Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

INSTRUCTION MANUAL

FM

D60400

Thank you for purchasing a Futaba digital proportional

radio control set.

Please read this manual carefully before using your set.

FEATURES OF FP-5NLH

The FP-5NLH for helicopters is an FM proportional radio con-

trol

set

for helicopters

result of the exhaustive pursuit of easier operation. Newly de-

signed sticks for smooth and positive operation, servo revers-

ing switches for all channels, aileron and elevator AST (Ad-

justable

Servo

Throw),

innovations based on the opinions of many RC modelers.

TRANSMITTER FP-T5NLH

• Reliability substantially improved by using industrial robots to assemble the PC board.

• Servo reversing switch for each channel. Servos are reversed by using

this switch

• Aileron and elevator AST (Adjustable Servo Throw). Servo throw can

be set as desired.

• Easy-to-adjust two knob type revolution mixing. Throttle pitch con-

trol rudder mixing.

• Pitch control trimmer. Approximately 30% of the pitch control servo

throw can be trimmed, this allows optimum pitch control of the

model.

• Throttle hold switch and trimmer for auto rotation.

• This allows the Rotor r.p.m. to maintained at an effective control

speed, even when the pitch is reduced, allowing maneuvers which

were impossible in the past to be performed.

• Newly designed open gimbal sticks operate smoothly and reliably.

Spring tension mechanism allows adjustment of the operating feel of

the stick lever.

• Nonslip adjustable lever head allows adjustment of the stick length as

desired.

• Throttle ATL. Adjustable throttle limiter type throttle trim. As the

high

side

does

convenient when connecting the linkage, etc.

• RF PC board module system.

• Functional case, created as a result of the exhaustive pursuit of easier

operation, has evolved a thick case which fits into the palm of the

hand.

• Square level meter at the transmitter indicates the power supply

voltage.

• Excellent radiation efficiency, strong 8-stage telescoping antenna.

• Neck strap bracket provided as standard. Operation is easier if the

transmitter is hung from your neck by using the optional neck strap.

• Built-in NiCad battery.

not

RECEIVER FP-R107N

• Compact, high performance FM 7-channel receiver with PC board

space reduced to a minimum.

•Special IF amp for radio communications improves the effective

receiving range stability.

• Narrow band ceramic filter improves rejection of adjacent channel

interference.

• Futaba original squelch circuit reduces erroneous operation by weak

signals (when passing a dead point, etc.) and erroneous operation by

natural noise when no signals are being received.

• Large capacitor copes with voltage changes when a battery is used.

• Vibration-resistant pin connectors.

• Fiberglass epoxy PC board with thru-the-hole plating is vibration and

shock resistant.

change

with

pitch

even

an

ergonomic

control

when

the

trim,

trim

case

crested

idle up,

is

altered,

and

it

as

other

is

very

a

SERVO FP-S130

SMALL, RUGGED, HIGH NEUTRAL SERVO

• Small, double ball bearing, water-tight & dusttight servo. High output

torque 55.6 oz-in (4kg-cm), high-speed 0.24sec/60°

• New indirect drive potentiometer improves vibration and shock resistance and neutral accuracy.

• Futaba low-power custom 1C provides extremely high torque, narrow

dead band, and superior tracking.

• Fiberglass reinforced PBT (polybutylene terephthalate) injection

molded servo case is mechanically strong and invulnerable to glow

fuel.

• Strong polyacetal resin ultra-precision servo gear features smooth

operation, positive neutral, and very little backlash.

• Fiberglass reinforced epoxy resin PC board with thru-the-hole plating

improves servo amp vibration and shock resistance.

• Three pin connector eliminates faulty contact and improves reliability

against vibration and shock. Housing has a reverse insertion prevention mechanism.

• Special grommet simplifies mounting of the servo and has an excellent cushioning effect.

• Six special adjustable splined horns.

SET CONTENTS AND RATINGS

(Specifications are subject to change without prior notice.)

FP-5NLH

PCM

Transmitter

Receiver

Servo

NiCad battery

Switch

Others

TRANSMITTER FP-T5NLH

Operating system

Transmitting frequency

Modulation system

Power requirement

Current drain

RECEIVER FP-R107N

Receiving frequency

Intermediate frequency

Power requirement

Current drain

Dimensions

Weight

Receiving range

SERVO FP-S130

Control system

Operating angle

Power requirement

Current drain (IDLE)

Output torque

Operating speed

Dimensions

Weight

FP-T5NLH x 1

FP-R107N x 1

FP-S130 x 4

NR-4J x 1

SSW-J

Charger, Ribbon, Spare horn. Mounting screw.

2 stick, 5 channels w/servo reverse, aileron

and elevator AST, helicopter mechanism

72MHz band.53MHz band

FM (Frequency modulation)

9.6 volts NiCad battery (NT-8LP)

170mA (at 12V)

72MHz band .53MHz band

455kHz

4.8V, NiCad battery (common use with servo)

13.5mA (4.8V reception)

1.38 x 2.42 x 0.8 in (35.2 x 61.7 x 20.3mm)

1.55oz (43g)

550 yards (500m) on the ground, 1,100 yard

(1000m) in the air. [FP-T5NLH]

(at the best conditions)

+pulse width control

One side 45° or more (at idle)

4.8V (Shared with receiver)

5.0V,

8mA

55.6 oz.in (4kg-cm)

0.24sec/60°

1.52 x 0.77 x 1.36 in (38.5 x 19.5 x 34.5mm)

1.47oz (42g)

Page 2

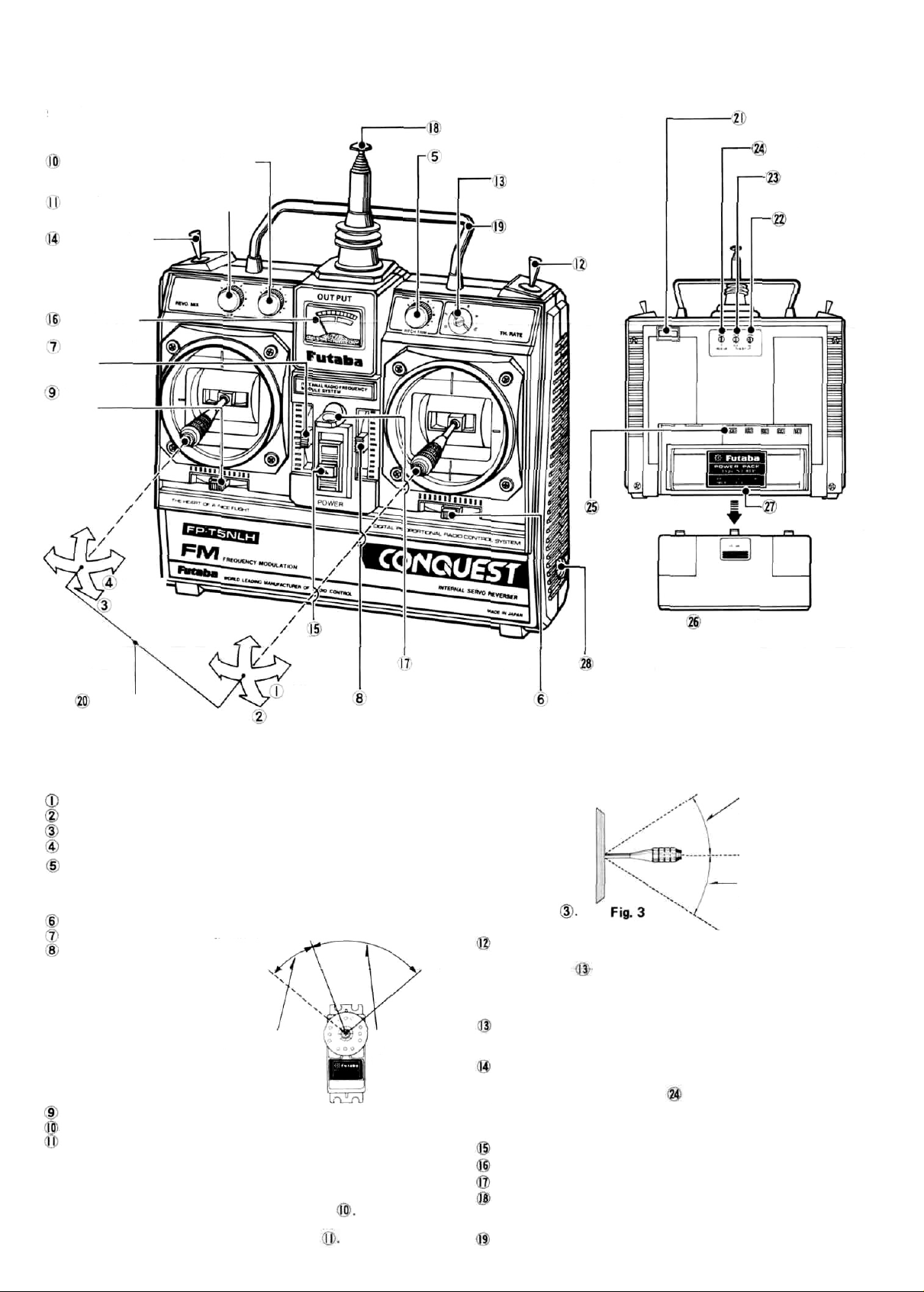

TRANSMITTER FP-T5NLH CONTROLS

Fig. 1 shows the name of each part of the transmitter.

Memorize the position and operation of each

switch and control.

Revolution mixing down knob

Revolution mixing up knob

Idle up switch

Level meter

Throttle trim

lever

Rudder trim

lever

Antenna

Pitch control trimming knob (CH5)

Throttle hold trimmer

Carrying bar

Throttle

hold switch

Transmitter crystal

Idle up trimmer

Elevator AST

trimmer

Aileron AST

trimmer

Rudder

Throttle

Power

Aileron

Elevator

knob

sides.

switch

(down

side

Exclusively

Servo throw

knob)

MODE II

Nonslip

adjustable lever head

In the following descriptions, all the servo reversing switches

are assumed to be in the normal position. When they are in the

reverse position, operation is the opposite of that described.

Aileron Aileron operation

Elevator Elevator operation

Throttle Throttle operation

Rudder Rudder operation

Pitch control trimming knob (CH5)

Pitch control trimming knob. Approximately 30% of the full throw

of the servo can be adjusted and set. Normally, it is set for the best

pitch during flight.

Aileron trim lever Aileron trimmer.

Elevator trim lever Elevator trimmer.

Throttle trim lever w/ATL

Adjustable throttle limiter

type

trim

lever.

a trim lever only when the

throttle stick is at the

SLOW side as shown in

Fig.

2.

As the HIGH side does not

change even when the trim

is altered, it is extremely

convenient when connect-

ing the linkage, etc.

Rudder trim lever Rudder trimmer.

Revolution mixing down side ratchet

Revolution mixing up side ratchet knob (up side knob)

• Knob which adjusts the throttle rudder mixing amount. Approximately 70% mixing

clockwise rotation.

The LOW side mixing amount from mid throttle (hovering point)

position is adjusted and set with the down side knob

The HIGH side mixing amount from mid throttle (hovering point)

position is adjusted and set with the up side knob

Operates

at

the up and

SLOW

as

Servo throw by

throttle trimmer

(30% of full throw;

Throttle servo

down

Neck strap bracket

Throttle trim

lever s/ATL

HIGH

by throttle

stick

Fig. 2

for

rotor

Servo reversing

switches

Transmitter

NiCad battery

NT-8LP

Battery cover

Charging jack

Aileron trim lever

Mixing circuit is used for cancelling the torque reaction of the main

rotor. The controls for set the minimum mixing necessary for helicopter flight.

• The amount of the

revolution mixing

up side knob 11

and down side

knob 10 begins

individually set

from the neutral

position of the

throttle stick

Throttle hold switch

When this switch is ON, the throttle servo stops at the position set

with trimmer and only the pitch servo is controlled toy the

throttle stick. It is used for auto rotation landings. When this, switch

is OFF, the throttle and pitch servos are mixed. The switch is turned on when pulled forward.

Throttle hold trimmer

Trimmer which

tle hold switch is ON. Full travel setting is possible.

Idle up switch

When this switch is pulled forward, it is turned on and the position

set with the idle up trimmer on the back of the transmitter

becomes the maximum slow position of the throttle servo. When

this switch is set to OFF, the normal slow position of the stick becomes the maximum slow position of the throttle servo.

Power switch The upper position is ON.

Level meter This level meter indicates the transmitter battery voltage

Neck strap bracket Bracket for the neck strap (optional).

Antenna

Strong telescoping antenna. Extend it to its full length when using

the transmitter.

Handle Use this bar to carry the transmitter.

sets

the

throttle

servo stop

Mixing is adjusted and

set over this range with

the revolution mixing

up side knob 11 .

.Throttle stick neutral

position

Mixing is adjusted and

set over this range with

the revolution mixing

down

side

knob®.

position

when the

throt-

Fig.1

Page 3

Nonslip adjustable lever head

The length of the lever head can be adjusted to fit the operator.

Adjust to the length of your hand

Lever head

Unlock lever heads

in the arrow direction, and adjust the head to

the most comfortable length, then lock it by

turning it in the direction opposite the arrows.

Transmitter crystal

Aileron AST trimmer

Elevator AST trimmer

AST is the abbreviation of

Adjustable Servo Throw. The

servo throw can be adjusted

and set as shown in the figure.

Trimmer

on and trimmer

elevator.

is for the ailer-

is

for the

and

Lever head

. by turning them

Neutral

Fig.

Throw can be

adjusted and

set over this

range. 40% —

100%

4

Fig.

Transmitter NiCad battery NT-8LP

The tension of the stick lever spring can be adjusted.

When these screws are

removed, the back cover

can be removed.

• The tension of the

spring can be adjusted

by removing the transmitter back cover and

turning the screw for

each stick. Set the

springs for the best

stick feel.

Aileron

Rudder

5

Idle up trimmer

This trimmer is effective

when the idle up switch

is ON. It adjusts and sets the

throttle hold maximum slow

position, and can be set as

shown in the figure.

MAXIMUM

FJ9. 6 the throttle up trimmer.

Servo reversing switches

Using the servo reversing switches

• The left side of each switch is the normal position.

• The servo reversing switches reverse the direction of operation of the

servos.

Elevator servo Throttle servo

reversing switch reversing switch

Aileron servo

reversing switch

After linkage is complete, inspect the servos. If the direction of

operation of the stick lever and the direction of operation of a

servo are opposite, switch the appropriate servo reversing switch.

Battery cover

Remove this cover

when switching the

servo reversing

switches.

Rudder servo

reversing switch

Throttle stick deflection

SLOW

The idle up amount of

the throttle servo can

be adjusted and set

within this range with

NORM-> Normal

REV -> Reverse

Pitch

control

servo

reversing

switch

HIGH

Fig.

7

Elevator

When adjusting the

aileron, and elevator

the inside module

is removed.

Charging jack

Battery charge jack for built-in NiCad battery.

•CHARGING OF

TRANSMITTER

AND RECEIVER

NI-CAD BATTERIES:

Battery Charger

Type FBC-8B(4)

Recharge the receiver and

transmitter NiCad batteries

as shown in Fig. 10.

Notes:

1) First, connect to TX NiCad

and red lamp goes on.

2) Then connect to RX NiCad

after connecting, L, E, D,

chanqes color from red to

greenish red (orange)

which indicates that

both TX and RX NiCads

are being charged.

3) In case of separate

charging

L, E, D, color will be:

RX NiCad - Green.

TX NiCad - Red.

Use a small Phillips

screwdriver.

Rx:

(NR-4J)

Fig.

LED

Charging

plug

Pig.

9

10

Remove the

battery

cover, by

pulling it in

the arrow

direction while

pressing

downward.

Fig.

8

• Connect the charging plug of the FBC-8B charge to the transmitter

charging jack, connect the 3P connector of the FBC-8B to the receiver NiCad battery (NR-4J), and plug the FBC-8B to a 117VAC

outlet as shown in this figure.

• The Receiver battery can be used about 10 times at 10 minutes per

flight between rechargings.

• Charge the batteries for about 15 hours. When the set is not in use for

some time, repeat discharge and charge two to three times before use.

(If the batteries are not used for a long time, their capacity will go

down).

• FBC-8B charges transmitter and receiver NiCad batteries independent-

ly or simultaneously.

Page 4

RECEIVER FP-R107N & SERVO FP-S130

Receiver, servos, switches, and battery connections

Receiver crystal

7-channel FM receiver FP-R107N

Aileron servo

4 servos are provided

as standard.

Elevator servo

Throttle servo

Rudder servo

Antenna wire

SSW-J

Power switch

Pay careful attention to the

connector polarity.

NR-4J

Fig.

12

Charging

Plug

Gyro output

switching

connector is not

connected.

Gyro output

polarity switch

Control

amp

Connector servo (rudder servo for helicopter)

neutral trimmer. (This trimmer is effective even

when the control box power switch is set toOFF.)

Pitch control

servo

C Connector Red

The parts enclosed

by the dotted lines

must be purchased

separately.

Rate gyro FP-G152

Gyro

Control box

Gyro output trimmer

Jumper connector

Five battery

pack 6V connector for motor

regulated power

supply. (When

the power supply

is used in common with the

receiver, insert

the jumper

connector.)

PRECAUTIONS

• Connect the receiver, servos, switches, and battery firmly as shown in

Pig.11. Then extend the transmitter and receiver antennas fully.

• Set the transmitter power switch to ON. Then set the receiver power

switch to ON. The servos stop near the neutral position. Operate the

transmitter sticks and check that each servo follows the movement of

the stick.

• Connect the pushrod to each servo horn, then check if the direction

of travel of each servo matches the direction of operation of its transmitter stick. To reverse the direction of servo travel, switch the servo

reversing switch.

• Operate each servo over its full stroke, and check if the pushrod binds

or

is

too

loose.

adversely affect the servo and quickly drain the battery. Always make

the travel of each control mechanism somewhat larger than the full

travel (including trim) of the servo horn. Adjust the servo horns so

that they move smoothly even when the trim lever and stick are

operated simultaneously in the same direction.

• Be alert for noise.

This set is noise-resistant, but is not completely immune to noise. We

recommend the use of noiseless parts.

• When installing the switch harness, cut a rectangular hole somewhat

larger than the full stroke of the switch and install the switch so that

it moves smoothly from ON to OFF. This also applies to the switch

mount when the switch is installed inside the fuselage and is turned

on and off from the outside with a piece of wire, etc. Install the

switch where it will not be exposed to engine oil, dust, etc.

• Even though the receiver antenna is long, do not cut or bundle it.

•

Install the

rubber

grommet

cushioning effect will be adversely affected.

Applying

servos

is

unreasonable force

securely.

crushed slightly.

Tighten the

If

mounting

the

screws are

to

the

screws

servo

too

horn

until

tight,

will

the

the

• The crystal can be changed from the outside of the receiver case.

Always use the Futaba transmitter/receiver matched crystal set to

change the band.

• Spare servo horns are supplied. Use them as needed.

• Wrap the receiver in sponge rubber. Waterproof and dustproof the

receiver by placing it in a plastic bag and wrapping a rubber band

around the open end of the bag. Do the same with the receiver/servo

battery.

• Use the rubber bands wrapped around the receiver to hold the servo

and switch leads.

• After mounting is complete, recheck each part, then check the range

by making the transmitter antenna as short as possible, extending the

receiver antenna fully, and operating the set from a distance of 20m

to 30m. The movement of each servo should follow the movement of

each stick of the transmitter.

• After mounting and checking are complete, take your model to the

shop where you purchased the set, or to an experienced radio control

modeler, and ask them to teach you how to handle your radio control

set in the proper manner and to inspect your set-up carefully.

• To enjoy radio control models fully, be sure to observe all safety

standards.

Page 5

• General adjustment

Make the linkages and adjustments as described in the model manu-

facturer's instruction manual.

When the throttle (engine control) stick is set from the SLOW side to

the HIGH side, the throttle servo operates as shown in Fig. 14A. If

revolution mixing is applied at this time, the rudder servo operates

together with the throttle servo as shown in Fig. 14B. This operating

width is called the mixing amount. The rudder stick operating width

becomes larger as the number of divisions of the scale become larger.

The rudder servo is operated as shown in Fig. 14B at right rudder stick.

However, if the throttle (engine control) stick is at SLOW, the neutral

position is from the left and if the throttle (engine control) stick is at

HIGH, the neutral position is from the right.

Throttle stick

neutral position

Right

Up side

mixing amount

B. Rudder

servo

gyro,

operation

is

used

HIGH

with a rate

SLOW

A. Throttle

servo

• Revolution mixing adjustment

When the main rotor rotates, the helicopter attempts to turn in the

opposite direction. To cancel this torque reaction, the pitch of the tail

rotor (rudder) is increased. Revolution mixing performs this operation

simu.ltaneously with the throttle (engine control), and is necessary to

fly a helicopter.

(If

Left

Down side

mixing amount

much

easier.)

Fig.

14

12 If the helicopter turns to the left during hovering, turn the revolu-

tion mixing up side knob clockwise. If the helicopter turns to the

right, turn the knob counterclockwise.

13 Rate gyro output adjustment (when FP-G153 used)

A position about 40% to 80% of the rate gyro control box scale

should be sufficient. (Differs somewhat with the model.)

If the tail of the helicopter whips back and forth, the gyro output

should be increased.

• Idle up adjustment

When the idle up switch is OFF, the throttle servo operates normally as

shown in Fig. 16A. When the switch is ON, when the idle up trimmer is

suitably set, the throttle servo changes to the maximum slow position

as shown in Fig. 16B.

When idle up is used, hovering is stable and the rotor speed can be held

even when the pitch is reduced during rolls and prettier maneuvers are

possible.

1 Set the transmitter throttle (engine control) stick to maximum slow

and set the idle up switch to ON and set the idle up trimmer to

about 20 to 25%.

2 Next, set the idle up switch to OFF, start the engine, hover, and

decide the speed at hovering. Set the idle up switch to ON, hover,

and adjust the idle up trimmer so that the speed is about the same

as, or somewhat slower than, that when the idle up switch is OFF.

When the idle up trimmer is turned clockwise, the speed increases.

When starting the engine and after use, always set the idle up switch

to

SLOW

OFF.

HIGH

SLOW

HIGH

When main rotor rotates

clockwise.

Tail rotor pitch is increased

so that the helicopter does

not turn to the left.

2 Helicopter turns to the left.

1 Check the direction of operation of each servo. To reverse the

direction of operation, switch the reverse switch.

2 Always set the idle up switch and throttle hold switch to

OFF (pushed to the opposite side).

3 Make the basic adjustments described by the model helicopter

manufacturer.

4 Check the left and right (up and down) throw of each servo. If the

throw is incorrect, correct it by changing the position of the servo

horn hole, etc.

5 Set the throttle stick to about the center (medium slow) and

install and link the servo horn at the neutral position.

6 Set the revolution mixing up side knob to about divisor 5 and

revolution mixing down side knob to about divisor 7.

7 Check the engine throttle linkage.

• Throttle opened fully at throttle stick HIGH (up).

Throttle closed fully at throttle MAXIMUM SLOW (down).

• Use ATL (Adjustable Throttle Limiter) trimming as much as possible.

This is convenient because the HIGH side does not change even if the

LOW side is changed. Then set the throttle stick to its full operating

width and set so that the pitch control servo operates over its maximum throw.

Regarding the main rotor variation width, select the servo horn

position as specified by the model manufacturer.

8 After starting the engine and adjusting the needle, hover and adjust

the aileron and elevator trim. Next, make the main rotor pitch at

hovering somewhat large with the linkage.

9 Adjust the linkage so that the rudder trim is neutral at hovering.

10 After adjusting all the trim levers, adjust revolution mixing.

11

If

the helicopter turns

turn the revolution mixing down side knob clockwise. If the

helicopter turns to the left, turn the knob counterclockwise.

to

the

right

during hovering after

Fig.

lift

15

off,

A. Throttle

servo

B. Throttle

servo

Fig. 16

• Aileron and elevator AST (Adjustable Servo Throw)

The servo throw is changed within the

range shown by the hatched lines in Fig.

17 with the aileron & elevator AST trimmer. The throw can be adjusted from a

maximum 100% to a minimum 40% by

turning each trimmer with a flat blade

screwdriver. Set to the throw matched to

the model.

Fig.

17

• Throttle hold adjustment

When the throttle hold switch is pulled on, the throttle servo stops at

the position set with the throttle trimmer. Trimmer scale division 0 is

maximum slow. Setting to the high side is possible as the number of

divisions increases. When the switch is OFF, the throttle servo is controlled by the transmitter throttle (engine control) stick. T his device is

used at auto rotation take off. After the engine is cut or at maximum

slow (during practice), only the pitch control servo is operated (pick

up) and safe take off is possible.

1 Set the throttle (engine control), throttle (engine control) switch

and throttle (engine control) trimmer so that the engine throttle is

fully closed at maximum slow.

2 Set the throttle trimmer so that the engine throttle becomes maxi-

mum slow when the throttle hold switch is set to ON (pulled forward) at autorotation practice. (Set so that the throttle is fully

closed when the engine is cut.)

3 When the throttle hold switch is set to OFF (pushed back), the

throttle (engine control) servo and pitch control servo mixing is

performed. When the switch is set to ON, the throttle servo is held

(maximum slow set by the throttle trimmer or fully closed) and

only the pitch control servo operates.

4 When the hold switch is used at take off, etc., always hold switch

to OFF after setting the transmitter throttle stick to slow. Also,

before starting the engine, check if the idle up switch and throttle

hold switch are OFF.

Page 6

This horn permits shifting of the

servo neutral position at the servo

horn. Setting and shifting the

neutral position

a) Angle divisions

Fig.

18

1) The splined horn has 25 segments. The amount of change per

segment is; 360 /25=14.4°

2) The minimum adjustable angle

is determined by the number of

arms or number of the holes. For

four arms, the minimum adjustable

angle is:

b) Effect

Baseline A

Fig.

19

To shift the holes center line to

the right (clockwise) relative to

baseline A, shift arm 2 to the position of arm 1 and set it to the

position closest to baseline A.

[Example] For a four arm horn,

the angular shift per segment is

14.4°. The shift to the right is 90°

- (14.4 x6) =3.6°

To shift by the same angle in the

opposite direction, use the opposite arm number.

Arm 3 shift 4.8° to the right, arm

6 shifts 2.4° to the left,and arm 4

shifts 7.2° to the right and left.

Fig.

20

For a six arm horn, turn the arm

counterclockwise and set arm 2

to the position of arm 1. The ad-

justable angle is 60° — (14.4 x 4)

=2.4°.

The following splined horns are optional.

HORN A HORN B HORN C HORN D HORN E HORN F

Insert the frequency flag into

the flag holder as shown here.

Fig.

Fig.

Fig.

21

22

24

No.

Upper case

1.

Middle case

2.

Bottom case

3.

4.

Ball bearing

5.

Potentiometer

6.

VR drive plate

Motor

7.

Motor pinion

8.

1st gear

9.

2nd gear

10.

11.

3rd gear

12.

Final-gear

13.

2nd shaft

14.

Intermediate shaft

Spacer washer 0.3T

15.

Seal ring

16.

0-ring

17.

18.

Servo horn D

19.

Horn mouting screw

S130 printed wiring board

20.

21:

Lead wire packing

22.

S1303PB WRB.300

Screw 0-ring

23.

24.

Case mounting screw

25

S130 Nameplale

Part Name

Fig.

Part No.

FCS-30

FCS-30

FCS-30

S04130

139995

S02753

S91243

S02461

FGS-30

FGS-30

FGS-30

FGS-30

S02481

S02480

S02486

S90415

S90426

FSH-6W

FSH-41

AS1220

S90045

FPC.8M

S90410

J50085

S6010)

23

First

digit

Second

digit

Staple or glue with

cyanoacrylate

ribbon here.

The flag can be attached to

and removed from the end

of the antenna with one touch.

To insure prompt service, please follow the instructions given below.

1.

Charge the

2.

Return

3. Plugs or other modifications which interfere with factory test procedures will be returned to

4. Carefully pack all components individually, using sufficient packing material to prevent

5. Include a brief but thorough explanation of all problems and service required and tape it to

6. Be sure to include your full address and tel No.. zip code inside the box as well as on the

7. Include a packing list of all items being returned, and double check to make sure that all

8. Upon receipt of your equipment at the Futaba factory, an estimate of the cost of repair

This factory repair service applies only to the continental U.S.A., Hawaii, and Alaska.

batteries

for

at

least

18 hours

prior

to

the

system

only.

Not

mounts and remove the foam padding from the receiver.

factory standard at your expense.

damage during shipment.

the back of the transmitter. Place a label describing the function of the servo on each servo-

outside.

items are packed.

(over $25 00 only) will be sent to you. Your equipment will then be repaired and returned

to you upon receipt of payment or C 0 D (cash)

your complete

shipment.

inital'alion.

Remove the

servos

from their

Loading...

Loading...