Page 1

El

ectronicForce

/T

M

r

orque

ete

Operation Manual

Version 1.062

10 Thomas Irvine, CA 92618 Ph. 949-465-0900

Page 2

Safety Warnings

!

Always wear safety glasses when operating this torque meter.

!

Always use the proper range transducer for the application. Over torque

may result in damage to the transducer or breakage resulting in personal

injury. Under torque may result in an incorrectly tightened fastener that

could loosen resulting in failure at a later date.

!

Do not use a transducer if it has been over-torqued.

!

Never apply torque in a situation where tool breakage may result in a fall or

slip resulting in personal injury. Pulling on the wrench, as opposed to

pushing on the wrench may help avoid this situation.

!

Always replace worn or rounded fasteners prior to applying torque.

Slippage may occur resulting in personal injury.

!

Never try to recharge a non rechargeable battery.

!

Never mount a transducer to a bench that is unstable or will tip when a

torque is applied.

!

Never use a torque transducer with an impact wrench.

1

Page 3

Introduction

The FUTEK Electronic Torque/Force Meter is a highly accurate torque/force

analyzer and production tool. Use it as a high end torque calibrator or bring it

to the work site to accurately apply torque to fasteners.

With the FUTEK Electronic Torque Meter you only have to buy one electronic

module. Simply add ranges as you need them by purchasing additional

torque transducers.

This Meter uses the very latest in computer technology including a small

microchip installed on each transducer for true “plug and play” recognition of

the attached torque sensor. Simply attach the transducer, turn the unit on and

you are ready to go to work.

A full compliment of modes and functions combined with an easy to use

interface make this torque meter the perfect device for all torque applications.

There are some very special features inside of this meter that distinguish it

from the competition. For example, there is a “first peak” mode that allows

you to test and calibrate micrometer (clicking) type torque wrenches.

However, just having this software mode is not enough, you must also have

circuitry that is fast enough to capture the fast “click” of a torque wrench or

the ultra fast torque peaks of DC tools and pulse tools when in peak mode

(always use a joint rate simulator when testing power tools, joint rate

simulators simulate the application with springs).

The sampling rate of this torque meter is over 8,000 samples per second

rivaling any torque data acquisition system.

Memory for up to 1350 torque data combined with a direct rs232c com port

make this small unit a powerful data acquisition system.

Additionally, the torque meter has an industry leading triple 4 digit numeric

display that shows you the limits settings at all times and prompts you with

information during set-up.

These features combines with many other useful functions will make this the

last electronic torque meter you will ever need!

2

Page 4

Feature Overview....4

3

Table of Contents

Keypad functions....

General Operation

Suggested positions....6

Quick Start....7

Tochangethe of operation....7

Tochangethe of measure....7

Toturn on/off....7

Toseta new when % is thedefault.....8

To the last cleared torque....8

To a torque value tomemory....8

Toviewthe attached ....8

Menu Functions

Toenterthe ....9

To 9

To to a printer or computer....10

To ....10

To ....10

Tochangethe ....11% tolerance value

Tomake thedefault tolerance method....11

Tochangethe method....12

Entering the limits value....12

Power Standby Mode

Entering Numbers

Zeroing the Display

Torque Sensors (transducers) andOverload

.5

mounting

mode

units

limits

target torque

recall

save

transducer information

menu mode

recall memory....

send memory

erase memory

set filters

high low limits

display clear (reset)

....12

....13

....13

....14

TransducerMounting Positions

Checking forAccuracy

Calibrating and bypassing thesmart transducer calibration data

Selecting Custom Transducers

Printing and Sending Data

Battery and Power

Specifications

....22

....16

....21

....15

....20

....20

....18

Page 5

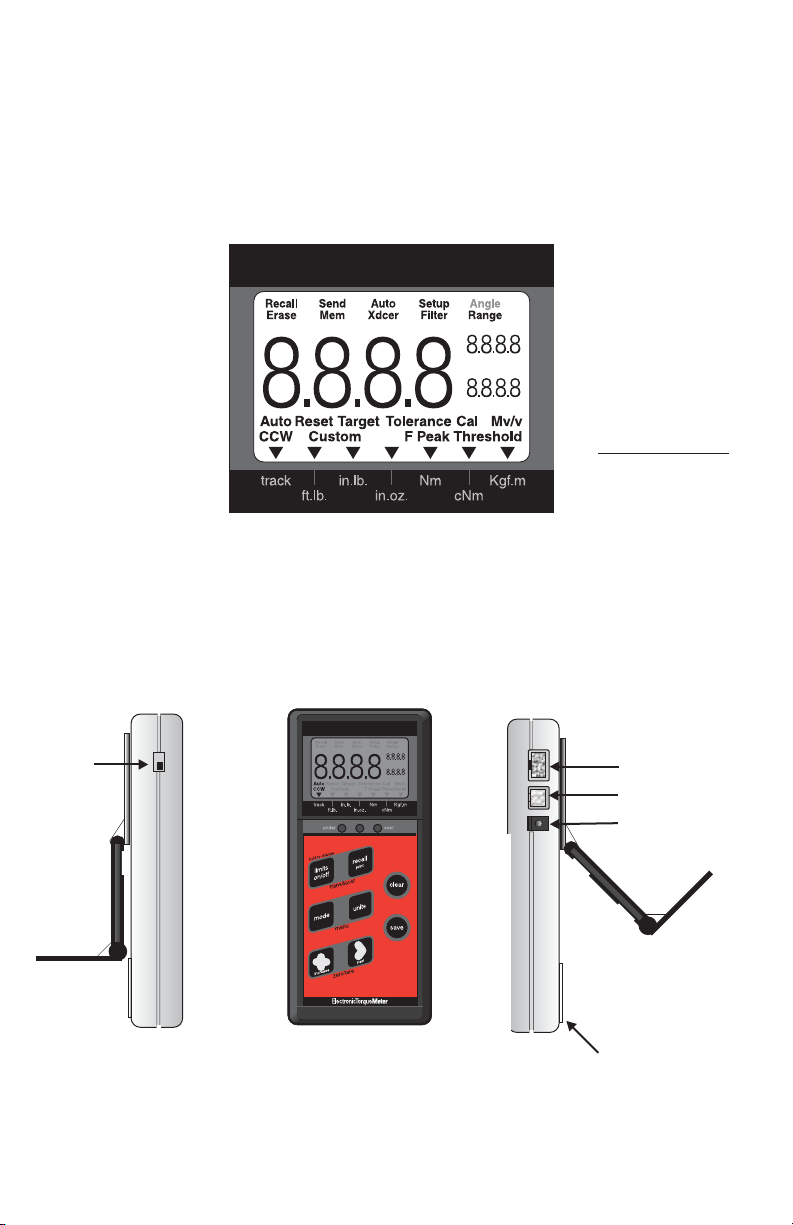

Features

Three reset

modes:

Auto

Manual

Timed

Super large

5/8 high digits

Memory for up to 1350

torque data.

User Friendly LCD with

Industry leading triple

numeric display

Custom transducer mode

allows easy adaptation

to third party transducers

Software selectable filters

Hi/Low

or %

tolerance

shown at all times

%

Track

Peak

and

First peak mode

Auto convert

engineering units

On/Off

switch

High impact plastic case

with sealed membrane

keypad

4

Transducer input

Rs232 port

External power

Fully adjustable

stand/swivel mount

Easy access

9 volt battery

compartment

Page 6

KeypadFunctions

Press once to turn limits on or off

Press and hold to set new limits

Press to change modes

(press save key to save new mode)

Recall last cleared torque

Press and hold to send data on display

to computer or printer

Press to view current torque in other units

Increases value of blinking digit

when setting numbers.

Selects next digit when setting numbers

Selects next function when in Menu mode.

Scrolls through data in memory when recalling memor

y

Clears data

on display

Saves data on display or

Selects the current function

when in menu mode

Press together to view the attached

transducer data

Press together to enter menu (set-up) mode

Press together to zero the meter

5

Page 7

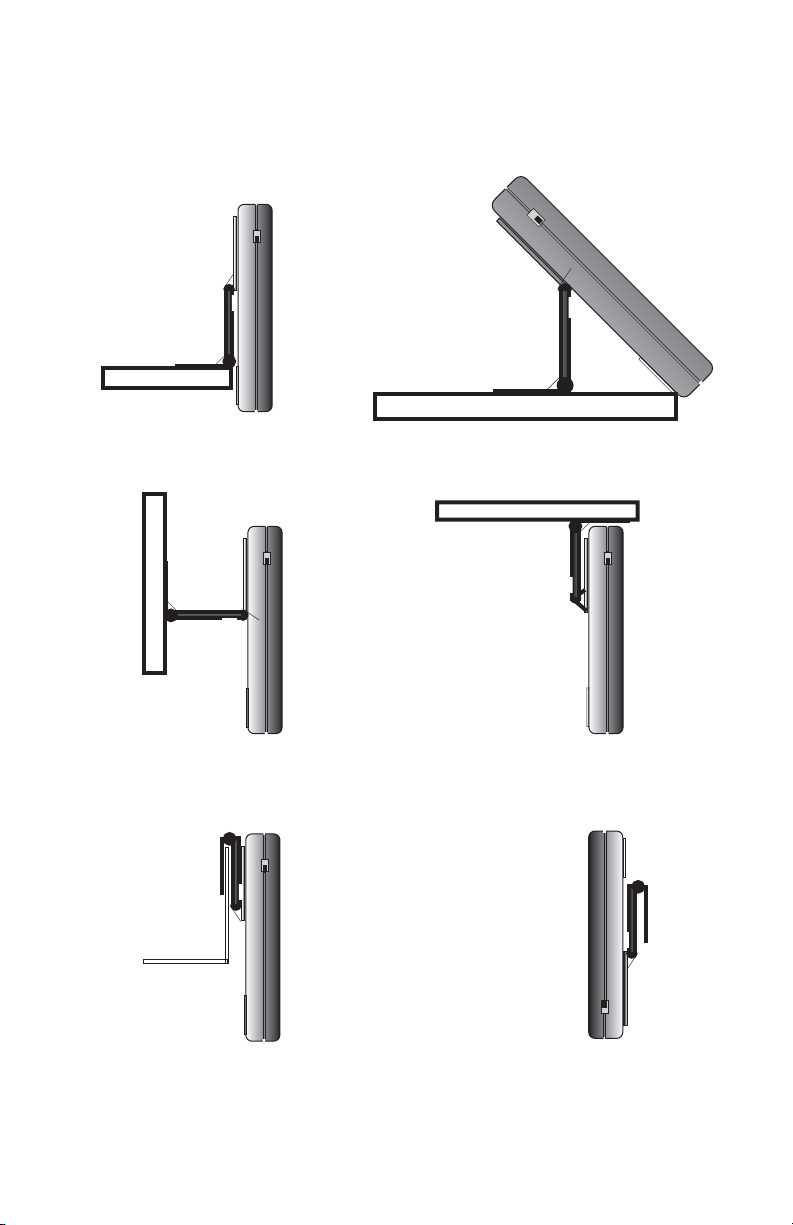

Suggested mounting positions

6

Loosen the 4 locking screws prior to adjusting

Over a ledge

Vertical wall

Typical bench mounting

Under a shelf

Reverse bracket and

hang on a thin shelf

Belt mount

Page 8

General Operation

Quick Start:

1. Turn off the power.

2. Plug in the proper range transducer- Turn on-wait for the display to show zero

(do not apply torque during this time). The meter reads the transducer smart chip when turned on.

3. Apply torque, (see warnings) you will see the reading increase as you increase the torque.

4. Clear the display with the clear key.

Or

5. Save torque to memory with the save key.

To change the mode of operation

1. Press the mode key until “peak”, “track” or “fpeak”

shows.

2. Press the save key to accept the new mode.

mode displays the torque as it increases and

Track

decreases.

mode tracks up but will hold on the peak value.

Peak

(first peak) mode will capture the click point of a

Fpeak

micrometer torque wrench and disregard further input.

This mode is used to test and calibrate click type torque

wrenches.

To change the units of measure

1. Press the units key until the arrow points to the desired

units (the set-up icon will also be on).

(EEEE will show if units are out of range for the transducer

attached).

2. Press the save key to select the new units of measure.

When you change the units of measure the limits

Note:

values (target or high and low) will be re-set to zero.

To turn limits on/off

1. Press limits key once to turn on.

2. Press the limits key again to turn off.

Note:

You will see the limits value in the secondary set of digits“%” and the current target torque will show if % is the

default or high and low arrows with the actual high and

low values if the high and low method of limits is selected

(see menu functions below to select the different methods).

7

04

%

100.0

Page 9

0

8

0

0

0

100.0

OR

To set a new target torque

(When % is the default limits mode)

1. Press and hold the limits key for 1 second.

(The current target torque shows with the first digit

blinking).

2. Use the increase and next key(s) to set the new target

04

%

torque (see “entering numbers” below).

3. Press the save key to accept the new target torque.

Note:

You will see the new target torque displayed in the

secondary set of digits when the limits mode is on. This

value will remain, even after turning the unit off, until you

either change the units of measure or plug in a new

transducer.

To recall the last cleared torque value

1. Press the recall key.

2. Press the clear key when finished viewing and return to

operation.

Note:

You can press the save key to save the recalled torque

value before pressing the clear key. This allows you to

recall and save a value that may have been accidentally

cleared prior to saving.

50.00

%

2.000

To save a torque value to memory

1. Press the save key to save the displayed torque value to

memory.

Note:

If you press the save key when zero is displayed

you will store the zero value in memory.

To view the attached transducer information

1. Press the transducer keys.

2. Press clear when finished viewing the data.

Note:

The range is in the upper right digits.

Page 10

The MV/v (cal factor) is in the lower digits.

Smart Transducers will show “Auto Xducer”

Menu functions:

1. Activate the menu function by pressing the mode and

units key at the same time (the display will show set-up).

2. Press the next key to step through the various options.

Press the save key to select the option that is displayed.

To recall memory

1. Press menu keys (set-up icon comes on).

2. Press the next key once or until the ”recall mem” icon is

on (if you miss keep pushing the next key until “recall

mem” shows.

3. Press save to select (SEL) the recall memory option.

The number of data in memory now shows.

4. Press the next key to view the data (press the increase

key to view the previous torque data).

5. Press the clear key when finished.

Note: The data number is shown in the upper right digits.

0005

0005

35.50

9

Page 11

send

e

…

Exit without erasing

or

Erase Memory

0005

To Send Memory to a printer or computer

1. Attach the torque meter serial communication

cable to your printer or computer com port. (set the

baud rate to 4800,8,n,1,hardware). refer to your

computer manual for details on how to

communicate with serial devices.

2. Press the menu keys.

3. Press the next key twice or until the display

shows send memory.

4. Press the save key to select the send memory

option.

5. The data in memory will now be sent (the data

number will count down as the data is sent out the

serial port.

See “printing and sending data” later in this

manual for more information.

To Erase Memory

1. Press the menu keys.

2. Press the next key three times or until the

”Erase mem” icon shows.

3. Press the save key to select the erase memory

function (the display will blink giving you a

second chance to decide if you really want to erase

memory).

4. Press the save key again to confirm and erase

the memory or clear to exit without erasing

memory.

Select

Filter 3

SEL 3

SEL 4

500

1000

500 Hz

To Set filters (500hz is common for hand

tool operations)

1. Press the menu keys.

2. Press the next key four times or until “filter” is

shown.

3. Press the save key to select the filter function.

4. Press the next key until the desired filter is

shown.

5. Press the save key to store the new filter

setting.

Note:

The standard filter setting is 500 Hz for hand type

applications and 1500 Hz for power tool

10

Page 12

applications. Filters are used to “screen” out any

non-torque noise or vibration that may be input

from a high speed power tool. Use a lower filter

setting if you are getting occasional spikes in the

reading.

To change the % tolerance value from the

current setting

1. Press the menu keys.

2. Press the next key 5 times or until “tolerance”

shows.

3. Press the save key to select the tolerance

function.

4. Press the next key until “% On” shows.

5. Press the save key.

6. Enter the new % value (01-99%) with the

increase and next keys (see “entering numbers”

below).

7. Press the save key when the value is correct.

…

On

02

%

%

To make high/low limits the default

tolerance mode

1. Press the menu keys.

2. Press the next key 5 times or until

“tolerance” shows.

3. Press the save key to select the tolerance

function.

4. Press the next key until the high/low arrows

show.

5. Press the save key to store the new tolerance

setting.

Note:

Once you change the tolerance mode it will

11

On

On

%

Page 13

become the new default tolerance mode each time

the torque meter is turned on.

Now when you set the limits (press and hold the

limits on/off key) you will be prompted to set the

high and low limits instead of the target torque.

To change the display clear method

…

…

AUto...OFF...1sec.....9sec

hold to change

1. Press the menu keys.

2. Press the next key 6 times or until the “Auto

Reset” icon shows.

3. Press the save key to select the Auto Reset

function.

4. Press the next key until:

“AUt0” shows (Auto sense)

“Off” (manual clear using the clear key)

“1…….9” (seconds before the display clears

itself)

5. Press the save key to store new setting.

Note:

If auto sense is selected the torque meter will

automatically clear the display when a new torque

cycle begins. This means that you do not have to

continually reach up and clear the display manually.

Entering the limits (tolerance) settings.

1. From the operation mode press and hold the

limits on/off key.

If you have set the % function set then the meter

will prompt you to enter the target tolerance (it will

automatically calculate the limits).

If you have the high/low function set then the meter

will first prompt you to enter the low limit and then

the high limit.

...

Power saving standby mode

When the torque meter has not been used for

approximately 3 minutes it will go into the power

12

Page 14

down or “standby” mode. The display will

show

“...”.

Press the clear key to get back to normal

operation. For the longest life from the batteries

turn the meter off when not used.

Entering Numbers

When a number needs to be entered, a default

value (or the last value entered) will be shown.

The digit that can be changed will blink.

Press the increase key to increase the value of

the blinking digit.

Press the next key to go to the next digit.

Press the increase key to increase the value of

the next blinking digit.

Repeat for digits 3 and 4.

When the number is correct, press the save key

to save the new value.

Zeroing the display

If you press the increase and next keys at the

same time you will “Zero” the unit. Make sure

that there is no load on the transducer when

pressing the zero keys. The meter will not read

torque until approximately 2% of the transducer

range has been reached, therefore you must zero

the unit even when the display shows zero.

000.0

0005

100.0

100.0

IMPORTANT!

Always zero the unit when changing direction.

If you plan to use the meter in the

counterclockwise direction load the transducer

three times in the counterclockwise direction (to

13

Page 15

full scale) and then zero the display. Press the zero keys even if the display shows

“000.0” This will compensate for small amounts of hysteresis (hysteresis is a natural

characteristic of steel).

Torque Sensors and OVERLOAD

Torque transducers are designed to give years of reliable operation if treated properly.

Torque transducers are sensitive electro-mechanical measurement devices and should

be handled with care.

Never over-torque a transducer beyond its usable range. It is good practice, when

possible, to select a transducer that is at least 25% greater in range than the expected

torque it will apply. This may help avoid accidental over-torque.

The torque transducers that are supplied with the torque meter will accept up to 50%

over torque without damage. However, if this should occur we recommend that you

return the unit for a calibration check.

The torque meter has an audible warning system that will alert you if you have

exceeded the usable range of the transducer. A constant beeping sound will occur.

Attach arm this end

F

Cable

Cable pointing down

Cable

Correct position for testing torque extensions

Mount this end

Page 16

Transducer mounting positions

e

for bench top style torque transducers:

Warning!

Always make sure the bench is strong enough and will not tip wen applying torqu

Bolting the bench to the ground may be necessary on higher range transducers.

3” bolt circle for 3/8 inch screws

or

2.175” bolt circle for ¼ inch screws

Make sure the cable is pointing down (4 O’CLOCK POSITION) when mounted on a

bench. This will place the primary axis in the correct position.

15

Page 17

Stop applying torque when you hear this sound, and press the clear key to stop the

buzzing.

Checking for accuracy

The Torque Meter and torque transducers are factory calibrated and should be

checked on a regular basis. We recommend that, provided the transducers are used

according to this manual, they be re-certified yearly. Since the frequency of use,

among other factors, may affect the calibration, the user must determine the best

calibration interval.

It is important to use the correct arm length since arms that are too short may

create excessive bending loads.

Recommended torque arm lengths:

4” 100 in lb

10” 250 in lb and 50 ft. lb.

24” 50 and 250 ft.lb.

1

48” 500 ft. lb.

These arm lengths closely represent the length of typical wrenches that will be

used on the transducers. They also allow for no more than 150 lbs of weights,

which also represents the “typical” amount of force required to generate the torque

with a wrench. Do not use a 10” arm to calibrate a 250 ft. lb. wrench. This would

require 300 lbs of weights, this is not good for the transducer and is not

representative of the typical weight needed to generate 250 ft.lb. applied by a

person. Most conventional torque wrenches are designed to be long enough to

allow a 150-175 lb person to generate the force required to generate the needed

torque. Using the above arm lengths will be consistent with this philosophy.

The accuracy of the meter is such that any incorrect zero caused by out of balance

arms, mis-alignment or sloppy adapters used on the torque arm system may cause

a “perceived”out of tolerance situation. This can happen when you use a female

drive torque arm on a female drive transducer and use a male-male adapter in

between. It can also happen when you use an adapter to reduce a ½” female drive

arm down to a 3/8” female drive using an off-the-shelf adapter. For this reason you

must always use the proper drive arm with the transducer. If the transducer is a ½”

female drive then you must use a ½” male drive torque arm.

Even benches that are not flat or deflect during high load calibrations are

unacceptable. In this case the transducer will not be perpendicular with the

16

Page 18

weights and this will show on the meter (yes the meter is that sensitive), resulting in a

possible out of tolerance condition.

Procedure for checking accuracy

Transducers are calibrated to within .5% (bench type) or 1% extension type

IV +/- .1 at the factory. If you require greater accuracy you can bypass the

smart chip in the transducer and perform a manual calibration on

transducers. This will account for variations in torque arm calibration

systems.

IMPORTANT!

MUST

YOU ALWAYS DO THE FOLLOWING:

MOUNT THE TRANSDUCER SO THE CABLE IS POINTING DOWN.

PUT THE METER IN MODE.

1. NEVER USE A TORQUE ARM THAT IS NOT BALANCED ABOUT ZERO. A

HIGH PRE-LOAD,OR AN OPPOSITE DIRECTION PRE-LOAD REDUCES

ACCURACY AND IS NOT INDICATIVE OF REAL APPLICATIONS. A SLIGHT

PRE-LOAD MAY, HOWEVER, BE NECESSARY TO TAKE UP DRIVE

TOLERANCES IN THE DIRECTION TO BE TESTED. A 1 OR 2 LB HANGER

WEIGHT SHOULD BE SUFFICIENT.

2. ALWAYS APPLY FULL SCALE TORQUE, THREE TIMES, WITH WEIGHTS,

IN THE DIRECTION YOU ARE TESTING PRIOR TO RUNNING AN

ACCURACY TEST.

3. AFTER STEP 2 ABOVE, WAIT AT LEAST 30 SECONDS OR FOR THE

WEIGHT HANGER TO STABILIZE. SWINGING HANGERS WILL GIVE AN

INCORRECT ZERO READING AND MAY THROW OFFACCURACY.

4. AFTER STEP 3 ABOVE PRESS THE ZERO BUTTONS (

DISPLAY SHOWS “000.0” DO NOT PRESS THEM AGAIN

A COMPLETE NEW TEST CYCLE (STARTING FROM STEP 1 ABOVE).

5. AFTER STEP 4 ABOVE APPLY 10% LOAD, LET THE HANGER STABILIZE

AND CHECK READING.

FINISHED CHECKING AT THIS POINT

6. AFTER STEP 5 ABOVE APPLY TO THE HANGER

TO BRING THE TORQUE TO 50% OF LOAD AND CHECK READING.

REMOVE THE WEIGHTS WHEN FINISHED CHECKING AT THIS POINT.

7.

AFTER STEP 6 ABOVE APPLY TO THE HANGER

TO BRING THE TORQUE TO 100% OF LOAD AND CHECK READING.

TRACK

EVEN IF THE

) UNTIL YOU START

DO NOT REMOVE THE WEIGHTS WHEN

.

ADDITIONAL WEIGHTS

DO NOT

ADDITIONAL WEIGHTS

THE MAJORITY OF ACCURACY PROBLEMS OCCUR DUE TO INCORRECT

LOADING SEQUENCE, ZERO PROCEDURES AND TORQUE ARMS THAT

17

Page 19

ARE NOT IN BALANCE WITH A SLIGHT PRE-LOAD IN THE DIRECTION TO

BE CHECKED.

Calibrating the torque transducer:

You can change the information on the smart chip within the transducer. If the values

on the chip need to be changed then one of two things MAY have happened:

1. The torque arm system, or the procedure, is introducing errors that when added are

creating an out of tolerance situation (SEE ACCURACY CHECKING ABOVE)..

2. The transducer has been damaged and needs repair (usually shown by significant

errors).

not

Bypassing the smart transducer feature.

If you want to bypass the smart chip calibration data, and use the calibration data that

you create with your torque arms, you can do so by assigning a “custom” transducer

number to the transducer and calibrating it using your own dead weight system.

This method stores the calibration data for the transducer in the memory of the meter,

in the memory chip inside the transducer

must select the custom transducer number when you power on the unit (see selecting

custom transducers below). If you do not select the custom transducer number the meter

will revert to the calibration data on the chip inside the transducer.

You can tell if the system is using the smart chip inside the transducer if, after pressing

the transducer keys you see the words “auto Xducer”. You will see the words “custom”

transducer if you have selected the transducer manually.

This method can be used to “fine tune” a transducer, possibly resulting in higher accuracy

and can also used for calibrating third party transducers to the torque meter.

manually

not

. In order to use the custom transducer data you

To manually calibrate a “custom” transducer

1. From normal operation mode press the menu buttons

2. Press the next key until the word “CAL” is displayed. Press the save key to select

the cal option.

The current default custom transducer number (01 to 15), will show and flash (unless it

is a smart transducer in which case you must press the next key to select a custom

transducer number).

Press the next key until the desired custom transducer number is shown (mark this

number on the transducer for future reference).

The current transducer settings for the transducer number will show as you scroll

Note:

through the transducers, all default values are “9999” or “1000” and 2.000 Mv/v.

Press the save key to select the desired transducer number.

The current full-scale range will now be displayed (will default to “9999” if this number

has never been assigned) with the first number flashing (do not worry about the position

of the decimal, that will be set next).

3. Press the increase and key to make the digits read the full-scale range of the transducer

you are going to calibrate. Press the save key

4. Now set the decimal position with the next key (keep pressing until you see the

18

Page 20

decimal point)..

Press the Save key.

5. Set the units by pressing he units key. Press Save.

6. Set the estimated clockwise (cw) Mv/v (if known, use 2.000 if not known). Press Save.

7. Set the Counterclockwise (ccw) Mv/v (if known, use 2.000 of not known). Press Save.

8. The display will now show “calc” (more on “calc” later). Press the next key until the

unit shows “cert”. which means you are going to calibrate (certify) a transducer with dead

weights.

The display will now show “CCW CAL0” This means it is ready to take a

counterclockwise zero reading.

SEE ACCURACY CHECKING PROCEDURES FOR THE PROPER METHOD TO

LOAD A TRANSDUCER.

9. Load the transducer, with a balanced arm and a slight pre-load, in the counter clockwise

direction three times to full scale with dead weights, and remove the weights but not the

arm and pre-load hanger. Wait 30 seconds or for the hanger to settle and press the Zero

buttons ( ).

even if the display shows 000.0

The Display will now show “CCW FS” which is prompting you to apply the ull- cale

weights to the arm in the counterclockwise direction.. Apply the full-scale weights in the

counterclockwise direction, stabilize the weights and press the save key.

Make the display read the full-scale counterclockwise value (within tolerance) with the

increase and next keys. Press the save key.

10. The display will now read “CW CAL0”. This means the meter is ready to read the

clockwise zero reading.

the clockwise direction three times to full scale with dead weights, and remove the weights

but not the arm and pre-load. Wait 30 seconds or for the hanger to settle and press the

Zero buttons ( ).even if the display shows 000.0

The display will now show “CW FS” which means load the arm to full scale in the

clockwise direction. Press the save key.

Make the display read as close as possible to the full scale clockwise value by pressing the

increase and next keys.

Press the save key.

You will now exit and be in the track mode with the display reading the calibrated full

scale clockwise value. The calibration data you just created will be saved in the memory of

the meter, under the custom transducer number you assigned to that transducer.

From now on, if you want to use the manual calibration values that you just entered you

simply need to select the proper transducer number when selecting custom transducers.

you do not have to re-select a smart transducer custom assigned number unless you have

disconnected the transducer from the meter.

Load the transducer, with a balanced arm and slight pre-load, in

FS

19

Page 21

You can repeat the above process adjusting the full scale value until the unit reads as

y

K

dF

ti

accurately as you desire at any point on the scale.

Selecting custom transducers:

If you have a non-smart custom transducer that you have calibrated manually, per the

above procedure, the meter will automatically recognize that the attached transducer is

not smart and prompt you with a transducer number every time you turn on the meter.

Simply press the next key to select the proper transducer number, then press save and

you will enter the normal operation mode. The meter will always turn on with this

transducer number active (on non-smart transducers) and will use the calibration data

that was entered during the manual calibration process.

If you have a smart transducer and have also assigned it a custom transducer number

you do not have to re-select the custom number as long as you do not detach the

transducer (even after power down). If you have detached the transducer then the meter

will re-read the smart chip and use the smart data, not the custom data, when it is turned

on. Select the custom transducer in this case. Do this by pressing the transducer keys

and pressing the next key until the display shows the transducer number you have

assigned to the transducer. Press the save key and the unit will now use the calibration

data that was stored in the memory of the meter for that transducer. Remember, you

only have to select the custom transducer number after you have detached the

transducer.

Printing and Sending Data

Note:

It is not within the scope of this manual to instruct the user on how to set his/her

computer or printer up for data transfer. Please refer to the operation manual of your

particular printer or computer.

The torque meter operates with an industry standard RS232C communication port. You

can use a program as simple as “Hyper terminal” that comes standard with Windows or

any third party data logging software.

The torque meter sends data is as follows:

RS232C, 4800, 8, 1, n

Refer to your computer or printer operation manual for a description of these settings.

The torque meter will send data out the communication port under the following

circumstances:

When the save key is pressed the data on the display will be sent (and saved).

When the “send mem” function is selected, from the menu function, it will send all the

20

Page 22

data in memory.

When the recall key is pressed and held for 1 second the torque meter will send the

torque value on the display.

Battery and Power

The torque meter uses either a common 9 volt battery (gives longest life) or a

rechargeable 9 volt battery (supplied standard for convenience).

Battery life depends significantly on the type of battery used. Non-rechargeable lithium

ion 9-volt batteries may last up to 40 hours. Common alkaline batteries may last up to

20 hours.

It is recommended that if you are going to use the meter on battery power that you keep

a standard 9 volt battery as a backup, or an additional charged 9 volt battery. Any

common re-chargeable 9 volt battery can be used in the torque meter.

The Torque meter has a power down (standby) mode that will activate after

approximately 3 minutes without use. This mode still uses battery power.

Press the clear key to resume operation when the power down mode is active (depicted

by “…” on the display). The sleep mode still takes power so if you are on battery power

it is best to turn the meter off when not in use, this will result in longest battery life.

The torque meter will show a “B” icon on the display when the battery is low and will

show a “B” with two dashes “- -“ on the main digits when the batteries are critically low.

The time between low battery and critically low battery may vary depending on the state

and type of battery.

+

Make sure battery is placed with + side

as shown

21

Page 23

The torque meter can be used while the batteries are charging with no adverse effect.

3

The supplied power adapter is a trickle charger that will take at least 14 hours to charge a 9

volt battery. You can use any standard external quick charger to charge the 9 volt battery.

Specifications

Range and Display: Direct reading triple numeric LCD display with large 4 digit

primary display (5/8” high) and two additional 4 digit displays.

Maximum reading 9999.

Floating Decimal Point.

Accuracy : : When used with:

Sampling Rate: Approx. 8,000 samples per second.

Power: Battery: common 9 volt - ( rechargeable NiCd supplied for

Battery life: Up to 20 hours with standard 9 volt battery under normal

Recharging Circuit: Internal. 110 volt input, 9 volt 300 mA output, adapter supplied

Meter Case: Dimensions: 7.25” long x 3.25 “ wide x 1.25” thick.

Stand: Folding and adjustable bench, wall or shelf stand supplied standard.

Memory: Up to 1,350 torque data. Includes data number, torque value and units.

Communication: Direct to serial computer or printer.

Operating Modes: Track, Peak and First Peak for calibration of Micrometer (clicking)

torque wrenches.

Limits setting: Tolerance values displayed on triple numeric display during operation.

Smart Bench top: .5% IV from 10 – 100 % of transducer range +/- .1.

Smart Extension: 1% IV from 10 – 100% of transducer range +/- .1.

Greater accuracy may be achieved with manual calibration.

convenience).

use*.

standard (center positive 2.1 mm connector).

Weight: Less than 8 ounces

RS232C 4800 BPS, 8, 1, n.

Communication cable and adapter supplied standard.

Quick on/off with one key.

User selectable % (1-99%) with programmable target.

or

Programmable high and low values.

Tolerance prompting: Triple lights and buzzer: Yellow (under), Green (within), Red (over)

Display Clear Modes: Automatic cycle complete.

Filters: 5 user selectable filter settings: 170hz, 250 Hz, 500 Hz, 1500 Hz,

Transducer Selection: Automatic “plug and play” with smart chip.

Tolerance values displayed on triple numeric display during operation.

Programmable timed auto reset from 1 – 9 seconds.

Manual Clear.

3600 Hz.

or manual “custom calibration”.

* Battery life will vary depending on quality of battery and usage-values estimates only.

Longest life will come from a lithium ion 9 volt battery.

22

Loading...

Loading...