Furuno 235DHT-LMSE Installation Instructions

OWNER’S GUIDE & INSTALLATION INSTRUCTIONS

IMPORTANT : Please read the instructions completely before proceeding with the installation.

These instructions supersede any other instructions in your instrument manual if they differ.

WARNING

Installation of the anti-rotation bolt is mandatory!

Failure to install the anti-rotation bolt may result in the fairing rotating while the

17-284-01 rev. 02 06/04

boat is underway. The effect may be violent movement and loss of steering. This

could result in serious injury or death to passengers and/or damage to the boat

or other property.

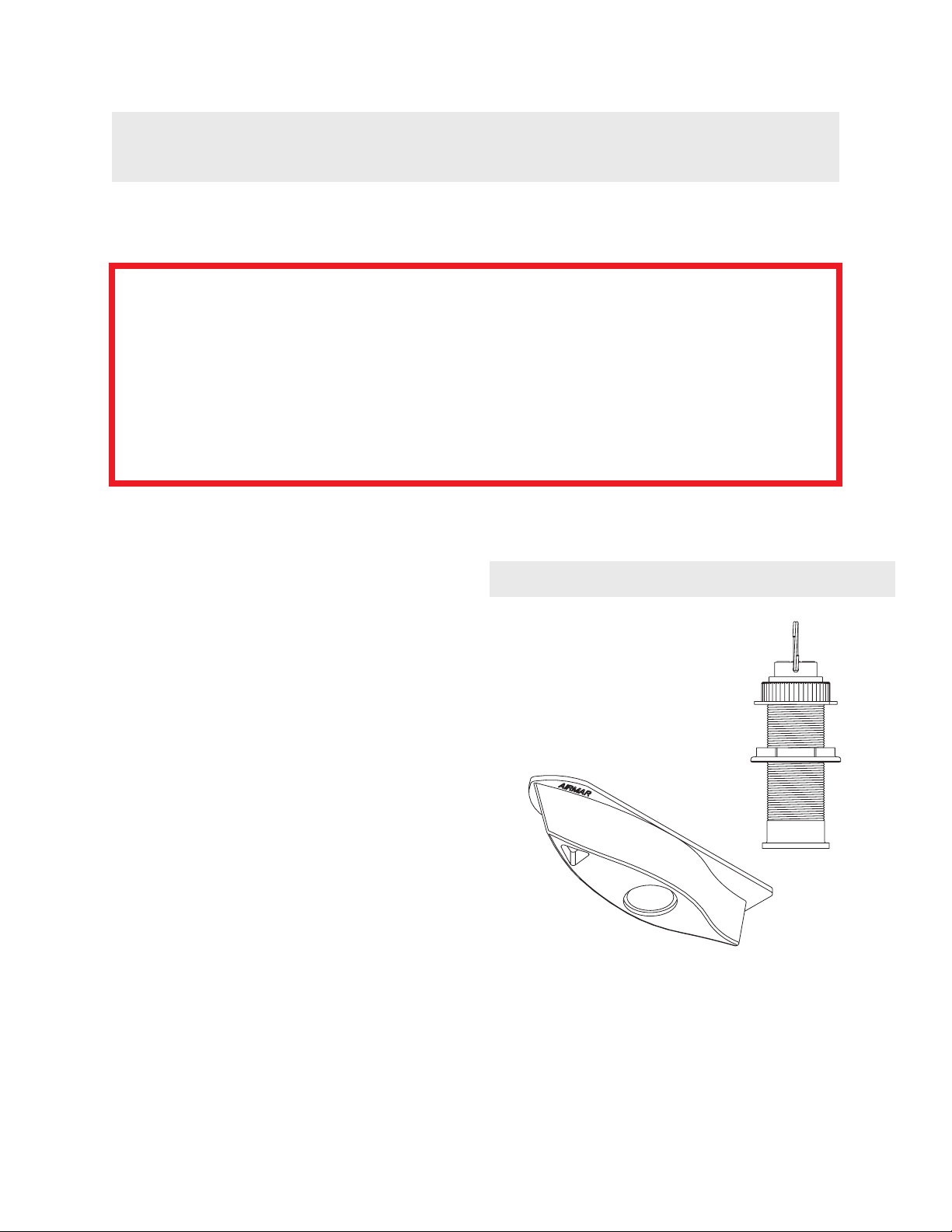

Retractable Thru-Hull Transducer

with High-Performance Fairing

Model: B122

Applications

• Bronze housing recommended for fiberglass or wood hulls only.

Caution : NEVER install a bronze housing in a metal hull

because electrolytic corrosion will occur.

• Caution : NEVER install a metal housing in a vessel with a

positive ground system.

• Maximum hull thickness with fairing (measured perpendicular to

the water surface): 47mm (1-7/8")

•Fairing can accommodate a deadrise angle of up to 35 °

Pre-test

Connect the transducer insert to the instrument. Hold the

transducer over the side of the boat with the active surface

submerged in the water and aimed at the bottom. Check for a depth

reading (and temperature if applicable). If there is no reading, check

all the connections and repeat the test. If there is still no reading or

it is inaccurate, return the product to your place of purchase.

Tools & Materials

Safety goggles

Dust mask

Electric drill with 10mm (3/8") or larger chuck capacity

Drill bits: pilot hole 3mm or 1/8"

anti-rotation bolt 10mm or 3/8"

Hole saw: 51 mm or 2"

Digital level or bubble level & protractor

Band saw or hand saw

Rasp or power tool

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

Sandpaper

Mild household detergent or weak solvent (alcohol)

Marine sealant (suitable for below waterline)

Slip-joint pliers

Mallet

Zip-ties

Water based anti-fouling paint ( mandatory in salt water )

Installation in a cored fiberglass hull

Tr ansducer—hole saw for hull interior: min. 60 mm or 2-3/8"

Anti-rotation bolt—drill bit for hull interior: min. 19mm or 3/4"

Cylinder, wax, tape, and casting epoxy

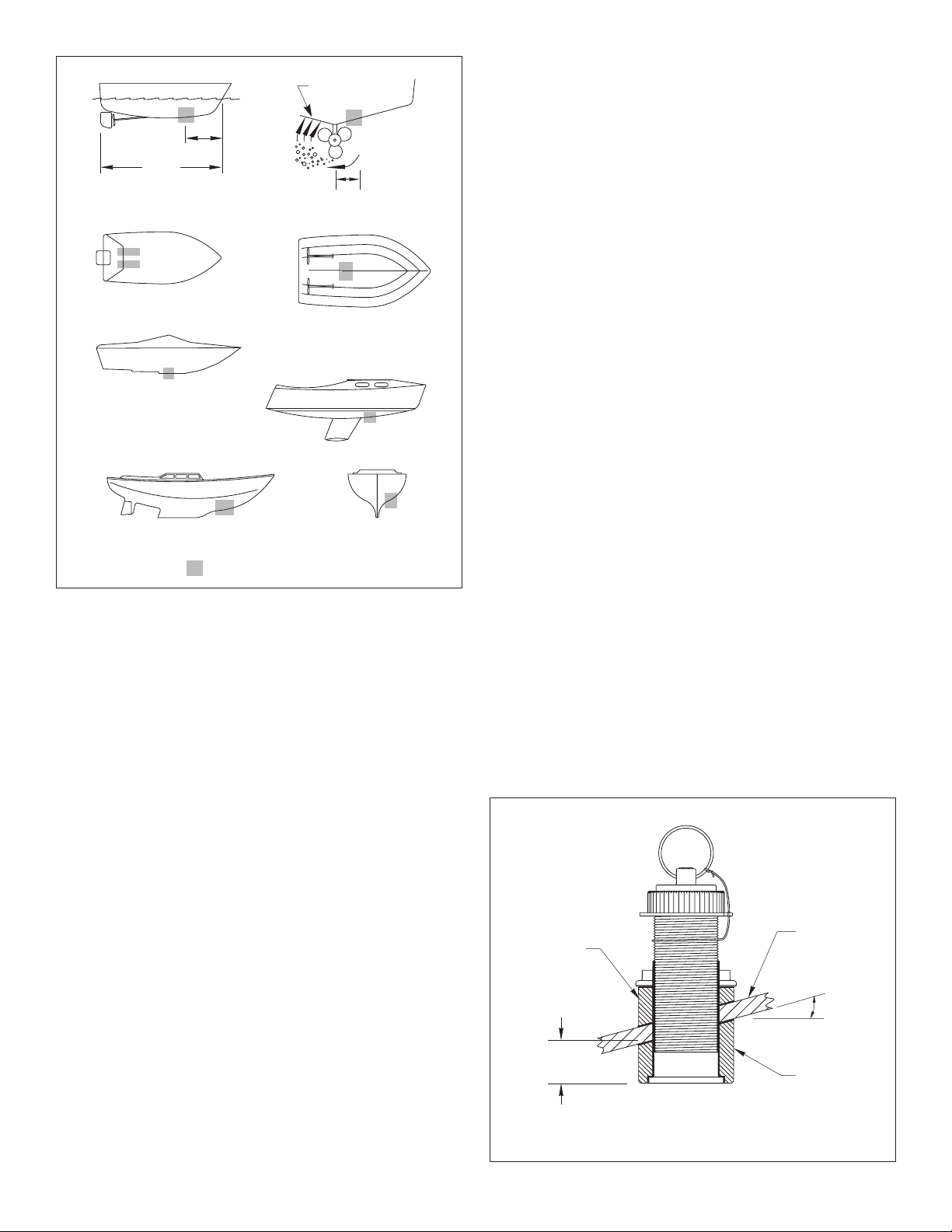

1/3 aft

LWL

(Load Waterline Length)

outboard and I/O

stepped-hull

Figure 1.

pressure waves

150- 300 mm

(6-12")

displacement hull

planing hulls

fin keel sailboat

full keel sailboat

inboard

Best location for the transducer

AIRMAR

®

Outboard and I/O —Mount just forward of the engine(s).

Inboard —Mount well ahead of the propeller(s) and shaft(s).

Stepped-hull —Mount just ahead of the first step.

Boat capable of speeds above 25kn (29MPH)—Review the

installation location and operating results of similar boats before

proceeding.

• Fin keel sailboat —Mount to the side of the centerline and

forward of the fin keel 300–600mm (1–2').

• Full keel sailboat —Locate amidships and away from the keel

at the point of minimum deadrise angle.

High-Performance Fairing

• Corrects for the deadrise angle of the hull, so the transducer

beam shoots straight down.

• Mounts the transducer deeper in the water for clean flow over

the transducer’s active surface.

• Long streamlined shape directs the water around the

transducer to minimize drag.

Installation

Cored fiberglass hull —Follow separate instructions on page 5.

Caution : Never use products containing strong solvents such as

acetone because solvents can greatly weaken plastic parts.

Caution : Never pull, carry, or hold the transducer by its cable; this

may sever internal connections.

Hole Drilling—Transducer

Mounting Location

Placement

Choose a location:

•Away from the propeller(s) and shaft(s), other machinery, and

other echosounders to minimize the effect of noise on the

echosounder display. The lower the noise level, the higher the gain

setting that can be used.

• Where the water flowing across the hull is smoothest with a

minimum of bubbles and turbulence (especially at high speeds).

• Where the transducer will be continuously immersed in water.

• Where the transducer beam will be unobstructed by the keel or

propeller shaft(s).

• Where there is a minimum deadrise angle.

• Where there is adequate headroom inside the vessel for the

height of the housing, tightening the nuts, and removing the

insert: 200mm (7-3/4") above the top of the housing.

Caution : Do not mount the transducer:

Near water intake or discharge openings,

Behind strakes, fittings, or hull irregularities,

Behind eroding paint (an indication of turbulence).

Boat Types

• Displacement hull powerboat —Locate 1/3 aft LWL and

150–300mm (6–12") off the centerline on the side of the hull

where the propeller blades are moving downward.

• Planing hull powerboat —Mount well aft, on or near the

centerline, and well inboard of the first set of lifting strakes to

insure that the transducer is in contact with the water at high

speeds. Mount on the side of the hull where the propeller

blades are moving downward.

(see Figure 1)

Warning : Always wear safety goggles and a dust mask.

1. Drill a 3mm or 1/8" pilot hole perpendicular to the waterline from

inside the hull (see Figure 2). If there is a rib, strut, or other hull

irregularity near the selected mounting location, drill from the

outside.

2. Using the 51mm or 2" hole saw, cut a hole from outside the hull.

Be sure to hold the drill plumb, so the hole will be perpendicular

to the water surface.

AIRMAR

aft view

hull

backing block

min. fairing

thickness

13mm (1/2")

slope of hull

deadrise

angle

parallel to

water surface

fairing

Figure 2. Measuring the deadrise angle and fairing thickness

®

2

Loading...

Loading...