Page 1

Pub. 42004-491A

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 379-002

Monitored Relay Module (MRM) Station

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

The Model 379-002 Monitored Relay Module (MRM) Station is used in SmartSeries ADVANCE

Systems. Operation is controlled by the system’s Master Control Unit (MCU) programming.

The MRM provides eight relay output circuits. Each relay contains two type “C” contacts rated for 5A.

Relay outputs are typically used for switching power to signaling devices such as beacons or strobes but

can be used for any switching application that does not exceed the relay’s current rating. Relay circuits

can be programmed to activate during system alarms, pages, or trouble condition.

The MRM also contains eight input circuits. Input circuits can be used supervise the cable integrity

connecting the relay output to the signaling device (as described above). During an inactive state, the

cable is monitored for open circuit, short circuit and ground fault conditions. If a cable fault is detected,

the relay circuit will not activate, preventing a possible dangerous condition. The fault condition is

automatically reported to the MCU.

For each relay circuit not requiring supervision, one input circuit is available for other functions. Inputs

are activated by a voltage-free contact (either opening or closing) or the presence/absence of a 24 V dc

input voltage. When using inputs from voltage-free contacts, the MRM can supervise the cabling

between the input terminal and the remote contact closure device. The cable is monitored for open

circuit, short circuit and ground fault conditions. The fault condition is automatically reported to the

MCU.

Each input circuit can be programmed to initiate one of the following functions in the ADVANCE

system.

Activate an alarm

Reset all alarms

Cancel the current alarm

Report a fault condition

Reset the system MCU

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 2 of 13

The Model 379-002 Monitored Relay Module (MRM) Station components are housed in a NEMA 4X

stainless steel enclosure measuring 13.00 W 14.30 H 6.23 D inches. Components include a 12 V dc

power supply and a 12579-002 Monitored Relay Module.

The 12579-002 Monitored Relay Module is comprised of three components: the 69248-102TR CPU and

the 69251-201TR Monitored-Input PCBA, and the 69252-001TR Relay PCBA. Refer to Figure 1 for

component locations.

The scope of this manual is limited to the mounting and wiring connections for the Model 379-002

Station. Refer to Pub. 42004-712L2 for additional information on the 12579-002 Monitored Relay

Module.

Figure 1. Model 379-002 MRM Station (Interior View)

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 3

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 3 of 13

Installation

CAUTION

Do not install this equipment in hazardous areas. Disconnect power before installing or removing

the MRM.

Mounting

The Model 379-002 MRM Station enclosure is not supplied with conduit or cable gland holes since cable

quantity, size, and entry location vary with each installation.

Drill or punch openings at the required locations before mounting the enclosure. Typically multiple

cables entries are required for power, serial data line, and input wiring. Refer to the Wiring section

below. Use caution when drilling or punching the enclosure to avoid damaging the internal components.

Bottom cable entry is recommended to prevent moisture from entering the enclosure and dripping onto

the terminals or circuit boards.

Mount the enclosure to a suitable surface using appropriate customer-supplied hardware. Refer to Figure

1 for mounting hole dimensions.

Remove the shipping tie-wrap that is securing the PCBA to its mounting Snaptrack.

Wir in g

The MRM Station requires 120 V ac power and a serial data line connection (RS-485) to the ADVANCE

System Control Cabinet. Up to eight input and relay output circuits are connected as needed. Each

connection is explained below.

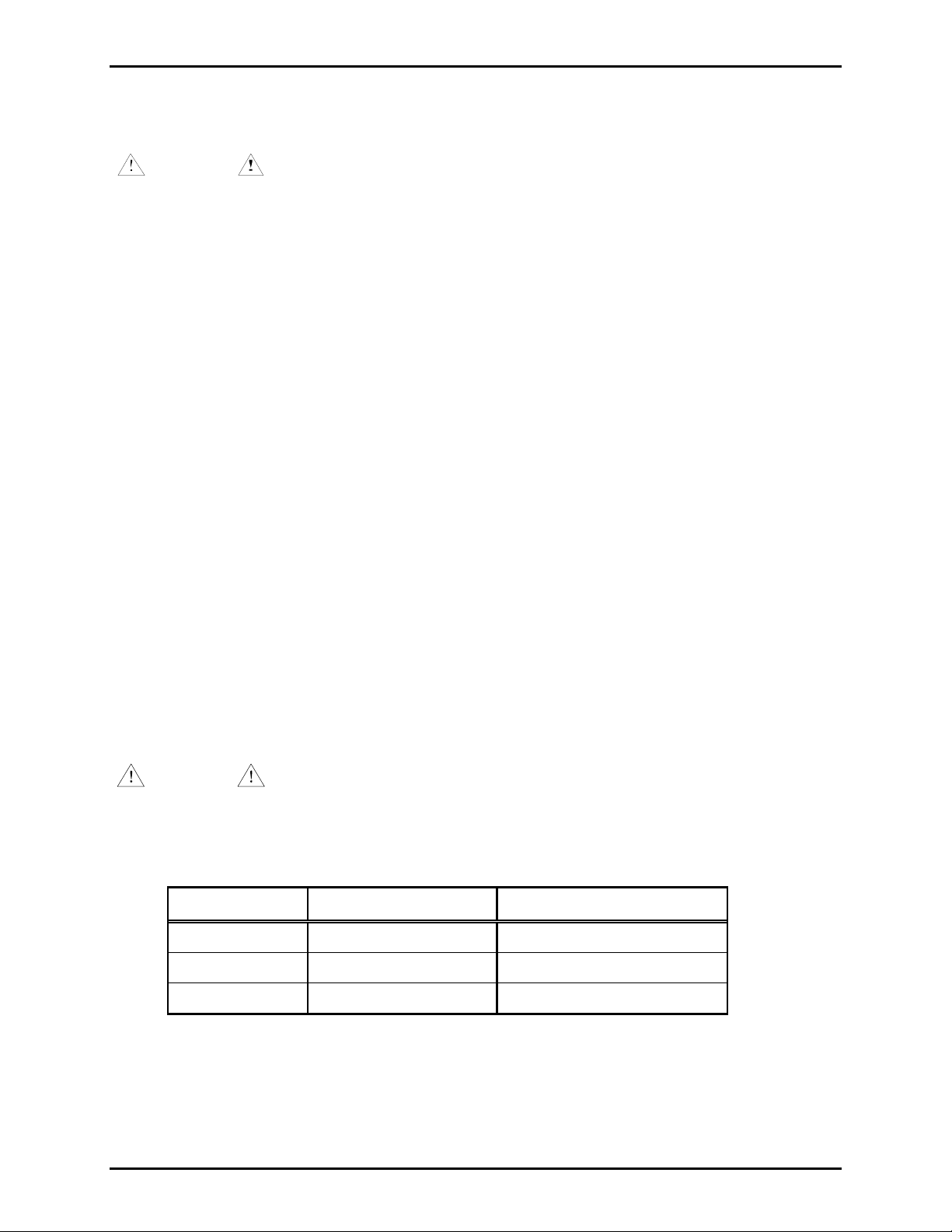

Power

120 V ac power is connected to terminal block TB13 at the top of the panel. Refer to Figure 1.

WARNING

Earth grounding provisions are provided.

Function Terminal Block Wire Color

AC Line (hot) TB13-1 Black

Neutral TB13-2 White

Ground TB13-3 Green/yellow

Insure proper grounding to protective earthing.

Table 1.

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 4

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 4 of 13

Data Communications

Terminal blocks TB11 and TB12 are for “feed-thru” connection of the RS-485 data cable. The data cable

should consist of a twisted pair with shield. One end of the data cable must be terminated to the

ADVANCE System Control Cabinet. A total of ten MR M and MIM modules can be parallel wired to

the data cable. The most distant MRM or MIM should have a termination resistor installed to the data

line by installing jumper P2 on the 69248-xxx CPU PCBA.

CAUTION

The RS-485 line is polarity-sensitive. Be sure to maintain circuit polarity throughout installation.

OTES:

N

Only one termination resistor should be installed across the RS-485 data line. Be sure jumper P2 is

installed on only the most distant MRM or MIM.

Address Setting

Each MRM and MIM on the RS-485 data line must be set with a unique hardware address. Consult the

System Administrator for the proper address prior to setting the address switch on the MRM or MIM.

Addresses for each module are determined by the System Administrator’s software configuration of the

ADVANCE system. The address is set using the hexadecimal switch on the 69248-xxx CPU PCBA.

Valid addresses are 5–F.

Relay - Co ntact Outpu ts

The MRM contains eight individually configurable relay-contact outputs, allowing it to control field

devices such as beacons. Connections with these field devices are made at connectors TB1 through TB8

of the 69252-xxx Power Relay Module.

Each connector corresponds to a single output (TB1 is used for output #1, TB2 is used for output #2, etc.).

If fewer than eight supervised relay-contact outputs are required, the unused outputs may be used to

receive inputs (dry contact closures or non-supervised 24 V dc wet contact closures) from field devices.

In this case, connections with these field devices are made at connectors TB1 through TB8 of the 69251xxx Monitored-In-8 PCBA. Each of these outputs may be configured to operate in one of six modes.

Two of these six modes are used to control signaling devices, while the remaining four modes are used to

receive inputs (contact closures) from field devices.

Each mode requires a unique connection scheme between the external field devices and the appropriate

connector on the MRM. The connection scheme for each mode is described below. Since the connection

scheme is independent of which output is used, only Output #1 will be discussed.

To ensure proper termination, ferrules must be crimped on the ends of all conductors that are terminated

on the terminal blocks. The size of the ferrule is dependent upon the size of the conductor used and can

be sourced from any supplier such as Phoenix, Altec or Weidmuller. The terminals accept a maximum

conductor size of No. 12 AWG and a minimum conductor size of No. 28 AWG.

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 5

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 5 of 13

Mode 0: Deactivate Circuit

In Mode 0, outputs may be used to control several signaling devices by connecting/disconnecting power

to these devices. In this mode, no supervision of the loop is supported. This mode supports both ac- and

dc-powered signaling devices.

Figure 2. Deactivate Circuit - AC-Powered Beacons

Figure 2 shows the recommended wiring diagram for ac-powered signaling devices, while Figure 3 shows

the recommended wiring diagram for dc-powered signaling devices (using Output #1 as an example.)

*NOTE: The MRM does not contain any current-limiting for the signaling device power. It is

recommended that an external fuse be provided for each output circuit with the appropriate voltage and

current ratings. The selected fuse should be of the slow-blow variety.

Figure 3. Deactivate Circuit - DC-Powered Beacons

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 6

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 6 of 13

Mode 1: IDC Line Supervision Multiple Switch

In this mode any number of normally-open dry contact closures may be installed on the line. The loop is

monitored for ground faults and open circuits in Mode 1. The end-of-line device is a 20 k, 5% tolerance

resistor.

Figure 4. IDC Line Supervision Multiple Switch

NOTE: The 20 k, 5% tolerance resistor is not included with the MRM. The resistor is included in a kit

(12509-004), which must be ordered separately.

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 7

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 7 of 13

Mode 2: IDC Single Normally-Open (N.O.) Switch

In this configuration, only one normally-open dry contact closure may be installed per supervised line. In

this mode, the loop is monitored for open circuits, wire-to-wire short circuits (across + and −), and ground

faults. When the contact closure is not active (open), the loop appears as 20.1 k load (15 k in series

with 5.1 k). This appears on the input to the MIM and indicates a healthy loop. When the contact

closure is active (closed), the 15 k resistor is bypassed.

Figure 5. IDC Single Normally-Open Switch

When the contact closure is active (closed), the 15 k resistor is bypassed. In this case, output #1 only

sees a 5.1 k load. When this occurs, it indicates to the MRM that the contact closure is active. If there

is a short across L1 and L2, if either leg is grounded, or if a break occurs on either leg, the MRM indicates

that a fault has occurred.

NOTE: The terminating resistors are not included with the MRM. These resistors are included in a kit

(12509-004), which must be ordered separately.

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 8

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 8 of 13

Mode 3: IDC Single Normally-Closed (N.C.) Switch

In this configuration, only one normally-closed dry contact closure may be installed per supervised line.

In this mode, the loop is monitored for open circuits, wire-to-wire short circuits (across + and –), and

ground faults. When the contact closure is not active (closed), the 15 k is bypassed and the circuit sees

only the 5.1 k load.

Figure 6. IDC Single Normally-Closed Switch

This change is sensed by the MRM and indicates to the MRM that the contact closure is active. If there is

a short across L1 and L2, if either leg is grounded, or if a break occurs on either leg, the MRM indicates

that a fault has occurred.

NOTE: The terminating resistors are not included with the MRM. These resistors are included in a kit

(12509-004), which must be ordered separately.

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 9

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 9 of 13

Mode 4: IAC Line Super vision

In Mode 4, outputs can be used to control several dc-powered signaling devices by connecting/

disconnecting power to these devices. In addition, this loop is monitored for open circuits, wire-to-wire

short circuits (across + and -), and ground faults. If any of these three conditions are detected by the

MRM, the MRM indicates that a fault has occurred. Please note that monitoring of the loop only occurs

while the loop is

inactive (signaling devices are off).

Figure 7. IAC Line Supervision – DC-Powered Beacons

It is recommended that Mode 4 only be used with dc-powered signaling devices. In Mode 4, one

blocking diode must be provided for every signaling device connected to the loop. Note that some

signaling devices already include a blocking diode in the unit - in this case, no additional blocking diode

is required. The end-of-line device is a 20 k, 2-watt, 5% tolerance resistor. Please observe all polarities

as indicated in Figure 7 above.

NOTE: The blocking diodes, the wire jumpers, and the 20 k, 2-watt, 5% tolerance resistor are not

included with the MRM. These components are included in a kit (12509-004), which must be ordered

separately.

*NOTE: The MRM does not contain any current-limiting for the signaling device power. It is

recommended that an external fuse be provided for each output circuit with the appropriate voltage and

current ratings. The selected fuse should be of the slow-blow variety.

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 10

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 10 of 13

CAUTION

If ac-powered signaling devices are being used on an output loop configured for Mode 4 (Figure 8),

observe the following limitations necessary for reliable operation for the loop monitoring feature:

The dc-resistance measured across the loop (with both end-of-line device and the MRM

removed from the loop must be at least 100 k

Do NOT use blocking diodes in this loop.

Figure 8. IAC Line Supervision – AC-Powered Beacons

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 11

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 11 of 13

Mode 5: IDC Non-supervision Multiple Switch (Dry Contact)

In this mode, any number of normally-open dry contact closures can be installed on the line. The loop

will not

be monitored for any faults in Mode 5.

Figure 9. IDC Non-Supervision Multiple Switch (Dry Contact)

Mode 5: IDC Non-Supervision (Wet Contact)

In this wet contact mode, shorting jumpers for each input must be moved from the factory default of

“dry” to “wet” contact mode. When in “wet” contact mode, the input can be activated during a 0 V

condition or a 24 V condition. The factory default setting is “24 V dc input when active” (position 2-3).

If “0 V dc input when active” is desired, move jumper from position 2-3 to position 1-2. The loop will

not

be monitored for any faults in Mode 5. Ensure the polarity of input connection is correct as it is

polarity sensitive.

Figure 10. IDC Non-Supervision (Wet Contact)

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 12

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 12 of 13

Table 2. Jumper Settings for Mode 5 Input Operation

Input No. Dry Contact

Input Selection

1 P1 – Pins 2 & 3

P2 – Pins 2 & 3

P3 – Pins 2 & 3

2 P4 – Pins 2 & 3

P5 – Pins 2 & 3

P6 – Pins 2 & 3

3 P7 – Pins 2 & 3

P8 – Pins 2 & 3

P9 – Pins 2 & 3

4 P10 – Pins 2 & 3

P11 – Pins 2 & 3

P12 – Pins 2 & 3

24 V DC Wet Contact Input

Selection

P1 – Pins 1 & 2

P2 – Pins 1 & 2

0 V dc – Active: P3 – Pins 1 & 2

24 V dc – Active: P3 – Pins 2 & 3

P4 – Pins 1 & 2

P5 – Pins 1 & 2

0 V dc – Active: P6 – Pins 1 & 2

24 V dc – Active: P6 – Pins 2 & 3

P7 – Pins 1 & 2

P8 – Pins 1 & 2

0 V dc – Active: P9 – Pins 1 & 2

24 V dc – Active: P9 – Pins 2 & 3

P10 – Pins 1 & 2

P11 – Pins 1 & 2

0 V dc – Active: P12 – Pins 1 & 2

24 V dc – Active: P12 – Pins 2 & 3

Factory Default

Setting

P1 – Pins 2 & 3

P2 – Pins 2 & 3

P3 – Pins 2 & 3

P4 – Pins 2 & 3

P5 – Pins 2 & 3

P6 – Pins 2 & 3

P7 – Pins 2 & 3

P8 – Pins 2 & 3

P9 – Pins 2 & 3

P10 – Pins 2 & 3

P11 – Pins 2 & 3

P12 – Pins 2 & 3

5 P13 – Pins 2 & 3

P14 – Pins 2 & 3

P15 – Pins 2 & 3

6 P16 – Pins 2 & 3

P17 – Pins 2 & 3

P18 – Pins 2 & 3

7 P19 – Pins 2 & 3

P20 – Pins 2 & 3

P21 – Pins 2 & 3

8 P22 – Pins 2 & 3

P23 – Pins 2 & 3

P24 – Pins 2 & 3

P13 – Pins 1 & 2

P14 – Pins 1 & 2

0 V dc – Active: P15 – Pins 1 & 2

24 V dc – Active: P15 – Pins 2 & 3

P16 – Pins 1 & 2

P17 – Pins 1 & 2

0 V dc – Active: P18 – Pins 1 & 2

24 V dc – Active: P18 – Pins 2 & 3

P19 – Pins 1 & 2

P20 – Pins 1 & 2

0 V dc – Active: P21 – Pins 1 & 2

24 V dc – Active: P21 – Pins 2 & 3

P22 – Pins 1 & 2

P23 – Pins 1 & 2

0 V dc – Active: P22 – Pins 1 & 2

24 V dc – Active: P22 – Pins 2 & 3

P13 – Pins 2 & 3

P14 – Pins 2 & 3

P15 – Pins 2 & 3

P16 – Pins 2 & 3

P17 – Pins 2 & 3

P18 – Pins 2 & 3

P19 – Pins 2 & 3

P20 – Pins 2 & 3

P21 – Pins 2 & 3

P22 – Pins 2 & 3

P23 – Pins 2 & 3

P24 – Pins 2 & 3

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 13

Pub. 42004-491A

Model 379-002 Monitored Relay Module Station Page 13 of 13

Specification s

Electrical

Power requirements ............................................................................ 120 V ac, 50/60 Hz @ 1A maximum

NOTE: Power requirements do NOT include power switched to external devices such as strobe lights.

Maximum current draw and switching voltage (per outlet) .......................... 5 amps @ 30 V dc or 132 V ac

Mechanical

Dimensions ........................................................................................... 13.00 W 14.30 H 6.23 D inches

Weight .................................................................................................................................................. 19 lbs.

Environmental

Humidity .......................................................................................... 95% non-condensing relative humidity

Temperature range .................................................................................. −22º F to 158º F (−30º C to 70º C)

Environmental rating .................................................................................................................... NEMA 4X

Replac ement Parts

Part Number Description

69248-102TR PCBA, CPU Module with RS-485

69251-201TR PCBA, Monitored-In-8

69252-001TR PCBA, Relay Module

40404-009 Power Supply, 12 V dc, 25W

f:\standard ioms - current release\42004 instr. man uals\42004-491a.doc

03/14

Page 14

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...