Page 1

All parts of this document are the property of Philips.

All rights reserved. is document and all the information herein is provided without liability deriving from any errors or omissions. Furthermore, no part may be reproduced, used or

collected, except where express authorisation has been provided in writing or through a contractual agreement.

Published by Philips

Subject to modi cation EN 4219 400 00033

Service

Service

Service

Service

Co ee Machine

Gaggia Anima

2015-July-30

Service

Service

Manual

Manual

Rev. 00 July 2015

General Information

Description Value

Housing material Thermoplastic type

Size (w x h x d) Anima OTC AMF CMF 221 x 340 x 430 mm (data may vary depending on the model)

Size (w x h x d) Anima XL 221 x 386 x 430 mm

Weight OTC AMF CMF 7,5 kg (data may vary depending on the model)

Weight Anima XL 8 kg

Power cord length 800 - 1200 mm

Control panel Front type

Cup size Up to 152 mm

Water tank OTC AMF CMF 1.8 litres - Removable type

Water tank Anima XL 2.5 litres - Removable type

Coffee bean hopper capacity Anima OTC AMF CMF 250 g

Coffee bean hopper capacity Anima XL

500 g

Coffee grounds drawer capacity 15

Milk carafe capacity 0,5 l (OTC version)

Pump pressure 15 bar

Boiler Stainless steel boiler

Safety devices Thermal fuse

Energy saving mode < 1 Wh

Nominal voltage - Power rating - Power supply Read the data plate placed inside the service door

Page 2

GAGGIA ANIMA

Table of contents Page

6. Standard checks

6.1. Repair schedule 1

6.2. Service schedule 1

6.3. Final test 2

7. Disassembly

7.1. Outer Shell

1

7.2.

Dispenser

2

7.3. Co ee grinder

3

7.4. Grinder blades

3

7.5. Co ee grinder adjustment

4

7.6.

Carafe connection and hot/Steam water dispenser

5

7.7.

Central plate

5

7.8. Pin boiler

6

7.9. Gear motor

6

7.10. Pump

7

7.11. Flow-meter

7

7.12.

Boiler

7

7.13. CPU board

8

7.14 Programming access for SSC (Saeco Service Center)

8

7.15. KYB interface and display

8

7.15. Fitting and removing Oetiker clamps

9

8. Notes

9. Water circuit diagram

10 Electrical diagram

Table of contents Page

1. Introduction

1.1. Documentation required 1

1.2. Tools and equipment required 1

1.3. Material 1

1.4. Safety warnings 1

1.5 Service Policy 2

1.6.1. External machine parts Anima XL

1.6.2. External machine parts Anima OTC 3

1.6.3. External machine parts Anima AMF - CMF 4

1.6.4. Internal machine parts 5

2. Technical speci cations

2.1. Technical speci cations 1

2.2.1. Speci cation for the measurement of the co ee products

temperature

2

2.2.2. Speci cation for the measurement of the milk products

temperature

3

2.3. Machine parameters and performance 5

3. User instructions

3.1. Customer menu 1

3.2. Operation, cleaning and maintenance 3

4. Operating logic

4.1. Water circuit 1

4.2. Milk carafe 2

4.3. Single microswitch 3

4.4. Temperature sensor 3

4.5. Co ee grinder 4

4.6.

Detection of co ee bean absence, dose adjustment,

blocked co ee grinder.

4

4.7.

Dose self-learning (SAS) only for 120v 5

4.8. Co ee grinder 6

4.9. Autodose sistem description 6

4.10. Co ee lack detection and co ee grinder blocked. 7

4.11. Co ee cycle 8

4.12. Water level detection (water tank) 9

4.14. Descaling request 9

4.14. Water lter 10

5. Troubleshooting

5.1. Test mode Incanto

1

5.1.1. SteamOut 7

5.2. Error Codes 9

Page 3

GAGGIA ANIMA

CHAPTER 1

INTRODUCTION

Page 4

GAGGIA ANIMA 01 INTRODUCTION

Pag. 1/6

1.1 Documentation required

The following documentation is needed for repair procedures:

• Instruction booklet for specifi c model

• Technical documentation for specifi c model (diagrams, exploded view, sympton cure and

service manual)

1.2 Tools and equipment required

As well as the standard equipment, the following is required:

Qty. Description Notes

1 Screwdriver

1 Pliers for Oetiker clamps

1 CC -A - Vdc tester

1 Digital thermometer Scale limit > 150°C

1 SSC (Saeco Service Center) Programmer (for programming and diagnostics mode)

1.3 Material

Description Notes

Thermal paste Heating element > 200°C

Descaler Saeco descaler

Grease solvent Personal choice

Silicone grease Safe to use with food

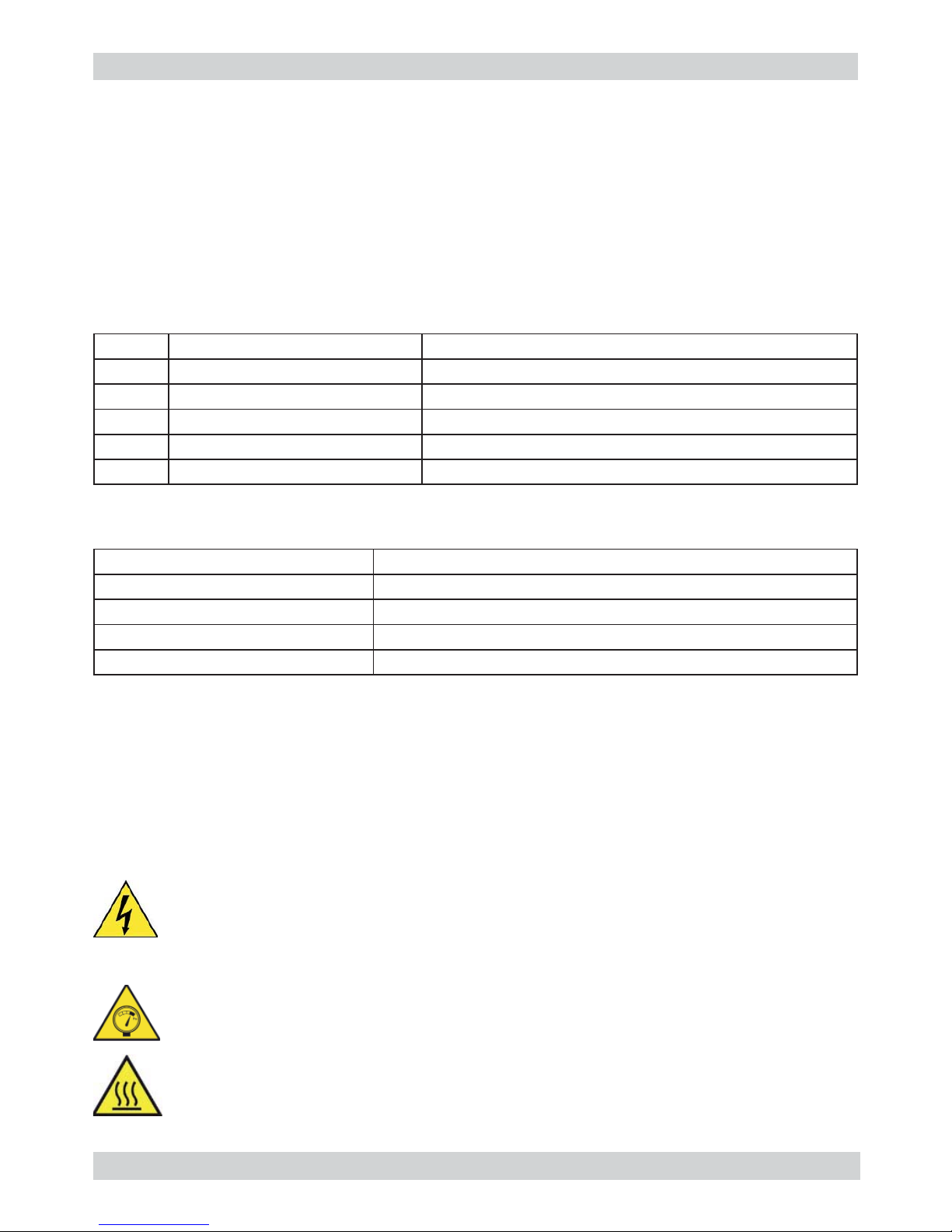

1.4 Safety warnings

We recommend you consult the technical manual of the machine before performing any maintenance work.

Observe all applicable standards relating to the repair of electrical appliances.

Always disconnect the power plug from the mains before beginning repair work.

Disassembling the machine, the operator must pay attention to hot and under

Pressure parts: boiler, pin-boiler, valves, dispensing, steam tube, brew unit,

connections and pipes to avoid burns. Please refer to specifi c hydraulic circuit

(Image1) to know the parts in detail.

The machine hydraulic circuit can reach maximum pressure of 16/18 bar.

To operate in safety condition is recommended to perform the Steam Out procedure in

order to remove the pressure and hot water inside the hydraulic circuit.

Simply turning off the main machine power switch is not an adequate safety

precaution.

This domestic appliance is rated as insulation class I.

On completion of the repair work, insulation and dielectric rigidity tests must be

performed.

Page 5

GAGGIA ANIMA 01 INTRODUCTION

Pag. 2/6

1.5

Service POLICY grid as used for coffee machine

Components Assembly use Single components available

COFFEE

GRINDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the machine or

of the Coffee Grinder on website

BREWING UNIT Only for OOW repairs

YES, to consult the specifi c exploded-view of the machine or

of the Brewing unit on website

BOILER Only for OOW repairs

YES, to consult the specifi c exploded-view of the machine on

website

GEAR

MOTOR

Only for OOW repairs

YES, to consult the specifi c exploded-view of the machine on

website

FILTER

HOLDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the machine on

website

MILK

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the machine on

website

THERMAL

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the Thermal

Carafe on website

MILK ISLAND Only for OOW repairs

YES, to consult the specifi c exploded-view of the Milk Island

on website

List of principal assembly present in all our coffee machines

For IN WARRANTY repairs is mandatory to use the single components (not the assembly) avail-

able in the exploded views of the coffee machines or of the specifi c components. If you fi nd the

information “SEE THE EXPLODED VIEW E........” in the assembly description fi eld, it means that

the single components of the assembly are available in the other pages of the exploded view. It’s

possible to use the assembly only if there is a specifi c Symptom Cure that include this possibility

or when the single components are not available for the order.

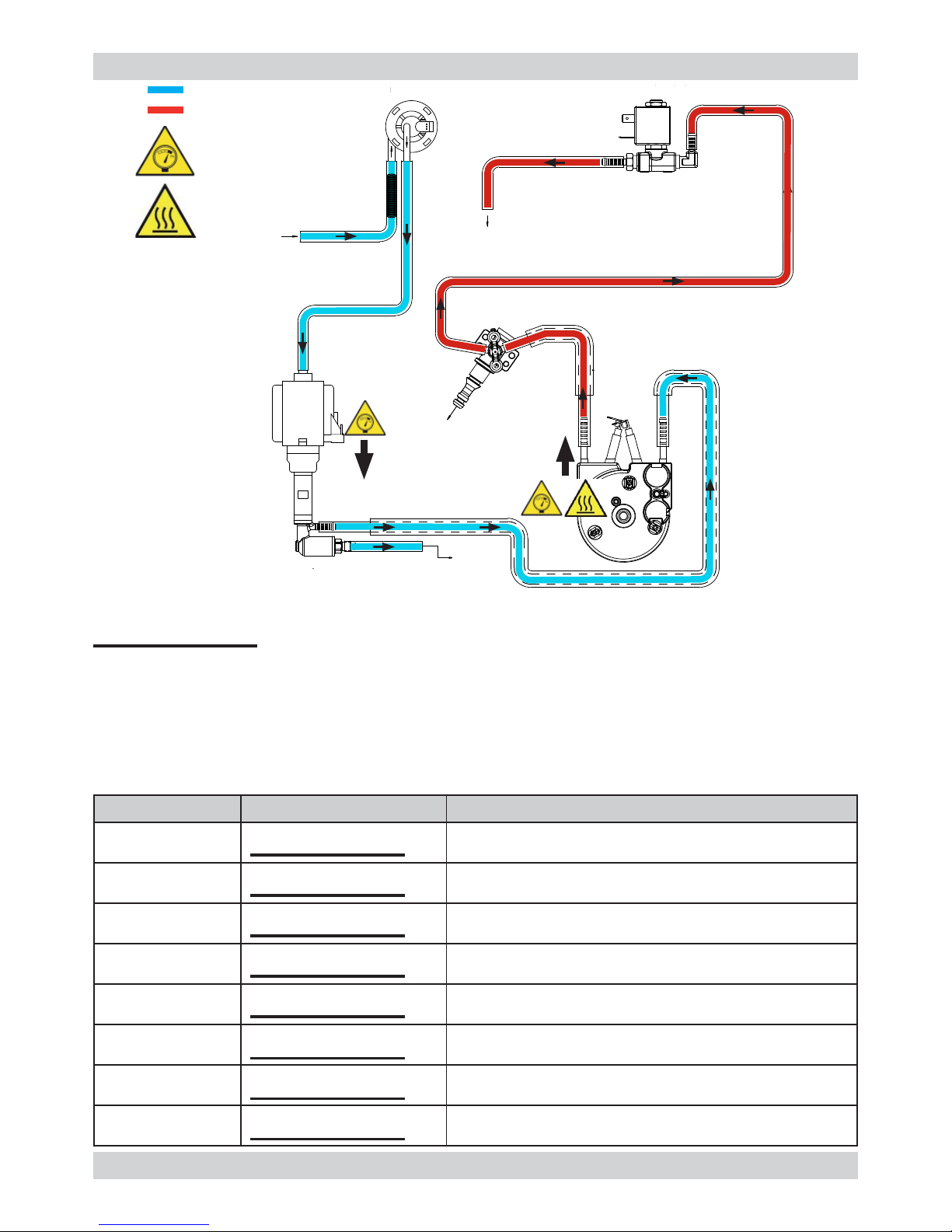

Pump

Safety valve

Water

discharge

Steam pipe

Water tank

Two-way solenoid valve

Brewing Unit

Flowmeter

Boiler

Water

Hot water /steam

From this point circuit

High temperaure

From this point circuit

in pressure

Flowmeter

Steam and hot water

Two-way solenoid valve

Pump

Brewing Unit

Boiler

Safety valve

Water

discharge

Water tank

Image 1

Page 6

GAGGIA ANIMA 01 INTRODUCTION

Pag. 3/6

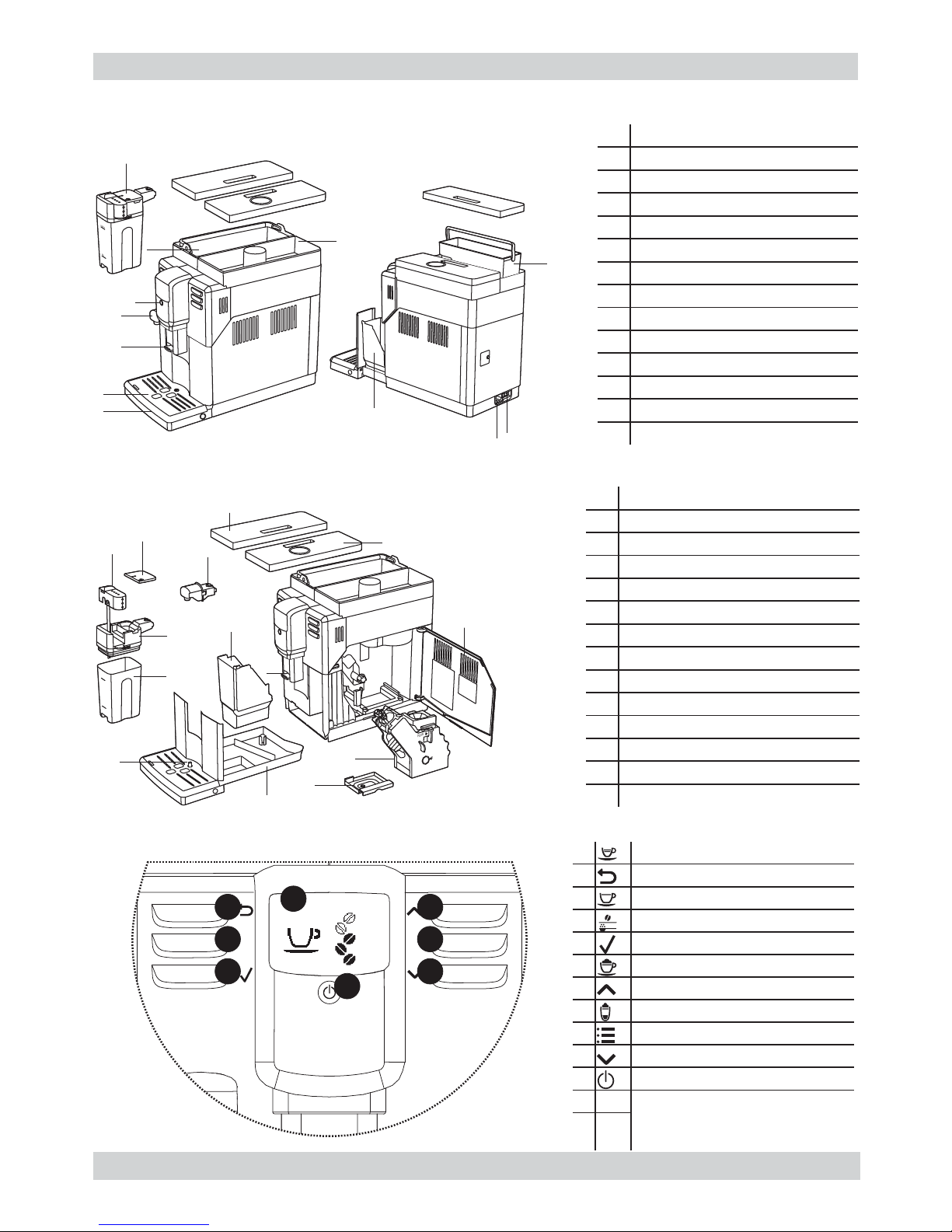

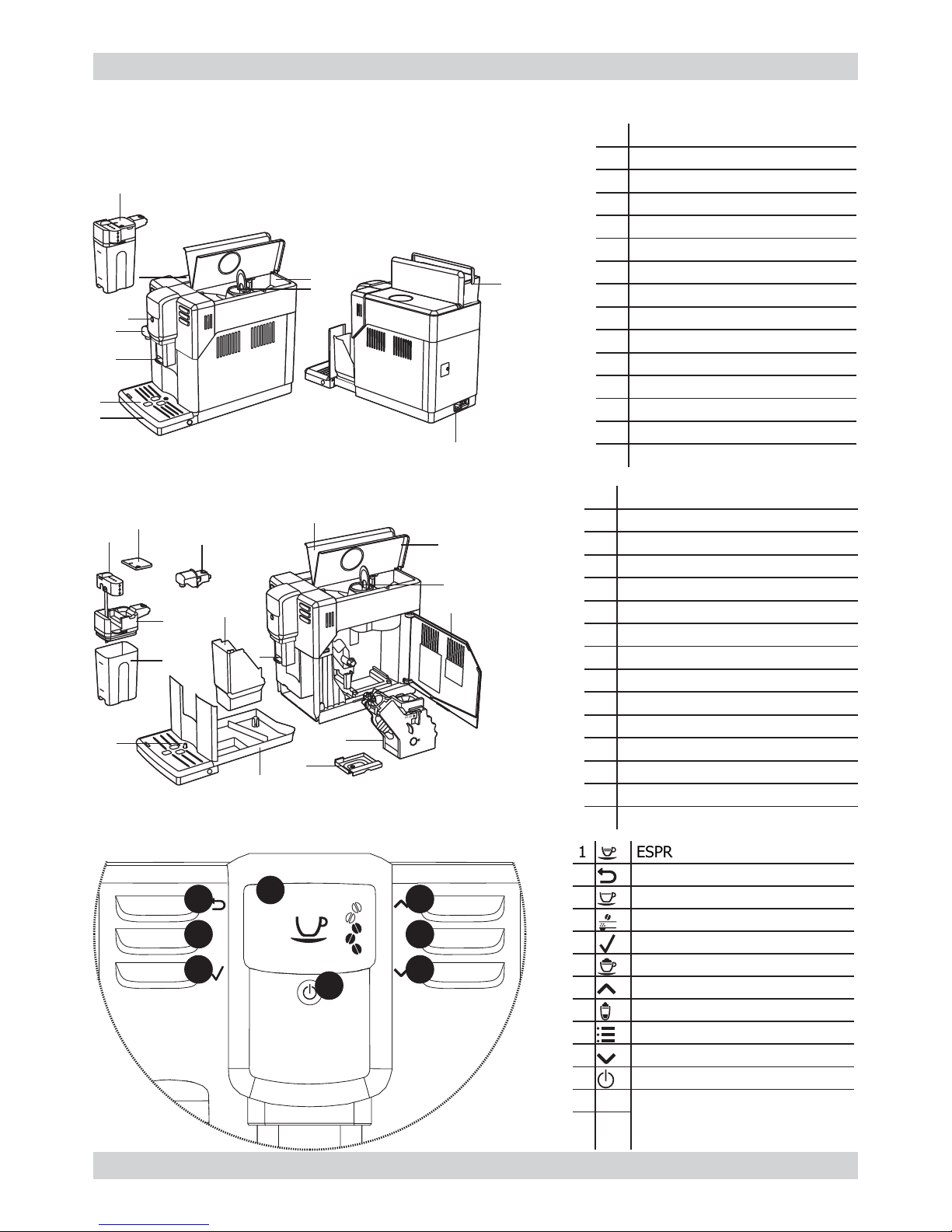

1.6.1. External machine parts Anima XL

1 ESPRESSO button

ESC button

2 ESPRESSO LUNGO button

3 AROMA STRENGTH button

OK button

4 CAPPUCCINO button

UP button

5 LATTE MACCHIATO button

6 MENU button

DOWN button

7 STAND-BY button

8 Display

In the example:

Main menu; ready for brewing

M

A

X

M

I

N

7

8

11

10

3

1

4

5

6

2

9

12

14

13

P

U

S

H

N

M

A

X

M

I

N

M

A

X

2

10

9

8

1

11

3

12

4

7

5

6

1 STAND-BY button

2 Water tank seat

3 Coffee bean hopper

4 Removable water tank

5 Main switch

I. ON

0. OFF

6 Power cord socket

7 Coffee grounds drawer

8 Drip tray

9 Drip tray grill

10 Coffee dispensing spout

11 Hot water dispensing spout

12 Milk carafe

1 Water tank lid

2 Coffee bean hopper lid

3 Service door

4 Coffee residues drawer

5 Brew group

6 Coffee dispensing spout

7 Drip tray

8 Coffee grounds drawer

9 ‘Drip tray full’ indicator

10 Hot water dispensing spout

11 Milk carafe lid

12 Milk carafe top

13 Milk frother dispensing spout

14 Milk container

1

8

2

3

4

5

6

7

ESPRESSO

ESPRESSO LUNGO

AROMA STRENGTH

CAPPUCCINO

LATTE MACCHIATO

MENU

Main components

Main removable parts

Page 7

GAGGIA ANIMA 01 INTRODUCTION

Pag. 4/6

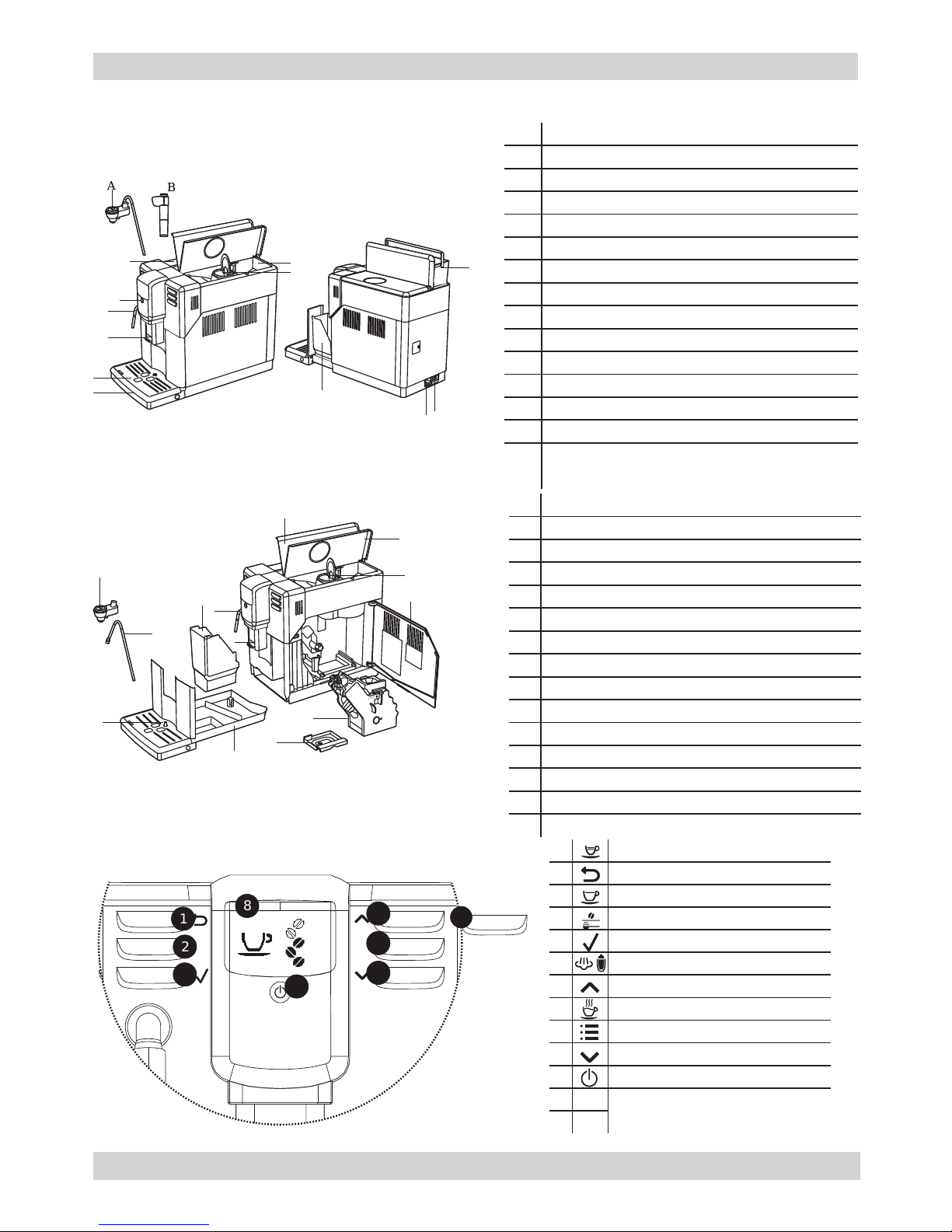

1.6.2. External machine parts Anima OTC

M

A

X

M

I

N

M

A

X

2

11

10

9

1

12

3

4

13

5

8

6

7

M

A

X

MI

N

8

9

12

11

4

1

5

6

7

2

3

10

13

15

14

P

U

S

H

N

1 ESPRESSO button

ESC button

2 ESPRESSO LUNGO button

3 AROMA STRENGTH button

OK button

4 CAPPUCCINO button

UP button

5 LATTE MACCHIATO button

6 MENU button

DOWN button

7 STAND-BY button

8 Display

In the example:

Main menu; ready for brewing

1 STAND-BY button

2 Water tank seat

3 Coffee bean hopper

4 Pre-ground coffee compartment

5 Removable water tank

6 Main switch

I. ON

0. OFF

7 Power cord socket

8 Coffee grounds drawer

9 Drip tray

10 Drip tray grill

11 Coffee dispensing spout

12 Hot water dispensing spout

13 Milk carafe

1 Water tank lid

2 Coffee bean hopper lid

3 Pre-ground coffee compartment lid

4 Service door

5 Coffee residues drawer

6 Brew group

7 Coffee dispensing spout

8 Drip tray

9 Coffee grounds drawer

10 ‘Drip tray full’ indicator

11 Hot water dispensing spout

12 Milk carafe lid

13 Milk carafe top

14 Milk frother dispensing spout

15 Milk container

Main components

Main removable parts

Control buttons and display OTC

1

8

2

3

4

5

6

7

ESPRESSO

MENU

LATTE MACCHIATO

CAPPUCCINO

AROMA STRENGTH

ESPRESSO LUNGO

Page 8

GAGGIA ANIMA 01 INTRODUCTION

Pag. 5/6

1.6.3. External machine parts Incanto AMF CMF

1 ESPRESSO button

ESC button

2 ESPRESSO LUNGO button

3 AROMA STRENGTH button

OK button

4 STEAM or MILK FROTH button

UP button

5 HOT WATER button

6 MENU button

DOWN button

7 STAND-BY button

8 Display In the example:

Main menu; ready for brewing

1 STAND-BY button

2 Water tank seat

3 Coffee bean hopper

4 Pre-ground coffee compartment

5 Removable water tank

6 Main switch

I. ON

0. OFF

7 Power cord socket

8 Coffee grounds drawer

9 Drip tray

10 Drip tray grill

11 Coffee dispensing spout

12 Steam/hot water dispensing spout

13A Automatic milk frother (AMF)

13B

Classic milk frother (CMF)

1 Water tank lid

2 Coffee bean hopper lid

3 Pre-ground coffee compartment lid

4 Service door

5 Coffee residues drawer

6 Brew group

7 Coffee dispensing spout

8 Drip tray

9 Coffee grounds drawer

10 ‘Drip tray full’ indicator

11 Steam/hot water dispensing spout

Steam wand (fi xed)

Rubber grip

12 Automatic milk frother top

13 Milk frother suction tube

Main components

Main removable parts

Control buttons and display CMF and AMF

AMF

M

A

X

2

11

10

9

1

12

3

4

13

13

5

8

6

7

8

9

4

1

5

6

7

2

3

10

11

13

12

P

U

S

H

N

A

B

1

8

2

3

4

5

6

7

ESPRESSO

ESPRESSO LUNGO

AROMA STRENGTH

STEAM

HOT WATER

MENU

4

MILK FROTH

Page 9

GAGGIA ANIMA 01 INTRODUCTION

Pag. 6/6

1.6.4 Internal machine parts

Flow-meter

Power board

BoilerThermostat

Pump

Coffee

dispenser

2-way

solenoid valve

Safety valve

Grinding

adjustment insert

Coffee grinder

Boiler pin

Page 10

GAGGIA ANIMA

CHAPTER 2

TECHNICAL

SPECIFICATIONS

Page 11

GAGGIA ANIMA 02 TECHNICAL SPECIFICATIONS

Pag. 1/5

2.1. Technical specifi cations

Power supply and output: 240 V~ 50 Hz 1850 W - 230 V~ 50/60 Hz 1850 W

120 V~ 60 Hz 1500 W

Temperature monitoring: (NTC) variable resistor sensor - transmits the value to the

electronic card

Safety system:

2 thermostats at 190°C one shot

Coffee heat exchanger output:

Stainless steel

(230 V~) 1900 W - (120 V~) 1300 W - (100 V~) 1100 W

for coffee, hot water and steam dispensing

Gear motor: 2 rotation directions; power supply 24VC

Pump: Ulka Type EP5/S GW approx. 13-15 bar with reciprocating

piston and thermal switch 100°C 48 W, 230V, 50 Hz, 120V,

60Hz 100V, 50/60 Hz

Overpressure valve: Opening at approx. 16-18 bar

Water fi lter: In tank

Coffee grinder: Direct current motor with fl at ceramic grinder blades

Automatic dosage: Dose adjustment controlled by the electronic system

Power consumption: During heating phase- approx. 5.6 A

Dimensions: W x H x D in mm:

221 x 340 x 430 mm (

Anima OTC AMF CMF)

(data may vary depending on the model)

221 x 386 x 430 mm (Anima XL)

Weight:

7.5kg (

Anima OTC AMF CMF)

(data may vary depending on the model)

8kg (

Anima XL)

Water tank capacity: 1.8 l. (Anima OTC AMF CMF) 2.5 l. (Anima XL)

Coffee bean hopper capacity: 250 g. (Anima OTC AMF CMF) 500 g. (Anima XL)

Dreg drawer capacity: 15

Water circuit fi lling time: Approx. 15 sec Max. on fi rst fi lling cycle

Heating time: Approx. 45 sec.

Grinding time: Approx. 8-10 sec.

Page 12

GAGGIA ANIMA 02 TECHNICAL SPECIFICATIONS

Pag. 2/5

2.2.1. Specifi cation for the measurement of the coffee products temperature.

The temperature is infl uenced by the fl ow from the dispenser and stratifi cation of temperatures in

the glass. In order to consider these phenomena and to introduce measures that allow comparisons

in controlled conditions, below guidelines must be followed:

Conditions:

a) Water temperature in tank: 23°C (+/-2°C).

b) It must be used a plastic cup (see picture N°1).

c) It must be used a thermocouple thermometer (e.g. type K - see picture N°2).

d) The coffee machine is tested without any change of parameters or calibrations, which may

affect the temperature of products, so the measurement of temperature must be done with

machine in default factory setting.

Procedure:

1. The temperature must be measured in the cup, immediately after dispensing. Cup has to be

placed on a non-metal surface using a thermocouple thermometer (Picture 1).

2. The temperature in the cup is measured by immersing the probe of the thermometer up to touch

the bottom.The probe then must be moved in a circular motion for 5/6 rotations. At the of the rotations, stop in the center of the cup (Picture 2).

3. The highest temperature measured during the rotations is the value we are searching for, and

that must be reported;

4. Test measurement: from end of dispensing to the end of rotations must be completed within 12

seconds.

5. the distance of the probe from the bottom of the glass is a function of the quantity of coffee dispensed: 10mm for 35gr - 17mm for 60gr - 35mm for 120gr and superior (Picture 3).

Limits of acceptability

The acceptance limits are divided by features and

products and are the following:

Espresso Coffee Italy Q.ty 25/40 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Coffee Q.ty 70/120 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Picture 1

Picture 2

OFF Tare ON

02

10 mm

for 120gr and

superior

Ø max 2mm

17 mmfor 60gr

35 mm

for 35gr

Picture 3

DISPLAY

Page 13

GAGGIA ANIMA 02 TECHNICAL SPECIFICATIONS

Pag. 3/5

2.2.2. Specifi cation for the measurement of the Milk products temperature.

Milk evaluation

To carry out the test, a partially skimmed UHT milk with a percentage of grease between 1.5-1.8%

at a refrigerator temperature Trefr. (between 4 to 10°C) must be used.

The milk product must be checked on a beaker of 250 ml of capability and with an inner diameter

of 70mm, brewing 100gr of product.

Parameters to be respected:

The parameters to be respected are: milk temperature and height of the cream. Each of these parameters, however, must be evaluated depending on the type of system used for the production of

hot milk.

Actually three types of devices are present on the appliances:

• Manual system (pannarello)

• Semi-Automatic system (cappuccinatore)

• Automatic system (carafe, Pinless wonder system, etc.)

Milk temperature in the beaker:

System without Pinless Wonder: e.g. Xelsis, Exprelia, Syntia, Intelia.

With milk at Trefr. (about 4-10 °C): ≥ 36

System with Pinless Wonder: e.g. New royal, Energica Pure, Intelia EVO Latte.

With milk at Trefr. (about 4-10 °C): ≥ 45

Height of the milk cream in the beaker:

Manual system (pannarello) ≥ 15mm on 100gr. of brewed product

Semi-automatic system (cappuccinatore) ≥ 20mm on 100gr. of brewed product

Automatic system: carafe, cappuccinatore, Pinless wonder e.g. (New Royal, Energica Pure, Intelia

EVO latte) ≥ 20mm on 100gr. of brewed product

How to measure the temperature of the milk.

1. The measurement is carried out in the beaker, immediately after the end of milk brew, positioned

on a non-metallic surface, using a thermocouple thermometer (eg. Type K). Stop the preparation

of mixed product: at the end of milk brewing, where “One Touch product” function is present.

2. The temperature is measured by immersing the probe of the thermometer, positioning the probe

inside the beaker at about 10mm from the bottom of the container, then the probe moves in

a circular motion for 3-5 turns, stopping at the end, at the center of the beaker. It detects the

maximum temperature reached in a time of relief between 3 to 5 seconds. It is important the

mixing of milk before the measurement at 10mm from the bottom of the beaker. If the mixing is

correct, temperature, for a few fractions of a second, during the measurement should not oscillate.

Page 14

GAGGIA ANIMA 02 TECHNICAL SPECIFICATIONS

Pag. 4/5

How to measure the milk cream.

The temperature (Trefr or Tamb) of the milk doesn’t affect as much the test result on measuring

the milk cream; by convection is assumed to always use milk at refrigerator temperature Trefr..

Manual systems (Pannarello)

Pour 100cc. of milk at Trefr. in a beaker of 250 ml of capacity and with a inner diameter of 70 mm;

with machine in steam mode:

1. Open the steam knob to discharger water circuit for 4 sec, then close the knob.

2. Place the beaker with the frother dipped in milk, open the steam knob to maximum and

start the chronometer.

3. After about 30 to 60 seconds, close the knob and check the result on milk.

Semi-automatic systems (cappuccino)

Pours milk at Trefr. in a container ; with the machine in steam mode:

1. Open the steam knob to discharge water circuit for 4 sec. then close the knob.

2. Insert the silicone tube in the milk container, placing a beaker of 250 ml capacity and with

an inner diameter of 70 mm under the cappuccino maker and open the steam knob.

3. After having provided 100gr. of product, close the knob and check the result obtained on

milk. Note: The same applies to machines which have a steam key on the user interface

and a solenoid valve in place of the steam tap.

Automatic: Carafe, Cappuccino Pinless wonder e.g.:(New Royal, Energica Pure, Intelia

EVO Latte), etc..

After setting the machine to delivery of 100gr. of product:

1. Launch the “hot milk” function.

2. Collect the product in a beaker with a 250ml of capacity and with an inner diameter of

70 mm, and verify the result obtained on milk. Carry out the test using milk at a Trefr..

In case the machine allows modify of the emulsion through the menu, use the machine with the

emulsion set to the default value.

Related to the above testing procedure derives the following table of acceptability:

Manual, Semi-Automatic and Automatic’s Milk System

Grams of Product Minimun Height of the milk cream

≥ 130 ≥ 30mm

120 ≥ 25mm

110 ≥ 22mm

100 ≥ 20mm

90 ≥ 16mm

80 ≥ 13mm

70 ≥ 11mm

NB: To verify more accurately the height of the cream, a practical expedient dictated by experience is to add to the product just delivered a small amount of coffee. The addition of coffee

immediately put in evidence the surface of separation between liquid and cream.

Page 15

GAGGIA ANIMA 02 TECHNICAL SPECIFICATIONS

Pag. 5/5

2.3. Machine parameters and performance

PRODUCT

QUANTITY

Default quantity

(Grams)

User

programmable

Programm. by

Production /

Service

Espresso 40 +/- 10gr Yes No

Espresso lungo 120 +/- 14% Yes No

Hot water Continues until the water supply has been exhausted (capacitive sensor)

Steam

pannarello

(frother)

time-out 03 minutes.

WATER TANK Description

Water reserve (pulses) with water fi lter 200

Water reserve (pulses) with no water fi lter 200

Water reserve modifi able by Production/Service

departments

No

"Fill tank" alarm Yes

"No tray" alarm Yes (Fill tank)

Water mains No

DREG DRAWER Description and values

Time-out for dreg drawer

5 sec.

Reset dreg counter

Dreg emptying alarm, if the dreg drawer is

removed for more than 5 seconds.

STANDBY Description and values

Inlet time (default) 15 minutes

Inlet time programmed by Production/Serv-

ice

Yes

Boiler temperature during Standby Boiler OFF

Descaling frequency

Hardness Water hardness Without anti-scale fi lter With anti-scale fi lter

1 Soft (up to 7°dH) 240 litres (480,000 pulses) 480 litres (960,000 pulses)

2 Medium (7° - 14°dH) 120 litres (240,000 pulses) 240 litres (480,000 pulses)

3 Hard (15° - 21°dH) 60 litres (120,000 pulses) 120 litres (240,000 pulses)

4 Very hard

(over 21°dH)

30 litres (60,000 pulses) 60 litres (120,000 pulses)

The default water hardness level is 3. Each litre of water corresponds to approximately 2,000 pulses

Page 16

GAGGIA ANIMA

CHAPTER 3

USER INSTRUCTIONS

Page 17

GAGGIA ANIMA 03 USER INSTRUCTIONS

Pag. 1/3

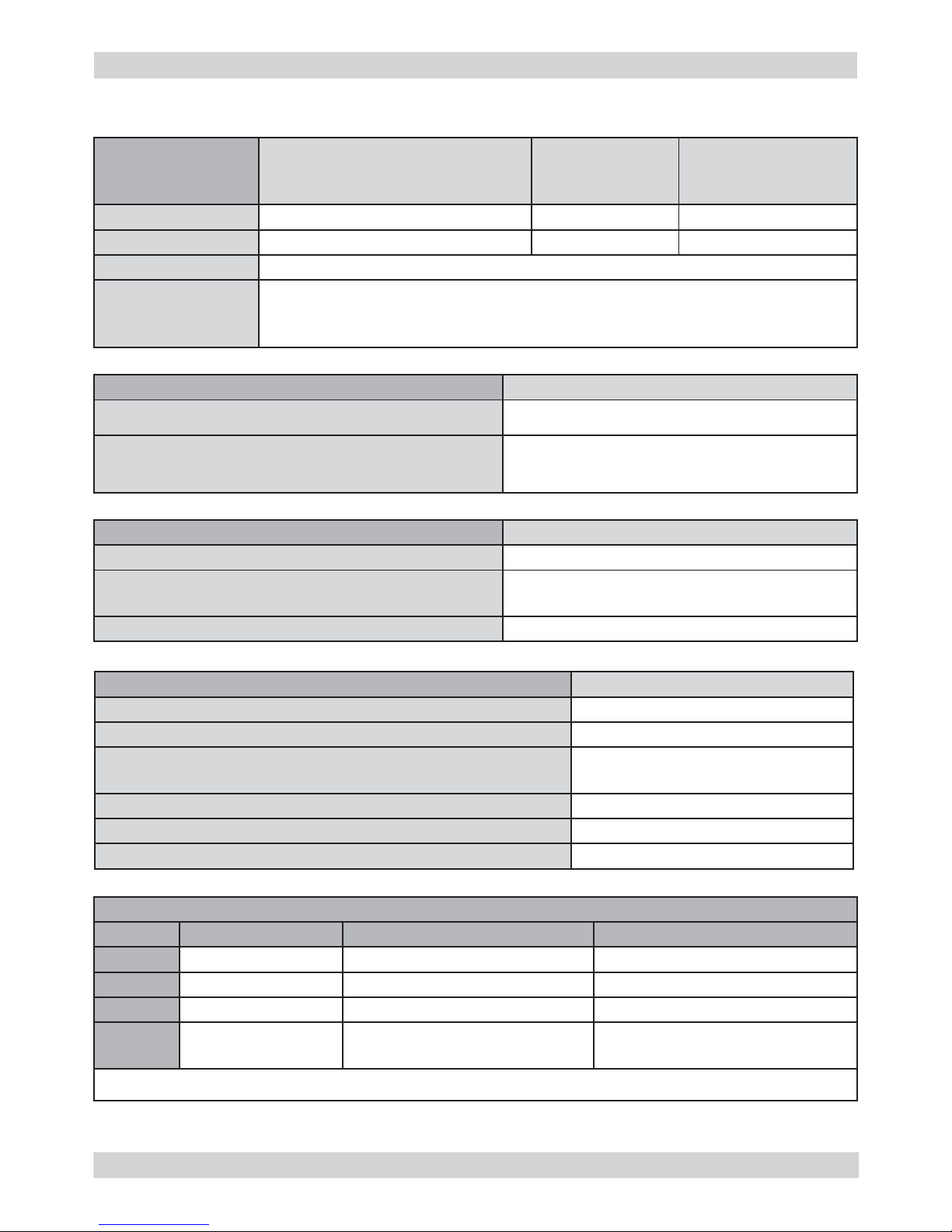

Display Setting Setting Value Description

Coffee

temperature

average

Coffee brewing temperature setting.

Stand-by

time

15 minu-

tes

Stand-by time setting.

Contrast average Display contrast setting.

Water

hardness

4 (very

hard

water)

Water hardness setting.

INTENZA+

water fi lter

OFF (not

installed)

INTENZA+ settings.

3.1. Customer menu

List of default settings

Changing the default settings

It is possible to customise the machine functions through the programming

menu. The machine must be turned on and ready to work.

If necessary, refer to the “8.1 List of default settings” chapter.

Press the MENU button and scroll through functions list to select the

function whose settings are to be modifi ed:

Note: the images at the side refer to a sample function.

Once selected:

Press the UP button to increase the value.

Press the DOWN button to decrease the value.

Press the OK button to confi rm the change.

When the change has been implemented, the OK message will be

displayed.

The modifi ed but unconfi rmed values will not be stored.

Press the ESC button to exit the programming function.

The machine automatically exits the programming mode if no button is

pressed for 3 minutes.

Press the OK button to select the desired function

MAX

MED

MIN

COFFEE

TEMP

DISPLAY

CONTRAST

180°

60°

30°

15°

STANDBY

3

4

3

2

1

WATER

HARDNESS

DISPLAY

CONTRAST

>

>

>

>

>

>

ON

FILTER

FILTER

WATER

FILTER

OFF

Page 18

GAGGIA ANIMA 03 USER INSTRUCTIONS

Pag. 2/3

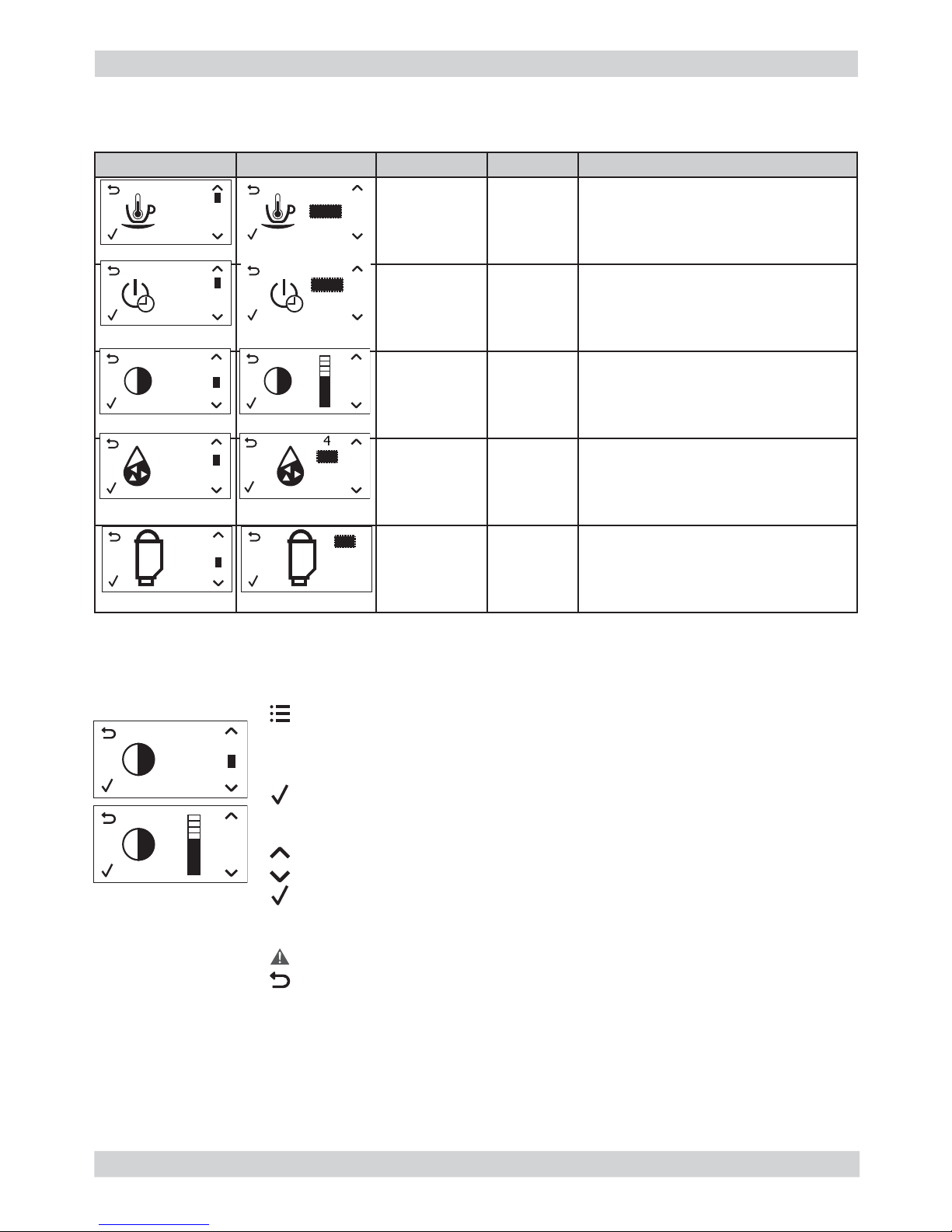

Reset to the default settings

Alarm signals summary: red display

Warnings signals summary

It is possible to restore the default settings through the programming

menu. The machine must be turned on and ready to work.

Press the MENU button and scroll through functions list to select the

RESET function.

Press the OK button to select the function.

When the change has been implemented, the OK message will be

displayed.

Press the ESC button to exit the programming function.

The machine automatically exits the programming mode if no button is

pressed for 3 minutes.

>

>

RESET

>

Display Description

Put back the drip tray

and coffee grounds

drawer; close the

service door.

Coffee bean

hopper empty.

Brew group not

inserted.

The machine is

out of service.

Display Description

Coffee grounds

drawer full.

Water tank empty.

XX

Display Description

The machine is ready to

brew products: coffee

bean hopper empty

The machine is ready to

brew products: replace

the INTENZA+

water fi llter.

The machine is waiting

to start the water circuit

priming process.

The milk carafe ducts

should be cleaned.

Display Description

The machine must be

descaled.

The machine is heating

up.

The machine is rinsing.

Brew group rebooting.

10

CLEAN

Only OTC

START

CALC

CLEAN

FILTER

Page 19

GAGGIA ANIMA 03 USER INSTRUCTIONS

Pag. 3/3

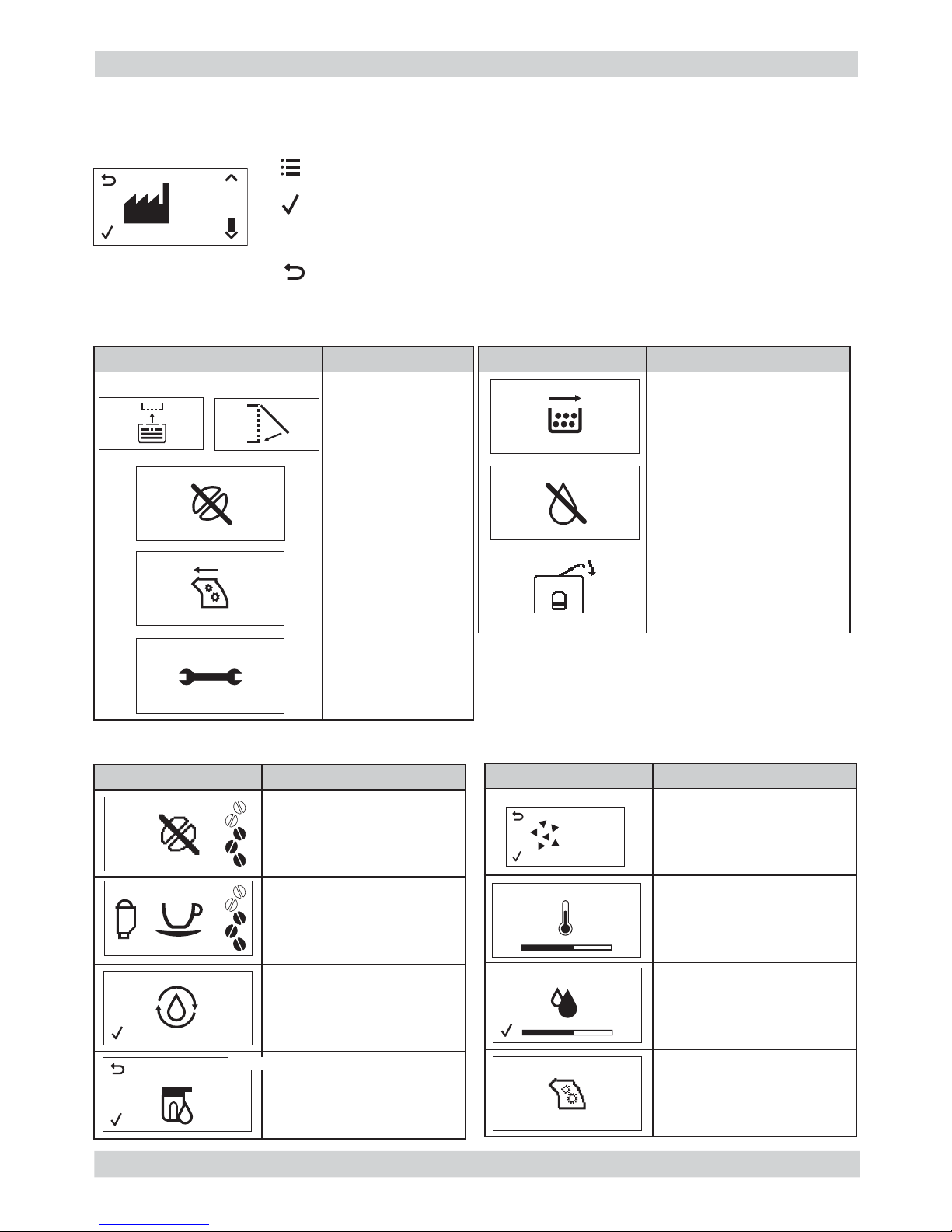

The machine is out of service

If the machine error alarm signal is triggered, the error code is

displayed in the bottom right corner of the display.

(Following table)

XX

Red Display

Error

code

Behaviour Cause Action

1

Coffee grinder

blocked

Coffee outlet duct

clogged

Clean the coffee outlet duct thoroughly.

3 - 4

Brew group locked,

cannot be taken out

The brew group is

incorrectly positioned.

Close the service door. Turn the machine off

and back on again. Wait for the ‘Ready for

brewing’ signal and then remove the brew

group.

5 Water circuit error

Air in the water

circuit

Remove and restore the water tank a couple

of times, making sure to position it correctly.

Check that the water tank seat is clean.

3.2. Operation, cleaning and maintenance

Operating the machine

1 Fill water tank

2

Fill the coffee bean hopper

3 Switch on the appliance

4

Press the button to start

the appliance

5 Heating When the heating phase begins, wait for it to fi nish

6 Rinse Carry out a rinse cycle for the internal circuits

7 Machine ready The machine is ready to dispense beverages

CLEANING AND TECHNICAL SERVICING

A Empty the dregs drawer When indicated

B Empty the drip tray As necessary

C Clean the water tank Weekly

D Clean the coffee bean hopper As necessary

E Clean the casing As necessary

F

Clean the brewing unit Every time the coffee bean hopper is fi lled or weekly

Lubricate the brewing unit

After 500 dispensing cycles or when the grease is

no longer present on the brewing unit

Clean the unit housing Weekly

H Descaling When indicated

Page 20

GAGGIA ANIMA

CHAPTER 4

OPERATING LOGIC

Page 21

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 1/10

4.1. Water circuit

Water

Hot water /steam

Pump

Safety valve

Water

discharge

Steam pipe

Water tank

Two-way solenoid valve

Brewing Unit

Flowmeter

Boiler

Flowmeter

Steam and hot water

Two-way solenoid valve

Pump

Brewing Unit

Boiler

Safety valve

Water

discharge

Water tank

Page 22

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 2/10

4.2. Milk Carafe

1) Steam input

2)Bring the cappuccino maker into dispensing

position

3) Milk tank

1

2

3

The steam passes

through the pipe creating

a sucking effect that pulls

the milk upwards

Steam

The milk is heated by the

steam and taken towards

the emulsion chamber

where it is mixed with

air and transformed into

foam

Page 23

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 3/10

Switching on

When the machine is switched on, the gear motor repositions itself as follows:

- It acts on microswitch 1

- The gear motor changes its rotation direction and moves upwards again by approx. 1-2 mm.

- The boiler begins to heat the water for approx. 45 sec., at full power, in order to reach the

optimal temperature. The temperature will then remain at a constant level.

An NTC is used as a temperature sensor; in the event of overheating this reduces boiler element

power consumption.

The electronic system detects the current boiler temperature from the drop in voltage of the

sensor and adjusts it accordingly.

Heating element values and corresponding temperatures: see table.

4.4. Temperature sensor (adjustment)

Temp. (°C) R nom (kΩ) ΔR (+/- %)

20 61.465 8.6

50 17.599 5.9

75 7.214 4.1

80 6.121 3.7

85 5.213 3.4

90 4.459 3.1

100 3.3 2.5

125 1.653 3.9

150 0.893 5.1

4.3. Single microswitch

The gear motor is powered by a direct current motor that engages with the smaller

double toothed wheel using a worm screw.

The unit is mounted on the axle of the large

gear wheel and when a coffee is requested, it

moves from the standby position to the dispensing position, and then back to the standby position again.

- Standby position: 1

- Dispensing position: 2

2

1

Page 24

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 4/10

4.5. Coffee grinder only for 120v

2

3

4

5

6

1

4.6. Detection of coffee bean absence, dose adjustment,

blocked coffee grinder

t1

V

t2

t3

t4

t

Without beans n=100%

With beans n=100%

Without beans n=50%

With beans n=50%

The coffee grinder is activated by a direct current motor (1) via helicoidal wheel transmission and

a worm screw (2).

The worm screw (2) activates a plastic toothed wheel (3), which turns the lower grinder blade (4)

and the increment pin (5).

There are two magnets (6) in the toothed wheel and with every rotation they transmit two pulses

to a Hall sensor, which in turn transmits them to the electronic system.

No coffee

When no coffee beans are present, this is detected by the Hall

sensor due to variations in the pulse frequency (with or without

coffee).

If there are no coffee beans (operation while empty), the number

of rotations and therefore the number of pulses, will be greater

t1 = no coffee signal

If there are coffee beans, the number of rotations will be

lower due to the force created during the grinding process

t2 = no signal

t3 and t4 = this reading is taken

at the end of each grinding process

Dose quantity adjustment

The dose quantity is adjusted in accordance with the pulses

detected

(number of rotations proportional to the weak, medium and

strong fl avour selection)

Blocked grinder blades

If the coffee grinder is blocked for any reason, pulses will no

longer be transmitted to the electronic system and the grinder

stops

Page 25

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 5/10

4.7. Dose self-learning (SAS) only for 120v

The aim of this function is to automatically regulate the average dose of ground coffee (SELFLEARNING); this takes place with an algorithm based on the following values and setting by the

user:

1. Number of coffee grinder pulses during the grinding cycle.

2. Max. average value of the power consumed by the gear motor during the coffee brewing cycle.

3. Aroma selected by the user.

The algorithm compares the maximum average value of the power consumed by the gear motor

with the value listed in the table for the selected aroma, in order to calculate the new grinding

pulse value for the next coffee produced.

If the power consumption value is less than the minimum current value, the grinding pulses will

be increased by 2.

If the power consumption value is greater than the maximum current value, the grinding pulses

will be decreased by 4.

If the power consumption value falls within the “over-torque” interval, the product will be dispensed and the grinding pulses will be decreased by 10.

If the power consumption value falls within the “abort cycle” interval, the dreg will be expelled

and the grinding pulses will be decreased by 10.

If the “pre-ground” fl avour is selected by the user, no modifi cation will be made.

This guarantees that, regardless of the coffee type used, the grinding level setting

and the wear on the grinders, the ground coffee dose always remains constant.

Important:

For perfect operation, machine adjustment should take place in the area of the fi elds

highlighted in green (A, B, C). When the type or brand of coffee is changed, there may be

variations in the size of the beans and their stickiness or roasting level. This leads to variations

in power consumption (mA), with resulting excessive or insuffi cient doses (until the necessary

adjustments have been made to compensate for this change).

Caution: In the case of excessive dosage, powder may be expelled into the dreg

drawer. This is not a fault, but can occur during preliminary operation or after a

service.

DOSE ADJUSTMENT (NUMBER OF GRINDER IMPULSES)

TO APPLY TO MED AROMA

3 levels 5 levels +2 0 -4 -10

-10 and

CYCLE

ABORTED

Aroma

of the

grinded

product

Light Very Light

MAX_CURRENT_mA

<150mA

<=150mA

MAX_CURRENT_mA

<=250mA

MAX_CURRENT_mA

>250mA

MAX_CURRENT_mA

>800mA

MAX_CURRENT_mA

>1000mA

Med

Light

MAX_CURRENT_mA

<250mA

<=250mA

MAX_CURRENT_mA

<=350mA

MAX_CURRENT_mA

>350mA

MAX_CURRENT_mA

>800mA

MAX_CURRENT_mA

>1000mA

Med

Strong

Strong

MAX_CURRENT_mA

<350mA

<=350mA

MAX_CURRENT_mA

<=500mA

MAX_CURRENT_mA

>500mA

MAX_CURRENT_mA

>800mA

MAX_CURRENT_mA

>1000mA

Very Strong

A

B

C

Page 26

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 6/10

4.8. Coffee grinder

2

3

4

5

1

The coffee grinder is driven by a direct current motor (1) using a worm screw helicoidal wheel

transmission (2).

The worm screw (2) drives a plastic gear wheel (3), which turns the lower grinder (4) and the

increment pin (5)

4.9. Autodose system description

mA

I

0

I0 + 100

I

0 + 55

I

0 + 200

Aroma 4/5

Aroma 2/3

Aroma 1

Auto-Zero

100≤ I

0 ≤300

I0 = current when the BU is moving without load, i.e. without coffee. It occurs, for example, dur-

ing the rinsing phase of coffee spout.

Current targets:

Aroma 1 55mA

Aroma 2/3 100mA

Aroma 4/5 200mA

100 mA ≤ I0 ≤ 300 mA

If the BU current is ≤ the current target the grinding time

If the BU current is ≥ the current target the grinding time

Page 27

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 7/10

The machine uses an ALGORITHM that considers the current absorbed by the coffee grinder,

beside it considers if the grinder is old or new and if it is warm or cold.

1) When the system get the stability (i.e. the system got the current target) the coffee doses

should be:

A1 A2/3 A4/5

7,5 9,0 10 ±1,5 grams

with medium grinding (500±60μm) and using coffee of test.

2) the 3 grinding times are always:

T

1<T2<T3

beside, every grinding time is, respectively:

4,0s ≤T3 ≤10s (10000ms)

3,5s ≤T2 ≤9s (9000ms)

3,0s ≤T1 ≤8,1s (8100ms)

4.10. Coffee lack detection and coffee grinder blocked

DOSE ADJUSTMENT

5 levels

Grinder

Time

Min

Grinder

Time

Max

Grinder

Time

Curret target

Aroma

of the

grinded

product

Aroma1

Very Light

T1 3s 8,1s I0 + 55mA

Aroma2

Light

T2 3,5s 9s I0 + 100mA

Aroma3

Med

Aroma4

Strong

T3 4s 10s I0 + 200mA

Aroma5

Very Strong

Page 28

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 8/10

4.11. Coffee cycle

Notes: * Only with Pre-brewing

Switching on

When the machine is switched on, the gear motor repositions itself as follows:

- It acts on microswitch 1 (see following chapter).

- The gear motor changes its rotation direction and moves upwards again by approx. 1-2 mm.

- The boiler begins to heat the water for approx. 45 sec., at full power, in order to reach the

optimal temperature. The temperature will then remain at a constant level.

Coffee cycle

1. The coffee grinder starts the grinding process (controlled by Time).

2. The gear motor (brewing unit) moves to the brewing position.

3. Preliminary dispensing phase (short pump activity, short pause).

4. Product dispensing (the pump operation period is defi ned by the amount of product dis-

pensed).

5. The gear motor moves to its home position (the dregs are expelled automatically).

Main switch ON START STOP

Time

Coffee grinder

Heating

Pump

Brewing unit gear

motor

Status Heating Ready Coffee cycle

Time

(Dosage)

Pump operation (fl ow

meter pulses) in

accordance with the

amount of product

selected.

approx.

45 sec.

*

Single microswitch gear motor

Status

Microswitch

OFF

ON

Page 29

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 9/10

4.12. Water level detection (water tank)

“Water low” message (water reserve)

Function:

The water level is monitored by a capacitative sensor, located one

third of the way up the water tank wall.

If the electronics assembly detects, by means of the sensor,

that the amount of water in the tank has dropped below the

above mentioned level, a water reserve remains available for

the dispensing process underway (this will cover 200 fl ow meter

pulses).

The product dispensing process will then come to an end.

If a dispensing cycle ends after the sensor has been triggered (in

the reserve) then the display “Water low” continues to be displayed

during the following dispensing cycle.

200 puls.

Sensor

Water tank

“Descaling” – message with water fi lter

inserted

(appliances with display only)

The water hardness is set on the basis of the

regional water hardness analysis

(1, 2, 3, 4).

Filter off:

If the function is turned o the electronics

assembly monitors the fl ow meter pulses,

recording one pulse each turn.

Filter on:

If the function is turned on the electronics

assembly monitors the fl ow meter pulses,

recording one pulse every two turns.

“Change water fi lter” message

The electronics assembly uses the fl ow meter

impulses to keep track of the amount of water

which has fl owed through; after the specifi ed

amount (set in accordance with the water

hardness level), the “Replace fi lter” message

appears.

4.13. Descaling request

360°

1 rev

Number of pulses

Filter

on

Filter

off

Flow meter pulses

Page 30

GAGGIA ANIMA 04 OPERATING LOGIC

Pag. 10/10

Bypass

4.14. Water fi lter

Function:

• Reduced limescale deposits which take longer to form.

• Improved water quality.

• Improved taste due to the ideal water hardness.

Life span / descaling performance:

• - 10 ° dH

• 60 litres

• 2 months

To achieve the best possible operating mode consistency

over the total life span, the water is channelled using

a 3-stage bypass (A, B, C) depending on the degree of

hardness. See small image.

Page 31

GAGGIA ANIMA

CHAPTER 5

TROUBLESHOOTING

Page 32

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 1/9

5.1. Test Mode

The Test Mode is organized into 6 different pages, each level the coffee machine can execute

different commands:

Page 0: The display shows:

a) Firmware version.

b) Version of machine (Focus ⇒ CMF, Class ⇒ AMF, Top ⇒ OTC).

c) Voltage of PCB.

d) Main supply frequency (50 or 60 Hz).

Page 1: Keyboard and display’s colour test:

a) Z1 button

b) Z2 button

c) Z3 button

d) Z4 button

e) Z5 button

f) Z6 button

g) Z7 button

h) Backlight colors

Page 2: Input signals test:

a) Water level sensor

b) Micro-switch door closed/opened

c) Microswitch presence of the Brew Unit

Page 3: Low voltage loads test:

a) Brew Unit movement upward and downward (24V DC)

Page 4: High/Low voltage loads test (Pump, E.Valve ) :

a) Pump (230V AC)

b) DC Solenoid valve (24V) ( The door must be closed !!)

c) Flow-meter

Introduction

This document describes the Test Mode of the Anima (CMF,AMF, OTC and XL) Coffee Machine.

This application is used in order to test the machine in its mechanics and electronic components.

To enter Test Mode

The machine enters in Test mode by holding pressed together Z1 and Z6 buttons while switching

on the machine by the main switch on the backside of the CA.

Once entered in Test Mode, the display shows the fi rmware version (Level 0).

Z1

Z2

Z3

Z6

Z7

Z5

Z4

Page 33

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 2/9

Verify the fi rmware version

Verify the fi rmware version

Page 0 (FIRMWARE)

Page 0 (FIRMWARE)

Firmware version on the display.

Firmware version on the display.

The machine model is shown

The machine model is shown (Focus ⇒CMF, Class ⇒AMF, Top ⇒OTC)..

The voltage of the main supply “230V”

The voltage of the main supply “230V”

The frequency of the main supply is shown (50 or 60 Hz)

The frequency of the main supply is shown (50 or 60 Hz)

The fi rmware version is the same as the label on MicroController

The fi rmware version is the same as the label on MicroController

ERROR: The fi rmware version is different from the label on MicroController;

change the CPU_POWER Boards !

ERROR:

ERROR:

If in machine model fi eld is written “Unknow” and backlight of display is Red, check the

If in machine model fi eld is written “Unknow” and backlight of display is Red, check the

jumper in interface.

jumper in interface.

The machine passes to the Page 1 (KEYBOARD)

The machine passes to the Page 1 (KEYBOARD)

ERROR: The page does not change; Check the interface board and

the fl at cable (JP21)

Press

Press Z7Z7

“

“

” to move to the next screen

” to move to the next screen

Page 5: High voltage loads test (Heater , Grinder ):

a) Heater (230V AC)

b) Grinder (320V DC)

The user can change the page by pressing the Z7 button.

Page 0 is accessible only entering Test Mode from power-off mode; at the start up all loads are

turned off.

TEST MODE Level0

TEST MODE Level1

TEST MODE Level2

TEST MODE Level3

TEST MODE Level4

TEST MODE Level5

Pressing button Z7

Pressing button Z7

Pressing button Z7

Pressing button Z7

Pressing button Z7

Pressing button Z7

Page 34

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 3/9

Press buttons from 1 to 7

Press buttons from 1 to 7

Only when a button is pressed a O appears on the relative position

of button pressed.

In the middle of display appears the name of the button pressed and

the backlight color changes from WHITE to RED.

When a button is pressed, also the Stand-By led (RED) turn ON.

Note: Press button Z7 as the last once, since it makes

change the test page.

Note: If 2 or more buttons are pressed the name that appears

on display could be wrong.

ERROR:

ERROR:

If nothing appears on display; check the interface board and the fl at cable (JP21).

If nothing appears on display; check the interface board and the fl at cable (JP21).

ERROR:

ERROR:

If during the movement the backlight remain WHITE check the wiring (JP1) from the

If during the movement the backlight remain WHITE check the wiring (JP1) from the

interface board and the display.

interface board and the display.

ERROR:

ERROR:

The name displayed is wrong; check the position of jumper in interface in JP5. It must

The name displayed is wrong; check the position of jumper in interface in JP5. It must

be the same of machine model.

be the same of machine model.

The machine passes to the level 2 (INPUTS)

The machine passes to the level 2 (INPUTS)

Insert a full Water Tank.

Insert a full Water Tank.

The indication H20 changes from “N” to “Y”.

The indication H20 changes from “N” to “Y”.

NOTE:

NOTE:

the switching from “N” to “Y” requires about 1-2 seconds.

the switching from “N” to “Y” requires about 1-2 seconds.

ERROR:

ERROR:

The indication TANK-H2O doesn’t change; check the ca-

The indication TANK-H2O doesn’t change; check the ca-

pacitive sensor (fi xing) and the wiring (JP23)

pacitive sensor (fi xing) and the wiring (JP23)

Page 1 (KEYBOARD)

Page 1 (KEYBOARD)

Page 2 (INPUTS)

Page 2 (INPUTS)

Start condition

Start condition

Start condition

Start condition

Press

Press Z7Z7

“

“

” to move to the next screen

” to move to the next screen

Page 35

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 4/9

Insert the BrewUnit

Insert the BrewUnit

The indications

The indications

BU-P

BU-P

changes from “N” to “Y”.

changes from “N” to “Y”.

Note:

Note:

removing the BrewUnit the indication from “Y” to “N” requires

removing the BrewUnit the indication from “Y” to “N” requires

about 2-3 seconds to switch.

about 2-3 seconds to switch.

ERROR: Check the BU presence Microswitch and the wiring (JP16).

Close the Door and Dreg Drawer

Close the Door and Dreg Drawer

The indication

The indication

DOOR

DOOR

change from “N” to “Y”

change from “N” to “Y”

ERROR: The indication DOOR does not change; check

the Microswitch for the door and the wiring (JP14).

Note: without the Dreg Drawer correctly inserted the DOOR indication cannot change!

The machine passes to the Page 3

The machine passes to the Page 3

(BU PAGE)

(BU PAGE)

Press

Press Z7Z7

“

“

” to move to the next screen

” to move to the next screen

Page 3 (BU)

Page 3 (BU)

Start condition

Start condition

Press the Z1 button to move the BU to Work

Press the Z1 button to move the BU to Work

IMPORTANT NOTE: If the DREGDRAWER is not inserted or the

DOOR is not closed the BU test cannot be performed. If these 2

inputs are not in the right position, a warning message will be

shown and the display turns to red.

When the BU reaches the work position the indication

When the BU reaches the work position the indication

WORK

WORK

chang-

chang-

es from “N” to “Y”, the number of the current is less than 200mA

es from “N” to “Y”, the number of the current is less than 200mA

(without BU) or 300mA (with BU).

(without BU) or 300mA (with BU).

ERROR:

ERROR:

The indication

The indication

WORK

WORK

doesn’t change and remain “N”,

doesn’t change and remain “N”,

the display backlight changes from white to red; Check the work

the display backlight changes from white to red; Check the work

microswitch (broken?), the BU motor (blocked?) and the wiring

microswitch (broken?), the BU motor (blocked?) and the wiring

(JP16).

(JP16).

ERROR:

ERROR: ((

Without BU

Without BU

) The absorbed current is more than

) The absorbed current is more than

200mA, the display backlight changes from white to red; check the

200mA, the display backlight changes from white to red; check the

BU and the motor.

BU and the motor.

Page 36

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 5/9

ERROR:

ERROR:

(With BU)

(With BU)

The absorbed current is more than 300mA,

The absorbed current is more than 300mA,

the display backlight changes from white to red; check the BU and

the display backlight changes from white to red; check the BU and

the motor

the motor

Press the Z3 button to move the BU to Home

Press the Z3 button to move the BU to Home

When the BU reaches the home position the indication HOME

changes from “N” to “Y”, the number of the current is minus than

200mA (without BU) or 300mA (with BU).

ERROR:

ERROR:

The indication

The indication

HOME

HOME

doesn’t change and remain “N”,

doesn’t change and remain “N”,

the display backlight changes from white to red; Check the work

the display backlight changes from white to red; Check the work

microswitch (is broken), the BU motor (is blocked) and the wiring

microswitch (is broken), the BU motor (is blocked) and the wiring

(JP16

(JP16

ERROR:

ERROR:

(Without BU)

(Without BU)

The absorbed current is higher than

The absorbed current is higher than

200mA, the display backlight changes from white to red; check the

200mA, the display backlight changes from white to red; check the

BU and the motor.

BU and the motor.

ERROR:

ERROR:

(With BU)

(With BU)

The absorbed current is higher than 300mA,

The absorbed current is higher than 300mA,

the display backlight changes from white to red; check the BU and

the display backlight changes from white to red; check the BU and

the motor.

the motor.

Press

Press Z7Z7

“

“

” to move to the next screen

” to move to the next screen

Press the Z1 button to open the Electro Valve

Press the Z1 button to open the Electro Valve

IMPORTANT NOTE: If the DREGDRAWER is not inserted or the

DOOR is not closed the EV test cannot be performed. If these 2

inputs are not in the right position, a warning message will be

shown and the display turns to red.

Start condition

Start condition

The machine passes to the Page 4

The machine passes to the Page 4

(EV - PUMP)

(EV - PUMP)

Page 4 (EV - PUMP)

Page 4 (EV - PUMP)

Page 37

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 6/9

Press and Release the Z4 button to switch on the pump (100

Press and Release the Z4 button to switch on the pump (100

impulses)

impulses)

The water goes out from the pipe and the indication

The water goes out from the pipe and the indication

IMP

IMP

shows

shows

increasing numbers. The indication L/H must be within the range

increasing numbers. The indication L/H must be within the range

10-18.

10-18.

ERROR:

ERROR:

The display backlight changes from white to red and the

The display backlight changes from white to red and the

impulse remains 0; If water comes out the pipe: check the wiring

impulse remains 0; If water comes out the pipe: check the wiring

from the fl owmeter to the CPU/POWER board (JP5). If no water

from the fl owmeter to the CPU/POWER board (JP5). If no water

comes out the pipe: check the pump and the wiring from the pump

comes out the pipe: check the pump and the wiring from the pump

to the CPU/POWER board (JP24).

to the CPU/POWER board (JP24).

ERROR:

ERROR:

The L/H is zero or very low; the Electro Valve does not

The L/H is zero or very low; the Electro Valve does not

open. Check the wiring from the Electro Valve to the CPU/POWER

open. Check the wiring from the Electro Valve to the CPU/POWER

board (JP3) and the Electro Valve.

board (JP3) and the Electro Valve.

The machine passes to the level 5 (Heater-Grinder)

The machine passes to the level 5 (Heater-Grinder)

It is possible to hear the “click” from Electro Valve. The indication

It is possible to hear the “click” from Electro Valve. The indication

beside the

beside the

EV1

EV1

changes from “OFF” to “ON”.

changes from “OFF” to “ON”.

Press

Press Z7Z7

“

“

” to move to the next screen

” to move to the next screen

Press the Z4 button to switch on the grinder.

Press the Z4 button to switch on the grinder.

The grinder rotates and in the indication

The grinder rotates and in the indication

GRINDER

GRINDER

the number

the number

increasing up to 5000 (5seconds test). The other numbers inside the

increasing up to 5000 (5seconds test). The other numbers inside the

GRINDER

GRINDER

box are not important for this test.

box are not important for this test.

ERROR:

ERROR:

The number remains 0 or the grinder does not run, the

The number remains 0 or the grinder does not run, the

display backlight changes from white to red; check the Grinder and

display backlight changes from white to red; check the Grinder and

the wiring from the Grinder to the CPU/POWER board (JP8)

the wiring from the Grinder to the CPU/POWER board (JP8)

Check the temperature

Check the temperature

The number shows the heater temperature.

ERROR:

ERROR:

In the indication

In the indication

HEATER

HEATER

appears

appears

“SHORT”

“SHORT”

, the

, the

NTC

NTC

temperature-sensor is shorted, the display backlight changes from

temperature-sensor is shorted, the display backlight changes from

white to red; check the wiring from the NTC temperature-sensor to

white to red; check the wiring from the NTC temperature-sensor to

the CPU/POWER board (JP13).

the CPU/POWER board (JP13).

Page 38

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 7/9

Press the Z1 button to switch on the Heater

Press the Z1 button to switch on the Heater

The absorbed current ( Amperometer on the main supply) is OK, the

The absorbed current ( Amperometer on the main supply) is OK, the

indication

indication

HEATER

HEATER

changes from “OFF” to “ON” and the temperature

changes from “OFF” to “ON” and the temperature

starts increasing.

starts increasing.

If temperature is over 100°C, the backlight change from WHITE to

If temperature is over 100°C, the backlight change from WHITE to

RED. This is a ALERT message to avoid heating the HEATER element over

RED. This is a ALERT message to avoid heating the HEATER element over

dangerous temperature.

dangerous temperature.

ERROR:

ERROR:

the absorbed current is KO or the temperature does not

the absorbed current is KO or the temperature does not

increase; check the wiring from the heater to the CPU/POWER

increase; check the wiring from the heater to the CPU/POWER

board (JP19) and the wiring of the NTC temperature-sensor (JP13).

board (JP19) and the wiring of the NTC temperature-sensor (JP13).

5.1.1. SteamOut

To enter in SteamOut

The machine enters in Steam-Out mode by holding pressed together:

the “ESPRESSO LUNGO” button and the MENU button;

while switching on the machine by main switch behind the machine.

This document describes the Steam-Out procedure; the application is used in order to empty the

heater.

ERROR:

ERROR:

In the indication

In the indication

HEATER

HEATER

appears

appears

“OPEN”

“OPEN”

, the

, the

NTC

NTC

temperature-sensor is detached or broken, the display backlight

temperature-sensor is detached or broken, the display backlight

changes from white to red; check the wiring from the NTC

changes from white to red; check the wiring from the NTC

temperature-sensor to the CPU/POWER board (JP13).

temperature-sensor to the CPU/POWER board (JP13).

Once entered the Steam Out mode the display shows the “STEAM

OUT” indication. Buttons can be released

IMPORTANT NOTE: to execute the Steam-out procedure the Ntc

sensor must work correctly; if some errors occurs on Ntc during the

steam-out, the procedure can’t continue and an error message is

shown on the display.

Page 39

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 8/9

IMPORTANT NOTE: to execute the Steam-Out procedure the

DREGDRAWER must be in place and the DOOR must be closed.

If these 2 conditions are not respected a warning message is shown

on the display and the Steam-Out is interrupted.

The machine starts the Steam Out and in the display appears the

indication “ON”.

While the Steam Out runs the Electro valve is opened and water

comes out the Water/Steam pipe.

When the Steam Out is complete the message “COMPLETE” is

shown on the Display.The Electro valves automatically closes and the

machine can be switched off.

When the Steam-Out is complete the following parameters are reset to their default values:

Length “Espresso” product (Default 145 impulses)

Length “Espresso Lungo” product (Default 345 impulses)

Length “Cappuccino” (Coffee + Milk product) (Default 170 impulses coffee & 34sec milk)

Length “Milk” product (Default 34 seconds)

Stand-By Time (Default 15 minutes)

Count Coffee (Default 0)

The request for Priming the Circuit at the fi rst switch on is set.

Brewing Unit Empty

Aroma Strength (Default 3 beans)

BU current array (BU during rinsing) (Default 150mA)

Grinder Sensing Array Default 2000ms)

Grinding time Aroma Very Light (1 Bean) (Default 3000ms)

Grinding time Aroma Light/Medium (2/3 Beans) (Default 3500ms)

Grinding time Aroma Strong/Extra Strong

(4/5 Beans)

(Default 4000ms)

Filter Presence (Default OFF)

Filter Pulses (Default 0)

Last Error Log (Default 0)

Coffee Duct Empty = TRUE (To grind more fi rst time after steam-out and refi ll duct with coffee)

Page 40

GAGGIA ANIMA 05 TROUBLESHOOTING

Pag. 9/9

ERROR

ERROR

CODES

CODES

DESCRIPTION

DESCRIPTION

01

01

The coffee grinder is blocked

02

02

The grinder is disconnected

03

03

The brewing unit is blocked in work position

04

04

The brewing unit is blocked in home position

05

05

The hydraulic circuit is clogged

10

10

The temperature sensor is in short circuit

11

11

The temperature sensor is opened

14

14

The temperature was up to 170°

15

15

The machine doesn’t heat up

19

19

The net is not stable

22

22

The keyboard is not recognized

5.2. Error codes

Page 41

GAGGIA ANIMA

CHAPTER 6

STANDARD CHECKS

Page 42

GAGGIA ANIMA 06 STANDARD CHECKS

Pag. 1/2

Action

1 Visual inspection (transport damage)

2 Machine data check (rating plate)

3 Operational check / problem analysis

4 Opening machine

5 Visual inspection

6 Operational tests

7 Repairing the faults encountered

8 Checking any modifi cations (view Symptom Cure, new software, etc.)

9 Service activities in accordance with the operating schedule

10 Internal cleaning

11 Operational test while the appliance is open

12 Assembly

13 Final inspection test

14 Draining the circuit (in winter)

15 External cleaning

16 Lubricating the brewing unit with suitable grease

17 Insulation test HG 701 (dielectric)

18 Documentation

S Replacement P Cleaning

ES Visual inspection TR Noise test

D Descaling R Adjustment

Component Action Support/tool

Water fi lter P/S

Water tank lip seal S

Boiler pin O-ring S

Brewing unit ES/P Grease solvent / Grease

Hoses, attachments and Oetiker clamps ES

Pump ES/TR

Gear motor ES/TR

Coffee grinder P/R Vacuum cleaner / brush

Water circuit D Saeco descaler

Hot water/steam valve ES/S

6.2. Service schedule

6.1. Repair schedule

Page 43

GAGGIA ANIMA 06 STANDARD CHECKS

Pag. 2/2

Test Procedure

Support/

tool

Standard Tolerance

Espresso

2-3 Espressos for

adjustment purposes

Measuring

scoop

Same amount 15%

Coffee

2-3 Coffees for

adjustment purposes

Measuring

scoop

Same amount 15%

Noise Standard

Amount of

cream

Blow into the cup until

the cream separates

The cream should

come together

again to form a

complete layer

Cream colour Hazel brown

Grinding level

Check the grain size of

the ground coffee

Hot water Dispense water

Steam Dispense steam

Dreg drawer

missing

indication

Remove the dreg drawer

Dreg drawer

missing indication

Low bean level

indication

Start brewing a coffee

while the coffee bean

hopper is empty

Low bean level

indication

6.3. Final test

Page 44

GAGGIA ANIMA

CHAPTER 7

DISASSEMBLY

Page 45

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 1/9

7.1. Outer Shell

Remove the water tank, coffee container cover,

drip tray, dreg drawer, brewing unit.

Cover a screwdriver with

adhesive paper to prevent

scratching the chromed

shell.

Remove the cover as in the

photo. In case of any issues

please you can try with the

alternative way below described.

Remove the cover as

in the photo.

Unscrew the screw

shown and remove

the cover.

Unscrew the screws shown

Unscrew the screw shown

Press the sides and remove the cover and

dispenser. Insert as before to reassemble the

dispenser in the rail and then the coverage.

Remuve the cap, unscrew the screw

shown and remove the steam tube.

Anima OTC

Anima XL

Upper cover

2

3

1

Page 46

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 2/9

7.2. Dispenser

Unscrew the screws shown

Unscrew the screws shown and

remove the dispenser

unlock where highlighted and remove the cover in the dispenser

Remove the insert the upper cover

Remove the support KYB assy.

and disconnect the fl at cable.

Remove the upper cover and remove the electrical and

water circuit connections.

remove the block support

KYB assy.

Page 47

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 3/9

7.3. Coffee grinder

Raise the coffee grinder and remove the connections.

When reassembling the coffee

grinder, make sure the spring is

repositioned correctly (see photo).

To extract the top support of the appliance, press

on the grinding adjustment spindle (A) and turn the

support anticlockwise until it unhooks.

Turn the grinder blades anticlockwise out of the support.

Turn the grinder blades clockwise out of the support. The

bayonet connections can be accessed from the rear.

7.4. Grinder blades

A

B

Page 48

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 4/9

For a standard adjustment, both markings must be

aligned.

7.5. Coffee grinder adjustment

The grinding adjustment can be set by the user (only with the coffee grinder in operation) by

pressing and turning (only by one click at a time) the insert inside the coffee bean hopper with

the aid of the wrench supplied.

Adjustment by a service center

To adjust grinding further, the engineer can work directly on the coffee grinder by pressing and turning

the ring nut (C) shown. (clockwise + to increase the particle size of the coffee and anticlockwise - to

decrease it).

If there are any remains of coffee powder between the two grinding blades it is recommended to

tighten by max. two marks at a time.

Lastly, move the arrow (A) on the adjustment knob to the center of the adjustment dots on the

cover (B).

B

A

+

-

C

+

-

Page 49

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 5/9

Loosen the screws holding

the carafe connection

When reassembling the assembly to be

careful to correctly position the spring.

Slide out the fork

as illustrated

7.6. Carafe connection and hot/steam water dispenser

hot water dispenser

Removes the covers shown

unscrew the screws

shown

7.7. Central plate

unscrew the screws shown

Lift up the center plate

Page 50

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 6/9

7.8. Pin boiler

Loosen the screws as illustrated and

remove the boiler pin (A).

A

The following are located inside the compartment protected

by the casing:

- Electric motor (A) with gears (B) and (C) for transmission

and timing of the dispenser.

- Brewing unit present microswitch (E).

- Microswitch (D) detecting brewing unit home and work positions.

- Remove the gear (C) that meshes with the motor transmission shaft.

- Remove the large gear (B).

- Remove the motor (A), complete with transmission shaft.

Replace the gear (B), making sure that the imprint of

the arrow is aligned with the opening containing the

pin (P).

When replacing the motor and the transmission

shaft, make sure the guide runners (L) are in the

right position.

Grease the shaft thoroughly and evenly.

E

A

B

C

D

B

P

H

L

7.9. Gear motor

Loosen the screws as illustrated and

remove the gear motor cover.

Page 51

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 7/9

7.11. Flow-meter

Lift the fl ow meter out of the casing assembly and remove the electrical

and water circuit connections.

Unscrew the screw shown and remove the

electrical and water circuit connections.

Unscrew the screw shown at

unthread the support boiler

7.12. Boiler

7.10. Pump

Disconnect the water circuit connections (A) and

electrical connections (B), loosen the safety valve (C) and

slide the pump off the brackets (D).

Unhook the pump

from the supports.

C

D

D

A

A

A

B

B

B

Page 52

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 8/9

7.15. KYB interface and display

Loosen the screws slide the

card off the support and

disconnect the electrical

connections.

Loosen the screw for

remove the cover.

7.13. CPU board

7.14. Programming access for SSC (Saeco Service Center)

Remove the cover.

Unscrew the screw shown

Press the sides and remove the cover and

dispenser. Insert as before to reassemble the

dispenser in the rail and then the coverage.

Remuve the cap, unscrew the screw

shown and remove the steam tube.

Unscrew the screws shown Remove the insert the upper cover

Page 53

GAGGIA ANIMA 07 DISASSEMBLY

Pag. 9/9

Loosen the screws for

remove the cover.

Disconnect the electrical

connections.

Use a suitable pair of pliers to remove

the clamp (as illustrated).

Tighten the clamp as illustrated.

1) Boiler connection.

2) Other connections.

7.16. Fitting and removing Oetiker clamps

Remove the support KYB assy.

and disconnect the fl at cable.

Page 54

GAGGIA ANIMA

CHAPTER 8

NOTES

Page 55

GAGGIA ANIMA 08 NOTES

Pag. 1/1

Page 56

GAGGIA ANIMA

CHAPTER 9

WATER CIRCUIT DIAGRAM

Page 57

GAGGIA ANIMA 09 WATER CIRCUIT DIAGRAM

Pag. 1/1

Flow meter

Turbina

Water tank

Serbatoio

acqua

Assy Solenoid valve

Assieme Elettrovalvole

Water drain

Scarico acqua

Pump

Pompa

Boiler

Caldaia

Safety valve

Valvola di sicurezza

Boiler pin

Perno caldaia

Steam and hot water

Page 58

GAGGIA ANIMA

CHAPTER 10

ELECTRICAL DIAGRAM

Page 59

GAGGIA ANIMA 10 WIRING DIAGRAM

Pag. 1/1

Loading...

Loading...