Page 1

Gaggenau

en Installation instruction

RC 462/472

RF 411/413

RF 461/463

RF 471

RW 414/

464

Page 2

2

Page 3

Table of Content

Safety and warning information ........................... 4

Installation possibilities ........................................ 5

Stand alone appliance ............................................ 5

Side-by-Side set up ................................................ 5

Stand alone appliance with dividing wall ................. 5

Stand alone appliance as an end section

to a row of kitchen units .......................................... 5

Installing the appliance ........................................ 6

Installation location ................................................. 6

Atmosphere grades ................................................ 6

Stable installation .................................................... 6

Installation niche ..................................................... 6

Neighbouring kitchen furniture ................................ 6

Subsurface ............................................................. 6

Aligning the appliance ............................................. 7

Electrical connection ............................................ 7

1. Sliding the appliance into the

installation niche .................................... 14

2. Adjusting the appliance

in the niche ............................................ 15

3. Fastening the appliance to the

niche ceiling ........................................... 15

4. Fastening the appliance to the side wall

of the installation niche .......................... 16

5. Checking that the finger guard

moves easily .......................................... 16

1. Fastening the plinth strip ........................ 18

2. Aligning the base cover ......................... 18

3. Switching the appliance on for

the first time ........................................... 19

4. Preparing the furniture doors ................. 19

5. Loading the appliance door ................... 19

6. Removing positioning aids ..................... 20

7. Fastening the adjusting rib to the

furniture door ......................................... 20

8. Fastening the fixing rib to the

furniture door ......................................... 20

Water connection ................................................. 7

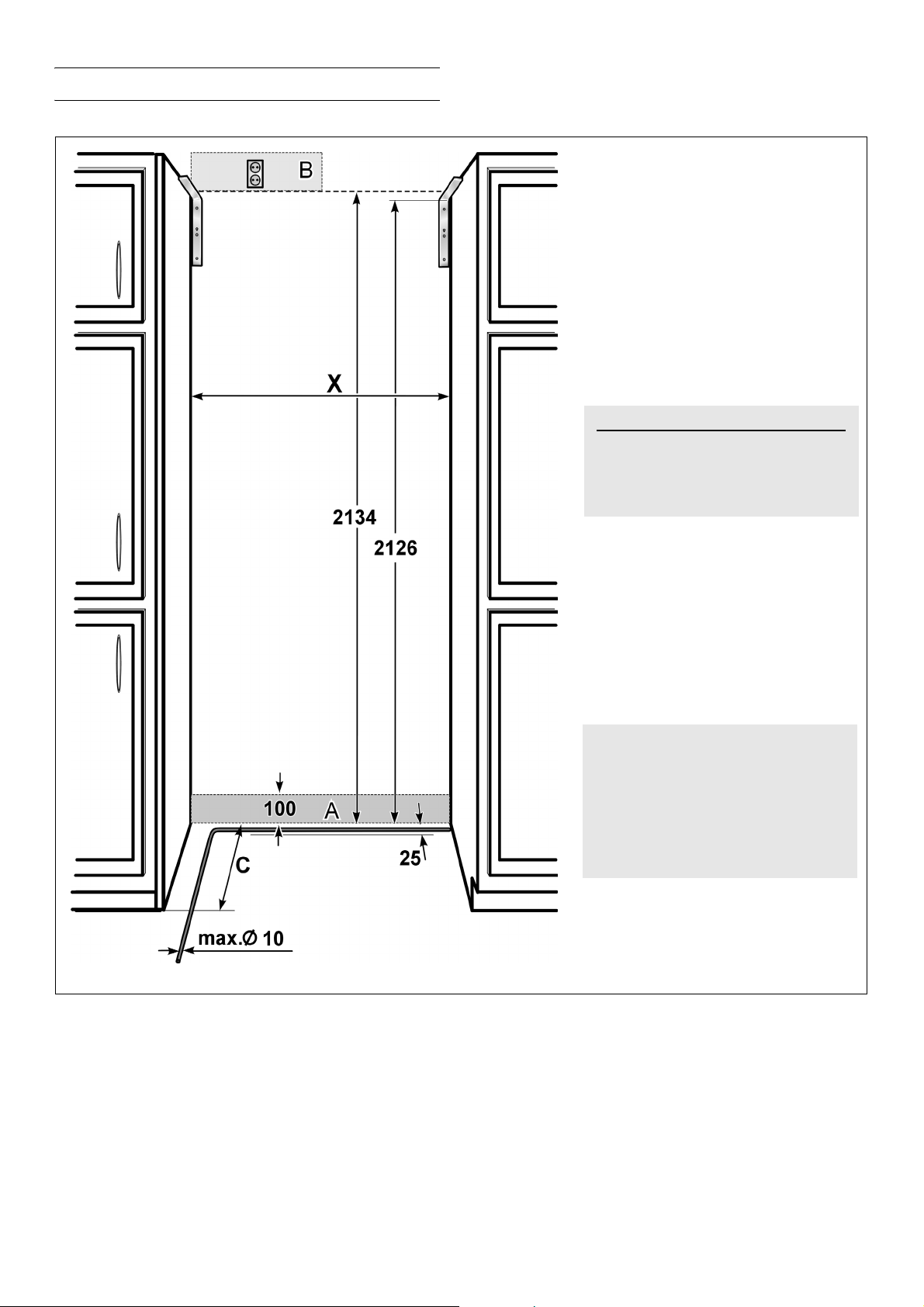

Dimensions of the installation niche .................... 8

Tools and accessories which are needed ........... 9

Scope of delivery .................................................... 9

Additional accessories ............................................ 9

Miscellaneous ......................................................... 9

Tools ...................................................................... 9

Installation manual ............................................... 10

1. Check the installation niche ................... 10

2. Removing the packaging ....................... 10

3. Transporting the appliance .................... 11

4. Installation preparation ........................... 11

5. Special installation steps ........................ 11

1. Attaching the anti-tipping brackets

to the wall .............................................. 12

2. Attaching alternative anti-tilt device ........ 13

9. Mounting the furniture door ................... 21

10. Screw on the lower fixing angle ............. 22

1. Fasten the finger protector .................... 23

2. Attaching the covers .............................. 23

3. Mounting the air seperator ..................... 24

4. Tensioning the hinge springs ................. 25

Special installation steps ..................................... 26

Changing over the door hinges ................. 26

Removing/changing the sealing mat ......... 28

Side-by-Side set up .................................. 29

Preparing the water connection ................ 31

Connecting the appliance to the

water supply ............................................. 31

Aligning ice and water dispenser .............. 32

Attaching covering strips .......................... 33

Setting the door opening angle ................. 34

3. Attaching the edge protectors ............... 13

4. Attaching the fastening sheets (lateral) ... 13

3

Page 4

Safety and warning information

These mounting instructions are designed to help you

install your new appliance.

The manufacturer cannot be held liable for mounting which

has been improperly carried out. We recommend that you

allow a qualified specialist to set up and switch the

appliance on for the first time.

Following all information and keeping to the instructions are

preconditions for mounting and switching the appliance on

safely for the first time.

Keep the mounting instructions safe for use later on.

Before setting up and switching the appliance on for the

first time, read the mounting instructions fully and

thoroughly.

ã Warning

The appliances are very heavy and must be secured

from tipping when transporting, when mounting and

when operating. It is absolutely necessary to fit an antitip device.

Keep the doors closed until the appliance has been

mounted completely and secured according to the

instructions in these mounting instructions.

Because of the weight / dimensions of the appliance

and to minimise the risk of injuries and damage to the

appliance at least two persons are necessary to set-up

the appliance securely.

Use the appliances according to the prescribed

application.

Pull out the plug or remove the fuse before

commencing work on the appliance.

Only customer service may change the power cord

and carry out any other repairs. Improper installations

and repairs may put the user at considerable risk.

Apart from statutory national regulations, you should

stick to the connection terms relating to the local

electricity and water companies.

ã Caution

Setting up and mounting this appliance requires

extensive expertise in various trades (mechanics,

carpentry, plumbing, electrics).

It is the duty of the person setting the appliance up to

guarantee that it is set up and commissioned securely.

Mistakes in setting the appliance up and damage

resulting from this do not come under the warranty of

the manufacturer. Terms of guarantee are found in the

operating instructions of the appliances.

4

Page 5

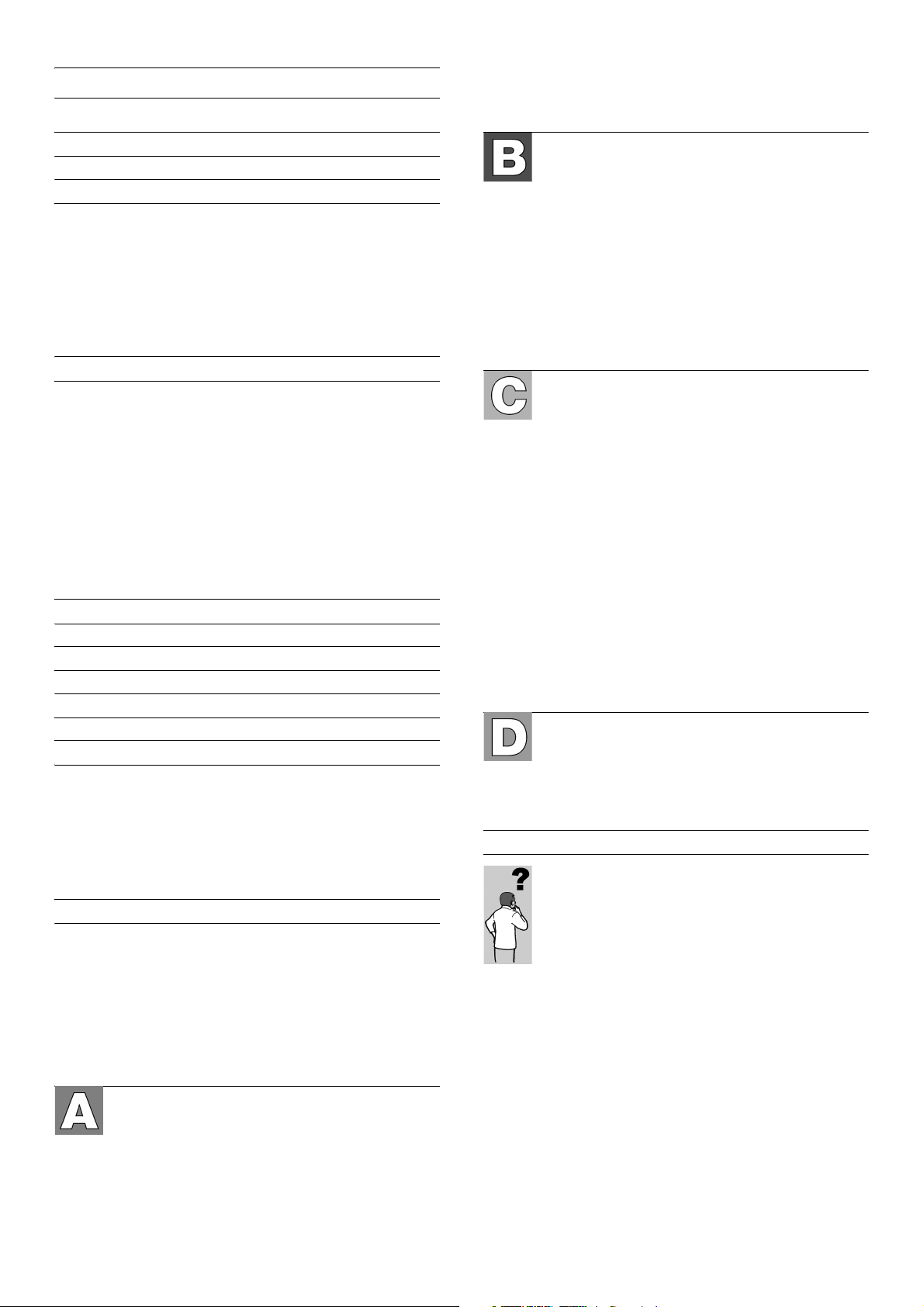

Installation possibilities

Various installation possibilities are available.

These are only limited by the kitchen design and the finger

protector function.

Stand alone appliance

Side-by-Side set up

Stand alone appliance with dividing

wall

– When measuring the dividing wall for model 4, pay

attention to the thickness of the furniture front to be

mounted in order to avoid damage when opening

doors at the same time.

– If the distance between the appliances is less than

160 mm, the auxiliary side heater must be used.

For further information see section “Tools and

Accessories which are needed”.

– The minimum thickness of the dividing walls is 16 mm.

Stand alone appliance as an end

section to a row of kitchen units

If a side of the appliance is visible, use a side covering.

The side covering must be connected firmly to the wall, the

floor and the upper cupboards before the appliance is slid

into the installation niche.

The dimensions of the side covering are governed by the

opposing niche wall. During installation, make sure that the

installation niche has right angles and has the exact size

necessary for the appliance(s).

5

Page 6

Installing the appliance

Installation location

ã Caution:

The appliance is very heavy. Data relating to the

weight when empty is found in the following table:

Appliance Weight (empty)

Refrigerator 60.3 cm approx. 131 kg

Refrigerator 75.6 cm approx. 145 kg

Freezer 45.1 cm * approx. 109 kg

Freezer 60.3 cm * approx. 131 kg

Freezer 75.6 cm * approx. 145 kg

Wine storage cabinet 45.1 cm approx. 109 kg

Wine storage cabinet 60.3 cm approx. 131 kg

* without water and ice dispenser

The appliance should be installed in a dry, well ventilated

space.

The location should not be exposed to the direct sunlight

and should not lie next to a source of heat such as a cooker

or a radiator etc. If installation next to a source of heat

cannot be avoided, either a suitable insulating plate should

be used or you should keep to the following minimum

distances:

– 3 cm to electric or gas cookers.

– 30 cm to an oil-fired or solid-fuel cooker.

The floor of the installation location must not give way;

if required, reinforce floor. To ensure that the ice maker

functions correctly, the appliance must be upright.

The safest method of installing the appliance in a stable

position is to use the supplied anti-tilt brackets.

If the installation cavity is adequately stable and the

appliance can be attached securely to the upper and side

walls of the cavity, it may be possible to dispense with the

anti-tilt brackets. A prerequisite for this is always a firm

connection between the cavity and back wall!

In the case of doubt, the help of architect or specialist

builder should be enlisted.

Installation niche

It is important to keep to the stated dimensions of the

installation niche with a view to trouble-free fitting, and the

subsequent appearance of the kitchen furniture frontage.

Special care should be taken that the niche has right

angles. The side walls should not exhibit areas that stick

out, projections or unevenness.

You should determine the right angles of the installation

niche with appropriate means, e.g. by measuring diagonally

and by using a spirit level.

The side walls and the upper end of the installation niche

must be at least 16 mm thick.

Neighbouring kitchen furniture

The new appliance is screwed down tightly using parts of

the cabinet and the upper cabinet.

Care should therefore be taken, that all upper cabinets to

which something has been fastened are securely

connected to the subsurface or wall by appropriate means.

The minimum thickness of the base should be a minimum

of 19 mm.

Subsurface

Atmosphere grades

The climate class can be found on the rating plate.

The climate class indicates within which ambient

temperatures the appliance can be operated.

Climate class Permitted ambient

temperature

SN +10 °C to 32 °C

N +16 °C to 32 °C

ST +16 °C to 38 °C

T +16 °C to 43 °C

Stable installation

The appliance is very heavy and has a tendency to tilt

forwards when the appliance door is opened.

The appliance must not be switched on until there

is no possibility of the appliance tilting over.

6

ã Caution:

A fully laden appliance is heavy, data relating to the

weight is found in the following table:

Appliance Weight (laden)

Refrigerator 60.3 cm approx. 400 kg

Refrigerator 75.6 cm approx. 500 kg

Freezer 45.1 cm * approx. 250 kg

Freezer 60.3 cm * approx. 350 kg

Freezer 75.6 cm * approx. 425 kg

Wine storage cabinet 45.1 cm approx. 245 kg

Wine storage cabinet 60.3 cm approx. 310 kg

* without water and ice dispenser

Page 7

Water connection

The subsurface must be level and even in order to ensure

that the appliance is securely installed and works correctly.

The subsurface must be made from a hard, non-flexible

material.

The floor of the installation space must have the same

height as the rest of the space.

On account of the weight of a fully-laden appliance, it is

necessary to have a bearing subsurface. In the case of

doubt, the help of architect or specialist builder should be

enlisted.

Aligning the appliance

To ensure that the appliance functions correctly, it must be

set level with a spirit level.

If the appliance is not level, water may flow out of the ice

maker, ice cubes may be irregular or the doors may not

close properly.

Electrical connection

The socket must be near the appliance and also freely

accessible following installation of the appliance.

The appliance complies with the protection class I.

Connect the appliance to 220-240 V/50 Hz alternating

current via a correctly installed socket with protective

conductor. The socket must be fused with a 10 to 16 A

fuse.

For appliances operated in non-European countries, check

whether the stated voltage and current type match the

values of your mains supply match the values of the mains

supply. These specifications can be found on the rating

plate.

ã Warning:

Never connect the appliance to electronic energy

saver plugs. Our appliances can be used with mains

and sine-controlled inverters.

Mains-controlled inverters are used for photovoltaic

systems which are connected directly to the power

supply system.

Sine-controlled inverters must be used for isolated

applications (e.g. on ships or in mountain lodges)

which are not connected directly to the national grid.

The water may be connected only by a competent fitter

according to the local regulations of the appropriate water

supply company.

The tap must be near the appliance and also freely

accessible following installation of the appliance.

The enclosed hose set is 2 metres long.

ã Caution:

Use only the enclosed hose set or a hose set purchased

from customer service for connection to the drinking water

mains.

Do not use existing or already used hose sets.

Connect the appliance to a drinking water line only:

– Minimum pressure: 0.2 Mpa (2 bar)

– Maximum pressure: 0.8 Mpa (8 bar)

– If the pressure is above 0.8 MPa (8 bar): install

a pressure limiter between drinking water connection

and hose set.

A separate shut-off valve should be installed in the coldwater inflow. The shut-off valve should not be located

behind the appliance. It is recommended that you mount

the shut-off valve directly next to the appliance or at another

place which is easily accessible.

When installing the water connection, pay attention to the

permissible installation area for the water mains. For more

information concerning the permissible installation areas,

see the section “Dimensions of the Installation Niche”.

For connection to the drinking water mains use only water

pipes which are suitable for drinking water. Observe

national regulations and the connection conditions of the

local water supply companies.

Note:

The maximum outside diameter of the water mains

(without connecting pieces) is 10 mm.

7

Page 8

Dimensions of the installation niche

Important:

The lateral niche walls must be

completely even and free from bumps.

If the niche is formed as a separate part,

the side walls must be completely even

up to a depth of at least 100 mm and

free from bumps.

Appliance X

451 mm 457 mm

603 mm 610 mm

756 mm 762 mm

Key:

A Area for installation of the water connection

B Area for installation of the electric current

C Depth of the installation niche, depending on the kitchen design

C = 610 mm minimum!

8

Page 9

Tools and accessories

which are needed

Scope of delivery

– Installation manual

– Operating instructions

– Installation accessories

Additional accessories

Installation accessories for side-by-side installation

For permanent connection of two appliances, e.g. a freezer

next to a refrigerator.

Lateral additional heating

Necessary when the distance between two appliances is

less than 160 mm.

Connecting element for furniture doors

For connecting two furniture doors (see explanation in

Section “4. Preparing the furniture doors”). It can be used

for standard height furniture doors without any preparation

work.

Miscellaneous

–Step ladder

– Trolley, wheelbarrow or sack barrow

– Hammer drill for drilling holes into the wall and floor

– Various size drills for various materials

– Wood plank, (min. 8 x 10 cm) as an alternative anti-tip

device. Length should correspond to the width of the

installation niche.

– Various size wood screws

– Screw (M8, at least 80 mm long), nut

– Thin (1.5 mm), material suitable for protecting the floor

against damage (e.g. linoleum)

– Suitable material for covering and protecting the

cabinets (e.g. protective film)

– Adhesive tape

Note:

Before using, check whether the removed adhesive

tape leaves adhesive residue on the work surfaces!

Otherwise do not use on high-quality work surfaces.

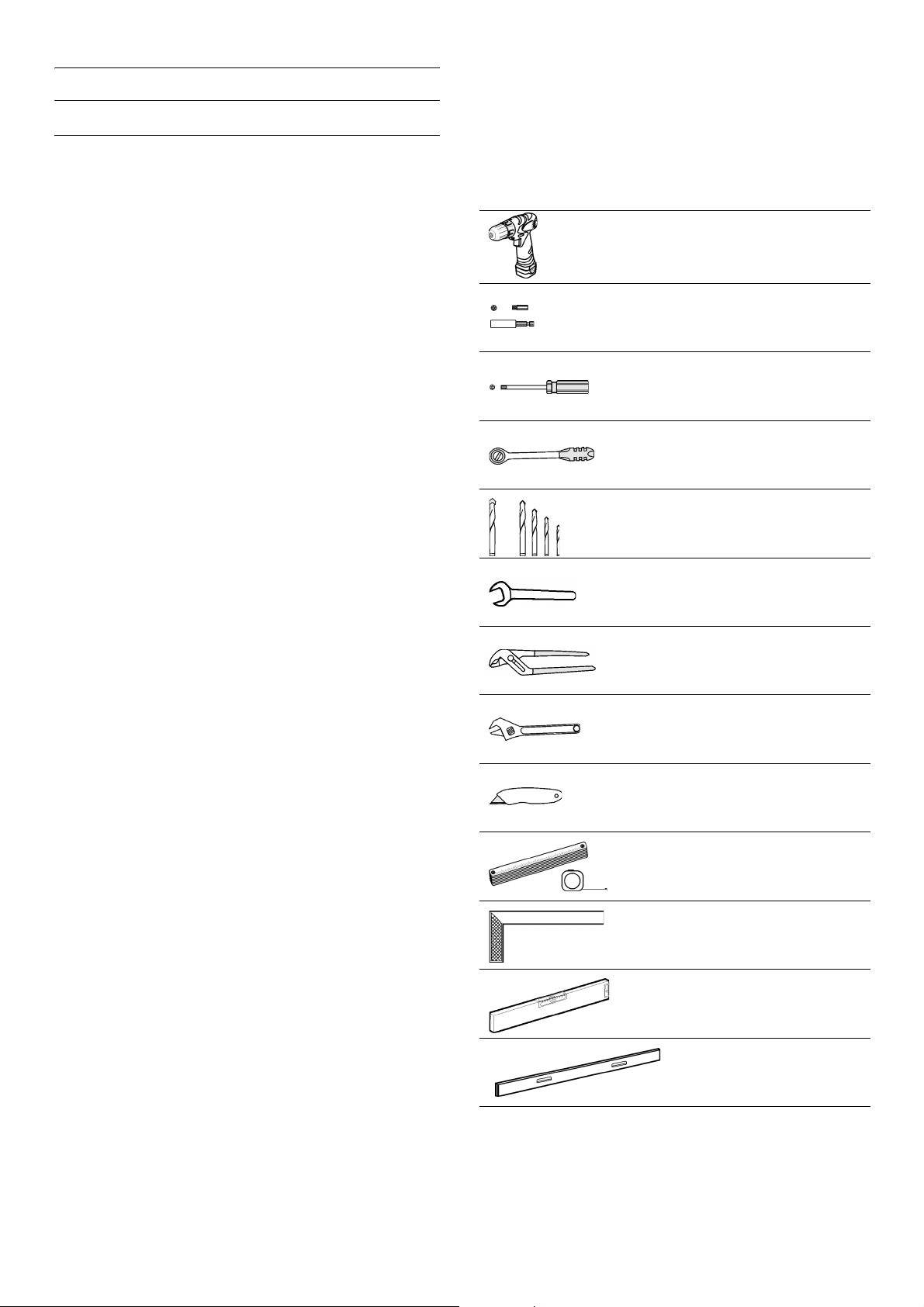

Tools

Rechargeable screwdriver

T20 Torx-bit + magnetic

holder

T20 Torx screwdriver

8 mm socket wrench

Various size drills

Fixed spanner SW 13 mm

Water pump pliers

Adjustable spanner

Knife with an adjustable

blade

Metal tape measure, folding

ruler

Angle of contact

60 cm and 120 cm spirit

levels

Level, min. 120 cm long

9

Page 10

Installation manual

The following mounting instructions describe mounting

steps for various appliance models.

Therefore, deviations may occur from that shown in the

diagrams.

Reference is made to specific mounting steps for individual

appliances.

1. Check the installation niche

Caution:

Before starting the installation, check carefully that

the installation cavity meets the require-ments for

a secure and trouble-free installation:

1. Check the subsurface.

Follow the notes in the section “Installing the

appliance”.

2. Check the dimensions of the niche.

3. Re-examine whether the niche has right angles.

4. Re-examine

Additionally follow the instructions in the sections

“Electrical connection” and “Dimensions of the

installation niche”.

5. Check the positioning of the water connection

(for appliances with ice maker)

Additionally follow the instructions in the sections

“Water connection” and “Dimensions of the installation

niche”.

6. Re-examine the stability and fastening of the

neighbouring cabinet parts. All cabinet parts in the

vicinity of the appliance have to be firmly connected to

the wall.

7. Re-examine that when opening the appliance door,

it does

(for door opening angle).

the

positioning of the plug.

not collide with

neighbouring kitchen parts

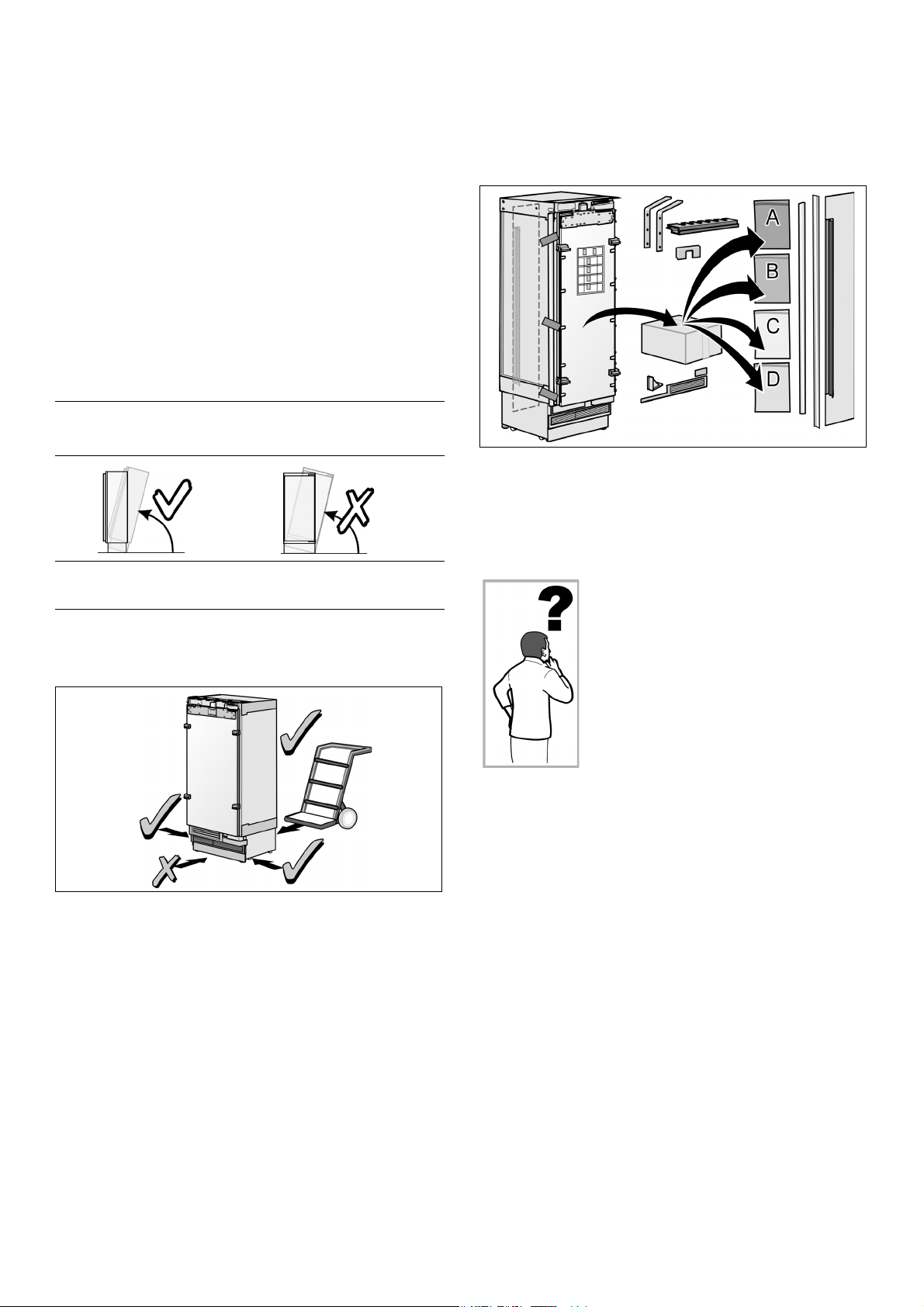

2. Removing the packaging

Warning:

– The appliance could tip over when unpacking.

– The appliance could tip over when the appliance

door is opened.

– The appliance is very heavy.

Risk of personal injury and damage to the appliance!

Note:

Check the appliance for damage. Do not install the

appliance if there is visible damage. If there are queries,

please contact the dealer.

To protect the subsurface from damage whilst installing:

1. Place cardboard or plywood under the appliance.

2. Remove packaging

knife so as not to damage the surface of the appliance.

3. Remove accessories from the outside of the

appliance.

Keep adhesive tape which was used to attach the

supplied accessories to the appliance. It is

used subsequently for attaching the edge protection

to the cavity walls (see Section

“B / 1. Sliding the appliance into the installation

niche”).

4. Remove transportation protection devices (a) and lift

appliance off the pallet – appliance is very heavy!

rton. Be careful when using the

ca

a

10

5. Carefully open the appliance – risk of tipping over –

and r

emove

accessories and installation materials from

inside the appliance. Close the door again.

Note:

Only remove the transporting securing units with which

the slide-in bases and the storage compartments in

the appliance are protected after completing the

installation as otherwise, parts could be damaged.

Page 11

3. Transporting the appliance

4. Installation preparation

ã Warning:

The appliance is very heavy. Handle it carefully, as

otherwise people helping to lift it could be hurt or the

appliance could be damaged.

The appliance has a height of 212.6 cm. If it is not possible

to support the appliance in a vertical position because of

the structure of the building, the appliance can be

transported on its side.

Note:

Never put the appliance up via its side! Risk of damage to

the appliance.

When putting the appliance up, pay attention to the

minimum height that is required at the assembly location

according to the following table.

Putting the appliance

up on via its back side

Minimum height

218.5 cm

Note:

Never push means of transportation under the front of the

appliance. Risk of damage to the appliance

Putting the appliance up

via its side wall

Never put the appliance

up via its side!

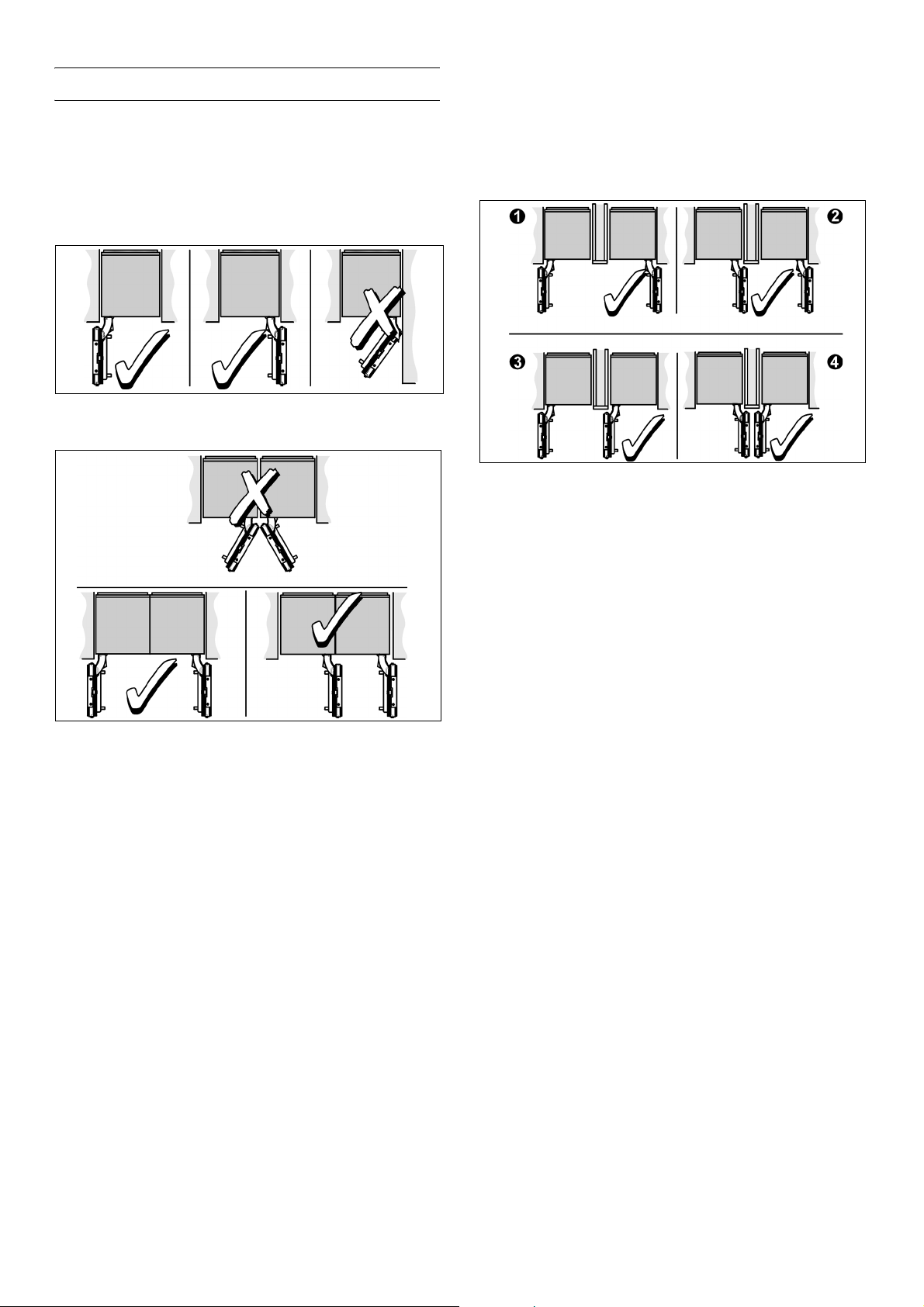

Unpack installation materials and accessories.

To simplify installation, the packages are identified with

labels A, B, C and D corresponding with the manual

sections.

5. Special installation steps

This symbol indicates that additional steps need to be

taken before proceeding to the next chapter.

Special installation steps are described after section D.

– Exchanging the door hinges see

“Changing over the door hinges”.

– Sealing mat, see “Removing/changing

the sealing mat”.

– Side-by-Side set up see “Side-by-Side

set up”.

– Water connection see “Preparing the

water connection“ and „Connecting

the appliance to the water supply”.

– Ice water dispenser, see “Aligning ice

and water dispenser”.

– Cover strips for the wine cooler, see

“Attaching covering strips”

– Door opening angle see “Setting the

door opening angle”.

1. Transport the appliance with an aid to transport which

is suitable (sack barrow, trolley or wheelbarrow).

2. When transporting, secure the appliance from being

tipped.

11

Page 12

1. Attaching the anti-tipping brackets

to the wall

ã Warning:

Ensure that in the wall area there are no electrical

wires or pipes which could be damaged by pipes.

Risk of injury or damage!

ã Warning:

When installing or working with floor anchors always

use protective glasses and other protective

equipment or protective clothing – risk of injury!

Notes:

– Each appliance requires 2 anti-tilt brackets.

– The set supplied, contains fastening screws for various

subsurfaces. Select the fastening screws

corresponding to the local conditions.

– A total of 2 anti-tilt brackets are used for a side-by-side

installation.

– If the anti-tilt brackets, and therefore the appliance,

cannot be securely attached with the supplied

fastening screws, another suitable method must be

used to attach the appliance securely.

– If a side-by-side set up of two appliances is envisaged,

the anti-tilt brackets are needed as installation aid.

Connect the appliances before the anti-tilt brackets

are fixed to the wall, see “Side-by-Side set up”.

The anti-tilt brackets (a) must overlap the appliance by at

least 105 mm to ensure that the appliance is stable.

If the minimum overlap cannot be observed due to

structural conditions, these can be overcome by the

attachment of a suitable device, e.g. an adequately

dimensioned beam (b) behind the brackets.

The length of the plank should correspond to the width of

the installation niche!

Important information concerning attachment with wall

plugs and screws:

– Not suitable for use in light-weight masonry such as

hollow blocks or tiles!

– Never use in fresh concrete which has not yet

hardened.

– Do not use spiral-flute counterbores (countersinking

tool) to drill the holes.

1. Determine the fastening points of the anti-tilt ribs.

Determine the actual dimensions according to the

section “Dimensions of the installation niche”.

2. Screw on the anti-tilt brackets tightly. Re-examine to

make sure that the screws are firmly tightened.

12

Page 13

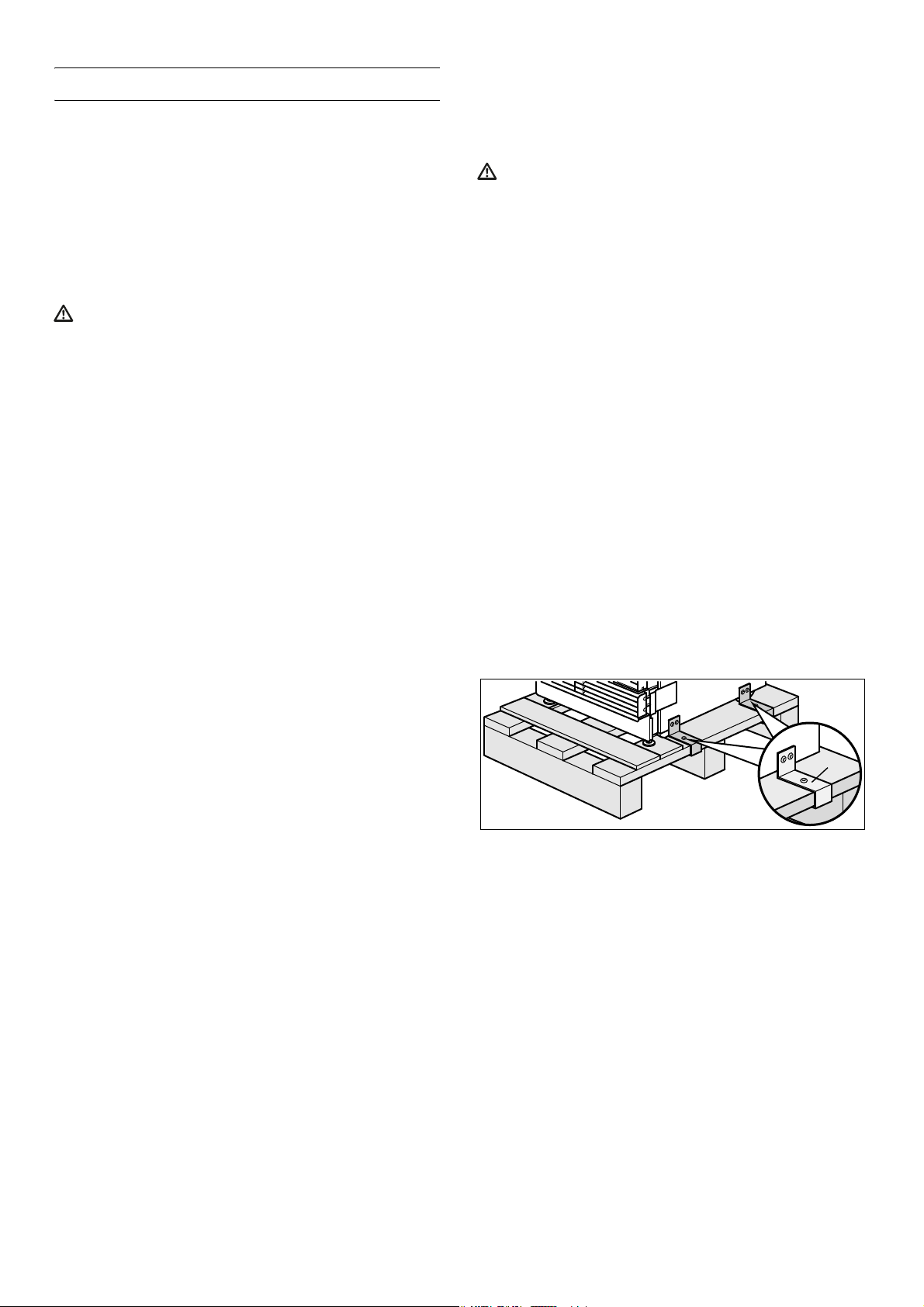

2. Attaching alternative anti-tilt device

3. Attaching the edge protectors

Important note:

If the anti-tilt brackets cannot be securely attached,

a wooden beam can be used above the appliance as an

alternative anti-tilt device. Care should be taken that there

is not a gap between the appliance and the wooden beam.

As far as possible, always screw the wooden plank to the

rear wall of the niche.

1. Cut the wooden plank to the required length (cross

section min. 8 x 10 cm). The length should correspond

to the width of the installation niche!

Notes:

– If the installation niche is deeper than the appliance,

select a stronger beam or use two, one behind the

other.

– The plank must overlap the appliance by at least

50 mm.

To protect the edges of the installation cavity, it is

recommended to attach edge protection made of

a suitable material.

Attach the edge protection with the adhesive tape which

was used to attach the accessories to the appliance.

4. Attaching the fastening sheets

(lateral)

Attach the fastening sheets (lateral) to the appliance.

2. Mark the installation height (underside edge of the

plank) on the rear wall of the niche.

3. Select the screws according to the thickness of the

wooden plank: Length min. 2.5 x wood thickness,

diameter 12 or 14 mm.

Note:

Select the number of screws corresponding to the

niche width so that you ensure that the plank can be

securely mounted.

According to the subsurface:

4. Look for the supports on the rear wall of the niche and

mark the drill holes on the plank corresponding to the

position of the support.

or

5. Fasten suitable dowel into the rear wall.

6. Pre-drill.

7. Screw the plank onto the rear wall of the niche.

These are special installation steps.

Instructions are provided after section D.

– Exchanging the door hinges see

“Changing over the door hinges”.

– Sealing mat, see “Removing/changing

the sealing mat”.

– Side-by-Side set up see “Side-by-Side

set up”.

– Water connection see “Preparing the

water connection”.

13

Page 14

1. Sliding the appliance into the installation niche

ã Caution:

Be careful when sliding the appliance into the

installation niche. Do not damage the water

connection or power cord.

Note:

If the floor or appliance is skew in relation to the installation

niche, the height-adjustable wheels should be

correspondingly adjusted before sliding the appliance into

the niche.

1. Remove the base panelling.

2. Unscrew the height-adjustable feet at the back of the

appliance by approx. 10 mm.

3. Insert water connection line into the protective pipe on

the rear of the appliance.

ã Warning:

The appliance may tilt when the water connection

line is inserted into the protective pipe (a)!

4. Connect the power cord to the appliance.

5. Protect the mains lead from getting wedged under or

behind the appliance.

Recommended procedure:

a) Tie a piece of string onto the power cord and guide

the string forwards over the appliance. When

pushing the appliance into the cavity, pull the cable

with the string forward.

or

b) Fasten the power cord onto the backside and the

top of the appliance with adhesive tape.

6. Slide the appliance carefully into the niche.

7. Plug the mains plug into the socket.

8. Remove edge protection from the installation cavity

(if previously attached).

14

Page 15

2. Adjusting the appliance in the niche

Notes:

– To ensure that the appliance functions correctly,

it must be set level with a spirit level.

– Do not tip the appliance in the niche! When screwing

down the height adjustable feet, proceed step by step.

Lower by alternating left to right.

– The rear feet can be set easier when the appliance is

not loaded on the rear.

– When using a wooden plank as an alternative anti-tilt

mechanism of these mounting instructions, turn the

appliance as far as it will go against the wooden plank.

Do not bend against the wooden plank.

The positioning supports are set out for the following overall

strengths of the furniture doors to be mounted.

–19 mm

–38 mm

Re-examine the actual thickness of the doors to be

mounted in order where necessary, to be able to

compensate possible digressions.

1. Adjust the appliance to the existing furniture.

Keep the straight edge on the door, above the

positioning supports.

2. Unscrew the height-adjustable feet at the front of the

appliance until the mark on the base has reached the

indicated height (32 mm).

3. Align the appliance vertically using the feet at the back.

Use spirit level.

The height-adjustable feet on the front and rear can all be

adjusted from the front.

Front: with a fixed spanner SW 13 mm

Rear: with a 8 mm socket spanner with flexible

shaft. Use cordless screwdriver.

A mark (a) is made on the base of the appliance which

serves as a standard measurement for setting the height.

When setting the height, raise the mark to 32 mm above

the ground. This dimension is very important for the

subsequent adjustment of the cabinet frontage.

The assembly gauge (b) is used to set this

height correctly. The upper edge of the

gauge must be in alignment with the mark

on the appliance.

3. Fastening the appliance to the

niche ceiling

Note:

It is essential to attach the appliance to the ceiling of the

cavity.

1. Screw on the front bars of the fastening sheets (above)

with the upper cabinets.

2. If there is a large crack available above the appliance,

integrate a wooden plank above the appliance and pay

attention that the crack is completely filled.

15

Page 16

3. If there enough room on the top of the appliance fix the

the lateral bars of the fastening sheets (above) to the

side of the niche.

Shorten the fitting strip (a) to fill the gap.

4.

Note: The appliance will be damaged if the fitting strip

is too long.

.

5. Press connection ribs (a) into the covering ribs.

6. Attach the covering ribs (b) onto the fastening sheets

(above),

Note:

If the installation is side-by-side, connect the cover rails of

both appliances using the bolt from the installation

accessories for side-by-side installation.

4. Fastening the appliance to the side

wall of the installation niche

Screw on the bars of the fastening sheets (lateral) with the

cabinet parts located next to them.

16

Note:

In the case of a Side-by-Side in

step is not possible. These parts have bee

stallation this installation

n removed.

Page 17

5. Checking that the finger guard

moves easily

It is now essential to check that the finger guard moves

easily. At a later time any required corrections will be more

difficult.

Notes:

– The supplied finger protector can be used for both

sides of the hinges.

– Because of different installation possibilities, the finger

protector has to be shortened to the required length.

1. Shorten the finger protector at the upper side above

the covering strip by 55 mm (1.).

2. Push the cut-off remnant on the hinge side into the gap

between the appliance and cavity wall.

The part must be easy to push in and pull out (2.)!

These is a special installation step.

Instructions are provided after section D.

– Water connection see “Connecting the

appliance to the water supply”.

3. Ensure smooth running at all positions of the door (3.).

17

Page 18

1. Fastening the plinth strip

2. Aligning the base cover

Note:

Never cover the ventilation cracks in the base panelling.

Risk of damage to the appliance.

Nominal dimensions to be observed:

1. Where necessary, cut the base strip to the required

length.

2. Place base cover on the appliance (do not screw on).

1. Place base cover on the appliance (do not screw on).

2. Measure the difference in depth A between the base

panelling and the base strip of the adjacent lower

cabinets.

3. Remove the base panelling again.

4. Adjust the brackets (a) to the dimensions A and

tighten.

3. Take the protective film off from the adhesive pads on

the Velcro strip.

4. Put the base strip onto the base panelling and push

firmly.

5. Base strip can be screwed to the base cover from

behind. There are holes in the base cover for this

purpose.

5. Fasten the base panelling.

18

Page 19

3. Switching the appliance on for the

first time

The appliance should now be switched on for the first time

in order to ensure the accuracy of the following mounting

steps and with it, the appearance of the entire kitchen

frontage.

1. Open the appliance door.

2. Actuate the appliance’s On/Off button.

Only for appliances with a water connection:

In the case of possible damage of the water mains, keep

the shut-off tap closed in order to avoid the risk of damage

from water coming out.

4. Preparing the furniture doors

Important note:

When working on the furniture doors, care should be taken

to the following:

– Always carry out screwing job s o n the most s t a ble p a r t

of the furniture door. Never screw into fillings or similar

areas.

– Always selects screws with a length smaller than the

thickness of the cabinet front.

– Protect the surfaces of the furniture doors during

installation against damage.

The overall weight of the furniture door including the handle

should not exceed the following values:

Appliance width Overall width of the furniture door

45.1 cm 20 kg (8.5 kg *)

60.3 cm 25 kg (14.5 kg *)

75.6 cm 29 kg

This metal strip is available from your dealer as an

installation accessory (Connection element for furniture

doors). For further information see section “Tools and

Accessories which are needed”.

Note:

The instructions for carrying out this work step can be

found in the separate installation instructions for this

accessory.

Important information for furniture doors with cutout

(appliances with ice and water dispenser, wine storage

cabinets):

The cut edges of the door cutout must be protected before

humidity penetrates. To do this, use the means suitable

for the material and the shape of the furniture door

(e.g. edge veneer, edge sealant).

5. Loading the appliance door

When attaching the furniture doors it is recommended to

load the storage sections in the door with weights in order

to ensure that the when adjusting crack dimensions turn

out to be as precise as possible.

Loading recommendations:

* Wine storage compartment

Instead of one large door, two furniture doors can be

mounted next to each other in the case of appliances with

a width of 76 and 91 cm. These furniture doors are then

connected using a metal strip on the rear.

Appliance width Loading of the appliance door

45.1 cm 10 kg

60.3 cm 15 kg

75.6 cm 20 kg

19

Page 20

6. Removing positioning aids

Unscrew the positioning aids from the appliance door.

Note:

The positioning aids will still be needed in the course of

mounting.

7. Tightly screw the adjusting rib.

The minimum number of screws required for this

depends on the width of the furniture door.

7. Fastening the adjusting rib to the

furniture door

1. Measure distance A between the adjusting rail and the

furniture parts above.

Notes:

– One screw should be screwed in under the threaded

rod in each case.

– The adjusting rib has a various holes for different

furniture door design variations. Always carry out

screwing jobs on the most stable part of the furniture

door.

8. Fastening the fixing rib to the

furniture door

1. Hang the furniture door on the threaded rod (a).

2. Adjust the furniture door using the threaded rod (Torx

screwdriver)

Re-examine the dimensions of the crack continuously.

To do this, use the assembly gauge (b).

2. Loosen the two nuts (a) and remove the adjusting rib

(b).

3. Mark this value A on the rear side of the furniture door.

4. Determine the middle of the door and label it.

5. Rest the adjusting rib on the furniture door and align to

the markings. Mark the drill holes.

6. Pre-drill the holes.

20

Page 21

3. Transfer the position of the fastening screws on the

outer edge of the appliance door to the furniture door

and mark.

4. Remove furniture door.

5. On both lengths of the furniture door, draw a parallel

with the help of the positioning aid.

9. Mounting the furniture door

Note:

Now attach the door handles which should have been

screwed from behind!

1. Remove fixing bracket (a) from the appliance door.

To do this, loosen the fastening screws (b) only.

2. Insert the removed fixing brackets (a) into the fixing ribs

(b) on the furniture door.

6. Lengthen the markings to the parallels using an angle

of contact.

7. Apply the fixing ribs (b) and mark out the holes.

8. Pre-drill the holes.

9. Screw on the fixing ribs (b).

21

Page 22

3. Open the appliance door.

4. Hang furniture door with the adjusting rail onto the

threaded rods (1.).

5. Lower furniture door and push the fixing brackets

down over the fastening screws on the appliance

door (2.).

6. Adjust the furniture door using the threaded rod (Torx

screwdriver) Re-examine the dimensions of the crack

continuously.

7. Close the door and re-examine to make sure that the

depth of the cabinet frontage corresponds with the

adjacent lying fronts. Correct if necessary.

8. Tighten the fixing anglescrews in order to fix the depth

adjustment.

9. Close the door and check the lateral adjustment.

Correct the adjustment by lightly banging on the edge

of the open door by hand.

10. Screw nuts onto the threaded rods of the adjusting rail

and tighten! This way, the lateral adjustment of the

door is fixed.

10. Screw on the lower fixing angle

The lateral adjustment of the door is fixed through the lower

fastening angles.

The number of the lower fastening angles depends on the

width and the design of the furniture door.

Screw on lower bracket. Pre-drill holes into the furniture

door!

1. Loosen screw.

2. Push bracket over the screw.

3. Check the lateral position of the door.

4. Screw in the wood screws.

5. Tighten the screws.

22

6. Insert the coverings via the fixing angle.

Page 23

1. Fasten the finger protector

1. When positioning the finger protector at the door,

ensure that the fixing holes in the cover strip

correspond with the boreholes in the fixing brackets.

Mark now the bottom edge of the finger protector and

shorten accordingly.

4. Attach the finger protector with the screws on the

fixing brackets.

5. Test functioning and smooth running of the finger

protector by repeatedly opening and closing the door.

2. Push the finger protector into the gap between the

appliance and the niche wall (1.).

3. Press the cover strip of the finger protector from top to

bottom between the front of the furniture and the door

of the appliance (2.). Ensure that the fixing holes in the

cover strip correspond with the boreholes in the fixing

brackets (3.)!

2. Attaching the covers

1. Attach the cover rail.

2. Attach the light switch cover.

The light switch cover can be screwed to the door.

23

Page 24

Only in the case of individual appliances:

1. Screw on the angle (a) for fastening the cover ribs.

2. Attach the cover ribs (c) to the fastening sheets (b) and

the angles (a).

3. Mounting the air separator

Using the air separator, air which is supplied and drawn

from the appliance is fed separately, in order to avoid

reduced operating capacity.

Only in the case of a side-by-side set up:

Only in the case of freezers with ice and water

dispenser:

Insert the cover rib in the crack between the appliances.

The cover rail is included in the installation accessories for

side-by-side installation.

24

Page 25

4. Tensioning the hinge springs

Turn the setting screw with a cross head screwdriver.

I = Spring tensioned

0 = Spring released

These are special installation steps.

Instructions are provided after section D.

– Ice water dispenser, see “Aligning ice

and water dispenser”.

– Cover strips for the wine cooler, see

“Attaching covering strips”

– Door opening angle see “Setting the

door opening angle”.

Installation of the appliance is now complete.

25

Page 26

Special installation steps

Changing over the door hinges

ã Warning:

Before carrying out any work to the door hinges,

release the spring pressure – risk of injury!

Notes:

– The door hinges cannot be exchanged in the case of

freezers with ice and water dispensers.

– It is easier to change over the door hinges if the

appliance is placed on its back (place transport pallet

underneath).

1. Release the spring pressure on the hinge.

In addition, set the screw from I to 0.

3. Unscrew the door.

4. Remove the hinges.

2. Remove the hinge covering.

5. Remove ventilation grille.

26

Page 27

6. Re-attach ventilation grille for the changed door

hinges.

7. Swap the hinge angle to the other side.

8. Attach ventilation grille.

A replacement part for the ventilation grille is enclosed with

the appliance for adjustment to the changed door hinges.

9. Swap the fixing parts on the door to the other side.

27

Page 28

10. Attach the hinges to the appliance.

Exchange the hinges crosswise!

11. Screw the door to the hinges.

Removing/changing the sealing mat

Freezers are fitted with a sealing mat at the factory

for side-by-side installation.

If a single appliance is installed, the sealing mat is not

required and can be removed.

The sealing mat is essential for side-by-side installation.

If the door hinges were fitted to the other side of the door,

the sealing mat must be attached to the other appliance.

Always attach sealing mat to the right side of the appliance

situated on the left.

12. Tighten the screw. In addition, set the screw

from I to 0.

13. Attach the hinge covers.

28

Page 29

Side-by-Side set up

If a side-by-side set up of two appliances is envisaged,

connect the two appliances to one another now.

1. Unpack the installation accessories for side-by-side

installation and check that none of the accessories

is missing.

Keep ready the anti-tilt brackets as an installation aid.

3. Unscrewing the base panelling.

Notes:

– Freezers are fitted with a sealing mat at the factory

for side-by-side installation.

In this case continue with Step 6.

– Always attach sealing mat to the right side of the

appliance situated on the left.

4. Place sealing mat on the appliance and secure with the

attachment pins.

2. Place appliances side-by-side in the planned

installation configuration.

29

Page 30

5. Screw the connection clamps from the installation

accessories for side-by-side installation to the side of

both appliances. Note the position of the clamps!

7. Push the appliances together until the angle brackets

interlock.

8. Insert pins through the angle brackets.

9. Push front of appliances completely together.

6. Screw the angle brackets from the installation

accessories for side-by-side installation to the handle

side of both appliances.

10. Unscrew screws from the top of the appliance and in

their place screw on the anti-tilt brackets as

installation aid.

30

Page 31

11. Press appliances completely together by gripping the

installation aids with water pump pliers.

12. When the appliances have been pushed completely

together, push the bar from above through the

connection clamps.

13. Press appliances completely together by gripping the

appliance base with water pump pliers.

14. When the appliances have been pushed completely

together, push the bar from the front through the

connection clamps. Use a suitable tool to insert the bar

all the way.

Preparing the water connection

(only for appliances which require a water connection)

Note:

Turn off the main water tap in order to avoid damage from

escaping water.

1. Insert filter screen into the filter housing.

2. Place seal in the filter housing and connect to the tap

(¾" threaded connection)

3. Using an open-end wrench, connect water supply

hose with seal to the filter housing.

15. Remove installation aids.

4. Lay the connection pipe. Always keep to the given

installed area in order to avoid damaging the

connection pipe when sliding the appliance in later.

Connecting the appliance to the water

supply

Note:

Do not kink the connection pipe when bending it, otherwise

there is a risk of leaks and water damage.

1. Remove the plugs from the appliance connection (1.).

2. Lay the water hose such that it ends at the appliance

connection (2.).

3. Slide the union nut and the sealing element onto the

water hose.

31

Page 32

4. Attach the water hose to the appliance connection and

screw on the union nut (3.). Screw tightly, using

manual force.

5. Screw the union nut tightly using the fixed spanner.

Do not over tighten!

6. Push water hose back as far as possible into the

protective pipe (4.).

Aligning ice and water dispenser

(only in the case of freezers with ice and water

dispenser)

Note:

Avoid misaligning the door while aligning the ice and water

dispenser!

The ice and water dispenser can be adjusted within the

section of the furniture door. In this way, it is possible to

undertake parallel adjustment to the furniture door in order

to achieve an optimal overall impression.

The gap must be exactly the same all the way round (a)

and

the front surface of the ice and water dispenser must be

aligned exactly parallel with the door front (b).

7. Turn the shut-off valve and the main water tap.

8. Re-examine the points of connection at the shut-off

valve and the appliance connection for leaks.

ã Warning

There must be no leaking water! If required, tighten the

threaded connections with a higher torque.

9. Close the shut-off valve.

Aligning ice and water dispenser:

1. Loosen the nuts on the 4 setting screws with

a wrench.

2. Use a Torx screwdriver to align the depth of the ice and

water dispenser on the setting screws.

Use a ruler as positioning aid.

32

Page 33

3. By moving by hand align the ice and water dispenser

exactly lateral and in the higth to ensure that the gap is

exactly the same all the way around.

4. Retighten the nuts on the setting screws to fix the

adjustment.

Attaching covering strips

(only for the wine storage cabinet)

1. In certain circumstances, if the frame width is narrow,

the side of the covering strip has to be shortened.

To determine the required length of the side, lay trial

pieces next to the covering strip.

2. Slide the covering strips on the longitudinal side into

the gap between the furniture door (a) and the glass

pane (b).

5. Slide in the covering frame provisionally to check the

adjustment.

The lateral spacing around the ice and water dispenser

must be exactly the same. Correct if necessary.

6. Slide in the covering frame and push firmly.

7. Insert the covers.

8. Insert the water capture bowl.

33

Page 34

3. Cut the covering strips of the shortest sides to the

required length.

4. Push cover strips into the gap between the furniture

door (a) and glass pane (b).

Setting the door opening angle

According to the set up conditions, it may be necessary to

limit the door opening angle. A door opening angle of 115°

is set at the factory.

To set the door opening angle to 90°:

1. Open the door to 90°.

2. Drive in the stop pin with a hammer.

34

Page 35

35

Page 36

Gaggenau Hausgeräte GmbH

Carl-Wery-Straße 34

D- 81739 München

www.gaggenau.com

Subject to alterations.

8001 069 994

en (9704 )

Loading...

Loading...