Page 1

INSTALLATION MANUAL

COLOR GPS/PLOTTER/SOUNDER

GP-1650F/1650DF

System Configuration .............................................i

Equipment Lists .....................................................ii

1. Installation of Standard Equipment ...............1-1

1.1 Installation of Display Unit ..............................................1-1

1.2 Installation of Antenna Unit (GP-1650DF only) ..............1-3

1.3 Installation of Transducers ...............................................1-4

1.4 Installation of Sensors ....................................................1-14

2. Wiring ...............................................................2-1

3. Initial Settings..................................................3-1

3.1 NMEA Setting ..................................................................3-1

3.2 Output Data Sentences .....................................................3-3

3.3 Antenna Height.................................................................3-4

3.4 Baud Rate Setting (GP-1650DF only)..............................3-5

3.5 Beacon frequency Setting (GP-1650DF only) .................3-6

3.6 Depth Adjustment.............................................................3-7

3.7 External Equipment Setup (Option) .................................3-8

4. Installation of DGPS Beacon Receiver

(for GP-1650F) .................................................4-1

APPENDIX TRIDUCER 525ST-PWC/PWD .......AP-1

PACKING LIST ....................................................A-1

OUTLINE DRAWINGS......................................... D-1

INTERCONNECTION DIAGRAM ........................ S-1

SCHEMATIC DIAGRAM ...................................... S-2

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080856801**00080856801*

*00080856801**00080856801*

*IME43942N00**IME43942N00*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

Your Local Agent/DealerYour Local Agent/Dealer

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. IME-43942-NIME-43942-N

(( TATATATA ))

GP-1650F/1650DFGP-1650F/1650DF

Printed in JapanPrinted in Japan

FIRST EDITION :FIRST EDITION : NOV.NOV. 19981998

N :N : FEB.FEB. 06,200206,2002

* 0 0 0 8 0 8 5 6 8 0 1 ** 0 0 0 8 0 8 5 6 8 0 1 *

*IME43942N00**IME43942N00*

* I M E 4 3 9 4 2 N 0 0 ** I M E 4 3 9 4 2 N 0 0 *

Page 3

SAFETY INSTRUCTIONS

CAUTION

WARNING

CAUTION

Safety Instructions for the Installer

WARNING

Do not work inside the

equipment unless totally

familiar with electrical

circuits.

Hazardous voltage which can

shock, burn or cause serious

injury exists inside the equipment.

Turn off the power at the

mains switchboard before

beginning the installation.

Post a sign near the switch

to indicate it should not be

turned on while the equipment is being installed.

Fire, electrical shock or

serious injury can result if the

power is left on or is applied

while the equipment is being

installed.

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

Confirm that the power supply voltage

is compatible with the voltage rating

of the equipment.

Connection to the wrong power supply

can cause fire or equipment damage. The

voltage rating appears on the label at the

rear of the display unit.

Use the correct fuse.

Use of a wrong fuse can cause fire or

equipment damage.

Keep the following compass safe

distance.

Standard Steering

Display Unit 0.82 m 0.62 m

CAUTION

When handling the transducer cable,

keep in mind the following points.

• Keep the cable away from oil and

fuel.

• Keep the cable away from the

place where it may be damaged

during the installation.

• Do not paint the cable.

The sheath of the transducer cable is

made of chlorophrene rubber (or vinyl

chloride). Therefore, do not paint the

sheath with organic liquid (such as

toluene) since it may harm the sheath.

A warning label is attached to the equipment. Do not remove the label. If the

label is missing or illegible, contact

a FURUNO agent or dealer.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label (1)

Type: 86-003-1011-0

Code No.: 100-236-230

Page 4

System Configuration

The GP-1650F/1650DF mainly consists of a display unit, a GPS antenna and a dual frequency transducer. A DGPS beacon receiver is

provided inside the display unit for GP-1650DF type. The chart card

drive in the display unit loads electronic charts. External equipment

which can be connected include water temperature and speed sensors, autopilot, and DGPS beacon receiver.

GPA-017

(for GP-1650F)

ANTENNA UNIT

Receives signal from

GPS satellite and beacon

reference station

(GP-1650DF only).

DISPLAY UNIT

Ship’s position is

calculated in longitude

and latitude from signal

received from the antenna unit and displayed

on the screen.

WHIP ANTENNA

1.2 m

GPA-018

(for GP-1650DF)

GPA-019

(for GP-1650DF)

Temp. sensor

(option)

Transducer

(option)

Ship’s mains

10.8—31.2 VDC

External equipment

(Autopilot, etc.)

DGPS beacon receiver

GP-1650F only

i

Page 5

Standard supply

.oNemaNepyT.oNedoCytQskrameR

Equipment Lists

1tinUyalpsiD

2tinUannetnA

3straPerapS10420-41PS036-473-4001

4

5seirosseccA

noitallatsnI

slairetaM

Optional equipment

.oNemaNepyT.oNedoCskrameR

1revieceRnocaeB

tiK

61-PGE-F05

61-PGE-DF05FD0561-PGrof

10-APG7 304-140-000

810-APG704-140-000FD0561-PGrof

910-APG

PC410-0150 -140-0000841

10320-41PF038-573-4001revocdraH

20320-41PF058-573-4001

810-A01-0561-208-RG156-140-000,,810-APG

810-N01-0561-208-RG284-140-000

155-140-000

1

1

GR-7000A, Whip ant.

R-7000AG,810-APG

F0561-PGrof

F0561-PGrof

FD0561-PGrof

,regnahrofswercs

hsulfrofswercs

.tnuom

S810-A51-0561-208-RG256-140-000

S810-N51-0561-208-RG384-140-000

910-N01-0561-208-RG056-140-000 -7000ARG,910-APG

S910-N51-0561-208-RG

2teSelbacannetnA00710-02PC011-273-400elbacannetnarof,m03

01710-02PC021-273-400elbacannetnarof,m05

3.yssaelbacannetnA51-D3-SP-CNT076-331-000

4.yssAelbaC10-037-631-000

5erutxiftnuomtsaM1110-02PC087-563-400

6annetnaelgna-thgiR

esab

7annetnaelgna-L

esab

8esabannetnA

MJ-A7SPF0003-050

033AQ-31.oN932-308-000

013AQ-31.oN042-308-000

0615CR-31.oN411-608-000

gnitnuomliarrof

356-140-000

-7000ARG,S810-APG

.tnapihW,51-D3-SP-CBT

-7000ARG,S810-APG

51-D3-SP-CBT

-7000ARG,S910-APG

51-D3-SP-CBT

noisnetxe

noisnetxe

elbacannetnarof,m51

noisnetxe

tinuannetnagnitnuomrof

ii

Page 6

Optional equipment (con't)

.oNemaNepyT.oNedoCskrameR

9tinUannetnA

01recudsnarT

11rosnesTS

21StiKlluhrennI1910S22895-208-000

31rosneserutarepmeT

41ycneuqerflauD

recudsnarT

525ST-MSD

S810-PG264-140-000FD0561-PGrof

610-PG635-040-000F0561-PGrof

S910-APG455-140-000FD0561-PGrof

DSP5-025521-510-000

DWP5-025621-510-000tnuommosnartelbacm8htiW

DSM5-025721-510-000foorpretawdnaelbacm8htiW

BSM20-TS689-731-000epytlluh-urhT

BSP20-TS789-731-000epytlluh-urht,elbacm8htiW

BTM20-T620-040-000

BSM20-T040-040-000

BSM30-T720-040-000

DSM-TS425422-510-000

DWP-TS025821-510-000

rotcennoc

000-015-263

51rterevnoC

rotcennoC

61reifitceR26-RP

71

81.yssAelbaC

19

RAM Card

DGPS Beacon

20

Receiver

annetnapihW

525ST-PWD

7414S20

2.1-WAF

00RAM02MC-004

GR-80

000-015-261

280-141-000

484-310-000CAV001rof

584-310-000CAV011rof

684-310-000CAV022rof

784-310-000CAV032rof

640-031-000S810/810-APGrof

001-2100FPS6A-JM718-331-000m01,P6-P6

001-7000FPS6A-JM732-521-000tolipotuarof,m01,P6-P6

050-2100FPS6A-JM424-431-000m5,P6-P6

050-1100FPS6A-JM442-231-000m5,P4-P6

001-1100FPS6A-JM633-231-000m01,P4-P6

004-371-790 2MB

-

for GP-1650F

iii

Page 7

1. Installation of Standard Equipment

1.1 Installation of Display Unit

Mounting considerations

The display unit can be installed on a tabletop, on the overhead or

flush mounted in a console or panel.

Figure 1-1 Tabletop, overhead mounting methods

OverheadTabletopHard Cover

When selecting a mounting location for the display unit keep the following in mind:

• Keep the display unit out of direct sunlight.

• The temperature and humidity should be moderate and stable.

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• Keep the unit away electromagnetic field generating equipment

such as motor, generator.

• For maintenance and checking purposes, leave sufficient space at

the sides and rear of the unit and leave slack in cables.

• A magnetic compass will be affected if placed too close to the

display unit. Observe the following compass safe distances to prevent disturbance to the magnetic compass:

Standard compass: 0.82 meters

Steering compass: 0.62 meters

1-1

Page 8

Mounting procedure

Follow the procedure below to mount the display unit on a tabletop

or the overhead.

Tabletop, overhead mounting

1. Fix the hanger by four pan head screws M5 X 16.

2. Screw knob bolts in display unit, set it to hanger, and tighten

knob bolts.

3. Attach hard cover to protect LCD.

WARNING

Figure 1-2 Tabletop, overhead mounting of display unit

Flush mounting

Note: Use supplied pan head screws when the thickness of the bulkhead is from 11 to 14 mm. For bulkhead which exceeds 14 mm in

thickness the length of the pan head screws should be bulkhead thickness+7.8

±

1.5 mm. Also the length of B should max. 8mm.

1. Prepare a cutout in the mounting location whose dimensions are

as shown in Figure 1-3.

2. Fix the display unit by six pan head screws M4 X 20. Refer to the

outline drawing on page D-2.

1-2

Page 9

216±1

Center pin (soldered)

Clamp nut

Connector shell

Gasket (reddish brown)

Washer

Shield

164±0.5

Flush mount

Pan head screws

6-R2.25

132±0.5

125±1

4.5

Figure 1-3 Flush mounting of display unit

1.2 Installation of Antenna Unit (GP-1650DF only)

Mounting considerations

Install the antenna unit referring to the installation diagram on page

D-3 or D-4. When selecting a mounting location for the antenna unit,

keep in mind the following points:

• Select a location out of the radar beam. The radar beam will obstruct or prevent reception of the GPS satellite signal.

• The location should be well away from a VHF antenna. A GPS

receiver is interfered by a harmonic wave of a VHF antenna.

• There should be no interfering object within the line-of-sight to

the satellites. Objects within line-of-sight to a satellite, for example,

a mast, may block reception or prolong acquisition time.

• Mount the antenna unit as high as possible. Mounting the antenna

unit as high as possible keeps it free of interfering objects and

water spray, which can interrupt reception of GPS satellite signal

if the water freezes.

• The length of the whip antenna for the GP-1650DF should be no

longer than 1.2 meter to prevent antenna damage. Do not use a 2.5

meter whip antenna.

• Do not shorten the antenna cable.

• If the antenna cable is to be passed through a hole which is not

large enough to pass the connector, you may unfasten the connector with a needle nose pliers and 3/8-inch open-end wrench. Refasten it as shown in Figure 1-4 after running the cable through the

hole.

Figure 1-4 How to assemble the connector

1-3

Page 10

1.3 Installation of Transducers

Installing the inside-hull mount transducer

Necessary tools

You will need the following tools:

• Sandpaper (#100)

• Silicone sealant

• Silicone grease

Remarks on installation

• Do the installation with the boat hauled out of the water.

• Turn off the engine while installing the equipment.

• Install the transducer in the engine room.

Selecting the mounting location

Keep the following points in mind when selecting a mounting location:

• The mounting location should be where the hull is of single-hull

thickness and is void of air or flotation materials other than solid

fiberglass between the transducer face and the water.

• Do not place the transducer over hull struts or ribes which run

under the hull.

• Avoid a location where the rising angle of the hull exceeds 15°, to

minimize the effect of the boat’s rolling.

• You will finalize the mounting location through some trial and

error. The procedure for this is shown later.

15cm

15cm

1/2

1/3

Mounting location

for transducer

Center line

50cm

50cm

1-4

Figure 1-5 Inside-hull transducer mounting location

Page 11

Attaching the transducer

1. Clean the transducer face to remove any foreign material. Lightly

roughen the transducer face with #100 sandpaper . Also, roughen

the inside of the hull where the transducer is to be mounted.

2. Warm the silicone sealant to 40°C before usage to soften it. Coat

the transducer face and mounting location with silicone sealant.

Transducer face

Silicone sealant

Figure 1-6 Coating the transducer face with silicone sealant

3. Press the transducer firmly down on the hull and gently twist it

back and forth to remove any air which may be trapped in the

silicone sealant.

Squeeze out

air bubbles.

Hull

Silicone

sealant

Figure 1-7 Attaching transducer to hull with silicone sealant

1-5

Page 12

Observing the picture

1. Press the [POWER] key to turn on the display unit.

2. Press the [SNDR] key to select the sounder display.

3. Press the soft key labeled "MODE/FREQ" to display the following message.

MODE/FREQ

▲

AUTO (CRUSING)

AUTO (FISHING)

MANUAL

▼

Figure 1-8 MODE FREQ selection screen

4. Select "MANUAL" by the arrow key.

5. Press the soft key labeled "RETURN".

6. Press the soft key labeled "GAIN" to display the following message.

GAIN

▲

50

HIGH

LOW

▼

Figure 1-9 GAIN adjustment screen

7. Confirm that Gain is set at 50 (midpoint).

8. Press the soft key labeled "RETURN".

1-6

9. Press the soft key labeled "RANGE".

10. Select "15ft" by the [▲] key.

11. Note the depth to the seabed.

Page 13

°C

30

20

0.0

SOUNDER

0

5

RANGE

10

0

32.8

10

15

DGPS 3D 50k

Figure 1-10 Video sounder picture

If the bottom is displayed in red and the light-blue color appears

the mounting location is suitable. You can leave the transducer in

position.

If the bottom is not displayed in reddish brown, the mounting

location is unsuitable. Relocate the transducer and do the following.

1. Press the [POWER] key to turn off the power.

2. Gently dismount the transducer with piece of wood.

3. Do steps 1 through 5 in the previous procedure. Repeat until

a suitable location is found.

GAIN

SHIFT

MODE/

FREQ

SNDR

FUNC

Final preparation

Support the transducer with a piece of wood to keep it in place wile it

is drying. Let the transducer dry 24–72 hours.

1-7

Page 14

Installing the thru-hull mount transducer

22

120

30

68 87

68

120

28

24

520-5PSD (option) 520-5MSD (option)

Ship's

bow

All dimensions

in millimeters

Transducer mounting location

This type of mounting provides the best performance of all, since the

transducer protrudes from the hull and the effect of air bubbles and

turbulence neat the hull skin is reduced. When the boat has a keel, the

transducer should be at least 30 cm away from it. Typical through

hull mountings are shown in the figure on the next page.

The performance of the video sounder is directly related to the mounting location of the transducer, especially for high-speed cruising. The

installation should be planned in advance, keeping the standard cable

length (8 m) and the following factors in mind:

• Air bubbles and turbulence caused by movement of the boat seriously degrade the sounding capability of the transducer. The transducer should, therefore, be located in a position where water flow

is the smoothest. Noise from the propellers also adversely affects

performance and the transducer should not be mounted nearby.

The lifting strakes are notorious for creating acoustic noise, and

these must be avoided by keeping the transducer inboard of them.

• The transducer must always remain submerged, even when the

boat is rolling, pitching or up on a plane at high speed.

• A practical choice would be somewhere between 1/3 and 1/2 of

the boat's length from the stern. For planing hulls, a practical location is generally rather far astern, so that the transducer is always

in water regardless of the planing attitude.

Transducer outline drawings

1-8

Figure 1-11 Transducer outline drawings

Page 15

Acceptable transducer mounting locations

• Within the wetted bottom area

• Deadrise angle within 15°

Flat washer

Rubber washer

Fairing block

Hull

bottom

Hull

bottom

Deep-V Hull Flat Hull

Deep-V hull

• Position 1/2 to 1/3 length of the hull from stern

• 15 to 30 cm off center line (inside first lifting strakes).

Figure 1-12 Transducer mounting location on deep-V hull

High speed V-planing hull

Figure 1-13 Transducer mounting location on high speed

V-planing hull

Typical through-hull mount transducer installations

Figure 1-14 Typical through-hull mount transducer installations

1-9

Page 16

Procedure for installing the thru-hull mount transducer

W

1. With the boat hauled out of the water, mark the location selected

for mounting the transducer on the bottom of the hull.

2. If the hull is not level within 15° in any direction, fairing blocks

made out of teak should be used between the transducer and hull,

both inside and outside, to keep the transducer face parallel with

the water line. Fabricate the fairing block as shown below and

make the entire surface as smooth as possible to provide an undisturbed flow of water around the transducer. The fairing block

should be smaller than the transducer itself to provide a channel

to divert turbulent water around the sides of the transducer rather

than over its face.

Hole for

stuffing tube

Upper

half

Lower

half

Saw along slope of hull.

BO

Figure 1-15 Construction of fairing block

3. Drill a hole just large enough to pass the threaded stuffing tube of

the transducer through the hull, making sure it is drilled vertically.

4. Apply a sufficient amount of high quality caulking compound to

the top surface of the transducer , around the threads of the stuffing tube and inside the mounting hole (and fairing blocks if used)

to ensure watertight mounting.

5. Mount the transducer and fairing blocks and tighten the locking

nuts. Be sure that the transducer is properly oriented and its working face is parallel to the waterline.

1-10

Note: Do not over-stress the stuffing tube and locking nuts through

excessive tightening, since the wood block will swell when the boat is

placed in the water. It is suggested that the nut be tightened lightly at

installation and retightened several days after the boat has been

launched.

Page 17

Installing the transom mount transducer

This type of mounting is very commonly employed, usually on relatively small I/O or outboard boats. Do not use this method on an

inboard motor boat because turbulence is created by the propeller

ahead of the transducer.

There are two methods of installation: flush with hull (for flat hulls)

and projecting from hull (for deep V-hulls).

D

D>

50 cm

Flat Hull Deep V-hull

Figure 1-16 Transom mount transducer mounting locations

Installing the transom mount transducer flush with hull

(for flat hulls)

A suitable mounting location is at least 50 cm away from the engine

and where the water flow is smooth.

1. Drill four pilot holes in the mounting location.

2. Attach the transducer to the bracket with tapping screws (supplied).

3. Adjust the transducer position so the transducer faces right to the

seabed.

Note: If necessary, to improve water flow and minimize air

bubbles staying on the transducer face, incline the transducer

about 5

°

at the rear. This may requir e a certain amount of experi-

mentation for fine tuning at high cruising speeds.

4. Fill the gap between the wedge front of the transducer and transom with epoxy material to eliminate any air spaces.

1-11

Page 18

M5 x 20

M5 x 20

5°

Tape

No. 1

M5 x 14

Figure 1-17 Transom mount transducer, mounting flush with hull

Installing the transom mount transducer projecting from hull

(for deep-V hulls)

This method is employed on deep-V hulls and provides good performance because the effects of air bubbles are minimal. Install the transducer parallel with water surface; not flush with hull. If the boat is

placed on a trailer care must be taken not to damage the transducer

when the boat is hauled out of the water and put on the trailer.

M5 x 20

M5 x 20

1-12

No. 2

M5 x 14

Figure 1-18 Transom mount transducer, projecting from hull

Transducer preparation

Before putting the boat in water, wipe the face of the transducer thor oughly with a detergent liquid soap. This will lessen the time necessary for the transducer to have good contact with the water. Otherwise

the time required for complete "saturation" will be lengthened and

performance will be reduced.

Do not paint the transducer. Performance will be affected.

Page 19

Triducer 524ST-MSD, 525ST-MSD

The triducer is designed for thru-hull mounting.

Mounting considerations

When selecting a mounting location keep the following points in mind:

• Air bubbles and turbulence caused by movement of the boat seri-

ously degrade the sounding capability of the transducer . The transducer should, therefore, be located in a position where water flow

is the smoothest. Noise from the propellers also adversely affects

performance and the transducer should not be mounted nearby.

The lifting strakes are notorious for creating acoustic noise, and

these must be avoided by keeping the transducer inboard of them.

• The transducer must always remain submerged, even when the

boat is rolling, pitching or up on a plane at high speed.

• A practical choice would be somewhere between 1/3 and 1/2 of

the boat’s length from the stern. For planing hulls, a practical location is generally rather far astern, so that the transducer is always

in water regardless of the planing attitude.

∅79 mm

133 mm

2.00"-12 UN

threads

∅51 mm

27 mm

140 mm

7 mm

Figure 1-19 Dimensions of triducer 524ST-MSD/525ST-MSD

1-13

Page 20

1.4 Installation of Sensors

Transom mount water temperature sensor

T-02MTB

• Fix the cable at a convenient location with cable clamp.

• When the cable is led in through the transom board, make a hole

of approx. 17 mm diameter to pass the connector. After passing

the cable, fill the hole with a sealing compound.

D>50 cm

D

M5 x 20

Mount sensor

flush with hull bottom.

Figure 1-20 How to install transom mount water temperature

sensor T-02MTB

1-14

Page 21

Thru-hull mount water temperature sensor

T-02MSB, T-03MSB

• Select a mid-boat flat position. The sensor does not have to be

installed perfectly perpendicular. The sensor must not be damaged

in dry-docking operation.

• Select a place apart from equipment generating heat.

• Select a place in the forward direction viewing from the drain hole,

to allow for circulation of cooling water.

• Select a place free from vibration.

Install the sensor as shown in Figure 1-21.

Figure 1-21 Thru-hull mount water temperature sensors

T -02MSB, T-03MSB

1-15

Page 22

Through-hull mount water temperature/speed

sensor ST-02MSB, ST-02PSB

Select a suitable mounting location considering the following:

• Select a mid-boat flat position. The sensor does not have to be

installed perfectly perpendicular. The sensor must not be damaged

in dry-docking operation.

• Select a place apart from equipment generating heat.

• Select a place in the forward direction viewing from the drain hole,

to allow for circulation of cooling water.

• Select a place free from vibration.

1. Dry-dock the boat.

2. Make a hole of approx. 51 mm diameter.

3. Unfasten locknut and remove the sensor section.

4. Apply high-grade sealant to the flange of the sensor.

5. Pass the sensor casing through the hole.

6. Face the notch on the sensor toward boat’s bow and tighten the

flange.

7. Set the sensor section to the sensor casing and tighten the lock-

nut.

8. Launch the boat and check for water leakage around the sensor.

Locknut

Face "notch"

toward bow.

Flange nut

Coat with

silicone sealant.

51

Brim

ø77

123

1-16

Figure 1-22 Water temperature/speed sensor ST-02MSB,

ST-02PSB

Page 23

Antenna unit

GPA-018

(GP-1650DF)

Earth

terminal

2. Wiring

All wiring are terminated at the rear of the display unit.

Earth terminal

DISPLAY UNIT

GPA-017

(GP-1650F)

NMEA

ANTENNA UNIT

ANT

DGPS

XDR

+

13GND

2

-

12-24

VDC

External

equipment

GPA-019

DGPS beacon receiver

(option for GP-1650F,

RS-232C only)

Black

White

Shieled

(GP-1650DF)

TRANSDUCER

Figure 2-1 Display unit, rear view

Power cable

Connect the power cable to the power connector. Connect the leads

to the battery (12 or 24 VDC); white to plus(+) terminal and black to

minus(-) terminal.

Cable connector

Power cable

w/fuse (3A)

Lead wire

Black

White

BATTERY

Figure 2-2 Connecting the power cable to the battery

2-1

Page 24

Antenna unit

Connect the antenna unit cable to the ANT connector.

Transducer

Connect the transducer cable to the XDR connector. Connect the water

temperature sensor (option) or water temperature/speed sensor (option) to the XDR connector with the converter connector (Type :

02S4147, Code No. : 000-141-082, option).

MJ-A6SRMD

SHIELD

TEMP

TEMP0V

NC

NC

NC

MJ-A10SRMD

NC

NC

NC

NC

NC

NC

NC

XDR+

XDR SHIELD

XDR-

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

MJ-A10SPF

1

SPD

4

TEMP

7

GND

3

GND

2

+12V

5

NC

6

NC

8

XDR-P

9

XDR-SHIELD

10

XDR-M

Figure 2-3 Wiring of converter connector for water temperature

sensor

MJ-A6SRMD

SHIELD

TEMP

TEMP0V/SPD0V

SPD

+V

NC

MJ-A10SRMD

NC

NC

NC

NC

NC

NC

NC

XDR+

XDR SHIELD

XDR-

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

MJ-A10SPF

4

TEMP

7

GND

3

GND

1

SPD

2

+12V

5

NC

6

NC

8

XDR-P

9

XDR-SHIELD

10

XDR-M

Figure 2-4 Wiring of converter connector for water temperature/

speed sensor

2-2

Page 25

Type : 02S4147

Code No. : 000-141-082

To connector at

rear of display unit

MJ-A10SPF

MJ-A6SRMD

Water temp., water temp/speed

sensor connector

Transducer connector

MJ-A10SRMD

Figure 2-5 Connection of transducer, water temperature sensor,

water temperature/speed sensor

Ground

The display unit

contains several

CPUs. While they

are operating, they

radiate noise, which

can interfere with

radio equipment.

Ground the unit to

prevent interference. The grounding wire should be 1.25 sq or larger

and as short as possible. Connect the grounding wire to ship's ground

On a fiberglass boat, it is best to install a ground plate that measures

about 20 cm by 30 cm on the outside of the hull bottom to provide a

ground point. If this is not practical, the engine block can be used.

Also, the antenna unit GPA-018S(option) is required to ground with

IV-1.25 sq cable as short as possible.

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

.

Note: Use a “closed” lug to make the ground connection at the display unit. Do not use an “open-type” lug (

).

2-3

Page 26

Extending antenna cable length

The standard cable is 10m long. For extension, in case of the GPA016, GP A-018S or GPA-019S, an antenna cable set of 30m or 50m is

available.

◆ Extension cable line-up

Fabricate the end of the antenna cable and attach the coaxial connector. Details are shown on next page.

Antenna Unit

(GPA-016,

GPA-018S,

GPA-019S)

Conversion

Cable Assy.

: Connector

1 m

Antenna Cable

30 m or 50 m 1 m

Fabricate locally. (See next page.)

To display unit

Figure 2-6 Cable extension

◆ Waterproofing connector

Wrap connector with vulcanizing tape and then vinyl tape. Bind

the tape end with cable-tie.

Figure 2-7 Waterproofing connector

2-4

Page 27

How to attach the N-P-8DFB connector

Outer Sheath

Cover with heat-shrink tubing and heat.

Armor

30

Clamp

Nut

Dimensions in millimeters.

Inner Sheath Shield

50

Gasket

(reddish

brown)

30

10

Clamp

Aluminum Foil

Remove outer sheath and armor by the dimensions

shown left.

Expose inner sheath and shield by the dimensions

shown left.

Cut off insulator and core by 10mm.

Twist shield end.

Ship on clamp nut, gasket and clamp as shown left.

Trim shield here.

Trim aluminum

tape foil here.

Clamp Nut

Insulator

1

5

Pin

Shell

Fold back shield over clamp and trim.

Cut aluminum foil at four places, 90° from one

another.

Fold back aluminum foil onto shield and trim.

Expose the insulator by 1mm.

Expose the core by 5mm.

Slip the pin onto the conductor. Solder them together

through the hole on the pin.

Insert the pin into the shell. Screw the clamp nut into

the shell.

Solder through

the hole.

(Tighten by turning the clamp nut. Do not tighten by

turning the shell.)

Figure 2-8 Fabrication of coaxial cable

2-5

Page 28

3.1 NMEA Setting

3. Initial Settings

NMEA port

1. Press the [MENU] key.

2. Press the software key labeled "CONFIGURATION".

3. Press the software key labeled "SETUP NMEA PORT1".

4. Select "FORMAT" by the arrow key.

5. Press the software key labeled "EDIT" to display the following

message.

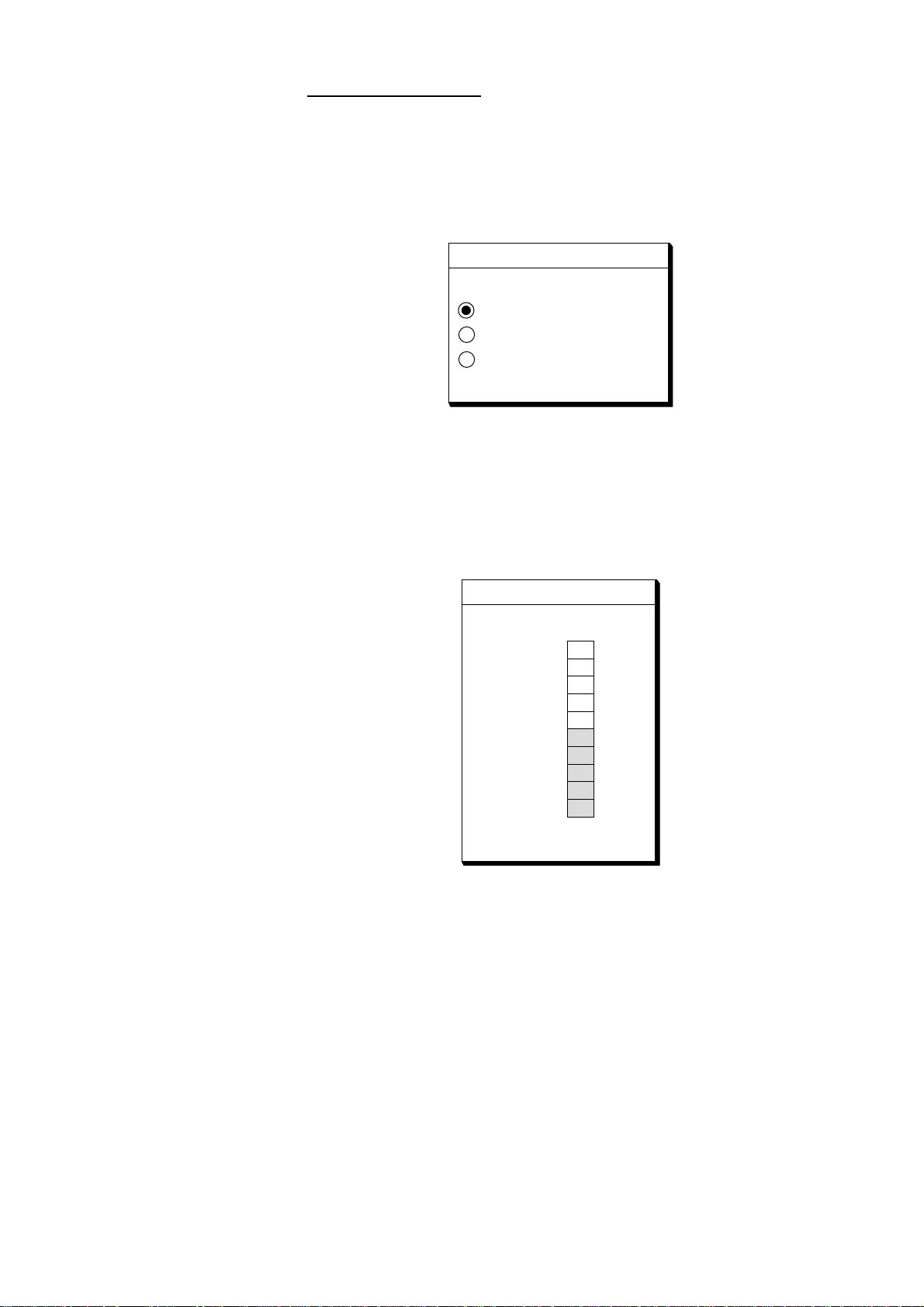

s FORMAT NMEA 0183

OUTPUT FORMAT

VER 1.5

PORT1

▲

NMEA0183 Ver1.5

' NMEA0183 Ver2.0

▼

ENTER

SETUP

DGPS 3D

Figure 3-1 Output Format Display

6. Select NMEA version by the arrow key. The selected item is indicated by black button.

CANCEL

7. Press the software key labeled "ENTER".

8. Press the [PLOT] key to finish.

3-1

Page 29

DGPS port

1. Press the [MENU] key .

2. Press the software key labeled "CONFIGURATION".

3. Press the software key labeled "SETUP NMEA/DGPS PORT2".

4. Select "FORMAT" by the arrow key.

5. Press the software key labeled "EDIT" to display the following

message.

s FORMAT NMEA 0183

DGPS 3D

OUTPUT FORMAT

▲

NMEA0183 Ver1.5

' NMEA0183 Ver2.0

RTCM104 (EXTRN)

RTCM104 (INTRN)

RTCM104 (OUTPUT)

▼

VER 1.5

▲▲▲

SETUP

PORT2

ENTER

CANCEL

Figure 3-2 Output Format Display

6. Select NMEA version, external DGPS or internal DGPS by the

arrow key. The selected item is indicated by black button.

NMEA0183 Ver1,5/Ver2,0 :Select one when connecting

PC or RS-232C equipment.

3-2

RTCM104(EXTRN) :Select this when connecting

external DGPS beacon

receiver.

RTCM104(INTRN) : Select this for builtin internal

DGPS beacon receiver.

RTCM104(OUTPUT) :Select this when outputting

differential data of the

internal DGPS beacon receiver

to other GPS navigator.

Note1) Note that you cannot setup sentences when you select

RTCM104 at the format.

Note2) For RS-422 format, the level converter (IF-1432) is requir ed

for connection of external equipment.

7. Press the software key labeled "ENTER" or the [ENTER] key.

8. Press the [PLOT] key to finish.

Page 30

3.2 Output Data Sentences

Select output data sentences for external equipment as follows.

1. Press the [MENU] key.

2. Press the software key labeled "CONFIGURATION".

3. Press the software key labeled "SETUP NMEA PORT1".

4. Press the software key labeled "SELECT SNTNC." to display

the following list.

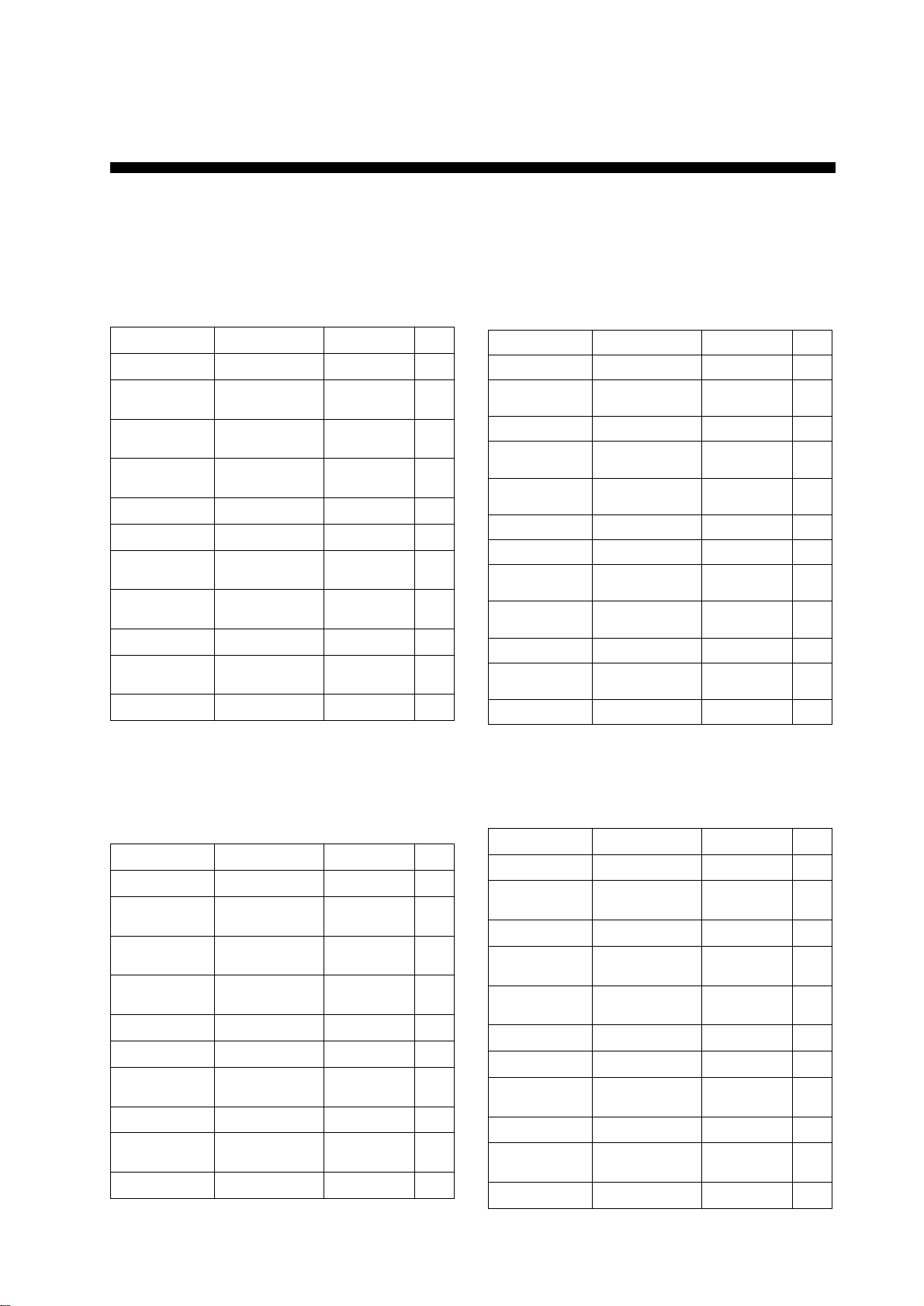

SELECT

SNTNC.

ON/OFF

RETURN

s

DGPS 3D

SELECT SENTENCE

sAAM

APB ON

BOD

BWR

DPT

GGA

GLL ON

MTW

RMA

RMB ON

RMC ON

VTG ON

WPL

XTE

ZDA ON

Figure 3-3 Output Date Sentences Display

5. Select data sentence you want to output data by the arrow key.

6. Press the software key labeled "ON/OFF". To output data, set to

"ON".

7. Repeat to select other sentences.

8. Press the software key labeled "RETURN".

9. Press the [PLOT] key to finish.

Input/Output Sentences

troPtamroFataDskrameR

tupnI

1

tuptuO

tupnI1*LPW,WTM,1*LLT

2

tuptuO

-AEMN

3810

0.2.reV

5.1.reV

.ylevitucesnoctupniebtonnaC:1*

1*LPW,WTM,MWD,1*LLT

,RWB/CWB,DOB,BPA,MAA

,BMR,AMR,LLG,AGG

,ADZ,ETX,LPW,GTV,CMR

2*DTG,WTM,TPD/TBD

,RWB/CWB,DOB,BPA,MAA

,BMR,AMR,LLG,AGG

,ADZ,ETX,LPW,GTV,CMR

2*DTG,WTM,TPD/TBD

.detcelessiALroCLnehwyllacitamotuatuptuO:2*

ylnoPG:LPW

)AEMN(ECRUOSPMET:WTM

ylno

CWB:ELCRICTAERG

RWB:ENILBMUHR

TBD:5.1reVAEMN

TPD:0.2reVAEMN

ylnoPG:LPW

)AEMN(ECRUOSPMET:WTM

ylno

CWB:ELCRICTAERG

RWB:ENILBMUHR

TBD:5.1reVAEMN

TPD:0.2reVAEMN

C232-SR

3-3

Page 31

3.3 Antenna Height

1. Press the [MENU] key .

2. Press the software key labeled "GPS/DGPS/TD OPTIONS".

3. Press the software key labeled "GPS SETUP OPTIONS".

4. Select "ANT. HEIGHT" by the arrow key.

5. Press the software key labeled "EDIT" to display the following

6. Enter the height (3 digits) of the antenna above sea level using

message.

ANT. HEIGHT

0 0 5 m

Figure 3-4 Antenna Height Display

the numeric keys.

If you enter wrong antenna height, press the software key labeled

"CLEAR".

7. Press the [ENTER] key.

8. Press the [PLOT] key to finish.

3-4

Page 32

3.4 Baud Rate Setting (GP-1650DF only)

1. Press the [MENU] key.

2. Press the software key labeled "GPS/DGPS/TD OPTIONS".

3. Press the software key labeled "DGPS SETUP OPTIONS" to display the following message.

s FORMAT NMEA 0183

DGPS MODE ON

BEACON FREQUENCY AUTO

s

BEACON BAUD RATE AUTO

DGPS ALARM OFF

VER 1.5

DGPS

OPTION

EDIT

DGPS 3D

Figure 3-5 DGPS Setup Options Display

4. Confirm that "ON" is selected at "DGPS MODE" field for GP1650DF.

5. Select "BEACON BAUD RATE" by the arrow key.

6. Press the software key labeled "EDIT" to display the following

message. Beacon baud rate cannot be set when "BEACON

FREQUENTRY" is set to "AUTO".

RETURN

BEACON BAUD RATE

▲

200

' 100

50

▼

Figure 3-6 Beacon Baud Rate Display

7. Select beacon baud rate corresponding to DGPS reference station to use.

8. Press the [ENTER] key.

9. Press the [PLOT] key to finish.

3-5

Page 33

3.5 Beacon frequency Setting (GP-1650DF only)

1. Press the [MENU] key .

2. Press the software key labeled "GPS/DGPS/TD OPTIONS".

3. Press the software key labeled "DGPS SETUP OPTIONS" to display the following message.

s FORMAT NMEA 0183

DGPS MODE ON

BEACON FREQUENCY AUTO

s

BEACON BAUD RATE AUTO

DGPS ALARM OFF

VER 1.5

DGPS

OPTION

EDIT

DGPS 3D

Figure 3-7 DGPS Setup Options Display

4. Select "BEACON FREQUENCY" by the arrow key.

5. Press the software key labeled "EDIT" to display the following

message.

RETURN

BEACON FREQUENCY

▲

' AUTO

MANUAL s 284.0 kHz

▼

Figure 3-8 Beacon Frequency Display

6. Select "AUTO" or "MANUAL" by the arrow key. When you select "MANUAL", operate the cursor pad to move the cursor to

frequency dialog box. And press the arrow key to select the frequency desired.

3-6

7. Press the [ENTER] key.

8. Press the [PLOT] key to finish.

Page 34

3.6 Depth Adjustment

1. Press the [MENU] key.

2. Press the software key labeled "DISPLAY OPTION".

3. Press the software key labeled "NEXT PAGE".

4. Select "DEPTH ADJ." by the arrow key.

5. Press the software key labeled "EDIT" to display the following

message.

6. Set depth adjustment by the arrow key. The adjustment range is

-9.9~+9.9 ft.

DEPTH ADJ

▲

+ 0.0 f t

▼

Figure 3-9 Depth Adjustment Display

For example, if the depth readout is 5 feet lower than actual depth,

enter +5 feet.

7. Press the software key labeled "RETURN".

8. Press the [PLOT] key to finish.

3-7

Page 35

3.7 External Equipment Setup (Option)

This section shows you how to set up the GP-1650F/1650DF when

external equipment is connected. If a water temperature/speed sensor

is installed, you should complete this section with the boat in the

water and running, to confirm speed/water temperature readout.

Speed Source

1. Press the [MENU] key .

2. Press the software key labeled "DISPLAY OPTIONS".

3. Press the software key labeled "NEXT PAGE" to display the following display.

s SPEED SOURCE GPS

TEMP SOURCE OWN XDCR

TEMP GRAPH OFF

ZOOM MARKER OFF

SPEED ADJ. +00%

TEMP ADJ. +00.0°F

DEPTH ADJ. +0.0ft

SPD

12.3kt

TEMP

62.5°F

DEPTH

2000.0ft

DGPS 3D

Figure 3-10 Display Setup 2 Display

4. Select "SPEED SOURCE" by the arrow key.

5. Press the software key "EDIT" to display the following message.

DISPLAY

SETUP2

EDIT

RETURN

SPEED SOURCE

▲

OWN PDDWHL

GPS

3-8

▼

Figure 3-11 Speed Source Display

6. Select source of speed by the arrow key; "OWN PDDWHL"

(speed sensor) or "GPS". The selected item is indicated by black

button.

Adjust speed when you select "OWN PDDWHL". Refer to next

page.

7. Press the software key labeled "ENTER".

8. Press the [PLOT] key to finish.

Page 36

Speed Adjustment

Adjust speed when you select own speed source "OWN PDDWHL".

1. Press the [MENU] key.

2. Press the software key labeled "DISPLAY OPTIONS".

3. Press the software key labeled "NEXT PAGE" to display the Following display.

s SPEED SOURCE GPS

TEMP SOURCE OWN XDCR

TEMP GRAPH OFF

ZOOM MARKER OFF

SPEED ADJ. +00%

TEMP ADJ. +00.0°F

DEPTH ADJ. +0.0ft

SPD

12.3kt

TEMP

62.5°F

DEPTH

2000.0ft

DGPS 3D

Figure 3-12 Display Setup 2 Display

4. Select "SPEED ADJ." by the arrow key.

5. For speed sensor-equipped sets, you may offset the speed readout

if it is wrong. Run the boat at various speeds and watch the speed

readout at the bottom of the screen. If it is unreasonably wrong,

press the software key "EDIT" to display the following message.

DISPLAY

SETUP2

EDIT

RETURN

SPEED ADJ

▲

+ 00 %

▼

Figure 3-13 Speed Adjustment display

6. Correct speed readout by the arrow key. The adjustment range is

-50%~+50%.

For example, if readout is 10% lower than actual speed, enter

+10%.

7. Press the software key "RETURN".

3-9

Page 37

8. Press the [PLOT] key to finish.

T emperature Adjustment

1. Press the [MENU] key .

2. Press the software key labeled "DISPLAY OPTIONS".

3. Press the software key labeled "NEXT PAGE" to display the following display.

s SPEED SOURCE GPS

TEMP SOURCE OWN XDCR

TEMP GRAPH OFF

ZOOM MARKER OFF

SPEED ADJ. +00%

TEMP ADJ. +00.0°F

DEPTH ADJ. +0.0ft

SPD

12.3kt

TEMP

62.5°F

DEPTH

2000.0ft

DGPS 3D

Figure 3-14 Display Setup 2 Display

4. Select "TEMP ADJ." by the arrow key.

DISPLAY

SETUP2

EDIT

RETURN

3-10

Page 38

4. Installation of DGPS Beacon Receiver (for GP-1650F)

The DGPS beacon receiver GR-7000A can be incorporated in the

GP-1650F to provide it with DGPS capability. Six installation kits

are available as shown.

GR-802-1650-10A-018 GR-802-1650-15A-018S

GR-802-1650-10N-018 (No whip ant.) GR-802-1650-15N-018S (No whip ant.)

emaNepyT.oNedoCytQ

tinUannetnA810-APG174-140-0001

nocaeB

revieceR

rotcennoC

.yssA

daehnaP

swercs

eitelbaC001-VC223-075-0002

wercS403SUS21X3M509-508-0006

.yssAelbaC

annetnapihW

)ylnoepytA01(

pmalCN2-PH000-075-0001

*.yssAelbaC

*wercS014SUS8X3159-208-0004

desutoN*

A0007-RG942-341-0001

042L-W-P6HP845-141-0001

W0072C01X3M504-188-0004

.yssA

-D-7.0PL2-2LF.S

)121(THW

2.1-WAF640-031-0001

-D-7.0PL2-2LF.S

)052(THW

194-141-0001

778-341-0001

wercS403SUS21X3M509-508-0006

emaNepyT.oNedoCytQ

tinUannetnAS810-APG264-140-0001

nocaeB

revieceR

.yssAelbaC51-D3-SP-CNT076-331-0001

rotcennoC

daehnaP

swercs

eitelbaC001-VC223-075-0002

.yssAelbaC

annetnapihW

)ylnoepytA51(

pmalCN2-PH000-075-0001

*.yssAelbaC

*wercS014SUS8X3159-208-0004

desutoN*

A0007-RG942-341-0001

042L-W-P6HP845-141-0001

W0072C01X3M504-188-0004

-D-7.0PL2-2LF.S

)121(THW

2.1-WAF640-031-0001

-D-7.0PL2-2LF.S

)052(THW

194-141-0001

778-341-0001

GR-802-1650-10N-019 (No whip ant.) GR-802-1650-15N-019S (No whip ant.)

emaNepyT.oNedoCytQ

emaNepyT.oNedoCytQ

tinUannetnA910-APG255-140-0001

nocaeB

revieceR

rotcennoC

.yssA

daehnaP

swercs

eitelbaC001-VC223-075-0002

wercS403SUS21X3M509-508-0006

.yssAelbaC

pmalCN2-PH000-075-0001

*.yssAelbaC

*wercS014SUS8X3159-208-0004

desutoN*

A0007-RG942-341-0001

042L-W-P6HP845-141-0001

W0072C01X3M504-188-0004

-D-7.0PL2-2LF.S

)121(THW

194-141-0001

-D-7.0PL2-2LF.S

)052(THW

778-341-0001

tinUannetnAS910-APG455-140-0001

nocaeB

revieceR

.yssAelbaC51-D3-SP-CNT076-331-0001

rotcennoC

.yssA

daehnaP

swercs

eitelbaC001-VC223-075-0002

wercS403SUS21X3M509-508-0006

.yssAelbaC

pmalCN2-PH000-075-0001

*.yssAelbaC

*wercS014SUS8X3159-208-0004

desutoN*

A0007-RG942-341-0001

042L-W-P6HP845-141-0001

W0072C01X3M504-188-0004

-D-7.0PL2-2LF.S

)121(THW

-D-7.0PL2-2LF.S

)052(THW

194-141-0001

778-341-0001

4-1

Page 39

Disassembly

Procedure

1. Turn off the power. Wait at least one minute before opening

the cover, to allow capacitors to discharge.

2. Remove nuts attached to DGPS, NMEA and power supply

connectors at the rear of the display unit.

Nut, Washer

Nut

COVER ASSEMBLY

Screws X 6 B

Screws X 6 A

WARNING

Do not connect the power

cable with the cover

removed.

Connector gasket

PANEL/CHASSIS ASSEMBLY

Figure 4-1 Removing cover assembly

3. Remove nuts and washer attached to ANT connector.

4. Remove twelve screws at rear of the display unit to detach

panel/chassis assembly from cover assembly.

Discard six screws A (3X12).

4-2

Page 40

A

View

Installation of DGPS receiver

Procedure

1. Disconnect 8P connector as shown in the figure below.

CHASSIS ASSEMBLY

A

CONNECTOR

PH8P

J106

(P) MAIN

PANEL ASSEMBLY

Figure 4-2 Dismounting chassis assembly

2. Dismount chassis assembly from panel assembly by disconnecting connector shown in the figure above.

3. Cut the cable ties as shown in the figure below.

ANLG board

J8

Cut cable tie.

Cut cable tie.

GN-7707

Figure 4-3 Cutting cable ties

4. Dismount heat sink from chassis assembly by unfastening four

screws on the ANLG board and disconnecting the connector of

the mini pin coaxial cable.

Handling of Coaxial Cable

• Do not touch the connector with bare hands;

use gloves.

• Use radio pincers to remove, and pull out

straightly.

• Plug in connector straightly.

4-3

Page 41

ANLG Board

Beacon receiver

GR-7000A

J1

Mini pin coax. cable

J3

Cable assy.

S.FL2-2LP0.7-D-WHT (121)

Notch

A

Mini pin coax. cable

Screws X 4

GN-7707

Heat sink

Figure 4-4 Chassis assembly

5. Take off the mini pin coaxial cable from J2 on the GN-7707.

6. Open the lid of GR-7000A.

7. Connect the mini pin coaxial cable to J1 of GN-7000A.

Figure 4-5 Beacon receiver

8. Connect cable assy. S.FL2-2LP0.7-D-WHT (121) (supplied) to

J3 of the GR-7000A.

4-4

9. Close the lid of the GR-7000A.

10. Connect connector assy. PH6P-W-L240 to J2 of GR-7000A (Refer to Figure 4-6).

11. Fasten the GR-7000A (Beacon receiver) to the heat sink with four

M3X10 screws (supplied) as shown in the figure below.

Page 42

Connect to

J2 on GN-7707.

Connect to

J106 on

MAIN Board.

GN-7707

HEAT SINK

S.FL2-2LPO.7-D-WHT (121)

Cover of GR-7000A

Cable Assy.

PH6P-W-L240

Beacon Receiver Board

GR-7000A

J2

Pan-head Screw B

M3X10, 4 pcs.

Notch

Connect to J107

on MAIN Board

Connect to

J8 on ANLG

Board.

GN-7707

GR-7000A

to J8 of

ANLG board

to J107 of

MAIN board

to J106 of

MAIN board

Connect PH6P-W-L240 between J2 of

GR-7000A and J107 of MAIN board.

Connect mini pin coaxial cable

between J1 of GR-7000A and J8 of

ANLG board.

Connect cable assy.

J3 of GR-7000A to

J2 of GN-7707.

J3

J1

J1

J2

J2

Connect cable assy.

J1 of GN-7707 to J106

of MAIN board.

HEAT SINK

Clamp

GR-7000A

GN-7707

Mini pin coxial cable

Cable tie

Figure 4-6 Installation of DGPS beacon receiver

12. Connect the cable assay. S.FL2-2LP0.7-D-WHT (121) of J3 to J2

of the GN-7707.

13. Pass the mini pin conxial cable J1 on the GR-7000A through the

mini plug on the ANLG Board and connect it to J8 on the ANLG

Board.

Figure 4-7 Wiring the Cable assembly

4-5

Page 43

14. Mount the ANLG board on the heat sink.

15. Mount chassis assembly on the panel assembly. Connect 8P connector and 6P connector to Main board as shown in the figure

below.

CHASSIS ASSEMBLY

A

CONNECTOR

View

A

PH8P

J106

(P) MAIN

PH6P

J107

PANEL ASSEMBLY

Figure 4-8 Attaching chassis assembly

16. Fasten 8P connector cable and 6P connector cable by cable tie as

shown in the figure below . Fasten mini pin coaxial cable by cable

tie as shown in the figure.

Note: After connecting, pull up cable

to remove slack so as not to pinch

the cable between cover panel

assembly.

Cable tie

MAIN Board

PH8P

J106

PH6P

J107

ANLG board

J8

Mini pin coax. cable

Cable tie

Figure 4-9 Attaching cable tie

17. Reassemble the display unit.

Use new screws size 3X12 (supplied).

4-6

Nut, Washer

Torque:

1.37~1.57 N

Nut

Torque: 0.74~0.78 N

m

COVER ASSEMBLY

Figure 4-10 Remounting the cover

Screws X 6

Torque:

0.74~0.78 N

New screws X 6

Torque:

0.74~0.78 N

m

m

m

Page 44

Note: When reattaching the cover, confirm the following parts are

attached.

.

.

Shield gasket, cover gasket (See figure 4-11.)

Connector gasket (See figure 4-1.)

Cover gasket

Shield gasket(1)

Shield gasket (2)

Figure 4-11 Gaskets

4-7

Page 45

Checking the DGPS installation

1. Press the [MENU] key.

2. Press the software key labeled "CONFIGURATION".

3. Press the software key labeled "SYSTEM MENU".

4. Press the software key labeled "SELF TEST".

5. Press the software key labeled "MEMORY•I/O TEST" to display

the following message.

TEST

PRPGRAM:OK

NO.14518020XX

SRAM:OK

DRAM:OK

PORT1:OK

PORT2:OK

INTERNAL

BATTERY: OK

GPS

RECEIVER:OK

NO.48502060XX

BEACON

RECEIVER:OK

NO.0850182-0XX

NO.

RETURN

Special connections are required to check these ports.

Otherwise, "--" appears.

Figure 4-12 Memory, I/O Test Display

6. Confirm that "BEACON RECEIVER: OK" is displayed.

7. Press the software key labeled "RETURN".

8. Press the [PLOT] key to return the plotter display.

4-8

Page 46

Connecting DGPS beacon receiver

A DGPS beacon receiver whose output format is RS-232C can be

connected to the GP-1650F.

Below is the example of interconnection between the GP-1650F and

FURUNO beacon receiver GR-80.

GP-1650F

DGPS

RD

SD

SG

1

2

3

4

5

6

7

Can use MJ-A7SPF0003-050

(OPTION).

YELLOW

RED

BLUE

Figure 4-13 Connecting DGPS beacon receiver

GR-80

(setting RS-232C)

1

3

7

DATA

TD-B

RD-B

GND

4-9

Page 47

APPENDIX TRIDUCER 525ST-PWC/PWD

This appendix provides a copy of the installation instructions for AIRMAR triducer. If you

loose the original supplied with the triducer, use this appendix.

INSTALLATION INSTRUCTIONS

Transom Mount Transducer or TRIDUCER®

Multisensor with Integral Release Bracket

U.S. Patents: 4,555,938; 4,644,787; 5,606,253; Des. 334,335

Model P66

Canadian Patent 1,233,341

IMPORTANT Please read the instructions completely before

proceeding with the installation. These directions supersede

any other instructions in your instrument manual if they differ.

Applications

• Powerboats with outboard, inboard, inboard/outboard, or jet drive.

Not recommended for boats with large or twin screw inboard motor.

• Bracket protects the sensor form frontal impact only

• Good operation up to 44kn (50MPH)

• Orients the sound beam vertically on hulls with a

deadrise angle up to 30°

• Adjusts to transom angles from 2-22°

Tools and Materials Needed

Scissors

Masking tape

Safety goggles

Dust mask

Electric drill

Drill bit for:

Bracket holes 4mm, #23, or 9/64”

Fiberglass hull chamfer bit (preferred), 6mm, or 1/4”

Transom hole 19mm or 3/4” (optional)

Cable clamp holes 3mm or 1/8”

Screwdrivers

Straight edge

Marine sealant

Pencil

Zip-ties

Water-based antifouling paint (mandatory in salt water).

Pre-test for Speed and Temperature

Connect the sensor to the instrument and spin the paddlewheel. Check

for a speed reading and the approximate air temperature. If there is no

reading, return the sensor to your place of purchase.

Mounting Location

To ensure the best performance, the sensor must be submerged in

aeration-free and turbulence-free water. Mount the sensor close to the

centerline of the boat. On slower heavier displacement hulls, positioning

it farther from the centerline is acceptable.

Allow adequate space above the bracket for it to release and rotate the

sensor upward (see Figure 1).

Caution: Do not mount the sensor in an area of turbulence or bubbles:

Near water intake or discharge openings;

Behind strakes, struts, fittings, or hull irregularities;

Behind eroding paint (an indication of turbulence).

Caution: Avoid mounting the sensor where the boat may be supported

during trailering, launching, hauling, and storage.

• Single drive boat—Mount on the starboard side at least 75mm

(3”) beyond the swing radius of the propeller (see Figure 2).

• Twin drive boat—Mount between the drives.

Height without

speed sensor

191mm (7-1/2")

Height with

speed sensor

213mm (8-1/2")

Figure 1. Height required at mounting location

height

75 mm(3")

minimum beyond

swing radius

Figure 2. Mounting location on single drive boat

AP-1

Page 48

APPENDIX TRIDUCER 525ST-PWC/PWD

P66 Installation template

for starboard side of boat

Drill at locations labeled "B"

for the following transom angles:

16° through 22°

BB B

AA A

Drill at locations labeled "A"

for the following transom angles:

2° through 15°

Align arrow with bottom of transom

Align template vertically

deadrise angle

Caution: Never Use Solvents!

Cleaners, gasoline, paint, sealants, and other products may contain

strong solvents such as acetone which can attack many plastics

dramatically reducing their strength.

Installation

Bracket

1. Cut out the installation template shown on the left.

2. At the selected location, position the template, so the arrow at the

bottom is aligned with the bottom edge of the transom. Being sure

the template is parallel to the waterline, tape it in place

(see Figure 3).

Warning: Always wear safety goggles and a dust mask.

3. Using a 4mm, #23, or 9/64” bit, drill three holes 22mm (7/8”) deep

at the locations indicated. To prevent drilling too deeply, wrap

masking tape around the bit 22mm (7/8”) from the point.

Fiberglass hull—Minimize surface cracking by chamfering the

gelcoat. If a chamfer bit or countersink bit is not available, start

drilling with a 6mm or 1/4” bit to a depth of 1mm (1/16”).

4. If you know your transom angle—The bracket is designed for a

standard 13° transom angle.

11°-18° angle—No shim is required. Skip to “Adjusting”, step 3.

Other angles—The shim is required. Skip to “Adjusting”, step 2.

If you do not know the transom angle—Temporarily attach the

bracket and sensor to the transom to determine if the plastic shim is

needed.

5. Using the two #10 x 1-1/4” self-tapping screws, temporarily screw

the bracket to the hull. Do not tighten the screws completely at this

time. Follow the instructions for “Attaching the Sensor to the

Bracket”, steps 1-4 before proceeding with “Adjusting”.

Figure 3. Template position

Step 1 Step 4Step 3Step 2

latch

retaining

cover

slope of hull

parallel to

waterline

Align template arrow with

bottom edge of transom

pivot

arm (2)

slot (2)

Figure 4. Attaching the sensor to the bracket

Adjusting

1. Using a straight edge, sight the underside of the sensor relative to

the underside of the hull. The stern of the sensor should be

1-3mm (1/16-1/8”) below the bow of the sensor or parallel to the

bottom of the hull (see Figure 5).

Caution: Do not position the bow of the sensor lower than the

stern because aeration will occur.

AP-2

Page 49

2°-10° transom angle 19°-22° transom angle

shim with

taper down

angle

reversed

Figure 5. Sensor angle adjustment on transom

2. To adjust the sensor’s angle relative to the hull, use the tapered

plastic shim provided. If the bracket has been temporarily fastened

to the transom, remove it, Key the shim in place on the back of the

bracket.

2°-10° transom angle (stepped transom and jet boats)—Position

the shim with the tapered end down.

19°-22° transom angle (small aluminum and fiberglass boats)—

Position the shim with the tapered end up.

3. If the bracket has been temporarily fastened to the transom,

remove it. Apply a marine sealant to the threads of the two

#10 x 1-1/4” self tapping screws to prevent water seeping into the

transom. Screw the bracket to the hull. Do not tighten the screws

completely at this time.

4. Repeat step 1 to ensure that the angle of the sensor is correct.

Caution: Do not position the sensor farther into the water than

necessary to avoid increasing drag, spray, and water noise and

reducing boat speed.

5. Using the vertical adjustment space on the bracket slots, slide the

sensor up or down to provide a projection of 3mm (1/8”). Tighten

the screws (see Figure 6).

11° transom angle

NO SHIM

YES YESYES

parallelparallel parallel

12-18° transom angle

NO SHIM

YES NONO

slight

angle

shim with

taper up

angle

too steep

APPENDIX TRIDUCER 525ST-PWC/PWD

Cable Routing

Route the sensor cable over the transom, through a drain hole, or

thorough a new hole drilled in the transom above the waterline.

Caution: Never cut the cable or remote the connector; this will void the

warranty.

Warning: Always wear safety goggles and a dust mask.

1. If a hole must be drilled, choose a location well above the waterline.

Check for obstructions such as trim tabs, pumps, or wiring inside

the hull. Mark the location with a pencil. Drill a hole through the

transom using a 19mm or 3/4” bit (to accommodate the connector).

2. Route the cable over or through the transom.

3. On the outside of the hull secure the cable against the transom

using the cable clamps. Position a cable clamp 50mm(2”) above the

bracket and mark the mounting hole with a pencil (see Figure 6).

4. Position the second cable clamp halfway between the first clamp

and the cable hole. Mark this mounting hole.

5. If a hole has been drilled in the transom, open the appropriate slot

in the transom cable cover. Position the cover over the cable where

it enters the hull. Mark the two mounting holes.

6. At each of the marked locations, use a 3mm or 1/8” bit to drill a

hole 10mm (3/8”) deep. The prevent drilling too deeply, wrap

masking tape around the bit 10mm (3/8”) from the point.

7. Apply marine sealant to the threads of the #6 x 1/2” self-tapping

screw to prevent water from seeping into the transom. If you have

drilled a hole through the transom, apply marine sealant to the

space around the cable where it passes through the transom.

8. Position the two cable clamps and fasten them in place. If used,

push the cable cover over the cable and screw it in place.

9. Route the cable to the instrument being careful not to tear the cable

jacket when passing it though the bulkhead(s) and other parts of the

boat. To reduce electrical interference, separate the sensor

cable from other electrical wiring and “noise” sources. Coil any

excess cable and secure it in place with zip-ties to prevent damage.

10. Refer to your echosounder owner’s manual to connect the sensor

to the instrument.

cable cover

cable clamp

Attaching the Sensor to the Bracket

1. If the retaining cover near the top of the bracket is closed, open it by

depressing the latch and rotating the cover downward

(see Figure 4).

2. Insert the sensor’s pivot arms into the slots near the top of the

bracket.

3. Maintain pressure until the pivot arms click into place.

4. Rotate the sensor downward until the bottom snaps into the

bracket.

5. Close the retaining cover to prevent the accidental release of the

sensor when the boat is underway.

Hull projection

3mm (1/8")

Figure 6. Vertical adjustment and cable routing

50mm (2")

AP-3

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Loading...

Loading...