Fusion Oxi-Gen 150-OXi-2P, Oxi-Gen 150-OXi-3P, Oxi-Gen 150-OXi-4P, Oxi-Gen 150-OXi-5P, Oxi-Gen 150-OXi-6P Installation, Operation And Maintenance Manual

Page 1

Installation, Operation and

Maintenance Manual

US Water Oxi-Gen Iron, Sulfur

and Manganese Eradication

System

Oxi-Gen 150-OXi-2P

Oxi-Gen 150-OXi-3P

Oxi-Gen 150-OXi-4P

Oxi-Gen 150-OXi-5P

Oxi-Gen 150-OXi-6P

US Water Systems, Inc.

1209 Country Club Road

Indianapolis, IN 46234

1-800-608-8792

info@uswatersystems.com

www.uswatersystems.com

Page 2

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Table of Contents

System Overview and Specifications .................................................................................... 3

How Your Oxi-Gen System Works/Backwash Frequency Table ........................................... 4

Stenner Injection Panel Specifications .................................................................................. 5

Injection System Installation Instructions .............................................................................. 6

Carbon Filter Media and Valve Installation ........................................................................... 8

Carbon Filter Installation Instructions .................................................................................... 9

Carbon Filter Valve Features .............................................................................................. 10

Carbon Filter Valve Features and Programming ................................................................. 12

Carbon Filter Valve Programming ....................................................................................... 13

Carbon Filter Start Up and Injection Panel Setting ............................................................. 14

What To Expect and Routine Maintenance ........................................................................ 15

Maintenance Schedule ....................................................................................................... 16

System Flow Schematic ..................................................................................................... 17

Warranty ............................................................................................................................. 18

2

Page 3

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

System Overview and Specifications

US Water has pioneered the use of hydrogen peroxide in water treatment for the eradication of

iron (rust), sulfur (hydrogen sulfide odor) and manganese for nearly 20 years. It can truly be

called an "Eradication System" because it TOTALLY removes iron, sulfur and manganese.

Properly sized, an OXi-Gen Hydrogen Peroxide System from US WATER is THE MOST

EFFECTIVE METHOD for removing iron, rust, sulfur, hydrogen sulfide and manganese and the

rotten-egg odor from your water supply. Hydrogen Peroxide is not a hazardous chemical - to

the contrary, hydrogen peroxide (H2O2) is composed of the elements of water: Hydrogen and

Oxygen. There is nothing foreign or chemical added to the water supply. Unlike chlorine,

hydrogen peroxide requires no contact time and the reaction (oxidation of iron, rust, sulfur,

manganese and hydrogen sulfide) is immediate. The Oxi-Gen Hydrogen Peroxide System is

the answer to practically any iron, rust, sulfur, hydrogen sulfide and manganese problem, and

is backed with our 90-Day 100% Satisfaction Guarantee. US Water Systems guarantees 100%

iron, manganese and sulfur removal with its OXiGEN System which utilizes Hydrogen Peroxide

or H2O2.

Sizing is based upon number of bathrooms

1 Bathroom - 5 GPM

2 Bathrooms - 8 GPM

3 Bathrooms - 10 GPM

4 Bathrooms - 12 GPM

5 Bathrooms - 15 GPM

6 Bathrooms - 20 GPM

Hydrogen peroxide or H2O2 is a powerful, yet versatile oxidant that is both safe and effective.

Consider the H2O2 advantages and you’ll know why this is the ONLY sure way to eradicate

iron, manganese and sulfur.

Powerful - H2O2 is one of the most powerful oxidizers known and is much stronger than

chlorine, chlorine dioxide, and potassium permanganate.

Safe - H2O2 is formed by the action of sunlight on water and is a natural purification system for

our environment. Consequently, H2O2 has none of the problems of gaseous release or

chemical byproducts that are associated with other chemical oxidants. And since H2O2 is

totally miscible with water, it reverts back to hydrogen and oxygen after the reaction is

complete.

Versatile - Hydrogen Peroxide is lethal to iron, sulfur and manganese. PERIOD!

Selective - In itself, H2O2 is a fantastic oxidizer, much better than chlorine and potassium

permanganate. It poses no health hazard and ERADICATES 100% OF THE IRON, SULFUR

OR MANGANESE – ALL THE TIME – GUARANTEED!

Consult one of water specialists for higher flow rates. US Water offers OXi systems up to 100

GPM and can custom design them at no extra charge. Call us at 800-608-USWA or e-mail us

at info@uswatersystems.com .

3

Page 4

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

How Your Oxi-Gen Water Treatment System Works

The Oxi-Gen iron, sulfur and manganese eradication system uses Hydrogen Peroxide (H2O2)

to oxidize contaminants in your water source. The chemical name for hydrogen peroxide is

H2O2. As you can see it is very similar to water (H2O) but with one additional oxygen

molecule. Hydrogen peroxide is injected into the water stream proportionally. The chemical

injection control panel will engage the pump based on the flow rate of the feed source water

and the settings on the pump control.

When water is being used the water meter on the injection panel sends a pulse to the pump

control to engage the pump. So when large amounts of water is being used the pump will run

more frequently during the usage period than in times when a small amount of water is being

used.

When hydrogen peroxide is injected into the water stream, it oxidizes the iron, sulfur and

manganese from solution. This reaction is immediate. When these contaminants are oxidized

with hydrogen peroxide (H2O2) the extra oxygen molecule oxidizes the contaminants and the

by product is H2O (water). This is much safer than using chlorine in that chlorine can cause

other problems in the water stream such as chloramines and trihalomethanes (THM’s).

Once the water has been injected with hydrogen peroxide it passes through the backwashing

carbon filter. The backwashing carbon filter uses catalytic carbon to act as a “catalysis” to

remove the oxidized contaminants. As the water passes through carbon filter the oxidized

contaminants are removed from the water and collected on the carbon media. Once the water

has passed through the carbon filter the water is iron, sulfur and manganese free!

The carbon filter will need to be backwashed on a frequency (in days) to flush out the collected

contaminants. The frequency varies on each system depending on the contaminant level.

Please use the following table as a guideline for backwash frequency combining iron, sulfur

and manganese values (these are baseline values and actual frequency may vary);

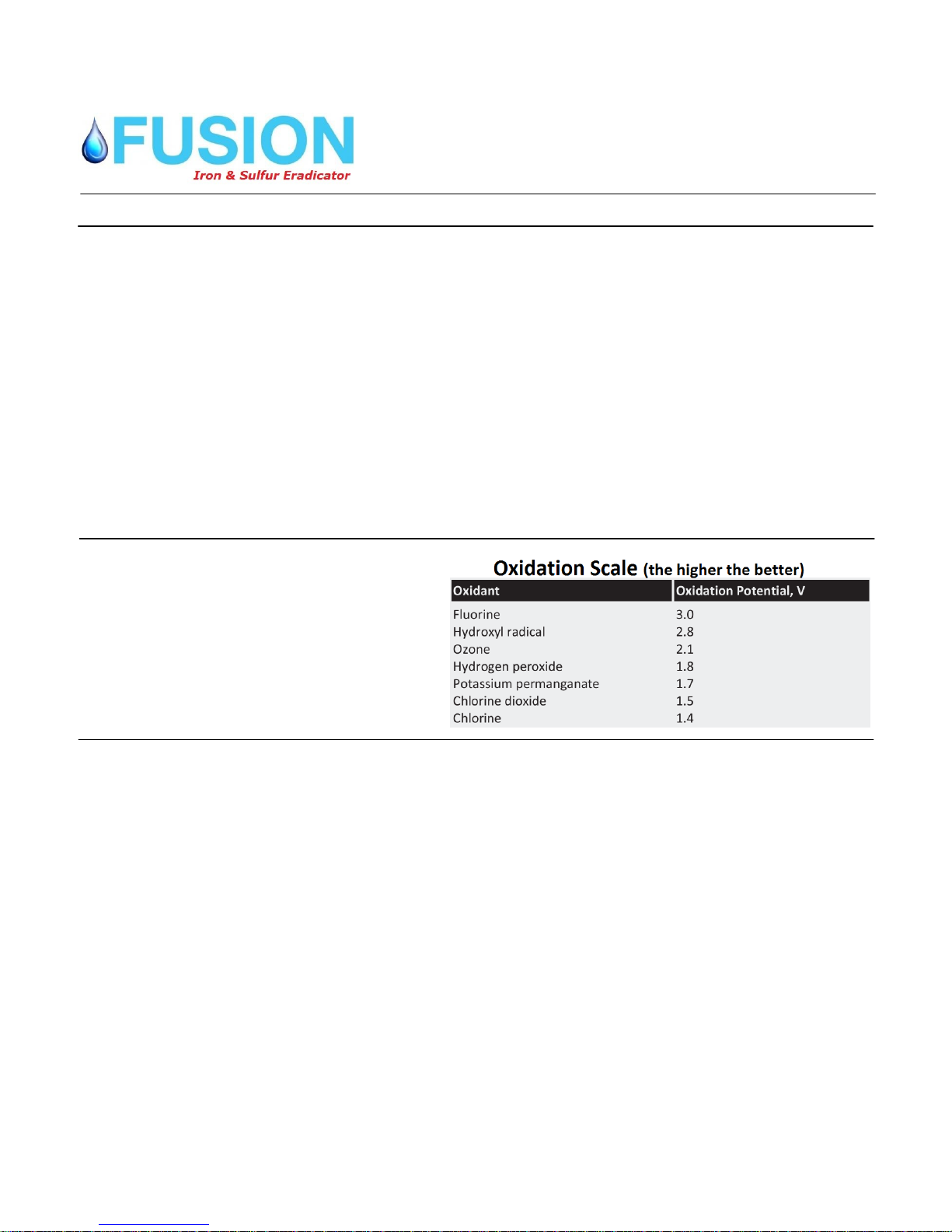

Combined Contaminant Level Days Between Backwashes

1-3 ppm Combined 3 Days

Catalytic Carbon Backwash Frequency

3-6 ppm Combined 2 Days

>6 ppm Combined 1 Day

4

Page 5

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

System Components

Stenner Proportional Injection System Specifications

The Stenner Proportional Injection System delivers precise dosing

proportional to the system's flow rate based on water volume.

The Stenner system is perfectly suited for constant pressure (variable speed) well pumps, poultry and

livestock houses, irrigation, systems with demand based backup wells and any application with varying

flow rates

The primary components are the Stenner Pump Control Module, Stenner Classic Series Fixed Output Pump and a

dry contact pulsing Water Meter. The Stenner Pump Control Module is a time adjusted controller that powers the

pump. A pulsing water meter sends a signal to the Stenner PCM which actuates the pump to deliver the desired

dose based on water volume. The Stenner PCM has a locking dial to assure the accuracy of the dosage. The

Stenner Proportional Injection System can be utilized to inject any number of chemicals including chlorine,

hydrogen peroxide, polyphosphate, Rid-O-Rust and many other chemicals.

The Stenner Proportional Injection System includes brackets to easily mount the panel to the wall for timely

installations and equipment accessibility. It is completely "plug and play." Simple to install, even simpler to set.

Available in 120V, accommodates 3/4" or 1" piping. Just plug into any electrical outlet, intercept a 3/4" or 1" line

and connect it and you are done. It's that simple.

Flows up to 22 GPM

Panel & panel fittings: Polyethylene

Mounting hardware: Stainless steel

Piping and associated fittings: PVC

Water meter: bronze

Filter: PVC with polycarbonate cover and two polyester screens 30 and 100 mesh

Note: Connections are socket weld union ¾” connections

Dimensions: 36 x 23 x 11 in.

Shipping Weight: 31 lbs

5

Page 6

Installation, Operation and Maintenance Manual

System Components

Stenner Proportional Injection System Installation Instructions

Note: If there is sediment in the water, it should be removed prior to the injection system using a pleated filter and

or multi-media filter. Sediment will clog the injection panel filter and could damage the water meter and pump in

extreme cases.

IMPORTANT!

Key for optimum performance:

READ THE MANUALS for the Pump, PCM, Filter and Water Meter for proper safety and

complete operation instructions.

1. Select a dry location to mount panel to avoid water intrusion. When selecting the location,

note the water flow direction as indicated on the filter of the panel flow assembly. Location

should allow mounting hardware to be anchored into studs or concrete to support the

weight of the panel.

2. Isolate and depressurize the water system.

3. The length of the panel's slip socket connections clearance required is 31 1/4". For existing

water systems cut necessary length of pipe to insert panel.

NOTE: Two 1" to 3/4" reducer couplings are included in the accessory kit to allow unit to adapt to 1" piping

systems.

4. Mark location of lag bolt holes 12 3/8" above center line of the horizontal pipe.

5. Secure wall mount bracket to wall studs using the included lag bolts or other suitable

hardware. Hang panel on to wall mount bracket.

6. Glue stubbed cut pipe into slip socket. After glue is cured, hand tighten the union

connections.

7. Install one of the provided filter screens with o-ring into the filter body. For high turbidity

water, use the more porous screen (30 mesh). Install filter cover hand tight. Close ball valve

on filter cover.

8. Drill a 1/4” hole in the top of the solution tank and feed the 1/4” tubing through the hole.

Pull the end inside the tank out the fill hole and push the weighted strainer on the end of the

tubing. Now lower the weighted strainer so that it is about 3/4” off the bottom of the tank.

Connect the other end of the 1/4” tubing to the suction side of the pump (port closest to the

pump mount). DO NOT use wrenches or threading tape. Connection needs to be finger

tightened. Pour the Hydrogen Peroxide in the tank.

9. Attach discharge tubing into injection fitting with the remaining nut and ferrule.

10. Priming of Pump (Set PCM to 50)

a. Remove the four screws on the power cord cover and disconnect the pump power cord

from the PCM and plug into a 120V outlet or leave cover on and run a temporary extension

cord to the male end of the pump cord.

b. Turn pump power switch on and observe the chemical being drawn from the solution tank.

c. When chemical reaches the injection point turn pump off.

6

Page 7

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

System Components

11. Plug pump back into the PCM. Plug PCM power cord into a 120V receptacle and reinstall

cord cover if applicable.

12. Open the 2 ball valves slowly, pressurize system with water and turn pump power switch to

"on".

13. Run water through the system and fine tune chemical readings by adjusting the PCM dial.

If desired lock the PCM setting with set screw on the dial.

14. Slide roof into pump mounting bracket over motor.

WARNING When pressurizing the system gradually allow water to flow. Shocking the meter by over

speeding it with high flow rates can damage the internal assembly.

CAUTION Ensure the piping is properly supported both upstream and downstream of the panel.

FOR INDOOR USE ONLY.

It is the installer's responsibility to comply with all national and local plumbing and electrical codes.

The Proportional Injection

System has two screws

installed in each side of

the pump wall mount

bracket to prevent shipping damage. Please

remove the screws upon

installation so the pump

can be removed from the

bracket when required.

7

Page 8

Installation, Operation and Maintenance Manual

System Components

Media Installation

Assembly Instructions

1. Remove the tank from carton.

2. Verify the riser is still fully engaged in the Vortech plate.

3. Place a piece of duct tape over the riser tube so no media enters the riser while filling.

4. Make sure the riser is centered to facilitate the valve installation after installation

of the media.

5. Use the Funnel provided, to pour the media into the tank. Pour it evenly around the hole

to ensure it is well distributed in the tank and pour slow enough, to keep from plugging

the hole.

Important: It is a good practice to hold a shop vac close to the funnel to collect any

dust that escapes during the filling process. Safety glasses and a dust mask are recommended.

6. When media is installed move tank side to side to settle the media.

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Valve Installation

1. Remove the tape from the riser and discard.

2. Lubricate the two o-rings with a light coat of Silicone.

3. Install the Upper Basket (cone shaped screen) to the valve, twisting it to lock it in

place.

4. Slip the Upper Basket over the Riser sliding it down into place and screw the valve

on and tighten.

5. Follow the installation procedures in this manual and program accordingly.

8

Page 9

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

System Components

Carbon Filter Installation Instructions

WATER PRESSURE: A minimum of 20 pounds of water pressure is required for regeneration valve to operate effectively.

ELECTRICAL FACILITIES: An uninterrupted alternating current (A/C) supply is required. Note: Other voltages are available. Please make sure your voltage supply is compatible with your unit before installation.

EXISTING PLUMBING: Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up

heavily with lime and/or iron should be replaced.

LOCATION OF FILTER AND DRAIN: The filter should be located close to a drain to prevent air breaks and back flow.

BY-PASS VALVES: Always provide for the installation of a by-pass valve if unit is not equipped with one.

CAUTION: Water pressure is not to exceed 125 psi, water temperature is not to exceed 110°F, and the unit cannot be subjected to freezing conditions.

1. Place the filter tank where you want to install the unit making sure the unit is level and on a

firm base.

2. During cold weather, the installer should warm the valve to room temperature before operat-

ing.

3. All plumbing should be done in accordance with local plumbing codes. The pipe size for

residential drain line should be a minimum of 1/2". Backwash flow rates in excess of 7

gpm or length in excess of 20’ require 3/4" drain line. Commercial drain lines should be

the same size as the drain line flow control.

4. The inlet on the bypass valve is indicated by an arrow that will point toward the valve.

The outlet will be indicated by an arrow pointing away from the valve.

5. Lubricate the distributor o-ring seal and tank "o" ring seal. Place the main control valve on

tank. Note: Only use silicone lubricant.

6. Solder joints near the drain must be done prior to connecting the Drain Line Flow Control

fitting (DLFC). Leave at least 6" between the DLFC and solder joints when soldering pipes

that are connected on the DLFC. Failure to do this could cause interior damage to the

DLFC.

7. Teflon tape is the only sealant to be used on the drain fitting.

8. On units with a by-pass, place in by-pass position. Turn on the main water supply. Open a

cold water tap nearby and let run a few minutes or until the system is free from foreign material (usually solder) that may have resulted from the installation. Once clean, close the water tap.

9. Slowly place the by-pass in service position and let water flow into the media tank until the

water flow stops.

10. Plug unit into an electrical outlet. Note: All electrical connections must be connected accord-

ing to local codes. (Be certain the outlet is uninterrupted).

9

Page 10

System Components

Carbon Filter Control Valve Features

Timer Features

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Error/

Information

Icon

Pa ram ete r Data PM

Display Display Indicator

S e r v i c e

Icon

Flow Indicator

x1000 Indicator

Programming

Icon

Extra Cycle

Button

Up

B u tt on

D o wn

B u tt on

Features of the SXT:

Power backup that continues to keep time and the passage of days for a minimum of 48 hours

in the event of power failure. During a power outage, the control goes into a power-saving

mode. It does not monitor water usage during a power failure, but it does store the days remaining at the time of power failure.

Settings for both valve (basic system) and control type (method used to trigger a regeneration).

Day-of-the-Week controls.

While in service, the display alternates between time of day and days to regeneration.

The Service Icon flashes if a backwash cycle has been queued.

A backwash can be triggered immediately by pressing the Extra Cycle button for five seconds.

The Parameter Display displays the current Cycle Step (BW, RR, etc) during backwash, and the

data display counts down the time remaining for that cycle step. While the valve is transferring

to a new cycle step, the display will flash. The parameter display will identify the destination cycle step (BW, RR, etc) and the data display will read "----". Once the valve reaches the cycle

step, the display will stop flashing and the data display will change to the time remaining. During

regeneration, the user can force the control to advance to the next cycle step immediately by

pressing the extra cycle button.

10

Page 11

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

System Components

Carbon Filter Control Valve Features

Setting the Time of Day

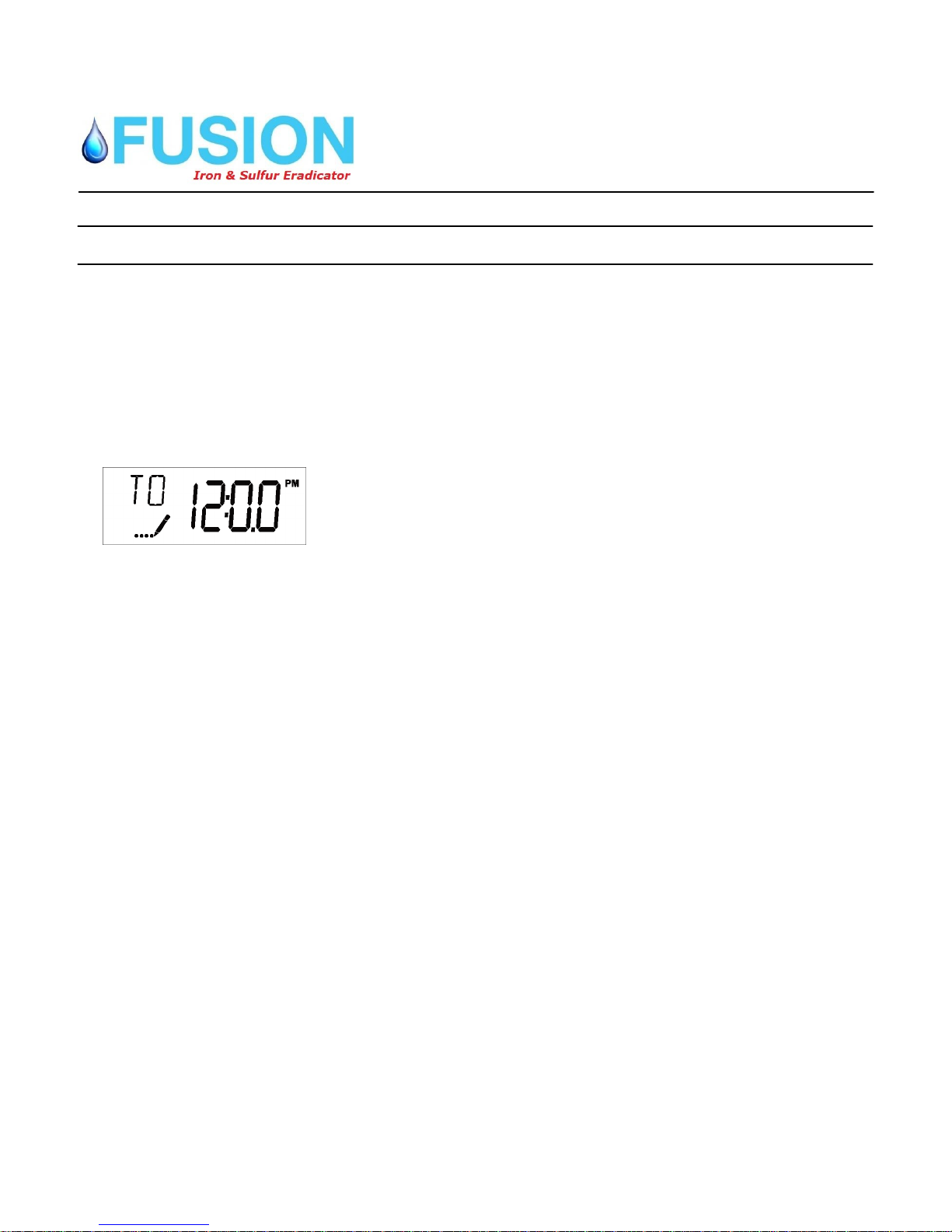

1. Press and hold either the Up or Down buttons until the programming icon replaces the

service icon and the parameter display reads TD.

2. Adjust the displayed time with the Up and Down buttons.

3. When the desired time is set, press the Extra Cycle button to resume normal opera-

tion. The unit will also return to normal operation after 5 seconds if no buttons are

pressed.

Queueing a Backwash

1. Press the Extra Cycle button. The service icon will flash to indicate that a backwash is queued.

2. To cancel a queued backwash, press the Extra Cycle button.

Backwashing Immediately

Press and hold the Extra Cycle button for five seconds.

Time Clock Delayed Control

A Time Clock Delayed Control regenerates the system on a timed interval. The control will

initiate a backwash cycle at the programmed backwash time when the number of days

since the last backwash equals the backwash day override value.

Day of the Week Control

This control regenerates the system on a weekly schedule. The schedule is defined in Mas-

ter Programming by setting each day to either "off" or "on." The control will initiates a regeneration cycle on days that have been set to "on" at the specified regeneration time.

Control Operation During Programming

The control only enters the Program Mode with the valve in service. Control programming

is stored in memory permanently, eliminating the need for battery backup power.

Manually Initiating a Backwash

1. When timer is in service, press the Extra Cycle button for 5 seconds on the main screen.

2. The timer advances to Backwash Cycle Step #1 (backwash), and begins programmed time

count down.

3. Press the Extra Cycle button once to advance valve to Regeneration Cycle Step #2 (brine

rapid rinse).

4. Press the Extra Cycle button once more to advance the valve back to in service.

11

Page 12

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Carbon Filter Control Valve Features and Programming

Control Operation During A Power Failure

The SXT includes integral power backup. In the event of power failure, the control shifts into a

power-saving mode. The control stops monitoring water usage, and the display and motor shut

down, but it continues to keep track of the time and day for a minimum of 48 hours.

The system configuration settings are stored in a non-volatile memory and are stored indefinitely

with or without line power. The Time of Day flashes when there has been a power failure. Press

any button to stop the Time of Day from flashing.

If power fails while the unit is in regeneration, the control will save the current valve position before it shuts down. When power is restored, the control will resume the regeneration cycle from

the point where power failed. Note that if power fails during a regeneration cycle, the valve will

remain in it's current position until power is restored. The valve system should include all required safety components to prevent overflows resulting from a power failure during regeneration. The control will not start a new backwash cycle without line power.

Master Programming Mode

When the Master Programming Mode is entered, all available option setting displays may be

viewed and set as needed. Depending on current option settings, some parameters cannot be

viewed or set. Use the following chart to program your filter. You will use the highlighted values. Items not highlighted either do not require a change or do not appear in filter mode.

Entering Master Programming Mode

Set the Time Of Day display to 12:01 P.M. Press the “extra cycle”. Then press and hold the Up

and Down buttons together until the programming icon replaces the service icon and the Display

Format screen appears. The extra cycle button will serve as an “enter/save” button. The up

and down arrows are used to change the value of each parameter and the extra cycle button

saves the parameter changes and will move the control to the next programming parameter.

Exiting Master Programming Mode

Press the Extra Cycle button to accept the displayed settings and cycle to the next parameter.

Press the Extra Cycle button at the last parameter to save all settings and return to normal operation. The control will automatically disregard any programming changes and return to normal

operation if it is left in Master Programming mode for 5 minutes without any keypad input.

Soft Reset: Press and hold the Extra Cycle and Down buttons for 25 seconds while in normal Service mode.

This resets all parameters to the system default values, except the volume remaining in meter immediate or meter de-

layed systems and days since regeneration in the time clock system.

Master Reset: Hold the Extra Cycle button while powering up the unit. This resets all of the parameters in the unit.

Check and verify the choices selected in Master Programming Mode.

Please use the following chart to program the carbon filter control valve. Use the highlighted settings. Days between backwashes will be determined using the chart on page

#4. Some parameters will not be shown depending on the valve configuration.

12

Page 13

Carbon Filter Control Valve Programming

Master Programming Options

Abbreviation Parameter Option

Abbreviation

GAL Gallons

DF Display Format

VT Valve Type

CT

NT

Control Type

Number of Tanks

Ur Liters

Cu Cubic Meters

dF1b

.

dF2b Standard Downflow/Upflow Double Backwash

Fltr Filter

UFbF Upfiow Brine First

Othr Other

Fd Meter (Flow) Delayed

Fl Meter (Flow) Immediate

tc Time Clock

dAY Day of Week

1 Single Tank System

2 Two Tank System

Ul Tank 1 in Service

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Options

Standard Downflow/Upflow Single Backwash

TS

C Unit Capacity

H

RS Reserve Selection

Tank in Service

Feedwater

Hardness

SF Safety Factor

RC

DO Day Override

RT Regen Time 2:00 The time of day the system will regenerate

BW, BD, RR,

BF

D1, 02, D3, D4,

D5, 06, & D7

CD Current Day

Fixed Reserve Capacity

Regen Cycle Step

Times

Day of Week

Settings

U2 Tank 2 in Service

rc Fixed Reserve Capacity

1-99

No

Changes

Here

Unit Capacity (Grains)

Hardness of Inlet Water

Percentage Safety Factor

Percentage of the system capacity to be used as a

reserve

Fixed volume to be used as a reserve

The system's day override setting

The time duration for each regeneration step. Adjustable from OFF and 0-199 minutes.

NOTE: If "Othr" is chosen under "Valve Type", then

RI, R2, R3, etc, will be displayed instead

Regeneration setting (On or OFF) for each day of the

week on day-of-week systems

The Current day of the week

13

Page 14

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Carbon Filter Start Up Procedure

The water filter should be installed with the inlet, outlet, and drain connections made in

accordance with the manufacturer's recommendations, and to meet applicable plumbing

codes.

1. Push and hold the “extra cycle” button (far left button with triangle shaped arrows on the but-

ton). This button will advance the valve to the next cycle if it is pushed and released.

2. This will position the valve to backwash. You will see BW and four dashes. The four dashes

will change to a time value that will start to count down. Once the time begins to count

down. Slowly open the bypass valve to the service position. Ensure the drain line flow remains steady for 10 minutes or until the water runs clear.

3. After the backwash cycle, the valve will move to the rapid rinse position. Check the drain line

flow, and run for 5-10 minutes or until the water runs clear.

4. The filter is now installed.

H2O2 Injection Setting

US Water Systems uses the “bubble method”. This is a visual method that works best for quick

and reliable H2O2 injection rates.

1. Set the proportional control on the Stenner injection panel (gray wall mount panel) to 40%

(there is a dial on the little black box (PCM) that the pump is plugged in to).

2. Run water for 10-15 minutes.

3. Take a sample after the carbon tank (or at a sink). The water in the sample container

(preferably glass) should be full of bubbles immediately after the sample is taken. If not the

installer will adjust the knob to 50%, run the water for 10-15 minutes and check again.

4. Continue adjusting the knob up in increments of 10% until the sample container is full of bubbles. Once the container is full of bubbles, it is an indicator that there is plenty of H2O2 in

the water.

5. Continue the same process decreasing the knob setting in 5% increments allowing the water

to run for 10-15 minutes between adjustments until there are just a few bubbles in the sample container (20-30 defined air bubbles) that come to the top of the water level and dissipate

immediately. This should be the optimal H2O2 injection setting.

This is an indicator that there is a small amount of residual H2O2 in the treated water and the contaminant

is being oxidized. Once this setting is determined the system will operate automatically.

Over the first 1-3 months it is important to monitor the H2O2 level in the storage/solution tank and start to

gain usage data that will help you determine the H2O2 usage and allow you to plan/order replenishment

H2O2 accordingly. This setting should be periodically checked and adjusted due to changes in the aquifer (well) and loss of H2O2 concentration by degradation. After 6-8 months the H2O2 can lose concentration, so only replenish the tank to a level that can be used in 6-8 months to ensure the H2O2 concentration

strength is consistent.

14

Page 15

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

What To Expect and Routine Maintenance

Now that the Oxi-Gen system has been installed here are a few things to expect;

1. The Oxi-Gen system will produce iron, sulfur and manganese free water immediately after

installation. Depending on the raw water quality there may be contaminants built up in the

water heater, plumbing system and other devices. Over the first few weeks as water is

used there could be traces of this build up that are being removed by the newly installed

system. This typically clears up after a couple weeks.

2. Depending on the contaminants being removed there may be iron bacteria or sulfur reducing bacteria in the plumbing system prior to the Oxi-Gen install. This bacteria can potentially survive after the Oxi-Gen installation. This is usually indicated by a sulfur smell that will

appear after a few weeks of initial usage. If this is the case, the well and entire plumbing

system will need to be chlorinated to remove any existing bacteria. If the bacteria is not removed, it will begin to “grow” backwards toward the treatment system and the sulfur smell

will not go away. If this does occur, it is easily eradicated with a chlorination procedure.

3. There may be “bubbles” in the water for a few weeks after installation. A few bubbles are

fine, but if there is “fizz” that remains for several seconds, it is an indication that the system

is being overfed with H2O2. This occurs because after installation the water will become

cleaner and the initial dosage of H2O2 may need to be adjusted to compensate for the lower contaminant level.

Routine Maintenance

Pressure Tank

If your plumbing system uses a bladder pressure tank it will be in the system prior to the OxiGen system. This tank should be drained periodically to remove the build up of contaminants.

Typically once a quarter is sufficient but that frequency may need to be increased on systems

with high contaminant levels.

Injection Panel

Sediment Filter/Strainer

The inline sediment filter on the injection panel has a “blow down” valve at the bottom. This

filter should be blown down once a month to clear collected sediment. If there is high levels of

sediment in the filter it may need to be removed and cleaned.

Pump Tube

The internal pump tube may need to be replaced periodically. They typically last 1-5 years depending on the usage. There is a spare tube shipped with the system and instructional videos

explaining how to change the tube at www.USWaterSystems.com.

Carbon Filter

The carbon filter is virtually maintenance free. However, if there is a power outage the clock

and other settings need to be checked to ensure the filter will backwash properly at the proper

time of day. It is crucial that the carbon filter backwashes at a time when there is no water being used in the house.

15

Page 16

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Maintenance Schedule

Component Action Frequency Replacement

Part #

Existing Well Pressure

Tank

Injection Panel Sediment Filter

Injection Panel Pump

Tube

Injection Panel Duck

Bill Check Valve

Drain tank until the water runs

clear.

Open blow down valve and

flush the filter.

Inspect pump tube and replace

as needed. #2 Tube.

Replace injection check valve

as needed.

H2O2 Solution Tank Periodically check the solution

level and refill as needed.

Carbon Tank Check the clock and settings

periodically or after a power

outage.

1-6 Months N/A

3-6 Months N/A

1-5 Years 411-UCCP202

1-5 Years 411-UCCVDBO

Varies by wa-

710-HP22N

ter usage.

4 Months N/A

16

Page 17

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Flow Schematic

17

Page 18

Installation, Operation and Maintenance Manual

Oxi-Gen Oxi-2P,3P,4P, 5P & 6P System

Warranty

Oxi-Gen

Limited Lifetime Warranty

For the lifetime of the original purchaser, at the original residential

place of installation of this OxiGen Water Treatment System, US WA-

TER SYSTEMS, INC. warrants the following:

Free of all costs to you except transportation and labor charges, we

warrant that we will replace or repair the fiberglass media and hydrogen peroxide storage tank, if for any reason it is found to be defective,

because of faulty materials or workmanship.

We warrant that for five (5) years from the date of installation, we will

replace the Backwashing Filter Valve and Electronics free of charge to

you except for transportation and standard labor charges.

We warrant that for two (2) years from the date of installation, we will

replace the STENNER Pump & Catalytic Media free of charge to you

except for transportation and standard labor charges.

This warranty does not apply to any commercial or industrial installations or to any part of the water conditioner which has been subjected

to misuse, neglect, alteration or accident; or to any damage caused

by fire, flood, freezing, Acts of God, or any other casualty, or if the

original serial numbers have been removed. Fouling or damage to

the resin caused by iron, sulfur, bacterial iron, silt, sand, tannins, organics, bacteria, hot water or chlorine voids the warranty on resin.

LIFETIME COVERAGE

Media Tank(s)

Hydrogen Peroxide Solution Tank

FIVE YEAR COVERAGE

Electronics

Drive Motor

TWO YEAR COVERAGE

STENNER PUMP

Catalytic Media

GENERAL PROVISIONS

These warranties are in lieu of all other warranties expressed

or implied, and we do not authorize any person to assume for us any

other obligation on the sale of this water conditioner. No responsibility is assumed for delays or failure to meet these warranties caused

by strike, government regulations or other circumstances beyond the

control of US WATER SYSTEMS, INC..

TO OBTAIN WARRANTY SERVICE, CALL OR WRITE: US WATER SYS-

TEMS, INC. 1209 COUNTRY CLUB ROAD INDIANAPOLIS, IN 46234

(317) 271-8600.

ANY IMPLIED WARRANTIES OF FITNESS OR MERCHANTABILITY

ARE LIMITED TO THE TERMS OF THIS EXPRESSED WARRANTY

AND THERE ARE NO WARRANTIES WHICH EXTEND BEYOND

THOSE HEREIN. US WATER SHALL NOT BE LIABLE FOR ANY

INCIDENTIAL OR CONSEQUENTIAL DAMAGES.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. THIS WARRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

THIS WARRANTY MAY BE TRANSFRRED TO A SUBSEQUENT

OWNER WITH WRITTEN APPROVAL OF US WATER AND PAY-

MENT OF STANDARD TRANSFER FEE.

FOR YOUR RECORDS:

Model _________________________________________

Serial __________________________________________

Date Installed ___________________________________

18

Loading...

Loading...