Page 1

Pub. 42004-096D

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 13314-003 Div. 2 Hazardous Area

70-Volt Horn Driver

Confidentiality Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

Introduction

The GAI-Tronics Model 13314-003 Div. 2 Hazardous Area 70-Volt Horn Driver is constructed of black

glass and fiber-reinforced polyester thermoplastic and has a rain-tight construction. It is built to

withstand harsh industrial environments and is approved for installation in hazardous areas.

Mounting Instructions

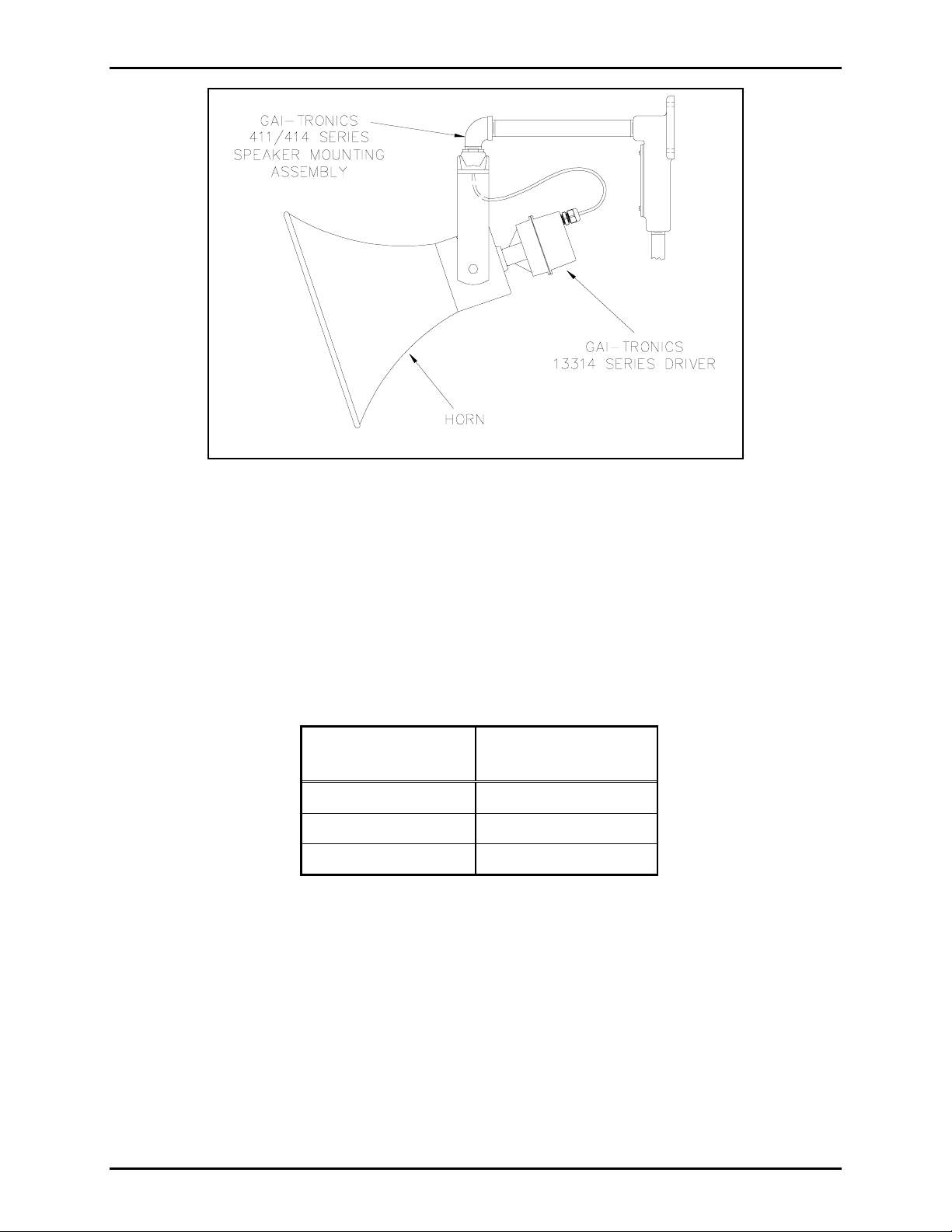

A typical installation of a 13314 Series Driver with associated horn and mounting assembly is shown in

Figure 3. The recommended mounting height for the driver is 9 feet (2.7 meters) from the floor. Refer to

the following chart to verify that the horn is paired with the correct speaker mounting assembly.

Horn

Series

13302 411A

13304 411A

13305 411A

13306 414-002

13309 411A

13340 411A

Speaker Mounting

Assembly

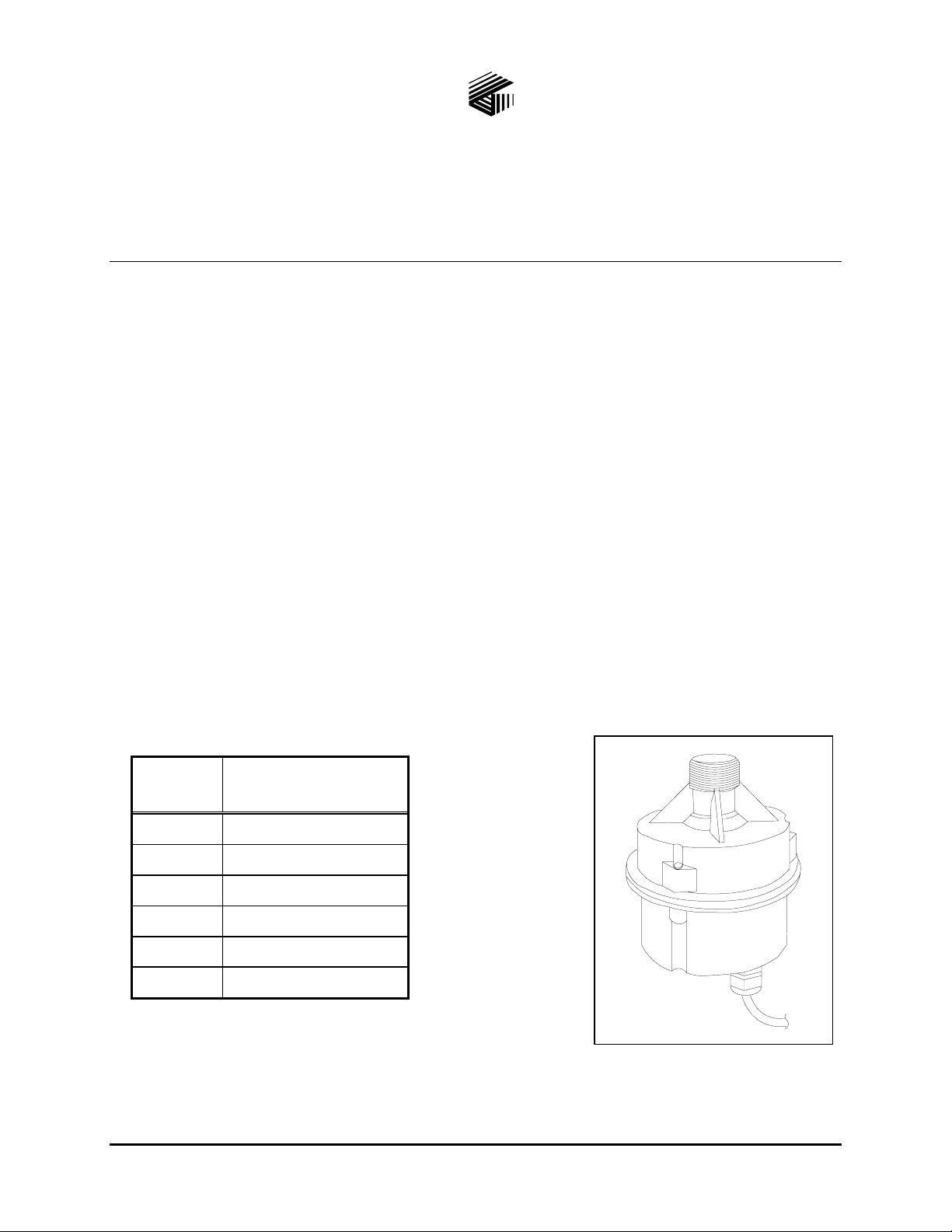

Figure 1. Model 13314-003 Div. 2

Hazardous Area 70-Volt Horn

Driver

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Pub. 42004-096D

Model 13314-003 Div. 2 Hazardous Area 70 Volt Horn Driver Page:

Figure 2. Typical Installation

2 of 4

The installation of this speaker assembly must conform to regulations governing electrical equipment for

hazardous locations and provisions of the National Electrical Code.

Install the mounting assembly and the horn, then complete the following instructions to install the driver

onto the horn.

Wiring Instructions

Refer to the following chart to determine the appropriate gauge speaker cable.

Cable

Options

No. 18 AWG 6,250

No. 16 AWG 9,900

No. 14 AWG 15,800

Field wiring to the driver must be made using the attached three-conductor type SO cord. Connect these

wires as follows:

Distance of Cable

Run in Feet

• Green: earth ground

• Black: amplifier 70V + terminal

• White: amplifier 70V − (com) terminal

The horn driver is factory-connected for 30-watt tap setting. If no wattage tap changes are required,

screw the driver assembly onto the rear of the horn as shown in Figure 2.

f:\standard ioms - current release\42004 instr. manuals\42004-096d.doc

05/11

Page 3

Pub. 42004-096D

Model 13314-003 Div. 2 Hazardous Area 70 Volt Horn Driver Page:

3 of 4

Changing the Wattage Tap Setting

1. If another wattage tap setting is desired, it is recommended that the driver assembly be disconnected

and removed from the horn for convenience of changing taps.

2. Remove the three Phillips screws that hold the driver together, and pull the rear assembly away from

the front assembly. See Figure 3. Use care to avoid damaging the gasket.

Figure 3. Driver Outline Diagram

3. Unscrew the wire nut from the driver transformer’s brown wire that is joined to the driver cable’s

(SO cable) black wire. Terminate the brown wire with a nut or approved connector to avoid shorting

out.

4. Select the desired wattage tap wire, as shown in Figure 3.

5. Strip the wire back approximately 3/8 inch. Connect the desired wattage tap wire to the driver

cable’s black wire using a wire nut or approved connector.

6. It is not recommended that these wires be cut in case of future changes. Carefully push all primary

transformer wires into the space in the rear section of the enclosure.

7. After ensuring that the gasket is properly seated on the front assembly, align the rear assembly holes

with the front assembly holes and re-install the three screws.

8. Re-install the driver assembly to the horn and reconnect the cable to the field connection.

f:\standard ioms - current release\42004 instr. manuals\42004-096d.doc

05/11

Page 4

Pub. 42004-096D

Model 13314-003 Div. 2 Hazardous Area 70 Volt Horn Driver Page:

Driver Specifica tions

4 of 4

Power handling ...................... 30 W

300–3000 Hz; pink noise 6 dB crest factor; ref. ANSI S4.26–1984

RMS

Frequency response..................................................................................... 300–4500 Hz (depends on horn)

Input taps for 70 V line.................................................. 3.7, 7.5, 15, and 30 watts (factory set for 30 watts)

Sensitivity ........................................... 109 dB spl @ 1 watt, 1 meter; swept sine average with 13304 Horn

Horn coupling ........................................................................................... Standard 1.375–18 UNEF threads

Housing................................................................ Black; glass and fiber reinforced polyester thermoplastic

Bushing .......................................................................................... Nylon body with neoprene sealing gland

Cable ......................................Extra hard usage flexible cord (Type SO, 18/3) 42 inches (1066.8 mm) long

Impedance...................................................................................................................Variable (transformer)

Shipping weight .................................................................................................................... 4.3 lbs. (1.9 kg)

Dimensions ....................................................5.0 inches (127 mm) in diameter × 5.5 inches (140 mm) long

Approvals...................UL & cUL Listed for Class I, Div. 2 Groups A, B, C, D – Temp Code T2C at +40C

Class I, Div. 2 Groups A, B, C, D – Temp Code T2B at +55C

Class II, Div. 2 Groups F & G – Temp Code T4 at +55C

Class III, Div. 2

Weatherproof rating..........................................................................................................................Type 4X

f:\standard ioms - current release\42004 instr. manuals\42004-096d.doc

05/11

Page 5

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...