Page 1

Page 2

A

(

C

9-52, Ashihara-cho,

Nishinomiya, Japan

Telephone: 0798-65-2111

Telefax: 0798-65-4200

ll rights reserved.

Printed in Japan

Your Local Agent/Dealer

FIRST EDITION : MAR. 1997

G : MAR. 7, 2001

PUB. No. OME-43861

DAMI)

GP-1610CF

Page 3

SAFETY INSTRUCTIONS

Use the proper fuse.

Use of a wrong fuse can result in fire or

permanent equipment damage.

GPS position and velocity accuracies

are controlled by the U.S. Department

of Defense. Position may be degraded

up to 100 meters.

Do not use the equipment for other than

its intended purpose.

Personal injury can result if the equipment

is used as a chair or stepping stool, for

example.

Do not place objects on the top of the

equipment.

The equipment can overheat or personal

injury can result if the object falls.

CAUTION

Safety Instructions for the Operator

WARNING

Do not open the equipment.

Hazardous voltage which can

cause electrical shock, burn or

serious injury exists inside the

equipment. Only qualified

personnel should work inside

the equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury

can result.

Turn off the power immediately if water

leaks into the equipment or the equipment is emitting smoke or fire.

Continued use of the equipment can cause

fire or electrical shock.

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if a

liquid spills into the equipment.

Do not operate the equipment with wet

hands.

Electrical shock can result.

Keep heater away from equipment.

Heat can alter equipment shape and melt

the power cord, which can cause fire or

electrical shock.

About the TFT LCD

The TFT LCD is constructed using the

latest LCD techniques, and displays

99.99% of its pixels. The remaining 0.01%

of the pixels may drop out or blink, however this is not an indication of malfunction.

Page 4

Safety Instructions for the Installer

WARNING

Do not work inside the

equipment unless totally

familiar with electrical

circuits.

Hazardous voltage which can

shock, burn or cause serious

injury exists inside the equipment.

Turn off the power at the

mains switchboard before

beginning the installation.

Post a sign near the switch

to indicate it should not be

turned on while the equipment is being installed.

Fire, electrical shock or

serious injury can result if the

power is left on or is applied

while the equipment is being

installed.

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

Confirm that the power supply voltage

is compatible with the voltage rating

of the equipment.

Connection to the wrong power supply

can cause fire or equipment damage. The

voltage rating appears on the label at the

rear of the display unit.

Use the correct fuse.

Use of a wrong fuse can cause fire or

equipment damage.

Keep the following compass safe

distance.

Standard Steering

Display Unit 0.7 m 0.6 m

Page 5

TABLE OF CONTENTS BY SUBJECT

FOREWORD

A Word to GP-1610CF Owners.................iv

Features....................................................... v

System Configuration................................vi

INSTALLATION

1.1 Equipment Lists............................. 1-1

1.2 Installation of Standard

Equipment ..................................... 1-3

1.3 Installation of Transducers .......... 1-10

1.4 Installation of Optional

Sensors ........................................ 1-19

1.5 Connection of Optional

Equipment ................................... 1-21

1.6 Initial Settings ............................. 1-24

OPERATIONAL OVERVIEW

2.1 Control Description ....................... 2-1

2.2 Inserting Chart Cards .................... 2-2

2.3 Turning On/Off the Power............. 2-2

2.4 Adjusting Tone and Brilliance....... 2-3

2.5 Plotter Displays ............................. 2-3

2.6 Sounder Displays........................... 2-5

2.7 Basic Menu Operation................... 2-7

VIDEO SOUNDER OPERATION

3.1 Principle of Operation ................... 3-1

3.2 Automatic Sounder Operation....... 3-2

3.3 Manual Sounder Operation ........... 3-2

3.4 Suppressing Low Level Noise....... 3-3

3.5 Selecting Picture Advance

Speed ............................................. 3-4

3.6 Suppressing Interference ............... 3-4

3.7 Erasing Weak Echoes .................... 3-4

3.8 Changing Zoom Magnification

Factor............................................. 3-5

3.9 Selecting Hue

(color arrangement) ....................... 3-5

3.10 Measuring Depth ........................... 3-5

3.11 Knowing Depth Change by

Audible Chime .............................. 3-5

3.12 Selecting Unit of Depth

Measurement ................................. 3-6

3.13 Offsetting the Depth Readout........ 3-6

3.14 Displaying the Water Temperature

Graph............................................. 3-6

3.15 Selecting Unit of Water

Temperature Measurement ............ 3-7

3.16 Offsetting Water T emperature

Readout.......................................... 3-7

3.17 Fish Alarm ..................................... 3-7

3.18 Bottom Alarm ................................ 3-8

3.19 Water Temperature Alarm ............. 3-8

3.20 Turning On/Off the Expansion

Range Marker ................................ 3-8

3.21 Receiver Sensitivity (gain)

Adjustment .................................... 3-9

3.22 Selecting Bottom-Lock

Expansion Width ........................... 3-9

3.23 Stopping Transmission .................. 3-9

3.24 Interpreting the Display............... 3-10

GPS, CHART OVERVIEW

4.1 Principle of GPS ............................ 4-1

4.2 Presentation Mode......................... 4-3

4.3 Shifting the Cursor ........................ 4-3

4.4 Selecting Screen Center by

Cursor ............................................ 4-4

4.5 Shifting the Display....................... 4-4

4.6 Centering Position ......................... 4-4

4.7 Changing Chart Scale/Range ........ 4-4

4.8 Chart Cards.................................... 4-4

TRACK

5.1 Stopping/Restarting Plotting of

Track.............................................. 5-1

5.2 Changing Track Color ................... 5-1

5.3 Erasing All Track........................... 5-1

5.4 Changing Track Plotting

Interval .......................................... 5-2

5.5 Smoothing Track ........................... 5-2

MARKS

6.1 Entering Marks .............................. 6-1

6.2 Entering Event Marks.................... 6-1

6.3 Erasing Individual Marks .............. 6-2

6.4 Changing Mark Attributes............. 6-2

6.5 Entering the MOB Mark ............... 6-3

6.6 Erasing All Marks.......................... 6-3

6.7 Radar Target Mark......................... 6-4

i

Page 6

WAYPOINTS, ROUTES

CUSTOMIZING THE DISPLAY

7.1 Entering Waypoints ....................... 7-1

7.2 Erasing Individual Waypoints ....... 7-3

7.3 Changing Waypoint Position......... 7-3

7.4 Changing Waypoint Mark Size ..... 7-4

7.5 Entering Routes ............................. 7-4

7.6 Editing Routes ............................... 7-5

7.7 Erasing Routes............................... 7-5

SETTING DESTINATION

8.1 Setting Destination ........................ 8-1

8.2 Skipping Route Waypoints ............ 8-3

8.3 Cancelling Destination .................. 8-3

PLOTTER-RELA TED ALARMS

9.1 Arrival/Anchor Watch Alarm ........ 9-1

9.2 XTE (Cross Track Error) Alarm.... 9-2

9.3 Speed Alarm .................................. 9-2

9.4 Trip Alarm ..................................... 9-2

POSITION-RELA TED

OPERA TIONS

10.1 Displaying Position in LOPs ....... 10-1

10.2 Offsetting GPS Position .............. 10-1

10.3 Selecting Navaid ......................... 10-2

10.4 Displaying True or Magnetic

Bearings....................................... 10-2

10.5 Magnetic Variation ...................... 10-2

10.6 Offsetting Chart Position............. 10-3

13.1 Plotter Display Marker

Attributes..................................... 13-1

13.2 Chart Attributes ........................... 13-1

13.3 Unit of Distance Measurement.... 13-2

13.4 Chart Range or Scale Indication.. 13-2

MAINTENANCE &

TROUBLESHOOTING

14.1 Maintenance ................................ 14-1

14.2 Replacement of Fuse, Battery ..... 14-1

14.3 Simple Troubleshooting .............. 14-2

14.4 Error Messages ............................ 14-3

14.5 Diagnostic Tests .......................... 14-4

14.6 GPS Monitor Display .................. 14-5

14.7 Demonstration Display................ 14-6

14.8 Memory Card Operations

(for technicians)........................... 14-6

14.9 Clearing the Memory .................. 14-7

APPENDIX

Specifications..........................................A-1

World Time Standards ............................A-2

Geodetic Chart List.................................A-3

Icons .......................................................A-4

Glossary ..................................................A-5

Menu Tree...............................................A-9

Decca Chains ........................................A-12

Packing List ..........................................A-13

GPS OPERATIONS

11.1 GPS Setup Menu ..........................11-1

11.2 Speed Averaging...........................1 1-2

OPTIONAL EQUIPMENT

SETUP

12.1 Selecting Sensors......................... 12-1

12.2 Selecting Autopilot, Remote

Display ........................................ 12-1

12.3 Setting up DGPS Beacon

Receiver....................................... 12-1

DRA WINGS

Antenna Unit...........................................D-1

Display Unit............................................D-2

SCHEMATIC DIAGRAMS

GPS Plotter Interconnection Diagram .... S-1

GPS Plotter Schematic Diagram............. S-2

GPS Plotter Schematic Diagram............. S-3

INDEX

ii

Page 7

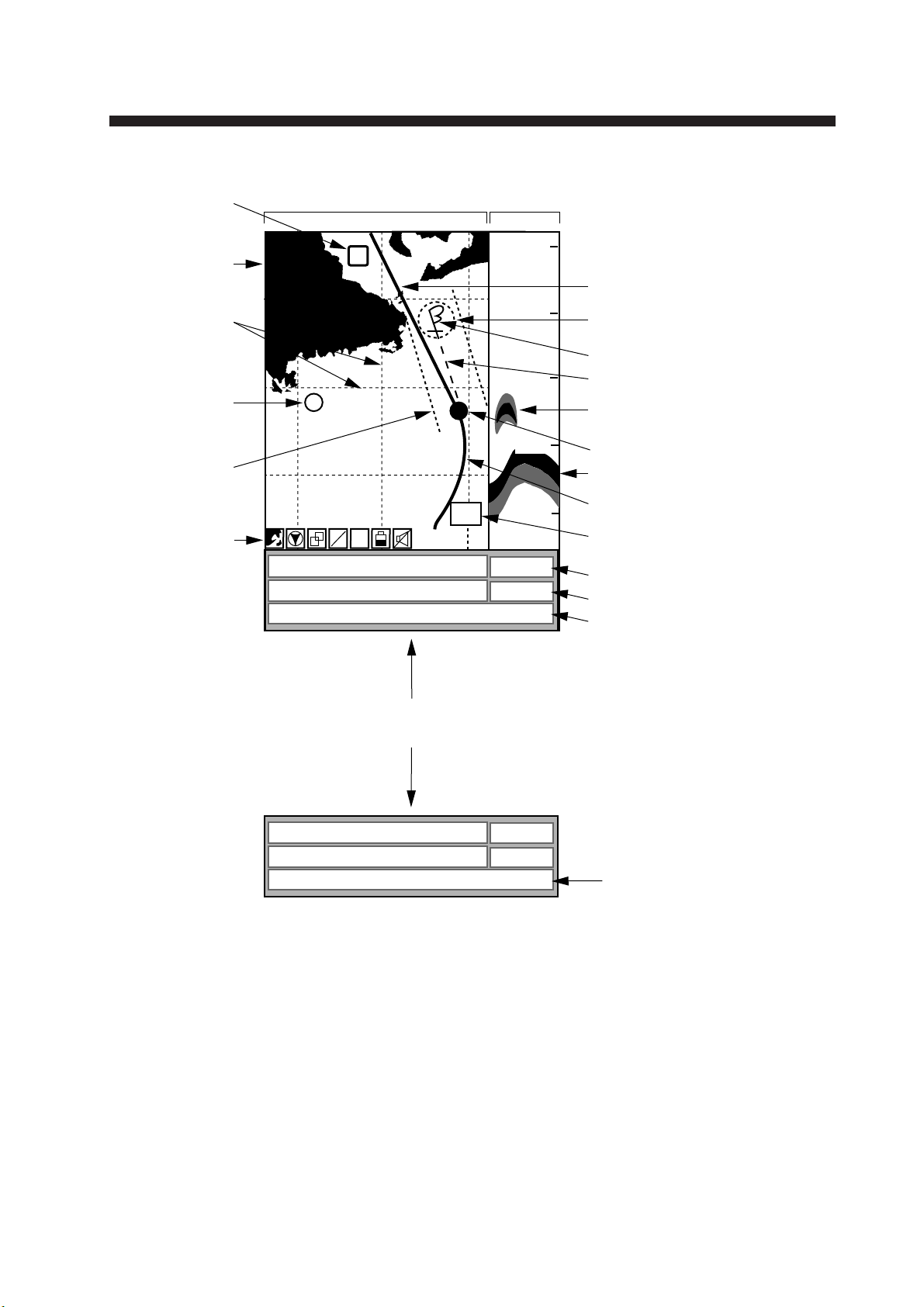

TABLE OF CONTENTS BY DISPLAY ITEM

Waypoint

(Page 7-1)

Chart (Page 4-4)

Grid (Page 13-1)

Marks (Page 6-1)

Cross-track error

alarm range

(Page 9-2)

Icons (Page A-4)

PLOTTER

DISPLAY (Page 2-3)

SOUNDER

DISPLAY

(Page 2-5)

01

100

150

50k

L

H

L

200

CSE 350.0° SPD 16.8kt 2D

DEP 110 m

TMP 16.0°C 13:42

POS 34°26.345’N 135°41.232’E

50

0

Course bar (Page 13-1)

Arrival alarm range (Page 9-2)

Flag (destination) (Page 8-1)

Course to destination (Page 8-1)

Fish school (Page 3-10)

Own ship mark (Page 5-1)

Bottom (Page 3-10)

Track (Page 5-1)

Sounder frequency (Page 2-5)

Position-fixing mode (Page 2-2)

Time (Page 11-2)

Position (Page 4-2)

CURS key alternates

these displays.

BRG+ 232.0° RNG+ 0.00nm 2D

DEP 110 m

TMP 16.0°C 13:42

+ 34°43.801’N 135°21.163’E

Cursor position

in latitude and

longitude (Page 4-3)

iii

Page 8

FOREWORD

A W ord to GP-1610CF Owners

Congratulations on your choice of the FURUNO GP-1610CF

COLOR GPS PLOTTER SOUNDER. We are confident you will

see why the FURUNO name has become synonymous with quality and reliability.

For over 40 years FURUNO Electric Company has enjoyed an

enviable reputation for innovative and dependable marine electronics equipment. This dedication to excellence is furthered by

our extensive global network of agents and dealers.

This equipment is designed and constructed to meet the rigorous

demands of the marine environment. However, no machine can

perform its intended function unless installed, operated and maintained properly. Please carefully read and follow the recommended

procedures for installation, operation and maintenance.

W e would appreciate hearing from you, the end-user , about whether

we are achieving our purposes.

Thank you for considering and purchasing FURUNO equipment.

iv

Page 9

Features

The GP-1610CF is a totally integrated GPS receiver, color video

plotter and color video sounder . It mainly consists of a display unit

and a GPS antenna.

Navigation information is displayed on a bright 5.6-inch color TFT

LCD. On-screen information shown are position, range and bearing to cursor position, range, bearing, ETA and TTG to waypoint,

etc.

A high sensitivity receiver tracks up to eight satellites simultaneously. An 8-state Kalman filter ensures optimum accuracy in

determination of vessel position, course and speed.

The main features of the GP-1610CF are

• Comprehensive navigation data displays.

• Bright 5.6-inch color LCD with temperature compensated tone

and brilliance control.

• Automatic coastline chart loading.

• Position display in latitude and longitude, Loran C LOPs or

Decca LOPs.

• Outputs steering information to FURUNO autopilots (FAP-50/

55/300/330).

• Improved position accuracy with connection of DGPS beacon

receiver (option).

• FURUNO and NAVIONICS chart cards.

• Memory capacity: 2,000 points of track, 100 marks, 100 event

marks, 200 waypoints and 20 routes.

• Alarms: Arrival, Anchor Watch, Cross-track Error, Depth, Fish,

Speed, Trip, and Water T emperature.

• Man overboard feature records latitude and longitude coordinates at time of man overboard and provides continuous updates of range and bearing to that point.

• "Highway" display provides graphic presentation of ship's track

and is useful for monitoring cross track error.

• Automatic or manual video sounder operation.

v

Page 10

System Configuration

C

The GP-1610CF mainly consists of a display unit and a GPS antenna. A dual frequency transducer is optionally available. The chart

card drive in the display unit loads electronic charts. External equipment which can be connected include water temperature and speed

sensors, autopilot, and DGPS beacon receiver.

ANTENNA UNIT

Receives signal from

GPS satellite.

DISPLAY UNIT

Ship’s position is

calculated in longitude

and latitude from signal

received from the antenna unit and displayed

on the screen.

Temp. sensor

(option)

Ship’s mains

10.2—31.2 VD

External equipment

(Autopilot, etc.)

DGPS beacon receiver

(option)

vi

Transducer

(option)

Page 11

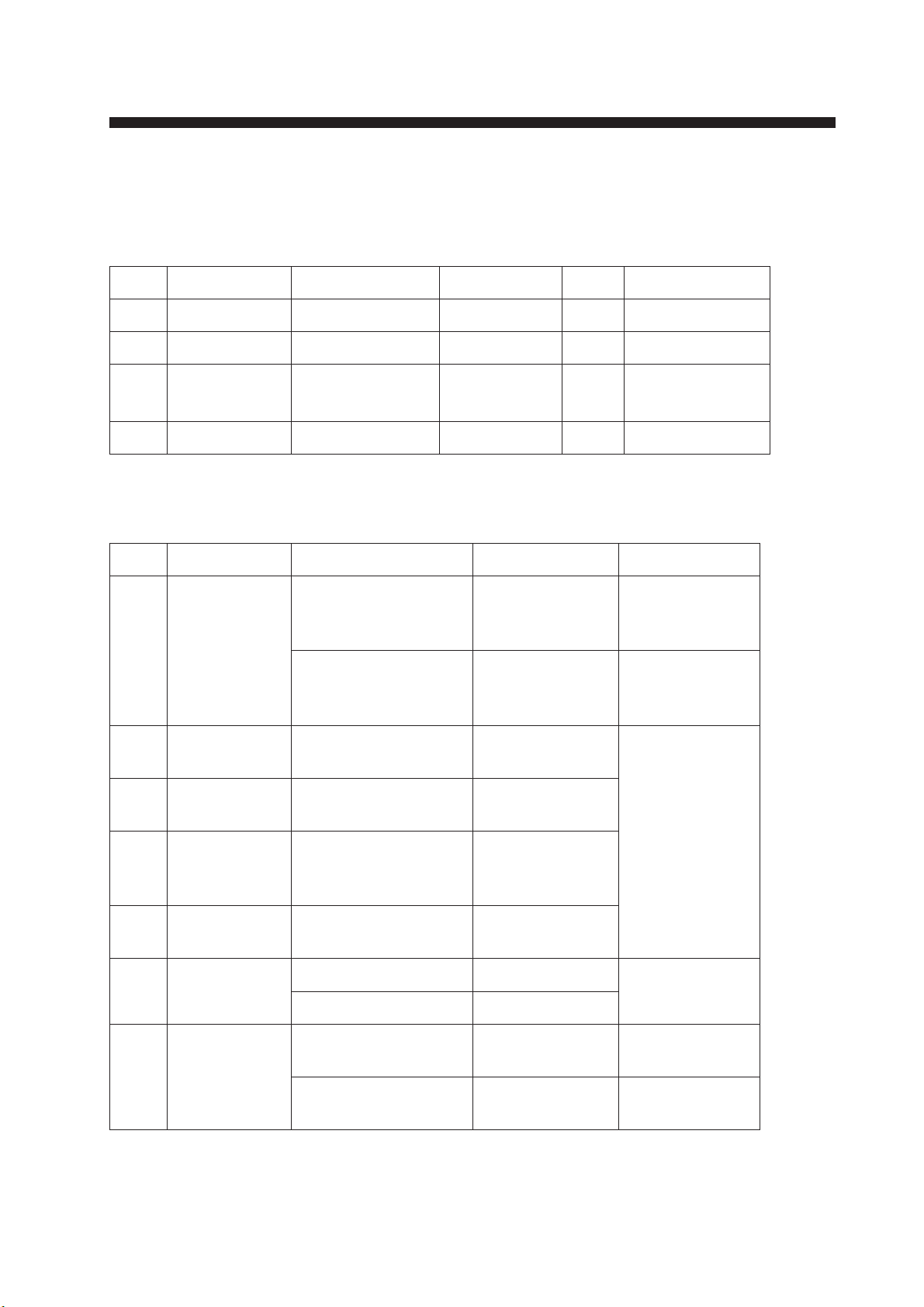

INSTALLATION

1.1 Equipment Lists

Standard supply

.oNemaNepyT.oNedoCytQskrameR

1tinUyalpsiD

2tinUannetnA

3

4straPerapS

noitallatsnI

slairetaM

E-FC0161-PG

610-APG

00300-68PC830-140-000tes1

00300-68PS

046-493-400tes1

1

1

Optional equipment

.oNemaNepyT.oNedoCskrameR

rof,m03

00710-02PC011-273-400

1

2

annetnA

teselbac

01710-02PC021-273-400

elgna-thgiR

esabannetna

033AQ-31.oN932-308-000

elbacannetna

noisnetxe

rof,m05

elbacannetna

noisnetxe

3

4

5

6rosnesTS

7

elgna-L

esabannetna

esabannetnA

liarrof

gnitnuom

tnuomtsaM

erutxif

erutarepmeT

rosnes

11110-02PC227-040-000

BSM20-TS689-731-000epytlluh-urhT

BSP20-TS789-731-000

BTM20-T620-040-000

BSM30-T720-040-000

013AQ-31.oN042-308-000

gnitnuomroF

tinuannetna

0615CR-31.oN411-608-000

,elbacm8htiW

tnuommosnart

,elbacm8htiW

epytlluh-urht

1-1

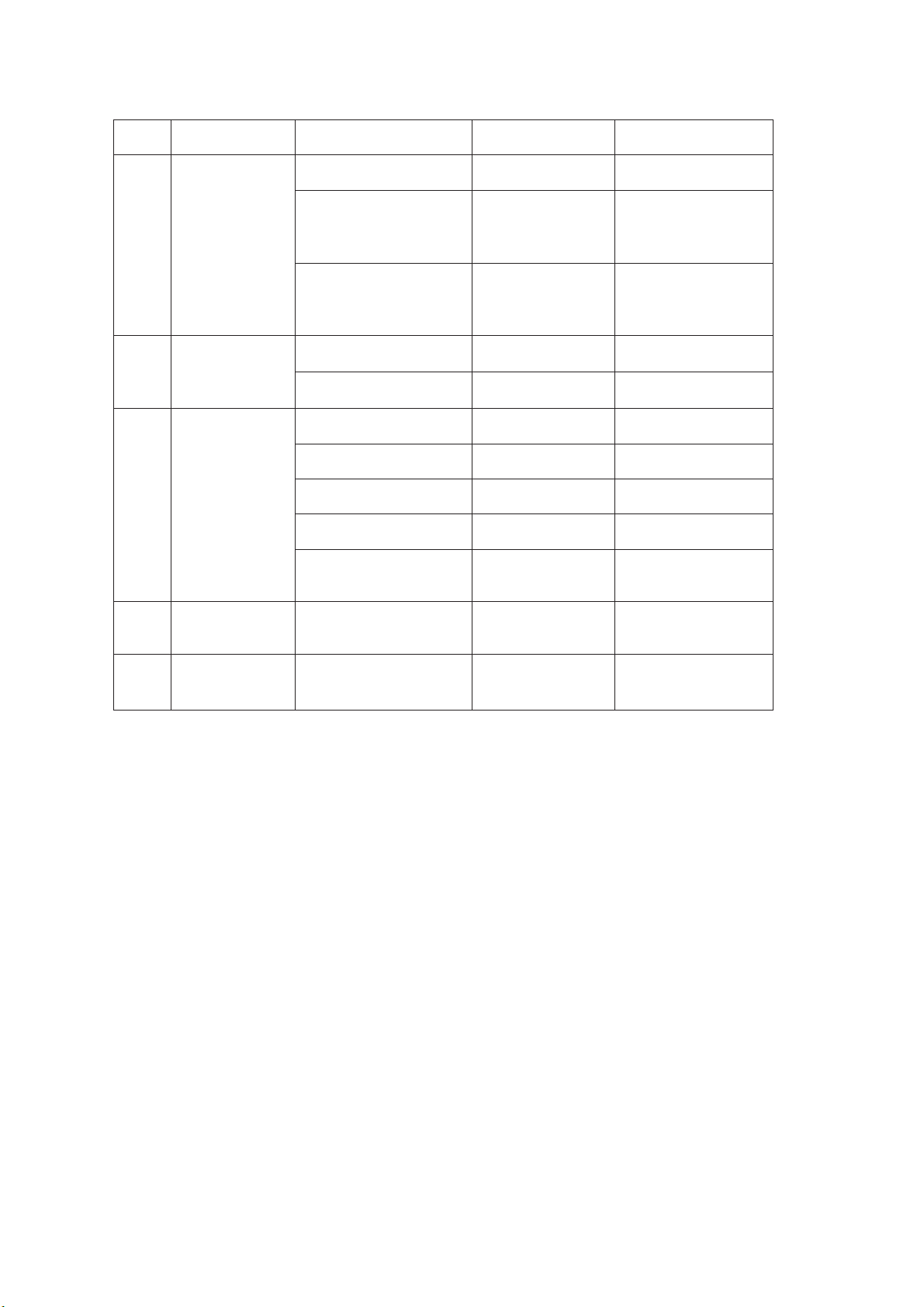

Page 12

Optional equipment (con't)

.oNemaNepyT.oNedoCskrameR

DSP5-025

DWP5-025621-510-000

8recudsnarT

DSM5-025721-510-000

lauD

9

01.yssaelbaC

11

ycneuqerf

recudsnart

lluhrennI

Stik

DSM-TS425422-510-000

DWP-TS025821-510-000

0-1910S22895-208-000

521-510-000

m8htiW

mosnart,elbac

tnuom

elbacm8htiW

foorpretawdna

rotcennoc

001-1100FPS6A-JM633-231-000

050-1100FPS6A-JM442-231-000

001-2100FPS6A-JM718-331-000

050-2100FPS6A-JM424-431-000

050-3000FPS7A-JM10-037-631-000

m01,P4-P6

m5,P4-P6

m01,P6-P6

m5,P6-P6

m5,P6-P7

SPGDrof

21

retrevnoC

tesrotcennoc

01300-68PC082-593-400

1-2

Page 13

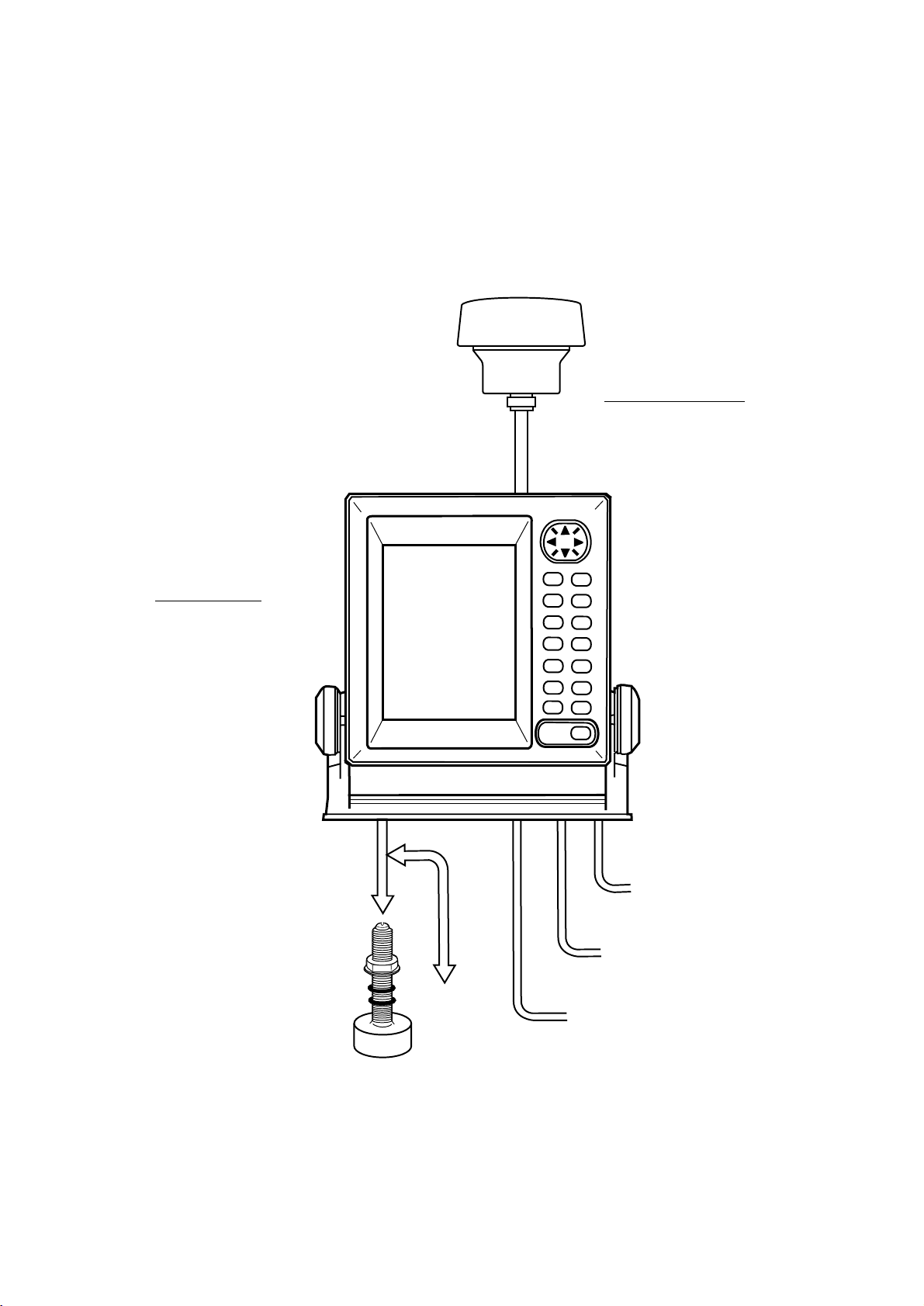

1.2 Installation of Standard Equipment

Installing the display unit

Mounting considerations

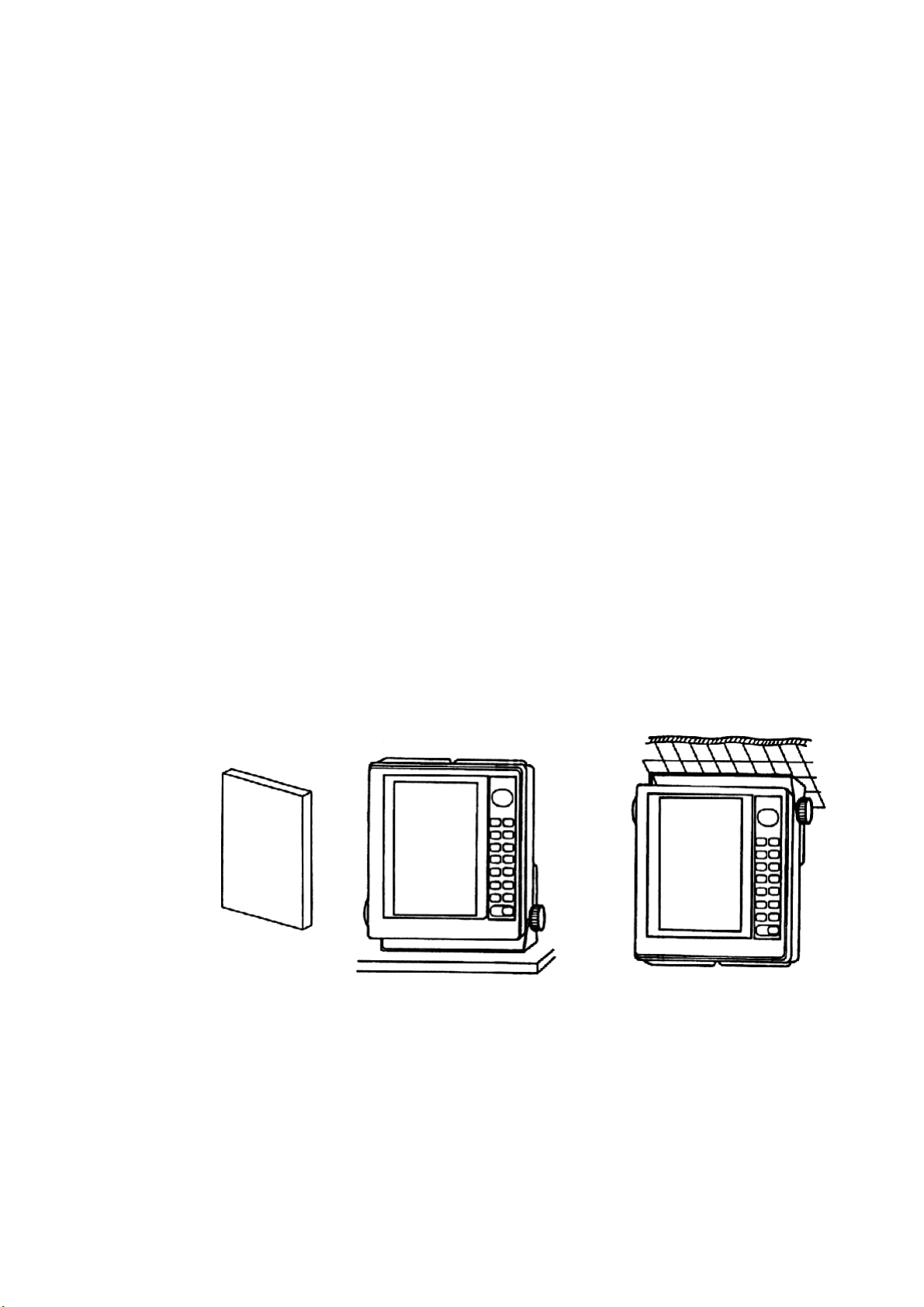

The display unit can be installed on a tabletop or on the overhead.

When selecting a mounting location for the display unit keep the

following in mind:

• Keep the display unit out of direct sunlight.

• The temperature and humidity should be moderate and stable.

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• Keep the unit away electromagnetic field generating equipment

such as motor, generator.

Cover

• For maintenance and checking purposes, leave sufficient space

at the sides and rear of the unit and leave slack in cables.

• A gyrocompass will be affected if placed too close to the display unit. Observe the following compass safe distances to prevent disturbance to the gyrocompass:

Standard compass: 0.7 meters

Steering compass: 0.6 meters

Tabletop Overhead

Figure 1-1 Display unit mounting methods

1-3

Page 14

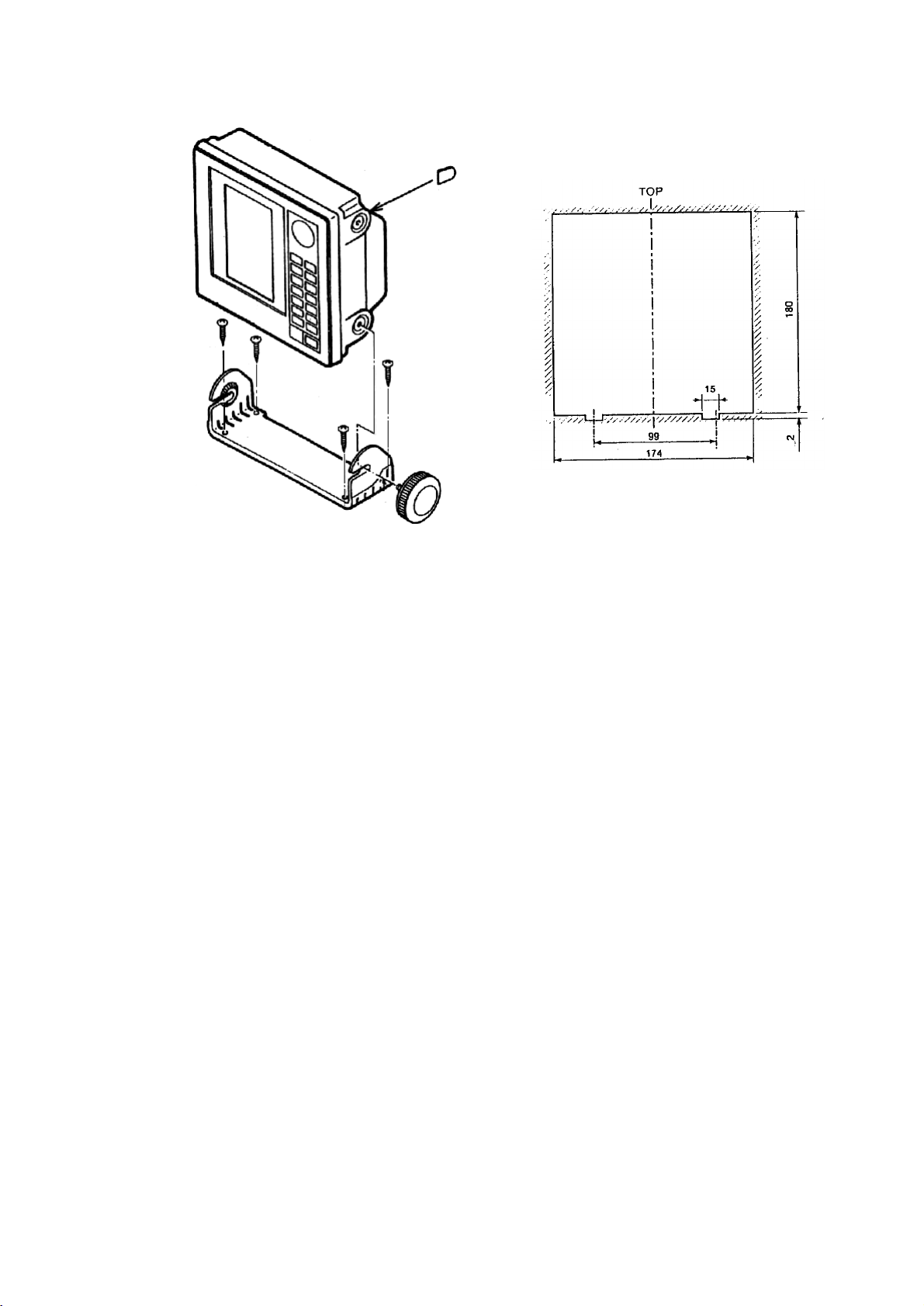

Tabletop mounting

y

Dumm

cover

Cutting size for flushmount

Figure 1-2 Display unit mounting methods

Installing the antenna unit

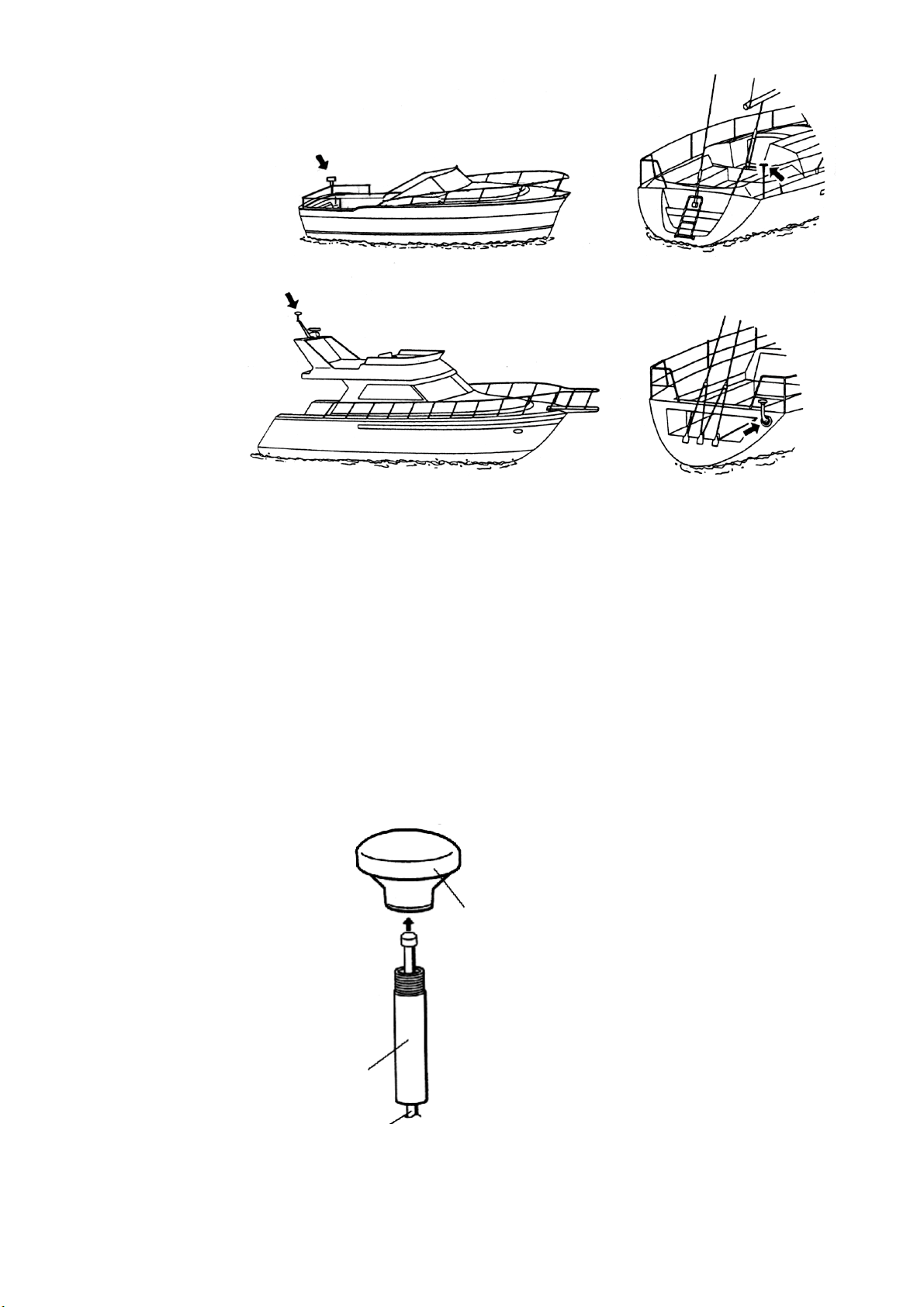

Mounting considerations

When selecting a mounting location for the antenna unit, keep in

mind the following points:

• Select a location out of the radar beam. The radar beam will

obstruct or prevent reception of the GPS satellite signal.

• Be sure the location offers a clean line-of-sight to satellite. Objects within line-of-sight to a satellite, for example, a mast or

funnel, block reception and cause prolonged acquiring time or

interruption of position fix.

• Mount the unit as high as possible. This will keep the unit free

of water spray, which can interrupt reception of GPS satellite

signal if frozen.

• Separate the unit well away from the antenna of radio equipment.

1-4

Page 15

Figure 1-3 Typical antenna unit mounting locations

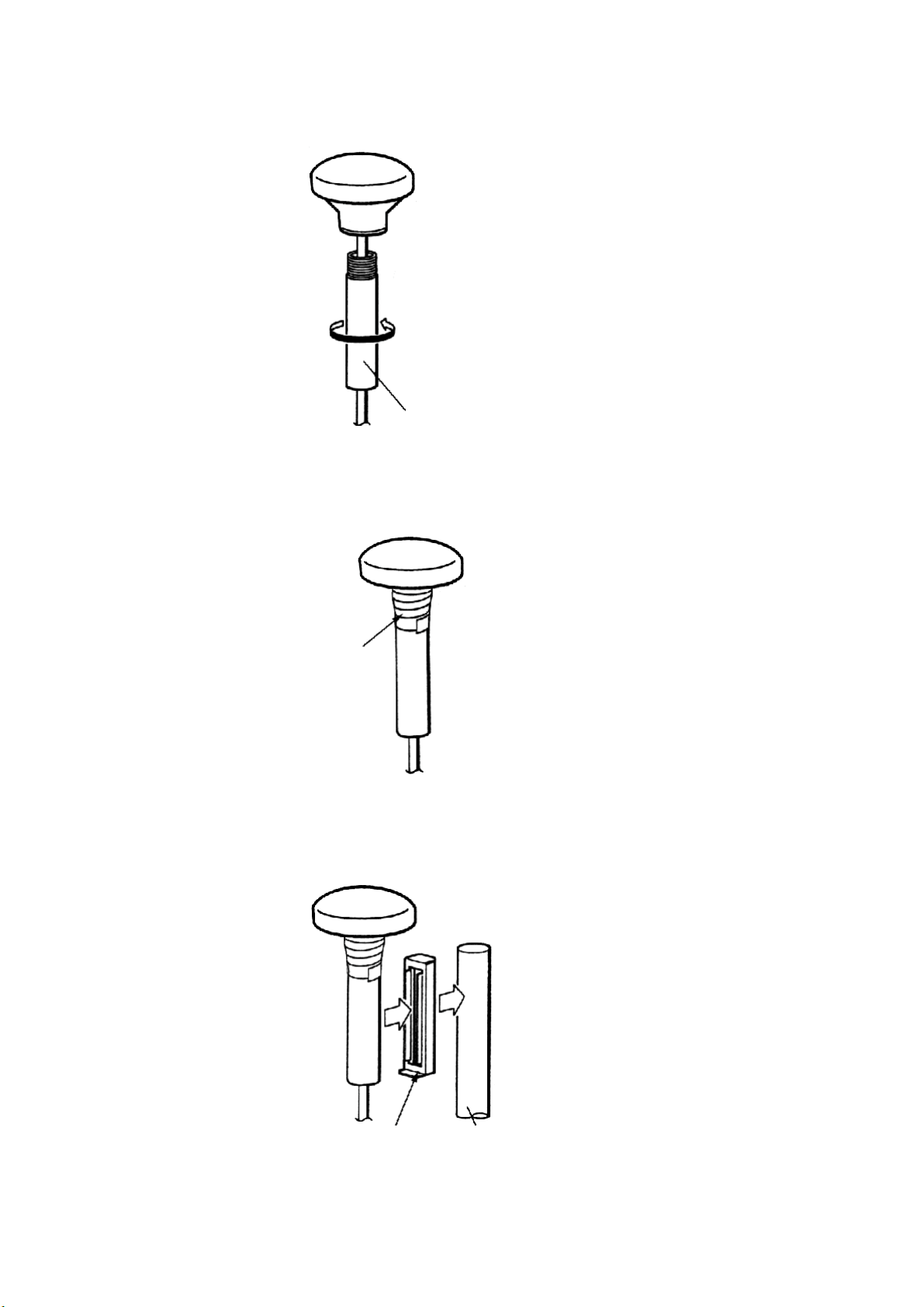

Antenna unit mounting procedure

You will need a medium size slotted-head screwdriver and vinyl

tape.

The standard antenna is usually fastened to a length of pipe and

fastened to a mast. (A mast mount fixture is optionally available

for this.) The threaded antenna base accepts a standard antenna

mount with a 1"-14 straight thread. Mount the antenna on a length

of pipe with a 1"-14 threaded end.

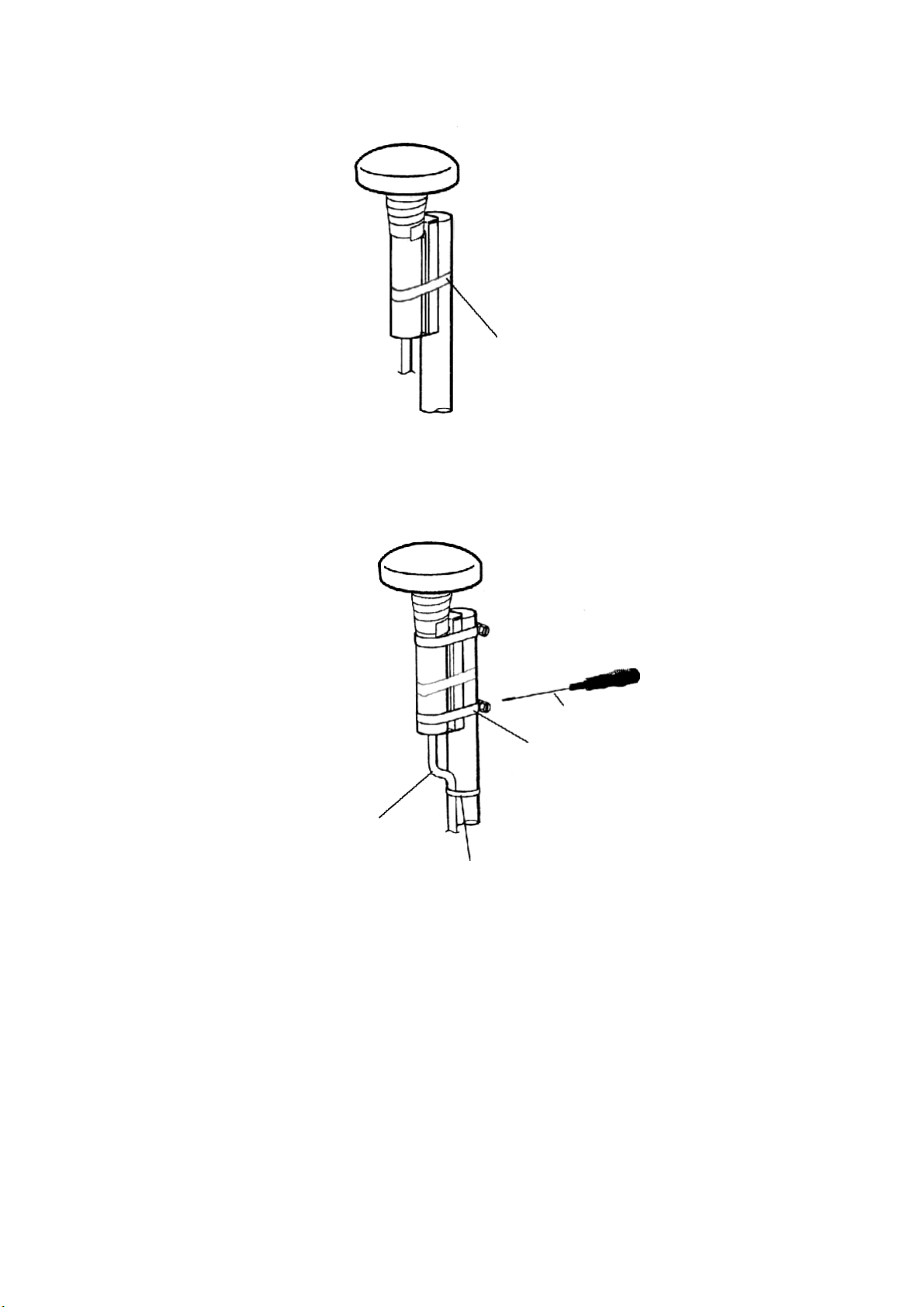

1. Pass the antenna cable through the pipe. Fasten the connector

on the cable to the antenna.

Antenna

Pipe

Antenna cable

Figure 1-4 Passing antenna cable through pipe

1-5

Page 16

2. Screw the pipe into the antenna. DO NOT USE TOOLS TO

FASTEN THE ANTENNA TO ITS MOUNTING; ONLY

HAND TIGHTEN.

Pipe

Figure 1-5 Fastening pipe to antenna

3. Tape the junction between the pipe and antenna unit with vinyl

tape.

Taping

Figure 1-6 Taping the antenna

4. Attach the mounting fixture to the mast and set the pipe with

antenna to the mounting fixture.

1-6

Mounting

fixture (note direction)

Mast

Figure 1-7 Attaching antenna to mounting fixture

Page 17

5. Tape the antenna unit, mounting fixture and mast with vinyl

tape.

Vinyl tape

Figure 1-8 Securing antenna to mast with vinyl tape

6. Attach a clamp to the antenna unit and tighten. Leaving some

slack in the antenna cable as shown, fix it with vinyl tape.

Slotted-head

screwdriver

Clamp

Leave slack

in cable.

Vinyl tape

Figure 1-9 Fixing the antenna cable with vinyl tape

1-7

Page 18

Wiring

All wiring are terminated at the rear of the display unit.

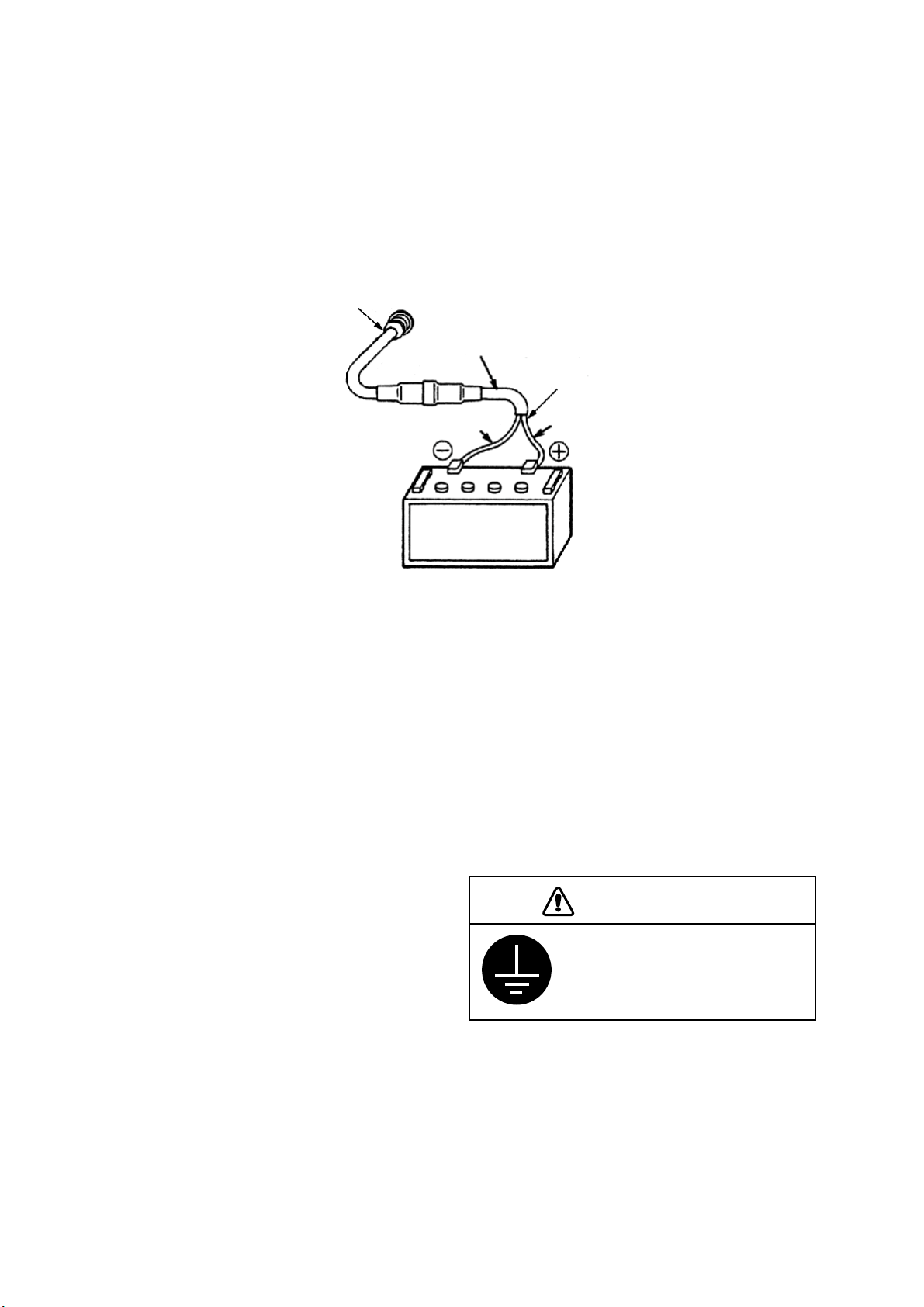

Power cable

Connect the power cable to the power connector . Connect the leads

to the battery (12 or 24 VDC); white to plus(+) terminal and black

to minus(-) terminal.

Cable connector

Power cable

w/fuse (3A)

Lead wire

Black

BATTERY

White

Figure 1-10 Connecting the power cable to the battery

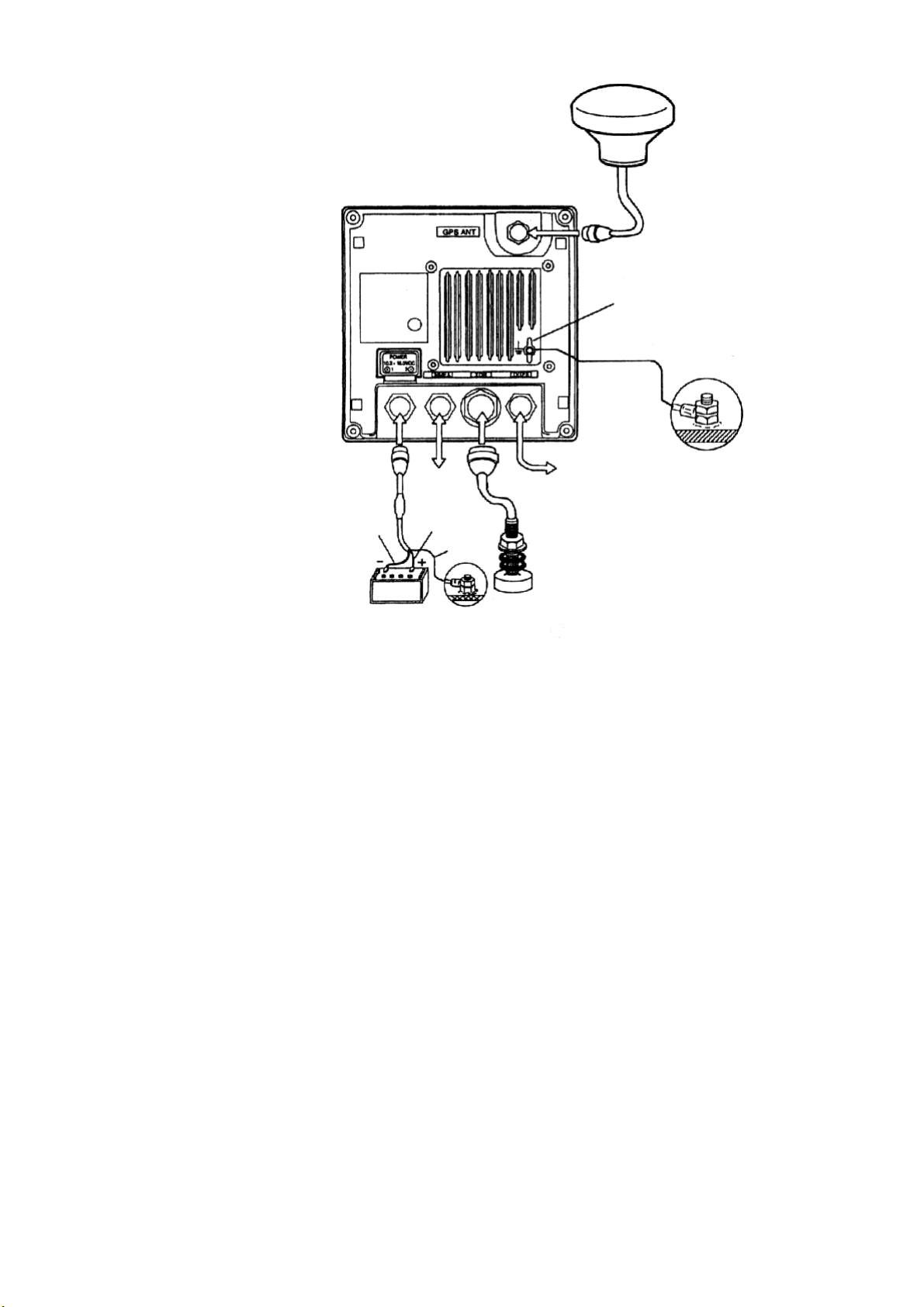

Antenna unit

Connect the antenna unit cable to the GPS ANT connector.

Transducer

Connect the transducer cable to the XDR connector.

Ground

1-8

The display unit

contains several

CAUTION

CPUs. While they

are operating, they

radiate noise,

which can interfere

Ground the equipment to

prevent electrical shock

and mutual interference.

with radio equipment. Ground the

unit to prevent interference. The grounding wire should be 1.25 sq

or larger and as short as possible. Connect the grounding wire to

ship's ground by silver-alloy brazing. On a fiberglass boat, it is

best to install a ground plate that measures about 20 cm by 30 cm

on the outside of the hull bottom to provide a ground point. If this

is not practical, the engine block can be used.

Page 19

Black

ANTENNA UNIT

DISPLAY UNIT

Earth terminal

Earth

DPGS beacon receiver

Ext.

equip.

White

Shield

TRANSDUCER

Figure 1-11 Display unit, rear view

1-9

Page 20

1.3 Installation of Transducers

Installing the inside-hull mount transducer

Necessary tools

You will need the following tools:

• Sandpaper (#100)

• Silicone sealant

• Silicone grease

Remarks on installation

• Do the installation with the boat hauled out of the water.

• Turn off the engine while installing the equipment.

• Install the transducer in the engine room.

Selecting the mounting location

Keep the following points in mind when selecting a mounting location:

• The mounting location should be where the hull is of singlehull thickness and is void of air or flotation materials other than

solid fiberglass between the transducer face and the water.

• Do not place the transducer over hull struts or ribes which run

under the hull.

• Avoid a location where the rising angle of the hull exceeds 15°,

to minimize the effect of the boat’s rolling.

• You will finalize the mounting location through some trial and

error. The procedure for this is shown later.

15cm

15cm

1/2

1/3

Mounting location

for transducer

Center line

50cm

50cm

Figure 1-12 Inside-hull transducer mounting location

1-10

Page 21

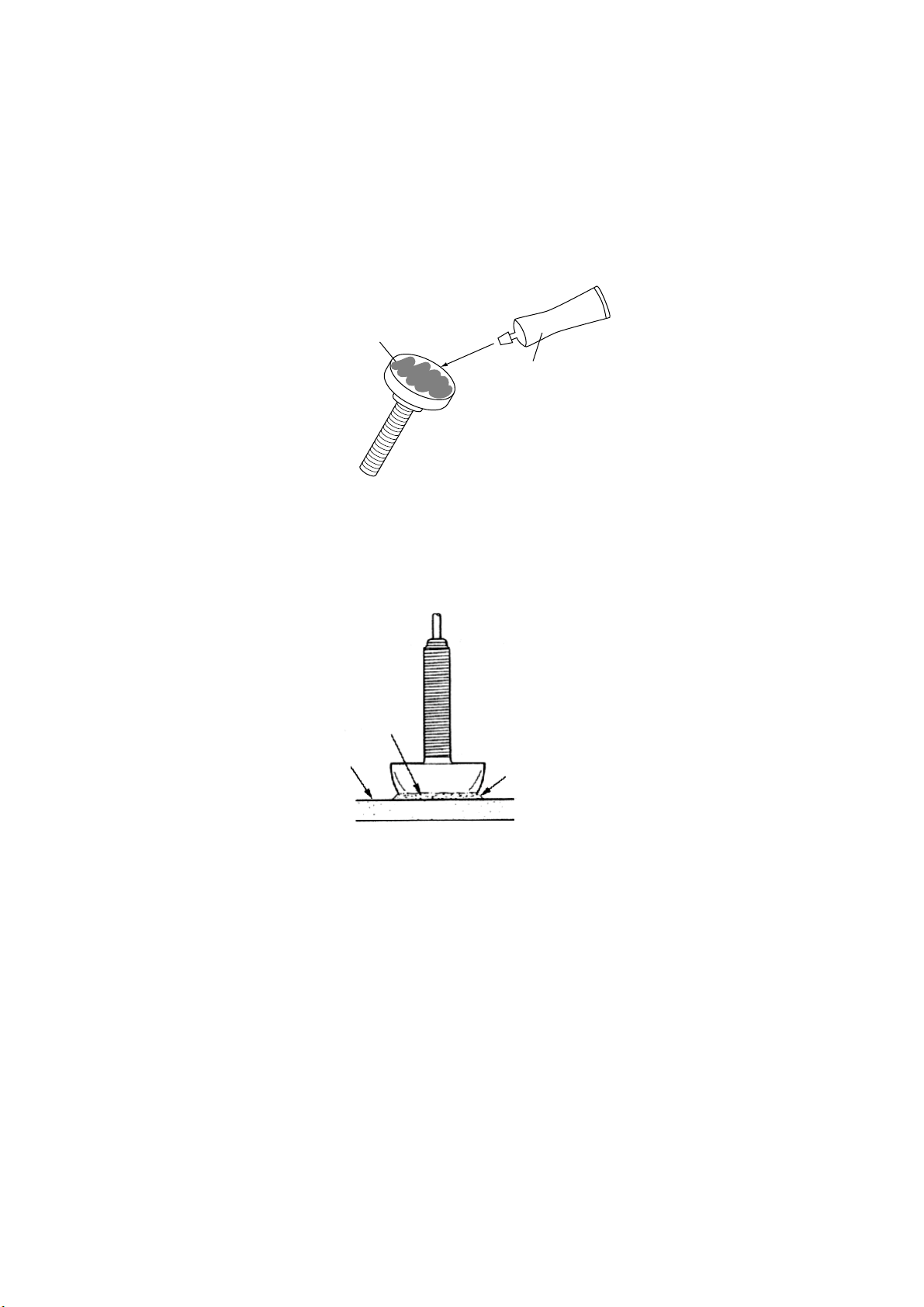

Attaching the transducer

1. Clean the transducer face to remove any foreign material.

Lightly roughen the transducer face with #100 sandpaper . Also,

roughen the inside of the hull where the transducer is to be

mounted.

2. Warm the silicone sealant to 40°C before usage to soften it.

Coat the transducer face and mounting location with silicone

sealant.

Transducer face

Silicone sealant

Figure 1-13 Coating the transducer face with silicone sealant

3. Press the transducer firmly down on the hull and gently twist it

back and forth to remove any air which may be trapped in the

silicone sealant.

Squeeze out

air bubbles.

Hull

Silicone

sealant

Figure 1-14 Attaching transducer to hull with silicone sealant

1-11

Page 22

Observing the picture

1. Press the POWER key to turn on the display unit.

2. Press the PLTR key.

3. Press the AUTO key.

AUTO MODE

Cruise

Fish

Manual

Figure 1-15 Auto mode selection screen

4. Press ▼ twice to select Manual.

AUTO MODE

Cruise

Fish

Manual

Low High

Gain

Range 5 10 20

40 80 160 300m

Shift 0m

Figure 1-16 Auto mode adjustment screen

5. Confirm that Gain is set at 5 (midpoint).

6. Press ▼ once to select Range.

7. Press t four times to select 10.

8. Note the depth to the seabed.

Reddish

brown

2

Color bar

Reddish

brown

Red

Depth

3.9

CSE 180.0° SPD 16.8kt

DEP 3.9 m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

4

6

8

10

2D

09:00

Zero

line

Bottom

Depth

scale

1-12

Figure 1-17 Video sounder picture

Page 23

If the bottom is displayed in red and the light-blue color appears

the mounting location is suitable. You can leave the transducer

in position.

If the bottom is not displayed in reddish brown, the mounting

location is unsuitable. Relocate the transducer and do the

following.

1. Press the POWER key to turn off the power.

2. Gently dismount the transducer with piece of wood.

3. Do steps 1 through 5 in the previous procedure. Repeat until

a suitable location is found.

Final preparation

Support the transducer with a piece of wood to keep it in place

wile it is drying. Let the transducer dry 24–72 hours.

1-13

Page 24

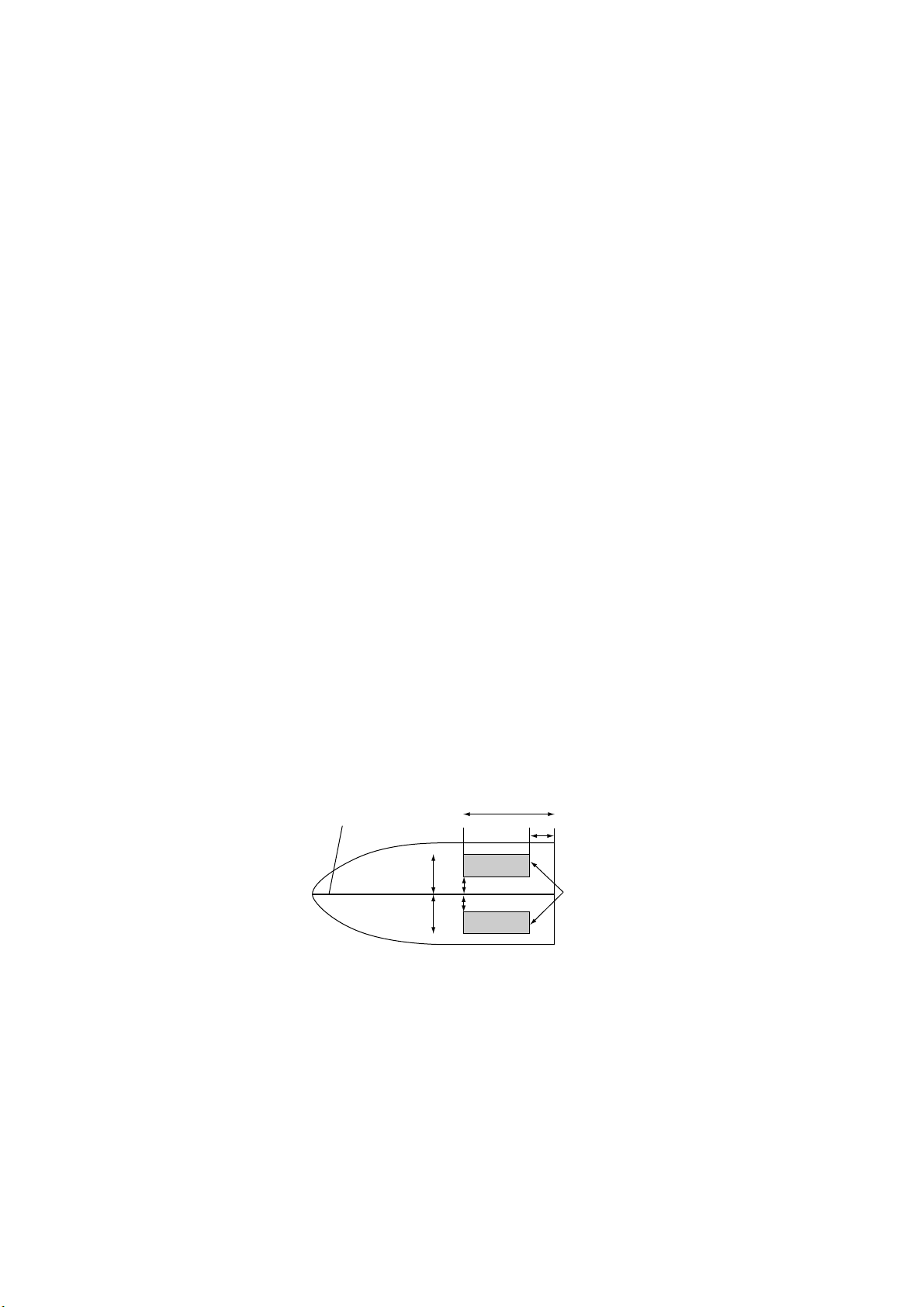

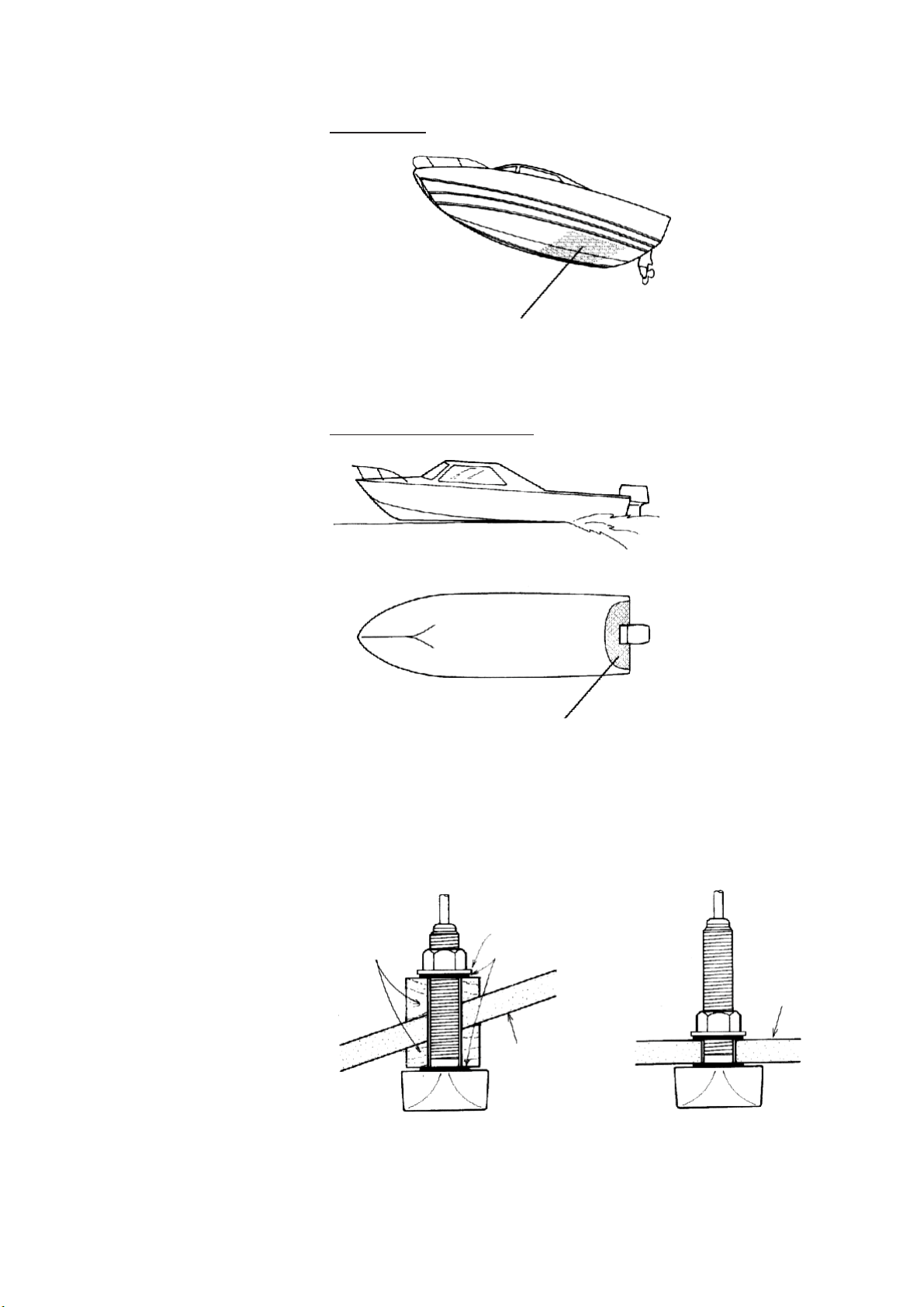

Installing the thru-hull mount transducer

Transducer mounting location

This type of mounting provides the best performance of all, since

the transducer protrudes from the hull and the effect of air bubbles

and turbulence neat the hull skin is reduced. When the boat has a

keel, the transducer should be at least 30 cm away from it. Typical

through hull mountings are shown in the figure on the next page.

The performance of the video sounder is directly related to the

mounting location of the transducer, especially for high-speed cruising. The installation should be planned in advance, keeping the

standard cable length (8 m) and the following factors in mind:

• Air bubbles and turbulence caused by movement of the boat

seriously degrade the sounding capability of the transducer . The

transducer should, therefore, be located in a position where water flow is the smoothest. Noise from the propellers also adversely affects performance and the transducer should not be

mounted nearby. The lifting strakes are notorious for creating

acoustic noise, and these must be avoided by keeping the transducer inboard of them.

• The transducer must always remain submerged, even when the

boat is rolling, pitching or up on a plane at high speed.

• A practical choice would be somewhere between 1/3 and 1/2 of

the boat's length from the stern. For planing hulls, a practical

location is generally rather far astern, so that the transducer is

always in water regardless of the planing attitude.

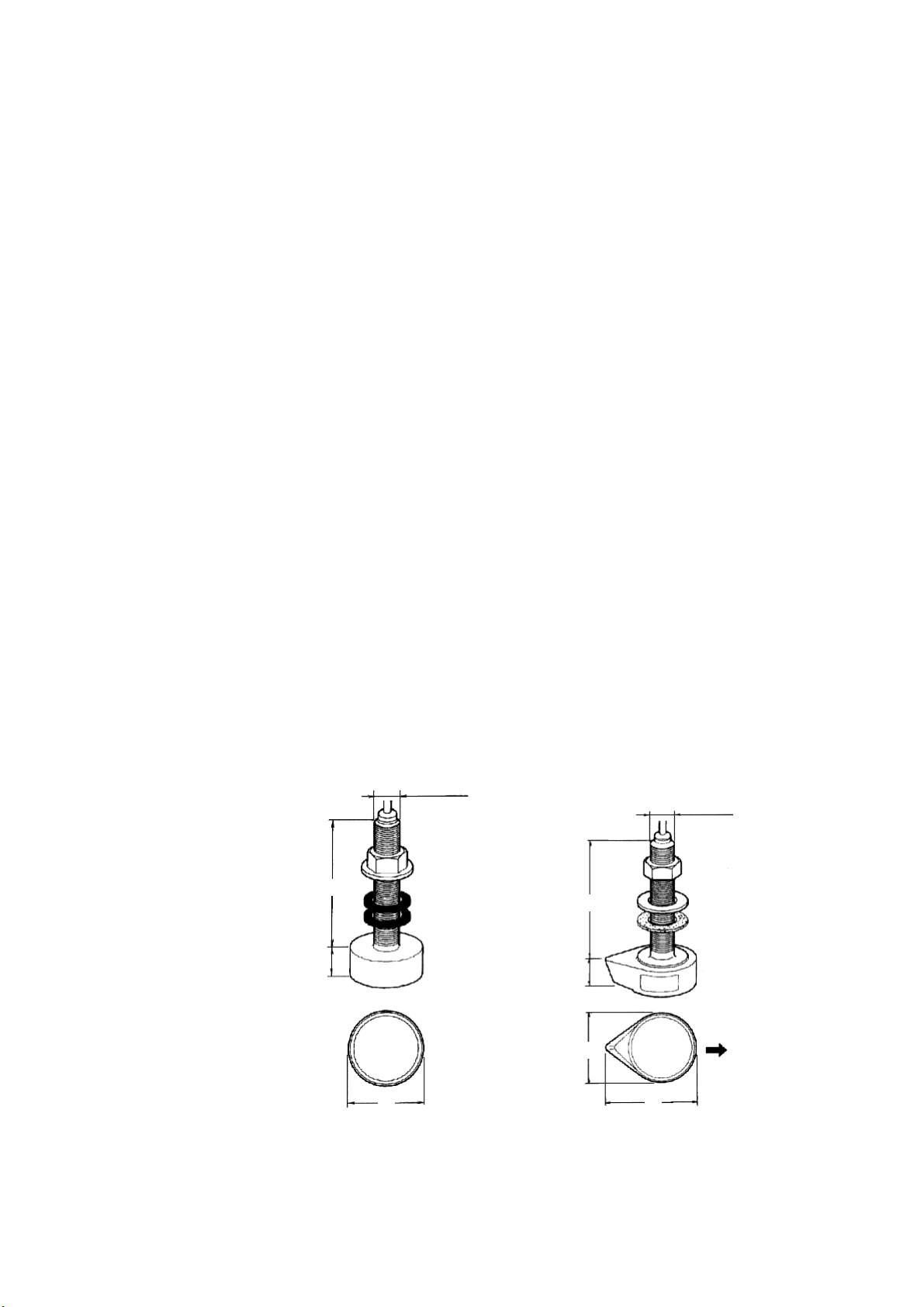

Transducer outline drawings

30

120

22

All dimensions

in millimeters

120

28

24

1-14

68

68 87

520-5PSD (option) 520-5MSD (option)

Figure 1-18 Transducer outline drawings

Ship's

bow

Page 25

Acceptable transducer mounting locations

Deep-V hull

• Position 1/2 to 1/3 length of the hull from stern

• 15 to 30 cm off center line (inside first lifting strakes).

Figure 1-19 Transducer mounting location on deep-V hull

High speed V-planing hull

• Within the wetted bottom area

• Deadrise angle within 15°

Figure 1-20 Transducer mounting location on high speed

V-planing hull

Typical through-hull mount transducer installations

Fairing block

Deep-V Hull Flat Hull

Flat washer

Rubber washer

Hull

bottom

Hull

bottom

Figure 1-21 Typical through-hull mount transducer installations

1-15

Page 26

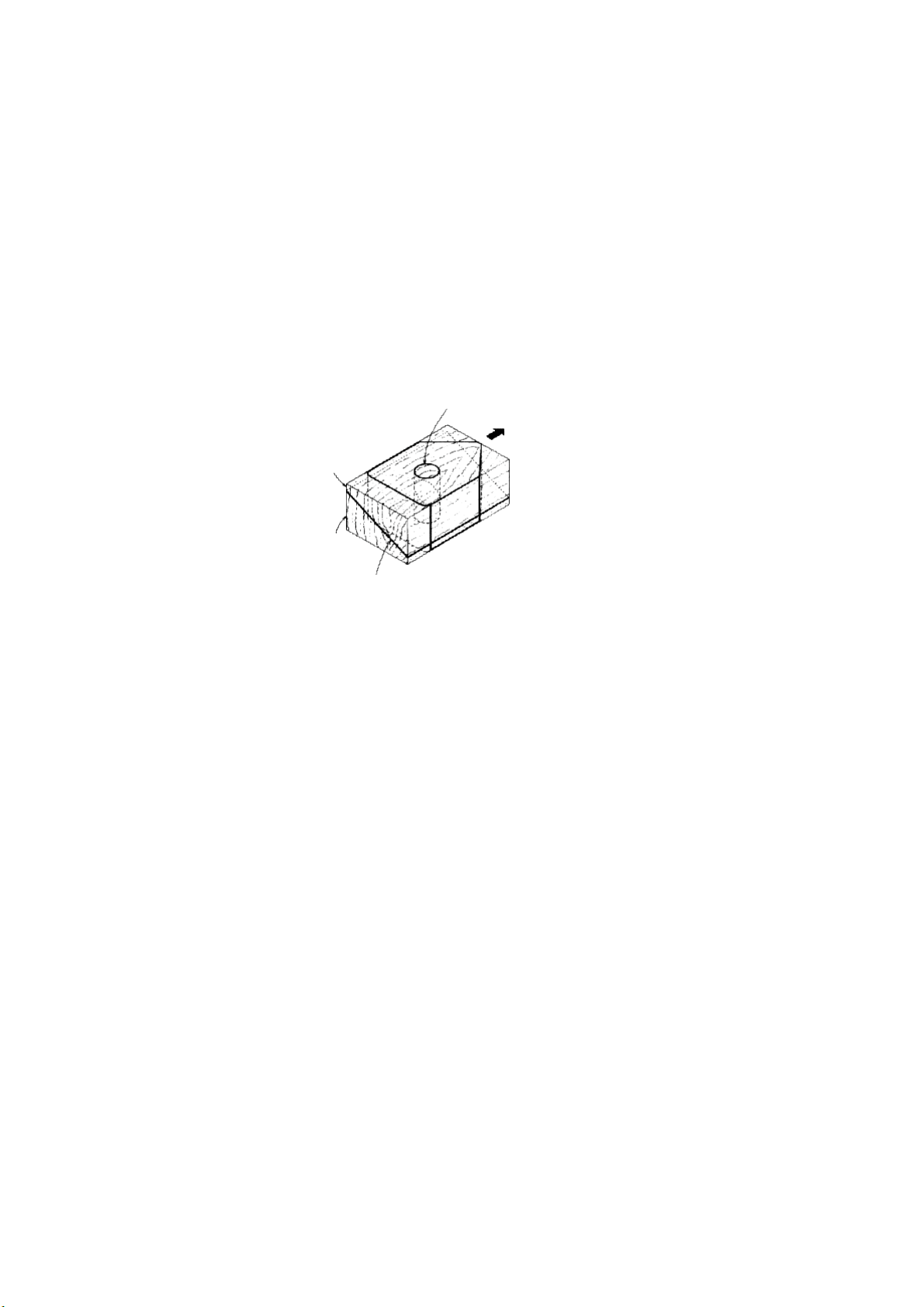

Procedure for installing the thru-hull mount transducer

1. With the boat hauled out of the water, mark the location selected for mounting the transducer on the bottom of the hull.

2. If the hull is not level within 15° in any direction, fairing blocks

made out of teak should be used between the transducer and

hull, both inside and outside, to keep the transducer face parallel with the water line. Fabricate the fairing block as shown

below and make the entire surface as smooth as possible to

provide an undisturbed flow of water around the transducer.

The fairing block should be smaller than the transducer itself

to provide a channel to divert turbulent water around the sides

of the transducer rather than over its face.

Hole for

stuffing tube

Upper

half

Lower

half

Saw along slope of hull.

BOW

Figure 1-22 Construction of fairing block

3. Drill a hole just large enough to pass the threaded stuffing tube

of the transducer through the hull, making sure it is drilled vertically .

4. Apply a sufficient amount of high quality caulking compound

to the top surface of the transducer, around the threads of the

stuffing tube and inside the mounting hole (and fairing blocks

if used) to ensure watertight mounting.

5. Mount the transducer and fairing blocks and tighten the locking nuts. Be sure that the transducer is properly oriented and its

working face is parallel to the waterline.

1-16

Note: Do not over-stress the stuffing tube and locking nuts through

excessive tightening, since the wood block will swell when the

boat is placed in the water . It is suggested that the nut be tightened

lightly at installation and retightened several days after the boat

has been launched.

Page 27

Installing the transom mount transducer

This type of mounting is very commonly employed, usually on

relatively small I/O or outboard boats. Do not use this method on

an inboard motor boat because turbulence is created by the propeller ahead of the transducer.

There are two methods of installation: flush with hull (for flat hulls)

and projecting from hull (for deep V-hulls).

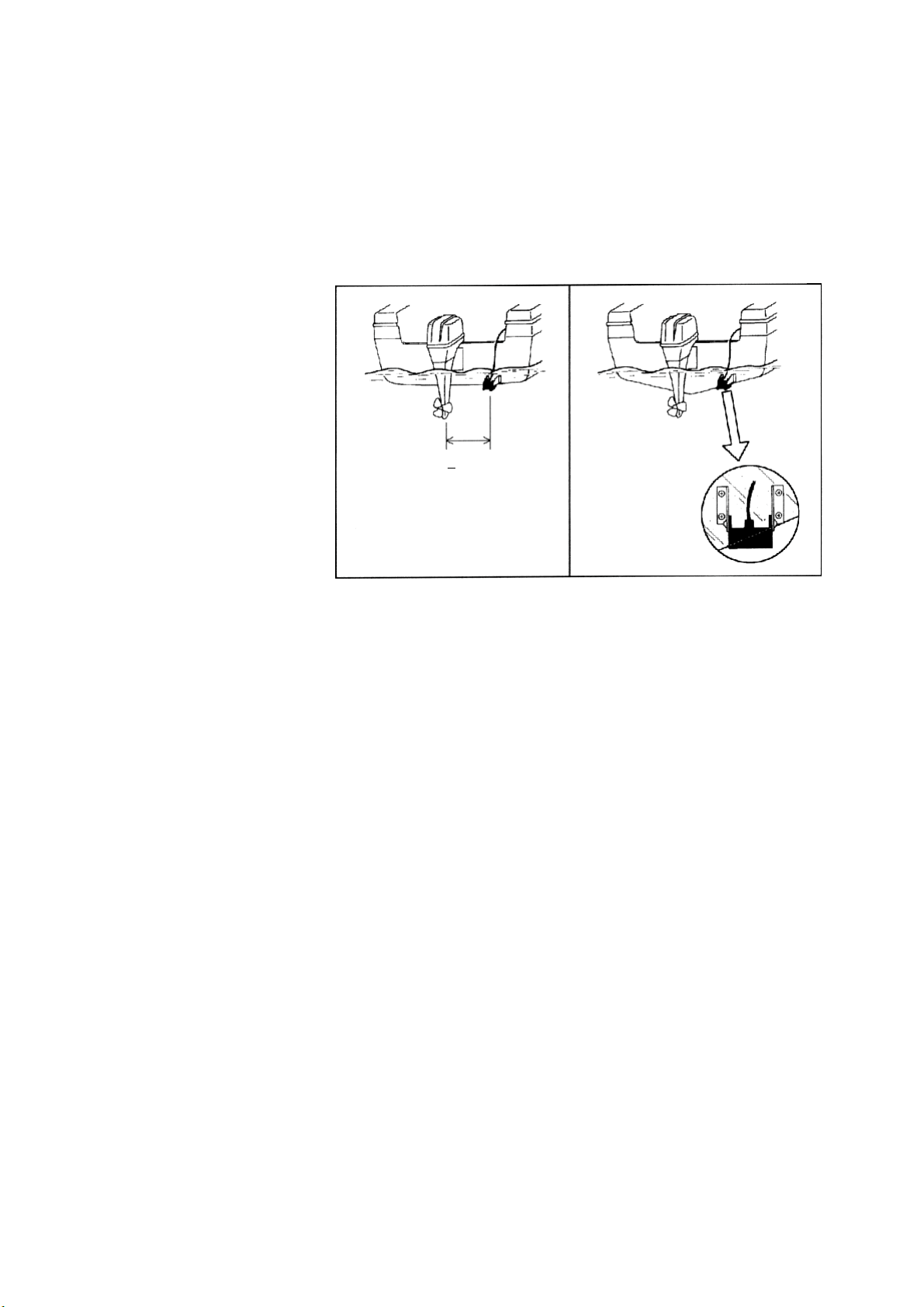

D

D

>50 cm

Flat Hull Deep V-hull

Figure 1-23 Transom mount transducer mounting locations

Installing the transom mount transducer flush with hull (for

flat hulls)

A suitable mounting location is at least 50 cm away from the engine and where the water flow is smooth.

1. Drill four pilot holes in the mounting location.

2. Attach the transducer to the bracket with tapping screws (supplied).

3. Adjust the transducer position so the transducer faces right to

the seabed.

Note: If necessary, to improve water flow and minimize air

bubbles staying on the transducer face, incline the transducer

about 5° at the rear. This may require a certain amount of

experimentation for fine tuning at high cruising speeds.

4. Fill the gap between the wedge front of the transducer and transom with epoxy material to eliminate any air spaces.

1-17

Page 28

M5 x 20

M5 x 20

5°

Tape

No. 1

M5 x 14

Figure 1-24 Transom mount transducer, mounting flush with hull

Installing the transom mount transducer projecting from

hull (for deep-V hulls)

This method is employed on deep-V hulls and provides good performance because the effects of air bubbles are minimal. Install

the transducer parallel with water surface; not flush with hull. If

the boat is placed on a trailer care must be taken not to damage the

transducer when the boat is hauled out of the water and put on the

trailer .

M5 x 20

M5 x 20

1-18

No. 2

M5 x 14

Figure 1-25 Transom mount transducer, projecting from hull

Transducer preparation

Before putting the boat in water, wipe the face of the transducer

thoroughly with a detergent liquid soap. This will lessen the time

necessary for the transducer to have good contact with the water.

Otherwise the time required for complete "saturation" will be

lengthened and performance will be reduced.

Do not paint the transducer. Performance will be affected.

Page 29

1.4 Installation of Optional Sensors

Through-hull mount water temperature/speed sensor

(ST-02MSB, ST-02PSB)

Select a suitable mounting location considering the following:

• Select a mid-boat flat position. The sensor does not have to be

installed perfectly perpendicular. The sensor must not be damaged in dry-docking operation.

• Select a place apart from equipment generating heat.

• Select a place in forward direction viewing from the drain hole

for cooling water.

• Select a place free from vibration.

1. Dry-dock the boat.

2. Make a hole of approx. 51 mm diameter.

3. Unfasten locknut and remove the sensor section.

4. Apply high grade sealant to the flange of the sensor.

5. Pass the sensor casing through the hole.

6. Face the notch on the sensor toward boat's bow and tighten the

flange.

7. Set the sensor section to the sensor casing and tighten the locknut.

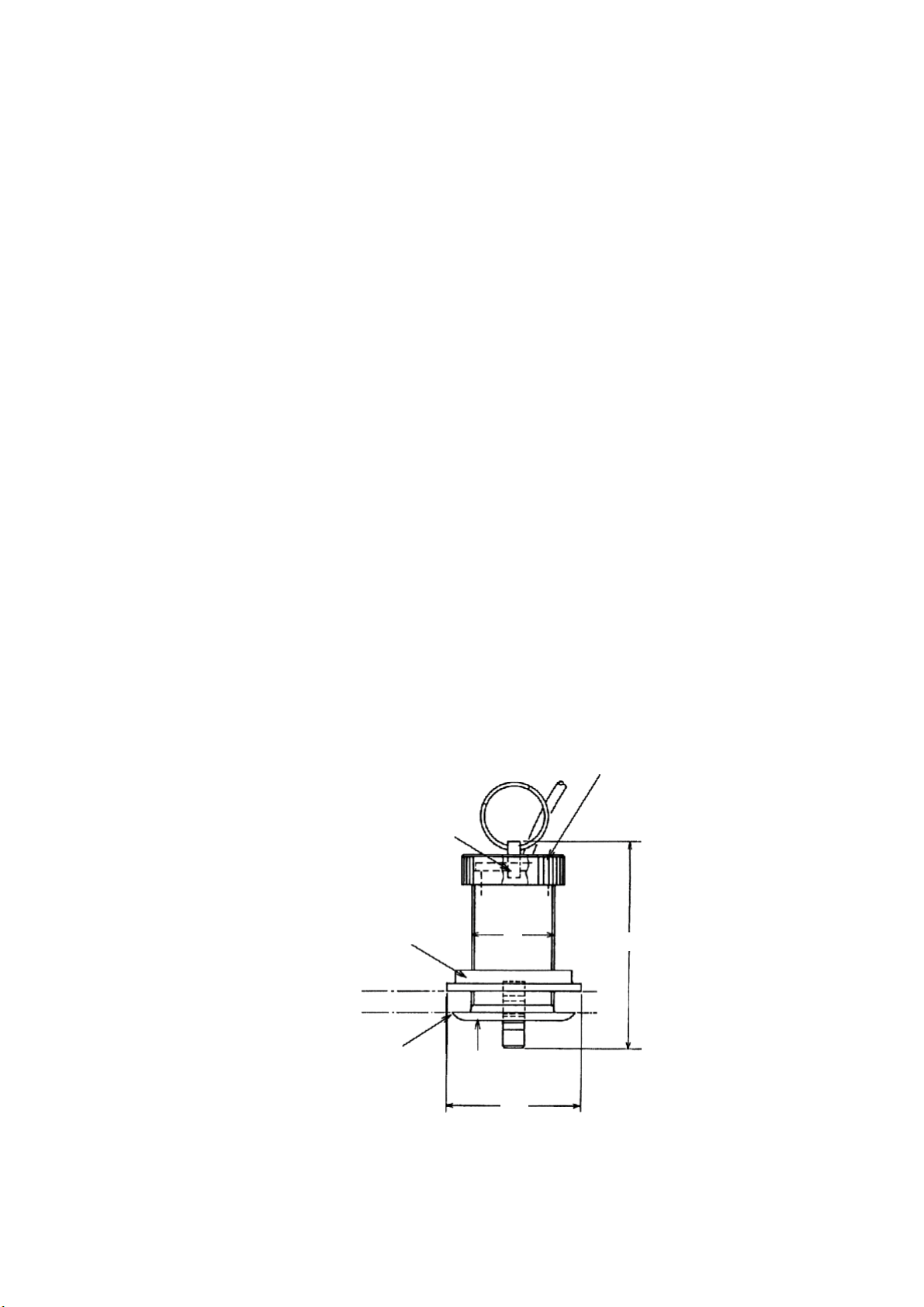

8. Launch the boat and check for water leakage around the sensor.

Locknut

Face "notch"

toward bow.

Flange nut

51

123

Coat with

silicone sealant.

Brim

ø77

Figure 1-26 Water temperature/speed sensor ST-02MSB,

ST02PSB

1-19

Page 30

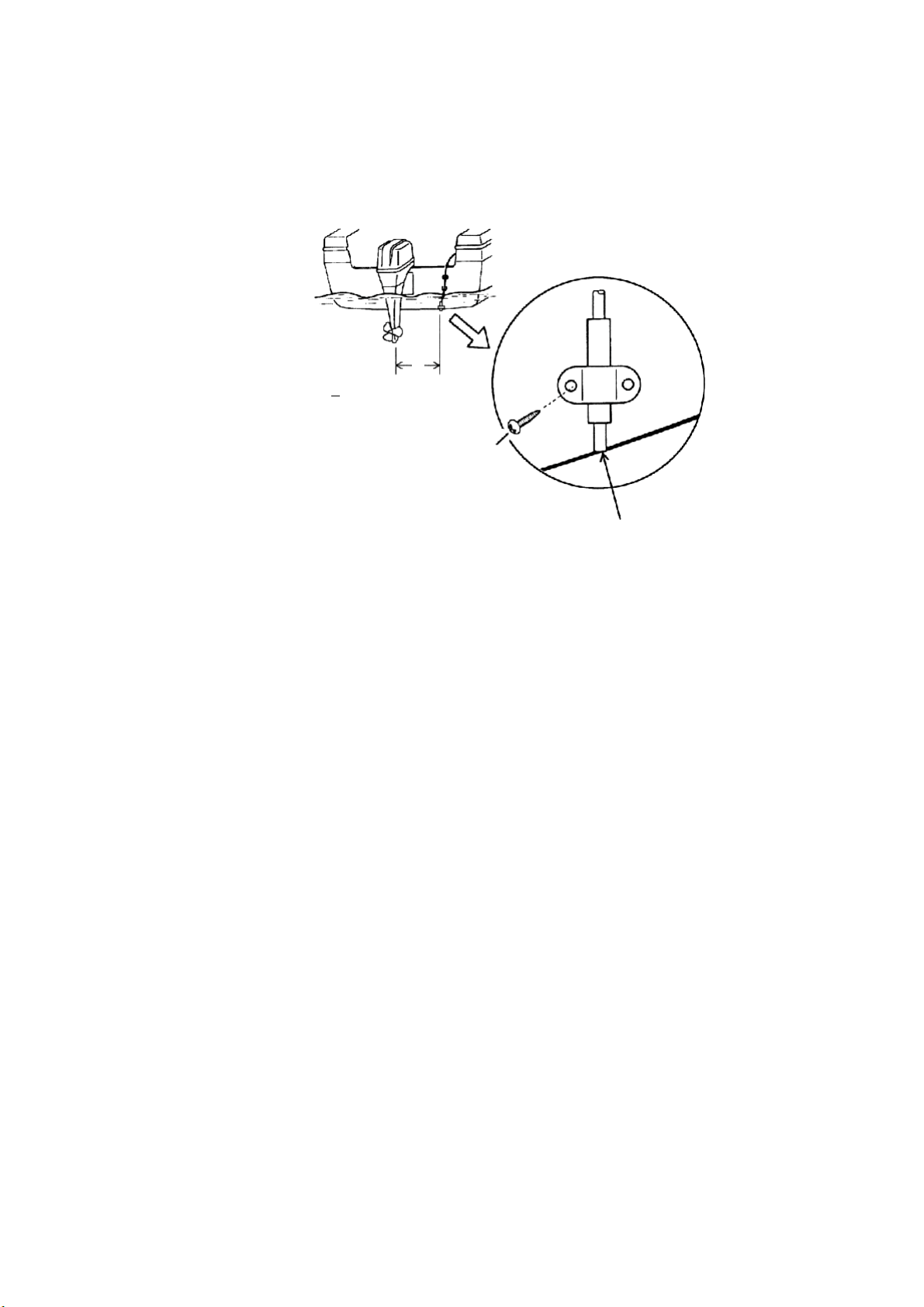

Transom mount water temperature sensor

T-02MTB

• Fix the cable at a convenient location with cable clamp.

• When the cable is led in through the transom board, make a

hole of approx. 17 mm diameter to pass the connector. After

passing the cable, fill the hole with a sealing compound.

D

D>50 cm

M5 x 20

Mount sensor

flush with hull bottom.

Figure 1-27 How to install transom mount water temperature

sensor T-02MTB

Thru-hull mount water temperature sensor

T-03MSB

• Select a mid-boat flat position. The sensor does not have to be

installed perfectly perpendicular. The sensor must not be damaged in dry-docking operation.

• Select a place apart from equipment generating heat.

• Select a place in forward direction viewing from the drain hole

for cooling water.

• Select a place free from vibration.

1. Dry-dock the boat.

2. Drill a hole of 25 mm in the hull.

3. Pass the sensor cable through the hull.

1-20

4. Pass the rubber washer, washer and locknut onto the cable in

that order.

5. Apply high grade sealant to the sensor flange, sensor and locknut. Tighten the locknut. Do not overtighten it.

6. Launch the boat and check for water leakage around the sensor.

Page 31

SENSOR HOLDER

Nut

Locknut

Washer

Rubber washer

Coat with

silicone sealant.

HOLDER GUIDE

Thickness of wood

plate should be within

25 mm.

Figure 1-28 Thru-hull mount water temperature sensor T-03MSB

1.5 Connection of Optional Equipment

Connecting a DGPS beacon receiver

Most any DGPS beacon receiver having RS-422 or RS-232C output level can be connected. (Connection of the FURUNO FR-80

requires no modification.) For RS-232C, a level converter (local

supply) is required. Connect the receiver to the DGPS connector at

the rear of the display unit.

GP-1610CF

RS-422

DGPS

RD-A

RD-B

GND

MJ-A7SPF003-050 (option)

3

4

5

6

7

YEL

GRN

GR-80

2

1

7

5

6

TD-A

TD-B

GND

RX-H

RX-C

DATA

RS-422

Current Loop

Note 1

Current Loop

Figure 1-29 Connection of the FURUNO GR-80 DGPS receiver

NMEA

TXD-H

TXD-C

1

2

3

4

5

6

WHT

BLK

Note 1:

This cable is required

for Auto L/L mode of

GR-80. It is not

required for Manual

mode.

1-21

Page 32

GP-1610CF

DGPS

RD-A

RD-B

GND

BEACON RCVR

3

4

5

6

7

YEL

GRN

BLU

TD-A

TD-B

GND

F.G

RS-422

Note 2

Note 2:

The signal names depend on

equipment connected. If data is not

input to the GP-1610CF, change

connection between TD-A and TD-B.

Figure 1-30 Connection of other DGPS beacon receivers

Connecting a sensor

Connect the water temperature sensor or water temperature/speed

sensor to the XDR connector with the converter connector kit (option). This kit contains only a connector; a cable is required.

MJ-A6SRMD

SHIELD

TEMP

TEMP0V

NC

NC

NC

MJ-A10SRMD

NC

NC

NC

NC

NC

NC

NC

XDR+

XDR SHIELD

XDR-

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

MJ-A10SPF

1

NC

4

TEMP

7

TEMP0V

3

NC

2

NC

5

NC

6

NC

8

XDR+

9

XDR SHIELD

10

XDR-

1-22

Figure 1-31 Wiring of converter connector for water

temperature sensor

Page 33

MJ-A6SRMD

SHIELD

TEMP

TEMP0V/SPD0V

SPD

+V

NC

MJ-A10SRMD

NC

NC

NC

NC

NC

NC

NC

XDR+

XDR SHIELD

XDR-

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

MJ-A10SPF

4

7

3

1

2

5

6

8

9

10

Figure 1-32 Wiring of converter connector for water

temperature/speed sensor

TEMP

TEMP0V

SPD0V/ SHIELD

SPD

+12.7V

NC

NC

XDR+

XDR SHIELD

XDR-

To connector at

rear of display unit

MJ-A6SRMD

Tape connector with

self-vulcanizing tape

and then vinyl tape

to waterproof

connector. Bind tape

end with cable tie.

MJ-A10SPF

MJ-A10SRMD

Water temp., water temp/speed

Transducer connector

sensor connector

Figure 1-33 Connection of transducer, water temperature sensor,

water temperature/speed sensor

1-23

Page 34

1.6 Initial Settings

Sensor connection

This section should be done with the boat in water.

1. Turn on the power and press the MENU key.

2. Press the [0] key.

3. Press the [5] key to select SENSOR SETUP.

SENSOR SETUP

SPD SENSOR

TEMP SENSOR

SPD CALIB

TEMP CALIB

DEPTH CALIB

: Cursor : +/ESC : Esc

Figure 1-34 Sensor setup menu

STW SOG

OWN

-00%(-50~+50)

+000°C

+0.0m

NMEA

4. Select source of ship's speed; STW (Speed-Through-Water):

local sensor, SOG (Speed-Over-Ground): GPS.

5. Press ▲ twice to select SPD CALIB.

6. If speed reading is higher or lower than actual speed you may

apply an offset to compensate for this. Enter offset with plus or

minus sign. The

key alternately displays plus and minus.

7. If a water temperature sensor is installed, press ▼ to select

TEMP SENSOR.

8. Press t to select OWN. (NMEA is for water temperature data

from external source.)

9. Press ▼ twice to select TEMP CALIB.

10. If temperature reading is higher or lower than actual temperature you may apply an offset to compensate for this. Enter off-

set with plus or minus sign. The

key alternately displays

plus and minus.

11. Press ▼ to select DEPTH CALIB.

12. Enter ship's draft, if applicable. Normally, depth is measured

from the transducer so enter positive figure.

1-24

13. Press the MENU key.

Autopilot or remote display connection

1. Press the MENU key.

2. Press the [0] key.

3. Press the [6] key.

Page 35

NMEA SETUP

FORMAT

EXT DEVICE

: Cursor ESC: Esc

183V1.5

REM

183V2.0

PILOT

Figure 1-35 NMEA setup menu

4. Press t or s to select data format of connected external equipment. If you are not sure, try both and select the one which

successfully receives data.

5. Press ▼ to select EXT DEVICE.

6. Press t or s to select type of external equipment (input and

output data); REMote display or AutoPILOT.

Table 1-1 Output data

tnempiuqEreklaTsecnetneS

tolipotuAPG,GTV,LLG,DOB,BPA,MAA

ETX

etomeR

PGTPD,)5.1noisrev(TBD,RWB

yalpsid

Table 1-2 Input data

reklaTsecnetneS

llaro,ED,CL

sreklat

GTV

enoNLLT,WTM

7. Press the MENU key.

,BMR,WTM,LLG,)0.2noisrev(

ADZ,GTV,CMR

,LLT,AMR,CMR,AGG,LLG

1-25

Page 36

DGPS beacon receiver connection

1. Press the MENU key.

2. Press the [0] key.

3. Press the [8] key.

DGPS SETUP

DGPS

RTCM VER

BYTE FORM

FIRST BIT

PARITY BIT

STOP BIT

BIT RATES

BAUD RATES

: Cursor

ENT : Sel ESC : Esc

ON OFF

1.0 2.0

8-6 8-8

LSB

8

MSB

EVEN ODD NONE

1 2

7

300 600 1200

2400 4800 9600

Figure 1-36 DGPS setup menu

4. Press t to select ON in the DGPS line.

5. Change settings referring to the operator's manual of the DGPS

beacon receiver. Circumscribed options are standard settings.

6. Press the MENU key.

1-26

Page 37

OPERATIONAL OVERVIEW

2.1 Control Description

All operations of the GP-1610CF are carried out with the controls on the front panel of the

display unit. All controls respond immediately to your command and the unit emits a beep to

signify correct key sequence. (Invalid key input emits several beeps.)

Cursor Pad

• Shifts cursor and screen.

• Selects items on menus.

• Opens/closes menu.

• Escapes from current

operation.

Selects video sounder

displays.

Selects automatic or manual

video sounder operation.

Registers waypoints.

Shrinks display range

(blows up chart).

Places own position or

cursor position at screen

center.

• Adjusts brilliance.

• Switches +, -, North, South,

East and West.

MENU

ESC

SNDR

AUTO

WPT

ZOOM

IN 4

CNTR

TONE

NU/CU

ENT

PLTR

1

2

3

5

6

EVENT

MOB 7

GOTO

8

ZOOM

OUT 9

CURS

0

CLR

POWER

• Alternately selects north-up and

course-up presentation modes.

• Registers items on menus.

Alternately selects plotter,

plotter/sounder, data, graphic

and highway displays.

Inscribes various marks.

Sets/cancels destination.

Expands display range

(shrinks chart).

Displays/erases cursor.

• Clears data.

• Erases selected waypoint,

mark.

• Silences audible alarm.

Turns power on/off.

Figure 2-1 Controls

2-1

Page 38

2.2 Inserting Chart Cards

Note: Insert chart card before turning on the

power. This enables automatic loading of

chart.

pleted, the GPS receiver status indication

"ACQ" (at the bottom right-hand corner)

changes to 2D (or 3D). ACQ means the receiver is acquiring the GPS signal, and 2D

(or 3D) means the position data is reliable.

1. Open the memory card slot cover at the

bottom of the display unit by unfastening

two screws.

Screws

Cover

Figure 2-2 Display unit, bottom

2. Insert the chart card label side up, arrow

forward.

Chart

card

EJECT

button

02522530**

=

=

OK

OK

OK

OK

ROM

RAM

VRAM

Battery

Program No.

Base Chart No.

— — WARNING— —

NO NATIONAL HYDROGRAPHIC

OFFICE HAS VERIFIED THE

INFORMATION IN THIS COASTLINE

DATA CARD AND NONE ACCEPT

LIABILITY FOR THE ACCURACY OF

REPRODUCTION OR ANY

MODIFICATIONS MADE THEREAFTER.

THIS PRODUCT WITH THIS

COASTLINE DATA CARD DOES NOT

REPLACE THE REQUIREMENT TO

USE THE APPROPRIATE PRODUCTS

FOR NAVIGATION ACCORDING TO

NATIONAL AND INTERNATIONAL

REGULATONS.

FURUNO ELECTRIC CO., LTD.

Displayed for

about one second.

** Program version

no.

Displayed for

about one minute.

Arrow forward

Figure 2-3 How to insert chart card

3. Close the cover and fix it.

Note: Always keep the cover closed to keep

foreign material out of the chart card drive.

2.3 Turning On/Off the Power

Press the POWER key to turn the power on/

off. When the unit is turned on, it proceeds in

the sequence shown in Figure 2-4. About 20

seconds after the start-up sequence is com-

Plotter display

BRG+ 232.0° RNG+ 0.00nm ACQ

DEP 110m TMP 16 .0°C 13:41

+ 34°43.801’N 135°21.163’E

GPS Fixing Status

ACQ (Acquiring)

is replaced by

2D or 3D when

position becomes

reliable.

Figure 2-4 Start-up sequence

2D: Ship's position is calcurated by using data

from 3 satellites.

3D: Ship's position is calcurated by using data

from 4 satellites.

2-2

Page 39

2.4 Adjusting Tone and Brilliance

1. Press the TONE key. The tone and bril-

liance setting display appears.

2. Press the PL TR key again to select a plotter mode. Each time the key is pressed

the mode changes in the following sequence:

Plotter Plotter/Sounder

Data

LOW HIGH

TONE : 5

LOW HIGH

BRILL : 8

Figure 2-5 Tone and display brilliance

setting display

2. Operate t or s to adjust display tone.

3. Press ▲ or ▼ to adjust display brilliance.

Note: Tone or brilliance must be adjusted

within about 10 seconds after pressing the

TONE key or the display will be erased.

2.5 Plotter Displays

There are five types of plotter displays: plotter, plotter/sounder, data, graphic and highway.

Selecting a plotter display

1. Press the PLTR key. The SELECT PLOT TER MODE screen appears.

SELECT PLOTTER MODE

Plotter

Plotter/Sounder

Data

Graphic

Highway

Highway Graphic

Y ou may also select a mode by pressing ▲

or ▼ and the ENT key.

3. Press the ESC key to conclude your selection.

Sample plotter displays

Plotter display

The plotter display mainly shows chart, ship's

track, waypoints, marks and various data.

Course bar

Own ship

mark

Icon

(chart)

Course,

speed

Depth

CSE 180.0° SPD 16.8kt 2D

DEP 110m TMP 16.0°C 12:13

POS 34°26.345’N 135°41.232’E

Position

Water temperature

(Requires optional

sensor.)

Track

GPS status

Time

Figure 2-7 Plotter display

PLTR: Sel ESC: Close

Figure 2-6 Select plotter mode screen

2-3

Page 40

Plotter/sounder display

Graphic display

This display provides a plotter display on the

left 2/3 of the screen an the normal sounder

display on the right 1/3. It is useful for searching fish schools at cruising speed.

Sounder

Plotter

Display

Display

0

50

100

150

200k

200

CSE 180.0° SPD 16.8kt 2D

DEP 110m TMP 16.0°C 12:13

POS 34°26.345’N 135°41.232’E

Figure 2-8 Plotter/sounder display

Data display

This display provides analog and digital displays of cross track error (XTE), course, etc.

It is useful for monitoring progress when steering by autopilot. The XTE scale shows direction and amount to steer to return to course.

POS

34° 26.345°N 135° 38.417' E

Course

Course

set

Distance

1nm

run

TRIP

ETA

Estimated time of

arrival at waypoint

Position

W

S

BRG

248°

CSE

323°

RNG

21.0

nm

TTG

23: 20

14

Bearing to

waypoint

Course

indicator

XTE

1nm

scale

112

nm

H

20

M

Range to

waypoint

Time-to-go to

waypoint

This display provides various navigation data,

such as position, course and speed, in digital

form.

Date

POS 1997.01.21 12:13

34° 26.345' N

Position

135°38.417' E

CSE

127.1 ° 16.8

DEP

110m 15.2

WP 001

RNG 173.4 nm

BRG 180.0°

XTE 0.25 nm

SPD

TMP

kt

°C

Course,

speed

Depth, water

temperature

Waypoint no.

Range to waypoint

Bearing to waypoint

Cross-track error

Figure 2-9 Data display

Figure 2-10 Graphic display

Highway display

The highway display provides a graphic presentation of ship’s track along a course. It is

useful for monitoring XTE-the XTE scale

shows direction and amount in nautical miles

to steer to return to course.

15

10

5

North

mark

WP001 120.6° 2.2nm

CSE 180.0° SPD 16.8kt 2D

DEP 113.6 m TMP 16.0°C 12:13

POS 34°26.345'N 135°41.232'E

Bearing and range

to waypoint

01

5

5

Waypoint

Own ship

mark

XTE

scale

2-4

Figure 2-11 Highway display

Page 41

2.6 Sounder Displays

50 kHz

200 kHz

Normal sounder display

Five sounder displays are available: normal,

marker zoom, bottom zoom, bottom-lock and

A-scope display. You may select a sounder

display with the SNDR key.

Selecting a sounder display

1. Press the SNDR key. The SELECT

SOUNDER MODE screen appears.

SELECT SOUNDER MODE

Normal

Marker Zoom

Bottom Zoom

Bottom Lock

A-Scope

50kHz

SNDR: Sel ESC: Close

200kHz

Figure 2-12 Select sounder mode screen

2. Press the SNDR key again to select a

sounder mode. Each time the key is

pressed the sounder mode changes in the

following sequence:

Normal Marker Zoom

Bottom Zoom

50 kHz

The sounder uses ultrasonic pulses to detect

seabed conditions. The lower the frequency

of the pulse, the wider the detection area.

Therefore, the 50 kHz frequency is useful for

general detection and judging seabed condition.

Figure 2-13 Detection area

200 kHz

The higher the frequency of the ultrasonic

pulse the better the resolution. Therefore, the

200 kHz frequency is ideal for detailed observation of fish schools.

Bottom-LockA-Scope

Y ou may also select a sounder mode by pressing ▲ or ▼ and the ENT key.

3. Press the ESC key to conclude your selection.

Water temp. display

Temp.

scale

Water

temp.

graph

Color

bar

Depth

°C

30

20

10

0

162

CSE 180.0° SPD 16.8kt

DEP 162m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

68.3

200k

0

50

100

150

200

2D

13:41

Depth scale

Variable

Range

Marker

(white)

Fish

school

Bottom

Tx

frequency

Figure 2-14 Typical 200 kHz normal

sounder display

2-5

Page 42

Marker zoom display

Bottom-lock display

This mode expands anywhere of the normal

picture to full vertical size of the screen on

the left-half window. You may specify the

portion to expand by operating the VRM

(V ariable Range Marker), which you can shift

with ▲ or ▼. The segment between the VRM

and zoom range markers are expanded. The

length of the segment is equal to one division

of the depth scale.

Fish school

Normal

Marker zoom

display

100

90.0

150

162

CSE 180.0° SPD 16.8kt

DEP 162m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

200

Fish

school

200k

0

50

100

150

200

2D

13:41

display

VRM

(white)

This part

is zoomed.

Expansion

range

marker

(yellow)

The bottom-lock display provides a compressed normal picture on the right half of the

screen and a 5 or 10 meter wide layer in contact with the seabed is expanded onto the left

half of the screen. (Y ou may select layer width

on the SOUNDER SETUP menu in the SYSTEM menu.) This mode useful for bottom

discrimination.

Bottom-lock

display

Fish

school

This part

is zoomed.

50

68.3

40

Fish

school

30

20

10

162

CSE 180.0° SPD 16.8kt

DEP 162m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

0

200k

50

100

150

200

2D

14:02

0

Expansion

range

marker

(yellow)

Normal

display

Figure 2-17 Bottom-lock display plus

normal display

Figure 2-15 Marker zoom display

plus normal display

Bottom zoom display

This mode expands bottom and bottom fish

echoes two to five times to vertical size of the

screen. This mode is useful for determining

bottom hardness. A bottom displayed with a

short echo tail usually means it is a soft, sandy

bottom. A long echo tail means a hard bottom.

200k

50

100

150

200

2D

14:02

0

Normal

display

Expansion

range

marker

(yellow)

Bottom zoom

display

Bottom

Display is

blown up

three times

larger than

normal display.

100

40.0

120

140

160

162

CSE 180.0° SPD 16.8kt

DEP 162m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

180

Note: The expansion marker is not displayed

in the defualt setting. It may be turned on in

the SNDR SETUP menu in the SYSTEM

menu.

A-scope display

This display shows echoes at each transmission with amplitudes and tone proportional to

their intensities, on the right 1/3 of the screen.

It is useful for estimating the kind of fish

school and seabed composition.

0

A-scope

display

2D

14:02

Normal

display

50

68.3

100

150

160

CSE 180.0° SPD 16.8kt

DEP 160m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

200

200k

Figure 2-18 A-scope display (right side)

Figure 2-16 Bottom zoom display plus

normal display

2-6

Page 43

2.7 Basic Menu Operation

3. Press ▲ or ▼ to select menu item.

1. Press the MENU key to display the MAIN

menu.

MAIN MENU

1. DISPLAY SETUP

2. TRACK/MARK SETUP

3. ERASE TRACK/MARK

4. ROUTE/ROUTE LIST

5. ALARM SETUP

6. VIDEO SOUNDER SETUP

7. MEMORY SAVE/LOAD

8. CLEAR MEMORY

0. SYSTEM MENU

: Cursor ESC: Esc

Figure 2-19 Main menu

2. Press appropriate numeric key or ▲ or ▼

and ENT key to select menu desired. The

highlighted cursor shifts with numeric key

or Cursor Pad operation. For example,

press the [1] key to display the DISPLA Y

SETUP menu.

4. Press t or s to select option.

5. To enter numeric data use the numeric

keys. The entry of leading zero is necessary; trailing zero is optional. For example, to enter 050, press [0] [5]. W rong

numeric data can be cleared with the CLR

key .

6. After entering numeric data, press the

ENT key. (It is not necessary to press the

ENT key after selecting an option which

does no require entry of numeric data.)

7. Press the MENU key to escape.

DISPLAY SETUP

HUE

LAND BRILL

LAND COLOR

PLACE NAME

GRID COLOR

COURSE BAR

TIME MARK

WPT MARK SIZE

CURSOR SIZE

: Cursor ESC: Esc

1 2

BRT DIM OFF

RED YEL GRN BLU PPL WHT OFF

RED YEL GRN BLU PPL WHT OFF

RED YEL GRN BLU PPL WHT OFF

RED YEL GRN BLU PPL WHT OFF

RED YEL GRN BLU PPL WHT OFF

L S

L S

Figure 2-20 Display setup menu

2-7

Page 44

VIDEO SOUNDER OPERATION

3.1 Principle of Operation

The video sounder of the GP-1610CF determines the distance between its transducer and

underwater objects such as fish, lake bottom

or seabed and displays the results on screen.

It does this by utilizing the fact that an ultrasonic wave transmitted through water travels

at a nearly constant speed of 4800 feet ( 1500

meters) per second. When a sound wave

strikes an underwater object such as fish or

sea bottom, part of the sound wave is reflected

back toward source. Thus by calculating time

difference between the transmission of a

sound wave and the reception of the reflected

sound wave, the depth to the object can be

determined.

The entire process begins in the display unit.

Transmitter power is sent to transducer as a

short pulse of electrical energy . The electrical

signal produced by the transmitter is converted

into an ultrasonic signal by the transducer and

transmitted into the water. Any returning signals from intervening objects (such as a fish

school) are received by the transducer and

converted into an electrical signal. The signals are then amplified in the amplifier section, and finally, displayed on screen.

The picture displayed is made up of a series

of vertical scan lines, one for each transmission. Each line represents a snapshot of what

has occurred beneath the boat. Series of snapshots are accumulated side by side across

screen, and the resulting contours of the bottom and fish between the bottom and surface

are displayed.

Figure 3-1 Underwater conditions and video sounder display

3-1

Page 45

3.2 Automatic Sounder

3.3 Manual Sounder

Operation

Automatic operation is useful when you are

preoccupied with other tasks and do not have

time to adjust the display.

How it works

The automatic function automatically selects

the proper gain and range scale according to

depth. It works as follows:

• Range changes automatically to locate the

bottom on the lower half of screen. It jumps

to one step shallower range when bottom

echoes reach a half way point of the full

scale from top and to one step deeper range

when they come to the lower edge of scale.

• The gain is automatically adjusted to display the bottom echo in reddish brown (default color arrangement).

• Clutter level, (on the VIDEO SOUNDER

SETUP menu), which suppresses low level

noise, is automatically adjusted.

Operation

Manual operation is useful for observing fish

schools and bottom using fixed gain setting.

The gain, range and range shifting functions

used together give you the means to select the

depth you can see on screen. The basic range

can be thought of as providing a "window"

into the water column and the range shifting

as moving the "window" to the desired depth.

Manually adjusting the sounder

picture

1. Press the AUTO key to display the AUTO

MODE menu.

2. Press ▼ to select Manual.

AUTO MODE

Cruise

Fish

Manual

Two types of automatic modes

Two types of automatic modes are available:

cruise and fish. Cruise is for tracking the bottom, and fish is for searching fish schools.

Since "Cruise" uses a higher clutter rejection

setting than "Fish," it is not recommended for

fish detection – weak fish echoes may be deleted by clutter rejection.

How to enable automatic sounder

operation

1. Press the AUTO key.

AUTO MODE

Cruise

Fish

Manual

Low High

Gain

Range 5 10 20

40 80

Shift 0 m

300 m160

Figure 3-3 Gain, range and shift

adjustment display

3. Press ▼ to select Gain.

Normally, set the gain to the point where

excessive noise does not appear on screen.

Use a higher gain setting for greater depths

and a lower setting for shallower waters.

4. Press t or s to set level.

Figure 3-2 Auto mode display

2. Press the AUTO key again to select Cruise

or Fish.

3. Press the ENT or MENU key.

3-2

Page 46

Too high Proper Too low

Figure 3-4 Examples of proper

and improper gain

5. Press ▲ to select Range.

MAIN MENU

1. DISPLAY SETUP

2. TRACK/MARK SETUP

3. ERASE TRACK/MARK

4. ROUTE/ROUTE LIST

5. ALARM SETUP

6. VIDEO SOUNDER SETUP

7. MEMORY SAVE/LOAD

8. CLEAR MEMORY

0. SYSTEM MENU

: Cursor ESC: Esc

6. Press t or s to select basic range desired.

7. Press ▼ to select Shift.

Shift

Display

Figure 3-5 Shift concept

8. Press t or s to shift the basic range, if

desired.

9. Press the MENU key.

3.4 Suppressing Low Level

Noise

Light-blue dots may appear over most of

screen. This is mainly due to dirty water or

noise. This noise can be suppressed by adjusting CLUTTER on the VIDEO SOUNDER

SETUP menu.

Figure 3-6 Main menu

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

VIDEO SOUNDER SETUP

CLUTTER

AUTO

ADVANCE STOP

NOISE LM OFF

DEP CHIME

TEMP GRP

SIG LEV

ZOOM

HUE

ESC : Esc

0 1 2 3

1/8 1/4

1/2 1/1 2/1

NL1

NL2 NL3

ON OFF

ON

SL0 SL1

X2 X3

: Cursor

1

OFF

X4 X5

2

345

SL2

0

40

80

120

2D

5:55

65 E

Figure 3-7 Video sounder setup menu

3. Press ▲ to select CLUTTER.

4. Press t or s to select clutter rejection

level desired; 0 (OFF), 1, 2, 3 or AUTO.

The higher the number the higher the degree of suppression. Note that weak echoes may not be displayed when the clutter

circuit is on.

5. Press the MENU key.

When the sounder mode is Auto, the clutter

suppression setting is fixed at AUTO. T o suppress low level noise in manual sounder operation do the following:

1. Press the MENU key.

Clutter Clutter removed

Figure 3-8 How the clutter function works

3-3

Page 47

3.5 Selecting Picture Advance Speed

When selecting a picture advance speed, keep

in mind that a fast advance speed will expand

the size of the fish school horizontally on the

screen and a slow advance speed will contract it.

1. Press the MENU key.

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

4. Press t or s to select degree of suppression desired; OFF , NL1, NL2 or NL3. The

higher the number the greater the degree

of suppression.

5. Press the MENU key.

3. Press ▲ or ▼ to select ADVANCE.

4. Press t or s to select advance speed (a

"fraction") desired, or STOP to suspend

advancement of the picture.

The fractions in the menu denote number

of scan lines produced per transmission.

For example, 1/8 means one scan line is

produced every 8 transmissions.

5. Press the MENU key.

Fast Slow

Figure 3-9 Comparison of picture

advance speeds

3.6 Suppressing Interference

Interference from other acoustic equipment

operating nearby or other electronic equipment on your boat may show itself on the display as shown in Figure 3-10.

Electrical

interference

Noise limiter

turned on

Interference from

other sounder

Figure 3-10 How the noise limiter works

Turn the noise limiter circuit off when no interference exists, otherwise weak echoes may

be missed.

3.7 Erasing Weak Echoes

Dirty water or reflections from plankton may

be painted on the display in green or light blue.

These weak echoes may be erased as follows:

1. Press the MENU key.

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

3. Press ▲ or ▼ to select SIG LEV.

To suppress interference, do the following:

1. Press the MENU key.

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

3. Press ▲ or ▼ to select NOISE LM.

3-4

4. Press t or s to select level of erasure;

SL0 (OFF), SL1 or SL2. The higher the

number the stronger the echo will be

erased.

5. Press the MENU key.

Page 48

Weak

echoes

3. Press ▲ or ▼ to select HUE.

4. Press t or s to select hue arrangement

number . (A portion of the sounder display

appears so you may see the result of your

selection.)

euH 12345

Signal level

adjusted

Figure 3-11 How SIG LEV works

3.8 Changing Zoom Magnification Factor

You may select the zoom magnification factor for the marker and bottom zoom modes.

This the amount the zoomed picture is magnified in relation to the normal picture.

dgkB

roloc

eulBthgiL

eulb

kcalBneerGkcalB

5. Press the MENU key.

3.10 Measuring Depth

The VRM (Variable Range Marker) functions

to measure the depth to fish schools, etc.

1. Press ▲ or ▼ to place the VRM on an

echo.

2. Read the VRM range just above the VRM.

0

Depth of

VRM

58.3

40

VRM

80

120

1. Press the MENU key.

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

3. Press ▲ or ▼ to select ZOOM.

4. Press t or s to select zoom factor de-

sired; x2, x3, x4 or x5.

5. Press the MENU key.

3.9 Selecting Hue (color arrangement)

The GP-1610CF provides several color arrangements to match lighting conditions.

1. Press the MENU key.

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

132

CSE 180.0° SPD 16.8kt

DEP 132m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

160

200k

2D

14:32

Figure 3-12 How to measure

depth with the VRM

3.11 Knowing Depth Change by Audible Chime

The depth chime function alerts you to change

in depth by audible chime Depth change direction is given by chime interval; the longer

the interval the greater the change in depth.

T o turn on or off the depth chime function, do

the following:

1. Press the MENU key.

3-5

Page 49

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

3. Press ▲ or ▼ to select DEP CHIME.

4. Press t or s to select ON or OFF.

5. Press the MENU key.

3.12 Selecting Unit of Depth

Measurement

You may display the depth in meters, feet or

fathoms as follows:

SYSTEM MENU

1. SELF TEST

2. PLTR SETUP

3. SOUNDER SETUP

4. UNIT SETUP

5. SENSOR SETUP

6. NMEA SETUP

7. GPS SETUP

8. DGPS SETUP

9. CHART POSN CALIB

: Cursor

ENT: Sel ESC: Esc

Figure 3-14 System menu

1. Press the MENU key.

2. Press the [0] key to select SYSTEM

MENU.

3. Press the [4] key to display the UNIT

SETUP menu.

UNIT SETUP

DISTANCE

DEPTH

TEMP

: Cursor ESC: Esc

nm

m

°C

km

ft

°F

sm

fa

Figure 3-13 Unit setup menu

4. Operate the Cursor Pad to select Depth.

5. Operate the Cursor Pad to select m, ft, or

fa.

6. Press the MENU key.

3. Press the [5] key to select SENSOR

SETUP.

SENSOR SETUP

SPD SENSOR STW SOG

TEMP SENSOR OWN NMEA

SPD CALIB +00%(-50~+50)

TEMP CALIB +00.0 °C

DEPTH CALIB +0.0 m

: Cursor : +/ESC: Esc

Figure 3-15 Sensor setup menu

4. Press ▲ or ▼ to select DEPTH CALIB.

5. Enter correction with numeric keys.

6. Press the ENT key.

7. Press the MENU key.

3.13 Offsetting the Depth Readout

If the depth displayed is not correct you may

offset to it to correct the correct value as follows:

1. Press the MENU key.

2. Press the [0] key to select the SYSTEM

SETUP menu.

3-6

3.14 Displaying the Water Temperature Graph

A water temperature graph can be displayed.

This function requires a water temperature

sensor.

To turn on/off the water temperature graph:

1. Press the MENU key.

2. Press the [6] key to display the VIDEO

SOUNDER SETUP menu.

Page 50

3. Press ▲ or ▼ to select TEMP GRP.

4. Press ▲ or ▼ to select TEMP CALIB.

4. Press t or s to select ON or OFF.

5. Press the MENU key.

Water temp.

scale

Water temp.

graph

°C

30

20

10

0

162

CSE 180.0° SPD 16.8kt

DEP 162m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

68.3

200k

50

100

150

200

2D

14:32

0

Fish

school

Bottom

Figure 3-16 Water temperature graph

3.15 Selecting Unit of Water Temperature Measurement

5. Enter correction with numeric keys.

6. Press the ENT key .

7. Press the MENU key.

3.17 Fish Alarm

The fish alarm sounds when a fish school is

detected within the selected range. When a

fish school comes within the range set the

audible alarm sounds and the alarm icon

and the indication FISH appear. You may si-

lence the alarm with the CLR key. The indication remains on the screen until the fish echo

is out of the alarm range.

1. Press the MENU key.

2. Press the [5] key to select ALARM

SETUP.

Y ou may display temperature in degrees Centigrade or Fahrenheit as follows:

1. Press the MENU key.

2. Press the [0] key to select SYSTEM

MENU.

3. Press the [4] key to display the UNIT

SETUP menu.

4. Operate the Cursor Pad to select T emp.

5. Operate the Cursor Pad to select °C or °F.

6. Press the MENU key.

3.16 Offsetting Water

Temperature Readout

In some instances the water temperature readout may be off by a few degrees. You can offset it to the correct temperature as follows:

1. Press the MENU key.

2. Press the [0] key to select the SYSTEM

SETUP menu.

ALARM SETUP

ARRIVAL

XTE

SPEED

TEMP

TRIP

: Cursor

ARRIVAL

Range

ON

Range

WITHIN

Speed

WITHIN

Temp

ON

Range

ANCHOR

00.500nm

00.250nm

OVER

11.0~15.0kt

OVER

+11.0~+15.0°C

0005.00nm

OFF

OFF

OFF

OFF

OFF

ESC: Esc

Figure 3-17 Alarm setup menu

3. Press ▼ to select FISH on page 2.

ALARM SETUP

FISH

BOTTOM

: Cursor

NORM B/L

B/L

ON

Range

003.4~004.6m

003.4~004.6m

OFF

OFF

ESC: Esc

1/2

2/2

3. Press the [5] key to select SENSOR

SETUP.

Figure 3-18 Alarm setup menu, page 2

3-7

Page 51

4. Press s or t to select NORMAL or B/L

(Bottom Lock).

5. Press ▼ to send the cursor to the second

line (Range or B/L).

sounds and the alarm icon

and the indica-

tion TEMP appears on the display. The indication remains on the display until the

temperature is no longer in the alarm range.

6. Key in the depth desired.

7. Press the ENT key.

8. Press the MENU key.

3.18 Bottom Alarm

The bottom alarm sounds when the seabed

depth is narrower than the alarm range set.

When the bottom echo enters the alarm range

set the audible alarm sounds and the alarm

icon

and the indication DEPTH appears.

You can silence the audible alarm with the

CLR key . The DEPTH indication remains on

the screen until the bottom echo goes out of

the alarm range.

1. Press the MENU key.

2. Press the [5] key to select ALARM

SETUP.

3. Press ▼ to select BOTTOM on page 2.

4. Press t to select ON.

5. Press ▼ to send the cursor to the fourth

line (Range).

6. Key in the range desired.

7. Press the ENT key.

8. Press the MENU key.

3.19 Water Temperature Alarm

The water temperature alarm sounds when the

water temperature is within (or over) the preset temperature range. This alarm is useful for

searching for specific species of fish, since

each species of fish has its own habitable water

temperature. (This alarm requires connection

of a water temperature sensor.)

When the water temperature becomes within

(or over) the alarm range the audible alarm

1. Press the MENU key.

2. Press the [5] key to select ALARM

SETUP.

3. Press ▲ or ▼ to select TEMP.

4. Press s or t to select WITHIN or

OVER.

5. Press ▼ to send the cursor to the eighth

line (Temp).

6. Key in the temperature desired.

7. Press the ENT key.

8. Press the MENU key.

3.20 Turning On/Off the

Expansion Range Marker

The expansion range marker appears in the

normal display picture in the bottom marker

and bottom zoom displays and marks the area

which is expanded in the bottom marker and

bottom zoom pictures. You may turn the

marker on or off as follows:

Fish school

Normal

200k

50

100

150

200

2D

13:41

0

display

VRM

(white)

This part

is zoomed.

Expansion

range

marker

(yellow)

Marker zoom

display

162

CSE 180.0° SPD 16.8kt

DEP 162m TMP 16.0 °C

POS 34° 26.245' N 135° 41.232' E

200

100

150

Fish

school

90.0

Figure 3-19 Marker zoom display

1. Press the MENU key.

2. Press the [0] key to select SYSTEM

MENU.

3. Press the [3] key to display the

SOUNDER SETUP menu.

3-8

Page 52

SNDR SETUP

EXP MARKER

GAIN ADJ

50k

200k

BTM-LOCK

TRANSMIT

: Cursor

ESC: Esc

ON OFF

(-20~+20)

+00

+00

NARROW WIDE

ON OFF

Figure 3-20 Sounder setup menu

4. Operate the Cursor Pad to select EXP

MARKER.

5. Operate the Cursor Pad to select ON or

OFF.

6. Press the MENU key.

3.22 Selecting Bottom-Lock Expansion Width

The expansion width for the bottom-lock display can be selected to narrow (5 meters) or

wide (10 meters) as follows:

1. Press the MENU key.

2. Press the [0] key to select SYSTEM

MENU.

3. Press the [3] key to display the

SOUNDER SETUP menu.

4. Operate the Cursor Pad to select BTM-

LOCK.

5. Operate the Cursor Pad to select NAR-

ROW or WIDE.