Page 1

IPM490 & IPM500

DIGITAL PANEL METER OWNERS MANUAL

10 Thomas, Irvine, CA 92618, USA

Tel: (949) 465-0900

• Fax: (949) 465-0905 • Website: www.futek.com

1

Page 2

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS............................................................................................... 2

2. TEDS INTRODUCTION............................................................................................... 2

3. IPM490 / IPM500 INTRODUCTION............................................................................. 3

4. RECEIVING & UNPACKING ....................................................................................... 4

5. SAFETY CONSIDERATIONS...................................................................................... 4

6. CONNECTOR WIRING INFORMATION ..................................................................... 5

7. MECHANICAL ASSEMBLY ......................................................................................... 7

8. FRONT PANEL SETUP KEYS .................................................................................... 9

9. ENABLING & LOCKING OUT MENU ITEMS .............................................................. 11

10. READING COORDINATES OF 2 POINTS SCALING METHOD................................. 12

11. DC VOLTS, AMPS, PROCESS, STRAIN INPUT......................................................... 13

12. LOAD CELL & MICROVOLT INPUT............................................................................ 18

13. AC RMS VOLTS & AMPS INPUT ................................................................................ 23

14. THERMOCOUPLE INPUT........................................................................................... 29

15. RTD & RESISTANCE INPUT ...................................................................................... 32

16. DUAL & QUAD RELAY OUTPUT OPTIONS .............................................................. 37

17. ANALOG OUTPUT OPTION ....................................................................................... 40

18. SERIAL COMMUNICATION OPTIONS ....................................................................... 41

19. TEDS INTERFACE ...................................................................................................... 44

20. EXCITATION OUTPUT & POWER SUPPLY............................................................... 46

21. METER CALIBRATION ............................................................................................... 47

22. SPECIFICATIONS ....................................................................................................... 50

23. GLOSSARY OF TERMS.............................................................................................. 54

2. TEDS INTRODUCTION

TEDS, or Transducer Electronic Data Sheet, is based on the IEEE 1451.4 standard. TEDS

enabled sensors contain an EEPROM that stores sensor information such as serial number,

calibration dates, and calibration factors. An IPM500 display with a TEDS reader will automatically retrieve this information once a TEDS enabled sensor is plugged into the system. This

greatly simplifies calibration and configuration of the sensor. Please see Section 19 for setup.

2

Page 3

3. IPM490 / IPM500 INTRODUCTION

IPM digital panel meters are versatile, cost effective solutions to a wide variety of monitoring

and control applications. Depending on the choice of signal conditioner, they are easily set up

for an accurate display of load, weight, pressure, torque, voltage or current, all in appropriate

engineering units and with zero and span adjustment. Setup can be via front panel pushbuttons or the meter’s serial interface. Selective security lockout of the front panel keys

protects against accidental changes to meter setup.

High read rates up to 60 per second (50 for 50 Hz operation) are made possible by Concurrent

Slope Conversion (Pat 5,262,780), which integrates the signal over an AC power line cycle for

maximum noise rejection. High read rates provide accurate peak and valley capture, and quick

response for control applications. An adaptive digital filter supplies a time constant for the

encountered signal noise level, yet responds rapidly to changes that exceed a selected

threshold. Self-calibration occurs automatically after every 17th reading.

The standard power supply is a high-efficiency switching unit that operates from AC or DC,

and allows the meters to be powered from worldwide AC without changes. A low-voltage

supply is optional for power from 10-48V batteries or from 12-30 Vac. Both supplies provide an

isolated 5, 10 or 24Vdc transducer excitation output.

The meter case conforms to the 1/8 DIN size standard. It is made of high impact, 94V-0 ULrated plastic and is watertight to NEMA-4 (IP65) when panel mounted (not verified for UL

certification). Mounting is from the front of the panel and requires less than 110 mm behind the

panel. Power and signal wiring is via removable plugs conforming to UL61010C safety

standards. All output options are isolated from meter and power ground to 250 Vac.

Extended IPM meter versions can linearize nonlinear inputs. Up to 180 data points may be

linearized by a computer program that stores setup parameters in nonvolatile memory.

Extended meters can also display rate of change, for example to display flow rate based on

changing tank level.

Alarm or setpoint control is provided by an optional relay board with two or four Form C 8A

mechanical relays or two or four Form A 130 mA solid state relays. The setpoints may be

latching or non-latching, be energized above or below the setpoint, or operate in a fail-safe

mode. The relays can operate from the filtered signal to reduce relay chatter or from the

unfiltered signal for fastest response. Snubber circuits and a programmable relay switching

time delay extend relay contact life.

An isolated analog output of 4-20 mA, 0-20 mA, 0-10V or -10 to +10V can be provided by an

optional analog output board. The output is linearized to the display and can operate from the

filtered or unfiltered signal input. It can be scaled via front panel pushbuttons or the meter’s

serial interface.

USB, RS232, or RS485 (2-wire half-duplex or 4-wire full-duplex) serial communications options

are available with Series 2 meters utilizing the Modbus protocol or a simpler custom ASCII

protocol. Modbus operation includes RTU or ASCII modes, up to 247 digital addresses, and up

to 32 devices per RS485 line without a repeater. A USB-to-RS485 converter board allows a

meter to be interfaced to a PC and to multiple meters on an RS485 network.

3

Page 4

4. RECEIVING & UNPACKING

Your meter was carefully tested and inspected prior to shipment. Should the meter be

damaged in shipment, notify the freight carrier immediately. In the event the meter is not

configured as ordered or the unit is inoperable, return it to the place of purchase for repair or

replacement. Please include a detailed description of the problem.

5. SAFETY CONSIDERATIONS

Warning: Use of this equipment in a manner other than specified may impair the pro-

tection of the device and subject the user to a hazard. Visually inspect the unit for signs of

damage. If the unit is damaged, do not attempt to operate.

Caution:

• This unit must be powered with AC (mains) from 95-240 Vac ±10% with the high voltage

power supply option, or 12-30 Vac (10-48 Vdc) with the low voltage power supply option.

Verify that the proper power option is installed for the power to be used. This meter has no

AC (mains) switch. It will be in operation as soon as power is connected.

• The 95-240 Vac mains connector (P1 Pins 1-3) is colored Green

other input and output connectors. The 12-30 Vac (10-48 Vdc) mains connector is colored

Black

.

• Do not make signal wiring changes or connections when power is applied to the instrument.

Make signal connections before power is applied. If reconnection is required, disconnect

the AC (mains) power before such wiring is attempted.

• To prevent electrical or fire hazard, do not expose the instrument to excessive moisture.

• Do not operate the instrument in the presence of flammable gases or fumes; such an

environment constitutes a definite safety hazard. This meter is designed to be mounted in a

metal panel.

• Verify the panel cutout dimensions, and mount according to instructions.

Symbols used

Caution (refer to accompanying documents)

Operating environment:

Caution, risk of electric shock. Both direct and alternating current.

Equipment protected throughout by double

insulation or reinforced insulation.

Earth (ground) terminal.

to differentiate it from

The meter is Class II (double insulated) equipment designed for use in Pollution degree 2.

4

Page 5

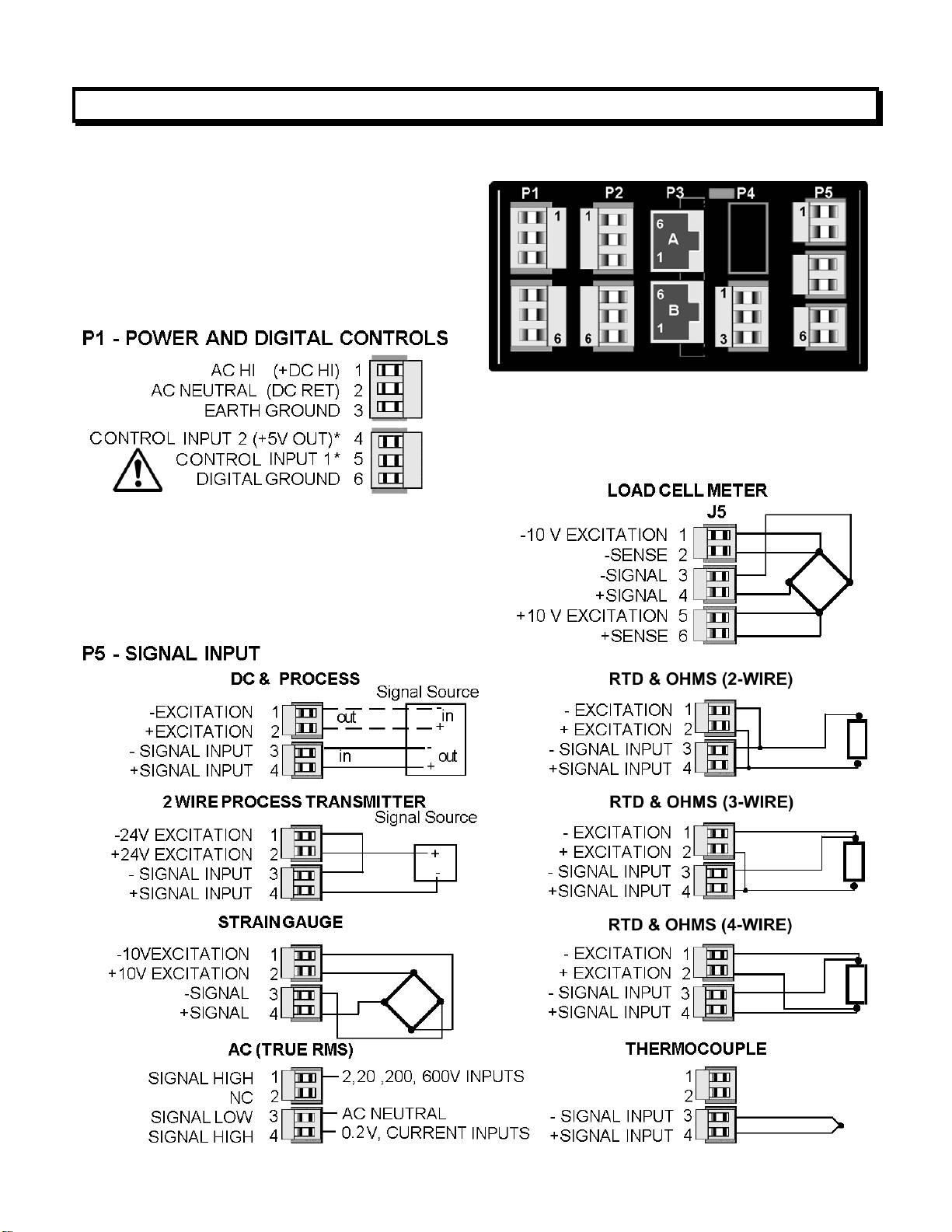

6. CONNECTOR WIRING INFORMATION

CONNECTORS

Connectors for signal and power are UL-rated

screw-clamp terminal blocks that plug into

mating jacks on the printed circuit board.

Communication connectors are a single RJ11

plug for RS232, dual RJ11 plugs for RS485,

dual RJ45 plugs for RS485 Modbus, or USB.

Note: Control inputs 1 & 2 of P1 are menu

selectable.

Warning: Hazardous voltages may be present

on pins 4, 5 & 6 of P1 since digital ground is tied

to pin 3 of P5 (-Signal Input). Keep pin 3 close to

earth ground to minimize common mode voltage

or shock hazard at pins 4, 5 & 6 of P1.

5

Page 6

P3 - SERIAL COMMUNICATIONS P4 - ANALOG OUTPUT

RS232 INTERFACE Computer

N/C

ISO GND

RX

TX

RTS

N/C

RS485 INTERFACE - FULL DUPLEX

ISO GND

BRX

ARX

ATX

BTX

ISO GND

6

5

4

3

2

1

GND

TX

RX

RTS

RS485 INTERFACE - HALF DUPLEX

6

5

4

3

2

1

GND

BTX

ATX

ARX

ARX

GND

ISO GND

ATX / ARX

BTX / BRX

ISO GND

6

5

4

3

2

1

GND

ATX / ARX

BTX / BRX

GND

RS485-MODBUS - FULL DUPLEX RS485-MODBUS - HALF DUPLEX

(A') RXD0 (B') RXD1 +

(B) TXD1 *

(A) TXD0 -

ISO GND

1

2

3

4

5

6

7

8

TXD0

TXD1

RXD1

RXD0

GND

(B) TX/RXD1

(A) TX/RXD0

ISO GND

6

1

2

3

4

5

6

7

8

(B) TX/RXD1

(A) TX/RXD0

GND

Page 7

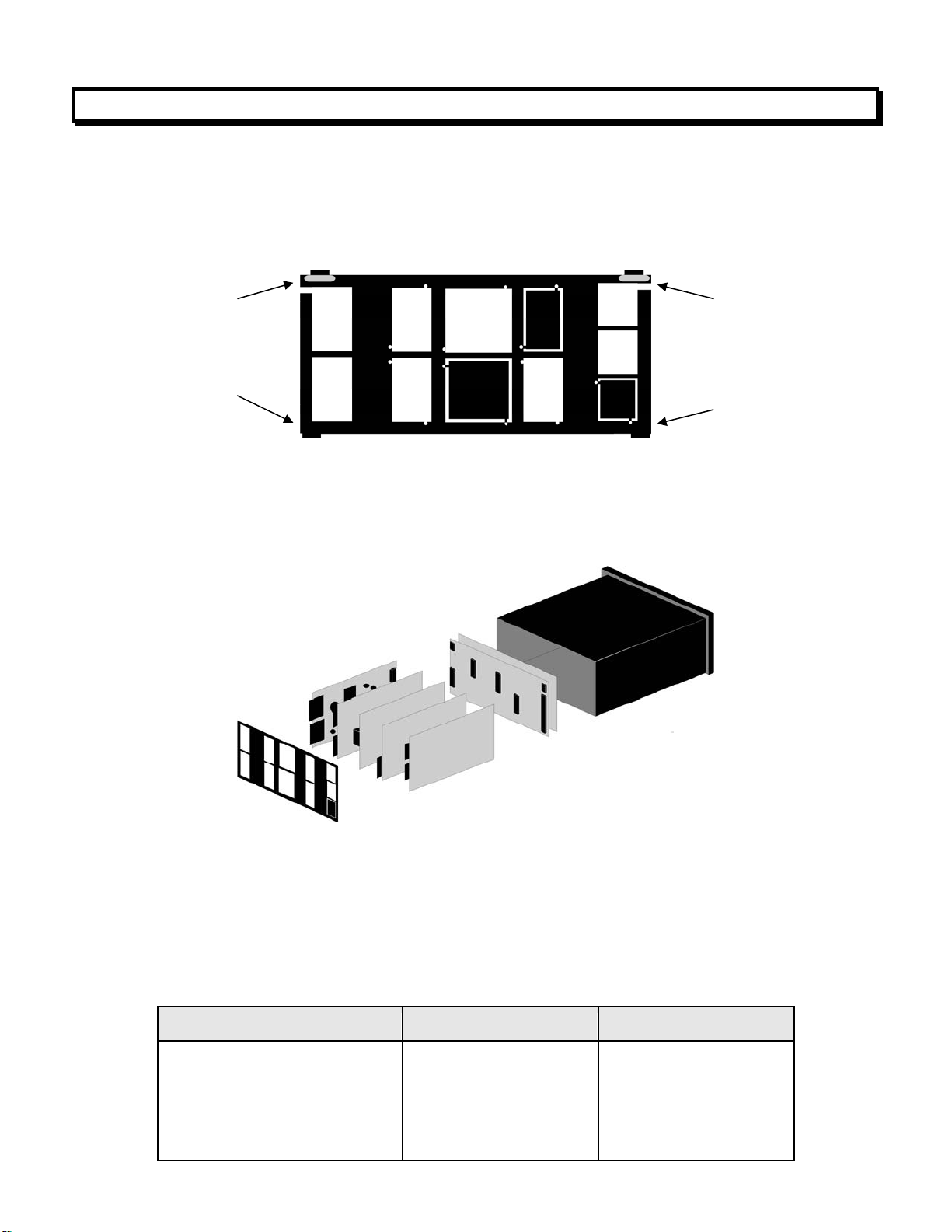

7. MECHANICAL ASSEMBLY

REMOVING THE REAR PANEL

First remove any connectors. Use one hand to press in the two sides of the rear of the

case, and the other hand to press down the two protruding tab releases at the top of the

rear panel (see figure below). This will unhook the rear panel from the case.

Retaining tab

with tab release

Retaining tab

Retaining tab

with tab release

Retaining tab

Rear Panel

REMOVING THE ELECTRONICS

With the rear panel removed, grasp the power supply board to the left and signal conditioner board to the right, and carefully slide the electronic assembly out through the rear of

the case. (see figure below).

INSTALLING NEW 0PTION BOARDS

Options boards plug into the main board at the front of the meter. These are plug-and-play

and may be

in the field. They will be recognized by the software, which will provide access to the menu

items associated with that board. If necessary, remove rear panel knockouts for new

boards. Boards plug into connectors as follows:

Option Board Main Board Plug Rear Panel Jack

Power supply

Relay board

Serial interface board

Analog output board

Signal conditioner board

P11

P12

P13

P14

P15

J1

J2

J3

J4

J5

7

Page 8

Note: Corresponding main board and option board connectors have the same number of

electrical lines. When an option board is correctly installed, the top and bottom edges of the

main board and option board are aligned.

REASSEMBLING YOUR METER

Slide the electronics assembly into the case until the display board is seated flush against

the front overlay. Insert the bottom tabs of the rear panel into the case, and then carefully

align the board connectors with the openings in the rear panel. If necessary, remove any

rear panel knockouts for new option boards that may have been installed. Ensure that all

option boards are properly aligned with the molded board retaining pins on the inside of the

rear panel. Once the rear panel is in place, reinstall the input/output screw clamp terminal

plugs.

PANEL MOUNTING

Ensure that the panel mounted gasket is in place against the back of the bezel. Turn the two

mounting screws counterclockwise until the space between the mounting pawl and the rear

of the gasket is greater than the panel thickness. Insert the meter in the panel cutout. Turn

the mounting screws clockwise until the meter is securely mounted in the panel. Do not

overtighten.

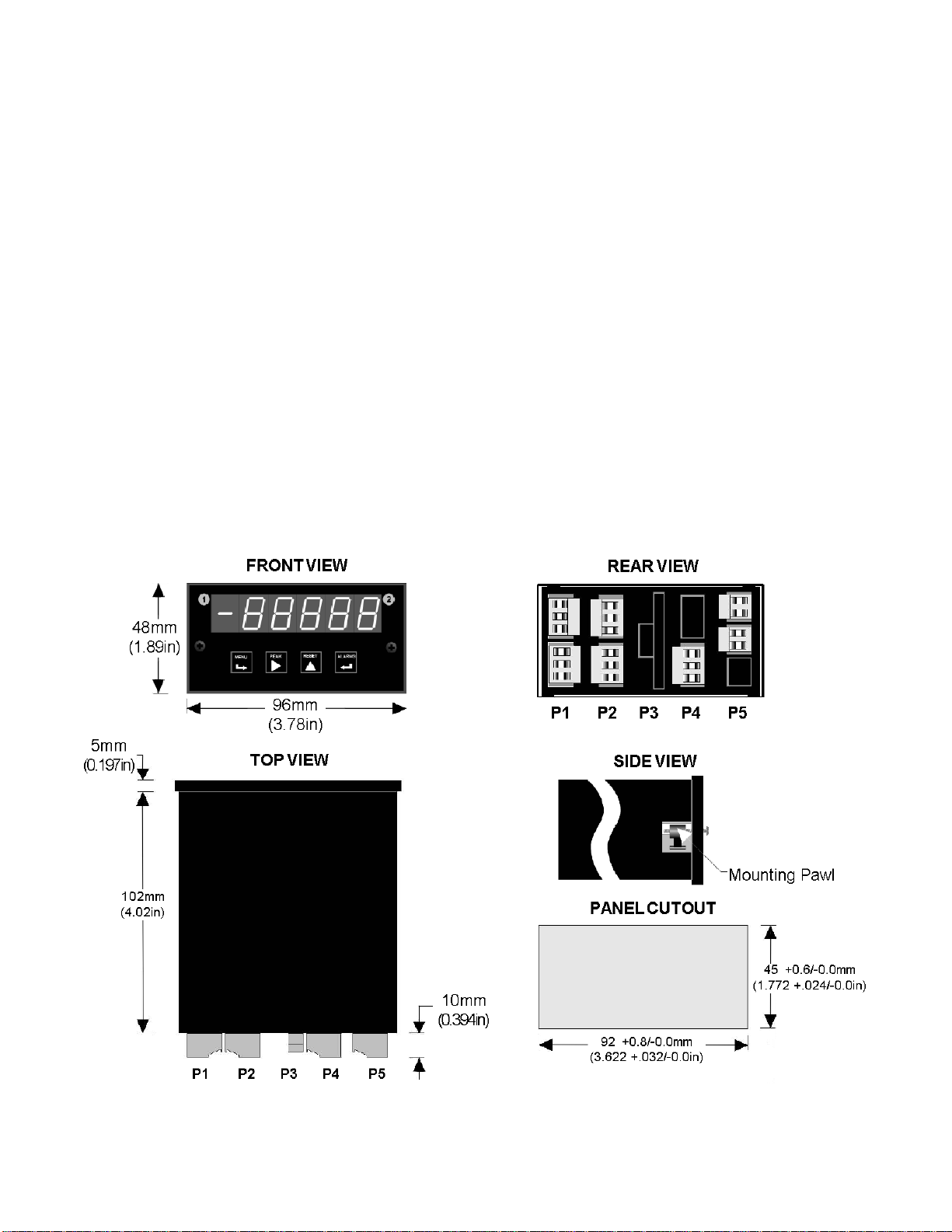

Dimensioned case drawings

8

Page 9

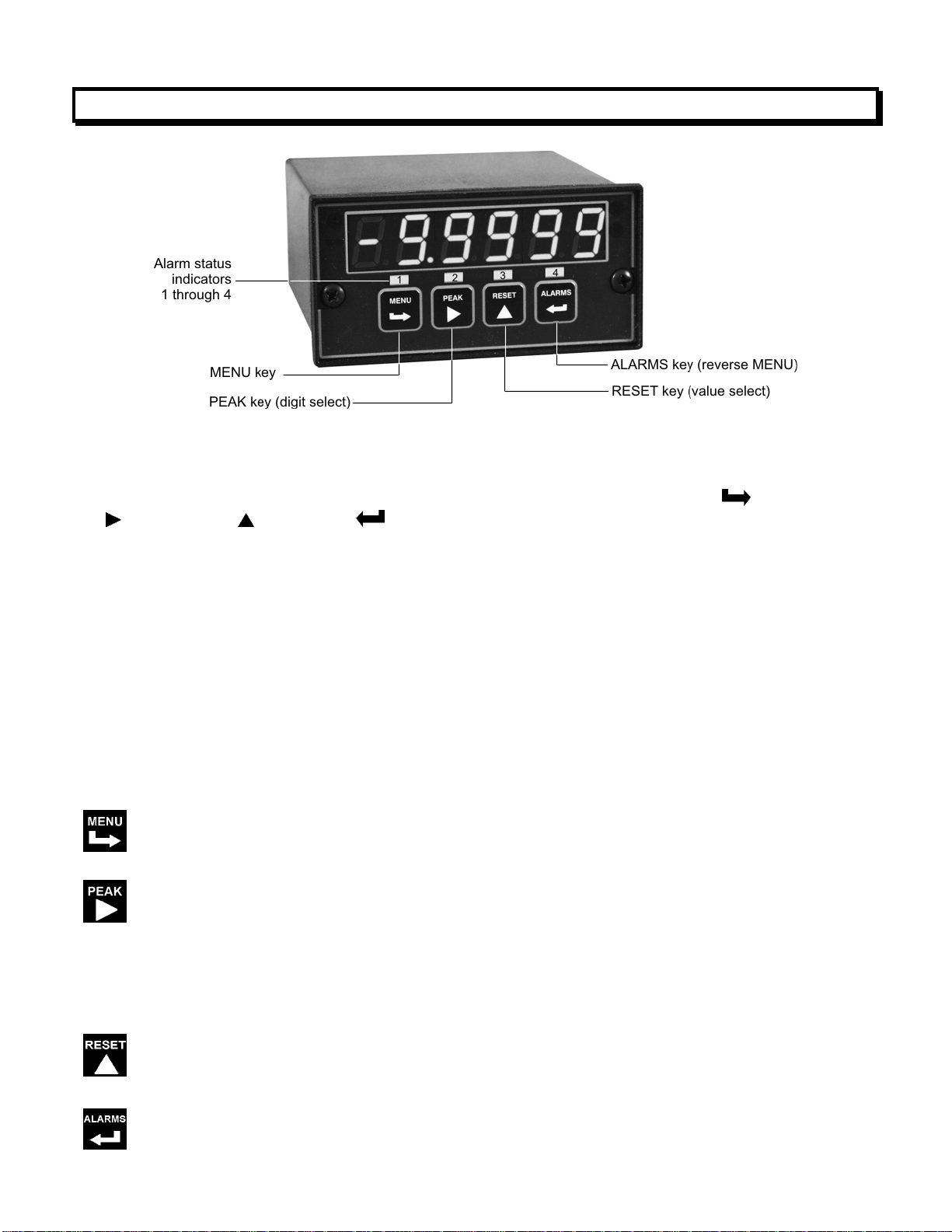

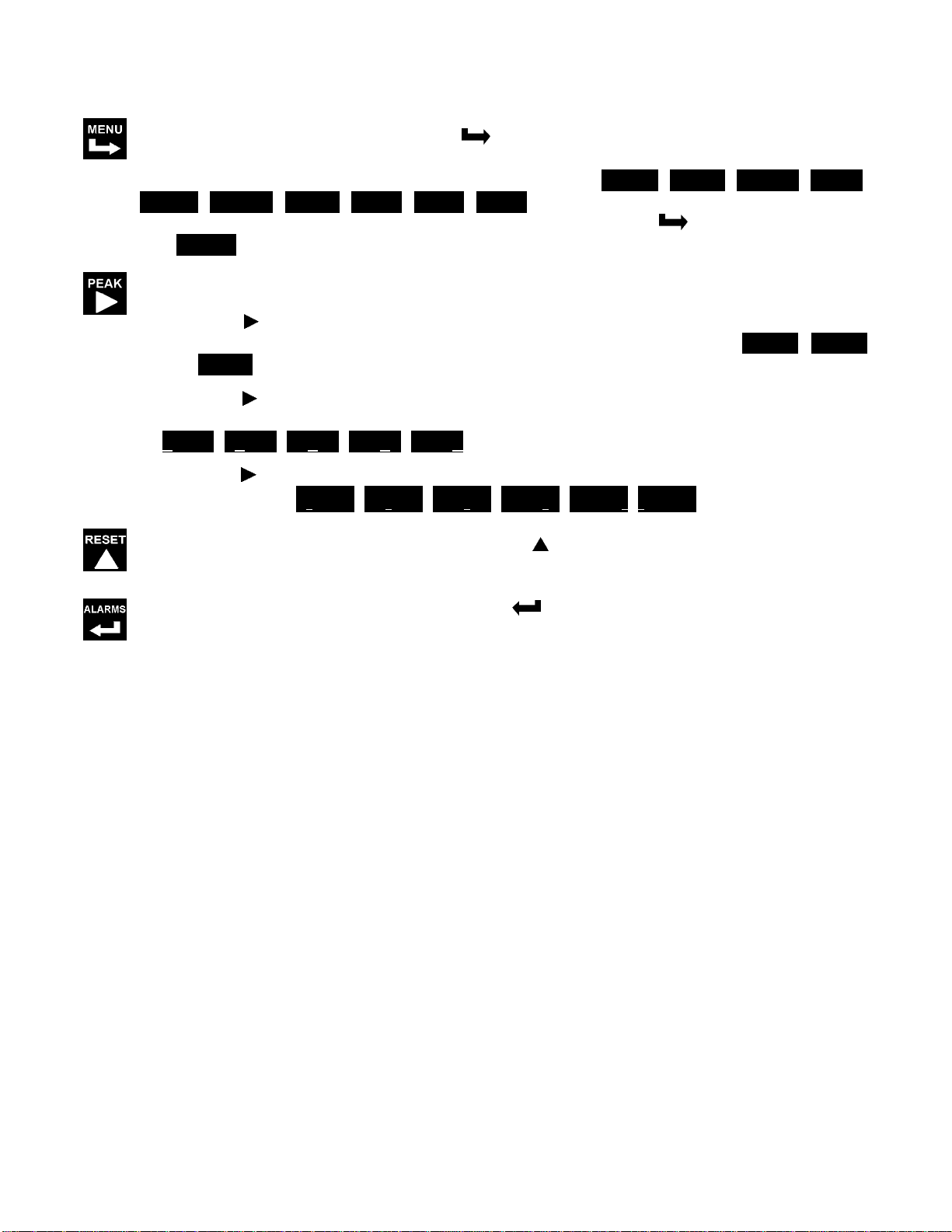

8. FRONT PANEL SETUP KEYS

Meter Front Panel

There are four front panel keys, which change function for the Run Mode and Menu Mode,

effectively becoming eight keys. The keys are labeled with alphanumeric captions (MENU,

PEAK, RESET, ALARMS) for the Run Mode and with symbols (

right triangle, up triangle, left arrow) for the Menu Mode.

FRONT PANEL LOCKOUT

right arrow,

The Menu Mode will not work with most meters as received from the factory, since all menu

items have been disabled in software and a lockout jumper is in place. That jumper needs to

be removed for the Menu Mode to work, and menu items under Loc 1, Loc 2 and Loc 3 then

need to be set to "0" via the front panel for these menu items to be unlocked See Section 9.

The paragraphs below assume that all menu items have been unlocked.

MENU MODE KEY ACTION

In the Menu Mode, pressing a key momentarily advances to the next menu item. Holding

down a key automatically advances through multiple menu items for fast menu navigation.

KEYS IN RUN MODE

MENU Key. Pressing MENU from the Run Mode enters the Menu Mode. Pressing

MENU repeatedly will step the meter through the various menu items (if these have not

been locked out) and then back to the Run Mode.

PEAK Key. Pressing PEAK normally causes the peak value of the input signal to be

displayed. The peak display then blinks to differentiate it from the normal present value

display. Pressing PEAK again returns the display to the present value. The PEAK key

can also be programmed to display Valley, alternating Peak or Valley, or to Tare the

reading to zero. When Peak or Valley is selected, periodic horizontals bars at the top of

the display indicate Peak, and periodic horizontals bars at the bottom indicate Valley.

RESET Key. Pressing RESET with PEAK resets peak and valley values. Pressing

RESET with ALARMS resets latched alarms. Pressing RESET with MENU performs a

meter reset (same as power on). Meter reset can also be applied via a rear panel

connect or a serial ASCII command.

ALARMS Key. Pressing ALARMS once displays the setpoint for Alarm 1. Pressing it

again displays the setpoint for Alarm 2. Pressing it again returns to the present value.

9

Page 10

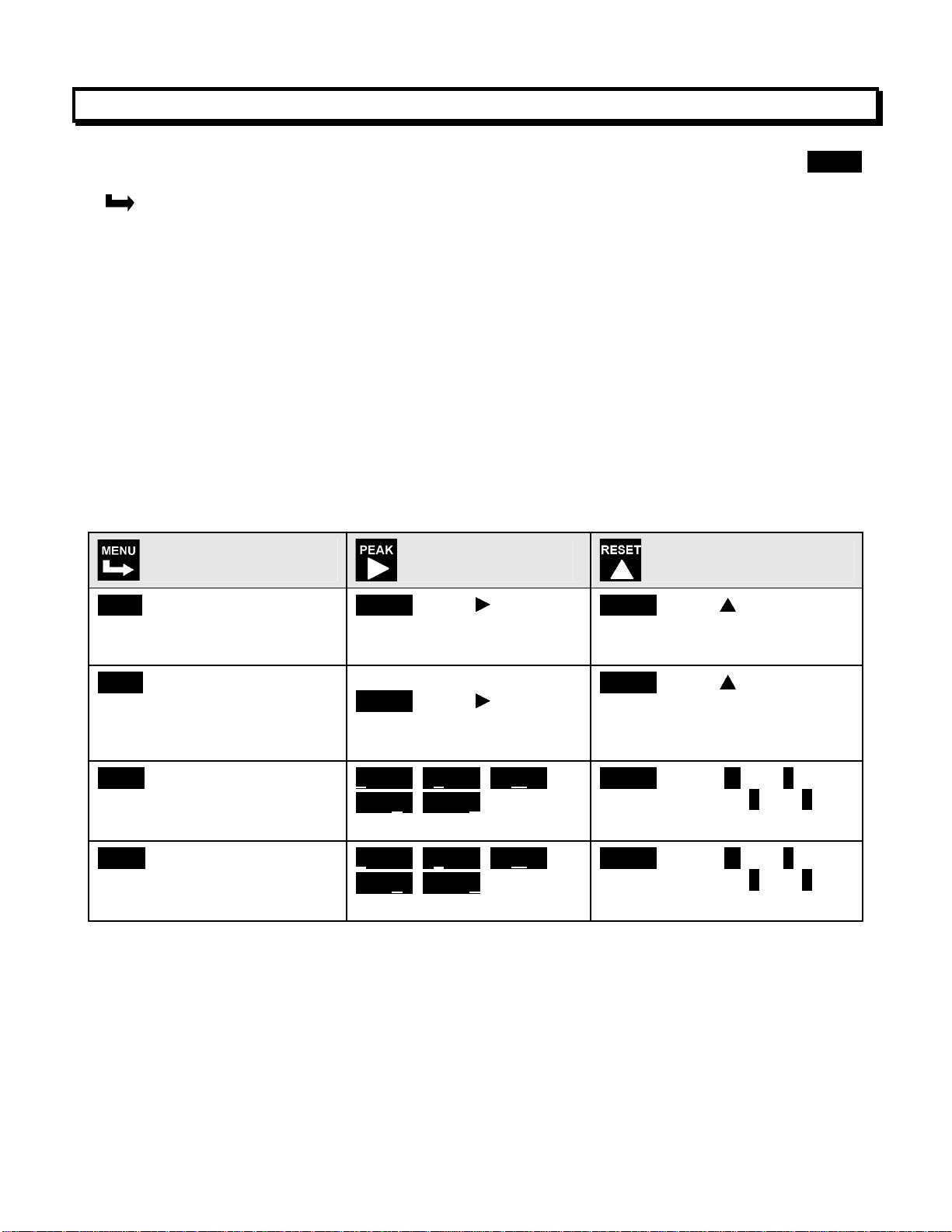

KEYS IN MENU MODE

Right Arrow Key (MENU). Pressing

have been enabled and then back to the Run Mode. With the DC signal conditioner

board and no option boards, available menu items are _InPut, SEtuP, ConFG, _FiLtr,

dEc.Pt, SCALE, OFFst, Loc 1, Loc 2, Loc 3. If a change has been made to a menu

item, that change is saved to non-volatile memory when the

and StoreE is displayed briefly.

Right Triangle Key (Digit Select).

steps the meter through all menu items that

key is pressed next,

• Pressing

meter's signal conditioner. For the DC signal conditioner, these are _dC U, _dC A

and _rAtio.

• Pressing

menus items sequentially selects digit positions 1 - 5, as indicated by a flashing digit:

00000, 00000, 00000, 00000, 00000.

• Pressing

which will flash: d.dddd dd.ddd ddd.dd dddd.d ddddd. .ddddd.

Up Triangle Key (Value Select). Pressing

decimal point position) will increment that item. Pressing MENU will save any changes.

Left Arrow Key (Reverse Menu). Pressing

except that menu items are brought up in reverse order.

from the InPut menu brings up all meter functions available with the

from the SEtuP, ConfFG, FiLtr, SCALE, OFFSt, Loc 1, Loc 2 or Loc 3

from the dEC.Pt menu item sequentially selects decimal point positions,

for a flashing item (digit position or

has the same effect as the MENU key,

10

Page 11

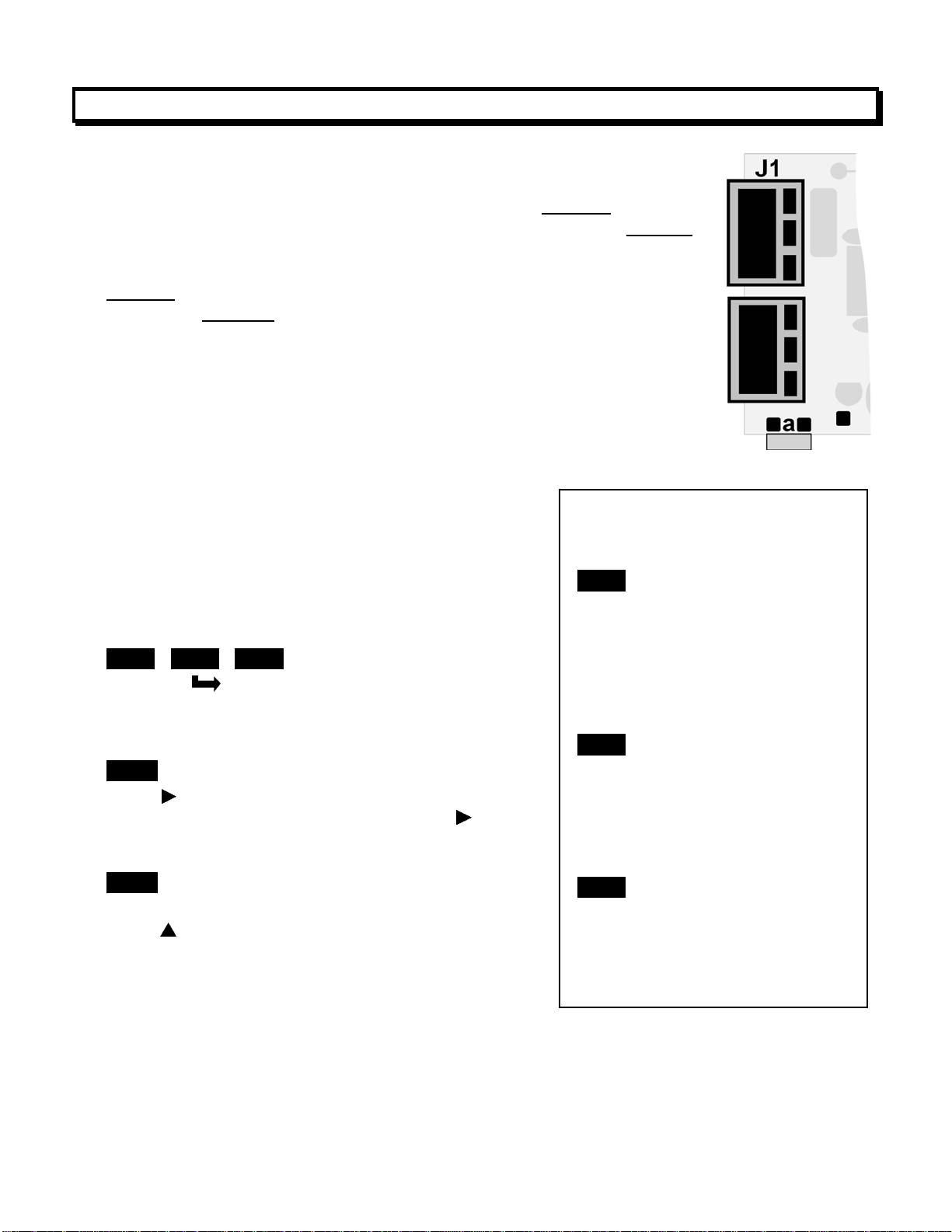

9. ENABLING & LOCKING OUT MENU ITEMS

For security reasons and ease of meter operation, any and all menu

items may be disabled or "locked out" so that they are no longer directly

accessible from the front panel. Each function to be disabled

in menu items Loc 1, Loc 2 or Loc 3, and each function to be enabled

set to "0." The top menu items Loc 1, Loc 2 and Loc 3 can in turn be

locked out by installing an internal hardware jumper. With the jumper

installed

the jumper removed

Loc 2 and Loc 3.

SETTING HARDWARE LOCKOUT JUMPER

To access the lockout jumper, remove the rear panel per Section 9 and

locate jumper “a” in the lower portion of the power supply board next to

the input connectors (see figure at right).

SETTING SOFTWARE LOCKOUTS

When setting up the meter, it may be necessary to

enable specific menu items by setting the corresponding lockout digit to 0. Be sure to reset the

lockout digit to "1" if you do not want the menu item

to be changed by an operator.

Loc 1 Loc 2 Loc 3

Press the MENU key until Loc 1, Loc 2 or Loc 3

is displayed, as desired. Note: the hardware lockout

jumper must be removed (see above).

11111

Press

1’s and 0’s. The left digit will flash. Press

step to the next digit, which will flash.

00000

12345

Press

menu item or to "1" to disable. Press MENU to enter.

See the table to the right for list of menu items that

can be enabled or disabled.

, the operator only has access only to enabled menu items. With

, the operator also has access to menu items Loc 1,

to display the lockout status, consisting of

again to

to set the flashing digit to "0" to enable the

is set to "1"

Enabled or Disabled

Menu Items

Loc 1

1 - Input type selection.

2 - Meter setup, configuration

& decimal pt.

3 - Filter selection.

4 - Scale or Lo, Hi input.

5 - Offset or Lo, Hi reading

Loc 2

2 - Alarm setup.

3 - Alarm setpoint value

programming.

4 - Analog output scaling.

5 - Serial interface setup.

Loc 3

2 - View peak value

3 - View alarm setpoints

4 - Reset (peak & latched alarms)

5 - Reset (meter reset)

is

11

Page 12

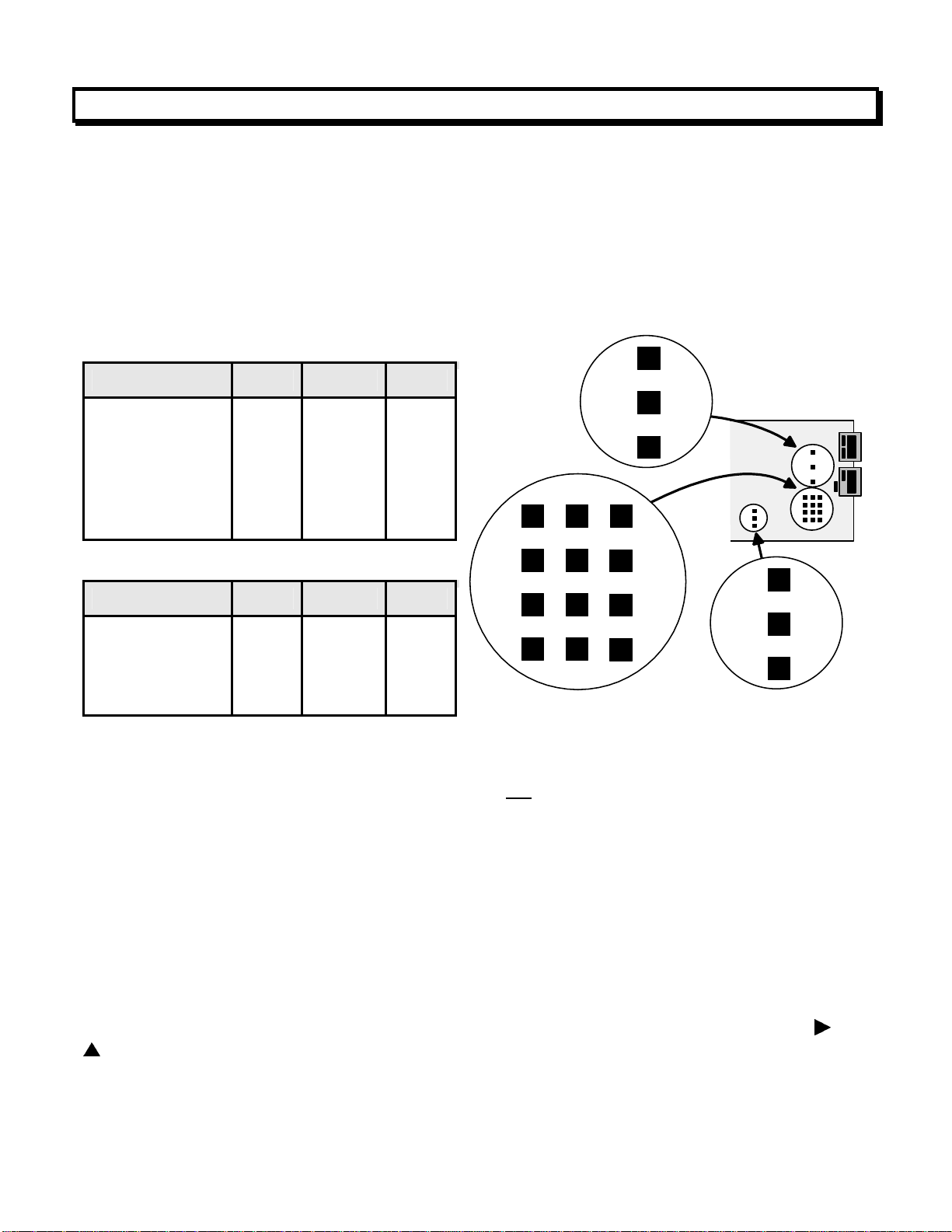

10. READING COORDINATES OF 2 POINTS SCALING METHOD

When the reading coordinates of 2 points scaling method has been selected under SEtuP,

the four menu items below will appear ahead of all other menu items when the MENU or

key is first pressed from the run mode.

This scaling method applies a straight line fit between two points, which are determined

from actual transducer signals and the desired corresponding meter readings. A low signal,

such as the output of a pressure transducer at zero pressure, and high signal, such as the

output of the same transducer at a known high pressure, are applied to the meter. The

desired corresponding low and high readings are then entered from the front panel. The

meter then applies straight line fit between the high and low calibration points. This scaling

method has the advantage of calibrating the transducer and meter as a system. The actual

voltage or current at either point does not need to be known. This method is ideal for

process and load cell meters, which require zero and span adjustment. It is also available

for DC or AC meters. It is not available with thermocouple or RTD meters.

The programming example below is for a process meter used with a 4-20 mA pressure

transducer for 0 to 100 psi. Decimal points are set separately using the dEC.Pt menu.

Press Menu Select

Key

Lo In Apply low signal input

(e.g., transducer output for 0

psi).

Hi In Apply high signal input

(e.g., transducer output for

known 100.00 psi source).

Lo rd

Mode to enter desired low

reading (e.g., 0.00).

Hi rd

Mode to enter desired high

reading (e.g., 100.00).

Press Digit Select

Key

_40.21 Press to display

reading at low signal input

(e.g., 4.021 mA).

200.94 Press to display

reading at high signal input

(e.g., 20.094 mA).

000.00 000.00 000.00

000.00 000.00 Select digit

to flash.

000.00 000.00 000.00

000.00 000.00 Select digit

to flash.

Press Value Select

Key

_40.21 Press to store low

reading.

200.94 Press to store high

reading.

100.00 Select -9 thru 9 for

flashing first digit, 0 thru 9 for

other flashing digits.

100.00 Select -9 thru 9 for

flashing first digit, 0 thru 9 for

other flashing digits.

12

Page 13

11. DC VOLTS, AMPS, PROCESS, STRAIN INPUT

The DC Volts, Amps, Process and Strain meters utilize the DC signal conditioner board, which

needs to be configured via jumpers for the desired voltage or current range. All signal ranges

are factory calibrated with calibration factors stored in EEPROM. The meter software

recognizes the board and will bring up the appropriate menu items for it; however, it does not

recognize the jumper settings. Please see further manual sections for setup of the following:

relay output (16), analog output (17), communications (18), and transducer excitation output

(19).

Voltage Ranges

FS Input E1 E2 E3

±200.00 mV

±2.0000 V

±20.000 V

±200.00 V

±300V (UL)

±600V (not UL)

A

A

B

B

B

B

f

f

h

h

g

g

b

a

b

a

a

a

B

A

a

E3

h

f

Current Ranges

b

g

FS Input E1 E2 E3

±2.0000 mA

±20.000 mA

±200.00 mA

±5.000 A

1. Use 5 mm (0.2") jumpers for locations designated by a capital letter.

2. Use 2.5 mm (0.1") jumpers for locations designated by a lower case letter.

3. Store spare jumpers on an unused jumper post not

SCALE & OFFSET SETUP

A

A

A

A

e, g

d, g

c, g

a, b, g

b

b

b

b

associated a capital letter.

c

d

e

E1

E2

b

a

For DC voltmeters & ammeters, a scale factor of 1 and an offset of 0 are used for direct

readings in (milli)volts or (milli)amperes. Decimal point selection does not affect the displayed

digits. For example, 0-20V or 0-20 mA signals can both be displayed as 0-20000. A full scale

of 20000 may be displayed as 20.000 mA or 20000 µA. Use with a current shunt will require a

scale factor to be set. For example, for a 500-100 (500A, 100 mV) shunt, divide 5000 (the

desired full scale display with 0.1A resolution) by 10000 (displayed value with 100 mV when

the scale factor is 1.0) for a scale factor of 0.5.

For process & strain meters, scaling is normally set up from the front panel using the

keys. The meter allows three scaling methods to be selected: 1) Scale and offset,

2) Coordinates of 2 points, and 3) Reading coordinates of 2 points. Only menu items

applicable to the selected method will be presented.

13

and

Page 14

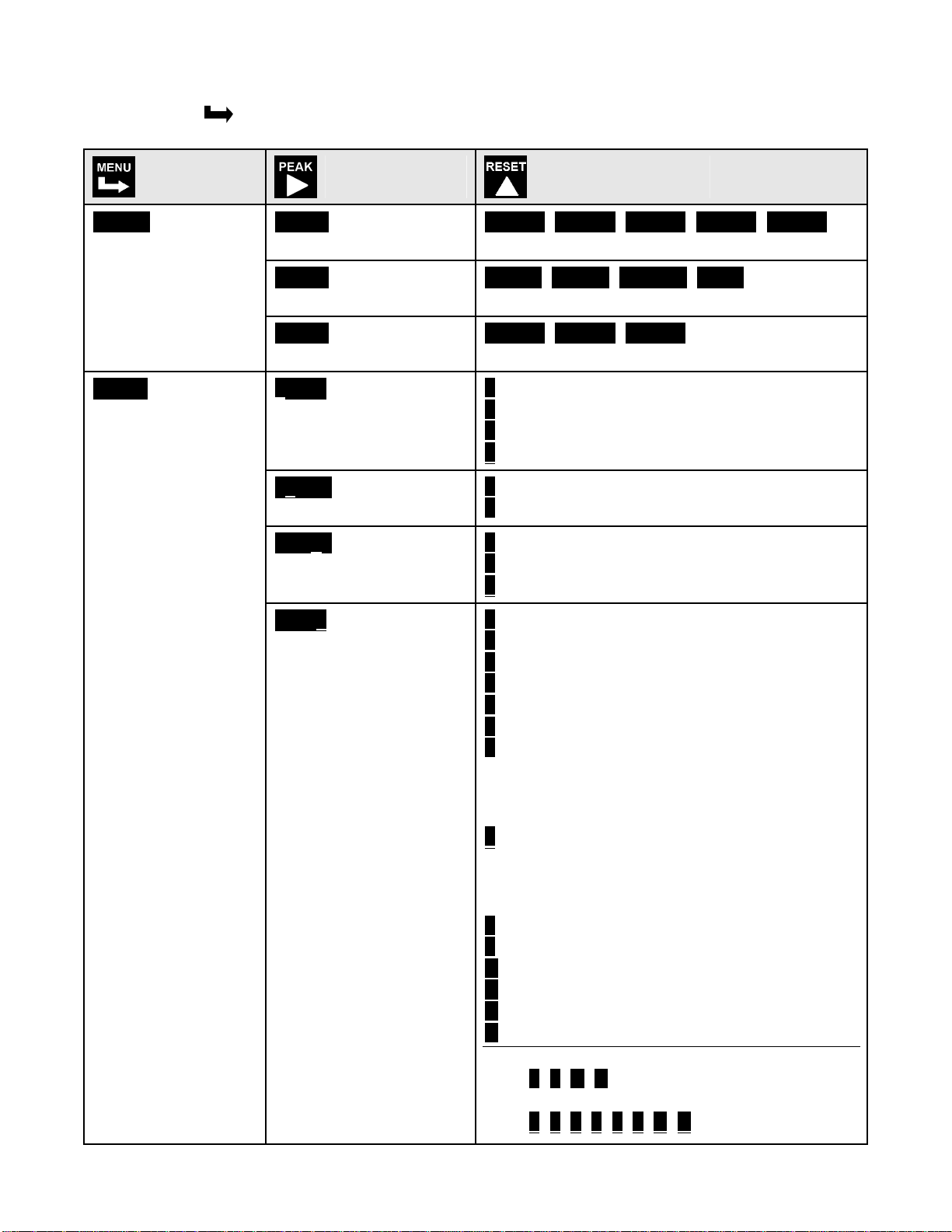

KEYSTROKES FOR SETUP

If the MENU

key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Press Menu

Select Key

_InPut

Selection of signal

input type & range

SEtuP

Meter Setup

Press Digit

Select Key

_dC U

DC Volts

_dC A

DC Amps

_rAtio

Strain gauge & ratio

00_00

Display selection with

scale factor of 1.

00 _00

Power line frequency

00_ 00

Scaling method

Press Value Select

Key

__0.2U __2.0U _20.0U 200.0U 600.0U

0.2, 2, 20, 200, 660V FS

__2.0a _20.0a _200.0a _5.0a

0.2, 20, 200 mA, 5A FS

__0.2U __2.0U _20.0U

0.2, 2, 20V FS.

0 4-1/2 digits (±20,000)

1 Remote display (±99,999)

2 4-1/2 digits, counts by 10 (±20,000)

3 3-1/2 digits (±2,000)

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

0 Scale and offset method

1 Coordinates of 2 points method

2 Reading coordinates of 2 points method

00_00

Control inputs 1 & 2:

True = logic 1 (0V or

tied to digital ground)

False = logic 0 (5V or

open)

0 1 = Reset, 2 = Meter Hold

1 1 = Function Reset, 2 = Peak or Valley

2 1 = Hold, 2 = Peak or Valley Display

3 1 = Hold, 2 = Tare

4 1 = Peak or Valley Display, 2 = Tare

5 1 = Tare, 2 = Reset

6 1 = 1, 2 = 1, decimal point = XXXXX

1 = 0, 2 = 1, decimal point = XXXX

.X

1 = 1, 2 = 0, decimal point = XXX.XX

1 = 0, 2 = 0, decimal point = XX

.XXX

7 1 = 1, 2 = 1, decimal point = XXXX.X

1 = 0, 2 = 1, decimal point = XXX

1 = 1, 2 = 0, decimal point = XX

1 = 0, 2 = 0, decimal point = X

.XX

.XXX

.XXX.X

8 1 = Function Reset, 2 = Display Blank

9 1 = Hold, 2 = Display Blank

A 1 = Peak or Valley, 2 = Display Blank

B 1 = Tare, 2 = Display Blank

C 1 = Valley Display, 2 = Peak Display

D 1 = Tare, 2 = Reset Tare to Zero

Both inputs 1 and 2 set to logic 1 for selec-

tions 2, 4, A, C = Function Reset

Both inputs 1 and 2 set to logic 1 for selec-

tions 0, 1, 3, 5, 8, 9, B, D = Meter Reset

14

Page 15

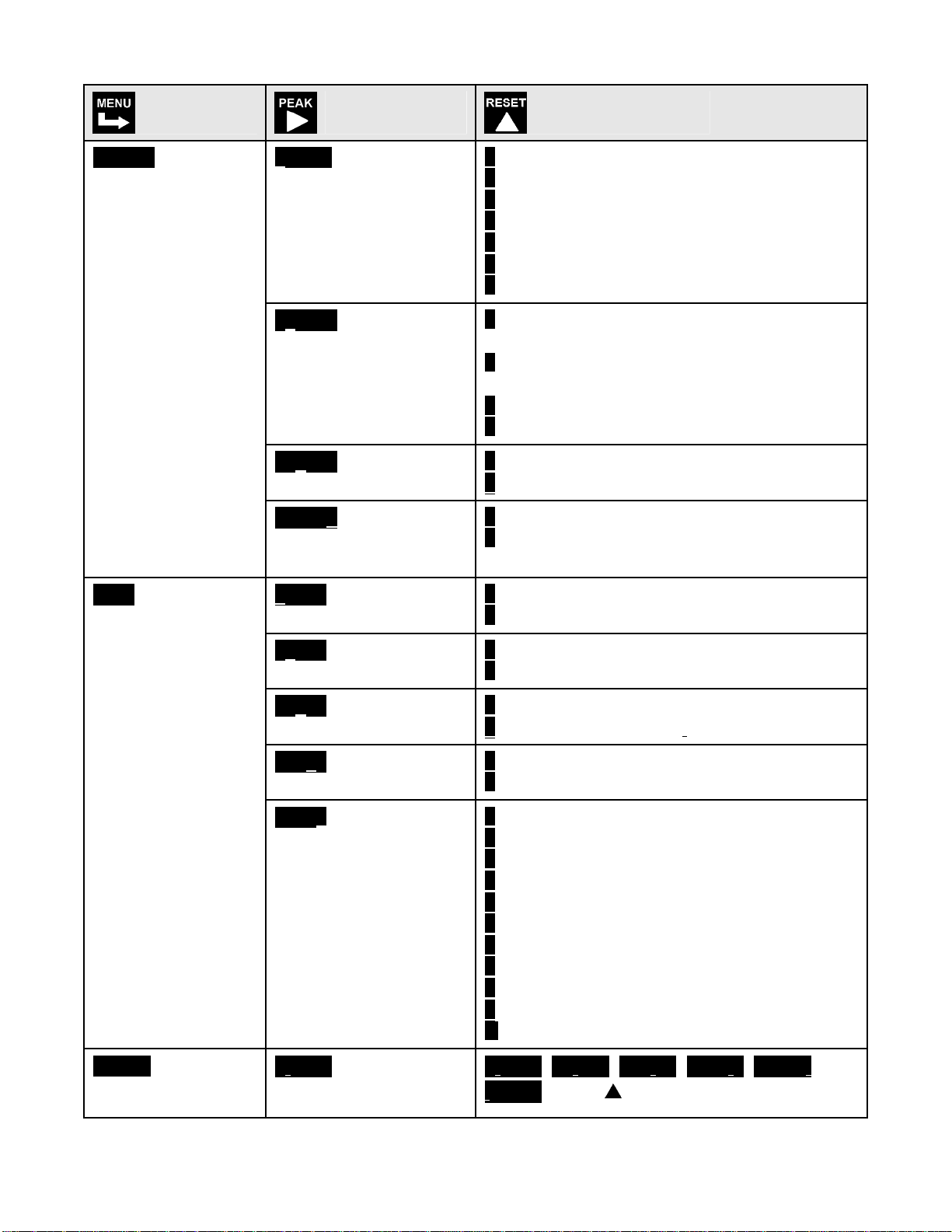

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

ConFG

Meter Configuration

FiLtr

Filtering

000 _0

Operation as a rate of

change meter.

Extended meter only.

_0 _ _0

Operation of front

panel PEAK button

and rear connector for

Peak or Valley Display

000 _ 0

Auto-tare

000 _ 0

Nonlinear input scaling

Extended meter only.

00000

Alarm filtering

0 Not rate of change

1 Rate x 0.1

2 Rate x 1

3 Rate x 10

4 Rate x 100

5 Rate x 1000

6 Rate x 10000

0 Peak Display. Also selects “Peak” in

“Peak or Valley” at connector above.

1 Valley Display. Also selects “Valley” in

“Peak or Valley” at connector above.

2 Peak (1st push), Valley (2nd push)

3 Front panel Tare

0 Meter comes up in normal run mode.

1 Meter comes up in auto-tare mode

0 Linear input

1 Custom curve linearization

0 Unfiltered output

1 Filtered output

dEc.Pt

Dec. point selection

00000

Peak & Valley filtering

00000

Display filtering

00000 Adaptive filter

threshold

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

d.dddd

Decimal point flashes.

0 Unfiltered Peak & Valley

1 Filtered Peak & Valley

0 Display batch average every 16 readings

1 Display filtered signal

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

0 Autofilter

1 Batch average, 16 readings

2 Moving average, 0.08 sec.

3 Moving average, 0.15 sec.

4 Moving average, 0.3 sec.

5 Moving average, 0.6 sec.

6 Moving average, 1.2 sec.

7 Moving average, 2.4 sec.

8 Moving average, 4.8 sec.

9 Moving average, 9.6 sec.

A Unfiltered

d.dddd dd.ddd ddd.dd dddd.d ddddd.

.ddddd Press to shift the decimal point.

15

Page 16

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

Scaling method “Scale and Offset” if selected under SEtuP

SCALE

Scale factor

OFFst

Offset value

0.0000 0.0000 0.0000

0.0000 0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Select decimal point

location when decimal point is flashing.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point

location is selected by dEC.Pt.

Scaling method “Coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal input.

Lo rd

Desired reading at

Lo In.

Hi In.

High signal input.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by input range chosen.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by input range chosen.

Hi rd.

Desired reading at

Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Scaling method “Reading coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal input.

Hi In.

High signal input.

Lo rd

Desired reading at

Lo In.

_0.021

Apply a low reference

signal to the meter.

_20.094

Apply a high reference

signal to the meter.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

_0.021

Press

to store the low signal input in the

meter.

_0.021

Press to store the high signal input in the

meter.

0.0000

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Hi rd.

Desired reading at

Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

6.7500

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

16

Page 17

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup These will only appear if a relay board is detected. If so,

please see Section16.

AnSEt. An Lo. An Hi..

Menu items related to analog output setup. These will only appear if an analog output

board is detected. If so, see Section 17.

SEr 1. SEr 2. SEr 3. SEr 4.

Menu items related to serial communications. These will only appear if an RS232, RS485

or USB I/O board is detected. If so, see Section 18.

Gain correction

-Gain .

Gain correction for negative

signals. Keep at 00.000% to

make positive and negative

gains equal.

Menu lockout items

Loc 1. Loc 2. Loc 3.

Menu items used to enable or lock out (hide) other menu items. Loc menu items may in turn

be locked out by a hardware jumper. Please see Section 9.

* Scaling method 2, “Reading Coordinates of 2 Points Scaling Method,” will appear before all

other Menu items, including _InPut. Decimal point is set by dEC.Pt.

0.0000 0.0000 0.0000

0.0000 0.0000

Gain correction from -29.999%

to +29.9999% of positive gain

for negative inputs.

Select -2 thru +2 for flashing

most significant digit. Select

0 thru 9 for other flashing

digits.

17

Page 18

12. LOAD CELL & MICROVOLT INPUT

The Load Cell and Microvolt meters utilize the load cell signal conditioner board, which offers

sensitivity to ±20 mV full scale and 4 or 6-wire load cell connection. This board needs to be

configured via jumpers for the desired voltage range. All signal ranges are factory calibrated

with calibration factors stored in EEPROM. The meter software recognizes the board and will

bring up the appropriate menu items for it; however, it does not recognize the jumper settings.

Please see further manual sections for setup of the following features: relay output (16),

analog output (17), communications (18), and transducer excitation output (19).

RANGE SELECTION VIA JUMPERS

Ranges & Display with

Scale Factor = 1

Input Jumpers

±20 mV

±50 mV

±100 mV

±250 mV

±500 mV

Notes 1. See Section 19 to select 10V excitation.

2. Jumpers are 2.5 mm (0.1 in).

SCALE & OFFSET SETUP

For DC microvolt meters, a scale factor of 1 and an offset of 0 are used for direct readings in

microvolts or millivolts. Decimal point selection does not affect the displayed digits. For

example, 20 mV can be displayed as 20.000 mV or 20000 µV. The decimal point is set

separately.

For load cell applications, scaling is set up from the front panel using the

meter allows three scaling methods to be selected: 1). Manual scale and offset, 2) Coordinates

of 2 points, and 3) Reading coordinates of 2 points. Please see the Glossary for an explanation

of each method.

e

a

b

c

d

Full scale

display

±20000

±50000

±10000

±25000

±50000

and keys. The

18

Page 19

KEYSTROKES FOR SETUP

If the MENU

key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Press Menu

Select Key

_InPut

Selection of signal

input type & range

SEtuP

Meter Setup

Press Digit

Select Key

_Strn

Strain or ratiometric

_dC U U

DC millivolts

00_00

Display type

00 _00

Power line frequency

00_ 00

Scaling method

00_00

Rear connector control

inputs 1 & 2.

True = logic 1 (0V or

tied to digital ground)

False = logic 0 (5V or

open)

Press Value Select

Key

_20.0____50.0_ _100.0 _250.0 _500.0

20, 50, 100, 250, 500 mV FS voltage

_20.0____50.0_ _100.0 _250.0 _500.0

20, 50, 100, 250, 500 mV FS voltage

0 4-1/2 digit meter, counts by 1

1 5-digit remote display (±99,999)

2 4-1/2 digit meter, counts by 10

3 3-1/2 digit meter

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

0 Scale and offset method

1 Coordinates of 2 points method

2 Reading coordinates of 2 points method

0 1 = Reset, 2 = Meter Hold

1 1 = Function Reset 2 = Pk or Valley Disp.

2 1 = Meter Hold 2 = Pk or Valley Disp.

3 1 = Meter Hold 2 = Tare

4 1 = Peak or Valley 2 = Tare

5 1 = Tare 2 = Reset

6 1 = 0, 2 = 0, decimal point 1= XXXXX

1 = 1, 2 = 0, decimal point 1 = XXXX.X

1 = 0, 2 = 1, decimal point 1 = XXX

.XX

1 = 1, 2 = 1, decimal point 1 = XX.XXX

7 1 = 0, 2 = 0, decimal point 2 = XXXX.X

1 = 1, 2 = 0, decimal point 2 = XXX

1 = 0, 2 = 1, decimal point 2 = XX

.XX

.XXX

1 = 1, 2 = 1, decimal point 2 = X.XXX.X

8 1 = Function Reset 2 = Display Blank

9 1 = Hold 2 = Display Blank

A 1 = Peak or Valley 2 = Display Blank

B 1 = Tare 2 = Display Blank

C 1 = Valley Display 2 = Peak Display

D 1 = Tare 2 = Tare Reset

Both control inputs 1 & 1 set to 1 for selec-

tions 2, 4, A, C = Function Reset.

Both control inputs 1 & 2 set to 1 for selec-

tions 0, 1, 3, 5, 8, 9, B, D = Meter Reset.

19

Page 20

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

ConFG

Meter Configuration

FiLtr

Filtering

000_0

Operation as a rate of

change meter.

Extended meter only.

000_0

Operation of front

panel PEAK button

and rear connector for

Peak or Valley Display

000_0

Auto-tare

000_ 0

Nonlinear input scaling

Extended meter only.

00000

Alarm filtering

0 Not rate of change

1 Rate x 0.1

2 Rate x 1

3 Rate x 10

4 Rate x 100

5 Rate x 1000

6 Rate x 10000

0 Peak Display. Also selects “Peak” in

“Peak or Valley” at connector above.

1 Valley Display. Also selects “Valley” in

“Peak or Valley” at connector above.

2 Peak (1st push), Valley (2nd push)

3 Front panel Tare

0 Meter comes up in normal run mode.

1 Meter comes up in auto-tare mode

0 Linear input

1 Custom curve linearization

0 Unfiltered output

1 Filtered output

dEc.Pt

Dec. point selection

00000

Peak & Valley filtering

00000

Display filtering

00000 Adaptive filter

threshold

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

d.dddd

Decimal point flashes.

0 Unfiltered Peak & Valley

1 Filtered Peak & Valley

0 Display batch average every 16 readings

1 Display filtered signal

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

0 Autofilter

1 Batch average, 16 readings

2 Moving average, 0.08 sec.

3 Moving average, 0.15 sec.

4 Moving average, 0.3 sec.

5 Moving average, 0.6 sec.

6 Moving average, 1.2 sec.

7 Moving average, 2.4 sec.

8 Moving average, 4.8 sec.

9 Moving average, 9.6 sec.

A Unfiltered

d.dddd dd.ddd ddd.dd dddd.d ddddd.

.ddddd

20

Page 21

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

Scaling method “Scale and Offset” if selected under SEtuP

SCALE

Scale factor

OFFst

Offset value

0.0000 0.0000 0.0000

0.0000 0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Select decimal point

location when decimal point is flashing.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point

location is selected by dEC.Pt.

Scaling method “Coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal input.

Lo rd

Desired reading at

Lo In.

Hi In.

High signal input.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by input range chosen.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by input range chosen.

Hi rd.

Desired reading at

Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Scaling method “Reading coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal input.

Hi In.

High signal input.

Lo rd

Desired reading at

Lo In.

_0.021

Apply a low reference

signal to the meter.

_20.094

Apply a high reference

signal to the meter.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

_0.021

Press

to store the low signal input in the

meter.

_20.094

Press to store the high signal input in the

meter.

0.0000

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Hi rd.

Desired reading at

Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

6.7500

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

21

Page 22

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup These will only appear if a relay board is detected. If so,

please see Section16.

AnSEt. An Lo. An Hi..

Menu items related to analog output setup. These will only appear if an analog output

board is detected. If so, see Section 17.

SEr 1. SEr 2. SEr 3. SEr 4. _Addr

Menu items related to serial communications. These will only appear if an RS232 or

RS485 I/O board is detected. If so, see Section 18.

Gain correction

-Gain .

Gain correction for negative

signals. Keep at 00.000% to

make positive and negative

gains equal.

Menu lockout items

Loc 1. Loc 2. Loc 3.

Menu items used to enable or lock out (hide) other menu items. Loc menu items may in turn

be locked out by a hardware jumper. Please see Section 9.

0.0000 0.0000 0.0000

0.0000 0.0000

Gain correction from -29.999%

to +29.9999% of positive gain

for negative inputs.

Select -2 thru +2 for flashing

most significant digit. Select

0 thru 9 for other flashing

digits.

22

Page 23

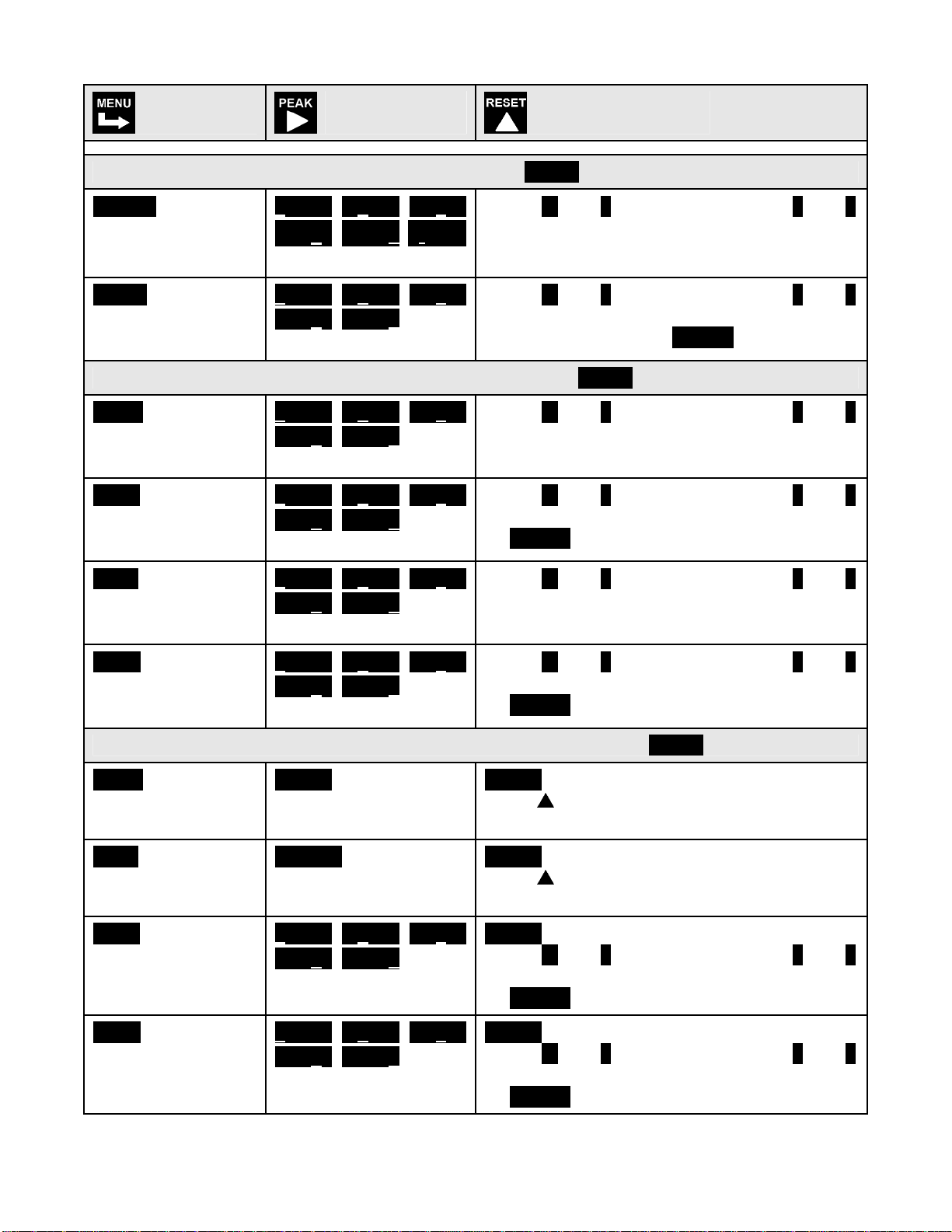

13. AC TRUE RMS VOLTS & AMPS INPUT

AC voltage or current measurement utilizes the True

RMS signal conditioner board which uses precision

circuitry to compute the root-mean-square of complex

waveforms from 10 Hz to 10 kHz. Accurate measurements are obtained with spikes up to 3 times the

maximum of each range. The input can be AC

coupled to read only the AC component, such as

ripple on a power supply, or DC coupled to read AC

plus DC. The board needs to be configured via

jumpers for the desired voltage or current range, and

for AC or DC coupling. All signal ranges are factory

calibrated with calibration factors stored in EEPROM.

The meter software recognizes the board and will bring up the appropriate menu items for it;

however, it does not recognize the jumper settings. These need to be set manually. Please

see further manual sections for setup of the following features: relay output (16), analog output

(17), and communications (18).

Voltage Ranges

Full Scale Input Counts Jumpers

200 mV

2V

20V

200V

300V (UL)

600V (not UL)

Current Ranges

Full Scale Input Counts Jumpers

2 mA

20 mA

200 mA

5A

AC or DC Coupling

Coupling Type Jumpers

DC coupling for AC + DC

AC coupling for AC only

METER SCALING

20000

20000

20000

20000

3000

6000

20000

20000

20000

5000

j

c, g, h

c, i

c, k

c, m

c, m

l, k

b, m

a, m

c, d, e, m

f

none

RANGE SELECTION VIA JUMPERS

1. Use 2.5 mm (0.1") jumpers.

2. Store spare jumpers on unused jumper post.

Refer to the above tables for the full scale counts (or displayed digits) produced by the

available full scale input ranges with a scale factor of 1 and an offset of 0. The decimal point

can be set for direct readout in (milli)volts or (milli)amperes. Decimal point selection does not

affect the counts. For example, a 20V input may be displayed as 20.000V or 20000 mV.

23

Page 24

The 5A range, designed for use with a 5A current transformer (CT), is scaled to produce 5000

counts with a scale factor of 1 and an offset of 0. Use with a specific CT will require the scale

factor to be set. For example, for an 800A input, 5A output CT, set a scale factor of 1.6. This is

the desired 8000 count display at 5A divided by the default 5000 count display at 5A. Then set

the decimal point to display to 800.0 at 5A.

All scaling methods applicable to DC, process, strain and load cell meters are available with

AC RMS meters.

INTERNAL SHIELD

To reduce noise pickup inside the meter or transmitter, the

RMS board is fitted with a flexible plug-on shield. If necessary,

This shield may be removed for jumper setting, but must be

reinstalled before closing the instrument.

SIGNAL SHIELDING

Signal Source

Sig High

Sig Low

Shield around twisted pair

Earth Ground

RMS

Board

Shielding for noise reduction

AC RMS measurements are susceptible to signal noise. This is especially true when the instrument has a wide bandwidth. To minimize noise pickup, the input signal wiring should utilize a

shielded twisted pair, and the shield should be connected to signal low at the meter, as

illustrated. If signal low is close to earth ground, such as within 2V, signal low can further be

connected to earth ground at the meter, as illustrated.

24

Page 25

KEYSTROKES FOR SETUP

If the MENU

key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Press Menu

Select Key

_InPut

Selection of signal

input type & range

SEtuP

Meter Setup

Press Digit

Select Key

_AC U

Strain or ratiometric

_AC A U

DC millivolts

00_00

Display selection with

scale factor of 1

00 _00

Power line frequency

00_ 00

Scaling method

00_00

Rear connector inputs

1 & 2

True = logic 1 (0V or

tied to digital ground)

False = logic 0 (5V or

open)

Press Value Select

Key

__0.2U __2.0U _20.0U 200.0U 600.0U

0.2, 2, 20, 200, 660V FS

__2.0a _20.0a _200.0a _5.0A

2, 20, 200 mA, 5A FS

0 4-1/2 digits (±20,000)

1 Remote display (±99,999)

2 4-1/2 digits, counts by 10 (±20,000)

3 3-1/2 digits (±2,000)

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

0 Scale and offset method

1 Coordinates of 2 points method

2 Reading coordinates of 2 points method

0 1 = Reset, 2 = Meter Hold

1 1 = Function Reset 2 = Pk or Valley Disp.

2 1 = Meter Hold 2 = Pk or Valley Disp.

3 1 = Meter Hold 2 = Tare

4 1 = Peak or Valley 2 = Tare

5 1 = Tare 2 = Reset

6 1 = 0, 2 = 0, decimal point 1= XXXXX

1 = 1, 2 = 0, decimal point 1 = XXXX.X

1 = 0, 2 = 1, decimal point 1 = XXX

.XX

1 = 1, 2 = 1, decimal point 1 = XX.XXX

7 1 = 0, 2 = 0, decimal point 2 = XXXX.X

1 = 1, 2 = 0, decimal point 2 = XXX

1 = 0, 2 = 1, decimal point 2 = XX

.XX

.XXX

1 = 1, 2 = 1, decimal point 2 = X.XXX.X

8 1 = Function Reset 2 = Display Blank

9 1 = Hold 2 = Display Blank

A 1 = Peak or Valley 2 = Display Blank

B 1 = Tare 2 = Display Blank

C 1 = Valley Display 2 = Peak Display

D 1 = Tare 2 = Tare Reset

Both control inputs 1 & 2 set to 1 for selec-

tions 2, 4, A, C = Function Reset.

Both control inputs 1 & 2 set to 1 for selec-

tions 0, 1, 3, 5, 8, 9, B, D = Meter Reset.

25

Page 26

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

ConFG

Meter Configuration

FiLtr

Filtering

000_0

Operation as a rate of

change meter.

Extended meter only.

00 _ _0

Operation of front

panel PEAK button

and rear connector for

Peak or Valley Display

000 _0

Auto-tare

000_ 0

Nonlinear input scaling

Extended meter only.

00000

Alarm filtering

0 Not rate of change

1 Rate x 0.1

2 Rate x 1

3 Rate x 10

4 Rate x 100

5 Rate x 1000

6 Rate x 10000

0 Peak Display. Also selects “Peak” in

“Peak or Valley” at connector above.

1 Valley Display. Also selects “Valley” in

“Peak or Valley” at connector above.

2 Peak (1st push), Valley (2nd push)

3 Front panel Tare

0 Meter comes up in normal run mode.

1 Meter comes up in auto-tare mode

0 Linear input

1 Custom curve linearization

0 Unfiltered output

1 Filtered output

dEc.Pt

Dec. point selection

00000

Peak & Valley filtering

00000

Display filtering

00000 Adaptive filter

threshold

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

d.dddd

Decimal point flashes.

0 Unfiltered Peak & Valley

1 Filtered Peak & Valley

0 Display batch average every readings

1 Display filtered signal

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

0 Autofilter

1 Batch average, 16 readings

2 Moving average, 0.08 sec.

3 Moving average, 0.15 sec.

4 Moving average, 0.3 sec.

5 Moving average, 0.6 sec.

6 Moving average, 1.2 sec.

7 Moving average, 2.4 sec.

8 Moving average, 4.8 sec.

9 Moving average, 9.6 sec.

A Unfiltered

d.dddd dd.ddd ddd.dd dddd.d ddddd.

.ddddd

26

Page 27

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

Scaling method “Scale and Offset” if selected under SEtuP

SCALE

Scale factor

OFFst

Offset value

0.0000 0.0000 0.0000

0.0000 0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Select decimal point

location when decimal point is flashing.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point

location is selected by dEC.Pt.

Scaling method “Coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal input.

Lo rd

Desired reading at

Lo In.

Hi In.

High signal input.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by input range chosen.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by input range chosen.

Hi rd.

Desired reading at

Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Scaling method “Reading coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal input.

Hi In.

High signal input.

Lo rd

Desired reading at

Lo In.

_0.021

Apply a low reference

signal to the meter.

_20.094

Apply a high reference

signal to the meter.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

_0.021

Press

to store the low signal input in the

meter.

_0.021

Press to store the high signal input in the

meter.

0.0000

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

Hi rd.

Desired reading at

Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

6.7500

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set

by dEC.Pt.

27

Page 28

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup These will only appear if a relay board is detected. If so,

please see Section16.

AnSEt. An Lo. An Hi..

Menu items related to analog output setup. These will only appear if an analog output

board is detected. If so, see Section 17.

SEr 1. SEr 2. SEr 3. SEr 4. _Addr

Menu items related to serial communications. These will only appear if an RS232 or

RS485 I/O board is detected. If so, see Section 18.

Menu lockout items

Loc 1. Loc 2. Loc 3.

Menu items used to enable or lock out (hide) other menu items. Loc menu items may in turn

be locked out by a hardware jumper. Please see Section 9.

* Scaling method 2, “Reading Coordinates of 2 Points Scaling Method,” will appear before all

other Menu items, including _InPut. Decimal point is set by dEC.Pt.

28

Page 29

14. THERMOCOUPLE INPUT

The thermocouple signal conditioner board used for temperature measurement can be configured via jumpers for 7 thermocouple types, each in a single range: J, K, T, E, N, S, R. The

meter software recognizes the board and will bring up the appropriate menu items for it;

however, it does not recognize the jumper settings. Display in °C or °F and resolution of 1°,

0.1° or 0.01° are user programmable. High resolution should only be used for relative readings,

not absolute readings. Although available, 0.01° resolution is not recommended for thermocouples. Offset adjustment is available for thermocouples and is normally set to 0000.0. If °C is

selected, entering an offset of 0273.2 will change the display to Kelvin. If °F is selected,

entering an offset of 0459.7 will change the display to Rankin.

The addition of a relay output board turns the thermocouple meter from a temperature indicator

into an on/off temperature controller. Please see further manual sections for setup of the

following features: relay output (Section 16), analog output (17), and communications (18).

SIGNAL CONDITIONER BOARD SETUP VIA JUMPERS

Type E4 Jumper

J, K, E, N

T, R, S

Open Indication E3 Jumper

Upscale

Downscale

1. Use 2.5 mm (0.1") jumpers.

2. Store spare jumpers on an

unused jumper post.

none

j

h

i

29

Page 30

KEYSTROKES FOR SETUP

If the MENU

key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Press Menu

Select Key

_InPut

Selection of signal

input type & range

SEtuP

Meter Setup

Press Digit

Select Key

__tC_

Thermocouple

00_00

Display selection.

00 _00

Power line frequency

00_ 00

Scaling method

Press Value Select

Key

--.J °F_ _.J °C_ Type J, °F or °C

...K °F_ _K-°C_ Type K, °F or °C

...n °F_ _-n °C_ Type N, °F or °C

_.E °F_ ...Ek°C- Type E, °F or °C

__t °F._ _.t °C_ Type T, °F or °C

_.S °F_ _.S °C_ Type S, °F or °C

_.r °F_ _.r °C._ Type R, °F or °C

0 0.1 degree resolution

1 Remote display (±99,999)

2 0.01 degree resolution

3 1 degree resolution

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

0 Offset only for thermocouple input.

00_00

ontrol inputs 1 & 2:

True = logic 1 (0V or

tied to digital ground)

False = logic 0 (5V or

open)

0 1 = Reset, 2 = Meter Hold

1 1 = Function Reset, 2 = Peak or Valley

2 1 = Hold, 2 = Peak or Valley Display

3 1 = Hold, 2 = Tare

4 1 = Peak or Valley Display, 2 = Tare

5 1 = Tare, 2 = Reset

6 1 = 0, 2 = 0, decimal point 1= XXXXX

1 = 1, 2 = 0, decimal point 1 = XXXX

1 = 0, 2 = 1, decimal point 1 = XXX

1 = 1, 2 = 1, decimal point 1 = XX

.X

.XX

.XXX

7 1 = 0, 2 = 0, decimal point 2 = XXXX.X

1 = 1, 2 = 0, decimal point 2 = XXX

1 = 0, 2 = 1, decimal point 2 = XX

1 = 1, 2 = 1, decimal point 2 = X

.XX

.XXX

.XXX.X

8 1 = Function Reset 2 = Display Blank

9 1 = Hold 2 = Display Blank

A 1 = Peak or Valley 2 = Display Blank

B 1 = Tare 2 = Display Blank

C 1 = Valley Display 2 = Peak Display

D 1 = Tare 2 = Tare Reset

Both control inputs 1 & 2 set to 1 for selec-

tions 2, 4, A, C = Function Reset.

Both control inputs 1 & 2 set to 1 for selec-

tions 0, 1, 3, 5, 8, 9, B, D = Meter Reset.

30

Page 31

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

ConFG

Meter Configuration

FiLtr

Filtering

000_0 0 No used.

00 _ _0

Operation of front

panel PEAK button

and rear connector for

Peak or Valley Display

00000

Alarm filtering

00000

Peak & Valley filtering

00000

Display filtering

00000 Adaptive filter

threshold

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

0 Peak Display. Also selects “Peak” in

“Peak or Valley” at rear connector.

1 Valley Display. Also selects “Valley” in

“Peak or Valley” at rear connector.

2 Peak (1st push), Valley (2nd push)

3 Front panel Tare

0 Unfiltered output

1 Filtered output

0 Unfiltered Peak & Valley

1 Filtered Peak & Valley

0 Display batch average every 16 readings

1 Display filtered signal

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

0 Autofilter

1 Batch average, 16 readings

2 Moving average, 0.08 sec.

3 Moving average, 0.15 sec.

4 Moving average, 0.3 sec.

5 Moving average, 0.6 sec.

6 Moving average, 1.2 sec.

7 Moving average, 2.4 sec.

8 Moving average, 4.8 sec.

9 Moving average, 9.6 sec. A Unfiltered

OFFst

Offset value

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup if a relay board is detected. Please see Section16.

AnSEt. An Lo. An Hi..

Menu items related to analog output if detected. Please see Section 17.

SEr 1. SEr 2. SEr 3. SEr 4.

Menu items related to serial communications if detected. Please see Section 18.

Menu lockout items

Loc 1. Loc 2. Loc 3.

Menu items used to enable or lock out (hide) menu items. Please see Section 9.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Use offset for display

in Rankine or Kelvin.

31

Page 32

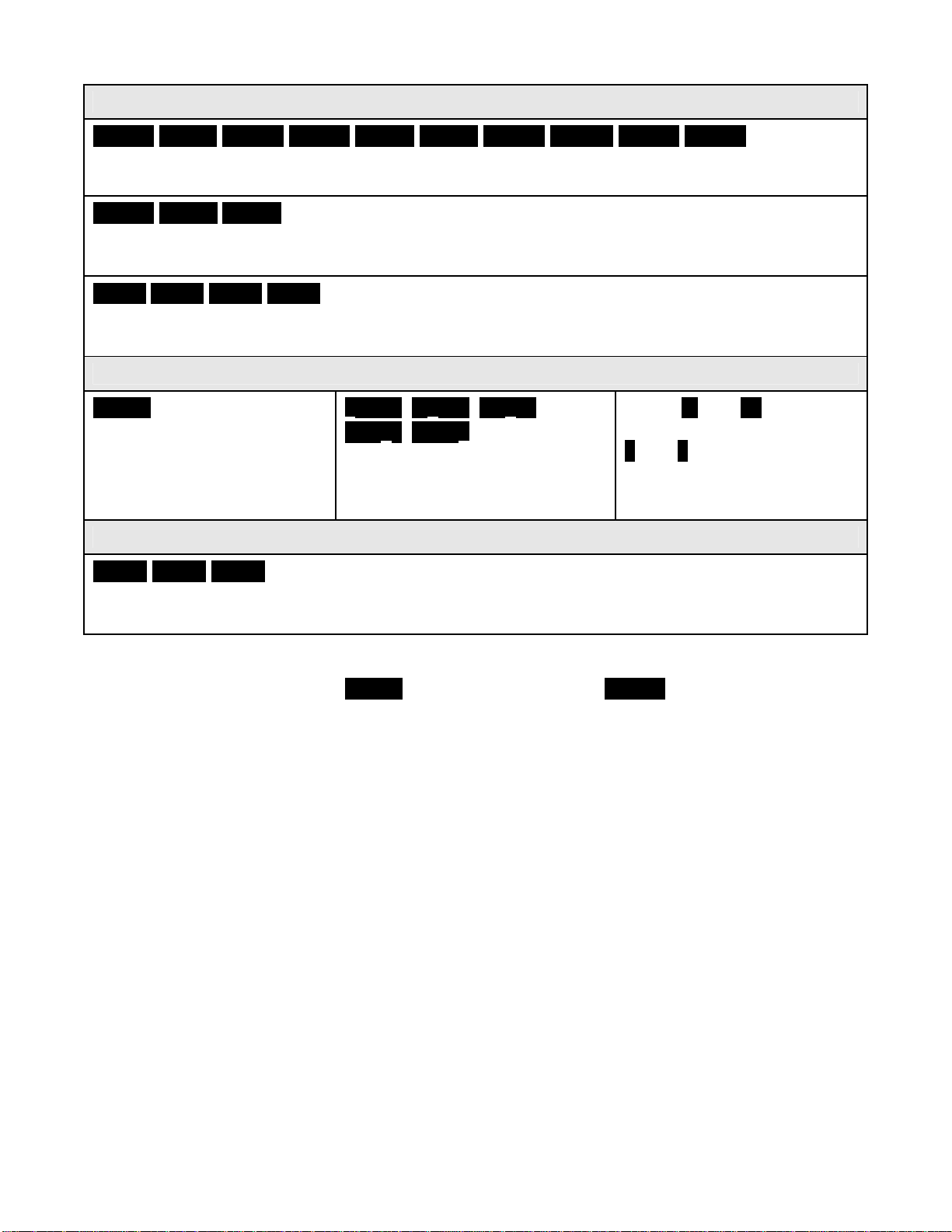

15. RTD & RESISTANCE INPUT

RTD and resistance measurement utilizes the same signal conditioner board, which can be

configured via jumpers for four RTD types (100Ω platinum with DIN or ANSI alpha, 10Ω copper, 120Ω nickel) or five resistance ranges (from 20.000Ω to 200.00 kΩ). All ranges are factory

calibrated with calibration factors stored in EEPROM on the signal conditioner board. The

meter software recognizes the board and will bring up the appropriate menu items for it;

however, it does not recognize the jumper settings. With RTDs, display in °C or °F and

resolution of 1°, 0.1° or 0.01° are user programmable. 0.01° resolution should only be used for

relative readings, not absolute readings, and with software selectable digital filtering.

The addition of a relay output board turns the meter from an indicator into an on/off controller.

Please see further manual sections for setup of the following features: relay output (Section

16), analog output (17), and communications (18).

SIGNAL CONDITIONER BOARD SETUP VIA JUMPERS

RTD Type or Ohms E1 Jumper

Pt100, Ni120

Cu10, 20 Ω

200 Ω

2000 Ω

20000 Ω

200 kΩ

Connection E2 Jumper

2 or 4 wire

3 wire

1. Use 2.5 mm (0.1") jumpers.

2. Store spare jumpers on an unused jumper post.

SCALE & OFFSET SETUP

a

b

c

d

e

f

none

g

Scale is normally set to 1.0000. Scale can be used as an RTD correction when actual

resistance is other than nominal, as stated on the RTD calibration sheet. For a Pt100 RTD,

divide 100 by the stated resistance at 0°C. For example, for a 99.04 ohm RTD, scale should be

set to 100 / 99.04 = 1.0097.

Offset is normally set to 0000.0. If °C is selected for an RTD, entering an offset of 0273.2 will

change the display to Kelvin. If °F is selected, entering 0459.7 will change the display to

Rankin.

32

Page 33

RTD & RESISTANCE CONNECTION

With the appropriate jumper settings, RTD

and resistance measurements allow 2, 3 or 4wire RTD hookup to the J5 connector, as

illustrated. The meter applies an excitation

current, which it monitors to make ratiometric

corrections for excitation supply variations.

In 2-wire hookup, the meter senses the

voltage drop across the load and both lead

wires. The effect of the lead wires can be

measured and subtracted by shorting out the

load during meter setup. The short should be

as close as possible to the load. Ambient

temperature changes will still cause some

error in the readings -- the higher the lead

resistance, the greater the error.

Under the .Short. menu selection, the load is

shorted out, the

proportional to lead resistance is displayed,

and that value is automatically stored in the

meter. After this step, the RTD type or resistance range need to be selected.

key is pushed, a value

In 3-wire hookup, the meter automatically compensates for lead resistance by measuring the

voltage drop in one current-carrying lead and assuming that the voltage drop in the other

current-carrying lead is the same.

In 4-wire hookup, no compensation for lead resistance is necessary. The step of shorting out

the RTD during meter setup is not necessary with either 3 or 4-wire hookup.

33

Page 34

KEYSTROKES FOR SETUP

If the MENU

key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Press Menu

Select Key

_InPut

Selection of signal

input type & range

Press Digit

Select Key

_-rtd_

RTD

OHnnS

Ohmmeter

Press Value Select

Key

.. d °F- Pt100 RTD, DIN alpha .00385, °F

.. d °C. Pt100 RTD, DIN alpha .00385, °C

.. A °F- Pt100 RTD, ANSI alpha .003902, °F

.. A °C- Pt100 RTD, ANSI alpha .003902, °C

. ni °F - Ni120 RTD, alpha .00672, °F

..ni °C- Ni120 RTD, alpha .00672, °C

.Cu °F- Cu10 RTD, alpha .00427, °F

.Cu °C- Cu10 RTD, alpha .00427, °C

.Short. Press to store selection for 2-

wire lead resistance compensation. While

holding

the two leads at the RTD. Press

press to reset the meter. Short

to store

the displayed value. Then return to _InPut

to make one of the RTD selections above.

.. 20- 0 to 20 ohms

.. 200. 0 to 200 ohms

..2000- 0 to 2000 ohms

.20000 0 to 20000 ohms

200.00 0 to 200.00 kohm

.Short. 2-wire lead resistance compensation

as for RTD.

SEtuP

Meter Setup

00_00

Display selection with

scale factor of 1.

00 _00

Power line frequency

00_ 00

Scaling method

00_00

Control inputs 1 & 2:

True = logic 1 (0V or

tied to digital ground)

False = logic 0 (5V or

open)

0 0.1° RTD or 4-1/2 digits for ohms

1 5-digit remote display (±99,999)

2 0.01° RTD, 4-1/2 digit ohms count by 10

3 1° RTD or 3-1/2 digits for ohms

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

0 Scale and offset method (RTD & ohms)

1 Coordinates of 2 points (ohms)

2 Reading coordinates of 2 points (ohms)

0 1 = Reset, 2 = Meter Hold

1 1 = Function Reset, 2 = Peak or Valley

2 1 = Hold, 2 = Peak or Valley Display

3 1 = Hold, 2 = Tare

4 1 = Peak or Valley Display, 2 = Tare

5 1 = Tare, 2 = Reset

34

Page 35

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

SEtuP

Meter Setup

(continued)

ConFG

Meter Configuration

00_00

Control inputs 1 & 2

(continued)

6 1 = 0, 2 = 0, decimal point 1= XXXXX

1 = 1, 2 = 0, decimal point 1 = XXXX

1 = 0, 2 = 1, decimal point 1 = XXX

1 = 1, 2 = 1, decimal point 1 = XX

7 1 = 0, 2 = 0, decimal point 2 = XXXX.X

1 = 1, 2 = 0, decimal point 2 = XXX

1 = 0, 2 = 1, decimal point 2 = XX

1 = 1, 2 = 1, decimal point 2 = X

8 1 = Function Reset 2 = Display Blank

9 1 = Hold 2 = Display Blank

A 1 = Peak or Valley 2 = Display Blank

B 1 = Tare 2 = Display Blank

C 1 = Valley Display 2 = Peak Display

D 1 = Tare 2 = Tare Reset

Both control inputs 1 & 2 set to 1 for selec-

tions 2, 4, A, C = Function Reset.

Both control inputs 1 & 2 set to 1 for selec-

tions 0, 1, 3, 5, 8, 9, B, D = Meter Reset.

000_0 0 Not used

00 _ _0

Operation of front

panel PEAK button

and rear connector for

Peak or Valley Display

0 Peak Display. Also selects “Peak” in

“Peak or Valley” at connector above.

1 Valley Display. Also selects “Valley” in

“Peak or Valley” at connector above.

2 Peak (1st push), Valley (2nd push)

3 Front panel Tare

.X

.XX

.XXX

.XX

.XXX

.XXX.X

FiLtr

Filtering

00000

Alarm filtering

00000

Peak & Valley filtering

00000

Display filtering

00000 Adaptive filter

threshold

0 Unfiltered output

1 Filtered output

0 Unfiltered Peak & Valley

1 Filtered Peak & Valley

0 Display batch average every 16 readings

1 Display filtered signal

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

35

Page 36

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

FiLtr

Filtering

(continued)

dEc.Pt

Decimal point

selection

SCALE

Scale factor

OFFst

Offset value

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

d.dddd

Decimal point flashes

if ohms are selected

under _InPut

0.0000 0.0000 0.0000

0.0000 0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0 Autofilter

1 Batch average, 16 readings

2 Moving average, 0.08 sec.

3 Moving average, 0.15 sec.

4 Moving average, 0.3 sec.

5 Moving average, 0.6 sec.

6 Moving average, 1.2 sec.

7 Moving average, 2.4 sec.

8 Moving average, 4.8 sec.

9 Moving average, 9.6 sec.

A Unfiltered

d.dddd dd.ddd ddd.dd dddd.d ddddd.

.ddddd

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Select decimal point

location when decimal point is flashing.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Use offset for display

in Rankine or Kelvin. Decimal point location

is selected by dEC.Pt.

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup These will only appear if a relay board is detected. If so,

please see Section16.

AnSEt. An Lo. An Hi..

Menu items related to analog output setup. These will only appear if an analog output

board is detected. If so, see Section 17.

SEr 1. SEr 2. SEr 3. SEr 4. _Addr

Menu items related to serial communications. These will only appear if an RS232 or

RS485 I/O board is detected. If so, see Section 18.

Menu lockout items

Loc 1. Loc 2. Loc 3.

Menu items used to enable or lock out (hide) other menu items. Loc menu items may in turn

be locked out by a hardware jumper. Please see Section 9.

36

Page 37

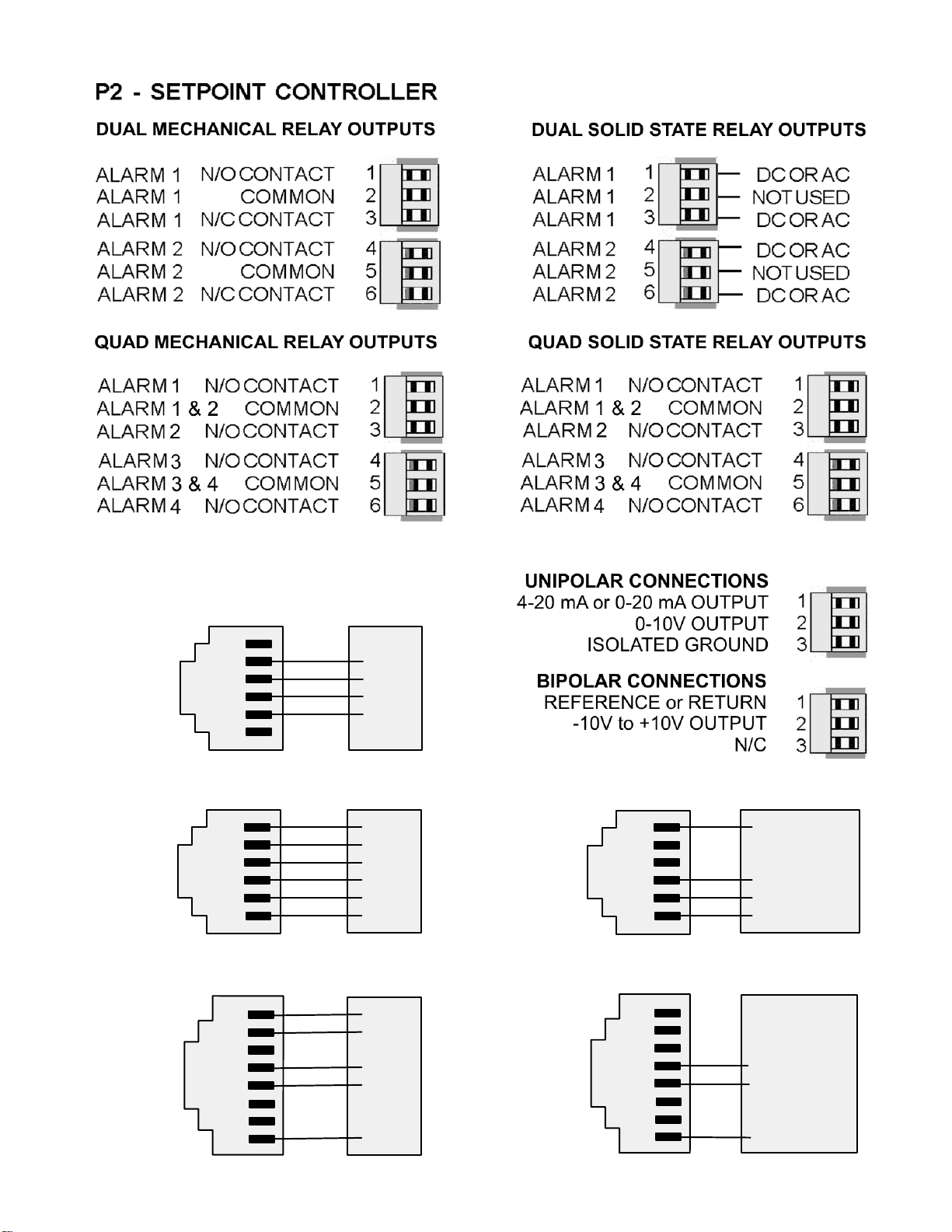

16. DUAL OR QUAD RELAY OUTPUT OPTION

An optional relay board may be installed in the

meter main board at plug position P2, adjacent to

the power supply board. Four board versions are

available: 2 or 4 relays, mechanical or solid state.

Once installed, the relay board is recognized by

the meter software, which will bring up the appropriate menu items. Relay menu items will not be

brought up if no relay board is detected. Menu

selections for relays 3 and 4 will not be brought up

if a dual relay board is detected.

All relay boards offer a choice of operating modes: normally off or on, latched or non-latched,

hysteresis band, deviation band, alarm based on the filtered or unfiltered signal, and selectable

number of readings in alarm zone to cause an alarm.

KEYSTROKES FOR VIEWING & CHANGING SETPOINTS

The

nues to make conversions and performs setpoint control. If the

a setpoint is displayed, conversion stops and the setpoint can be changed. After pressing

you have 30 seconds, or the meter reverts to the normal display. To view setpoints, menu item

Loc1, digit 4, must have been set to 0. To change setpoints, menu item Loc4, digit 6, must

have been set to 0.

300.24

Press

to display Alarm 1

setpoint.

395.00

Press (Alarms)

to display Alarm 2

setpoint.

395.00

Press

to display Alarm 3

setpoint.

(Alarms) key can be used to step through and view setpoints while the meter conti-

(Peak) key is pressed while

Press Alarms

Key

(Alarms)

(Alarms)

_200.00

Current setpoint 1 value blinks, and

Alarm 1 LED indicator lights. Press

to select a digit, which will blink.

_395.00

Current setpoint 2 value blinks, and

Alarm 2 LED indicator lights. Press

to select a digit, which will blink.

_395.00

Current setpoint 3 value blinks, and

Alarm 3 LED indicator lights. Press

to select a digit, which will blink.

Press Digit

Select Key

Press Value Select

Key

_295.00

To change setpoint 1 value,

press

blinking digits.

_305.00

To change setpoint 2 value,

press

blinking digits.

_305.00

To change setpoint 3 value,

press

blinking digits.

to change selected

to change selected

to change selected

,

395.00

Press (Alarms)

to display Alarm 4

setpoint.

300.24 Press (Alarms) again. Meter will reset and display current reading.

_395.00

Current setpoint 4 value blinks, and

Alarm 4 LED indicator lights. Press

to select a digit, which will blink.

37

_305.00

To change setpoint 4 value,

press

blinking digits.

to change selected

Page 38

KEYSTROKES FOR SETPOINT SETUP

If the MENU key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Press Menu

Select Key

ALSEt

Alarm Setup for

relays 1 & 2 if

detected.

Press

ALSEt is displayed.

until

Press Digit

Select Key

00000

Relay state when

alarm is active.

00000

Alarm latching or non-

latching (auto reset).

00000

Alarm operates at and

above setpoint (active

high) or at and below

setpoint (active low).

Press Value Select

Key

0 Relay 1 on Relay 2 on

1 Relay 1 off Relay 2 on

2 Relay 1 on Relay 2 off

3 Relay 1 off Relay 2 off

0 Alarm 1 auto reset Alarm 2 auto reset

1 Alarm 1 latching Alarm 2 auto reset

2 Alarm 1 auto reset Alarm 2 latching

3 Alarm 1 latching Alarm 2 latching

0 AL1 active high AL2 active high

1 AL1 active low AL2 active high

2 AL1 disabled AL2 active high

3 AL1 active high AL2 active low

4 AL1 active low AL2 active low

5 AL1 disabled AL2 active low

6 AL1 active high AL2 disabled

7 AL1 active low AL2 disabled

8 AL1 disabled AL2 disabled

ALS34

Alarm Setup for

relays 3 & 4 if

detected.

00000

Hysteresis mode or

band deviation mode

00000

Number of consecutive

readings in alarm zone

to cause an alarm.

00000

Relay state when

alarm is active.

00000

Alarm latching or non-

latching (auto reset).

0 AL1 band deviation AL2 band deviation

1 AL1 hysteresis AL2 band deviation

2 AL1 band deviation AL2 hysteresis

3 AL1 hysteresis AL2 hysteresis

4 No deviation or hysteresis in menu.

0 After 1 reading 4 After 16 readings

1 After 2 readings 5 After 32 readings

2 After 4 readings 6 After 64 readings

3 After 8 readings 7 After 128 reading

0 Relay 3 on Relay 4 on

1 Relay 3 off Relay 4 on

2 Relay 3 on Relay 4 off

3 Relay 3 off Relay 4 off

0 Alarm 3 auto reset Alarm 4 auto reset

1 Alarm 3 latching Alarm 4 auto reset

2 Alarm 3 auto reset Alarm 4 latching

3 Alarm 3 latching Alarm 4 latching

38

Page 39

Press Menu

Select Key

Press Digit

Select Key

Press Value Select

Key

ALS34

Alarm Setup for

relays 3 & 4

(continued)

dEU1H

Alarm 1

hysteresis

DEU2H

Alarm 2

hysteresis

00000

Alarm operates at and

above setpoint (active

high) or at and below

setpoint (active low).

00000

Hysteresis mode or

band deviation mode

(see Glossary)

00000

Number of consecutive

readings in alarm zone

to cause an alarm.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0 AL3 active high AL4 active high

1 AL3 active low AL4 active high

2 AL3 disabled AL4 active high

3 AL3 active high AL4 active low

4 AL3 active low AL4 active low

5 AL3 disabled AL4 active low

6 AL3 active high AL4 disabled

7 AL3 active low AL4 disabled

8 AL3 disabled AL4 disabled

0 AL3 band deviation AL4 band deviation

1 AL3 hysteresis AL4 band deviation

2 AL3 band deviation AL4 hysteresis

3 AL3 hysteresis AL4 hysteresis

0 After 1 reading 4 After 16 readings

1 After 2 readings 5 After 32 readings

2 After 4 readings 6 After 64 readings

3 After 8 readings 7 After 128 reading

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Alarms will activate

above the setpoint by the value entered and

deactivate below the setpoint by the value

entered.

DEU1b

Alarm 1 band

deviation

DEU2b

Alarm 2 band

deviation

dEU3H

Alarm 3

hysteresis

DEU4H

Alarm 4

hysteresis

DEU3b

Alarm 3 band

deviation

DEU4b

Alarm 4 band

deviation

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000 0.0000 0.0000