Gaggia PLATINUM VOGUE, PLATINUM EVENT, PLATINUM SWING, PLATINUM SWING UP, PLATINUM VISION Technical & Service Manual

Page 1

Emissione Luglio 2007

REV.00

TECHNICAL SERVICE

MANUAL

Page 2

Ideas with Passion

PLATINUM TECHNICAL SERVICE MANUAL (Rev 00 Aug.06): CONTENTS

1. Introduction (rev.00)

1.1 Documentation required

1.2 Tools and equipment required

1.3 Safety warnings

1.4 Platinum range

2. Technical data (rev.00)

2.1 Product technical data

2.2 Internal / external machine components

3. Summarised instructions (rev.00)

3.1 Client and programming menu (rev.00)

3.2 Maintenance and cleaning (rev.00)

4. Diagrams (rev.00)

4.1 Wiring diagram (rev.00)

4.2 Water circuit diagram (rev.00)

5. Troubleshooting (rev.00)

5.1 Test functions (rev.00)

5.2 Diagnostics function (rev.00)

5.3 Error messages for Service personnel (rev.00)

5.4 Problems, Causes, Remedies (rev.00)

6. Operating logic (rev.00)

6.1 Resetting coffee grounds drawer (rev.00)

6.2 Water reserve (rev.00)

6.3 Motorized tank (rev.00)

6.4 Prima water (rev.00)

6.5 SBS valve (rev.00)

6.6 Solenoid pilot (rev.00)

7. Component assembly / disassembly (rev.00)

7.1 Top cover (rev.00)

7.2 Right and left-side cover (rev.00)

7.3 Electronics (rev.00)

7.4 Gearmotor (rev.00)

7.5 Pump (rev.00)

7.6 Heater and solenoid pilot unit (rev.00)

7.7 Oetiker clamp assembly and disassembly (rev.00)

7.8 Coffee grinder (rev.00)

7.9 Grinder adjustment/assembly and disassembly (rev.00)

7.10 Grinder adjustment during servicing (rev.00)

7.11 Motorized drip tray (rev.00)

8. Service schedule (rev.00)

8.1 Routine maintenance Check list (rev.00)

9. Exploded drawing (rev.00)

TALEA Contents

REV00 - August 06

1/1

Page 3

SECTION 1

INTRODUCTION

REV.00

TALEA Section 01

REV00 - August 06

Page 4

1.1 Documentation required

The following technical documentation is required for repairs:

Instruction booklet for specific model.

Technical documentation for specific model (diagrams, exploded drawings).

1.2 Tools and equipment required

As well as the standard equipment, the tools listed below are required.

1 special screwdriver with Torx T10 tip.

1 digital thermometer with full 200°C scale.

This must be suitable for measuring in liquids and on surfaces.

1 set of pliers for Oetiker clamps.

1 pincer.

1 CC -A - Vdc tester.

1.3 Safety warnings

Before starting operations on the machine, consult the relative instruction booklet.

Observe all current standards related to the repair of domestic appliances.

Always disconnect the power plug from the mains before carrying out repairs. Simply turning

off the main switch is not sufficient to prevent electrical discharge.

This domestic appliance is rated with insulation class I.

On completion of repairs, the insulation and dielectric rigidity tests must be performed.

1/2

TALEA Section 01

REV00 - August 06

Page 5

Ideas with Passion

1.4 Platinum range

- Touch Screen

- S B S

- Cup warmer

- Motorized tank

- Milk adapter

- Rapid Steam

- Pre-ground option

- 24x2 display

- Ring selector

- S B S

- Cup warmer

- Motorized tank

- Milk adapter

- Rapid Steam

- Pre-ground option

- 10x2 display

- Ring selector

- S B S

- Milk adapter

- Rapid Steam

- Pre-ground option

- Height adjustment ringnut

- S B S

- Milk adapter

- Rapid Steam

VISION

SWING UP

SWING

VOGUE

TALEA Section 01

REV00 - August 06

2/2

Page 6

EVENT

- S B S

- Rapid Steam

TALEA - ODEA Cap. 01

REV00 - Luglio 07

3/3

Page 7

SECTION 2

TECHNICAL DATA

REV.00

TALEA Section 02

REV00 - August 06

Page 8

2.1 Product technical data

Power supply and output: 230 V~, 50/60 Hz, 1300 W.

Temperature control: 1 (NTC) variable resistor sensor – transmits the value

to the electronic board.

Safety system: 2 x 175°C manual reset thermostats.

Coffee heat exchanger output:

Stainless steel

1300 W – to dispense cof

fee, hot water and steam.

Motorized tank only on

Platinum Vision e Swing Up

24V stepper motor.

Water level and drip

tr

ay sensor:

Capacitive sensor

Gearmotor: 33VC with 2 dir

ections of rotation.

Cup warmer plate:

Solo Platinum Vision e Swing Up

Activated via MENU display.

PTC Type.

Pump: Ulka r

eciprocating piston type with thermal cutout at

100°C,

48 W, 230V, 50 Hz, Type EX5 approx. 13-15 bars.

Pressure relief valve: Opening at approx. 18-20 bars.

Water filter: In tank.

Coffee grinder: DC motor with ceramic plate

grinders.

S

olenoid pilot: 15 VA.

Coffee dose control: Hall sensor – Pulse control. Dose adjustment can

be set from approx. 7 to 10.5 g.

Amps: During heating phase- appr

ox. 5.6 A.

Dimensions: l x h x d in mm: 310/390/440

W

eight: 10 kg (average).

Water tank capacity: 1.7 l.

Coffee container capacity: 250g coffee granules.

Coffee grounds drawer capacity: 14

Heatex changer capaci

ty: Approx. 10 cc.

Water circuit filling time: Approx. 15 sec on first filling cycle.

Heating time: Appr

ox. 45 sec.

Dispensed drink temperature: Approx. 73°C - 83°C

Grinding time: Appr

ox. 8-10 sec.

1/4

TALEA Section 02

REV00 - August 06

Page 9

on 02

REV00 - August 06

4/4

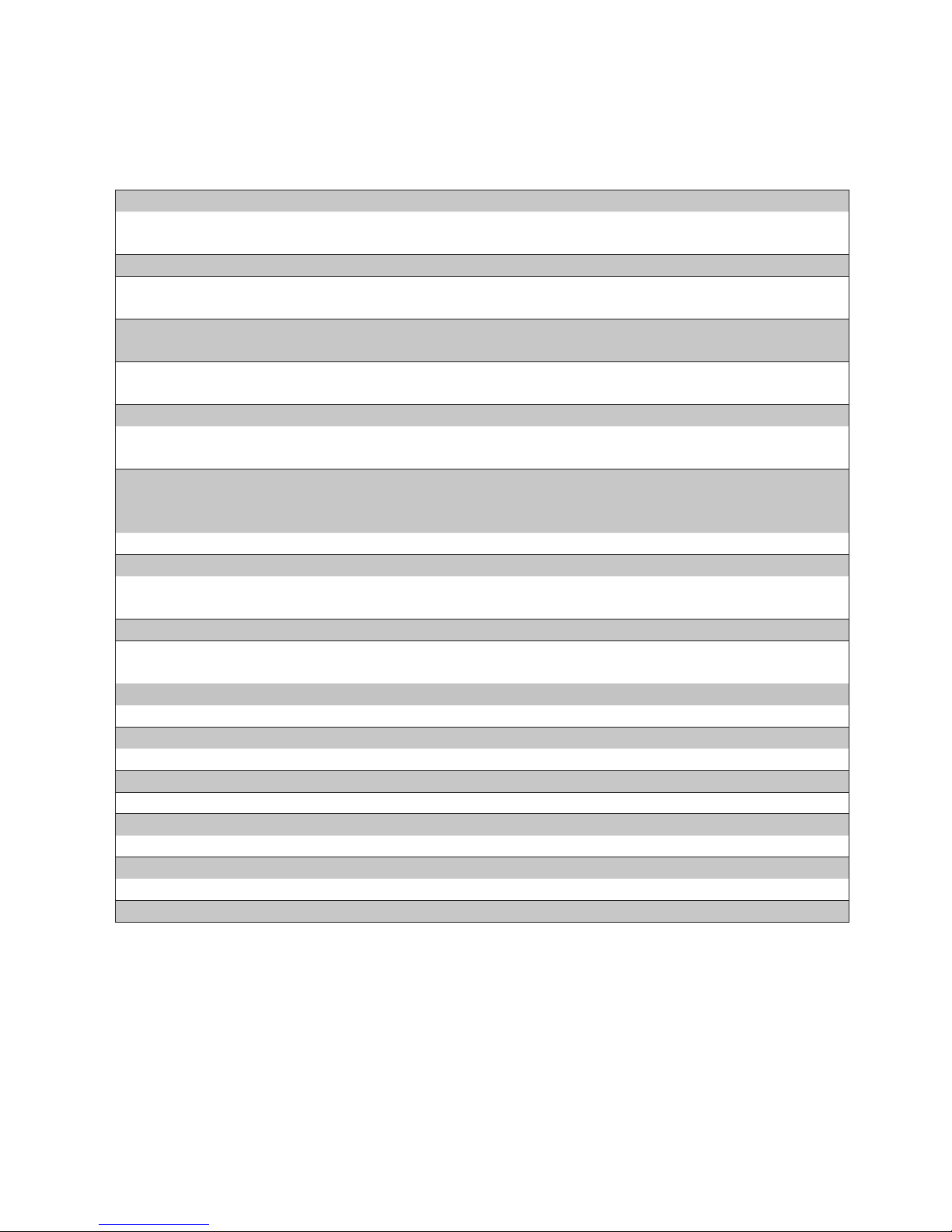

Internal components

Pump

Static

eliminator

Turbine

Heater

Coffee grinder

Power

board

CPU

Card

Motorized tank

stepper

motor

Solenoid pilot

Page 10

Ideas with Passion

SECTION 3

BRIEF

INSTRUCTIONS

REV.00

TALEA Section 03

REV00 - August 06

Page 11

Ideas with Passion

3.1 Client and programming menu

Platinum Vision

Press “go to menu”

Show text

8:30 a

Go to

diagnostics

Main menu

Beverage

set

tings

Maintenance

set

tings

Machine

set

tings

Clock

Next

Go

back

The programming menu will open.

Detailed

beverage programming

Machine function

programming

Exit

Next

page

After set

ting each of the following menus, press:

- “Go back” to be returned to the previous screen and save any new

set

tings.

- “Previous settings” to reset previous values.

- “Go back to menu” to be returned to the main menu and save new

set

tings.

Machine settings

Language &

display

Cup warmer

Water

set

tings

Go

back

Go back to

menu

Machine settings menu.

- Language & display = to set menu language and display contrast.

- Water settings = to set some water functions.

- Cup warmer = to set cut warmer functions.

To set current

time

Beverage settings

Espresso

Coffee

Long coffee

Go

back

Go back

to menu

Beverage settings menu

To set general parameters for the dispense of beverages containing coff

ee, press the “beverage settings” key in the main menu.

Coffee settings

Pre-brewing

normal

Go

back

Go back to

menu

Temperature

medium

Aroma

normal

Water quantity

240 / 500

The following can be set for each beverage selected:

Pre-brewing

of coffee

The temperature of the

dispensed coffee.

The amount of coffee to be

ground and use of

pre-ground coffee.

The amount of water to be

used in dispensed coffee.

Clock settings

Time

Stand-by

Go

back

Go back to

menu

Clock menu

To set the current time and timer (for

standby), press the “clock settings”

key on the main menu.

To set current

time.

To set stand-by parameters after cof

fee is

dispensed.

1/3

TALEA Section 03

REV00 - August 06

Page 12

Ideas with Passion

2/3

TALEA Section 03

REV00 - August 06

Platinum Swing Up

MENU

Strong aroma

Espresso coffee 08:33

To open program-

ming menu.

To select milk-based

beverage.

Confirm key.

Hot water key.

Use the touch-ring to select the

type of bev

erage you want.

To select coffee

aroma.

Beverage settings

To set bev

erage preparation parameters: press the MENU key and use the touch-ring to select “beverage settings”.

MENU

1 Beverage settings

Exit the

programming page.

Reset default (factory) settings.

Function depends on the current pr

ogramming level.

To save new settings.

Rotate the touch-ring to vary the

following settings:

- The amount of coffee dispensed

(1 square = approx. 15 ml).

- The amount of water added

(1 square = approx. 15 ml).

- Coffee temperature.

- Pre-brewing of coffee.

To select coffee

aroma.

At this point, you can:

Machine settings

To set general machine settings, press the MENU key, select “machine settings” then use the touch-ring to select:

2.1 Language

Italian

2.2 Cup warmer

Disabled

2.3 Beeps

Enabled

2.4 Filter alarm.

Enabled

2.5 Rinse

Enabled

2.6 Water har

dness

1

2.7 Clock

To set menu language.

To set cup w

armer function. To enable beep warnings.

To set machine function with

“Aqua Prima” filter.

To set water

hardness.

To set internal clock.

MENU

2 Machine settings

To exit at any time from

“Machine settings”

without saving any changes made,

press the MENU key.

To set circuit rinsing.

Page 13

Ideas with Passion

3.2 Maintenance and cleaning

3/3

TALEA Section 03

REV00 - August

STEPS

A Empt

y coffee grounds drawer. As instructed.

B Empt

y drip tray. As necessary.

C Clean w

ater tank. Once a week.

D Clean the cof

fee granule container. As necessary.

E Clean casing. As necessary

F Clean and gr

ease the brew group. Monthly or every

500 coffees.

H Descal

ing. As instructed.

J Clean drip tr

ay. Weekly.

K Clean cof

fee circuit. Weekly.

Descaling.

Hardness Water hardness

Descaling frequency

*

1 Soft water (up to 7ºdH) Approx. every 3 months/120 litres

2 Medium w

ater (7º-14ºdH) Approx. every 2 months / 90 litres

3 Har

d water (15º-21ºdH) Approx. every 6 weeks / 60 litres

4 V

ery hard water (over 21ºdH) Approx. every 4 weeks / 30 litres

* Without Prima water filter

Page 14

Ideas with Passion

SECTION 4

DIAGRAMS

REV.00

TALEA Section 04

REV00 - August 06

Page 15

Ideas with Passion

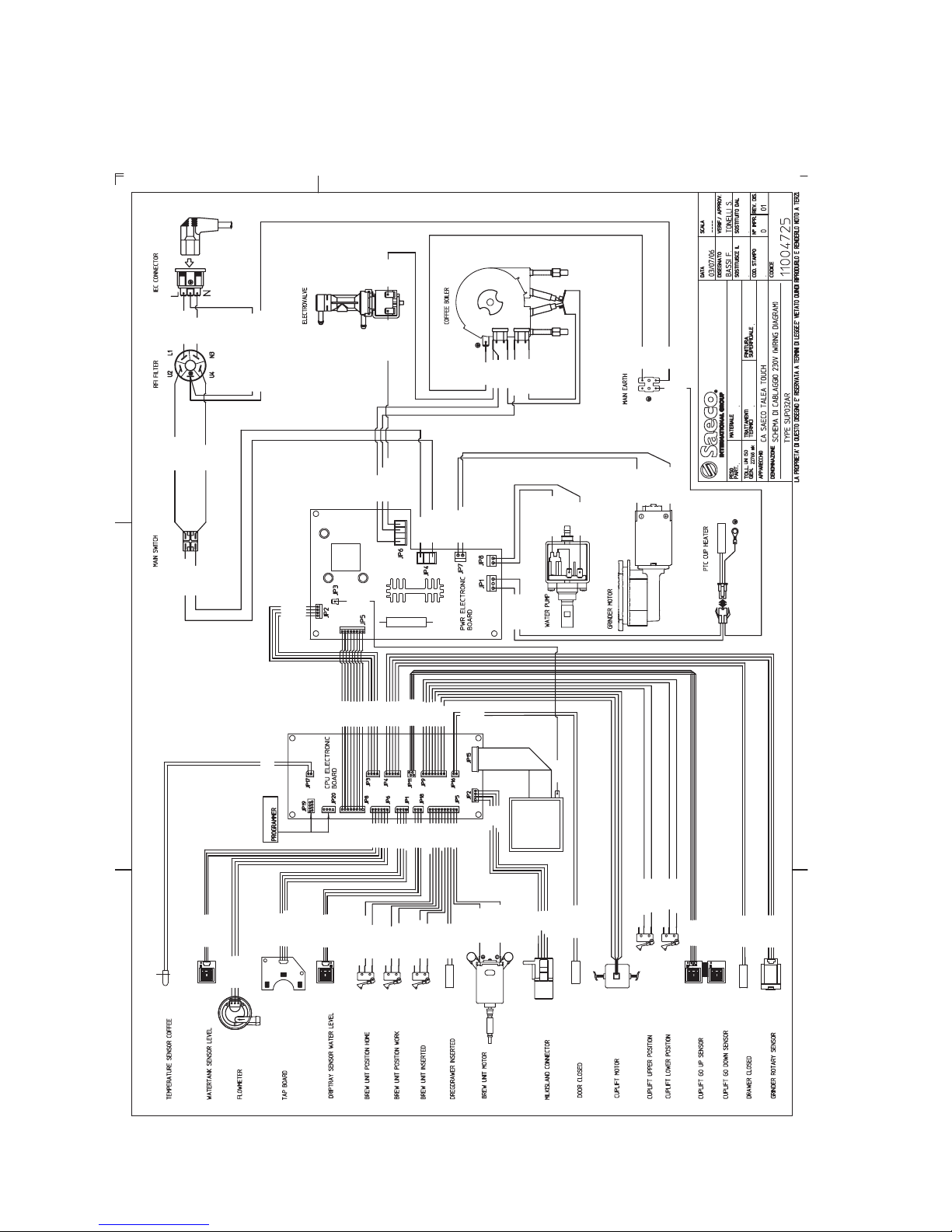

4.1 Wiring diagram

Platinum Vision

1/5

TALEA Section 04

REV00 - August 06

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

RED

RED

GREEN

WHITE

WHITE

BLUE

BLACK

GREEN

RED

FLAT-CABLE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

BLACK

RED

BLACK

GREEN

BLACK

BLACK

BLACK

BLACK

WHITE

WH

ITE

BLACK

RED

GREEN

BLUE

DISPLAY

RED

RED

Y-G

Y-G

Y-G

Y-G

Y-G

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

FLAT-CABLE

BLACK

YELLOW

RED

WH

ITE

BLUE

RED

BL

ACK

BLACK

BLACK

BLACK

B

LACK

BLACK

YELLOW

BLUE

BLUE

WHITE

YELLOW

BLACK

WHITE

BLUE

BLUE

BLACK

BLUE

YELLOW

BLUE

BLUE

BLUE

BLUE

BLACK

BLACK

Y-G

YELLOW-GREEN

YELLOW-GREEN

Page 16

Ideas with Passion

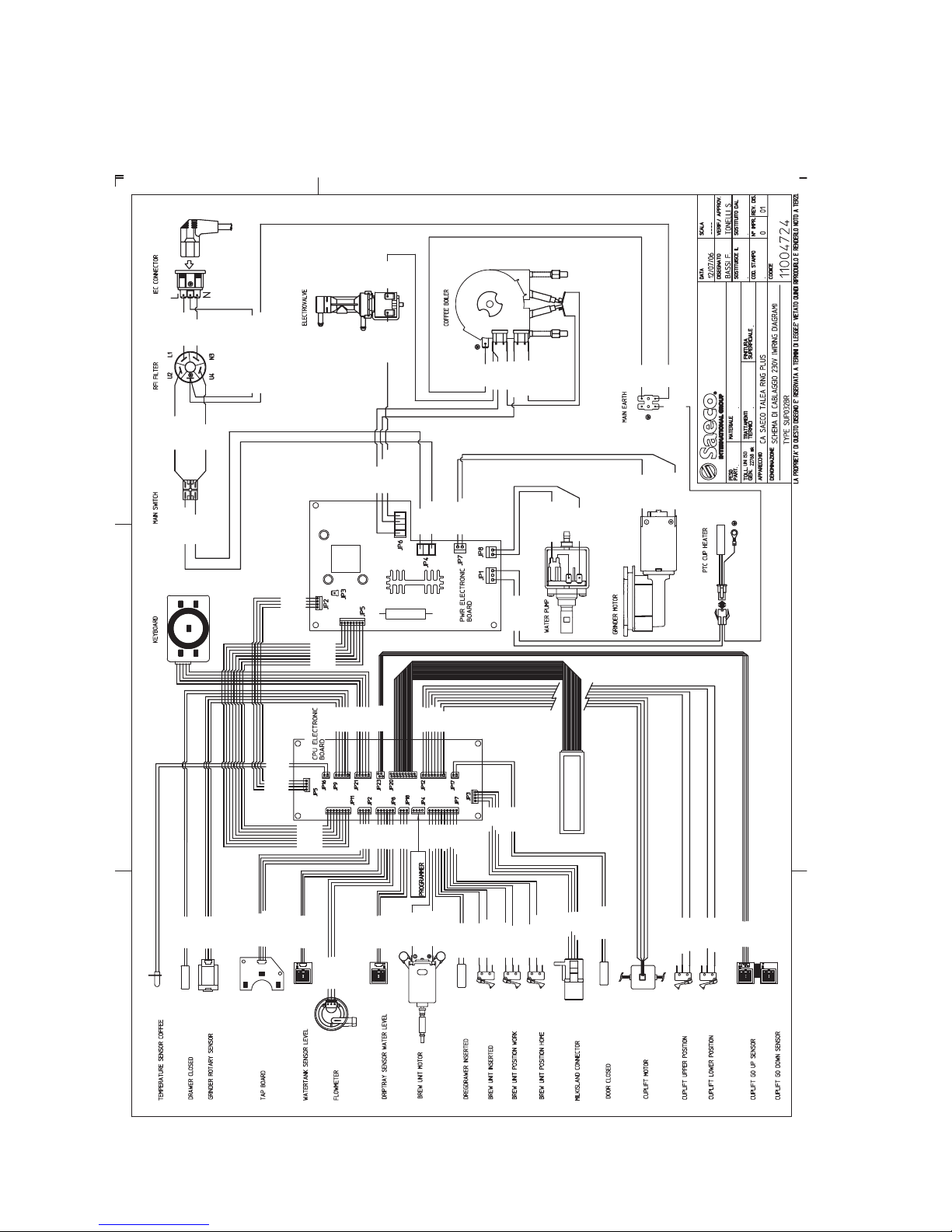

Platinum Swing UP

2/5

TALEA Section 04

REV00 - August 06

GREEN

FLAT-CABLE

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

WHITE

RED

GREEN

BLACK

RED

GREEN

BLUE

BLACK

BLACK

DISPLAY

WHITE

RED

RED

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

FLAT-CABLE

BLACK

BLACK

YELLOW

RED

WH

ITE

BLUE

RED

BL

ACK

BLACK

BLACK

BLUE

BLUE

BLACK

BLUE

YELLOW-GREEN

YELLOW-GREEN

YELLOW

BLUE

Y-G

BLUE

BLUE

BLUE

B

L

ACK

BLACK

Y-G

Y

-G

Y-G

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

BLUE

BLUE

WHITE

YELLOW

BLACK

WHITE

BLACK

BLACK

BL

ACK

BL

ACK

BL

ACK

B

L

ACK

BLACK

BL

ACK

BLACK

BLACK

BL

ACK

BLACK

BLUE

BLACK

GREEN

RED

WHITE

RED

YELLOW

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

RED

BLACK

BLACK

BL

ACK

BL

ACK

BL

ACK

BL

ACK

BL

ACK

B

LACK

BLACK

BLACK

BL

ACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

Page 17

Ideas with Passion

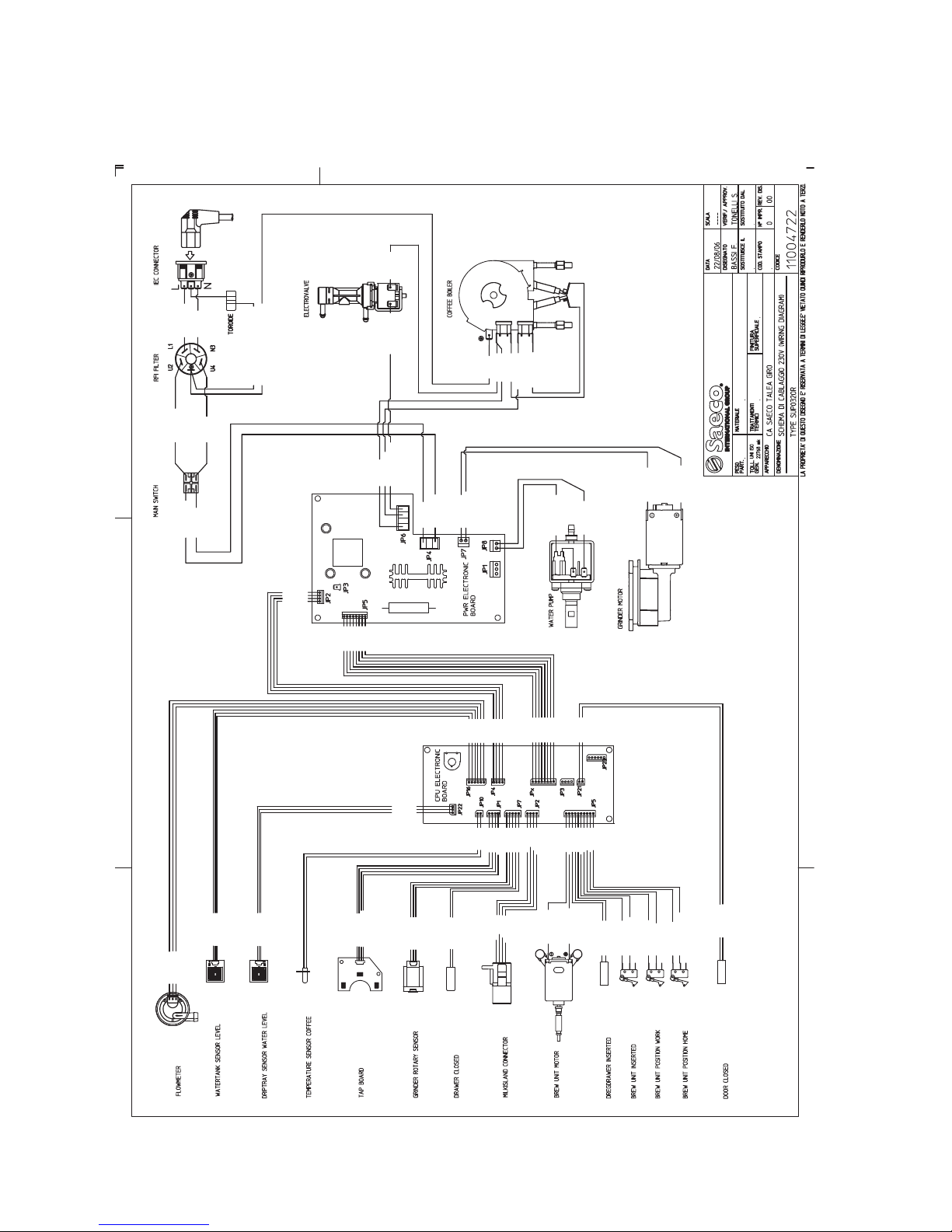

Platinum Swing

3/5

TALEA Section 04

REV00 - August 06

DIPLAY

BLACK

BLACK

WHITE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

BLACK

BLACK

BLACK

GREEN

BLACK

RED

YELLOW

BLACK

BLACK

BLUE

BLACK

GREEN

RED

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

B

LACK

B

LACK

BLACK

B

LACK

BLACK

B

LACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

WH

ITE

B

LACK

BLACK

BLACK

BLACK

BLACK

YELLOW

W

H

ITE

RED

BL

ACK

GREEN

BLACK

RED

GREEN

BLUE

BLACK

BLACK

BLACK

BLACK

BL

ACK

BL

ACK

RED

RED

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLUE

BLUE

BLACK

BLUE

YELLOW-GREEN

YELLOW-GREEN

YELLOW

BLUE

Y-G

BLUE

BLUE

BLUE

BL

ACK

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

BLUE

BLUE

WHITE

YELLOW

BLACK

WHITE

BLACK

BLACK

BL

ACK

BL

ACK

BL

ACK

BLACK

BL

ACK

BLACK

BL

ACK

BLACK

BLACK

BLACK

Page 18

Platinum Vogue

4/5

TALEA Section 04

REV00 - August 06

BLACK

BLACK

BLACK

BLACK

WHITE

BLUE

BLACK

GREEN

RED

BLACK

WHITE

GREEN

RED

BLACK

YELLOW

BLACK

BLACK

BLACK

YELLOW

RED

WH

ITE

B

LACK

RED

BL

ACK

WHITE

GREEN

BLUE

B

L

ACK

BLACK

GREEN

BL

ACK

BLACK

BLACK

BLACK

BLUE

WHITE

YELLOW

BLACK

BLACK

BLUE

BLUE

YELLOW-GREEN

Y-G

B

L

ACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

RED

RED

BL

ACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLUE

YELLOW-GREEN

BLACK

BLUE

BLACK

YELLOW

YELLOW

BLACK

BLACK

WHITE

BLUE

BLUE

BLUE

BLUE

BLACK

BLACK

Page 19

Ideas with Passion

4.2 Platinum water circuit

5/5

TALEA Section 04

REV00 - August 06

Turbine

Steam tube

Silicon tube

TANK

Silicon tube

Pump

Silicon tube

Reinforced silicon hose

Reinforced silicon hose

Reinforced silicon hose

Reinforced silicon hose

Reinforced silicon hose

STEAM/WATER

DISPENSE

1300W heater

WATER DRAINED

TO DRIP TRAY

Water drain connector

Water/steam valve

Water drain connector

WATER DRAINED

TO TANK

COFFEE

DISPENSE

SBS valve

Connector with 3 bar relief valve

MILK ISLAND STEAM

DISPENSE

Brew unit

Brew unit pin

Coffee dispense valve (3-5 bars)

Drain valve

Relief valve (16-19 bars)

Page 20

Ideas with Passion

4

2

3

1

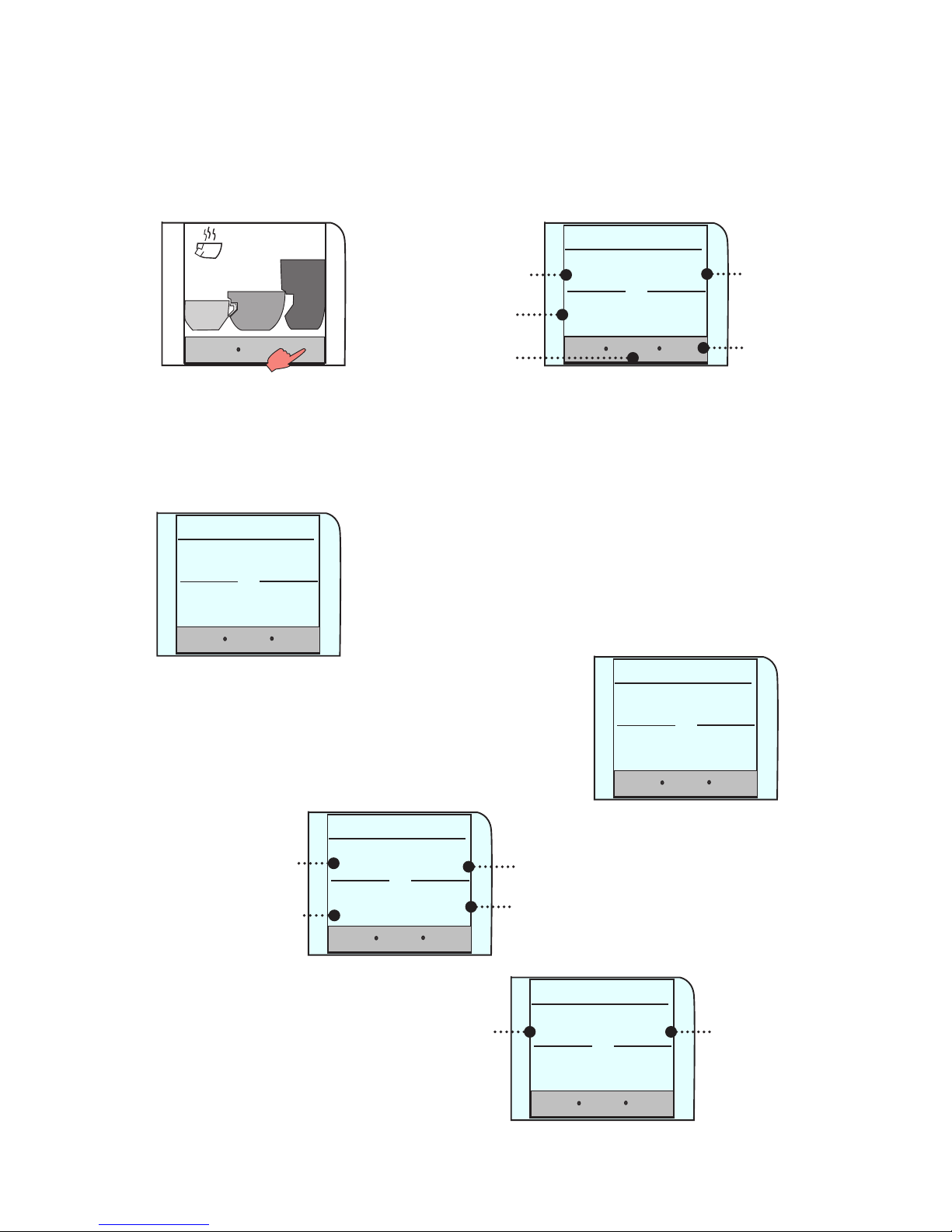

5.1 Test functions

Platinum Vision

In the first three seconds after the

appliance is switched on, you can

enter test mode by pressing the keys

in the sequence shown on the left.

1/17

TALEA Section 05

REV00 - August 06

On entering test mode, the screen

shown in the screenshot opens.

Pr

ess the next key to move on to

subsequent levels.

t.0

Software version

Next

CPU_V01.04.09

*

* *

t.1 - Brewing unit

Next

bu_current (mA) = 3

bu_home = OFF

bu_work = ON

bu_present = ON

bu_dregdrawer = ON

bu_door = ON

bu go

home

bu go

work

bu go

stop

Level T1 – brew group

At this level, brew group gearmotor and associated microswitches function is tested.

- bu_current (mA) - indicates current absorbed b

y gearmotor.

- bu_home - indicates state of brew gr

oup home position microswitch.

- bu_work - indicates state of brew gr

oup work position microswitch.

- bu_present - indicates state of brew gr

oup presence microswitch.

- bu_dregdraver - indicates state of coff

ee grounds drawer presence microswitch.

- bu_door - indicates state of side door closed microswitch.

- By pr

essing “bu go home” once, the gearmotor moves the brew group to the home position.

- By pressing “bu go work” once, the gearmotor moves the brew group to the work position.

- By pressing “bu stop” once, the gearmotor stops the brew group.

t.2 -

Heating unit

Next

boiler_temp (C°) =79.8

Cup

heater

Boiler

*

Level T2 – heating unit

At this level, you can check heater function and the associated ntc sensor.

- boiler_temp (C°) - indicates the temperatur

e of the water heater.

- Pressing “cup heater” once will turn the cup warmer on.

- Pressing “boiler” once will turn the heater on.

Level T3 – hydraulic circuit

At this level, you can test pump, solenoid valve, drip tray/water tank level, milk island and water/steam valve status sensor

function.

t.3

Hydraulic circuit

Next

flow_meter (p/s) = 0

driptray_sens = OFF

waterlevel_sens = ON

knob_milk = OFF

knob_water&steam = ON

knob_closed = OFF

milk island present = OFF

caraffe present = OFF

valve

pump

water

*

- flow_meters (p/s) - indicates revolutions per second of the hall sensor in the turbine.

- driptray_sens - indicates the state of the capacitiv

e sensor reading the water level in the

drip tray.

- waterlevel_sens - indicates the state of the capacitiv

e sensor reading the water level in the

water tank.

- knob_milk - indicates the state of the water/steam/mi

lk-island knob in the milk position.

- knob_water&steam - indicates the state of the

water/steam/milk-island knob in the water/

steam position.

- knob_closed - indicates the state of the water/steam/milk-island knob in the closed posi-

tion.

Page 21

Ideas with Passion

2/17

TALEA Section 05

REV00 - August 06

t.4 - Grinder unit

Next

pulses_counter = 0

delay_time (msec) = 0

bean_door = ON

bean_alarm = OFF

grinder

* bean

test

Level T4 – Grinder unit

At this level, you can test coffee grinder function.

- pulse_counter - indicates the number of grinding pulses the grinder perf

orms.

- delay_time (msec) - indicates revolutions per second of the hall sensor in the coffee

grinder.

- bean_door - indicates the state of the coffee bean container lid magnetic sensor.

- bean_alarm - indicates the no coffee beans left alarm during last grinding.

- Holding and pressing “grinder” starts the coffee grinder for at least 200 grinding pulses.

- Pressing “bean test” once starts the coffee grinder to check the no coffee bean alarm.

t.5 - Cup lift

Next

upper_switch = OFF

lower_switch = OFF

key_up = OFF

key_down = OFF

cup_lift

up

cup_lift

down

*

Level T5 – Cup lift

At this level, you can check cup-lift function.

- upper_switch - indicates the state of the mo

ving tray up position microswitch in the up

position of the moving tray.

- upper_switch - indicates the state of the moving tray lower position microswitch in the

lower position of the moving tray.

- key_up - indicates the state of the capacitive sensor that raises the moving tray.

- key_up - indicates the state of the capacitive sensor that lowers the moving tray.

- Holding and pressing “cup_lift” moves the cup lift up to the uppermost position.

- Holding and pressing “cup_down” moves the cup lift up to the lowermost position.

Level T6 – Grinder dose

At this level, you can test and modify the amount of coffee that is ground.

t.6 - Grinder dose

Next

Mild dose = 63

Medium dose = 70

Strong dose = 77

Mild Medium Strong

Value

up

Value

down

Value

test

- Mild dose - indicates the number of grinding pulses to set for a mild coffee.

- Medium dose - indicates the number of grinding pulses to set for a medium-strength cof-

fee.

- Strong dose - indicates the number of grinding pulses to set for a strong coffee.

- Pressing “value up” increases the number of grinding pulses for a medium-strength coffee in

steps of 5.

- Pressing “value down” reduces the number of grinding pulses for a medium-strength coffee

in steps of 5.

- “Mild” and “strong” values are equal to 10% less and 10% more respectively than the average value set.

- Pressing “value test” starts grinding at the selected strength (mild, medium or strong).

- Milk island present indicates the state of the milk island present microswitch.

- Caraffe present indicates the state of the milk carafe present microswitch.

- Pressing “valve” once will excite the solenoid valve.

- Pressing “water pump” once will start the pump.

- Pressing “valve” once will activate the solenoid valve.

Page 22

Level T7 – Coffee grounds drawer

At this level, you can modify the current value of the number of coffee grounds (maximum of 13).

t.7 - Dreg counter

Next

Max dreg counter = 13

Current dreg counter = 9

Value

up

Value

down

*

- max dreg counter - indicates the maximum number of coffee grounds that the drip tray

can contain.

- current dreg counter - indicates the current number of cof

fee grounds

Level T8 – Steam out

At this level, you can drain the water circuit..

t.8 - Steam out

Next

Boiler_temp (C°)

Start

* *

- boiler_temp (C°) - indicates the temperature of the water heater.

Pressing start will run the procedure.

If the knob state is not in the water/steam/milk-island position, the message shows below

will appear on the display.

t.8 - Steam out

Next

Boiler_temp (C°)

Open knob to water & steam

Start

* *

- open knob to water & steam - indicates that the knob is not in the water/steam position.

Moving the knob to the water/steam state will start the procedure to drain the water circuit.

t.8 - Steam out

Next

boiler_temp (C°) = 105.9

counter = 7.4

Start

* *

- boiler_temp (C°) - indicates the temperature of the water heater.

- counter - indicates the time remaining until the end of the cycle.

When the water heater reaches 100°C, it switches off and the counter starts.

- pass - indicates that the procedure has been completed.

Press next to move on.

t.8 - Steam out

Next

boiler_temp (C°) = 105.9

counter = 7.4

pass..

Start

* *

3/17

T

REV00 - August 06

Page 23

Ideas with Passion

4/17

TALEA Section 05

REV00 - August 06

Platinum Swing e Swing Up

MENU

AROMA

When in test mode

Switch the appliance on (double-pole switch on right side) and wait for the CA to finish initializing; then

press and hold the illustrated menu key for 2 seconds until the string “Exit” appears on the screen. Press

the capacitive keypad keys in the order shown on the left within the next two seconds.

Exit

The following string appears when you enter test mode:

*Test* M0 12345 oo:mm:ss

SWvx.xx.xx FFHz

Where:

- *Test* indicates that the C.A. is in test mode.

- M0 indicates the test level.

- 12345 indicate the keys pressed in the sequence shown in figure 1.

- oo:mm:ss indicates the hours and minutes of the CPU clock.

- SWvx.xx.xx indicates the SW version instal

led in the CPU card microcontroller.

- FFHz indicates actual supply voltage frequency.

To move from one test level to another, use the touch-ring around the coffee key, turning it clockwise to move to the next level

and anticlockwise to go back a level.

*Test* MO oo:mm:ss

DLv:1.01.10.FT 50HZ

STEAM

WATER

COFFEE

MENU

Level M1

The state of the microswitch is shown at this level; the following string is shown on the second line:

Inputs 123456789ABCDEFG

Where:

1 Brew group presence microswitch excited.

2 Brew group work position microswitch excited.

3 Brew group home position microswitch excited.

4 Turbine sensor excited.

5 Tank water level capacitive sensor excited.

6 Side door closed microswitch excited.

7 Coffee grounds drawer presence microswitch excited.

8 Coffee bean container sensor excited.

9 Coffee grinder direction of rotation sensor excited.

A Drip tray level capacitive sensor excited.

B Water/steam knob in milk-island position.

C Water/steam knob in water/steam position.

D Milk-island presence microswitch excited.

E Milk carafe presence microswitch excited.

F Cup-lift-down microswitch excited (only on Ring Plus).

F Cup-lift-up microswitch excited (only on Ring Plus).

H Water/steam knob in closed position.

Numbers 6 and 7 are not displayed if the coffee grounds drawer is removed.

4

2

3

1

Page 24

Ideas with Passion

Level M2

Gearmotor function is tested at this level. To move the gearmotor, the coffee grounds drawer and side door microswitches must

be excited. The status of the microswitches listed below is shown at the right of the top line on the display:

1 Brew group presence microswitch excited.

2 Brew group work position microswitch excited.

3 Brew group home position microswitch excited.

6 Side door closed microswitch excited.

7 Coffee grounds drawer presence microswitch excited.

Gearmotor status after the aroma key and capacitive keypad menu have been pressed is shown on the second line on the

display:

- Aroma key - the gearmotor brings the group to the home position.

- Menu key - the gearmotor brings the group to the work position.

Power absorbed (mA) by the gearmotor during movement is shown on the right of the second line on the display.

Level M3

Coffee grinder, pump, cup warmer (Ring Plus only) and solenoid valve function are tested at this level. The above are primed by

pressing the following keys:

- Steam key: coffee grinder.

- Water key: pump.

- Aroma key: varies grinding aroma.

- Menu key: solenoid valve.

- Coffee key: coffee grinder pulses.

COFFEE GRINDER TEST:

Coffee bean container sensor must be excited.

When the appropriate key is pressed, the following string appears on the second line of the display:

- Grinder ON 8 GG %%

Where:

- 8 indicates that the coffee bean container sensor has been excited.

- GG indicates the number of rotations performed by the coffee grinder.

- %% indicates the ratio between coffee grinder revolutions at 100% and 50% supply.

To set medium aroma pulses, press the coffee key then use the touch-ring to choose aroma pulses. After this, press the coffee

key to save the number of impulses selected. Press the steam key to restore default settings.

By pressing the aroma key, you can vary grinding aroma. The value of the selected aroma is shown on the bottom left of the

display, classified as follows:

1 - mild aroma.

2 - medium aroma.

3 - strong aroma.

PUMP TEST:

By pressing the appropriate key, the following string appears on the display:

- Flowmeter (Imp/s) GG

Where:

- GG indicates the number of revolutions performed by the turbine.

SOLENOID VALVE TEST:

By pressing the menu key, the following string appears on the second line of the display:

- Ev Brew On

5/17

TALEA Section 05

REV00 - August 06

Page 25

Ideas with Passion

Level M4

At this level you can check water heater, relative ntc sensor and cup warmer function.

- When you press the steam key, the ambient temperature (tt.t) is shown on the second line of the display in degrees centigrade.

-

When you press the water key, the state of the ntc sensor (open or short), on the water heater

(open or short), or the water heater temper

ature in degrees centigrade are shown on the second line of the display.

- Pressing the aroma key switches on the water heater (pressing the water key shows the rising temperature) and the string

Heater ON appears on the second line of the display.

- When you press the menu key, the cup warmer is switched on and the string

Cup Heater (Ring Plus only) appears on the second line of the display.

Steamout

Open the knob in the water/steam posi

tion to prepare for steamout (draining water heater). Press the coffee key to start, the

water heater will be brought to 120°, at which time the machine emits a sequence of beeps.

WARNING: At the end of this procedure, the machine will automatically switch to English.

Level M5 (Cup lift position) on Ring Plus only.

At this level, you can check cup-lift function.

- Press the aroma key to move the cup-lift down to its lowermost position.

- Press the menu key to raise the cup-lift to its uppermost position.

Level M6 (LCD contrast)

You can change display contrast at this level.

- Press the coffee key to edit display contrast (the percentage value starts blinking).

- You can use the touch-ring to change this value: turn clockwise to increase it, and anticlockwise to decrease it.

- Press the coffee key again to save the value selected.

Level M7 (LCD backlight)

You can change display brightness at this level.

- Press the coffee key to change display brightness

(the percentage value starts blinking).

- You can use the touch-ring to change this value: turn clockwise to increase it, and anticlockwise to decrease it.

- Press the coffee key again to save the value selected.

Level M9

- Exit.

Press the coffee key to exit test mode and fully restart the appliance.

Level M8 (Self-test)

The machine automatically tests its main functions in the self-test. The brew group must be present and the doors

closed.

On completion of this procedure (which lasts approx. 10 seconds), the outcome will appear on the display.

Pass!! and 2 consecutive beeps if it was successful.

If an error was encountered, 10 beeps will be emitted and a message appears on the display.

6/17

TALEA Section 05

REV00 - August 06

Page 26

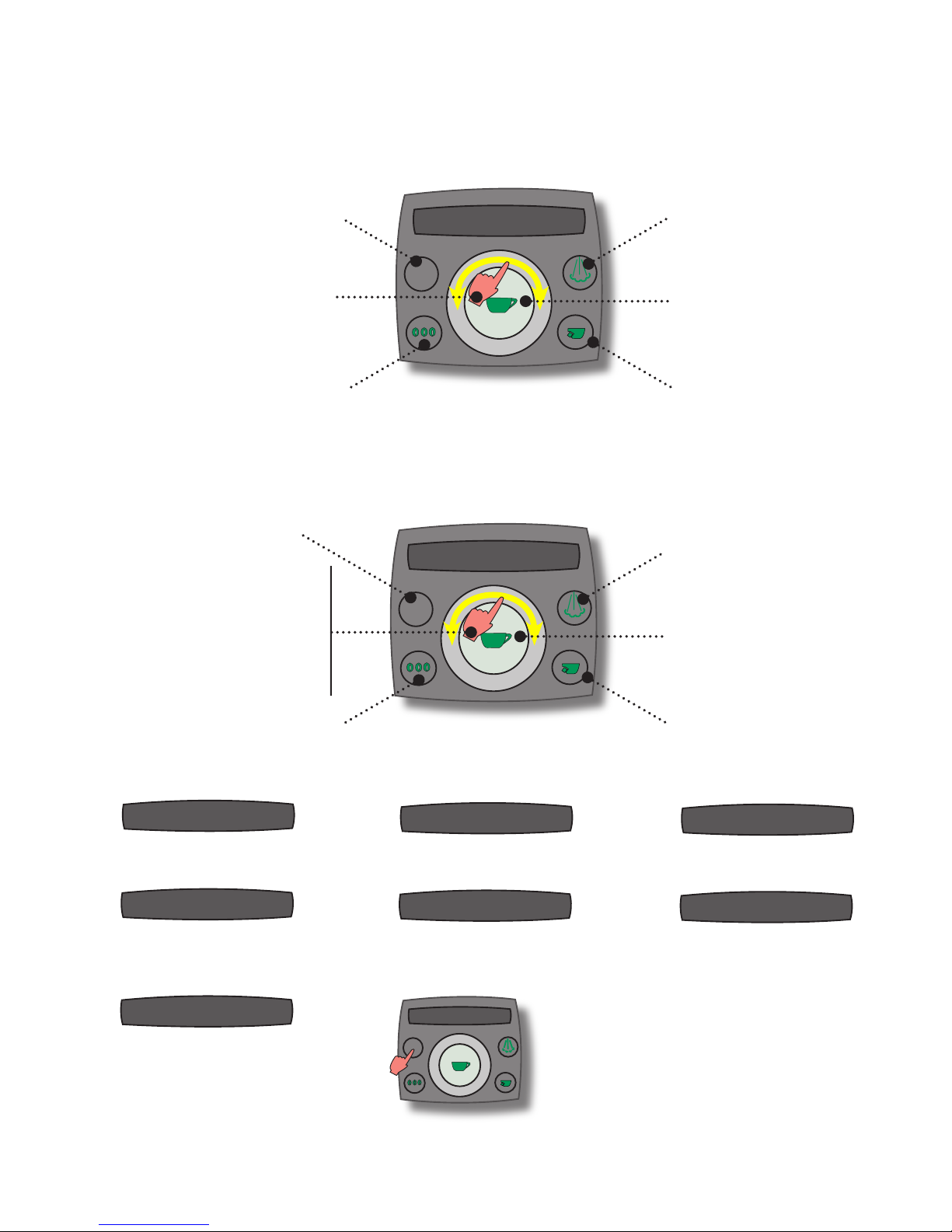

Platinum Vogue

Coffee key

Press once to select a coffee.

Press twice to select a double coffee.

Stops coffee from being dispensed when pressed during dispensing.

Water/steam key

To select either water or steam.

Press and hold for 6 seconds to “reset” descaling alarm.

When off, indicates that the machine is ready to release steam.

When on, indicates that the machine is ready to dispense water.

Aroma key

To select either a mild coffee, a medium coffee or a strong coffee.

Middle button

To select length of coffee required.

7/17

TALEA Section 05

REV00 - August 06

Page 27

Ideas with Passion

Messages/Alarms

Temperature ready LED Fixed on. Indicates “Coffee ready” or “Steam ready”.

Temperature ready LED Slow blinking. The correct temperature has not been reached.

Water/steam LED Off The appliance is in steam mode.

Water/steam LED Fixed on. The appliance is in water mode.

Aroma LED Fixed on. To set aroma.

General alarms LED Fixed on. Fill water tank.

Empty drip tray.

Out of coffee (*)

General alarms LED Slow blinking. Door open.

Brew group missing.

Drip tray missing.

Coffee container cover missing.

Milk island or carafe missing.

General alarms LED Fast blinking. Prime circuit.

Coffee grounds drawer

LED

Fixed on. Indicates that grounds drawer needs emptying.

Descaling LED

(60 litres)

Slow blinking. Indicates that descaling (manual) is required.

Coffee grounds drawer

and descaling LEDs

Blinking alternately. Max. brew group torque exceeded.

Brew group timeout or microswitch error.

Coffee grinder blocked.

OUT OF SERVICE

Temperature ready LED

Descaling LED

General alarms LED

Coffee grounds drawer

LED

Light up one after the

other anticlockwise.

Indicates that the appliance is running a “rinse

cycle”.

(*) Removing and replacing the coffee bean container will reset the “out of coffee” alarm.

Test mode

To open Test Mode, press and turn the appliance on at the same time (Power On). Entering Test Mode is indicated by the

rapid flashing of LEDs (lighting up repeatedly ANTICLOCKWISE one after the other), continuing until

is released.

8/17

TALEA Section 05

REV00 - August 06

Page 28

Ideas with Passion

POSITION

POTENTIOMETER

ACTION CHECK

Press

Solenoid pilot

Press

Coffee grinder

Press

Set aroma.

(default: 90-100-110 pulses).

Valve open.

lights up and stays on.

Brew group missing microswitch

blinks slowly.

Drawer missing microswitch

blinks slowly.

Door open microswitch.

blinks slowly.

Coffee container cover microswitch

blinks slowly.

Carafe present microswitch

(with valve closed).

lights up and stays on.

Turbine sensor

(during pump function)

blinks (turb. freq.)

Water tank sensor

lights up and stays on.

Coffee grounds drawer

lights up and stays on.

POSITION

POTENTIOMETER

ACTION CHECK

Press

Coffee heater.

Press

Unit down.

Press

Set aroma.

(default: 90-100-110 pulses).

Unit down microswitch.

+ Steam key pressed.

blinks quickly.

Valve open.

lights up and stays on.

Brew group missing microswitch

blinks slowly.

Drawer missing microswitch

blinks slowly.

Door open microswitch.

blinks slowly.

Coffee container cover microswitch

blinks slowly.

Carafe present microswitch

(with valve closed).

lights up and stays on.

Turbine sensor

(during pump function)

blinks (turb. freq.)

Water tank sensor

lights up and stays on.

Coffee grounds drawer

lights up and stays on.

9/17

TALEA Section 05

REV00 - August 06

Page 29

Ideas with Passion

POSITION

POTENTIOMETER

ACTION CHECK

Press

Pump

Press

Unit up.

Press

Set aroma.

(default: 90-100-110 pulses).

Unit microswitch up.

+ Steam key pressed.

blinks quickly.

Valve open.

lights up and stays on.

Brew group missing microswitch

blinks slowly.

Drawer missing microswitch

blinks slowly.

Door open microswitch.

blinks slowly.

Coffee container cover microswitch

blinks slowly.

Carafe present microswitch

(with valve closed).

lights up and stays on.

Turbine sensor

(during pump function)

blinks (turb. freq.)

Water tank sensor

lights up and stays on.

Coffee grounds drawer

lights up and stays on.

Special functions mode

The “Special Functions” mode allows you to:

1) Activate the steamout procedure.

2) Identify which microswitch is responsible for the

“General Alarms” LED lighting up.

To enter Special Functions Mode, press and switch on the appliance (Power On) at the same time. Entering Special

Functions Mode is indicated by the rapid flashing of LEDs (lighting up repeatedly CLOCKWISE one

after the other), continuing until

is released.

10/17

TALEA Section 05

REV00 - August 06

Page 30

Ideas with Passion

POSITION

POTENTIOMETER

ACTION CHECK

Open valve and

press

Steamout procedure.

While the procedure is underway (for a total of 30 seconds), the following

LEDs light up alternately one after the other in a clockwise direction

Press light up and each time the key is pressed, the number of

pulses for AVERAGE AROMA is reduced by 5 pulses to a minimum of 60

pulses.

Brew group missing

microswitch

lights up and stays on.

Drawer missing

microswitch

lights up and stays on.

Door open

micr

oswitch.

lights up and stays on.

Coffee container

cover microswitch

lights up and stays on.

POSITION

POTENTIOMETER

ACTION CHECK

Press

No action!

Press

No action!

Brew group missing

microswitch

lights up and stays on.

Drawer missing

microswitch

lights up and stays on.

Door open

micr

oswitch.

lights up and stays on.

Coffee container

cover microswitch

lights up and stays on.

POSITION

POTENTIOMETER

ACTION CHECK

Press

No action!

Press

light up and each time the key is pressed, the number of

pulses for AVERAGE AROMA is increased by 5 pulses up to a maximum of

150 pulses.

Brew group missing

microswitch

lights up and stays on.

Drawer missing

microswitch

lights up and stays on.

Door open

micr

oswitch.

lights up and stays on.

Coffee container

cover microswitch

lights up and stays on.

11/17

TALEA Section 05

REV00 - August 06

Page 31

Ideas with Passion

ON

1

2 3

ON

1

2 3

DIP SWITCH

CONFIGURATION

PLATINUM EVENT

CONFIGURATION

PLATINUM VOGUE

AROMA PULSES

MILD STRENGTH MEDIUM STRENGTH STRONG STRENGTH

54 60 66

59 65 71

63 70 77

68 75 82

72 80 88

77 85 93

81 90 99

86 95 104

90 100 110

95 105 115

99 110 121

104 115 126

108 120 132

113 125 137

117 130 143

122 135 148

126 140 154

131 145 159

135 150 165

DEFAULT DATA

12/17

TALEA Section 05

REV00 - August 06

Page 32

Ideas with Passion

4

2

3

1

When in diagnostics mode

Switch the appliance on (double-pole switch on right side) and wait for the CA to finish initializing; then

press and hold the menu key for 2 seconds until the string “Exit” appears on the screen. Press the capacitive keypad keys in the order shown on the left within the next two seconds.

5.2 Diagnostics function

Platinum Swin up

MENU

AROMA

Exit

STEAM

WATER

COFFEE

MENU

To move from one test level to another, use the touch-ring around the coffee key, turning it clockwise to move to the next level

and anticlockwise to go back a level.

Press the coffee key to open the sub-menus.

Press the coffee again to confirm any changes.

Press the menu key to exit sub-menus.

Level M1 : Product Counters

The following counters are shown at this level:

1.1 Total Products

1.2 Total number of espressos.

1.3 Total ml of espresso

1.4 Total number of coffees.

1.5 Total ml of coffee.

1.6 Total number of long coffees.

1.7 Total ml of long coffee.

1.8 Total number of waters.

1.9 Total ml of water.

Level M2 : Total Counters

The following counters are shown at this level:

2.1 Water S.L.Descale water since last descaling.

2.2 Water S. 1 Descale water since last descaling.

2.3 Water S. 2 Descale water since second last descaling.

2.4 Water S. 3 Descale water since third last descaling.

2.5 Water Since Prod. water used since production.

2.6 Descaling N° total number of times appliance descaled.

2.7 B.U. Cleanings N° times group cleaned.

2.8 Water Filters N° filters used.

2.9 E2prom writes N°

13/17

TALEA Section 05

REV00 - August 06

Page 33

Ideas with Passion

Level M3 : Error Log

3.1 Errors List

The following are shown at this level:

-) The last 20 errors involving the CA

-) The date the error occurred.

The error map is shown below:

3.2 Clear all?

pressing YES will delete all errors at level 3.1.

Code Brief description Description

COFFEE GRINDER ERRORS

01

Coffee grinder blocked. The coffee grinder won’t turn: there may be something obstructing

the grinders or beverage signal has not been read correctly by the Hall

probe in the coffee grinder.

BREW GROUP ERRORS

03

TORQUE_FAULT_FWD Maximum force exceeded in forward movement to dispense position

(second attempt).

TIMEOUT_FWD Maximum time ex

ceeded to reach dispense position.

TIMEOUT_FWD_DOWN Maximum time ex

ceeded to clear home position microswitch.

HOME_WHILE_WORKING Home posi

tion microswitch activated while moving to work position.

04

TORQUE_FAULT_RWD Maximum force exceeded returning to home position.

TIMEOUT_RWD Maximum time ex

ceeded returning to rest position.

WORK_WHILE_HOMING W

ork position microswitch activated while moving to home position.

16

HOME_AND_WORK_PRESSED Both the work and home microswitches are activated at the same time.

WATER CIRCUIT ERRORS

05

Water circuit blocked. This can happen for a variety of reasons ...(trips when water not flow-

ing in turbine).

TEMPERATURE CONTROL ERRORS

10

SENSOR1_SHORT Coffee heater sensor shorted.

11

SENSOR1_OPEN Coffee heater sensor in open circuit.

14

TEMPERATURE_BO_TOO_HIGH Coffee heater temperature too high.

15

TEMPERATURE_BO_OUT_CONTROL Coffee heater temperature out of control (not responding to stimuli:

e.g. heater on but temperature not rising).

GENERAL ERRORS

19

No zero crossing. No zero crossing on card, could be caused by power card.

14/17

TALEA Section 05

REV00 - August 06

Page 34

Ideas with Passion

Level M5 : System Settings

System parameter values are shown at this level:

5.1 SW Version

5.2 Boot Version

5.3 Aroma Setup (imp.) Number of pulses set for medium aroma.

5.4 Temp. Standby From 50° to 80°C.

5.5 Cup. temp.

5.6 Standby temp. Standby time can be varied in 15 minute intervals.

5.7 Flowrate (L/h) Water flowrate.

5.8 Language

5.9 Water Hardness

5.10 Lcd Backlight Display brightness.

5.11 Lcd contrast Display contrast.

5.12 Grounds Limit Stop coffee grounds.

5.13 Grounds Left Coffee grounds counter.

5.14 Grounds Warning Empty coffee grounds.

5.15 W.Filter C. Date Date Aqua Prima filter was installed.

5.16 Service Date (to be added after servicing).

5.17 Production Date

Level M4 : Products Settings

The parameters for each different beverage are shown at this level; these parameters can be modified by opening each item

using the coffee key and selecting with the touch-ring.

4.1 Espresso Settings:

4.1.1 Product Qty. (imp.) Number of water pulses.

4.1.2 Aroma Displays coffee grinder pulses in 60-150 pulse range.

0: pre-ground (0 pulses); 1: mild (- 10% medium); 2: medium; 3: strong (+10% medium).

4.1.3 Prebrewing Prebrewing 1: enabled; 0: disabled; 2: long.

4.1.4 Temperature Shows temperature in °C. Low (-3°C average), average, high (+3°C average).

4.2 Coffee Settings:

4.2.1 Product Qty. (imp.) Number of water pulses.

4.2.2 Aroma 0: pre-ground; 1: mild; 2: medium; 3: strong.

4.2.3 Prebrewing 1: enabled; 0: disabled; 2: long.

4.2.4 Temperature in °C

4.3 Long Coffee Settings:

4.3.1 Product Qty. (imp.) Number of water pulses.

4.3.2 Aroma 0: pre-ground; 1: mild; 2: medium; 3: strong.

4.3.3 Prebrewing 1: enabled; 0: disabled; 2: long.

4.3.4 Temperature in °C

15/17

TALEA Section 05

REV00 - August 06

Page 35

Ideas with Passion

5.3 Error messages for service personnel

16/17

PRIMEA Section 05

REV00 - August 06

Code

Applicable models:

Brief description Description

01 All models Coffee grinder 1 blocked.

The cof

fee grinder is blocked (grinders blocked or sensor not reading

properly).

03 All models Brew group block

ed in work position.

Microswitch not released in up position after 3”, torque error trying to

move down, descent time out exceeded.

04 All models Brew group block

ed in home position.

Microswitch not released in down position after 3”, torque error trying to

move up, ascent time out exceeded.

05 All models Water circuit blocked. No water in turbine.

10-11 All models Various sensor errors. Water heater sensors shorted or in open cir

cuit.

14-15 All models Various temperature errors. Heater temperatures out of control.

16 All models Both microswi

tches activated on brew group. The work and home microswitches have both been activated.

17 All models Memory error. Impossible to read or write to e2prom.

18 All models Clock error. Memory defect or impossible to set.

19 Al

l models No zero crossing. No z

ero crossing on card, could be caused by power card.

20 All models Cup lift error

.

The two stroke end position microswitches are activated at the same

time.

On models in the new Platinum ranges, errors recorded can be viewed on the display (during diagnosis) or on a PC (with programmer). The fol-

lowing are sa

ved:

A) The last 20 errors to be recorded.

B) Total number of errors (not all models).

• Since production (total).

• Since last service (partial).

• Current.

Page 36

Ideas with Passion

5.4 Problems, causes, remedies

HELP MESSAGES DISPLAYED HOW TO RESET MESSAGE

Turn the appliance off and on to solve the problem. Switch off and after 30 sec. turn on the appliance to

restore normal operating conditions.

Call the Service Center. Problem requiring assistance of Service Center.

Insert drip tray. Insert drip tray.

Close coffee granule container cover. Close the coffee granule container to enable delivery

of any beverage.

Insert ground coffee. This message guides the user when this type of cof-

f

ee has been selected during personalised beverage

programming.

Insert brew group. Insert brew groupin seat.

Insert coffee grounds drawer. Insert coffee grounds drawer.

Empty coffee grounds drawer. Remove coffee grounds drawer and empty.

N.B: The coffee grounds drawer must only be emptied

when the appliance is switched on. The drawer must

be removed for at least 5 seconds. If the drawer is

emptied when the appliance is switched off the message is not r

eset.

Close side door Close service door

.

Fill water tank. Fill tank.

Empty drip tray below brew group. Empty drip tray.

Insert milk container. Insert container in milk compartment.

Prime circuit. Start filling water circuit automatically. The appliance

will automatically try to fill the circuit 5 times; if it

fails, contact the Service Centre.

The descaling cycle did not run correctly. Repeat the operation as described in the relative

chapter in the instruction booklet.

R

eplace Aqua Prima filter. This message is only displayed if the filter control is

enabled (see instruction booklet).

R

eplace the filterif:

1) 60 litres of water have been dispensed.

2) 90 days have elapsed since installation.

3) 20 days have elapsed since the coffee maker was

last used.

The cleaning cycle did not run correctly. Repeat the operation as described in the relative

chapter in the instruction booklet.

I

nsert cappuccinatore. Insert cappuccinatore in milk compartment.

Rinse milk container. Clean container after use.

Descale appliance. R

un descaling cycle

Standby. Press “ start”.

17/17

PRIMEA Section 05

REV00 - August 06

Page 37

SECTION 6

OPERATING

LOGIC

REV.00

TALEA Section 06

REV00 - August 06

Page 38

6.1 Reset coffee grounds drawer.

The “empty coffee grounds drawer” message is signalled by a “coffee” beverages counter

controlled by the appliance electronics.

The counter is cleared “empty coffee grounds drawer” reset message:

1. After 13 coffees, if the grounds drawer is removed for more than 5 seconds.

2. Each time the grounds drawer is removed for more than 5 seconds when an “empty

coffee grounds drawer” alarm has been generated (it is assumed that the grounds

drawer has been emptied).

N.B:

If the 12th coffee is actually a “double coffee”, the “empty coffee grounds drawer” alarm will be

generated at the 14th coffee. As a result, the counter for the “empty coffee grounds drawer” in

this case would be reset at the 14th coffee.

6.2 Water reserve

Platinum models have a fixed reserve (turbine pulses) to ensure the selected beverage can be fully

(partially or totally) dispensed each time the capacitive sensor registers the presence of water

in the water tank. Otherwise, the appliance displays the “fill water tank” message and will not

dispense the beverage.

The beverage will be dispensed in full or in part depending on whether the remaining reserve is

enough to cover the programmed length of the selected beverage.

On selection, a message requests that the water tank is filled.

Example:

e.g: sensor registers presence of water (+10cc).

Hypothesis 1) A 60cc beverage is selected, 50cc is taken from the reserve, the beverage is

dispensed in full, and the “fill water tank” message appears.

Hypothesis 2) A 110cc beverage is selected, 90cc is taken from the reserve, the product is

dispensed in part (100cc), and the “fill water tank” message appears.

Hypothesis 3) A double 110cc coffee is selected; the first is dispensed in part (100cc),

the fill tank message appears, then the second one is dispensed in full (110cc).

Hypothesis 4) Double 40cc coffees are selected; the appliance dispenses both in full.

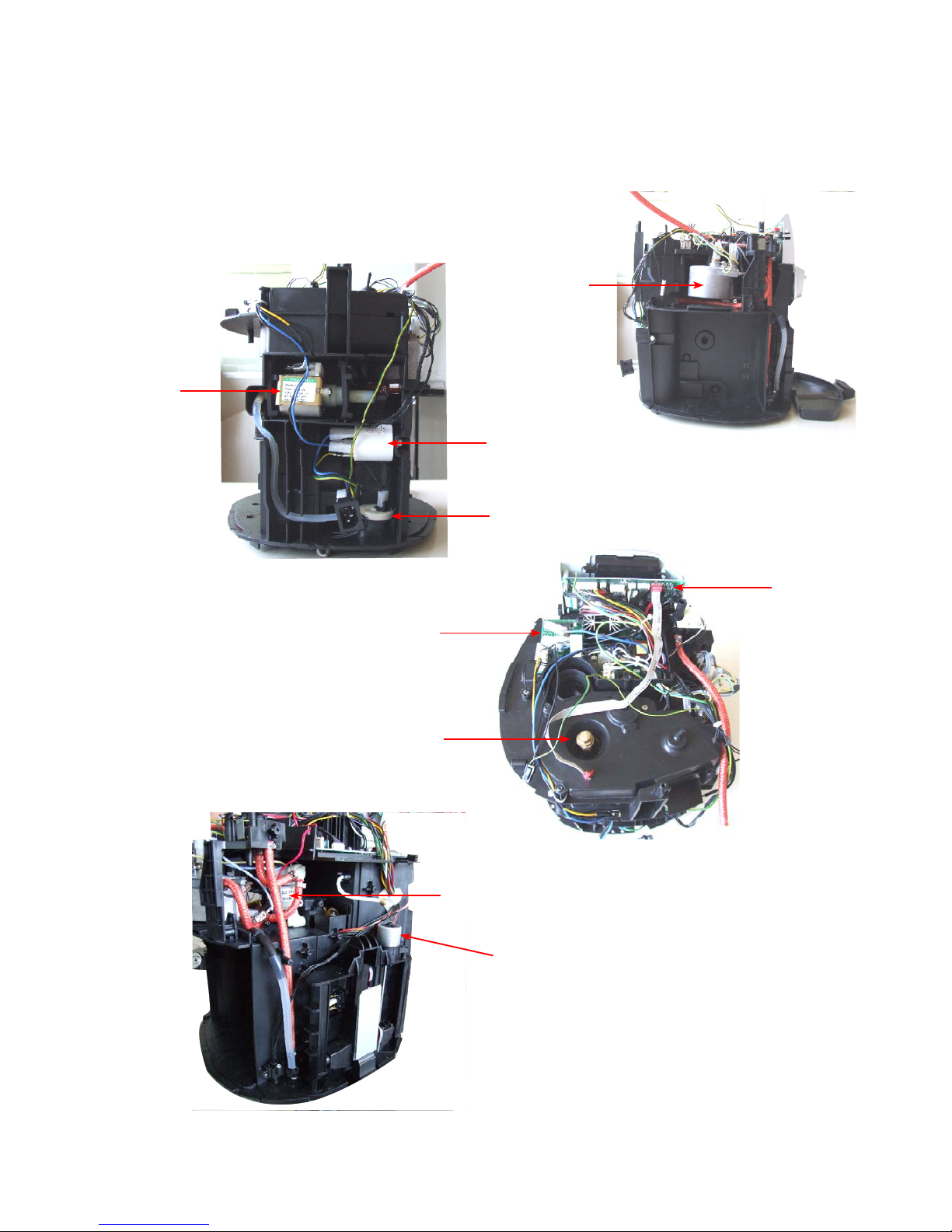

10 cc

Starting water level

Capacitive sensor

actual 90 cc level

not configurable

via SW

1/6

TALEA Section 06

REV00 - August 06

Page 39

Ideas with Passion

6.3 Motorized tray

2/6

The movement of the motorized tray is mechanical by means of a stepper motor (1) in 24V

DC, controlled by two capacitive pushbuttons (2) located at the front of the tray.

The two microswitches (3) are for the limit switch, and operation can be checked in test mode

(see section 5.1).

3

1

2

3

3

2

3

TALEA Section 06

REV00 - August 06

Page 40

Ideas with Passion

3/6

6.4 Aqua Prima

TALEA Section 06

REV00 - August 06

Operating logic with “AQUA PRIMA” filter.

When use of the “aqua prima” filter is selected on the user menu or via the control panel, the

system water count logic is as follows:

If the “aqua prima” function is enabled the electronics perform a pulse count of the turbine,

recording one pulse every 2 revolutions.

If the “aqua prima” function is disabled, the electronics perform a pulse count of the turbine,

recording one pulse every revolution.

The graph in the figure below illustrates this function:

360°

1 rev

360°

1 rev

360°

1 rev

360°

1 rev

Turbine revs

= 1 pulse

Aqua Prima

on

Aqua Prima

off

Page 41

Ideas with Passion

6.5 SBS Valve

4/6

TALEA Section 06

REV00 - August 06

Beverage dispensing

The SBS brewing system valve (see Fig. 2) controllable via the knob, enables variation (increasing or decreasing according to the position of the knob) of the water flow rate for brewing.

This adjusts the coffee brewing time (extraction time) and consequently the intensity of taste,

keeping the cream quality constant.

Function

With the SBS valve in the open position, coffee is accumulated in the membrane valve due to a

low back-pressure of the SBS valve. Consequently the membrane valve needle remains in the

maximum open position, due to resistance of the spring. Coffee exits quickly (see fig. 3).

With the SBS valve in the closed position, coffee is accumulated on the membrane of the valve

with a consequent increase in pressure in the valve. The spring yields to the back-pressure and

the needle then reduces the coffee passage (see Fig. 4).

Fig.4

Fig.1

Fig.2

Fig.3

Page 42

Ideas with Passion

5/6

TALEA Section 06

REV00 - August 06

SBS valve operation check

To ensure correct operation of the valve SBS a long coffee should be made, and during

preparation of the latter, check the difference in dispensing speed between the maximum and

minimum positions.

The difference in dispensing speed is approx. 2.5 times greater (and therefore VERY

obvious!!).

Knob MAX

position

Knob MED

position

Knob MIN

position

-> Rapid coffee delivery

-> Good coffee brew -> Good coffee brew -> Maximum coffee brew

-> Medium counter-pressure

-> Medium coffee delivery

-> Medium-high counter-pressure

-> Slow coffee delivery

-> High counter-pressure

CAFFÈ CREME ESPRESSO RISTRETTO

SBS

SBS

SBS

(Light coffee) (Medium-strong coffee) (Strong coffee)

Page 43

Ideas with Passion

6/6

TALEA Section 06

REV00 - August 06

6.6 Solenoid pilot

Brew

group

drain valve

Drain

Brew group valve

(3 - 5 bars)

Needle

Solenoid pilot function:

1. Brew group drain:

before the group is lowered, the solenoid pilot opens briefly creating a depression

that in turn opens the valve in the opposite direction from dispensing, allowing any

water left in the group to be drained and keeping the pad dry.

2. Coffee ready after steam:

when a coffee or water are selected, the solenoid pilot opens the drain valve

to lower pressure in the heater.

3. Prime heater:

after a period in standby or when the appliance has not been used for an extended period

(1st coffee), the pump loads briefly during grinding to get rid of any water between the

heater pin and heater, and to pre-heat the elements.

4. Fill circuit: the solenoid pi

lot discharges and recharges automatically. The discharge occurs via the drain

pipe and not via the valve.

5. Relief valve: the solenoid pilot also serves as a relief valve (not present on pump), opening in the event

of pressure in excess of 16-19 bars.

6. Lower pressure: pressure is lowered by the circuit being discharged for 10 seconds after water or steam

have been dispensed (see variables A and B).

A) Confi

guration with dual-sensor valve card (water/steam position sensor + Milk Island posi-

tion sensor):

After w

ater has been dispensed - > the solenoid pilot opens to the discharge side as soon as the sensor is

disengaged.

I

mmediately after steam has been dispensed - > the solenoid pilot opens to the discharge side as soon as

the sensor is disengaged.

W

ater dispensed after steam has been dispensed -> the solenoid pilot opens to the discharge side as soon

as the sensor is disengaged.

- After each bev

erage has been dispensed -> the solenoid pilot opens to the discharge side.

-

Each time the appliance is switched on and the temperature is reached -> the solenoid pilot opens to the

discharge side.

- When the temperature is reached -> the solenoid pilot opens to the discharge side.

B) Confi

guration with three-sensor valve card (water/steam sensor + closed position sensor +

milk island position sensor):

I

n addition to the functions described in configuration A, the following also occur:

Each time the closed position centr

al sensor is disengaged -> always open the solenoid pilot towards the

discharge side.

Turbine

Steam tube

Silicon tube

TANK

Silicon tube

Pump

Silicon tube

Reinforced silicon hose

Reinforced silicon hose

Reinforced silicon hose

Reinforced silicon hose

Reinforced silicon hose

STEAM/WATER

DISPENSE

1300W heater

WATER DRAINED

TO DRIP TRAY

Water drain connector

Water/steam valve

Water drain connector

WATER DRAINED

TO TANK

COFFEE

DISPENSE

SBS valve

Connector with 3 bar relief valve

MILK ISLAND STEAM

DISPENSE

Brew unit

Brew unit pin

Coffee dispense valve (3-5 bars)

Drain valve

Relief valve (16-19 bars)

Page 44

Ideas with Passion

6.7 Milk Island

Electrical connection to appl

iance.

Water pipe connected to

appliance for steam inlet.

Button to

attach/release

Milk Island

from appliance.

Steam

outf

eed

Carafe

present

LED

Anchor pin

between Milk Island

and appliance.

Unscrew bolts

indicated to

dissassemble.

2

1

3

4

5

6

7

8

9

Cappucinator

e cover.

Cappucinatore valve cover.

Vernay valve.

Cappucinatore valve

cover insert.

Cappucinatore body.

Carafe handle.

Carafe milk suction pipe.

Carafe steamout pipe.

Top part carafe.

2

1

3

4

5

6

7

8

9

Page 45

Ideas with Passion

SECTION 7

COMPONENT

ASSEMBLY

AND DISASSEMBLY

REV.00

TALEA Section 07

REV00 - August 06

Page 46

Remove the coffee top container ,

unscrew the three screws pointed

out and lift the upper cover.

Disconnet the cups warmer

( where included ), the ground

wire cable and the coffee top

container sensor.

In order to dismantle the distributor completely, extract the regulation stick and, following the

screws sequence, dismantle the different parts.

Page 47

Unscrew the four screws which block the frontal panel, so that it can move.

Unnhook the anterior riser, by unblocking firstly the two lower hooks and then the upper ones ( see

photo ), paying attention to not break the riser’s hooks. After having removed the riser, it is possible

to remove the frontal panel.

Page 48

Ideas with Passion

Loosen the screw as shown.

7.2 Right and left side casing

Split the two sides of the casing (see Fig..1).

Press from the bottom (see Fig.2).

Release and take it off from the side and at the bottom

(see Fig. 3), pulling tow

ards you at the same time (see Fig. 4).

2/11

TALEA Section 07

REV00 - August 06

1

4

2

3

To remove the right

side, loosen the

screws as indicated.

To remove the left

side, loosen the

scr

ews as indicated.

To take the left-side off, release the small

clamp and pull out the wire mesh pipe

connecting the steam pipe to the valve,

removing the metal band as shown.

Page 49

Ideas with Passion

3/11

TALEA Section 07

REV00 - August 06

7.3 Electronics

CPU card

Fig.1 Loosen the screws as indicated and turn the front piece upwards to get to the card.

Fig.2 Take off the small clamp.

Fig.3 Disconnect all connectors and loosen the screws as indicated.

3

2

1

Power board

Remove the small clamps, disconnect all connectors and loosen the screws indicated.

Page 50

4/11

TALEA Section 07

REV00 - August 06

7.4 Gearmotor

Remove the safety guard (A)

by loosening the screws as

indicated.

Loosen the f

our screws indicated

and remove the heater valve asm.

When refitting it, be careful with

the two oil-rings shown in the

smaller picture.

Disassemble the protection plate (B) b

y

loosening the screws as

indicated.

The f

ollowing are located inside the compartment

protected by the guard:

- Electric motor (A) with gears (B) and (C) for

transmission and timing of the brew group.

- The drip tray present reed switch

sensor (D).

- Brew group present microswitch (E).

- Microswitch (F) brew group at Home position.

- Microswitch (G) brew group at dispensing

position.

Withdraw the gear (C) that meshes with the motor

transmission shaft.

Withdraw the large gear (B).

Pull out the motor (A) complete with transmission

shaft (H).

A

B

A

B

E

C

D

F

G

Insert the gear (B), taking care

that the arrow stamped on the

element is within the opening that

contains pin (P).

P

B

Install the motor and transmission shaft,

inserting the guides (L) in the relative seat.

L

Page 51

Ideas with Passion

5/11

TALEA Section 07

REV00 - August 06

7.5 Pump

Take the pump out from the rubber support guides.

Withdraw the faston connectors as indicated.

2

1

Pull out the adapter.

Take off the oetiker

clamp as indicated and

pul

l out the reinforced

flexible hose.

Page 52

Ideas with Passion

6/11

TALEA Section 07

REV00 - August 06

7.6 Heater and solenoid pilot unit

Loosen the screws as indi-

cated.

A

B

C

Take off the oetiker clamp A,

pull out the reinforced flex-

ible hose, loosen screw B and

wi

thdraw the drain pipe C

from the solenoid pilot.

Loosen the screws on the

relief valve assembly.

A

Unhook the teeth anchor-

ing to the body and li

ft the

heater and solenoid pilot.

Heater

Solenoid pi

lot.

Page 53

Ideas with Passion

7. 7 OETIKER clamp assembly and disassembly

Heater clamps

Figure (1) shows the assembly position of the clamp on the heater connector.

HEATER

SOLENOID PILOT

Figur

e (2) shows the assembly position of the clamp on the plastic solenoid pilot connectors.

Solenoid pilot

Use suitable pliers to tighten the clamp.

Ensure correct tightening (A) and positioning as shown in illustrations (1) / (2).

1

2

A

To remove the clamp, use a pincer as shown in (B)

B

TALEA Section 07

REV00 - August 06

7/11

Page 54

Ideas with Passion

7.8 Coffee grinder

8/11

TALEA Section 07

REV00 - August 06

Loosen the screws on the cover

and lift it off, being careful to

withdraw damper A.

A

Unclamp and remove the connector inserted in the car

d.

When refitting the motor assembly

, be careful to reinsert the

spring.

Page 55

9/11

TALEA Section 07

REV00 - August 06

To remove the upper grinder support, use a wrench, turning it clockwise to release the

grinder support from the bayonet coupling.

On the lower burr, keep the increment pin as

indicated locked in position and proceed as

shown in the figure above.

When refitting the upper grinder support, take care to reposition the mark as

shown in the picture.

To remove the upper burr, rotate

anti-clockwise until it detaches from

the bayonet coupling.

7.9 Coffee grinder setting, assembly and disassembly

Page 56

Ideas with Passion

10/11

7.10 Grinder adjustment during servicing

To vary the grinding setting,

tighten or loosen with wrench “A”

supplied.

(+) = Coarse grinding

(

- ) = Fine grinding.

WARNING:

- Grinding must be adjusted with the motor in movement.

- Adjust the grinding level by one step at a time.

- After setting grinding, run two grinding cycles and check the resulting granules and dose.

- Repeat if further adjustment is required.

TALEA Section 07

REV00 - August 06

+

-

A

To adjust the coffee grinder (in addition to user-permitted adjustments of “C” with the grinding

adjustment tool “A”

), remove the coffee granule container and turn adjustment insert “B” to

widen or tighten grinding. This insert can be reposi

tioned to move interval “C”.

Be very careful not to separate the grinders from their supports.

C

B

Page 57

Ideas with Passion

7.11 Motorized drip tray

Loosen the screws as indicated.

Pull the motorized tray towards you.

11/11

TALEA Section 07

REV00 - August 06

Loosen the two screws to release

the electric motor with worm gear

To withdraw the stop (A) use pliers to grip the tabs

securing the lifting system to the base and pull outwards. Withdraw the electric motor with worm gear

from above.

Disassembling the motorized tank stepper motor

Page 58

Ideas with Passion

SECTION 8

SERVICE

SCHEDULE

REV.00

TALEA Section 08

REV00 - August 06

Page 59

Ideas with Passion

S= Replacement

R= Service

P= Cleaning

D= Descaling

C= Inspection

*= Number of beverages dispensed

Parts Task Reason Item

Service

5,000*

10,000*

Casing, tanks, containers, power

cable.

C C C Dirty, damaged. See documentation (exp. drawing).

Water coffee andè milk lines.

GACO DIM 14 seals S S S W

ear

Water filter S S S Dirty, hygiene.

Silicon tube C D D Dirty, scale, leaks. See documentation (exp. drawing).

Turbine C D D Dirty, scale, leaks. See documentation (exp. drawing).

Heater C D D Dirty, scale, leaks. See documentation (exp. drawing).

Multi-valve C D D Dirty, scale, leaks. See documentation (exp. drawing).

Heater pin o-ring S S S Dirt

y, scale, leaks.

Brew group P P P Dirt

y, hygiene. See documentation (exp. drawing).

Cappuccinatore P P P Dirty, hygiene. See documentation (exp. drawing).

Coffee grinder

Grinders

Check grinding and dose.

PCPCPCDirty, hygiene.

Grain size and dose

See documentation (exp. drawing).

Brew group

Cleaning C R R Dirty, hygiene.

Lubrication C R R Dirty, hygiene.

O-ring C S S Wear See documentation (exp. drawing).

Full service C C C Wear

Othertasks

Descale C D D

Then check condi

tion of

parts.

Temperature check C C C Client inf

ormation

Explanation of fault C C C Client information

Safety check C C C Always

Packing C C S Check, alw

ays. Use new packaging if necessary.

8.1 Routine maintenance check list

TALEA Section 08

REV00 - August 06

1/1

Loading...

Loading...