Page 1

OPERATOR'S MANUAL

VOYAGE DATA RECORDER

SIMPLIFED VOYAGE DATA RECORDER

VR-3000

MODEL

VR-3000S

www.furuno.co.jp

Page 2

9-52 Ashihara-cho,

*

00015707816

**00015707816

*

Nishinomiya, 662-8580, JAPAN

Telephone : +81-(0)798-65-2111

Fax :+81-(0)798-65-4200

The paper used in this manual

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

Pub. No. OME-44370-G1

(TATA ) VR-3000/3000S

Printed in Japan

A : APR 2006

.

G1 : NOV . 24, 2010

*00015707816**00015707816*

* 0 0 0 1 5 7 0 7 8 1 6 *

Page 3

IMPORTANT NOTICES

Cd

General

• The operator of this equipment must read and follow the descriptions in this manual. Wrong

operation or maintenance can cancel the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens

you see on your display. The screens you see depend on your system configuration and

equipment settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO

will cancel the warranty.

• All brand and product names are trademarks, registered trademarks or service marks of their

respective holders.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For

disposal in the USA, see the homepage of the Electronics Industries Alliance

(http://www.eiae.org/) for the correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery, see the

chapter on Maintenance. Follow the instructions below if a battery is used. Tape the + and terminals of battery before disposal to prevent fire, heat generation caused by short circuit.

In the European Union

The crossed-out trash can symbol indicates that all types of

batteries must not be discarded in standard trash, or at a trash site.

Take the used batteries to a battery collection site according to your

national legislation and the Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd

and lead-acid rechargeable batteries must be recycled. Take the used

batteries to a battery collection site according to local laws.

Ni-Cd Pb

In the other countries

There are no international standards for the battery recycle symbol. The number of symbols can

increase when the other countries make their own recycling symbols in the future.

i

Page 4

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Immediately turn off the power

(BATTERY, DC and AC switches in

that order) at the DCU and also turn off

off the power at the ship's mains

switchboard if water leaks into the

equipment or the equipment is emitting

smoke or fire.

Continued use can cause fatal damage to

the equipment.

WARNING

Do not disassemble the battery.

Battery fluid is harmful to the eyes and skin,

particularly the eyes. If the fluid contacts

skin or eyes, flush area with fresh water

and contact a physician immediately.

Do not dispose of the battery or acoustic

beacon in fire.

Those components may burst if disposed of

in fire. Further, dispose of the battery in

accordance with appropriate regulations.

Do not touch any electricaly conductive

parts.

Touching electrically conductive parts can

result in electrical shock. Use rubber gloves,

etc. when conducting inspection or

maintenance work.

Do not short battery terminals.

Only authorized personnel shall

disassemble the DRU.

Pressure may build up inside the unit when

it is subjected to fire or is retrieved from a

great depth.

Do not allow rain or water splash to

contact the equipment.

Fire or electrical shock can result.

WARNING LABELS

Warning labels are attached to the DCU.

Do not remove the labels. If the label is missing or

damaged, contact a FURUNO agent or dealer

about replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label 1

Type: 86-003-1011-2

Code No.: 100-236-232-10

Short can lead to bursting or fire.

CAUTION

Do not:

- use batteries of different capacities

- mix old batteries with new

- mix batteries of different makes

Batteries themselves may become

damaged or damage to electrical

parts may result.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label 2

Type: 03-129-1001-2

Code No.: 100-236-742-10

ii

Page 5

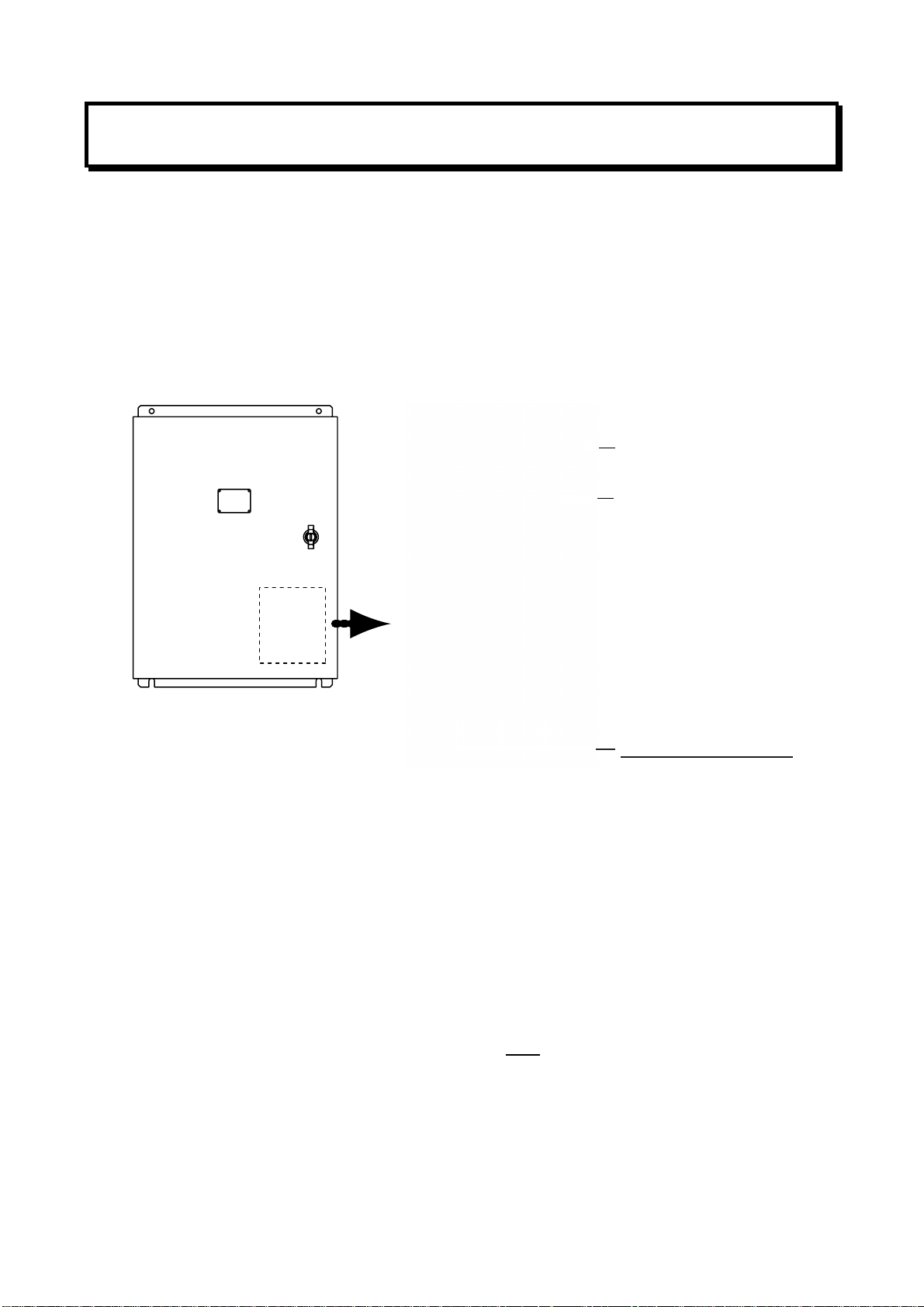

POWERING DATA COLLECTING UNIT

On the power control panel in the Data Collecting Unit (DCU), confirm that the status display

shows “- - -“ and the NORMAL LED is lit after the power has been on for two minutes. If not, see

Chapter 3.

Procedure for turning on power

1. Turn the AC breaker switch on.

2. Turn the DC breaker switch on if DC power is connected.

3. Turn the BATTERY BACKUP breaker switch on.

Status Display

NORMAL LED

Breaker switches (from left)

Battery Backup, DC, AC

Power control panel/status display inside the DCU

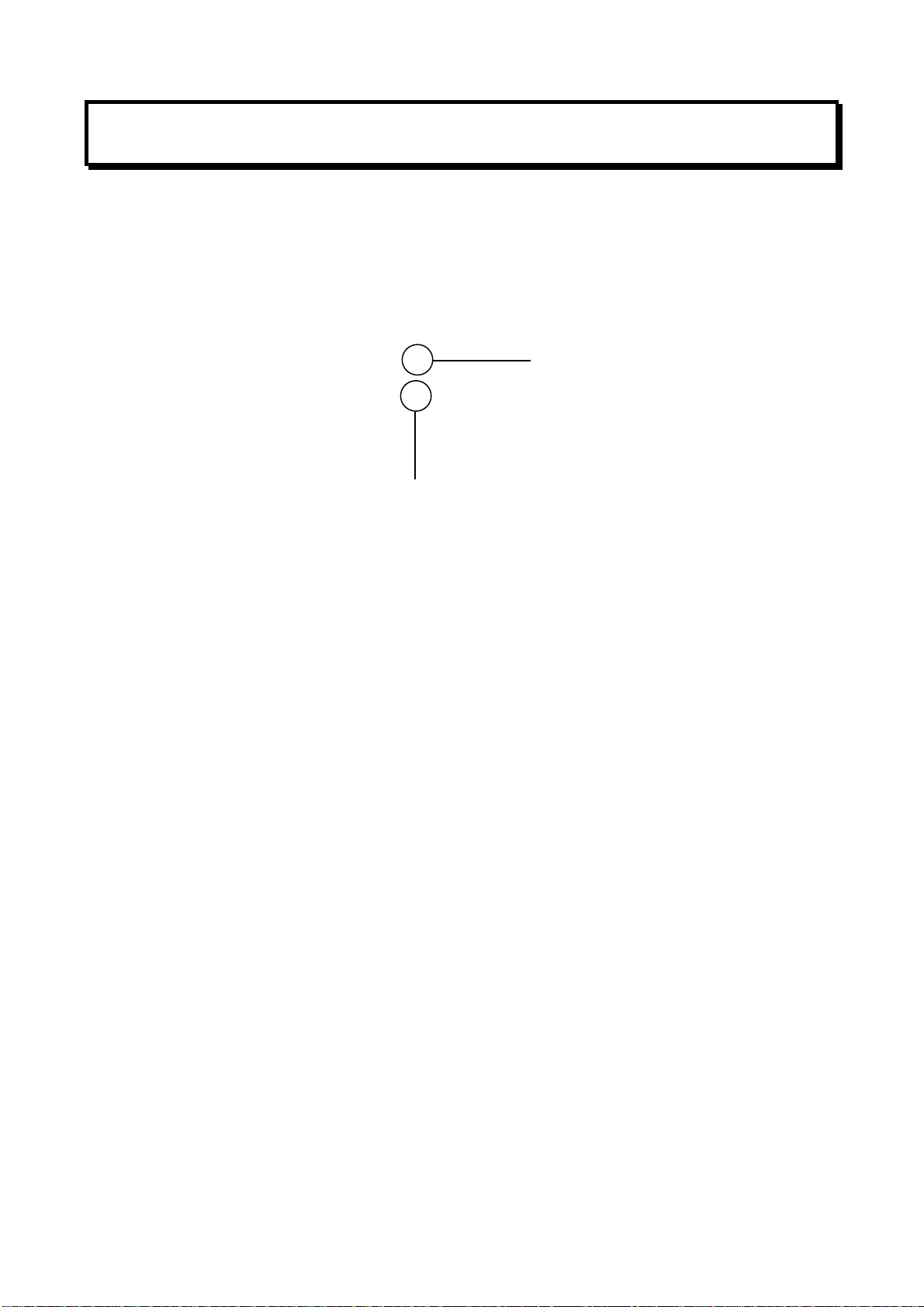

Error indication on Remote Alarm Panel (RAP)

If the ERROR LED (red) lights on the RAP, check the error number on its status display and refer

to the error code tables in Chapter 3.

ERROR LED

Remote Alarm Panel

iii

Page 6

IF AN INCIDENT OCCURS

Press the SAVE button on the Remote Alarm Panel. Bring the HDD with you after an incident

occurs, if possible.

SAVE LED

(yellow)

SAVE button

• The SAVE LED (yellow) starts flashing and shortly thereafter lights. Then, recording to the

current memory area in the backup HDD in the Data Collecting Unit is stopped and recording

to another memory area starts. The memory in the backup HDD is divided into four areas.

If you press the SAVE button on the RAP, one recording area stops recording. If you press

the SAVE button four times, all four areas stop recording. If you pressed the SAVE button,

consult a FURUNO dealer to restore the HDD after an investigation of the incident is

completed by the authorities.

• Recording at the Data Recording Unit continues.

iv

Page 7

TABLE OF CONTENTS

FOREWORD...............................................................................................vi

SYSTEM CONFIGURATION......................................................................vii

Record of PUB REV., PROG. No.............................................................viii

1. OPERATION............................................................................................ 1

1.1 Overview ...........................................................................................................................1

1.2 Operating Procedure.........................................................................................................6

1.2.1 Powering, recording........................................................................................................6

1.2.2 Stopping recording..........................................................................................................6

1.3 Operation on Remote Alarm Panel ...................................................................................7

1.4 Removing HDD at an Incident...........................................................................................8

1.5 How to Release DRU ........................................................................................................8

2. MAINTENANCE.......................................................................................9

2.1 Annual Recertification .......................................................................................................9

2.2 Cleaning ............................................................................................................................9

2.3 Software Maintenance ....................................................................................................10

2.3.1 Software list ..................................................................................................................10

2.3.2 Checking software version of system program .............................................................10

2.3.3 Checking software version of RAP ...............................................................................10

2.4 Replacing Batteries ......................................................................................................... 11

2.5 Replacing Acoustic Beacon.............................................................................................12

2.6 Replacing Backup HDD ..................................................................................................13

2.7 Replacing Fuses .............................................................................................................14

2.8 Replacing Parts...............................................................................................................14

2.9 Verifying Recording Function of the DRU.........................................................................15

2.10 Confirmation of Peripheral Devices ................................................................................16

3. TROUBLESHOOTING...........................................................................17

3.1 General Troubleshooting.................................................................................................17

3.2 Error Codes.....................................................................................................................18

3.3 Testing Display of Remote Alarm Panel..........................................................................20

4. LOCATION OF PARTS.......................................................................... 21

4.1 Parts Location .................................................................................................................21

4.1.1 Data Collecting Unit (VR-3010) ....................................................................................21

4.1.2 Data Recording Unit (VR-5020-9G or VR-5020-6G) ....................................................22

4.1.3 Junction Box (IF-8530) .................................................................................................23

4.1.4 Remote Alarm Panel (VR-3016)...................................................................................23

4.2 Parts List .........................................................................................................................24

5. INTERFACE (IEC 61162-1, IEC 61162-2)..............................................25

5.1 Data Sentences...............................................................................................................25

5.2 Interface Circuits .............................................................................................................38

5.2.1 IEC 61162-1..................................................................................................................38

5.2.2 IEC 61162-2..................................................................................................................39

APPENDIX: PLAYING BACK RECORDED DATA.................................... 40

SPECIFICATIONS.......................................................................................................SP-1

v

Page 8

FOREWORD

A Word to the Owner of the VR-3000, VR-3000S

Thank you for purchasing the FURUNO Voyage Data Recorder (VDR) VR-3000, Simplified

Voyage Data Recorder (S-VDR) VR-3000S. We are confident you will discover why FURUNO

has become synonymous with quality and reliability.

What is a VDR, S-VDR?

A VDR records various data and events encountered aboard ship. The purpose of the VDR is to

help investigators locate the causes of marine incidents. There is no principle difference between

a VDR and an S-VDR. The difference is the amount of information required to be recorded. The

VDR is required to record more data than the S-VDR. Note that this manual refers to either the

VDR or S-VDR as VDR.

The revised SOLAS Chapter V requires the installation of VDRs on passenger ships of 150 GT

and above on all voyages and other ships of 3000 GT and above on international voyages and for

newly built ships on and after 1 July, 2002.

The basic VR-3000/VR-3000S consists of a Data Collecting Unit (DCU), a Data Recording Unit

(DRU), a Remote Alarm Panel (RAP) and microphones to record bridge audio. The VR-3000 is

also equipped with a Junction Box (JB), which is optional on the VR-3000S. The DCU contains

the Data Processor Unit, interface modules and backup batteries. It collects data from sensors as

required by the IMO and IEC standards. The DCU processes the incoming data and information

in the order of occurrence while old data is overwritten with new data for storage in the DRU for a

12 h period. The batteries supply power to the DCU to record bridge audio for 2 h in case of a

main ship’s power failure.

The flash memory in the DRU stores the data coming from the DCU. All essential navigation and

status data including bridge conversation, VHF communications, and radar images are recorded.

The data can be retrieved by using playback software for investigation after an incident. The DRU

components are embodied in the protective capsule. The capsule ensures survival and recovery

of the recorded data after an incident. An acoustical pinger helps locate the DRU underwater.

Features

• Reliable and fast data exchange between DCU and DRU via a single IEEE1394 cable.

• Easy commissioning and maintenance by PC downloading/uploading.

• 12-hour recording of normal sensor loading in standard memory.

• UTC time tagged for system synchronization and easy data retrieval.

• Choice of flash memory capacity in the Data Recording Unit.

• Backup hard disk (HDD) for storage and retrieval of data.

• Meets IMO A.861 (20), IEC 61996 and other relevant standards.

vi

Page 9

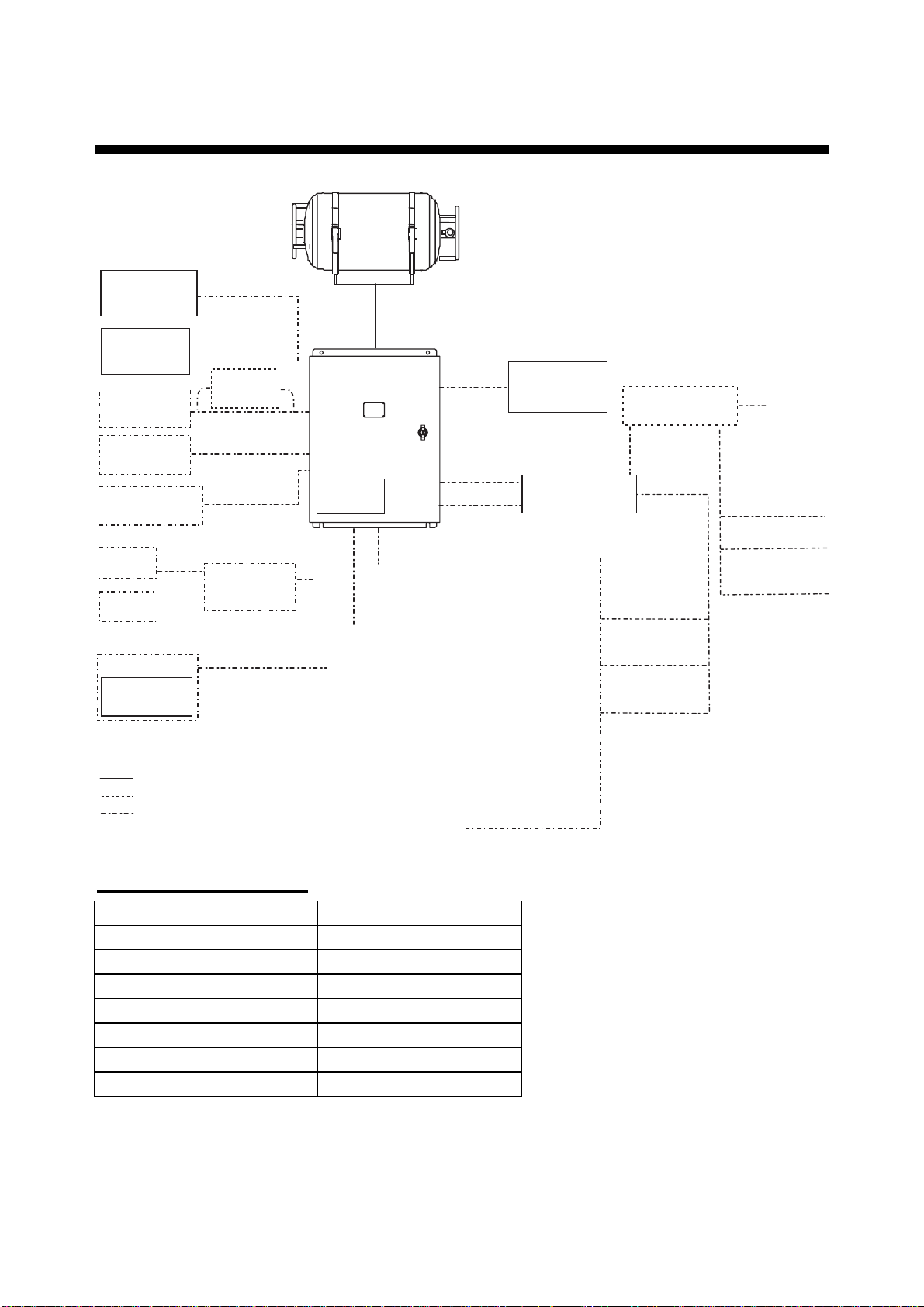

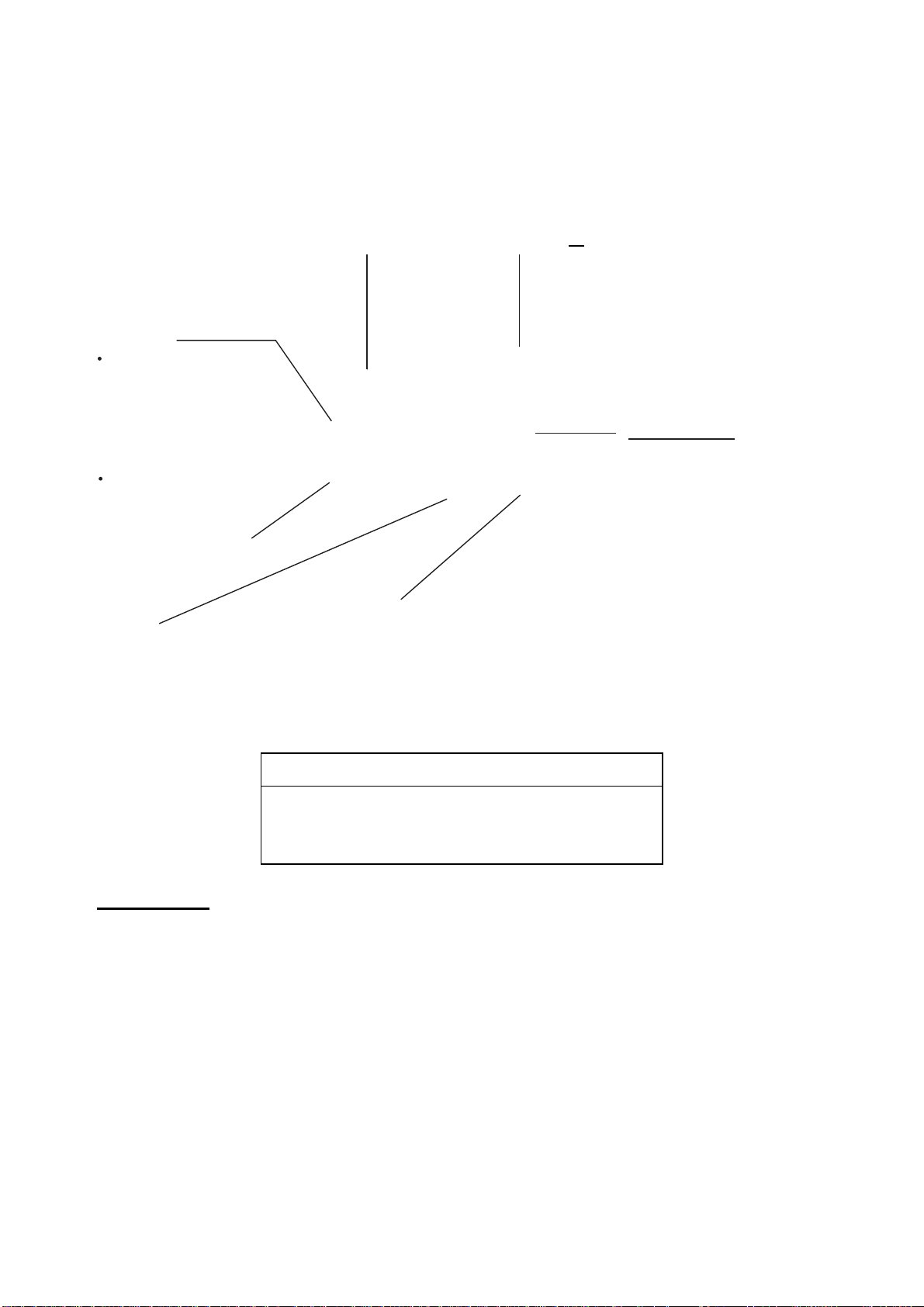

SYSTEM CONFIGURATION

Data Recording Unit (DRU)

VR-5020-6G/VR-5020-9G

Waterproof MIC

VR-3012W

Bridge MIC

VR-5011

VHF Audio

IEC 61162

serial data

Alarm Monitoring

System

No. 1

Radar

No. 2

Radar

PC

Live Player V4

VR-3020

: Standard supply equipment and cable

: Optional supply equipment and cable

: Local supply equipment and cable

* Optional with VR-3000S

Max. 6 ch

VHF I/F

IF-5200

Serial (Max. 8 ch)

Radar Video

SW Interface

IF-1000RVC

Max. 2 ch

Max.

2 ch

Data Collecting

Unit (DCU)

VR-3010

Radar I/F

RI-3010*

100-230 VAC

24 VDC

Remote Alarm

Panel (RAP)

VR-3016

Junction Box (JB)

IF-8530*

GPS

Speed log

Heading

Echosounder

Autopilot

Engine telegraph

Steering gear

M/E remote system

Main air compressor

Bow thruster

Shell door system

Watertight doors

Fire doors

Anemometer

Fire detection

Main alarms

Others

Junction Box (JB)

IF-8530 (max. 2)

Serial

(1ch)

Serial (Max. 8)

Analog

(Max. 16 ch)

Digital (Max. 64 ch)

24 VDC

Analog

(Max. 16 ch)

Digital (Max. 64 ch)

Serial (1 ch)

Environmental category

DCU Protected from weather

DRU Exposed to weather

RAP Protected from weather

Bridge MIC Protected from weather

Waterproof MIC Exposed to weather

VHF I/F unit Protected from weather

JB Protected from weather

Radar Video SW Interface Protected from weather

For the S-VDR, where it is impossible to obtain radar data, the AIS target data should be recorded

as a source of information from other ships. (Ref. IMO Res.MSC.163(78), section 5.4.7.)

vii

Page 10

RECORD OF PUB REV., PROG. NO.

Revision No.,

Date of Revision

A

Apr. 19, 2006

A1

June 2, 2006

B

June 16, 2006

C

July 24, 2006

D

May 17, 2007

E

July 9, 2008

F

Dec 15, 2008

G

Jul. 20, 2010

Program No.

(software)

VR-3000 SYSTEM

2450031-01

RAP

2450026-01

Same as above

Same as above

Same as above

Same as above

VR-3000 SYSTEM

2450031-02

RAP

Same as above

Same as above

Same as above

Outline of Revision

st

1

printing.

Revised system configuration drawings to include

Waterproof MIC.

Changed error code no. as follows:

035→034 Storage failure

041→042 Grabber failure

048→046 DRU Index error

Revised specifications

All pages revised.

Added beacon cover.

Changed flush disk.

For new standard.

Miner program modification

Miner program modification

Revised the replacing parts.

Added error codes; 173, 174, 431 and 432.

Revised section 2.9.

viii

Page 11

1. OPERATION

1.1 Overview

The VR-3000/VR-3000S consists of Data Collecting Unit (DCU), Data Recording Unit (DRU),

Remote Alarm Panel (RAP), Junction Box (JB, optional supply with VR-3000S) and bridge

microphone units. The VDR system continuously stores data from the past 12 hours onto the

Flash Memory in the capsule, erasing the oldest data stored as new data is recorded. The data to

be recorded includes the following:

Parameters to be recorded IEC 61162 formatter Notes

Date and time ZDA

Ship’s position and datum used GNS and DTM

Speed (water and/or ground) VBW

Heading (true) HDT

Heading (magnetic) HDG

AIS-VHF data-link message VDM

AIS-VHF data-link own-vessel message VDO

Depth (echo sounder) DPT

Alarms ALR

Rudder order/response manual RSA

Rudder order/response automatic HTC, HTD

Engine order/response RPM, XDR

Hull openings, watertight doors XDR

Accelerations and hull stress XDR, ALR

Wind speed and direction MWV

VDR alarm output $VRALR

Radar data

Bridge audio

VHF communication audio

No requirement for S-VDR to

send alarm messages

Power supply precaution

If ship’s mains power source (100-230 VAC) and emergency source fail, the VR-3000/VR-3000S

continues to record bridge audio for 2 h from backup batteries. When using the backup batteries,

suspend power to the IF-8530 Junction box..

1

Page 12

Continuity of storing data

The VDR should be provided with power to store data for 12 h on a first-in, first-out basis.

Recording is terminated only under the following circumstances:

a) During essential maintenance while the vessel is in port.

b) When the vessel is laid-up.

c) In case of emergency, when the backup HDD is removed.

Data Collecting Unit

The DCU mainly consists of Data Processor Unit and Power Control Panel. The DCU includes

two 12 V backup batteries with a lifetime of approximately four years. The DCU collects the data

from various sensors and radar and records them in the DRU and backup HDD.

Recording interval of data and audio is as follows:

- Radar video signal: every 15 seconds

- Bridge and VHF audio: real time

- IEC sentences: when received

- Analog and digital data: every second

LEDs: Light (green) when respective power is applied.

Status Display

LEDs (from left)

SAVE (yellow):

When stopping the data

recording, this starts

blinking from OFF state,

then lights steadily.

If the HDD is disconnected,

this LED lights also.

NORMAL (Green):

On at normal operation.

ERROR (red):

Lights for error.

Breaker switches (from left)

Battery Backup, DC, AC

2

Page 13

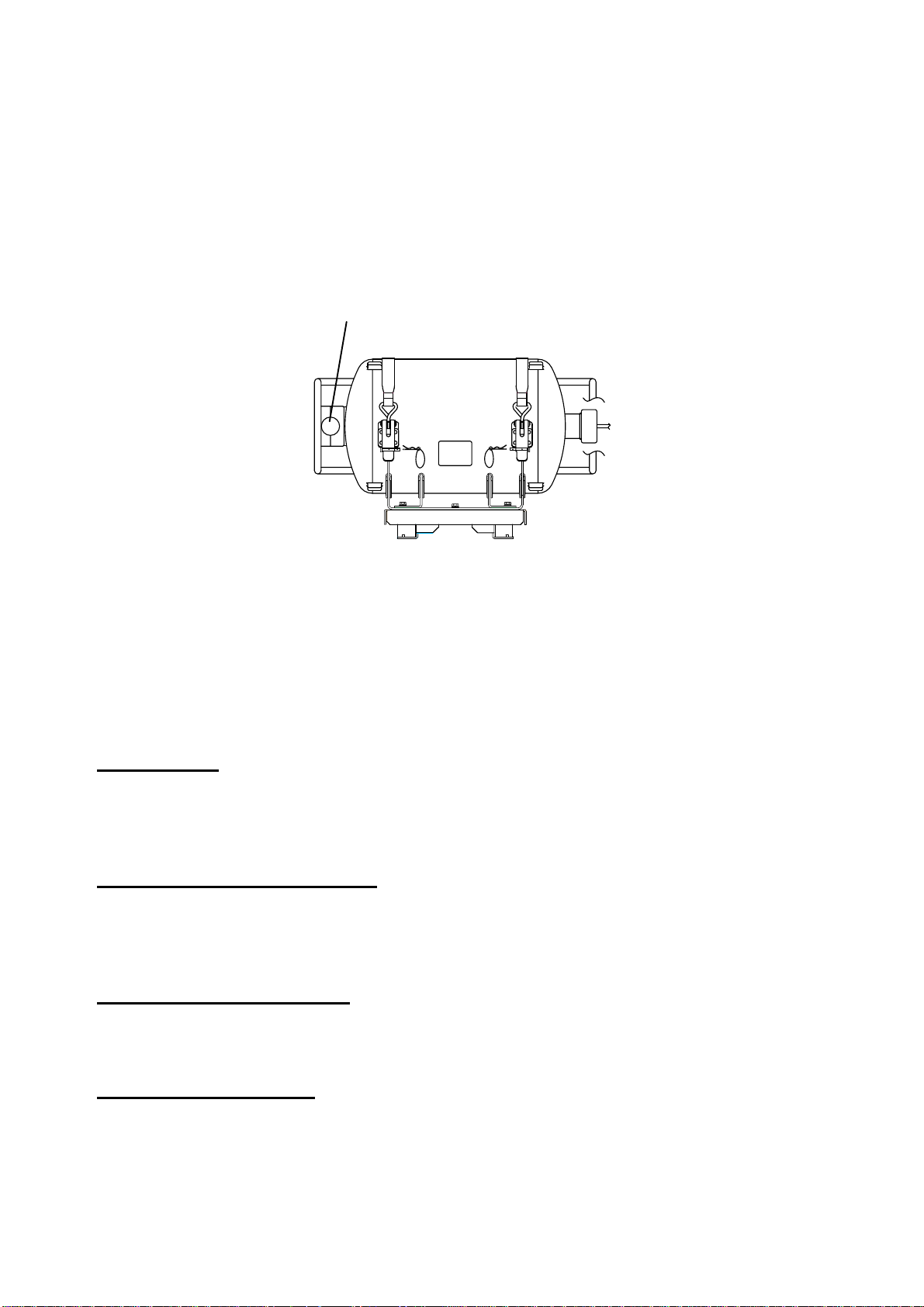

Data Recording Unit

The Data Recording Unit is housed in a highly visible protective capsule which can withstand a

fire of 1100°C for 1 hour and deep-sea pressure of 6000 m.

The underwater acoustic beacon (pinger) on the capsule automatically transmits 10 ms pulses at

37.5 kHz for at least 30 days when it is submerged in water. The expected life of the beacon is 6

years. The DRU is connected to the Data Collecting Unit (DCU) with a non-halogen FireWire

cable (IEEE1394).

Underwater Acoustic Beacon

Data Recording Unit

Integrity

The recording integrity is ensured by continuous monitoring of power supply, record function, bit

error rate, and microphone functionality. Visual alarm is generated for malfunction of any of these.

Alarm status is also indicated by relay contacts.

Data items to be recorded

Date and time

Date and time are obtained from an external GPS navigator referenced to UTC. Time information

is recorded at intervals of 1 s. Without date and time data, no data except audio signal is

recorded.

Ship’s position and datum used

Latitude, longitude and datum are obtained from a GPS navigator, Loran-C receiver or other

EPFS or INS available on standard digital interface. The source of data is identifiable on

playback.

Speed (water and/or ground)

Speed through the water (STW) or speed over the ground (SOG) is recorded at intervals of 1 s.

The resolution is 0.1 kt. Transverse speed is also indicated when available on board.

Heading (true, magnetic)

Heading is recorded at intervals of 1 s to a resolution of 0.1°. The data is labeled G

(gyrocompass), GPS, GLONASS, MAG. If heading information is not available in IEC 61162

format, an appropriate interface may be necessary.

3

Page 14

AIS-VHF data-link message, AIS-VHF data-link own-vessel message

Where there is no commercial off-the-shelf interface available to obtain radar data then AIS target

data shall be recorded as a source of information regarding other ships, otherwise AIS

information may be recorded additionally as a beneficial secondary source of information on both

other and own ship.

The VDM message (UAIS VHF Data-link) shall be recorded in such a way that all target data

available from the onboard AIS are acquired. If the VDO message (UAIS VHF Data-link

Own-vessel report) is recorded, this shall be additional to the recording of individual sensor data.

Depth (echo sounder)

Depth under keel up to a resolution of 0.1 m as available on the ship is recorded.

Alarms

The status of all IMO mandatory alarms is recorded individually with ID number and time stamp.

Audible alarms from the alarm units are stored simultaneously by the bridge audio microphones.

Rudder order/response

Rudder order and response angles are recorded up to a resolution of 1° as available on the ship.

The rudder information is recorded. If more than one rudder is provided, the circuitry can be

duplicated.

Engine order/response

The DCU obtains the engine order and response from the engine telegraph or direct engine

control. The signal level is normally 0-10 V. The engine parameters with shaft revolution and

ahead/astern indicators are recorded to a resolution of 1 rpm.

All order and response from bow, stern, thruster, tunnel thrusters and controllable pitch propellers

shall be recorded. The S-VDR shall record this data if said serial data is available.

Hull openings, watertight doors

Inputs digital or RS-422 serial can be connected individually. The data is received at intervals of 1

s and stored with time stamps. Serial data sentence XDR is received at a data rate of 1,200-9,600

baud.

Accelerations and hull stresses

The DCU obtains signals from appropriate hull stress and response monitoring devices. The

inputs are recorded individually and stored with time stamps. Serial data sentence XDR is

received at a data rate of 1,200-9,600 baud.

Wind speed and direction

The DCU obtains the signal from appropriate wind speed and direction sensor. The inputs are

recorded individually and stored with time stamps. Serial data sentence XDR is received at a data

rate of 1,200-9,600 baud.

VDR alarm output

There is no requirement for the S-VDR to send alarm messages. If, as an option, such messages

are sent then the appropriate sentence format is ALR.

4

Page 15

Radar data

Radar image including range rings, EBLs, VRMs, plotting symbols, radar maps, parts of SENC,

voyage plan, and other essential navigational indications, is recorded in the DRU via the interface

in the DCU which is connected to the buffered video output of the radar display unit. One

complete picture frame is captured at intervals of 15 s.

The radar display complying with IEC 60936-1 should have a buffered output (VESA DMTS

compatible) with resolutions between 640 x 480 and 1280 x 1024, and can be directly connected

with the VDR. Scanning may be interlaced or non-interlaced.

Bridge audio

Up to six microphones are supplied as standard to record conversation at conning station, radar

display and chart table. If possible, the microphones should be positioned to capture the audio

from the intercom, public address system, and audible alarms on the bridge. The microphones

are labeled Mic1, Mic2, etc. Microphone captures conversation in the bridge, audio signals from

equipment and sound from machinery. The microphone generates a test beep every 12 hours

which is also recorded. The microphone picks up audio signals ranging from 150 to 6000 Hz.

Communications audio

A maximum of two VHF communications are recorded for both transmitted and received audio

signals. The VHF radio connections are labeled VHF1 and VHF2.

5

Page 16

1.2 Operating Procedure

The VDR comes with a key to lock the DCU to protect against any unauthorized access. The key

must be kept securely after installation.

1.2.1 Powering, recording

On the power control panel in the DCU, turn on the AC SUPPLY MAINS, DC SUPPLY MAINS and

BATTERY BACK-UP switches in this order. Confirm that the NORMAL LED on the power control

panel and RAP lights. The VDR records data automatically in the DRU and backup HDD.

NORMAL LED

REMOTE ALARM PANEL

Breaker switches (from left)

Battery Backup, DC, AC

POWER CONTROL PANEL

NORMAL LED

1.2.2 Stopping recording

Recording is terminated only under the following conditions:

- During essential maintenance purposes while the vessel is in port.

- When the vessel is laid-up.

To stop recording, turn off the BATTERY BACKUP, DC SUPPLY MAINS and AC SUPPLY MAINS

switches in this order. DO NOT turn off the system by the main breaker while the BATTERY

BACKUP switch is on. If this is done, the system operates on the batteries. The system stops

after running on batteries after 2 hours.

6

Page 17

1.3 Operation on Remote Alarm Panel

No power switch is provided on the Remote Alarm Panel; it is turned on and off by the power

switch on the DCU. When the ERROR LED (red) on the Remote Alarm Panel is on, identify the

error by checking code number in the error code tables in Chapter 3. The buttons on the Remote

Alarm Panel work as described in the figure below.

Buzzer

DIMMER:

Adjust panel backlighting;

Setting range: 0 - 10

Default: 8 (Just after

power on)

At setting 0: ERROR

LED lights at level 1.

Other LEDs are off.

Display software version

no. (pressed together).

TEST: Tests LCD.

ACK: Silences buzzer.

SAVE: Stops recording onto current memory area in the backup

HDD and starts recording onto another menory area.

Status Display

--X: Indicates that X no. of recording

areas exist. (X: 4, 3, 2, 1)

---: Recording area is not yet known.

(at startup or when recognizing HDD)

LEDs (from left)

SAVE (yellow):

Starts blinking from OFF

state when recording is

stopped, then lights

steadily.

If the HDD is disconnected,

this LED lights also.

NORMAL (Green):

On at normal operation.

ERROR (red):

Lights for error.

Note: The buzzer sounds every time the radar connected to the VDR is turned off. Press the

ACK button to silence the alarm.

NOTICE

After pressing the SAVE button four times, data

will not be recorded. Replace the HDD with an

initialized one, or contact a FURUNO agent for

ecessary procedure.

SAVE button

If you press the SAVE button, the current memory area in the backup HDD stops recording and

another area starts recording. If an incident occurs, press this button immediately. If another

incident occurs, press the button again. The memory in the backup HDD is divided into four areas.

When you press the SAVE button, the number of recording area in the HDD is reduced by one.

After saving is completed, the buzzer sounds intermittently for 10 seconds. However, if an alarm

is violated during the saving, the alarm buzzer has priority. If you press the SAVE button four

times, all four areas stop recording. To remove the HDD, see paragraph 1.4.

If you pressed the SAVE button during an incident, consult a FURUNO dealer to restore the HDD

after the authorities complete an investigation of the incident.

7

Page 18

1.4 Removing HDD at an Incident

VDR information is copied automatically into the backup hard disk drive (HDD) for more than 12

hours (max. 13 hours) and is then automatically written over with new data. Bring the HDD with

you after an incident if possible. Press the SAVE button only when an incident occurs. To replace

the HDD under other circumstances, see section 2.6.

To remove the HDD, do the following:

1. Press the SAVE button (long press) on the RAP (Remote Alarm Panel). The yellow LED starts

blinking, showing that recording is being terminated.

2. Wait until the LED lights steadily. If the LED does not light, press the SAVE button

consecutively until the LED lights.

Note: Turning off the power is not required at an incident. However, to replace the HDD, turn

off the power after the step 2.

3. Pull the knob on the HDD holder to open the holder.

4. Disconnect the IEEE1394 cable.

5. Remove the HDD.

Knob

DCU, showing location of HDD

1.5 How to Release DRU

To remove the DRU from the bracket (cradle)

do the following:

1. Loosen the hand-tightened cap.

2. Pull the DRU cable straight out.

(The cable may be cut after an incident.)

3. Remove two snap pins and then two hinge

pins.

4. Lift the release levers.

HD

3. Hinge pin

HDD

IEEE1394

Cable

4. Release levers.

1. Cap

2. DRU cable

3. Snap pin

8

Page 19

2. MAINTENANCE

Periodic checks and maintenance are important for proper operation of any electronic systems.

This chapter contains maintenance instructions to be followed to obtain optimum performance

and the longest possible life of the equipment. Any maintenance must be executed by a suitably

qualified technician.

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

2.1 Annual Recertification

The VDR must undergo an annual performance test to recertify suitability. This test is conducted

by a test engineer authorized by the manufacturer and certified by a relevant ship classification

society, the content and procedure of the test in accordance with the regulations of that society.

For further details about the VDR performance test, contact your ship classification society.

2.2 Cleaning

Dirt or dust may be removed from units with a soft cloth.

Fresh water-moistened cloth may be used to remove

stubborn dirt. DO NOT use any commercial cleaning

agents to clean any unit. They can remove paint and

markings. This is especially important with the

Waterproof Microphone VR-3012W. The watertight

integrity of the microphone will be compromised if any

commercial cleaning agent contacts the ventilation

sheet behind the MIC cover.

MIC COVER

Waterproof microphone VR-3012W (bulkhead type)

9

Page 20

2.3 Software Maintenance

2.3.1 Software list

The software and software version of the VR-3000/VR-3000S are as shown in the table below.

VR-3000/VR-3000S software list

Software name Software version Date

VR-3000 System Program 2450031-02 July 2008

VR-3000 RAP 2450026-01 Mar 2006

2.3.2 Checking software version of system program

Follow the procedure below to check software version of system program.

1. Start up a PC that uses Windows XP or Windows 2000 OS.

2. Change the IP address to 10.0.0.102 and the subnet address to 255.0.0.0.

3. Connect the cross LAN cable (supplied) between the LAN port on the PC and J14 (Data) in

the DCU of the VR-3000/VR-3000S.

4. Start up the VDR Maintenance Viewer from the PC.

5. Open the menu of this program from Maintenance/VDR Config Management. The VDR

Config Management screen appears.

6. Click the Download button on the screen.

7. Click the software tab to change the screen. The program version is displayed at the right side

of the VDR system program.

2.3.3 Checking software version of RAP

Push and hold down the RAP’s plus and minus buttons together. A three-digit number appears

(for example, “101”) and these digits are the version number.

10

Page 21

S

ry

2.4 Replacing Batteries

Every four years, the back-up batteries (2 pcs.) in the DCU must be replaced with new ones

(Type: OP24-12 Code no.: 004-385-010) by a qualified service engineer. Note that the batteries

should be recycled. Contact a FURUNO dealer for further details.

Observe the following precautions with the batteries:

WARNING

Battery handing precautions

- Do not attempt to dismantle the battery. If

accidental skin/eye contact is made with

the battery fluid, wash the affected

area/part immediately with liberal amounts

of clean fresh water and seek IMMEDIATE

medical attention.

- DO NOT INCINERATE batteries as they

are liable to rupture if placed into a fire.

Batteries that have reached the end of

their service life must be disposed of in

accordance with appropriate regulations.

- Do not short battery terminals. Short can

lead to bursting or fire.

Do not:

- use batteries of different capacities

- mix old batteries with new

- mix batteries of different makes

Batteries themselves may become

damaged or damage to electrical

parts may result.

CAUTION

To replace the batteries, do the

following:

1. Open the DCU door with its key.

2. Power off the DCU.

Battery

Battery leads

(under vinyl boot)

Batte

3. Unfasten J3 connector from the

PDU Board (24P0083)

4. Unfasten two screws securing the

batteries.

crew

Screw

J3

5. Disconnect four battery leads,

which are covered with the “vinyl

boots”.

6. Use the handle to remove

batteries from the DCU.

7. Replace batteries.

8. Lock the DCU.

DCU, inside view

11

Page 22

2.5 Replacing Acoustic Beacon

The life of the underwater acoustic beacon is approximately 6 years. It must be replaced (Type:

DK-120, Code no. 000-148-648) by a qualified service technician before validity date marked on

the beacon.

1. Unfasten two bolts and remove the beacon cover.

2. Use box screwdriver (7 mm) or slotted screwdriver to unfasten four bolts and then remove

the beacon.

3. Attach a new beacon.

Bolts

Water switch is right side.

(The label is upside-down.)

Validity date should face in front.

Acoustic beacon

DRU (Beacon cover removed)

NOTICE: As the acoustic beacon contains a battery, it must be disposed of in accordance with

appropriate regulations.

12

Page 23

4

Knob

2.6 Replacing Backup HDD

On some vessels several backup HDDs (Type: VR-3011, Code No.:004-385-000, Option) are

carried onboard, replacing one when it is necessary to transport it from the vessel for playback

and extract.

A backup HDD may only be replaced in the follow situations:

1) When the equipment can be powered off; for example, maintenance while in port, etc.

2) An incident has occurred and the Save button on the RAP (VR-3016) was operated to stop

recording.

An HDD may not be re-used for recording after the Save button has been operated four times.

Contact a FURUNO dealer for further details.

A backup HDD records navigation data for more than past 12 hours (13 hours max). For longer

recording, use Live Player Backup.

DCU

VR-3010

HDD

VR-3011

DRU

VR-5020

RAP

VR-3016

Replacing backup HDD

1. Open the DCU with its key. Turn off the

DCU.

2. Pull the knob on the HDD holder to open

the holder.

3. Disconnect IEEE1394 cable from the HDD.

Remove the HDD.

4. Set new HDD to holder.

5. Connect IEEE1394 cable.

6. Push knob on the HDD holder to close the

holder. Turn on the DCU.

7. Confirm that HDD is operating (DCU power

is ON, Save LED is OFF) with no error.

8. Close the DCU and lock it with its key.

9. Refer to the operator’s manual of the Live

Player

Pro for how to playback/extract recorded

data from the Backup HDD.

Change

AC Adapter

HDD

VR-3011

IEEE1394

(4Pin – 6Pin)

PC for

Playback / Extract

HD

HDD

IEEE139

Cable

13

Page 24

2.7 Replacing Fuses

The battery cable in the DCU contains two 10A fuses in fuse holders. If a fuse blows, the

BACKUP BATTERY LED may not be lighting. Find the cause before replacing a fuse. Have a

serviceman replace any fuse.

Fuses

2.8 Replacing Parts

Interval-specific parts

The batteries in DCU and the acoustic beacon on the DRU must be replaced every 4 and 6 years

respectively to comply with IMO conventions. Record the date of expiration on the card in the

card holder on the door of the DCU.

Part Replacement

interval

Battery in DCU 4 years 2 pcs., replace together

Acoustic underwater beacon in DRU 6 years

Consumable parts

Remarks

The parts in the table below should be replaced before the estimated lifetime shown. The period

of expiration begins from the date of installation. Record the date of replacement on the card in

the card holder on the door of the DCU.

Consumable part Life Remarks

Backup HDD 2 years / 25℃ Data cannot be recorded to the backup HDD

when it fails. Error 018 is generated when

this occurs.

DC-DC converter 4 years / 25℃* If DC power supply fails, RAP indicates 082

and AP in DCU indicates 84.

DCU chassis fan 6 years / 25℃*

DCU CPU fan 6 years / 25℃*

CMOS battery on CPU board

in DCU

AC power supply 6 years / 25℃ If AC power supply fails, RAP indicates 214

* = Product has a 90% probability of achieving full lifespan

6 years / 25℃ Failure of this battery prevents GPS time

Failure of one or both of these fans prevents

the CPU from operating, which may prevent

start up of the VDR.

synchronization. Error 026 is generated

when this occurs.

with AC power switch ON.

14

Page 25

2.9 Verifying Recording Function of the DRU

Verify the DRU’s recording function at the annual inspection and when repairing or maintaining the

VDR or sensors connected to the VDR. The verification requires the Live Player V4. Refer to its

Operator's Manual for the operating procedure. Note that data cannot be extracted during recording.

1 Set the Playback/CPU switch in the DCU to the Playback position.

2. Wait about 1

3 Connect the PC to DCU as shown in the Figure below.

0 minutes and verify that Alarm 174 occurs.

DCU

Set slide SW to Playback.

J8 (DRU)

DRU

Disconnect cable

from HDD.

PC

J6 (Playback)

IEEE1394 cable

4 Disconnect the cable attached to the Backup HDD.

5.Start the Live Player V4 on the PC.

6 Open the Too l menu and select Source Select. Select DRU from the pull-down menu.

7 Click the Analyze Track button.

8 Click the Connect button.

9. Select Extract from the Tool menu to show the Extraction dialog box.

10. Select the track to extract.

11. Click the Select button and select the location where to save data.

12. Click the Start button.

13. After the extraction is completed, click OK, Close and Close in that order. Then, do the following.

a) Disconnect the cable between the PC and J6 on the DCU.

b) Connect the Backup HDD.

c) Set the Playback/CPU slide switch in the DCU to the CPU position.

15

Page 26

2.10 Confirmation of Peripheral Devices

Confirm the data from serial signal output devices, analog signal output devices and contact signal

output devices. To do this, connect the PC to the DCU and use the Live Player software.

Serial signal output devices

The threshold levels of the time-out for serial signal input are preset. If the data is not input to the VDR,

an error code appears on the Remote Alarm Panel (see paragraph 3.2). Confirm the accuracy of the

input signal, comparing the value of the input sensor and preset value in the VDR.

Analog and contact signal output devices

Confirm the signal value and accuracy, comparing the indication of the input device and the input

value on the VDR.

16

Page 27

3. TROUBLESHOOTING

This chapter provides information on possible causes of problems you may experience with your

VDR. If you still have a problem after referring to the table, contact your local dealer or national

distributor for further advice. Always provide the product serial number.

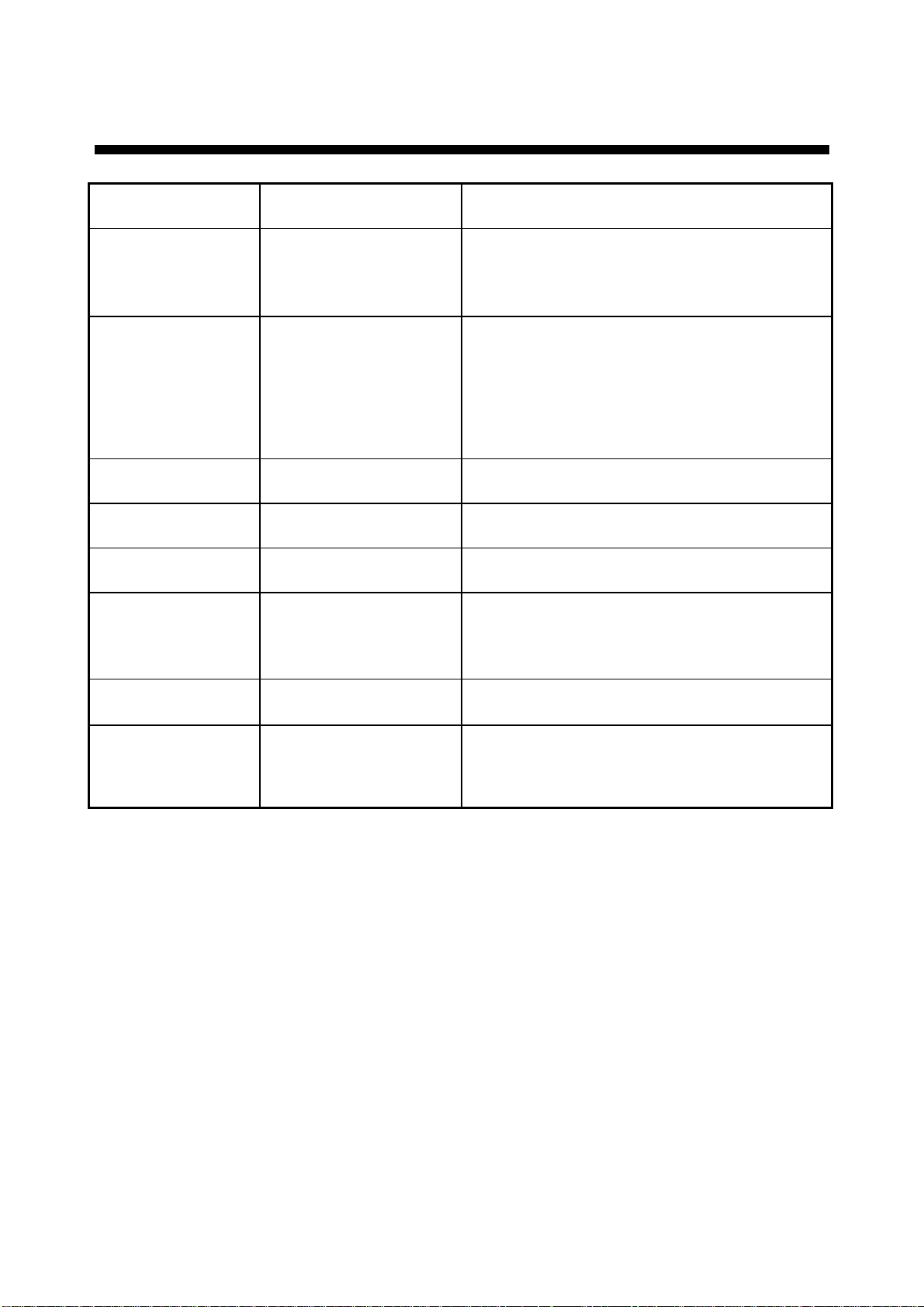

3.1 General Troubleshooting

Use the table below to identify the trouble, cause and possible solution.

Troubleshooting table

Symptom Possible causes Possible solution

AC and/or DC LED not lit No power supply

BATTERY BACKUP LED not lit No power from the battery Call for service.

ERROR LED lighting in red Malfunction of the system

Check the breaker switches on

ship’s mains switchboard.

Restart the system. If the problem

still remains, call for service.

Check integrity of DRU

connection.

17

Page 28

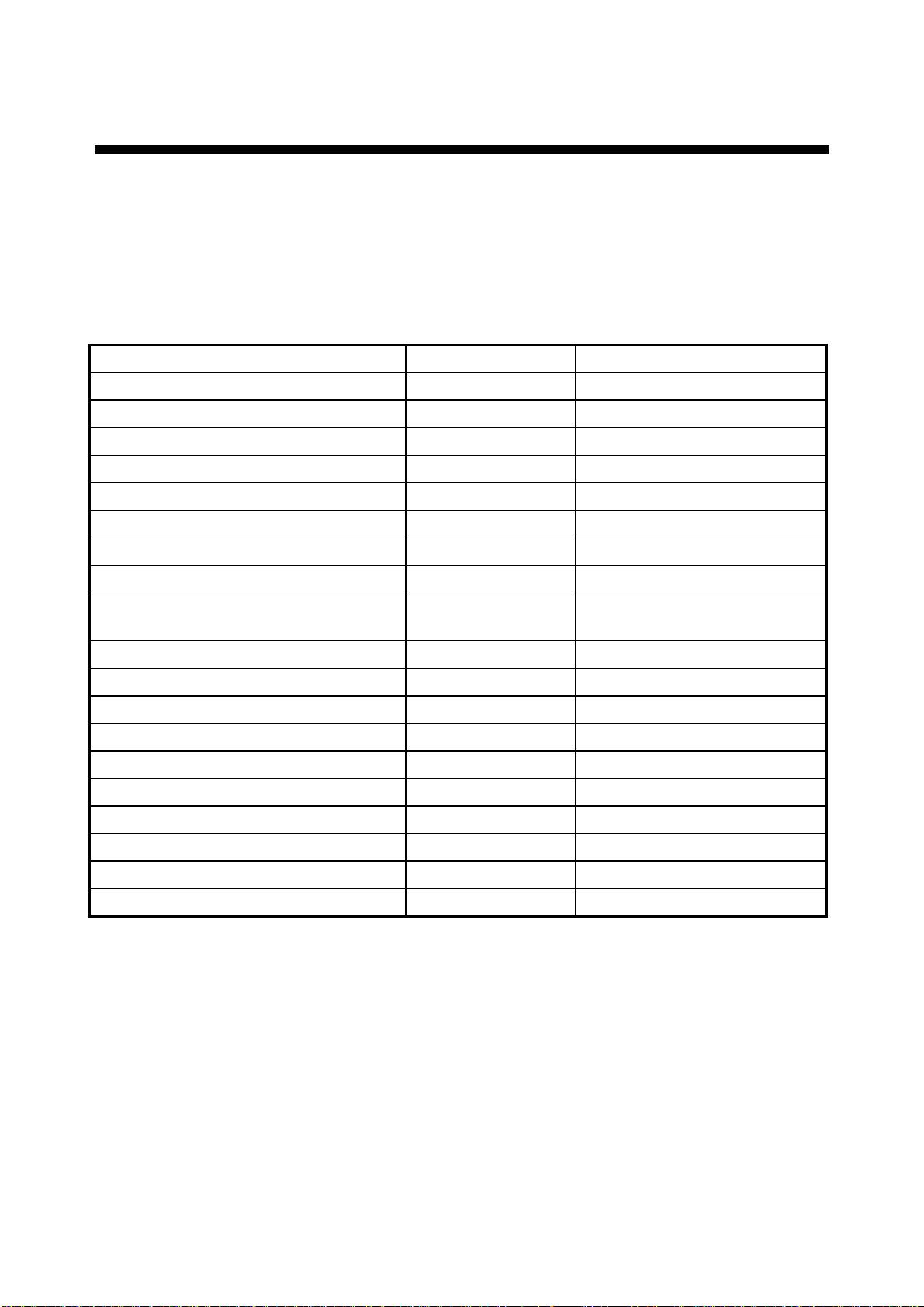

3.2 Error Codes

A

Error codes may appear on the status display on the Power Control Panel to alert to possible

trouble. Below is a list of those codes.

System software: 2450031-02

Error Error Name Description

--4

--3

--2

--1

---

HDD BACKUP_HDD_MISSINGBackup HDD not connected to VDR,

Normal operation. "--X" (X:1,2,3,4)

means number of exting recording

area in the HDD. "---" is shown at

startup or when recognizing HDD.

or no memory area.

1) SAVE button pressed and backup

HDD removed: Replace backup HDD

2) Other situations: Reset VDR. If

normal operation not restored,

request service.

ction

018 Backup HDD No

Connection

022 DRU No Connection DRU has been discontinued more

026 GPS Large Time

Difference

042 Radar No Connection One of the active/enabled video

082 RAP No Connection RAP is missing. Connection to RAP

084 AP No Connection No alarm panel connection Check connection to alarm panel.

088 JB No Connection Indicates that Junction Box (No.1) is

This indicates that the BACKUP has

been disconnected more than 120

seconds.

than 120 seconds.

This indicates that the time difference

between system time and time

supplied by UTC source is more than

the specified time.

channels can’t grab from the

channel. This can be either because

radar is turned OFF or wrong

configuration.

is lost.

missing.

Connect BACKUP HDD or

investigate LOG and repair/replace.

Connect DRU again or investigate

LOG and repair or replace.

Restart VR-3000/S. Try to see if the

CMOS clock is set correctly. If not,

set it and restart VR-3000/S. If yes,

find out why the time source device

GPS is delivering "out of bands" time

info.

If radar is turned OFF, press ACK on

the RAP to silence alarm. Turn on

radar. If no error appears, the system

is normal. If the error appears, check

cable connections or setting.

Check cable connected to RAP.

Reconnect RAP.

Check cable and IP-address setting.

094 Backup HDD Recording

Fail

098 DRU Recording Fail Indicates that DRU is inactive-not

170 VDR Configuration Fail Data can not be stored because VDR

171 VDR Recording Buffer

Overflow

173 Fatal System Failure

174

IEEE1394 Bus Recover

Giveup

Indicates that Backup is inactive-not

storing data.

storing data.

setting data is corrupted.

Radar video inputs over the capacity

of the recording buffer memory.

Fatal system error. VR-3000/S

rebooted automatically after an error

occurred.

Cannot Recover DRU and Backup

HDD.

Check connection to Backup HDD. If

not still storing, request service.

Check connection to DRU. If not still

restarting recording, request service.

Restore VDR settings data. If not,

request service.

Check or reduce the radar channels

or video resolusion.

If VR-3000/S repeat continuously,

request service

Restart VDR. If VR-3000/S does not

recover, request service

(Continued on next page)

18

Page 29

Error codes (con’t from previous page)

Error Error Name Description Action

186 DRU Memory Shortage It looks that data cannot be recorded

more than 12 hours.

Modify radar recording setting. Max.

recordable channel: two channels.

214 Battery Running Both AC and DC power are down and

switching to battery drive. Audible

alarms are generated for max. two

218 MIC Test Fail This ALARM is issued when the

microphone test fails. This test can

be run from Audio tab in the VDR

Maintenance Viewer, and is run every

12-hours during normal operation.

226 DRU Flash Device No

match

234 GPS No Connection System does not receive UTC

246 PDU No Connection Cable connection inside DCU is

254 Self Test Fail System failed by the self test. Request service.

3xx

(301-372)

401 Battery No Connection

402 Terminal Board No

403 Battery Voltage Low Batter voltage is lowered. It is required replacement of battery.

Serial No Connection Data is not delivered from a serial

or Battery Voltage Low

Connection

This indicates that no. of FLASH

devices found in DRU and defined in

CONFIGURATION is not same.

information.

faulty.

ohannel within an assigned time.

Battery voltage is not coming or it is

low.

Terminal board is abnormal. Confirm cable connection between

Reconnect AC and/or DC power.

Check MIC TEST in the VDR

Maintenance Viewer. If this is OK,

locate the faulty microphone and

check/replace it.

Check if no. of FLASH devices and

configuration setting are same.

Check that a valid UTC source is

connected to the serial port defined

as UTC source.

Check cable between PDU and CPU

block in DCU.

Reconnect serial data. Check failed

device.

Confirm that the battery switch is

turned on. If ok, battery is required to

replace a new one.

terminal board and audible interface

board.

406 DRU Exchanged This indicates that DRU is replaced. Restart VR-3000/S

407 Backup HDD Exchanged This indicated that backup HDD is

replaced.

411 Frame Grabber Board

Fail

412 Audio Board Fail Audible interface board is available

413 Serial Board Fail Serial interface board is available but

42x

(422-428)

431

432 JB Buffer overflow

JB No Connection Poor connection between JB(No.2-

DCU Serial Buffer

overflow

Radar interface board is available but

it is not recognized.

but it is not recognized.

it is not recognized.

8)and DCU.

Serial data from DCU serial channels

(1-8) aren't recorded to DRU and

Backup HDD correctly.

Serial, analog and digital data from

Junction Box aren't recorded to DRU

and Backup HDD correctly.

Restart VR-3000/S

Request service.

Request service.

Request service.

Check cable and IP-address setting.

Restart VDR. If error occurs again,

request service.

Restart VDR. If error occurs again,

request service.

19

Page 30

3.3 Testing Display of Remote Alarm Panel

Press the TEST button on the RAP to check that all LCD segments are displayed properly.

20

Page 31

4. LOCATION OF PARTS

4.1 Parts Location

4.1.1 Data Collecting Unit (VR-3010)

Fuses

From top:

1) RADAR I/F

Board (RI-3010)

2) AUDIO Board

3) SERIAL Board

4) Riser Card

(24P0068)

5) CPU Board

Compact Flash

Card

CONNECTOR

PANEL board

(24P0081)

Power Supply

(RTW28-11RN-1)

(underneath)

DC-DC

Converter

(ACE-716C-RS)

(underneath)

Battery

(OP24-12)

(2 pcs.)

Backup Hard Disk (HDD)

(VR-3011)

PDU Board

(24P0083)

AP PANEL Board

(24P0076B)

AP MAIN Board

(24P0075B) (underneath)

LED PANEL Board

(24P0082)

Terminal Board 2

(24P0079)

Terminal Board 1

(24P0078)

(w/WAGO connectors)

Data Collecting Unit (VR-3010)

21

Page 32

4.1.2 Data Recording Unit (VR-5020-9G or VR-5020-6G)

Underwater Acoustic

Beacon (DK-120)

DRU

FLASH DISK Board

(FW-ATA2501-1)

2.5-inch FLASH DISK

(SLFLD25-8GM1U1 (for 6G) or

DK0090G88TNO (for 9G))

REPEATER

Board (24P0080)

(Firewire cable connects

to CONNECTOR Board.)

CONNECTOR Board

(24P0042)

CONNECTION Board

(24P0087)

Components inside capsule

Data Recording Unit (VR-5020-9G or VR-5020-6G)

22

Page 33

4.1.3 Junction Box (IF-8530)

MAIN Board

(24P0069)

Terminal Board

(24P0077)

(w/WAGO connectors)

Junction Box (IF-8530)

4.1.4 Remote Alarm Panel (VR-3016)

Remote Alarm Panel (VR-3016)

RAP PANEL Board

(24P0076A)

(underneath)

RAP MAIN Board

(24P0075A)

(underneath)

23

Page 34

4.2 Parts List

This equipment contains complex modules in which fault diagnosis and repair down to

component level are not practical (IMO A.694(17)/8.3.1. Only some discrete components are

used. FURUNO Electric Co., Ltd. believes identifying these components is of no value for

shipborne maintenance; therefore, they are not listed in this manual. Major modules can be

located on the parts location on previous pages.

Name Type Code No.

Data Collecting Unit (VR-3010)

AP MAIN Board 24P0075B 004-385-320

AP PANEL Board 24P0076B 004-385-330

AUDIO Board PCI-9111-DG 000-148-411

Battery (2 sets) OP24-12 004-385-010

Compact Flash Card CFI-128MDG(H02AA) 004-385-140

CONNECTOR PANEL Board 24P0081 004-385-110

CPU Board PEB3730VL2A 004-383-400

DC-DC Converter ACE-716C-RS 004-385-450

RADAR I/F Board RI-3010 004-388-070

LED PANEL Board 24P0082 004-385-340

PDU Board 24P0083 004-384-750

Power Supply RTW28-11RN-1 004-385-390

Riser Card 24P0068 004-385-070

SERIAL Board 99033-8 000-156-911

Terminal Board 1 24P0078 004-385-350

Terminal Board 2 24P0079 004-385-700

Backup Hard Disk (HDD) VR-3011 004-385-000

Data Recording Unit (VR-5020-9G or VR-5020-6G)

CONNECTION Board 24P0087 000-166-816-10

CONNECTOR Board 24P0042 004-381-030

SLFLD25-8GM1U1 (for 6G) 000-166-792-10 FLASH DISK

DK0090G88TNO (for 9G) 000-166-822-10

FLASH DISK Board FW-ATA-2501-1 000-161-500-11

REPEATER Board 24P0080 000-155-924-01

Underwater Acoustic Beacon DK-120 000-148-648

Junction Box (IF-8530)

MAIN Board 24P0069 004-385-490

Terminal Board 24P0077 004-385-510

Remote Alarm Panel (VR-3016)

RAP MAIN Board 24P0075A 004-385-520

RAP PANEL Board 24P0076A 004-385-560

24

Page 35

5. INTERFACE

(IEC 61162-1, IEC 61162-2)

5.1 Data Sentences

Some sentences described here are the ones proposed by the recent IEC TC80/WG6 (Digital

Interface Working Group) at the time of this publication. They are marked with PAS 101 or PAS

102.

ALA - Set detail alarm condition

0 1 2 3 4 5 6 7 8 9

$xxALA, hhmmss.ss, aa, aa, xx, xxx, A, A, c—c *hh<CR><LF>

0: Header 1:

3: Sub-system/equipment/item indicator of alarm source 4: Number of equipment / units / items

5: Number of alarm source 6: Alarm condition 7: Alarm’s acknowledge state

8: Alarm’s description text 9: Check-sum

ALR - Set alarm status (PAS 101)

Updated the text label of the alarm identification field to be the same as that field in the ACK

sentence.

$--ALR,hhmmss.ss,xxx,A,A,c--c*hh<CR><LF>

Event time (Optional) 2: System indicator of alarm source

Alarm’s description text

Alarm’s acknowledge state, A = acknowledged, V=

unacknowledged

Alarm condition (A = threshold exceeded, V = not exceeded)

Unique alarm number (identifier) at alarm source

Time of alarm condition change, UTC

25

Page 36

DOR - Door status indication

This sentence indicates the status of watertight doors, fire doors and other hull openings /

doors. Malfunction alarms of the watertight door, fire door and hull opening/door controller

should be included in the “ALA” sentence.

$xxDOR, A, hhmmss.ss, aa, aa, xxx, xxx, A, c—c, *hh<cr><lf>

0 1 2 3 4 5 6 7 8 9

0) Header

1) Message type

S: Status for section: the number of faulty and/or open doors reported in the division specified in

field 4. The section may be a whole section (one or both of the division indicators are empty) or a

sub-section. (If S is used then it shall be transmitted at regular intervals.)

E: Status for single door. (E may be used to indicate an event).

F: Fault in system: If limited to one section, indicated by division indicator fields, if not, division

indicators empty. (F may be used to indicate an event.)

2) Time stamp

Time when this status/message was valid.

3) System indicator of door status

Indicator characters as door system. The field is two fixed characters.

4) Division indicator of door allocation (1)

Indicator showing division where door is located. This field is two characters.

It may be physical fire zone or entity identifier for control and monitoring system, e.g., central number.

5) Division indicator of door allocation (2)

Indicator showing in which division the door is located. This field is three numeric characters.

It may bephysical deck number or identifier for control and monitoring system sub-system,

e.g., loop number.

6) Door number or door open count

Number showing door number or number of doors that are open/faulty.

This field is three fixed numeric characters.

7) Door status

This field includes a single character specified by the following: when S status indicated in 2nd field,

this field is ignored

O = Open

C = Close

F = Free status (for watertight door)

X = Fault (impossible to know state)

8) Message's description text

Additional and optional descriptive text/door tag. Also if a door allocation identifier is string type, it is

possible to use this field instead of above door allocation fields.

Maximum number of characters will be limited by maximum sentence length and length of other fields.

DPT - Depth

IMO Resolution A.224 (VII). Water depth relative to the transducer and offset of the measuring

transducer. Positive offset numbers provide the distance from the transducer to the waterline.

Negative offset numbers provide the distance from the transducer to the part of the keel of

interest.

$--DPT, x.x, x.x*hh<CR><LF>

Checksum

Offset from transducer, in meters = distance from transducer to water-line

Water depth relative to the transducer, in meters

26

Page 37

DTM - Datum reference (to be further developed)

Local geodetic datum to which a position location is referenced.

$--DTM, ccc, a*hh<CR><LF>

Country sub-division code

W72 - WGS 72, W84 - WGS 84,

IHO - datum code,

999 - user defined

ETL - Engine telegraph operation status

The ETL sentence indicates engine telegraph position including operating location and

sub-telegraph indicator.

$xxETL, hhmmss.ss, a, xx, xx, a, x, *hh<cr><lf>

0 1 2 3 4 5 6 7

0) Header

1) Event Time

2) Indicator of command

O = Order

A = Answerback

3) Position indication of engine telepgraph

00 = Stop engine

01 = [AH] Dead Slow

02 = [AH] Slow

03 = [AH] Half

04 = Full

05 = [AH] Nav. Full

11 = [AS] Dead Slow

12 = [AS] Slow

13 = [AS] Half

14 = [AS] Fulll

15 = [AS] Crash Astern

4) Position indication of sub telegraph

20 = S/B (Stand-by engine)

30 = F/A (Full away – Navigation full)

40 = F/E (Finish with engine)

5) Operating location indicator

B = Bridge

P = Port wing 1

S = Starboard wing 1

C = Engine control room

E = Engine side

6) Number of engine or propeller shaft

0 = single or on centre-line

Odd = starboard

Even = port

7) Checksum

27

Page 38

FIR - Fire detection (PAS 102)

0

$

>

1 2 3 4 5 6 7 8 9 10

xxFIR, A, hhmmss.ss, aa, xx, xxx, xxx, A, A, c--c, *hh<CR><LF

0: Header 1: message type 3: System indicator of fire detection 4: Division indicator of

door allocation (1) 5: Division indicator of door allocation (2) 6: Fire detector number or

activation detection number count 7. Condition 8: Alarm’s acknowledge state 9: Alarm’s

description text 10: Check-sum

GEN - Generic status information

This sentence provides a means of transmitting multi-sensor generic status information from

any source, in a format that can be registered by the VDR. The sentence is designed for

efficient use of the bandwidth and must be accompanied with a description of how to interpret

the information. Each sentence holds a base address for all status groups. Each group is

assigned a 16-bit address. Up to eight contiguous groups with increasing address may be

transmitted in a single sentence. Data is blocked in 16-bit groups. Unused bits shall be

assigned a fixed value to simplify data compression.

A separate configuration with interpretation of bit equal to "1" and "0" for all sentence groups

and bit positions that are used, must be provided as this information is not included in the

sentence. It is the responsibility of the talker to provide this information.

$xxGEN, hhhh, hhmmss.ss, hhhh[,hhhh], *hh<cr><lf>

0 1 2 3 4

0) Header

1) Address of first group in sentence

Address of first group in GEN sentence. Address is represented in hexadecimal format in range

0x0000 through 0xFFFF.

The 16-bit address is formatted as fixed 4-character HEX field.

2) Time stamp

Time when status was valid.

3) Packed generic status group

The packed generic status group is represented as a 6-bit value.

The 16-bit value is formatted as fixed 4-character HEX field.

4) Optional repeat of field 3

Optional repeated packed generic status field. Each repeat increases the status address by one.

Up to seven repetitions yielding a total of 128 status bits per sentence is possible.

hh = Check sum

28

Page 39

GNS - GNSS fix data

Fix data for single or combined satellite navigation systems (GNSS).

$--GNS,hhmmss.ss,llll.lll,a,yyyyy.yyy,a,c--c,xx,x.x,x.x,x.x,x.x,x.x*hh<CR><LF>

| | | | | | | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | +------ 10

| | | | | | | | | | +---------- 9

| | | | | | | | | +-------------- 8

| | | | | | | | +------------------ 7

| | | | | | | +---------------------- 6

| | | | | | +------------------------- 5

| | | | | +------------------------------ 4

| | | +-------+--------------------------------- 3

| +---+--------------------------------------------- 2

+------------------------------------------------------------- 1

1. UTC of position

2. Latitude, N/S

3. Longitude, E/W

4. Mode indicator

5. Total number of satllite in use,00-99

6. HDOP

7. Antenna altitude, metres, re:mean-sea-level(geoid)

8. Geoidal separation

9. Age of differential data

10. Differential reference station ID

11. Checksum

HDG - Heading Magnetic

$--HDG,x.x,x.x,a,x.x,a*hh<CR><LF>

| | | | | |

| | | | | +--------- 4

| | | +--+----------- 3

| +----+----------------- 2

+------------------------ 1

1. Magnetic sensor heading, degrees

2. Magnetic deviation, degrees E/W

3. Magnetic variation, degrees E/W

4. Checksum

HDT - Heading True

$--HDT, x.x, T*hh<CR><LF>

$--HDT,x.x,T*hh<CR><LF>

| | |

| | +--------- 2

+----+----------- 1

1. Heading, degrees true

2. Checksum

29

Page 40

HSS - Hull stress surveillance systems (PAS 102)

0

$

1 2 3 4

xxHSS, c--c, x.x, A, *hh<cr><lf>

0: Header 1: Measurement point ID 2: Measurement value

3: Data status, A = data valid, V = data invalid 4: Check-sum

Note: This must be verified by Ship Classification. VDR is required to log such data if HSS is fitted

on ship.

HTC - Heading/Track control command

$--HTC,A,x.x,a,a,a,x.x,x.x,x.x,x.x,x.x,x.x,x.x,a*hh<CR><LF>

| | | | | | | | | | | | | |

| | | | | | | | | | | | | +--- 14

| | | | | | | | | | | | +----- 13

| | | | | | | | | | | +-------- 12

| | | | | | | | | | +------------ 11

| | | | | | | | | +---------------- 10

| | | | | | | | +-------------------- 9

| | | | | | | +------------------------ 8

| | | | | | +---------------------------- 7

| | | | | +-------------------------------- 6

| | | | +----------------------------------- 5

| | | +------------------------------------- 4

| | +--------------------------------------- 3

| +------------------------------------------ 2

+--------------------------------------------- 1

1. Override, A = in use, V = not in use

2. Commanded rudder angle, degrees

3. Commanded rudder direction, L/R = port/starboard

4. Selected steering mode

5. Turn mode R = radius controlled

T = turn rate controlled

N = turn is not controlled

6. Commanded rudder limit, degrees(unsigned)

7. Commanded off-heading limit, degrees(unsigned)

8. Commanded radius of turn for heading changes, n.miles

9. Commanded rate of turn to heading changes, deg/min

10. Commanded heading-to-steer, degrees

11. Commanded off-track limit, n.miles(unsigned)

12. Commanded track, degrees

13. Heading reference in use, T/M

14. Checksum

30

Page 41

HTD - Heading/Track control data

$--HTD,A,x.x,a,a,a,x.x,x.x,x.x,x.x,x.x,x.x,x.x,a,A,A,A,x.x*hh<CR><LF>

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | +--- 18

| | | | | | | | | | | | | | | | +------ 17

| | | | | | | | | | | | | | | +--------- 16

| | | | | | | | | | | | | | +----------- 15

| | | | | | | | | | | | | +------------- 14

| | | | | | | | | | | | +--------------- 13

| | | | | | | | | | | +------------------ 12

| | | | | | | | | | +---------------------- 11

| | | | | | | | | +-------------------------- 10

| | | | | | | | +------------------------------ 9

| | | | | | | +---------------------------------- 8

| | | | | | +-------------------------------------- 7

| | | | | +------------------------------------------ 6

| | | | +--------------------------------------------- 5

| | | +----------------------------------------------- 4

| | +------------------------------------------------- 3

| +---------------------------------------------------- 2

+------------------------------------------------------- 1

1. Override, A = in use, V = not in use

2. Commanded rudder angle, degrees

3. Commanded rudder direction, L/R = port/starboard

4. Selected steering mode

5. Turn mode R = radius controlled

T = turn rate controlled

N = turn is not controlled

6. Commanded rudder limit, degrees(unsigned)

7. Commanded off-heading limit, degrees(unsigned)

8. Commanded radius of turn for heading changes, n.miles

9. Commanded rate of turn to heading changes, deg/min

10. Commanded heading-to-steer, degrees

11. Commanded off-track limit, n.miles(unsigned)

12. Commanded track, degrees

13. Heading reference in use, T/M

14. Rudder status A = within limits, V = limit reached or exceeded

15. Off-heading status A = within limits, V = limit reached or exceeded

16. Off-track status A = within limits, V = limit reached or exceeded

17. Vessel heading, degrees

18. Checksum

31

Page 42

MWV - Wind speed and angle (PAS 102)

When the reference field is set to relative, data is provided giving the wind angle in relation to the

vessel’s heading and wind speed, both relative to the moving vessel.

When the reference field is set to true, data is provided giving the wind angle relative to the

vessel’s heading and wind speed, both with reference to the moving water. True wind is the

vector sum of the relative apparent wind vector and the vessel’s velocity vector along the heading

line of the vessel. If represents the wind at the vessel if it were stationary relative to the water and

heading in the same direction.

$--MWV,x.x,a,x.x,a,A*hh<CR><LF>

| | | | | |

| | | | | +--------- 6

| | | | +----------- 5

| | | +------------- 4

| | +---------------- 3

| +------------------- 2

+---------------------- 1

1. Wind angle, 0 to 359 (degrees)

2. Reference, R=relative, T=true

3. Wind speed

4. Wind speed units, K/M/N

5. Status, A=data valid, V=data invalid

6. Checksum

PRC - Propulsion remote control status

This sentence indicates the engine control status (engine order) on a M/E remote control

system. This provides the detail data not available from the engine telegraph.

$xxPRC, x.x, A, x.x, A, x.x, A, x, *hh<cr><lf>

0 1 2 3 4 5 6 7 8

0) Header

1) Lever demand position

-100 - 0 - 100% from "full astern" (crash astern) to "full ahead" (navigation full) "stop engine"

2) Data status

A = data valid

V = data invalid

3) RPM demand

4) Data status

R = relative (%): 0-100% from zero to maximum rpm

T = true (rpm): "-"Astern

V = data invalid

5) Pitch demand

6) Data status

R = relative (%): -100 - 0 - 100% from "full astern" (crash astern) to "full ahead" (navigation full) "stop engine"

T = true (degree): "-"Astern

V = data invalid

7) Number egine or propeller shaft

0 = single or on centre-line

Odd = starboard

Even = port

8) Checksum

32

Page 43

RPM - Revolutions (PAS 102)

Shaft or engine revolution rate and propeller pitch.

$--RPM, a, x, x.x, x.x, A*hh<CR><LF>

Status: A = data valid

Propeller pitch, % of maximum, “-” = astern

Speed, revolutions/min, “-” = count er-clockwise

Engine of shaft number, numbered from center-line

Odd = starboard, even = port, 0 = single or no center-line

Source, shaft/engine S/E

RSA - Rudder sensor angle

$--RSA, x.x, A, x.x, A*hh<CR><LF>

Port rudder sensor ( s ee note), Status: A = data valid

Starboard (or single) rudder sensor (see note), Status: A = data valid

NOTE - Relative measurement of rudder angle without units, “-” = turn to port. Sensor output is

proportional to rudder angle but not necessarily 1 : 1.

TRC - Thruster control data

This sentence provides the control data for thruster devices

$xxTRC, x, x.x, A, x.x, A, x.x, *hh<cr><lf>

0 1 2 3 4 5 6 7

0) Header

1) Number of thrusters

Odd = Bow thruster

Even = Stern thruster

2) RPM demand

3) Data status

R = relative (%): 0-100% from zero to maximum rpm

T = true (deg) V = data invalid

4) Pitch demand value

"-" port

5) Data status

R = relative (%)

T = True (deg)

V = Data invalid

6) Azimuth demand

Direction of thrust in degrees (0 deg - 360 deg)

for thrusters capable of rotating direction of thrust

7) Checksum

33

Page 44

TRD - Thruster response data

This sentence provides the response data for thruster devices.

$xxTRD, x, x.x, A, x.x, A, x.x, *hh<cr><lf>

0 1 2 3 4 5 6 7

0) Header

1) Number of thrusters

Odd = Bow thruster

Even = Stern thruster

2) RPM demand

3) Data status

R = relative (%): 0-100% from zero to maximum rpm

T = true (deg) V = data invalid

4) Pitch response value

"-" port

5) Data status

R = relative (%)

T = True (deg)

V = Data invalid

6) Azimuth demand

Direction of thrust in degrees (0 deg - 360 deg)

for thrusters capable of rotating direction of thrust

7) Checksum

VBW - Dual ground/water speed: This sentence to be expanded as shown below:

$--VBW,x.x,x.x,A,x.x,x.x,A,x.x,A,x.x,A*hh<CR><LF>

| | | | | | | | | | |

| | | | | | | | | | +--- 11

| | | | | | | | | +----- 10

| | | | | | | | +-------- 9

| | | | | | | +----------- 8

| | | | | | +-------------- 7

| | | | | +----------------- 6

| | | | +-------------------- 5

| | | +------------------------ 4

| | +--------------------------- 3

| +------------------------------ 2

+---------------------------------- 1

1. Longitudial water speed, knots

2. Transverse water speed, knots

3. Status: water speed, A=data valid V=data invalid

4. Longitudial ground speed, knots

5. Transverse ground speed, knots

6. Status: ground speed, A=data valid V=data invalid

7. Stern transverse water speed, knots

8. Status: stern water speed, A=data valid V=data invalid

9. Stern transverse ground speed, knots

10. Status: stern ground speed, A=data valid V=data invalid

11. Checksum

34

Page 45

VDM - UAIS VHF Data-link Message (IEC 61162-2, for AIS)

!--VDM,x,x,x,x,s--s,x*hh<CR><LF>

| | | | | | |

| | | | | | +--- 7

| | | | | +----- 6

| | | | +-------- 5

| | | +------------ 4

| | +-------------- 3

| +---------------- 2

+------------------ 1

1. Total number of sentences needed to transfer the message, 1 to 9

2. Message sentence number, 1 to 9

3. Sequential message identifier, 0 to 9

4. AIS channel Number

5. Encapsulated ITU-R M.1371 radio message

6. Number of fill-bits, 0 to 5

7. Checksum

VDO - UAIS VHF Data-link Own-vessel report (IEC 61162-2, for AIS)

!--VDO,x,x,x,x,s--s,x*hh<CR><LF>

| | | | | | |

| | | | | | +--- 7

| | | | | +----- 6

| | | | +-------- 5

| | | +------------ 4

| | +-------------- 3

| +---------------- 2

+------------------ 1

1. Total number of sentences needed to transfer the message, 1 to 9

2. Message sentence number, 1 to 9

3. Sequential message identifier, 0 to 9

4. AIS channel Number

5. Encapsulated ITU-R M.1371 radio message

6. Number of fill-bits, 0 to 5

7. Checksum

35

Page 46

WAT - Water level detection (PAS 102)

This sentence provides detection status of water leakage and bilge water level, with monitoring

location data. Malfunction alarm of the water level detector should be included in the “ALA”

sentence.

$xxWAT, A, hhmmss.ss, aa, aa, xx, xxx, A, c—c, *hh<cr><lf>

0 1 2 3 4 5 6 7 8 9

0) Header

1) Message type

S: Status for section: Number of faulty and activated condition reported as number in field 4.

The section may be a whole section (one or both of the division indicators are empty) or a

sub-section. (If S is used then it shall be transmitted at regular intervals)

E: Status for each water level detector. (E may be used to indicate an event.)

F: Fault in system: If limited to one section, indicated by division indicator fields, if not, division

indicators [empty]. (F may be used to indicate an event).

2) Time stamp

Time when this status/message was valid.

3) System indicator of alarm source

Indicator characters showing system detecting water level. The field is two characters.

4) Location (1)

Indicator characters showing detection location. The field is two characters.

5) Location (2)

Indicator characters showing detection location. The field is two characters.

6) Number of detection point or detection point number

Number showing high-water-level detecting point or the number of the water leakage

detection point. This field is three fixed numeric characters.

7) Alarm condition

This field is a single character specified by the following:

N = normal state

H = alarm state (threshold exceeded)

J = alarm state (extreme threshold exceeded)

L = alarm state (Low threshold exceeded i.e. not reached)

K = alarm state(extreme low threshold exceeded i.e. not reached)

X = Fault (state unknown)

When S status indicated in 2nd field, this field is ignored

8) Descriptive text

Additional and optional descriptive text/level detector tag.

9) Checksum

36

Page 47

XDR - Transducer measurements

Measurement data from transducers that measure physical quantities such as temperature, force,

pressure, frequency, angular or linear displacement, etc. Data from a variable number of

transducers measuring the same of different quantities can be mixed in the same sentence. This

sentence is designed for use by integrated systems as well as transducers that may be

connected in a “chain” where each transducer receives the sentence as an input and adds its own