Page 1

INSTALLATION INSTRUCTIONS

compression

nut

Threaded-Stem Stuffing Tube

Bronze or Stainless Steel

IMPORTANT: Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

17-423-01 rev. 03 05/19/10

Applications

A stuffing tube seals the hull forming a water-tight conduit for the

cable.

CAUTION: The stuffing tube must be compatible with the hull

material (see table below).

• Metal hull—Use a stainless-steel stuffing tube.

Never install a bronze stuffing tube in an aluminum hull

because electrolytic corrosion will occur.

• Fiberglass hull—The stuffing tube must be installed in solid

fiberglass, not in coring.

Hull Material

fiberglass

wood

fiberglass

wood

aluminum

steel

Stuffing Tube

Material

bronze

stainless steel

stainless steel

Cable Diameter

up to 12mm

(0.47”)

up to 12mm

(0.47”)

up to 12mm

(0.47”)

Tools & Materials

Safety goggles

Dust mask

Electric drill with 10mm (3/8") or larger chuck capacity

Drill bit: 3mm or 1/8"

Hole saw (see table above)

Sandpaper

Mild household detergent or weak solvent (such as alcohol)

File (installation in a metal hull)

Marine sealant (suitable for below waterline)

Slip-joint pliers

Hull

Hole Diameter

44mm (1-3/4") 33-511-01

44mm (1-3/4") 33-541-01

50mm (2") 33-541-01

Airmar

Part No.

plastic

washers

hull nut

rubbery

washer

Installing the Stuffing Tube

WARNING: Always wear safety goggles and a dust mask.

WARNING: Metal hull—The stainless-steel stuffing tube must be

isolated from the metal hull to prevent electrolytic corrosion.

WARNING: Metal hull—The rubbery washer must lay flat against

the hull for the stuffing tube to be firmly installed.

1. At the selected mounting location, inspect the hull interior to

ensure there is adequate clearance for the stuffing tube and any

bolts used to install the transducer. Be sure no cables, ribs, or

struts will interfere. Mark the site for the stuffing tube.

2. From inside the hull, drill a 3mm or 1/8" diameter pilot hole

perpendicular to the hull. If there is a hull irregularity near the

selected mounting location, drill from the outside.

3. Using the appropriate size hole saw, cut a hole from outside the

hull perpendicular to the hull surface (see table).

4. Sand and clean the area around the hole, inside and outside, to

ensure that the marine sealant will adhere properly to the hull. If

there is any petroleum residue inside the hull, remove it with

either a mild household detergent or a weak solvent (alcohol).

Metal hull—Remove all burrs with a file and sandpaper.

5. Remove the compression nut and hull nut from the stuffing tube.

6. Use marine sealant to seal the hull and hold the hull nut. Apply

a 2mm (1/16") thick layer of marine sealant around the flange of

the stuffing tube that contacts the hull and up the sidewall of the

tube (see Figure 1). The sealant must extend 6mm (1/4") higher

than the combined thickness of the hull, rubbery washer, and

the hull nut.

Metal hull—To isolate the stainless-steel stuffing tube from the

fiberglass or wood hull

marine sealant on flange

and sidewall of stuffing tube

stuffing tube

hull nut

rubbery washer

hull

Figure 1. Installing the stuffing tube

Copyright © 2006 - 2010 Airmar Tech nology Corp.

metal hull with stainless-steel stuffing tube

stuffing tube

hull nut

rubbery washer

hull

isolation

marine sealant on flange

and sidewall of stuffing tube, and

isolation bushing where it contacts the hull

bushing

Page 2

metal hull, slide the isolation bushing onto the stuffing tube.

Apply additional marine sealant to the surfaces of the isolation

bushing that will contact the hull, filling any cavities in and

around the bushing.

7. From outside the hull, push the stem of the stuffing tube

through the mounting hole using a twisting motion to squeeze

out excess sealant.

8. From inside the hull, slide the rubbery washer onto the stuffing

tube.

Metal hull—The rubbery washer must contact the hull. Do not

tighten the hull nut with the rubbery washer against the isolation

bushing. The stuffing tube will not be firmly installed. If

necessary, sand the isolation bushing until the rubbery washer

rests against the hull.

9. Screw the hull nut in place. Tighten it with slip-joint pliers.

Wood hull—Allow the wood to swell. After the hull has

expanded, tighten the hull nut securely.

Installing the Transducer & Fairing

Follow the instructions that came with the transducer and fairing.

After they are installed, follow the instructions below to seal the

cable inside the stuffing tube.

Sealing the Cable in the Stuffing Tube

WARNING: To form a watertight seal inside the stuffing tube,

stagger the splits in the compliant bushings.

1. The stuffing tube kit contains two sets of plastic washers. Four

are marked 8mm (0.33") diameter and four are marked 12mm

(0.47") diameter. Choose the set of plastic washers with the

smallest diameter that will fit around your cable. (Discard the

other set; it is not needed.) Put two of the plastic-washer pieces

around the cable and press the halves together to form a closed

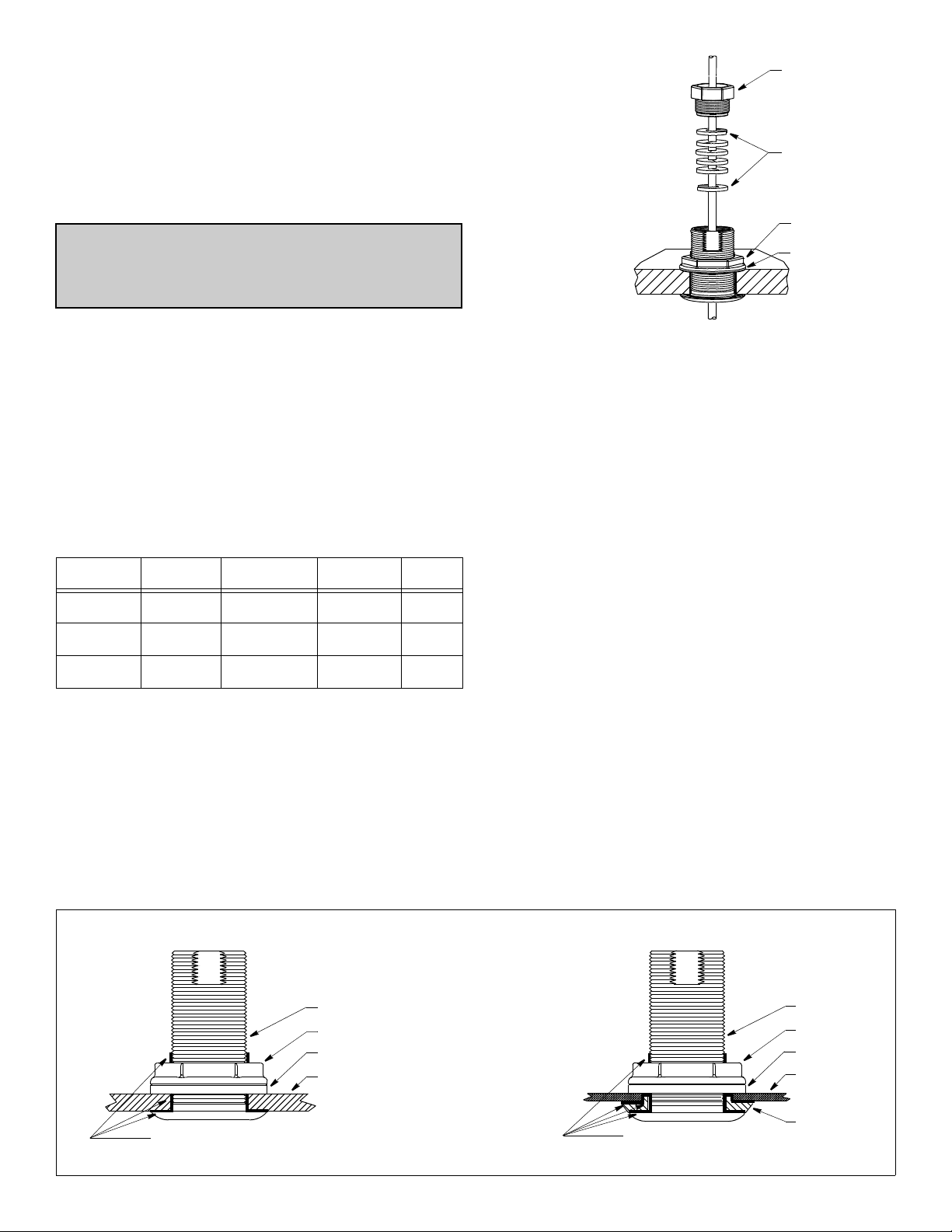

ring (see Figure 2).

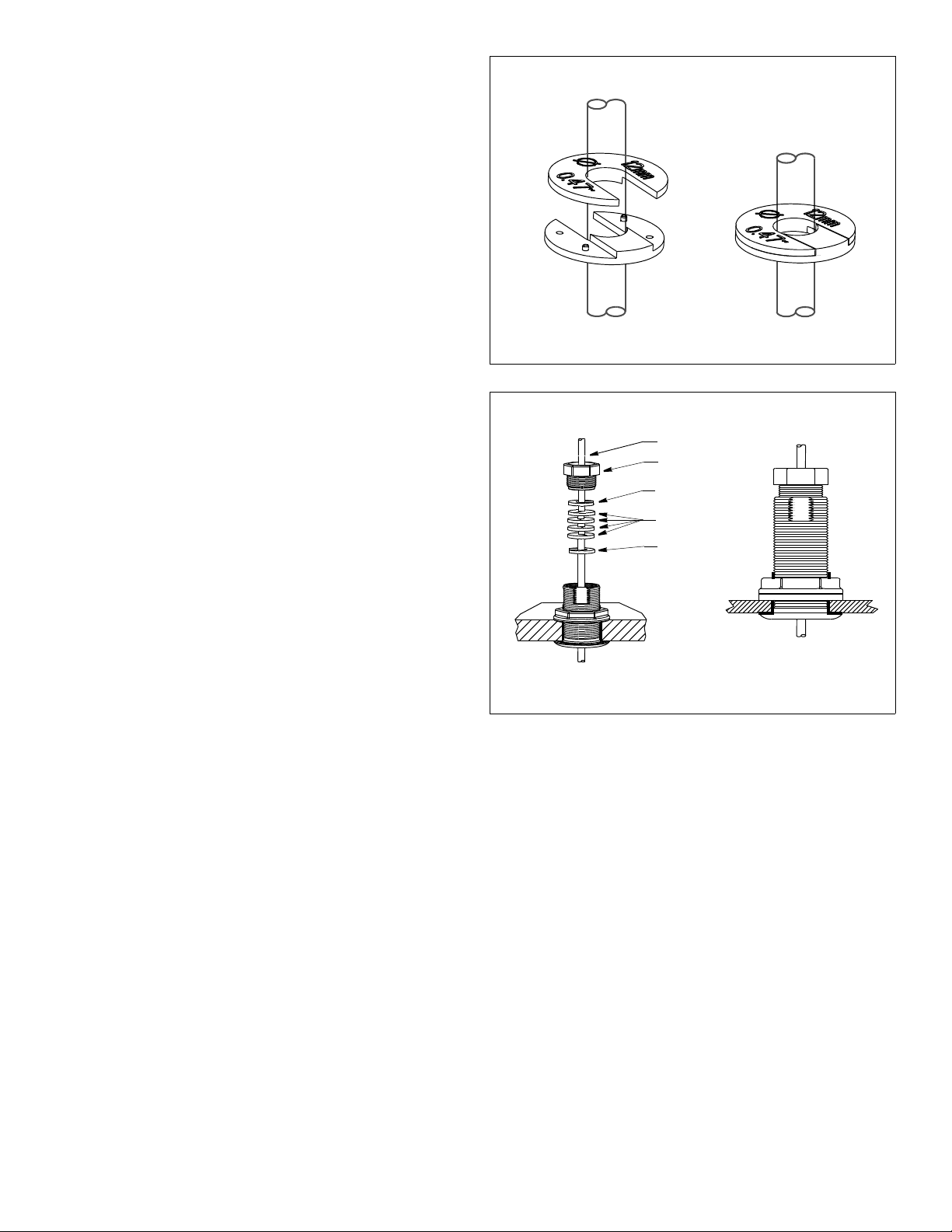

2. The kit also contains four sets of compliant bushings with four

bushings in each set. Choose the set of compliant bushings with

the smallest diameter that will fit around your cable. (Discard the

other sets; they are not needed.) Place the four compliant

bushings around the cable above the plastic washer (see Figure

3). Arrange the bushings so that the splits are staggered—not

aligned. At the top of the stack, press the second pair of plastic

washers together to form a closed ring. Be sure the plastic

washers and compliant bushings are stacked as shown in

Figure 3.

3. To seal the cable inside the stuffing tube, push the plastic

washers and compliant bushings into the stuffing tube forming a

tight stack. Be sure the stack of plastic washers and compliant

bushings is seated securely inside the stuffing tube.

4. Screw the compression nut into the stuffing tube until it is snug.

Using slip-joint pliers, tighten the compression nut 2-1/2 turns.

This will compress the compliant bushings slightly to form a

watertight seal. Do not over-tighten.

Checking for Leaks

WARNING: Do not leave the boat in the water unchecked for

several days.

When the boat is placed in the water, immediately check around

the stuffing tube for leaks. Note that very small leaks may not be

exploded view

Figure 2. Plastic washers—12mm (0.47”) diameter shown

Copyright © 2004 Airmar Technolog y Corp.

installedexploded view

cable

compression

nut

plastic

washer

compliant

bushings

plastic

washer

NOTE: stagger the

splits in the

compliant bushings

Figure 3. Sealing the cable in the stuffing tube

Copyright © 2006 2010 Airmar Technology Corp.

readily observed. Do not leave the boat in the water unattended

for more than 3 hours before checking it again. If there is a small

leak, there may be considerable bilge water accumulation after 24

hours.If a leak is observed around the stuffing tube, tighten the

compression nut another quarter turn and see if the leakage

stops. If the stuffing tube continues to leak, repeat the installation

and sealing procedures immediately.

Parts

Bronze Stuffing Tube (B165) 33-511-01

Stainless-steel Stuffing Tube (SS571) 33-541-01

Plastic Washers 20-457-01

Compliant Bushings 20-488-01

Obtain parts from your sensor manufacturer or marine dealer.

Gemeco Tel: 843.210.7000

(USA) Fax: 843.210.7170

email: sales@gemeco.com

Airmar EMEA Tel: +33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: +33.(0)2.23.52.06.49

email: sales@airmar-emea.com

®

AIRMAR

TECHNOLOGY CORPORATION

2

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

•

Copyright © 2005-2010 Airmar Technology Corp. All rights reserved.

www.airmar.com

Loading...

Loading...