Page 1

www.furuno.co.jp

Installation Manual

COLOR GPS/PLOTTER/SOUNDER

GP-7000F

SAFETY INSTRUCTIONS............................................................................i

SYSTEM CONFIGURATION .......................................................................ii

EQUIPMENT LISTS....................................................................................iii

1. INSTALLATION .....................................................................................1

1.1 Display Unit .................. ........................................................... .....................................1

1.2 Antenna Unit.................................................................................................................4

1.3 Transducer ...................................................................................................................5

1.4 Optional Speed/Water Temperature Sensor ST-02MSB, ST-02PSB.........................18

2. WIRING................................................................................................19

3. ADJUSTMENTS ..................................................................................26

3.1 Choosing Position Data Source..................................................................................26

3.2 Choosing Port I/O Format...........................................................................................28

3.3 Echo Sounder Settings............................................................................................... 30

3.4 Choosing Data Source(s)...........................................................................................32

3.5 Calibrating NMEA Depth, Speed and Water Temperature Data................................33

3.6 Waypoint, Route Format.............................................................................................34

3.7 External Event Format.................... ............................................................................34

3.8 Primary, Secondary Unit (C-link)............ ............................................... .....................35

PACKING LIST........................................................................................ A-1

OUTLINE DRAWINGS............................................................................. D-1

INTERCONNECTION DIAGRAM ............................................................ S-1

Page 2

9-52 Ashihara-cho,

*

00014914012

**00014914012

*

Nishinomiya, 662-8580, JAPAN

Telephone : +81-(0)798-65-2111

Fax :+81-(0)798-65-4200

The paper used in this manual

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

Pub. No. IME-44291-C1

(HIMA ) GP-7000F

Printed in Japan

A : AUG 2004

.

C1 : JUN . 21, 2007

*00014914012**00014914012*

* 0 0 0 1 4 9 1 4 0 1 2 *

Page 3

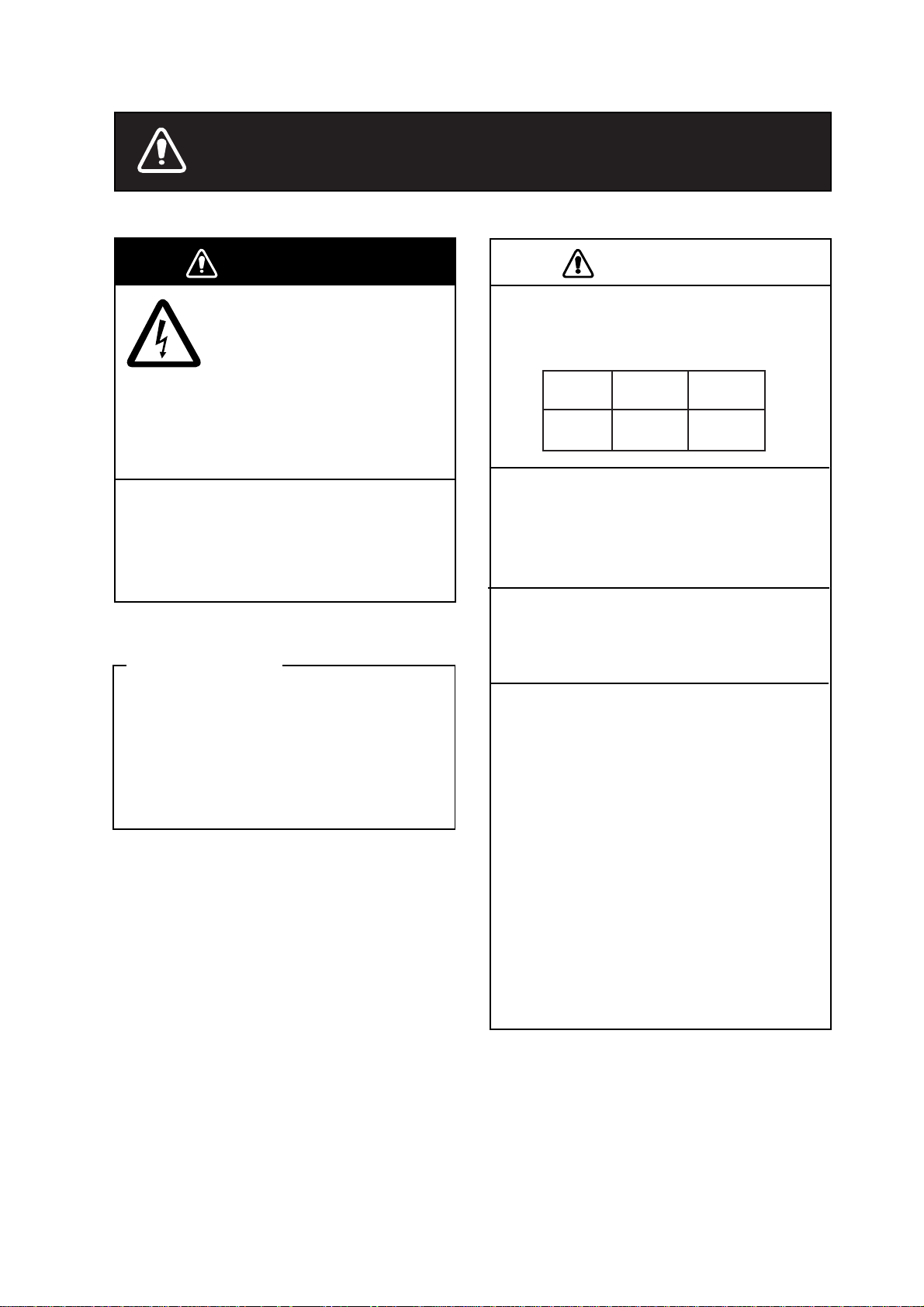

SAFETY INSTRUCTIONS

WARNING

CAUTION

Organic solvent

ELECTRICAL SHOCK HAZARD

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

should work inside the

equipment.

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not apply paint, anti-corrosive sealant

or contact spray to coating or plastic

parts of the equipment.

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Standard Steering

compass compass

Display

unit

Use the power cable supplied with the

installation materials.

Use of other power cables may cause fire

or damage the equipment.

Use the proper fuse.

Use of the wrong fuse may damage the

equipment.

Observe the following precautions when

handling the transducer cable:

0.70 m 0.45 m

Those items contain organic solvents that

can damage coating and plastic parts,

especially plastic connectors.

- Keep away from oils.

- Choose a working area where the

cable will not be damaged during

installation.

- Do not paint the cable.

The sheath of the cable is made of

chloroprene (or polyvinyl chloride).

Those materials easily deteriorate in

the presence of organic solvents

(toulene, etc.) found in paints. For

that reason keep the cable away from

ship's paint house.

i

Page 4

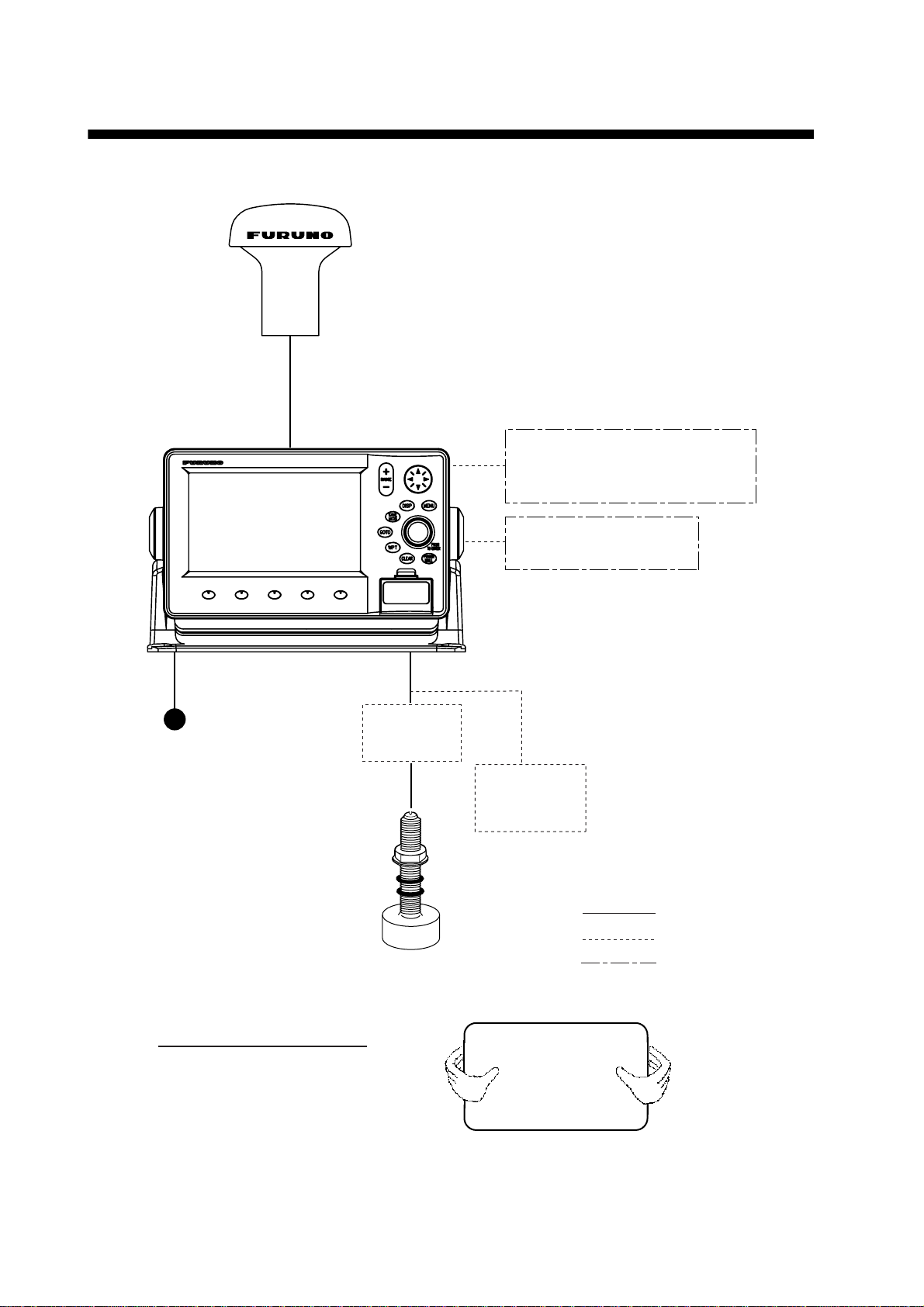

SYSTEM CONFIGURATION

ANTENNA UNIT GPA-017

DISPLAY UNIT

GP-7000F

NMEA1 and NMEA2 ports:

Radar, autopilot, video sounder,

temperature indicator, etc.

PC/NMEA IN port:

PC, NMEA device, buzzer

Power Source

12-24 VDC

How to remove the hard cover

Place your thumbs at the center

of the cover, and then lift the cover

while pressing it with your thumbs.

* Required when using

1 kW transducer.

Distributor

MB-1000*

TRANSDUCER

Speed/Water

Temp Sensor

(option)

: Standard

: Option

: User Supply

ii

Page 5

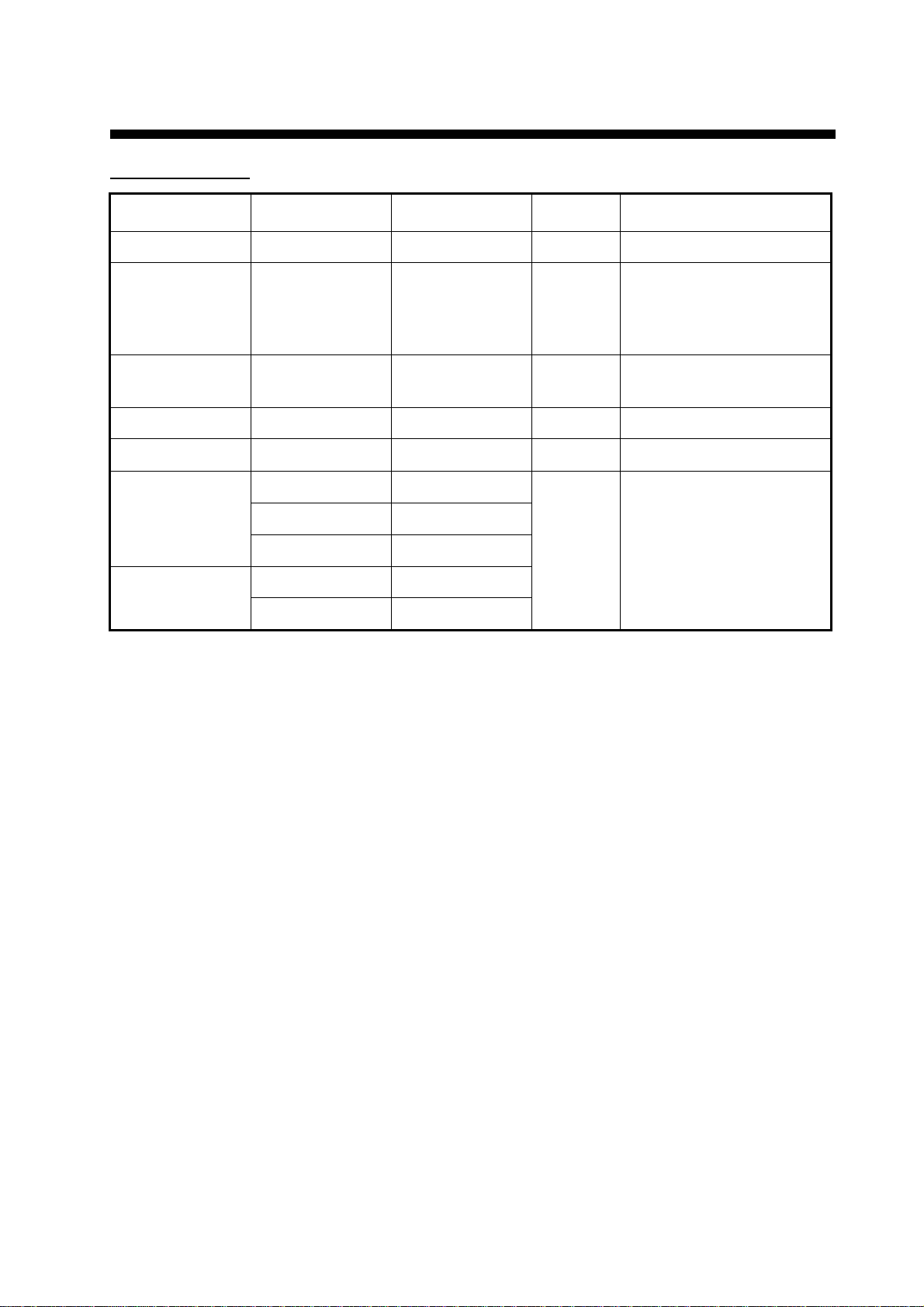

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Display Unit GP-7000F - 1

Antenna Unit GPA-017 - 1

System also available without antenna (for boats

which already have an

appropriate antenna)

Installation

Materials*

Accessories* FP20-01100 000-042-239 1

Spare Parts* SP14-03201 004-371-980 1

Transducer

Triducer

*: See list at back of this manual.

CP14-06400 000-041-183 1

520-5PSD 000-015-204

525-5PWD 000-146-966

520-5MSD 000-015-212

525ST-MSD 000-015-263

525ST-PWD 000-015-261

Choose

one

Signal cable and power

cable

Also available without transducer (for boats with transducer already installed)

iii

Page 6

Optional equipment

Name Type Code No Qty

GPS Antenna GPA-017S 000-040-541

Antenna Cable

Set

Right Angle

Antenna Base

L-angle Antenna

Base

Antenna Base for

Rail Mounting

Mast Mounting Kit CP20-01111 004-365-780

Cable Assy.

CP20-01700 004-372-110 30 m, antenna cable extension

CP20-01710 004-372-120 50 m, antenna cable extension

No.13-QA330 000-803-239

No.13-QA310 000-803-240

No.13-RC5160 000-806-114

MJ-A6SPF0012-050C 000-154-053-10 6P - 6P, 5 m

MJ-A6SPF0012-100C 000-154-037-10 6P - 6P, 10 m

MJ-A6SPF0003-050C 000-154-054-10 6P, 5 m

MJ-A7SPF0007-050C 000-154-028-10 7P, 5 m

50B-6 000-015-042

50B-6G 000-015-016

For mounting antenna unit

For mounting antenna unit on a

mast

Transducer

Inner Hull Kit S 22S0191-2 000-802-598

Distributor MB-1000 000-040-809 For 1 kW transducer

Cable Assy.

Sensor ST-02PSB 000-137-987

Sensor ST-02MSB 000-137-986

200B-5S 000-015-029

200B-5 000-015-027

50/200-1T 000-015-170

02S4089 000-133-622 For Distrib utor MB-1000

02S4147-0 000-141-082 For sensor

Speed/water temperature sensor

iv

Page 7

1. INSTALLATION

1.1 Display Unit

The display unit may be mounted on a desktop, overhead or flush mounted in a console.

Mounting considerations

Choose a mounting location for the display unit considering the following points:

• Choose a location where the controls can be easily operated.

• Leave sufficient space around the unit to facilitate checking and maintenance. See the outline

drawing at the back of this manual for recommended maintenance space.

• Locate the unit out of direct sunlight because of heat that can build up inside the cabinet.

• The operating temperature range is -15

• Locate the unit well away from exhaust gases and other active gases.

• The location should be well ventilated.

• Choose a location where shock and vibration are minimal.

• Be sure the mounting location is strong enough to support the weight of the unit, particularly in

overhead mounting. If necessary reinforce the mounting location.

• A magnetic compass will be affected if the display unit is placed too close to the compass.

Observe the following compass safe distances to prevent deviation to the compass.

Standard compass, 0.70 m, Steering compass, 0.45 m.

°C to 55°C (5°F to 131°F).

1

Page 8

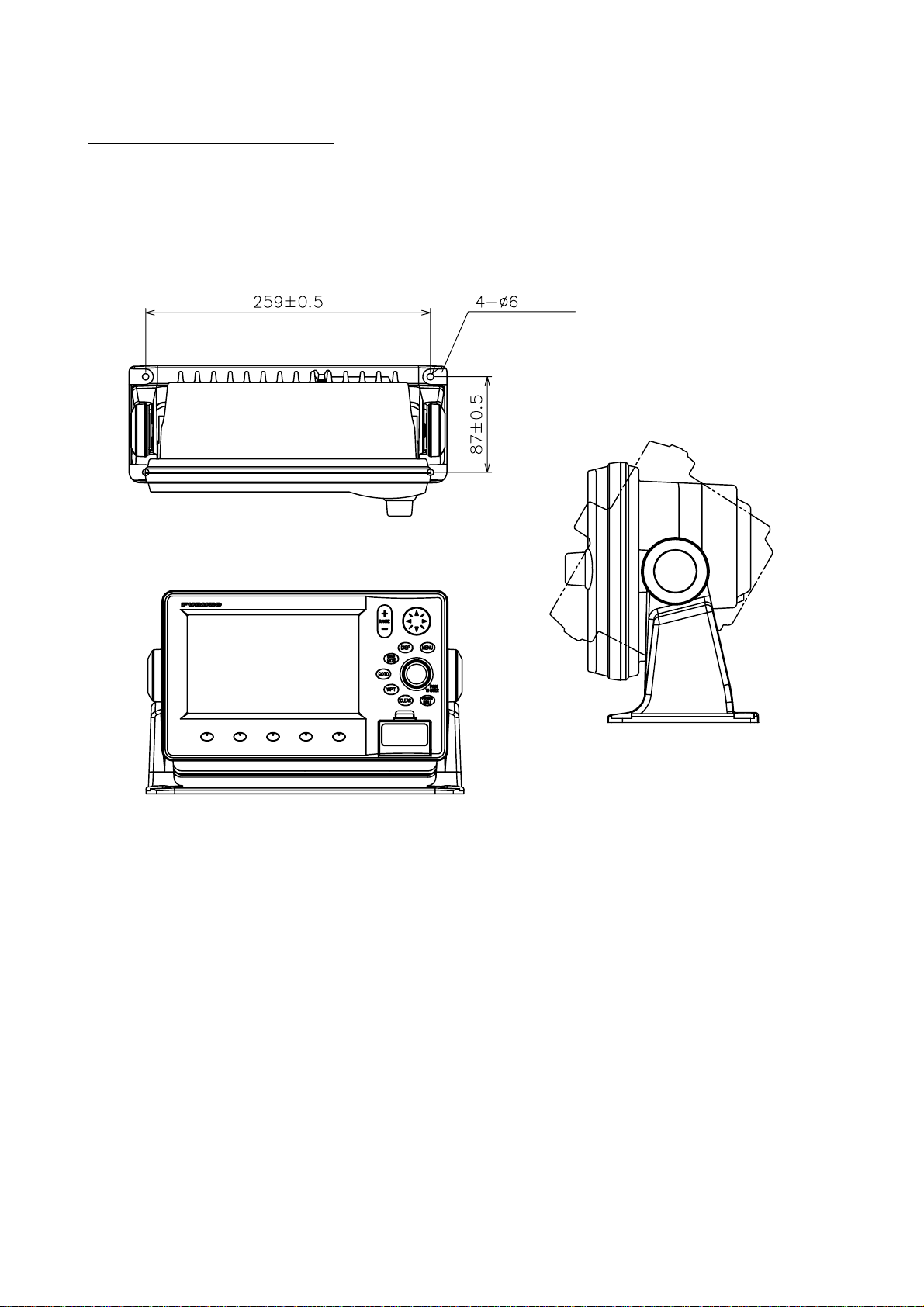

Mounting

Desktop, overhead mounting

1. Fix the hanger to the mounting location with four self-tapping screws (5x20). See the outline

drawing on page D-1 for complete mounting dimensions.

2. Loosely screw the knob bolts into the display unit.

3. Set the display unit to the hanger and tighten the knob bolts.

4. Attach the hard cover to the display unit to protect the LCD.

FIXING HOLE

Unit: mm

Display unit, mounting dimensions for desktop or overhead mounting

2

Page 9

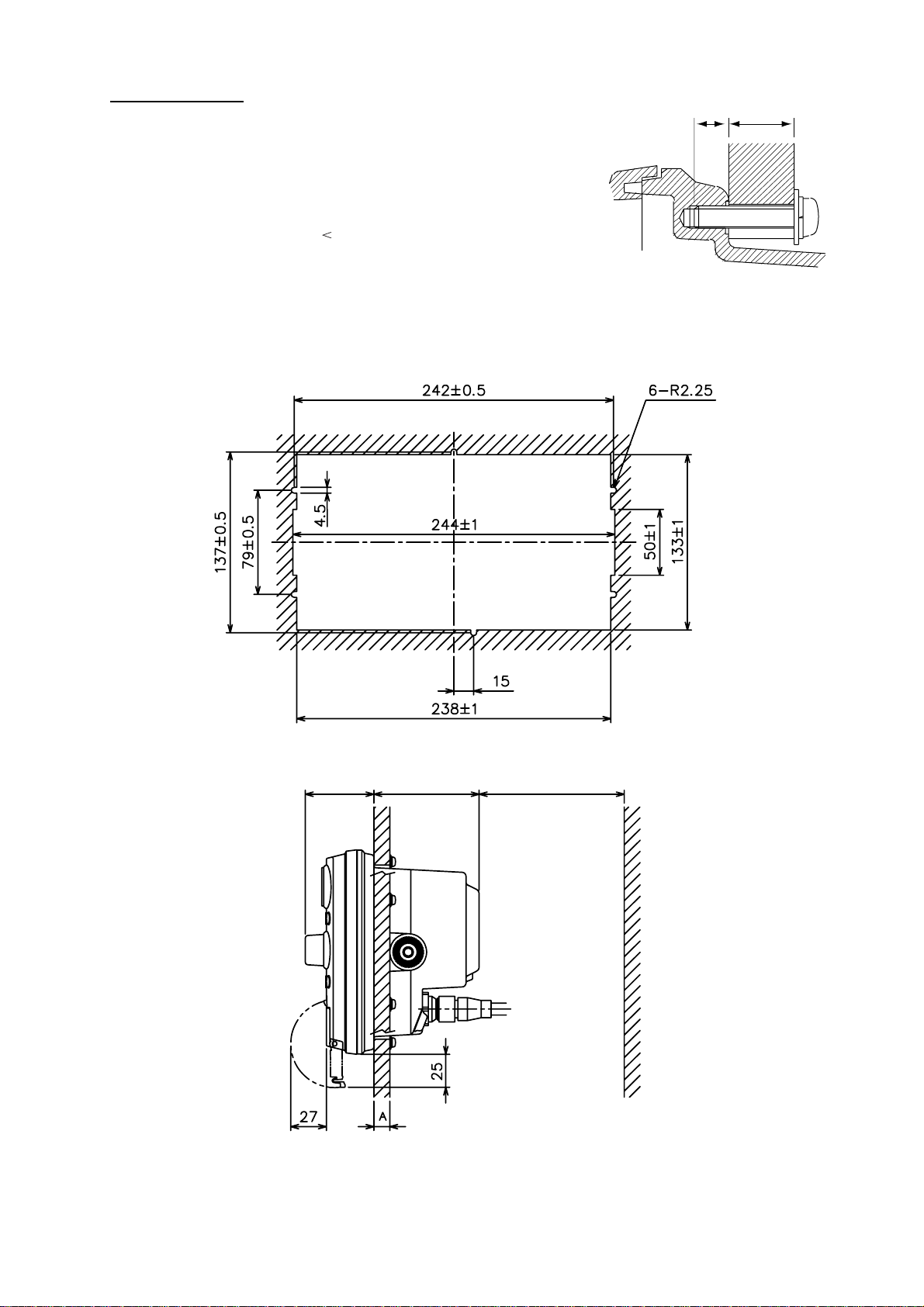

Flush mounting

If the thickness of the console is 11-14 mm, use the washer head

screws (M4x20) supplied with the installation materials. If it is

thicker than those dimensions, the length of the screws should

be the thickness of the console plus 7.3 mm

± 1.5 mm. The

length of the threaded portion to be inserted to the display unit

should not exceed 7 mm (B 7).

=

A: Thickness of console

1. Prepare a cutout in the mounting location using the template provided.

2. Fix the display unit with six washer head screws (M4x20) provided.

B

A

52 80 150

Service

Clearance

Mounting dimensions for flush mounting

Unit: mm

3

Page 10

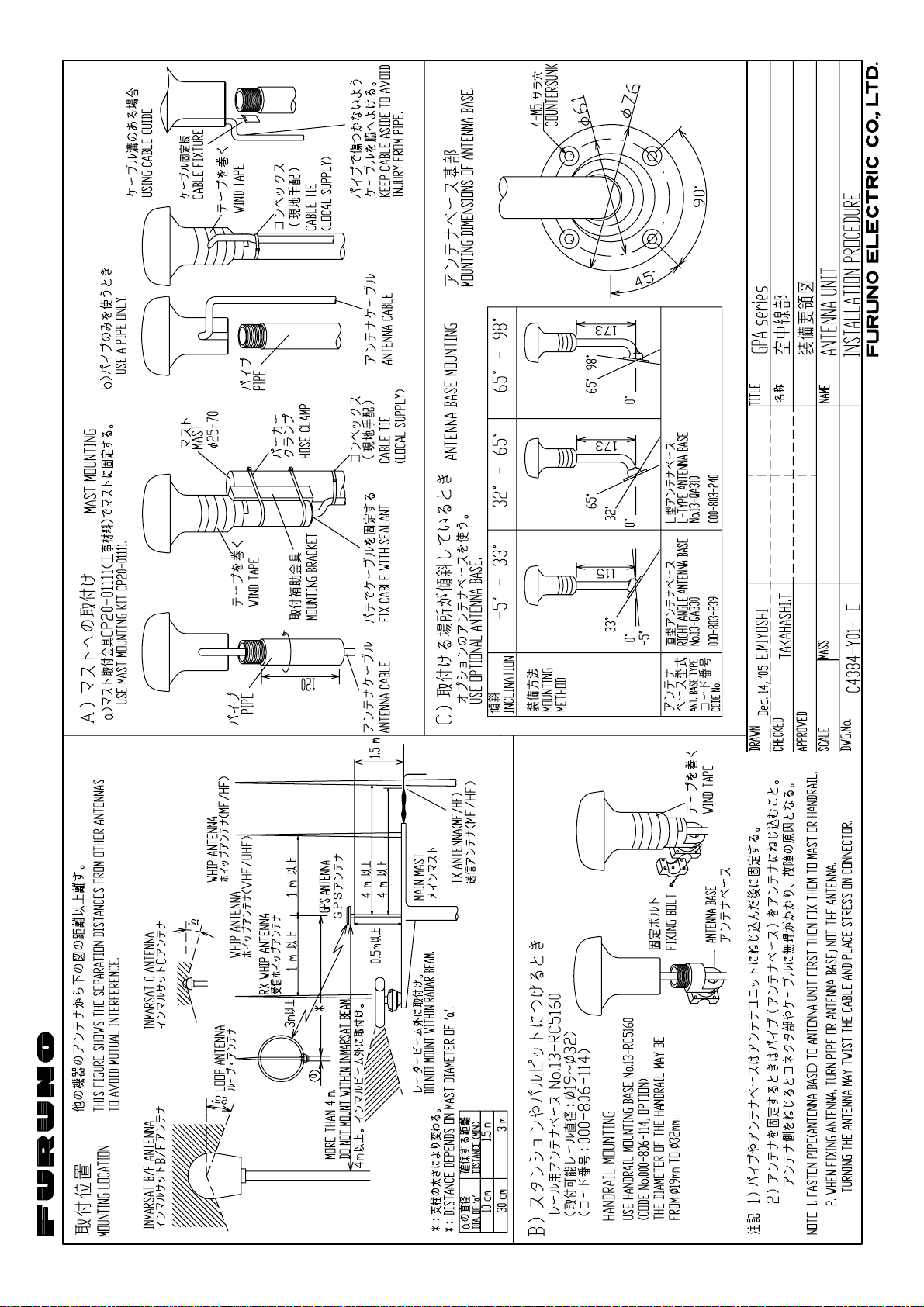

1.2 Antenna Unit

Refer to the antenna unit outline drawing at the back of this manual for mounting instructions.

When selecting a mounting location consider the following points:

• Select a location out of the radar and Inmarsat beams. Those beams will obstruct or prevent

reception of the GPS satellite signal.

• There should be no interfering object within the line-of-sight to the satellites. Object s within lin e-

of-sight to a satellite, for example, a mast, may block reception or prolong acquisition time.

• Locate the antenna well away from the antenna of a VHF radiotelephone to prevent interfer-

ence.

• Mount the antenna unit as high as possible. Mounting it this way keeps it free of interfering

objects and water spray, which can interrupt reception of GPS satellite signal if the water

freezes.

Note: If the antenna cable is to be passed through a hole in a bulkhead which is too small to pass

the connector, disassemble the connector with radio pincers and a monkey wrench. After passing

the cable through the hole assemble the connector as below.

Washer

Clamping Nut

How to assemble the antenna connector

Gasket

Shield

Pin (Solder.)

Housing

4

Page 11

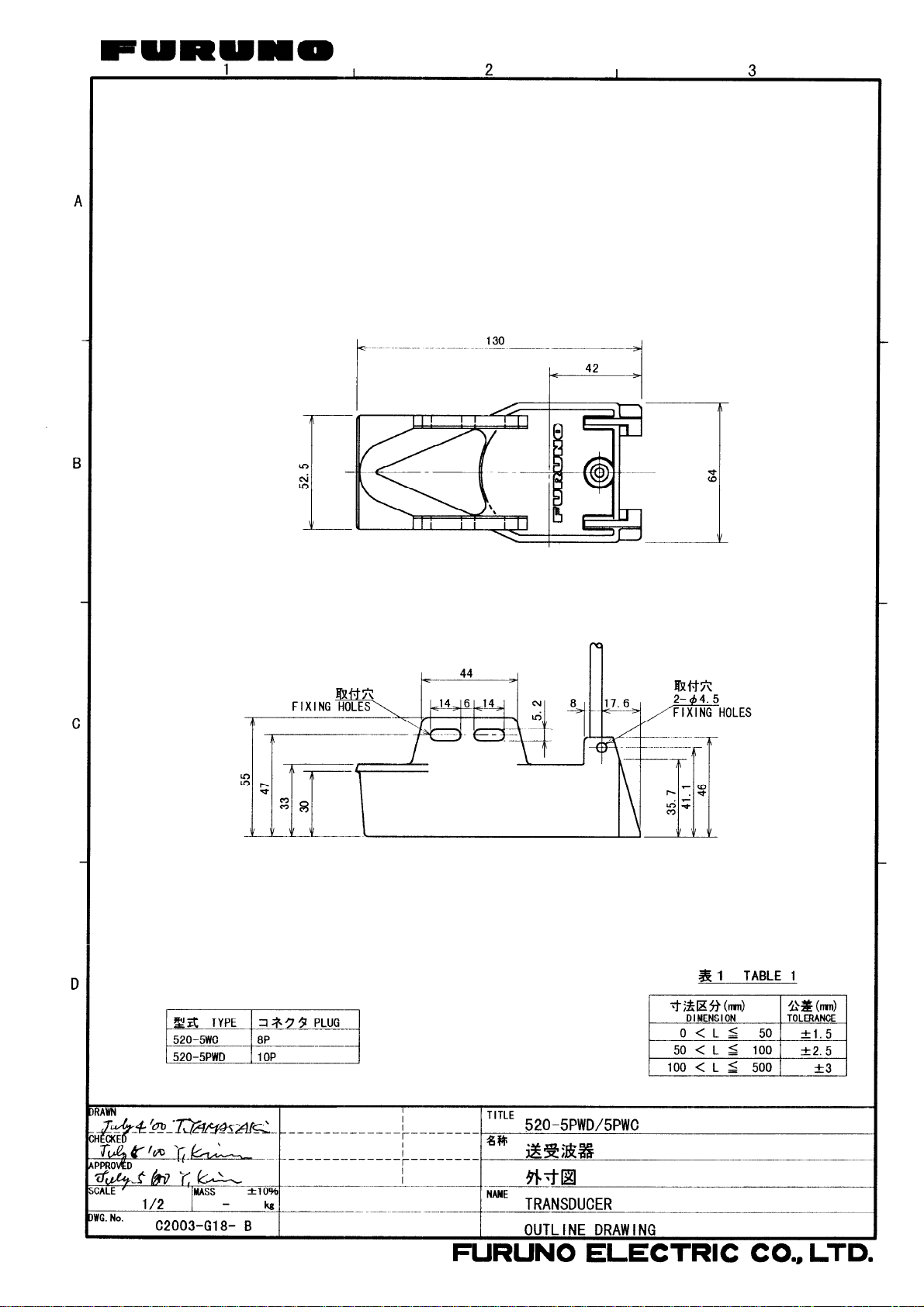

1.3 Transducer

r

Inside-hull mounting

The thru-hull mount transducer (520-5PSD, 520-5MSD) may also be installed inside the hull, following the procedure below.

Necessary tools

You will need the following tools:

• Sandpaper (#100)

• Silicone sealant

Remarks on installation

• Turn off the engine and anchor the boat while installing the equipment.

• Install the transducer in the engine room.

• Do not turn on the echo sounder except if installing the transducer by the inside-hull mounting

method. The transducer may become damaged if the power is turned on in other types of

installations.

Choosing the mounting location

Keep the following points in mind when choosing a mounting location:

• The mounting location should be where the hull is of single-hull thickness and is void of air or

flotation materials other than solid fiberglass between the transducer face and the water.

• Do not place the transducer over hull struts or ribs that run under the hull.

• Avoid a location where the rising angle of the hull exceeds 15°, to minimize the effect of the

boat's rolling.

• You will finalize the mounting location through some trial and error. The procedure for this is

shown later.

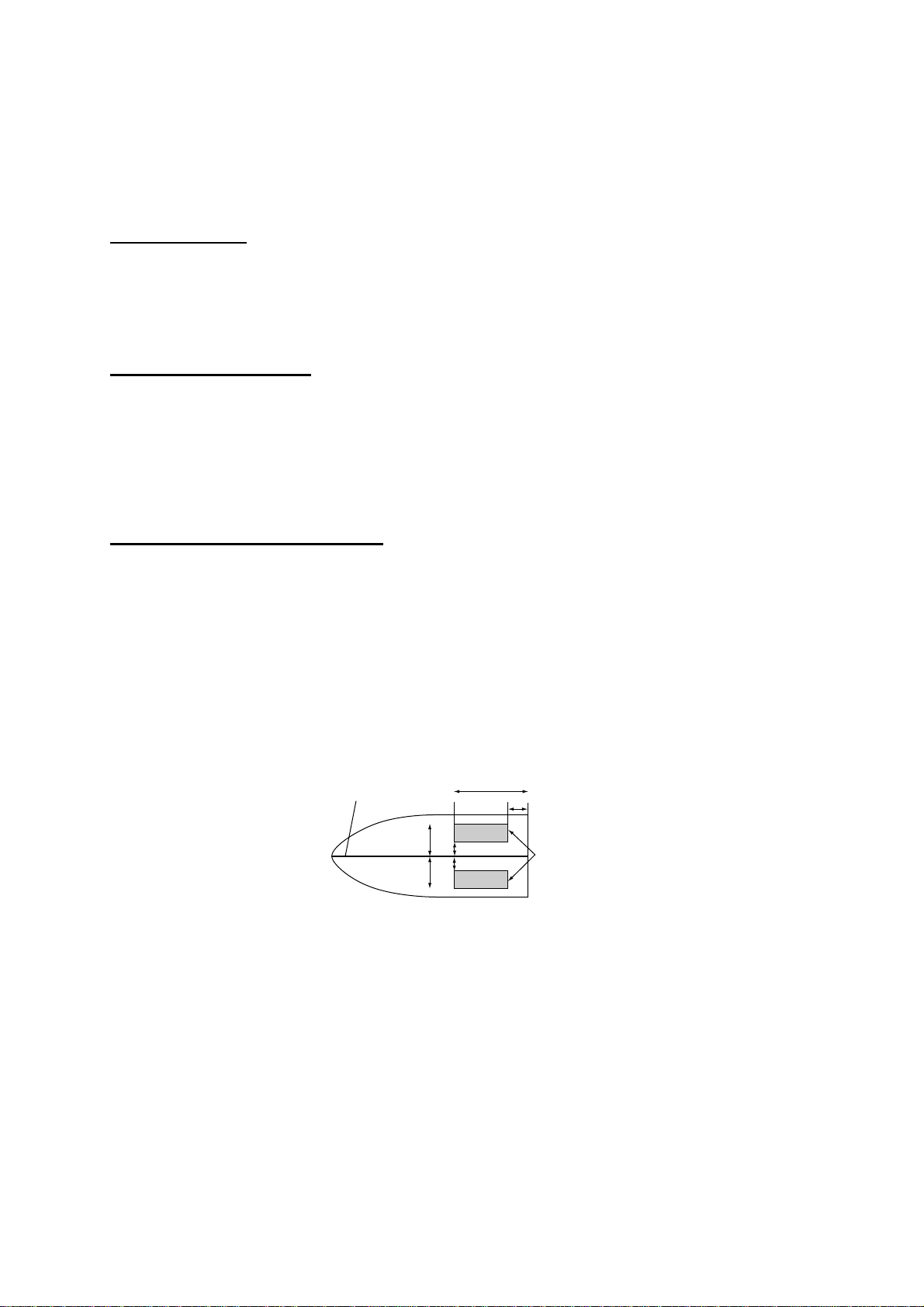

Centerline

50 cm

50 cm

Inside-hull transducer mounting location

1/2

15 cm

15 cm

1/3

Transduce

mounting

location

5

Page 12

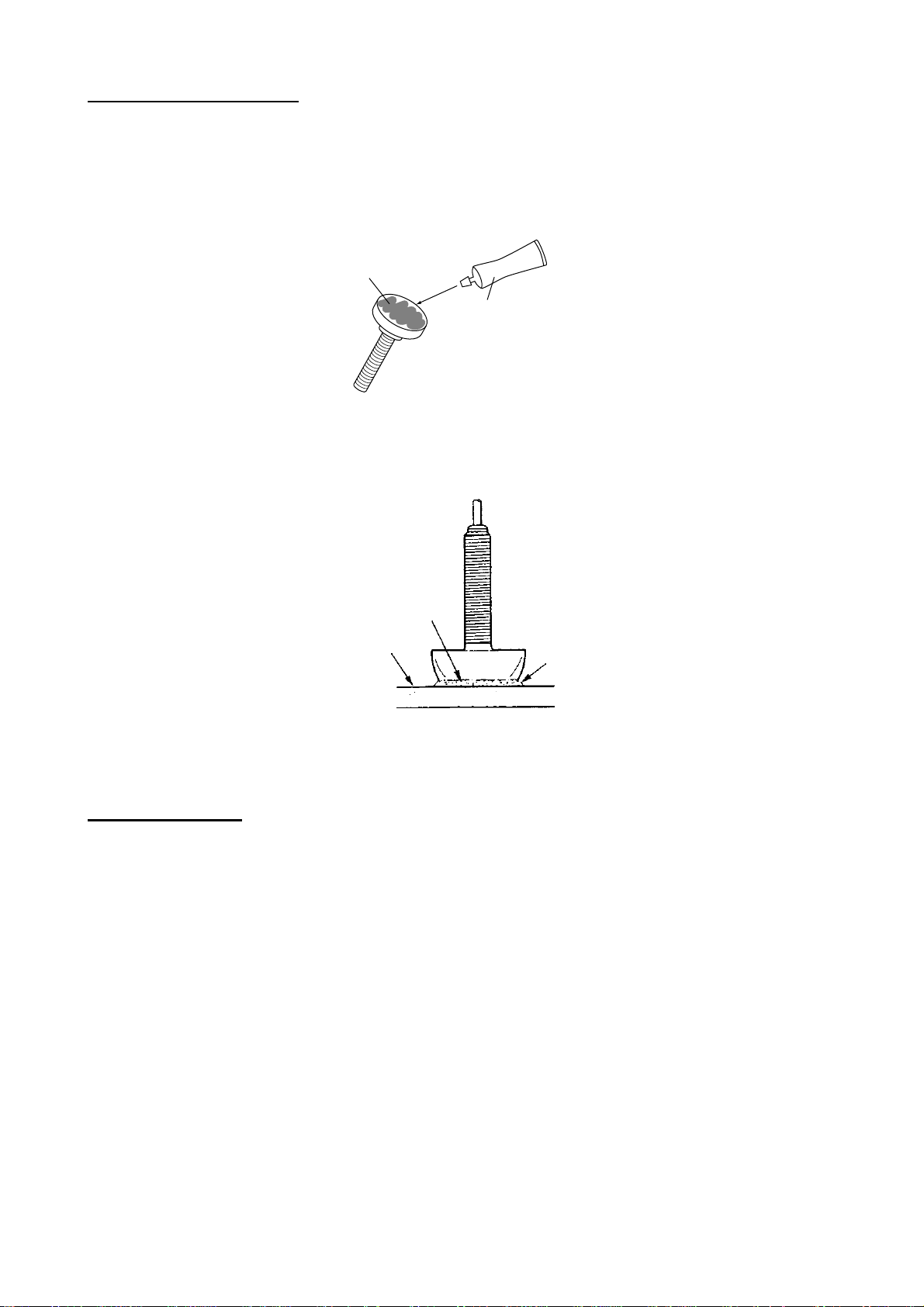

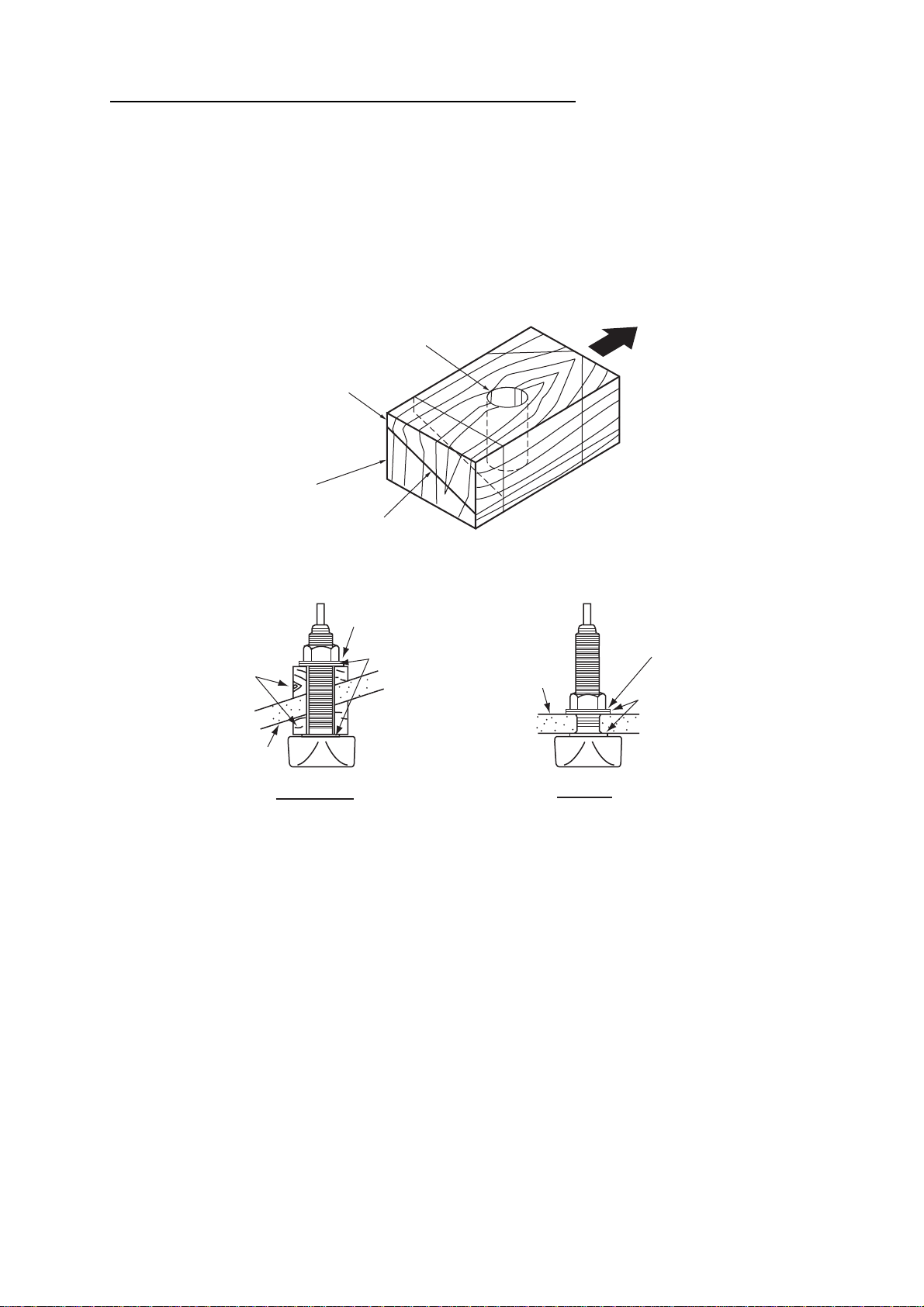

Attaching the transducer

1. Clean the transducer face to remove any foreign material. Lightly roughen the transducer face

with #100 sandpaper. Also, roughen the inside of the hull where the transducer is to be

mounted.

2. Warm the silicone sealant to 40°C before usage to soften it. Coat the transducer face and

mounting location with silicone sealant.

Transducer

Silicone

Sealant

Coating transducer face with silicone sealant

3. Press the transducer firmly down on the hull and gently twist it back and forth to remove any

air that may be trapped in the silicone sealant.

Press down to

remove air bubbles.

Hull plate

Adhesive

Squeezing out air bubbles in adhesive

Final preparations

Support the transducer with a piece of wood to keep it in place while the adhesive is drying. Let

the adhesive dry 24 - 72 hours.

6

Page 13

Thru-hull mounting

Transducer mounting location

The thru-hull mount transducer (520-5PSD, 520-5MSD) provides the best performance of all,

since the transducer protrudes from the hull and the effect of air bubbles and turbulence near the

hull skin is reduced. When the boat has a keel, the transducer should be at least 30 cm away from

it. Typical thru-hull mountings are shown in the figure on the next page.

The performance of a sounder is directly related to the mounting location of the transducer, especially for high-speed cruising. The installation should be planned in advance, keeping the standard

cable length (8 m) and the following factors in mind:

• Air bubbles and turbulence caused by movement of the boat seriously degrade the sounding

capability of the transducer. The transducer should, therefore, be located in a position where

water flow is the smoothest. Noise from the propellers also adversely affects performance and

the transducer should not be mounted nearby. The lifting strakes are notorious for creating

acoustic noise, and these must be avoided by keeping the transducer inboard of them.

• The transducer must always remain submerged, even when the boat is rolling, pitching or up

on a plane at high speed.

• A practical choice would be somewhere between 1/3 and 1/2 of the boat's length from the

stern. For planing hulls, a practical location is generally rather far astern, so that the transducer

is always in water regardless of the planing attitude.

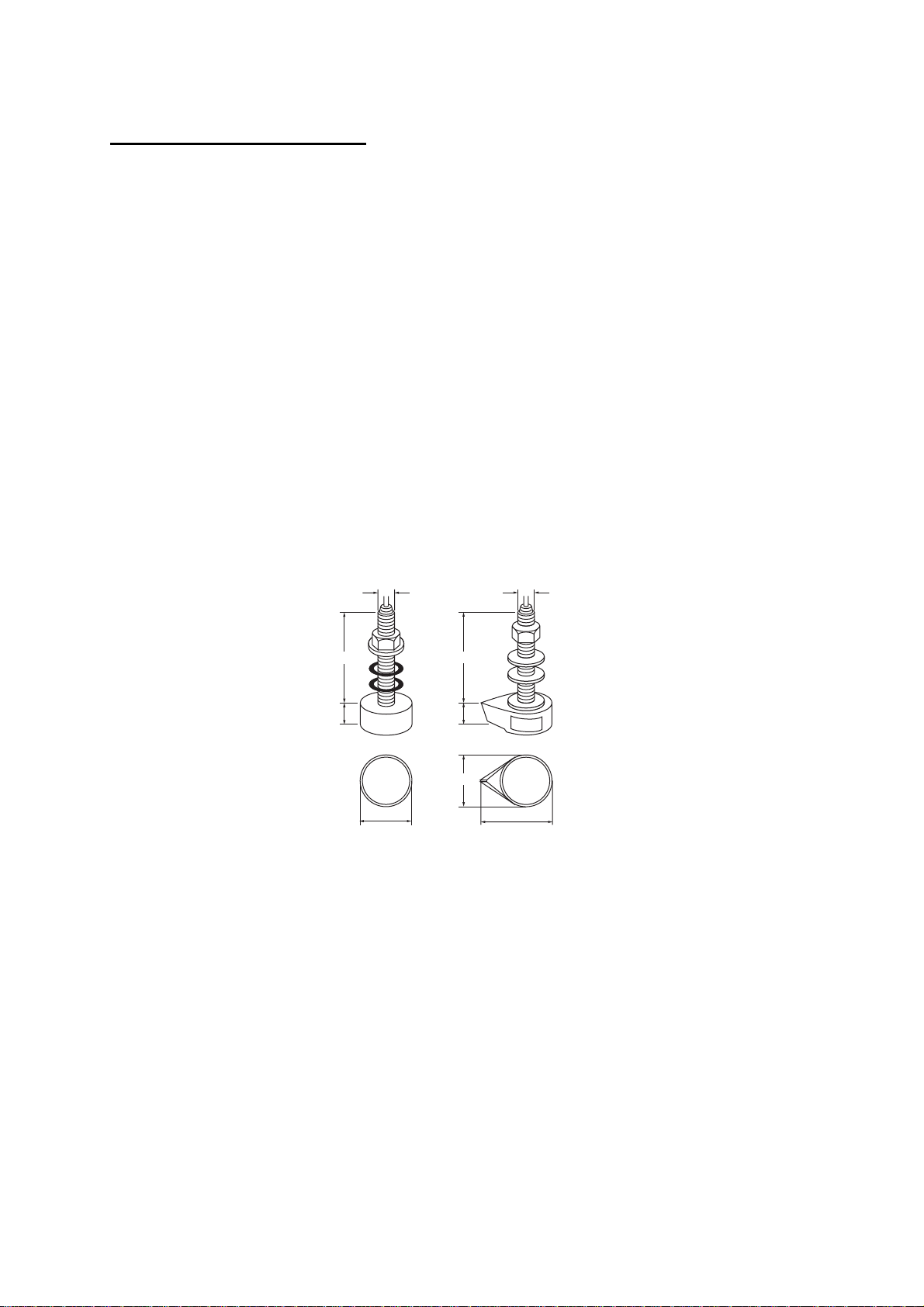

120

30

520-5PSD

22

120

28

68

68

24

90

520-5MSD

Unit: mm

Thru-hull mount transducer mounting dimensions (millimeters)

7

Page 14

Acceptable transducer mounting locations

DEEP-V HULL

Position 1/2 to 1/3 of the hull

from stern.

15 to 30 cm off center line

(inside first lifting strakes.)

HIGH SPEED-V HULL

Within the wetted bottom area

Deadrise angle within 15°

Suitable transducer mounting locations

8

Page 15

Procedure for installing the thru-hull mount transducer

r

1. With the boat hauled out of the water, mark the location chosen for mounting the transducer

on the bottom of the hull.

2. If the hull is not level within 15° in any direction, fairing blocks made out of teak should be

used between the transducer and hull, both inside and outside, to keep the transducer face

parallel with the water line. Fabricate the fairing block as shown below and make the entire

surface as smooth as possible to provide an undisturbed flow of water around the transducer.

The fairing block should be smaller than the transducer itself to provide a channel to divert turbulent water around the sides of the transducer rather than over its face.

Fairing

Block

Hull

Upper Half

Lower Half

Saw along slope

of hull.

Construction of fairing block

Flat Washer

Rubber Washer

Hole for

stuffing tube

BOW

Flat Washer

Hull

Rubber Washe

Deep-V Hull

Flat Hull

Transducer mounting

3. Drill a hole just large enough to pass the threaded stuffing tube of the transducer through the

hull, making sure it is drilled vertically.

4. Apply a sufficient amount of high quality caulking compound to the top surface of the transducer, around the threads of the stuffing tube and inside the mounting hole (and fairing blocks

if used) to ensure watertight mounting.

5. Mount the transducer and fairing blocks and tighten the locking nuts. Be sure that the transducer is properly oriented and its working face is parallel to the waterline.

Note: Do not over-stress the stuffing tube and locking nuts through excessive tightening, since

the wood block will swell when the boat is placed in the water. It is suggested that the nut be tightened lightly at installation and retightened several days after the boat has been launched.

9

Page 16

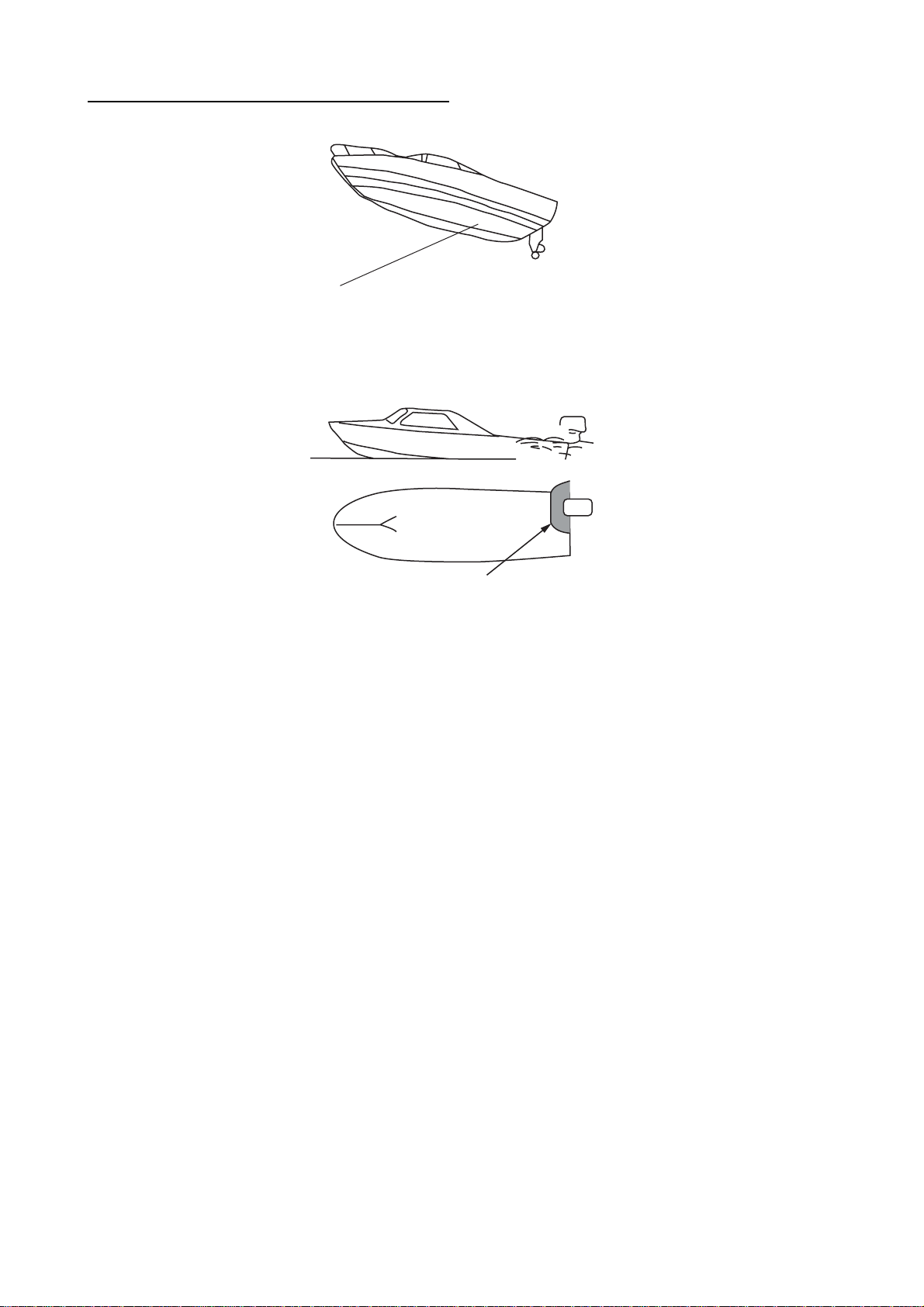

Transom mount transducer

The transom mount transducer (525-5PWD) is very commonly employed, usually on relatively

small inboard/outboard or outboard boats. Do not use this method on an inboard motor boat because turbulence is created by the propeller ahead of the transducer.

There are two methods of installation: flush with hull (for flat hulls) and projecting from hull (for

deep V-hulls).

D

D>50 cm

Deep-V

Flat Hull

Transom mount transducer mounting locations

Installing the transom mount transducer on a flat hull

Hull

A suitable mounting location is at least 50 cm away from the engine and where the water flow is

smooth.

1. Drill four pilot holes in the mounting location.

2. Attach the transducer to the bracket with 5x20 tapping screws (supplied).

3. Adjust the transducer position so the transducer faces right to the bottom.

Note: If necessary, to improve water flow and minimize air bubbles staying on the transducer

face, incline the transducer about 5° downward at the rear - loosen the screws fixing the transducer, tilt the transducer and tighten screws. This may require a certain amount of expe rimentation for fine tuning at high cruising speeds.

4. Fill the gap between the wedge front of the transducer and transom with epoxy material to

eliminate any air spaces.

5x20

5x20

5°

Tape

No.1

M5x14

Transom mount transducer, mounting flush with hull

10

Page 17

Installing the transom mount transducer on a deep-V hull

This method is employed on deep-V hulls and provides good performance because the effects of

air bubbles are minimal. Install the transducer parallel with water surface; not flush with hull. If the

boat is placed on a trailer, care must be taken not to damage the transducer when the boat is

hauled out of the water and put on the trailer.

Transom mount transducer, mounted projecting from hull

Transducer preparation

Before putting the boat in water, wipe the face of the transducer thoroughly with a detergent liquid

soap. This will lessen the time necessary for the transducer to have good contact with the water.

Otherwise the time required for complete "saturation" will be lengthened and performance will be

reduced.

DO NOT paint the transducer. Performance will be affected.

11

Page 18

Optional triducer

525ST-MSD

The optional triducer 525ST-MSD is designed for thru-hull mounting. For how to install it, see "thru-hull mounting” on page 7.

φ79 mm

133 mm

2.00"-12 UN

threads

φ51 mm

7 mm

27 mm

Triducer 525ST-MSD

140 mm

525ST-PWD

The Transom Mount Transducer or TRIDUCER® Multisensor with Integral Release Bracket

525ST-PWD is manufactured by AIRMAR Co. These instructions are included with the sensor.

Pre-test for speed and temperature

Connect the sensor to the instrument and spin the paddlewheel. Check for a speed reading and

the approximate air temperature. If there is no reading, return the sensor to your place of purchase.

Tools and materials needed

Scissors

Masking tape

Safety goggles

Dust mask

Electric drill

12

Page 19

Drill bit for:

Bracket holes: 4 mm, #23, or 9/64"

Fiberglass hull: chamfer bit (preferred),

6 mm, or 1/4"

Transom hole: 19 mm or 3/4" (optional)

Cable clamp holes: 3 mm or 1/8"

Screwdrivers

Straight edge

Marine sealant

Pencil

Zip-ties

Water-based antifouling paint (mandatory in salt water).

Mounting location

To ensure the best performance, the sensor must be submerged in aeration-free and turbulencefree water. Mount the sensor close to the centerline of the boat. On slower heavier displacement

hulls, positioning it farther from the centerline is acceptable.

Allow adequate space above the bracket for it to release and rotate the sensor upward.

Height without

speed sensor

191 mm (7-1/2")

Height with

speed sensor

213 mm (8-1/2")

Height

Height required at mounting location

Note 1: Do not mount the sensor in an area of turbulence or bubbles: near water intake or discharge openings; behind strakes, struts, fittings, or hull irregularities; behind eroding paint (an indication of turbulence).

Note 2: Avoid mounting the sensor where the boat may be supported during trailering, launching,

hauling, and storage.

Note 3: For single drive boat, mount on the starboard side at least 75 mm (3") beyond the swing

radius of the propeller.

75 mm (3")

minimum beyond

swing radius

Mounting location on single drive boat

Note 4: For twin drive boat, mount between the drives.

13

Page 20

Installation of bracket

1. Cut out the installation template shown below.

2. At the selected location, position the template, so the arrow at the bottom is aligned with the

bottom edge of the transom. Being sure the template is parallel to the waterline, tape it in

place.

Installation template

for starboard side of boat

Drill at locations labeled "B"

for the following transom angles:

16

°

through 22

°

Align template vertically.

B

B

B

AAA

Drill at locations labeled "A"

for the following transom angles:

2

°

through 15

°

Align arrow with bottom of transom

Align template arrow with

bottom edge of transom.

Positioning the template

Deadrise angle

Slope of hull

parallel to

waterline

Warning: Always wear safety goggles and a dust mask.

3. Using a 4 mm, #23, or 9/64" bit, drill three holes 22 mm (7/8") deep at the locations indicated.

To prevent drilling too deeply, wrap masking tape around the bit 22 mm (7/8") from the point.

Fiberglass hull: Minimize surface cracking by chamfering the gelcoat. If a chamfer bit or

countersink bit is not available, start drilling with a 6 mm or 1/4" bit to a depth of 1 mm (1/16").

4. If you know your transom angle, the bracket is designed for a standard 13° transom angle.

11° - 18° angle: No shim is required. Skip to step 3 in "Adjusting".

Other angles: The shim is required. Skip to step 2 of "Adjusting".

If you do not know the transom angle, temporarily attach the bracket and sensor to the transom to determine if the plastic shim is needed.

5. Using the two #10 x 1-1/4" self-tapping screws, temporarily screw the bracket to the hull.

DO NOT tighten the screws completely at this time. Follow the step 1-4 in "Attaching the Sensor to the Bracket", before proceeding with "Adjusting".

14

Page 21

Adjusting

1. Using a straight edge, sight the underside of the sensor relative to the underside of the hull.

The stern of the sensor should be 1-3 mm (1/16-1/8") below the bow of the sensor or parallel

to the bottom of the hull.

2°-10°

transom

angle

shim with

taper down

parallel

angle

reversed

11° transom angle

NO SHIM

YES

12°-18° transom angle

NO

YES

parallel

NO SHIM

YES

slight

angle

19°-22°

transom

angle

shim with

taper up

YES

parallel

NO

angle

too steep

Sensor position and transom angle

Note: Do not position the bow of the sensor lower than the stern because aeration will occur.

2. To adjust the sensor's angle relative to the hull, use the tapered plastic shim provided. If the

bracket has been temporarily fastened to the transom, remove it. Key the shim in place on the

back of the bracket.

2° - 10° transom angle (stepped transom and jet boats): Position the shim with the t apered

end down.

19° - 22° transom angle (small aluminum and fiberglass boats): Position the shim with the

tapered end up.

3. If the bracket has been temporarily fastened to the transom, remove it. Apply a marine sealant

to the threads of the two #10 x 1-1/4" self tapping screws to prevent water seeping into the

transom. Screw the bracket to the hull. Do not tighten the screws completely at this time.

4. Repeat step 1 to ensure that the angle of the sensor is correct.

Note: Do not position the sensor farther into the water than necessary to avoid increasing drag,

spray, and water noise and reducing boat speed.

15

Page 22

5. Using the vertical adjustment space on the bracket slots, slide the sensor up or down to provide a projection of 3 mm (1/8"). Tighten the screws.

Cable cover

Cable

clamp

50 mm (2")

Hull projection 3 mm (1/8")

Vertical adjustment and cable routing

Attaching the sensor to the bracket

1. If the retaining cover near the top of the bracket is closed, open it by depressing the latch and

rotating the cover downward.

Step 1

Latch

Pivot

arm (2)

Retaining

cover

Step 2

Step 3

Step 4

Slot (2)

Attaching the sensor to the bracket

2. Insert the sensor's pivot arms into the slots near the top of the bracket.

3. Maintain pressure until the pivot arms click into place.

4. Rotate the sensor downward until the bottom snaps into the bracket.

5. Close the retaining cover to prevent the accidental release of the sensor when the boat is

underway.

Cable routing

Route the sensor cable over the transom, through a drain hole, or through a new hole drilled in

the transom above the waterline.

Never cut the cable or remote the connector; this will void the warranty. Always wear safety goggles and a dust mask.

1. If a hole must be drilled, choose a location well above the waterline. Check for obstructions

such as trim tabs, pumps, or wiring inside the hull. Mark the location with a pencil. Drill a hole

through the transom using a 19 mm or 3/4" bit (to accommodate the connector).

2. Route the cable over or through the transom.

3. On the outside of the hull secure the cable against the transom using the cable clamps. Position a cable clamp 50 mm (2") above the bracket and mark the mounting hole with a pencil.

16

Page 23

4. Position the second cable clamp halfway between the first clamp and the cable hole. Mark this

mounting hole.

5. If a hole has been drilled in the transom, open the appropriate slot in the transom cable cover.

Position the cover over the cable where it enters the hull. Mark the two mounting holes.

6. At each of the marked locations, use a 3 mm or 1/8" bit to drill a hole 10 mm (3/8") deep. The

prevent drilling too deeply, wrap masking tape around the bit 10 mm (3/8") from the point.

7. Apply marine sealant to the threads of the #6 x 1/2" self-tapping screw to prevent water from

seeping into the transom. If you have drilled a hole through the transom, apply marine sealant

to the space around the cable where it passes through the transom.

8. Position the two cable clamps and fasten them in place. If used, push the cable cover over the

cable and screw it in place.

9. Route the cable to the instrument being careful not to tear the cable jacket when passing it

though the bulkhead(s) and other parts of the boat. To reduce electrical interference, separate

the sensor cable from other electrical wiring and "noise" sources. Coil any excess cable and

secure it in place with zip-ties to prevent damage.

17

Page 24

1.4 Optional Speed/Water Temperature Sensor

ST-02MSB, ST-02PSB

1. Dry-dock the boat.

2. Make a hole of approx. 51 mm diameter in the mounting location.

3. Unfasten locknut and remove the sensor section.

4. Apply high-grade sealant to the flange of the sensor.

5. Pass the sensor casing through the hole.

6. Face the notch on the sensor toward boat's bow and tighten the flange.

7. Set the sensor section to the sensor casing and tighten the locknut.

8. Launch the boat and check for water leakage around the sensor.

Locknut

Face "notch"

toward bow.

Brim

51

123

φ

77

Unit: mm

Flange Nut

Coat with

silicone sealant.

Speed/water temperature sensor ST-02MSB, ST-02PSB

18

Page 25

2. WIRING

The figure below shows the basic wiring scheme.

ANTENNA UNIT

GPA-017

FROM LEFT

PC/NMEA IN: Connection of PC, NMEA device, AIS

NMEA 2: Radar, autopilot, video sounder,

temperature indicator, etc.

NMEA 1: Same as NMEA 2

Transducer

Speed/Water

Temp Sensor

(option)

Antenna Cable 10 m

Ground

Black

Power

Source

Display unit, rear view

MJ-A15A3F0013-035-3A,

3.5 m

White

Shield

19

Page 26

Power source

The power source is a 12-24 VDC battery. Be sure the power cable is tightly fastened to the power

source and the polarity (plus and minus) is correct. Connect the white lead to the positive terminal

(+) and the black lead to the negative terminal (-).

Transducer

Connect the transducer to XDR port on the rear of the display unit. If the optional speed/water temperature sensor is connected, connect the transducer with the optional cable 02S4147 (Code No.

000-141-082).

Connect to XDR port on display unit

MJ-A10SPF

Connection Cable

Type: 02S4147

Code No.: 000-141-082

MJ-A6SRMD

Connect water temperature

sensor, speed/water temperature

sensor.

MJ-A10SRMD

Connect transducer.

How to connect transducer and sensor with optional cable 02S4147

20

Page 27

MJ-A6SRMD

GP-7000F

MJ-A10SPF

Speed/Water

Temp.

Sensor

Transducer

Wiring for connection of speed/water temperature sensor with cable 02S4147

SHIELD

TEMP

TEMP0V/SPD0V

SPD

+V

NC

MJ-A10SRMD

NC

NC

NC

NC

NC

NC

NC

XDR+

XDR SHIELD

XDR-

10

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

4

7

3

1

2

5

6

8

9

10

TEMP

TEMP0V

TEMP0V/SHIELD

SPD

+12V

NC

NC

XDR+

XDR-SHIELD

XDR-

Ground

Connect the ground wire to the boat's grounding bus. If the unit is not grounded, noise may result.

If noise is a problem on an FRP vessel, fasten a ground plate of 20 cm x 30 cm to the outside of

the ship's hull and connect the ground wire there.

Use a closed-type lug ( ) for the connection on the display unit. Do not use an open-type lug

().

21

Page 28

Antenna cable

Types of antenna cables

If a longer len gt h of antenna cable is required, use the optional ant enna cable set, wh ic h is av ailable in 30 and 50 m lengths.

Antenna cable set

Antenna

cable set

CP20-01700 004-372-110

CP20-01710 004-372-120

Code no. Contents

1) Converter cable assy. NJ-T-3DX-1, Code No. 000-123

2) Vinyl tape NO.360 Code No. 000-835-215

3) Connector N-P-8DFB-CF, Code No. 000-156-918-10

4) Self-bonding tape U-tape, Code No. 000-165-833-10

5) Antenna cable assy. 8D-FB-CV*30m*, Code No. 000-117-547

Items 1) - 4) above plus:

Antenna Cable Assy. 8D-FB-CV*50m*, Code No. 000-117-549

Connecting the antenna cable

If you are us ing the antenna c able set, a coa x ial connecter is fi tted at one end of th e c able as

shown be low.

Antenna Unit

GPA-017

Antenna Cable

10 m

Connector fitted at factory.

Connect at

rear of

display unit

Connec t ion of standard ant enna cable (T N C -PS3D-15)

Antenna Unit

GPA-017S

20 cm

1m

ANTENNA CABLE KIT

Conversion Cable

Assy.

Antenna Cable

30 m or 50 m

Connector fitted at factory

1 m

Attached during installation

(See page 8.)

Connection of extension cable (CP20-01700, CP20-01710)

Connect at

rear of

display unit

22

Page 29

Waterproofing the connector

If you are using the extension cable, connect the cable and then wrap the connector with self-vulcanizing tape and then vinyl tape to waterproof it. Bind ends of vinyl tape with cable ties (local supply) to prevent unraveling.

How to waterproof the connector

23

Page 30

How to attach N-P-8DFB connector (for extension cable kit)

Outer Sheath

Cover with heat-shrink tubing and heat.

Armor

30

Clamping

Nut

Dimensions in millimeters.

Inner Sheath Shield

50

Flat Washer

Gasket

(reddish

brown)

30

10

Clamp

Aluminum Foil

Remove outer sheath and armor by the dimensions

shown left.

Expose inner sheath and shield by the dimensions

shown left.

Cut off insulator and core by 10 mm.

Twist shield end.

Slip on clamping nut, flat washer, gasket and clamp

as shown left.

Trim shield here.

Trim aluminum

tape foil here.

Clamping Nut

Insulator

5

Pin

Washer 2

Spacer

Housing

Fold back shield over clamp and trim.

Cut aluminum foil at four places, 90° from one

another.

Fold back aluminum foil onto shield and trim.

Remove insulator up to edge of washer 2.

Expose the core by 5 mm.

Slip the pin onto the conductor. Solder them together

through the hole on the pin.

Insert the spacer and housing. Screw the clamping

nut into the housing.

Solder through

the hole.

(Tighten by turning the clamping nut. Do not tighten

by turning the housing.)

How to attach N-P-8DFB connector

24

Page 31

Optional transducer

The optional Distributor MB-1000 is required to connect the optional transducers 50B-6, 50B-6G,

200B-5S, 200B-5S, 50/200-IT. The optional cable assy 02S4089 (Code No. 000-133 -622, 1 m) is

required to connect the Distributor.

* R/W = Red/White

Transducer

50B-6/6G

50kHz

200kHz

SHIELD

R/W*

R/W*

BLK

BLK

TB2

J2 J1

1

2

3

4

5

02P6168

TB1

3

2

1

BLK

WHT

200B-5/5S

Detach grommet;

attach cord lock.

Distributor MB-1000, cover removed

Distributor MB-1000 (Code No.: 000-040-809)

Part Type Code No. Qty Remarks

Distributor MB-1000 000-040-805 1

Crimp-on Lug FV1.25-3, red 000-538-113 6

Shield

Connect 8P connector to

cable assy. 02S4089.

Cord Lock NC-1 000-516-650 1 Used to connect two transducers

Fabricating the transducer cable

Fabricate the transducer cable as below and connect it to the Distributor, referring to the interconnection diagram.

Vinyl Sheath

Crimp-on Lug

FV1.25-3, Red

Clamp here.

Taping

Shrink Tubing

Shield

How to fabricate the transducer cable

25

Page 32

3. ADJUSTMENTS

This chapter shows you how to adjust your unit, from the menu. When choosing item or option

from the menu, you may use the [ENTER] knob or the CursorPad ( ). For sake of brevity the

descriptions contained herein use the [ENTER] knob.

3.1 Choosing Position Data Source

1. Press the [MENU] key to show the menu bar.

Menu Bar

2. Rotate the [ENTER] knob to choose ADVANCED from the menu bar and then push the

[ENTER] knob.

GENERAL PLOTTER MAP ALARMS ADVANCED INFO FIND

Menu bar

FIX

NAVIGATE

COMPASS

INPUT/OUTPUT

EXT NMEA

GPS SIMULATION

ECHO SOUNDER SIMULATION On

AIS SETUP

C-MAP WEATHER SERVICE

SYSTEM UPDATE

ADVANCED menu

26

Page 33

3. Rotate the [ENTER] knob to choose INPUT/OUTPUT and then push the [ENTER] knob.

INTERNAL GPS SETUP

NMEA 1 INPUT NMEA-0183 4800-N81-N

NMEA 1 OUTPUT

NMEA 2 INPUT NMEA-0183 4800-N81-N

NMEA 2 OUTPUT

RS232/NMEA 3 INPUT NMEA-0183 4800-N81-N

RS232C 3 OUTPUT

INPUT 3 MODE RS232C

WPL/RTE FORMAT Standard

EXTERNAL EVENT Off

C-LINK Off

DEPTH SOURCE Sounder

TEMP SOURCE NMEA

STW SOURCE NMEA

INPUT/OUTPUT menu

4. Rotate the [ENTER] knob to choose INTERNAL GPS SETUP and then push the [ENTER]

knob.

RESTART GPS

INTERNAL GPS On

DIFF CORR SOURCE WAAS

WAAS SEARCH Auto

INTERNAL GPS SETUP menu

5. Rotate the [ENTER] knob to choose INTERNAL GPS and then push the [ENTER] knob.

Off

On

6. Rotate the [ENTER] knob to choose Off or On and then push the [ENTER] knob.

Off: Use external navigator

On: Use internal GPS navigator

7. Press the [MENU] key to close all open windows and erase the menu bar.

27

Page 34

3.2 Choosing Port I/O Format

1. Press the [MENU] key to show the menu bar.

2. Rotate the [ENTER] knob to choose ADVANCED from the menu bar and then push the

[ENTER] knob.

3. Rotate the [ENTER] knob to choose INPUT/OUTPUT and then push the [ENTER] knob.

4. Rotate the [ENTER] knob to choose appropriate INPUT or OUTPUT item and then push the

[ENTER] knob.

NMEA-0183 1200-N81-N

NMEA-0183 4800-N81-N

NMEA-0183 4800-N82-N

NMEA-0183 9600-N81-N

NMEA-0183 9600-O81-N

C-COM

AIS 38400

Disabled

NMEA1/NMEA 2/

RS232/NMEA 3 Input*

GLL On

VTG On

BWR Off

DBT Off

DPT Off

MTW Off

VHW Off

WCV Off

APA Off

APB On

HDG Off

BOD Off

XTE Off

RMA Off

RMB On

RMC On

GGA Off

HSC Off

AAM Off

GTD Off

MWV Off

ZDA Off

WPL On

RTE On

TLL OUT On

RS232CW

NMEA

INPUT 3 MODE*

*: For AIS, set as below.

RS232/NMEA 3 INPUT: "AIS 38400"

INPUT 3 MODE: "RS232C"

(Choose format for

PC/NMEA IN port)

NMEA1/NMEA2/RS232 Output

NMEA 1 INPUT, NMEA 1 OUTPUT menus

5. Do one of the following depending on item selected.

Input

1) Rotate the [ENTER] knob to choose appropriate option and then push the [ENTER] knob.

Below is the meaning of the NMEA options. "C-COM" is for connection of a GSM modem.

For details about the GSM modem, see its owner's manual.

NMEA-0183 4800-N81-N

1 2 3 4 5 6

1 Data format

2 Baud rate: 1200, 4800, 9600(bps)

3 Parity: N (No parity) or O (Odd parity)

4 Character length (8)

5 Stop bit: 1 or 2

6 X-On/Off (non)

Description of NMEA options

2) Press

W to close the window.

28

Page 35

Output

1) Rotate the [ENTER] knob to choose appropriate option and then push the [ENTER] knob.

Off

On

2) Rotate the [ENTER] knob to choose Off or On as appropriate and then push the [ENTER]

knob followed by W.

6. Repeat step 5 to set up other ports.

7. Press the [MENU] key to close all open windows and erase the menu bar.

I/O format

Port I/O format Data sentence Remarks

Input NMEA 1, NMEA 2 IEC-61162-1,

NMEA-0183

Ver. 1.5/2.0/3.0

PC/NMEA IN RS232, and IEC

and NMEA above

Output NMEA 1, NMEA 2 IEC-61162-1,

NMEA-0183

Ver. 1.5/2.0/3.0

PC/NMEA IN RS232

Input data, sentence priority

Data Sentence priority order Remarks

Speed thru water VHW

See table below.

For NMEA IN, see

table below.

GLL, VTG, BWR, DBT,

DPT, MTW, VHW,

WCV, APA, APB,

HDG, BOD, XTE,

RMA, RMB, RMC,

GGA, HSC, WPL,

RTE, TLL OUT, AAM,

GTD, MWV, ZD A

BWR: Rhumb line

True heading HDT, HDG, HDM

Magnetic heading HDT, HDG, HDM

Target position TLL

Radiotelephone target position DSC, DSE

Waypoint data RMB

Depth DPT, DBT

Water temperature MTW

Wind current, speed MWV

29

Page 36

3.3 Echo Sounder Settings

Setting transducer model, output power

The GP-7000F is preset to use a 600 W transducer (520-5PSD, 525-5PWD, 520-5MSD). For a 1

kW transducer, follow the procedure below. Note that the optional Distributor MB-1000 and cable

assy. 02S4089 are necessary in order to use a 1 kW transducer.

Output Power Transducer

600 W 520-5PSD, 525-5PWD, 520-5MSD

1 kW 50B-6, 50B-6G, 200B-5, 200B-5S, 50/200-IT

1. Use the [DISP] key to choose an echo sounder display.

2. Press the [MENU] key to show the menu bar.

3. Rotate the [ENTER] knob to choose SOUNDER from the menu bar and then push the

[ENTER] knob.

AUTO MODE PRESET FISH

DISPLAY MODE NORMAL

FREQUENCY 50 KHz

PICTURE ADVANCE 1/1

TEMPERATURE GRAPH On

ZOOM MARKER On

A-SCOPE Off

SOUNDER SETUP

SENSOR SETUP

ECHO SOUNDER SYSTEM SETUP menu

4. Rotate the [ENTER] knob to choose SOUNDER SETUP and then push the [ENTER] knob.

TRANSMISSION On

TRANSMISSION POWER High

TRANSDUCER 600W

50 KHz TVG 00

200 KHz TVG 00

50 KHz ECHO OFFSET +000

200 KHz ECHO OFFSET +000

50 KHz BOTTOM LEVEL +000

200 KHz BOTTOM LEVEL +000

SMOOTHING SM2

DEPTH INFORMATION Large

PLAYBACK SOUNDER IMAGE Off

ECHO SOUNDER SIMULATION

Off

SOUNDER SETUP menu

5. Rotate the [ENTER] knob to choose TRANSDUCER and then push the [ENTER] knob.

600W

1KW

6. Rotate the [ENTER] knob to choose 1KW and then push the [ENTER] knob.

7. Press the [MENU] key to close all open windows and erase the menu bar.

30

Page 37

Calibrating speed/water temperature sensor, setting draft

The optional speed/water temperature sensor may be calibrated as below to compensate for error. If you require depth from the sea surface (rather than the transducer), set it with "DRAFT SETUP."

For either sensor calibration or draft setting, enter a minus value if the actual value is lower than

the sensor data, or a plus value if the actual value is higher than the sensor data. For example, if

the actual speed is 11.0 kt and the speed data output by the sensor is 10.0 kt, enter +10(%).

1. Use the [DISP] key to choose an echo sounder display.

2. Press the [MENU] key.

3. Rotate the [ENTER] knob to choose SOUNDER from the menu bar and then push the

[ENTER] knob.

AUTO MODE PRESET FISH

DISPLAY MODE NORMAL

FREQUENCY 50 KHz

PICTURE ADVANCE 1/1

TEMPERATURE GRAPH On

ZOOM MARKER On

A-SCOPE Off

SOUNDER SETUP

SENSOR SETUP

ECHO SOUNDER menu

4. Rotate the [ENTER] knob to choose SENSOR SETUP and then push the [ENTER] knob.

DRAFT +000.0 Ft

SPEED CALIBRATION +00 %

TEMP CALIBRATION +00.00°F

ACOUSTIC SPEED CALIBRATION +00 m/s

SENSOR SETUP menu

5. Rotate the [ENTER] knob to choose DRAFT, SPEED CALIBRATION, TEMP CALIBRATON or

ACOUSTIC SPEED CALIBRATION as appropriate.

DRAFT: Enter ship's draft to get depth from sea surface (instead of transducer).

SPEED CALIBRATION: Find correct speed from known source and enter offset to correct on-

screen speed indication.

TEMP CALIBRATION: Find correct water temperature from known source and enter offset to

correct on-screen water temperature indication.

ACOUSTIC SPEED CALIBRATION: Water temperature or salinity content can affect the

depth measurement. Find correct acoustic speed from know source and enter offset to correct

on-screen depth indication.

6. Push the [ENTER] knob. The cursor is selecting the plus sign (or minus sign). If it is necessary

to switch from plus to minus or vice versa, rotate the [ENTER] knob to choose plus or minus

and then push the [ENTER] knob. If not necessary, go to step 7. (Choose minus if the actual

value is lower than the value output by the sensor, or choose plus if the actual value is higher

than the value output by the sensor.)

7. Push the [ENTER] knob.

31

Page 38

8. Rotate the [ENTER] knob to set digit and push the [ENTER] knob. To clear a line of data,

press the [CLR FLD] soft key (one of the keys below the screen).

Setting range

Draft setup: -20 - +39.9 (ft)

Speed calibration: -50 - +50 (%)

Temp calibration: -50 - +5 (

Acoustic speed calibration: -50 - +50 (ms)

9. Set other digits as you did in step 8.

10.Press the [SAVE] soft key (one of the keys below the screen).

11.If necessary, follow steps 5-11 to set other items.

12.Press the [MENU] key to close all open windows and erase the menu bar.

°F)

3.4 Choosing Data Source(s)

Choose the source of depth, water temperature and speed data as follows:

1. Press the [MENU] key to show the menu bar.

2. Rotate the [ENTER] knob to choose ADVANCED on the menu bar and then push the

[ENTER] knob.

3. Rotate the [ENTER] knob to choose INPUT/OUTPUT and then push the [ENTER] knob.

4. Rotate the [ENTER] knob to choose DEPTH SOURCE, TEMP SOURCE or STW SOURCE

(speed) depending on your system configuration and then push the [ENTER] knob.

NMEA

Sounder

5. Rotate the [ENTER] knob to choose NMEA or Sounder as appropriate and then push the

[ENTER] knob. Choose Sounder if you wish to use sounder-generated depth, water temperature or speed data. (Optional water temperature/speed sensor required to use Sounder-generated water temperature/speed data.)

6. Press

7. If applicable, repeat steps 4 thru 6 to choose other data sources.

8. Press the [MENU] key to close all open windows and erase the menu bar.

Note:The following data sentences are required to display respective data. Depth: DPT (Ver. 2.0)

or DBT (Ver. 1.5), Temperature: MTW, and STW (Speed Thru Water): VTG, RMC or RMA.

W to close the window.

32

Page 39

3.5 Calibrating NMEA Depth, Speed and Water

Temperature Data

NMEA speed, depth and water temperature data may be corrected from the GP-7000F if they cannot be done from the equipment that outputs the data. Enter a minus value if the actual value is

lower than the NMEA data, or a plus value if the actual value is higher than the NMEA data. For

example, if the actual water temperature is 20° and the water temperature data output by the sensor is 17°, enter +3(°).

1. Press the [MENU] key to show the menu bar.

2. Rotate the [ENTER] knob to choose ADVANCED from the menu bar and then push the

[ENTER] knob.

3. Rotate the [ENTER] knob to choose EXT NMEA and then push the [ENTER] knob.

DRAFT SETUP +00.0 Ft

SPEED CALIBRATION +00 %

TEMP CALIBRATION +00.00°F

EXT NMEA menu

4. Rotate the [ENTER] knob to choose appropriate item.

DRAFT SETUP: Enter ship's draft to get NMEA depth from sea surface (instead of transducer). To get depth from hull bottom, measure distance between bottom of transducer and

hull bottom and enter that value with a minus.

SPEED CALIBRATION: Find correct speed from known source and enter offset to correct

NMEA speed indication.

TEMP CALIBRATION: Find correct water temperature from known source and enter offset to

correct NMEA water temperature indication.

5. Push the [ENTER] knob. The cursor is selecting the plus sign (or minus sign). If it is necessary

to switch from plus to minus or vice versa, rotate the [ENTER] knob to choose plus or minus

and then push the [ENTER] knob. If not necessary, go to step 6.

6. Push the [ENTER] knob, rotate the [ENTER] knob to set digit and then push the [ENTER]

knob. To clear a line of data, press the [CLR FLD] soft key, which is the third key from the left

of the keys below the screen.

Setting range

Draft setup: -20 - +39.9 (ft)

Speed calibration: -50 - +50 (%)

Temp calibration: -50 - +50 (°F)

7.Set other digits as you did in step 6.

8.Press the [SAVE] soft key, which is the fourth key from the left of the keys below the screen.

9.If necessary, repeat step 4-8 to choose and set another calibration item.

10.Press the [MENU] key to close all open windows and erase the menu bar.

33

Page 40

3.6 Waypoint, Route Format

You may transfer waypoint and route data to another GP-7000 series unit or a PC in Standard or

Furuno format, via the NMEA1 port, NMEA2 port or PC NMEA IN port.

1. Press the [MENU] key to show the menu bar.

2. Rotate the [ENTER] knob to choose ADVANCED from the menu bar and then push the

[ENTER] knob.

3. Rotate the [ENTER] knob to choose INPUT/OUTPUT and then push the [ENTER] knob.

4. Rotate the [ENTER] knob to choose WPL/RTE FORMAT and then push the [ENTER] knob.

Standard

Furuno

5. Choose Furuno or Standard as appropriate and then push the [ENTER] knob.

Standard: NMEA format WPL and RTE sentences are output when “SEND” is executed to

transfer waypoint list or route list.

Furuno: Furuno format WPL and RTE sentences are output when “SEND” is executed to

transfer waypoint list or route list. Waypoint color, shape and comment data are sent.

6. Press the [MENU] key to close the menu.

3.7 External Event Format

If the equipment is equipped with an external event switch you may choose what mark is inscribed

on the screen when the switch is pressed. For connection of an external event switch, see the interconnection diagram.

1. Press the [MENU] key to show the menu bar.

2. Rotate the [ENTER] knob to choose ADVANCED from the menu bar and then push the

[ENTER] knob.

3. Rotate the [ENTER] knob to choose INPUT/OUTPUT and then push the [ENTER] knob.

4. Rotate the [ENTER] knob to choose EXTERNAL EVENT and then push the [ENTER] knob.

Off

WPT

MOB

5. Choose Off, WPT or MOB as appropriate and then push the [ENTER] knob.

Off: No event swith is connected.

WPT: Waypoint is registered at ship’s position if the cursor is not displayed, or at cursor posi-

tion if the cursor is displayed.

MOB: MOB is registered at ship’s position.

6. Press the [MENU] key to close the menu.

34

Page 41

3.8 Primary, Secondary Unit (C-link)

The C-link feature, available when several GP-7000 series units are interconnected via NMEA

ports or PC/NMEA IN ports (see the illustration below), lets you duplicate on secondary stations

the destination set at the primary station. With this feature active de stination may only be set from

the primary station.

Primary station

GP-7000

series

Secondary stat ion

GP-7000

series

NMEA1

NMEA2

PC/NMEA IN

NMEA1

NMEA2

PC/NMEA IN

Secondary stat ion

GP-7000

series

PC/NMEA IN

Secondary stat ion

GP-7000

series

PC/NMEA IN

NMEA1

NMEA2

NMEA1

NMEA2

*

*

*: Either port

**: Either port

**

**

Note: Secondary stations cannot

be connected to one another.

1. Press the [MENU] key to show the menu bar.

2. Rotate the [ENTER] knob to choose ADVANCED from the menu bar and then push the

[ENTER] knob.

3. Rotate the [ENTER] knob to choose INPUT/OUTPUT and then push the [ENTER] knob.

4. Rotate the [ENTER] knob to choose C-LINK and then push the [ENTER] knob.

Secondary Station

Primary Station

Off

5. Choose Off, Secondary Station, Primary Station as appropriate and then push the [ENTER]

knob.

6. Press the [MENU] key to close the menu.

35

Page 42

1

A-1

1

1

1

1

1

1/1

14CR-X-9851 -12

NAME OUTLINE Q'TYDESCRIPTION/CODE №

000-154-054-10

MJ-A6SPF0003-050C

000-145-880-00

MJ-A15A3F0013-035-3A

**

000-149-136-1*

IM*-44290-*

**

000-149-135-1*

OS*-44290-*

**

000-149-134-1*

OM*-44290-*

000-149-985-1*

E42-00401-*

14CR-X-9851

ケーブル組品MJ

SIGNAL CABLE ASSEMBLY

ケーブル組品MJ

1

POWER CABLE

1

図書 DOCUMENT

装備要領書

**

INSTALLATION MANUAL

1

SP14-03201

GP-7000/F-E-C-017,GP-7000/F-E-N-017

000-041-403-00

GPA-017

000-041-184-00

GP-7000-E-C

FGBO-A 3A AC125V

FGB0-A 125V 3A PBF

操作要領書(英)

OPERATOR'S GUIDE

1

FP20-01100

000-549-063-00

000-155-850-10

02-155-1082-1

取扱説明書

OPERATOR'S MANUAL

CP14-06400

100-332-651-10

フラッシュマウント型紙

TEMPLATE

1

100-323-890-00

14-074-1032-0

6

000-162-652-10

M4X20 SUS304

M4X20 SUS304

4

000-804-742-00

5X20 SUS304

000-802-081-00

000-162-608-10

5X20 SUS304

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

空中線部

ANTENNA UNIT

指示器

DISPLAY UNIT

予備品 SPARE PARTS

ヒューズ

FUSE

付属品 ACCESSORIES

フイルタークリーナー

FILTER CLEANER

工事材料 INSTALLATION MATERIALS

Fマウントヨウスポンジ

+ナベセムスネジB

FLUSH MOUNTING SPONGE

WASHER HEAD SCREW

+トラスタッピンネジ 1シュ

SELF-TAPPING SCREW

1.コ-ド番号末尾の[**]は、選択品の代表型式/コードを表します。

CODE NUMBER ENDED BY "**" INDICATES THE NUMBER OF TYPICAL MATERIAL.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

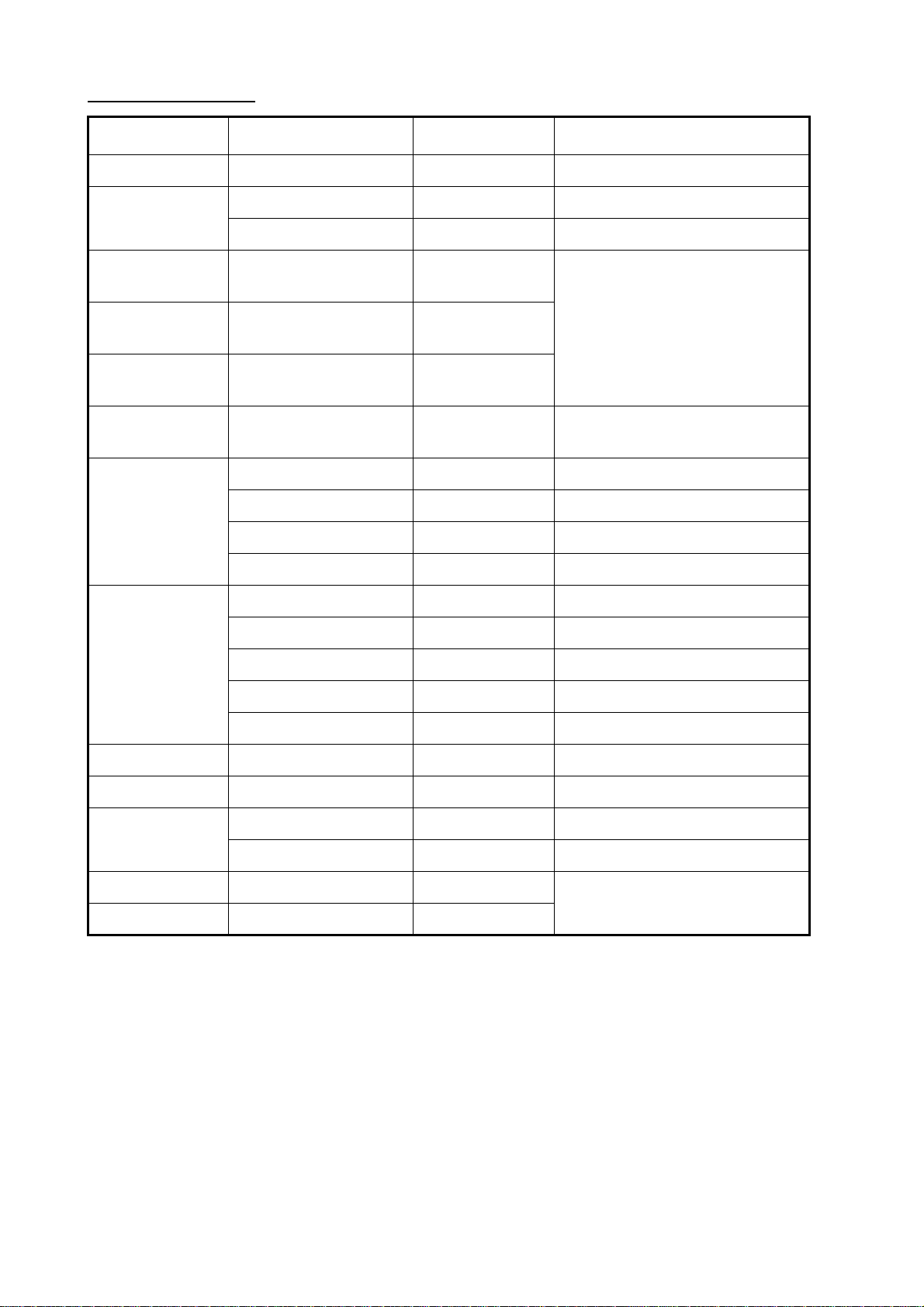

Page 43

1

A-2

1

1

1

1

1/1

14CR-X-9852 -13

NAME OUTLINE Q'TYDESCRIPTION/CODE №

000-145-880-00

MJ-A15A3F0013-035-3A

**

000-149-136-1*

IM*-44290-*

**

000-149-135-1*

OS*-44290-*

**

000-149-134-1*

OM*-44290-*

000-149-985-1*

E42-00401-*

14CR-X-9852

POWER CABLE

1

図書 DOCUMENT

装備要領書

**

INSTALLATION MANUAL

1

ケーブル組品MJ

SP14-03201

GP-7000/F-E-C,GP-7000/F-E-N

000-041-184-00

GP-7000-E-C

FGBO-A 3A AC125V

FGB0-A 125V 3A PBF

操作要領書(英)

OPERATOR'S GUIDE

1

FP20-01100

000-549-063-00

000-155-850-10

02-155-1082-1

取扱説明書

OPERATOR'S MANUAL

CP14-06400

100-332-651-10

フラッシュマウント型紙

TEMPLATE

1

100-323-890-00

14-074-1032-0

6

000-162-652-10

M4X20 SUS304

M4X20 SUS304

4

000-804-742-00

5X20 SUS304

000-802-081-00

000-162-608-10

5X20 SUS304

1

000-154-054-10

MJ-A6SPF0003-050C

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

指示器

DISPLAY UNIT

予備品 SPARE PARTS

ヒューズ

FUSE

付属品 ACCESSORIES

フイルタークリーナー

工事材料 INSTALLATION MATERIALS

FILTER CLEANER

Fマウントヨウスポンジ

FLUSH MOUNTING SPONGE

+ナベセムスネジB

WASHER HEAD SCREW

+トラスタッピンネジ 1シュ

SELF-TAPPING SCREW

ケーブル組品MJ

SIGNAL CABLE ASSEMBLY

1.コ-ド番号末尾の[**]は、選択品の代表型式/コードを表します。

CODE NUMBER ENDED BY "**" INDICATES THE NUMBER OF TYPICAL MATERIAL.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

Page 44

Y.Hatai

D-1

Page 45

Y.Hatai

D-2

Page 46

. Hatai

hatai

2005.12.19

11:57:12

+09'00'

D-3

Page 47

D-4

Mar,27'07R.Esumi

Page 48

Feb. 17, '03

D-5

Page 49

D-6

Page 50

D-7

Page 51

Mar.03'05

D-8

Page 52

IEC 61162-1

Y.Hatai

S-1

NMEA0183 Ver1.5/2.0/3.0

Ver1.5/2.0/3.0

NMEA0183

IEC 61162-1

NMEA0183 Ver1.5/2.0/3.0

*2

*2

PC ETC.

パソコンなど

YEL

キ

GRN

ミドリ

BUZZER

ブザー

BLK

RED

クロ

アカ

(0.1A)

イベントスイッチ

EVENT SW

GP-7000F

カラーGPSプロッタ魚探

COLOR GPS PLOTTER/SOUNDER

INTERCONNECTION DIAGRAM

相互結線図

P

6BUZZER

7

3

12V_P

BUZZER

4

RD3-C

RD3-H

SHIELD

SHIELD

BLK

WHT

MJ-A6SPF0003-050C,5m,φ6

クロ

シロ

P

MJ-A6SPF

12345

TD1-B

TD1-A

NMEA1

GRN

YEL

キ

P

RD1-H

ミドリ

NC

RD1-C

6

SHIELD

BLK

WHT

MJ-A6SPF0003-050C,5m,φ6

MJ-A6SPF0012-050C/100C,5/10m

クロ

シロ

P

MJ-A6SPF

12345

TD2-A

NMEA2

YEL

キ

RD2-H

TD2-B

P

GRN

ミドリ

NC

RD2-C

6

SHIELD

BLU

YEL

WHT

MJ-A7SPF0007-050C,5m,φ6

アオ

キ

シロ

P

MJ-A7SPF

1234567

RD3-H

RS232C_RD

RS232C_TD

PC/NMEA IN

GRN

ミドリ

P

RD3-C

3

GP-7000F

指示部

DISPLAY UNIT

TNC-P-3

1m,φ5.3

NJTP-3DXV-1

N-J-3

N-P-8DFB

*3

30/50m,φ14.3

8D-FB-CV

ANT

TNC-P-3

GPS-SIG

GPS-SHIELD

(+)

12-24 VDC

1

MJ-A3SPF

WHT

シロ

3A

MJ-A15A3F0013

3.5m,φ8.0

(-)

2

クロ BLK

SHIELD

3

6

12V_P 5

BUZZER

XDR-

10

9

XDR-SHIELD

XDR+

8

TEMP0V

7

NC

6

NC

5

TEMP

4

SPD0V/SHIELD

3

12V-P

2

1

SPD

XDR

XDR-

10

XDR-SHIELD

9

XDR+

8

XDR

MJ-A10SPF

7

SHIELD

*1GND

IV-1.25sq.

8m,φ5.410m,φ5.4

MJ-A10SPF

FM-342-8P

8P

02S4089,1m,φ5.4

520-5MSD

520-5PSD

525ST-MSD

525ST-PWD

FM-14-8P

8P

02S4072,1m,φ5.2

525-5PWD

送受波器

送受波器

水温・船速センサー付

クロ BLK

シロ WHT

TRANSDUCER

TEMP/SPEED SENSOR

TRANSDUCER W/

531 24

選択 SELECT

*2

13

2

13254

TB1

MB-1000

TB2

TITLE

E. MIYOSHI

MAY 8,'06

DRAWN

10m

アカ RED

クロ BLK

クロ BLK

アカ RED

10m

アカ RED

ミドリ GRN

アオ BLU

クロ BLK

10m,φ12

名称

TAKAHASHI.T

CHECKED

φ12

(1kW)

φ12

APPROVED

200B-

50B-

(1kW)

NAME

MASS

SCALE

5/5S

6/6G

50/200-1T

14-074-5001

DWG No.

kg

C4429-C02- G

DWG No.

N-P-8DFB

N-J-3

TNC-J-3

TNC-P-3

1m,φ5.3

NJTP-3DXV-1

10m,φ5.5

*2

0.2m

12 4

空中線部

空中線部

ANTENNA UNIT

ANTENNA UNIT

GPA-017S

GPA-017

A

MJ-A10SPF

XDR-

10

9

XDR-SHIELD

XDR+

8

TEMP0V

7

NC

12-24 VDC

6

NC

5

TEMP

4

3

SPD0V/SHIELD

2

12V-P

1

SPD

*2

02S4147

0.2m

B

MJ-A10SRMD

10

XDR-M

9

8

2

1

6

5

4

3

2

1

XDR-SHIELD

XDR-P

525-5PWD

520-5PSD

520-5MSD

TRANSDUCER

NC

NC

+V

SPD

TEMP0V

TEMP

MJ-A6SRMD

ST-02PSB

ST-02MSB

SPD0V/SHIELD

10m,φ5.4

TEMP/SPEED SENSOR

*2)オプション。

*1)造船所手配。

*3)コネクタは現地にて取付け。

注記

NOTE

*1. SHIPYARD SUPPLY

*2. OPTION

*3. ATTACH CONNECTOR LOCALLY.

C

Loading...

Loading...