Page 1

OPERATOR'S MANUAL

取扱説明書

MONITOR UNIT

表示部

MODEL

MU-190

www.furuno.com

Page 2

(Elemental Chlorine Free)

The paper used in this manual

is

elemental chlorine free.

・ 機器の修理・使用方法等に関するお問い合わせは、お買い上げの販売店・代理店、最寄りの

当社支店・営業所あてへお願いします。

・

FURUNO Authorized Distributor/Dealer お問い合わせは

本書の無断複写複製(コピー)は特定の

場合を除き、当社権利侵害になります。

Printed in Japan

Pub. No. OMC-44670-A1

( YOTA) MU-190

A

: M AY 2011

A1

: JUL. 5, 2011

Page 3

IMPORTANT NOTICES

General

• This manual has been authored with simplified grammar, to meet the needs of international users.

• The operator of this equipment must read and follow the descriptions in this manual. Wrong operation or maintenance can cancel the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens

you see on your display. The screens you see depend on your system configuration and equipment settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO

will cancel the warranty.

• All brand and product names are trademarks, registered trademarks or service marks of their

respective holders.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For disposal

in the USA, see the homepage of the Electronics Industries Alliance (http://www.eiae.org/) for the

correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery, see the chapter

on Maintenance. Follow the instructions below if a battery is used. Tape the + and - terminals of

battery before disposal to prevent fire, heat generation caused by short circuit.

In the European Union

The crossed-out trash can symbol indicates that all types of batteries

must not be discarded in standard trash, or at a trash site. Take the

used batteries to a battery collection site according to your national

legislation and the Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd

and lead-acid rechargeable batteries must be recycled. Take the used

batteries to a battery collection site according to local laws.

In the other countries

Ni-Cd Pb

Cd

There are no international standards for the battery recycle symbol. The number of symbols can

increase when the other countries make their own recycle symbols in the future.

i

Page 4

WARNING

WARNING

CAUTION

SAFETY INSTRUCTIONS

Read these safety instructions before you operate the equipment.

WARNING

CAUTION

Warning, Caution

Indicates a condition that can cause death or serious

injury if not avoided.

Indicates a condition that can cause minor or moderate

injury if not avoided.

Prohibitive Action

Safety Instructions for the Operator

WARNING

Immediately turn off the power at the

switchboard if water leaks into the

equipment or something is dropped

into the equipment.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Immediately turn off the power at the

switchboard if the equipment is

emitting smoke or fire.

Continued use of the equipment can

cause fire or electrical shock. Contact a

FURUNO agent for service.

WARNING

Use the proper fuse.

Use of a wrong fuse can cause fire or

damage to the equipment.

Do not place any object near the

exhaust or intake vent.

Fire may result.

Do not connect/disconnect the signal

cable while turning the power on.

CAUTION

Mandatory Action

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury

can result.

Turn off the power immediately if you

feel the equipment is behaving

abnormally.

Turn off the power at the switchboard if

the equipment becomes abnormally

warm or is emitting odd noises. Contact

a FURUNO dealer or agent for advice.

The unit may be damaged.

Handle the LCD monitor with care.

The face of the LCD monitor is made

of glass.

glass breaks.

ii

Injury may result if the

Page 5

Safety Instructions for the Installer

WARNING

CAUTION

About the TFT LCD

SAFETY INSTRUCTIONS

WARNING

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can result in fire,

electrical shock or damage to the

equipment.

About the TFT LCD

About the TFT LCD

The TFT LCD is constructed using the latest LCD techniques, and displays

99.99% of its pixels. The remaining 0.01% of the pixels may drop out or

blink, however this is not an indication of malfunction.

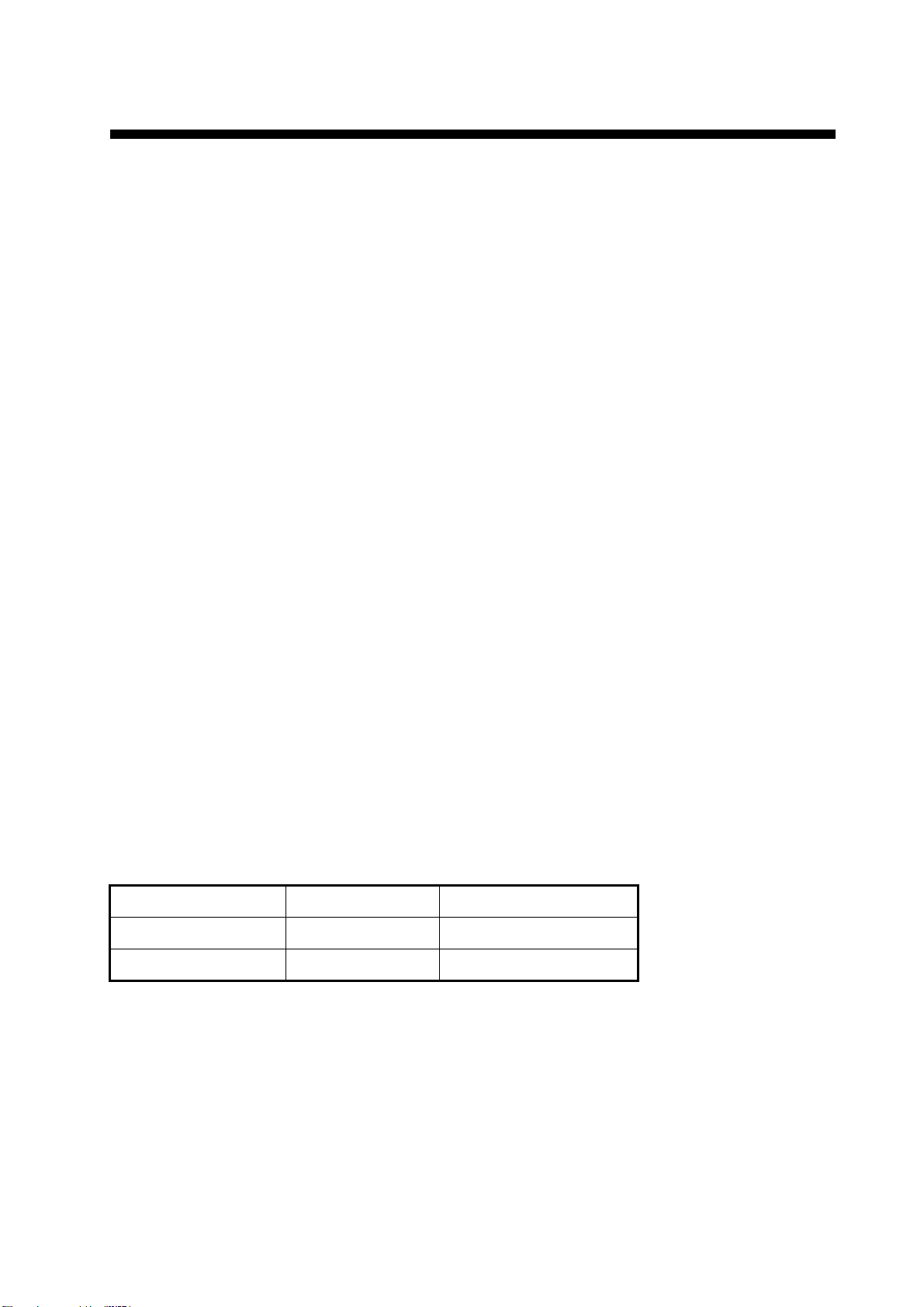

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

CAUTION

Standard

compass

MU-190

1.65 m 1.05 m

Steering

compass

iii

Page 6

TABLE OF CONTENTS

Note: This manual contains both English and Japanese instructions. The Installation

Materials, Outline Drawings, and Interconnection Diagram are located at the back of this

manual.

FOREWORD ................................................................................................................. v

SYSTEM CONFIGURATION ....................................................................................... vi

EQUIPMENT LISTS.................................................................................................... vii

1. MOUNTING, WIRING............................................................................................. 1

1.1 Preparation................................................................................................................. 1

1.2 Flush Mount, Fixed at Front ....................................................................................... 2

1.3 Flush Mount, Fixed at Front, with Hood ..................................................................... 3

1.4 Flush Mount, Fixed at Rear........................................................................................ 5

1.5 Flush Mount, Fixed at Rear, with Hood...................................................................... 7

1.6 Tabletop Mount .......................................................................................................... 8

1.7 Flush Mount a Series Side by Side.......................................................................... 10

1.8 Wiring .......................................................................................................................11

2. ADJUSTMENTS................................................................................................... 12

2.1 Installation Settings .................................................................................................. 12

2.2 RGB/DVI Setting (For Non-SOLAS)......................................................................... 14

2.3 Video Composite Signal Setting (For Non-SOLAS)................................................. 16

2.4 The Menu Window Setting (For Non-SOLAS) ......................................................... 17

2.4.1 How to adjust the menu window ....................................................................... 17

2.4.2 How to change the signal name ....................................................................... 18

3. OPERATION ........................................................................................................ 19

3.1 Controls.................................................................................................................... 19

3.2 How to Turn the Power On/Off................................................................................. 19

3.2.1 Turn the power on/off........................................................................................ 19

3.2.2 Unlock the key operation .................................................................................. 20

3.3 How to Adjust the Display Brilliance......................................................................... 20

3.4 How to Select the Source for Main Picture .............................................................. 21

3.5 How to Display the PIP Window............................................................................... 21

3.6 SYSTEM Menu ........................................................................................................ 21

3.6.1 How to set the auto dimmer .............................................................................. 21

3.6.2 How to clear the memory.................................................................................. 22

4. MAINTENANCE, TROUBLESHOOTING............................................................. 23

4.1 Maintenance............................................................................................................. 23

4.2 Troubleshooting ....................................................................................................... 24

4.3 Parts Location and Parts List ................................................................................... 24

SPECIFICATIONS .................................................................................................. SP-1

INSTALLATION MATERIALS .................................................................................. A-1

OUTLINE DRAWINGS.............................................................................................. D-1

INTERCONNECTION DIAGRAM ..............................................................................S-1

Declaration of Conformity

iv

Page 7

FOREWORD

A Word to the Owner of the MU-190

FURUNO Electric Company thanks you for purchasing the MU-190 19” Monitor Unit. We are confident you will discover why the FURUNO name has become synonymous with quality and reliability.

For over 60 years FURUNO Electric Company has enjoyed an enviable reputation for quality and

reliability throughout the world. This dedication to excellence is furthered by our extensive global

network of agents and dealers.

Your equipment is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless properly installed and

maintained. Please carefully read and follow the operation, installation and maintenance procedures set forth in this manual.

We would appreciate feedback from you, the end-user, about whether we are achieving our purposes.

Thank you for considering and purchasing FURUNO.

Features

The main features of the MU-190 are as shown below.

• Selectable screen from RGB (1 port), Digital (2 ports) or Composite (1 port).

• Main or remote display for radars, video sounders, sonars, plotter. For the connectable equipment, see the SYSTEM CONFIGURATION on page vi.

• High resolution display of 1280 x 1024 (SXGA)

• Automatic brilliance adjustment by the light sensor.

• Picture-in-picture function

• Power on/off automatically through the DVI signal.

Program

Program Name Version Date of Change

APR PROGRAM 2651020-01.xx May. 2011

FPGA PROGRAM 2651021-01.xx May. 2011

xx: minor change

You can see these program numbers on the [SYSTEM] menu (see section 3.6). To open the

[SYSTEM] menu, unlock the key operation (see paragraph 3.2.2).

Note: When you connect the monitor unit to FAR-21x7 series, FEA-2107 or FCR-21x7 series, lock

the key operation (see paragraph 3.2.2) after confirming the program numbers.

v

Page 8

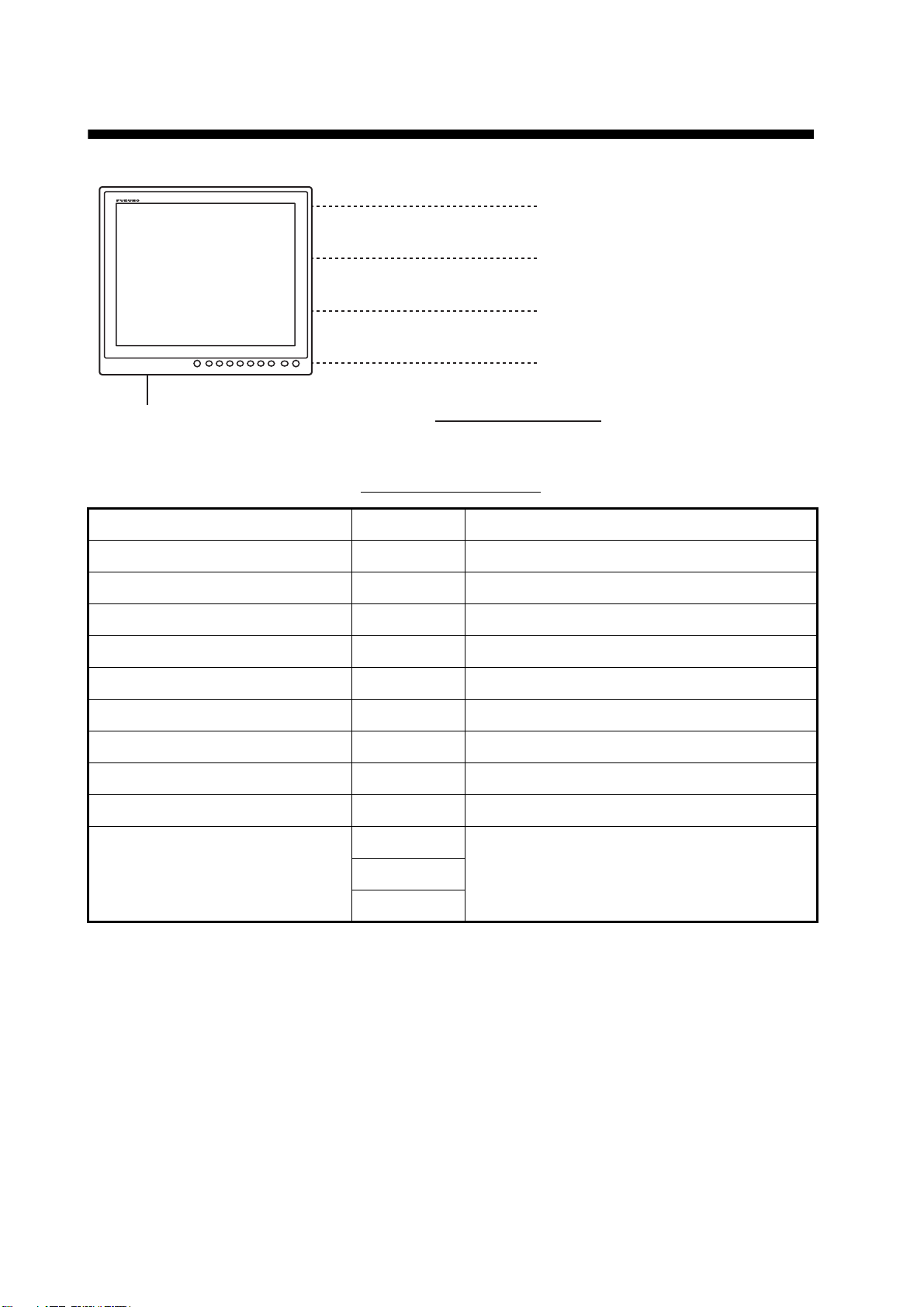

SYSTEM CONFIGURATION

100-230 VAC

MONITOR UNIT

MU-190

RGB

DVI (2 ports)

VIDEO (NTSC/PAL)

RS-232C

Environmental category

MU-190: Protected from the weather

FSV-30/30S, etc.

FAR-21x7, FEA-2107, FCR-21x7, etc.

CCD camera, DVD recorder, etc.

FEA-2107, FCR-21x7, etc.

Connectable equipment

Equipment Resolution Signal

FCV-1200L/1200LM VGA* Analog RGB, via IF-8000

FSV-24/24S SXGA Analog RGB

FSV-30/30S SXGA Analog RGB

FSV-84/84L SXGA Analog RGB

FSV-85/85L SXGA Analog RGB

FCV-30 SXGA Analog RGB

FAR-21x7 SXGA DVI

FEA-2107 SXGA DVI

FCR-21x7 SXGA DVI

SVGA*

MFDBB (NAVnet 3D)

SXGA

DVIXGA*

Note 1: Landscape orientation only.

Note 2: *: When inputting VGA, SVGA or XGA, a circle may be displayed as an ellipse because

the aspect ratio differs (see "DISP MODE*" on page 15).

vi

Page 9

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Monitor Unit MU-190 - 1

Installation

Materials

Accessories FP26-00401 001-080-780 1 set LCD Cleaning Cloth (19-028-3125,

Spare Parts SP26-00501 001-116-240 1 set Glass Tube Fuse (FGBO 250V 1A PBF,

Optional supply

Name Type Code No. Qty Remarks

Cable Assembly 3COX-2P-6C 5M001-077-230-10 1 Cable length: 5 m (15 pin D-sub

Bracket Assembly

(w/knobs)

Hood Assembly OP26-6 001-080-930 1 set

Dust Cover 26-007-1201 001-116-260-10 1

Flush Mount Kit OP26-12 001-116-280 1 set • Flush Mounting Sponge H 19

CP26-01600 000-019-210 1 set • Installation Materials (CP26-01601, Code

No.: 001-116-250, See page A-1.)

• Cable Assembly (DVI-D/D S-LINK 5M,

Code No.: 001-132-960-10)

Code No.: 100-360-671-10)

Code No.: 000-155-828-10) 3 pcs.

connector at both ends)

3COX-2P-6C

10M

DVI-D/D

S-LINK 5M

DVI-D/D

S-LINK 10M

OP26-5 000-016-270 1 set

OP26-13

(Two units

installed side

by side)

OP26-14

(Three units

installed side

by side)

001-077-220-10 1 Cable length: 10 m (15 pin

D-sub connector at both ends)

001-132-960-10 1 Cable length: 5 m

(with DVI-D connector at both

ends)

001-133-980-10 1 Cable length: 10 m

(with DVI-D connector at both

ends)

001-116-290 1 set

001-116-300 1 set

(26-005-3123, Code No.:

100-351-550-10)

• Flush Mounting Sponge V 19

(26-005-3124, Code No.:

100-351-560-10)

• Washer Head Screw B

(M4x10, Code No.: 000-163836-10)

• Flush Mount Fixture 19

(CP26-01401, Code No.: 001080-890)

Note: The quantity of each part

depends on the number of units

connected.

Connection Stand (19) OP26-20 001-139-300 1 set

Bracket Assembly OP26-21 001-139-310 1 set

Hood (19) Assembly OP26-24 001-139-370 1 set

Monitor Replacement

Kit

OP26-22 001-139-320 1 For flush mount

OP26-23 001-139-360 1 For tabletop mount

OP26-26 001-139-390 1 For hood mount

vii

Page 10

1. MOUNTING, WIRING

1.1 Preparation

Mounting method

You can install the monitor unit as follows. See the outline drawings at the back of this manual for

mounting dimensions.

• Flush mount, fixed at front (standard)

• Flush mount, fixed at front, with hood (option)

• Flush mount, fixed at rear (option)

• Flush mount, fixed at rear, with hood (option)

• Tabletop mount (option, hood-mountable)

• Flush mount a series side by side, fixed at rear

Note 1: The face of the LCD is made of glass. Handle it with care.

Note 2: For flush mount, take care so that the monitor unit does not fall during the installation.

Mounting location

Select a mounting location considering the following points. This equipment is free from electromagnetic fields.

• Make sure the mounting location is strong enough to support the weight of the unit.

• Locate the unit away from direct sunlight. An LCD may darken if it is exposed to direct sunlight

for a long time.

• Select a location where the screen can be easily viewed and the controls can be easily operated.

• Leave enough space around the unit for service and maintenance. See the outline drawings at

the back of this manual for minimum service clearance.

• Locate the unit away from areas subject to water splash and rain.

• Observe the compass safe distances (see page iii) to prevent interference to a magnetic compass.

Run cables before installing the monitor unit

Run all cables before you install the monitor unit. See the interconnection diagram at the back of

this manual.

1

Page 11

1. MOUNTING, WIRING

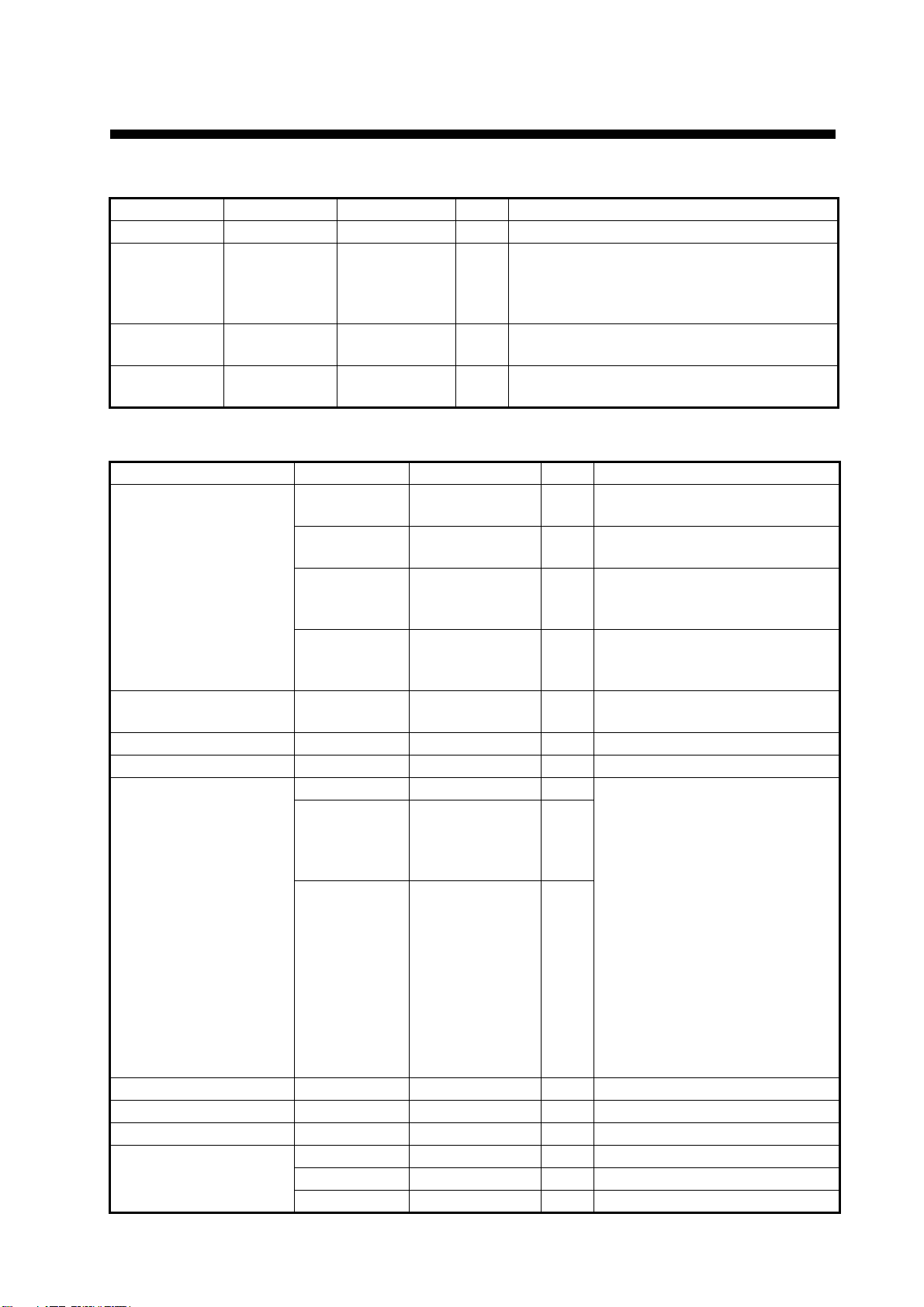

1.2 Flush Mount, Fixed at Front

Flush mount, fix at front is the standard installation method.

1. Use the flush mounting template (supplied) to make a cutout in the mounting location.

2. Attach the flush mounting

sponges H19 and V19 to the

back of the monitor unit in the

order shown in the figure at

right.

3. Attach the flush mount panels 19 to the monitor unit from the rear with the binding head

screws (M4x10, 6 pcs., supplied).

Flush Mounting

Sponge H19 (5 mm)

for top and bottom

Flush Mounting

Sponge V19 (2 mm)

for left and right

Binding Head Screw

Flush Mount Panel 19

Note: Attach the flush mount panels to both sides of the monitor unit with no gap.

4. Connect all cables at the back of the monitor unit. See section 1.8.

5. Set the monitor unit assembly to the cutout.

6. Fix the monitor unit to the cutout with the self-tapping screws (5x20, 4 pcs., supplied).

Self-Tapping Screw

(4 places)

2

Page 12

1. MOUNTING, WIRING

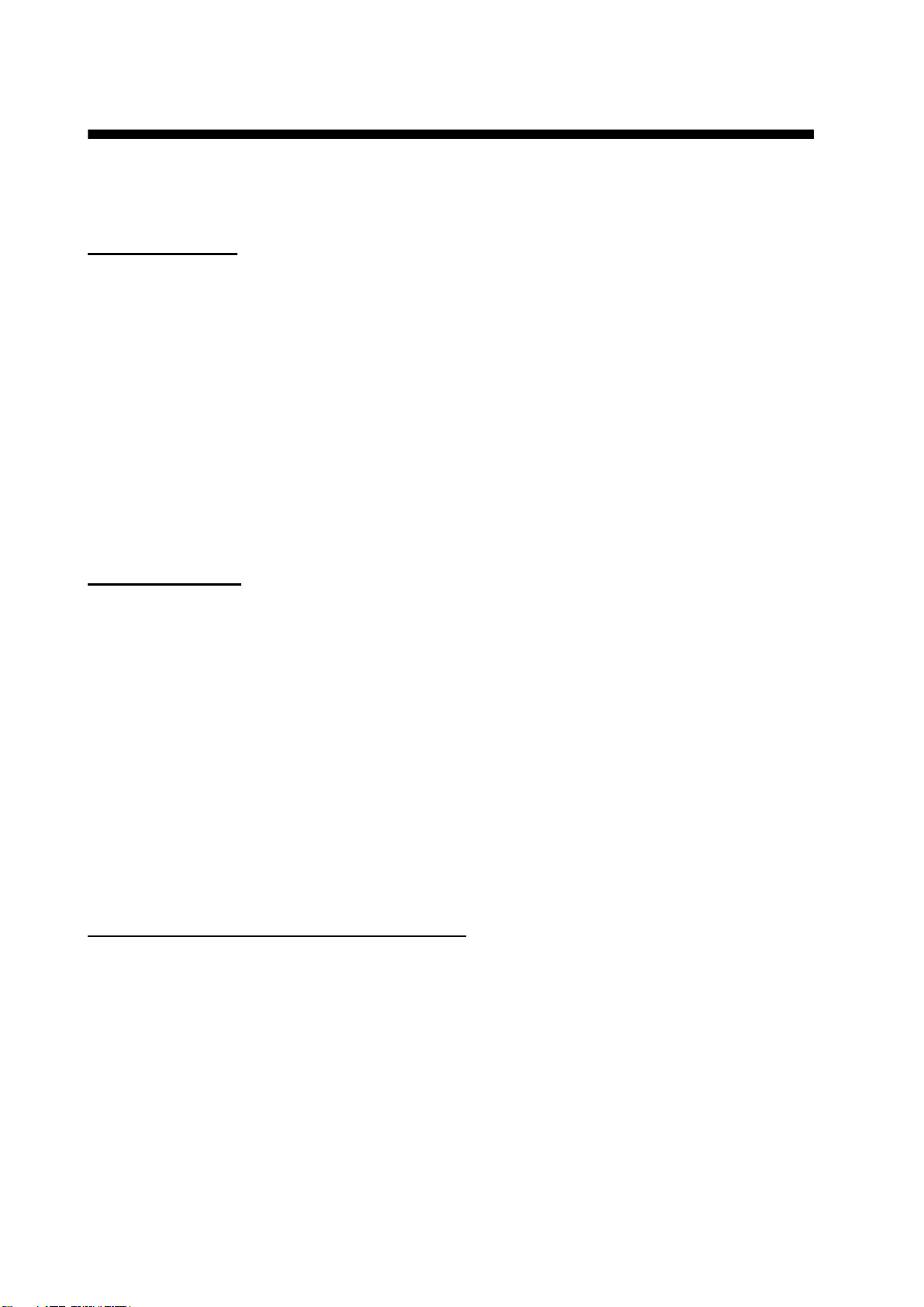

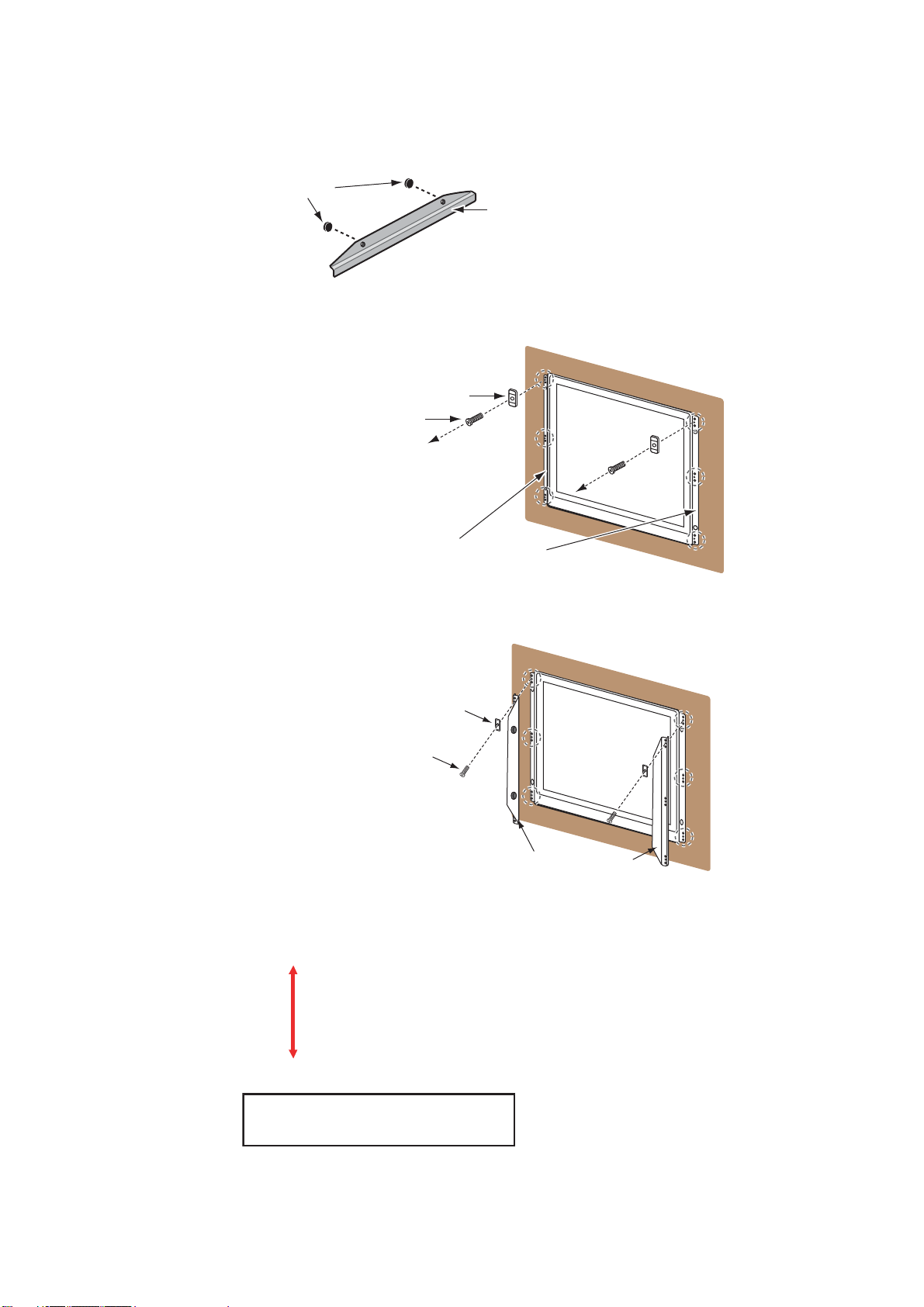

7. Set the masking panel to each side of the monitor unit.

Masking Panel for 19” LCD

How to attach or detach the masking panel for 19” LCD

Do the following to attach or detach the masking panel for 19” LCD.

Reverse view of masking panel for 19” LCD

b

Tab A

Tab B

To attach, follow order of right arrow (→). To detach, follow order of left arrow (←).

Monitor unit

Masking

panel

Set tab B to

the edge of

the monitor

unit.

→→

←

Attach: Push the

masking panel for 19”

LCD in the direction

, rotate the panel

toward the monitor

unit, then set each tab

A one by one (three

places of a, b and c) .

c

Set the masking panel for 19” LCD to each side

of the monitor unit. Attach each tab A to the

monitor unit. Be careful not to break the tabs.

2

1

←

Detach: Push the masking panel for 19”

LCD in the direction 1, then release each

tab A one by one

in the direction 2.

a

Front side of

monitor unit

2

1

(three places of a, b and c)

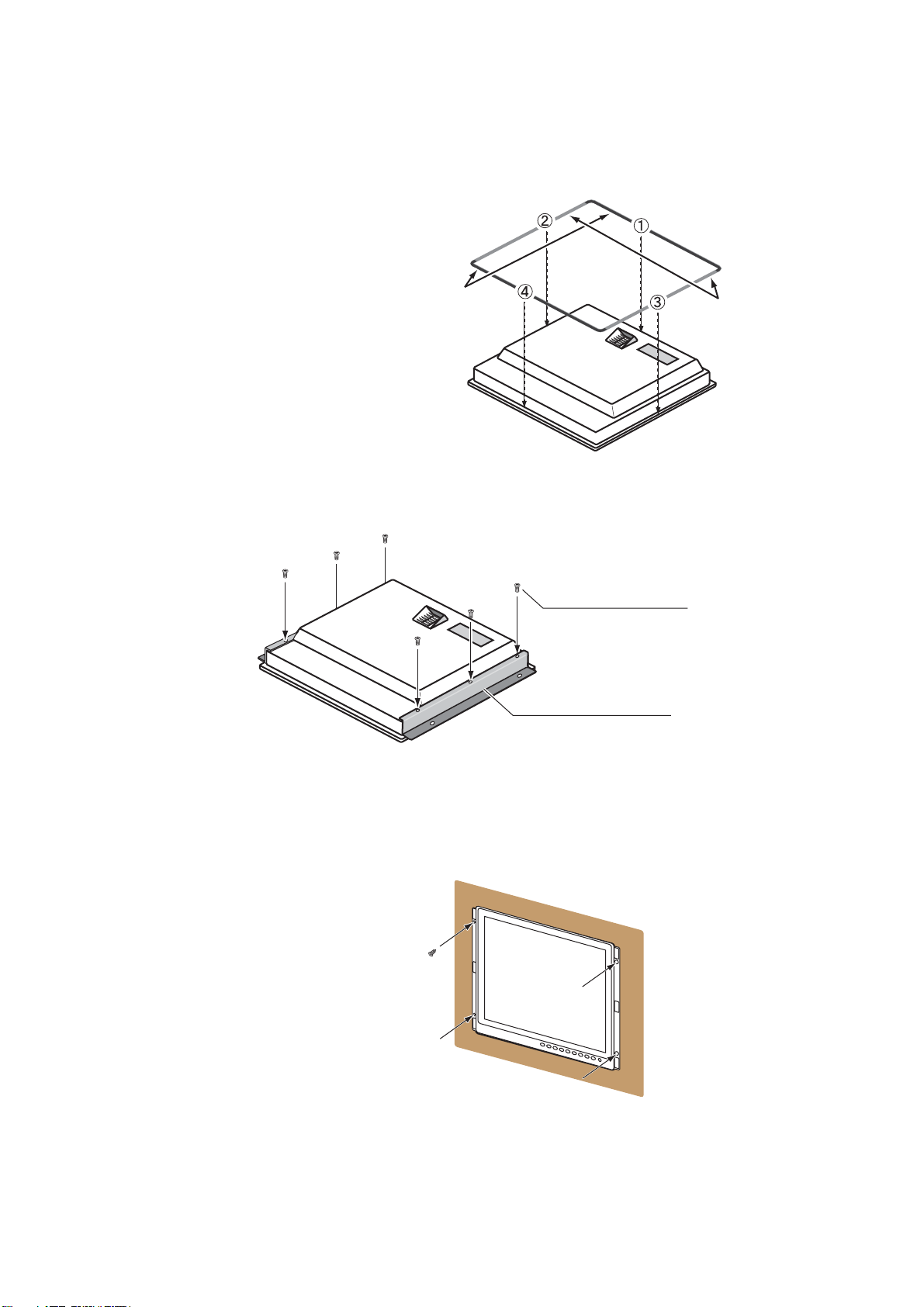

1.3 Flush Mount, Fixed at Front, with Hood

The flush mount, fixed at front method allows you to attach a hood (19) assembly OP26-24 (option) to the monitor unit.

Hood (19) assembly OP26-24 (Code No.: 001-139-370)

Name Type Code No. Qty

Hood (19) Assembly OP26-6-1 001-080-970 1

Knob M4 03-163-2303 100-343-602-10 4

Hood Fixing Plate (19) 26-007-1128 100-366-350-10 2

Binding Head Screw M3x8 000-172-166-10 6

3

Page 13

1. MOUNTING, WIRING

1. Use the flush mounting template (supplied) to make a cutout in the mounting location.

2. Follow steps 2 to 6 in section 1.2.

3. Loosely fix the knobs (4 pcs.) to the hood fixing plates (19) from inside the plates.

Knob

Hood Fixing Plate (19)

4. Remove the binding head screws (M3x5, 6pcs.) and the side panel bases (6 pcs.) from the

flush mount panels 19 attached to the monitor unit.

Side Panel Base (6 pcs.)

Binding Head Screw (6 pcs.)

Flush Mount Panel 19

5. Attach the hood fixing plates (19) and the side panel bases to the right and left sides of the

monitor unit with the binding head screws (M3x8, 6pcs.)

Side Panel Base (6 pcs.)

Binding Head Screw (6 pcs.)

Hood Fixing Plate (19)

6. Press and rub folds on the hood with your hands to make creases clearly. The degree of

creases should be within 90° when the hood is opened.

Hood

Correct

Press and move your hands to

upward and downward several times.

4

Improper

insufficient

Page 14

1. MOUNTING, WIRING

7. Set the cutouts of the hood (19) assembly to the knobs on the hood fixing plates (19).

Knob (4 pcs.)

Hood (19) Assembly

Hood Fixing Plate 19

Cutout (4 places)

8. Press the top of the hood (19) assembly to set the knobs in the cutouts.

Press

Press

9. Set the hood (19) assembly with the knobs tightly (4 pcs.).

1.4 Flush Mount, Fixed at Rear

The flush mount, fixed at rear method requires the flush mount kit OP26-12 (option, see page vii).

1. Use the flush mounting template (supplied) to make a cutout in the mounting location.

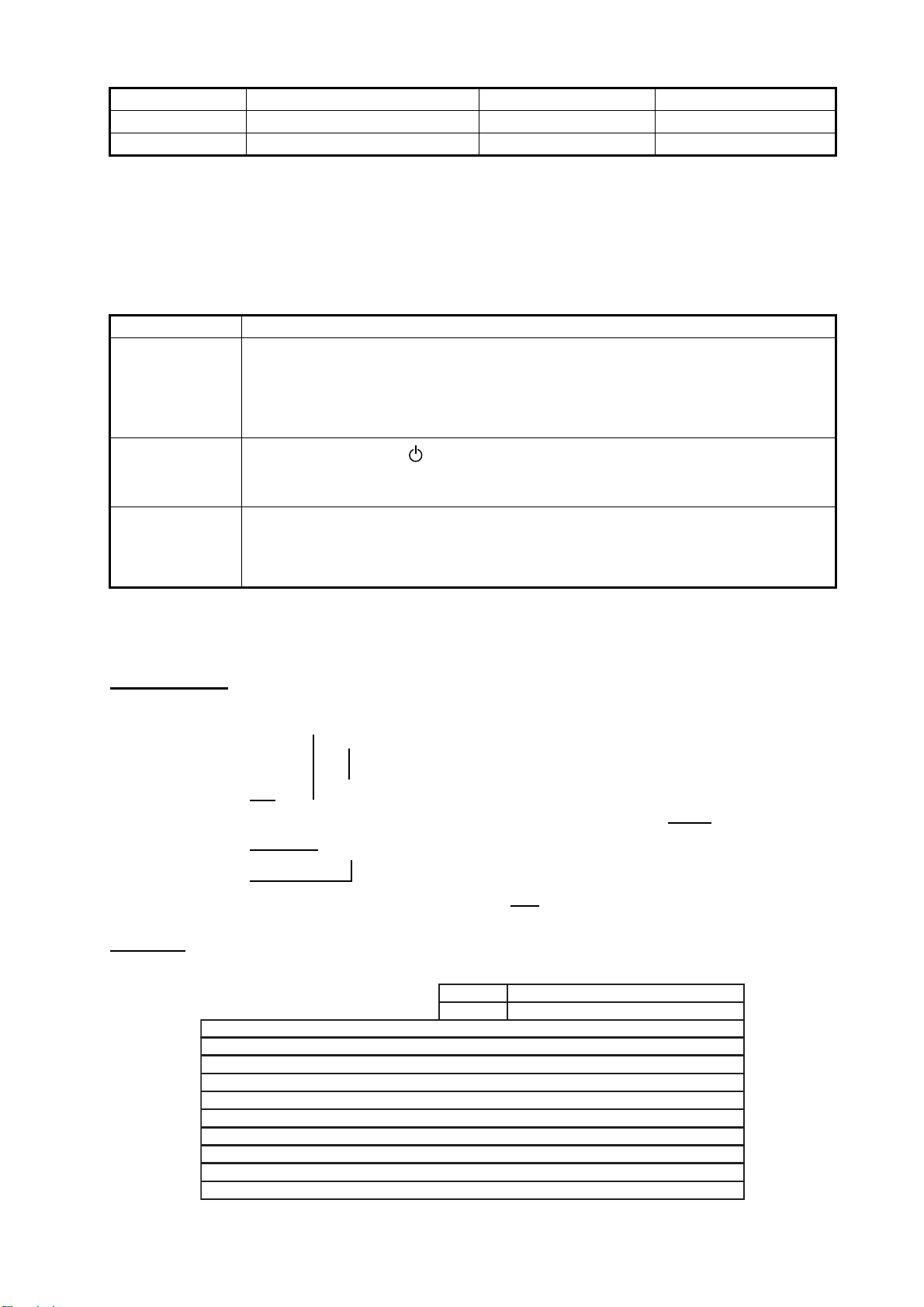

2. Attach the flush mounting sponges

H 19 and V 19 to the back of the

monitor unit in the order shown in

the figure at right.

Flush Mounting

Sponge H 19 for

top and bottom

5

Flush Mounting

Sponge V 19 for

left and right

Page 15

1. MOUNTING, WIRING

3. Screw the wing bolts and the wing nuts of the flush mount fixture 19 so that the protector for

screw moves to the fixing plate.

Wing Bolt

Wing Nut

Fixing Plate

Protector for

Screw

Flush Mount Fixture 19

Move to the fixing plate.

4. Connect all cables at the back of the monitor unit. See section 1.8.

5. Set the monitor unit to the cutout.

6. Fasten the flush mount fixture 19 to the right and left sides of the rear of the monitor unit with

the washer head screws B (6 pcs.).

Washer Head Screw B

(6 places)

Flush Mount Fixture 19

7. Fasten each wing bolt in the order shown in the figure below so that the protector for screw

touches the mounting panel.

8. Fasten the wing bolts tightly to secure the monitor unit.

9. Fasten the wing nuts tightly.

Wing Bolt

Wing Nut

Fixing Plate

Protector for Screw

Mounting

Panel

6

Page 16

1. MOUNTING, WIRING

1.5 Flush Mount, Fixed at Rear, with Hood

The flush mount, fixed at rear method allows you to attach a hood assembly OP26-6 (option) to

the monitor unit.

Hood assembly OP26-6 (Code No.: 001-080-930)

Name Type Code No. Qty

Hood (19) Assembly OP26-6-1 001-080-970 1

Flush Mounting Sponge V 19 26-005-3124 100-351-560-10 2

Hood Fixing Plate 19 26-005-3302 100-351-611-10 2

F-Mount Hood Packing 19 26-005-3305 100-351-620-10 2

Knob M4 03-163-2303 100-343-602-10 4

Flat Head Screw M3x8 000-172-167-10 6

Flush Mounting Template C42-00910 000-172-637-10 1

1. Use the flush mounting template (supplied) to make a cutout in the mounting location.

2. Fix the hood fixing plates 19 to the right and left sides of the monitor unit with the flat head

screws (6 pcs.).

Hood Fixing Plate 19

Flat Head Screw

3. Attach the F-mount hood packing 19 to the top and bottom brims. Then, attach the flush

mounting sponge V 19 to the right and left brims of the monitor unit from the rear side.

F-Mount Hood

Packing 19 for

top and bottom

Flush Mounting

Sponge V 19 for

left and right

4. Follow steps 3 to 9 in section 1.4 to fix the monitor unit to the mounting location.

5. Loosely fix the knobs (4 pcs.) to the hood fixing plate 19 from inside the plate.

7

Page 17

1. MOUNTING, WIRING

6. Set the cutouts of the hood (19) assembly to the knobs on the hood fixing plates 19.

Knob (4 pcs.)

Hood (19) Assembly

Hood Fixing Plate 19

Cutout (4 places)

7. Press the top of the hood assembly to set the knobs in the cutouts.

Press

Press

8. Set the hood assembly with the knobs tightly (4 pcs.).

1.6 Tabletop Mount

You can fix the monitor unit to a tabletop, using the bracket assembly OP26-5 (option).

Bracket Assembly OP26-5 (Code No.: 000-016-270)

Name Type Code No. Qty

Mounting Bracket (19) OP26-5-1 001-080-910 1

Bracket Support w/Knobs OP26-5-2 001-080-920 1

Self-Tapping Screw 5x20 000-162-608-10 4

Binding Head Screw M4x10 000-172-165-10 9

1. Loosen the knobs of the bracket support to separate the mounting bracket (19) from the bracket support.

Mounting Bracket (19)

Bracket Support w/Knobs

Knob

8

Page 18

1. MOUNTING, WIRING

2. Set the mounting bracket to the mounting location with four self-tapping screws.

Self-Tapping Screw

(4 places)

Mounting Bracket (19)

3. Attach the bracket support to the rear of the monitor unit with the binding head screws (9 pcs.).

Bracket Support w/Knobs

Binding Head Screw (9 places)

Binding Head

Screw

Rear view

4. Connect all cables at the back of the monitor unit. See section 1.8.

5. Loosen the knobs of the bracket support and set knobs in the notches on the mounting bracket.

Mounting Bracket (19)

Knob

6. Adjust the angle of the monitor unit and fix the knobs tightly.

How to attach the hood

You can attach a hood to the tabletop-mounted monitor unit, using the hood assembly OP26-6

(option).

1. Follow steps 1 to 3 in section 1.6.

2. Fix the hood fixing plates 19 to the right and left of the monitor unit with the flat head screws

(6 places). (See step 2 in section 1.5.)

3. Follow steps 4 to 5 in section 1.6.

4. Follow steps 5 to 8 in section 1.5.

9

Page 19

1. MOUNTING, WIRING

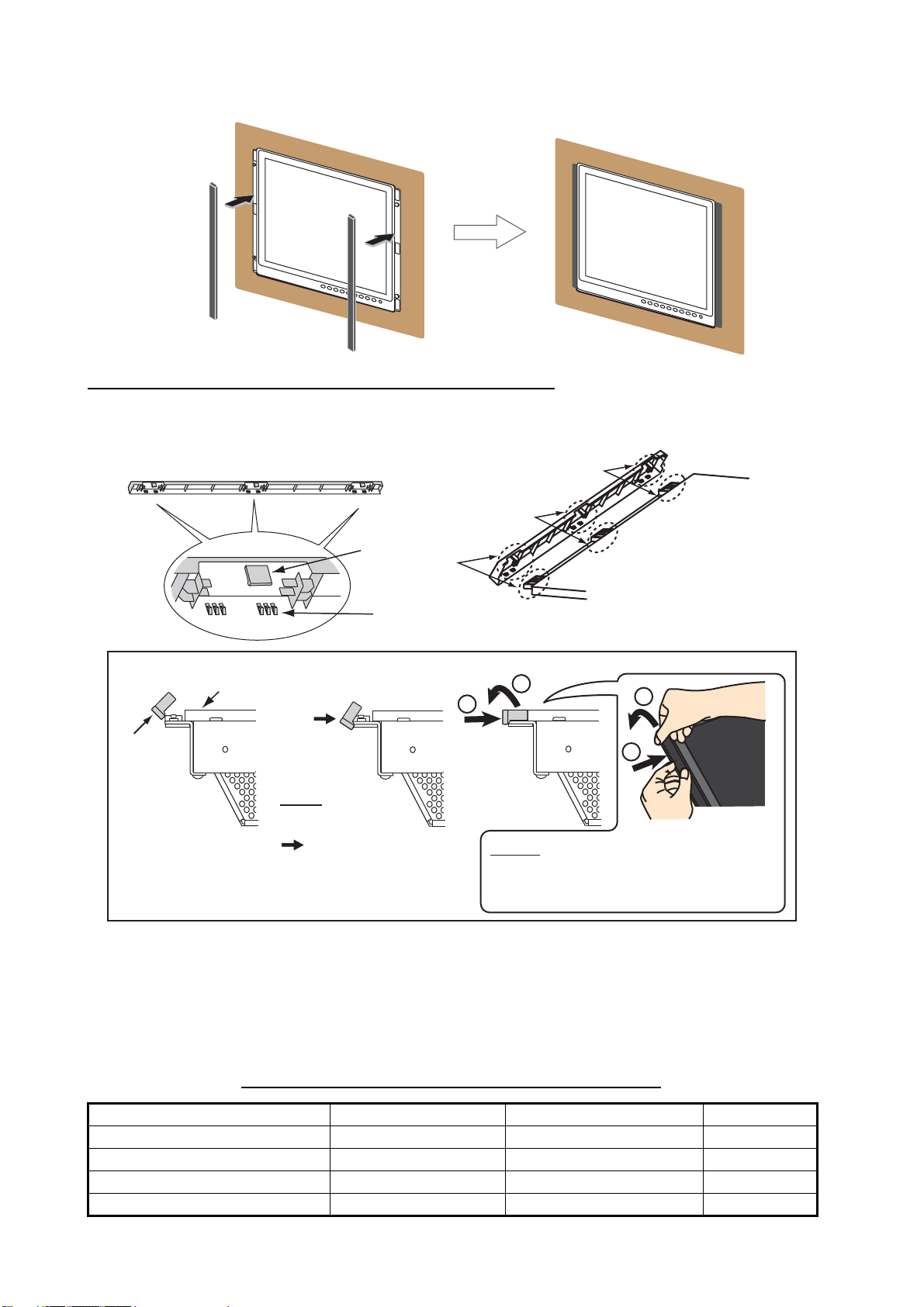

1.7 Flush Mount a Series Side by Side

You can flush mount two or three monitor units side by side, using the optional flush mount kit

OP26-13 for two monitor units or OP26-14 for three monitor units (see page vii).

1. Make a cutout in the mounting location as shown below (see page D-4).

±1

389

892±1

4-Ø18

(9)

(9)

For two monitor units

±1

389

4-Ø18

(9)

(9)

For three monitor units

1342±1

2. Follow steps 2 to 5 in section 1.4 to set the two or three monitor units in the mounting location.

3. Attach the flush mount fixtures 19 with the washer head screws B to join the two or three monitor units.

Join the two monitor units with the

flush mount fixtures 19 (4 pcs.).

Join the three monitor units with the

flush mount fixtures 19 (6 pcs.).

4. Fasten two or three monitor units tightly. See steps 7 to 9 in section 1.4.

10

Page 20

1. MOUNTING, WIRING

FSV-84/84L

FSV-30/S-BB

FSV-24/S-BB

FCV-30

FCV-1200L/M

FAR-21x7

FEA-2107

FCR-21x7

FEA-2107

FCR-21x7

RGB signal

3COX-2P-6C

5 m/10 m (option)

Digital signal

DVI-D/D S-LINK

5 m (standard)/

10 m (option)

Composite

signal cable

CCD camera

DVD recorder

BRILL CTRL

port *

3

BRILL CTRL

port *

3

*

1

IV-8 sq

(local supply) *

1

DPYC-1.5

(or equivalent)

Slide

switch *

2

Slide

switch *

2

RS-232C cable

(Max. 10 m)

1.8 Wiring

Refer to the figure below and the interconnection diagram at the back of this manual to connect

cables.

Connector

Attach the Terminal Board Gear Cover

again after connecting cables.

Power

switch

Fuse

DPYC-1.5

Armor

Sheath

Conductor

S = 1.5 mm

2

φ = 1.56 mm

φ = 11.7 mm

100-230 VAC

The bottom of the rear of the monitor unit

Slide

IV-8 sq

IV-8 sq

(local supply)

(local supply) *

switch *

1

To ground

terminal on hull

RGB signal

RGB signal

3COX-2P-6C

3COX-2P-6C

5 m/10 m (option)

5 m/10 m (option)

DPYC-1.5

DPYC-1.5

(or equivalent)

(or equivalent)

FSV-84/84L

FSV-30/S-BB

FSV-24/S-BB

FCV-30

FCV-1200L/M

Composite

2

Digital signal

Digital signal

DVI-D/D S-LINK

DVI-D/D S-LINK

5 m (standard)/

5 m (standard)/

10 m (option)

10 m (option)

Composite

signal cable

signal cable

CCD camera

CCD camera

DVD recorder

DVD recorder

FAR-21x7

FEA-2107

FCR-21x7

BRILL CTRL

3

port *

RS-232C cable

RS-232C cable

(Max. 10 m)

(Max. 10 m)

FEA-2107

FCR-21x7

*1: Attach a crimp-on lug (inner dia. φ4) for monitor unit side. Make the length of the ground wire

as short as possible.

*2: Slide switch

• ON (upward): Allow digital signal from external equipment to control on/off of the monitor unit.

• OFF (downward): Set to OFF for analog RGB signal.

Note: Turn the slide switch off when you connect equipment to both the DVI and RGB ports.

*3: BRILL CTRL port

No use. Do not remove the sticker from the connector.

How to fix power cable

Fix the power cable with the cable clamp to prevent it from loosening.

MU-190

Cable

clamp

Replace MU-201CE with MU-190

Cut the connector of the power

cable (15-565, supplied on the

MU-201CE). Attach a crimp-on lug

(supplied on the MU-190) to each

cable core then connect the

cables as in the figure at right.

Length: 40 mm

Length: 60 mm

Local supply

11

Page 21

2. ADJUSTMENTS

Slide switch ON (Default setting)

䋨Ꮏ႐⩄ᤨ䈱⁁ᘒ䋩

Adjust the MU-190 according to the equipment connected.

Note: Sections 2.2, 2.3 and 2.4 are for Non-SOLAS.

2.1 Installation Settings

The [INSTALLATION SETTING] menu appears only when the power is turned on for the first time

after installation.

INSTALLATION SETTING

EXT BRILL CTRL

SERIAL BAUDRATE

COLOR CALIBRATION

KEY LOCK

SAVE AND EXIT

RS-232C

9600bps

ON

ON

YES

(OFF/DVI1/DVI2/RS-232C/RS-485/USB)

(4800/9600/19200/38400)

(OFF/ON)

(OFF/ON)

(NO/YES)

Menu

Menu item

For ECDIS (FEA-2107) or chart radar (FCR-21x7), no adjustment is necessary. Keep this equipment in the default settings.

For IMO radar (FAR-21x7) or Non-SOLAS, adjust this equipment according to the equipment connected, referring to the following table.

Connected

equipment

FEA-2107, FCR-21x7 RS-232C 9600 ON ON ON

FAR-21x7 DVI *1 - OFF ON ON

Other OFF - OFF OFF OFF

EXT BRILL

CTRL

SERIAL

BAUDRATE

COLOR

CALIBRATION

KEY

LOCK

DVI PWR

SYNC *2

Gray items: Default setting

*1: To connect to the processor unit of a radar, connect the video signal cable to the DVI-D1 port.

Then, select DVI1 to display the radar picture (see section 3.4).

*2: "DVI PWR SYNC" is the slide switch at the bottom rear of the monitor unit. See the “Slide

switch” below.

Slide switch

Set the slide switch (located between RGB and DVI ports) to OFF when you connect the RGB

signal or both RGB and DVI signals. Otherwise, the monitor will not turn on. The slide switch is set

at the factory to ON to control the power on/off from the equipment connected via DVI signal.

Slide switch

RGB port

Bottom rear of the monitor unit

ON (Default setting)

DVI port

OFF

12

Page 22

2. ADJUSTMENTS

1. Press the S or T key to select the menu item to adjust on the [INSTALLATION SETTING]

menu. The menu item and setting currently selected (the cursor) is shown in orange.

2. Press the W or X key to change the setting.

3. After you adjust all settings, press the T key to select [SAVE AND EXIT]. The confirmation

message appears.

INSTALLATION SETTING

EXT BRILL CTRL

SERIAL BAUDRATE

COLOR CALIBRATION

KEY LOCK

SAVE AND EXIT

Save configuration changes and exit now? YES[

RS-232C

9600bps

ON

ON

YES

(OFF/DVI1/DVI2/RS-232C/RS-485/USB)

(4800/9600/19200/38400)

(OFF/ON)

(OFF/ON)

(NO/YES)

]

NO[]

4. Press the X key. The settings are saved and the menu is closed.

Note: To cancel the settings, press the W key. The indication changes from [YES] to [NO] and

you can move the cursor to the menu items with the S key.

[INSTALLATION SETTING] menu descriptions

Menu item Function Setting

[EXT BRILL CTRL] Adjust the brilliance of the monitor unit from the external

equipment.

[OFF]: You can not adjust the brilliance from the external

[OFF], [DVI1],

[DVI2], [RS-232C],

[RS-485], [USB]

equipment. You can adjust the brilliance with the /

BRILL key.

[DVI1]: When the DVI1 signal is shown, you can adjust

the brilliance of this display from the equipment connected to DVI-D1 port. For the screen other than the DVI1,

you can adjust the brilliance with the /BRILL key.

[DVI2]: When the DVI2 signal is shown, you can adjust

the brilliance of this display from the equipment connected to DVI-D2 port. For the screen other than the DVI2,

you can adjust the brilliance with the /BRILL key.

[RS-232C]:You can adjust the brilliance from the equipment connected to RS-232C port.

[RS-485], [USB]: No use.

[SERIAL

BAUDRATE]

Select the serial baud rate according to the equipment

connected.

Note: This function is available when you set [EXT

BRILL CTRL] to [RS-232C].

[4800bps],

[9600bps],

[19200bps],

[38400bps]

[COLOR

CALIBRATION]

Select whether to use color-adjusted correction data or

not.

[OFF]: Do not use the adjusted data.

[ON]: Use the adjusted data.

[KEY LOCK] Select whether to lock the key operation or not (see

paragraph 3.2.2).

[OFF]: Do not lock the key operation.

[ON]: Lock the key operation.

[SAVE AND EXIT] Select whether to save the settings or not.

[NO]: Cancel the settings.

[YES]: Save the settings.

13

[OFF], [ON]

[OFF], [ON]

[NO], [YES]

Page 23

2. ADJUSTMENTS

How to open the [INSTALLATION SETTING] menu

Turn off the monitor unit. While you hold the DISP key, press the /BRILL key to turn on the monitor unit. Press and hold the DISP key for more than five seconds.

Note: When the "DVI PWR SYNC" slide switch is ON, turn on the connected external equipment

while you press the DISP key to turn on the monitor unit.

2.2 RGB/DVI Setting (For Non-SOLAS)

You can adjust the screen from the RGB, DVI-D1 and DVI-D2 ports individually. Turn on each external equipment and adjust the monitor unit as follows.

1. Select the signal to adjust at the DISP selection window. See section 3.4.

1) Press the DISP key.

2) Press the S or T key to select [RGB], [DVI1] or [DVI2].

2. Press the MENU key to show the menu. The main menu closes automatically when there is

no operation for one minute.

3. Press the W or X key to select [RGB], [DVI1] or [DVI2]. The current setting (the cursor) is

shown in orange. The menu items available depend on the selected menu. The [DVI1] and

[DVI2] setting menus contain the same items.

Note: The menus in gray are not available because of no signal.

RGB DVI1 DVI2 VIDEO OSD SYSTEM

H_SIZE

V_SIZE

PHASE

BRIGHTNESS

CONTRAST

H_POSITION

V_POSITION

R_LEVEL

G

_LEVEL

B_LEVEL

TEMPERATURE

B STRETCH

W

STRETCH

DISP MODE

SHARPNESS

1280

1024

(1~32)

16

(1~256)

128

(1~64)

32

(1~99)

50

(1~40)

20

(1~256)

128

(1~256)

128

(1~256)

128

(5000K~9300K)

7000K

(OFF, 1~10)

OFF

(OFF, 1~10)

OFF

(FULL/NORMAL)

FULL

(1~10)

5

Menu

Menu

item

RGB DVI1 DVI2 VIDEO OSD SYSTEM

(1~256)

BRIGHTNESS

CONTRAST

H_POSITION

V_POSITION

R_LEVEL

G

_LEVEL

B_LEVEL

TEMPERATURE

B STRETCH

W

STRETCH

DISP MODE

SHARPNESS

128

(1~64)

32

(1~50)

25

(1~40)

20

(1~256)

128

(1~256)

128

(1~256)

128

(5000K~9300K)

7000K

(OFF, 1~10)

OFF

(OFF, 1~10)

OFF

(FULL/NORMAL)

FULL

(1~10)

1

DVI setting menu

RGB setting menu

4. Press the S or T key to select the menu item to adjust.

5. Press the W or X key to adjust the setting.

6. Press the MENU key to close the menu.

14

Page 24

2. ADJUSTMENTS

[RGB], [DVI1/2] menu descriptions

Menu item Function Setting

H_SIZE (Only for

RGB menu)

V_SIZE (Only for

RGB menu)

PHASE** (Only

for RGB menu)

BRIGHTNESS Adjust the red, green and blue color level at one time. 1 to 256

CONTRAST Adjust the contrast level.

H_POSITION Move the image position horizontally.

V_POSITION Move the image position vertically.

R_LEVEL Adjust the red color level.

G_LEVEL Adjust the green color level.

B_LEVEL Adjust the blue color level.

TEMPERATURE Adjust the color temperature.

B STRETCH Emphasize the black color.

W STRETCH Emphasize the white color.

DISP MODE* Select the display method.

SHARPNESS** Sharpen the edges horizontally.

Adjust the image size horizontally.

Horizontal size: W (narrow), X (wide)

Adjust the image size vertically.

Vertical size: W (narrow), X (wide)

Adjust the sample timing so that the flicker disappears and

the text is clear.

W (darken), X (brighten)

W (leftward), X (rightward)

W (upward), X (downward)

W (weaken), X (strengthen)

W (weaken), X (strengthen)

W (weaken), X (strengthen)

W (strengthen the red color level),

X (strengthen the blue color level)

[OFF] (standard), W (weaken), X (strengthen)

[OFF] (standard), W (weaken), X (strengthen)

[FULL]: Show the input signal on entire screen.

[NORMAL]: Show the input signal with original aspect ratio.

W (soften characters and lines),

X (sharpen characters and lines)

Depending on input signal

1 to 32

1 to 64

1 to 99 (RGB),

1 to 50 (DVI1,

DVI2)

1 to 40

1 to 256

1 to 256

1 to 256

5000 to 9300K

(Step is 100.)

[OFF], 1 to 10

[OFF], 1 to 10

[FULL],

[NORMAL]

1 to 10

*: When inputting VGA, SVGA or XGA, a circle may be displayed as an ellipse because the aspect

ratio differs. In this case, set [DISP MODE] to [NORMAL] on the [RGB], [DVI1], or [DVI2] menus.

A black bar appears on the top and bottom of the picture, but this is normal.

**: If the characters are not clear, adjust [PHASE] and [SHARPNESS].

15

Page 25

2. ADJUSTMENTS

2.3 Video Composite Signal Setting (For Non-SOLAS)

You can adjust the VIDEO signal from the VIDEO port. The VIDEO signal is also displayed in the

PIP window (see section 3.5).

1. Select the signal to adjust at the DISP selection window.

2. Press the MENU key to show the menu.

3. Press the W or X key to select [VIDEO].

RGB DVI1 DVI2 VIDEO OSD SYSTEM

PIP_SIZE

CONTRAST

R_LEVEL

G

_LEVEL

B_LEVEL

TEMPERATURE

B STRETCH

W

STRETCH

5

(1~10)

32

(1~64)

128

(1~256)

128

(1~256)

128

(1~256)

7000K

(5000K~9300K)

OFF

(OFF, 1~10)

OFF

(OFF, 1~10)

4. Press the S or T key to select the menu item to adjust.

5. Press the W or X key to adjust the setting.

6. Press the MENU key to close the menu.

[VIDEO] menu descriptions

Menu item Function Setting

PIP_SIZE Adjust the size of the picture-in-picture window.

Note: This setting is available when the PIP window is displayed.

CONTRAST Adjust the contrast level.

1 (52 mm x 35

mm) to 10 (285

mm x 194 mm)

1 to 64

W (darken), X (brighten)

R_LEVEL Adjust the red color level.

1 to 256

W (weaken), X (strengthen)

G_LEVEL Adjust the green color level.

1 to 256

W (weaken), X (strengthen)

B_LEVEL Adjust the blue color level.

1 to 256

W (weaken), X (strengthen)

TEMPERATURE Adjust the color temperature.

W (strengthen the red color level),

5000 to 9300K

(Step is 100.)

X (strengthen the blue color level)

B STRETCH Emphasize the black color.

[OFF], 1 to 10

[OFF] (standard), W (weaken), X (strengthen)

W STRETCH Emphasize the white color.

[OFF], 1 to 10

[OFF] (standard), W (weaken), X (strengthen)

16

Page 26

2. ADJUSTMENTS

2.4 The Menu Window Setting (For Non-SOLAS)

2.4.1 How to adjust the menu window

You can adjust the position and transparency of the menu window on the [OSD] (On Screen Display) menu.

1. Press the MENU key to show the menu.

2. Press the W or X key to select [OSD].

RGB DVI1 DVI2 VIDEO OSD SYSTEM

H_POSITION

V_POSITION

TRANSLUCENT

CUSTOM NAME

RGB : RGB

DVI1 : DVI1

DVI2 : DVI2

VIDEO : VIDEO

14

33

OFF

(1~29)

(1~37)

(OFF/ON)

3. Press the S or T key to select the menu item to adjust.

4. Press the W or X key to adjust the setting.

5. Press the MENU key to close the menu.

[OSD] menu descriptions

Menu item Function Setting

H_POSITION Move the menu window horizontally.

W (leftward), X (rightward)

V_POSITION Move the menu window vertically.

W (upward), X (downward)

TRANSLUCENT Adjust the transparency of the background color (blue) on

the menu window.

[OFF]: Blue, [ON]: Translucent

Note: Alpha blending technology is used for transparency

effects.

1 to 29

1 to 37

[OFF], [ON]

CUSTOM NAME See paragraph 2.4.2.

17

Page 27

2. ADJUSTMENTS

2.4.2 How to change the signal name

You can change the signal name ([RGB], [DVI1/2] or [VIDEO]) to a name (ex. the equipment

name) which is easy to understand. The name is shown in the DISP selection window and the

indication shown at the upper right of the screen (see section 3.4).

1. Press the MENU key to show the menu.

2. Press the W or X key to select [OSD].

3. Press the S or T key to select the signal to change its name in the signal name area. In the

example below, [RGB] is selected.

RGB DVI1 DVI2 VIDEO OSD SYSTEM

Signal

name area

H_POSITION

V_POSITION

TRANSLUCENT

CUSTOM NAME

RGB : RGB

DVI1 : DVI1

DVI2 : DVI2

VIDEO : VIDEO

14

33

OFF

(1~29)

(1~37)

(OFF/ON)

4. Press the X key to select the character to change. In the example below, "G" of RGB is se-

lected.

CUSTOM NAME

RGB : RGB

DVI1 : DVI1

DVI2 : DVI2

VIDEO : VIDEO

5. Press the S or T key to select an appropriate alphanumeric character. In the example below,

"5" is selected. You can use a maximum of ten characters. “A to Z”, “0 to 9”, “–”, “.”, “ ” (space)

are available.

CUSTOM NAME

RGB : R5B

DVI1 : DVI1

DVI2 : DVI2

VIDEO : VIDEO

6. To change another signal name, press the W key several times to return the cursor to the sig-

nal name area. Repeat steps 3 to 5.

7. Press the MENU key to close the menu.

18

Page 28

3. OPERATION

Note: When you connect the monitor unit to FAR-21x7, FEA-2107 or FCR-21x7, you can turn the

power on/off and adjust the brilliance via the application of the FAR-21x7, FEA-2107 or FCR-21x7

only (see section 2.1).

3.1 Controls

MENU DISP

PIP

L

B

L

I

R

- Power On/Off. (Available

when the slide switch at the

bottom rear is OFF.)

- Display the brilliance

Open/Close the menu.

MENU DISP

Light sensor

(Automatically

detect the ambient

brightness.)

- Select the menu and

menu items.

- Adjust the setting.

- Move the PIP window.

Select the signal to display.

PIP

Display/Hide

the PIP window.

adjustment window.

B

L

R

L

I

Power LED

(Lights when power is on.)

Green: The signal is input.

Orange: No signal.

The dimmer for the power LED and keys changes with the display brilliance. Also, when you connect the monitor unit to FAR-21x7, FEA-2107 or FCR-21x7, the dimmer for the power LED and

keys changes with the brilliance modes (Day, Dusk, Night) of those models. When you connect

the monitor unit to the equipment other than FAR-21x7, FEA-2107 or FCR-21x7, the control is

done from the MU-190. If the keys of MU-190 are not illuminated, provide external, dimmable illumination, e.g. gooseneck lamp.

3.2 How to Turn the Power On/Off

3.2.1 Turn the power on/off

How to turn on/off the power depends on the setting of the slide switch. The slide switch is set

when the monitor unit is installed. See section 1.8.

Note: The screen refreshes slower in low ambient temperature.

19

Page 29

3. OPERATION

Slide switch “ON”

The external equipment connected to the DVI port (DVI-D1 or DVI-D2) can turn on/off the monitor

unit. See the operator’s manual for the external equipment connected.

Note 1: You can not turn on the power with the /BRILL key on MU-190.

Note 2: When you connect the cables to both DVI-D1 and DVI-D2 ports, turn off the power of both

equipment to turn off the monitor unit.

Slide switch “OFF”

1. Press the /BRILL key to turn on the monitor unit.

2. Press and hold the /BRILL key for three seconds to

turn off the monitor unit. While you hold the key, the

message shown right appears on the screen.

This monitor will shut down in three seconds.

SHUT DOWN

3.2.2 Unlock the key operation

All the keys of the monitor unit are locked by default. Unlock the keys to operate all menus.

1. Turn off the monitor unit.

2. While you hold the PIP key, press the /BRILL key to turn on the monitor unit. Press and hold

the PIP key for more than five seconds. The key operation is unlocked.

Note: When the slide switch is ON, turn on the connected external equipment while you press

the PIP key to turn on the monitor unit.

3. To lock the key operation, turn off the monitor unit and then turn it on while you hold the PIP

key.

The setting of [KEY LOCK] in the [INSTALLATION SETTING] menu ([OFF/ON]) is mutually

changed.

3.3 How to Adjust the Display Brilliance

You can adjust the display brilliance as follows:

Note: This function is available when [AUTO DIMMER] on the [SYSTEM] menu is [OFF] and [EXT

BRILL CTRL] on the [INSTALLATION SETTING] menu is [OFF]. See section 2.1 and

paragraph 3.6.1.

1. Press the /BRILL key momentarily to show the BRILL

adjustment window. The window shown right disappears if there is no operation for five seconds.

2. Press the W or X key to adjust the brilliance (setting range: 1 - 50).

3. Press the S or T key to close the window.

Warning: If you turn off the monitor unit with minimum brilliance, the unit starts with minimum brilliance the next time it is turned on. This can make it difficult to see warnings from applications connected, etc. depending on current lighting conditions. If this occurs, do the following according to

the equipment connected;

For FAR-21x7, FEA-2107, FCR-21x7: The brilliance of the monitor unit is adjusted only via the

application of those equipment. See the appropriate operator’s manual.

For Non-SOLAS: Press the /BRILL key repeatedly to adjust the brilliance.

BRILL 46

20

Page 30

3. OPERATION

3.4 How to Select the Source for Main Picture

Select the signal to display on the entire screen as follows:

1. Press the DISP key to show the DISP selection window. The window shows

the signal names as you customized them at paragraph 2.4.2. This window

disappears if there is no operation for five seconds.

2. Press the S or T key to select a signal.

[RGB]: Show the signal from the RGB port.

[DVI1], [DVI2]: Show the signal from the selected DVI port.

[VIDEO]: Show the external video from the VIDEO port.

3. Press the W or X key to close the window. The name of the selected signal appears at the

right top corner for five seconds after the DISP selection window disappears. If there is no signal, "NO SIGNAL" appears.

RGB

DVI1

DVI2

VIDEO

3.5 How to Display the PIP Window

The PIP (picture-in-picture) window, which displays the picture input to the VIDEO port, is available on the RGB, DVI1 and DVI2 displays.

PIP window

1. With the RGB, DVI1 or DVI2 display shown, press the PIP key to show the PIP window. To

hide the PIP window, press the PIP key again.

2. You can move the PIP window by pressing the arrow keys when the menu is closed.

Note: You can adjust the size of the PIP window on the [VIDEO] menu (see section 2.3).

3.6 SYSTEM Menu

The [SYSTEM] menu controls the brilliance, clears the memory and shows signal status and program number.

3.6.1 How to set the auto dimmer

The auto dimmer feature automatically adjusts the brilliance according to the ambient brightness

detected by the light sensor on the front panel. Also, you can select the interval at which the brilliance is adjusted.

Note: Do not put any objects in front of the light sensor.

1. Press the MENU key to show the menu.

21

Page 31

2. Press the X key to select [SYSTEM].

RGB DVI1 DVI2 VIDEO OSD SYSTEM

3. OPERATION

AUTO DIMMER

DEFAULT RESET

INFORMATION

RGB :

DVI1 :

DVI2 :

VIDEO

SERIAL No.

APR PROGRAM No.

FPGA PROGRAM No.

ELAPSED TIME

OFFNO(OFF, 1~5)

(NO/YES)

1280*1024 Fh : 80.0kHz Fv : 75Hz

1280*1024 Fh : 64.0kHz Fv : 60Hz

NO SIGNAL

: NTSC

: 8073-5578, 987655

: 2651020-01.XX

: 2651021-01.XX

: 100000

Signal status,

serial number,

program number

and elapsed time

3. Press the S or T key to select [AUTO DIMMER].

4. Press the W or X key to select an interval to check brightness.

• [OFF]: Turn of this function. • [3]: Every minute

• [1]: Every two seconds • [4]: Every three minutes

• [2]: Every 30 seconds • [5]: Every five minutes

Note: When you connect the monitor unit to FAR-21x7, FEA-2107 or FCR-21x7, set to [OFF].

5. Press the MENU key to close the menu.

3.6.2 How to clear the memory

You can clear the memory to restore the default settings.

1. Press the MENU key to show the menu.

2. Press the X key to select [SYSTEM].

3. Press the S or T key to select [DEFAULT RESET].

4. Press the X key. The indication changes from "NO" to "YES".

RGB DVI1 DVI2 VIDEO OSD SYSTEM

AUTO DIMMER

DEFAULT RESET

ALL CUSTOM SETTINGS WILL BE LOST.

← KEY: CANCEL → KEY: RESET

INFORMATION

RGB :

DVI1 :

DVI2 :

VIDEO

SERIAL No.

APR PROGRAM No.

FPGA PROGRAM No.

ELAPSED TIME

OFF

(OFF, 1~5)

YES

(NO/YES)

1280*1024 Fh : 80.0kHz Fv : 75Hz

1280*1024 Fh : 64.0kHz Fv : 60Hz

NO SIGNAL

: NTSC

: 8073-5578, 987655

: 2651020-01.XX

: 2651021-01.XX

: 100000

Note: To cancel, press the W key. The indication changes from "YES" to "NO".

5. Press the X key to select [RESET].

22

Page 32

4. MAINTENANCE,

WARNING

TROUBLESHOOTING

NOTICE

Do not apply paint, anti-corrosive sealant or contact spray

to coating or plastic parts of the equipment.

Those items contain organic solvents that can damage coating

and plastic parts, especially plastic connectors.

4.1 Maintenance

Routine maintenance

Regular maintenance is important for good performance. Check the following on a regular basis

to keep the equipment in good condition.

• Check that the connectors at the bottom of the monitor unit are tightly fastened.

• Check the ground wire and ground terminal for rust. Clean if necessary. Confirm that the ground

wire is tightly fastened.

• Remove dust and dirt from the monitor unit with a dry, soft cloth. Do not use chemical cleaners to

clean any part of the monitor unit. They can remove paint and markings.

• Wipe the LCD carefully to prevent scratching, using an LCD cleaning cloth (supplied as accessory). To remove dirt or salt deposits, use an LCD cleaner, wiping slowly with tissue paper so as to

dissolve the dirt or salt. Change paper frequently so the salt or dirt will not scratch the LCD. Do

not use solvents such as thinner, acetone or benzene for cleaning. Also, do not use degreaser or

antifog solution, as they can strip the coating from the LCD.

Fuse replacement

The fuse in the fuse holder at the bottom of the display

protects the equipment from overvoltage and overcurrent.

If the fuse blows, find the cause before you replace it. If the

fuse blows again after replacement, request service.

Name Type Code Number Remarks

Glass Tube Fuse FGBO 250V 1A PBF 000-155-828-10

LCD replacement

Use the proper fuse.

Use of a wrong fuse can cause

fire or damage to the equipment.

WARNING

The life of the LCD is approximately 50,000 hours. The actual number of hours depends on ambient temperature and humidity. When the brilliance cannot be raised sufficiently, replace the

LCD.

Fan replacement

The life of the each fan is shown in the table on the next page. The actual number of hours depends on ambient temperature. When the fan does not rotate sufficiently, the message "FAN ERROR" is shown. Turn off the power and call for service to request replacement of the fan.

23

Page 33

4. MAINTENANCE, TROUBLESHOOTING

Item Life Type Code Number

FAN1 Approximately 40,000 hours MFB52A-12HA-001 000-172-023-10

FAN4 Approximately 60,000 hours LQ0DDB0094 000-172-144-10

4.2 Troubleshooting

See the following table to find the possible causes of trouble and the actions to restore normal

operation. If repair of the equipment is necessary, report the result of the troubleshooting to the

service technician.

Case Remedy

You can not turn

on the power.

You can not turn

off the power.

No picture • Fasten the cables tightly.

• Check if the power switch at the bottom of the display is on.

• Check the setting of the slide switch.

• Check the battery voltage with a multimeter.

• Check the fuse at the bottom of the display.

• Fasten the power cable tightly.

• Press and hold the /BRILL key for eight seconds.

• When the slide switch is set to ON, turn off the external equipment connected

to turn off the monitor.

• Check the input signal. See section 3.6.

• Check the setting for DISP selection window. See section 3.4.

• Check if the display brilliance is not set to minimum.

4.3 Parts Location and Parts List

Parts location

MFB52A-12HA-001, 26S0028 (Fan (FAN1), Wind direction: top-left)

LQ0DDB0094, 26S0048 (Fan motor assembly (FAN4), Wind direction: upward)

OZP-120-12/15-J06

26P0023

ESSIP33A-1C

(AD board)

Parts list

ELECTRICAL PARTS

PRINTED CIRCUIT BOARD Code No.

OZP-120-12/15-J06

26P0023 (PSW board)

ESSIP33A-1C (AD board)

26P0013

LCD

LQ190E1LX51, 26S0027

FAN

MFB52A-12HA-001, 26S0028 (FAN1)

LQ0DDB0094, 26S0048 (FAN4)

26P0013

Model

Unit

MU-190

Monitor unit MU-190

Code No.

Code No.

LQ190E1LX51,

26S0027 (LCD)

-

-

-

-

-

-

-

24

Page 34

FURUNO

SPECIFICATIONS OF MONITOR UNIT

MU-190

1 GENERAL

1.1 Display 19-inch color LCD

1.2 Effective area 376.32 x 301.06 mm

1.3 Resolution SXGA (1280 x 1024 pixel)

1.4 Pixel pitch 0.294 mm (Horizon/Vertical)

1.5 Brightness 450 cd/m2 typical

1.6 Contrast 900: 1

1.7 View angle 160° (up/down, left/right 80° or more)

1.8 Visible distance 1.02 m nominal

1.9 Input signal

RGB analog 1 port, non-interlace, RGB signal: 0.7 Vp-p, Sync. Signal: TTL level

MU-190

DVI-D 2 ports, DVI-standard, VESA DDC2B

Composite signal 1 port, NTSC/PAL-standard, Video signal: 0.7 Vp-p

USB USB1.1, 12 Mbps (for dimmer control)

RS-232C EIA/TIA-232, 9600 bps (4800/19200/38400 bps)

2 POWER SUPPLY

100-230 VAC: 0.7-0.4 A, 1 phase, 50/60Hz

3 ENVIRONMENTAL CONDITION

3.1 Ambient temperature -15°C to +55°C

3.2 Relative humidity 93% or less at 40°C

3.3 Degree of protection IP22

3.4 Category of equipment Protected from the weather

3.5 Vibration IEC 60945 Ed.4

5 UNIT COLOR

N2.5

SP - 1 E3519S04C

Page 35

工事材料表

,

A-1

INSTALLATION MATERIALS

番 号

NO.

1

2

3

4

5

6

7

8

名 称

NAME

FマウントスポンジV19

FLUSH MOUNTING SPONGE

V 19

化粧パネル19

MASKING PANEL FOR 19"

LCD

FマウントスポンジH19

FLUSH MOUNTING SPONGE

H19

+トラスタッピンネジ 1シュ

SELF-TAPPING SCREW

コンベックス

CONVEX

圧着端子

CRIMP-ON LUG

+バインドコネジ

BINDING HEAD SCREW

Fマウントパネル19組品

FLUSH MOUNT PANEL 19

MU-190

略 図

OUTLINE

CODE NO.

TYPE

型名/規格

DESCRIPTIONS

26-005-3124-0

CODE NO.

26-007-1124-2

CODE NO.

26-007-1127-0

CODE NO.

5X20 SUS304

CODE NO.

CV-125N

CODE NO.

FV1.25-4(LF)

CODE NO.

M4X10 SUS304

CODE NO.

CP26-01603

CODE NO.

001-116-250-00

CP26-01601

100-351-560-10

100-363-462-10

100-363-240-10

000-162-608-10

000-172-164-10

000-166-666-10

000-172-165-10

001-134-900-00

数量

Q'TY

2

2

2

4

1

2

6

2

26AH-X-9401

用途/備考

REMARKS

-2

1/1

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER PRODUCT.

QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

FURUNO ELECTRIC CO .

LTD.

26AH-X-9401

Page 36

D-1

Page 37

D-2

Page 38

D-3

Page 39

D-4

Page 40

レーダー制御部

S-1

RADAR PROCESSOR UNIT

DVI-D

DVIOTX2_N

J3

12345

RPU-013(FAR-2117ser.)

NC

DVIOTX2_P

A_GNDNCNC

6NC7

NC

8

NCNCNCNCGND

A_GND

DVIOTX1_N

DVIOTX1_P

9

101112131415161718192021222324

VccNCDVIOTXD_N

DVIOTXD_P

A_GND

A_GND

DVIOTXC_P

DVIOTXC_N

ECDIS演算部

DVI1/2

ECDIS PROCESSOR UNIT

EC-1000C

COM1

輝度制御用

DCD

RXD

123

FOR BRILL. CONTROL

TXDRIDTR

4

GND

DSR

RTS

CTS

56789

TITLE

MU-190/231

表示部

名称

相互結線図

NAME

MONITOR UNIT

INTERCONNECTION DIAGRAM

*2

6NC7

8

9

NC

DDC_DATA

DDC_CLOCK

TMDS_DATA1_N

RGB

RED

J2

1234567NC8

P

101112131415161718192021222324

NCNCNC

TMDS_DATA1_P

TMDS_DATA1_SHIELD

GND

GREEN

BLUE

5V_P

GND

GND

GND

HOT_PLUG_DETECT

GND

P

TMDS_DATA0_N

TMDS_DATA0_P

TMDS_DATA0_SHIELD

GNDNCNC

9

1011121314

NC

NC

TMDS_CLOCK_SHIELD

HSYNC_N

VSYNC_N

P

TMDS_CLOCK_P

TMDS_CLOCK_N

NC

15

3

DVI-D/D SINGLELINK5M/10M

5/10m,φ7

12345

J3

DVI-D1

TMDS_DATA2_N

表示部

MONITOR UNIT

MU-190/231

P

TMDS_DATA2_P

TMDS_DATA2_SHIELD

POWER

TB1

*1

NC

AC

AC

1

2

VIDEO

J5

*1

BNC

*1

*2

DVI-D/D SINGLELINK5M

5m,φ7

24 24

J4DVI-D2

同上

DITTO

VBUSD-D+

BRILL CTRL

J6

123

*3

123

J7 Dsub-9P

NC

RS-232C

GND

4

DSUB9P-DSUB9P-5M

TXD

RXD

4

56789

GND

RD-C

TD-B

REF.No.

kg

T.YAMASAKI

MASS

T.TAKAHASHI

C3524-C01- A

*1

NC

TD-A

RD-H

IV-8sq.

DRAWN

31/Aug/2010

31/Aug/2010

DWG No.

SCALE

APPROVED

CHECKED

DPYC-1.5

100-230VAC

12 4

1φ,50/60Hz

*2

3COX-2P-6C,5/10m,φ8.5

魚群探知機

ソナー

レーダー

プロッタ

A

ECHO SOUNDER

SONAR

RADAR

PLOTTER

COAX. CABLE (75Ω)

VIDEO DEVICE

B

USB CABLE,MAX.5m

EXTERNAL EQUIPMENT

注記

*1)造船所手配。

*2)オプション。

*3)EC-1000C構成組品。

C

NOTE

*1: SHIPYARD SUPPLY.

*2: OPTION.

*3: CABLE ASSY. INCLUDED IN MATERIAL FOR EC-1000C.

Page 41

Loading...

Loading...