Page 1

Back

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

x

A

A

*00080637800**00080637800*

*00080637800**00080637800*

*OME23520L10**OME23520L10*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

faxfa

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. OME-23520OME-23520

0798-65-42000798-65-4200

::

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : OCT.OCT. 19941994

L1L1 :: DEC.DEC. 24,200324,2003

(( TENITENI ))

FCV-292FCV-292

* 0 0 0 8 0 6 3 7 8 0 0 ** 0 0 0 8 0 6 3 7 8 0 0 *

*OME23520L10**OME23520L10*

* O M E 2 3 5 2 0 L 1 0 ** O M E 2 3 5 2 0 L 1 0 *

Page 3

Page 4

SAFETY INFORMATION

FOR THE OPERATOR

WARNING

Do not open the cover of

the equipment.

This equipment uses high voltage

electricity which can shock, burn,

or cause death.

Only qualified personnel should

work inside the equipment.

Do not dissasemble or modify the

equipment.

Fire, electrical shock or serious injury can result.

Immediately turn off the power at the

ship's mains switchboard if water or

foreign object falls into the equipment

or the equipment is emitting smoke or

fire.

Continued use of the equipment can cause fire,

electrical shock or serious injury.

CAUTION

Do not place liquid-filled containers

on the top of the equipment.

Fire or electrical shock can result if a liquid

spills into the equipment.

Do not place heater near the equipment.

Heat can melt the power cord, which can

result in fire or electrical shock.

Do not operate the unit with wet hands.

Electrical shock can result.

Use the correct fuse.

Use of the wrong fuse can cause fire or

equipment damage.

(Continued on next page)

ii

Page 5

Page 6

SAFETY INFORMATION

FOR THE INSTALLER

WARNING

Only qualified personnel

should work inside the

equipment.

This equipment uses high voltage

electricity which can shock, burn,

or cause death.

Turn off the power at the ship's mains

switchboard before beginning the

installation. Post a warning sign near

the switchboard to ensure that the

power will not be applied while the

equipment is being installed.

Serious injury or death can result if the power is

not turned off, or is applied while the equipment

is being installed.

CAUTION

Ground the equipment to

prevent electrical shock and

mutual interference.

Ungrounded equipment can give

off or receive electro-magnetic

interference or cause electrical

shock.

Confirm that the power supply voltage

is compatible with the voltage rating

of the equipment.

Connection to the wrong power supply can

cause fire or equipment damage. The voltage

rating appears on the label at the rear of the

equipment.

NOTICE

The mounting location must satisfy the

following conditions:

Away from rain and water splash

Out of direct sunlight

Away from air conditioner vents

Away from magnets and magnetic fields

Moderate and stable in temperature and

humidity

iv

Page 7

Page 8

Page 9

Table of Contents

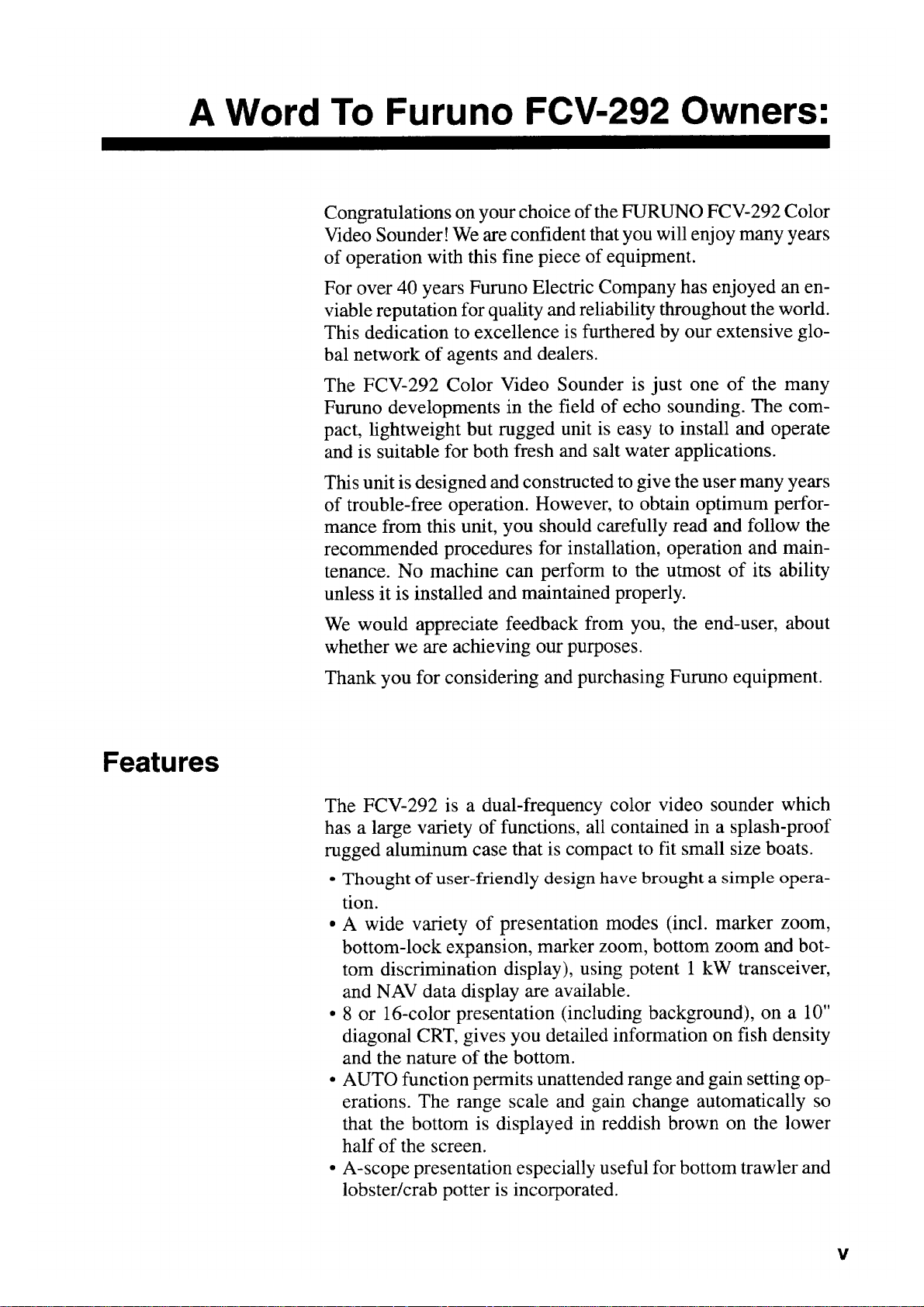

A Word To Furuno FCV-292 Owners:..................................................................i

Features................................................................................................................................i

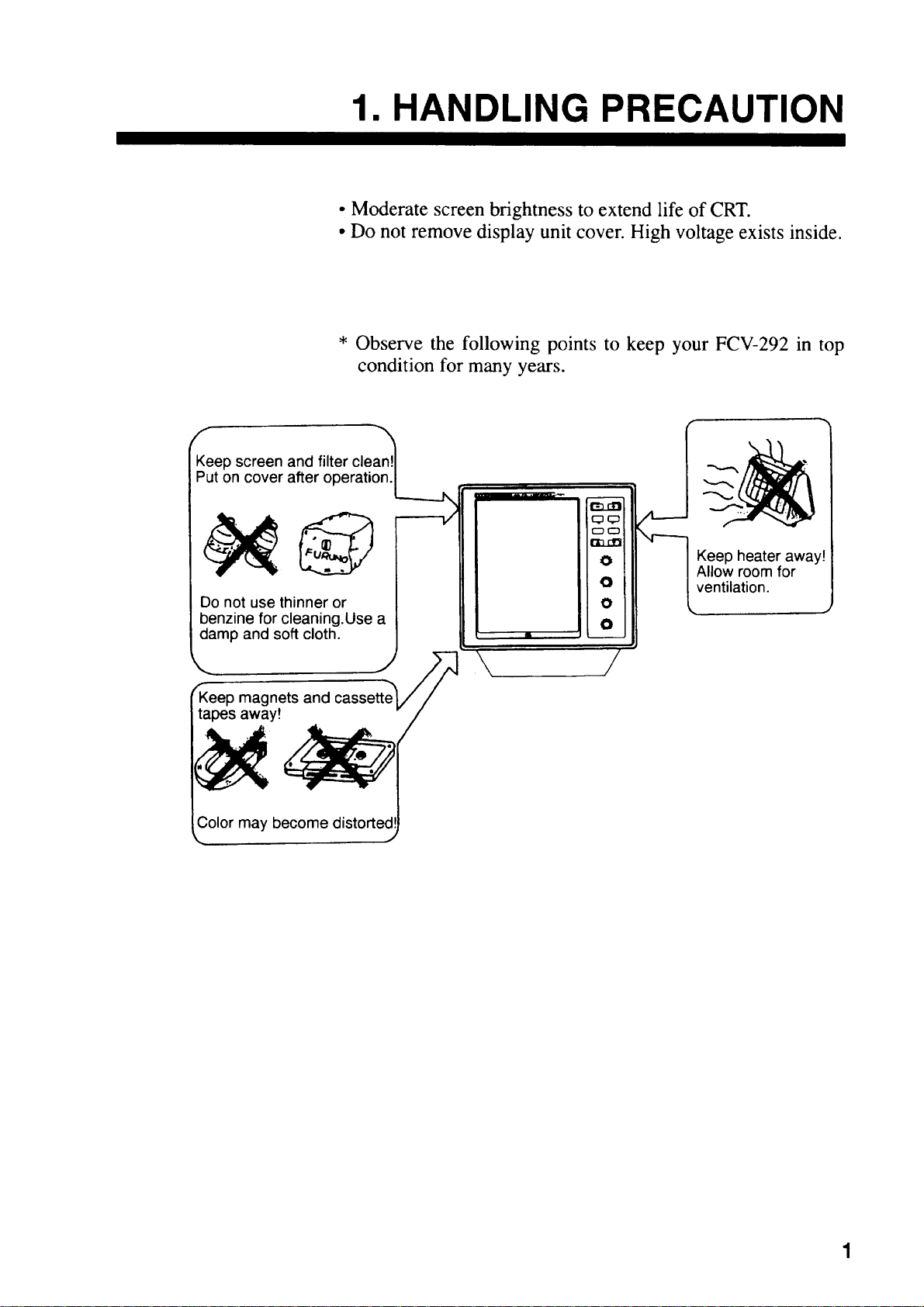

1.HANDLING PRECAUTION................................................................................1

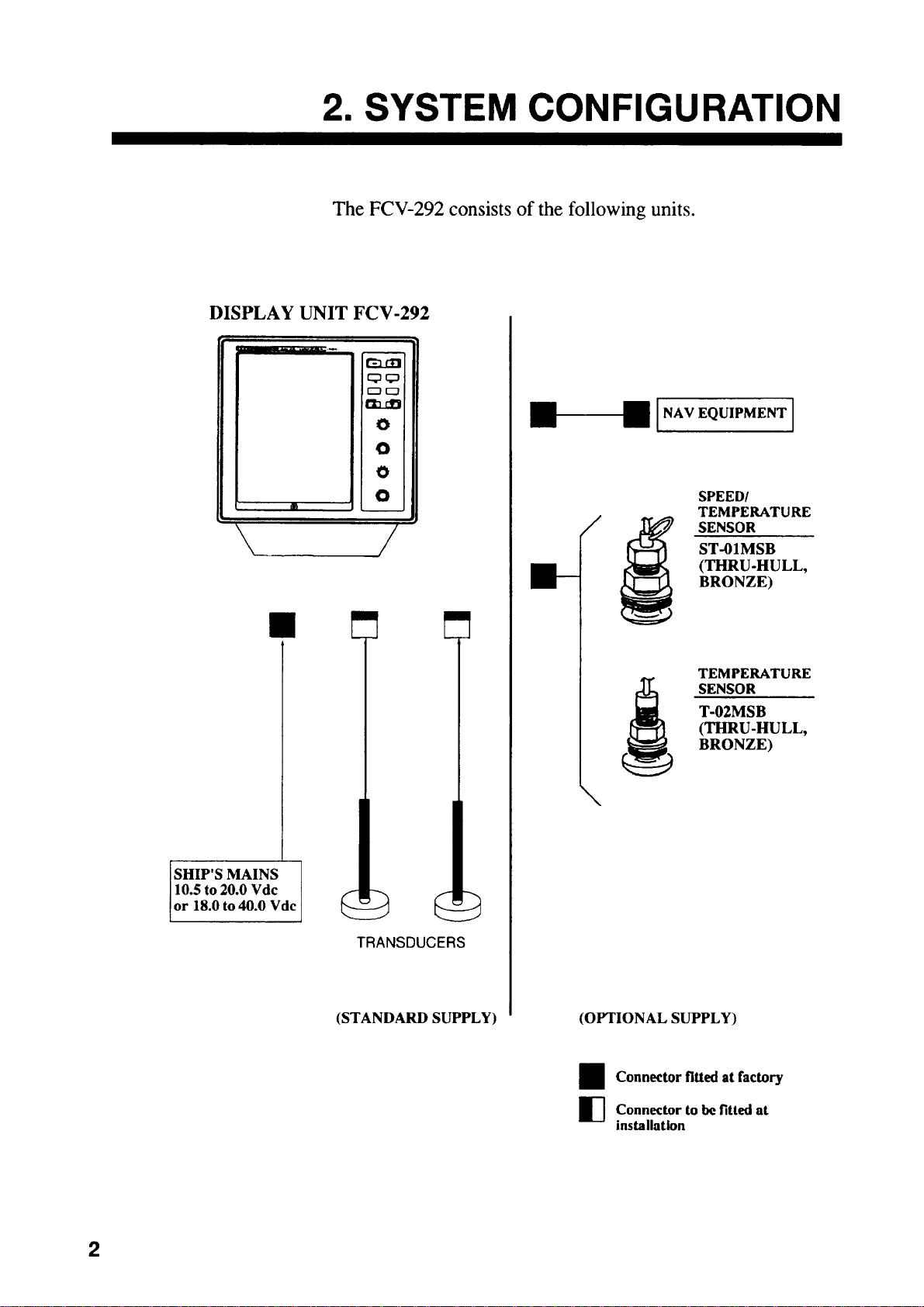

2.SYSTEM CONFIGURATION.............................................................................. 2

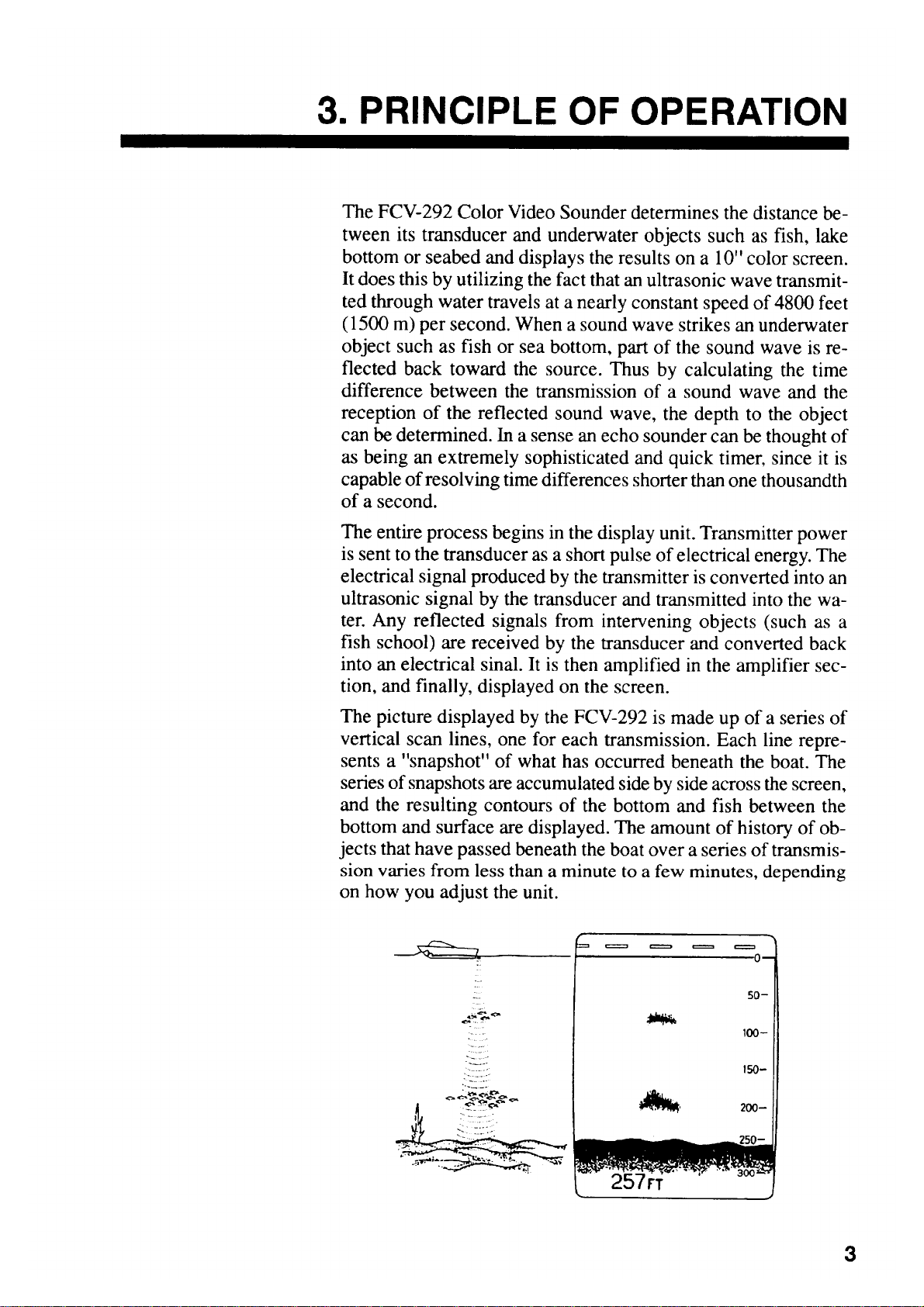

3.PRINCIPLE OF OPERATION ............................................................................3

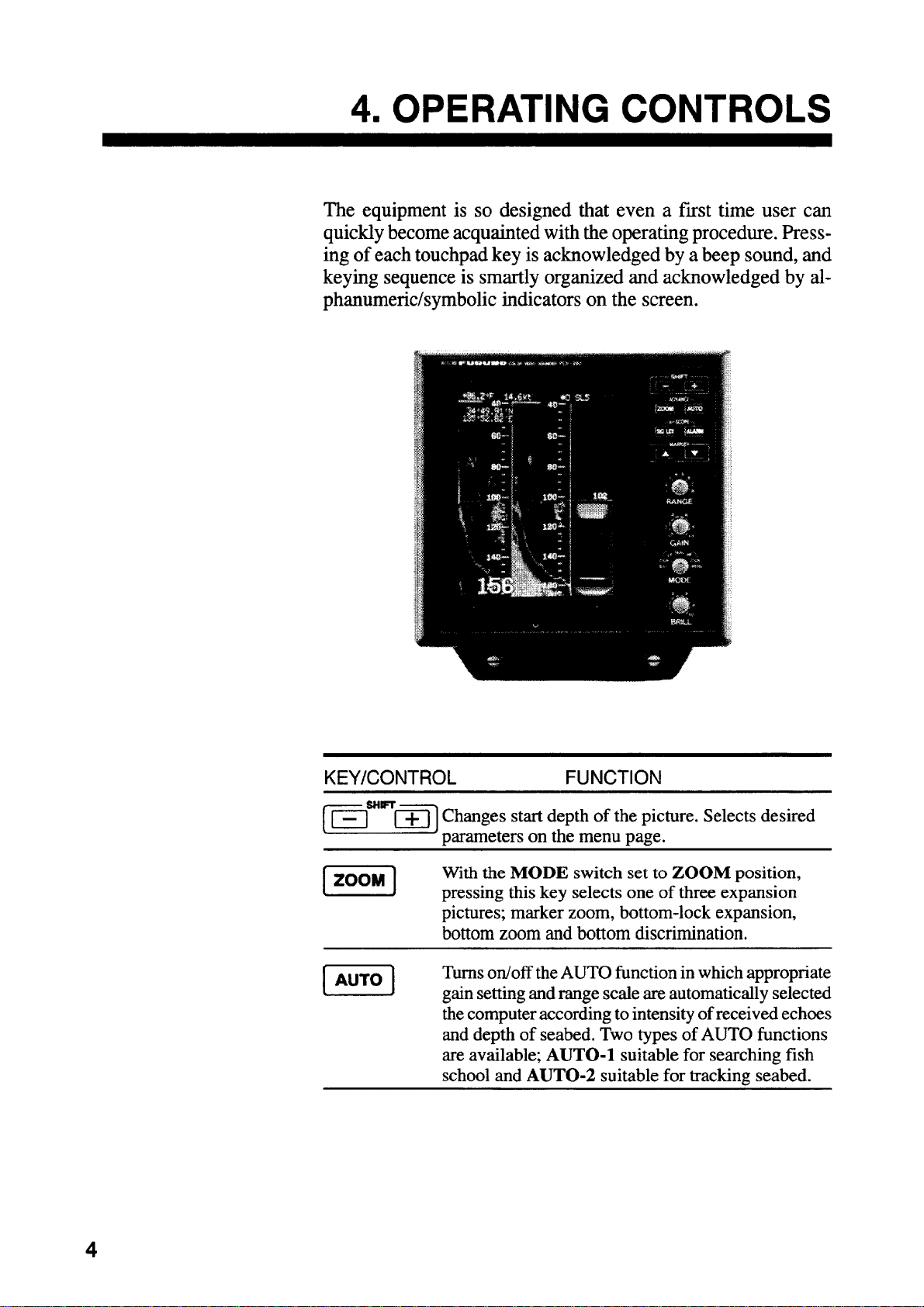

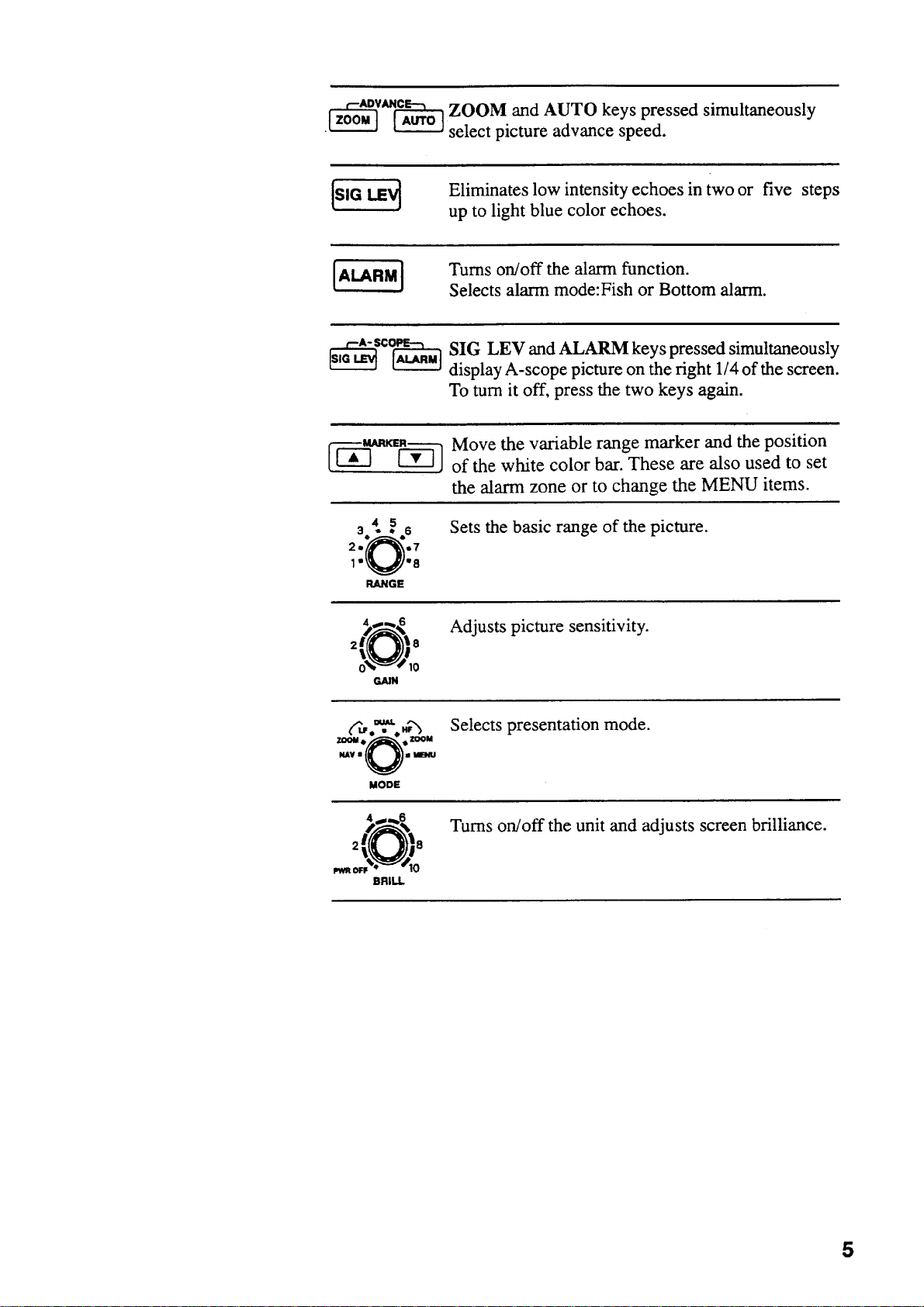

4.OPERATING CONTROLS .................................................................................4

5.BASIC OPERATION ..........................................................................................6

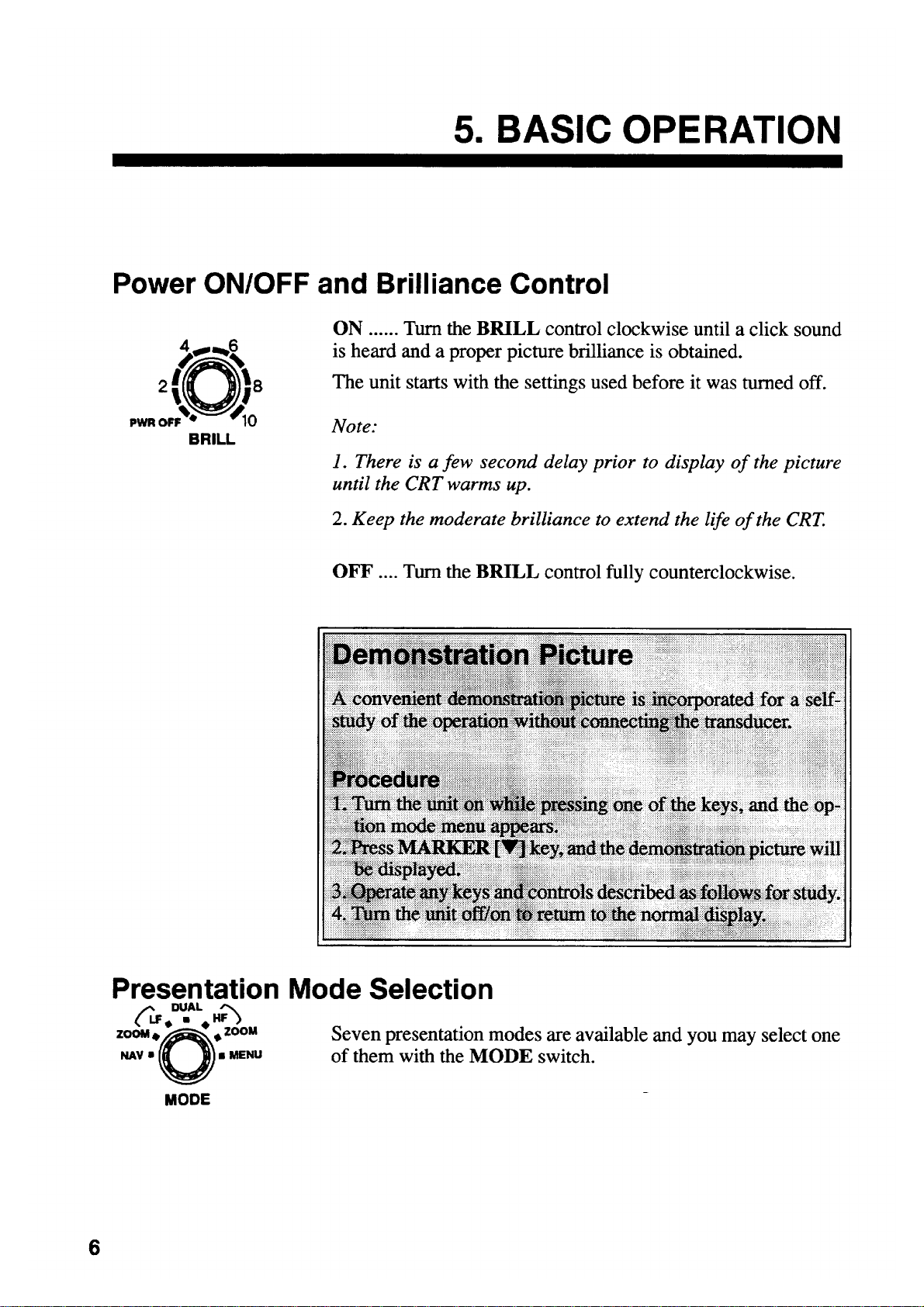

Power ON/OFF and Brilliance Control...................................................................................6

Demonstration Pictur e ...........................................................................................................6

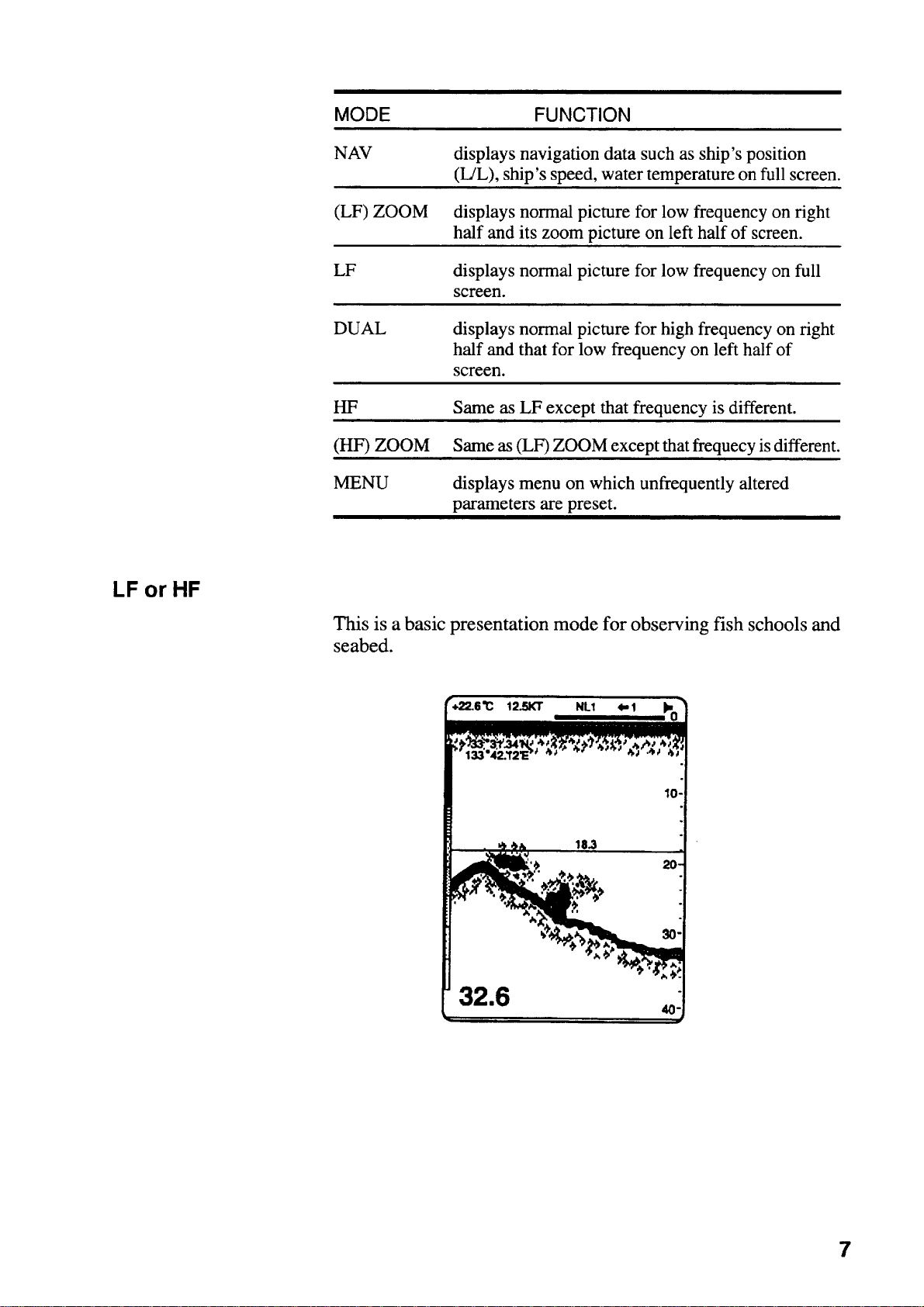

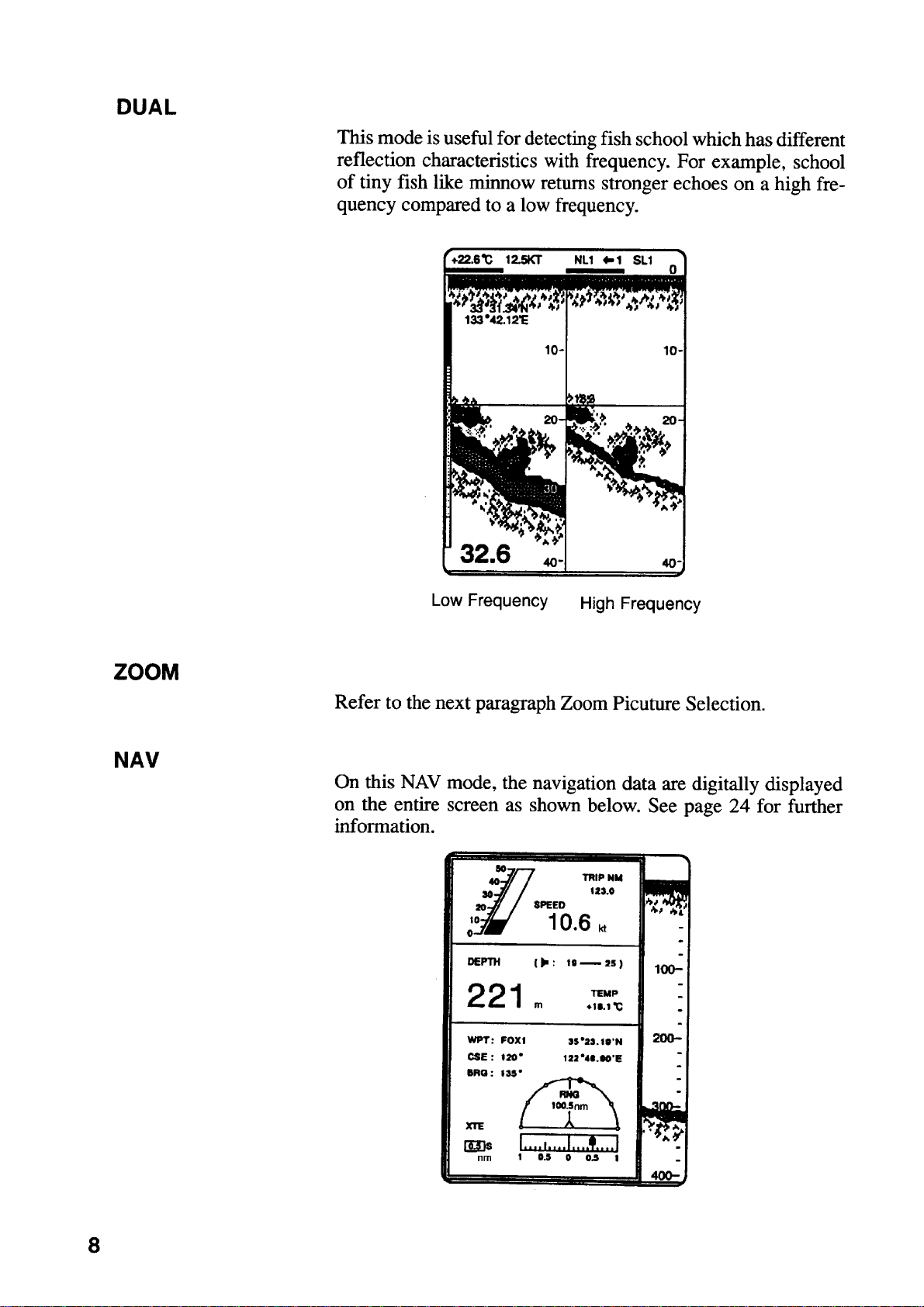

Presentation Mode Selection................................................................................................6

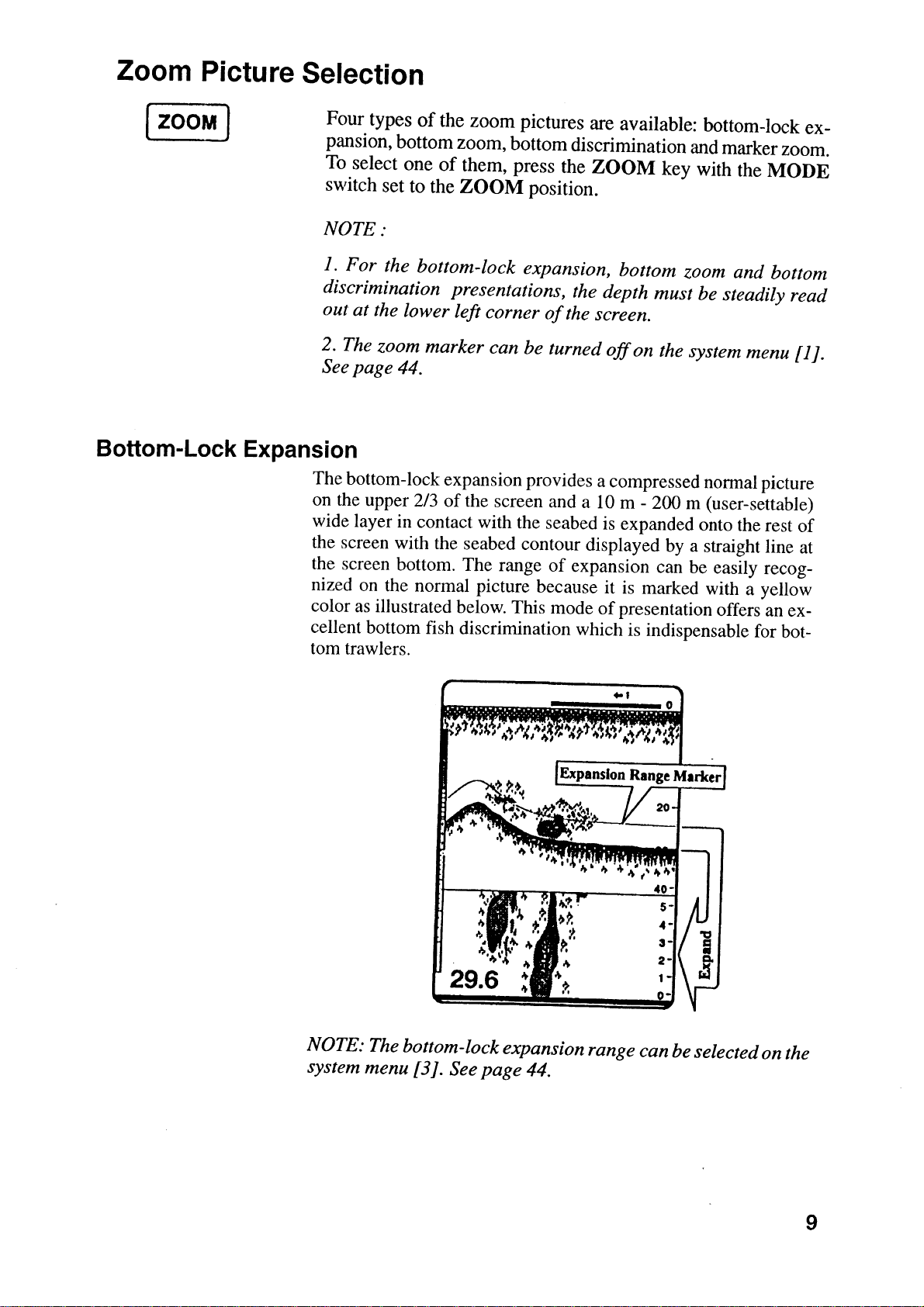

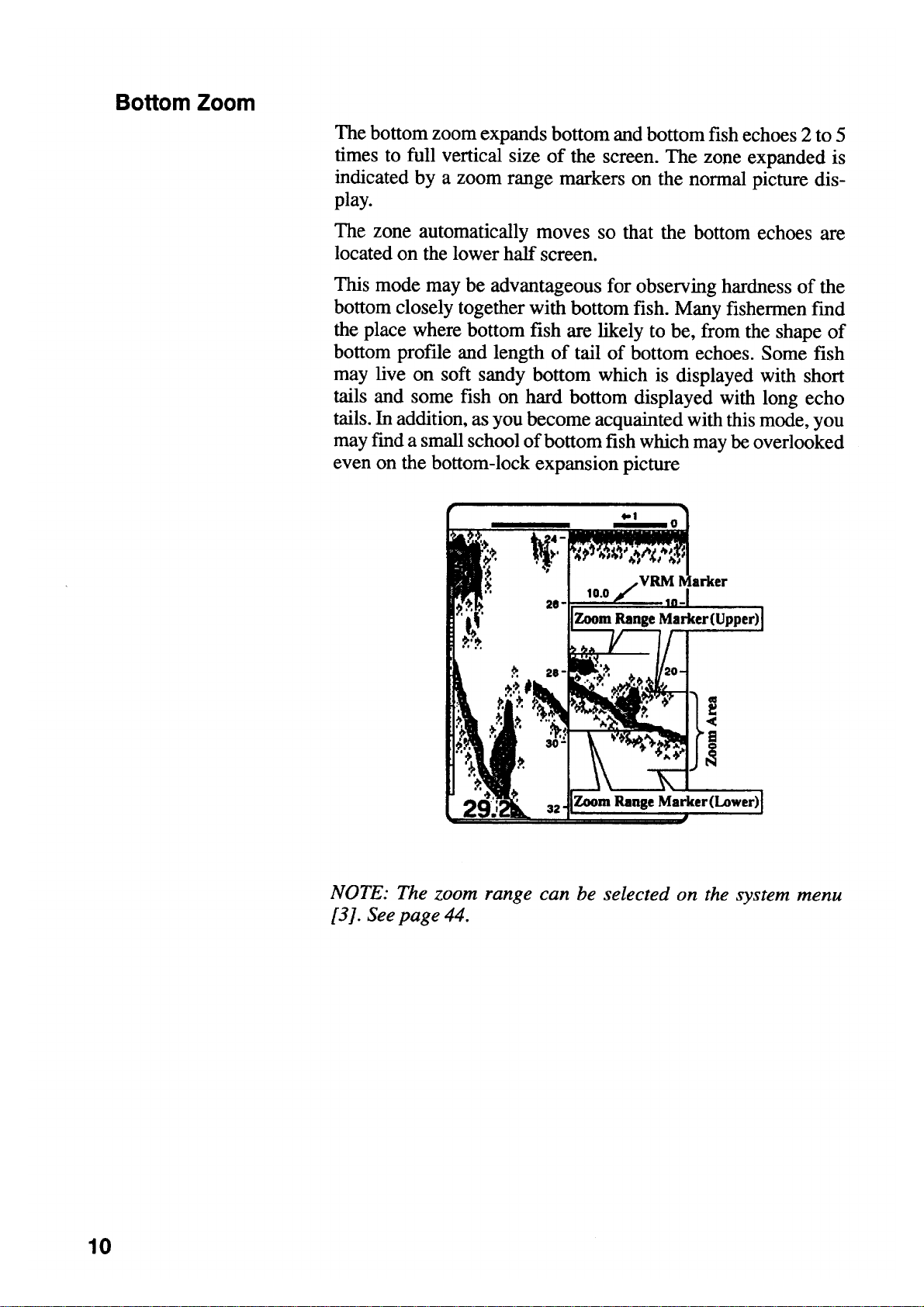

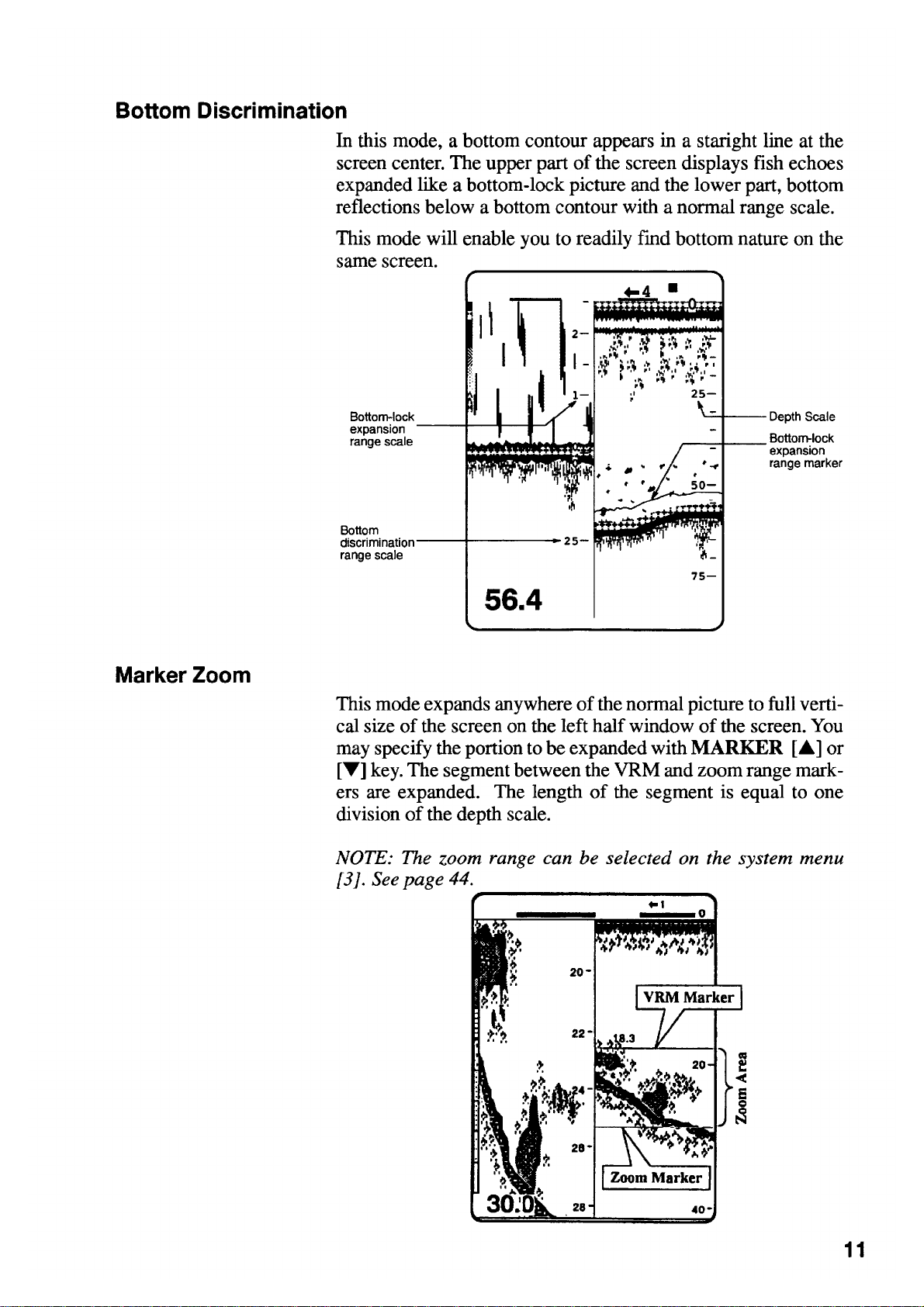

Zoom Pictur e Selecti on.........................................................................................................9

Automatic Operation........................................................................................................... 12

Manual Operation ...............................................................................................................12

Picture Advance Speed Selection....................................................................................... 14

Eliminating Low Intensity Echoes........................................................................................15

Turning on A-Scope Presentation .......................................................................................15

Measuring Depth to Fish School.........................................................................................15

6.FISH AND BOTTOM ALARMS........................................................................ 16

7.ADJUSTING PICTURE BY MENU ..................................................................18

Eliminating Interference (NOISE LIMITER).........................................................................18

Eliminating Low Level Noise (CLUTTER LEVEL)................................................................19

Adjusting Preset Gain.........................................................................................................19

Selecting Background Color and Echo Color (HUE SELECTION).......................................20

8.DISPLAYS ........................................................................................................21

Video Sounder Picture........................................................................................................21

Navigation Data..................................................................................................................24

9.INTERPRETING THE DISPLAY ...................................................................... 25

Frequency...........................................................................................................................25

Detecting Area....................................................................................................................25

Zero Line ............................................................................................................................26

Fish School Echoes............................................................................................................ 27

Bottom Echo.......................................................................................................................27

Surface Noise/Aeration....................................................................................................... 28

vii

Page 10

10.MAINTENANCE............................................................................................. 29

Fuse Replacement..............................................................................................................29

Cleaning ..............................................................................................................................29

Maintenance of Transducer.................................................................................................30

11.TROUBLESHOOTING ...................................................................................31

Basic Troubleshooting.........................................................................................................31

Diagnostic Self-Check.........................................................................................................33

Transducer Check...............................................................................................................34

Speed/Temperature Sensor (Option) Check........................................................................34

12.INSTALLATION..............................................................................................35

Display Unit Installation.......................................................................................................35

Transducer Installation........................................................................................................37

Tr ansd ucer Pr ep ar ation and Painti n g..................................................................................37

Speed/Temperature Sensor.................................................................................................38

Cable Connections..............................................................................................................39

13.SYSTEM MENU SETTING............................................................................. 41

Operation Procedure...........................................................................................................41

Descriptio n of Syst em Menu It em........................................................................................42

Restoring Factory Settings..................................................................................................44

14.SPECIFICATIONS.......................................................................................... 45

Complete Set.......................................................................................................................47

Installation Materials............................................................................................................48

Accessories.........................................................................................................................48

Spare Parts.........................................................................................................................48

Option..................................................................................................................................48

Transducer & Hull Bottom Installation Materials...................................................................49

APPENDIX

1. Changing T r a nsd ucer Ou tp ut Power Se tti n g.......................................................................A-1

2. Changing Transducer Frequency Specifications.................................................................A-2

3. Adjustment After Replacement of MAIN or AMP Board (entering amplifier

gain offset) ..........................................................................................................................A-4

4. Transducer 50BL-12/50BL-24H...........................................................................................A-6

5. New BLT Transducers.........................................................................................................A-7

OUTLINE DRAWING................................................................................ D-1

INTERCONNECTION DIAGRAM........................................................................... S-1

viii

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

4.Transducer 50BL-1 2/50B L- 24H

When using the transduce r 50B L-12/50B L- 24H, see thi s s ec tion.

50BL-12 cod e no.: 000-015-013

50BL-24H co de no.: 000-015-040

Transducer, thru-hull pipe and tank list

Frequency

(kHz)

50

50/200 50BL-12/200B-8B

28/50 28F-24H/50BL-24H

50/88 50BL-24H/88F-126H

Transducer

(Code No.)

50BL-12

50BL-24H

Material

Steel

FRP

Steel

FRP

Steel

FRP

Steel

FRP

Steel

FRP

Hull

Tank

(Code No.)

T-702

(000-015-041)

T-702F

(000-015-240)

T-694

(000-015-046)

T-694F

(000-015-242)

T-693

(000-015-044)

T-693F

(000-015-241)

T-696

(000-015-048)

T-696F

(000-015-244)

T-697

(000-015-239)

T-697F

(000-015-245)

Fasten inside

hull (Code No.)

TFB-5000

(000-015-206)

TRB-1000

(000-015-215)

TFB-5000

(000-015-206)

TRB-1000

(000-015-215)

TWB-6000

(000-015-207)

TRB-1100

(000-015-218)

TWB-6000

(000-015-207)

TWB-1100

(000-015-218)

TWB-6000

(000-015-207)

TWB-1100

(000-015-218)

Fasten outside

hull (Code No.)

-

-

TFB-4000

(000-015-205)

-

TWB-7000

(000-015-209)

-

TFB-7000

(000-015-209)

-

TFB-7000

(000-015-209)

-

Steel

50/200 50BL-24H/200B-12H

FRP

T-695

(000-015-047)

T-695F

(000-015-243)

TWB-6000

(000-015-207)

TRB-1100

(000-015-218)

(000-015-209)

Setting

For the loc ations of JP10 and J P 11, see page A -1.

Board Frequency (kHz) Output (kW) Transducer JP10 and JP11 setting

2 5BL-12 B 02P6204

50

MAIN

3 50BL-24H D

S1

Board Frequency (kHz)

1 2 3 4

28/50 ON ON ON ON

02P6204

50/88 ON OFF ON OFF

MAIN

50/200 ON OFF OFF ON

TFB-7000

-

A-6

Page 65

5.New BLT Transducers

A new type BLT transducer (Bolt-clam p Langevin Transducer) has been developed for this

echo sounder. The BLT transducer has large bandwidth, good sound efficiency, compact

structure and is reinfor c ed for protection against slam m ing.

28BL-6HR co de no.: 000-015-081

28BL-12HR c ode no.: 000-015-082

38BL-9HR co de no.: 000-015-083

38BL-15HR c ode no.: 000-015-092

50BL-12HR c ode no.: 000-015-093

50BL-24HR c ode no.: 000-015-094

Transducer, thru-hull pipe and tank list

Frequency

(kHz)

28/200 28BL-6HR/200B-8B

38/200 38BL-9HR/200B-8B

50/200 50BL-12HR/200B-8B

28/38 28BL-12HR/38BL-15HR

28/50 28BL-12HR/50BL-24HR

Transducer

Hull

Material

Steel

FRP

Steel

FRP

Steel

FRP

Steel

FRP

Steel

FRP

Tank

(Code No.)

T-693

(000-015-044)

T-693F

(000-015-241)

T-693

(000-015-044)

T-693F

(000-015-241)

T-693

(000-015-044)

T-693F

(000-015-241)

T-681

(000-015-849)

T-681F

(000-015-850)

T-681

(000-015-849)

T-681F

(000-015-850)

Fasten inside

hull (Code No.)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

Fasten outside

hull (Code No.)

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

Steel

38/50 38BL-15HR/50BL-24HR

FRP

Steel

28/88 28BL-12HR/88F-126H

FRP

T-681

(000-015-849)

T-681F

(000-015-850)

T-682

(000-015-851)

T-682F

(000-015-852)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

A-7

Page 66

NEW BLT TRANSDUCERS

Steel

38/88 38BL-15HR/88F-126H

FRP

Steel

50/88 50BL-24HR/88-126H

FRP

Steel

28/200 28BL-12HR/200B-12H

FRP

Steel

38/200 38BL-15HR/200B-12H

FRP

Steel

50/200 50BL-24HR/200B-12H

FRP

T-682

(000-015-851)

T-682F

(000-015-852)

T-682

(000-015-851)

T-682F

(000-015-852)

T-683

(000-015-853)

T-683F

(000-015-854)

T-683

(000-015-853)

T-683F

(000-015-854)

T-683

(000-015-853)

T-683F

(000-015-854)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

28/150 28BL-12HR/150B-12H

38/150 38BL-15HR/150-12H

38/150 50BL-24HR/156-12H

Steel

FRP

Steel

FRP

Steel

FRP

T-683

(000-015-853)

T-683F

(000-015-854)

T-683

(000-015-853)

T-683F

(000-015-854)

T-683

(000-015-853)

T-683F

(000-015-854)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-219)

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

A-8

Page 67

NEW BLT TRANSDUCERS

A

Setting

For the locations of JP10 and JP11, see page A-1.

Board Fr equency (kHz) O u t put (kW) Transducer JP10 and JP11 setting

28

02P6204

MAIN

38

50

Board Frequency (kHz)

28/50 ON ON ON ON

02P6204

MAIN

38/50 OFF ON ON ON

50/88 ON OFF ON OFF

50/200 ON OFF OFF ON

2 28BL-6HR B

3 28BL-12HR C

2 38BL-9HR C

3 38BL-15HR E

2 50BL-12HR D

3 50BL-24HR E

S1

1 2 3 4

-9

Page 68

Page 69

321

Oct. 1, '02

S-1

A

B

C

指示器

DISPLAY UNIT

CV‑291/292

NMEA

J4

TXD‑H

TXD‑C

RXD‑H

RXD‑C

NC

SHIELD

SPEED/TEMP

J5

GND

VTH‑H

VTH‑C

SPD

+10V

POWER

J3

(+)

(‑)

GND

MJ‑A6SPFD

1

2

3

4

5

6

MJ‑A6SPFD

1

2

3

4

5

6

MJ‑A3SPFD

1

2

3

MJ‑A6SPF0012,5m

P

P

8m

P

FUSE

7A: 12V

3A: 24/32V

シロ WHT

クロ BLK

航法装置

NAV AID

船速・水温センサー

SPEED/TEMP SENSOR

ST‑01MSB

T‑02MSB

MJ‑A3SPF0013,3.5m,φ6

船内電源

SHIP'S MAINS

12/24‑32 VDC

D

DRAWN

Sep. 30 '02

CHECKED

Oct. 1 '02

APPROVED

SCALE

DWG.No.

J1 J2

*3

注記

*1)造船所手配

*2)工場にて接続済み

*3)FCV‑292のみ

T.YAMASAKI

Y.KIMURA

MASS

kg

C2351‑C01‑ F

TX‑HTX‑L

NCS‑254PNCS‑254P

送受波器送受波器

XDCRXDCR

NOTE

*1: SHIPYARD SUPPLY.

*2: FITTED AT FACTORY.

*3: ONLY FOR FCV‑292.

GND

IV‑2.0SQ

21

整流器

RECTIFIER

PR‑62

56

43214321

DPYC‑1.5 *1

100/110/220 VAC

50/60 Hz, 1φ

TITLE

名称

FCV‑291/292

カラー魚群探知機

相互結線図

NAME

COLOR VIDEO SOUNDER

INTERCONNECTION DIAGRAM

Loading...

Loading...