Page 1

Installation Manual

GPS PLOTTER/SOUNDER GP-1670F

GP-1870F

SAFETY INSTRUCTIONS ................................................................................................ i

1. MOUNTING .............................................................................................................. 1-1

1.1 Mounting of Display Unit ............................................................................................... 1-1

1.2 Replacement Kit (option) .............................................................................................. 1-2

2. INSTALLATION OF TRANSDUCERS ..................................................................... 2-1

2.1 How to Mount a T ransducer through the Unit ............................................................... 2-1

2.2 Transom Mount Tr ansducer .......................................................................................... 2-3

2.3 How to Mount a T ransducer inside the Hull .................................................................. 2-4

3. WIRING .................................................................................................................... 3-1

3.1 Display Unit ................................................................................................................... 3-1

3.2 Transducer .................................................................................................................... 3-2

3.3 External Equipment ....................................................................................................... 3-2

PACKING LIST ........................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAMS ............................................................................. S-1

www.furuno.com

All brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Page 2

SAFETY INSTRUCTIONS

WARNING

WARNING

Do not open the equipment.

The equipment uses high voltage that

can cause electrical shock. Refer any

repair work to a qualified technician.

If water leaks into the equipment or

something is dropped into the equipment, immediately turn off the power

at the switchboard.

Fire or electrical shock can result.

If the equipment is giving off smoke

or fire, immediately turn off the power

at the switchboard.

Fire or electrical shock can result.

If you feel the equipment is acting

abnormally or giving off strange

noises, immediately turn off the

power at the switchboard and contact

a FURUNO service technician.

Mandatory Action

Prohibitive Action

WARNING

CAUTION

Warning, Caution

The operator must read the safety instructions before attempting to operate the equipment.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING

WARNING

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury

can result.

Make sure no rain or water splash

leaks into the equipment.

Fire or electrical shock can result if

water leaks into the equipment.

Do not place liquid-filled containers

on or near the equipment.

Fire or electrical shock can result if a

liquid spills into the equipment.

Do not operate the equipment with

wet hands.

Electrical shock can result.

Use the proper fuse.

Use of the wrong fuse can cause fire or

electrical shock.

The user and installer must read the appropriate safety instructions before attempting to install or

operate the equipment.

i

Page 3

1. MOUNTING

1.1 Mounting of Display Unit

Mounting considerations

The display unit can be installed on a tabletop or flush mounted in a console.

Select a suitable mounting location considering the following:

• Keep the display unit out of direct sunlight.

• The temperature and humidity should be moderate and stable.

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• Keep the unit away electromagnetic field generating equipment such as motor, generator.

• For maintenance and checking purposes, leave sufficient space at the sides and

rear of the unit and leave slack in cables.

• A magnetic compass will be affected if placed too close to the display unit. Observe

the compass safe distances shown in the Safety Instructions to prevent disturbance

to the magnetic compass:

Mounting procedure

Follow the procedure below to mount the display unit on a tabletop or in a console.

Refer to the outline drawing at the back of this manual.

• Tabletop, mounting

1. Fix the hanger by four tapping screws φ4.8×22.

2. Screw knob bolts in display unit, set it to hanger, and tighten knob bolts.

3. Attach hard cover to protect LCD.

• Flush mounting

Follow the procedure below to mount the display unit in a console. Refer to the outline drawing at the back of this manual.

1. The thickness of the cutout should be 5 to 20 mm.

2. Prepare a cutout in the mounting location whose dimensions are shown in the

outline drawing at the back of this manual.

3. Screw in four threaded rods into the display unit.

4. Peel the paper from flush mount gasket and set the gasket to the display unit.

5. Set the display unit to the cutout and fasten it with the washers and nuts.

1-1

Page 4

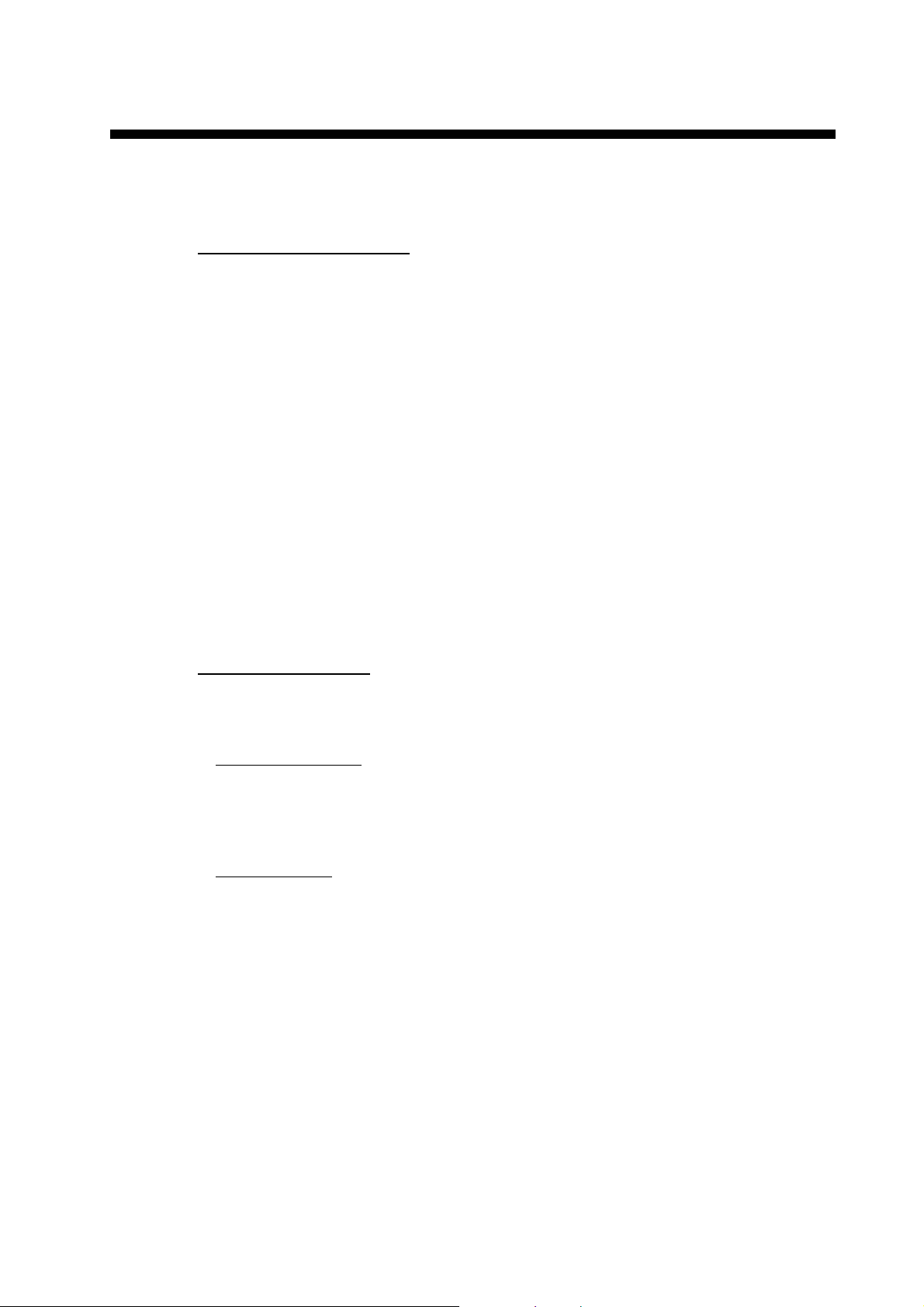

1. MOUNTING

260

160

240

140

210

202

132

50.8

5

4-φ6

GP-1670/1670F Replacement Kit

GP-1870/1870F Replacement Kit

286

266

238

230

132

160

140

50.8

4-φ6

5

1.2 Replacement Kit (option)

For replace from the flush mounted former type display unit (GP-1650 ser.) to GP1670F/1870F, the replacement kit (option) is available. Follow the procedure below to

replace a display unit.

1. Remove the former display unit from panel.

2. Fix the display unit GP-1670F/1870F onto the repracement kit by four lods, washer and nuts.

3. Set the display unit to the cutout and fasten it with four tapping screws φ5×20.

1-2

Page 5

2. INSTALLATION OF TRANSDUC-

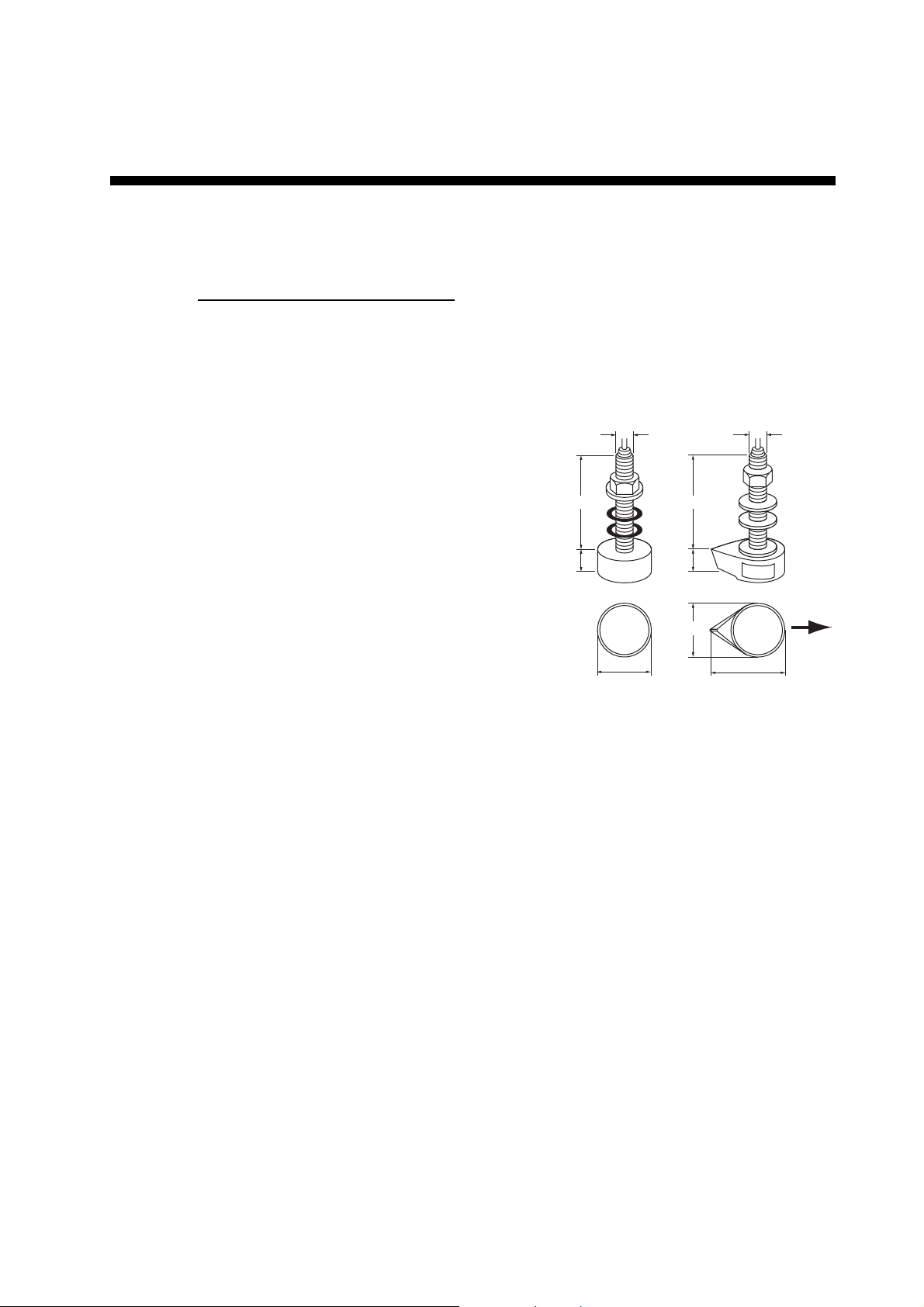

28

22

120

68

30

24

120

68

87

Unit: mm

520-5PSD

520-5MSD

BOW

ERS

2.1 How to Mount a Transducer through the Unit

Transducer mounting location

The thru-hull mount transducer provides the best performance of all, since the transducer protrudes from the hull and the effect of air bubbles and turbulence near the hull

skin is reduced. When the boat has a keel, the transducer should be at least 30 cm

away from it.

The performance of this fish finder is directly related to the mounting location of the transducer, especially for high-speed cruising. The

installation should be planned in advance,

keeping the length of the transducer cable and

the following factors in mind:

• Air bubbles and turbulence caused by movement of the boat seriously degrade the

sounding capability of the transducer. The

transducer should, therefore, be located in a

position where water flow is the smoothest.

Noise from the propellers also adversely affects performance and the transducer should

not be mounted nearby. The lifting strakes

are notorious for creating acoustic noise, and these must be avoided by keeping the

transducer inboard of them.

• The transducer must always remain submerged, even when the boat is rolling,

pitching or up on a plane at high speed.

• A practical choice would be somewhere between 1/3 and 1/2 of the boat's length

from the stern. For planing hulls, a practical location is generally rather far astern,

so that the transducer is always in water regardless of the planing attitude.

2-1

Page 6

2. INSTALLATION OF TRANSDUCERS

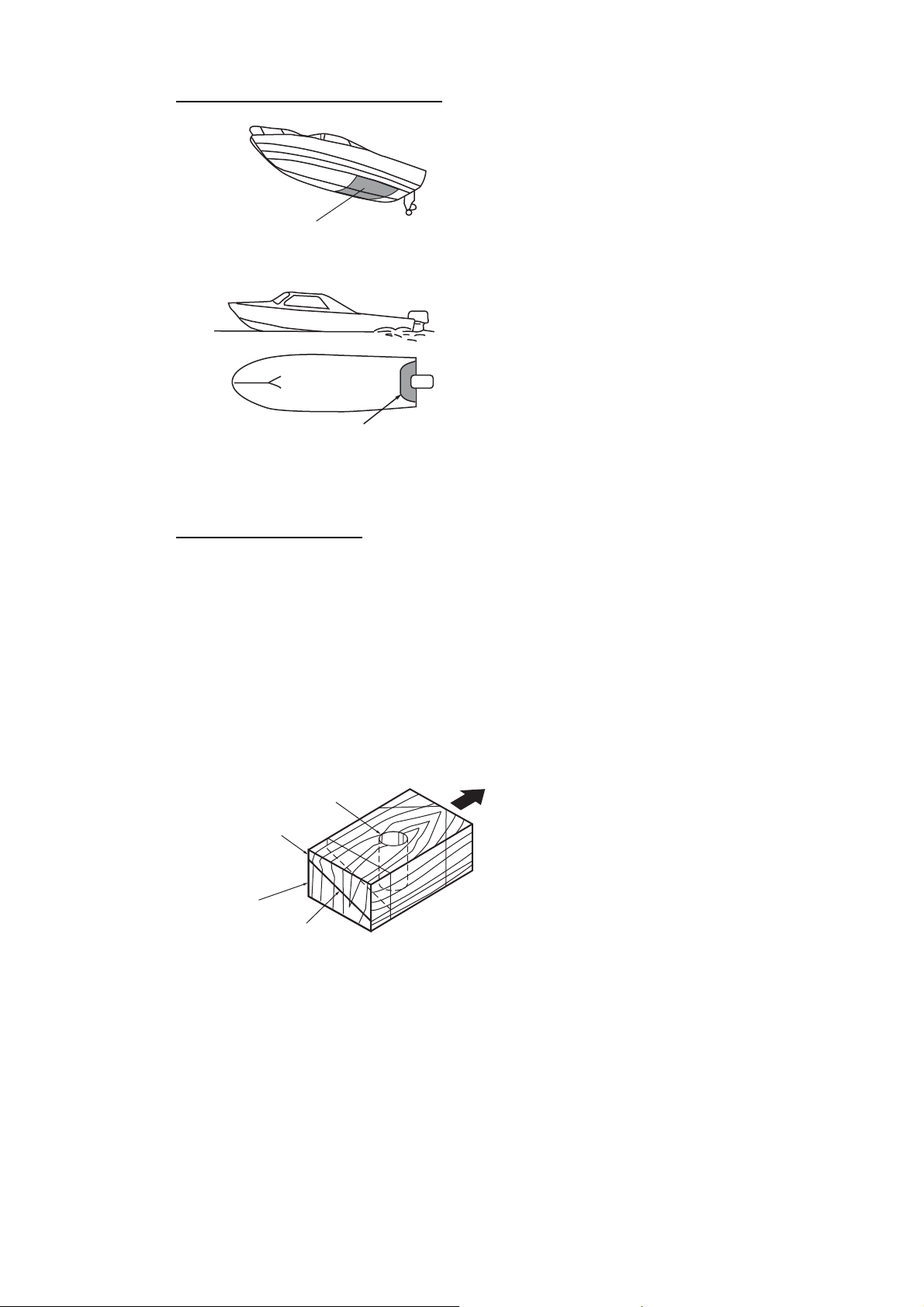

Within the wetted bottom area

Deadrise angle within 15°

Position 1/2 to 1/3 of the hull from stern.

15 to 30 cm off center line (inside first lifting

strakes.)

DEEP V

HULL

HIGH SPEED

V HULL

Hole for

stuffing tube

Saw along

slope of hull.

Upper Half

Lower Half

BOW

Transducer mounting locations

Installation procedure

1. With the boat hauled out of the water, mark the location chosen for mounting the

transducer on the bottom of the hull.

2. If the hull is not level within 15° in any direction, fairing blocks made out of teak

should be used between the transducer and hull, both inside and outside, to keep

the transducer face parallel with the water line. Fabricate the fairing block as

shown below and make the entire surface as smooth as possible to provide an undisturbed flow of water around the transducer. The fairing block should be smaller

than the transducer itself to provide a channel to divert turbulent water around the

sides of the transducer rather than over its face.

3. Drill a hole just large enough to pass the threaded stuffing tube of the transducer

through the hull, making sure it is drilled vertically.

4. Apply a sufficient amount of high quality caulking compound to the top surface of

the transducer, around the threads of the stuffing tube and inside the mounting

2-2

hole (and fairing blocks if used) to ensure watertight mounting.

Page 7

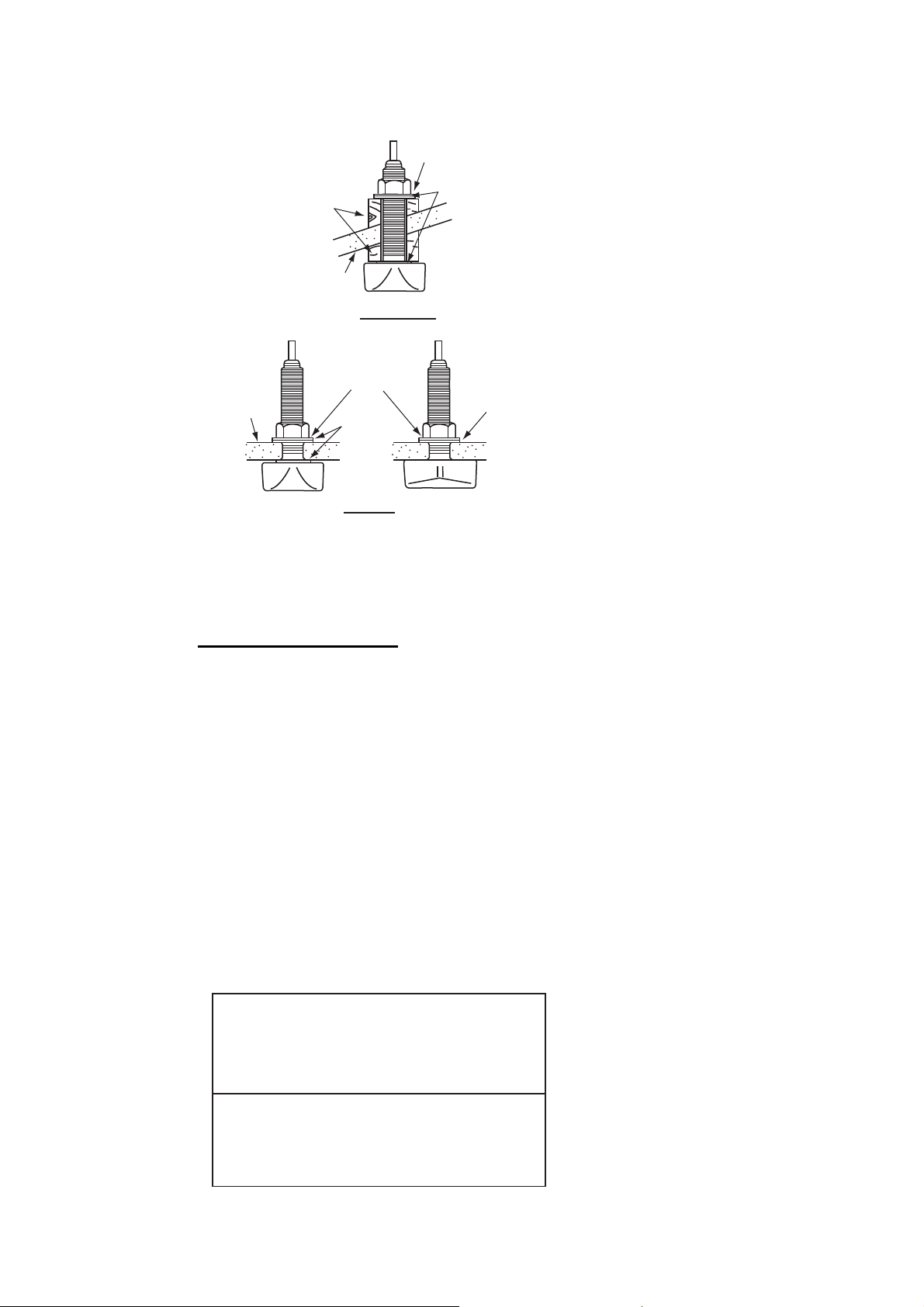

2. INSTALLATION OF TRANSDUCERS

5. Mount the transducer and fairing blocks and tighten the locknut. Be sure that the

transducer is properly oriented and its working face is parallel to the waterline.

Flat Washer

Fairing

Block

Hull

Deep-V Hull

Flat Washer

Hull

Rubber

Washer

Flat Hull

Rubber Washer

Cork

Washer

Note: Do not over-stress the stuffing tube and locknut through excessive tightening,

since the wood block will swell when the boat is placed in the water. It is suggested

that the nut be tightened lightly at installation and retightened several days after the

boat has been launched.

Transducer preparation

Before putting the boat in water, wipe the face of the transducer thoroughly with a detergent liquid soap. This will lessen the time necessary for the transducer to have good

contact with the water. Otherwise the time required for complete "saturation" will be

lengthened and performance will be reduced.

DO NOT paint the transducer. Performance will be affected.

2.2 Transom Mount Transducer

The optional transom mount transducer is very commonly employed, usually on relatively small I/O or outboard boats. Do not use this method on an inboard motor boat

because turbulence is created by the propeller ahead of the transducer.

DO NOT overtighten screws; they may be damaged.

Parallel with hull

Transom

Less than 10°

Mount at the stripe.

Transom

Stripe

Over 10°

2-3

Page 8

2. INSTALLATION OF TRANSDUCERS

5x20

M5x14

5°

Taping

Bracket

Transducer

Hull

2 to 5°

Epoxy material

Installation procedure

A suitable mounting location is at least 50 cm away from the engine and where the

water flow is smooth.

1. Drill four pilot holes for self-tapping screw (5x20) in the mounting location.

2. Coat the threads of the self-tapping screws (5x14) for the transducer with silicone

sealant for waterproofing. Attach the transducer to the mounting location with the

self-tapping screws.

3. Adjust the transducer position so the transducer faces right to the bottom. If necessary, to improve water flow and minimize air bubbles staying on the transducer

face, incline the transducer about 5° at the rear. This may require a certain amount

of experimentation for fine tuning at high cruising speeds.

4. Tape the location shown in the figure below.

5. Fill the gap between the wedge front of

the transducer and transom with epoxy

material to eliminate any air spaces.

6. After the epoxy hardens, remove the

tape.

2.3 How to Mount a Transducer inside the Hull

The transducer may also be installed inside the hull on FRP boats. However, this installation method affects the ability to detect the bottom, fish and other objects because the ultrasound pulse is weakened when it passes through the hull.

Note: This mounting method should not be used to mount the transducer that sup-

TM

ports the ACCU-FISH

mance is greatly degraded.

Necessary tools

You will need the following tools:

and/or bottom discrimination display feature, since perfor-

2-4

• Sandpaper (#100)

• Silicone sealant

• Silicone grease

Page 9

2. INSTALLATION OF TRANSDUCERS

1/3

1/2

Centerline

Transducer

mounting

location

50 cm

50 cm

15 cm

15 cm

Transducer

Silicone

Sealant

Remarks on installation

• Do the installation with the ship moored at a dock, etc. The water depth should be 6.532 feet (2-10 meters).

• Turn off the engine.

• Install the transducer with the engine room.

• Do not power the unit with the transducer in the air, to prevent damage to the transducer.

• Do not use this method on a double layer hull.

• Before attaching the transducer to the hull, check that the site is suitable. Put the

transducer in a water-filled plastic bag. Connect the transducer to the display unit and

put the transducer on the installation site. Turn on the display unit and check that the

depth indication appears.

Installation procedure

If the thickness of the hull varies, then the attenuation of the ultrasound pulse. Select

a location where attenuation is the lowest.

1. Select 2-3 locations considering the four points mentioned below. (You will finalize

the mounting location through some trial and error later.)

• Mount the transducer at a location 1/2 to 1/3 of the length of the boat from the

stern.

• The mounting location is between 15 to 50 cm from the centerline of the hull.

• Do not place the transducer over hull struts or ribs which run under the hull.

• Avoid a location where the rising angle of the hull exceeds 15°, to minimize the

effect of the boat's rolling.

2. Clean the face of the transducer to remove any foreign material. Lightly roughen

the face with #100 sandpaper. Also, use the sandpaper to roughen the inside of

the hull where the transducer is to be mounted.

3. Wipe off any sandpaper dust from the face of the transducer.

4. Dry the face of the transducer and the hull.

Coat the transducer face and mounting location with silicone sealant. Hardening begins in

approx. 15-20 minutes so do this step without

delay.

2-5

Page 10

2. INSTALLATION OF TRANSDUCERS

5. Attach the transducer to the hull.

Press the transducer firmly down on the hull

and gently twist it back and forth to remove

any air which may be trapped in the silicone

sealant.

6. Support the transducer with a piece of wood

to keep it in place while the sealant is drying.

It takes 24-72 hours to harden completely.

Hull

Silicone

Sealant

2-6

Page 11

3. WIRING

Black

White

Shield

Display unit (back)

GPS antenna unit

GPA-017/017S (option)

CAN bus

equipment

Transducer

WARNING ELECTRICAL SHOCK

DO NOT touch the pins inside

connector. Put the cap (supplied) on

the connector when power is off or

the transducer is disconnected.

BATTERY

Cable connector

Power cable

w/fuse (3A)

Lead wire

White

Black

Shield

Ground

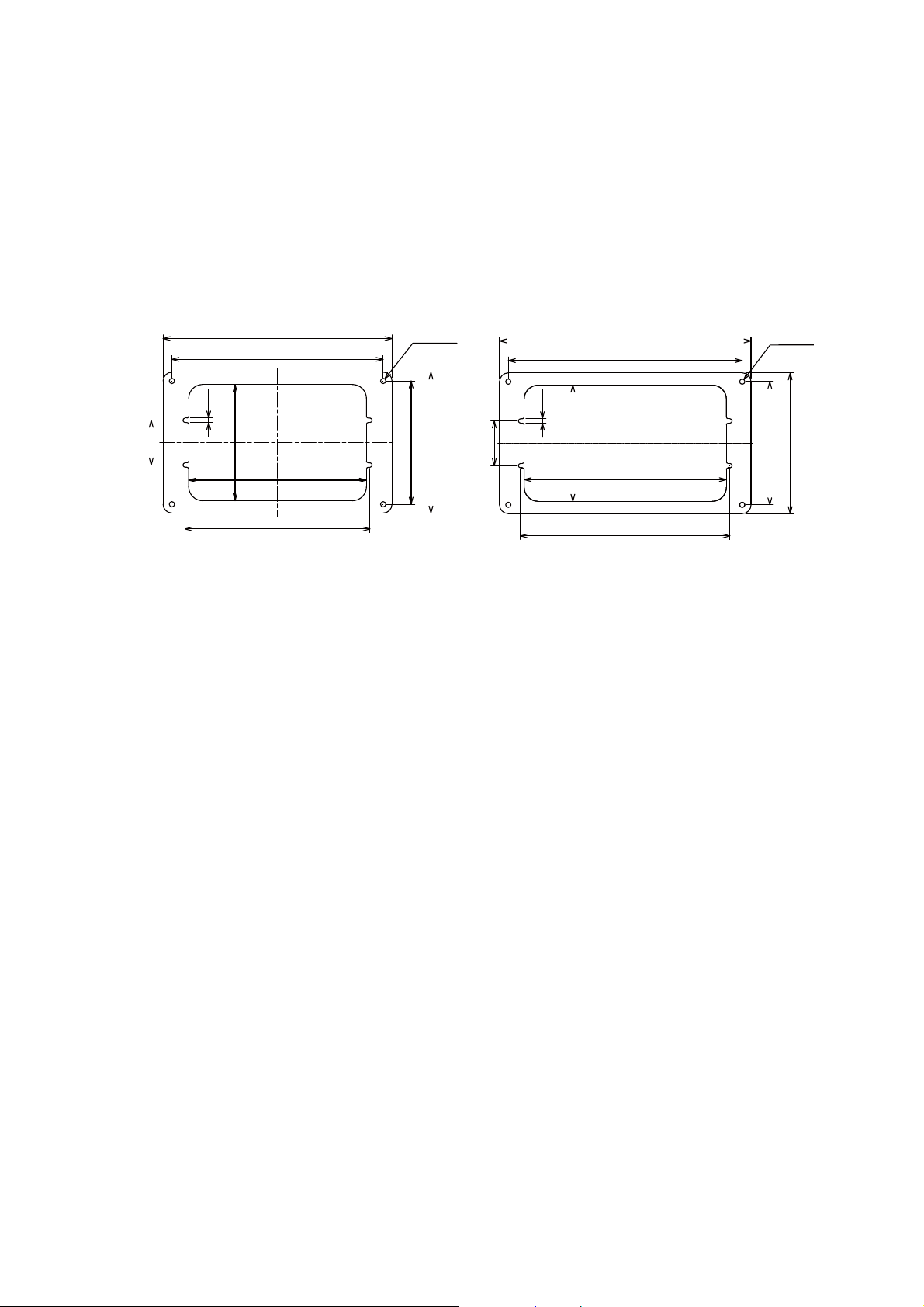

3.1 Display Unit

All wiring are terminated at the rear of the display unit. Refer to the interconnection

diagram on page S-1.

Power cable

Connect the power cable to the

power connector. Connect the

leads to the battery (12 or 24

VDC); white to plus(+) terminal

and black to minus(-) terminal.

Ground the shield to ship’s

ground.

Note: The fuse is not waterproof.

Wrap the fuse holder with vinyl

tape to keep water out of the fuse

holder.

3-1

Page 12

3. WIRING

Jumper block setting

J2: No output reduction (default)

J1: Output reduction

Transducer

50B-6/6B

50kHz

200kHz

SHIELD

BLK

RED

TB2

1

2

3

4

5

J2 J1

WHT

3

2

1

BLK

TB1

02P6348

BLK

RED

Connect 10P

connector to

XDR port on

rear of

display unit.

Green

(shield)

Detach grommet;

attach cord lock.

Transducer

200B-5S

Vinyl Sheath

Taping

Shrink Tubing

Shield

Crimp-on Lug

FV1.25-3 (LF)

3.2 Transducer

Connect the transducer cable to the XDR port.

Transducer and sensor

Use the optional conversion cable (02S4147) to connect the optional speed/temperature sensor and the transducer to the XDR port. Refer to Operator’s Manual in detail.

Matching box (option, required for 1 kW transducer)

The optional matching box (Type: MB-1100, Code No.: 000-041-353) is required to

connect the optional transducers 50B-6, 50B-6B, 200B-5S, 50/200-1T and 50/20012M.

Part Type Code no. Qty

Matching Box* MB-1100 000-041-000 1

Crimp-on Lug FV1.25-3 (LF) 000-116-756-10 6

Cord Lock** NC-1 000-168-230-10 1

*: With 10P connector cable

**: For connecting two transducers

3.3 External Equipment

About CAN bus connections

CAN bus is a communication protocol that shares multiple data and signals through a

single backbone cable. You can simply connect any CAN bus devices onto the backbone cable to expand your network onboard. With CAN bus, IDs are assigned to all

the devices in the network, and the status of each sensor in the network can be detected. All the CAN bus devices can be incorporated into the NMEA2000 network. For

detailed information about CAN bus wiring, see “Furuno CAN bus Network Design

Guide” (Type: TIE-00170) on Tech-Net), or contact your dealer.

3-2

Page 13

1

A-1

4

(*)

1

(*)

1

(*)

1

(*)

1

(*)

☆

1/1

14CW-X-9852 -1

NAME OUTLINE Q'TYDESCRIPTION/CODE №

000-176-666-10

MJ-A3SPF0013A-035C

999-999-179-00

VTATM4.8X22 TCC INX

999-999-187-00

C42-01201-*

999-999-190-00

GP-1X70 O/M *CD-ROM*

999-999-189-00

OS*-44770-*

999-999-192-00

IMC-44770-*

C4477‑Z01‑B

ケーブル(クミヒン)MJ

GP-1670F-E

CABLE ASSEMBLY

1

GP-1670F

タッピンネジ

(*)

図書 DOCUMENT

EXTERNAL BRACKET

FIXING SCREWS

1

999-999-194-00

0312 003.MXP

FLUSH MOUNTING TEMPLATE

フラッシュマウント型紙

(*)

999-999-186-00

2

OPERATOR'S MANUAL CD

取扱説明CD

(*)

999-999-197-00

VTSPKNOB-M6 FRN

OPERATOR'S GUIDE(E/J)

操作要領書(英/和)

1

(*)

999-999-184-00

HBS47A

INSTALLATION MANUAL

装備要領書

1

(*)

999-999-183-00

MINU CLOTH FRN

4

(*)

999-999-180-00

K10LC3005A

1

(*)

999-999-181-00

HGB10AX

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

GPSプロッタ/魚探

GPS PLOTTER/SOUNDER

予備品 SPARE PARTS

ヒューズ

付属品 ACCESSORIES

GLASS TUBE FUSE

ノブ

KNOB

ハンガー

EXTERNAL BRACKET

CLEANING CLOTH

フィルタークリーナー

工事材料 INSTALLATION MATERIALS

Fマウントネジキット

FLUSH MOUNT SCREWS KIT

FLUSH MOUNT GASKET

Fマウントパッキン

(*)は、ダミーコードに付き、注文できません。

(*) THIS CODE CANNOT BE ORDERED.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

Page 14

1

A-2

4

(*)

1

(*)

1

(*)

1

(*)

1

(*)

☆

1/1

14CX-X-9852 -1

NAME OUTLINE Q'TYDESCRIPTION/CODE №

000-176-666-10

MJ-A3SPF0013A-035C

999-999-179-00

VTATM4.8X22 TCC INX

999-999-187-00

C42-01201-*

999-999-190-00

GP-1X70 O/M *CD-ROM*

999-999-189-00

OS*-44770-*

999-999-192-00

IMC-44770-*

C4479‑Z01‑B

ケーブル(クミヒン)MJ

GP-1870F-E

CABLE ASSEMBLY

1

GP-1870F

タッピンネジ

(*)

図書 DOCUMENT

EXTERNAL BRACKET

FIXING SCREWS

1

999-999-196-00

0312 003.MXP

FLUSH MOUNTING TEMPLATE

フラッシュマウント型紙

(*)

999-999-186-00

2

OPERATOR'S MANUAL CD

取扱説明CD

(*)

999-999-197-00

VTSPKNOB-M6 FRN

OPERATOR'S GUIDE(E/J)

操作要領書(英/和)

1

(*)

999-999-185-00

HBS48AX

INSTALLATION MANUAL

装備要領書

1

(*)

999-999-183-00

MINU CLOTH FRN

4

(*)

999-999-180-00

K10LC3005A

1

(*)

999-999-182-00

HGB11AX

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

GPSプロッタ/魚探

GPS PLOTTER/SOUNDER

予備品 SPARE PARTS

ヒューズ

付属品 ACCESSORIES

GLASS TUBE FUSE

ノブ

KNOB

ハンガー

EXTERNAL BRACKET

CLEANING CLOTH

フィルタークリーナー

工事材料 INSTALLATION MATERIALS

Fマウントネジキット

FLUSH MOUNT SCREWS KIT

FLUSH MOUNT GASKET

Fマウントパッキン

(*)は、ダミーコードに付き、注文できません。

(*) THIS CODE CANNOT BE ORDERED.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

Page 15

1

A-3

(*)

1

4

(*)

1

(*)

1

(*)

1

(*)

1

(*)

☆

1/1

14CW-X-9854 -0

NAME OUTLINE Q'TYDESCRIPTION/CODE №

999-999-181-00

HGB10AX

000-176-666-10

MJ-A3SPF0013A-035C

999-999-179-00

VTATM4.8X22 TCC INX

999-999-187-00

C42-01201-*

999-999-190-00

GP-1X70 O/M *CD-ROM*

999-999-189-00

OS*-44770-*

999-999-192-00

IMC-44770-*

C4477‑Z02‑A

Fマウントパッキン

GP-1670F-J

FLUSH MOUNT GASKET

ケーブル(クミヒン)MJ

1

(*)

GP-1670F

CABLE ASSEMBLY

タッピンネジ

1

999-999-194-00

0312 003.MXP

図書 DOCUMENT

EXTERNAL BRACKET

FIXING SCREWS

(*)

999-999-186-00

1

FLUSH MOUNTING TEMPLATE

フラッシュマウント型紙

(*)

999-999-198-00

NEWPEC AND9**.**

OPERATOR'S MANUAL CD

取扱説明CD

2

(*)

999-999-197-00

VTSPKNOB-M6 FRN

OPERATOR'S GUIDE(E/J)

操作要領書(英/和)

1

(*)

999-999-184-00

HBS47A

INSTALLATION MANUAL

装備要領書

1

(*)

999-999-183-00

MINU CLOTH FRN

4

(*)

999-999-180-00

K10LC3005A

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

GPSプロッタ/魚探

GPS PLOTTER/SOUNDER

予備品 SPARE PARTS

ヒューズ

付属品 ACCESSORIES

GLASS TUBE FUSE

SDカード(NEWPEC)

NEWPEC JAPAN JHA-NP SD

CARD

ノブ

KNOB

ハンガー

EXTERNAL BRACKET

フィルタークリーナー

CLEANING CLOTH

工事材料 INSTALLATION MATERIALS

Fマウントネジキット

FLUSH MOUNT SCREWS KIT

(*)は、ダミーコードに付き、注文できません。

(*) THIS CODE CANNOT BE ORDERED.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

Page 16

☆

A-4

1

1

4

(*)

1

(*)

1

(*)

1

(*)

1

(*)

1/1

14CX-X-9854 -0

NAME OUTLINE Q'TYDESCRIPTION/CODE №

999-999-182-00

HGB11AX

000-176-666-10

MJ-A3SPF0013A-035C

999-999-179-00

VTATM4.8X22 TCC INX

999-999-187-00

C42-01201-*

999-999-190-00

GP-1X70 O/M *CD-ROM*

999-999-189-00

OS*-44770-*

999-999-192-00

IMC-44770-*

C4479‑Z02‑A

Fマウントパッキン

GP-1870F-J

FLUSH MOUNT GASKET

ケーブル(クミヒン)MJ

1

(*)

GP-1870F

CABLE ASSEMBLY

タッピンネジ

1

999-999-196-00

0312 003.MXP

図書 DOCUMENT

EXTERNAL BRACKET

FIXING SCREWS

(*)

999-999-186-00

1

FLUSH MOUNTING TEMPLATE

フラッシュマウント型紙

(*)

999-999-198-00

NEWPEC AND9**.**

OPERATOR'S MANUAL CD

取扱説明CD

2

(*)

999-999-197-00

VTSPKNOB-M6 FRN

OPERATOR'S GUIDE(E/J)

操作要領書(英/和)

1

(*)

999-999-185-00

HBS48AX

INSTALLATION MANUAL

装備要領書

1

(*)

999-999-183-00

MINU CLOTH FRN

4

(*)

999-999-180-00

K10LC3005A

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

GPSプロッタ/魚探

GPS PLOTTER/SOUNDER

予備品 SPARE PARTS

ヒューズ

付属品 ACCESSORIES

GLASS TUBE FUSE

SDカード(NEWPEC)

NEWPEC JAPAN JHA-NP SD

CARD

ノブ

KNOB

ハンガー

EXTERNAL BRACKET

フィルタークリーナー

CLEANING CLOTH

工事材料 INSTALLATION MATERIALS

Fマウントネジキット

FLUSH MOUNT SCREWS KIT

(*)は、ダミーコードに付き、注文できません。

(*) THIS CODE CANNOT BE ORDERED.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

Page 17

6/Apr/2012H.Maki

D-1

Page 18

6/Apr/2012H.Maki

D-2

Page 19

6/Apr/2012H.Maki

D-3

Page 20

6/Apr/2012H.Maki

D-4

Page 21

REDアカ

S-1

22/Mar/2012 Y.NISHIYAMA

351

24

MB-1100

10

XDR

XDR-M

10

XDR-SHIELD

43

XDR-P

TEMP0V

NC

TD_ID

TEMP

SPD0V/TDID0V/SHIELD

12V-P1

SPD

XDR

9

8

7

6

5

4

3

2

1

1m

MJ-A10SPF

*2

MB-1100

12345

02S4147,0.2m

クロ BLK

REDアカ

クロ BLK

REDアカ

ミドリ GRN

アオ BLU

クロ BLK

10

9

8

1

MJ-A10SRMD

6

5

4

3

2

1

MJ-A6SRMD

6

5

4

3

2

1

200B-5S

(1kW)

50B-6/6B50/200-1T

(1kW)

10m MJ-A10SPF

50/200-12M

GP-1670F/1870F

カラーGPSプロッタ魚探

相互結線図

GPS PLOTTER/SOUNDER

*2

525-5PWD

520-5PSD

520-5MSD

TRANSDUCER

送受波器

*2

ST-02MSB

ST-02PSB

TEMP/SPEED SENSOR

水温・船速センサー

または

OR

*2

T-02MSB

T-02MTB

T-03MSB

TEMP SENSOR

水温センサー

TITLE

T.YAMASAKI

名称

H.MAKI

INTERCONNECTION DIAGRAM

NAME

REF.No.

kg

XDR-M

10

9

XDR-SHIELD

8

XDR-P

7

TEMP0V

6

NC

5

TD_ID

4

TEMP

3

SPD0V/TDID0V/SHIELD

2

12V-P1

1

SPD

XDR

DISPLAY UNIT

指示部

GP-1670F/1870F

NET-S

NET-C

NET-H

GPS

J1

2

空中線部

ANTENNA UNIT空中線部

TNC-P-3

10m

GPA-017

1

GPA-017S

ANTENNA UNIT

USB

NJTP-3DXV

1m

N-J-3

N-P-8DFB

*2

30/50m

8D-FB-CV,

N-P-8DFB

1m

NJTP-3DXV

TNC-J-3

0.2m

USB2.0

4

A TYPE

USB CABLE

パソコン(保守用)

CAN bus

12345

M12-05PMMP

*2

PC (FOR MAINTENANCE)

ジャンクションボックス

SHIELD

NET-L

REDアカ

クロ BLK

シロ WHT

アオ BLU

M12-05BFFM,1/2/6m

*2

または OR

DATA CONVERTER

JUNCTION BOX

データ変換器

FI-5002

(+)

PWR

123

MJ-A3SPF

シロ WHT

3A

MJ-A3SPF0013-035,

*2

12-24VDC

IF-NMEA2K2

(-)

クロ BLK

3.5m

SHIELD

*1

100/110/

1

2

(+)

(-)

整流器

RECTIFIER

5

6

DPYC-1.5

220/230VAC

1φ,50/60Hz

MJ-A10SPF

*1

*2

PR-62

IV-2sq.

*2

8m,φ5.4

*2

10m,φ5.4

520-5PSD

525-5PWD

OR

または

525STID-MSD

525STID-PWD

520-5MSD

送受波器

送受波器

水温・船速センサー付

TRANSDUCER

TRANSDUCER

W/ TEMP/SPEED SENSOR

21/Mar/2012

21/Mar/2012

CHECKED

DRAWN

APPROVED

SCALE MASS

C4477-C01- A

DWG.No.

*2)オプション。

NOTE

*1: SHIPYARD SUPPLY.

*2: OPTION.

注記

*1)造船所手配。

A

B

C

Loading...

Loading...