

tared

b)

Aweight

on

the

infusion

scale,

compared

the

tared

more

than

grammed

ofkg

INF + 200g.

|

I

alarm

increase

than

100

infusion

value.

decrease

value,

the

pro-

amount

to

to

of

g

Reason

1

Extra

added

AUTO

1

Theinfusion

have

was

activated.

infusion solution

to

the

was

been

removed

Operator

has

infusion

activated.

container/bags

scale

after

AUTO

been

after

action

Action

Reprogram

the

amountof

Hang

having

automatically

table

the

up

the

rectified

amount

kg

DIFF.

infusion

container/bags

the

fault

corrected.

of

the

kg

INF

alarm

and

if

necessary

again.

condition

After

will

be

Linearity

a)

The

weight

than

lue

selected

the

selected

is

less

alarm

calculated

200

g.

b)

The

gained

300 g within

first

c)

The

ight

0.5

ring

after a reprogram-

ming.

22

1.

ceo

LI

4

tto

alarm

patients

loss

calculated

minus

10%

value.

weight

than

2.0

limit

is

value

patient

more

hour.

patient’s

gain

exceeds

kg/15

min

the

first

is

less

kg,

set

has

than

the

we-

hour

va-

of

If

loss

the

at

minus

du-

1

The

2

the

filtrate

30

ml/min.

The

into

filtrate

filtrate

the

line

flow

drain

filtrate

is

kinked

rate

is

more

line

is

container

but

not

than

placed

Straighten

When

the

fault

alarm

condition

by

having a higher

pump.

Supervise

Do

not

reprogram.

Place

the

this

case

it

weight

loss.

out

the

is

rectified

and

flow

the

patient

filtrate

may

drain

be

kink.

the

HFM

compensate

necessary

rate

in

during

line

for

the

into

will

automatically

the

patient’s

filtrate

pump

the

alarm

the

filtrate

to

reprogramme

7

see

Li

D

3

The

filtrate

pump

is

not

running.

Actionon

page

2!

correct

excess

weight

than

in

the

condition.

container.

for

less

the

gain

infusion

In

全

Total

amount

a)

Aweight

of

more

on

compared

tared

b)

Aweight

of

more

programmed

amount

+

kg

on

compared

tared

.

1.

alarm

decrease

than

the

filtrate

to

value.

increase

than

of

kg

DIFF + 200g

the

filtrate

to

value.

100g

scale

the

the

INF

scale

the

1

The

filtrate

removed

vated.

1

Something

the

AUTO

after

filtrate

was

container

AUTO

has

container

activated.

been

has

been

was

placed

after

acti-

on

Hang

up

the

filtrate

Remove

to

treatment.

condition

place

the

anything

offending

After

will

be

container

article

on

the

having

automatically

again.

and

filtrate

container

rectified

the

corrected.

make

sure

never

during

fault the

alarm

23

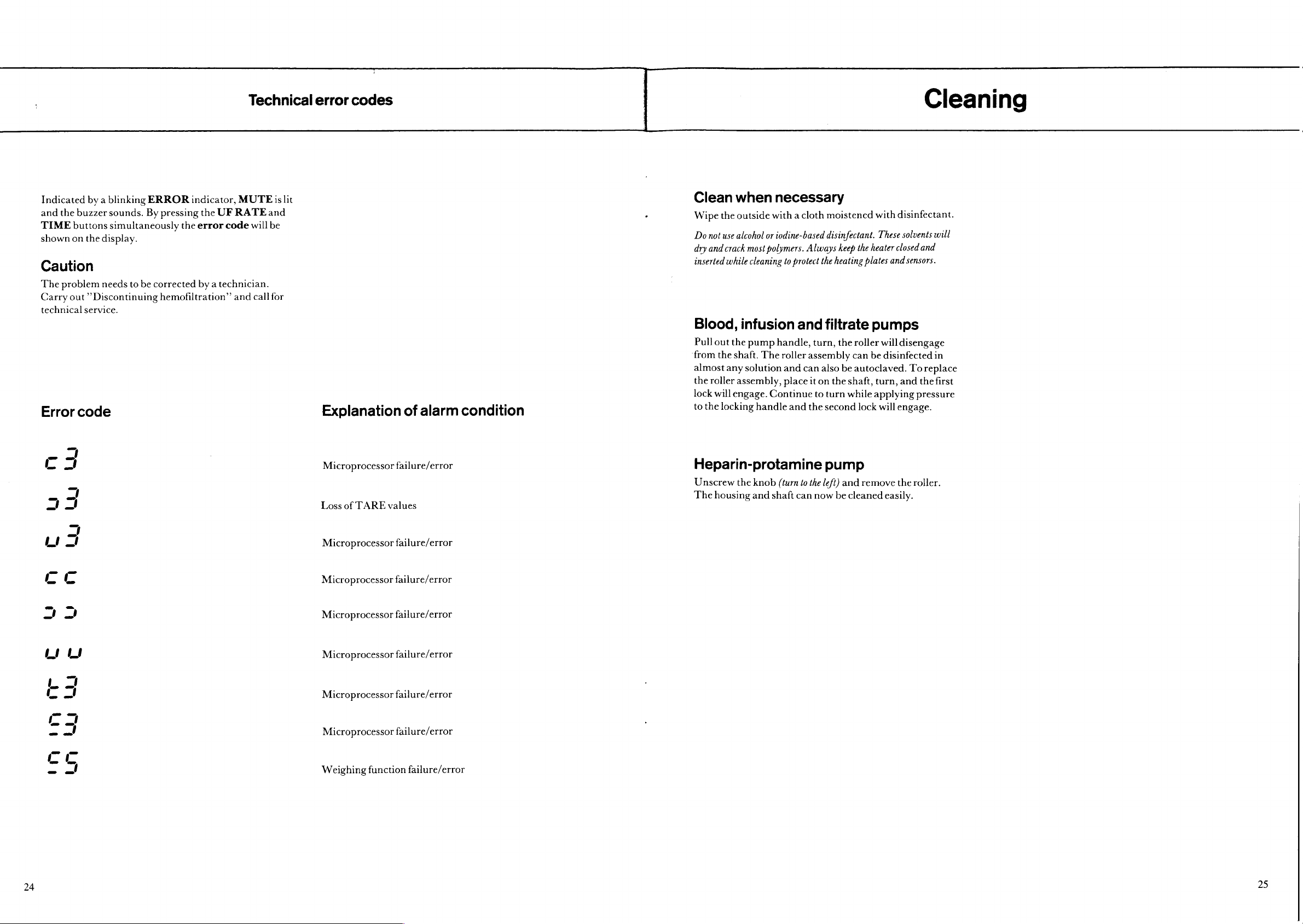

Technical

Indicated

and

TIME

shown

by a blinking

the

buzzer

buttons

on

the

ERROR

sounds.

simultaneously

display.

By

indicator,

pressing

the

the

UF

error

MUTE

RATE

code

will

is

and

be

Caution

The

problem

Carry

technical

Error

needs

out’

Discontinuing

service.

code

to

be

corrected

hemofiltration”

by a technician.

and

call

for

lit

error

codes

Explanation

of

alarm

condition

Clean

Wipe

the

Do

not

use

dry

and

crack

inserted

while

Blood,

Pull

out

‘from

the

almost

any

the

roller

lock

will

to

the

locking

when