Page 1

Revised July 2006

IPM520

OPERATOR'S MANUAL

10 THOMAS IRVINE , CA 92618

Tel- (949) 465-0900 Fax - (949) 465-0905

Internet: www.futek.com

Page 2

Our recommendations, if any, for those of these products are based on tests

believed to be reliable. The greatest care is exercised in the selection of our raw

materials and in our manufacturing operations. However, since the use of this

product is beyond the control of the manufacturer, no guarantee or warranty,

expressed or implied is made as to such use or effects incidental to such user

handling or possession or the results to be obtained, whether in accordance with

the direction or claimed so to be. The manufacturer expressly disclaims

responsibility therefore. Furthermore, nothing contained herein shall be construed

as a recommendation to use any product in conflict with existing laws and/or

patents covering any material or use.

Warranties or sale, disclaimer thereof and limitations of liability are covered

exclusively by DigiTec's printed warranty statement, for the Enclosed Products.

These instructions do not expand, reduce, modify or alter

Futek's warranty

statement and no warranty or remedy in favor of a customer or any other person

arises out of these instructions.

Call Futek for all your instrumentation and process and control

applications. Application Engineers are available to answer any

questions.

10 Thomas • Irvine, CA 92618

Phone: (949) 465-0900

Fax: (949) 465-0905

Internet: www.futek.com

1

Page 3

Table of Contents

Section Topic Page

Section 1 Introduction and Description

Section 1.1 Product Description 3

Section 1.2 Dimensional Drawings 4

Section 1.3 Exploded View 4

Section 2 Pin Outs and Wiring Diagram

Section 2.1 Main Board and Option Board Connections 5

Section 2.2 Option Board Connections 6

Section 2.2 RS232 connection drawings 8

Section 2.4 Channel 1 Input Connections 10

Section 2.5 Channel 2 Input Connections (3722A Only) 11

Section 3 Operation and Programming

Section 3.1 Front Panel Keys 12

Section 3.2 Setup Mode Key Functions 12

Section 3.3 Run Mode Key Functions 13

Section 3.4 Programming Tips 18

Section 3.5 Enter Setup 19

Section 3.6 Main Programming Branch 21

Section 3.7 Channel Setup Programming Branch 22

Section 3.8 Output Setup Programming Branch 26

Section 3.9 Display Programming Branch 29

Section 3.10 Special Features Programming Branch 29

Section 4 Options 36

Section 5 Specifications 38

Inside Back Cover 3700 Flow Chart

2

Page 4

SECTION 1

INTRODUCTION AND DESCRIPTION

SECTION 1.1: UNIT DESCRIPTION:

The single input and the dual input intelligent process

meters features 5 ½ digit resolution, 6 digit display, high speed, 5 front key

operation and a NEMA 4X, industrialized aluminum case. One Form A relay is

provided standard for use as an Alarm output or shunt cal relay. The

emphasizes the features required in today’s applications, especially scaling of the

meter to display in engineering units. Three methods are provided to scale the

meter: No calculation scale and offset, load calibration and shunt calibration

Stock #'s:

FSH00248- one input channel

FSH00947- two input channels; Options C, H, P, T installed

Options:

"C" 3 Form C Relays

"H" Analog & Excitation Output

"P" Excitation Supplies 10/24 VDC

"T" Serial RS-232C Communication

Ordering Example:

3720A-01CH Single Input with 3 Relays, Analog output,

and Screw Terminals.

IPM500

only.

3

Page 5

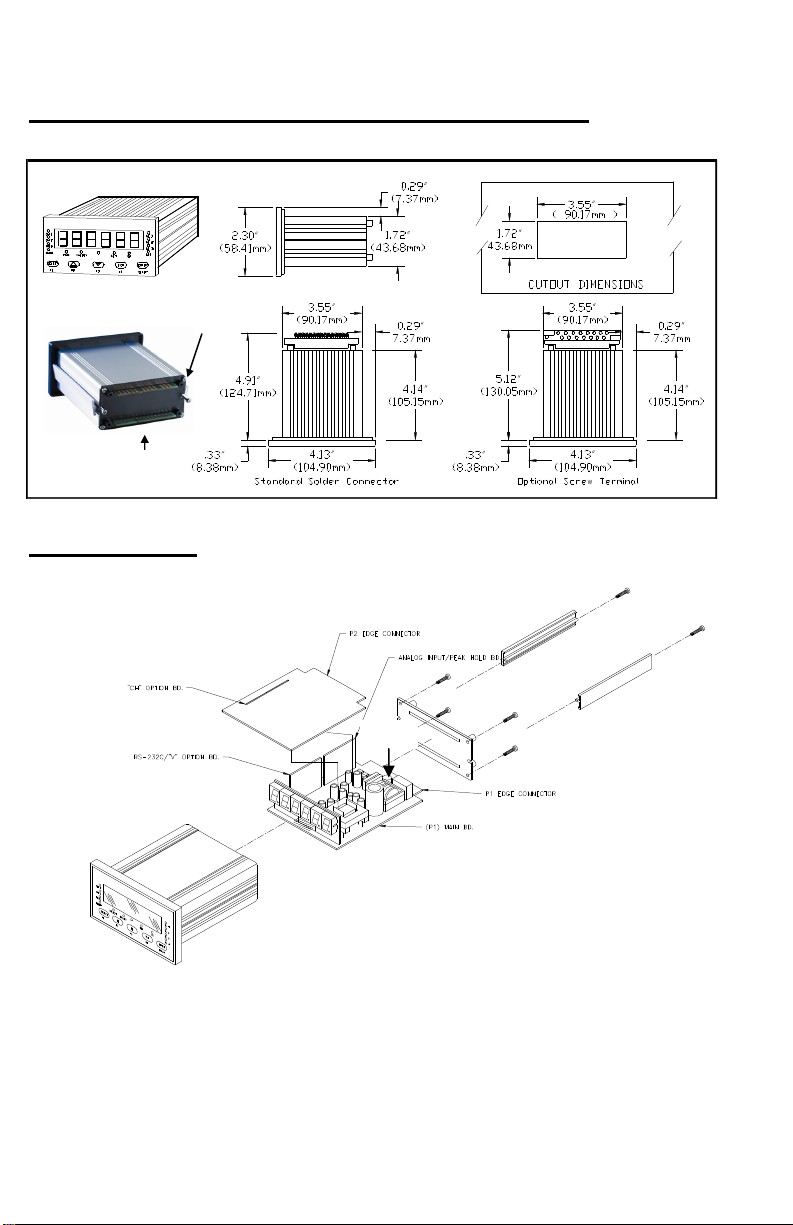

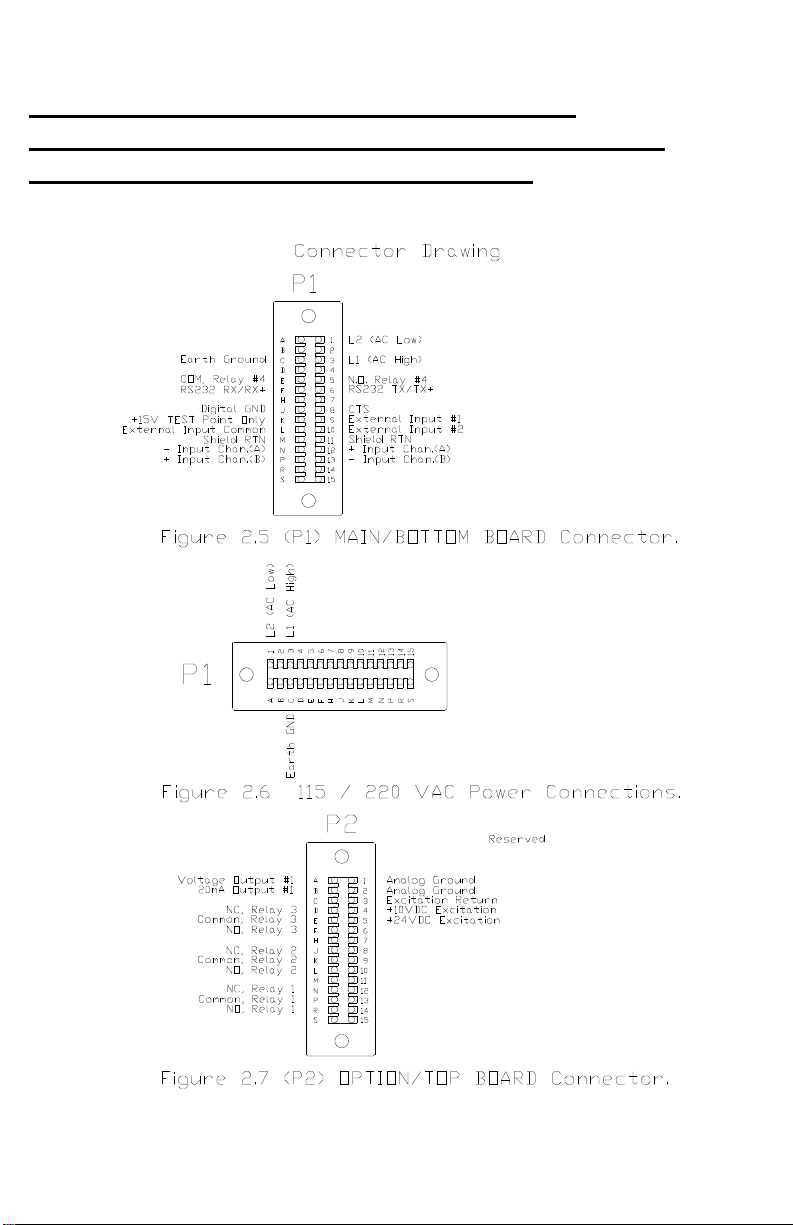

SECTION 1.2: DIMENSIONAL DRAWINGS

P2 (Option Board/Top

Connector)

P1 (Main Board /Bottom

Connector)

SECTION 1.3

FUSE

4

Page 6

SECTION 2

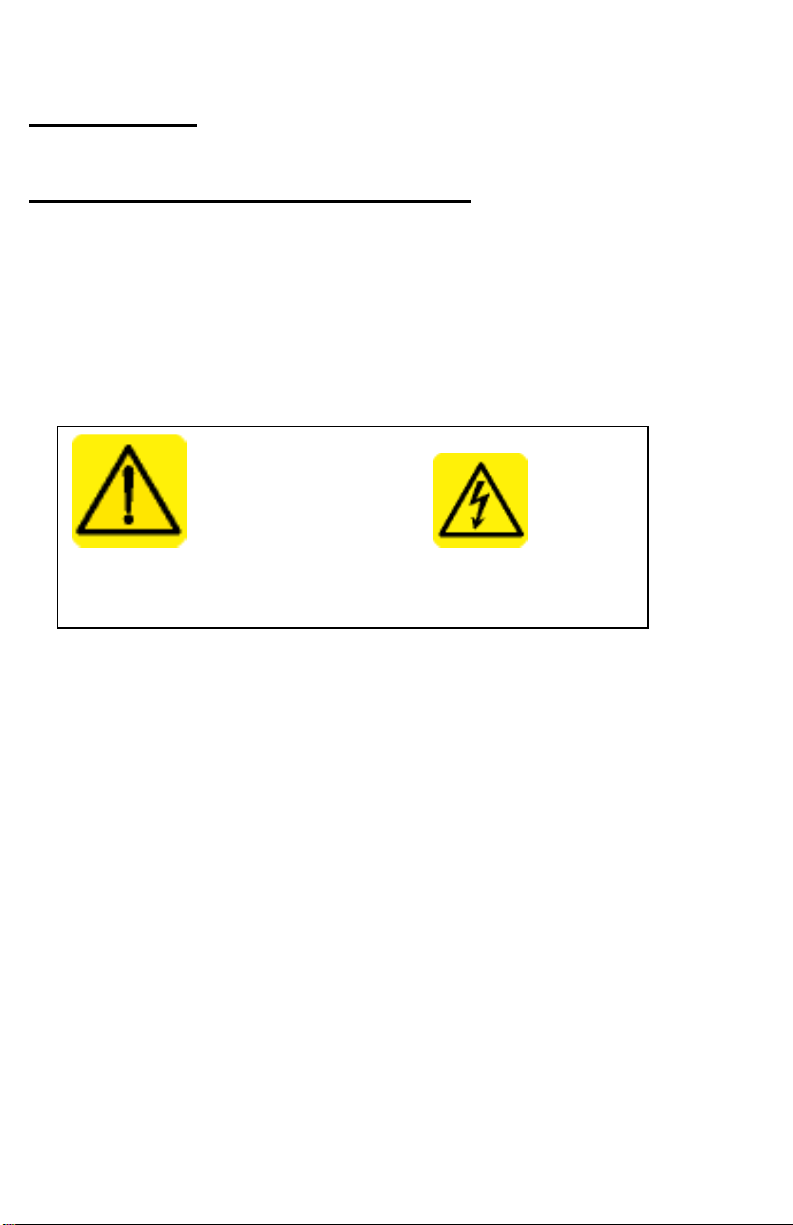

SECTION 2.0 SAFETY SUMMARY

All safety related regulations; local codes and instructions that appear in this

literature or on equipment must be observed to ensure personal safety and to prevent

damage to either the instrument or equipment connected to it. If equipment is used in a

manner not specified by the manufacture, the protection provided by the equipment may be

impaired.

Do not use this unit directly command motors, valves, or other actuators not

equipped with safeguards. To do so can be potentially harmful to persons or equipment in

the event of a fault to the unit.

CAUTION: Read complete CAUTION: Risk of Electric shock

Instructions prior to installation

And operation of the unit.

The unit must be properly grounded. Ground connection is tied to the Main Board “P1”

connector pin C.

Fuse replacement must be performed with power disconnected. Use only the same type

fuse. The fuse must be a TR5 microfuse, Time Lag (T), 1 amp, 250VAC. Fuse location

shown in section 1.3

5

Page 7

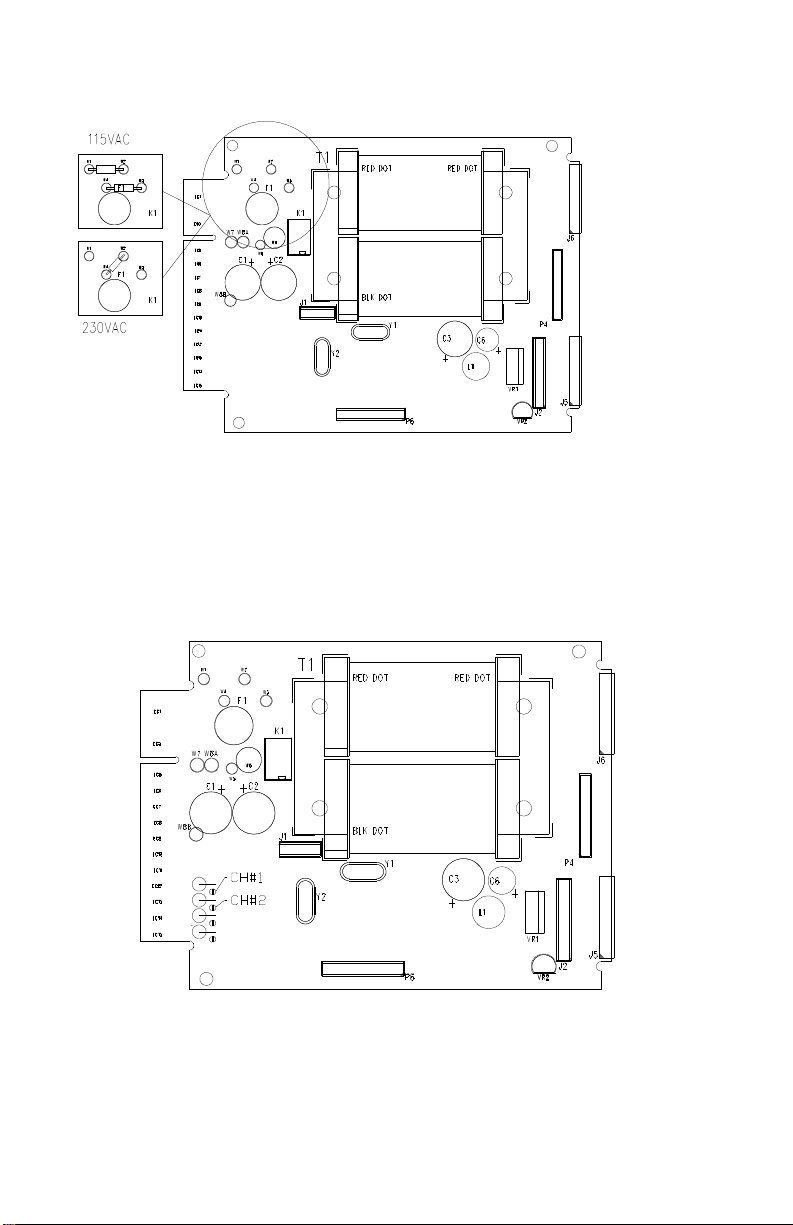

POWER 115 OR 230VAC SELECTION:

configuring the jumpers in the above drawing.

20MA SOLDER JUMPER LOCATION

The IPM500 can be configured to operate on 115VAC or 230VAC by

To select 4-20ma input range solder across solder pads shown above.

6

Page 8

PIN OUTS AND WIRING DIAGRAMS

SECTION 2.1: MAIN BOARD/BOTTOM (P1) AND

OPTION BOARD/TOP (P2) PIN OUTS

7

Page 9

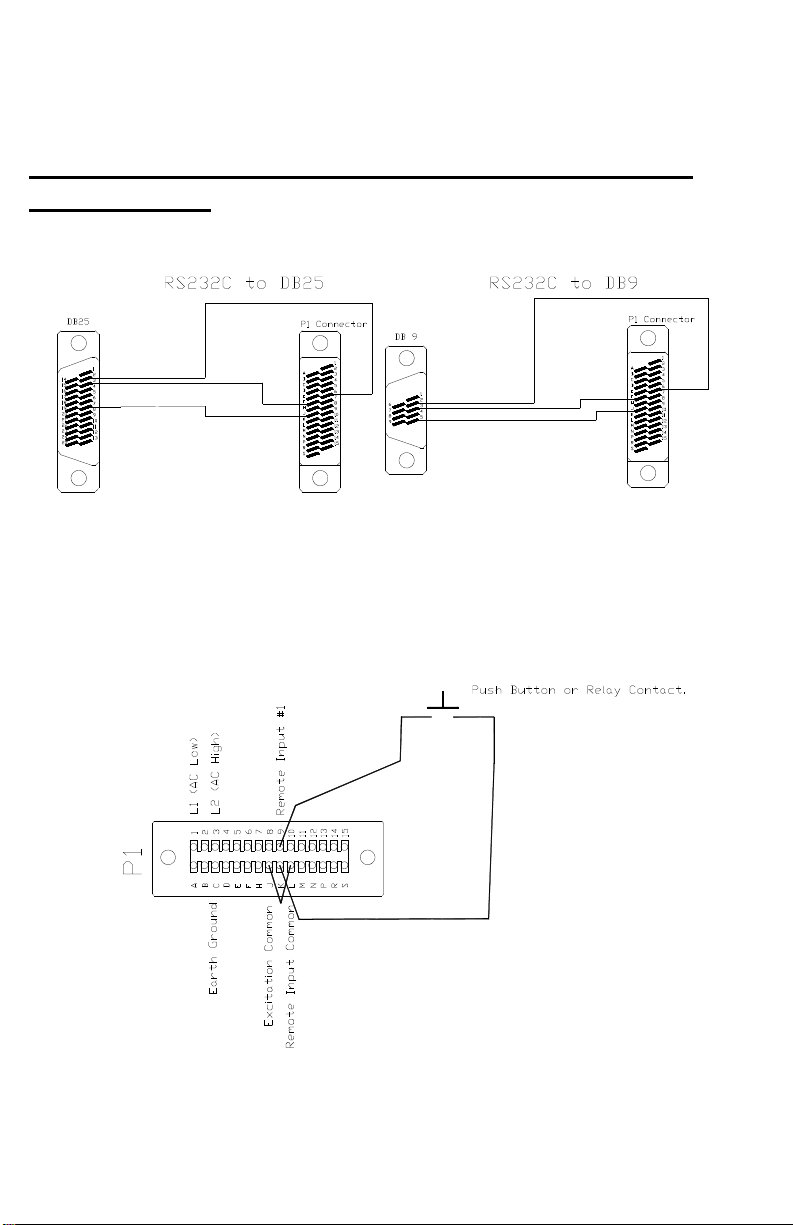

SERIAL RS-232C CONNECTIONS ON P1(MAIN BD)

CONNECTOR

EXAMPLE REMOTE INPUT WIRING

8

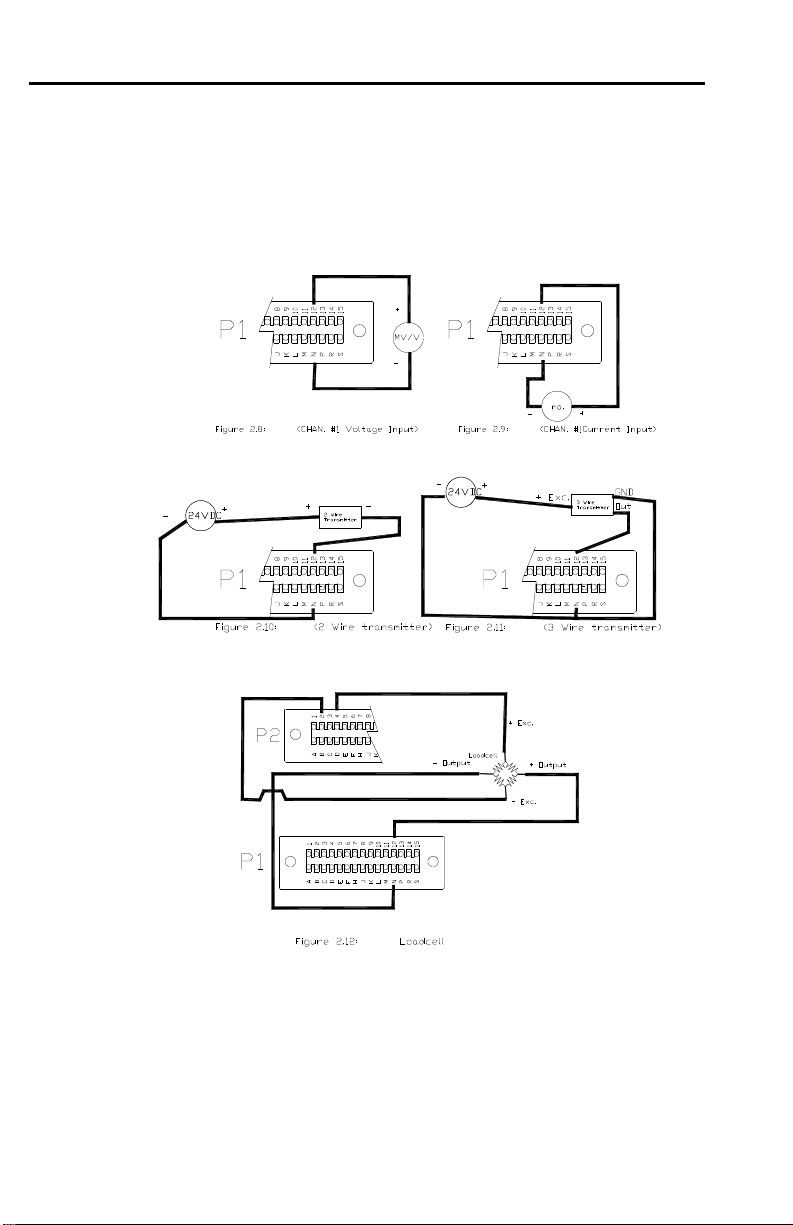

Page 10

SECTION 2.4: CHANNEL #1 INPUT CONNECTIONS

9

Page 11

LED's

SECTION 3

OPERATION AND PROGRAMMING

SECTION 3.1: FRONT PANEL KEYS

Channel

LED's

Function

The front panel keyboard has two modes of operation - SETUP and RUN

SETUP MODE KEYS

SELECT EXIT ENTER

RUN MODE KEYS

F1 F2 F3 F4 SETUP

Alarm

LED's

Function

Keys

SECTION 3.2: SETUP MODE KEY FUNCTIONS

1. SELECT KEY ( on flow chart indicates to use this key)

• Selects choice of functions within the menu you are setting up.

> Moves you left/right in the program menu.

• When entering numeric data, it allows the selection of digit to be

changed.

> Indicated by digit flashing.

• When selecting decimal point, it moves the decimal point

location.

2. UP ARROW KEY

• When entering numeric data, it increments the current value of

the flashing digit by one with each push.

3. DOWN ARROW KEY

10

Page 12

• When entering numeric data, it decrements the numeric value of

the flashing digit by one with each push.

4. EXIT KEY

• If at a Main branch prompt (CODE, CHAN, OUTPUT, DISPLY

or SPEC), it exits to you back to RUN mode.

• If in a programming branch, it returns you to Main branch

prompt.

NOTE: It does note store data to memory on its return.

ENTER key should be pushed first to store selected entry,

then EXIT key.

5. ENTER KEY ( on flow chart indicates to use this key)

• Enters selected Main program branch.

> Moves you down in the program branch menu.

> Menu steps can be skipped by repeatedly pushing ENTER

key till desired menu step is reached.

• Enters selected choices, numeric data or decimal point, it stores

the value and advances to next step in the program menu.

SECTION 3.3: RUN MODE KEY FUNCTIONS

A. Entering SETUP

Push and hold SETUP key for 4 seconds. Meter will first

display “SET CH” then display “CODE” or flash “SETUP then

display “CHAN”.

• “CODE” is flashed with 00 if a lockout code has been

under the Main program branch heading SPEC, CODE

menu.

> The preset lockout must be entered at this time. If

wrong code is entered or if no code is entered within

20 seconds, meter will return to RUN mode.

> Upon correct lockout code entry, meter enters the

SETUP mode.

> The unmarked yellow LED just above the Down/F4

key will light, indicating you are in the SETUP mode.

• If no lockout code, “SETUP” flashed then “CHAN”

displayed, indicating you have entered the SETUP mode.

11

Page 13

If no key is pressed within 20 seconds, meter will return

to RUN mode.

B. If SETUP key pushed and released meter will enter select

channel program.

• “SET CH” (SET CHANNEL) will be display.

> Push F1 to select Channel 1 for display

> Push F2 to select Channel 2 for display

(3722A only)

> Push F3 to select Channel 3 for display

(3722A only)

C. USER PROGRAMMABLE MENU LOCKOUT.

To enter, push and hold SETUP key, then enter lockout code

“55”. This program allows user to disable/lockout the following

menus from the SETUP program. When the menus are

programmed to be locked, the unit will display “DISABL” when

you try to enter the menu.

NOTE: A code # must be preprogrammed under

SPEC, CODE to get the prompt for the code value.

To disable one or more of the selections add the values from the table and

enter that number. If 0 is entered, all programs under that heading are

enabled.

• “LEVEL1” is flashed with current selected number, valid

values 0-15

0 Don’t Skip any branches

1 Skip all channel programs "CHAN"

2 Skip all output programs "OUTPUT"

4 Skip all display program "DISPLY"

8 Skip all special programs "SPEC"

Example: Enter number 12 to skip DISPLY

and SPEC branches from normal setup

selections.

12

Page 14

• “CHAN1”, (Only if CHAN is not disabled from above),

is flashed with current selected number. Valid values 0-

15.

0 Don’t disable any channel 1

1 Skip input range selection "INPUT"

2 Skip user calibration branch "USER"

4 Skip input calibration branch "INPUT"

8 Skip shunt calibration branch "SHUNT"

• “CH” (Only if CHAN is not disabled from above) is

flashed with current selected number. Valid values 0-7.

0 Don’t skip Channel 2

1 Skip input range selection "INPUT"

2 Skip user calibration branch "USER"

4 Skip input calibration branch "INPUT"

• “CH3” (Only if CHAN is not disabled from above) is

flashed with current selected number. Valid values 0-1.

0 Don’t skip Channel 3

1 Skip Channel 3 "CHAN 3"

• “OUTPUT” (Only if OUTPUT is not disabled from

above) is flashed with current selected number. Valid

values 0-31.

0 Don’t disable any output menus

1 Disable Alarm 1 menu

2 Disable Alarm 2 menu

4 Disable Alarm 3 menu

8 Disable Alarm 4 menu

16 Disable the Source menu

13

Page 15

• “SPEC” (Only if SPEC is not disabled from above) is

flashed with current selected number. Valid values 065535 (default 32768)

0 Don’t disable any menus

1 Disable ‘F1 SET’

2 Disable ‘F2 SET’

4 Disable ‘F3 SET’

8 Disable ‘F4 SET’

16 Disable ‘r In 1’

32 Disable ‘r In 2’

256 Disable ’20 Pt’

512 Disable ‘PEAK 1’

1024 Disable ‘PEAK 2’

2048 Disable ‘SCALE2’

4096 Disable ‘CODE’

8192 Disable ‘DEFAUL’

• If EXIT key is push at any of the 6 main heading,

exit back to run mode.

• If EXIT key is push while in a main branch, exit

back to that main branches heading.

• If SELECT key is push while at main branch

heading, advance to next main branch.

• When “skip code number” is entered by ENTER

key, advance to next branch heading.

14

Page 16

D. F1, F2, F3 and F4 keys

The RUN mode keys (F1-F4) functions are selected in the

SETUP mode under the Main program branch heading

SPEC. The functions are described under the SPECIALS

FEATURES PROGRAMMING BRANCH section of the

manual (See pg. 26). The following are the available

selections.

• "ALARM 1" through "ALARM 4"

• "TARE1", "TARE 2" and "TARE 3"

• "RESET"

• "CHAN 1, 2 or 3"

• "PEAK 1"

• "PEAK 2"

• "SCALE 2"

• "NET"

• "SHUNT" (display/calibration)

SECTION 3.4: PROGRAMMING TIPS

SELECT Key

This represents SELECT key on flow charts

ENTER Key

Numeric values are entered by;

• Entering a number in flashing digit with the “UP” and “DOWN”

keys.

• Advance to the next digit using SELECT key. Enter value and

advance using ENTER key.

ENTER key sets number into memory and advances to next program.

EXIT key :

1. From MAIN BRANCH heading, takes you back to run mode

2. From PROGRAM BRANCH, takes you back to MAIN

BRANCH heading you are in.

TIMED OUT EXITS:

1. If no key is pushed within 20 seconds while at CODE or main branch

heading, meter will automatically exit back to run mode.

This represents ENTER key on flow charts

15

Page 17

2. If no key is pushed within 2 minutes while in any other program branch,

meter will automatically exit back to run mode.

SECTION 3.5: ENTER SETUP

• Press and hold SETUP key for 4 seconds. Meter will display

“SEL CH” at first then will enter into the Setup mode. The meter

will display “CODE” or “CHAN”.

• “CODE” is flashed with 00 if a lockout code has

been set under the Main program branch heading

SPEC, CODE menu.

• The preset code (1-50) must be entered at this

time. If wrong code is entered or if NO code is

entered within 20 seconds, meter will return to

RUN mode.

• Upon correct lockout code entry, meter enters the

SETUP mode. The status LED between Valley

and NET will light indicating the meter is in the

Programming/Setup mode.

• The unmarked yellow LED just above the

Down/F3 key will light, indicating you are in the

SETUP mode.

• If NO lockout code, “SETUP” flashed, then

“CHAN” displayed, indicating you have entered

the SETUP mode. If NO key is pressed within 20

seconds, meter will return to RUN mode.

SECTION 3.6: MAIN PROGRAMMING BRANCHES

16

Page 18

Run Mode

Press the

"ENTER" for 4

Sec.

Flashes

SEtuP/COdE

CHAn

Chan1,Chan2,

Chan3

setup routines and

calibrations are

under

this main menu.

Press &

release

"ENTER"

SEL CH

Main

Programming

Branches

OutPut

Alarms,Analog

Ouput,

Setup are under this

menu.

To move Side ways in the chart

below press the (SELECT) button.

To move down through the chart

press the (ENTER) key.

"F1"

Display

Channel #1

DiSPlY

Update Rates, Filter,

and Snap functions

are set under this

menu.

"F2"

Display

Channel #2

Quick Access F1-F4,

keys, Remote R1-R4

Code,Default settings.

Channel #3

SPEC

inputs, 20pt

Linearization,Peaks

1&2 ,Access

"F3"

Display

For more

Description

see Sec.

3.7

For more

description

see Sec.

3.8

See back page

for

complete Flow

Chart.

For more

description

see Sec.

3.9

For more

description

see Sec.

SECTION 3.6 (cont.)

"CODE" is displayed if a lock out code has been programmed.

3.10

17

Page 19

• If "CODE", then enter your Lockout Code number (1-50)

• If NO "CODE" then "CHAN" is displayed

Use SELECT key to choose which branch you wish to enter. Then press

ENTER key to select that branch to program. Selections are: "CHAN",

"OUTPUT", "DISPLY", and "SPEC".

SECTION 3.7: CHANNEL SETUP PROGRAMMING

BRANCH

Press SELECT key to choose which channel you wish to program. Then

press ENTER key.

CHAN 1 is input Channel 1

CHAN 2 is input Channel 2

CHAN 3 is the math Channel

There are 3 separate channel setups. Two for the analog input channel

(Channel 1 and Channel 2) and one for the math channel (Channel 3)

1. Channel 1 and Channel 2 Scaling and Offsetting methods, to display in

engineering units

• There are 3 methods to perform the setup of Channel 1.

• There are 2 methods to perform the setup of Channel 2.

At the beginning of each of the calibration methods there is a

display that shows the raw unscaled input signal. This allows

the user to verify the incoming signal is present and what

value it is.

a. Method 1 (U CAL)

1. Raw input is displayed. For exact calibration purposes

you can input the low and high inputs and record their

value for entry in the low and high input values below.

Push ENTER key to advance.

2. "DEC PT" selects decimal point. Push SELECT key for

displaying decimal point selections and ENTER key to

confirm choice.

3. "IN LO" enter in low input value

4. "DSP LO" (display low) enter in display value

corresponding to low input value.

5. "IN HI" enter in high input value.

18

Page 20

6. "DSP HI" (display high) enter in display value

corresponding to high input value.

b. Method 2 (LD CAL)

NOTE: Input Signal must be applied to the unit for low and high

display values. The meter compares the input signal to the

display value entered and scales the meter based on the two

inputs.

1. Raw input is displayed. This can be used to make sure

the correct input is being applied and/or that the meter is

properly measuring it. Push enter to advance.

2. "DEC PT" selects decimal point. Push SELECT key for

displaying decimal point selections and ENTER key to

confirm choice.

3. "DSP LO" (display low).

Either select "YES" or "NO" here.

"YES" allows you to apply corresponding low input

signal to input and enter in corresponding low display

value. Push ENTER key to make displayed value equal

input. If “NO” is selected it skips over this program and

leaves values to what they were.

4. "DSP HI" (display high).

Either select "YES" or "NO"

If "YES" is selected, this allows you to apply

corresponding high input signal to input and enter in

corresponding high display value. Push ENTER key to

make displayed value equal input. If “NO” is selected it

skips over this program and leaves values to what they

were.

5. "ENABLE" (Enable). This enables the above calibration

setup by the inputs. This allows for the low value and

high values to be set at different times and then enabled

when both are complete.

• "NO" leaves calibration unchanged

• "YES" enables this calibration and overrides any

previous calibration by the USER or SHUNT type

calibration

19

Page 21

c. Channel 1 only has a third method of setup

"SHUNT" cal method (Also known as R-CAL):

1. Raw input is displayed. This can be used to make sure

the correct input is being applied and/or that the meter is

properly measuring it. Push ENTER to advance.

2. "DEC PT" selects decimal point. Push SELECT key for

displaying decimal point selections and ENTER key to

confirm choice.

3. "DSP LO" (display low). Enter in display value

corresponding to low input value.

4. "DSP Hi" (display high). enter in display value

corresponding to shunt calibration resistor.

5. At this time the unit stores the values and waits for a

Function key (F1-F4) programmed for shunt calibration

to start the following calibration.

a. DPM measures input & sets display low equal to

input.

b. Shunt cal relay is closed automatically.

c. 5 sec later DPM measures input & sets display

high equal to shunt cal input.

d. Shunt relay opened.

e. Return to the RUN MODE.

2. Channel 3 (Math channel)

a. "TYPE” Select for Channel 3 to be one of following:

• "CHAN 1" Channel 1’s raw input count

• "CHAN 2" Channel 2’s raw input count

• "Add" Sum of Channel 1 + 2

• "Sub" Difference of Channel 1 – 2

• “Div” Result of Channel 1 ÷ 2

• “Mul” Multiply of CH1 x CH2

• “P1-P2” Peak1 – Peak2

b. Raw input is displayed. For exact calibration purposes you can

input the low and high inputs and record their value for entry in

the low and high input values below. NOTE: The low and high

20

Page 22

values are the result of the above selected math formulas. Push

ENTER key to advance.

c. "DEC PT" selects decimal point. Push SELECT key for

displaying decimal point selections and ENTER key to enter

choice.

d. "In LO", enter in low input value

e. "DSP LO", (display low) enter in display value corresponding to

low input value.

f. "In HI", enter in high input value.

g. "DSP HI", (display high) enter in display value corresponding to

high input value.

h. “ OFFSE” Enter an offsetting factor from –9999 to 9999, which

is applied after the above scaling.

SECTION 3.8: OUTPUT SETUP PROGRAMMING

BRANCH

Push SELECT key to choose which output you wish to program. Then

press ENTER key.

"AL AR" is the 4 alarm output setups; "ANALOG" is analog output

setup

1. ALARMS

This setup menu programs the 4 alarms.

NOTE: Relays 1 through 3 are optional FORM “C” relays

and located on the option/top board.

Relay 4 is standard FORM “A” relay and located on the

main/bottom board.

a. "AL AR" selects which alarm is to be programmed. Use

SELECT key to view choices of alarms 1 through 4. Use the

ENTER key to enter choice.

Note: 1. Each alarm is treated completely

independent thus allowing all 4 to be programmed

with same channel or different channels

controlling one alarm.

21

Page 23

2. Alarm one is different from one standpoint. It has

the additional selection of "SAFE"(fail safe)

selection. The selection "SAFE" here controls

relays 1 through 3 for the fail-safe operation.

b. "CHANEL" selects which channel alarm is being assigned to.

Use SELECT key to view choice of channels. Use ENTER key

to enter choice.

c. "RELAY" selects which relay (1 through 4) is being

programmed. Use SELECT key to view choices of outputs. Use

the ENTER key to enter choice.

NOTE: Relays 1 through 3 are optional and located on the

option/top board. Relay 4 is standard and located on the

main/bottom board.

d. "TYPE" selects what type of alarm. Use SELECT key to view

following choices. Use the ENTER key to enter choice.

1. "ALAR HI" (alarm high) selects alarm to trigger when

input goes over programmed set point.

2. "ALAR LO" (alarm low) selects alarm to trigger when

input goes under programmed set point.

e. "SET PT" (set point) enter number at which alarm will occur.

• Set point can also be programmed from the RUN mode when

an F key is assigned to display alarm. If F key is held for 4

seconds, the display will start flashing the right hand digit

signifying the new set point can be entered.

Note: The corresponding front panel alarm LED is on when

in alarm.

Note: Alarm set point can only be changed enabled on the

alarm setup menu, otherwise you can only view the set point.

f. "HYST" (hysteresis / deadband) enter number. This number is

added to a low limit or subtracted from a high limit before an

alarm condition is cancel. It is typically used to prevent alarm

chatter.

g. "LATCH" selects alarm to latching or non-latching (follows

input). If LATCHING is selected, alarm will remain on till

manually reset. Use SELECT key to view “YES” for latching

22

Page 24

and “NO” for non-latching. Use the ENTER key to enter choice.

Note: “RESET” function programmable for front panel key or

remote input, is used to reset the latched alarm.

h. "SAFE" ("ALARM 1" ONLY) selects alarms 1 through 3 to be

in a safe mode (de-energizes on alarm) or standard (energizes on

alarm). Use SELECT key to view “YES” for safe and “NO” for

standard. Use the ENTER key to enter choice. Note: This is

used to determine what the alarms do when loss of power occurs

to meter. With "SAFE" selected alarm will turn on when power

fails.

i. "FLASH" selects alarm to flash display when in alarm. Use

SELECT key to view “YES” for flash display and “NO” don’t

flash display. Use the ENTER key to enter choice.

j. “ENABLE” selects if set point is changeable in the run mode, or

just viewing a load.

2. ANALOG OUTPUT

This setup menu programs the analog output/retransmission.

a. "SOURCE" selects what the analog output will be based upon.

Use SELECT key to view choices. Use ENTER key to enter

choice. After choice is entered then addition choices are entered.

1. Selections are:

• "CHAN 1" Channel 1

a) "GROSS" gross value (default)

b) "NET" net value

c) "PEAK 1" peak 1 value

• "CHAN 2" Channel 2

a) "GROSS" gross value

b) "NET" net value

c) "PEAK 1" peak 1 value

• "CHAN 3" Channel 3

a) "GROSS" gross value

b) "NET" net value

c) "PEAK 1" peak 1 value

• "DISPLY" What ever is currently

selected

23

Page 25

b. "OUT" selects what the analog output will be

• "4-20" 4-20mA

• "0-10" 0-10VDC

• "0-20" 0-20mA

• "0-5" 0-5VDC

• "-5 +5" -5 to +5VDC

c. "DSP Lo" enter what the low display value that will represent

the low analog output value

d. "DSP HI" enter what the high display value that will represent

the high analog output value

SECTION 3.9: DISPLAY SETUP PROGRAMMING

BRANCH

"FILTER"/"SNAP" - "FILTER" AND "SNAP" work together to provide a

digital filter. The filter is applied to both Channel 1 and Channel 2 inputs.

The NO filter setup is

The Filter formula is active only when New Reading < Old Reading +/Snap Value.

New Display Reading = (Old Reading + (Filter (New Reading- Old)))

"FILTER"= 1.000, "SNAP"=0.000

SECTION 3.10: SPECIAL FEATURES PROGRAMMING

BRANCH

Use SELECT key to choose which function you wish to program. Then

press ENTER key.

24

Page 26

• "F1 SET" thru "F4 SET" programs the RUN mode function of

the 4 F keys

• "r in 1" thru "r in 2" programs the function of the 2 remote inputs

• "20 Pt" programs the 20 point linearization table and assigns it to

one channel

• "PEAK 1" programs the peak or valley function of each channel

• "PEAK 2" programs second the peak or valley function of each

channel

• "SCALE2" programs the second scaling parameters of each

channel

• "CODE" programs the lockout code for authorized entry into

SETUP

• "DEFAUL" sets meter setup back to default setup

1. "F1 SET", "F2 SET", "F3 SET" and "F4 SET" - RUN MODE function

key setup

This programs the function of the 4 front panel F keys.

A. "ALAR 1" thru "ALAR 4” assigns alarm function to F keys

• Pushing F key displays current alarm set point

• Pushing F key for 4 seconds allows point value to be

changed.

Current set point is displayed with the right most digit

flashing. The set point can now be changed with the

UP and DOWN keys. Select digit to be changed with

SELECT key. Press ENTER key to enter new value

into memory and return to RUN mode

B. "TARE 1", "TARE 2" and "TARE 3" assigns F key for tare

function. 1 for channel 1, 2 is for channel 2 and 3 for math

channel 3.

• Pushing F key will zero the Channel for the input

present.

• Pushing F key for 4 seconds will reset the tare value to

zero.

"CHAN 1" assigns F key to display Channel 1

"CHAN 2" assigns F key to display Channel 2

"CHAN 3" assigns F key to display Channel 3

25

Page 27

C. "RESET" assigns F key for resetting latched outputs

• Pushing F key will reset all relays in an alarm condition.

D. "SCALE2" assigns F key to initiate 2nd scaling to be applied.

• Pushing F key will switch displayed channel to 2nd

scaling.

• Front panel S2 LED will light to indicate 2nd scaling is

applied.

• Push F key while S2 is selected will change scaling back

to initial scaling

• If different channel is selected while 2nd scaling is

selected, it will also use the 2nd scale factor applied to it.

E. "SHUNT" assigns F key to "SHUNT" Cal function.

• If assigned to display calibration, pressing F key for 3

seconds will initiate shunt cal relay to close. This

displays calibration value.

Note: input should be unloaded.

F. "NET" assigns F key to switch displayed channel between gross

and net

• Pushing F key will switch displayed channel to display

net.

• Front panel NET LED will light to indicate NET is being

displayed.

• Push F key while net is selected will change display back

to gross.

If different channel is selected while net is selected, it

will also display net.

• If assigned to do a "SHUNT" calibration, pressing F key

triggers display of CAL with selection of "YES or NO".

"NO" aborts and returns to Run mode.

"YES" initiates the shunt calibration procedure.

G. "PEAK 1" and "PEAK 2" assigns programmed peak function to

F key

26

Page 28

• Pushing F key will display the assigned peak function. If

peak was assigned peak LED on front panel will also

light. If Valley then valley LED will light.

• Pushing F key for 4 seconds will reset the peak/valley.

2. "r in 1", and "r in 2” remote inputs. RUN mode remote/external input

setup

The 2 Remote input functions are selected under the Main program

branch heading "SPEC". A TTL level applied to the input enables

the following.

! "RESET" - Resets latched relays

! "TARE" - Zeros display for channel being displayed.

! "HOLD" - Freezes display and suspends measurements

! "SCALE2" - Selects second scaling to be applied to channel

being displayed. S2 light on front panel is lit.

! "LOCK" - Locks out access to the SETUP programs

! "PEAK 1" - Display PEAK 1

! "PEAK 2" - Display PEAK 2

! "ALARM" - Disables alarms. Meter functions normally but no

alarms are activated when they go beyond their preset limits.

! "DEC PT" - Selects the decimal point programmed

! "CHAN" - Selects the channel programmed

! "PRESET" - Resets both peak and valleys.

! "NET/GROSS" - Displays Gross value of channel

! “PRINT” – Initiates a print of the current display through the

RS-232C serial port. (T option required for this function.)

3. 20 point linearization

Allows the user to program and assign a 19-segment linearization

program to one channel.

"On"/"OFF" - On enables the linearization table, off disable the

linearization table

"CHAN 1"

"CHAN 2 " Assigns the linearization to a channel

"CHAN 3"

"SEGS" - Total number of segments (1-19)

"In 1” through "In 19" - Enter the 19 input values

"OUT 1" through "OUT 19" - Enter the 19 output values

27

Page 29

4. "PEAK 1" and "PEAK 2" setup

Programs the functions of the 2 peak capture inputs. Each peak can

be individually programmed.

"TYPE" Select if peak to be highest or lowest valley

"HI" High/Peak selection

"Lo" Low/Valley selection

"CHAN 1", "CHAN 2,"CHAN 3” Select channel to do peak on

5. "SCALE 2" setup

Programs the setup and assignment of the second scale factor. This

would typically be used to switch the display between English and

Metric engineering units. The selection of scale 2 can be activated

from a Front Panel Key (F1 - F4) or a remote input. They must be

programmed to perform the switch to scale 2 under the "SPEC"

branch programming.

"CHAN 1", "CHAN 2" Select which channel the second scale

factor is being setup for. Both Channel 1 and Channel 2 can be setup

for an individual second scale factor.

"DEC PT" selects decimal point. Push SELECT key for displaying

decimal point selections and ENTER key to confirm choice.

"IN Lo" enter in low input value

"DSP Lo" (display low) enter in display value corresponding to low

input value.

"IN HI" enter in high input value.

"DSP HI" (display high) enter in display value corresponding to high

input value.

6. LOCK OUT CODE SETUP

This enables the program of a lockout code (0 to 50) to limit the

entry into the setup mode. Once a code is entered here, it must be

enter upon trying to enter the setup mode when the meter prompts

for "CODE". Setting the code to 00 disable the lockout code

function.

"CODE" is flashed with the lock out code currently programmed.

Enter in a new code or exit the program (EXIT key).

28

Page 30

7. DEFAULT program

This program is used for any of the following:

• Reset the meter back to the factory defaults.

• Set the user defined defaults into memory

• Reset the meter to the user defined defaults

"DEFAUL" default program prompt

"YES"/"NO" "NO" to exit this menu

"YES" if one of the 3 defaults is to be done.

Continue to next step

"USER"/"FAC"

• "FAC" (factory) allows the reset of the meter back

to factory defaults. When the prompt

a) "FACTORY" is displayed, the SELECT key

must be pushed and held (10 seconds) until

the prompt "DONE” and returns to "SPEC"

branch. If any other key is push it will abort

the default operation and return to "SPEC"

branch.

• "USR" (User) allows the setup of custom defaults

or default to the custom defaults

b) "STORE" allows the custom defaults to be

set. This will set the defaults to the setup of

the meter it is currently programmed.

• "SET DF" When this is displayed

the SELECT key must be pushed

and held until the "DONE"

prompt. Meter then returns to

"SPEC" branch heading.

• "GET DF" When this is displayed

the SELECT key must be pushed

and held until the "DONE"

prompt. This takes approximately

29

Page 31

SECTION 4

OPTION C:

• 3 form C (single pole double throw) relays rated at 5 amp @

• Located on the option/top printed circuit board

OPTION H:

• Analog output with menu selection of 0-20mA, 4-20mA, 0-

• Update rate of 25/second (3720A)

• Resolution - 16 bit D/A

• Located on the option/top printed circuit board

OPTION P:

Accuracy: .5%

OPTIONS

240VAC, 5amps @ 30VDC.

5VDC, 0-10VDC and +5/-5VDC

24VDC @ 150mA

10 seconds. Meter then returns to

"SPEC" branch heading.

OPTION T:

10VDC @ 250mA supply

Accuracy: .5% (adjustable)

• Serial RS-232C Communication.

30

Page 32

range

• Configuration of 9600 baud, NO Parity Check, 8 DATA Bits,

with CTS handshaking available.

SECTION 5 SPECIFICATIONS:

±±±±20 mA

Accuracy 0.02% 0.02% 0.02% 0.02% 0.02% 0.02%

Zero Drift Autozero Autozero Autozero Autozero Autozero Autozero

Span Drift 10 ppm/°C 10 ppm/°C 10 ppm/°C 10 ppm/°C 10 ppm/°C 10 ppm/°C

Input

Impedance

Resolution 1 uA 1 uV 10 uV 10 uV 100 uV 1 mV

OverCapability,

minimum

Normal Mode Rejection

Ratio

Common Mode

Rejection Ratio

Response Time 100 msec max to display (10 updates / sec)

Internal Resolution 22 bits

Conversion Time 100 mS

Digital filter 10 Hz

Warm Up Time 15 minutes

Operating Temp range -20°C to 60°C

Storage Temp range -20°C to 85°C

Humidity To 95%, non-condensing

50 Ohms 10 Mohm 10 Mohm 10 Mohm 10 Mohm 10 Mohm

10%

+/- 30 mV +/- 100 mV +/- 200 mV +/- 2V

10%

63 bB, 50/60 Hz

130 dB, 50/60 Hz

10%

10%

10%

±±±±10V

10%

AC supply voltage 115 or 230 VAC

Power Consumption 15 Watts maximum (all options installed)

Isolation

Signal Input to Earth Ground: Safety rated to 450 Vrms, 2200Vp high voltage test

Option board to Earth Ground: Safety rated to 450 Vrms, 2200Vp high voltage test

Option board to Signal Input: 400 Vp

Power to Earth Ground: Safety rated to 500 Vrms, 4000 Vp high voltage test

Shunt Cal. Relay Contact Rating : 30VDC @ 1 A

31

Loading...

Loading...