Page 1

i

GALaxy eHydro

Elevator Controller Manual

GAL Manufacturing Corporation LLC

50 East 153rd Street

Bronx, NY 10451

Technical Support: 1‐877‐425‐7778

Page 2

ii

Foreword

GAL Manufacturing has developed this manual with usability and safety in mind. General and specific

safety notices and precautions are defined in the manual.

However,

GAL Manufacturing cannot be

responsible for any injury to persons or damage to property (including the elevator equipment) resulting

from negligence, misuse of the equipment, misinterpretation of instructions included in this manual, or

due to any other cause beyond the control of GAL Manufacturing.

All drawings, illustrations, and information herein are the property of GAL Manufacturing and must not

be made public or reproduced by any individual or entity other than the purchaser hereof without the

express written permission of GAL Manufacturing.

Revision 7.1

GAL Part Number: DOC-0119N

Page 3

iii

GALaxy eHydro Controller Manual………………………………………………………………………………i

Foreword...…………………………………………………………………………………………………………...ii

Table of Contents………..…………………………………………………………………………………………iii

Section 1 - Product Description ........................................................................................................... 1-1

1.1 Product Code Compliance ......................................................................................................... 1-1

1.2 Specifications ............................................................................................................................. 1-1

1.3 Physical Layout of the Controller ............................................................................................... 1-2

1.4 Selector System ......................................................................................................................... 1-3

1.4.1 Absolute Position System (APS) Selector .......................................................................... 1-3

1.4.2 Primary and Secondary Position Feedback ....................................................................... 1-4

1.5 Sequence of Operation .............................................................................................................. 1-5

1.6 Modes of Operation .................................................................................................................... 1-6

1.6.1 Reset Mode ........................................................................................................................ 1-6

1.6.2 Safety String Open Mode ................................................................................................... 1-6

1.6.3 Controller Inspection Mode ................................................................................................ 1-6

1.6.4 Car Top Inspection Mode ................................................................................................... 1-6

1.6.5 Access Mode ...................................................................................................................... 1-7

1.6.6 Independent Service Mode ................................................................................................ 1-7

1.6.7 Load Weighing Bypass Mode ............................................................................................ 1-7

1.6.8 Attendant Service Mode ..................................................................................................... 1-8

1.6.9 Code Blue Hospital Service Mode ..................................................................................... 1-8

1.6.10 Fire Service Phase I Mode ................................................................................................. 1-8

1.6.11 Fire Service Phase I Alternate Return Mode...................................................................... 1-9

1.6.12 Fire Service Phase II Mode ................................................................................................ 1-9

1.6.13 Emergency Power Sequencing .......................................................................................... 1-9

1.6.14 Emergency Power Battery Lowering ................................................................................ 1-10

1.6.15 Earthquake Mode ............................................................................................................. 1-10

1.6.16 Stalled (Low Oil) Mode ..................................................................................................... 1-10

1.6.17 Automatic Mode ............................................................................................................... 1-10

Section 2 - Installation .......................................................................................................................... 2-1

2.1 General Information.................................................................................................................... 2-1

2.2 Site Selection ............................................................................................................................. 2-1

2.3 Environmental Considerations ................................................................................................... 2-1

2.4 Wiring Guidelines and Instructions ............................................................................................. 2-1

2.4.1 Wiring Schematics .............................................................................................................. 2-2

2.4.2 Proper Field Wiring ............................................................................................................. 2-2

2.4.3 Ground Wiring .................................................................................................................... 2-2

2.4.4 Hoistway Wiring .................................................................................................................. 2-2

2.4.5 Elevator Car Wiring ............................................................................................................ 2-3

2.4.6 Machine Room Wiring ........................................................................................................ 2-3

2.5 Normal and Top Terminal Slowdown Limits .............................................................................. 2-3

2.6 Top Terminal Limit Switches ...................................................................................................... 2-4

2.7 Selector Installation .................................................................................................................... 2-4

2.7.1 APS (Absolute Position System) Selector Installation ....................................................... 2-4

2.7.1.1 Installation of the Encoded Tape and APS Camera ...................................................... 2-4

2.7.2 APS Selector Floor Position Setup (Hoistway Learn) ...................................................... 2-14

2.7.2.1 Verify that the APS Selector Camera is Installed Correctly and Communicating. ....... 2-14

2.7.2.2 Set the Adjustable Variables – “NTS Proc Adj Vars” in the Controller. ........................ 2-15

2.7.2.3 Zero the Hoistway ........................................................................................................ 2-15

2.7.2.4 Setting Hoistway Floor Levels with APS Selector ........................................................ 2-16

Section 3 - GALaxy Startup and Adjustment ...................................................................................... 3-1

3.1 Procedure for Initial Power-up of Controller ............................................................................... 3-1

3.1.1 Checking Main Line Voltage............................................................................................... 3-1

Table of Contents

Page 4

iv

3.1.3 Verify the Main CPU is Operating ...................................................................................... 3-1

3.2 Start-Up Procedures................................................................................................................... 3-2

3.2.1 Requirements for a running platform during initial startup ................................................. 3-2

3.2.2 Complete the Installation of Equipment ............................................................................. 3-4

3.3 Adjustment Procedures .............................................................................................................. 3-5

3.3.1 Set Toggle Switches ........................................................................................................... 3-5

3.3.2 Ready the Car to Run on Inspection .................................................................................. 3-5

3.3.3 Prepare for the Car for Hoistway Learn ............................................................................. 3-6

3.3.4 Verify the Hoistway ............................................................................................................. 3-7

3.4 Adjust the Elevator ..................................................................................................................... 3-7

3.4.1 Automatic Run .................................................................................................................... 3-7

3.4.2 Adjust the Slowdown Distances ......................................................................................... 3-8

3.4.3 Adjust the Stop ................................................................................................................... 3-9

3.4.4 Verify Proper Operation of All Safety Circuits and Signal Devices .................................. 3-10

3.4.5 Perform Required Tests ................................................................................................... 3-10

Section 4 Troubleshooting ................................................................................................................... 4-1

4.1 General Information.................................................................................................................... 4-1

4.2 Microprocessor CPU .................................................................................................................. 4-1

4.3 Input/Output Boards ................................................................................................................... 4-1

4.4 Run Sequence ............................................................................................................................ 4-2

4.5 The Safety PAL Functions ......................................................................................................... 4-3

4.6 Safety PAL ................................................................................................................................. 4-5

4.7 System Faults ............................................................................................................................. 4-6

4.8 Main CPU Inputs and outputs .................................................................................................... 4-6

4.9 NTS Processor Inputs and Outputs ......................................................................................... 4-11

4.10 Relocate I/Os ............................................................................................................................ 4-12

4.10.1 Relocate I/Os – Add IO Relocation .................................................................................. 4-13

4.10.2 Relocate I/Os – Remove Relocation IO ........................................................................... 4-14

4.10.3 Car Trace Screen ............................................................................................................. 4-15

Section 5 LCD Interface ........................................................................................................................ 5-1

5.1 Operating the LDC Interface ...................................................................................................... 5-1

5.2 LCD Menus ................................................................................................................................ 5-2

5.2.1 Elevator Status ................................................................................................................... 5-2

5.2.2 Main Menu ........................................................................................................................ 5-12

5.2.3 Date and Time .................................................................................................................. 5-13

5.2.4 Set Calls and Lockouts ..................................................................................................... 5-14

5.2.5 Inputs and Outputs ........................................................................................................... 5-17

5.2.6 Job Statistics .................................................................................................................... 5-20

5.2.7 Adjustable Variables ......................................................................................................... 5-21

5.2.8 Diagnostics ....................................................................................................................... 5-22

5.2.9 Software Utilities ............................................................................................................... 5-29

5.2.10 Hoistway Tables ............................................................................................................... 5-33

5.2.11 Fault Log........................................................................................................................... 5-39

Section 6 - Main CPU Faults & Detailed Faults ................................................................................ 6-40

6.1 Main CPU Faults ...................................................................................................................... 6-40

6.2 Device Fault in Fault Log ......................................................................................................... 6-84

6.3 Detailed Faults Data and Description....................................................................................... 6-99

6.3.1 Detailed Fault I/O Data Example .................................................................................... 6-112

6.3.2 Detailed Fault I/O Data Form ......................................................................................... 6-115

Section 7 - Main CPU Adjustable Variables ........................................................................................ 7-1

Section 8 - Appendix A ......................................................................................................................... 8-1

8.1 Testing Stall Mode & Low Oil Operation .................................................................................... 8-1

8.2 Reset Low Oil, Hot Oil, or MC/SPD Fault................................................................................... 8-2

8.3 Performing a Stop Ring Test ...................................................................................................... 8-2

Page 5

v

8.4 Testing NTSD ............................................................................................................................. 8-2

8.5 Testing Terminal Speed Reducing Device ................................................................................. 8-3

8.6 Testing the Load Weighing Device ............................................................................................ 8-3

8.7 Testing Phase 2 Operation With a Ground or Short Circuit ....................................................... 8-3

8.8 Testing Phase 1 & 2 Operation After Power Interruption and Restoration ................................ 8-3

8.9 Testing Recycling Operation ...................................................................................................... 8-4

8.10 Testing Plunger Gripper Operation ............................................................................................ 8-4

8.11 Testing Phase 1 Operation Under Special Conditions ............................................................... 8-4

8.12 Testing Phase 2 Operation Under Special Conditions ............................................................... 8-5

8.13 Testing Plunger Following Guide Protection .............................................................................. 8-6

8.14 Testing the Auxiliary Power Supply With the Disconnect Switch Open ..................................... 8-6

8.15 Testing Low Pressure Switch ..................................................................................................... 8-6

8.16 Testing Low Pressure Switch ..................................................................................................... 8-6

Page 6

vi

SYMBOLS USED IN THIS MANUAL

CAUTION

This manual uses the CAUTION symbol to identify procedures and practices that may result

in personal injury and/or equipment damage, if not followed correctly.

DANGER

This manual uses the DANGER symbol as an alert to a danger of electrocution or an acute

electrical shock. The DANGER symbol provides elevator personnel with a warning of

severe personal injury or potential fatality that can result if safety precautions are not

observed.

NOTE / INFORMATION

In this manual, this symbol identifies information helpful to elevator personnel when carrying

out a specific procedure or task.

NOT APPLICABLE / DOES NOT EXIST

When this symbol appears inside a table, it indicates that a value or property is not defined,

or is nonexistent, for the item listed.

Page 7

vii

WARNINGS AND CAUTIONARY NOTES

Installation and wiring must be in accordance with the national electrical code, all local

codes, and all elevator safety codes and standards. The 3‐phase AC power supply to

the equipment must originate from a properly fused disconnect or circuit breaker that is

properly designed and sized for the specific controller requirements and the “Short

Circuit Current Rating” listed on the controller. Improper motor branch circuit

protection will void warranty and may create a hazardous condition.

Wiring to the controller terminals must be installed in a careful, neat manner. Stranded

wire conductors must not have strands left out of the terminals. Leaving strands of wire

out of the terminals can create a potential short circuit. All terminals and cable

connectors must be seated properly. (See the IMPORTANT notice on the next page.)

Elevator control products must be installed by elevator personnel who have been

trained in the construction, maintenance, repair, inspection, and testing of elevator

equipment. The elevator personnel must comply with all applicable safety codes and

standards. This equipment is an O. E. M. product designed and manufactured to

comply with ASME A17.1-2016/CSA B44-16 Safety Code for Elevators and Escalators.

It is the responsibility of the installer to ensure that the installation is performed safely

and that the installation complies with all applicable codes.

Proper grounding is vitally important to the safe and successful operation of this

system, and proper grounding should be installed to comply with all applicable codes.

A separate ground wire should be installed from the building earth ground to the earth

ground terminal in each controller. Proper conductor size must be utilized for

grounding. In order to minimize resistance to ground, the shortest possible length

should be used for the ground conductor.

Do not install the controller in a hazardous area where excessive vapors and chemical

fumes are present. Do not install the controller in a dusty area. Do not install the

controller in a carpeted area. The space in which the controller equipment is installed

should be temperature controlled, moisture free, and should be maintained within a

temperature range of 32° F and 110°F. The space in which the controller equipment is

installed should be kept clean. The controller should be kept dry and should not be

exposed to moisture or water condensation. Make sure the power supply voltage

feeding the controller equipment does not fluctuate by more than +/- 10%.

Every safety precaution, whether or not specifically stated in this document, must be

implemented when installing, adjusting, or servicing elevator equipment. All safety

precautions must be followed to ensure the safety of elevator personnel and the general

public.

Use only the correct rated fusing for controller protection. Use of improperly rated

fusing will void the warranty.

Page 8

viii

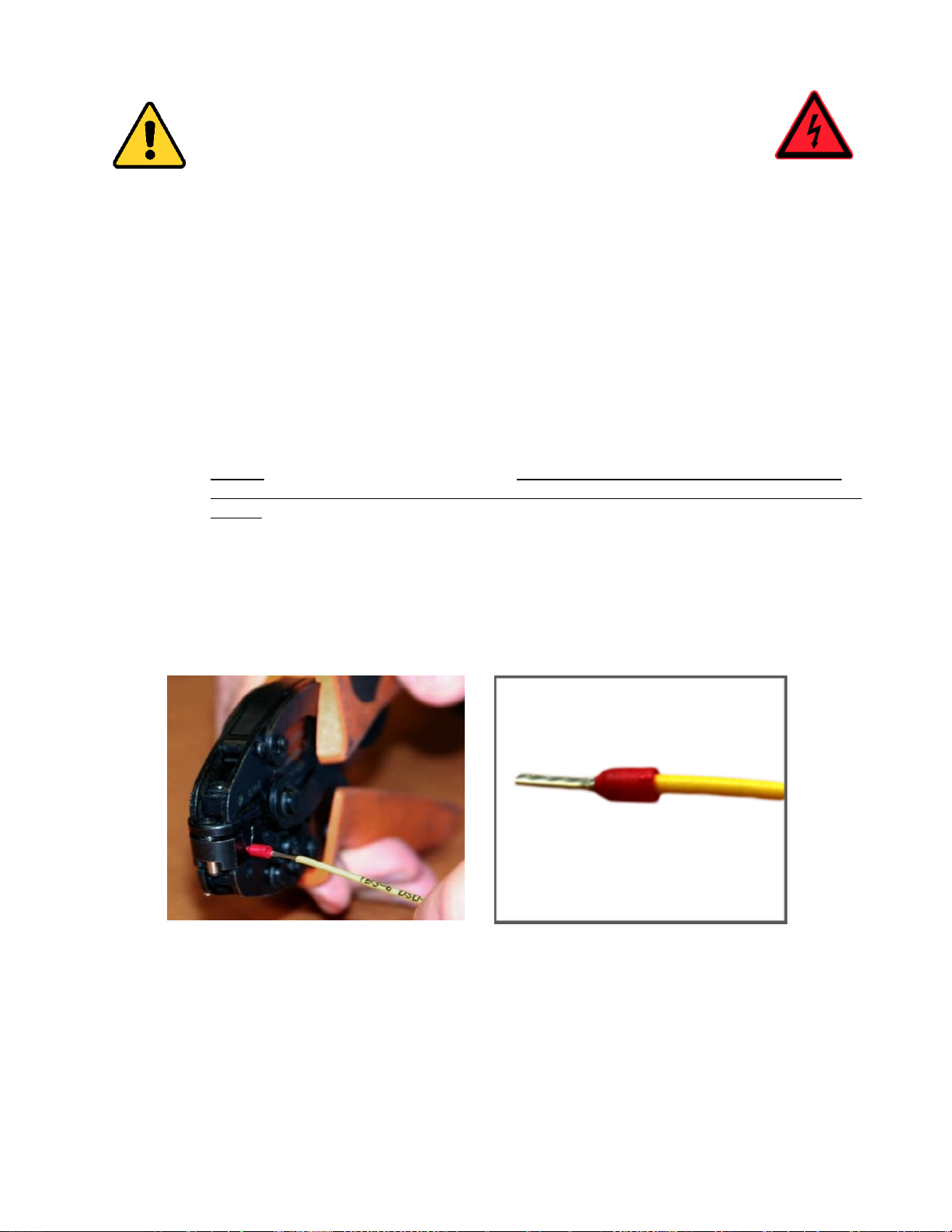

IMPORTANT NOTICE

Most of the field connections to GALaxy controls are made using stranded wire. When inserting this stranded

wire into the terminals – especially those for EPD’s (Electrical Protective Devices) – care must be taken to

ensure that all the strands are properly inserted into the terminals. Improper stripping and insertion may leave

strands outside of the terminals. Strands not properly inserted into the terminals may make contact with wires

from an adjacent terminal.

The danger associated with an occurrence as described above has led GAL Manufacturing to recommend that,

for all connections to the Electrical Protective Devices listed in ASME A17.1-2016/CSA B44-16, Requirements

2.26.2.1 through 2.26.2.39, elevator personnel must follow the guidelines listed below:

• Inspect all terminals used to connect Electrical Protective Devices. Ensure that the cage clamp is fully

open before inserting a wire into the terminal block.

• Perform corrective action for wires with stray strands by one of the following methods:

o Reconnect the wire with all wire strands correctly installed into the terminal. Visually verify that

no wire strands are outside of the terminal. The conductor should be stripped and inserted

completely into the terminal in such a manner that no more than two millimeters of bare wire is

visible; or

o Attach a ferrule to the end of field wire for safety devices (as pictured below in Figures 0-1 and

0-2) and insert the ferrule into the terminal; or

o Use an acceptable method such as tinning.

• After removal and replacement of any of these field wires, the actual Electrical Protective Device

should be checked for proper operation.

Figure 0-1

Crimp Tool for Ferrule

Figure 0-2

Stranded Wire with Ferrule

Attached

Page 9

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-1

Section 1 - Product Description

The GALaxy traction elevator controller is a computer-based system that offers superior performance,

flexibility and reliability. It has been designed to save time in installation and troubleshooting, but it is still

very important that the field personnel familiarize themselves with this manual before attempting to

install the equipment.

1.1 Product Code Compliance

• CSA B44.1-14/ASME A17.5-2014

• ASME A17.1-2016/CSA B44-16

1.2 Specifications

Standard Features:

• Inspection Operation (car top and controller)

• Access Operation

• Independent Service

• Fire Service Phase I

• Fire Service Phase I Alternate Return

• Fire Service Phase II

• Emergency Power

• Earthquake Service

• On Board Diagnostics LEDs

• On Board LCD Interface

• Motor Protection Timers

• Door Motor Protection Timer

• Field Adjustable Parameters

• Elevator Duty Rated NEMA Motor

Environment:

• 32° F to 110° F ambient

• 12,000 feet altitude

• 95% humidity

Optional Features:

• Selective Rear Doors

• Attendant Service

• Code Blue Hospital Service

• Security

• Remote Diagnostics

• Emergency Power

Page 10

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-2

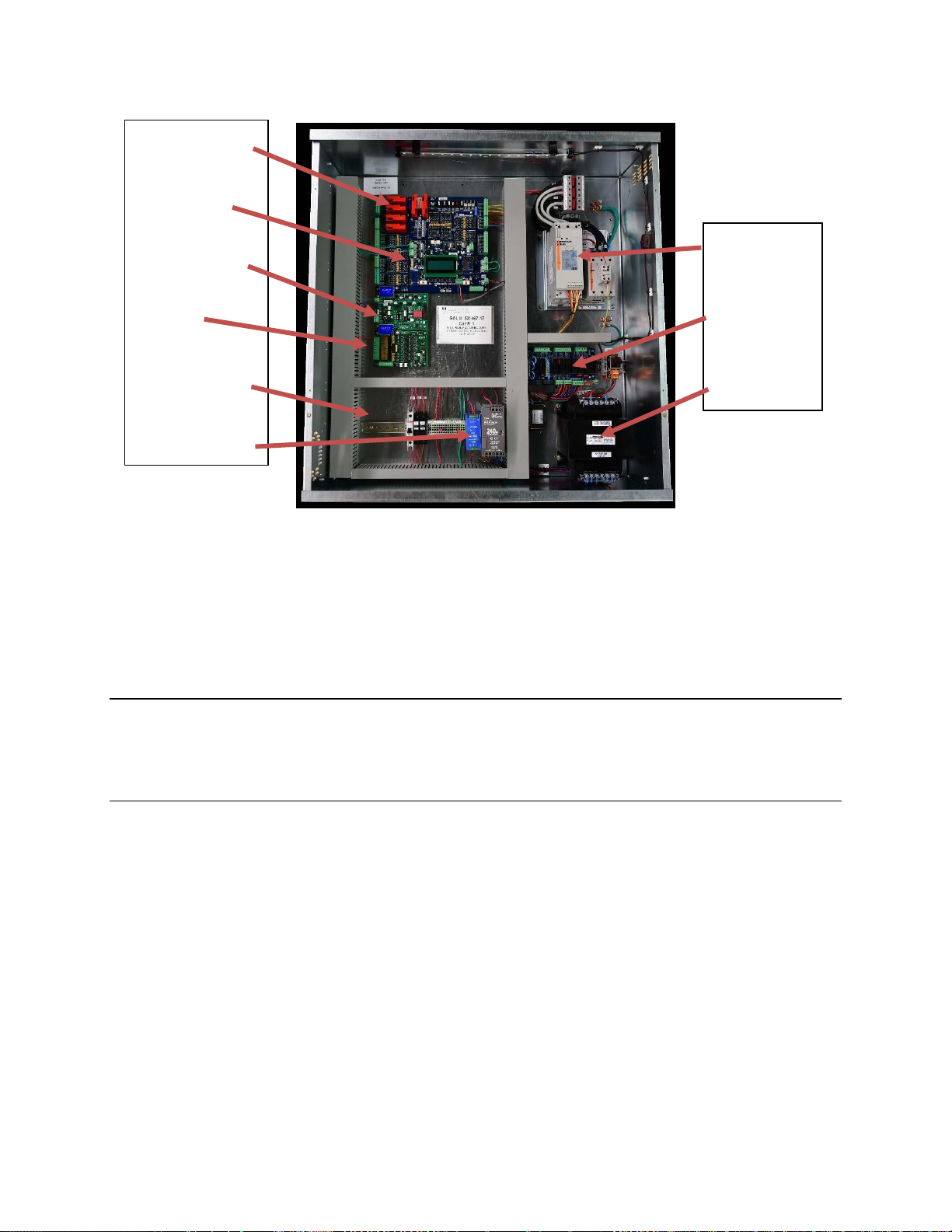

1.3 Physical Layout of the Controller

Figure 1-0 shows the general layout of the GALaxy eHydro Controller cabinet. The components in the

cabinet include the following items.

1) Main I/O Board:

The 1121 main control board contains input and output

devices, controller switches, fuses and field wiring

terminal connections. This board also includes the, the

Safety PAL and the NTS Processor.

2) Main CPU:

The 1132 CPU board is a dual core 32-bit CPU. It

executes the main control system programs. The main

core runs the car operation and the secondary core runs

the group operation. The LCD Interface mounted on the

Main CPU provides a user interface to all controller

adjustment and setup parameters. It also shows

diagnostic information.

3) PI Driver Board:

Driver for CE or E-Motive Position Indicator Displays.

4) Car I/O Panel:

Provides space for additional car I/O.

5) Terminal Block and Options:

Space for additional terminal blocks, optional contactors

and circuit breakers.

6) Power Supplies:

A 5 VDC power supply for the controller 5 Volt power and

a 24 VDC supply for all call button and lantern power.

7) Soft Starter:

Controls the soft start and running of the pump motor.

8) Power Distribution Board:

Contains fuses and distributes 120 VAC and 24 VDC for

the system.

9) Transformer:

Transforms the line voltage to the proper voltages for

signals and other controller functions.

Page 11

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-3

Figure 1-0: Typical Physical Layout of Top Cabinet

1.4 Selector System

The selector system for the GALaxy controller is an Absolute Position System with an encoded

touchless tape.

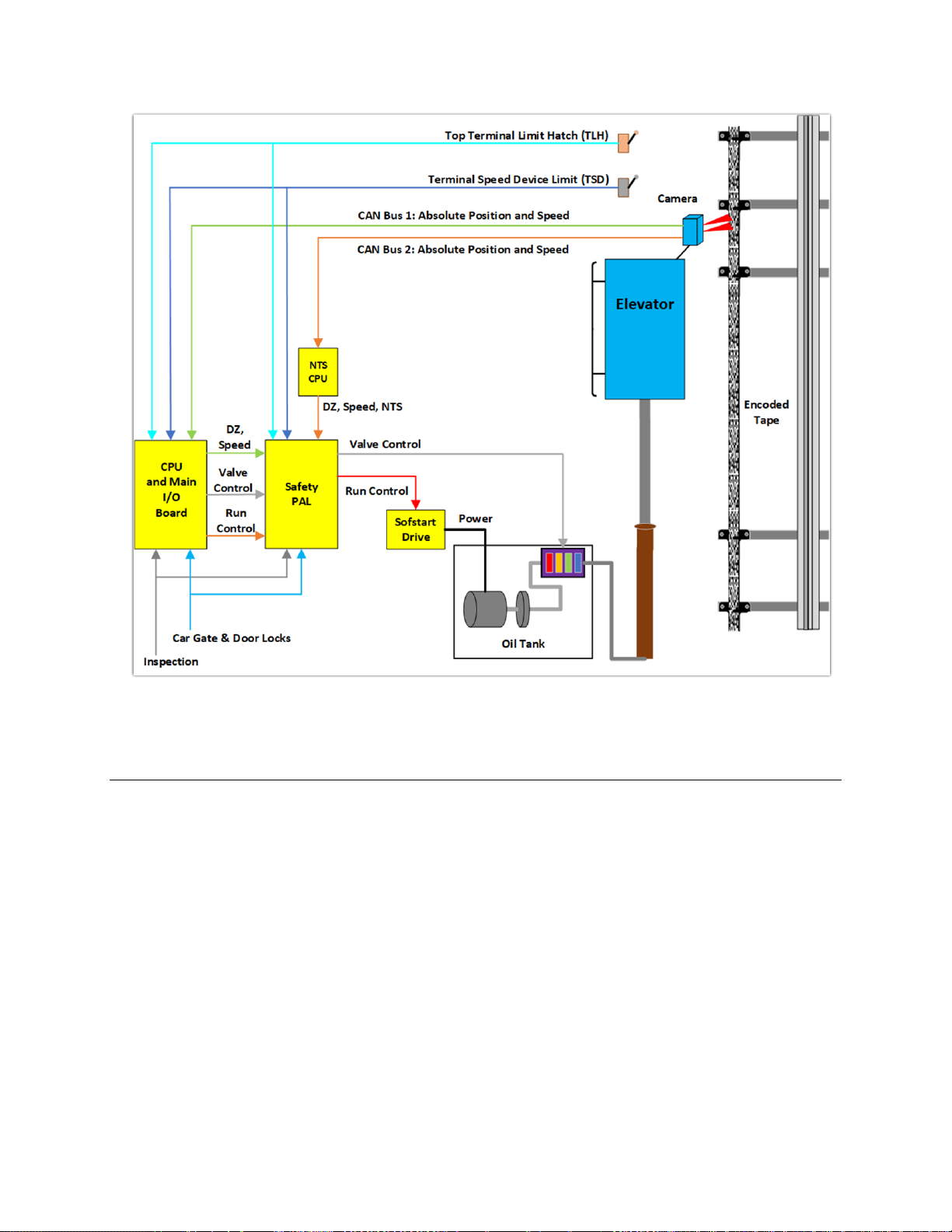

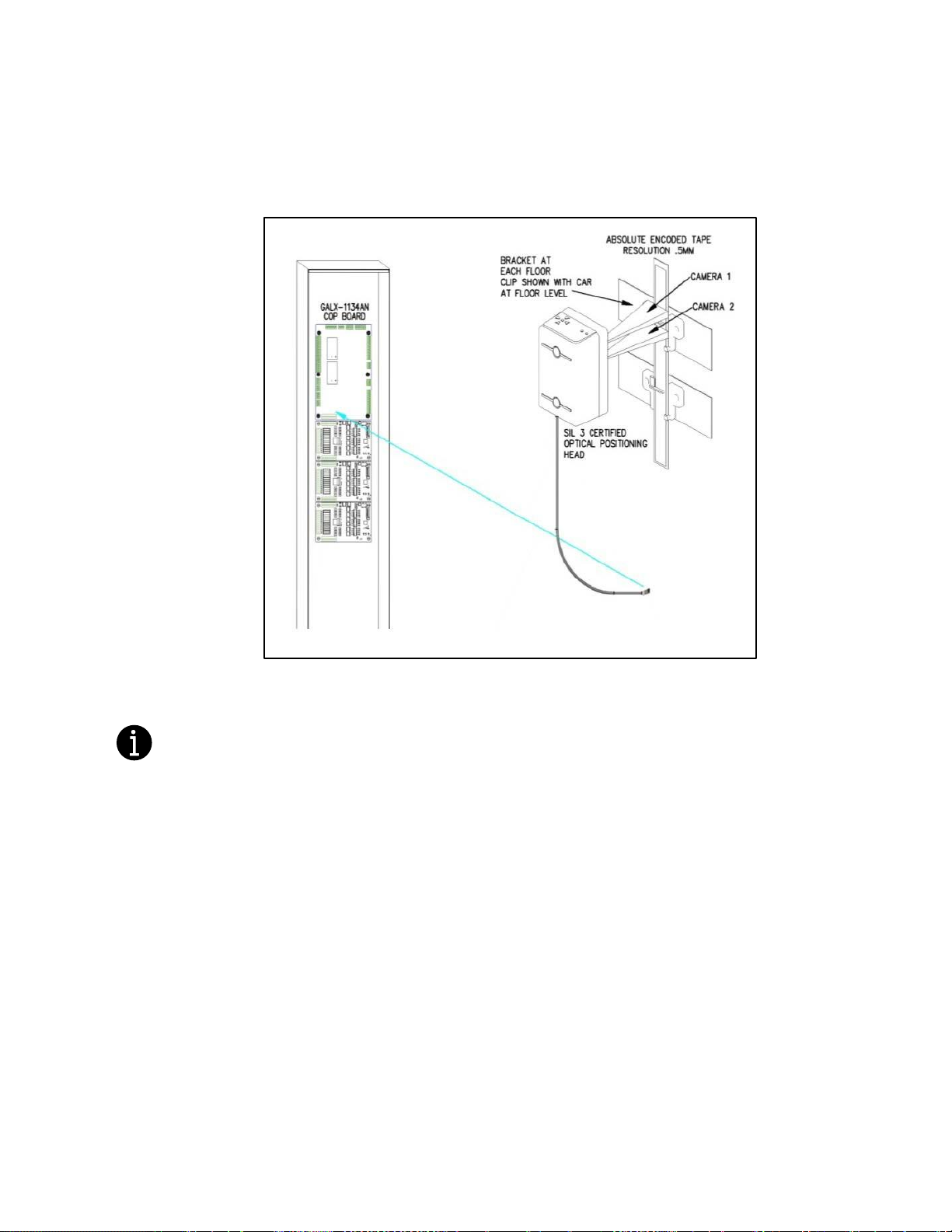

1.4.1 Absolute Position System (APS) Selector

The Absolute Position System Selector uses an encoded tape that is read by two independent

cameras. The dual camera device is SIL3 rated to supply position and velocity data over two

independent CAN bus channels. One CAN bus channel connects directly to the MAIN CPU and the

second CAN bus channels connects directly to the NTS processor. During setup both processors learn

the hoistway floor positions and slowdown limits. Each processor’s outputs control signals and door

zone status to the Safety PAL for independent redundancy checking.

This selector system delivers 0.5mm accuracy, 50.8 pulses per inch. A block diagram of the Absolute

Position System is shown in Figure 1-1.

. 1 Main I/O Board

. Main CPU

2

3

. PI Driver Board

4

. Car I/O

5

. Terminal Block

and Option

Section

6

.

Power

Supplies

7

.

Soft

-

Starter

8 . Power

Distribution

9

. Transformer

Page 12

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-4

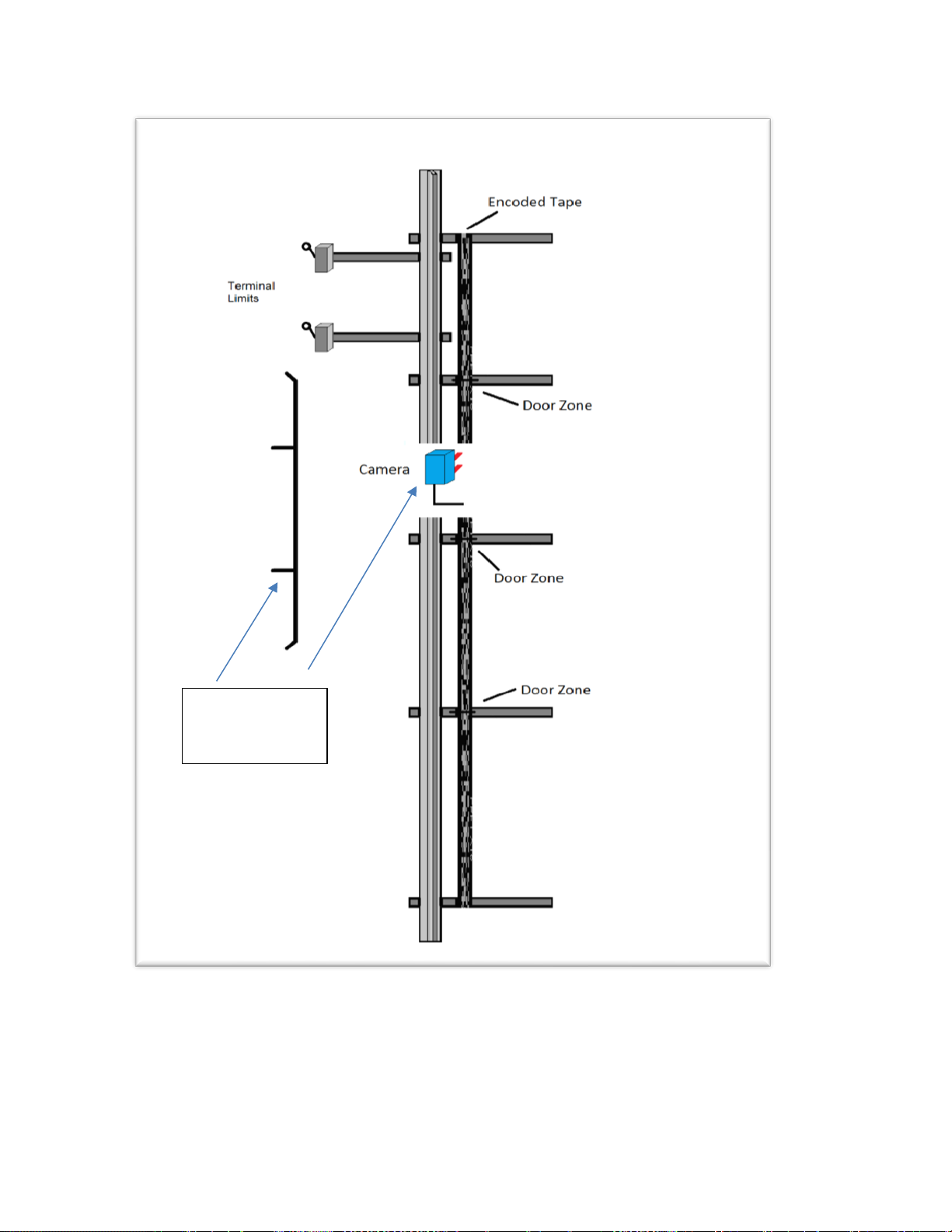

Figure 1-1: Absolute Position System Selector

1.4.2 Primary and Secondary Position Feedback

The Main CPU receives position feedback from the channel A camera CAN bus and builds a table of

floor positions and slowdowns for each floor during setup. On a normal run, the Main CPU uses the

slowdown points to initiate a slowdown to the appropriate floor and uses the floor position to determine

the door zone and exact stopping position.

The NTS processor receives position feedback from the channel B camera CAN bus and builds an

independent table of floor door zone positions and normal terminal slowdown limits (UN, UT, DN, and

DT) during setup. On a normal run, the NTS processor uses the NTS slowdown points to

independently remove power from the appropriate run valves as a redundancy to slowdown and stop

the car at terminal landings.

Both the Main CPU and NTS processor outputs door zone and control signals, (SU, SUF, SD, SDF for

the Main CPU and UN, UT, DN, DT for the NTS processor), to the Safety PAL to make hardwarecontrolled decisions that the car is safe to run.

To protect the car from hitting the stop ring at a speed greater than 50 fpm in the up direction, two

mechanical switches are wired in the hoistway at the top terminal landing. The first switch actuated

Page 13

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-5

while running up to the top terminal floor is the Terminal Speed Device (TSD) limit switch that directly

removes power from the up fast valve. The top most limit switch is the Terminal Limit Hatch switch

(TLH) that directly removes power from pump motor and all valves.

1.5 Sequence of Operation

Normal elevator operation, Automatic Mode, is selective-collective. When the elevator is traveling

upwards to answer calls, all up hall calls at floors above the car are answered in the order reached by

the car, regardless of the order in which the calls were registered. Upon reaching each landing with a

car call or hall call registered, the car and hall doors at that floor are automatically opened.

The doors stay opened for a dwell time that is field adjustable. There are three different dwell times

depending on whether it is a lobby call, car call, or hall call. The door will close before the set dwell time

has elapsed if a passenger presses the door close button and the minimum door open time has expired.

The door will reopen before it is fully closed if the door open button is pressed, if a passenger pushes

on the safety edge, if the photo-eye light beam is interrupted, or if a call for that floor in the direction of

travel is pushed. The door will close when the door opening condition is eliminated. When the door has

fully closed, the calls are answered.

When all up hall calls and car calls above the car have been answered, the elevator reverses direction

and travels downward to answer car calls and down hall calls placed below the car. The calls are

answered as previously described for up calls. When all calls below a down car are answered, the car

reverses direction to repeat the cycle. In short, an elevator traveling up will bypass down hall calls, and

an elevator traveling down will bypass up hall calls.

In buildings with more than one elevator grouped together, the actual time of arrival, “real time”, is used

to estimate how long each elevator will take to answer a hall call. The elevator that can respond the

fastest takes the call. Real-time based dispatching permits the controllers to quickly respond to actual

demand for elevator service. Some of the criteria used to estimate the time of arrival are as followed:

• Actual elevator floor to floor run times.

• Actual run time to the floor whether it is a multi-floor run or a one floor run.

• Whether the elevator is in or out of service.

• Whether the elevator is in load weigh bypass mode.

• The direction and position of each elevator in the group.

• The average door cycle time at each stop.

• Status of each elevator, accelerating, full speed, decelerating, actual time in motion.

• Number of stops required due to car calls.

• Number of stops required due to previously assigned hall calls.

• System demand.

The above performance criteria are continuously measured and stored for improved accuracy in the

dispatching algorithm. All of the above data is continuously scanned, and the hall calls are reassigned if

the conditions change and another car can respond faster. The ability to measure actual hall waiting

time virtually eliminates long waiting and improves the average hall call waiting intervals throughout the

building.

Page 14

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-6

1.6 Modes of Operation

1.6.1 Reset Mode

Reset mode is initiated when the elevator power is first turned on, or when the system is reset. When

the reset mode is initiated, the controller performs internal tests to ensure that both the car and

controller are electrically operational before putting the car into service. The car will not move until reset

mode is completed. Some of the internal tests that the controller performs are as follows: is the safety

string made up; is the elevator on inspection operation; is the door close limit open; are the interlocks

made up; is hoistway position correct. If all the safeties are made up, and the elevator is on automatic

operation, and it is at floor level, the elevator will go into automatic mode. If the elevator is not at floor

level, it will run slow speed down to the nearest floor, level into the floor, and reset the floor position

count.

1.6.2 Safety String Open Mode

Safety string open mode is initiated when a safety is open. Some of the safeties are listed below:

• Reverse phase relay

• Governor overspeed switch

• Top Terminal Limit Switch

• Pit switch

• Hatch Safety Switch

• Exit Door Switch

• Car Safeties

• Car top stop switch

• Fire Fighters Stop Switch

• In-Car Stop Switch

• Controller Stop Switch

When the safety string is made back up, the elevator will go back to reset mode.

1.6.3 Controller Inspection Mode

The controller inspection mode is initiated by placing the “INS” switch on the 1121 board in the

inspection position (down). Controller inspection mode permits operation of the car from the machine

room. This mode performs the following operations:

• Enables the controller inspection “ENABLE”, “UP” and “DOWN” push buttons

• Door locks are active and must be closed to move the car.

• Pressing the controller “ENABLE” and “UP” pushbuttons causes the elevator to move at

inspection speed in the up direction.

• Pressing the controller “ENABLE” and “DOWN” pushbuttons causes the elevator to move at

inspection speed in the down direction.

1.6.4 Car Top Inspection Mode

This inspection mode is initiated by placing the inspection switch on top of the car in the inspection

position. Inspection mode permits operation of the car from the car top inspection station. This mode

performs the following operations:

Page 15

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-7

• Disables access top and access bottom hall switches.

• Disables the controller "ENABLE", "UP" and "DOWN" push buttons.

• Door locks and Car gates/locks are active and must be closed or the door lock and gate bypass

switch or switches must be active to move the car.

• Enables the car top inspection station "SAFE", "UP" and "DOWN" push buttons

• Pressing the inspection station "UP" and "SAFE” pushbuttons causes the elevator to move at

inspection speed in the up direction.

• Pressing the inspection station "DOWN" and "SAFE" pushbuttons causes the elevator to move

at inspection speed in the down direction.

1.6.5 Access Mode

The access mode is initiated by placing the key operated access switch located in the car operating

panel to the on position. Access mode allows entrance into the Hoistway by qualified and authorized

elevator personnel for equipment inspection and service. Access to the top of the car is possible from

the top landing, and access to the pit is possible from the bottom landing. Enabling this mode permits

the following operation:

• Enables the access key switches at the top and bottom landing in the entrance door jambs.

• Bypasses the gate switch to allow car movement with the car door open.

• Bypasses the top or bottom landing hall door lock, depending on which terminal access switch

is being keyed.

• Turning the access key switch to the up position causes the elevator to move at access speed

in the up direction.

• Turning the access key switch to the down position causes the elevator to move at access

speed in the down direction.

1.6.6 Independent Service Mode

The independent service mode is initiated by placing the key operated independent switch located in

the car operating panel to the on position, or by placing the controller toggle switch “IND” to the down

position. Independent mode permits operation of the car with an operator. This mode performs the

following operations:

• Hall initiated calls are ignored.

• Hall lanterns and gongs are disabled.

• The doors open automatically and stay open until closed by the operator.

• Closing the doors requires constant pressure on the door close button.

• When the car door is closed, the car answers the nearest car-initiated call in the direction of

travel.

1.6.7 Load Weighing Bypass Mode

The load weighing bypass mode is initiated when the car is loaded to a predetermined percentage of full

capacity, by closing a connection between terminals “LC” and “LW” or from serial communication from a

load weighing device. Load weigh bypass mode allows the car to answer car calls and lighten the load

before answering any more hall calls. This mode performs the following operations:

• Hall initiated calls are ignored.

• All other elevator functions operate as if on fully automatic service.

Page 16

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-8

1.6.8 Attendant Service Mode

The attendant service mode is initiated by placing the key operated attendant switch located in the car

operating panel to the on position. Attendant mode permits operation of the car with an attendant. This

mode performs the following operations:

• The doors open automatically and stay open until closed by the attendant.

• Closing the doors requires a momentary pressure on the door close button, or the up or down

buttons located in the car operating panel.

• Hall initiated calls are answered unless there is constant pressure on the bypass button.

• Hall lanterns and gongs are enabled.

• The direction of preference can be specified by momentary pressure on the up or down buttons

located in the car operating panel.

1.6.9 Code Blue Hospital Service Mode

Code blue hospital service mode is initiated by turning one of the code blue switches, located at each

floor where medical emergency service is required, to the on position. A car is selected to respond to

the code blue call. That car will perform the following:

• Cancel all car calls

• Any hall calls previously assigned will be transferred to another car.

• If traveling toward the code blue call, it will proceed nonstop to the code blue call floor.

• If traveling away from the code blue call, it will slow down and stop at the nearest floor, maintain

doors closed, reverse direction and proceed nonstop to the code blue call floor.

• If at a floor other than the code blue call floor, the elevator will close the doors and proceed

nonstop to the code blue call floor.

• Once at the code blue call floor, the doors will open and remain open.

• The code blue in car switch located in the car operating panel must then be turned to the on

position. If the code blue in car switch is not turned to the on position within 60 seconds from

the time the doors reach full open on the code blue call floor, the car will revert back to normal

operation.

• Upon activation of the key switch, it will allow the car to accept a car call for any floor, close the

doors, and proceed nonstop to the floor desired.

• The return of the code blue in car key switch to the normal position will restore the car to normal

service.

1.6.10 Fire Service Phase I Mode

Fire service phase I is initiated when the primary smoke sensor is activated, or the fire key switch

located in the hall station on the primary return floor is turned to the on position. The primary return floor

is usually the lobby floor but could be another landing if it better serves the needs of emergency

personnel when fighting a fire or performing rescues. When fire service phase I is enabled:

• The fire emergency return light illuminates, and the fire buzzer sounds.

• The emergency stop switch is disabled when the door closes (depending on code requirement).

• The car travels to the primary return floor without answering any calls, then parks with the door

open. The fire buzzer turns off, but the fire emergency return light stays illuminated.

Page 17

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-9

• If the car is at a landing with the doors open, the doors will close, and the car will return non-

stop to the primary return floor.

• If the car is traveling away from the primary return floor, the car will stop at the next landing, and

then go immediately to the primary return floor.

• Turning the fire service key switch to the bypass position will restore the elevator to normal

service.

• The elevator will perform per ASME A17.1 requirement 2.27.3 unless otherwise specified.

1.6.11 Fire Service Phase I Alternate Return Mode

Fire service phase I alternate return is initiated when the smoke sensor in front of the elevator at the

primary return floor is activated. When fire service phase I alternate return is enabled:

• The fire emergency return light illuminates and the fire buzzer sounds.

• The emergency stop switch is disabled when the door closes (depending on code requirement).

• The car travels to the alternate return floor without answering any calls, then parks with the door

open. The fire buzzer turns off, but the fire emergency return light stays illuminated.

• If the car is at a landing with the doors open, the doors will close, and the car will return nonstop

to the alternate return floor. If the car is traveling away from the alternate return floor, the car

will stop at the next landing, and then go immediately to the alternate return floor.

• Turning the fire service key switch to the bypass position will restore the elevator to normal

service.

• The elevator will perform per ASME A17.1 requirement 2.27.3 unless otherwise specified.

1.6.12 Fire Service Phase II Mode

To initiate fire service phase II, the car must first have been placed in fire service phase I, and, as a

result, be parked at the designated level with the door fully open. Following that, the key operated fire

service phase II switch, located in the car operating panel must be placed in the on position. Fire

service phase II permits operation of the car by a fire fighter. This mode performs operations in

accordance with ASME A17.1 requirement 2.27.3 as follows:

• The doors close only with constant pressure on the door close button, after they have been fully

opened.

• The doors open only with constant pressure on the door open button, after they have been fully

closed.

• Hall lanterns and gongs are disabled. Safety edge and electric eye are disabled

• All registered car calls can be canceled with momentary pressure on the call cancel button

located in the car operating panel.

• All hall calls are disabled.

• To remove the car from fire service phase II the car must be at the fire return landing with the

doors in the fully open position and the phase II switch turned to the off position.

• See ASME A17.1 requirement 2.27.3 for specific operation of fire service phase II.

1.6.13 Emergency Power Sequencing

Emergency Power is initiated when a connection is made between terminals “HC” and “EMP”. This

mode performs the following operations:

• All cars are returned to the bottom floor one at a time, and cycle the door.

• The door open button remains active.

Page 18

GALaxy eHydro Elevator Controller Section 1 – Product Description

1-10

• If a car is selected to run it will go back into normal operation.

• Removing the connection between terminals “HC” and “EMP” will remove the cars from

emergency power operation.

1.6.14 Emergency Power Battery Lowering

Emergency Power Lowering is initiated when power is lost, and the Normal Power Relay drops out.

When this occurs, the power circuit switches to the UPS backup power and activates the EMP input.

This mode performs the following operations:

• The car returned to the bottom floor and cycles the door.

• The car cannot run but the door open button remains active.

• When normal power is returned to the controller, the Normal Power relay is picked removing

power from the EMP input and the car will return to normal operation.

1.6.15 Earthquake Mode

Earthquake mode is initiated upon activation of a seismic switch. This mode performs the following

operations:

• If in motion the car will proceed to the nearest available floor.

• Once at a floor, the car will cycle the doors and shut down.

• The door open button remains active.

1.6.16 Stalled (Low Oil) Mode

Stalled mode is initiated when the elevator has been in run mode longer than the field adjustable anti-

stall timer. This mode performs the following operations:

• Turns off the pump motor and stops the elevator.

• The car is returned nonstop to the bottom floor.

• Upon reaching the bottom floor, the doors cycle, then the elevator is shut down.

• The door open button remains active.

1.6.17 Automatic Mode

Since this is the normal operating mode, the controller automatically enters this mode if none of the

previously described modes are activated, and if no fault is detected. The following operations are

performed in automatic mode:

• The car operates in selective-collective control sequence when answering calls.

• Hall and car calls are functional.

• Hall lanterns and gongs are operational.

• Simplex Cars Park at the last call answered unless simplex lobby parking has been enabled in

the program. In a multi-car group, a car is parked at the lobby if no other demand exists and

parking is enabled.

• The doors remain closed when the car is parked

Page 19

GALaxy eHydro Elevator Controller Section 2 –Installation

2-1

Section 2 - Installation

2.1 General Information

This section provides basic guidelines and recommendations for the proper installation of the controller

equipment. These guidelines should be used as general instructions. They are not intended to usurp

local codes and regulations.

2.2 Site Selection

There are several factors that elevator personnel should consider when choosing a location for installing

this product. The elevator controller should be installed at a location that provides the most convenient

access for adjustment, inspections, and repairs. If at all possible, elevator personnel should have an

unobstructed view of the machine when standing in front of the controller. A safe and adequate

workspace around the controller must be provided. Work areas must be free of any items that might

interfere with the proper routing of conduits or hinder the opening of cabinet doors. All clearances,

workspaces, lighting, and guarding around the controller must comply with governing codes.

2.3 Environmental Considerations

The controller package is provided with a standard type 1 enclosure. This type of controller should be

installed in a clean, dry, and non-corrosive environment. Ideally, the equipment room should be

temperature controlled between 70° F and 90° F. However, control equipment will function properly within

an ambient temperature range of 32° to 110° F. If temperatures remain at the upper and lower extremes

of this range for an extended period of time, the life expectancy of the control equipment may be reduced.

It is important to always keep the controller dry, clean, and free of any dust and debris.

The control system is designed to have a high immunity to electrical noise, radio frequency radiation, and

magnetic interference. However, high levels of these items could cause interference with certain parts of

the control system.

The power supply feeding the controller should have a fluctuation of no greater than + or - 10%.

2.4 Wiring Guidelines and Instructions

See the IMPORTANT NOTICE on page “viii” of this manual

Page 20

GALaxy eHydro Elevator Controller Section 2 –Installation

2-2

2.4.1 Wiring Schematics

A complete set of wiring schematics and connection diagrams will be provided for each job. Each set of

wiring schematics and connection diagrams are job specific. The job name and number will be listed in the

bottom right corner of each page of these documents.

2.4.2 Proper Field Wiring

Most of the field connections to GALaxy controls are made using stranded wire. When inserting this

stranded wire into the terminals – especially those for EPD’s (Electrical Protective Devices) – care must

be taken to ensure that all the strands are properly inserted into the terminals. Improper stripping and

insertion may leave strands outside of the terminals. Strands not properly inserted into the terminals

may make contact with wires from an adjacent terminal.

The danger associated with an occurrence as described above has led GAL Manufacturing to

recommend that, for all connections to the Electrical Protective Devices listed in ASME A17.12016/CSA B44-16, Requirements 2.26.2.1 through 2.26.2.39, elevator personnel must follow the

guidelines listed below:

• Inspect all terminals used to connect Electrical Protective Devices. Ensure that the cage clamp is

fully open before inserting a wire into the terminal block.

• Perform corrective action for wires with stray strands by one of the following methods:

o Reconnect the wire with all wire strands correctly installed into the terminal. Visually

verify that no wire strands are outside of the terminal. The conductor should be stripped

and inserted completely into the terminal in such a manner that no more than two

millimeters of bare wire is visible; or

o Attach a ferrule to the end of field wire for safety devices (as pictured in Figures 0-1 and

0-2) and insert the ferrule into the terminal; or

o Use an acceptable method such as tinning.

• After removal and replacement of any of these field wires, the actual Electrical Protective Device

should be checked for proper operation.

2.4.3 Ground Wiring

Proper grounding of the power supply, controller, elevator car, and hoistway is required. Separate

conductors should be run for EG (earth ground) and GND terminals. These terminals and conductors

are detailed on the wiring schematics.

2.4.4 Hoistway Wiring

All hoistway wiring is detailed on the wiring schematics and connection diagrams. The number of

required hoistway conductors is listed in the connection diagrams. A job specific “pull sheet” is also

included in the connection diagrams.

Page 21

GALaxy eHydro Elevator Controller Section 2 –Installation

2-3

2.4.5 Elevator Car Wiring

All elevator car wiring is detailed on the wiring schematics and connection diagrams including the wiring

to the car station, door operator, car top selector, and inspection station. The number of required

traveling cable conductors is listed in the connection diagrams. A job specific “pull sheet” is also

included in the connection diagrams.

2.4.6 Machine Room Wiring

All machine room wiring is detailed on the wiring schematics and connection diagrams including the

main power supply wiring, motor wiring, and field wiring.

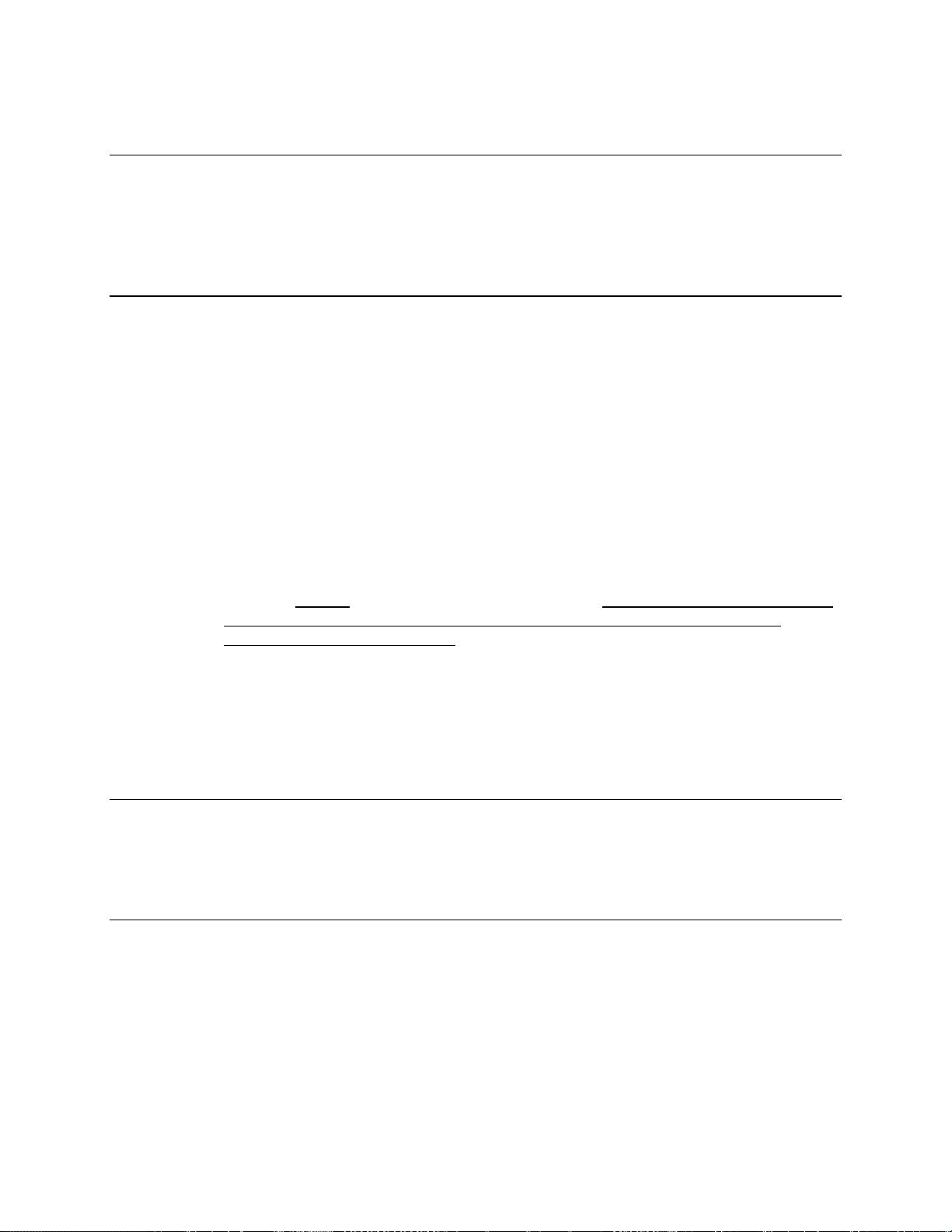

2.5 Normal and Top Terminal Slowdown Limits

The terminal slowdown limits include the Normal Terminal Slowdown Limits (including UN, UT, DN and

DT) and the Top Terminal Limits (including TSD and TLH). The Normal Terminal Slowdown Limits are

read from absolute positions on an encoded tape. The TSD and TLH limits are mechanical switches.

The Normal Terminal Limits are used to cause the car to slowdown and stop at or near the terminal

landing if the normal stopping means does not function properly. The NTS processor monitors the

position of the car in the hoistway from the APS selector camera and turns off the appropriate limit

switch, when the limit position is reached, independent of the Main CPU.

The Top Terminal Slowdown limits are used to prevent the car from hitting the stop ring on the hydraulic

jack at a speed greater 50 fpm. TSD and TLH limits must be mechanical switches installed on all

GALaxy eHydro controlled elevators and must be set to activate mechanically from the movement of the

car.

The distance that the limits are placed from the terminal landing depends on the speed of the car. Table

2-0 shows the slowdown limit locations with respect to contract speed. All distances are shown in

inches. The distances listed represent the distance from the terminal landing when the slowdown switch

is actuated.

Table 2-0: Slowdown Distances from Terminal Landings

Page 22

GALaxy eHydro Elevator Controller Section 2 –Installation

2-4

• * UT and DT limit distances are setup by parameters in the NTS Processor. UN and DN limits are

always 2” above and below the top and bottom terminal landings respectively.

The up and down directional limit switches UN and DN will be set to open two inches past the terminal

floor levels on the NTS processor and MAIN CPU. With the Absolute Position System (APS) selector

camera, the slowdown limit positions are automatically calculated by the NTS processor and Main CPU

boards. If the calculated slowdown values are not adequate, the distances for the NTS Processor and

the Main CPU can be modified from the Main CPU LCD Interface under the “NTS Proc Adj Vars” menu.

The Main CPU slowdown distances will always match the NTS processor distances.

2.6 Top Terminal Limit Switches

The Top Terminal Limit Hatch (TLH) switch should be set to open four inches above the top terminal

floor level. The Terminal Slowdown (TSD) switch should be set to open at the appropriate table value.

These two switches must be mechanical switches.

For the requirements for a running platform during initial start-up, refer to the GALaxy eHydro

Quickstart Guide or Section 3.2.1 of this manual.

2.7 Selector Installation

2.7.1 APS (Absolute Position System) Selector Installation

2.7.1.1 Installation of the Encoded Tape and APS Camera

Always handle the encoded tape with care to make sure that the encoded surface of

the tape is not damaged. Do not kink the tape or bend the tape in too tight of a

radius. When installing the tape, make sure that no grease, dirt, or debris is on the

encoded surface of the tape.

The general configuration of the APS (Absolute Position System) Selector is shown in Figure 2-0.

Page 23

GALaxy eHydro Elevator Controller Section 2 –Installation

2-5

Figure 2-0: APS Selector General Configuration

Camera and

Cam mounted

on the Elevator

Page 24

GALaxy eHydro Elevator Controller Section 2 –Installation

2-6

To install the APS Selector, follow steps 1 through 8 below:

Step 1: Install top selector bracket and attach the encoded tape.

• Mount the top J-hook selector bracket to the rail.

• Make sure the bracket is high enough that, when the car is on the stop ring above the top

terminal landing, that the encoded tape is still within the field of view of the APS cameras, and

that nothing on the car contacts the bracket.

• Attach the encoded tape to the top bracket keeping the encoded tape as close to the rail as

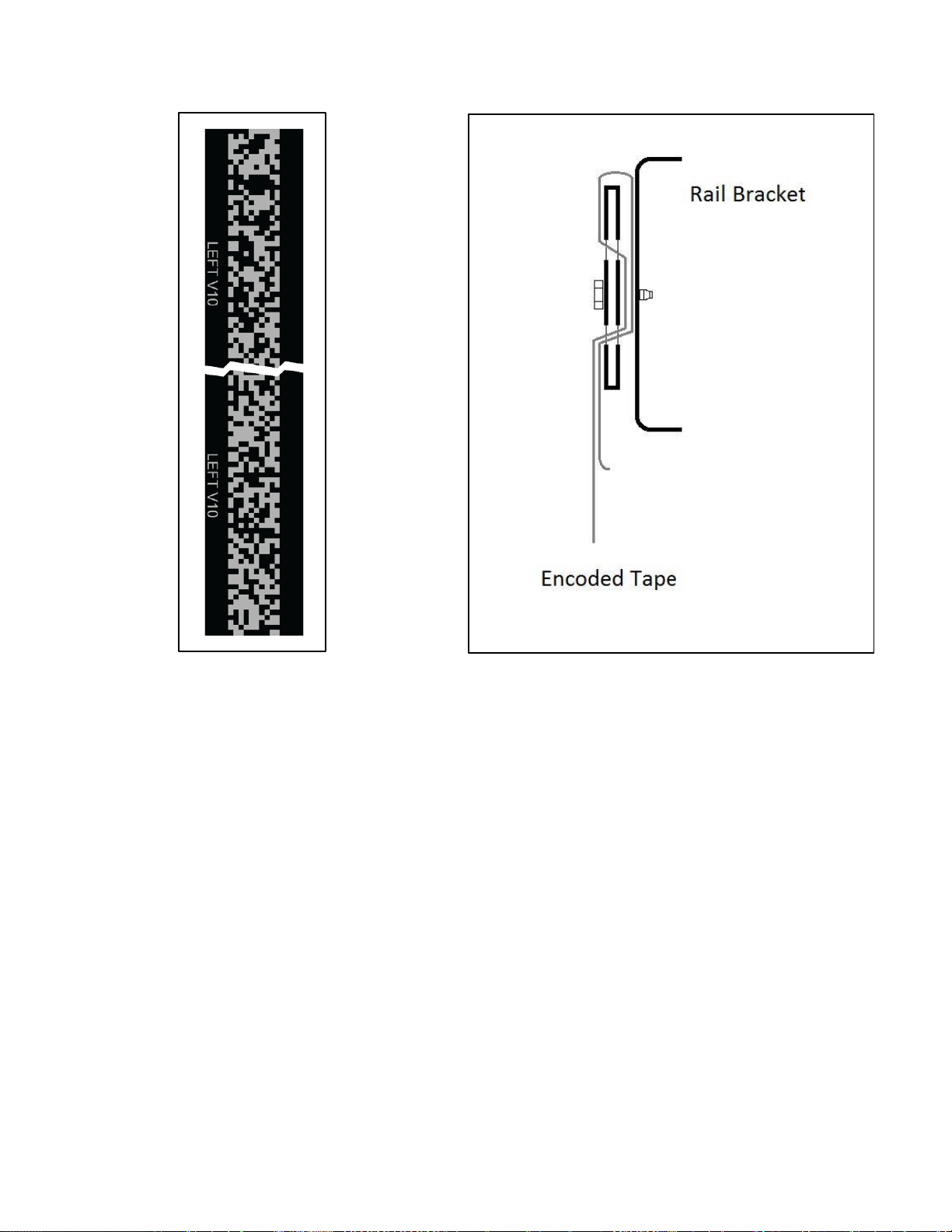

possible. See Figure 2-1.

• Make sure to feed the tape through the front side of the bracket first (the side facing the car), and

then bend it around the top of the bracket and lace it back down. Make sure that the encoded

side of the tape faces the car and that the “LEFT” markings on the tape are on the left side. See

Figures 2-2 and 2-3.

• Fasten the tape with the supplied bracket and screws.

Figure 2-1: Encoded Tape Mounting – Top Bracket

Page 25

GALaxy eHydro Elevator Controller Section 2 –Installation

2-7

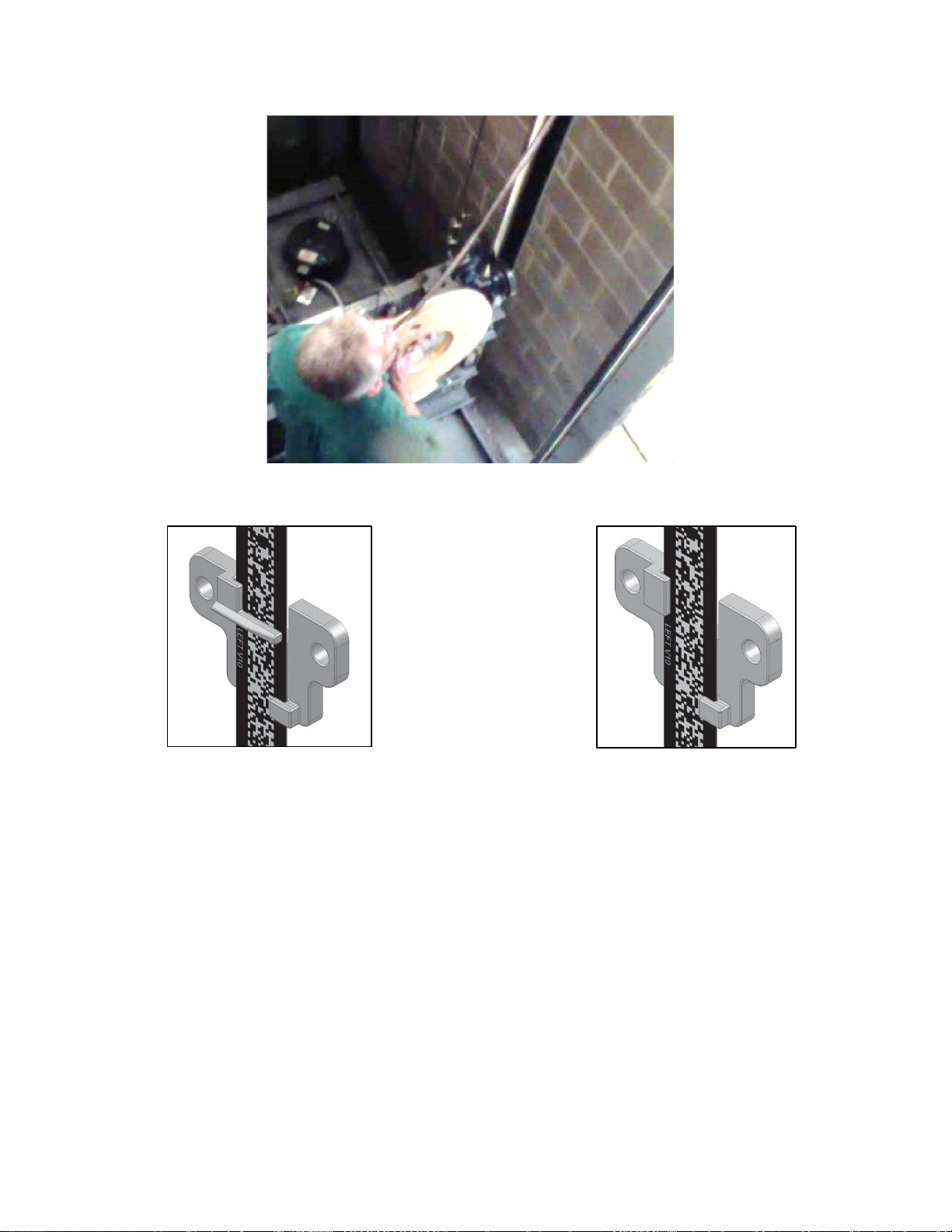

Step 2: Run down on inspection while unrolling the encoded tape.

• Run down on inspection while unrolling the tape. See Figure 2-4.

• Make sure you do not kink the tape or bend it in too tight of a radius. The tape can be

damaged, and it should be handled with care.

• Mount a J-hook selector bracket and guide clip with a door zone bridge for each floor. See

Figures 2-5 and 2-10.

• When the elevator is at floor level the door zone bridge should be positioned at the midpoint

between the two APS cameras. See Figure 2-14. The exact positioning of this bracket and guide

clip will be set in section 2.7.2.4.

• Where there are tall floor heights or blind hoistways, mount J-hook selector brackets and guide

clips without door zone bridges, at locations as needed, that will hold the encoder tape at the

proper position with respect to the guide rails and APS camera. See Figure 2-6.

• Make sure your hands are clean and you do not leave any grease or dirt on the front of the tape.

Figure 2-2: Front View of Encoded Tape

Figure 2-3: Side View of Top Bracket

Page 26

GALaxy eHydro Elevator Controller Section 2 –Installation

2-8

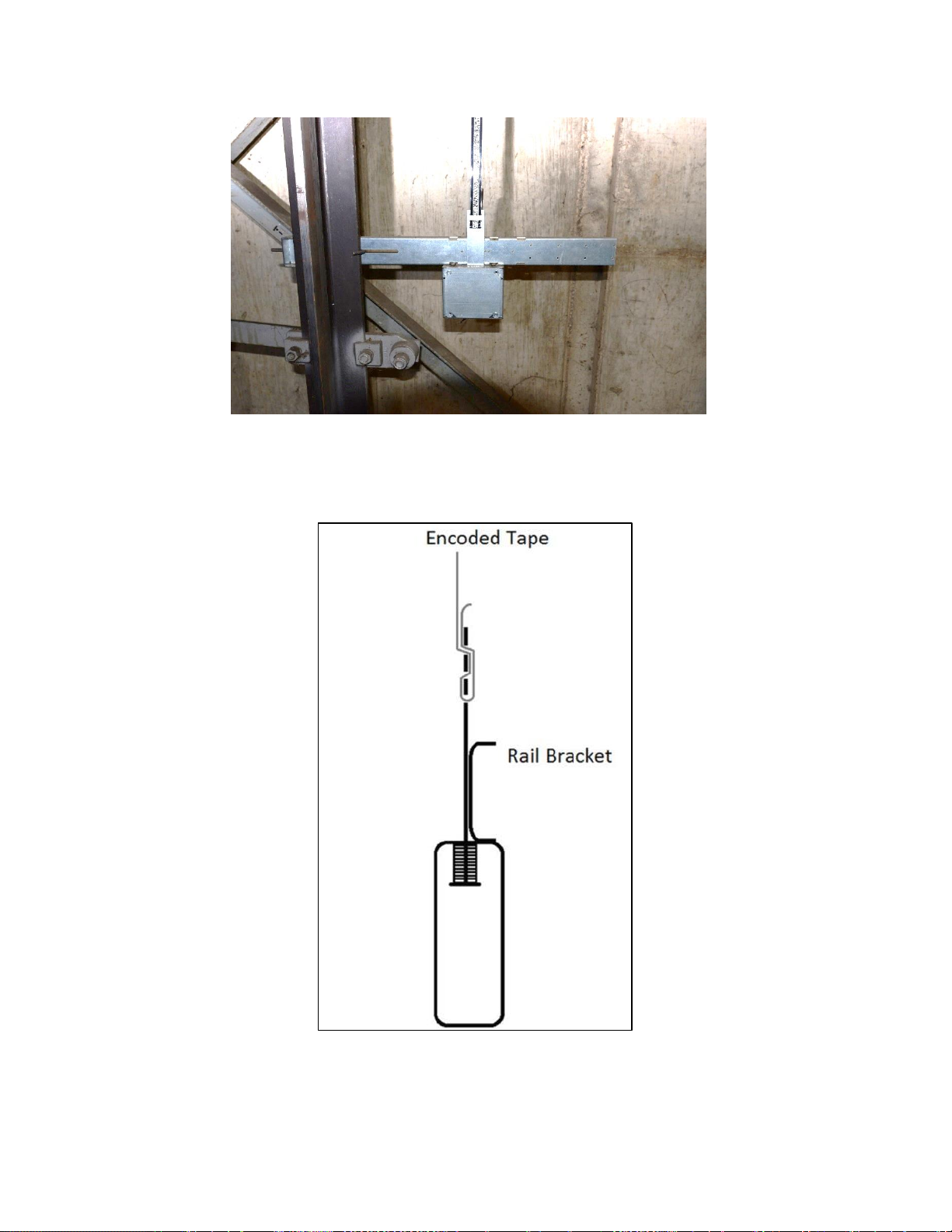

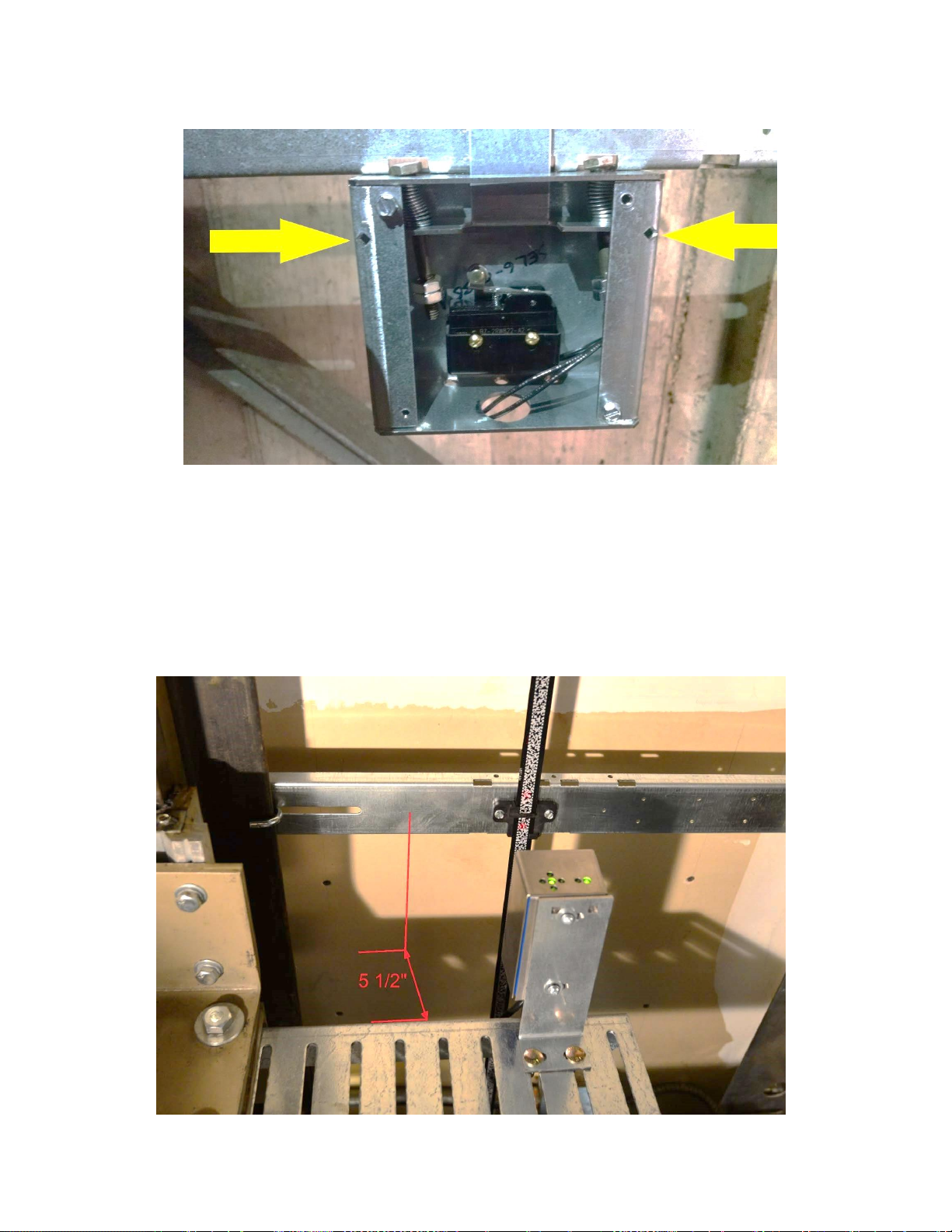

Step 3: Install the bottom selector bracket and attach the encoded tape.

• Mount the bottom selector bracket onto the car guide rail as shown in Figure 2-7.

• Make sure the bracket is low enough that, when the car fully compresses car buffer, that the

encoded tape is still within the field of view of the APS cameras, and that nothing on the car

contacts the bracket.

• Attach the encoded tape to the rail bracket with the slack tape switch.

• Make sure to feed the tape through the front side of the bracket (the side facing the car) first, and

then bend it back up toward the back of the tape. See Figure 2-8.

• Push the bracket down until the springs are depressed to the mark in order to properly tension

the encoded tape. See Figure 2-9.

• The slack tape switch should be properly installed and wired according to the wiring schematics

and connection diagrams

Figure 2-4: Unroll the Encoded Tape

Figure 2-5: Guide Clip with

Door Zone Bridge

Figure 2-6: Guide Clip without

Door Zone Bridge

Page 27

GALaxy eHydro Elevator Controller Section 2 –Installation

2-9

Figure 2-8: Side View of Encoded Tape Attachment to the Bottom Bracket

Figure 2-7: Lower Bracket Mounting

Page 28

GALaxy eHydro Elevator Controller Section 2 –Installation

2-10

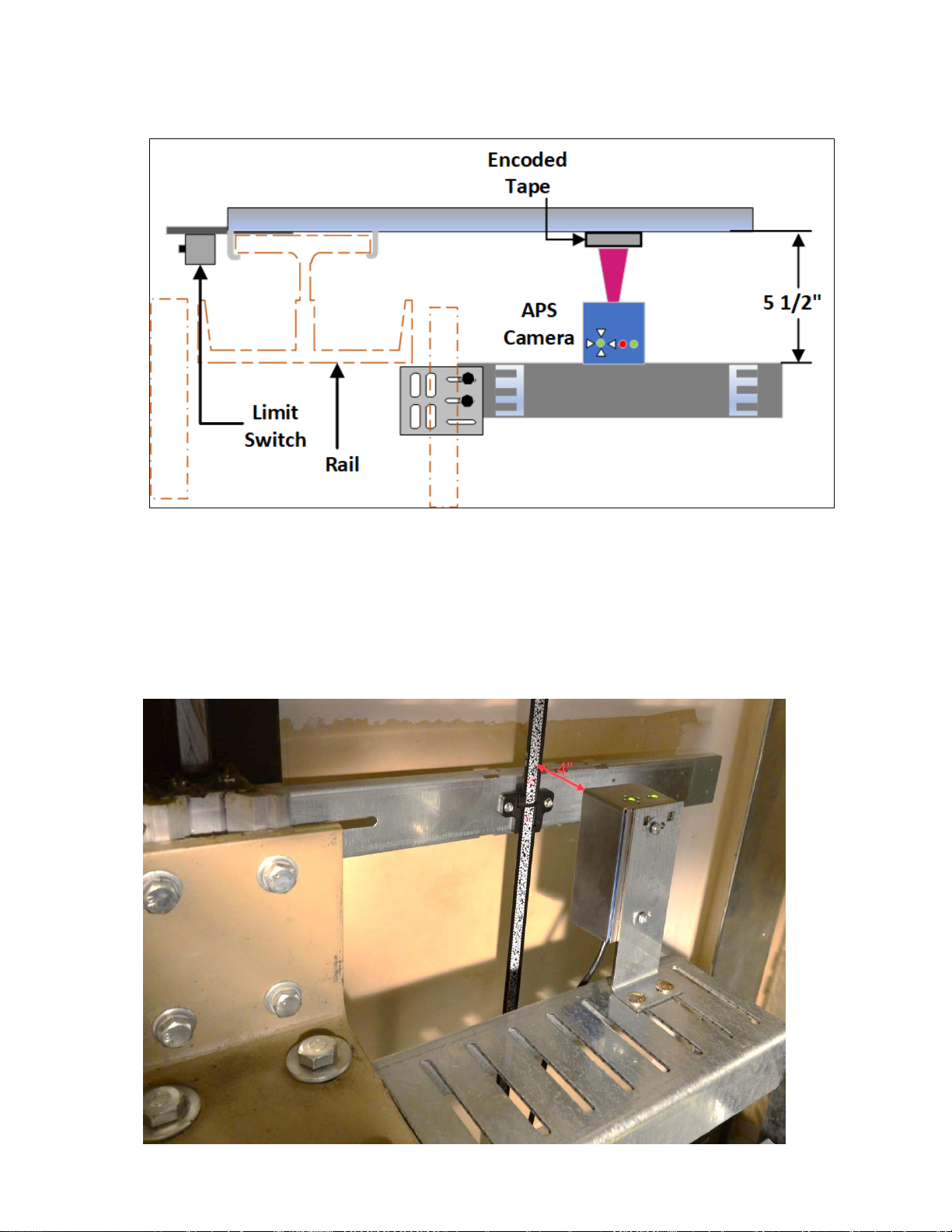

Step 4: Install the selector mounting bracket.

• Mount the selector mounting bracket to the cross head.

• Use the roller or slide shoe guide bolts to hold the camera bracket. The face of the bracket

should be about 5 ½ inches from the back of the rail. See Figures 2-10 and 2-11.

• The back of the bracket should be as close as possible to the crosshead channel.

• Use a level and make sure it is plumb and level.

Figure 2-9: Lower Bracket with Springs Properly Compressed to the Marks

Figure 2-10: APS Camera and Mounting Bracket

Page 29

GALaxy eHydro Elevator Controller Section 2 –Installation

2-11

Step 5: Install the APS Camera.

• Mount the camera on the mounting bracket.

• The APS camera should be centered with the encoded tape.

• The face of the camera should be 4 inches from the face of the tape. See Figure 2-12.

Figure 2-11: Top View of APS Camera and Mounting Bracket

Figure 2-12: APS Camera Mounted 4 Inches From Encoded Tape

Page 30

GALaxy eHydro Elevator Controller Section 2 –Installation

2-12

Step 6: Wire the APS Selector Camera according to the connection diagrams.

• The APS selector should be wired according to the job specific wiring schematic and

connection diagrams. See Figure 2-11.

Prior to performing “Step 7” below, the eHydro controller must be installed, and the APS selector

must be properly wired according to the wiring schematics. See Section 3 of this manual.

Step 7: Perform a fine adjustment of the APS camera.

• Make the fine adjustment of the camera using the LED array on the top of the APS camera. See

Figure 2-14.

• Adjust the camera so only the green LED in the middle of the 4 red arrows is on. See Figure

2-16.

• Temporarily obstruct the field of view of the APS camera for 5 seconds, and then remove the

obstruction. Two red alignment spotlights should appear on the encoded tape. These spotlights

represent the center of the field of view of each APS camera. Adjust the camera so the

spotlights are in the center of the encoded tape. See Figure 2-15.

• Level the APS camera with a leveling device. The APS camera must be parallel and square to

the encoded tape. See Figure 2-17.

• The PWR and STAT LED’s indicate the status of the APS. See Table 2-1.

Figure 2-13: Wire APS Camera According to Wiring Schematic and Connection Diagram

Page 31

GALaxy eHydro Elevator Controller Section 2 –Installation

2-13

LED

Color

Function

OFF

ON

Slow Blinking (1 Hz)

Fast Blinking (5 Hz)

PWR

Green

Supply voltage

No power

Power OK

--

--

STAT

Red

Status signal

No errors

Reading error

APS internal fault

Communication error

Figure 2-14: LED Array on

APS Camera

Figure 2-15: APS Camera Alignment

Spotlights

Figure 2-16: Fine Adjustment of the Camera Sensor

Table 2-1: APS Camera, PWR and STAT LED’s

Page 32

GALaxy eHydro Elevator Controller Section 2 –Installation

2-14

2.7.2 APS Selector Floor Position Setup (Hoistway Learn)

The hoistway learn procedure requires that the selector camera communicates properly with the Main

CPU and the NTS processor. The hoistway learn procedure also requires that the APS camera module

communicates properly with both CPUs on the selector interface board and with the main CPU in the

controller.

Proceed to Section 3 of this manual, and, once the “Prepare the Car for Hoistway Learn” section

is reached in section 3.3.3, return to section 2.7.2.1.

2.7.2.1 Verify that the APS Selector Camera is Installed Correctly and Communicating.

From the Diagnostic menu on the LCD Interface, select the Sel CAN Com Status. Verify that the CPU

to Selector Rx Error Cnt is zero, that the Rx Data Cnt is counting and that the On-line status equals 1.

Verify that the CNT A is not zero, that there are no Errors or Warnings and that the alignment is

centered and contrast shows OK. Also verify that the NTS to Selector status shows that the Rx Error

Cnt is zero, that the Rx Data Cnt is counting and that the On-line status equals 1. Continue to verify

that the CNT B value for NTS Processor is not zero, that there are no Errors or Warnings and that the

alignment is centered and contrast shows OK.

Figure 2-17: APS Camera Orientation

Page 33

GALaxy eHydro Elevator Controller Section 2 –Installation

2-15

2.7.2.2 Set the Adjustable Variables – “NTS Proc Adj Vars” in the Controller.

The following parameters must be setup prior to learning any floor positions.

• Set “Top Speed” to the contract speed of the job.

• Set “Num Valid Fl” to the number of floors with openings on this elevator.

• Set “UT Limit Dist” and “DT Limit Dist”. If set to zero, the distance is set automatically from the

slowdown table in the manual. If the parameter is changed, it will not take effect until a learn

operation is done at the top and bottom floor. It is recommended to set both parameters to zero

unless the slowdown distance need to be adjusted.

• Set “Can Baud Rate” to 0. 0 is 115.2K Baud. This parameter should not need to be changed.

2.7.2.3 Zero the Hoistway

After the NTS Processor parameters are setup, navigate to the Elevator Setup menu and select Learn

Hoistway. The diagram below, Figure 2-18, shows the initial part of Learn Hoistway process if done

from the machine room. To setup the hoistway from the car, you will only have to enter this menu the

first time to zero the hoistway table. Note that the number of valid floors and top speed will be verified

during this process. Be sure to select YES for First Time Setup and press ENTER. When you see the

message, “Setup Active. Hit Up or Dn to Scroll thru”, press MODE to escape to the main menu. You

are now ready to setup the floors from the car.

Figure 2-18: Learn Hoistway From Car

Page 34

GALaxy eHydro Elevator Controller Section 2 –Installation

2-16

2.7.2.4 Setting Hoistway Floor Levels with APS Selector

• Put the elevator on car top inspection.

Temporarily set the car door bypass switch to the BYPASS position. Setting the car door

bypass switch to the BYPASS position will allow the car to be moved on car top

inspection with the car door open. All safety precautions must be followed to ensure the

safety of elevator personnel and the general public when moving the car on car top

inspection with the car door bypass switch in the BYPASS position.

• Move the jumper on the GALX-1134AN COP board to the setup position. See Figure 2-19.

Run/Setup

Jumper

Figure 2-19: GALX-1134AN COP Interface Board Setup Jumper

Page 35

GALaxy eHydro Elevator Controller Section 2 –Installation

2-17

• Move the car on inspection so that it is exactly level with a floor.

Pressing the door open button, while moving the car on inspection, will change the

inspection speed to 3 fpm during the inspection run. This allows the car to be positioned

at exactly floor level. The inspection speed will return to the value set for “Inspect Speed”

in the “Car Motion” Sub Menu when the door open button is not pressed.

• Adjust the J-hook bracket and guide clip so the door zone bridge is positioned at the

midpoint between the two APS cameras. If the alignment spotlights are not visible,

temporarily obstruct the field of view of the APS camera for 5 seconds, and then remove

the obstruction. Two red alignment spotlights should appear on the encoded tape. See

Figures 2-15 and 2-20.

Figure 2-20: APS Selector Alignment Spotlights

Page 36

GALaxy eHydro Elevator Controller Section 2 –Installation

2-18

• To record the floor position, press the buttons on the car operating panel in the following

sequence.

o Press the 2nd floor car call button

o Press the 1st floor car call button

o Press the 2nd floor car call button

o Press the 1st floor car call button

o Press the Door close button

The car call light for floors 1 and 2 will illuminate momentarily and then turn off.

After the two car call lights turn off, press the following button on the car operating panel.

o Press the car call button for the floor where the car is currently located.

This car call light will flash on and off for approximately 5 seconds and then remain off.

This indicates that the floor position was recorded successfully. If the car call light does

not flash, but remains illuminated, the floor was not recorded successfully. If the floor

position was not recorded successfully, verify that the APS SEL adjustable variables are

set properly.

The 1st floor car call is the car call for the bottom terminal landing. The 2nd floor car call is

the car call for the landing that is one floor above bottom terminal landing. The actual

floor markings for these floors may not be “1” and “2”.

• Repeat this process until all valid floors have been recorded.

Set the car door bypass switch to the OFF position.

• The hoistway learn is now complete.

• Proceed to section 3.3.3.

Page 37

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment

3-1

Section 3 - GALaxy Startup and Adjustment

3.1 Procedure for Initial Power-up of Controller

3.1.1 Checking Main Line Voltage

Prior to powering up the controller or attempting to run the hydraulic pump motor, the following steps

should be completed:

• Familiarize yourself with the wiring schematics.

All safety precautions, including precautions related to electrical safety, must be followed

to ensure the safety of elevator personnel and the general public.

• Before applying power to the controller, the following items should be verified by the

proper electrical authority.

o Verify that the disconnecting means is properly sized and is lockable.

o Verify that the voltage supplying the elevator controller is correct as indicated

on the “Controller Input” of the controller data tag.

o Verify that the conductors supplying the disconnecting means are properly

sized.

o Verify that the conductors from the disconnecting means to the controller are

properly sized.

o Verify that power supply feeding the controller has the proper fuse protection

or circuit breaker protection.

Verify that the power supply feeding the controller is properly grounded and that the grounding

conductor is properly sized.

3.1.2 Check Controller Voltage

Turn the main line disconnect to the on position. Check the voltage at R, S, and T on the Soft-Starter.

Verify that all three phases are present. Check the voltage at fuses L1 and L2 on controller. If correct,

check that the voltage at terminals “S10” and “L120” with respect to “GND” reads 120 VAC. Check that

the voltage across terminals “C24V” to “C24C”and “L24V” to “L24C” each reads 24 VDC. If any of these

voltages are not correct, check wiring diagram to determine problem before continuing. Verify what the

voltage for “FEP” and “HCP” match the voltage specified on the schematic.

3.1.3 Verify the Main CPU is Operating

Check to make sure that the “axy” of GALaxy on the Main CPU LCD interface is blinking. If the “axy” is

blinking, continue to the next step. If not, check voltage at terminals 5V to 0V on the 1121 Main I/O

board to insure 5VDC. If 5VDC is present and the “axy” on the Main CPU LCD interface is not blinking,

then contact factory.

Page 38

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment

3-2

3.2 Start-Up Procedures

3.2.1 Requirements for a running platform during initial startup

1) Wire Hydraulic Pumping Unit and Main Line Power as shown in the job connection diagrams.

2) If elevator requires a Governor, install and wire the Governor as shown in the job connection

diagrams.

3) Add temporary connections on the GALX-1121 Main I/O Board and on the I/O expansion boards

as shown in Figures 1, 2, and 3.

4) Set the toggle switches on the Main I/O Board as shown in Figure 3.

5) Place CN18 on pins 2 and 3, in the temporary “Test Mode” configuration, on the GALX-1121 Main

I/O Board, as shown in Figure 3.

All temporary connections must be removed before placing the elevator in service.

Figure 3-0: Typical I/O Expansion Board

Fire I/O Board

Figure 3-1: GALX-1121 Main I/O Board With

Run Bug. See Figure 3-2 For

Run Bug Stop Switch.

Page 39

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment

3-3

Figure 3-2: GALX-1121 Main I/O Board

See

Figure 3-1

For Run Bug

Connections

Page 40

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment

3-4

6) Check/set parameters in the controller LCD user interface. See “eHydro Controller Settings” in

Table 3-0.

Preset the following parameters from the LCD User Interface “Adjustable Variables” menu.

Adjustable Variables - Car Motion

Adjustable Variables - System Options

APS Dead Zone = 0.25 inches

Hall Lan Baud = 3 (19,200)

Stop On PosCnt = 0 (To be set in final setup)

Adjustable Variables - NTS Processor

High Spd Ins = 0 (0=slow speed inspection)

Top Speed = Contract Speed

Number Valid Fl = Number of Valid Floors

UT Limit Dist = 0

DT Limit Dist = 0

7) Preset the hydraulic valve according to the manufacturer’s instructions.

8) Verify that the hydraulic pumping unit motor rotates in the correct direction.

9) If the motor rotation is not correct, disconnect power and swap the motor starter wires connected

to the “Softstarter” terminals 1-L1 and 3-L2. After swapping these wires, re-apply power and

verify that the motor rotates in the correct direction.

10) If the Sprecher Schuh Softstarter generates a “Phase Reversal” fault, verify that dip switch 9 on

the Softstarter is set properly. See the Sprecher Schuh Softstarter manual for instructions on the

proper setting for dip switch 9.

• Verify that the elevator is safe to operate as a running platform and that all individuals are

clear of moving machinery.

• Make sure all hoistway and car doors are closed.

11) Adjust the speed of the platform in the up and down directions according to the hydraulic valve

manufacturer’s instructions.

3.2.2 Complete the Installation of Equipment

Before beginning the adjustment process, the installation of all equipment should be complete including

the following items. See Section 2 for the installation procedures.

• All field wiring, safety circuits, and safety devices should be installed.

• The APS selector system should be installed including the “door zone bridge” guide clips.

• All Terminal Limit switches should be installed.

• All car doors and car door electric contacts or car door interlocks should be installed.

• All hoist doors and hoistway door interlocks should be installed.

Table 3-0: eHydro Controller Settings

Page 41

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment

3-5

3.3 Adjustment Procedures

• Remove all temporary connections.

• Verify that all safety circuits and safety devices are installed and functioning properly.

• Verify that all car door electric contacts or car door interlocks are functioning properly.

• Verify that all hoistway door interlocks are functioning properly.

• Verify that all hoistway doors and car doors are closed.

• Verify that the elevator is safe to operate and that all individuals are clear from moving

equipment.

3.3.1 Set Toggle Switches

Set all toggle switches on the 1121 Main I/O board as follows:

• DOOR LOCKS - "OFF"

• IND - "IND"

• AUTO DOOR - "OFF"

• STOP - "RUN"

3.3.2 Ready the Car to Run on Inspection

The car should be ready to run on inspection if all is wired correctly. Select the “Elevator Status” on the

Main CPU LCD interface. The display should show INS on the car service area of the first main display.

Pressing the DOWN button to the next display will show the type of inspection the car is on as in the list

below:

• Machine Room

• Car Top

• Access

• In-Car

• Car Top Lock Bypass

• Car Top Gate Bypass

• Car Top G & L Bypass

• COB HW Setup Jumper

To run the car from the machine room, Machine Room inspection should be displayed.

The “inspection string” consists of contacts from the inspection switches and the gate and lock bypass

switches in series as shown in Figure 3-3. One and only one of the five inspection inputs should be on

for the car to run..

NOTE: Any one of the following conditions will generate an inspection error.

• More than one inspection input is on

• No inspection input is on

• Gate or Lock Bypass switch in the BYPASS position when the car is not on car top inspection

Page 42

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment

3-6

Figure 3-3: Inspection String Circuit

3.3.3 Prepare for the Car for Hoistway Learn

Return to section 2.7.2.1, “Veirfy that the APS Selector Camera is installed Correctly and

Communicating”. Complete sections 2.7.2.1 through 2.7.2.4. After completing section 2.7.2.4,

return to this section, 3.3.3, and complete the following items.

Page 43

GALaxy eHydro Elevator Controller Section 3 – GALaxy Startup and Adjustment