Page 1

Installation Manual

COLOR LCD SOUNDER FCV-1150

SAFETY INSTRUCTIONS ............................................................................i

SYSTEM CONFIGURATION ......................................................................iii

EQUIPMENT LISTS.................................................................................... iv

1. MOUNTING............................................................................................1

1.1 Display Unit ..................................................................................................................1

1.2 Transducer ...................................................................................................................1

1.3 Water Temperature/Speed Sensor ..............................................................................2

2. WIRING .................................................................................................. 5

2.1 Interconnection .............................................................................................................5

2.2 Wiring Standard Equipment..........................................................................................6

2.3 Input/Output Sentences................................................................................................8

3. INITIAL SETTING ................................................................................ 10

3.1 Language Setting .......................................................................................................10

3.2 Transducer Data.........................................................................................................11

3.3 Speed/Water Temperature Sensor Calibration ..........................................................14

3.4 NMEA Port Setting .....................................................................................................16

3.5 Heaving Setting ..........................................................................................................17

APPENDIX TRANSDUCER 82B-35R .................................................AP-1

PACKING LIST........................................................................................ A-1

OUTLINE DRAWINGS............................................................................. D-1

INTERCONNECTION DIAGRAM ............................................................ S-1

www.furuno.com

All brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Page 2

Page 3

SAFETY INSTRUCTIONS

WARNING

WARNING

The operator and installer must read the applicable safety instructions before attempting to

install or operate the equipment.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

Warning, Caution

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

can result in minor or moderate injury.

Prohibitive Action

Mandatory Action

ELECTRICAL SHOCK HAZARD

Do not open the equipment

Turn off the power at the switchboard

before beginning the installation.

Connect to a dedicated breaker in the power

distributor.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can result in fire,

electrical shock or damage the equipment.

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

should work inside the

equipment.

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or damage the equipment.

The voltage rating of the equipment

appears on the label above the power

connector.

Install the transducer according

to the installation instructions.

Failure to install the transducer correctly

may result in water leakage and damage to

the ship's hull.

For wooden or FRP vessel using a steel

tank, attach a zinc plate to the hull to

prevent electrolytic corrosion.

Electrolytic corrosion can, in the worst

case, result in loss of the transducer.

Be sure no water leaks in at the transducer mounting location.

Water leakage can sink the vessel. Also,

confirm that the transducer will not loosen

by ship's vibration. The installer of the

equipment is solely responsible for the

proper installation of the equipment.

FURUNO will assume no responsibility for

any damage associated with improper

installation.

i

Page 4

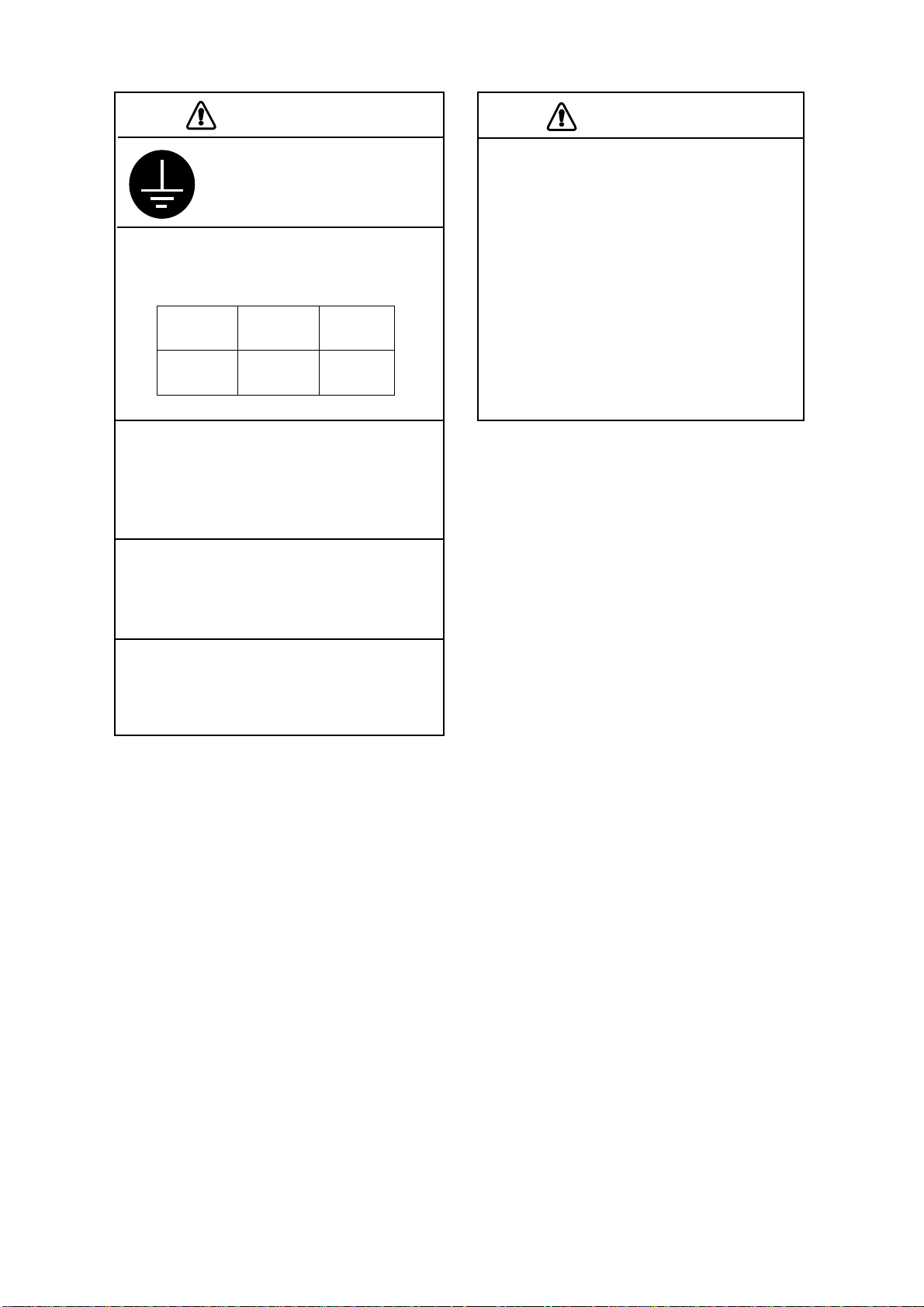

CAUTION

Ground the equipment to

CAUTION

prevent mutual interference.

The transducer cable must he handled

carefully, following the guidelines

below.

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Standard

compass

CV-1150

Do not allow warm water or any other

liquid other than seawater or freshwater

to contact the transducer.

The transducer may become damaged.

Do not turn on the power when the

transducer is in air.

The transducer may become damaged.

Do not install the transducer where

noise or air bubbles is present.

0.75 m 0.50 m

Steering

compass

Performance will be affected.

• Keep fuels and oils away from the

cable.

• Locate the cable where it will not be

damaged.

• The cable sheath is made of chloro-

phrene or polychloride vinyl, which

are easily by damaged plastic solvents

such as toulene. Locate the cable

well away from plastic solvents.

ii

Page 5

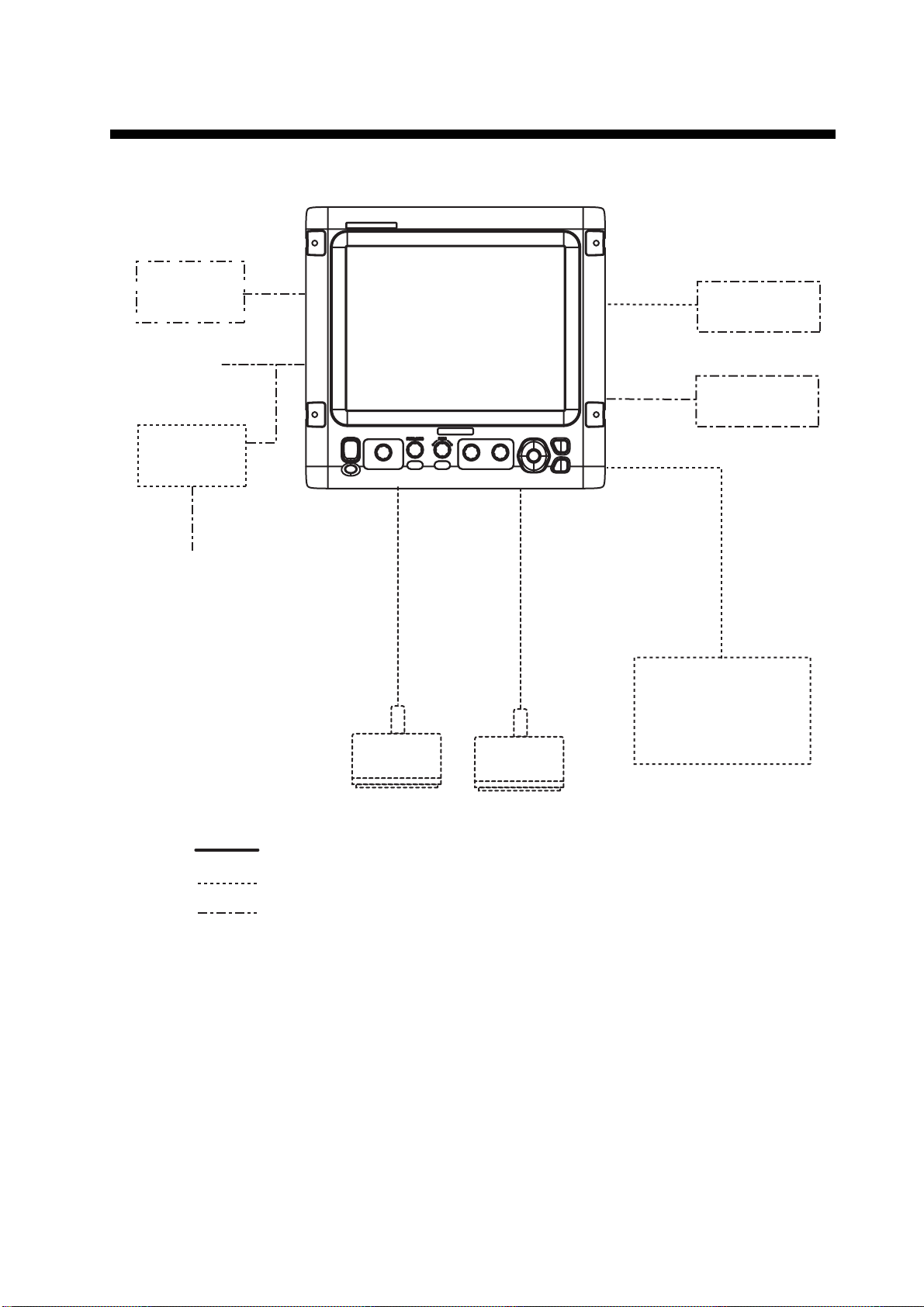

SYSTEM CONFIGURATION

Display unit

CV-1150

NavNet 3D

12-24 VDC

Rectifier

PR-62

100/110/115/

220/230 VAC

1㱢, 50/60 Hz

High

Navigator

Satellite

compass

Temperature sensor

T-02MSB, etc.

Speed/temp sensor

ST-02MSB, etc.

Low

Transducer

: Standard supply

: Optional supply

: Local supply, External device

Transducer

iii

Page 6

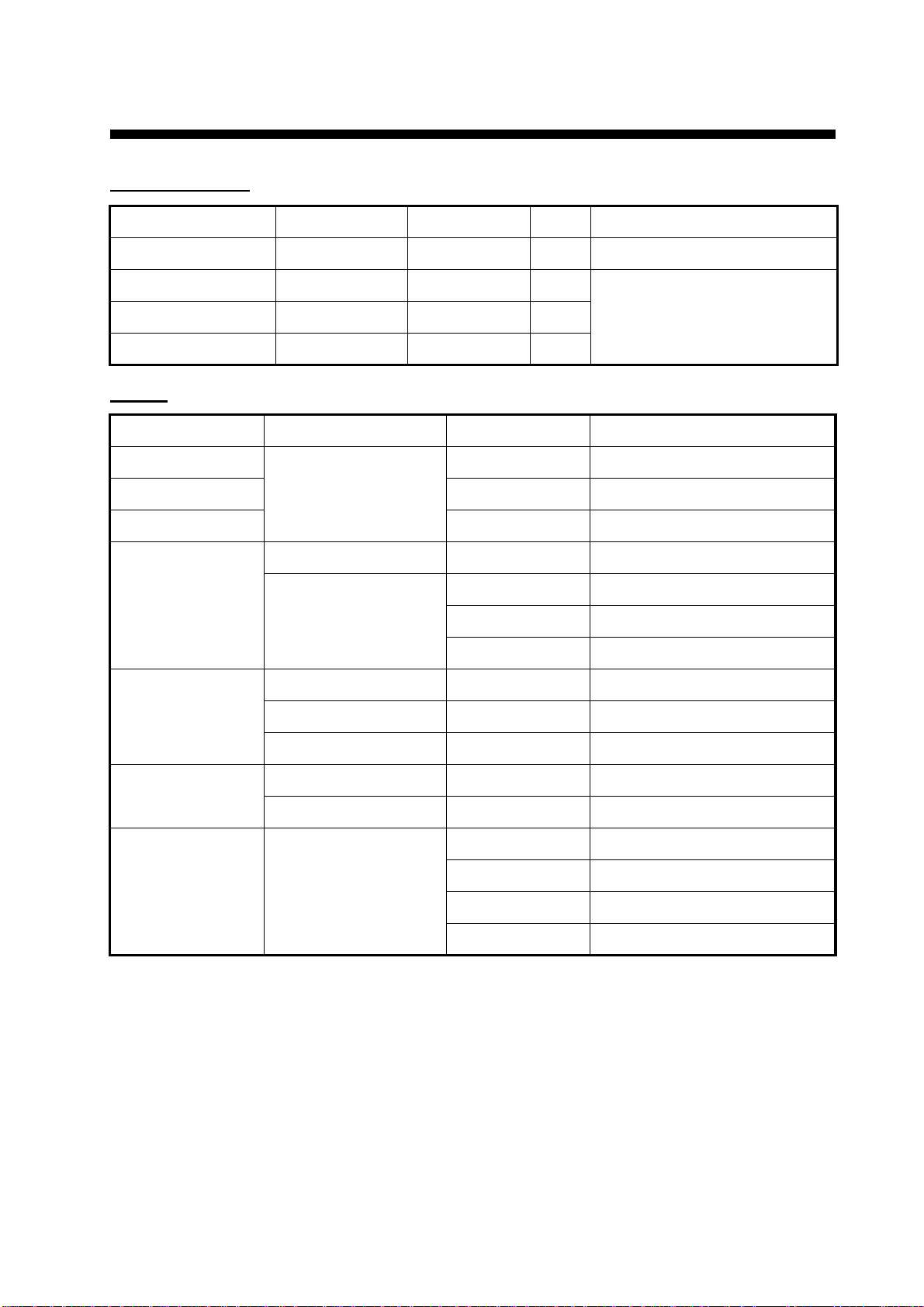

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Display Unit CV-1150 - 1

Spare Parts SP02-05401 001-032-550 1 set

Accessories FP02-05700 000-011-976 1 set

Installation Materials CP02-08301 001-032-560 1 set

Option

Name Type Code No. Remarks

See back of this manual.

Transducer

Thru-hull pipe -

Ta nk -

Cable MJ-A6SPF0003-050C 000-154-054-10 one end 6 pin, 5 m, for navigator

Water temperature

sensor

Speed/Temperature sensor

Rectifier PR-62 000-013-484 100 V AC

See next pages.

CO-SPEVV-SBC

2Px0.2SQ LF

T-02MSB 000-040-040 Thru-hull type

T-02MTB 000-040-026 Transom type

T-03MSB 000-040-027 Thru-hull type

ST-02MSB 000-137-986-01 Thru-hull type

ST-02PSB 000-137-987-01 Thru-hull type

000-111-680-10 5 m

000-120-792-10 10 m

000-120-793-10 15 m

000-013-485 110 V AC

000-013-486 220 V AC

-

000-013-487 230 V AC

iv

Page 7

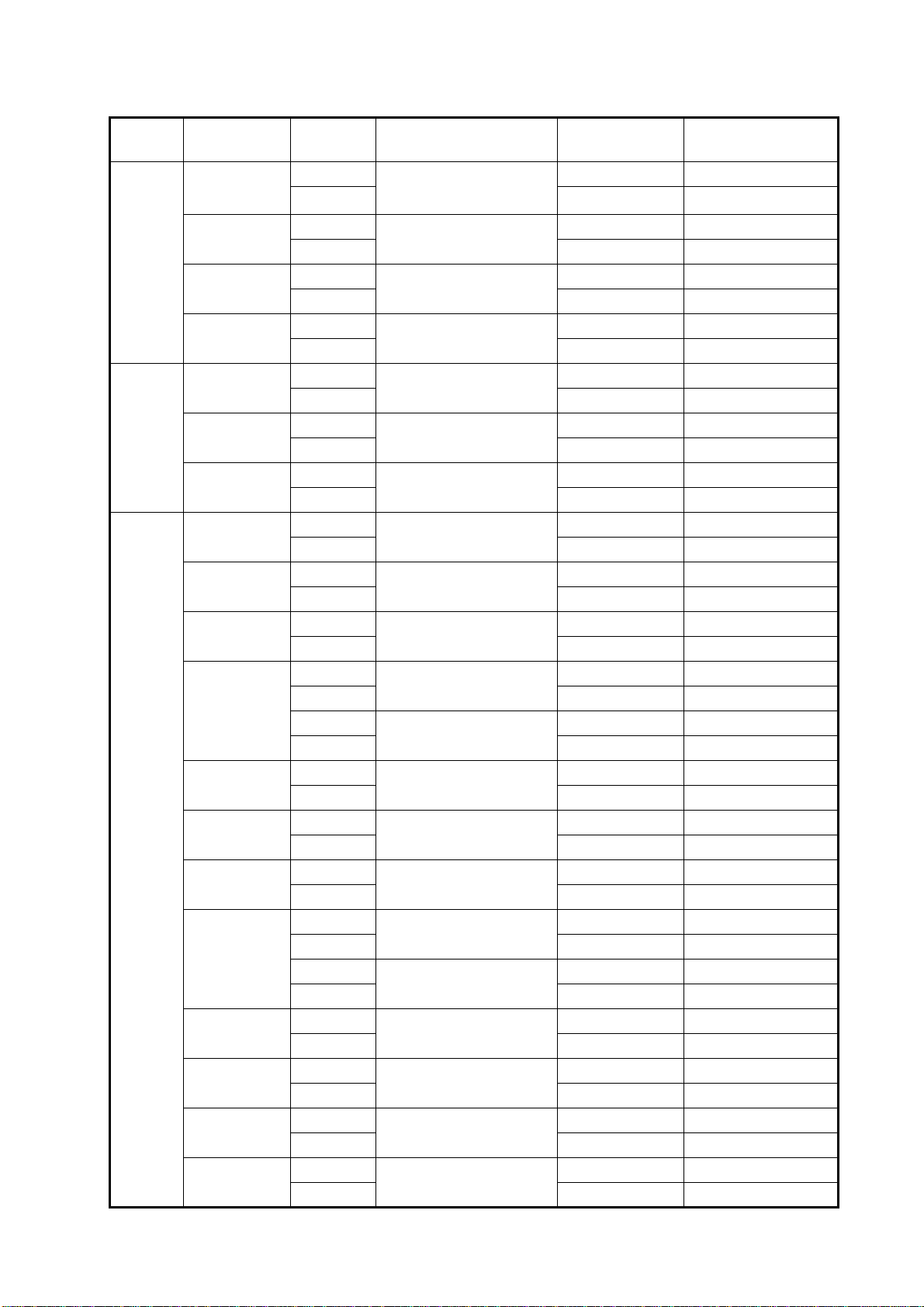

Combination of transducer, thru-hull pipe and tank

Output

(W)

1k/1k 28/50 Steel 28F-8

1k/2k 28/200 Steel 28F-8

2k/2k 28/50 Steel 28F-18

Frequency

(kHz)

28/88 Steel 28F-8

50/88 Steel 50B-9B

50/200 Steel 50/200-1T

50/200 Steel 50B-9B

88/200 Steel 88B-8

28/82 Steel 28F-18

28/88 Steel 28F-18

28/200 Steel 28F-18

38/200 Steel 38BL-9HR

50/82 Steel 50B-12

50/88 Steel 50B-12

50/200 Steel 50B-12

50/200 Steel 50BL-12

82/200 Steel 82B-35R

88/200 Steel 88B-10

28/107 Steel 28F-18

Ship type Transducer Thru-hull pipe Tank

FRP

FRP - -

FRP - -

FRP - T-603F

FRP - -

FRP - -

FRP - -

FRP TRB-1100(2) T-634-F

FRP TRB-1100(2) T-636-F

FRP TRB-1100(2) T-636-F

FRP TRB-1100(2) T-638-F

Steel 28BL-6HR

FRP TRB-1100(2) T-693-F

FRP TRB-1100(2) T-693-F

FRP TRB-1100(2) T-643-F

FRP TRB-1100(2) T-643-F

FRP TRB-1100(2) T-645-F

Steel 50BL-12HR

FRP TRB-1100(2) T-693-F

FRP TRB-1100(2) T-693-F

FRP TRB-1100(2) T-649-F

FRP TRB-1100(2) T-649-F

FRP TRB-1100(2) T-636-F

50B-9B

88B-8

88B-8

50/200-1ST

200B-8/8B

200B-8/8B

200B-8/8B

50B-12

82B-35R

88B-10

200B-8/8B

200B-8/8B

200B-8/8B

82B-35R

88B-10

200B-8/8B

200B-8/8B

200B-8/8B

200B-8/8B

200B-8/8B

100B-10H

TWB-6000(2) T-656

-

TWB-6000(2) T-657

TWB-6000(2) T-658

TFB-5000(1) T-603

TWB-6000(2) T-657

TWB-6000(2) T-658

TWB-6000(2) T-659

TFB-7000(2) T-634

TFB-7000(2) T-636

TFB-7000(2) T-636

TFB-7000(2) T-638

TFB-7000(2) T-693

TFB-7000(2) T-693

TFB-7000(2) T-643

TFB-7000(2) T-643

TFB-7000(2) T-645

TFB-7000(2) T-693

TFB-7000(2) T-693

TFB-7000(2) T-649

TFB-7000(2) T-649

TFB-7000(2) T-636

-

v

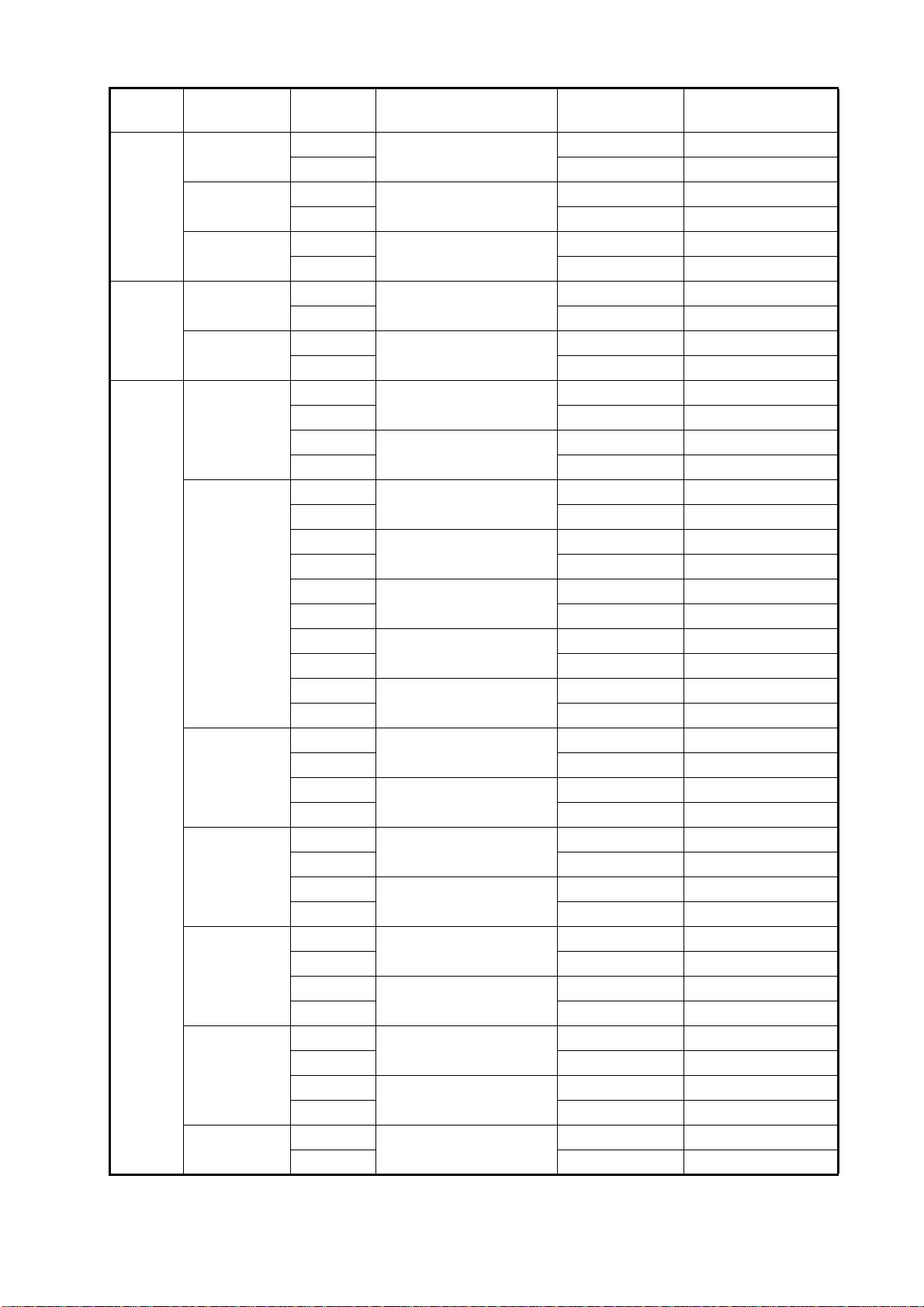

Page 8

Output

(W)

2k/3k 28/150 Steel 28F-18

3k/2k 68/200 Steel 68F-30H

3k/3k 28/38 Steel 28BL-12HR

Frequency

(kHz)

50/107 Steel 50B-12

50/150 Steel 50B-12

107/200 Steel 100B-10R

28/50 Steel 28BL-12HR

28/88 Steel 28BL-12HR

28/150 Steel 28BL-12HR

28/200 Steel 28BL-12HR

38/50 Steel 38BL-15HR

38/88 Steel 38BL-15HR

Ship type Transducer Thru-hull pipe Tank

FRP TRB-1100(2) T-637-F

FRP TRB-1100(2) T-643-F

FRP TRB-1100(2) T-644-F

FRP TRB-1100(2) T-647-F

FRP TRB-1100(2) T-649-F

FRP TRB-1100(2) T-681-F

Steel 28F-24H

FRP TRB-1100(2) T-681-F

FRP TRB-1100(2) T-681-F

Steel 28BL-12HR

FRP TRB-1100(2) T-681-F

Steel 28F-24H

FRP TRB-1100(2) T-696-F

Steel 28F-24H

FRP TRB-1100(2) T-681-F

Steel 28F-24H

FRP TRB-1100(2) T-681-F

FRP TRB-1100(2) T-682-F

Steel 28F-24H

FRP TRB-1100(2) T-682-F

FRP TRB-1100(2) T-683-F

Steel 28F-24H

FRP TRB-1100(2) T-683-F

FRP TRB-1100(2) T-683-F

Steel 28F-24H

FRP TRB-1100(2) T-683-F

FRP TRB-1100(2) T-681-F

Steel 38BL-15HR

FRP TRB-1100(2) T-681-F

FRP TRB-1100(2) T-682-F

150B-12H

100B-10R

150B-12R

200B-8/8B

200B-8/8B

38BL-15HR

38BL-15HR

50BL-24HR

50F-24H

50BL-24H

50BL-24HR

50F-24H

88F-126H

88F-126H

150B-12H

150B-12H

200B-12H

200B-12H

50BL-24HR

50F-24H

88F-126H

TFB-7000(2) T-637

TFB-7000(2) T-643

TFB-7000(2) T-644

TFB-7000(2) T-647

TFB-7000(2) T-649

TFB-7000(2) T-681

TFB-7000(2) T-681

TFB-7000(2) T-681

TFB-7000(2) T-681

TFB-7000(2) T-696

TFB-7000(2) T-681

TFB-7000(2) T-681

TFB-7000(2) T-682

TFB-7000(2) T-682

TFB-7000(2) T-683

TFB-7000(2) T-683

TFB-7000(2) T-683

TFB-7000(2) T-683

TFB-7000(2) T-681

TFB-7000(2) T-681

TFB-7000(2) T-682

vi

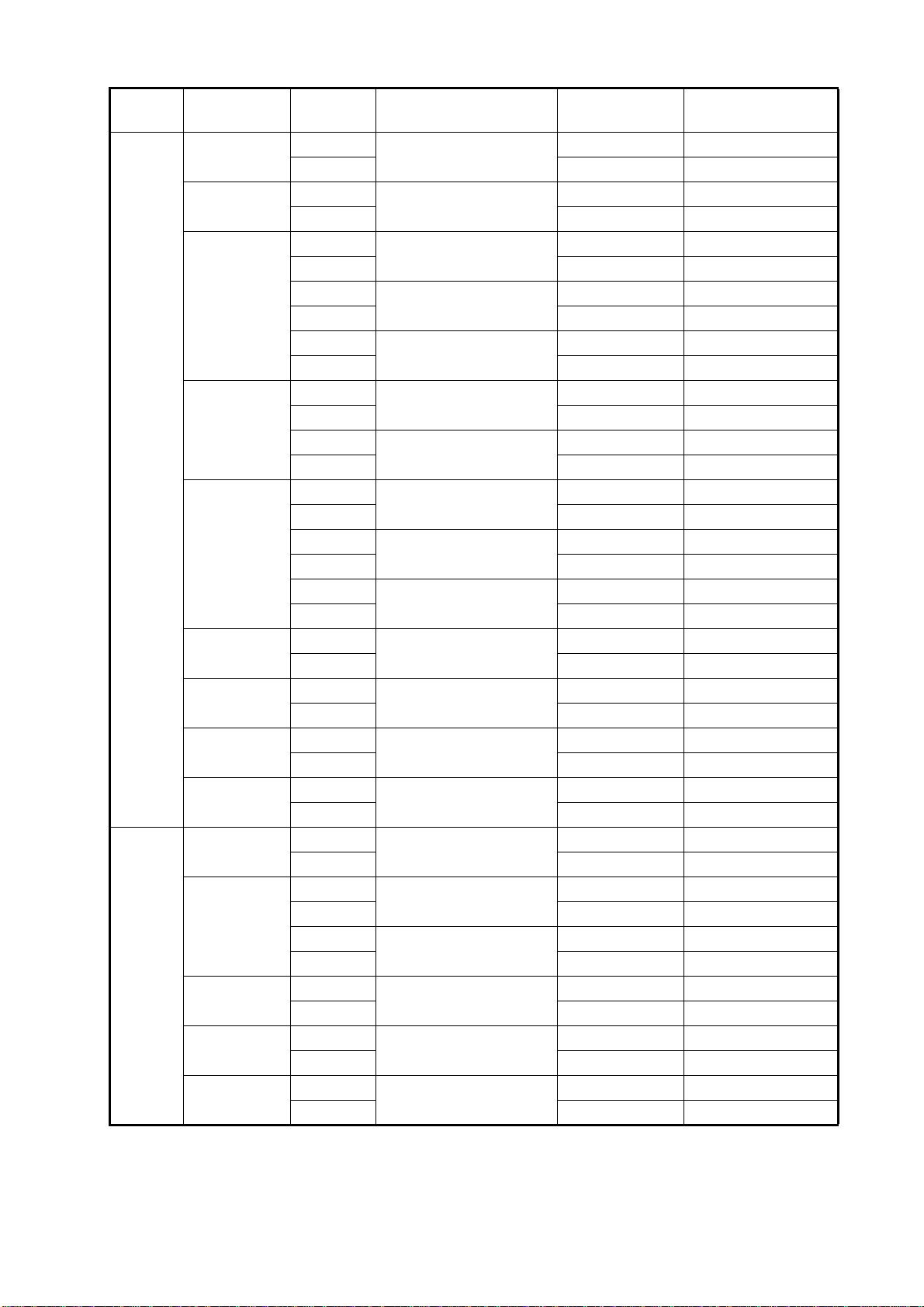

Page 9

Output

(W)

3k/3k 38/150 Steel 38BL-15HR

1k 28 Steel 28F-8 TFB-5000(1) T-604

Frequency

(kHz)

38/200 Steel 38BL-15HR

50/88 Steel 50BL-24H

50/150 Steel 50BL-24HR

50/200 Steel 50BL-24H

68/150 Steel 68F-30H

68/200 Steel 68F-30H

88/150 Steel 88F-126H

88/200 Steel 88F-126H

50 Steel 50B-6/6B TFB-5000(1) T-605

68 Steel 68F-8H TFB-5000(1) T-621

88 Steel 88B-8 TFB-5000(1) T-606

200 Steel 200B-5S TFB-5000(1) T-605

Ship type Transducer Thru-hull pipe Tank

TFB-7000(2) T-683

FRP TRB-1100(2) T-683-F

FRP TRB-1100(2) T-683-F

FRP TRB-1100(2) T-697-F

Steel 50BL-24HR

FRP TRB-1100(2) T-682-F

Steel 50F-24H

FRP TRB-1100(2) T-682-F

FRP TRB-1100(2) T-683-F

Steel 50F-24H

FRP TRB-1100(2) T-683-F

FRP TRB-1100(2) T-695-F

Steel 50BL-24HR

FRP TRB-1100(2) T-683-F

Steel 50F-24H

FRP TRB-1100(2) T-683-F

FRP TRB-1100(2) T-646-F

FRP TRB-1100(2) T-646-F

FRP TRB-1100(2) T-685-F

FRP TRB-1100(2) T-685-F

FRP TRB-1000(1) T-604-F

FRP TRB-1000(1) T-605-F

Steel 50B-9B TFB-5000(1) T-603

FRP TRB-1000(1) T-603-F

FRP TRB-1000(1) T-621-F

FRP TRB-1000(1) T-606-F

FRP TRB-1000(1) T-605-F

150B-12H

TFB-7000(2) T-683

200B-12H

TFB-7000(2) T-697

88F-126H

TFB-7000(2) T-682

88F-126H

TFB-7000(2) T-682

88F-126H

TFB-7000(2) T-683

150B-12H

TFB-7000(2) T-683

150B-12H

TFB-7000(2) T-695

200B-12H

TFB-7000(2) T-683

200B-12H

TFB-7000(2) T-683

200B-12H

TFB-7000(2) T-646

150B-12H

TFB-7000(2) T-646

200B-12H

TFB-7000(2) T-685

150B-12H

TFB-7000(2) T-685

200B-12H

vii

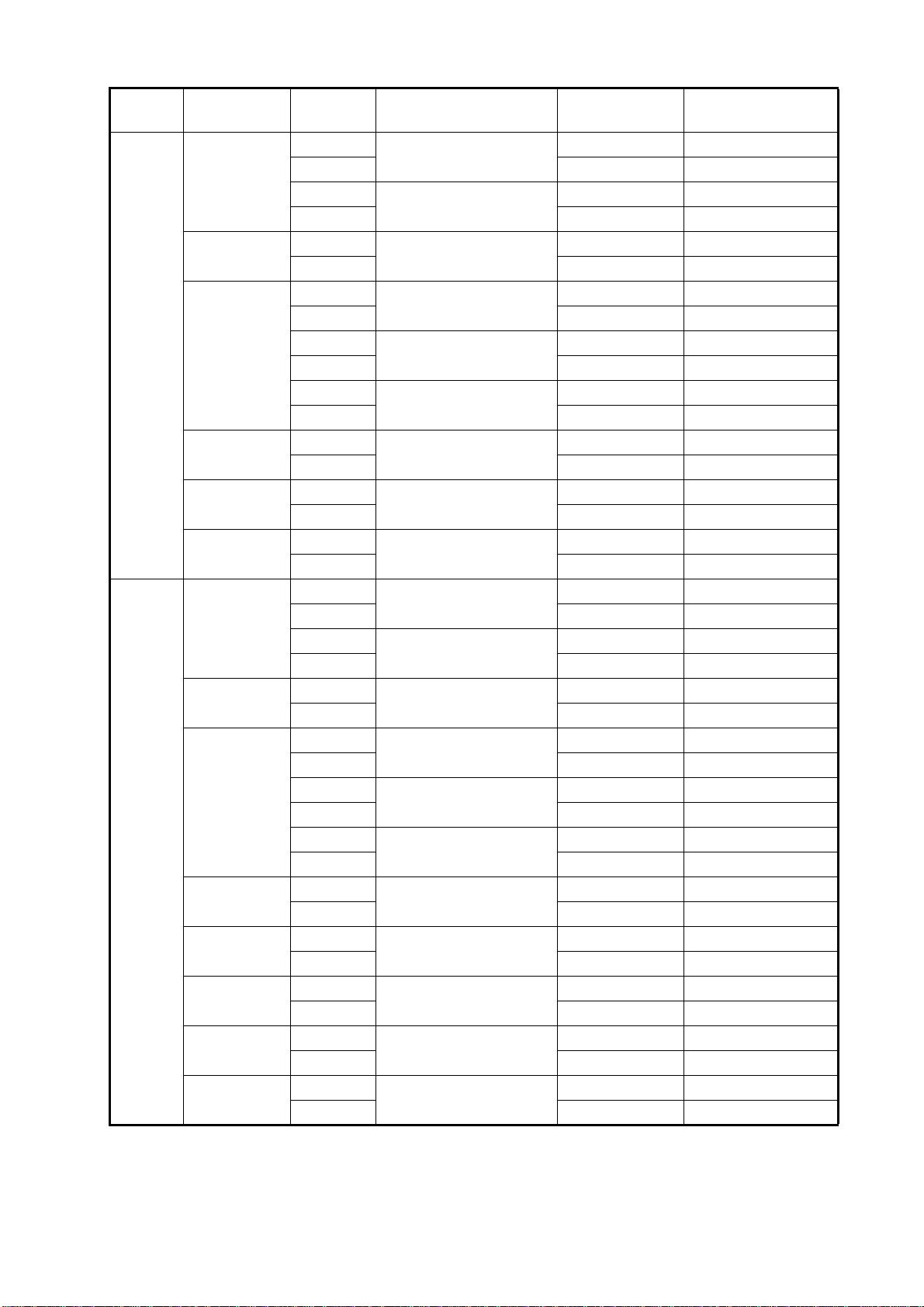

Page 10

Output

(W)

2k 28 Steel 28F-18 TFB-5000(1) T-612

3k 28 Steel 28F-24H TFB-4000(1) T-616

Frequency

(kHz)

38 Steel 38BL-9HR TFB-5000(1) T-702

50 Steel 50B-12 TFB-5000(1) T-611

82 Steel 82B-35R TFB-5000(1) T-609

88 Steel 88B-10 TFB-5000(1) T-609

200 Steel 200B-8/8B TFB-5000(1) T-608

38 Steel 38BL-15HR TFB-4000(1) T-616

50 Steel 50F-24H TFB-4000(1) T-616

68 Steel 68F-30H TFB-5000(1) T-614

88 Steel 88F-126H TFB-4000(1) T-618

107 Steel 100B-10R TFB-5000(1) T-609

150 Steel 150B-12H TFB-5000(1) T-615

200 Steel 200B-12H TFB-5000(1) T-615

Ship type Transducer Thru-hull pipe Tank

FRP TRB-1000(1) T-612-F

Steel 28BL-6HR TFB-5000(1) T-702

FRP TRB-1000(1) T-702-F

FRP TRB-1000(1) T-702-F

FRP TRB-1000(1) T-611-F

Steel 50BL-12 TFB-5000(1) T-702

FRP TRB-1000(1) T-702-F

Steel 50BL-12HR TFB-5000(1) T-702

FRP TRB-1000(1) T-702-F

FRP TRB-1000(1) T-609-F

FRP TRB-1000(1) T-609-F

FRP TRB-1000(1) T-608-F

FRP TRB-1000(1) T-616-F

Steel 28BL-12HR TFB-4000(1) T-616

FRP TRB-1000(1) T-616-F

FRP TRB-1000(1) T-616-F

FRP TRB-1000(1) T-616-F

Steel 50BL-24HR TFB-4000(1) T-616

FRP TRB-1000(1) T-616-F

Steel 50BL-24H TFB-4000(1) T-694

FRP TRB-1000(1) T-694-F

FRP TRB-1000(1) T-614-F

FRP TRB-1000(1) T-618-F

FRP TRB-1000(1) T-609-F

FRP TRB-1000(1) T-615-F

FRP TRB-1000(1) T-615-F

viii

Page 11

1. MOUNTING

WARNING

Do not apply paint, anti-corrosive sealant

or contact spray to coating or plastic

parts of the equipment.

Those items contain organic solvents that

can damage coating and plastic parts,

especially plastic connectors.

1.1 Display Unit

Turn off the power at the switchboard

before beginning the installation.

NOTICE

Fire or electrical shock can result if the

power is left on.

Mounting considerations

• Locate the unit out of direct sunlight.

• The operator should face the bow while viewing the display screen.

• Select a location where the display screen can be easily observed while operating the control

panel.

• Leave sufficient space around the unit for maintenance and servicing. Recommended maintenance space appears in the outline drawing at the back of this manual.

• Observe the compass safe distances on page ii to prevent deviation of a magnetic compass.

The display unit can be mounted on the tabletop or on the panel (flush mounting). Mount the unit,

referring to the outline drawing at the back of this manual.

1.2 Transducer

The performance of the echo sounder depends upon the transducer position. A place least affected by air bubbles should be selected since turbulence blocks the sounding path. Further, select a

place least influenced by engine noise. It is known that air bubbles are fewest at the place where

the bow first falls and the next wave rises, at usual cruising speed.

Note: The face of the transducer must be facing the sea bottom in normal cruising trim of the boat.

1

Page 12

1.3 Water Temperature/ Speed Sensor

Transom mount water temperature sensor T-02MTB

• Fix the cable at a convenient location on the transom with the cable clamp.

• When the cable is led through the transom board, make a hole of approx. 17 mm in diameter to

pass the connector. After passing the cable, seal the hole with a sealing compound.

D>500

How to mount transom mount water temperature sensor T-02MTB

D

5X20

Flush with hull bottom

[Units: mm]

2

Page 13

Thru-hull mount water temperature sensor T-02MSB, T-03MSB

Select a suitable mounting location considering the following points:

• Select a mid boat flat position. The sensor does not have to be installed perfectly perpendicular; however, the location should not be such that the transducer may be damaged when the

boat is dry-docked.

• Locate away from equipment which gives off heat.

• Locate away from drain pipes.

• Select a location where vibration is minimal.

T-02MSB T-03MSB

Sensor Holder

cable

8 m

Sensor

cable

8 m

Locknut

Washer

Gasket

Locknut

Locknut

φ21 mm

M20

70

φ42

Mounting procedure

1. Drill a hole of 21 mm in diameter in

the mounting location.

2. Pass the sensor cable through the

hole.

3. Pass gasket, washer and locknut

onto cable in that order.

4. Coat the sensor flange with high

quality sealant and then fasten the

sensor with the locknut.

(Torque: max. 59N·m)

5. Launch the boat to check for water

leakage around the sensor.

Coat with

sealant.

Washer

Gasket

φ25 mm

Coat with

sealant.

Plate thickness within

Holder Guide

Mounting procedure

1. Drill a hole of 25 mm in diameter in the mounting

location.

2. Coat holder guide with high quality sealant, and

pass gasket, washer and locknut onto holder

guide in that order and then tighten the locknut.

3. Set the sensor holder to the holder guide from

inside the boat and then tighten the locknut.

4. Launch the boat to check for water leakage

around the sensor.

25 mm

Assembling thru-hull water temperature sensor T-02MSB, T-03MSB

3

Page 14

Through-hull mount water temperature/speed sensor ST-02MSB,

ST02-PSB

Select a suitable mounting location considering the following:

• Select a mid-boat flat position. The sensor does not have to be installed perfectly perpendicular. The sensor must not be located where it might get damaged in dry-docking operation.

• Select a place apart from equipment generating heat.

• Select a place in the forward direction viewing from the drain hole, to allow for circulation of

cooling water.

• Select a place free from vibration.

1. Dry-dock the boat.

2. Make a hole of approx. 51 mm diameter.

3. Unfasten locknut and remove the flange of the sensor.

4. Apply high-grade sealant to the flange of the sensor.

5. Pass the sensor casing through the hole.

6. Face the notch on the sensor toward boat's bow and tighten the flange.

7. Set the sensor section to the sensor casing and tighten the locknut.

8. Launch the boat and check for water leakage around the sensor.

Locknut

Face "notch"

toward bow.

Flange nut

51

123

Coat with

silicone sealant.

Brim

φ77

Water temperature/speed sensor ST-02MSB, ST-02PSB

4

Page 15

2. WIRING

2.1 Interconnection

Refer to the interconnection diagram at the back of this manual for detailed information.

Display unit rear panel

(connector cover removed)

IV-2.0sq

NavNet 3D

Speed/

Water temperature

sensor

Rectifier

PR-62

DPYCY-1.5

100/110/115/

220/230 VAC

φ

, 50/60 Hz

1

DPYCY-1.5

CO-SPEVV-SBC 2Px0.2SQ

TTYCS-1

Satellite

compass

12-24 VDC

(Connect to a dedicated

breaker in the power

distributor.)

MJ-A6SPF0003-050C

Navigator

High

Transducer

*

Transducer

Grounding wire:

As short as possible

Low

*

: Standard supply

: Option

: Local supply, External device

Wiring diagram for FCV-1150

5

*: This unit cannot accept transducers of

53 to 65 kHz, 111 to 139 kHz and 171

to 183 kHz.

Page 16

2.2 Wiring Standard Equipment

A

Power cable

This video sounder is designed to be powered with 12-24 VDC power. Use the cable DPYCY-1.5

(Japan Industry Standard) or equivalent.

6

Approx. 70

3

30

DPYCY-1.5

Armor

Sheath

Conductor

S = 1.5 mm

Ǟ = 1.56 mm

(AWG16)

2

Climp-on lug

FV2-M4

Sheath

Vinyl tape

Clamp armor with cable clamp.

Armor

Sheath

Ǟ = 13.7 mm

Power cable DPYCY-1.5 (JIS cable)

Transducer

Separate the transducer cable well away from power cables to prevent interference. Connect the

cable to the transducer port (for high frequency and/or low frequency) at the rear of the display

unit. Fabricate the cable as below.

Approx. 100

Shield

Extract cores from here and cut inner materials.

Sheath

Shield

6

ttach WAGO

connector.

(See next page.)

Vinyl tape

30

Wrap shield around sheath 30 mm and cut

excess shield. Clamp here with cable clamp.

Vinyl tape

Note: Never connect the shield to #2 of

[Composite transducer]

the WAGO connector.

BLK, RED: L side

BLU, GRN: H side

Fabrication of transducer cable

Note: FCV-1150 cannot accept the transducers of 53 - 65 kHz, 111 to 139 kHz and 171 - 183 kHz.

6

Page 17

NMEA port

Connect a GPS navigator, etc. to NMEA port J2 #1 to #4. You can connect two sensors (for example, GPS receiver GP-310B and smart sensor). One connects to NMEA port J2 #1 to #2 and

the other connects to the NMEA port J2 #3 to #4. A satellite compass can be connected to NMEA

port J2 #5 to #6.

Cable connected to NMEA port: Furuno cable MJ series

Approx. 30

Shield

6

Cut shield here and

solder vinyl wire.

Cable connected to NMEA port: Furuno cable CO-SPEVV-SB-C

6

Cable connected to NMEA port: JIS cable TTYCS-1Q

6

Approx. 80

Approx. 80

Cut shield here and

solder vinyl wire.

Vinyl tape

Clamp vinyl sheath with cable clamp.

3

30

Armor

Clamp armor with cable clamp.

3

30

Sheath

TTYCS-1Q (Four cores twisted)

Cut shield here and

solder vinyl wire.

Vinyl tape

Sheath

Armor

Vinyl tape

Ǟ = 11.3 mm

Clamp vinyl sheath with cable clamp.

7

Shield

Conductor

S = 0.75 mm

Ǟ = 1.11 mm

(AWG18)

Armor

Sheath

2

Page 18

WAGO connector (for transducer and NMEA port)

Press

Opener (attached inner side of shield cover).

1. Twist conductors

2. Insert opener and press it down.

3. Insert core to hole.

Twist.

Core

4. Release opener.

5. Pull the core to confirm to make sure it is

tightly fastened.

2.3 Input/Output Sentences

Input sentences

Sentence Data Remarks

BWC Range/bearing to waypoint

GGA Time, position GPS position

GLC GRI, Time difference Loran C

GLL Latitude and longitude GPS position

GNS GNSS position fixing

GTD Time difference Loran C

HDG Ship's heading, deviation, variation

HDT True heading

MDA Weather information

MTW Water temperature

MWV Wind direction, wind speed (true or apparent)

RMA Latitude and longitude, TD, ground speed and course Loran C

RMB Recommended minimum navigation information

RMC Latitude and longitude, speed over ground and course over ground GPS

VHW True/magnetic bearing, speed through water

VTG Speed over ground and course over ground

XTE Cross track error

att Roll, pitch

hve Heaving data

req Output request for specified attribute

8

Page 19

Output sentences

Sentence Data Remarks

DBT Depth below transducer Ver. 1.5

DPT Depth below transducer and offset Ver. 2.0

MTW Water temperature

TLL Marker line position Ver. 2.0

SDmrk Mark position (L&L) and its additional data

VHW Speed thru water

RMB Navigation information

dat Data of specified attribute (device name)

DBS Depth below sea surface

With connection of water

temperature sensor

9

Page 20

3. INITIAL SETTING

This chapter provides the information necessary for initial setup of the equipment. First turn on the

power and set display language. Then, set transducer used, by model number (FURUNO transducer only) or by specifications.

3.1 Language Setting

1. Press [ /BRILL] key to turn on the power. The following display appears.

Language setting screen

2. Press T or S to select English as an example, and then press the ENTER key to set. The unit

setting screen appears.

Unit setting screen

3. Set the units of measurement if necessary. For example, to set the distance unit, press T to

select “Distance Unit” and press the ENTER key. The list of selectable distance units is dis-

played.

10

Page 21

4. Press T or S to select necessary unit and then press the ENTER key to set.

CAUTION

• Depth: m, ft, fa, pb, HR (Japanese unit)

• Temp: °C, °F

• Speed: kt, km/h, mph

• Wind: kt, km/h, mph, m/h

• Distance: nm, km, sm

5. Press the MENU key. The following message appears.

6. Press any key. The transducer setting screen appears. Proceed to next section.

3.2 Transducer Data

Set the transducer model number

properly.

Wrong transducer setting can damage the

transducer and void the warranty.

Entering transducer data by transducer model

The following table shows the transducers programmed in the FCV-1150.

Type Output (kW) Tap Type Output (kW) Tap

28F-8 1 B 50BL-24HR 3 D

28BL-6HR 2 A 50F-24H 3 B

28F-18 2 B 68F-8H 1 A

28BL-12HR 3 A 68F-30H 3 B

28F-24H 3 D 82B-35R 2 E

38BL-9HR 2 B 88B-8 1 D

38BL-15HR 3 D 88B-10 2 C

50B-6B 1 A 88F-126H 3 E

*

50/200-IT

50/200-1ST (50 kHz) 1 B 150B-12H 3 C

(50 kHz)

1 B 100B-10R 3 E

50B-9B 1 A 200B-5S 1 D

50B-12 2 A

50BL-12 2 A 50/200-1ST (200 kHz) 1 A

50BL-12HR 2 B 200B-8B 2 C

50BL-24H 3 D 200B-12H 3 C

*: for ACCU-FiSH (Fish information display)

50/200-1T

*

(200 kHz)

1C

11

Page 22

Note: The “XDCR Setting” dialog box (see the illustration that follows step 1 below) only appears

when turning on the power after installation, after setting the desired language and the units of

measurement (see section 3.1). To open the “XDCR Setting” dialog box after completion of the

transducer setting, turn off the power, then turn on the power while pressing any key. Release the

key after the "XDCR Setting" dialog box appears.

1. At the transducer setting screen, confirm that "XDCR Select" is set to "XDCR Type" (default

setting).

Transducer setting screen

2. If a high frequency transducer is fitted, press T to select “HF Connection” and then press the

ENTER key.

Connected

Not connected

3. Press S to select “Connected” and then press the ENTER key.

4. Press T to select “Freq” and then press the ENTER key.

12

Page 23

5. Press T or S to select the transducer frequency and then press the ENTER key.

6. Press S to select “Transducer” and then press the ENTER key. The list of programmed transducers appears.

200B-5S

50/200-1T

50/200-1ST

200B-8B

200B-12H

7. Press T to select transducer connected and then press the ENTER key.

8. Jot down the alphabet which appears on the “TAP” line. You may need to change the tap setting at the rear of the display unit depending on the transducer type which is connected. For

details, see below.

9. If a low frequency transducer is fitted, repeat steps 2 to 8.

Note: Leave the “Tx Power” setting at “Auto”.

10.To connect to the NavNet 3D system, press T to select “NavNet Mode” and then press the

ENTER key. Select “On” and press the ENTER key.

The following program versions can be connected to the FCV-1150.

MFD8/12: 1950055-02.01 and later

MFDBB: 1950064-02.01 and later

(Example: 200 kHz)

11.Press and hold down the [ /BRILL] key to turn off the power.

Tap setting

Set the tap according to the alphabet shown when you selected transducer type.

Display unit rear panel

(connector cover removed)

Tap setting plug

(for high frequency)

Tap setting plug

(for low frequency)

Common point

E D C B A

jumper

connection

Set this side according to indication.

13

Page 24

Entering transducer data by transducer specifications

To connect the transducers which are not programmed, do as follows:

Note: The transducers of 53 - 65 kHz, 111 to 139 kHz and 171 - 183 kHz cannot be connected to

the FCV-1150 because of noise.

1. At the XDCR Setting dialog box, select “XDCR Select” and press the ENTER key.

The following screen appears.

XDCR Type

Manual

2. Press T to select “Manual”, and then press the ENTER key.

3. If a high frequency transducer is fitted, press T to select “HF Connection” and then press the

ENTER key.

Connected

Not connected

4. Press S to select “Connected” and then press the ENTER key.

5. Press T to select “Freq” and then press the ENTER key.

--- kHz

6. Press T or S to set the value for the frequency which is connected and then press the

ENTER key.

7. Press T to select “Band width” and then press the ENTER key.

8. Press T or S to set the value for the band width and then press the ENTER key. If the band

width is not entered manually, it is automatically set to 1/10 of the transducer frequency.

9. If a low frequency transducer is fitted, repeat steps 3 to 8.

Note: Leave the “Tx Power” at “Auto”.

10.Press and hold down the [ /BRILL] key to turn off the power.

3.3 Speed/Water Temperature Sensor Calibration

If the optional speed and/or water temperature sensor is connected, set up as follows:

1. Turn on the power and press the MENU key.

The main menu and sub-menu appears.

2. Press T to select “System” and “Club” and then press the ENTER key.

14

Page 25

3. Press T to select "Temp" and then press the ENTER key.

Temperature calibration screen

4. Press T or S to set the value for the temperature calibration and then press the ENTER key.

For example, if the temperature indication is 2.5°C higher than the actual value,

set “-2.5°C”.

5. To calibrate the speed value, press T to select "Speed(STW)" and then press the ENTER

key.

6. Press T or S to set the value for the speed calibration and then press the ENTER key.

For example, if the speed indication is 5% lower than the actual value, set +5%.

7. To close the menu, press the MENU/ESC key twice.

15

Page 26

3.4 NMEA Port Setting

If a GPS navigator and/or other sensor are connected, set up as follows.

1. Press the MENU key.

2. Press T to select "System" and "NMEA" and then press the ENTER key.

NMEA setting menu

3.Press T to select the item to set and then press the ENTER key.

4.Press T or S to select an appropriate one and then press the ENTER key.

Description for each item of the NMEA menu

NMEA0183: Choose NMEA0183 version of navigation equipment connected to the NMEA port,

among Ver. 1.5, Ver. 2.0 or Ver. 3.0. "SPECIAL" is for use with a navigator whose baud rate is

600 bps.

NMEA Port: The NMEA terminals in the NMEA port can function as input ports or input/output

port. Change the setting to "In/In" when connecting GP-310B/320B and a wind sensor. When connecting the GP-320B and a wind sensor, first turn on "WAAS Setup" and then select "In/In" as the

NMEA Port setting.

• In/Out: NMEA port J2 #1 & #2 is output port and J2 #3 & #4 is input port.

• In/In: NMEA port J2 #1 & #2 changes to input port. (Available with connection of the GP-310B/

320B and a wind sensor.)

NMEA Output: Set the output data sentences.

• Off: Outputs the "output data sentences" (see page 9).

• On: Outputs the "output data sentences" of FCV-1150 and sentences which are input from

other equipment.

16

Page 27

WAAS Setup: Choose how to use the WAAS signal when connecting with a WAAS receiver, for

example GP-320B. The message types (WAAS-00 to WAAS-27) are used as WAAS correction.

Choose WAAS-00 to enable WAAS.

Note: Currently, WAAS is only available in North America, and Japan and it is in the developmental stage in Europe and Japan. During the developmental phase the reliability and availability of

the WAAS signal cannot be guaranteed. Therefore, any position data should be verified against

other sources to confirm reliability. This function is available only when In/Out is selected at NMEA

Port.

TLL Output: Output the position specified by the MARK key to the plotter connected.

• Off: Does not output latitude/longitude.

• TLL: Outputs latitude/longitude.

• FURUNO-TLL: Outputs latitude/longitude, depth and water temperature. This requires

FURUNO-TLL enabled device.

Port Monitor: Port Monitor provides information for the data sentences input from the NMEA port.

Press the ENTER key to display the latest data sentence information. To display this information

on the Port 2 screen when two sensors are connected, set NMEA Port on the NMEA menu to In/In.

3.5 Heaving Setting

For the heaving feature to function correctly, set the distance between satellite compass antenna

(GPS sensor) and transducer as follows.

1. Press the MENU key to display the main menu.

2. Press T to select “Stabi” and then press the ENTER key.

3. Press T or S to select “Stabilization” and then press the ENTER key.

4. Press T to select “On” and then press the ENTER key.

5. Press T to select “Sensor” and then press the ENTER key.

SC50/110

SC30

6. Select the type of satellite compass connected and then press the ENTER key.

17

Page 28

7. Press T to select “Stabi. Area“ and then press the ENTER key.

8. Press T or S to select desired Stabi. Area and then press the ENTER key.

When heaving exceeds the value set here, stabilization is stopped and the stabilizer icon

at the top of the screen disappears. However, the heaving mode is kept “On“. When heaving

is once again less than the value set here, stabilization is restarted and the stabilizer icon

reappears.

9. Set the distance between transducer(s) and antenna unit (or sensor) of the satellite compass

as follows.

TD fore-aft: Set the distance from antenna unit to the transducer in fore-aft direction. When

the transducer is located on the fore side, set a positive value.

TD port-stbd: Set the distance from antenna unit to the transducer in port-starboard direction.

When the transducer is located on the starboard side, set a positive value.

ANT-TD height: Set the distance from the transducer to the antenna unit in the vertical direction.

Note: For the heaving feature, set the output of satellite compass SC-50/110/30 as follows.

SC-50/110

(DATA OUT menu)

Sentence ATT, HVE ATT, HVE

Baud rate 38400 BPS 38400 BPS

Cycle 25 ms 25 ms

Format IECED1 -

SC-30

(Set IF-NMEASC)

18

Page 29

APPENDIX TRANSDUCER 82B-35R

The 82B-35R is a transducer with wide bandwidth of 65 kHz-110 kHz. It is constructed to provide

protection against slamming.

Transducer, thru-hull pipe and tank list

Frquency

(kHz)

28/82 28F-18/82B-35R Steel T-636

50/82 50F-8G/82B-35R Steel T-636

82/200 82B-35R/200B-8/

Transducer Hull

Material

FRP T-636F

FRP T-636F

50B-12/82B-35R Steel T-643

FRP T-643F

Steel T-649

200B-8B/200B-8N

FRP T-649F

(Code No.)

(000-015-813)

(000-015-814)

(000-015-813)

(000-015-814)

(000-015-821)

(000-015-822)

(000-015-833)

(000-015-834)

Tank

Fasten inside

hull (Code No.)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-218)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-218)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-218)

TWB-6000 (2)

(000-015-207)

TRB-1100 (2)

(000-015-218)

Fasten outside

hull (Code No.)

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

TFB-7000 (2)

(000-015-209)

-

Connection

Connect the 82B-35R transducer to either the "HF" or "LF" connector, referring to page S-1.

Tap Setting

Referring to page 13, set the tap to E.

AP-1

Page 30

Setting for dual frequency transmitting

1. Set the XDCR SELECT menu as follows (see page 12 and 13).

Setting for “HF” connection

Setting for “LF” connection

2. Press the [PWR] key to turn the power off, and turn it on again.

3. Press the MENU key to show the menu.

4. Select [Sounder] and press the ENTER key.

5. See the section "1.20.1 Sounder menu" in the Operator's Manual for how to set "Freq Choice"

and "Freq Control" for high and low frequencies.

AP-2

Page 31

1

A-1

1

1

1

1

1/1

02GD-X-9851 -2

NAME OUTLINE Q'TYDESCRIPTION/CODE №

100-342-010-10

02-157-1302-0

000-167-734-1*

MLG-23780-*

C22-00702-* ワ/エイ

**

000-167-736-1*

000-167-732-1*

IM*-23780-*

**

000-167-728-1*

OM*-23780-*

02GD-X-9851

Fマウントヨウスポンジ

FCV-1150-J/E

図書 DOCUMENT

FLUSH MOUNTING SPONGE

1

**

000-011-708-00

CV-1150

操作要領書(タゲン)

OPERATOR'S GUIDE

フラッシュマウント型紙

4

SP02-05401

000-157-493-10

FGMB 125V 7A PBF

FLUSH MOUNTING TEMPLATE

1

FP02-05700

02-155-1082-1

装備要領書

INSTALLATION MANUAL

CP02-08301

100-332-651-10

取扱説明書

OPERATOR'S MANUAL

2

000-157-229-10

FV2-M4

1

000-147-417-10

734-230

5

000-162-608-10

5X20 SUS304

1

000-165-800-10

231-131

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE №

ユニット UNIT

指示器

DISPLAY UNIT

予備品 SPARE PARTS

ヒューズ

FUSE GLASS TUBE TYPE

付属品 ACCESSORIES

フィルタークリーナー

LCD CLEANING CLOTH

工事材料 INSTALLATION MATERIALS

圧着端子

CRIMP-ON LUG

操作レバー

TERMINAL OPENER

+トラスタッピンネジ 1シュ

SELF-TAPPING SCREW

操作レバー

TERMINAL OPENER

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

Page 32

Oct.4'07R.Esumi

D-1

Page 33

Oct.3'07R.Esumi

D-2

Page 34

43

S-1

相互結線図

パソコン(保守用)

PC FOR MAINTENANCE

または OR

マルチファンクションディスプレイ

MULTI-FUNCTION DISPLAY

MFD8/12/BB

カラー魚群探知機

TRANSDUCER

FCV-1150

TITLE

名称

TD_LF-COLD

3

NC

2

TD_LF-HOT

1

*2

8m

T-02MSB

T-03MSB

T-02MTB

水温センサー

TEMP. SENSOR

J5

TD_HF-COLD

3

NC

2

TD_HF-HOT

1

J4

RED

BLK

GRN

BLU

アカ

クロ

ミドリ

アオ

10m(1ST:15m)

50/200-1T

50/200-1ST

*2

送受波器

INTERCONNECTION DIAGRAM

COLOR LCD SOUNDER

NAME

P

+12V

12V_0V

10

6

NC

*2

10m

1B1 02P6352

ST-02MSB

ST-02PSB

TD_LF-COLD

NC

TD_LF-HOT

J5

LF

TD_HF-COLD

NC

TD_HF-HOT

J4

HF

TEMP/SPEED SENSOR

水温・速度センサー

*1

3

2

1

3

2

1

IV-2sq.

BLKクロ

BLKクロ

A02-157-1001-0

REF.No.

T.YAMASAKI

16/Apr/09

DRAWN

T.TAKENO

9/Jun/09R.Esumi

16/Apr/09

CHECKED

APPROVED

SCALE MASS

C2378-C01- F

DWG.No.

アカ RED

アカ RED

HIGH LOW

*4

送受波器

TRANSDUCER

CO-0.2x2P: CO-SPEVV-SB-C 0.2x2P,φ10.5

NETWORK

CV-1150

DISPLAY UNIT

指示部

RJ45

(CROSS)

STP CABLE(CAT5)

P

P

P

1234567

J5

TXN

TXP

12-24VDC

(+)

TB1

1

RXP

(-)

2

NC

NC

1B2 02P6350

NMEA

RXN

J2

P

8

NC

NC

NMEA1_TD-A

NMEA1_TD-B

NMEA1_RD-A

NMEA1_RD-B

3

2

1

*3

MJ-A6SPF

12345

J3

TEMP

SHIELD

NMEA2_RD-A

NMEA2_RD-B

564

P

TEMP

SPEED

TEMP_SPEED_0V

12V_P

SHIELD

SHIELD

789

2

YEL

GRN

WHT

BLK

キ

ミドリ

シロ

*1

DPYC-1.5

2

1

(+)

(-)

*2PR-62

RECTIFIER

整流器

5

6

3

*1

*1

DPYC-1.5

IV-2sq.

*2

MJ-A6SPF0003,5m,φ6

*3

MJ-A6SPF

P

1

TD-A

2

TD-B

P

3

RD-A

クロ

RD-B

J2

TD-A(RD-A)

TD-B(RD-B)

RD-A

RD-B

J2

2

1

P

TTYCS-1(*1) OR

CO-0.2x2P (*2)

564

NC

GND

TD-A

TD-B

3

P

TD-A

4

TD-B

SHIELD

7

*2

MJ-A7SPM0001,0.5m

TD-A

TD-B

2

1

WHT

BLU

シロ

アオ

2

175

12V_P

SHIELD

9

7

YEL

キ

6

12V_OV

10

GRN

ミドリ

1

220/230VAC,

100/110/115/

1φ,50/60Hz

12-24 VDC

NAV1

TWO SETS CONNECTION (CHANGE SETTING FROM MENU)

2台接続の場合(メニューにて設定変更)

SATELLITE COMPASS

SC-30/50/110

ETC.

NAV EQUIPMENT

航法装置など

サテライトコンパス

A

NAV2

B

MJ-A7SPF0013

RADIO TRANSMITTER CONNECTION (CHANGE SETTING FROM MENU)

FN6-2

無線送信機接続の場合(メニューにて設定変更)

注記

*1)造船所手配。

*2)オプション。

C

*3)コネクタは工場にて取付済み。

*4)送受波器82B-35RはHF/LFのいずれかに接続。

NOTE

*1: SHIPYARD SUPPLY.

*2: OPTION.

*3: CONNECTOR PLUG FITTED AT FACTORY.

*4: CONNECT THE 82B-35R TRANSDUCER TO EITHER HF OR LF.

Page 35

Page 36

9-52 Ashihara-cho,

*

00016773313

**00016773313

*

*

00016773313

**00016773313

*

Nishinomiya, 662-8580, JAPAN

Telephone : +81-(0)798-65-2111

Fax : +81-(0)798-65-4200

The paper used in this manual

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

Pub. No. IME-23780-D

(REFU ) FCV-1150

Printed in Japan

A : DEC 2007

D : NOV. 16, 2011

* 0 0 0 1 6 7 7 3 3 1 3 *

.

Loading...

Loading...