Page 1

INTEGRATED HEADING SENSOR PG-500

Back

FLUXGATE HEADING SENSOR C-500

Page 2

TABLE OF CONTENTS

SAFETY INSTRUCTIONS...................................................................................... i

FOREWORD .........................................................................................................ii

SYSTEM CONFIGURATION................................................................................iii

EQUIPMENT LIST................................................................................................ iv

1. OPERATION......................................................................................................1

1.1 Controls and Indications....................................................................................................1

1.2 Turning the Powe r On/Off.................................................................................................. 1

1.3 Automatic Distortion Compensation...................................................................................3

1.4 Damping Control...............................................................................................................3

1.5 Selecting Ou tput Data Format...........................................................................................4

2. MAINTENANCE & TROUBLESHOOTING

2.1 Maintenance......................................................................................................................5

2.2 Troubleshooting.................................................................................................................5

2.3 Diagnostic Test..................................................................................................................6

2.4 Error Status.......................................................................................................................7

2.5 Clearing the Memory.........................................................................................................7

3. INSTALLATION

3.1 Mounting...........................................................................................................................8

3.2 Connections......................................................................................................................9

3.3 Correcting Magnetic Field Distortion................................................................................10

3.4 Heading Alignment.......................................................................................................... 11

3.5 Setting Output Data.........................................................................................................12

3.6 Setting Baud Rate...........................................................................................................13

SPECIFICATIONS...........................................................................................SP-1

PACKING LIST.................................................................................................. A-1

OUTLINE DRAWING

INTERCONNECION DIAGRAM

Page 3

SAFETY INSTRUCTIONS

Safety Information for the Installer

WARNINGWARNING

Turn off the power at the mains

switchboard before beginning the

installation.

Post a sign near the switch to indicate

it should not be turned on while the

equipment is being installed.

Fire or electrical shock can result if the

power is left on or is applied while the

equipment is being installed.

CAUTION

Confirm that the power supply voltage

is compatible with the voltage rating

of the equipment.

Connection to the wrong power supply

can cause fire or damage the equipment.

Use the supplied power cable.

Use of a wrong power cable can cause

fire or damage the equipment.

Maintain the compass safe distance to

prevent deviation to a magnetic

compass.

Standard compass

0.3 m

Steering compass

0.3 m

Safety Information for the Operator

WARNINGWARNING

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Turn off the power immediately if water

leaks into the equipment or the

equipment is emitting smoke or fire.

Continued use of the equipment can cause

fire or electrical shock.

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if a liquid

spills into the equipment.

CAUTION

Turns off the autopilot before selecting

output data format.

The autopilot may turn the rudder suddenly.

Turns off the autopilot before aligning

heading.

The autopilot may turn the rudder suddenly.

i

Page 4

FOREWORD

A Word to PG-500/C-500 Owners

Congratulations on your choice of the FURUNO PG-500 Integrated Heading Sensor, C-500

Fluxgate Heading Sensor. We are confident you will see why the FURUNO name has become

synonymous with quality and reliability.

For over 50 years FURUNO Electric Company has enjoyed an enviable reputation for inno vat ive

and dependable marine electronics equipment. This dedication to excellence is furthered by our

extensive global network of sales and service.

Your heading sensor is designed and constructed to meet the rigorous demands of the marine

environment. However, no machine can perform its intended function unless installed, operated

and maintained properly. Please carefully read and follow the recommended procedures for

installation, operation and maintenance.

We would appreciate hearing from you about whether we are achieving our purposes.

Thank you for choosing FURUNO equipment.

Features

• The PG-500 uses a fluxgate magnetic sensor in conjunction with a solid-state angular rate

heading.

• The C-500 uses a fluxgate magnetic sensor.

• The PG-500/C-500 can correct magnetic devia tion automatically.

• The PG-500/C-500 can convert magnetic heading to true head ing (requires FURUNO GPS

Navigator).

ii

Page 5

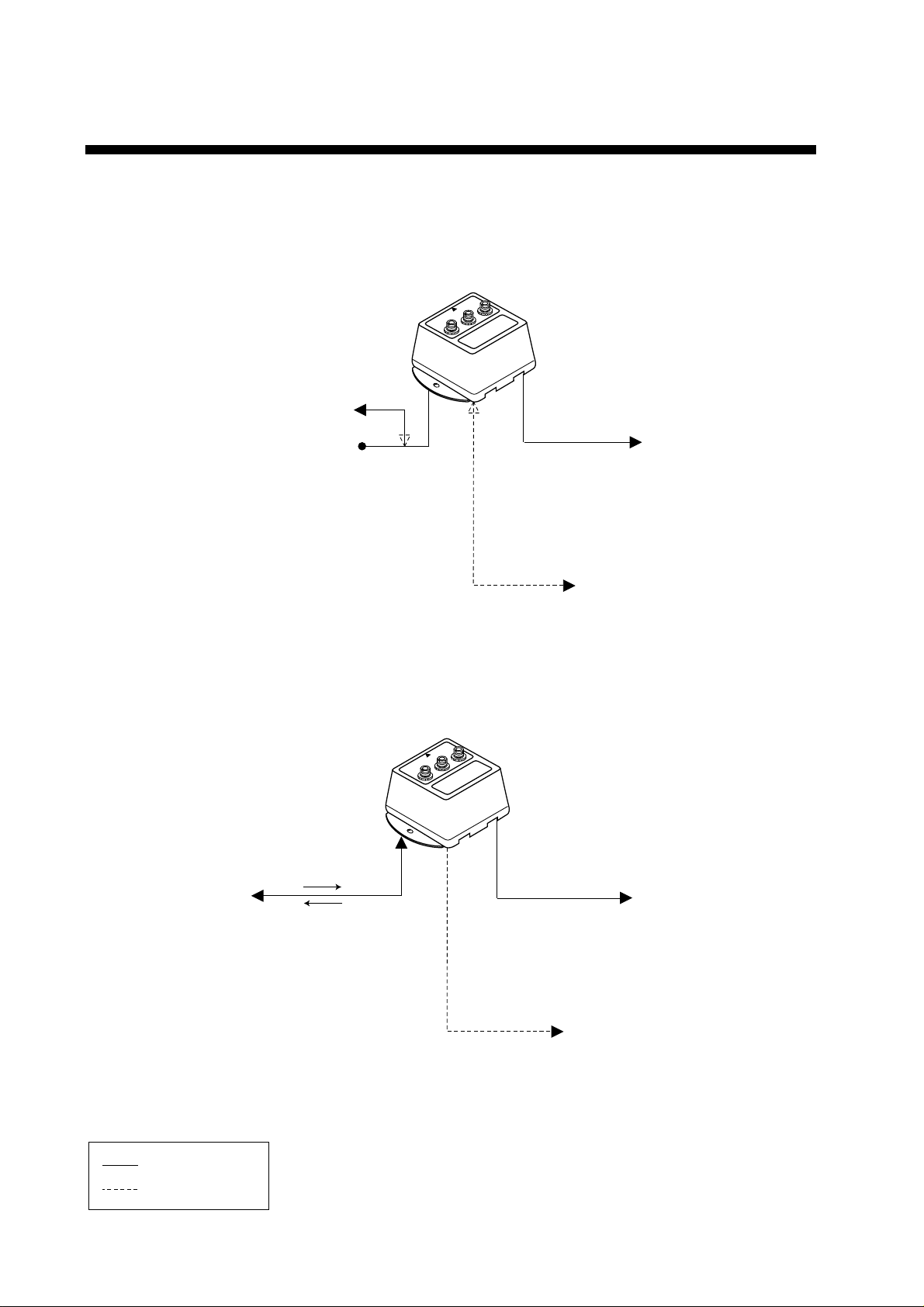

SYSTEM CONFIGURATION

Standard connection

PG-500/C-500

EXTERNAL EQUIPMENT

(NAVnet series, etc.)

12-24 VDC

Connection with NAVpilot-500

NMEA

Format

PG-500

NMEA

Format

AD-10 Format

RADAR/ARPA

(MODEL1832, 1721Mk-2, etc.)

EXTERNAL EQUIPMENT

(NAVnet series, etc.)

NAVpilot-500

Processor unit

Standard Supply

User Supply

Power,

operation command

NMEA Format

(Magnetic heading)

AD-10 Format

(Magnetic heading)

RADAR/ARPA

(MODEL1832, 1721Mk-2, etc.)

NMEA Format

(Magnetic heading)

EXTERNAL EQUIPMENT

(NAVnet series, etc.)

iii

Page 6

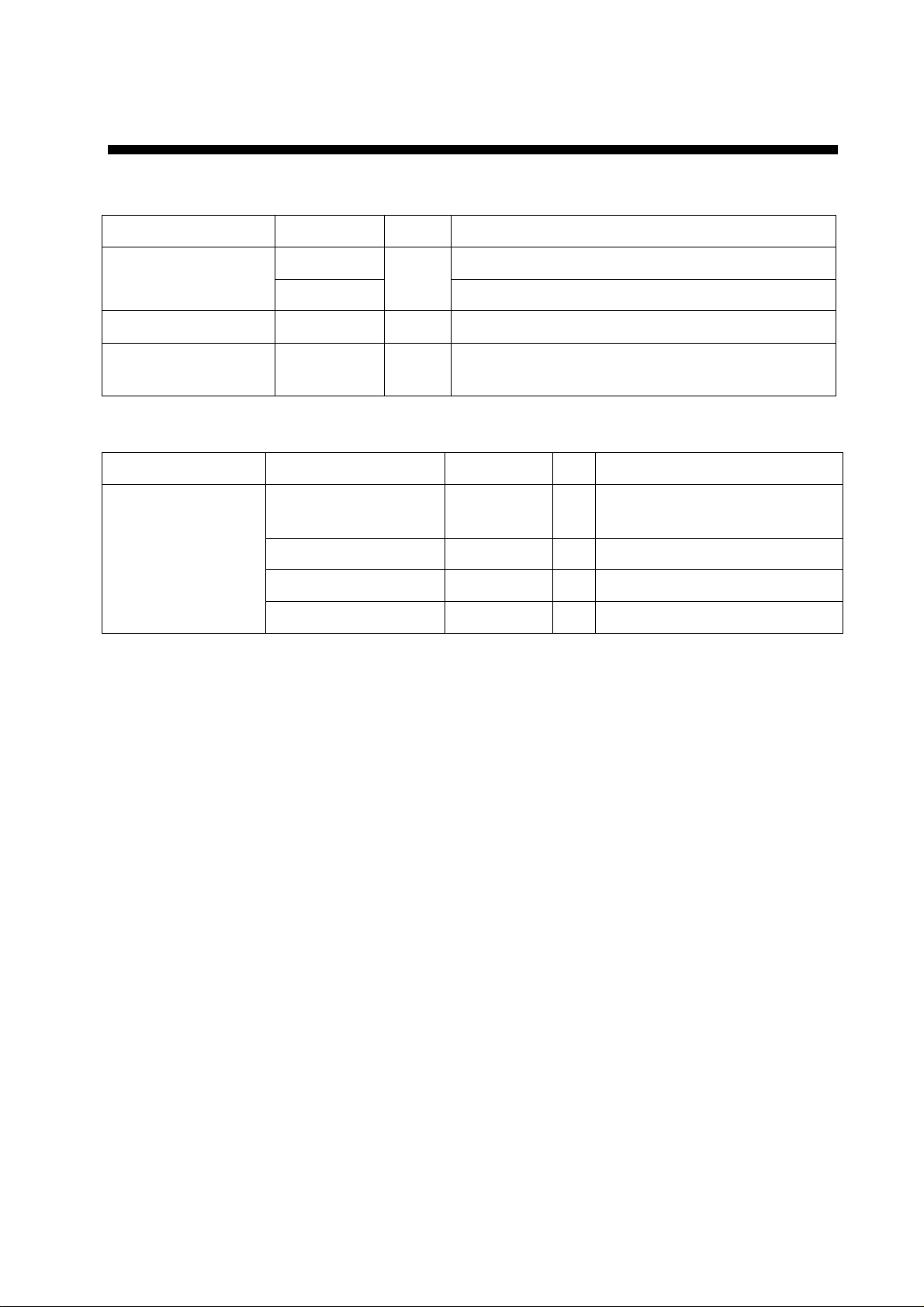

v

EQUIPMENT LIST

Standard set

Name Type Qty Remarks

PG-500-E Fluxgate and rate sensor

Sensor

C-500-E

Installation Materials CP64-02100 1 set Refer to the packing list at the back of this manual.

1

Fluxgate sensor

Spare Parts

Option

Name Type Code No. Qty Remarks

Cable assy.

SP64-01301 1 set Fuse

(Type: FGMB 1A 125V, Code No.: 000-114-805)

MJ-A6SPF0003-050 000-117-603 1

MJ-A6SPF0007-100 000-125-237 1 6P-6P, 10 m (for AD-10 format)

MJ-A7SPF0006-100 000-143-578 1 7P-7P, 10 m (for NMEA/Power)

MJ-A7SPF/SRMD-100 000-144-534 1 For extension. 7P-7P, 10 m

6P connector, 5 m

(for AD-10 format, NMEA)

i

Page 7

1. OPERATION

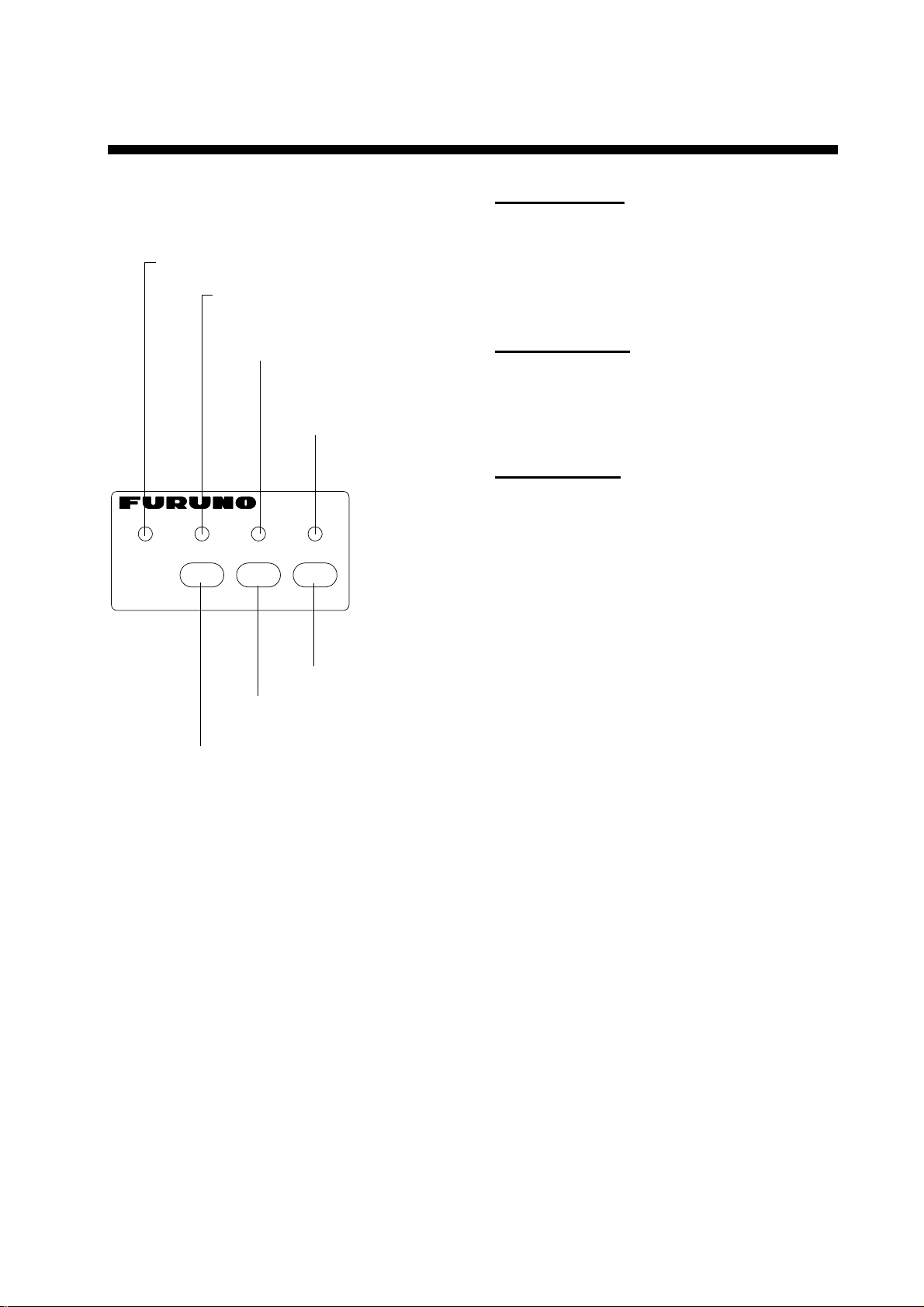

1.1 Controls and Indications

On: Auto correction is on.

Off: Auto correction is off.

On: True heading is output.

Off: Magnetic heading is output.

Off: Normal

Blinking: Correcting the deviation.

(For installation)

On: Normal

Off or blinking: Error

CALBTRUE STATUSAUTO

CALIBRATION

ADJDAMPAUTO

Program version

The program version, denoted by the LEDs

in binary notation, is shown. For example,

the LED state shown on the next page

means the program version is “1.03”.

ROM, RAM check

AUTO LED lights: ROM is normal.

TRUE LED lights: RAM is normal.

(CALB and STATUS LEDs are always lit.)

Deviation status

All LEDs blink twice when the calibration is

completed.

After the diagnostic tests are completed;

• C-500 outputs heading data and the

STATUS LED lights immediately.

Corrects the heading.

Smoothes the heading data to output.

Turns deviation corrections on and off.

Front panel of sensor

1.2 Turning the Power On/Off

Power to the sensor may be turned on or off

at the mains switchboard.

Turn the mains switch on.

The sensor checks the program version,

LED, ROM, RAM and deviation status in that

order for proper operation.

• PG-500 calculates the rate sensor offset.

The STATUS LED blinks during the

calculation, which takes about two minutes.

When the STATUS LED lights, bearing is

reliable.

Note: Confirm that the STATUS LED is lit

(not blinking) before leaving port.

1

Page 8

1. OPERATION

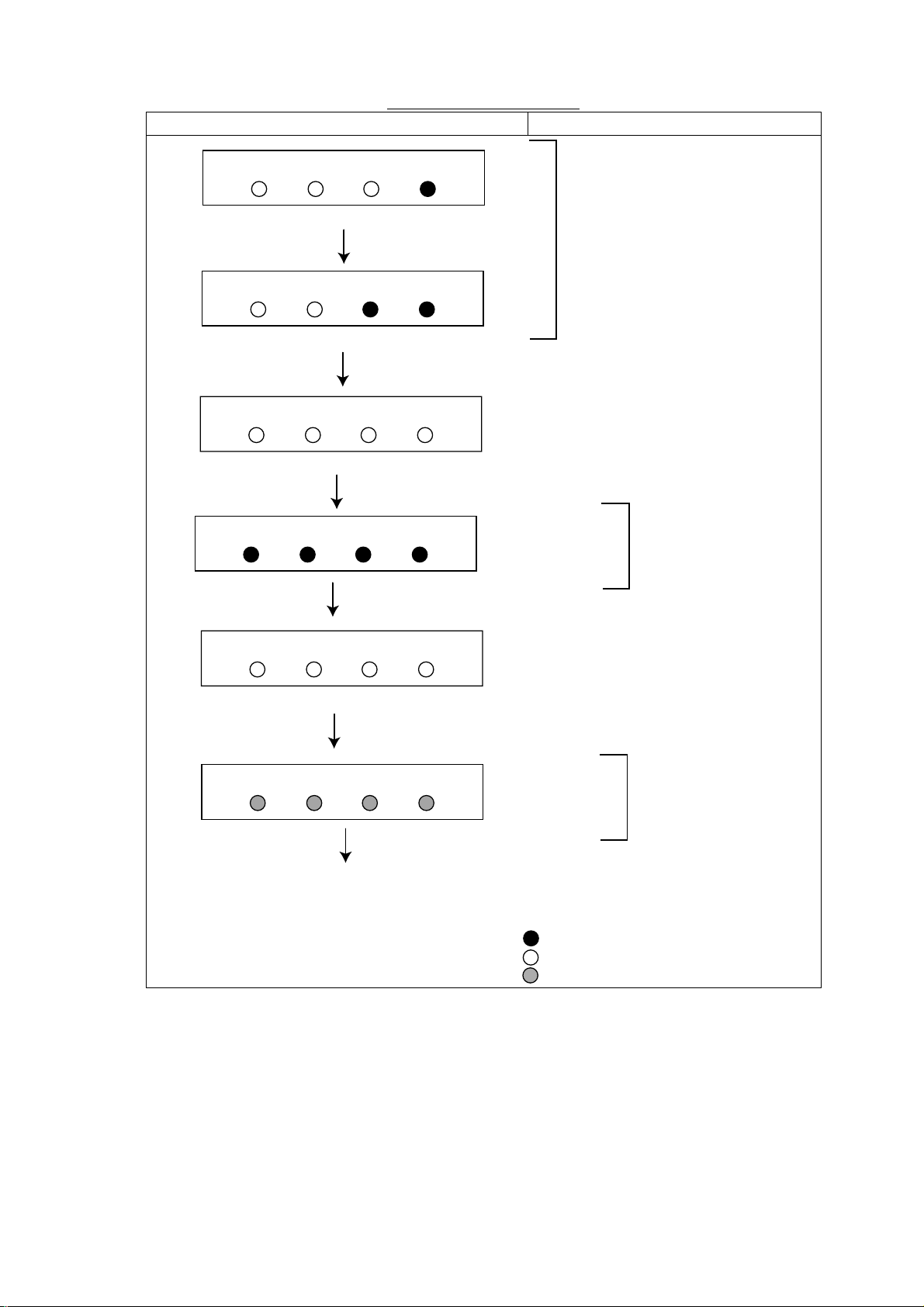

Sequence of Start up test

LED Sequence Test name

AUTO TRUE CALB STATUS

8421

0.5 seconds

AUTO TRUE CALB STATUS

8421

0.5 seconds

AUTO TRUE CALB STATUS

8421

0.5 seconds

AUTO TRUE CALB STATUS

0.5 seconds

AUTO TRUE CALB STATUS

Program V ersion No.

All LEDs go off.

ROM, RAM check

All LEDs go off.

8421

0.5 seconds

AUTO TRUE CALB STATUS

Twice

Deviation status

0.5 seconds

Normal operation

: On

: Off

: Blinking

2

Page 9

1. OPERATION

1.3 Automatic Distortion Compensation

Magnetic field distortion on your vessel has

been compensated at the installation. When

the magnetic field distortion changes, it can

be compensated automatically as follows.

Note: This function is only effective after

compensating for magnetic field

distortion. (Refer to page 10.)

1. Press the [AUTO] key more than two

seconds to light the AUTO LED.

AUTO

The STATUS LED lights during the automatic

distortion compensation functions.

2. To cancel automatic compensation, press

the [AUTO] key more than two seconds,

to turn off the AUTO LED.

Note 1: Do not conduct this procedure when

your boat is near a steel ship or iron

bridge, since they affect sensor

performance.

Note 2: Correct distortion whenever you feel

heading error is excessive.

TRUE CALB STATUS

:On

:Off

:State depends on settings

Auto compensation

1.4 Damping Control

The damping control determines how

sensitively the sensor responds to change of

ship’s heading. When the damping value is

large, the sensor responds smoothly but a

small boat may wander after the turning. Use

a small damping value as possible.

Note: When connecting with the autopilot

NAVpilot-500, use the default damping

setting (PG-500: damping 1, C-500:

damping 2).

1. Press the [DAMP] key more than two

seconds.

All LEDs go off, and then the current damping

setting is shown by the LEDs.

2. Press the [DAMP] key to change the

damping setting in the sequence of

damping 1→2→3→4→1→…

AUTO

TRUE CALB

STATUS

Damping 1

Damping 2

Damping 3

Damping 4

: On

: Off

Damping LED state

If three seconds passes with no operation,

the damping setting is fixed, and the

damping control mode is terminated.

3

Page 10

1. OPERATION

1.5 Selecti ng O ut put Data Format

The sensor can output true or magnetic

heading. The default setting is magnetic, in

AD-10 format.

CAUTION

Turn off the autopilot before selecting

output data format.

The autopilot may turn the rudder suddenly.

To output true heading, do the following:

1. Connect Furuno GPS Navigator which

can output data sentence RMC or VTG.

2. Set up magnetic variation (manual or

automatic) at the GPS Navigator.

When RMC or VTG is input to the sensor, the

TRUE LED lights and then true heading is

output to other equipment.

4. To return to magnetic heading output,

disconnect the GPS Navigator.

Note 1: If the TRUE LED does not light

within 90 seconds, check the

navigator setting and cable

connection.

Note 2: If the sensor stops receiving

magnetic variation data while

outputting true heading, the TRUE

LED stops lighting and blinks. The

last-used variation data is used.

Note 3: Magnetic variation cannot be

corrected manually at the sensor.

Therefore, if you desire true heading

output but do not have a navigation

aid, you may enter appropriate

variation as shown in 3.4 Heading

Alignment on page 11. HDM

sentence, however, cannot be

changed to true heading. For HDG

sentence, it can be changed to true

heading at the equipment connected,

by using the magnetic heading and

magnetic variation data in the

sentence.

4

Page 11

2. MAINTENANCE & TROUBLESHOOTING

2.1 Maintenance

Regular maintenance is important to maintain intended performance over a long period.

Regularly check the following:

• Clean the component with a soft cloth. Do not use chemical cleaners; they can remove paint

and markings.

• Make sure all connections are tight.

• Check the ground terminal for corrosion. Clean if necessary.

2.2 Troubleshooting

The table below provides simple troubleshooting procedures which the user can follow to

restore normal operation. If normal operation cannot be restored do not check inside the

equipment; there are no user-serviceable parts inside. Any repair work should be referred to a

qualified technician.

Symptom Remedy

• Check power connector.

Unit cannot be powered.

LEDs do not light.

Heading data error.

The heading data is not output to

external equipment.

• Check the ship’s mains.

• Check the fuse.

• Check power connector.

• Do the diagnostic test.

(Refer to the next page.)

• Do the diagnostic test.

(Refer to the next page.)

• Check connections.

• Do the diagnostic test.

(Refer to the next page.)

5

Page 12

MAINTENANCE & TROUBLESHOOTING

2.3 Diagnostic Test

This equipment has a diagnostic test which

checks the LED, key operation, ROM, RAM,

EEPROM, magnetic sensor, rate sensor

(PG-500 only) and loop back for proper

operation. Do this test after dismounting the

sensor.

1. Disconnect the power cable from the

equipment.

2. While pressing the [AUTO] and [DAMP]

keys together, reattach the power cable.

3. Release the [AUTO] and [DAMP] keys

when the AUTO LED lights.

Then, the test is executed in the sequence

shown in the right column.

*1: If STATUS LED does not light (NG),

this test cannot be carried out. Contact

your dealer.

Also, if the sensor is not turned within

one minute after the EEPROM test,

the test is carried out with the “Mag

sensor” is NG.

*2: The loop back test requires a special

test connector.

It is skipped when the test connector

is not connected.

Start

AUTO LED

:

OK

TRUE LED

OK

:

CALIB

LED: OK

STATUS

LED: OK

All LEDs

blink twice.

AUTO lights

automatically.

AUTO TRUE CALB

STATUS

Press the [AUTO] key.

AUTO key

: OK

Press the [DAMP] key.

DAMP key

: OK

Press the [ADJ] key.

ADJ key

: OK

Press the [AUTO] and [DAMP] keys together again.

All LEDs

go off.

ROM:

OK

RAM:

OK

EEPROM

: OK

Turn the sensor more than 180 until STATUS LED lights.*1

Mag.

sensor: OK

All LEDs

go off.

Rate

OK

sensor:

Loop back

OK*2

:

All LEDs

go off.

: On (normal)

Normal operation

: Off (error)

(PG-500 only)

: Blink

Sequence of diagnostic test

6

Page 13

2.4 Error Status

When error is detected, all LEDs go off and

then the STATUS LED blinks or goes off

depending on error type as shown in the

table below.

LED status Meaning Remarks

STATUS LED

blinks slowly.

STATUS LED

blinks quickly.

STATUS LED

goes off.

Magnetic

deviation error

EEPROM error

Other than the

above.

Appropriate LED

blinks.

CALIB LED:

Rate sensor

error

TRUE: Cable of

the magnetic

sensor is cut.

2. MAINTENANCE & TROUBLESHOOTING

2.5 Clearing the Memory

The memory can be cleared to start afresh

with default settings.

1. Disconnect the power cable from the

equipment.

2. Reattach the cable while pressing the

[AUTO] and [ADJ] keys together.

After the memory has been cleared, the

sensor returns to the normal mode.

If the memory could not be cleared, the

STATUS LED blinks quickly.

7

Page 14

3. INSTALLATION

3.1 Mounting

This sensor must be mounted indoors on the

horizontal plane.

When selecting a mounting location, keep in

mind the following points:

• Vibration at the mounting location should

be minimal.

• Install the sensor as far as possible from

power cables and ferrous materials.

• Install the sensor near the ship's center of

gravity.

• Align the bow mark with the ship's bow on

the fore-and-aft-line.

Fix the sensor by using tapping screws

(supplied).

Ship's bow

Fixing hole

( 4.5 mm)

This line should be at right

angles to the fore and aft line.

Bow mark

1

6

141

152

3

0

5

5.5

Material: Brass

All dimensions in mm.

For added support, use M4 nuts, bolts

and washers instead of tapping screws.

Secure sufficient clearance around the

sensor for maintenance and checking.

Mounting the sensor

Note: Do not overtighten the screws or bolts;

the sensor may crack.

8

Page 15

3. INSTALLATION

3.2 Connections

Connect cables as shown below.

Leave sufficient slack in cables for

maintenance and checking ease. If cables

run outside the bridge, run them through

conduit to protect them from corrosion.

Note: The NMEA port (the mid position) can

receive and send data. However,

when connecting with the

NAVpilot-500 or RD-30, the NMEA

port is for output only.

12-24 VDC: MJ-A7SPF0009-020 (supplied)

NAVpilot-500: MJ-A7SPF0010-100

(supplied with the NAVpilot-500)

Ground cable

(Local supply)

Grounding

12-24 VDC

+

BOW

NMEA

-

AD10

Grounding

Ground the equipment as follows to prevent

loss of sensitivity:

• The ground wire should be as short as

possible.

• The ground wire should be about 1.25 sq

and not contain steel.

• Use only a closed-end lug.

Pan head screw

Spring washer

Crimp-on lug

(closed,

local supply)

Ground term inal, sect ional view

Flat washer

Ground wire

(1.25 sq,

local supply)

Seal washer

12-24 VDC

or

Processor Unit

of NAVpilot-500

MJ-A6SPF0003-050 (option)

Ground

terminal

External equipment

(Current Indicator, etc.)

MJ-A6SPF0007-100

(supplied as installation material)

Sensor, top view

External equipment

(Radar, etc.)

Connection of external equipment

NMEA: Digital interface NMEA format

input/output terminal.

Output: HDG, HDT, HDM (Magnetic

Heading)

Input*: RMC or VTG

AD-10: Outputs heading information in

AD-10 format.

12-24VDC: Power input, Digital interface

NMEA format input/output terminal

Output: HDG, HDT, HDM (Magnetic

Input*: RMC or VTG

*Only one port can be for Input.

Note: Cover unused connector(s) with the

Heading)

rubber cap (supplied) to prevent

ingress of water.

9

Page 16

3. INSTALLATION

3.3 Correcting Magnetic Field Distortion

The magnetic field around the sensor is

subject to change with the ship structure,

engines, electronic equipment or any ferrous

materials in the vicinity.

The equipment contains an automatic

magnetic field distortion correction facility.

Do the following to correct magnetic field

distortion on calm water.

1. Steer the boat clockwise or

counterclockwise in a circular course.

Take about two minutes to complete the

circle (at about 3 kt). While turning the

boat, go to step 2.

2 minutes for a circle

(at about 3 kt)

Note: Complete circle within 2 minutes,

otherwise large error may result.

2. Press [ADJ] and [DAMP] keys together

more than two seconds. The CALB LED

blinks.

AUTO TRUE CALB STATUS

: Blinking

: Off

light. Wait 30 seconds for the sensor to

return to normal operation, or press any

key for quick return.

AUTO TRUE CALB STATUS

: On

LED status at successful correction

Note 1: Do not turn off the power supply

during the correction. Data may be

corrupted.

Note 2: Continue turning the boat even if the

CALB LED status changes from

blinking to lighting. Keys are

inoperative when the CALB LED is

lighting.

Note 3: The sensor does not output heading

data during the correction.

4. Anchor the boat at the pier to check

sensor heading to a known point (for

example, lighthouse).

If there is error, see "3.4 Heading

Alignment.”

If some LED does not light, change

sensor location and repeat step 2

through 4.

If the correction failed, the LED status is

as shown below. This continues until you

press any key to clear the display.

(Turning off the power at switchboard will

not clear the LED display.) Try the

correction again.

AUTO TRUE CALB STATUS

LED status during compensation

Note: You can return to normal operation

at any time by pressing the

[DAMP] key.

3. Continue turning the boat in a circle

(three to five times) until a result is shown

with the LEDs.

When correction is successful, all LEDs

10

: Blinking

: Off

LED status, compensation failed

Page 17

3. INSTALLATION

3.4 Heading Alignment

Heading alignment is required when sensor

heading is different from actual heading.

This alignment must be done using magnetic

heading (default setting).

CAUTION

Turn off the autopilot before aligning

heading.

The autopilot may turn the rudder suddenly.

Procedure

1. Press the [ADJ] key more than two

seconds. All LEDs go off.

AUTO

TRUE CALB STATUS

: Off

AUTO

+1°

+2°

+3°

+4°

+5°

+6°

+7°

Repeat

TRUE CALB

STATUS

: On

: Off

LED state and pressing of [DAMP] key

When pressing the [ADJ] key, the above

sequence begins from the STATUS LED

side.

Note: Complete the next step within 10

seconds, otherwise normal operation

is restored.

2. Set difference between sensor heading

(output) and actual heading with the

[DAMP] key for “+” or [ADJ] key for “-”.

For example, the heading output by the

sensor is 70° and the actual heading is

75°. Therefore, the difference is +5°.

Press the [DAMP] key five times to set

+5°. Each time the [DAMP] key is

pressed, the LEDs light as shown below.

11

Page 18

3. INSTALLATION

3.5 Setting O ut put Data

Setting output interval

The default setting is 200 ms.

Refer to the table shown on the next page

for proper setting.

1. Disconnect the power connector from the

sensor.

2. Reattach the connector to the sensor

while pressing the [DAMP] key. The

equipment is powered on, and the

current output interval is shown by the

LEDs.

AUTO TRUE CALB

1 s

200 ms

100 ms

25 ms

LED state and output inte r val

If step 2 was not completed satisfactorily, the

STATUS LED blinks quickly. Try step 2

again.

3. Press the [DAMP] key to change interval.

The sensor returns to the normal mode if

there is no operation for three seconds.

Setting the output sentence(s)

STATUS

: On

: Off

AUTO TRUE CALB STATUS

HDT HDG

:On (current setting)

:Off

: True heading

HDT

: Magnetic heading

HDM

: Magnetic heading & Magnetic variation value

HDG

AUTO LED has no function.

HDM

(sentence)

LED and output sentence

3. Press key corresponding to sentence to

output.

Sentence Key

HDT [AUTO]

HDG [DAMP]

HDM [ADJ]

To cancel output, press the same key again.

Note 1: Several sentences may be

output simultaneously. However,

delay may result when the output

interval is 100 ms or 200 ms.

Note 2: "HDT" outputs true heading data.

However, if variation data is not

input from the GPS navigator,

magnetic bearing will be output.

The equipment returns to the normal mode if

there is no operation for three seconds.

Select which type(s) of heading data to

output. The default setting is HDG.

1. Disconnect the power connector from the

sensor.

2. Reattach the connector to the sensor

while pressing the [ADJ] key. The

equipment is powered on, and LED(s)

light to show which output sentence(s) is

being output.

12

Page 19

3. INSTALLATION

3.6 Setting Ba ud Rate

Set the baud rate of external equipment.

The default setting is 4800 bps.

When connecting with the NAVpilot-500, use

the default setting (4800 bps).

1. Disconnect the power connector from the

sensor.

2. Reattach the connector to the sensor

while pressing the [AUTO] key. The

sensor is powered on, and the current

baud rate is shown by the LEDs.

3. Press the [AUTO] key to change the

baud rate as appropriate.

AUTO TRUE CALB

4800

9600

19200

38400

LED and baud rate

STATUS

: On

: Off

Relation baud ra te and output interval

Baud rate Output interval Available sentences

25 No output

4800

9600

19200

38400

Note: When an error message occurs, the above

sentences may be changed

100

200

1000

25

100

200

1000

25

100

200

1000

25

100

200

1000

Up to two sentences can

be output.

Up to three sentenc es can

be output.

HDT or HDM

Up to three sentenc es can

be output.

Up to two sentences can

be output.

Up to three sentenc es can

be output.

.

If baud rate could not be set, the STATUS

LED blinks quickly. Try again.

The sensor returns to the normal mode if

there is no operation for three seconds.

13

Page 20

SPECIFICATIONS OF INTEGRATED HEADING SENSOR

PG-500

1 GENERAL

1.1 Heading Accuracy 1.0°rms (horizontal)

1.5°rms (within 30°)

1.2 Display resolution 0.1°

1.3 Follow-up 30°/s rate-of turn

1.4 I/O Port Input: 1 port

Output: 2 ports (one port drives 3 outputs)

1.5 Interface

Output FURUNO AD-10 format

IEC 61162-1 (NMEA 018 3 Ver2.0)

HDG, HDT, HDM

Input IEC 61162-1 (NMEA 018 3 Ver1.5/2.0)

RMC, VTG

1.6 Data Update AD-10 formatted: 25 ms

IEC 61162-1 (NMEA 018 3): 100ms, 200 ms or 1 s selected

2 POWER SUPPLY

12-24 VDC: 0.12-0.03 A

3 ENVIRONMENTAL CONDITION

3.1 Ambient Te mper ature -15°C to +55°C

3.2 Relative H umidity 95% at 40°C

3.3 Waterproof IP5 (IEC 60529), CFR-46 (USCG standard)

3.4 Vibration IEC 60945

4 COLOR

N3.0

SP - 1 E7255S01B

Page 21

PACKING LIST

C7255‑Z01‑B

A-1

PG‑500/C‑500

64AV‑X‑9851 ‑1

1/1

NAME

OUTLINE

DESCRIPTION/CODE№

ユニット UNIT

ハイブリッドヘディングセンサー

INTEGRATEDHEADINGSENSOR

ヘディング゙センサー

FLUXGATEHEADINGSENSOR

PG‑500

000‑040‑467

C‑500

000‑040‑468

予備品 SPAREPARTS SP64‑01301

ヒューズ

FUSE

FGMB1A125V

000‑114‑805

工事材料 INSTALLATIONMATERIALS CP64‑02101

+トラスタッピンネジ

+TAPPINGSCREW

4X16SUS3041シュ

000‑802‑080

その他工材 OTHERINSTALLATIONMATERIALS

ケーブル組品MJ

MJ‑A6SPF0007‑100

Q'TY

1

(*1)

1

(*1)

2

2

CABLEASSY.

ケーブル組品MJ

CABLEASSY.

1

000‑125‑237

MJ‑A7SPF0009‑020

1

000‑145‑612

(*1)のユニットは仕様により決定されます。

(*1)UNITHASBEENDETERMINEDBYSPECIFICATION.

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 22

Y.Hatai

Page 23

1

Y. Hatai

23

A

ヘディングセンサー

HEADING SENSOR

PG‑500/C‑500

AD10

AD10DATAH

AD10DATAC

AD10CLKH

AD10CLKC

IEC61162

B

NMEA0183 OUT

NMEA0183 IN

12‑24 VDC

NMEA

TDA

TDB

RDH

RDC

12‑24 VDC

TDA

TDB

RDH

RDC

GND

GND

(+)

(‑)

GND

NC

NC

MJ‑A6SPFD

1

2

3

4

5

6

MJ‑A6SPFD

1

2

3

4

5

6

MJ‑A7SPFD

1

2

3

4

5

6

7

*3

P

P

*3

P

P

P

P

MJ‑A6SPF0007,10m,φ6

シロ

クロ

キ

ミドリ

MJ‑A6SPF0003,5m,φ6

シロ

WHT

クロ

BLK

キ

YEL

ミドリ

GRN

*3

シロ WHT

アオ BLU

キ YEL

ミドリ GRN

アカ

RED

クロ BLK

WHT

BLK

YEL

GRN

*2

MJ‑A7SPF0009, 2m,φ7

1A

1A

*3

MJ‑A6SPFD

P

P

1

DATAH

2

DATAC

3

CLKH

4

CLKC

5

NC

6

GND

NAVnet シリーズ

NAVnet series

航法装置

NAV. EQUIPMENT

NAVnet シリーズ

NAVnet series

オートパイロット

AUTOPILOT

航法装置

NAV. EQUIPMENT

12‑24 VDC

オートパイロット

レーダー

潮流計

AUTOPILOT

RADAR

CURRENT INDICATOR

*4

C

D

*1

GND

IV‑1.25SQ.

注記

*1)造船所手配。

*2)オプション。

*3)工場にて取付済み。

*4)NAVpilot‑500を接続する場合、相互結線図はNAVpilot‑500の装備要領書を参照(PG‑500のみ)。

NOTE

*1. SHIPYARD SUPPLY.

*2. OPTION.

*3. FITTED AT FACTORY.

*4. WHEN NAVpilot‑500 IS CONNECTED TO PG‑500, REFER TO INTERCONNECTION DIAGRAM IN INSTALLATION MANUAL OF NAVpilot‑500.

DRAWN

Aug. 27, '04

CHECKED

APPROVED

SCALE

DWG.No.

E. MIYOSHI

TAKAHASHI.T

MASS

kg

C7255‑C01‑ C

TITLE

PG‑500/C‑500

名称

ハイブリッドヘディングセンサー/ヘディングセンサー

相互結線図

NAME

INTEGRATED HEADING SENSOR/HEADING SENSOR

INTERCONNECTION DIAGRAM

Page 24

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*

00014725601

**00014725601

*

*

00014725601

**00014725601

*

*

OME

72550

C

20

**OME

72550

C

20

**OME

72550

C

20

**OME

72550

C

20

*

Nishinomiya 662-8580, JAPANNishinomiya 662-8580, JAPAN

Telephone :Telephone : 0798-65-21110798-65-2111

FaxFax 0798-65-42000798-65-4200

ll rights reserved.

ll rights reserved.

::

Printed in JapanPrinted in Japan

Pub. No.Pub. No. OME-72550OME-72550

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : APRAPR.. 20032003

C2C2 :: OCTOCT.. 13, 200413, 2004

(( YOTAYOTA ))

PG-500/C-500PG-500/C-500

* 0 0 0 1 4 7 2 5 6 0 1 ** 0 0 0 1 4 7 2 5 6 0 1 *

* O M E 7 2 5 5 0 C 2 0 ** O M E 7 2 5 5 0 C 2 0 *

Loading...

Loading...