Page 1

Pub. 42004-455B

p

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 352-101, 352-102, 352-103, and 352-104

Division 1 SMART Hazardous Area Telephones

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

GAI-Tronics’ Class I, Division 1 SMART Hazardous Area

Telephones are constructed of cast aluminum and are

weatherproof and corrosion resistant. They combine

standard telephone operation with GAI-Tronics’ SelfMonitoring and Reporting Telephone (SMART)

technology to provide optimum performance and

flexibility.

When used with the GAI-Tronics’ Telephone

Management Application (TMA) each telephone is

monitored and the status is reported. For complete details,

please refer to the on-line help included with TMA.

This manual applies to the following models:

Model 352-101 Division 1 SMART Hazardous Area

Telephone

Model 352-102 Division 1 SMART Hazardous Area

Telephone with Ring Relay

Model 352-103 Division 1 SMART Hazardous Area

Telephone with Headset

Model 352-104 Division 1 SMART Hazardous Area Telephone with Ring Relay and Headset

Figure 1. Model 352-101 Division 1

SMART Hazardous Area Tele

hone

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 2 of 17

The GAI-Tronics SMART Telephone product line provides the flexibility to address a diverse range of

applications. A wide variety of functions can be achieved by altering the configuration data stored in the

telephone’s non-volatile memory. These configuration options include:

Call progress detection, control, and call logging

Auto-calling, auto-answering, and auto-dialing facilities

Function inhibiting (e.g. tone pad and manual keypad dialing)

Maximum call duration

These functions are initially programmed during manufacturing and testing. After installation, they can

be programmed remotely via DTMF data call.

All SMART Telephones are line-powered and can be connected to the 24 V dc or 48 V dc analog station

port of Private Branch Exchange (PBX), Private Automatic Branch Exchange (PABX) or KSU.

Connection may not be made to pay telephone extensions or shared service (party) lines.

TMA users can schedule auto-dial maintenance calls to alert maintenance personnel of any unusual sensor

or fault conditions that exist. SMART Telephones can also be programmed to generate an auto-dial

maintenance call when certain sensor events are discovered. Access to the SMART Telephone’s

maintenance mode is restricted through the use of the maintenance access PIN. The maintenance access

PIN should be distributed only to trained maintenance personnel.

Installation

Installation Guidelines

These enclosures must be installed by trained, qualified and competent personnel. Installation must

comply with state and national regulations, as well as safety practices for this type of equipment.

CAUTION

on the approval listing in the “Specifications” section of this manual. Such installation may cause a

safety hazard and consequent injury or property damage.

The mounting location must be flat and provide proper clearance, rigidity and strength to support the

enclosure and all contained devices.

WARNING

steel mounting bolts and washers, or washer head bolts.

WARNING

Insure proper grounding to protective earthing.

WARNING

removed, the cover must be adequately supported.

Do not install this equipment in hazardous areas other than those indicated

Securely fasten the enclosure to the mounting location, using 3/8-inch diameter

Do not disconnect equipment while energized.

The front cover is not hinged to the rear enclosure. When the cover bolts are

ATTENTION

accordance with the National Electric al Code or applicable local codes.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Installation should be performed by qualified personnel and only in

Page 3

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 3 of 17

Inspect and clean the machined flange flame joint surfaces of both the cover and box. Surfaces must be

smooth, free of nicks, scratches, dirt or any foreign particle build-up that would prevent a proper seal.

Surfaces must seat fully against each other to provide a proper explosion-proof joint. Clean surfaces by

wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

When installing any GAI-Tronics telephone equipment, please adhere to the following guidelines to

ensure the safety of all personnel:

Electrostatic Discharge (ESD) Protection: Your telephone has an earth ground terminal provision.

Ensure that it is connected to ground in accordance with all local safety regulations and the National

Electrical Code (NEC). Grounding must be ensured for safe and stable communications. Do not use

long and coiled ground wires. Please note proper grounding does not eliminate the need for lightning

protection for the telephone or the telephone system.

NEVER install telephone during a lightning storm.

Install a UL Listed lightning arrestor on any telephone installed where the telephone or telephone

cable is at risk of being exposed to lightning strikes. The lightning arrestor must be installed as close

to the telephone as possible in a non-hazardous environment to maximize the protection. The

lightning arrestor must not be installed within the enclosure supplied with the telephone.

NEVER install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

NEVER touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

USE CAUTION when installing or modifying telephone lines.

GAI-Tronics’ SMART Telephones are designed to operate on telephone lines as detailed in the “General

Information” section of this manual. The telephones are designed to operate with one telephone per line.

If telephones are operated in parallel or party-line configuration you may experience sporadic telephone

operation, difficulties with programming, or premature disconnection of calls. Additionally, if special

features, e.g. voice mail, call waiting, etc, are not disabled, the telephone may not function.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 4

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 4 of 17

Mounting

NOTE: The mounting surface must be able to support the weight of the aluminum enclosure, which is 28

lbs.

The enclosure must be securely fastened with 3/8-inch diameter steel mounting bolts located on all four

mounting feet. Stainless steel hardware is recommended in outdoor applications. Refer to Figure 2. The

suggested mounting height is 48 inches to the bottom of the enclosure.

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit

N

for additional enclosure information.

Figure 2. 352 Series Division 1 SMART Hazardous Area Telephone Enclosure Mounting Details

Cable Entries

Refer to Figure 3 for the NPT conduit entries. Ensure any unused openings are sealed with proper fittings

per local standards. Use field wiring suitable for the ambient temperature. Any conduit NPT plugs

(blanking elements) must be explosion-proof with a Type 4X rating.

Figure 3. 352 Series Division 1 SMART Hazardous Area Telephone Conduit Entries

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 5

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 5 of 17

Hardware Description

External

Models 352-101 and 352-102 each contain a handset with an approved gland, standard keypad, volume

control button, and applicable approval labeling. The handset rests on a cradle, which has a magnetic

reed switch located behind it to signal an off-hook condition. The enclosure is sealed with ten cover

mounting bolts located around the perimeter of the enclosure’s flange. See Figure 4.

Figure 4. 352 Series Division 1 SMART Hazardous Area Telephone Outline Drawing

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 6

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 6 of 17

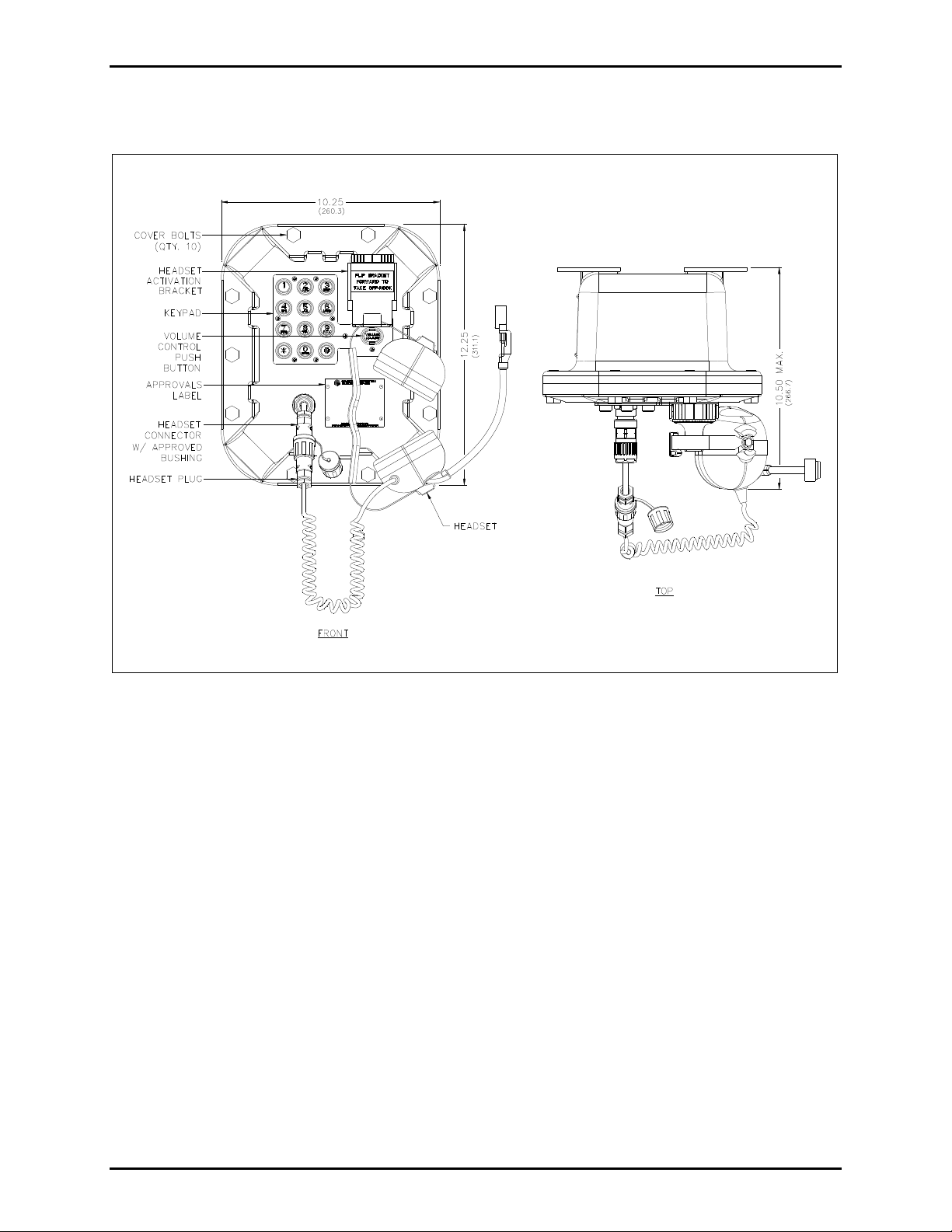

For the Division 1 SMART Telephone models with the headset option, the cradle and handset are

replaced with a removable headset and headset activation bracket.

Figure 5. 352 Series Division 1 SMART Hazardous Area Headset Telephone Outline Drawing

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 7

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 7 of 17

Internal

With the exception of the ring relay (when fitted), all standard components are mounted to the rear of the

front cover. See Figure 6 for the parts layout.

WARNING

The front cover is not hinged to the rear enclosure. When the flange bolts are

removed, the cover must be adequately supported.

Figure 6. 352 Series Division 1 SMART Hazardous Area Telephone - Internal View

Ring Relay PCBA

The Ring Relay PCBA allows the telephone to activate an external beacon or sounder when the telephone

receives a call. When installed, the Ring Relay PCBA is connected to the Main PCBA via a two-wire

cable assembly. This cable assembly allows communication between the Main PCBA and the Ring Relay

PCBA. The Ring Relay PCBA is located in the rear enclosure. See Figure 6 for mounting, and steps 3

through 5 in the “Wiring” section.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 8

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 8 of 17

Wir in g

WARNING

The front cover is not hinged to the rear enclosure. When the cover bolts are

removed, the cover must be adequately supported.

1. While supporting the front cover, remove the ten cover bolts from the enclosure flange. Pull the front

cover far enough away to expose the internal connections and disconnect any wiring between the

front cover and rear enclosure. Place the front cover aside.

2. Connect the incoming subscriber line or the telephone line suppressor (if applicable) to TB1 on the

Main PCBA. See Figure 7.

Figure 7. Main PCBA

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 9

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 9 of 17

3. When a Ring Relay PCBA option is present, connect incoming 120 V ac power to the TB1 terminal

block. See Figure 8.

Figure 8. Ring Relay PCBA

Figure 9.

4. Connect the external sounder or beacon to TB2, for activation with an incoming telephone call.

5. Reconnect the communication cable between the Main PCBA and Ring Relay PCBA, if

disconnected, before reattaching the front cover.

WARNING

Any external equipment connected to the Ring Relay PCBA must be rated for the

hazardous area where it will be located. Improper installation or equipment may cause a safety hazard

and consequent injury or property damage.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 10

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 10 of 17

PCBA Hardware Configuration

The PCBA hardware configuration options are explained in detail in the following sections and the

necessary jumper settings are identified to enable or disable each option. We recommend reading the

following sections, recording the desired parameters, and then making the necessary changes. We also

recommend that you make a record of your settings. The following options are controlled by specific

hardware configurations. See Figure 7 on page 8 for the jumper locations.

Auto-answer Configuration

Factory Setting: Auto-answer feature enabled

The Auto-answer feature enables or disables the automatic answering of an incoming call, which allows

TMA to monitor the health of this telephone via polling. When the Auto-answer feature is enabled, the

telephone automatically answers the call and attempts to communicate with TMA.

Enable: Place the J14 jumper in position EN.

Disable: Place the J14 jumper in position DIS. (Do not use this setting except under the direction of

GAI-Tronics personnel.)

N

OTE: The Auto-answer feature must be enabled during remote programming, and to allow the

GAI-Tronics Telephone Management Application PC to contact the telephone.

Polarity Configuration

Factory Setting: Non-polarity sensitive

This telephone can be configured to be polarity or non-polarity sensitive. With the non-polarized setting,

the telephone operates with the telephone line’s positive terminal connected to either the tip or the ring.

With the polarized setting, the telephone only operates with the telephone line’s positive terminal

connected to the tip.

Non-polarity Sensitive: Place the J6 jumper in position NON.

Polarity Sensitive: Place the J6 jumper in position POL.

DTMF Gain Select Configuration

Factory Setting: Low Gain selected

Two gain selections are available in the DTMF detection circuit. In most installations, the low gain

setting is recommended. The high gain setting may be necessary if the telephone is not responding to

manual or TMA-generated DTMF commands.

Low Gain Selected: Place the J17 jumper in position LO.

High Gain Selected: Place the J17 jumper in position HI.

Low-Power Mode Configuration

Factory Setting: Low-Power Mode Disabled

For some installations in which only minimal loop current is available, the performance of the telephone

may be improved by enabling this feature. Symptoms of minimal loop current may include low speaker

volume and/or momentary muting of audio. In the majority of applications, however, the low-power

mode should be disabled. The low-power mode is enabled by installing the following three jumpers: J21,

J22, and J23.

Low-Power Mode Enabled: Jumpers installed at J21, J22, and J23.

Low-Power Mode Disabled: Jumpers NOT installed at J21, J22, and J23.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 11

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 11 of 17

Auxiliary Outputs

Each telephone includes two isolated solid state switches capable of switching a maximum of 48 V dc,

125 mA or 28 V

ac, 80 mA

RMS

. TB2 (OUT1) and TB5 (OUT4) on the Main PCBA provide the

RMS

connections for the auxiliary outputs. Refer to Figure 7 for the location of TB2 and TB5.

Output 1 connects to TB2 on the Main PCBA. Refer to Figure 7. This output activates at the start of an

incoming call and will extinguish when the handset is lifted from its cradle (call answered). This output

will activate with a cadence of 2 seconds ON followed by 4 seconds OFF during this time interval.

OTE: This output is not available on models containing the Ring Relay option.

N

Output 4 connects to TB5 on the Main PCBA (adjacent to TB2). This output can be remotely controlled

via an appropriate DTMF command. This remote control output could be used to activate or control a

door latch, gate relay solenoid, alarm, etc. from the called party location.

Extreme Cold Temperature Operation

GAI-Tronics’ 352 Series Division 1 SMART Telephones are equipped for operation in extremely cold

temperatures ranging to −40º C. Operation at these temperatures requires 5 V dc to be supplied to the

telephone.

To connect the power, remove the jumper from header P17 pins 3 and 4 and plug it into the adjacent J18

header. Refer to Figure 7 for connector locations.

Attach the Front Cover

After all adjustments have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit

N

for additional information.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 12

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 12 of 17

Programming

All SMART Telephone models are programmable. The telephone settings are initially programmed

during manufacturing and testing. After the SMART Telephone is installed, you have the option of

changing the default settings. This manual provides instructions for programming basic features needed

to initially set up the telephone from another touch-tone telephone.

More advanced programming requires a PC and the TMA software. For programming using the TMA

terminal, refer to the manual provided with the software (Part No. 12509-037), or contact the GAITronics Field Service Department.

NOTE

Use a handset telephone exclusively when programming the SMART Telephone remotely. If a

speakerphone is used for programming background noise could lead to the incorrect settings. (Cellular

telephone is not recommended.)

Enter the Programming Mode

Read the entire “Programming” section and carefully plan your programming before beginning the

process. Write down the key sequence from the Command column of Table 1, Basic Programming

Commands, for the features that you need. Having your programming information written down allows

you to enter the key sequence at a steady pace.

Complete the following steps to enter the programming sequence from a remote DTMF telephone:

1. Call the SMART Telephone to be programmed. (Do not use a cellular telephone.)

2. Listen for a confirmation tone during ringing, which signals that the telephone has answered.

3. Press

*** to enter the programming mode.

4. Wait two seconds.

5. Enter **0000

OTE: After sending the maintenance PIN # to the telephone, entering *20 will allow for

N

(0000 is the factory default maintenance PIN #.)

confirmation of maintenance access to the telephone. If access is granted, the telephone responds

with six DTMF digits.

If access is denied, the telephone responds with two DTMF digits. If access is denied, repeat step 5 to

again request access.

6. Complete the desired programming. Refer to the “Basic Programming” section for options.

7. Listen for a confirmation tone at the end of each programming sequence, which indicates the

programming change was accepted.

NOTE

Delays during programming greater than 5 seconds cause a programming time-out. If this occurs,

you will hear a beep before the programming sequence is completed and you must reenter the

sequence.

8. When finished programming, press *99 to exit the programming mode.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 13

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 13 of 17

Basic Programming

The following programming command can be entered from any touch-tone telephone. Acceptance of a

data transfer command is indicated via a return code transmitted as an audible DTMF tone.

Call Time-out

The call time-out feature, which is used to limit the duration of calls, can be set between one minute and

4.5 hours. The time limit is set by entering a number from 120 to 32400.

This number represents the number of half-second increments of duration. Entering 0 results in a call

time-out of 4.5 hours.

Enter *37<120~32400>#

*37

<120~32400>

#

to assign a time limit, or change an existing time limit.

Data transfer command

Call duration (60–16,200 seconds, 0 = 4.5 hours) – See example below.

End of sequence indicator

Multiply the desired time limit, in minutes, by 120 to determine the call duration.

Example: For a call duration of 5 minutes:

5 minutes 120 = 600

Therefore, enter the character string *37600#, and the telephone returns a DTMF check-digit.

Table 1. Basic Programming Commands

Command

*37<120~32400># c

Return Description

Write Call Time-out (120–32400 ½ sec, 0 disables)

‘c’ in the above return fields is the success tone (DTMF check digit).

Default

Setting

10 min.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 14

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 14 of 17

Operation

Models 352-101 and 352-102 Handset Operation

1. Lift the handset to place a call.

2. The handset receiver volume control, which is located on the front cover keypad, can be adjusted to

the desired level by pressing the volume control push button.

OTE: Pressing the volume control push button increases the volume in 5-dB increments. The

N

volume starts at 0 dB and increases to a maximum volume of 20 dB. Pressing the volume control

push button a fifth time will return the volume to 0 dB.

3. Dial the desired number.

4. After completion of the call, place the handset on-hook.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Figure 10.

Page 15

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 15 of 17

Models 352-103 and 352-104 Headset Operation

1. To connect the headset, plug it into the flexible plug on the front of the telephone by removing the

sealing cap from the receptacle, aligning the connector pins, and screwing the two ends together.

Figure 11.

2. To place a call, remove the headset from the headset activation bracket and flip the headset bracket

forward to its preset position. See Figure 11.

3. The handset receiver volume control, which is located on the front cover keypad, can be adjusted to

the desired level by pressing the volume control push button.

OTE: Pressing the volume control push button increases the volume in 5-dB increments. The

N

volume starts at 0 dB and increases to a maximum volume of 20 dB. Pressing the volume control

push button a fifth time will return the volume to 0 dB.

4. Dial the desired number.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 16

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 16 of 17

5. Flip the headset activation bracket to its vertical preset position to hang up. If applicable, place the

headset on the bracket after the completion of the call. Otherwise, disconnect the flexible receptacle

and plug by unscrewing the two ends, and pulling them apart. When disconnected, reattach the

sealing cap to the end of the receptacle. See Figure 12.

Figure 12.

Maintenance

Service

If your telephone requires depot service, contact your Regional Service Center for a return authorization

number (RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number

and a purchase order number. If the equipment is under warranty, repairs will be made without charge.

Please include a written explanation of all defects to assist our technicians in their troubleshooting efforts.

Call 800-492-1212 inside the USA or 610-777-1374 outside the USA for help identifying the Regional

Service Center closest to you.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 17

Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 17 of 17

Specification s

TMA Compatibility profile type .......................................................................................... Type A Handset

Electrical

Minimum loop current (48 V dc only) ................................................................................................ 20 mA

Volume control ...................................................................... Five steps (0 dB, 5 dB, 10 dB, 15 dB, 20 dB)

Inter-digit pause .................................................................................................................................. 100 ms

Signaling tone (DTMF) ................................................................................................ 100 ms tone duration

Supervisory dc voltage ..................................................................................................... 24 V dc or 48 V dc

Network interface .......................................................................................................................... Loop Start

Auxiliary output (isolated solid state switch) .................................................................. 48 V dc @ 125 mA

28 V

Ring Relay PCBA output mechanical relay contact ............................................................ 250 V ac @ 5 A

30 V dc @ 5 A

Network signaling ............................................................................................................................... DTMF

Ringer Equivalence Number (REN) ....................................................................................................... 0.5B

ac @ 80 mA

RMS

RMS

Environmental

Operating temperature .......................................................................... −4º F to +140º F (−20º C to +60º C)

Humidity ...................................................................................................................... 90% non-condensing

Mechanical

Enclosure .............................................................................. Cast aluminum with aluminized lacquer paint

Handset Cord ....................................................... “G” style handset/PVC 6-foot extended length (standard)

Connections................................................................................ Internal screw-type barrier terminal blocks

Dimensions, Outside ............................... 10.25 W 12.25 H 9.50 D inches (260.3 311.1 241.3 mm)

Mounting .................................................. Wall or column, four 3/8-inch (10 mm) mounting feet with slots

Shipping weight ................................................................................................................ 30.0 lbs. (13.6 kg)

Net weight ......................................................................................................................... 28.0 lbs. (12.7 kg)

Approvals

NRTL listed ...................................................... Hazardous locations Class I, Division 1, Groups B, C, & D

(USA and Canada) Class II, Division 1, Groups F & G

Class III, Division 1

Type 4X

T6 - Gas

T4A - Dust

User Instructions (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

f:\standard ioms - current release\42004 instr. man uals\42004-455b.doc

02/13

Page 18

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will reperform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor's personnel from the work

site. Re-performance of services shall be Buyer's sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...