Page 1

Installation Manual

COLOR LCD SOUNDER

FCV-1200L/FCV-1200LM

SAFETY INSTRUCTIONS .......................................................................... i

SYSTEM CONFIGURATION .................................................................... iii

EQUIPMENT LISTS .................................................................................. v

1. MOUNTING

1.1 Monitor Unit, Control Unit .........................................................................................1-1

1.2 Processor Unit.......................................................................................................... 1-8

1.3 Interface Unit............................................................................................................1-9

1.4 Transducer ............................................................................................................... 1-9

1.5 Water Temperature Sensor (option)..........................................................................1-9

1.6 Booster Box (option)...............................................................................................1-10

2. WIRING

2.1 Wiring Standard Equipment ...................................................................................... 2-5

2.2 Wiring Optional Equipment.......................................................................................2-8

2.3 Input/Output Sentences..........................................................................................2-10

3. INITIAL SETTINGS

3.1 Language Setting ..................................................................................................... 3-1

3.2 Display Type............................................................................................................. 3-2

3.3 Transducer Data (FCV-1200L only) .......................................................................... 3-3

3.4 Adjustment for Transceiver Unit, Video Sounder, Telesounder, Picture Recorder ..... 3-7

3.5 Water Temperature Sensor Setting.........................................................................3-12

3.6 Net Sonde Setting .................................................................................................. 3-14

3.7 Nav Data, Heading Sensor Setting.........................................................................3-16

3.8 Stabilization (heaving compensation)......................................................................3-18

3.9 Propagation Velocity...............................................................................................3-19

3.10 Demonstration Mode.............................................................................................. 3-20

3.11 Restoring Default Settings...................................................................................... 3-21

3.12 DIP Switch Setting .................................................................................................3-22

APPENDIX 1 TRANSDUCER 50BL-12/50BL-24H.............................. AP-1

APPENDIX 2 BLT TRANSDUCERS.................................................... AP-2

APPENDIX 3 TRANSDUCER 82B-35R............................................... AP-4

PACKING LISTS ................................................................................... A-1

OUTLINE DRAWINGS .......................................................................... D-1

INTERCONNECTION DIAGRAMS.........................................................S-1

www.furuno.co.jp

Page 2

9-52 Ashihara-cho,

*

00080900712

**00080900712

*

Nishinomiya, 662-8580, JAPAN

Telephone : +81-(0)798-65-2111

Fax :+81-(0)798-65-4200

The paper used in this manual

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

Pub. No. IME-23650-T1

(YOSH ) FCV-1200L/LM

Printed in Japan

A : APR 2000

.

T1 : JUN . 18, 2007

*00080900712**00080900712*

* 0 0 0 8 0 9 0 0 7 1 2 *

Page 3

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

should work inside the

equipment.

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can result in fire,

electrical shock or equipment damage.

WARNING

Install the transducer according

to the installation instructions.

Failure to install the transducer correctly

may result in water leakage and damage to

the ship's hull.

For wooden or FRP vessel using a steel

tank, attach a zinc plate to the hull to

prevent electrolytic corrosion.

Electrolytic corrosion can, in the worst

case, result in loss of the transducer.

Be sure no water leaks in at the transducer mounting location.

Water leakage can sink the vessel. Also,

confirm that the transducer will not loosen

by ship's vibration. The installer of the

equipment is solely responsible for the

proper installation of the equipment.

FURUNO will assume no responsibility for

any damage associated with improper

installation.

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

i

Page 4

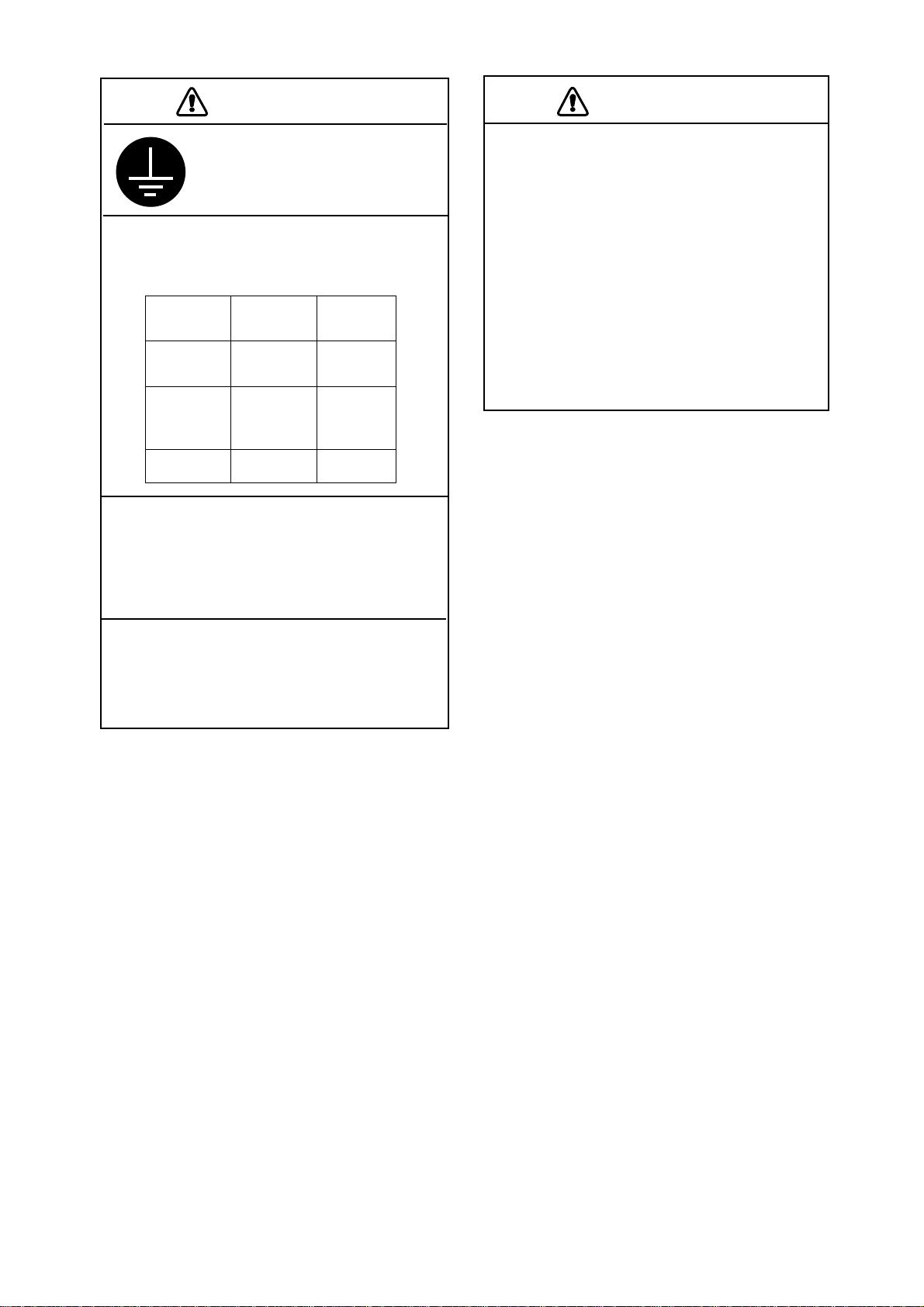

CAUTION

CAUTION

Ground the equipment to

prevent mutual interference.

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

CV-1201

CV-1202

CV-1203

CV-1203M

MU-101C

IF-8000

Standard

compass

0.3 m 0.2 m

0.75 m 0.5 m

0.95 m 0.65 m

Steering

compass

Do not allow warm water or any other

liquid other than seawater or freshwater

to contact the transducer.

The transducer cable must he handled

carefully, following the guidelines

below.

• Keep fuels and oils away from the

cable.

• Locate the cable where it will not be

damaged.

• The cable sheath is made of chloro phrene or polychloride vinyl, which

are easily by damaged plastic solvents

such as toulene. Locate the cable

well away from plastic solvents.

Damage to the transducer may result.

Do not install the transducer where

noise or air bubbles is present.

Performance will be affected.

ii

Page 5

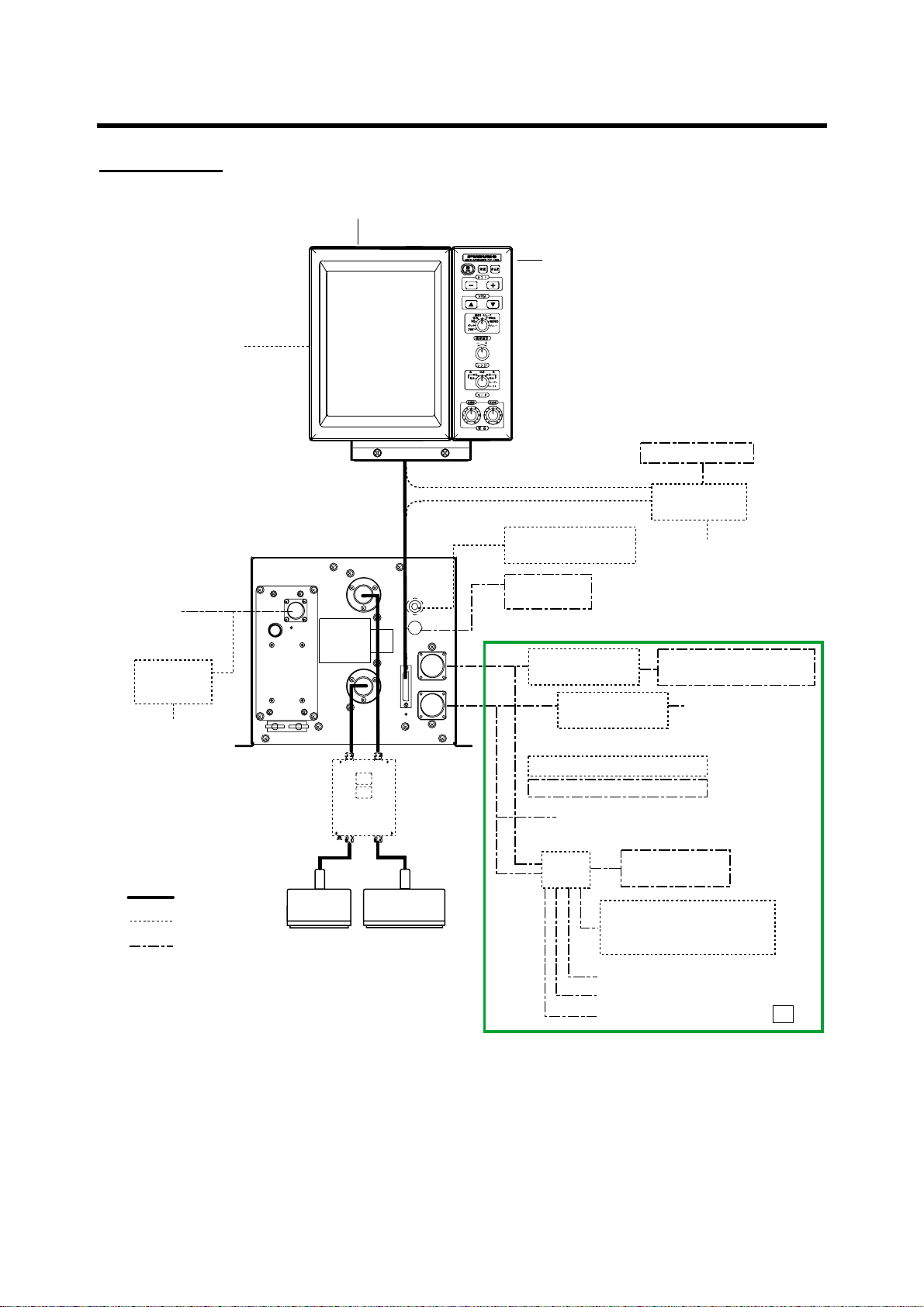

SYSTEM CONFIGURATION

Standard type

MONITOR UNIT MU-101C

CONTROL UNIT

CV-1201: Portrait type

CV-1202: Landscape type

Navigator *4

Ship's Mains

12-24 VDC

Rectifier

RU-1746B-2

100/110/115/200/

220/230 V AC

1φ, 50/60 Hz

NMEA 0183

PROCESSOR UNIT

CV-1203 (FCV-1200L)

CV-1203M (FCV-1200LM)

Booster Box

BT-5

: Standard

: Option

: Local Supply

Low

Frequency

Transducer*1

HI

LO

High

Frequency

Transducer*1

Water Temp. Sensor

(T-02MSB, etc.)

Net Sonde

FNZ-18

E/S Interface

VI-1100A

E/S Interface

VI-1100A

OR

Transceiver Unit ETR-5D/10D

T elesounder TS-7000/8000 *3

Same as above

OR

Switch Box

EX-7

Picture Recorder

E/S Interface VI-1100A

Transmitter Unit ETR-5D/10D

External Monitor

Interface Unit

IF-8000

Navigator *4

Sonar, Net Recorder,

Telesounder TS-50/80 *3

Same as above

MT-12

OR

*1: FCV-1200L only

*2: EXIF Assy. required for FCV-1200L.

*3: For sister ship one unit only

Sister ship: EXIF Assy. required for FCV-1200L

Master ship: FCV-1200LM or FCV-1200L equipped with EXIF Assy.

*4: Navigator may be connected to interface unit or monitor unit.

iii

Same as above

Same as above

Same as above

*2

Page 6

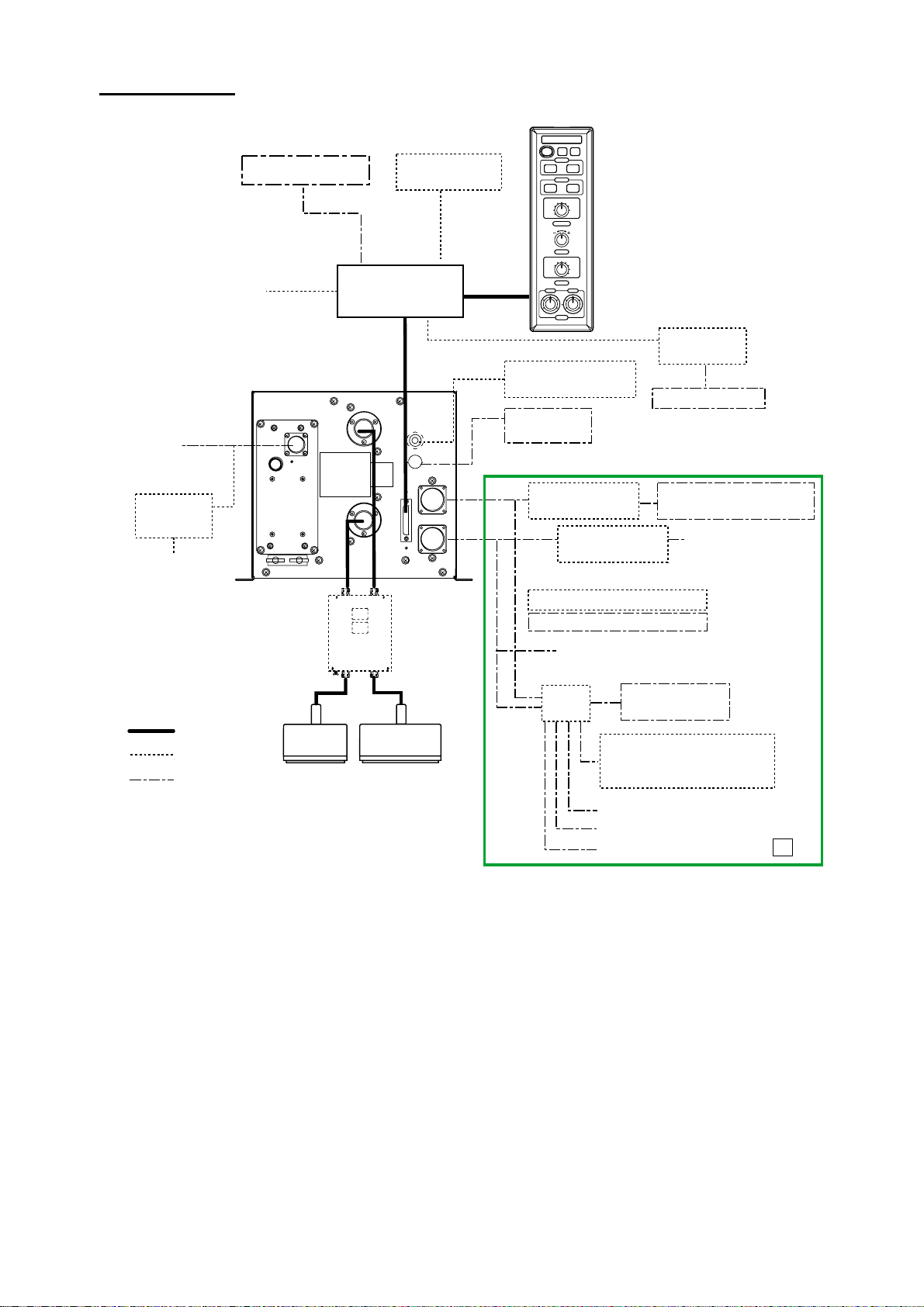

Blackbox type

Ship's Mains

12-24 VDC

Rectifier

RU-1746B-2

100/110/115/200/

220/230 V AC

1φ, 50/60 Hzz

External Monitor

Navigator

PROCESSOR UNIT

CV-1203 (FCV-1200L)

CV-1203M (FCV-1200LM)

: Standard

: Option

: Local Supply

NMEA 0183

Booster Box

BT-5

Low

Frequency

Transducer*1

MONITOR UNIT

MU-101C

Interface Unit

IF-8000

HI

LO

High

Frequency

Transducer*1

CONTROL UNIT

*4

Water Temp. Sensor

(T-02MSB, etc.)

Net Sonde

FNZ-18

E/S Interface

VI-1100A

OR

Transceiver Unit ETR-5D/10D

T elesounder TS-7000/8000 *3

OR

Switch Box

EX-7

CV-1201: Portrait type

CV-1202: Landscape type

E/S Interface

VI-1100A

Same as above

Picture Recorder

E/S Interface VI-1100A

Transmitter Unit ETR-5D/10D

Interface Unit

IF-8000

External Monitor

Sonar, Net Recorder,

Telesounder TS-50/80 *3

Same as above

MT-12

OR

*1: FCV-1200L only

*2: EXIF Assy. required for FCV-1200L.

*3: For sister ship one unit only

Sister ship: EXIF Assy. required for FCV-1200L

Master ship: FCV-1200LM or FCV-1200L equipped with EXIF Assy.

*4: When connecting optional monitor unit, connect it to control unit.

iv

Same as above

Same as above

Same as above

*2

Page 7

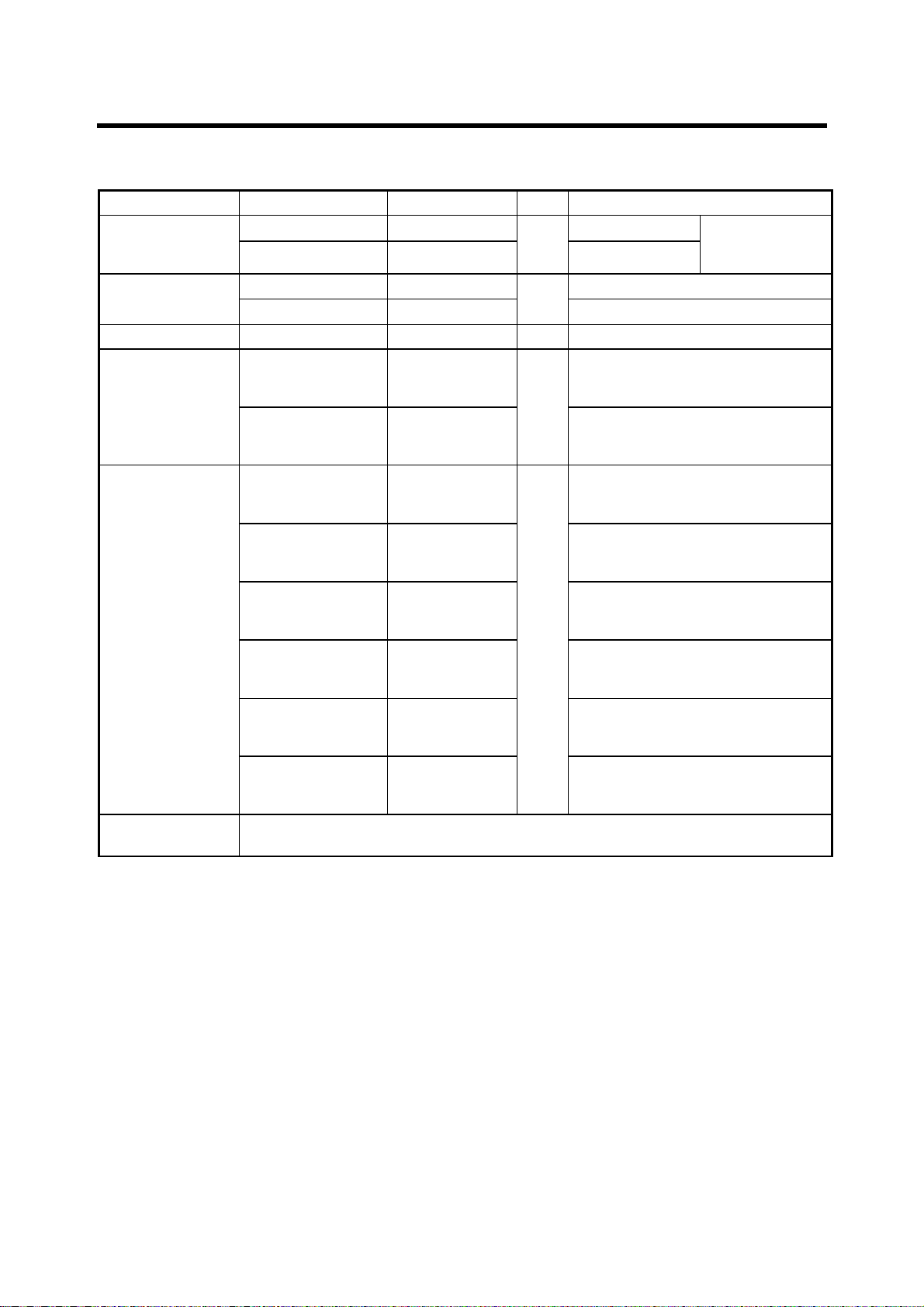

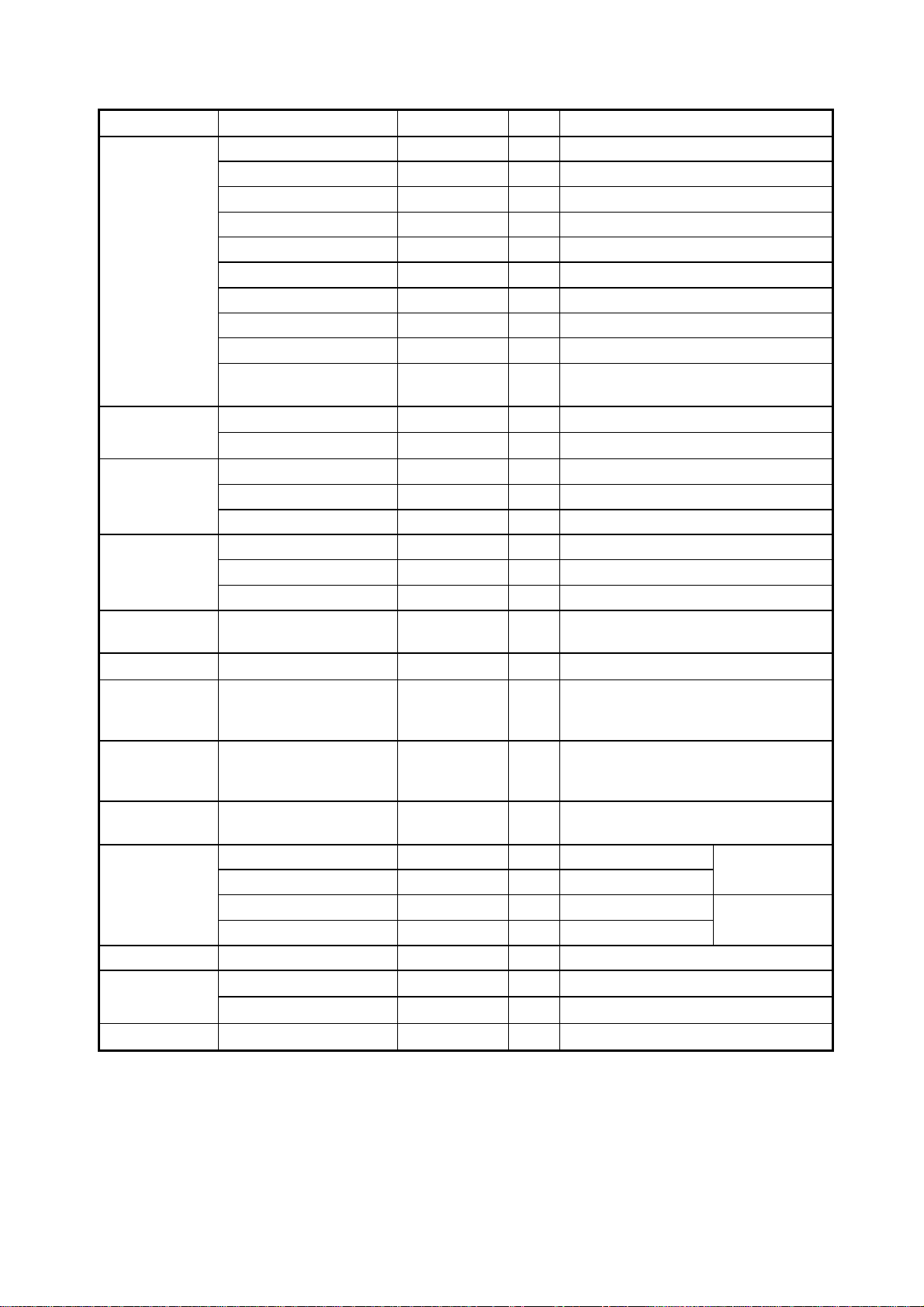

EQUIPMENT LISTS

Standard supply

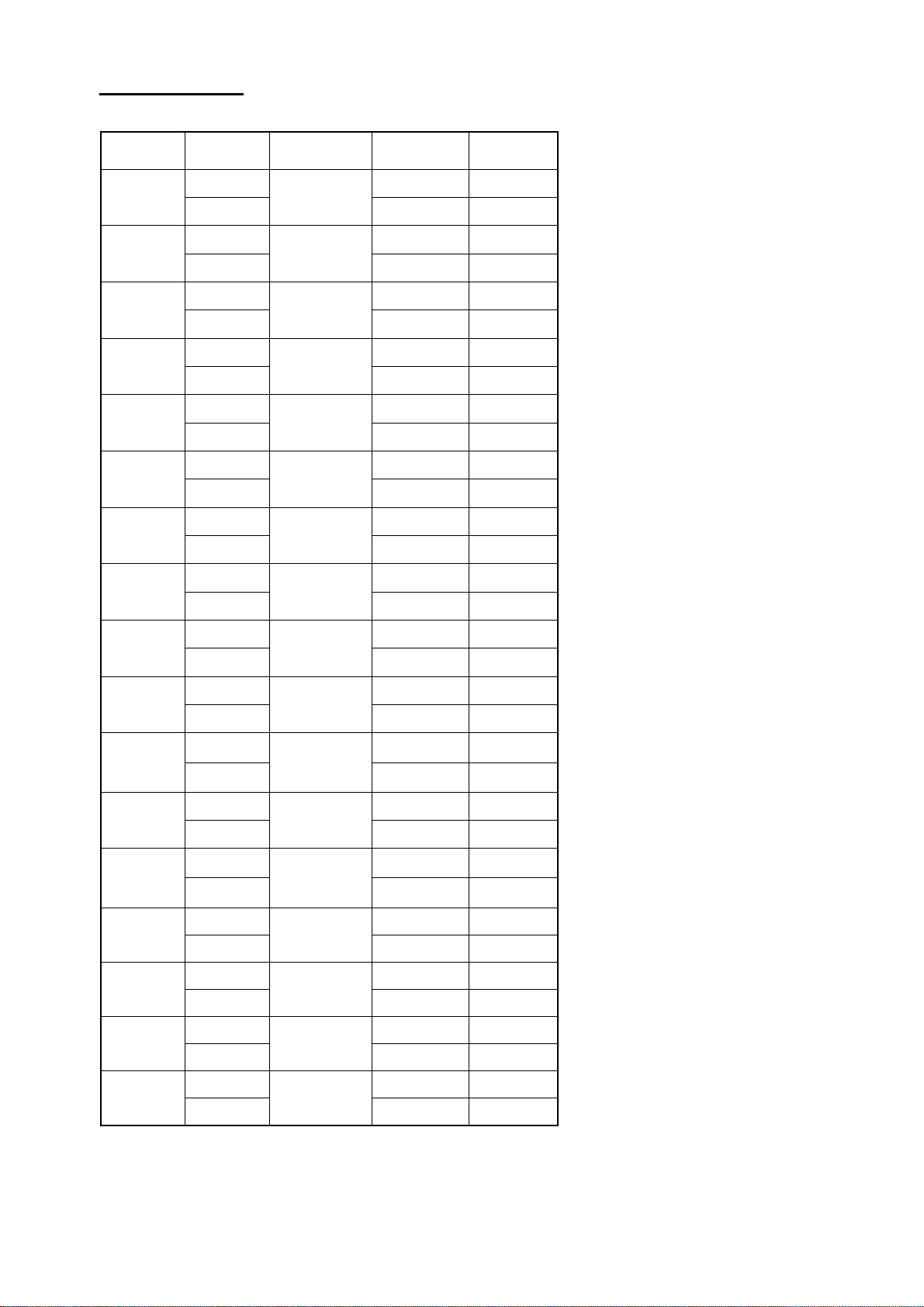

Name Type Code No. Qty Remarks

CV-1201/MU-101C

Monitor Unit

Processor Unit

Spare Parts SP02-04200 000-012-451 1 set SP02-04001 (Processor Unit)

Accessories

Installation

Materials

Transducer

CV-1202/MU-101C

CV-1203

CV-1203M

FP02-05100 000-012-474

FP02-05110 000-012-475

CP02-06540

(FCV-1200L,

unibody)

CP02-06560

(FCV-1200LM,

unibody)

CP02-06500

(FCV-1200L,

unibody)

CP02-06510

(FCV-1200LM,

unibody)

CP02-06550

(FCV-1200L,

unibody)

CP02-06570

(FCV-1200LM,

unibody)

Transducer available in 1, 2 and 3 kW models. See page ix - xx for details. No selection

also available.

000-012-464

000-012-466

000-012-453

000-012-454

000-012-465

000-012-467

−

−

−

−

1 set

1 set

Portrait type

1

Landscape type

For FCV-1200L

1

For FCV-1200LM

For landscape-type monitor unit,

FP02-05101 (Hanger),

FP06-01102 (Hood)

For portrait-type monitor unit,

FP02-05101 (Hanger), FP02-05022

(Hood)

06S4078 *1.5* m

MJ-A10SPF0002-0015 (0.15 m)

CP02-06501

06S4078 *1.5* m

MJ-A10SPF0002-0015 (0.15 m)

CP03-06511

06S4078 *5* m

MJ-A10SPF0002-0015 (0.15 m)

CP02-06501

06S4078 *5* m

MJ-A10SPF0002-0015 (0.15 m)

CP02-06511

06S4078 *10* m

MJ-A10SPF0002-0015 (0.15 m)

CP02-06501

06S4078 *10* m

MJ-A10SPF0002-0015 (0.15 m)

CP02-06511

Select one, with

SP06-01101 (for

dislay unit)

v

Page 8

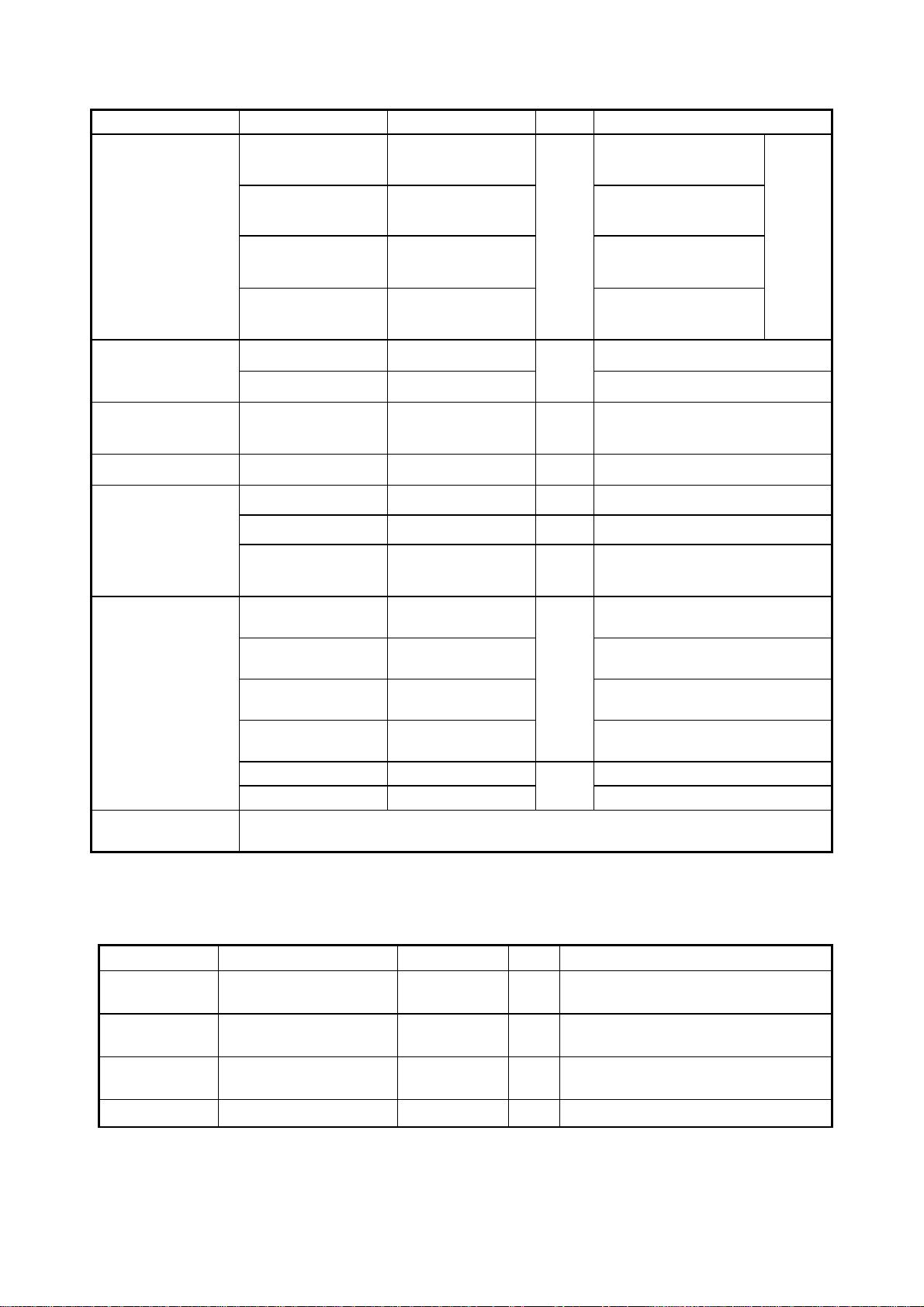

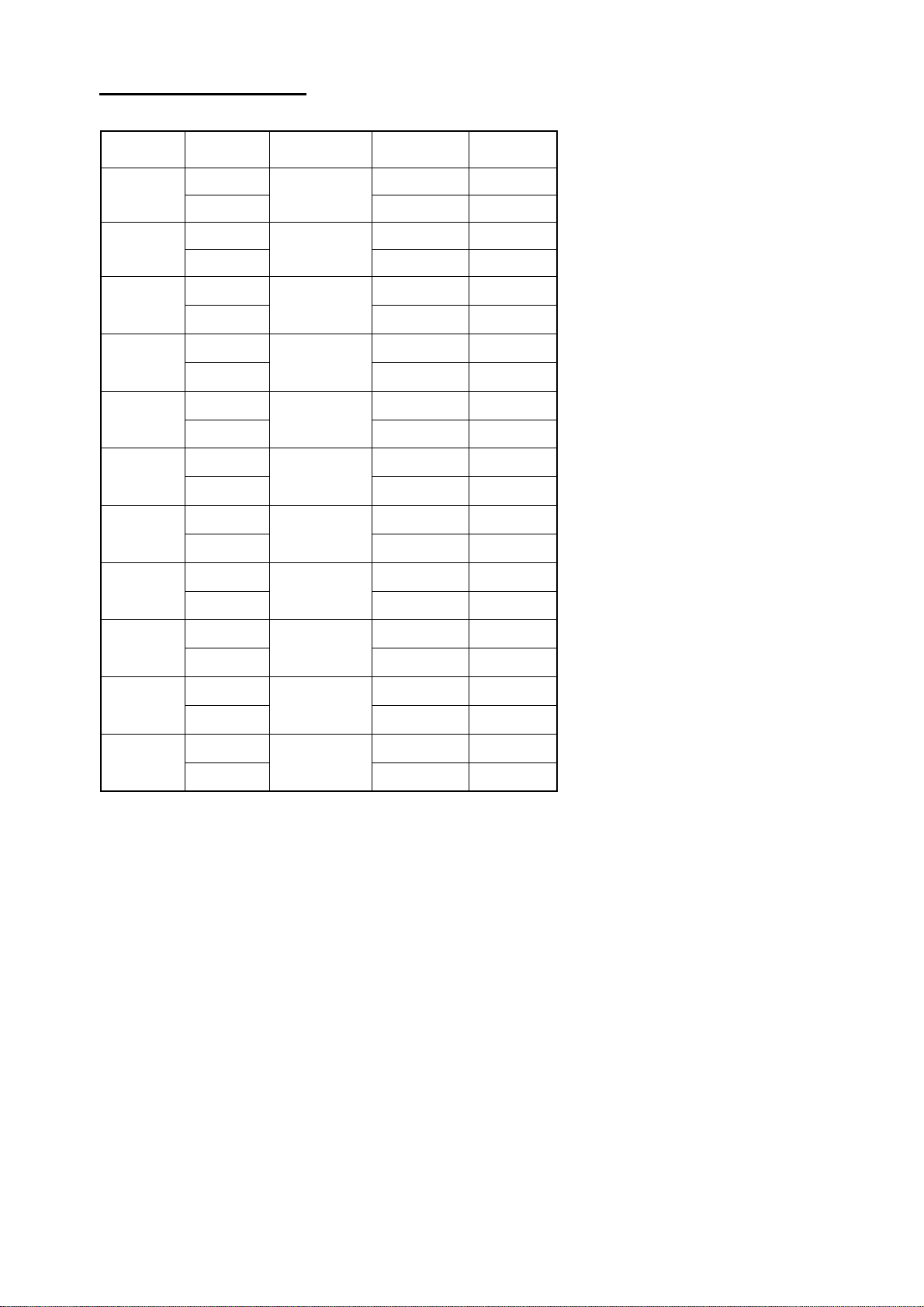

Blackbox type

Name Type Code No. Qty Remarks

CV-1201-E-15

−

1.5 m cable,

portrait type

CV-1201-E-50

Control Unit

CV-1202-E-15

CV-1202-E-50

CV-1203

Processor Unit

CV-1203M

−

1

−

−

−

1

−

Spare Parts SP02-04210 000-012-452 1 set

Interface Unit

IF-8000

−

1

FP06-01120 006-556-260 1 set Landscape-type

Accessories

FP02-05111 001-413-710 1 Flush mount type

06-021-2121 100-320-101 1

Installation

Materials

Transducer

CP02-06520

(FCV-1200L)

CP02-06530

(FCV-1200LM)

CP02-06680

(FCV-1200L)

CP02-06690

(FCV-1200LM)

CP02-06610 000-012-480 1.5m cable

CP02-06620 000-012-481

Transducer available in 1, 2 and 3 kW models. See page ix - xx for details. No selection

also available.

000-012-455

000-012-456

1 set

000-012-468

000-012-469

1 set

5 m cable,

portrait type

1.5 m cable,

Select

one

landscape type

5 m cable,

landscape type

No transducer

With transducer

SP02-04001 (Processor Unit)

SP06-01111 (Interface Unit)

Hard cover

For Control Unit

06S4078 *5* m

CP02-06501

06S4078 *5* m

CP02-06511

06S4078 *10* m

CP02-06501

06S4078 *10* m

CP02-06511

5m cable

Optional equipment

Name Type Code No. Qty Remarks

Monitor Unit MU-101C-H

Monitor Unit MU-101C-V

Echosounder

VI-1100A

Interface

Switch Box EX-7

(Continued on next page.)

−

−

−

−

vi

1 set Landscape type, with spare parts

and accessories

1 set Portrait type, with spare parts and

accessories

Page 9

Optional equipment (con’t)

Rectifier RU-1746B-2

Cable

Transceiver

Unit

Water

Temperature

Sensor

Connector

EXIF Board

Assy.

Interface Unit IF-8000

Unibody

monitor unit

flush mount kit

Separate

monitor unit

flush mount kit

Control unit

flush mount kit

Separate

installation kit

Cable Assy. 80-0654 001-413-880 1 For program ver.up

Booster Box BT-5

MJ-A6SPF0012-050 000-134-424 1 6 pin-6 pin, 5 m, for navigator

MJ-A6SPF0012-100 000-133-817 1 6 pin-6 pin, 10 m, for navigator

MJ-A6SPF0011-050 000-132-244 1 6 pin-4 pin, 5 m, for navigator

MJ-A6SPF0011-100 000-132-336 1 6 pin-4 pin, 10 m, for navigator

MJ-A10SPF0002-0015 000-142-879 1 10 pin-10 pin, 0.15 m, for control unit

MJ-A10SPF0002-050 000-131-411 1 10 pin-10 pin, 5 m, for control unit

06S4078*1.5 m* 000-142-901 1 For monitor unit

06S4078*5 m* 000-142-902 1 For monitor unit

06S4078*10 m* 000-142-900 1 For monitor unit

NCS255AD-254P-L500 000-142-518 1 For unibody dual-frequency

ETR-5D

ETR-10D

T-02MSB 000-040-040 1 Thru-hull mount

T-02MTB 000-040-026 1 Transom mount

T-03MSB 000-040-027 1 Thru-hull mount

SRCN6A25-24P 000-508-676 1 For EXIF Board Assy.

FM14-8P 000-511-408 1 For FNZ-18

NCS-254-P 000-506-505 1 For connection of transducer

OP02-81 000-012-463 1 set For FCV-1200L

OP06-16 006-556-300 1 set For monitor unit and control unit

OP06-17 006-556-310 1 set For monitor unit

OP06-18 006-556-320 1 set For control unit, Blackbox type

OP02-83-1.5 001-413-600 1 set 1.5 m cable

OP02-83-5 001-413-610 1 set 5 m cable

OP06-15-1.5 006-559-140 1 set 1.5 m cable

OP06-15-5 006-559-150 1 set 5 m cable

CV-1201-E

CV-1202-E

−

−

−

−

−

−

−

transducer

1 set

1 set

1 set

1 Portrait type Control Unit

1 Landscape type

1

Unibody flush

mount

Unibody

tabletop

vii

Page 10

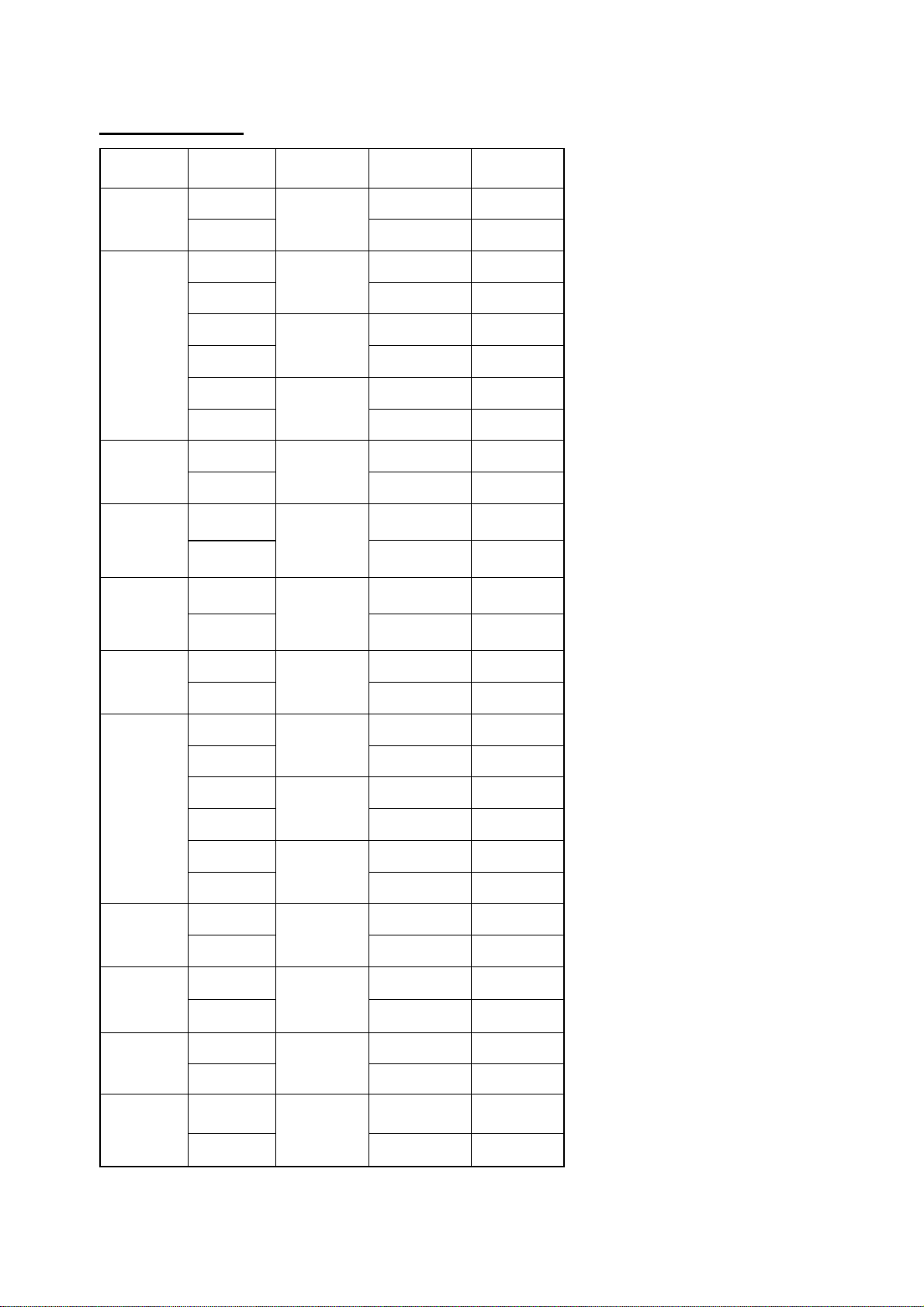

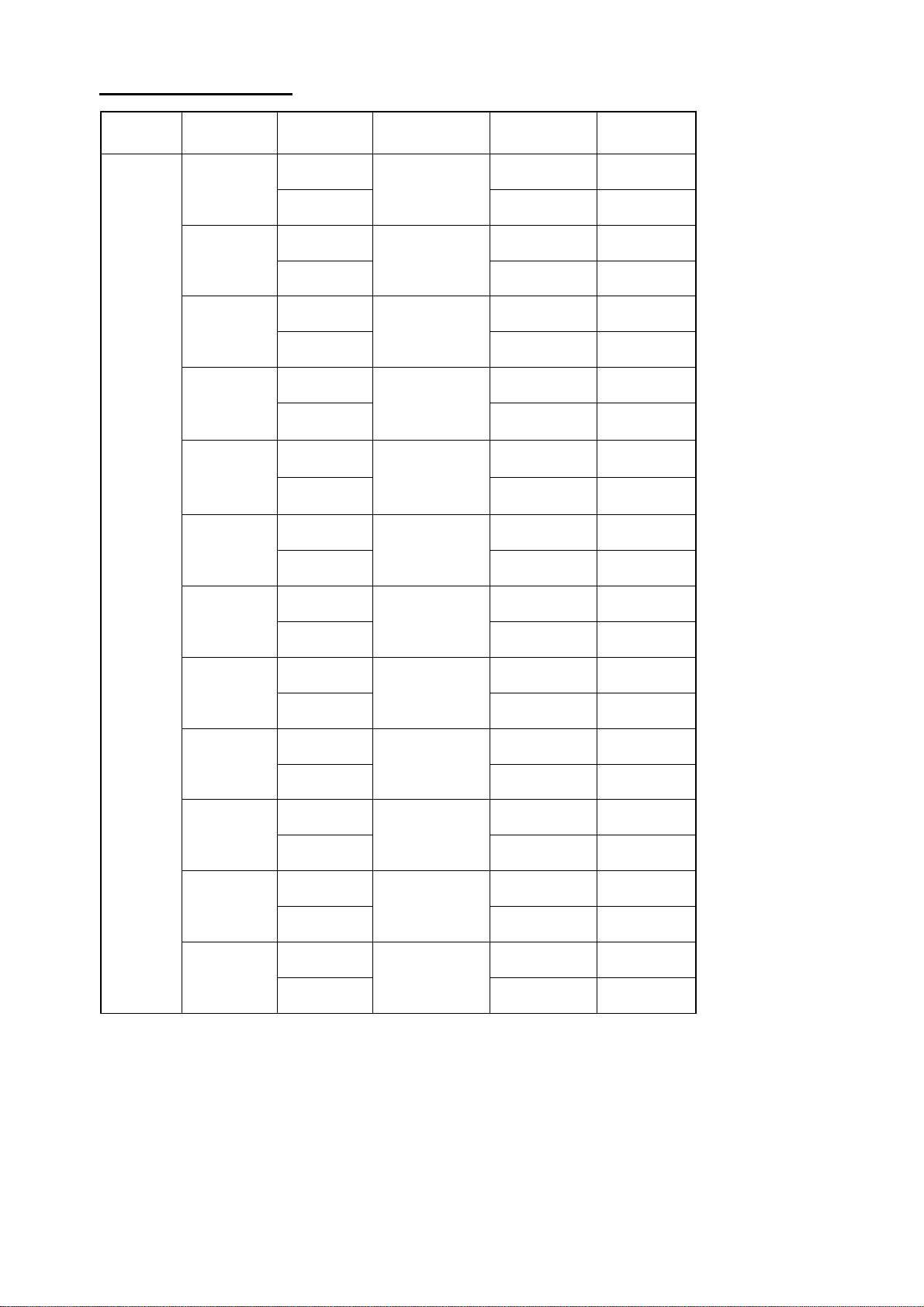

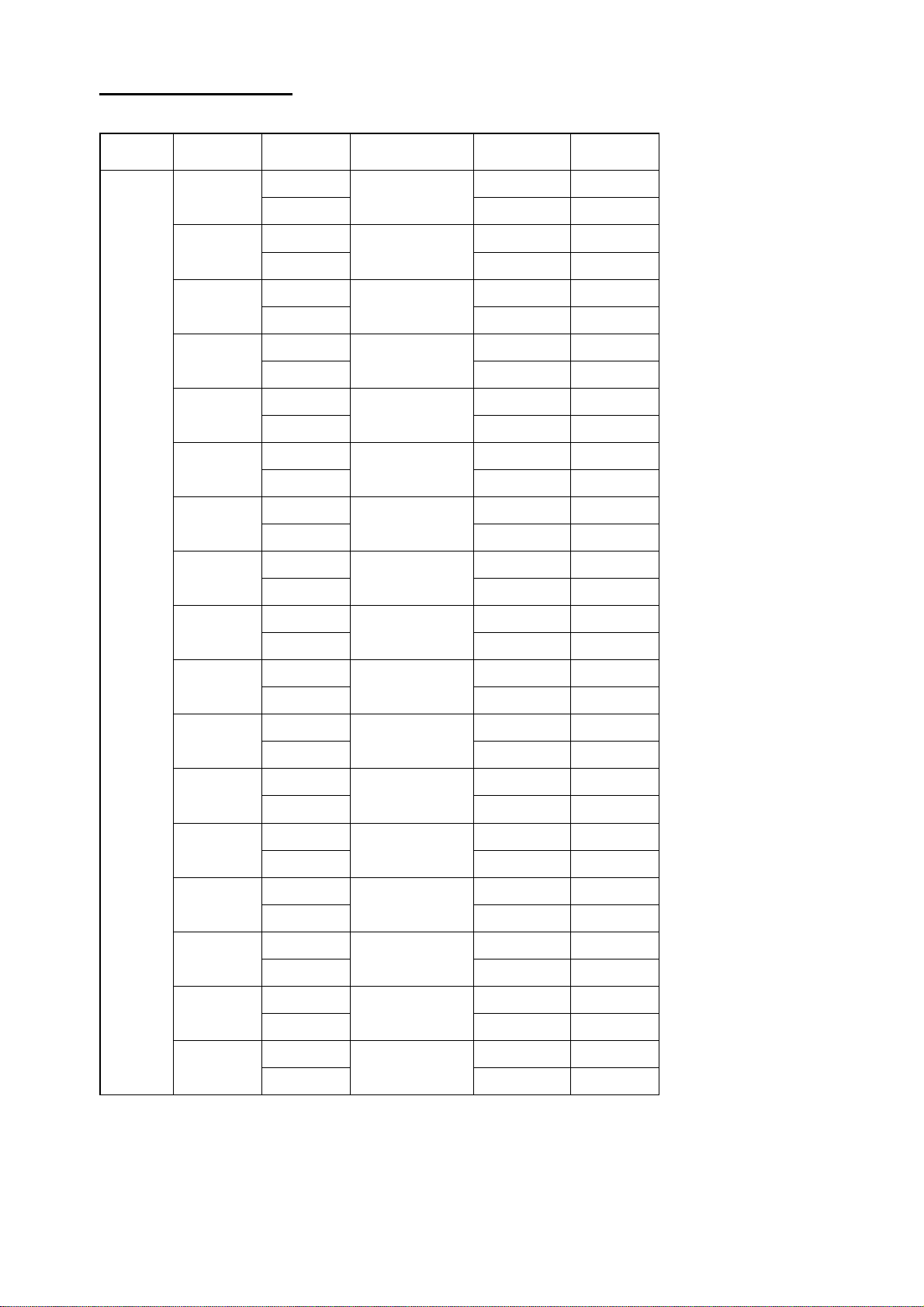

Available transducers

1 kW transducer

ycneuqerF

)zHk(

54/51

05/51

86/51

88/51

002/51

lluH

lairetaM

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

recudsnarT

S4-F51

H3-F54

S4-F51

B6/6-B05

S4-F51

B9-B05

S4-F51

G8-F05

S4-F51

H8-F86

S4-F51

8-B88

S4-F51

S5-B002

lluH-urhT

epiP

knaT

leetS

54/82

PRF

leetS

PRF

leetS

05/82

PRF

leetS

PRF

leetS

86/82

PRF

leetS

88/82

PRF

leetS

002/82

PRF

leetS

88/54

PRF

8-F82

H3-F54

8-F82

B6/6-B05

8-F82

B9-B05

8-F82

G8-F05

8-F82

H8-F86

8-F82

8-B88

8-F82

S5-B002

H3-F54

8-B88

)2(0006-BWT656-T

)2(0006-BWT756-T

viii

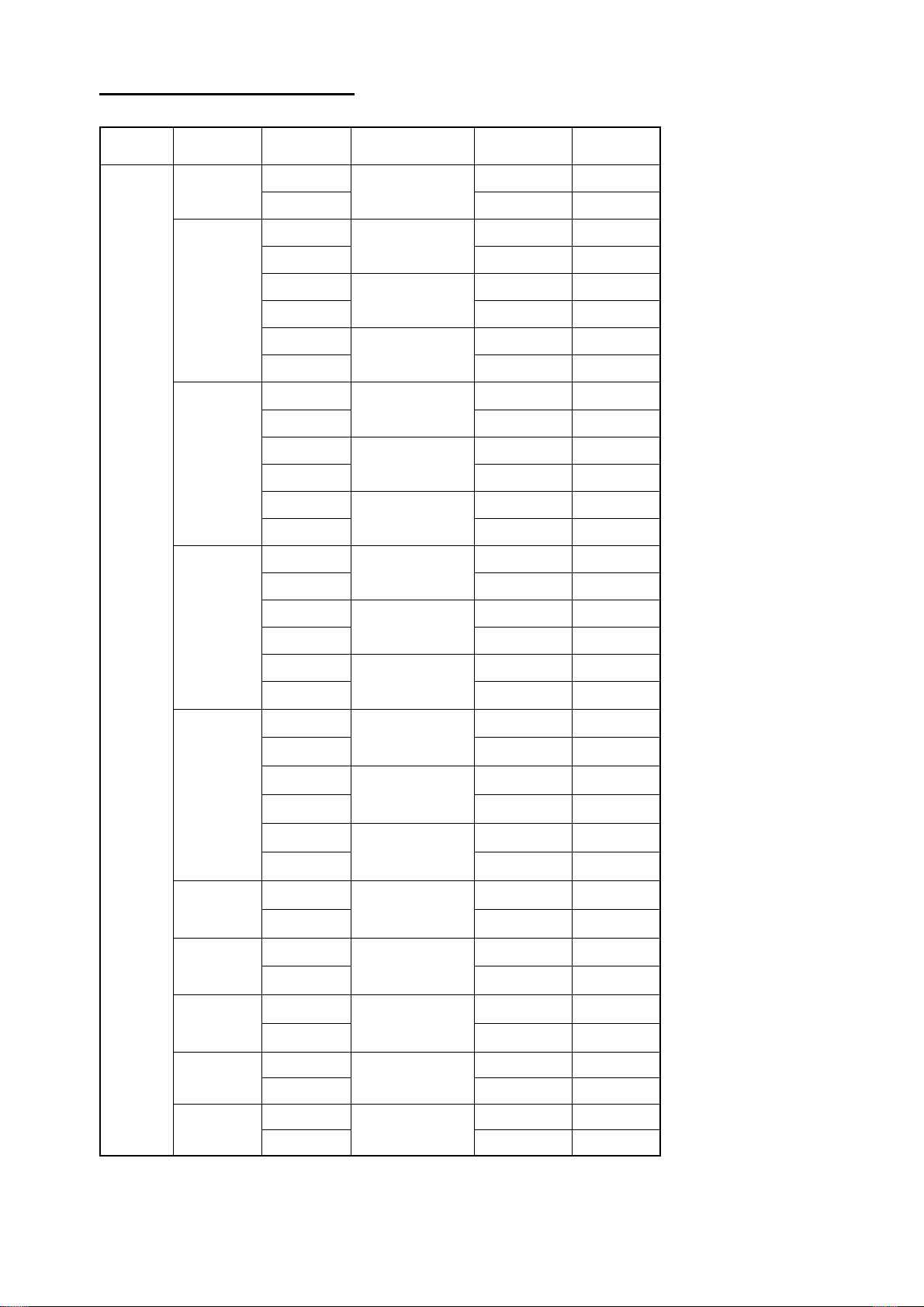

Page 11

1 kW transducer (con’t)

ycneuqerF

)zHk(

002/54

88/05

lluH

lairetaM

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

8-B88

8-B88

8-B88

recudsnarT

H3-F54

S5-B002

B6/6-B05

B9-B05

G8-F05

B6/6-B05

S5-B002

B9-B05

S5-B002

lluH-urhT

epiP

)2(0006-BWT856-T

knaT

leetS

002/05

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

004/05

PRF

leetS

PRF

leetS

002/86

PRF

G8-F05

S5-B002

T1-002/05

TS1-002/05

B6/6-B05

25-B004

B9-B05

25-B004

G8-F05

25-B004

H8-F86

S5-B002

002/88

leetS

PRF

8-B88

S5-B002

ix

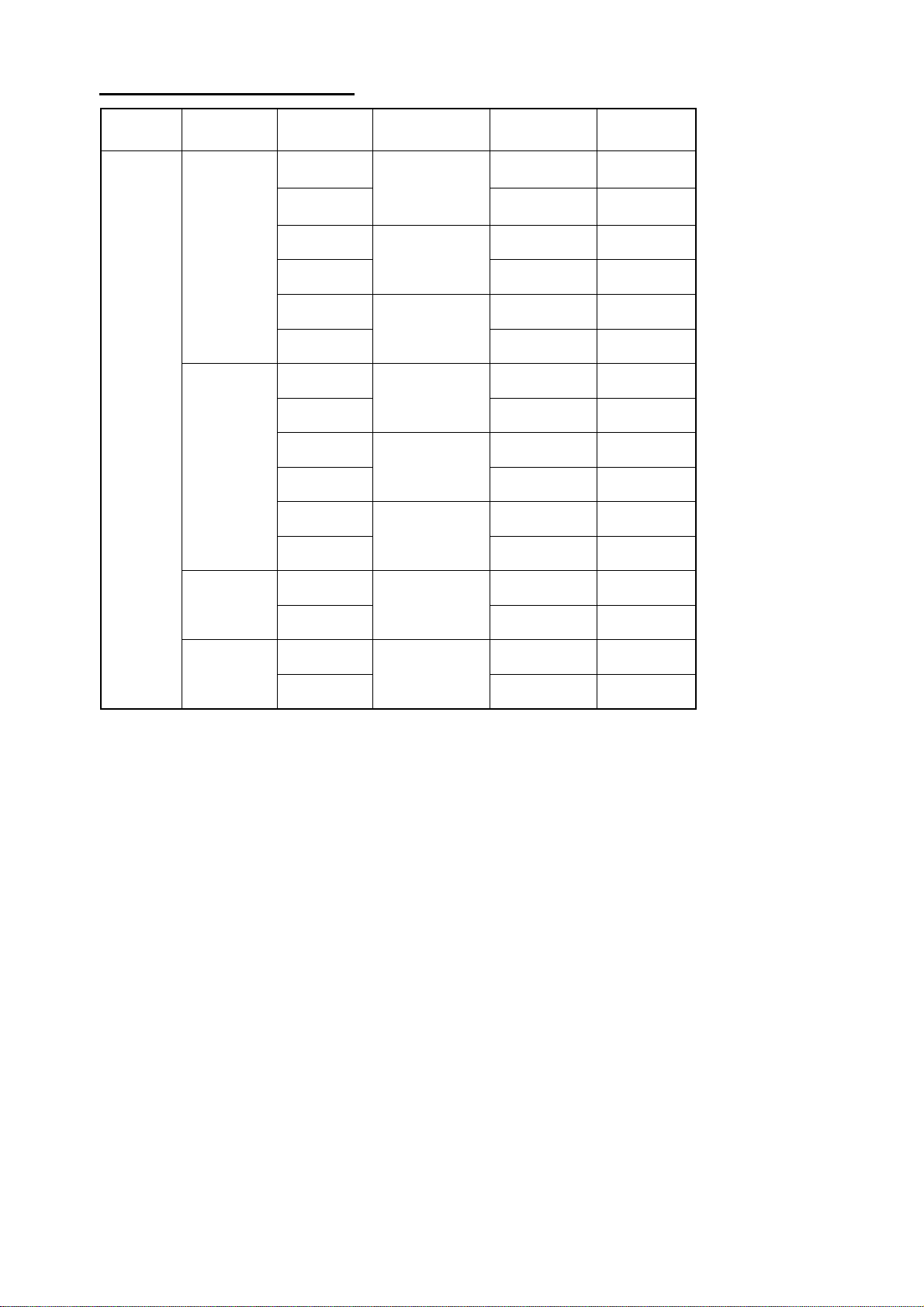

Page 12

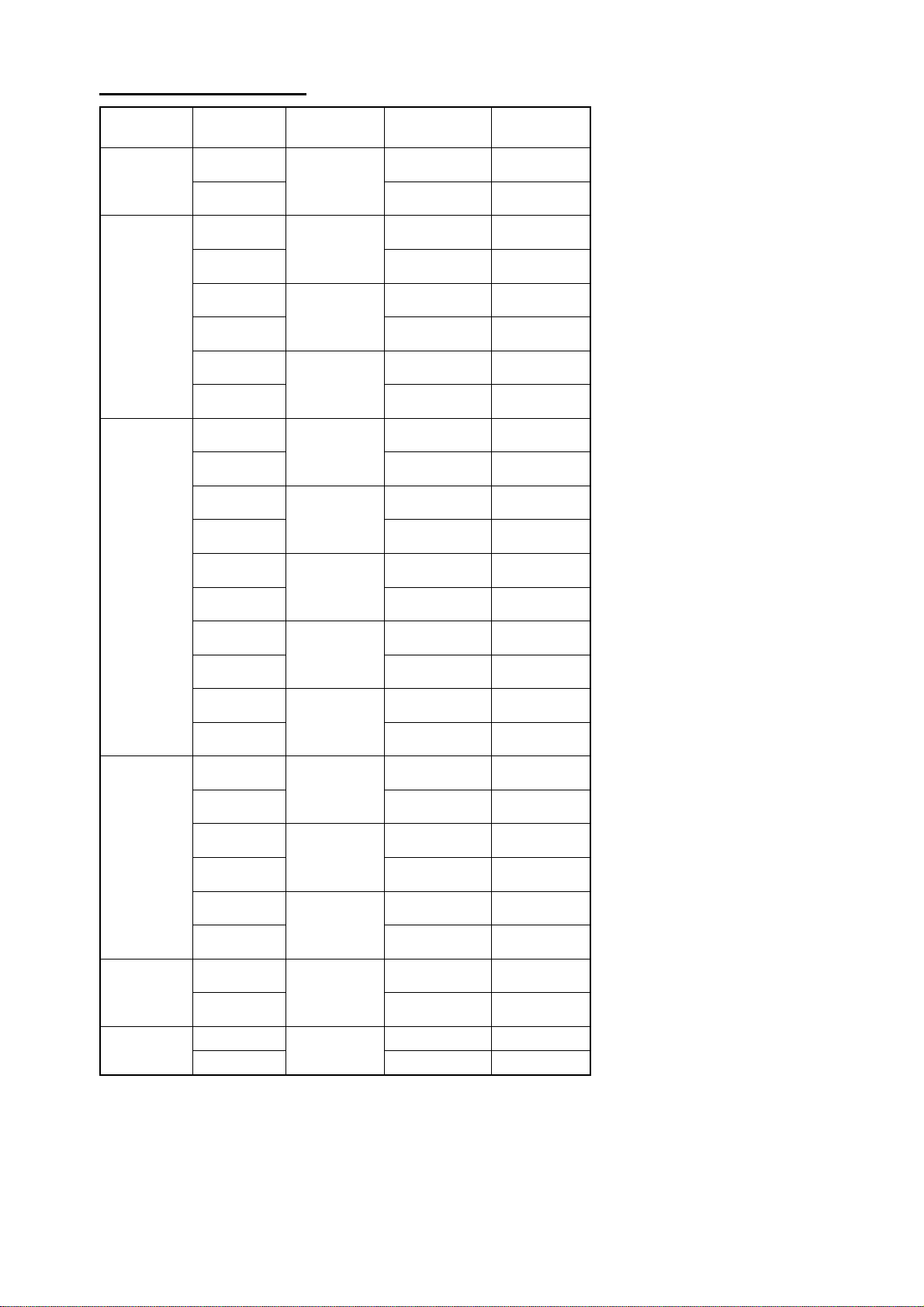

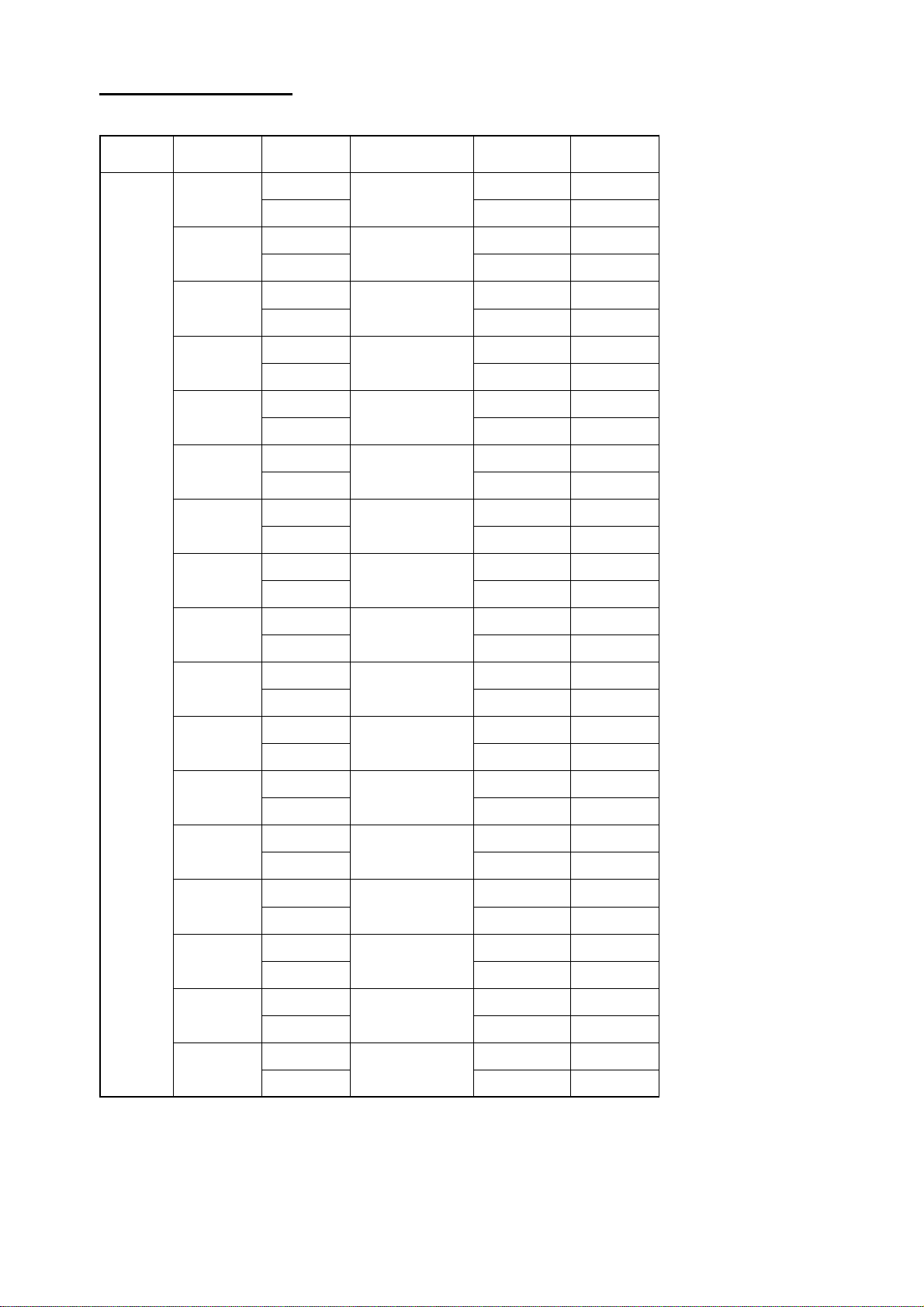

2 kW transducer

ycneuqerF

)zHk(

54/51

05/51

86/51

88/51

002/51

54/82

05/82

lluH

lairetaM

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF)2(0011-BRTF-926-T

leetS

PRF)2(0011-BRTF-236-T

leetS

PRF

leetS

PRF

01-F51

H6-F54

01-F51

21-B05

01-F51

H03-F86

01-F51

01-B88

01-F51

81-F82

H6-F54

81-F82

21-B05

recudsnarT

N8/B8/8-B002

lluH-urhT

epiP

)2(0007-BFT726-T

)2(0007-BFT926-T

)2(0007-BFT236-T

)2(0007-BFT436-T

knaT

leetS

86/82

PRF)2(0011-BRTF-436-T

leetS

88/82

PRF)2(0011-BRTF-636-T

leetS

002/82

PRF)2(0011-BRTF-836-T

leetS

88/54

PRF

002/54

88/05

002/05

leetS

PRF

leetS

PRF)2(0011-BRTF-346-T

leetS

PRF

81-F82

H03-F86

81-F82

01-B88

81-F82

N8/B8/8-B002

H6-F54

01-B88

H6-F54

N8/B8/8-B002

21-B05

01-B88

21-B05

N8/B8/8-B002

)2(0007-BFT636-T

)2(0007-BFT836-T

)2(0007-BFT346-T

)2(0007-BFT546-T

leetS

002/86

PRF)2(0011-BRTF-546-T

002/88

leetS

PRF)2(0011-BRTF-946-T

H03-F86

N8/B8/8-B002

01-B88

N8/B8/8-B002

)2(0007-BFT946-T

x

Page 13

3 kW transducer

ycneuqerF

)zHk(

leetS

54/51

PRF

*: 5 kW transducer.

lluH

lairetaM

recudsnarT

2X01-F51

H21-F54

lluH-urhT

epiP

knaT

05/51

leetS

PRF

leetS

86/51

PRF

leetS

88/51

PRF

leetS

701/51

PRF

leetS

051/51

PRF

leetS

002/51

PRF

leetS

54/82

PRF

leetS

05/82

PRF)2(0011-BRTF-186-T

2X01-F51

H42-F05

2X01-F51

H03-F86

2X01-F51

H*621-F88

2X01-F51

R01-B001

2X01-F51

H21-B051

2X01-F51

H*21-B002

H42-F82

H21-F54

H42-F82

H42-F05

)2(0007-BFT186-T

86/82

leetS

PRF

leetS

88/82

PRF)2(0011-BRTF-286-T

leetS

701/82

PRF

leetS

051/82

PRF)2(0011-BRTF-386-T

leetS

002/82

PRF)2(0011-BRTF-386-T

leetS

88/54

PRF

leetS

701/54

PRF

leetS

051/54

PRF

H42-F82

H03-F86

H42-F82

H*621-F88

H42-F82

R01-B001

H42-F82

H21-B051

H42-F82

H21-B002

H21-F54

H621-F88

H21-F54

R01-B001

H21-F54

H21-B051

)2(0007-BFT286-T

)2(0007-BFT386-T

)2(0007-BFT386-T

xi

Page 14

3 kW transducer (con’t)

ycneuqerF

)zHk(

002/54

lluH

lairetaM

leetS

PRF

*: 5 kW transducer.

recudsnarT

H21-F54

H*21-B002

lluH-urhT

epiP

knaT

88/05

leetS

PRF)2(0011-BRTF-286-T

leetS

701/05

PRF

leetS

051/05

PRF)2(0011-BRTF-386-T

leetS

002/05

PRF)2(0011-BRTF-386-T

leetS

701/86

PRF

leetS

051/86

PRF)2(0011-BRTF-646-T

leetS

002/86

PRF)2(0011-BRTF-646-T

leetS

051/88

PRF

H42-F05

H*621-F88

H42-F05

R01-B001

H42-F05

H21-B051

H42-F05

H*21-B002

H03-F86

R01-B001

H03-F86

H*21-B051

H03-F86

H21-B002

H*621-F88

H21-B051

)2(0007-BFT286-T

)2(0007-BFT386-T

)2(0007-BFT386-T

)2(0007-BFT646-T

)2(0007-BFT646-T

002/88

leetS

PRF)2(0011-BRTF-586-T

leetS

002/701

PRF)2(0011-BRT

H*621-F88

H*21-B002

R01-B001

H*21-B002

)2(0007-BFT586-T

)2(0007-BFT

xii

Page 15

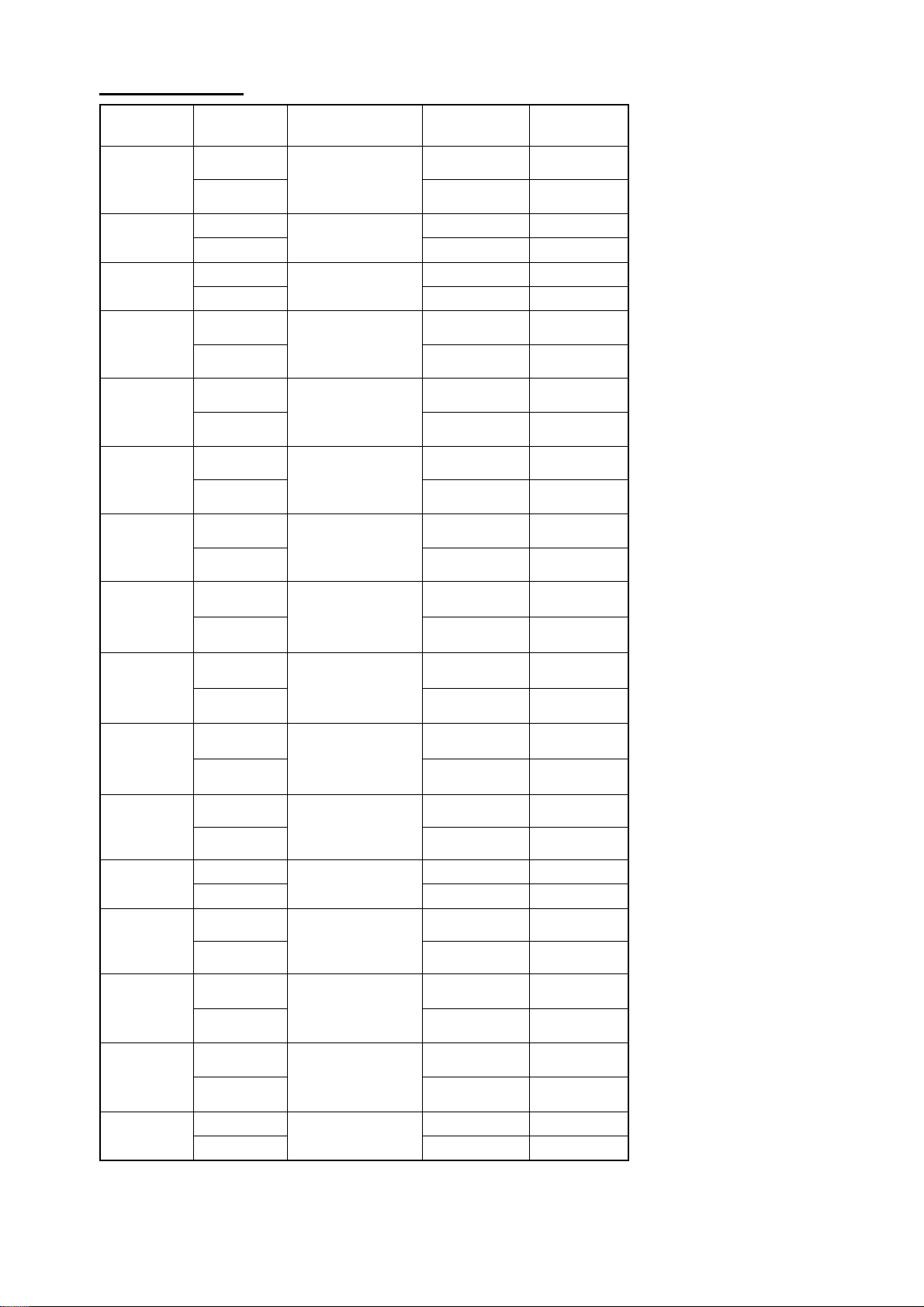

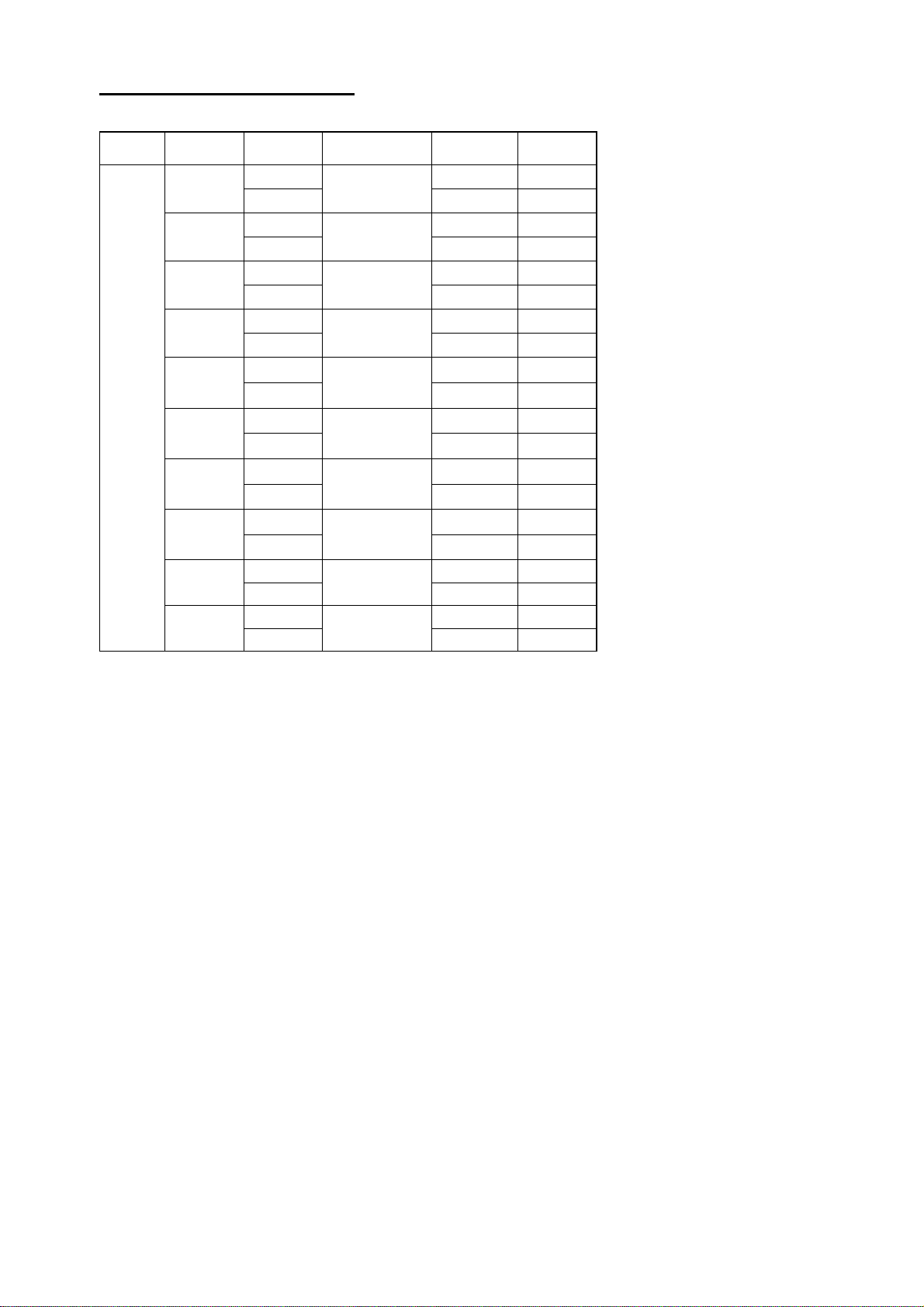

1 kW/2 kW transducer

tuptuO

)W(

k2/k1

ycneuqerF

)zHk(

54/51

05/51

86/51

88/51

002/51

54/82

05/82

lluH

lairetaM

leetS

PRF

leetS

PRF)2(0011-BRTF-626-T

leetS

PRF

leetS

PRF)2(0011-BRTF-826-T

leetS

PRF)2(0011-BRTF-136-T

leetS

PRF

leetS

PRF

S4-F51

H6-F54

S4-F51

21-B05

S4-F51

S4-F51

01-B88

S4-F51

8-F82

H6-F54

8-F82

21-B05

recudsnarT

H03-F86

N8/B8/8-B002

lluh-urhT

epiP

)2(0007-BFT626-T

)2(0006-BWT826-T

)2(0006-BWT136-T

knaT

leetS

86/82

PRF

leetS

88/82

PRF

leetS

002/82

PRF

leetS

88/54

PRF

leetS

002/54

PRF

8-F82

H03-F86

8-F82

01-B88

8-F82

N8/B8/8-B002

H3-F54

01-B88

H3-F54

N8/B8/8-B002

)2(0006-BWT756-T

xiii

Page 16

1 kW/2 kW transducer (con’t)

tuptuO

)W(

k2/k1

ycneuqerF

)zHk(

88/05

002/05

lluH

lairetaM

leetS

PRF

leetS

PRF

leetS

PRF)2(0011-BRTF-636-T

leetS

PRF

leetS

PRF

leetS

PRF)2(0001-BRTF-836-T

01-B88

B9-B05

01-B88

G8-F05

01-B88

9-B05

G8-F05

recudsnarT

B6/6-B05

B6/6-B05

N8/B8/8-B002

N8/B8/8-B002

N8/B8/8-B002

lluh-urhT

epiP

)2(0007-BFT636-T

)2(0006-BWT856-T

)2(0007-BFT836-T

knaT

leetS

002/86

PRF

leetS

002/88

PRF

H8-F86

N8/B8/8-B002

8-B88

N8/B8/8-B002

)2(0006-BWT956-T

xiv

Page 17

1 kW/3 kW transducer

tuptuO

)W(

ycneuqerF

)zHk(

54/51

PRF

*: 5 kW transducer.

lluH

lairetaM

leetS

S4-F51

H21-F54

recudsnarT

lluH-urhT

epiP

knaT

05/51

86/51

88/51

701/51

051/51

002/51

54/82

k3/k1

05/82

86/82

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF)2(0011-BRTF-736-T

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

S4-F51

H42-F05

S4-F51

H03-F86

S4-F51

H*621-F88

S4-F51

R01-B001

S4-F51

H21-B051

S4-F51

H*21-B002

8-F82

H21-F54

8-F82

H42-F05

8-F82

H03-F86

)2(0007-BFT736-T

88/82

leetS

PRF

leetS

701/82

PRF

leetS

051/82

PRF

leetS

002/82

PRF

leetS

88/54

PRF

leetS

701/54

PRF

leetS

051/54

PRF

8-F82

H*621-F88

8-F82

R01-B001

8-F82

H21-B051

8-F82

H*21-B002

H3-F54

H*621-F88

H3-F54

R01-B001

H3-F54

H21-B051

xv

Page 18

1 kW/3 kW transducer (con’t)

tuptuO

)W(

ycneuqerF

)zHk(

002/54

lluH

lairetaM

leetS

PRF

*: 5 kW transducer.

recudsnarT

H3-F54

H*21-B002

lluH-urhT

epiP

knaT

leetS

PRF

88/05

701/05

051/05

k3/k1

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

B6/6-B05

H*621-F88

B9-B05

H*621-F88

G8-F05

H*621-F88

B6/6-B05

R01-B001

B9-B05

R01-B001

8-F05

R01-B001

B6/6-B05

H21-B051

B9-B05

H21-B051

G8-F05

H21-B051

leetS

PRF

leetS

002/05

PRF

leetS

PRF

leetS

701/86

PRF

leetS

051/86

PRF

leetS

002/86

PRF

leetS

051/88

PRF

leetS

002/88

PRF

B6/6-B05

H*21-B002

B9-B05

H*21-B002

G8-F05

H*21-B002

H8-F86

R01-B001

H8-F86

H21-B051

H-F86

H*21-B002

8-B88

H21-B051

8-B88

H*21-B002

xvi

Page 19

2 kW/3 kW transducer

tuptuO

)W(

ycneuqerF

)zHk(

54/51

PRF

*: 5 kW transducer.

lluH

lairetaM

leetS

01-F51

H21-F54

recudsnarT

lluH-urhT

epiP

knaT

05/51

86/51

88/51

701/51

051/51

002/51

54/82

k3/k2

05/82

86/82

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

01-F51

H42-F05

01-F51

H03-F86

01-F51

H*621-F88

01-F51

R01-B001

01-F51

H21-B051

01-F51

H*21-B002

81-F82

H21-F54

81-F82

H42-F05

81-F82

H03-F86

88/82

leetS

PRF

leetS

701/82

PRF)2(0011-BRTF-636-T

leetS

051/82

PRF)2(0011-BRTF-736-T

leetS

002/82

PRF

leetS

88/54

PRF

leetS

701/54

PRF

leetS

051/54

PRF

81-F82

H*621-F88

81-F82

R01-B001

81-F82

H21-B051

81-F82

H*21-B002

H6-F54

H*621-F88

H6-F54

R01-B001

H6-F54

H21-B051

)2(0007-BFT636-T

)2(0007-BFT736-T

xvii

Page 20

2 kW/3 kW transducer (con’t)

tuptuO

)W(

k3/k2

ycneuqerF

)zHk(

002/54

88/05

701/05

051/05

002/05

701/86

051/86

002/86

051/88

002/88

lluH

lairetaM

leetS

PRF

leetS

PRF

leetS

PRF)2(0011-BRTF-346-T

leetS

PRF)2(0011-BRTF-446-T

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

*: 5 kW transducer.

recudsnarT

H6-F54

H*21-B002

21-B05

H*621-F88

21-B05

R01-B001

21-B05

H21-B051

21-B05

H*21-B002

H03-F86

R01-B001

H03-F86

H21-B051

H03-F86

H*21-B002

01-B88

H21-B051

01-B88

H*21-B002

lluH-urhT

epiP

)2(0007-BFT346-T

)2(0007-BFT446-T

knaT

xviii

Page 21

3 kW/2 kW transducer

tuptuO

)W(

ycneuqerF

)zHk(

54/51

PRF

*: 5 kW transducer.

lluH

lairetaM

leetS

H6-F54

recudsnarT

2X01-F51

lluH-urhT

epiP

knaT

05/51

86/51

88/51

002/51

54/82

05/82

86/82

k2/k3

88/82

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

leetS

PRF

2X01-F51

21-B05

2X01-F51

H03-F86

2X01-F51

01-B88

2X01-F51

N8/B8/8-B002

H42-F82

H6-F54

H42-F82

21-B05

H42-F82

H03-F86

H42-F82

01-B88

002/82

leetS

PRF

leetS

88/54

PRF

leetS

002/54

PRF

leetS

88/05

PRF

leetS

002/05

PRF

leetS

002/86

PRF)2(0011-BRTF-746-T

leetS

002/88

PRF

leetS

002/001

PRF)2(0011-BRTF-946-T

H42-F82

N8/B8/8-B002

H21-F54

01-B88

H21-F54

N8/B8/8-B002

H42-F05

01-B88

H42-F05

N8/B8/8-B002

H03-F86

N8/B8/8-B002

H*621-F88

N8-B002

R01-B001

N8/B8/8-B002

)2(0007-BFT746-T

)2(0007-BFT946-T

xix

Page 22

This page is intentionally left blank.

Page 23

1. MOUNTING

1.1 Monitor Unit, Control Unit

The monitor and control units can be installed as one unit (unibody) or two separate units. The

optional “separate monitor unit installation kit” is necessary when installing them as separate

units. Further, these units can be mounted in a panel (requires optional flush mount kit), together

or separately. See the outline drawings at the back of this manual for details.

Mounting considerations

•

Locate the units out of direct sunlight.

•

The operator should face the bow while viewing the display screen.

•

Select a location where the display screen can be easily observed while operating the control

unit.

•

Leave sufficient space around the units for maintenance and servicing. Recommended

maintenance space appears in the outline drawing at the back of this manual.

Mounting procedure

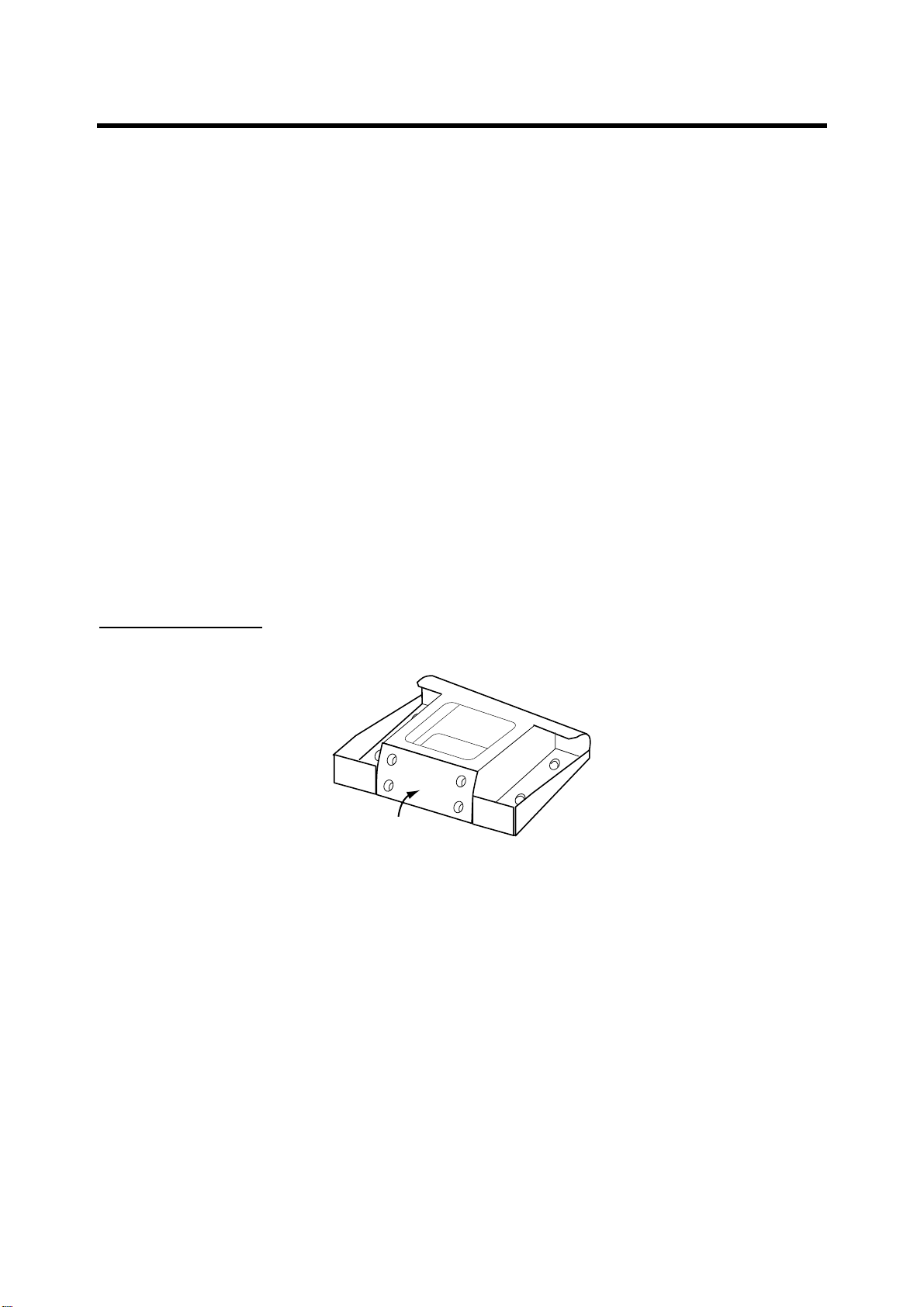

Desktop mounting

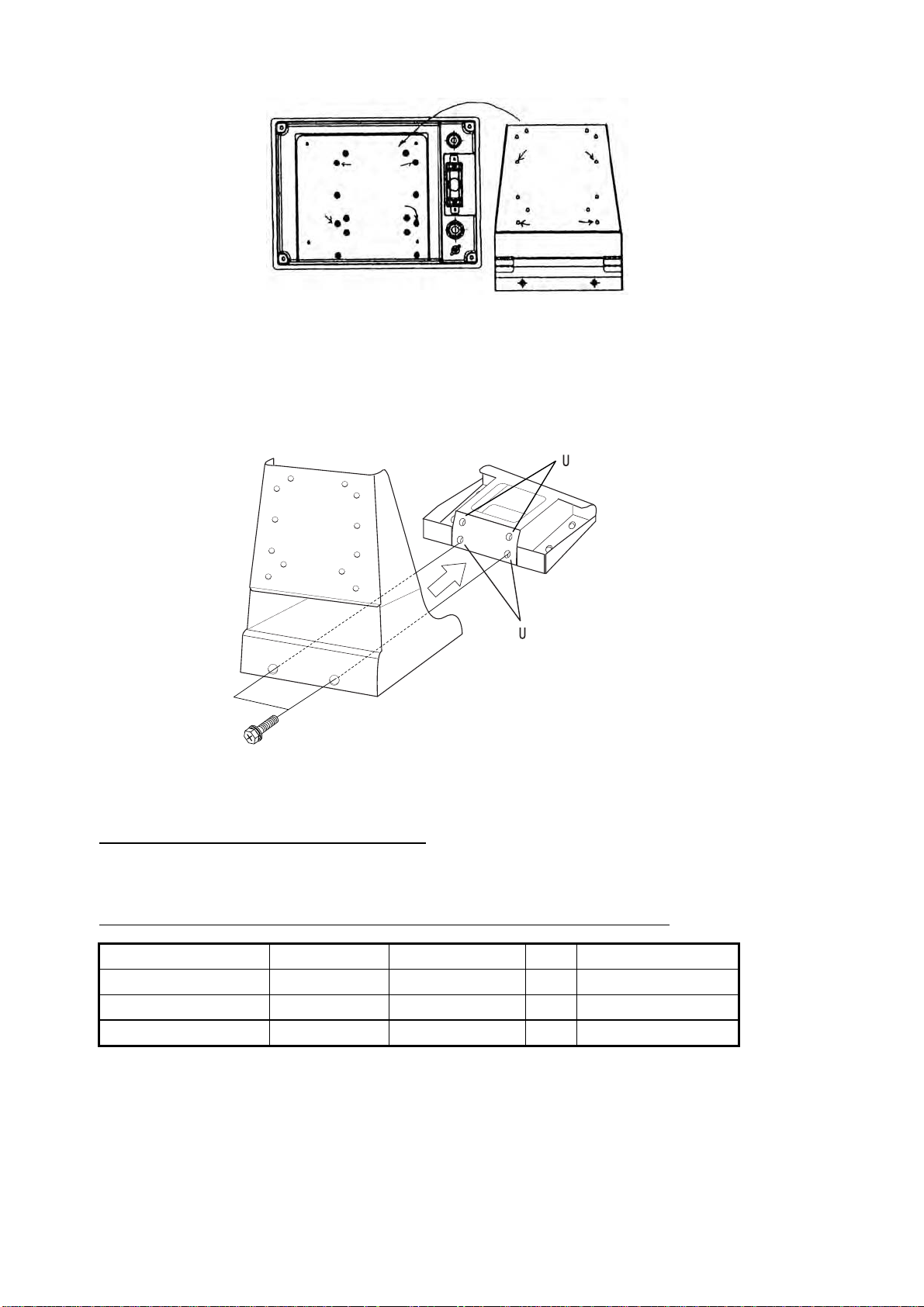

1. Fasten the mounting base to the mounting location with four tapping screws.

FRONT

Figure 1-1 Mounting base

1-1

Page 24

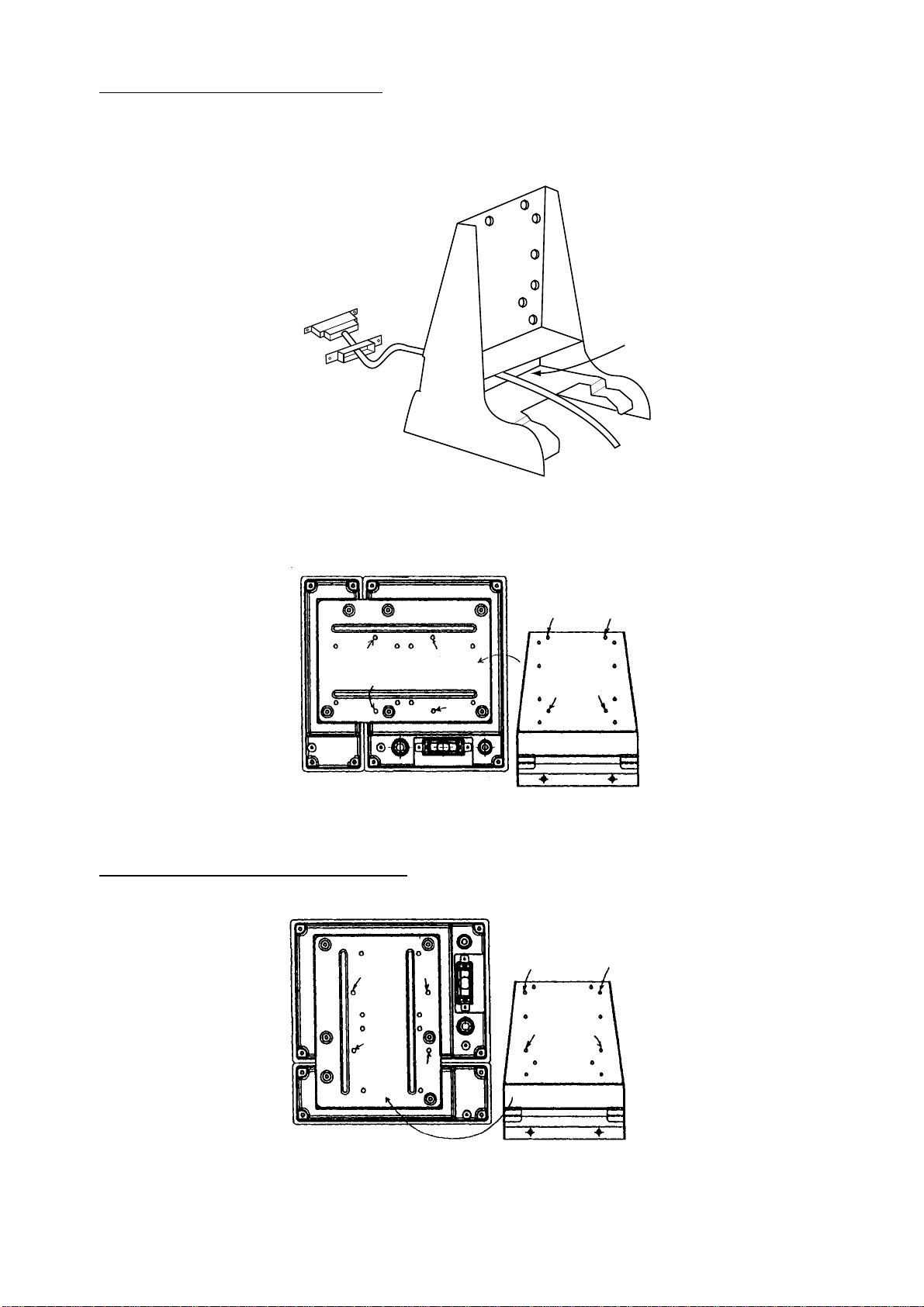

For portrait-type unibody monitor unit

a) Pass the signal cable (connects between interface unit and display unit) through the slot in

the hanger and then connect the cable to the display unit.

HANGER

Signal Cable

Slot

Figure 1-2 Hanger

b) Fasten the hanger at the rear of the display unit with four binding screws (M4X10).

Hanger (rear view)

1

1

3

2

3

2

4

4

Figure 1-3 Hanger, rear view

For landscape-type unibody monitor unit

a) Attach the hanger at the rear of the display unit with four binding screws (M4X10).

Hanger (rear view)

1

2

1

3

3

2

4

1-2

4

Figure 1-4 Hanger, rear view

Page 25

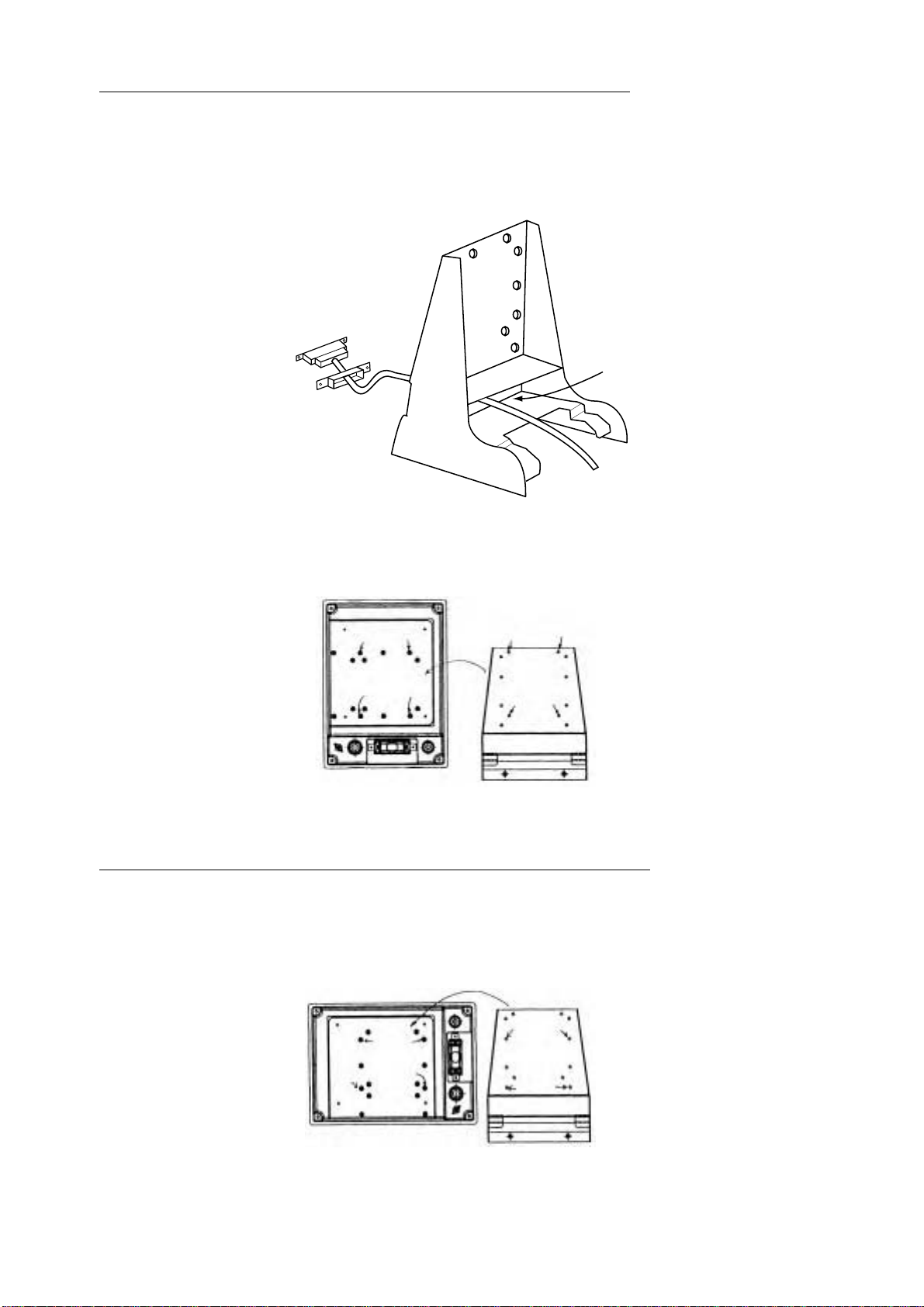

Display unit for separate type, blackbox type (vertical-type control unit)

1. Dismount the coupling place from the rear of the display unit to separate display unit from

control unit.

2. Pass the signal cable (connects between interface unit and display unit) through the slot in

the hanger and then connect the cable to the display unit.

HANGER

Signal Cable

Slot

Figure 1-5 Monitor unit, rear view

3. Attach the hanger at the rear of the display unit with four binding screws (M4X10).

Hanger (rear view)

2

1

4

3

2

1

4

3

Figure 1-6 Hanger, rear view

Display unit for separate type, blackbox type (horizontal-type control unit)

1. Dismount the coupling place from the rear of the display unit to separate display unit from

control unit.

2. Attach the hanger at the rear of the display unit with four binding screws (M4X10).

Hanger (rear view)

1

1

2

3

4

3

Figure 1-7 Hanger, rear view

2

4

1-3

Page 26

Hanger (rear view)

1

1

2

3

4

2

4

3

Figure 1-7 Hanger, rear view

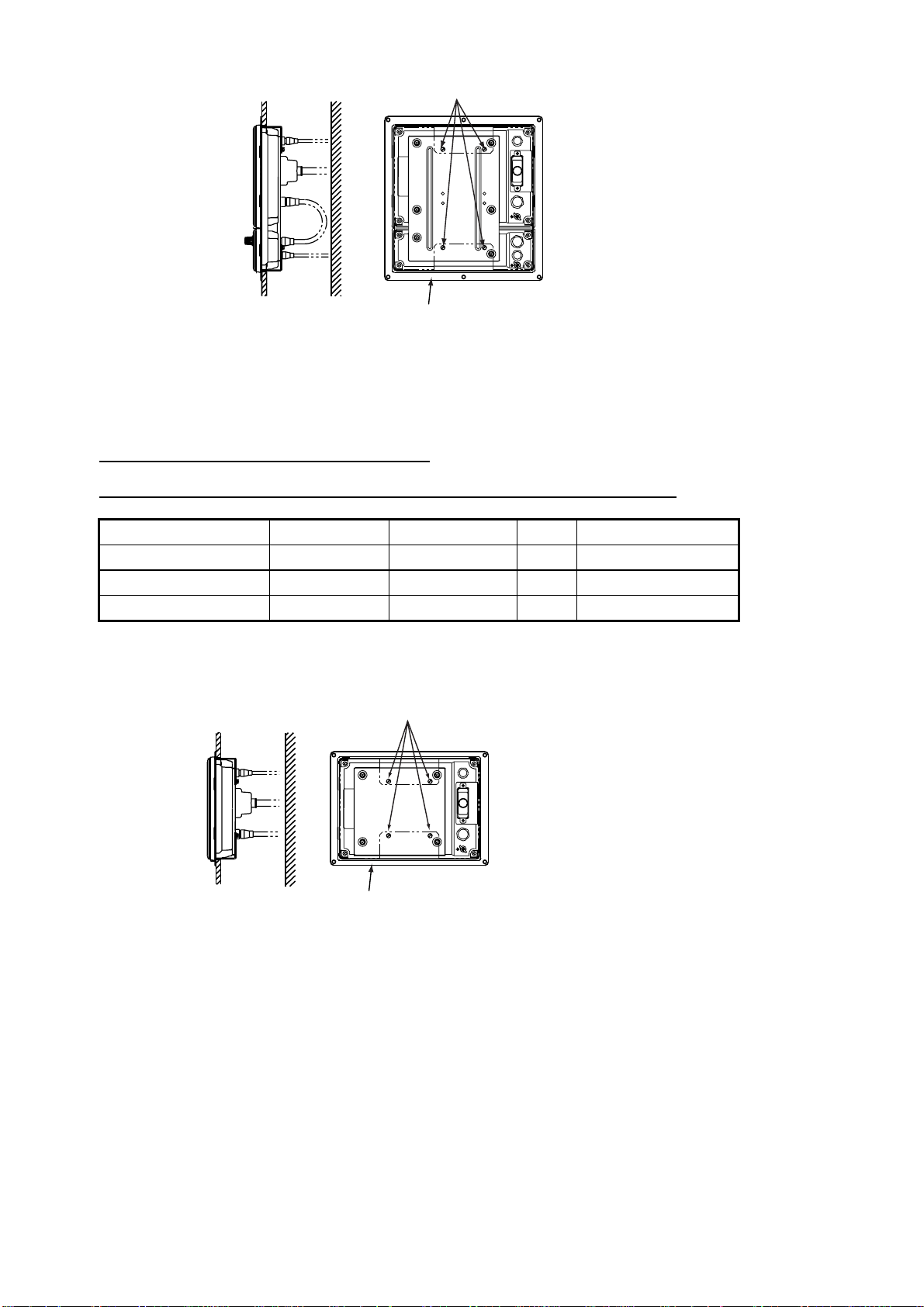

3. Coat threads of upset screws (M6X16, 2 pcs.) used to fasten hanger to mounting base.

4. Fasten the hanger (or display unit) to the mounting base with two upset screws. (Use the

upper holes to tilt the display unit 20°; lower holes to tilt it 9°.)

se these holes to

tilt monitor unit 20˚.

MOUNTING

BASE

se these holes to

tilt monitor unit 9˚.

HANGER

Upset Screw

Figure 1-8 Fastening hanger to mounting base

Unibody monitor unit flush mount kit

Refer to the outline drawing at the back of this manual.

Unib ody monitor un it flush moun t kit: Type OP06-16, Code no. 006-556-300

Name Type Code No. Qty Remarks

Mounting Fixture 06-021-1311 100-279-610 1

Self-tapping Screw 5×20 000-162-609-10 6

Hex-head Screw M4×12 000-162-939- 10 4

1. Make cutout in mounting location referring to page D-2A/D-2B.

2. Using four hex-head screws, fasten control and monitor units together with the mounting

fixture.

1-4

Page 27

Hex-head screws

Mounting fixture

location changes

with monitor

orientation.

Mounting fixture

Figure 1-9 How to flush mount unibody type monitor unit

3. Fasten the monitor unit to the mounting location with six self-tapping screws.

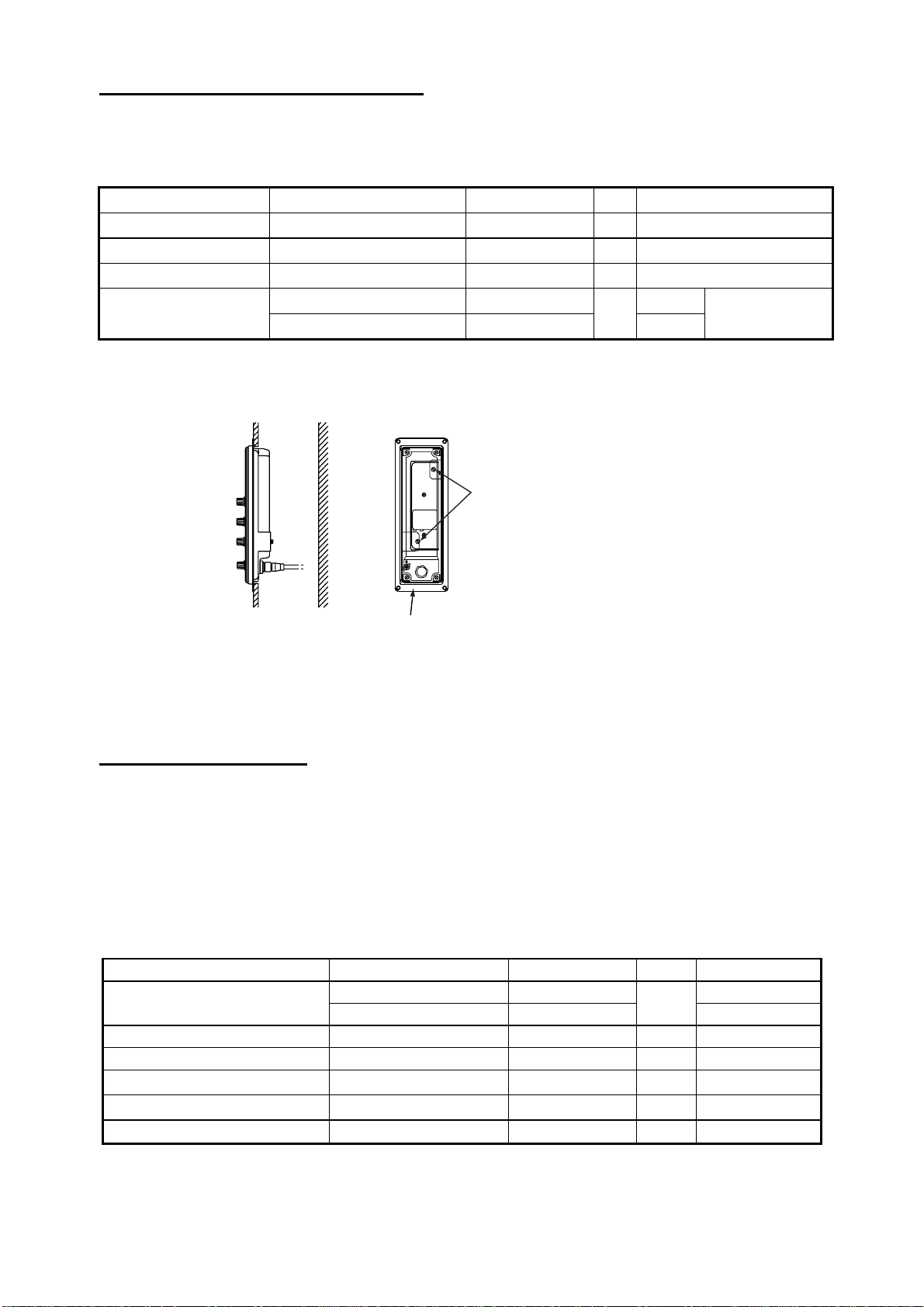

Separate monitor unit flush mount kit

Separate monitor unit flush mount kit: Type OP06-17, Code no. 006-556-310

Name Type Code No. Qty Remarks

Mounting Fixture 06-021-1321 100-279-622 1

Self-tapping Screw 5×20 000-162-609-10 4

Hex-head Screw M4×12 000-162-939- 10 4

1. Make cutout in mounting location referring to page D-8A/D-8B.

2. Fasten mounting fixture to monitor unit four hex-head screws.

Hex-head screws

Mounting fixture location

changes with monitor unit

orientation.

Mounting fixture

Figure 1-10 How to flush mount the control unit

3. Fasten monitor unit with mounting fixture to mounting location with four self-tapping screws.

1-5

Page 28

Separate control unit flush mount kit

Control unit flush mount kit OP06-18 (Code no. 006-556-320)

Separate installation kit OP02-83-1.5 (Code no. 001-413-600)

Separate installation kit OP02-83-5 (Code no. 001-413-610)

Name Type Code No. Qty Remarks

Mounting Fixture 06-021-2101 100-279-731 1

Self-tapping Screw 5×20 000-162-609-10 4

Hex-head Screw M4×12 000-162-939-10 2

Cable Assy.

1. Make cutout in mounting location referring to page D-5A/D-5B.

2. Faste n mounting fixtur e to c o ntr ol unit with two hex- hea d screws.

MJ-A10SPF002-015 000-142-878 1.5 m

MJ-A10SPF002-050 000-131-411 1 5 m

Hex-head screws

OP02-83 only

Mounting fixture location

changes with unit orientation.

Mounting fixture

Figure 1-11 How to flush mount separate type control unit

3. Fasten the control unit to the mounting location with four self-tapping screws.

Separate installation kit

The optional “separate installation kit” or “control unit flush mount kit” is required to install the

monitor and control units separate from one another. Below are the contents of the separate

installation kit. Installation procedure is the same as for the control unit for the blackbox type.

(See next page.) For control unit flush mount kit refer to above section.

Separate installation kit OP06-15-1.5 (with 1.5 m cable, code no. 006-559-140)

Separate installation kit OP06-15-5 (with 5 m cable, code no. 006-559-150)

Name Type Code Qty Remarks

Cable

Control Unit Brack et 06-021-2112 100-281- 880 1

Control Unit Mounting Base 06-021-2111 100-279-740 1

Self-tapping Scr ew 5×20

Hex-head Screw M4×12

Cosmetic Plug DP-687 000-808-417 2

MJ-A10SPF0002-015 000-142-878 1.5 m

MJ-A10SPF0002-050 000-131-411

000-162-608-10

000-162-939-10

1

5 m

2

4

1-6

Page 29

Blackbox type

Supply monitor and interconnection cable (D-sub connector, three rows of 15 pins, max. length

15 m) locally. The monitor connects to the interface unit, and should satisfy the specifications

shown below.

• VGA type

• Analog RGB , 0.7 Vp p, po s iti v e polarity

• TLL level H, V, negative polarity

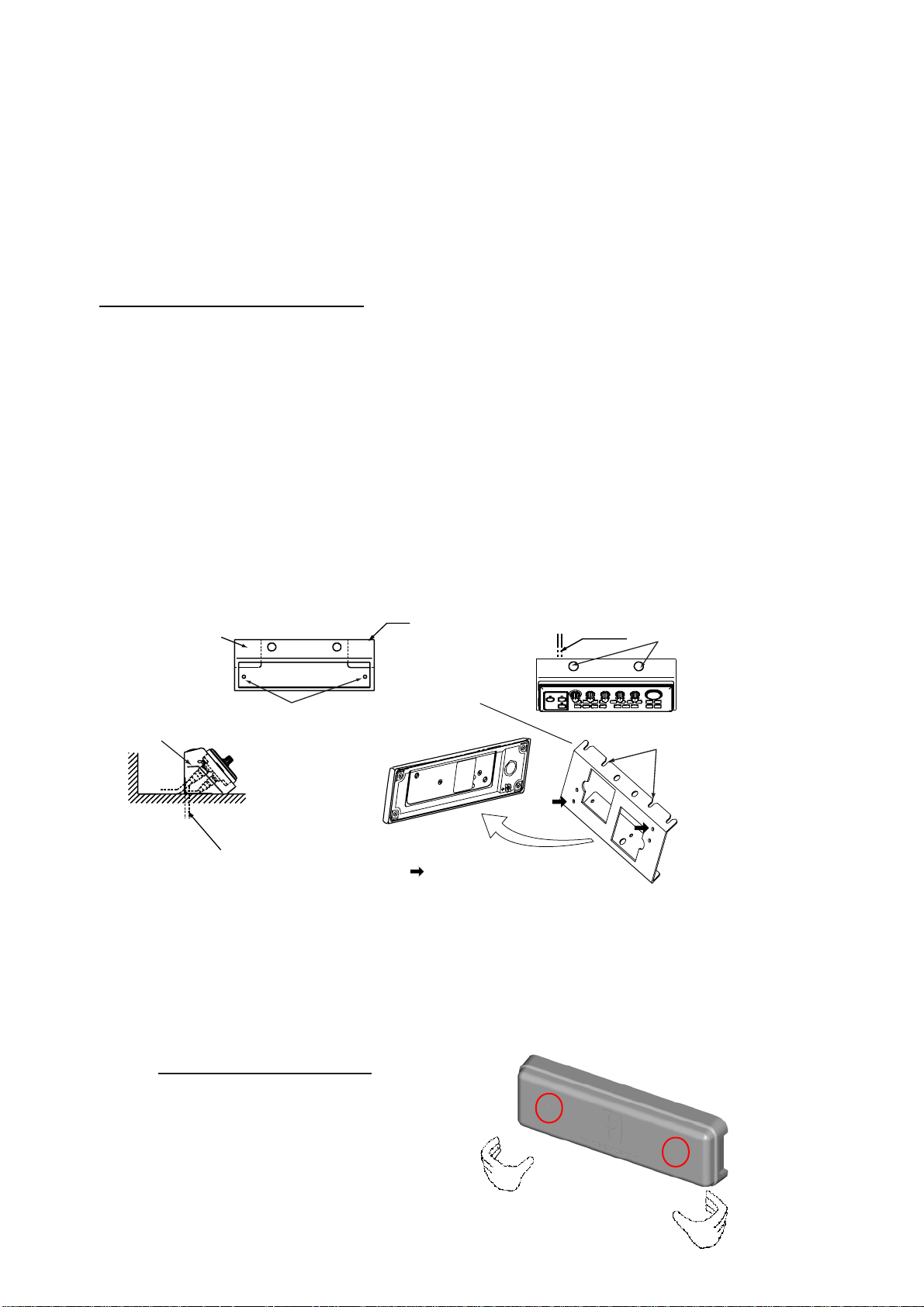

Control unit for blackbox type

The control uni t com es in two types: portrait and lan dsc a pe . T h e la nds c a pe- type control uni t ca n

be installed on a desktop or flush mounted in a panel. For desktop, the control unit should be

fastened to the control unit mounting base (supplied with accessories). The portrait-type control

unit is designed for flush mounting. For flush mount, the control unit should be fastened to the

mounting fixture (supplied with accessories).

For mounting dimensions see the outline drawing at the back of this manual.

1. Fasten the control unit mounting base to the mounting location with two 5×20 self-tapping

screws.

2. Fasten the control unit to the control unit bracket with two M4×12 hex-head screws.

3. Inserting screwdriver through holes at the top of the control unit mounting base, loosely

screw in two M4×12 hex-head screws.

Cable

entrance

Control unit

bracket

Self-tapping screw

x

20)

(M5

Control unit

(rear)

Cable can be led in

through here.

Control unit

mounting base

Control unit

bracket

: Fix with hex-head screws.

Cable

Fasten control unit

bracket from here.

Set to screws loosely

fastened at step 3.

Figure 1-12 How to mount the control unit for blackbox type

4. Set the control unit to the control unit mounting base and fasten hex-head screws inserted

at step 3.

5. Set cosmetic plugs (2 pcs.) to the holes at the top of the control unit mounting base.

6. Attach hard cover to protect the control unit.

How to remove the hard cover

Place your thumbs at the locations shown with

circles in the illustration at right, and then lift the

cover while pressing it with your thumbs.

1-7

Page 30

1.2 Processor Unit

There are two types of Processor Units: CV-1203 (FCV-1200L) and CV-1203M (FCV-1203LM).

With the EXIF Board Assy. (standard on FCV-1200LM, optional on FCV-1200L) external

equipment such as an echosounder interface, switch box, etc. can be connected.

The unit can be mounted on the deck, a desktop or on a bulkhead. Select a mounting location

considering the points below.

• Locate the uni t out o f direc t su nl i gh t.

• Select a location where temperature and humidity are moderate and stable.

• Consider the length of the cable connected between the processor unit and monitor and/or

interface unit.

• Locate the unit where its cover can be easily removed and cabling easily accessed.

• For mounting on a bulkhead be sure the mounting location is strong enough to support the

unit under the pitching and rolling normally encountered on the v essel.

• Leave sufficient space around the unit for maintenance and servicing. Recommended

maintenance space appears in the outline drawing at the back of this manual.

Tabletop or deck mounting: Fasten with four self-tapping screws.

Bulkhead mounting: Screw in four

protrudi n g. Set the pr ocessor unit to t he scr ew s a nd ti gh te n scr ews.

self-tapping screws in mounting location, leaving 5 mm

1-8

Page 31

1.3 Interface Unit

-

The Interface Unit IF-8000 is supplied with the blackbox-type system, and is optional with the

standard type system. It can be mounted on the deck, a desktop or a bulkhead. Select a

mounting location for it considering the following:

• Locate the unit away from areas subject to water splash.

• The length of the cable to processor unit is 10 max.

• Leave sufficient space around the unit for maintenance and servicing. Recommended

maintenance space appears in the outline drawing at the back of this manual.

• For mounting on a bulkhead be sure the mounting location is strong enough to support the

unit under the pitching and rolling normally encountered on the v essel.

Tabletop or deck mounting: Fasten with four self-tapping screws.

Bulkhead mounting: Screw in self-tapping screws for the upper fixing holes, leaving 5 mm

protruding. Set the interface unit to the screws. Screw in screws for lower fixing holes and

tighten. Finally, tighten screws in upper fi xing holes.

1.4 Transducer

The perfor m an ce o f th e vid eo so un der de pe n ds upo n the tr an s d uc er pos i tion. A place least

affected by air bubbles should be selected since turbulence blocks the sounding path. Further,

select a place least influenced by engine noise. It is known that air bubbles are fewest at the

place where the bow first falls and the next wave rises, at usual cruising speed. In small,

slow-speed boats, the position between 1/3 and 1/2 of the ship’s length from the bow is usually

a good place.

Note: The face of the transducer mu st be facing the sea bottom in normal cruising trim of the

boat.

1.5 Water Temperature Sensor (option)

Transom mount water tem per a t ure sens or T-02 MTB

• Fix the cable at a convenient location

on the transom with the cable clamp.

• When the cable is led through the

transom board, make a hole of

approx. 17 mm in diam eter to pass

the connector. Afte r pass ing the

cable, seal the hole with a sealing

compound.

D>50 cm

D

Figure 1

13 How to m ount transom mount

water temp er ature sensor T-02MTB

5X20

Flush with hull bottom

1-9

Page 32

Thru-hull m ount wa ter t emper at ure se ns or T-02MSB, T-03MSB

Select a suitable mounting location considering the following points:

• Selec t a mid- b oat flat positio n. The sensor do es n ot have to be instal led perfectl y

perpendicular; however, the location should not be such that the transducer may be damaged

when the boat is dry-docked.

• Locate aw ay from equipm en t which gives off heat.

• Locate away from drain pipes.

• Select a location where vibration is minimal.

T-02MSB T-03MSB

Sensor Holder

Sensor

cable

Locknut

Washer

Gasket

φ21 mm

φ25 mm

Locknut

Locknut

Washer

Gasket

Coat with

sealant.

Coat with

sealant.

Mounting procedure

1. Drill a hole of 21 mm in diameter in

the mounting location.

2. Pass the sensor cable through the

hole.

3. Pass gasket, washer and locknut

onto cable in that order.

4. Coat the sensor flange with high

quality sealant and then fasten the

sensor with the locknut.

(Torque: max. 59N·m)

5. Launch the boat to check for water

leakage around the sensor.

Holder Guide

Mounting procedure

1. Drill a hole of 25 mm in diameter in the mounting

location.

2. Coat holder guide with high quality sealant, and

pass gasket, washer and locknut onto holder

guide in that order and then tighten the locknut.

3. Set the sensor holder to the holder guide from

inside the boat and then tighten the locknut.

4. Launch the boat to check for water leakage

around the sensor.

Plate thickness within

25 mm

Figure 1-14 Assembling thru-hull water temperature sensor T-02MSB, T-03MSB

1.6 Booster Box (option)

The Booster Box enables connection of a 5 kW transducer (28F-38M, 50F-38). You can also

connect a 10 kW transducer (28F-72, 50F-70), however the maximum output power will be 5

kW

. For furt her details see i ts operator’s manual.

1-10

Page 33

2. WIRING

Refer to the interconnection diagram at the back of this manual for detailed information.

If the D-sub connector (used with monitor unit, processor unit, interface unit) is too large to pass

through a hole, remove the connector cover. Cover wiring with vinyl tape and pass cable

through hole. This will permit passing of the cable through a hole of 30 mm diameter.

Standard-type FCV-1200L

CONTROL UNIT

CV-1201: Portrait type

CV-1202: Landscape type

PROCESSOR UNIT

CV-1203

Ship's Mains

12-24 VDC

DPYCYS-2.0

Rectifier

RU-1746B-2

100/110/115/200/

220/230 VA C

1φ, 50/60 Hz

: Standard

: Option

: Local Supply

*1: FCV-1200L only

*2: Requires EXIF Assy.

*3: For sister ship one unit only

Sister ship: Requires EXIF Assy.

Master ship: Requires EXIF Assy.

*4: Navigator may be connected to either monitor unit or interface unit.

*5: Cable between monitor unit and control unit

Unibody - MJ-A10SPF0002-0015

Separate - MJ-A10SPF0002-015, MJ-A10SPF0002-050

*6: A + B < 15 m

A + C < 15 m

06S4078 (1.5m/5m/10m)

High

Frequency

Transducer*1

*5

06S4078

*1.5m/5m/10m*

Low

Frequency

Transducer*1

MONITOR UNIT

MU-101C

NMEA 0183

Navigator *4

06S4078 (1.5m/5m/10m)

TEMP

SONDE

HI

LO

Water Temp. Sensor

(T-02MSB, etc.)

Net Sonde

FNZ-18

Transceiver Unit ETR-5D/10D

T elesounder TS-7000/8000 *3

E/S Interface

VI-1100A

E/S Interface

VI-1100A

OR

Same as above

OR

Switch Box

EX-7

Transmitter Unit ETR-5D/10D

Same as above

Same as above

Same as above

External Monitor

B

Interface Unit

IF-8000

A

Navigator *4

External Monitor

Sonar, Net Recorder,

Telesounder TS-50/80 *3

Same as above

Picture Recorder

MT-12

E/S Interface VI-1100A

OR

*2

Figure 2-1 Wiring diagram for standard-type FCV-1200L

2-1

Page 34

Blackbox-type FCV-1200L

CONTROL UNIT

CV-1201: Portrait type

CV-1202: Landscape type

Ship's Mains

12-24 VDC

Rectifier

RU-1746B-2

100/110/115/200/

220/230 VA C

1φ, 50/60 Hz

Navigator

DPYCYS-2.0

External Monitor

NMEA 0183

06S4078 (1.5m/5m/10m)

PROCESSOR UNIT

CV-1203

MONITOR UNIT

MU-101C

06S4078 (1.5m/

5m/10m)

Interface Unit

IF-8000

A

LO

C

*4

06S4078 (1.5m/5m/10m)

HI

MJ-A10SPF0002-015

MJ-A10SPF0002-050

Water Temp. Sensor

(T-02MSB, etc.)

Net Sonde

FNZ-18

E/S Interface

VI-1100A

E/S Interface

VI-1100A

OR

Transceiver Unit ETR-5D/10D

T elesounder TS-7000/8000 *3

B

Interface Unit

IF-8000

External Monitor

Sonar, Net Recorder,

Telesounder TS-50/80 *3

Same as above

High

Frequency

Transducer*1

Low

Frequency

Transducer*1

: Standard

: Option

: Local Supply

*1: FCV-1200L only

*2: Requires EXIF Assy.

*3: For sister ship one unit only

Sister ship: Requires EXIF Assy.

Master ship: Requires EXIF Assy.

*4: When connecting optional monitor unit, connect it to control unit.

*5: A + B < 15 m

A + C < 15 m

Figure 2-2 Wiring diagram for blackbox-type FCV-1200L

Same as above

OR

Switch Box

EX-7

Picture Recorder

MT-12

E/S Interface VI-1100A

OR

Transmitter Unit ETR-5D/10D

Same as above

Same as above

Same as above

*2

2-2

Page 35

Standard-type FCV-1200LM

CONTROL UNIT

CV-1201: Portrait type

CV-1202: Landscape type

PROCESSOR UNIT

CV-1203M

Ship's Mains

DPYCYS-2.0

12-24 VDC

Rectifier

RU-1746B-2

100/115/200/

220/230 V AC

1φ, 50/60 Hz

*4

06S4078

*1.5m/5m/10m*

06S4078(1.5m/5m/10m)

MONITOR UNIT

MU-101C

NMEA 0183

Navigator *2

06S4078 (1.5m/5m/10m)

Water Temp. Sensor

(T-02MSB, etc.)

TEMP

SONDE

HI

LO

Net Sonde

FNZ-18

Transceiver Unit ETR-5D/10D

T elesounder TS-7000/8000 *3

E/S Interface

VI-1100A

E/S Interface

VI-1100A

OR

External Monitor

B

Interface Unit

IF-8000

A

Navigator *2

External Monitor

Sonar, Net Recorder,

Telesounder TS-50/80 *1

Same as above

: Standard

: Option

: Local Supply

*1: Sister ship only

*2: Navigator may be connected to either monitor unit or interface unit.

*3: Cable between monitor unit and control unit

Unibody - MJ-A10SPF0002-0015

Separate - MJ-A10SPF0002-015, MJ-A10SPF0002-050

*4: A + B < 15 m

A + C < 15 m

Figure 2-3 Wiring diagram for standard-type FCV-1200LM

Same as above

OR

Switch Box

EX-7

Picture Recorder

MT-12

E/S Interface VI-1100A

OR

Transmitter Unit ETR-5D/10D

Same as above

Same as above

Same as above

2-3

Page 36

Blackbox-type FCV-1200LM

CONTROL UNIT

CV-1201: Portrait type

CV-1202: Landscape type

PROCESSOR UNIT

CV-1203M

Ship's Mains

12-24 VDC

Rectifier

RU-1746B-2

100/110/115/200/

220/230 V AC

1φ, 50/60 Hz

Navigator

DPYCYS-2.0

External Monitor

NMEA 0183

06S4078(1.5m/5m/10m)

MONITOR UNIT

MU-101C

06S4078(1.5m/

5m/10m)

Interface Unit

IF-8000

*3

TEMP

SONDE

HI

LO

MJ-A10SPF0002-015

MJ-A10SPF0002-050

C

*3

06S4078(1.5m/5m/10m)

Water Temp. Sensor

(T-02MSB, etc.)

Net Sonde

FNZ-18

E/S Interface

OR

Transceiver Unit ETR-5D/10D

T elesounder TS-7000/8000 *1

VI-1100A

E/S Interface

VI-1100A

External Monitor

B

Interface Unit

IF-8000

A

C

Interface Unit

IF-8000

External Monitor

Sonar, Net Recorder,

Telesounder TS-50/80 *1

Same as above

OR

Switch Box

: Standard

: Option

: Local Supply

*1: Sister ship only

*2: When optional monitor unit is connected, connect it to the control unit.

*3: A + B < 15 m

A + C < 15 m

Figure 2-4 Wiring diagram for blackbox-type FCV-1200LM

Same as above

Picture Recorder

EX-7

E/S Interface VI-1100A

Transmitter Unit ETR-5D/10D

Same as above

Same as above

Same as above

MT-12

OR

2-4

Page 37

2.1 Wiring Standard Equipment

Transducer (FCV-1200L only)

Separate the transducer cable well away from power cables to prevent interference. Connect the

cable to the transducer connector at the rear of the processor unit. Fabricate the cable as below.

Shield

Connector

Cable Clamp

Shield Foam 71TS-10-1

Cable

Figure 2-5 Fabrication of transducer cable

Note:

For connection of dual-frequency transducer, use cable assy. NCS255AD-254P-L500

(option).

Echosounder interf ace (FCV-1200LM only)

The Echosounder Interface VI-1100A connects external equipment such as a color video

sounder, Transceiver Unit (ETR-5D/ETR-10D), Switch Box EX-7, etc. Attach connector

SRCN6A25-24P (supplied) to the signal cable assy. supplied with the Transceiver Unit.

Note 1:

equipment. Connector SRCN6A25-24P is optionally available.

For the FCV-1200L, the EXIF board assy. (option) enables connection of external

Note 2:

Telesounder may be connected to EXT-H or EXT-L.

(1) Solder connector terminals.

Sheath

Shield

Solder connector terminals.

(2) Cover shield with shield foam where shield is to be clamped.

Sheath

Shield foam (conductive resin tape)

(3) Tighten clamp.

CABLE

Pass connector case onto cable.

Clamp

Sheath

Shield foam

Unfasten two screws.

Figure 2-6 Fabrication of cable, connector for echosounder interface

2-5

Page 38

Power cable

This video sounder is designed to be powered with 12-24 VDC power. To prevent power loss,

use power cable DPYCYS-2.0 (or equivalent) or equivalent. The armor should lie within the

connector case. Confirm polarity when connecting pins.

Lay armor in cable

#1 pin (+)

#2 pin (-)

#3 pin

Taping

Sheath

Core

S = 3.5 mm

φ = 2.4 mm

2

Vinyl Sheath

Shield

Figure 2-7 Fabrication of power cable

Ground

The processor unit, monitor unit and interface unit should be grounded to prevent mutual

interference. Connect an earth plate or earth wire (interface unit) between unit and ship’s

superstructure to ground.

Armor

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

Interface unit IF-8000

The Interface Unit IF-8000 is supplied standard with the FCV-1200LM and is optionally available

with the FCV-1200L.

DATA/VIDEO IN DATA/VIDEO OUT RGB OUT

Cable (06S4078)

from processor

unit

Cable (06S4078)

from monitor unit

or interface

unit

CONT

VGA

Monitor

Cable (06S4079)

from control

unit

NMEA

Navigator

Earth terminal

(Ground to ship's

superstructure.)

GROUND TO

PREVENT MUTUAL

INTERFERENCE.

2-6

Figure 2-8 Interface unit, rear view

Page 39

Use a monitor cable (max. length 15 m) to connect a commercial monitor. A D-sub 15P

connector with three rows of pins is required for connection at the interface unit. The monitor

must satisfy the following requirements:

VGA type

Analog RGB, 0.7Vpp, positive polarity

TTL level H, V, negative polarity

Note 1:

Note 2:

DATA/VIDEO OUT its connector will touch the connector of DATA/VIDEO IN. To prevent this, cut

and remove the rubber covers and fixing metals from the connectors as below to attach them to

the interface unit.

Two interface units may be connected.

When connecting the Monitor Unit MC-101C or an interface unit to the terminal

Connectors touch here.

Remove

fixing metals.

Cut and

remove

covers.

Figure 2-9 Remover fixing metals and covers from connectors

of DATA/VIDEO IN and DATA/VIDEO OUT

Note 3:

interface units in parallel, cable lengths should be as below. Further, two cables (type 06S4078)

of 10 m in length cannot be used.

When connecting the interface unit to the Monitor Unit MU-101C or connecting two

2-7

Page 40

2.2 Wiring Optional Equipment

Navigator

Use cable type MJ-A6SPF0011/0012 (option) to connect the navigator to the NMEA connector

on the standard LCD monitor unit or Interface Unit in case of blackbox system. For detailed

information see the interconnection diagram at the back of this manual.

Water temperature sensor T-02MSB, T-02MTB, T-03MSB

Connect the water temperature sensor cable to the TEMP connector on the processor unit.

Net Sonde FNZ-18

Use connector type FM14-8P (option) and five-pair cable CO-SPEVV-SB-C 0.2X5P (or

equivalent, local supply) to connect the Net Sonde to the SONDE connector on the processor

unit. Attach the connector to the cable as below.

Analog sonde signal and sonde temperature may also be input. For details see the

interconnection diagram at the back of this manual.

1. Remove sheath by 15 mm.

3.Solder cores to connector

pins; clamp shield.

Figure 2-11 Fabrication of cable for net sonde

2. Fold back shield onto cable;

cut unused cores.

Wrap with vinyl tape.

4. Tape shield with vinyl tape,

leaving no gap between

clamp and tape.

2-8

Page 41

EXIF board assy.

The EXIF board assy. (type OP02-81, code no. 000-012-463), installed inside the processor unit

CV-1203, is necessary when connecting a telesounder (on sister ship and ma ster ship),

transceiver or other video sounder to the FCV-1200L. Below are the contents of the EXIF board

assy. kit. For connection cable use type S-02-6-10 (24P, 10 m, Code No. 002-962-030).

Name Type Code No. Qty Remarks

EXIF Assy. OP02-81 001-413-440 1

Pan Head Screw M4×10 000-163-191-10 3

SRCN Connector S RCN6A 25- 24P 000-160-740- 10 2

1. Remove the cover o f the pr ocessor unit by unfastenin g 13 sc r ews (M4X8).

Unfasten 13 screws to remove cover.

Left, right, top: 6 (2 screws each side)

Heat sink: 7 screws

Unfasten two screws to remove dummy plate.

Dummy plate

Figure 2-12 Processor unit CV-1203, rear view

2. Unfasten two screws to remove the dummy plate. (The screws and plate may be

discarded.)

3. Unfasten screw marked with % in the figure below. (The screw may be discarded.)

4. Fasten the EXIF board assy. to the chassis with three screws (M4×10, supplied).

*Screw

(M4x10)

J7

POWER

SECTION

Screw

x10)

(M4

MAIN

Board

*- Fasten screw here.

J1

EXIF Board

Assy.

Figure 2-13 Processor unit CV-1203, left side view

5. Connect the EXIF Assy. between J1 on the pcb 02P6278 and J7 on the MAIN board. For

log-type video sounder, see page 3-23.

6. Close the cover.

2-9

Page 42

2.3 Input/Output Sentences

Input sentences

Sentence Data Remarks

GGA Time, position

GLC GRI, TD (Loran C)

GLL Latitude and longitude

GTD TD (Loran C)

MTW Water temperature

RMA Latitude and longitude, TD (Loran C), ground speed and course

RMB Recommended minimum navigation information

RMC Latitude and longitude (GPS), ground speed and course

VTG Speed through the ground and course

hve Heaving data (satellite compass) P sentence

att Roll angle, Pitch angle (satellite compass) P sentence

Output sentences

Sentence Data Remarks

DBS Depth below sea surface Ver. 1.5

DBT Depth below transducer Ver. 1.5

DPT Depth below transducer Ver. 2.0

MTW Water temperature Ver. 1.5. Ver. 2.0 with connection of water

temperature sensor

TLL Target position Ver. 2.0

VRM Water depth Ver. 1.5. Ver. 2.0

CIF input signal

Signal Data Remarks

66 Current (tide) speed, current course

D3 Sonde water temperature, depth

2-10

Page 43

3. INITIAL SETTINGS

This section provides the information necessary for initial setup of the equipment. First turn on

the power and set display language. For the FCV-1200L, enter transducer used, by model

number (FURUNO transducer only) or by specifications. For either model, execute other

procedures as applicable.

3.1 Language Setting

1. Turn on the power. The following display appears.

Note:

The picture on your set may be turned 90

section 3.2.

Please set language.

([ / ]: Select, [+]: Enter)

XXXXXXXX

XXXXXXXX

English

XXXXX

Figure 3-1 Initial display screen

2. Press [ ] to select English, and then press the [+] key to set. The following display appears

on the FCV-1200L only.

Carrry out transducer setting.

Press any key to go to Transducer setting menu.

FCV-1200L:

3.

applicable section(s).

FCV-1200LM:

3.4 and follow the appropriate procedure according to equipment connected (transceiver unit,

external video sounder, picture recorder, telesounder). Then, go to other applicable sections.

Change picture orientation (if necessary) and set transducer type. Then, go to

Change picture orientation (if necessary) and turn off the power. Go to section

(For Japanese customers)

(Japanese)

°

. Picture orientation may be corrected at

3-1

Page 44

3.2 Display Type

If your picture is turned 90° do the following:

1. Press any key to show the installation main menu.

XDCR SETTING INSTALLATION DEMO

XDCR SELECT : XDCR TYPE

[HIGH] FREQ : --- kHz

TRANSDUCER : -----

PWR REDUCTION : OFF

OUTPUT POWER : -- kW

SUPPL Y V OLT : -- V

[LOW] FREQ : --- kHz

TRANSDUCER : -----

PWR REDUCTION : OFF

OUTPUT POWER : -- kW

SUPPL Y V OLT : -- V

[-/+]: Change setting, Turn OFF to exit

Figure 3-2 Installation main menu

2. Press [+] to selection INSTALLATION.

XDCR SETTING INSTALLATION DEMO

MONITOR TYPE : LANDSCAPE

SOUND SPEED : 1500.0 m/s (1~2000)

3-2

[-/+]: Change setting, Turn OFF to exit

Figure 3-3 INSTALLATION menu

Page 45

3. Press [ ] to select MONITOR TYPE, and then press [+] to open the dialog box.

PORTRAIT LANDSCAPE

4. Use [+] or [-] to select appropriate monitor type, and then press [+] to close the dialog box.

5. Turn off the power to change picture orientation.

3.3 Transducer Data (FCV-1200L only)

This paragraph provides information necessary for entering transducer data. You enter

transducer data by either transducer model number (for FURUNO transducer, page 3-4) or

specification (page 3-5). The FCV-1200L is programmed for use with the following

non-FURUNO transducers.

Maker Frequency Transducer Type Remarks

Simrad 38kHz 38E-9-18S1(2kW)

Airmar 38kHz 38E-M42(3kW)

Honda

28kHz 28/55/100(3kW)

33kHz 36/65/110(3kW)

36kHz 32/40(3kW)

41kHz 40/75(3kW)

50/200/400(2kW) 50kHz

50/3K/3F(3kW)

55kHz 28/55/100(3kW)

60kHz 36/65/110(3kW)

67kHz 40/75(3kW)

100kHz 28/55/100(3kW)

118kHz 36/65/110(3kW)

200kHz 50/200/400(2kW)

400kHz 50/200/400(2kW)

50kHz TGM50/200 Suzuki

200kHz TGM50/200

Same as FURUNO 50/200-1T(1kW)

CAUTION

Set the transducer model number

properly.

Wrong transducer setting can damage the

transducer and void the warranty.

CAUTION

Do not enter transducer data by specifications if model number of transducer

used is programmed in the equipment.

Wrong transducer setting can damage the

transducer and void the warranty.

3-3

Page 46

Entering transducer data by transducer model number

Note 1: If you are continuing from paragraph 3.1 go to step 2.

Note 2: If you have already entered transducer settings and want to reconfirm them turn on the

power while pressing any key.

1. Turn on the power.

2. Press any key to show the following menu.

XDCR SETTING INSTALLATION DEMO

XDCR SELECT : XDCR TYPE

[HIGH] FREQ : --- kHz

TRANSDUCER : ---- TX POWER : MAX

OUTPUT POWER : -- kW

SUPPL Y V OLT : -- V

[LOW] FREQ : --- kHz

TRANSDUCER : ---- TX POWER : MAX

OUTPUT POWER : -- kW

SUPPL Y V OLT : -- V

[-/+]: Change setting, Turn OFF to exit

Figure 3-4 Ins tallati on m ai n m en u

3. Press [

] to select [HIGH] FREQ or [LOW] FREQ (whichever is installed), and then press

[+] to show the dialog box. (The appearance of the dialog box depends on the type of

monitor unit used.) The scroll bar at the bottom of the dialog box shows cursor position in

relation to the entire menu.

15 kHz 28 kHz 33 kHz 36 kHz 38 kHz 41 kHz 45 kHz 50 kHz

Scroll bar

4. Press [+] or [-] to select transducer frequency, and then press [

] or [ ] to close the dialog

box.

5. Press [

] to select TRANSDUCER, and then press [+] to open the dialog box. The dialog

box below is for the 200 kHz transducer.

200B-5S (1kW) 50/200-1ST (1kW) 50/200-1T (1 kW) 200 -8/8 (2 kW)

6. Press [+] or [-] to select model number, and then press [

] or [ ] to close the dialog box.

7. To operate the transducer in reduced power (for example, when vessel is in dry dock), press

] to select TX POWER, and then press [+] to open the dialog box.

[

3-4

Page 47

MAX 1/2 1/4 1/8 1/16 MIN

8. Press [+] or [-] to select appropriate power, and then press [

] or [ ] to close the dialog box.

Normally set to MAX. MIN means transmission power less than 1W.

9. Follow steps 1-6 to enter model number of other transducer if installed.

Note: For dual-frequency transducer, enter both high and low frequencies and set the same

transducer model number for both high and low frequencies.

10. Confirm settings and turn off the power.

Note: If the system detects frequency mismatch the message “Frequency unmatch error! Press

any key to go to Transducer setting menu.” appears at the next powering of the equipment.

Press any key to go to the transducer setting menu and reenter transducer data.

Entering transducer data by transducer specifications

For new transducer or other make of transducer see FURUNO Information for further

information.

Note 1: If you are continuing from paragraph 3.1 go to step 2.

Note 2: If you have already entered transducer settings and want to reconfirm them turn on the

power while pressing any key.

1. Turn on the power.

2. Press any key.

3. Press [

TYPE MANUAL

] to select XDCR SELECT, and then press [+] to show the dialog box below.

4. Press [+] to select MANUAL, and then press [

should now look something like the one below.

XDCR SETTING INSTALLATION DEMO

XDCR SELECT : MANUAL

[HIGH] FREQ : --- kHz

SUPPL Y V OLT : --- V

TX POWER : MAX

[LOW] FREQ : --- kHz

SUPPL Y V OLT : --- V

TX POWER : MAX

INVERTER FREQ : STD (62/125/188 kHz)

NOTE: Don't select the item which is

within +/- 3kHz of power supply freq.

Select how to set XDCR type.

] or [ ] to close the dialog box. The display

[-/+]: Change setting, Turn OFF to exit

Figure 3-5 Menu for manual entry of transducer specifications

3-5

Page 48

5. Do the following for both the high and low frequency transducers, or whichever transducer

is installed.

a) Press [ ] to select [HIGH] FREQ or [LOW] FREQ, and then press [+] to open the dialog box.

--- kHz

b) Press [+] or [-] to enter transducer frequency, and then press [ ] or [ ] to close the dialog

box.

c) Press [

d) Press [+] or [-] to enter transducer supply voltage, and then press [

] to select SUPPLY VOLT, and then press [+] to open the dialog box.

--- V

] or [ ] to close the

dialog box.

e) To operate the transducer in reduced power (for example, when vessel is in dry dock),

press [

MAX 1/2 1/4 1/8 1/16 MIN

f) Press [-] to select MAX and then press [ ] or [ ] to close the dialog box.

g) If the transducer frequency and power frequency are the same, noise will be present in the

picture. To prevent this, change the inverter (power) frequency. Press [

INVERTER FREQ, and then press [+] to open the dialog box.

6. Press [+] or [-] to select appropriate power frequency, and then press [

] to select TX POWER, and then press [+] to open the dialog box.

] to select

LO(59/118/177kHz) STD(62/125/188kHz) HI(66/132/198kHz)

] or [ ] to close the

dialog box.

7. Confirm settings and turn off the power.

3-6

Page 49

3.4 Adjustment for Transceiver Unit, Video Sounder,

Telesounder, Picture Recorder

This section provides the settings necessary when connecting a Transceiver Unit (ETR-5D,

ETR-10D, etc.), Color Video Sounder, Telesounder (TS-30/507000/8000) or the Picture

Recorder MT-12.

Note 1: For the FCV-1200L, first install the EXIF board assy. See page 2-7.

Note 2: For the FCV-1200LM, only a master ship’s telesounder can be connected. Further, the

Picture Recorder MT-12 can only play back the echosounder signal; it cannot be used for

recording.

Transceiver unit, video sounder

1. Turn on the power.

2. Turn the [FUNCTION] switch to the MENU position.

3. Press [

] and [+] to select SYSTEM at the top of the screen.

DISP ALM TX/RX USER-1/2 SYSTEM

SYSTEM SETTING

ES/DRAFT SETTING

RANGE SETTING

TEMP SETTING

NET SONDE SETTING

USER COLOR SETTING

USER CLUTTER SETTING

NAV DATA SETTING

TARGET ECHO

STABILIZATION

TEST MODE

DEFAULT SETTING

Menu for system setting.

[+]: Go to setting [EXIT (knob)]: Exit

Figure 3-6 SYSTEM menu

3-7

Page 50

4. Press [ ] to select E/S DRAFT SETTING, and then press [+] to open that menu.

DISP ALM TX/RX USER-1/2 SYSTEM

E/S DRAFT SETTING

<High Frequency>

XDCR CONNECT : INTERNAL

TX POWER : MAX

DRAFT : +0.0 ft (-15~+90)

FREQ CHOICE : **kHz

<Low Frequency>

XDCR CONNECT : INTERNAL

TX POWER : MAX

DRAFT : +0.0 ft (-15~+90)

FREQ CHOICE : ***kHz

E/S SIG OUT : OFF

KP SETTING : INTERNAL

Select transducer connected.

[-/+]: Change set, [EXIT (knob)]: Exit

Figure 3-7 E/S DRAFT SETT ING menu

5. Do the following for both the high and low frequencies, or whichever is installed.

a) Select XDCR CONNECT, and then press [+] to open the dialog box.

INTERNAL ETR TS/OTHER

b) Select INTERNAL or ETR referring to the table below, and then press [ ] or [ ] to close the

dialog box.

Equipment connected

Transceiver Unit ETR OFF

External Video Sounder INTERNAL LF, HF, LF/HF

E/S DRAFT SETTING menu item

XDCR CONNECT E/S SIG OUT

c) If the transceiver or external video sounder is to be used when vessel is in dry dock, select

TX POWER and press [+] to open the dialog box.

MAX 1/2 1/4 1/8 1/16 MIN

d) Press [+] to select appropriate power, and then press [ ] or [ ] to close the dialog box.

3-8

Page 51

For transceiver unit

1. Do the following for both high and low frequencies, or whichever is installed.

a) Use [ ] or [ ] to select DRAFT and press [+] to open the dialog box.

+0.0

b) Use [+] or [-] to enter ship’s draft, and then press [

] or [ ] to close the dialog box.

2. Press [ ] to select E/S SIG OUT, and then press [+] to open the dialog box.

OFF LF HF LF/HF

3. Select OFF, and then press [

] or [ ] to close the dialog box.

4. Turn the [FUNCTION] switch to the EXIT position to quit.

For external video sounder

1. Turn the [FUNCTION] switch to the EXIT position.

2. Do the following for both the high and low frequencies, or whichever is installed.

a) Set the [MODE] switch in the LF, HF or DUAL (dual-frequency transducer only) position.

b) Measure how many feet the transmission line is shifted, by using the VRM marker.

c) If the transmission line is shifted go to step 3, and if it has not shifted, go to step 6.

3. Turn the [FUNCTION] switch to the MENU position.

4. Press [

] and [+] to show the SYSTEM menu.

5. Do the following for both the high and low frequencies, or whichever is installed.

a) Use [ ] or [ ] to select DRAFT, and then press [+] to open the dialog box.

+0.0

b) Use [+] or [-] to enter value measure at step 2, and then press [ ] or [ ] to close the dialog

box.

6. Press [ ] to select E/S SIG OUT, and then press [+] to open the dialog box.

OFF LF HF LF/HF

7. Select LF, HF or LF/HF as appropriate, and then press [

8. Press [

INTERNAL EXTERNAL

] to select KP SETTING and [+] to open the dialog box.

] or [ ] to close the dialog box.

3-9

Page 52

9. Press [+] to select EXTERNAL, and then press [ ] or [ ] to close the dialog box.

10. Turn the [FUNCTION] switch to the EXIT position to quit.

Telesounder

The FCV-1200LM can only be connected to a telesounder on board a master ship and the

FCV-1200L to a telesounder on board a master ship or sister ship.

1. Turn on the power.

2. Turn the [FUNCTION] switch to the MENU position.

3. Press [

4. Press [

] and [+] to select SYSTEM at the top of the screen.

] to select E/S DRAFT SETTING, and then press [+] to open that menu.

5. Do the following for both the high and low frequencies, or whichever is installed.

a) Select XDCR CONNECT, and then press [+] to open the dialog box.

INTERNAL ETR TS/OTHER

b) Select TS / OTHER or INTERNAL referring to the table below, and then press [ ] or [ ] to

close the dialog box.

Equipment connected

Telesounder installed on sister ship INTERNAL LF/HF

Telesounder installed on master ship TS / OTHER OFF

E/S DRAFT SETTI NG menu i t em

XDCR CONNECT E/S SIG OUT

6. Press [ ] to select E/S SIG OUT, and then press [+] to open the dialog box.

OFF LF HF LF/HF

7. Select OFF, LF, HF, LF/HF referring to the table above.

8. Press [

] or [ ] to close the dialog box.

9. Follow the procedure below to set up for telesounder installed on a master ship, or turn the

[FUNCTION] switch to the EXIT position to quit.

Do the following for telesounder installed on master ship

1. Turn the [FUNCTION] switch to the EXIT position.

2. Do the following for both the high and low frequencies, or whichever is installed.

a) Set the [MODE] switch in the LF, HF or DUAL (dual-frequency only) position.

b) Measure how many feet the transmission line is shifted, by using the VRM marker.

c) If the transmission line is shifted go to step 3, and if it has not shifted, go to step 6.

3. Turn the [FUNCTION] switch to the MENU position.

4. Press [

3-10

] and [+] to show the SYSTEM menu.

Page 53

5. Do the following for both the high and low frequencies, or whichever is installed.

a) Use [ ] or [ ] to select DRAFT, and then press [+] to open the dialog box.

+0.0

b) Enter value measured at step 2 with [+] or [-], and then press [ ] or [ ] to close the dialog

box.

Final adjustment (master ship and sister ship)

1. Observer the picture from the sister ship and master ship. The dynamic range of the signal

received at the telesounder is about 6 dB less than that of the raw signal, so set the clutter

control on the telesounder between 2 and 3. This should produce the same picture on both

the master and sister ships.

2. Turn the [FUNCTION] switch to the EXIT position to quit.

Picture recorder

The FCV-1200L can only playback the echosounder signal; FCV-1200LM can record and play

back the echosounder signal.

1. Turn on the power and turn the [FUNCTION] switch to the MENU position.

2. Press [

3. Press [

] and [+] to select SYSTEM at the top of the screen.

] to select E/S DRAFT SETTING, and then press [+] to open that menu.

4. Do the following for both the high and low frequencies, or whichever is installed.

a) Select XDCR CONNECT, and then press [+] to open the dialog box.

INTERNAL ETR TS/OTHER

b) Select INTERNAL or TS / OTHER referring to the table below, and then press [ ] or [ ] to

close the dialog box.

Equipment connected

Record INTERNAL LF + HF

Playback TS / OTHER OFF

E/S DRAFT SETTI NG menu i t em

XDCR CONNECT E/S SIG OUT

5. Press [ ] to select E/S SIG OUT, and then press [+] to open the dialog box.