Page 1

Pub. 42004-680L2E

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

69257-101

Access Panel Interface

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains sensitive

business and technical information that is confidential and proprietary to GAI-Tronics. GAI-Tronics retains

all intellectual property and other rights in or to the information contained herein, and such information may

only be used in connection with the operation of your GAI-Tronics product or system. This manual may

not be disclosed in any form, in whole or in part, directly or indirectly, to any third party.

General Information

The 69257-101 Access Panel Interface (API) allows up to eight access panels to be interfaced to an

ADVANCE system. It is installed in a 10457 Series Card Rack and is controlled by a Master Control Unit

(MCU) installed in that same card rack. The API is designed exclusively for use in an ADVANCE system,

and is not intended for use with other types of equipment.

Description of Major Components

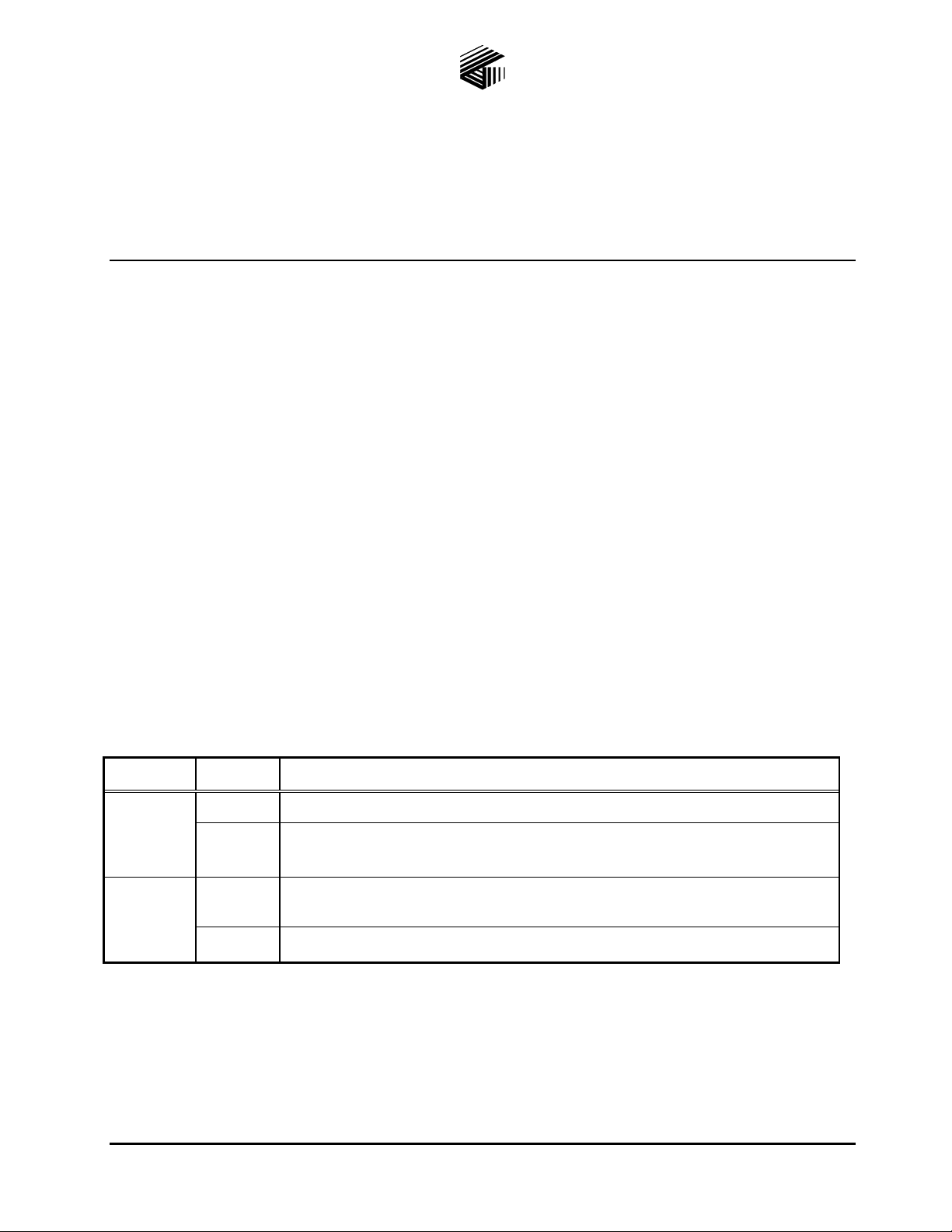

API Front Panel LEDs

The following table describes the API front panel LEDs and their functions:

LED Status Description

ON LINE On The MCU is running and is configured to recognize the API.

Off The API is not receiving power from the card rack or the MCU is not properly

configured to recognize the API.

FAULT On The MCU has detected at least one failure in any of the access panels attached

to the API.

Off All access panels attached to the API are healthy.

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-680L2E

69257-101 Access Panel Interface Page: 2 of 7

Connections t o the Field Wiring T erminal Blocks

Connections to the API are typically accessed via one 26-pin terminal block module mounted inside the

system’s control cabinet. A ribbon cable connects the terminal block module to the rear of the card rack

housing the API card. The terminal block module connects to the top connector associated with the API;

the bottom connector is unused.

The actual location of the terminals is shown on the control cabinet outline and connection drawings.

Figure 1 illustrates the terminal block assignments. Figure 2 illustrates a connection from the terminal

block to an access panel.

Figure 1. System Cabinet Terminal Block Assignments

Figure 2. Typical access panel connection

f:\standard ioms - current release\42004 instr. manuals\42004-680l2e.doc

11/10

Page 3

Pub. 42004-680L2E

69257-101 Access Panel Interface Page: 3 of 7

Figure 3. 69257-101 Component Locations

f:\standard ioms - current release\42004 instr. manuals\42004-680l2e.doc

11/10

Page 4

Pub. 42004-680L2E

69257-101 Access Panel Interface Page: 4 of 7

Switch and Jumper Settings

Description

Several switch and jumper settings are required for proper operation of the API Card. The following

settings are set during the system commissioning and programming and should not be changed. If replacing

an existing API card for maintenance purposes, be sure to duplicate the switch and jumper setting of the

card being replaced. Refer to Figure 3 for the switch and jumper locations.

The 2xx/3xx Address header (P2) and shorting clip select part of the base input/output address used by the

MCU when accessing the API.

The Board Address rotary switch (SW4) selects part of the base input/output port address used by the MCU

when accessing the API.

The Board Identification rotary switch (SW3) lets the MCU distinguish between multiple APIs installed in

the same card rack. Set SW3 to either “1” or “2”.

The Clock Master/Clock Slave header (P3) and shorting clip configure the API as either the backplane

ST-Bus clock master (source of the clock) or a backplane ST-Bus clock slave (recipient of the clock).

The ST-Bus Stream In rotary switch (SW2) is unused. Set SW2 to “F”.

The ST-Bus Stream Out rotary switch (SW1) is unused. Set SW1 to “F”.

Party Line Isolation headers (P12 and P13) and shorting clips either connect or isolate the API from the

backplane party lines. Pin #1 is toward the front of the API; pin #3 is toward the back of the API. Place the

shorting clip across pin #1 and pin #2 (1-2 position) to isolate the API from the backplane party line. Place

the shorting clip across pin #2 and pin #3 (2-3 position) to connect the API to the backplane party line.

Both P12 and P13 must be in the same position.

OTE: The MCU controls which backplane party line, party line #1 or party line #2, the API connects to

N

when the P12 and P13 shorting clips are in the 2-3 position.

The API-to-access panel data line isolation headers (P5, P7, P8, P9, P11, P14, P15, and P16) and shorting

clips either ground or float a particular API-to-access panel data line. Place the shorting clip across pin #1

and pin #2 (1-2 position) to ground a particular API to access panel data line. Place the shorting clip across

pin #2 and pin #3 (2-3 position) to float a particular API to access panel data line. The first access panel is

associated with the top header (P5); the last, eighth, access panel is associated with the bottom header

(P16); all access panels’ associated headers are located sequentially from top to bottom.

f:\standard ioms - current release\42004 instr. manuals\42004-680l2e.doc

11/10

Page 5

Pub. 42004-680L2E

69257-101 Access Panel Interface Page: 5 of 7

Changing to a 69257-101 API from a previous version

NOTES:

1. The 69257-101 API is not electrically compatible with its predecessors. If further information on the

differences is needed, please contact the GAI-Tronics Field Service Department at 800-492-1212.

2. When upgrading to a 69257-101 API, the following four upgrades are required:

• Any 69266-001 or 69320-001 VNAs must be upgraded to the 69320-101 VNA.

• Any 69257-003, 69257-002, or 69257-001 APIs must be upgraded to the 69257-101 API.

• Any 69510-001, 69215-003, 69215-002, or 69215-001 backplane termination boards must be

upgraded to the 69510-101 Termination board. Two of these boards are required per card rack.

• The upgraded cards must be installed in the proper backplane slot. This task involves moving the

card and the associated ribbon cable at the rear of the card rack assembly.

Revisions of the API prior to the 69257-101 revision (the –003, -002, and –001 revisions) used a different

switch and jumper collection than the 69257-101 revision. The following text states how to convert the

previous revisions’ switch and jumper settings into the 69257-101 switch and jumper settings.

The 2xx/3xx Address header (P2) and shorting clip should be set to the 2xx position if W1 is inserted in the

API being replaced; otherwise, set to the 3xx position.

The Board Address rotary switch (SW4) is present on all versions of the API.

The Board Identification rotary switch (SW3) is present on all versions of the API.

The Clock Master/Clock Slave header (P3) and shorting clip should be set to M

clips were installed on header J8 (labeled M

N

OTE: The 69257-001 API has two shorting clips instead of three.

ASTER). Otherwise, set the jumper to SLAVE.

ASTER if the three shorting

The ST-Bus Stream In rotary switch (SW2) should be set to “F”.

The ST-Bus Stream Out rotary switch (SW1) should be set to “F”.

If a 69320-101 Voice Network Adapter is installed in the system, then the P12 and P13 shorting clips

should be in the 1-2 position (ISOLATED). Otherwise, the P12 and P13 shorting clips should be in the 2-3

position (CONNECTED).

API-to-access panel data line isolation headers (P5, P7, P8, P9, P11, P14, P15, and P16) and shorting clips

should be in the 1-2 position (GROUNDED). However, if this setting results in a ground loop between the

API and a particular access panel, then set the shorting clip associated with that access panel to the 2-3

position (FLOATING).

f:\standard ioms - current release\42004 instr. manuals\42004-680l2e.doc

11/10

Page 6

Pub. 42004-680L2E

69257-101 Access Panel Interface Page: 6 of 7

Operation

After installation, the 69257-101 Access Panel Interface (API) should start automatically. The API requires

no direct user intervention during normal operations. See your system manual for more information on how

the API operates in your customized system.

Installation and Maintenance

Direct questions about installation of this product to the GAI-Tronics Field Service Department at

800-492-1212 inside the USA or 610-777-1374 outside the USA.

Installa tion Guidelines

WARNING

Disconnect power to the card rack before performing any maintenance.

Installa tion Instructions

1. Remove the API from its protective carton.

2. Verify that power is disconnected to the card rack prior to installation.

3. Verify that the five board switch and jumper settings described in the Switch and Jumper Settings

section beginning on page 4 are set in accordance with the instructions in your system manual.

4. Align the API into the upper and lower tracks for the card rack slot.

5. Slide the API toward the rear of the card rack until it comes in contact with the connector on the

backplane.

6. Firmly press on the front bezel until the API is seated in the backplane connector, and tighten the two

screws located on the front bezel to secure it to the card rack.

Remo ving the API Card from Card Rack

1. Remove power from the card rack.

2. Remove the two screws on the front bezel that secures the API to the card rack.

3. Gently disengage the API from the connector on the backplane and slide the API out of the card rack.

f:\standard ioms - current release\42004 instr. manuals\42004-680l2e.doc

11/10

Page 7

Pub. 42004-680L2E

69257-101 Access Panel Interface Page: 7 of 7

Specification s

Electrical

Board

Power ................................................................................................... 500 mA maximum @ +5 V dc ± 5%

65 mA maximum @ +12 V dc ± 10%

65 mA maximum @ −12 V dc ± 10%

Access Panel Cabling

Twisted pair cable........................................................................................................ Category 3 minimum

Nominal cable characteristic impedance......................................................................................... 100 ohms

Frequency response............................................................................................................... 32.0 to 256 kHz

Maximum attenuation........................................................................................................................... 24 dB

Signal level..................................................................................................................... 1.000 to 1.125 Vp-p

Signal-to-noise level ...................................................................................... >16.5 dB, 300 kHz bandwidth

Line length ................................................ 3.0 km with Category 3, No. 24 AWG; attenuation = 8.0 dB/km

Digital Audio

Encoding ................................................................................... µ-Law per CCITT Recommendation G.711

Sampling rate ....................................................................................... 8,000 samples per second ±100 ppm

Card Rack Page Audio from one API to another API

Frequency response............................................................................................ 250 Hz to 3.5 kHz ± 0.5 dB

Distortion + Noise............................................. THD <2.0% @ 1,020 Hz sine wave, −10 dB ref. 1.5 Vrms

Card Rack Party Audio from one API to another API

Frequency response............................................................................................ 250 Hz to 3.5 kHz ± 0.5 dB

Distortion + Noise............................................. THD <2.0% @ 1,020 Hz sine wave, −10 dB ref. 1.5 Vrms

Environmental

Temperature range (operating/storage)................................................ +32° F to +122° F (0° C to +50° C)

Relative humidity:................................................................................................ 10–85% non-condensing

Mechanical

Unit dimensions ............................................. 10.3 H × 0.780 W × 9.07 D inches (262 × 19.9 × 231 mm)

Unit weight....................................................................................................... 0.93 lbs. nominal (0.42 kg)

Approval

CE Mark

Replac ement Parts

The API has no field replaceable components.

f:\standard ioms - current release\42004 instr. manuals\42004-680l2e.doc

11/10

Page 8

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...