Page 1

Pub. 42004-474A

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 12593-101

Redundant PPI Switching Module

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

The Model 12593-101 Redundant PPI Switching Module is designed to provide connection for a primary

and a secondary PPI card when redundant circuits are required in GAI-Tronics ADVANCE cabinets. The

module controls audio line switching from the PPI cards to SmartSeries Page/Party

module is capable of switching one zone. The switching action is controlled by an external contact

closure.

®

stations. Each

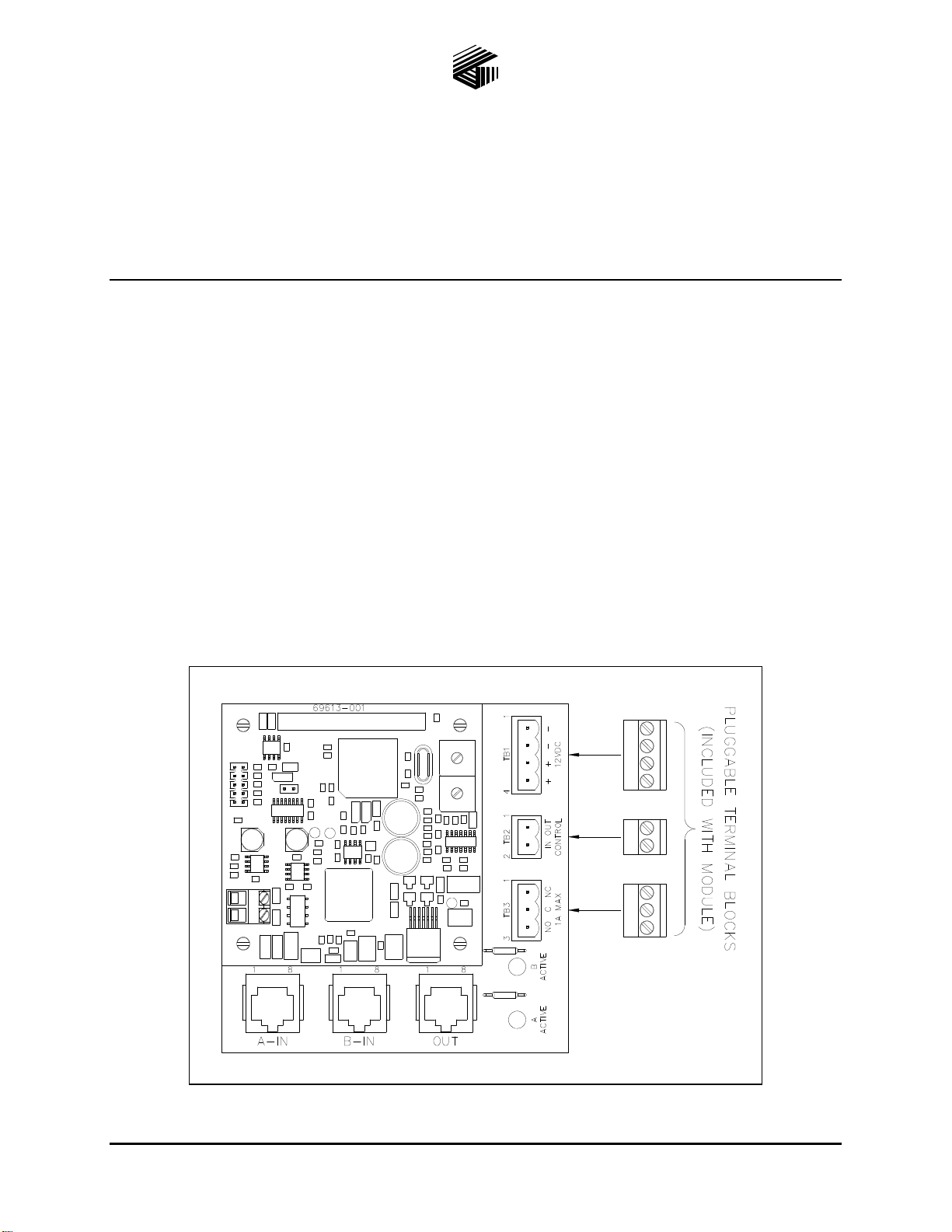

Figure 1. Model 12593-101 Redundant PPI Switching Module

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Pub. 42004-474A

Model 12593-101 Redundant PPI Switching Module Page 2 of 5

Hardware Configuration

The Model 12593-101 Redundant PPI Switching Module is comprised of two printed circuit board

assemblies (PCBAs). The lower base board contains the switching relays and measures 4 L 4 W inches

(102 102 mm). The relay switching PCBA is equipped with six small DPDT relays, two LEDs, three

RJ45 jacks and three modular (plug-in type) terminal blocks.

The upper CPU PCBA employs a micro-controller and has two address switches (S1 and S2). The small

terminal block located on the opposite side is for external power when used in other applications.

Installation

CAUTION

When installing or replacing this module, be sure power is not applied to

avoid damage to the module circuits.

The Model 12593-101 Redundant PPI Switching Module is designed for mounting in 4-inch Snap Trak

When inserting the module in SnapTrak

SnapTrak

Once installed in the SnapTrak

to avoid damage to the module’s printed circuit board and components.

, be sure the module edges are secured in the channels so that the module

, exercise care when pressing the module edges into the

does not dislodge during transport or operation if subjected to vibration. Also, if this module is used with

other modules in the SnapTrak

, be sure to leave spacing between modules to facilitate wiring at any

edge-mounted terminal blocks.

Terminations

The Model 12593-101 Redundant PPI Switching Module is equipped with three RJ45 jacks and three

modular (plug-in type) terminal blocks, which simplify external connections during installation, and

provide quick disconnect if replacement is ever required.

The following is a breakdown of each connector and terminal block and its function(s):

J1 – is the primary PPI card connection; a standard straight through Cat5E cable is required.

J2 – is the secondary PPI card connection; a standard straight through Cat5E cable is required.

®

J3 – is the output connection to the Page/Party

Cat5E cable is required.

TVP connection module; a standard straight through

.

TB1 – is the 12 V dc power input to the module.

TB2 – is the control input to the module to activate the relays to switch between primary and secondary

PPI cards.

TB3 – is the form “C” dry contact output, which can be used to activate additional switching modules, or

for remote status indication. The maximum switching capacity for the contact is 30 V dc @ 1 amp.

f:\standard ioms - cur rent release\42004 instr. man uals\42004-4 74a.doc

04/13

Page 3

Pub. 42004-474A

Model 12593-101 Redundant PPI Switching Module Page 3 of 5

The following is a summary of each connector and terminal block function(s):

J1 – A-IN (RJ45 j ack) J2 – B-IN (RJ45 j ack)

Pin No. Function Pin No. Function

1 & 2 Page Line 1 & 2 Page Line

3 & 6 Party Line 1 3 & 6 Party Line 1

4 & 5 Party Line 2 4 & 5 Party Line 2

7 & 8 Control input (CLS) 7 & 8 Control input (CLS)

J3 – OUT (RJ45 jac k) TB1 – 12 V dc Power Inp ut

Pin No. Function Terminal No. Function

1 & 2 Page Line 1 12 V (−)

3 & 6 Party Line 1 2 12 V (−)

4 & 5 Party Line 2 3 12 V (+)

7 & 8 Control input (CLS) 4 12 V (+)

TB2 – Switching C ont rol Input TB3 – Relay Contact Output

Terminal No. Function Terminal N o. Function

1 Control Line (active low) 1 Normally Close

2 Control Line (active low) 2 Common

3 Normally Open

Address Switch Settings

Address switches S1 and S2 on the upper CPU PCBA must each be set to position F for a board address

of FF. When using multiple modules, address FF must be set on ALL modules. Address FF allows the

module to operate as a Multi-Station Simulator (MSS), with its designated PPI cards. Refer to the

operation section for information on the MSS feature.

f:\standard ioms - cur rent release\42004 instr. man uals\42004-4 74a.doc

04/13

Page 4

Pub. 42004-474A

Model 12593-101 Redundant PPI Switching Module Page 4 of 5

Operation

The module switches the SmartSeries Page/Party® Stations between the Page/Party® Interface (PPI) cards

in the primary and secondary card racks. The switching action is initiated whenever a primary control

care or primary AMI fault occurs in the system. The signals being switched are the page line, party line

1, party line 2 and the control input (CLS).

The module has essentially two modes of operation, normal and fault. Each mode is described in detail

below.

Normal Co ndition

Connecting the Control Input (TB2) to dc ground will energize all relays on the module. LED1 (AActive) will illuminate to indicate the Primary system is active. The SmartSeries Page/Party

®

stations

(J3) are connected to the Primary PPI card (J1) via relays K3-K6.

The module’s CPU PCBA, is connected to the page line of the Secondary PPI card (J2) via relay K2. The

CPU PCBA simulates all the SmartSeries Page/Party

®

stations by responding to all station polling

requests from the Secondary Master Control Unit (MCU). This action prevents SmartSeries station faults

from occurring in the secondary system.

Fault Condition

The dc ground is removed from TB2 during a fault condition. LED2 (B-Active) will illuminate to

indicate the Secondary system is active. Relays K1–K7 are de-energized. Relay K1 contacts are wired to

TB3 and will change state for the duration of the fault condition. Relays K2–K6 switch the SmartSeries

Page/Party

®

stations (J3) to the Secondary PPI card (J2). The CPU PCBA is connected to the page line of

the Primary PPI card (J1).

Maintenance

If the module requires service, contact your Regional Service Center for a return authorization number

(RA#). The module should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the module is under warranty, repairs or a replacement will be made in

accordance with GAI-Tronics’ warranty policy. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 inside the USA or 610-777-1374 outside the USA for help identifying the Regional

Service Center closest to you.

f:\standard ioms - cur rent release\42004 instr. man uals\42004-4 74a.doc

04/13

Page 5

Pub. 42004-474A

Model 12593-101 Redundant PPI Switching Module Page 5 of 5

Troubleshooting

Problem Solution

SmartSeries station faults are

present in the secondary system.

SmartSeries stations squeal

when party line 1 or 2 are

accessed.

Module LEDs do not illuminate

and relays do not switch when

input control is provided.

Module still does not function after

all checks described in this section.

Specification s

Electrical

Verify 12 V dc power is applied to the module.

Verify CPU PCBA address is set to FF.

Verify cables are properly inserted into connectors J1, J2, J3.

Ensure pins of CPU PCBA are correctly inserted into J4 of

lower relay switching PCBA.

Verify connectors J1, J2, J3 are properly inserted. If

disconnected, the page, and party lines 1 and 2 will be unloaded

resulting in oscillation of the SmartSeries handset amplifier.

Verify 12 V dc power is applied to the module.

Verify 12 V dc (−) is being switched to the C

ONTROL inputs

at TB2.

Contact GAI-Tronics service for repair or replacement of the

module.

Power requirements ............................................................... 10.8–13.2 V dc (12 V dc @ 265 mA nominal)

Number of control inputs ............................................................................................................................. 1

Number of fault outputs ............................................................................................................................... 1

Fault output type .......................................................................................................... Form “C” dry contact

Fault output contact rating .................................................................................... 1 A maximum @ 30 V dc

Connections

RJ45 jack ...................................................................................................................................................... 3

Modular (plug-in) terminal blocks ............................................................................................................... 3

Minimum terminal block conductor size .................................................................. No. 28 AWG (0.5 mm

Maximum terminal block conductor size .................................................................. No. 12 AWG (3.0 mm

2

2

Mechanical

Module dimensions ........................................ 4.00 L 4.00 W 1.56 H inches (101.6 101.6 39.7 mm)

Module weight .................................................................................................................. 0.43 lbs. (0.20 kg)

Environmental

Temperature range (operating/storage) .................................................... −4 F to 158 F (−20 C to 70 C)

Humidity .......................................................................................... 85% non-condensing relative humidity

)

)

f:\standard ioms - cur rent release\42004 instr. man uals\42004-4 74a.doc

04/13

Page 6

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will reperform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor's personnel from the work

site. Re-performance of services shall be Buyer's sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...