Page 1

Pub. 42004-337F

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 226-001, 246-001, 256-001, and 276-001

Industrial Telephones with K eypa ds

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

GAI-Tronics industrial telephones are ideally suited for conditions that are too harsh for a standard

telephone. The telephones operate the same as a standard telephone—simply lift the handset and dial the

desired telephone number. The telephones are fully line-powered and do not require internal batteries.

This manual applies to the following telephones:

Model 226-001 Public Access Telephone

Model 246-001 Indoor Industrial Telephone

Model 256-001 Weatherproof Industrial Telephone

Model 276-001 Flush-Mount Telephone

Operation

1. Lift the handset to place a call.

2. The handset receiver volume control, which is located on the handset, can be adjusted to the desired

level by pressing the handset pressbar.

OTE: Pressing the handset pressbar increases the volume in 3-dB increments. The volume starts at

N

0 dB and increases to a maximum volume of 18 dB. Pressing the pressbar a seventh time will return

the volume to 0 dB.

3. Dial the desired number.

4. After completion of the call, place the handset on-hook.

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 2 of 18

Installation

ATTENTION

Installation should be performed by qualified personnel and only in

accordance with the National Electrical Code or applicable local codes.

Safety Guidelines

When installing any GAI-Tronics telephone equipment, please adhere to the following guidelines to

ensure the safety of all personnel:

NEVER install telephone wiring during a lightning storm.

Install a UL Listed lightning arrestor on any telephone installed where the telephone or telephone

cable is at risk of being exposed to lightning strikes. The lightning arrestor must be installed as close

as possible to maximize the protection. It must not be installed within the enclosure supplied with the

telephone. Please consult our Service Center at 800-492-1212 for further information.

Do not install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

Do not touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

Security Hardware

Models 226-001 and 276-001 are vandal resistant, with the front panel for each telephone attached to its

enclosure with security screws. A GAI-Tronics Model 233-001 Security Screwdriver or Torx T-25

security head tip (sold separately) is recommended for installing the security screws. Model 246-001 and

256-001 Telephones’ front panels are attached with standard Phillips head screws.

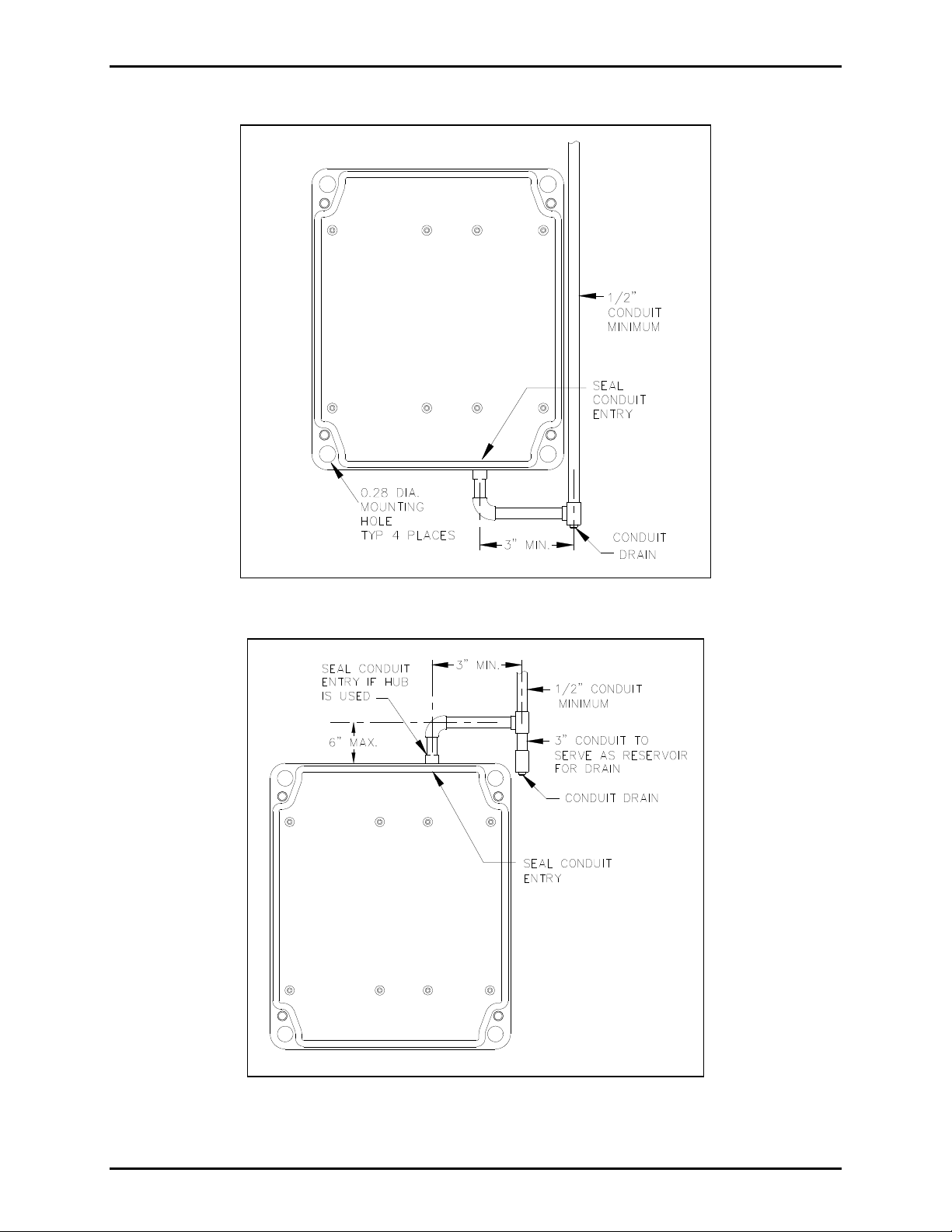

Conduit Installation Details (Applicable to Models 246-001 and 256-001)

GAI-Tronics recommends installing telephone lines in conduit to protect against accidental damage and

vandalism. To prevent moisture from entering the enclosure, we strongly recommend the following:

Conduit should enter the enclosure from the bottom whenever possible.

Sealed fittings should be installed at all cable entry points.

Silicone sealant or equivalent should be applied around and inside all conduit entries to prevent

moisture ingress.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 3

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 3 of 18

Refer to Figure 1 and Figure 2.

Figure 1. Bottom entry conduit installation details (RECOMMENDED for non-metallic enclosures)

Figure 2. Top entry conduit installation details (NOT RECOMMENDED)

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 4

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 4 of 18

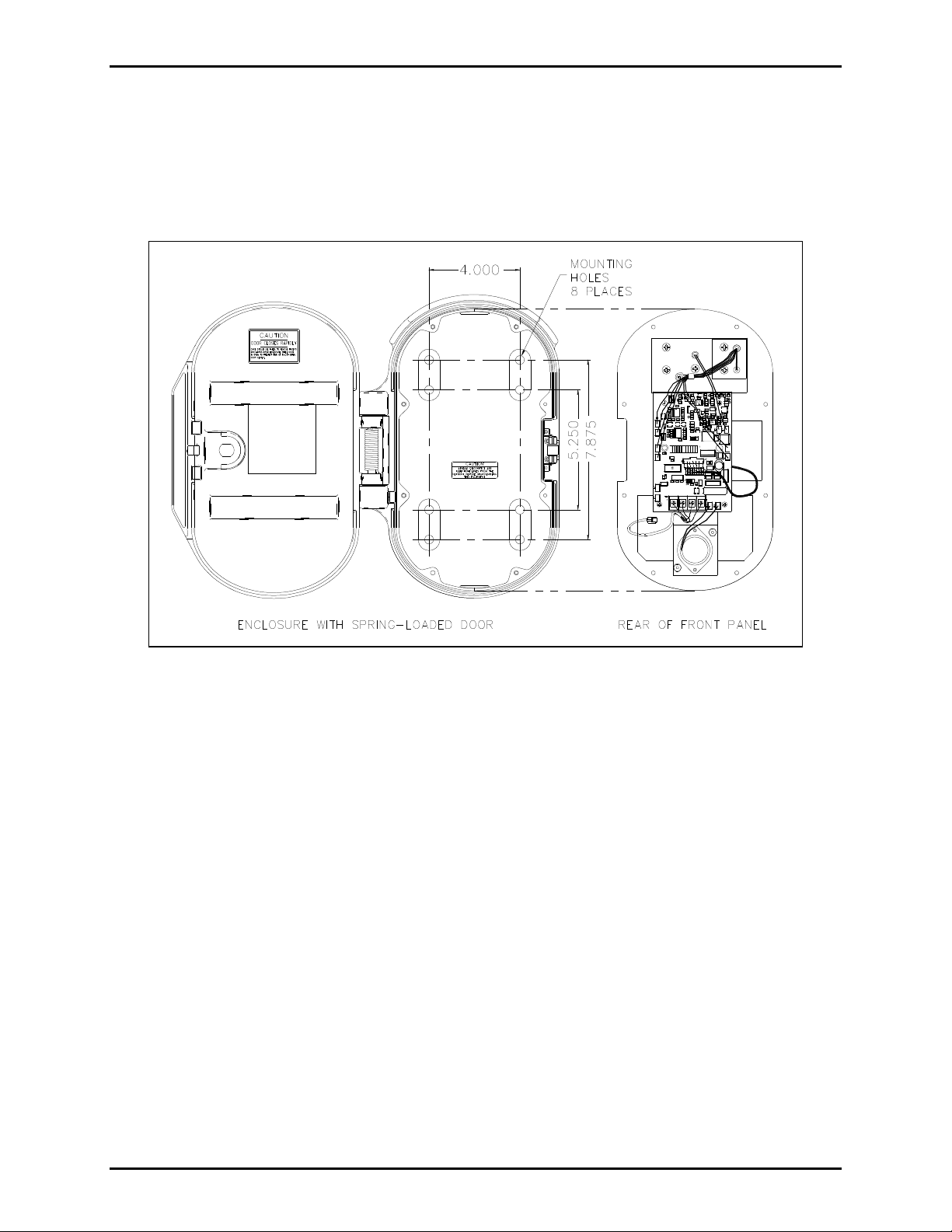

Model 226-001

The mounting and wiring instructions for the Model 226-001 Public Access Telephone are as follows:

1. Remove the eight security screws

from the front panel. Remove the

front panel and set aside.

OTE: There is a 7-foot half-

N

modular telephone cord attached to

the PCBA on the rear.

2. There are eight mounting holes in

the back of the enclosure in two 4hole patterns. Determine which hole

pattern will be used for mounting.

See Figure 5.

For best results, use the

7.875 4.0-inch hole pattern for

mounting to a wall (outside

pattern).

Figure 3. Model 226-001 Public Access Telephone with

spring loaded door in the open position

3. Insert four hole plugs (provided) in the unused holes.

4. Position the enclosure on the mounting surface and

secure it with four fasteners.

The holes in the telephone enclosure accept 3/8-

inch screws or bolts.

The Model 232-001 Pole Mounting Kit includes

four 3/8-16 1-inch shoulder bolts with Teflon

seal washers.

NOTE

Use only the round head, hexagon

head, or pan head screws that are provided.

Do not

use screws designed to be countersunk for

mounting the enclosure.

5. Install a conduit fitting in one of the ½-inch NPT

conduit entrances provided at both the top and bottom

of the unit, and insert the conduit into the fitting. (The

bottom location is preferred. See Figure 4.) Plug the

unused access hole using the 3/8-inch Allen drive plug

provided.

Use the 5.25 4.0 hole

pattern when using the Model

232-001 Pole Mounting Kit

(inside pattern).

OTE: Use silicone sealant or equivalent around

N

and inside all conduit entries.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Figure 4. Model 226-001 Outline

Page 5

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 5 of 18

6. If mounted outdoors, install a telephone line suppressor (customer-supplied) on the telephone line.

7. Pull the telephone line through the conduit and into the enclosure. Connect the telephone’s modular

cord to the incoming subscriber line with the appropriate connector. Verify operation by calling to

and from another telephone.

8. Replace the front panel assembly and tighten the eight front panel screws.

Figure 5. Model 226-001 Outline and Mounting Drawing

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 6

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 6 of 18

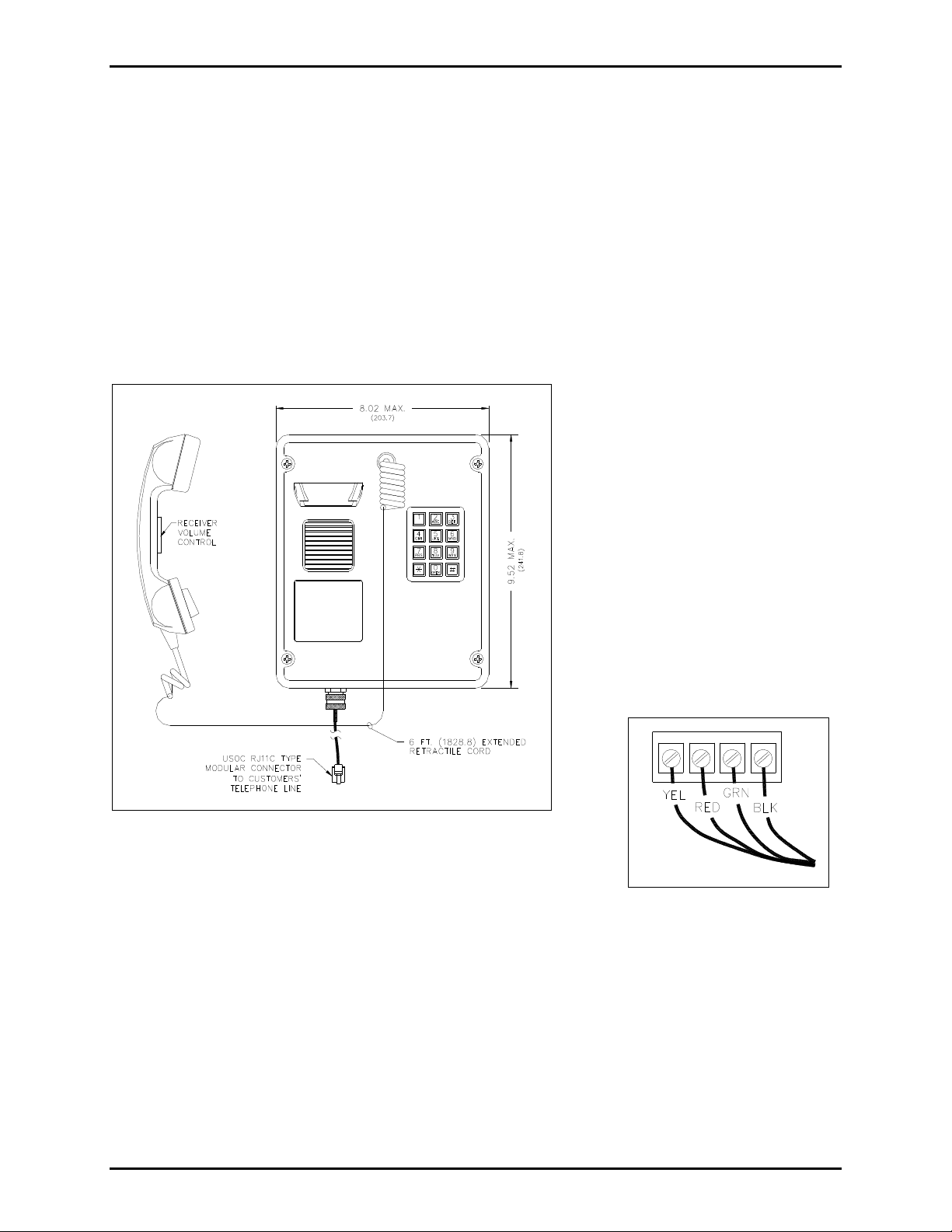

Model 246-001

1. Remove the four front panel screws using a standard Phillips screwdriver, and remove the front panel

assembly and set aside. Disconnect the 7-foot half-modular telephone cord from the PCBA terminal

strip (if connected). See Figure 7.

2. Please refer to Figure 1 and Figure 2 if utilizing conduit for cable installation. If using the gland

bushing provided with the unit, drill a 0.688-diameter hole at either drill spot on the bottom of the

rear enclosure.

3. Push the free end of the telephone cord through the gland bushing using needle-nose pliers. Allow

8–10 inches of telephone cord to extend past the bushing. Tighten the bushing around the cord. Feed

the free end of the telephone cord through the hole in the enclosure.

4. Secure the bushing in the hole with

the supplied locknut using a 7/8inch wrench and channel locks to

tighten.

5. There are four mounting holes in

the rear enclosure. Mount the

enclosure to the wall using either

four 1/4-20 machine screws with

nuts and washers, or #14 wood

screws of appropriate length for the

mounting surface. Refer to Figure

8.

6. Connect the telephone cord to the

PCBA terminal strip. See Figure 7.

Figure 6. Model 246-001 Outline Drawing

7. Replace the front panel assembly, and secure with the four front

panel screws.

Figure 7. PCBA Connection

8. Connect the telephone cord’s modular connector to the incoming subscriber line using the appropriate

mating connector.

9. Check for proper telephone operation by calling to and from another telephone.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 7

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 7 of 18

Figure 8. Model 246-001 Mounting Diagram

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 8

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 8 of 18

Model 256-001 Mounting and Wiring Instructions

1. Open the front door and remove the four outermost screws from the mid-section using a standard

Phillips screwdriver. Carefully pull the enclosure apart until encountering a slight resistance on the

left side.

2. Open the front half of the enclosure to the left until the length of the telephone cord inside the

enclosure can be disconnected from the PCBA terminal strip (if connected). See Figure 10. Pull on

the left side of the enclosure until the hinge plugs pull loose to separate the front and rear halves. Set

the front half of the enclosure aside.

Figure 9. Model 256-001 Outline Drawing

3. Please refer to Figure 1 and Figure 2 if utilizing conduit for cable installation. If using the gland

bushing provided with the unit, drill a 0.688-diameter hole at either drill spot on the bottom of the

rear enclosure.

4. Push the free end of the telephone cord through the gland bushing using needle-nose pliers. Allow 8–

10 inches of telephone cord to extend past the bushing. Tighten the bushing around the cord. Feed

the free end of the telephone cord through the hole in the enclosure.

5. Secure the bushing in the hole with the supplied locknut using a 7/8-inch wrench and channel locks to

tighten.

6. There are four mounting holes in the rear enclosure. Mount the enclosure on the wall using four ¼-20

machine screws with nuts and washers or #14 wood screws of appropriate length for the mounting

surface. Refer to Figure 10.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 9

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 9 of 18

7. If mounted outdoors, install a telephone line suppressor (customer-supplied) on the telephone line.

8. Connect the telephone cord to the PCBA terminal strip. See Figure 7 for details.

9. Close the front half of the enclosure and secure it by replacing the four outermost screws.

10. Connect the telephone’s modular cord to the incoming subscriber line with the appropriate mating

connector. Verify operation by calling to and from another telephone.

Figure 10. Model 256-001 Mounting Detail

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 10

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 10 of 18

Model 276-001 Mounting and Wiring Instructions

Flush-Mounting

Refer to Figure 12 for additional installation information.

Figure 11. Model 276-001 Outline Drawing

1. When mounting in a Model 234 Series Stanchion or for flush-mount installations, the supplied back

box must be used to mount the Model 276-001 Telephone. Mount the back box to the structure using

appropriate hardware.

2. If mounted outdoors, install a telephone line suppressor (customer-supplied) on the telephone line.

3. Remove the tapered plug from the back cable entry hole in the back box, and install the telephone line

(customer-supplied) and cable fitting.

4. Recommendation—use silicone sealant or equivalent around and inside all conduit entries.

5. Connect the USOC RJ11C modular connector of the 7-foot supplied telephone cord to the incoming

subscriber line or the telephone line suppressor (if applicable) using the appropriate mating connector.

6. Attach telephone’s front panel to the mounting flanges of the back box using the six supplied #10

security screws and the six black flat washers. A Model 233-001 Security Screwdriver (sold

separately) is recommended for installing the security screws.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 11

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 11 of 18

Figure 12. Model 276-001 Back Box Diagram

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 12

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 12 of 18

Surface-Mount using 236-00x Series or Model 238-001 Enclosure

NOTE: The back box is not required for use with a Model 236 Series or Model 238-001 Surface-Mount

Enclosure and should be removed.

1. Drill or punch conduit entries. (The Model 238-001 already includes a rear-access hole with gasket.)

WARNING

To prevent accidentally damaging equipment, drill all holes before

mounting the telephone.

2. Install the telephone line suppressor (customer-supplied) on the telephone line, if applicable.

3. Connect the telephone’s modular plug to the incoming subscriber line or the telephone line suppressor

(if applicable) using the appropriate mating connector.

4. Complete the installation by attaching the telephone’s front panel to the mounting flanges of the Model

236 Series or 238-001 Surface-Mount Enclosure using the six supplied #10-32 security screws and the

six black flat washers. A Model 233-001 Security Screwdriver (sold separately) is required for

installing the security screws. 10–12 in-lbs. of torque is recommended.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 13

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 13 of 18

Maintenance

Service

If your telephone requires service, contact your GAI-Tronics Regional Service Center for a return

authorization number (RA#). Equipment should be shipped prepaid to GAI-Tronics with a return

authorization number and a purchase order number. If the equipment is under warranty, repairs will be

made without charge. Please include a written explanation of all defects to assist our technicians in their

troubleshooting efforts.

Call 800-492-1212 inside the USA or 610-777-1374 outside the USA for help identifying the Regional

Service Center closest to you.

Preventive Maintenance for Model 276-001

Stainless steel does not require maintenance to prevent corrosion from occurring. Different installation

locations may require more regular maintenance than others, depending on the environment and exposure

to airborne contaminants. The following maintenance steps should be performed on a regular basis or

when corrosion is first noticed on your Model 276-001.

Cleaning

For general cleaning, wipe the surface with a cleanser or a cleanser and water mixture. Any cleanser

that is safe for glass is usually safe for stainless steel. Wipe dry.

If corrosion or rusting is noticed, remove with a non-abrasive commercial cleanser and water. Rub

stained areas in the same direction as the existing grain. Stubborn stains may be removed with a

magnesium oxide, ammonia, and water paste. Wipe clean with water rinse and dry.

Prevention

Automotive wax provides the best results in preventing corrosion on stainless steel. Simply apply wax,

let dry to a haze, and buff to a shine with a clean dry cloth. This application should protect the telephone

surface for many months as it will allow natural reformation of the chromium oxide layer.

Do NOT use steel wool, sandpaper, mineral acids, bleaches, or chlorine cleansers on the stainless

surface.

Volume Control Jumper Setting

The handset receiver volume control is factory set to default to its original setting (0 dB) when the

telephone is hung up. To save the volume control setting, jumper J4, which is factory set at positions 2

and 3, must be moved to positions 1 and 2. Refer to Figure 13 for the location of J4.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 14

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 14 of 18

Auxiliary Output

Each telephone includes one isolated solid state volt-free closure capable of switching a maximum of 48

V dc, 125 mA; or 28 V

for the auxiliary output. Refer to Figure 13 for location of TB2.

The auxiliary output allows peripheral equipment, such as beacons, video cameras, and alarm generators,

to be activated when the handset is off hook

ac, 80 mA

RMS

. TB2 (AUX OUT) on the Main PCBA provides the connections

RMS

. The relay remains energized for the duration of the call.

Figure 13. Location of TB2 on Main PCBA

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 15

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 15 of 18

Specification s

Electrical (Typical)

Frequency response .............................................................................................................. 300 to 3,000 Hz

Inter-digit pause .................................................................................................................................. 100 ms

Minimum loop current ........................................................................................................................ 20 mA

Signaling tone (DTMF) ................................................................................................ 100 ms tone duration

Supervisory dc current ................................................................ Minimum 20 mA dc; maximum 60 mA dc

Supervisory dc voltage ................................................................ 24 V dc to 60 V dc (not polarity sensitive)

Network interface .......................................................................................................................... Loop Start

Network signaling ............................................................................................................................... DTMF

Auxiliary output (isolated solid state switch) ................................................................. 48 V dc @ 125 mA

28 V

Environmental

Operating temperature ........................................................................ −40º F to +140º F (−40º C to +60º C)

Humidity ...................................................................................................................... 90% non-condensing

ac @ 80 mA

RMS

RMS

Mechanical

Model 226-001

Construction

Enclosure ...................................................... Thick-walled cast aluminum with protective gray coating

Panel ........................................................................................................ 0.125-inch brushed aluminum

Finish ................................................................................................................... Gray polyurethane enamel

Handset/cord ...................................................................... “G” style with armored cord and volume switch

Dial pad ........................................................................................................................... Chrome-plated zinc

Front panel ...................................................................................... 0.125-inch brushed anodized aluminum

Hookswitch ............................................................... Chrome-plated zinc, Stationary switching mechanism

Models 246-001 and 256-001

Enclosure ........................................................................................ High-impact, glass-reinforced polyester

®

Handset Cord ....................“G” style handset/Hytrel

6-foot extended length (standard) and volume switch

Connections........................................................................................... 6.5-foot (1.98 m) modular line cord

Dimensions, Outside .................. Model 246-001 . 8.00 W 9.50 H 6.90 D inches (204 242 174 mm)

Model 256-001 9.40 W 13.20 H 7.40 D inches (239 344 188 mm)

Mounting ...................................................................................................... Four 0.280-inch diameter holes

Weight ........................................ Model 246-001 ................................................................ 6.0 lbs. (2.70 kg)

Model 256-001 ................................................................ 8.2 lbs. (3.72 kg)

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 16

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 16 of 18

Model 276-001

Enclosure construction: Front panel ........................ 14-gauge (0.075 inch) type 304 brushed stainless steel

Enclosure construction: Back box......... 16-gauge (0.060 inch) cold-rolled steel with black polyester finish

Dimensions

Front panel .......................................................................... 12.00 H 10.00 W inches (305 254 mm)

Back box (overall) ...................................... 10.06 H 8.43 W 2.50 D inches (256 214 63.5 mm)

Cutout for mounting back box .............................................. 10.13 H 7.63 W inches (257 194 mm)

Weight ................................................................................................................................... 6.5 lbs. (3.0 kg)

Handset/cord ...................................................................... “G” style with armored cord and volume switch

Dial pad ........................................................................................................................... Chrome plated zinc

Hookswitch ............................................................... Chrome plated zinc; stationary switching mechanism

Approvals

Safety of Information Technology Equipment .................. UL 60950 and CAN/CSA-C22.2 NO. 60950-00

Enclosures for Electrical Equipment ................................................................. UL 50 TYPE 3R/NEMA 3R

FCC Information

FCC Registration Number .............................................................................. US: ADGTE10A-46048HAC

Ringer Equivalence Number (REN) .............................................................................................. 1.0A/1.3B

Network Connection (USOC) ................................................................................................................ RJ 11

Meets hearing aid compatibility magnetic field intensity and volume control technical standards per FCC

Sections 68.316 and 68.317.

IC Information (Canada)

IC Certification Number ................................................................................................................ 82211754

Ringer Equivalence Number (REN) .............................................................................................. 1.0A/1.3B

Connecting Method ............................................................................................................................ CA11A

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 17

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 17 of 18

User Instructions (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

This equipment complies with Part 68 of the FCC rules. Located on the equipment is a label that contains, among other information,

the FCC registration number and ringer equivalence number (REN). If requested, this information must be provided to the telephone

company. The REN is used to determine the quantity of devices which may be connected to the telephone line. Excessive REN’s on

the telephone line may result in the devices not ringing in response to an incoming call. In most, but not all areas, the sum of the

REN’s should not exceed five (5.0). To be certain of the number of devices that may be connected to the line, as determine by the

total REN’s contact the telephone company to determine the maximum REN for the calling area. This equipment cannot be used on

the telephone company-provided coin service. Connection to Party Line Service is subject to State Tariffs. If this equipment causes

harm to the telephone network, the telephone company will notify you in advance that temporary discontinuance of service may be

required. If advance notice isn’t practical, the telephone company will notify the customer as soon as possible. Also, you will be

advised of your right to file a complaint with the FCC if you believe it is necessary. The telephone company may make changes in

its facilities, equipment, operations, or procedures that could affect the operation of the equipment. If this happens, the telephone

company will provide advance notice in order for you to make the necessary modifications in order to maintain uninterrupted service.

If trouble is experienced with this equipment, please contact:

GAI-Tronics Corporation

400 E. Wyomissing Ave.

Reading, PA 19540 USA

800-492-1212 or 610-777-1374

If the trouble is causing harm to the telephone network, the telephone company may request you to remove the equipment from the

network until the problem is resolved. This equipment uses the following USOC jacks: RJ11CIt is recommended that the customer

install an ac surge arrester in the ac outlet to which this device is connected. This is to avoid damaging the equipment caused by

local lightening strikes and other electrical surges. This equipment is Hearing-Aid Compatible (HAC). The telephone Consumer

Protection Act of 1991 makes it unlawful for any person to use a computer or other electronic device, including fax machines, to

send any message unless such message clearly contains in a margin at the top or bottom of each transmitted page or on the first page

of the transmission, the date and time it is sent and an identification of the business or other entity, or other individual sending the

message and the telephone number of the sending machine or such business, other entity, or individual. (The telephone number

provided may not be a 900 number or any other number for which charges exceed local or long-distance transmission charges.)

User Instructions (Canada) CP-01, Issue 8, Par t I: Section 14.1

NOTICE: The Industry Canada label identifies certified equipment. This certification means that the equipment meets certain

telecommunications network protective, operational and safety requirements as prescribed in the appropriate Terminal Equipment

Technical Requirements document (s). The Department does not guarantee the equipment will operate to the user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. The customer

should be aware that compliance with the above conditions may not prevent degradation of service in some situations. Repairs to

certified equipment should be coordinated by a representative designated by the supplier. Any repairs or alterations made by the user

to this equipment, or equipment malfunctions, may give the telecommunications company cause to request the user to disconnect the

equipment. Users should ensure for their own protection that the electrical ground connections of the power utility, telephone lines

and internal metallic water pipe system, if present, are connected together. This precaution may be particularly important in rural

areas.

CAUTION

Users should not attempt to make such connections themselves, but should contact the appropriate electric

inspection authority, or electrician, as appropriate.

CP-01, Issue 8, Part I: Section 14.2

NOTICE: The Ringer Equivalence Number (REN) assigned to each terminal device provides an indication of the maximum

number of terminals allowed to be connected to a telephone interface. The termination on an interface may consist of any

combination of devices subject only to the requirement that the sum of the Ringer Equivalence Numbers of all the devices does not

exceed 5.

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 18

Pub. 42004-337F

Model 226-001, 246-001, 256-001, and 276-001 Industrial Telephones with Keypads Page 18 of 18

Replacement Parts & Accessories

Part No. Description

Replacement P ar t s

10111-101 Handset Assembly with 6-foot Hytel®

Coiled Cord, Volume Control, and NoiseCanceling

10117-001 Handset Assembly with 15-inch Armored

Cord, Volume Control, and NoiseCanceling

10117-003 Handset Assembly with 29-inch Armored

Cord, Volume Control, and NoiseCancelling

12512-001 Hookswitch/Cradle Kit

12512-002 Hookswitch/Cradle Kit

12516-001 Replacement Mounting Screw Kit

(Phillips, 10 pack)

12542-002 Replacement Mounting Screw Kit

(Security, 15 pack)

13707-004 Replacement Ringer Assembly

226-001 246-001 256-001 276-001

12513-006 Replacement Door Kit

51035-005A

Replacement Keypad Assembly

69147-104 Replacement PCB Assembly

Accessories

12573-001 Spring Door Kit

12576-116 Front Panel Replacement Kit

230-001 Pole Mounting Kit

231-001 Pole Mounting Kit

232-001 Pole Mounting Kit

233-001 Security Screwdriver, Torx T-25 Tip

f:\standard ioms - current release\42004 instr. man uals\42004-337f.doc

06/12

Page 19

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...