Page 1

MARINE RADAR

MODEL1833/1933/1943

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080918701**00080918701*

*00080918701**00080918701*

*IME35020E00**IME35020E00*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

Your Local Agent/DealerYour Local Agent/Dealer

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. IME-35020-EIME-35020-E

(( HIMAHIMA ))

MODEL1833/1933/1943MODEL1833/1933/1943

Printed in JapanPrinted in Japan

FIRST EDITION :FIRST EDITION : APR.APR. 20012001

E :E : APR.APR. 22,200222,2002

* 0 0 0 8 0 9 1 8 7 0 1 ** 0 0 0 8 0 9 1 8 7 0 1 *

*IME35020E00**IME35020E00*

* I M E 3 5 0 2 0 E 0 0 ** I M E 3 5 0 2 0 E 0 0 *

Page 3

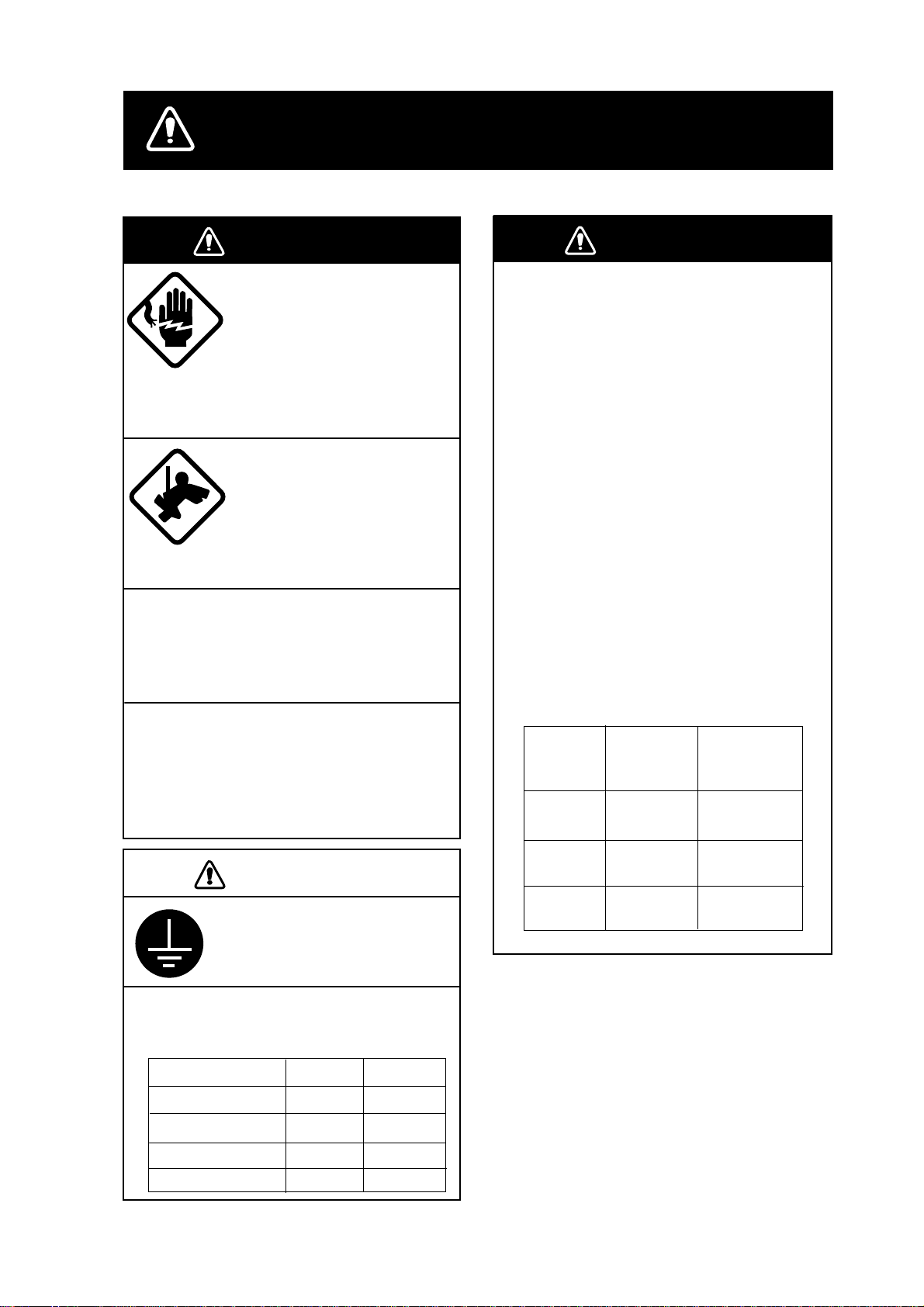

SAFETY INSTRUCTIONS

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service platform

from which to install the antenna unit.

Serious injury or death can result if someone falls from the radar mast.

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Only qualified personnel

should work inside the

equipment.

Wear a safety belt and hard

hat when working on the

antenna unit.

Serious injury or death can

result if someone falls from

the radar mast.

WARNING

Radio Frequency

Radiation Hazard

The radar antenna emits electromagnetic

radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never

look directly into the antenna aperture from

a close distance while the radar is in

operation or expose yourself to the transmitting antenna at a close distance.

Distances at which RF radiation levels of

100 and 10 W/m

table below.

Note: If the antenna unit is installed at a

close distance in front of the wheel house,

your administration may require halt of

transmission within a certain sector of

antenna revolution. This is possible - Ask

your FURUNO representative or dealer to

provide this feature.

MODEL

1833

2

exist are given in the

Distance to

100 W/m

point

Nil

Distance to

2

10 W/m

Worst case

point

0.50 m

2

CAUTION

Ground the equipment to

prevent electrical shock and

mutual interference.

Observe the following compass safe

distances to prevent deviation of a

magnetic compass.

Display unit

1833 antenna unit

1933 antenna unit

1943 antenna unit

Standard

0.85 m

0.90 m 0.70 m

1.00 m

1.00 m

Steering

0.55 m

0.80 m

0.80 m

1933

1943

Worst case

0.20 m

Nil

Worst case

3.00 m

Worst case

2.50 m

i

Page 4

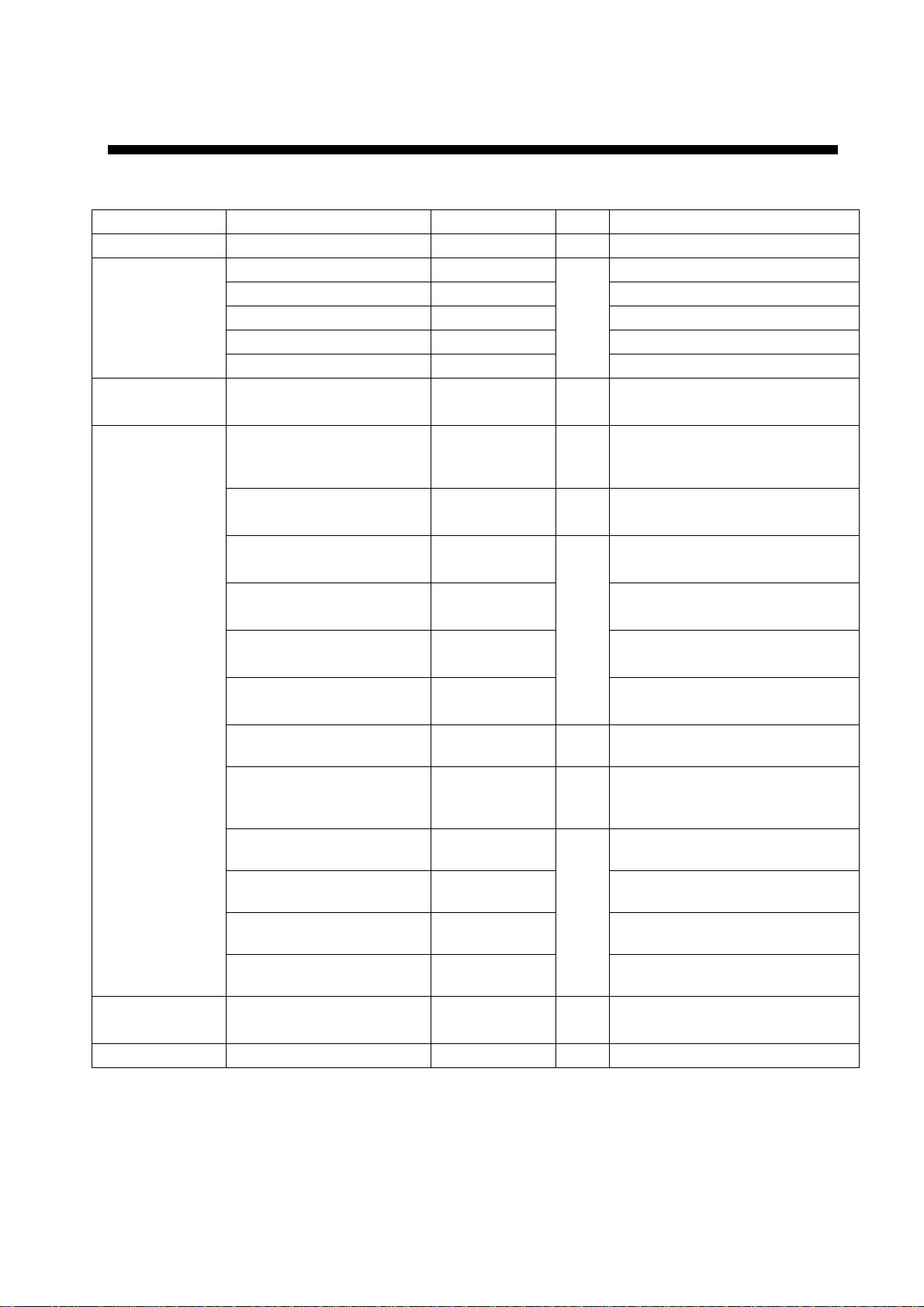

TABLE OF CONTENTS

SAFETY INSTRUCTIONS........................................................................................i

EQUIPMENT LISTS ................................................................................................. iii

SYSTEM CONFIGURATIONS.................................................................................. v

1. MOUNTING .......................................................................................................... 1-1

1.1 Installation of Display Unit............................................................................................................... 1-1

1.2 Mounting of Antenna Unit for MODEL 1833 ................................................................................... 1-4

1.3 Mounting of Antenna Unit for MODEL 1933/1943 .......................................................................... 1-11

2. W IRING.................................................................................................................2-1

2.1 Standard Wiring..............................................................................................................................2-1

2.2 External Buzzer (OP03-136, option) Connection............................................................................ 2-3

2.3 How to Connect with PC................................................................................................................. 2-4

3. ADJUSTMENT ..................................................................................................... 3-1

3.1 How to Access to Installation Menu................................................................................................ 3-1

3.2 NETWORK SETUP Menu .............................................................................................................. 3-2

3.3 RADAR SETUP Menu .................................................................................................................... 3-4

3.4 Checking Magnetron Heater Voltage..............................................................................................3-10

3.5 Navigation Data Source.................................................................................................................. 3-11

3.6 Setting up Data Ports......................................................................................................................3-15

3.7 Remote Controller Setting............................................................................................................... 3-17

4. OPTIONS..............................................................................................................4-1

4.1 ARP Kit ARP-1 1.............................................................................................................................. 4-1

4.2 Connection of External Monitor/Remote Display............................................................................ 4-3

PACKING LISTS.......................................................................................................A-1

OUTLINE DRAWINGS .............................................................................................D-1

SCHEMATIC DIAGRAMS.........................................................................................S-1

ii

Page 5

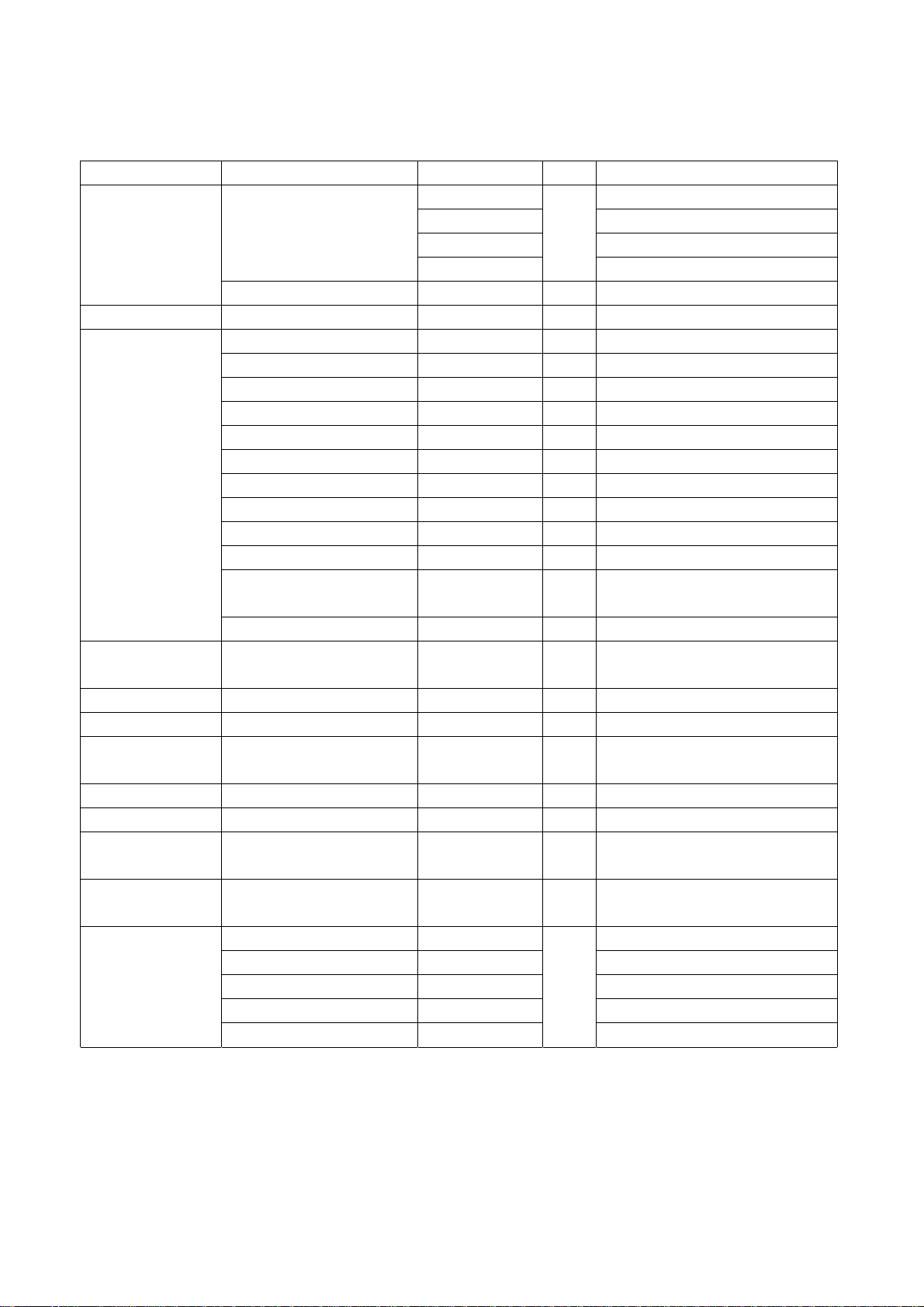

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Display unit RDP-127 - 1

RSB-0071-057 - MODEL 1833

XN10A-RSB-0070-064 - MODEL1933, 24 rpm

Antenna unit

Remote

controller set

Installation

materials

Accessories FP03-09200 000-080-020 1set FP03-09301, FP03-09202,

Spare parts SP03-14001 000-080-018 1set Fuses

XN10A-RSB-0073-064 - MODEL1933, 48 rpm

XN12A-RSB-0070-059 - MODEL1943, 24 rpm

XN12A-RSB-0073-059 -

RMC-100 000-089-885 1

CP03-21900 000-080-019 1set

CP03-16901 008-478-750

CP03-21800 000-080-014 For MODEL1833

CP03-21810 000-080-015 For MODEL1833

CP03-21820 000-080-016 For MODEL1833

CP03-21830 000-080-017

CP03-18401 008-503-360 1set

CP03-22901 008-523-690 1set

CP03-22000 000-080-021

CP03-22010 000-080-022

CP03-22020 000-080-023

CP03-22030 000-080-024

1

1set

1

1

MODEL1943, 48 rpm

Remote controller, vinyl case,

battery, labels

For display unit,

MJ-A3SPF0018-050Z cable,

CP03-21901

For MODEL1833

antenna unit

10 m signal cable

15 m signal cable

20 m signal cable

For MODEL1833

30 m signal cable

For MODEL1933/1943

antenna unit

For MODEL1933/1943

antenna radiator

XN10A/XN12A

For MODEL1933/1943

10 m signal cable

For MODEL1933/1943

15 m signal cable

For MODEL1933/1943

20 m signal cable

For MODEL1933/1943

30 m signal cable

FP03-09203, FP03-09204

iii

Page 6

Optional supply

Name Type Code No. Qty Remarks

Rectifier

External buzzer OP03-136 000-086-443 1

Cable assy.

RGB output

cable kit

Filter FP03-09101 008-523-060 1

ARP kit ARP-11 008-523-050 1 ARP Board

Mounting

bracket (1)

Chart card - - - Specified when ordering.

RAM card 00RAM02MC-004 004-371-790 1 2 MB

Remote

controller set

Modification kit

for C-map

Cable set for

remote display

PR-62

RU-3423 000-030-443 1 For MODEL1933/1943

MJ-A6SPF0014-010 000-144-421 1 For NavNet, 1 m

MJ-A6SPF0014-050 000-144-422 1 For NavNet, 5 m

MJ-A6SPF0014-100 000-144-423 1 For NavNet, 10 m

MJ-A6SPF0014-200 000-144-424 1 For NavNet, 20 m

MJ-A6SPF0014-300 000-144-425 1 For NavNet, 30 m

MJ-A6SPF0012-050 000-134-424 1 For navaid, 5 m

MJ-A6SPF0012-100 000-133-817 1 For navaid, 10 m

MJ-A6SPF0003-050 000-117-603 1 w/6P connector, 5 m

MJ-A6SPF0009-100 000-125-236 1 w/6P connector, 10 m

MJ-A6SPF0007-100 000-125-237 1 For compass, 10 m

MJ-A7SPF0007-050 000-144-418 1

MJ-A6SRMD/TM11AP8-005

OP03-176 008-526-360 1 For external display

OP03-92 008-445-070 1 For MODEL1833

RMC-100 000-089-885 1

MODEL 17*2/C-MAP 008-525-200 1 See modification instruction

OP03-174-5 008-523-000 5 m

OP03-174-10 008-523-010 10 m

OP03-174-15 008-523-020 15 m

OP03-174-20 008-523-030 20 m

OP03-174-30 008-523-040 1 30 m

000-013-484 F or MODEL1833, 100 VAC

000-013-485 F or MODEL1833, 110 VAC

000-013-486 F or MODEL1833, 220 VAC

000-013-487

000-144-463 1 Adapter cable for HUB

1

For MODEL1833, 230 VAC

For external buzzer, PC,

w/7P connector, 5 m

E42-0005-x

iv

Page 7

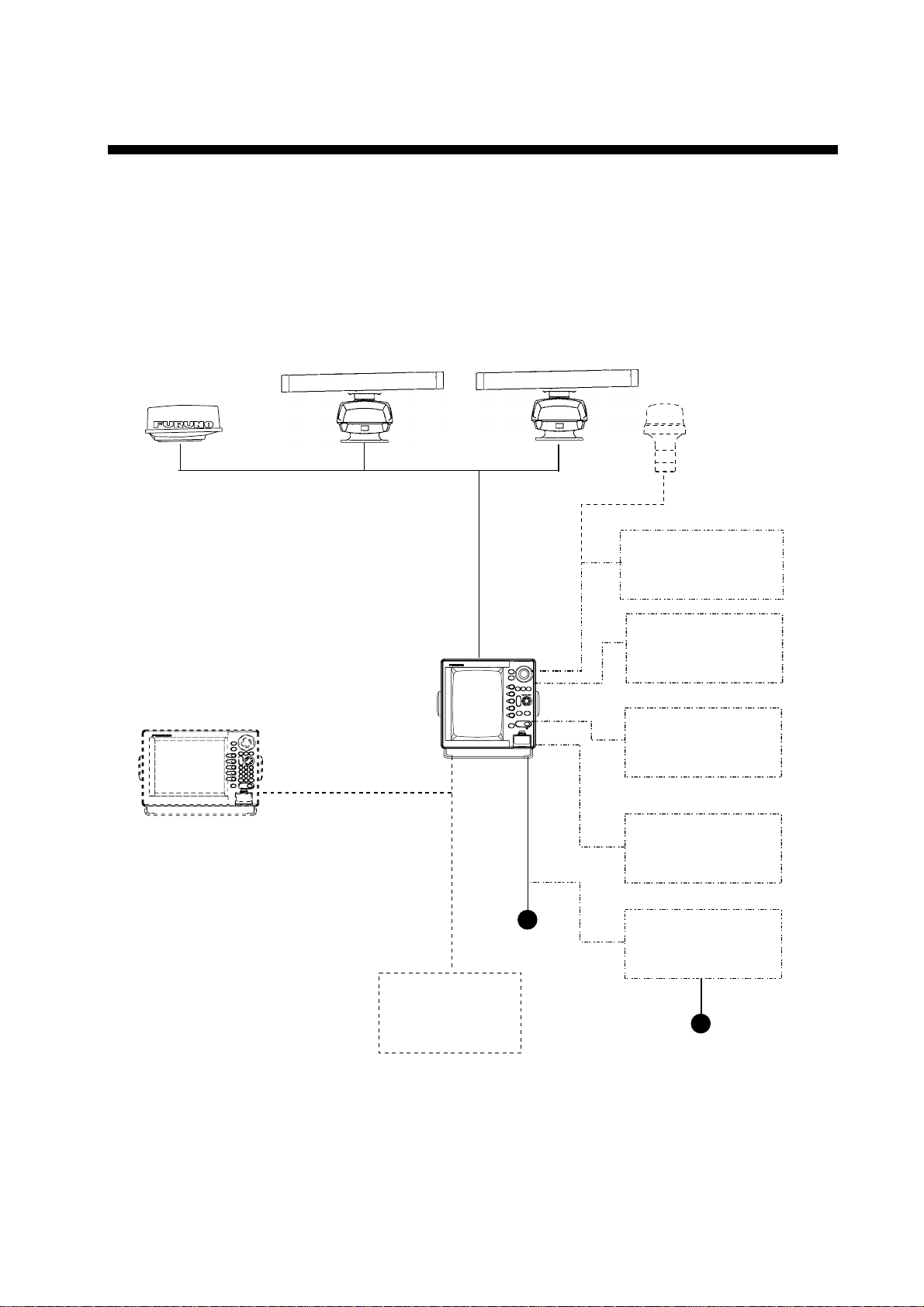

SYSTEM CONFIGURATIONS

The MARINE RADAR MODEL 1833/1933/1943 has IP address to communicate with the

“NavNet” products located within the network, based on the TCP/IP protocol through

Ethernet 10Base-T. A NavNet system may consist of one, two, three or four display unit and

one ETR. For a system incorporating three or more products a “hub” is required to process

data. Simple system such as Figure1 below, or integrated systems Figure 2 are explained.

Antenna Unit

MODEL1833

MODEL1933

Display Unit

RDP-127

MODEL1943

GPS receiver

GP-310B/320B

Echo sounder

Navigator

External buzzer

PC

Echo sounder

VGA monnitor

Remote display

Other NavNet unit

(GD-1900C etc.)

* PR-62: MODEL1833

RU-3423: MODEL1933/1943

Figure 1 Single unit NavNet system

12/24 VDC

Network

sounder

ETR-6/10N

100/110/115/220/230 V AC

1φ, 50/60 Hz

Heading

sensor

Rectifier*

PR-62

RU-3423

Ship's mains

v

Page 8

Antenna Unit

GP-310B/320B

Radar data

HUB

Network

Transducer

ETR-6/10N

Plotter data

Sounder data

Figure 2 (a) NavNet system, three-unit connection

Antenna Unit

GP-310B/320B

Radar data

Figure 2 (b) NavNet system, two-unit connection

vi

Plotter data

Page 9

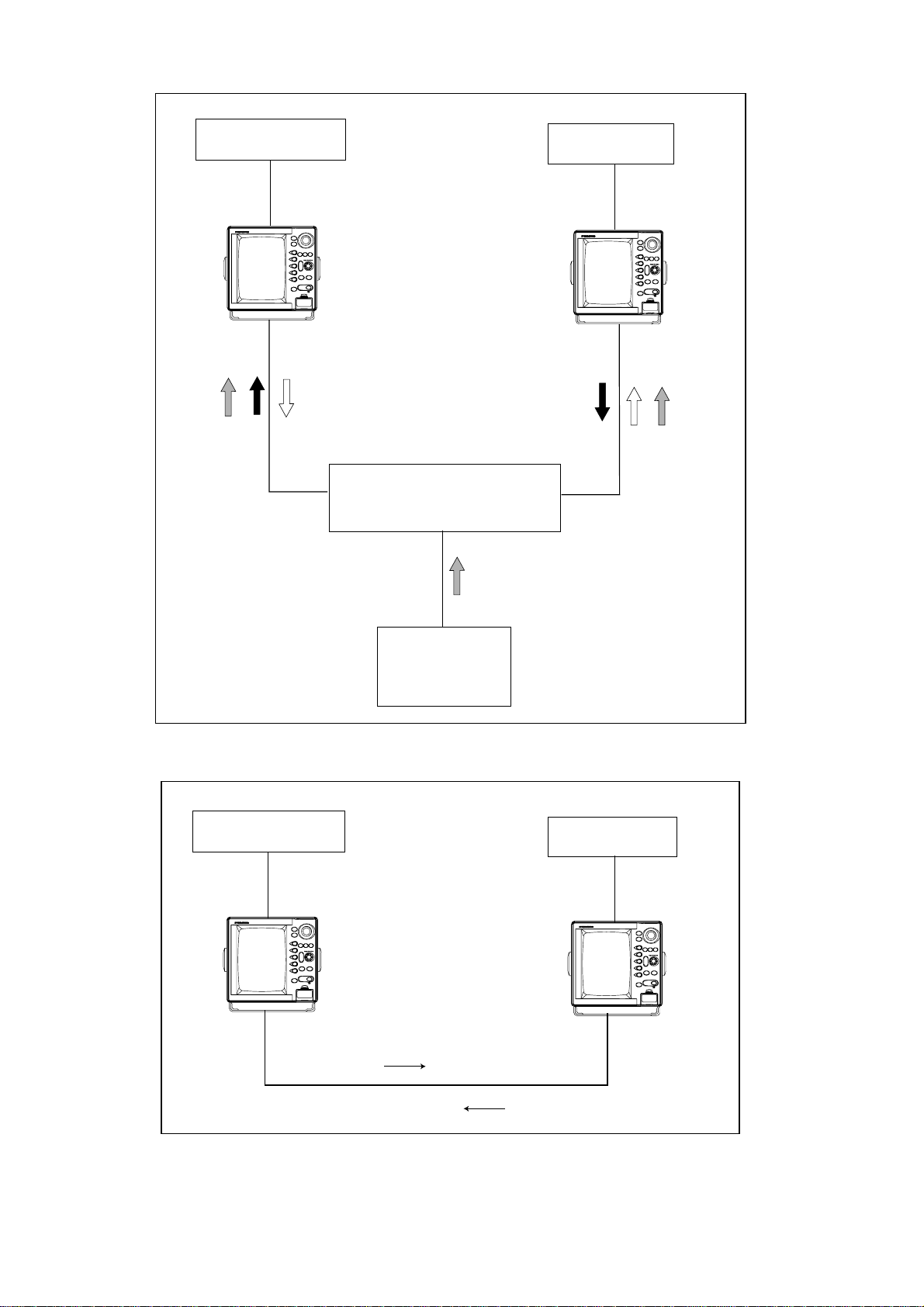

1. MOUNTING

1.1 Installation of Display Unit

The display unit can be installed on a tabletop, on the overhead or flush mounted in a

console or panel.

Tabletop, overhead mounting method

When selecting a mounting location for the display unit keep the following in mind:

Even though the display unit is waterproof, it is recommended that the display unit must

•

be mounted inside an enclosed cabinet.

Keep the display unit out of direct sunlight.

•

The temperature and humidity should be moderate and stable.

•

Locate the unit away from exhaust pipes and vents.

•

The mounting location should be well ventilated.

•

Mount the unit where shock and vibration are minimal. If the mounting location is subject

•

to heavy vibration, fix the display unit to the hanger perpendicular.

Keep the unit away electromagnetic field generating equipment such as motor, generator.

•

For maintenance and checking purposes, leave sufficient space at the sides and rear of

•

the unit and leave slack in cables.

A magnetic compass will be affected if the display units placed too close to the magnet

•

compass. Observe the following compass safe distances to prevent disturbance to the

magnetic compass; standard compass: 0.85 m, steering compass: 0.55 m.

1-1

Page 10

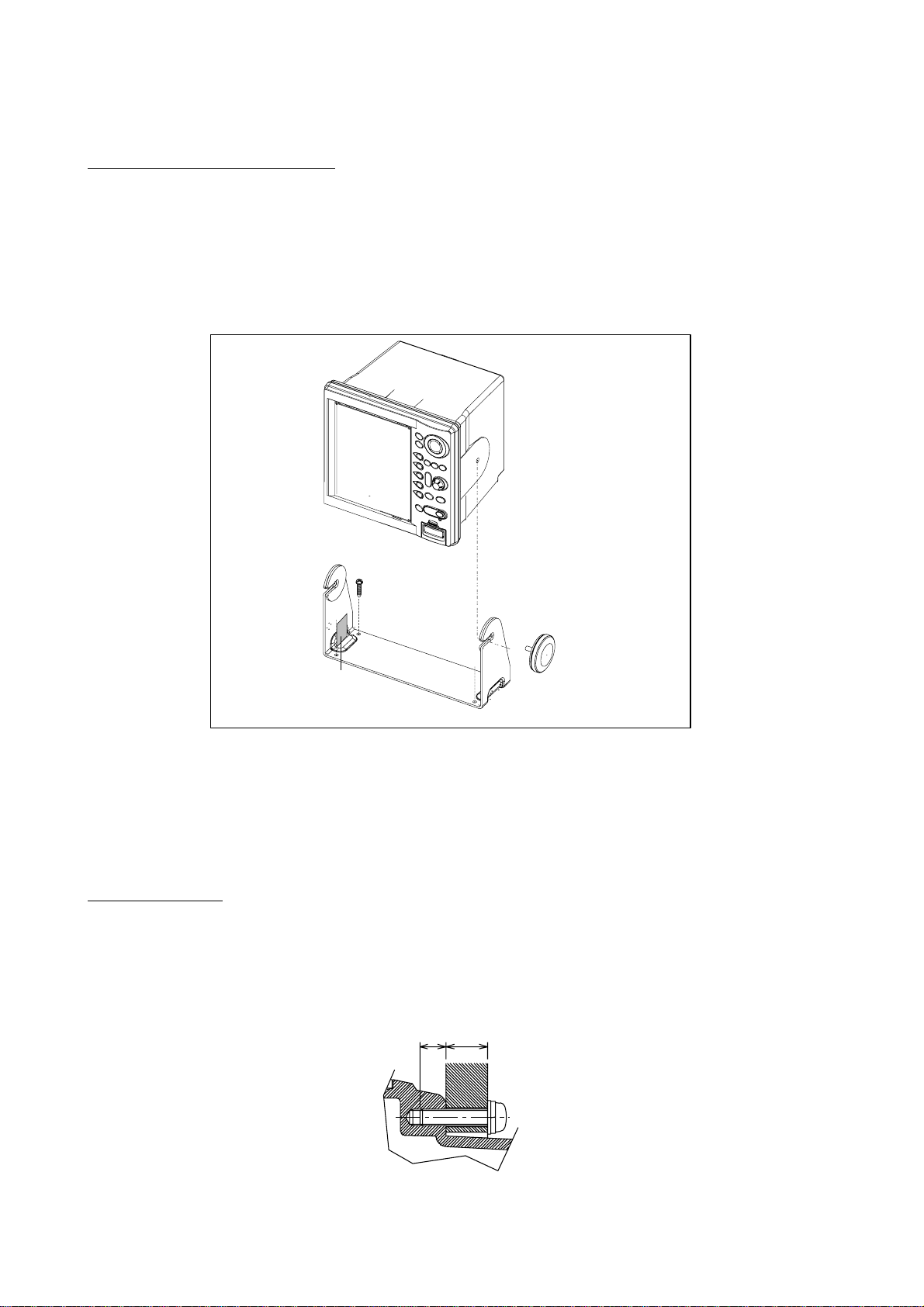

1.1.1 Mounting procedure

Tabletop, overhead mounting

Follow the procedure below to mount the display unit on a tabletop or the overhead.

1. Fix the hanger by f our tapping screw.

2. Screw knob bolts in display unit, set it t o hanger, and tighten knob bolts.

3. Attach hard cover to protect CRT.

Display unit

Tapping screws

(4 pcs.)

Knob bolts (2 pcs.)

Anti-vibration

rubber

Hanger

Tabletop, overhead mounting of display unit

Note: For overhead mounting, reinforce the mounting locat ion and secure the hanger will

bolts, nuts and washers (local supply).

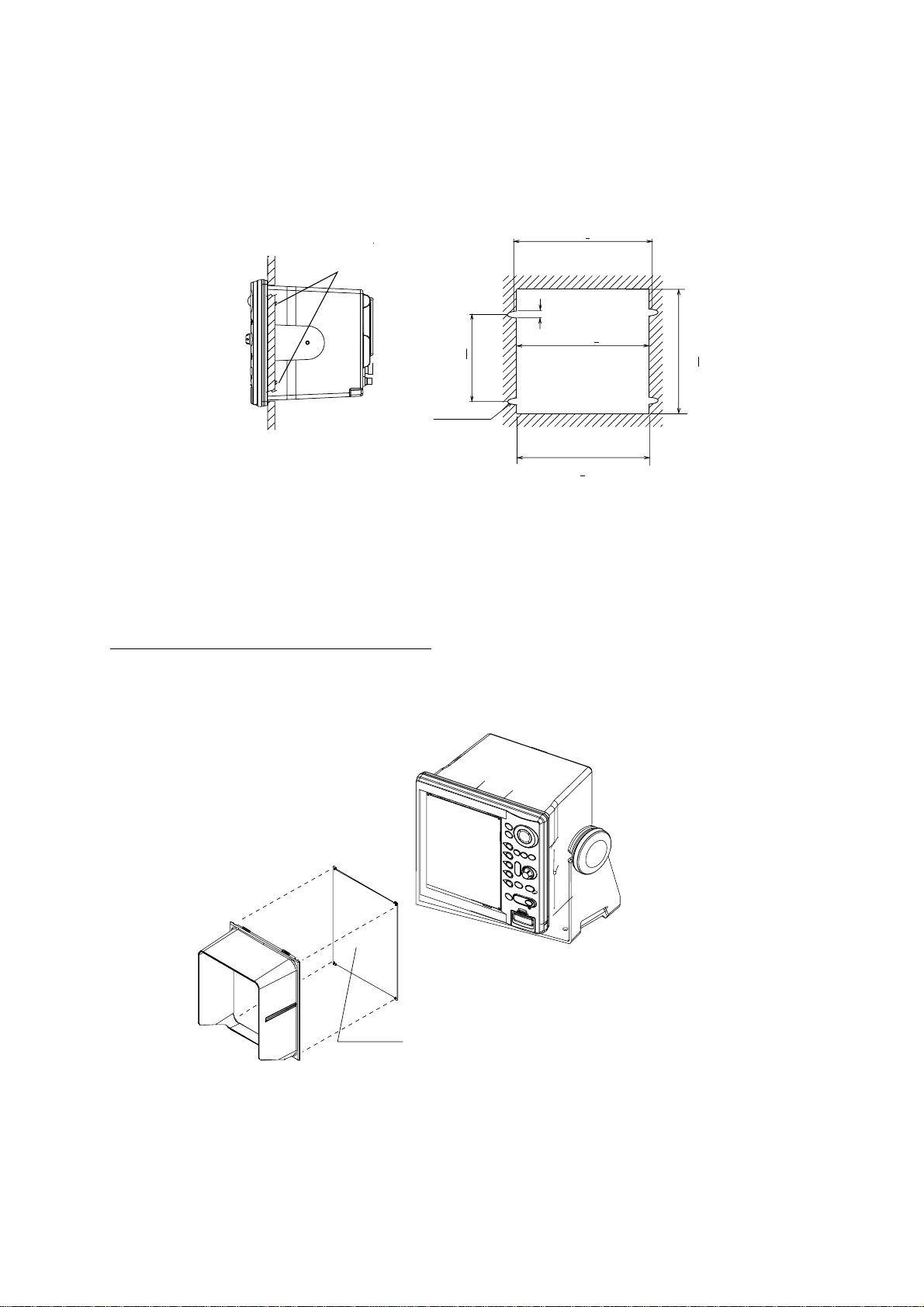

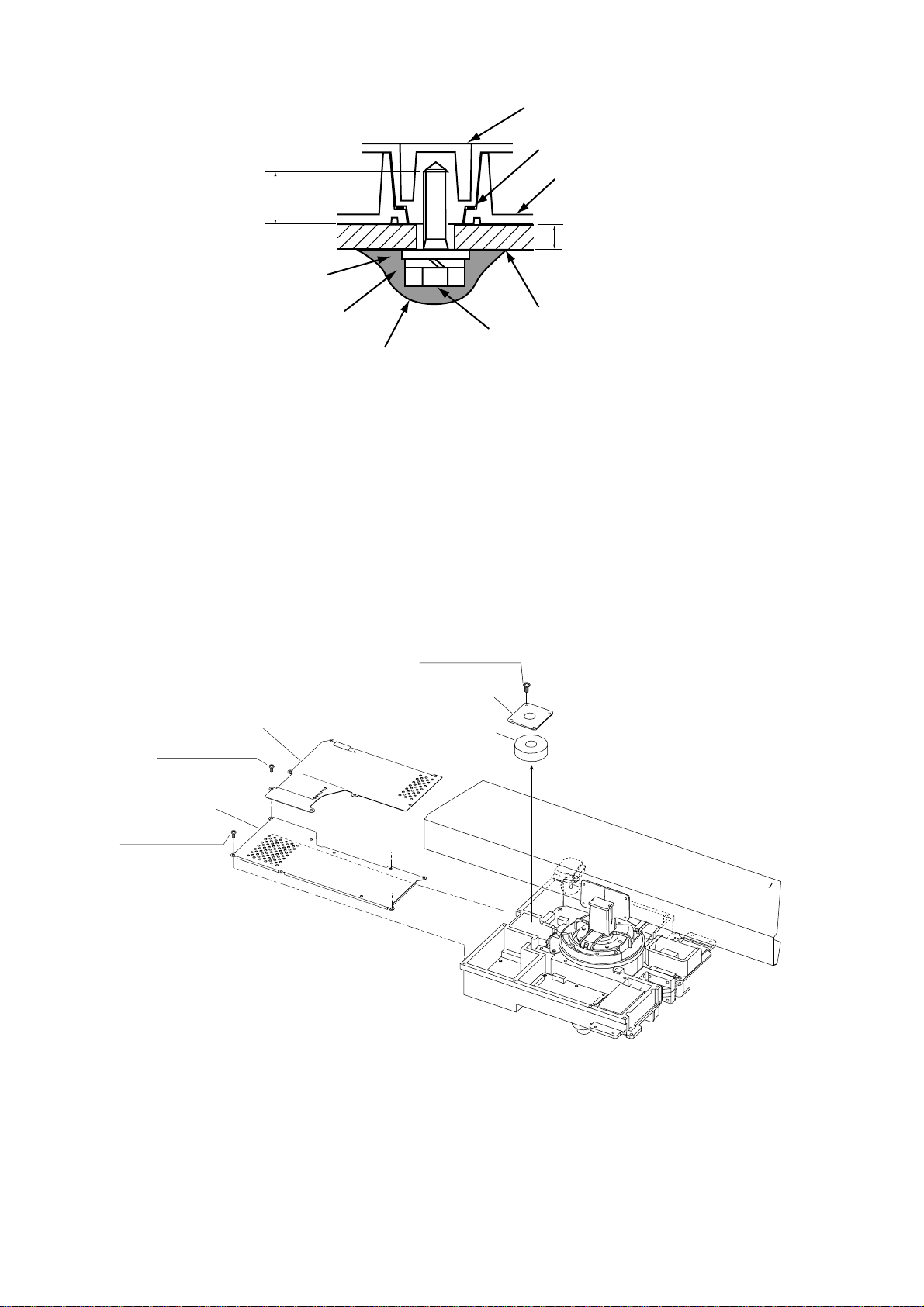

Flush mounting

Note: Use supplied six pan head screws when the thickness of the bulkhead is from 11 to

14 mm. For bulkhead which exceeds 14 mm in thickness the length of the pan head

screws should be bulkhead thickness (A) plus 7.8 ±2 mm. Also the length of B should

be max. 8 mm.

B

A

1-2

Fixing screw, side view

Page 11

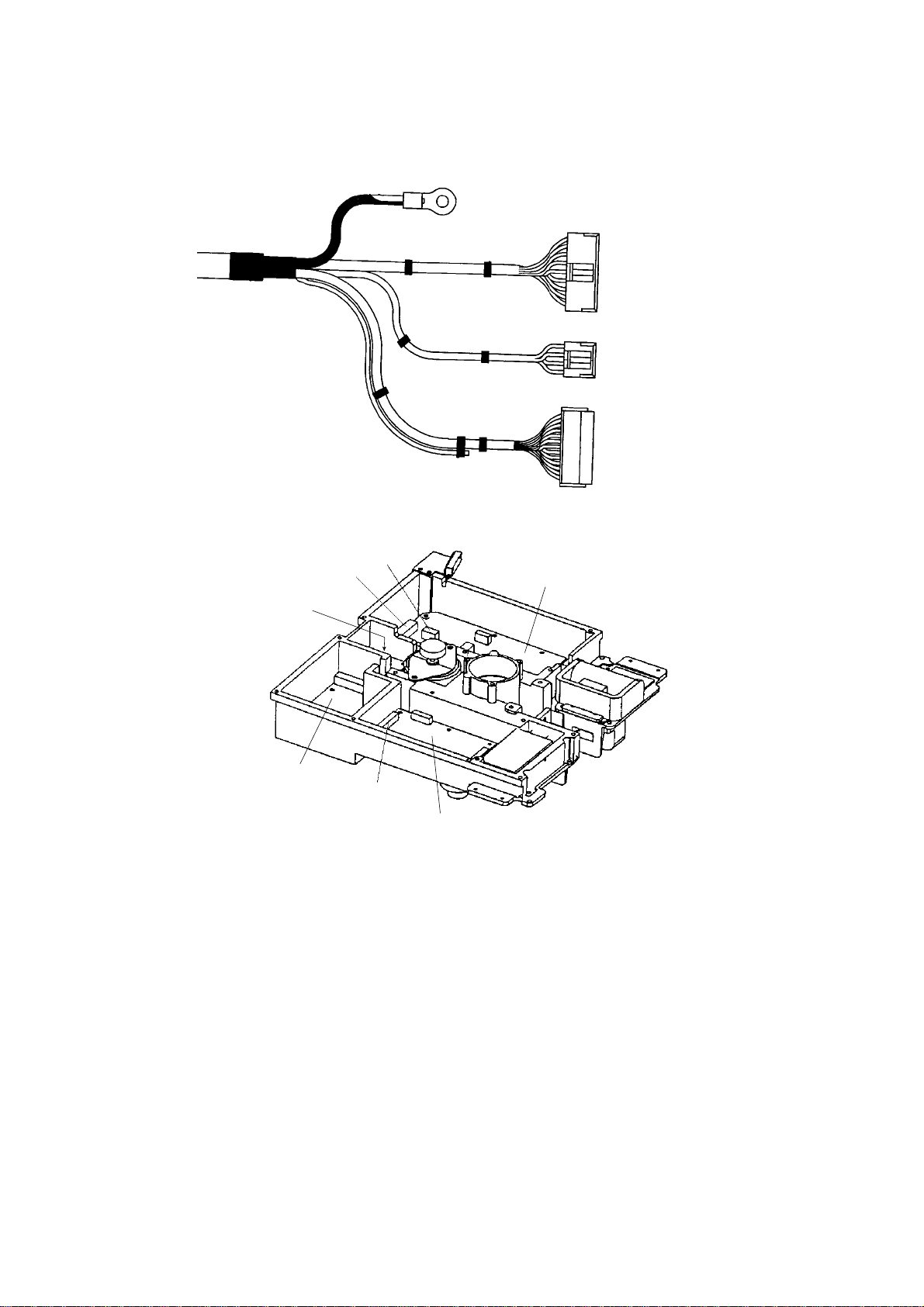

1. Prepare a cutout in the mounting location by using the template sheet supplied as the

installation material.

2. Fix the display unit by f our washer head screws M4x20. Refer to the outline drawing at

back of this manual.

264+0.5

Washer head screws

4.5

258+1

165+0.5

4-R2.25

285+1

243+1

Flush mounting of display unit

Note: When installing the display unit in a panel, attach the vinyl tube (Ф6, local supplied) to

the drain hole at the back of the display unit to allow moisture to escape. Then fasten

the tube to the drain hole with a cable tie.

Attachment of hood and filter (option)

Set four notches of hood to grooves on the display unit. When using the optional filter,

attach the filter to the hood with non-glare side outward, and then set the hood t o the

display unit.

Hood

Display unit

Filter (option)

(FP03-09101: Code no. 008-523-000)

Non-glare side

Attaching of hood and filter (option)

1-3

Page 12

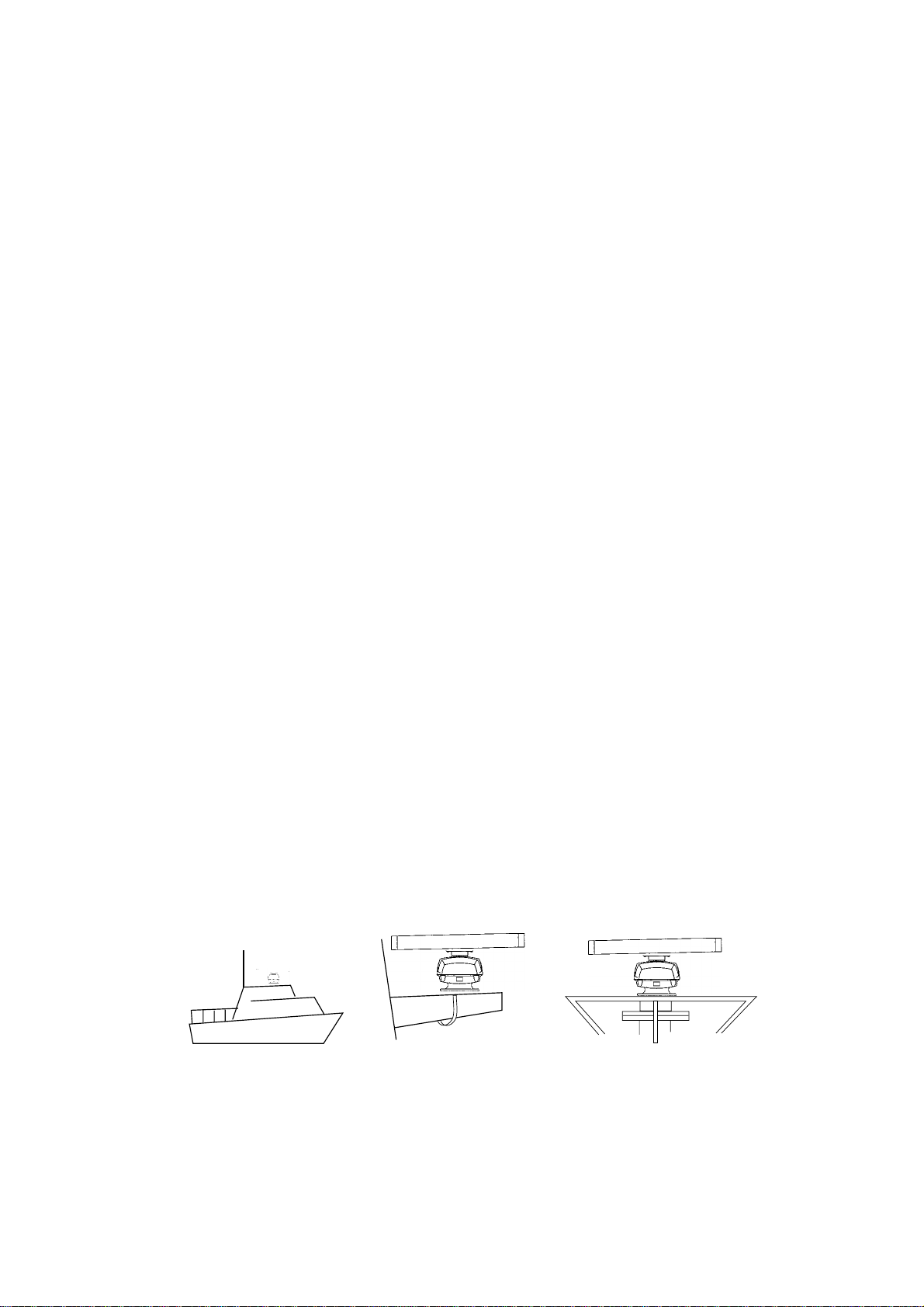

1.2 Mounting of Antenna Unit for MODEL1833

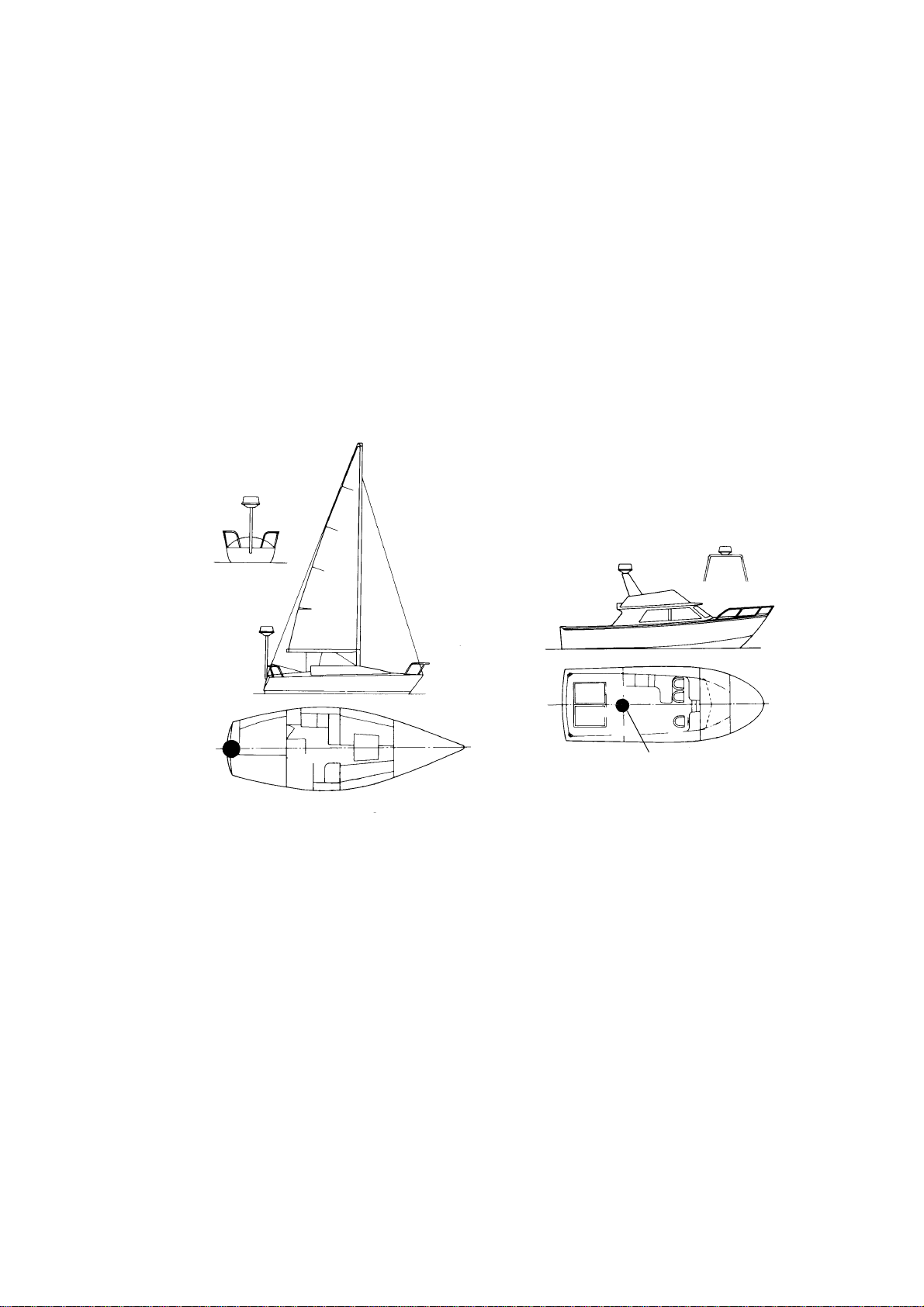

1.2.1 Mounting considerations

When selecting a mounting location for the antenna unit keep in mind the following points.

Install the antenna unit on the hardtop, radar arch or on a mast on an appropriate

•

platform. (F or sailboats, a mounting bracket is optionally available.) It should be placed

where there is a good all-round view with, as far as possible, no part of the ship’s

superstructure or rigging intercepting the scanning beam. Any obstruction will cause

shadow and blind sectors. A mast, for instance, with a diameter considerably less than

the width of the antenna unit, will cause only a small blind sector. However, a horizontal

spreader or crosstrees in the same horizontal plane would be a much m ore serious

obstruction; place the antenna unit well above or below it.

Antenna unit

Antenna unit

Antenna unit

Typical antenna unit placement on sailboat and powerboat

In order to minim ize the chance of picking up electrical interference, avoid where possible

•

routing the antenna cable near other electrical equipm ent onboard. Also avoid running

the cable in parallel with power cables.

The compass safe distance of 0.90 meters (standard compass) and 0.70 meters (steering

•

compass) should be observed to prevent deviation of the magnetic compass.

Antenna unit

1-4

Page 13

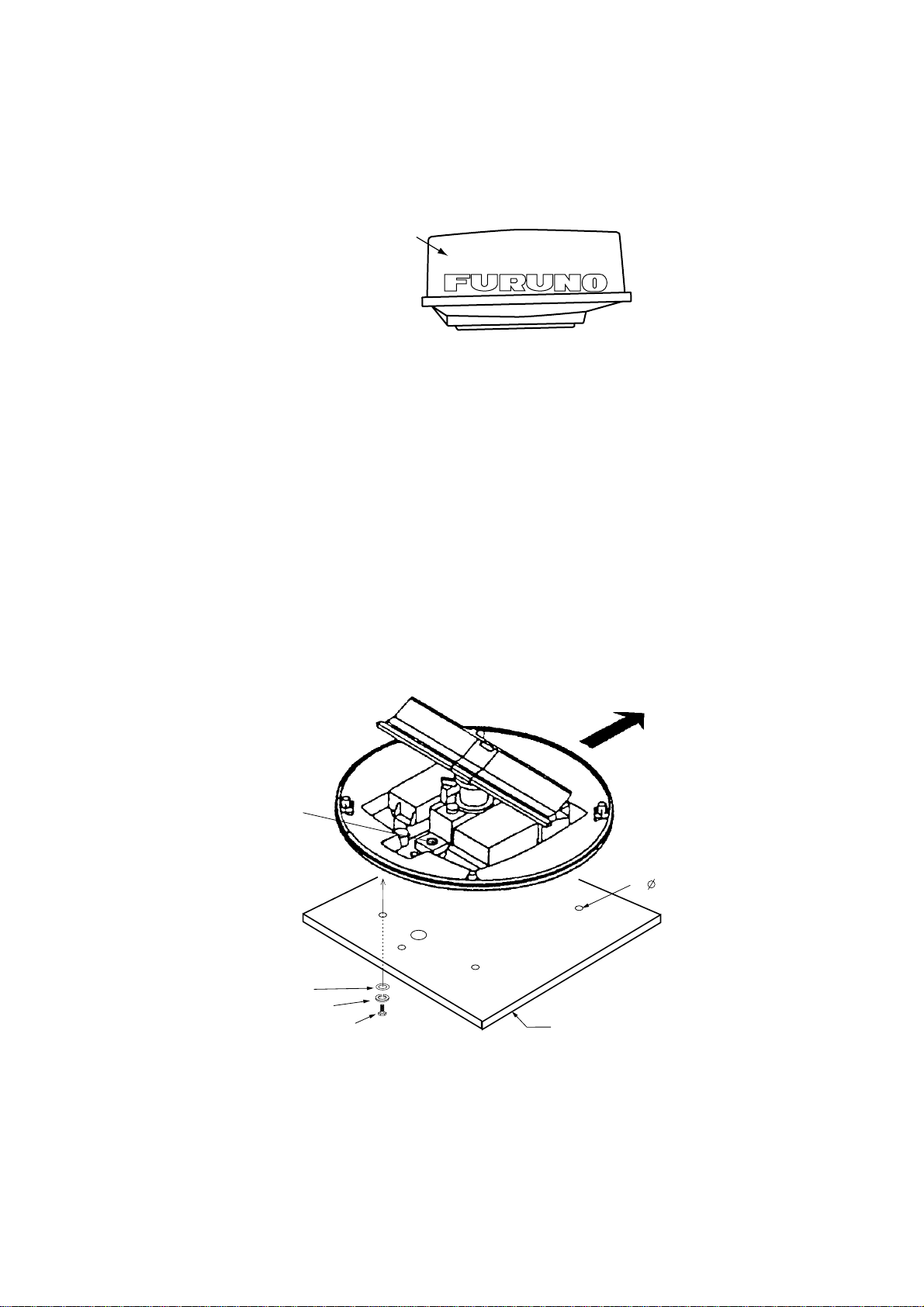

1.2.2 Mounting antenna unit of MODEL 1833

1. Open t he antenna unit packing box carefully.

2. Unbolt t he four bolts at the base of the radome to remove the radome cover.

Radome cover

Antenna unit

The mounting surface must be parallel with the waterline and provided with five holes

whose dimensions are shown in the outline drawing attached at the end of this manual.

The unit is adjusted so a target echo returned from the bow direction will be shown on the

zero degree (heading line) position on the screen. W hen drilling holes, be sure they are

parallel with the fore and aft line.

3. Prepare a platform of 5 to 10 millimeters in thickness for the antenna unit.

A mounting bracket for mounting the antenna unit on a sailboat mast is optionally

available. (Refer to page 1-9.) Find the cable entry on the radome base. Next, position

the radome base so the cable entry faces the stern direction. This alignment must be as

accurate as possible.

Ship's bow

Cable

entry

4- 12 Holes

Flat washer

Spring washer

M10 x 25 Hex bolt

Platform

Antenna unit, cover removed

1-5

Page 14

Antenna base plate

Effective

thread length

25 mm

Flat

washer

Spring

washer

Apply silicone sealant.

M10 x 25

Hex bolt

Gasket

Radome

5 - 10 mm

Platform

How to fasten the radome base to the mounting platform

Wiring and final preparation

4. Drill a hole of at least 20 millimet ers diameter through the deck or bulkhead to run the

signal cable between the antenna unit and the display unit. (To prevent electrical

interference avoid running the signal cable near other electrical equipment and in

parallel with power cables.) Pass the cable through the hole. Then, seal the hole with

sealing compound for waterproofing.

5. Remove two shield covers in the radome.

6. Remove the cable clamping plate by unfastening f our screws and rem oving a gasket.

Pan head screws

M4x8 4 pcs.

Cable clamping plate

Shield cover

Pan head screws

M4x8 7 pcs.

Shield cover

Pan head screws

M4x8 7 pcs.

Gasket

Antenna unit, inside view

7. Pass the cable through the hole at the bottom of the radome base.

8. Secure the cable with the cable clamping plate and gasket. Ground the shield and vinyl

wire by one of the screws of the cable clamping plate.

9. Connect t he wire to the RF unit .

1-6

Page 15

Cable

entry

to one of the screws

of the cable clamping plate

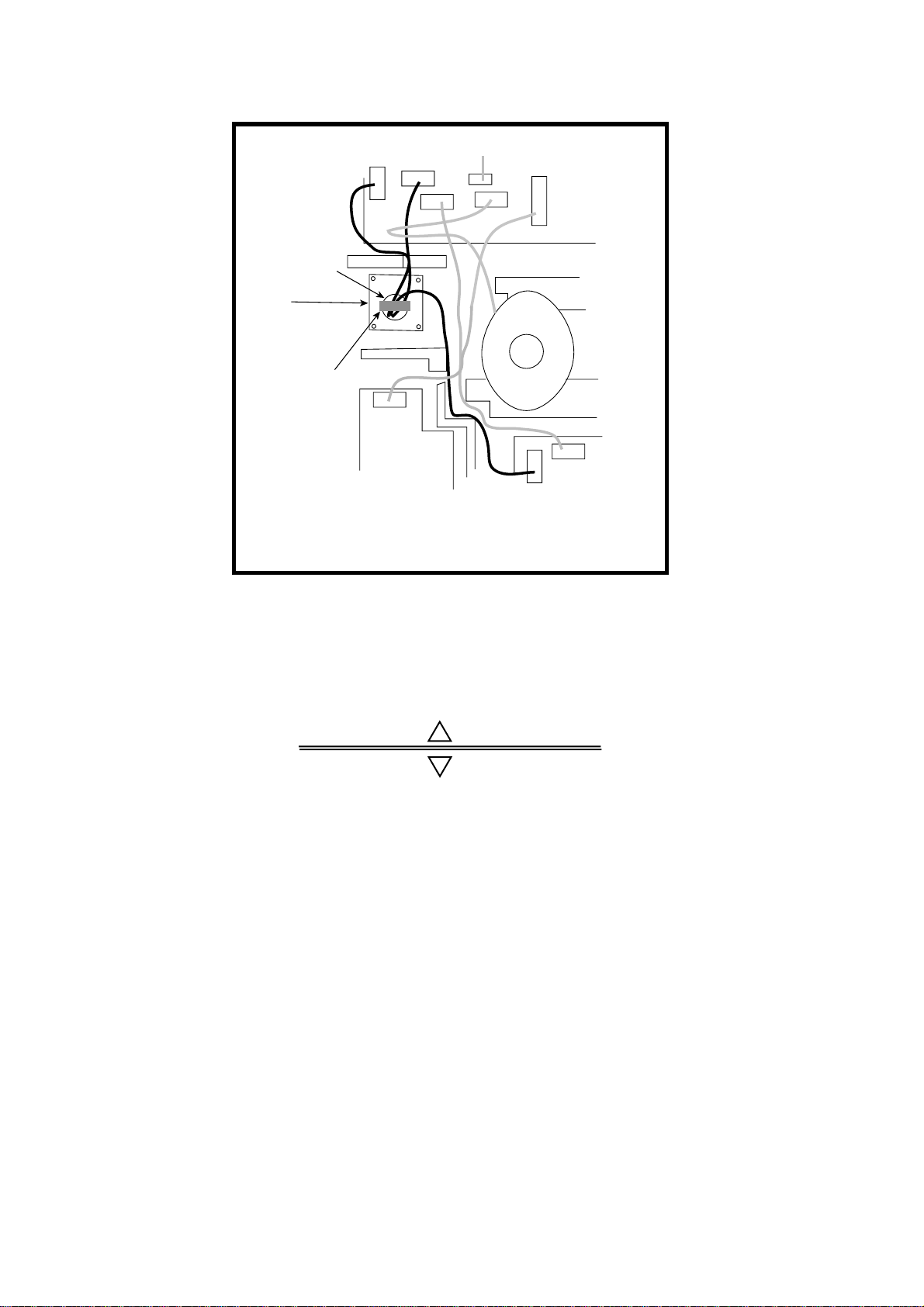

Signal cable, antenna unit side

J802

J801

9-pin connector:

to J801 on MD-9208

4-pin connector:

to J802 on MD-9208

13-pin connector:

to J611 on IF-9214A

MD-9208

PTU-9335

J611

IF-9214

RF unit

1-7

Page 16

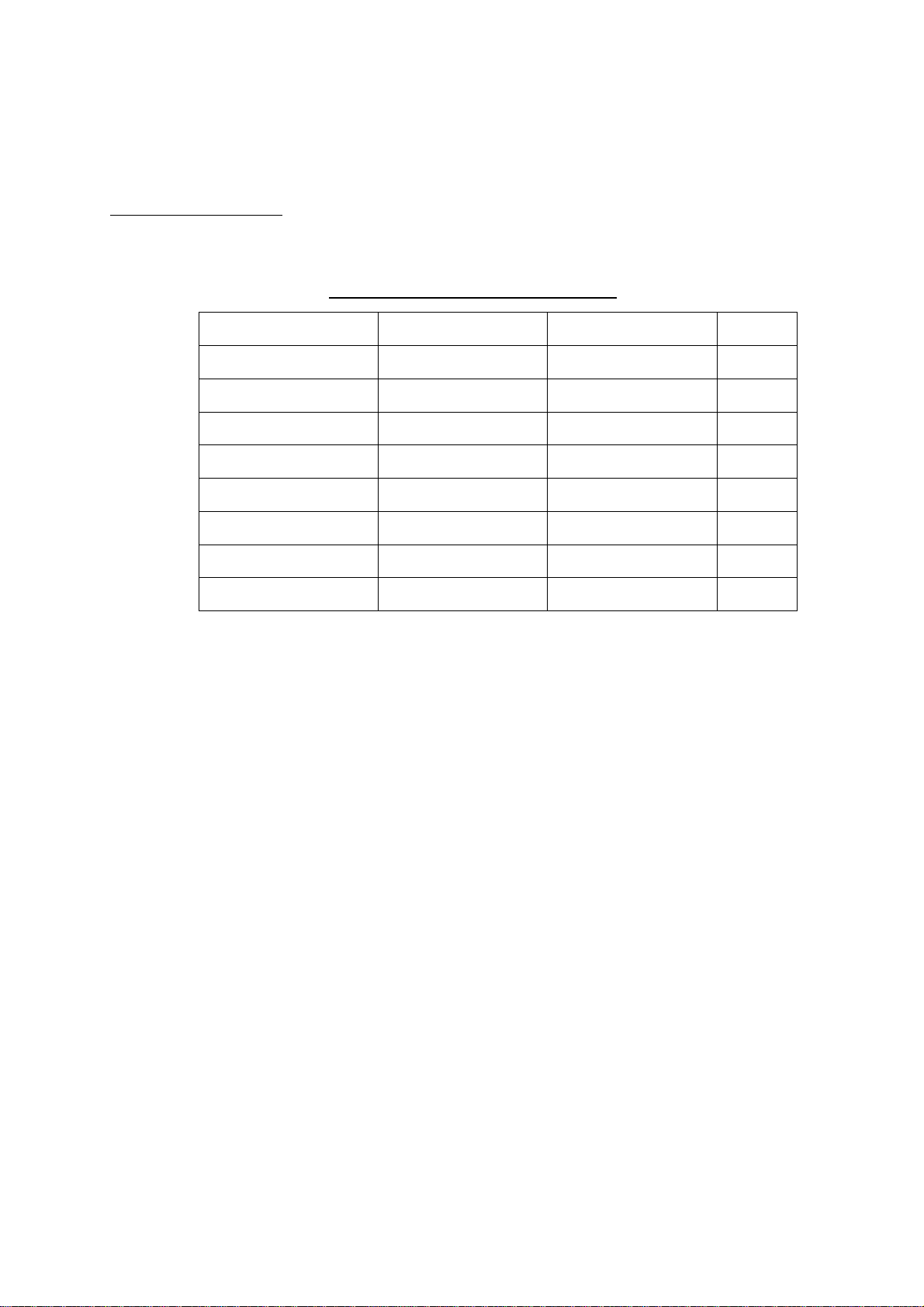

10. Attach the EMC core supplied as shown below.

J801

Cable

entrance

Cable

clamping plate

EMC core

E04SS251512

(Above cable

clamping

plate)

PTU-9335

J1

J802

J804

J805

J803

Motor

J611

MD9208

J806

J613

IF9214IF9214A

How to attach EMC core

11. Fix the shield cover. Do not pinch the cable.

12. Attach the radome cover, aligning triangle mark on radome cover with that on radome

base.

Radome cover

Radome base

How to position the radome cover

13. Loosely fasten the radome f ixing bolts. You will tighten them after confirming magnetron

heater voltage.

1-8

Page 17

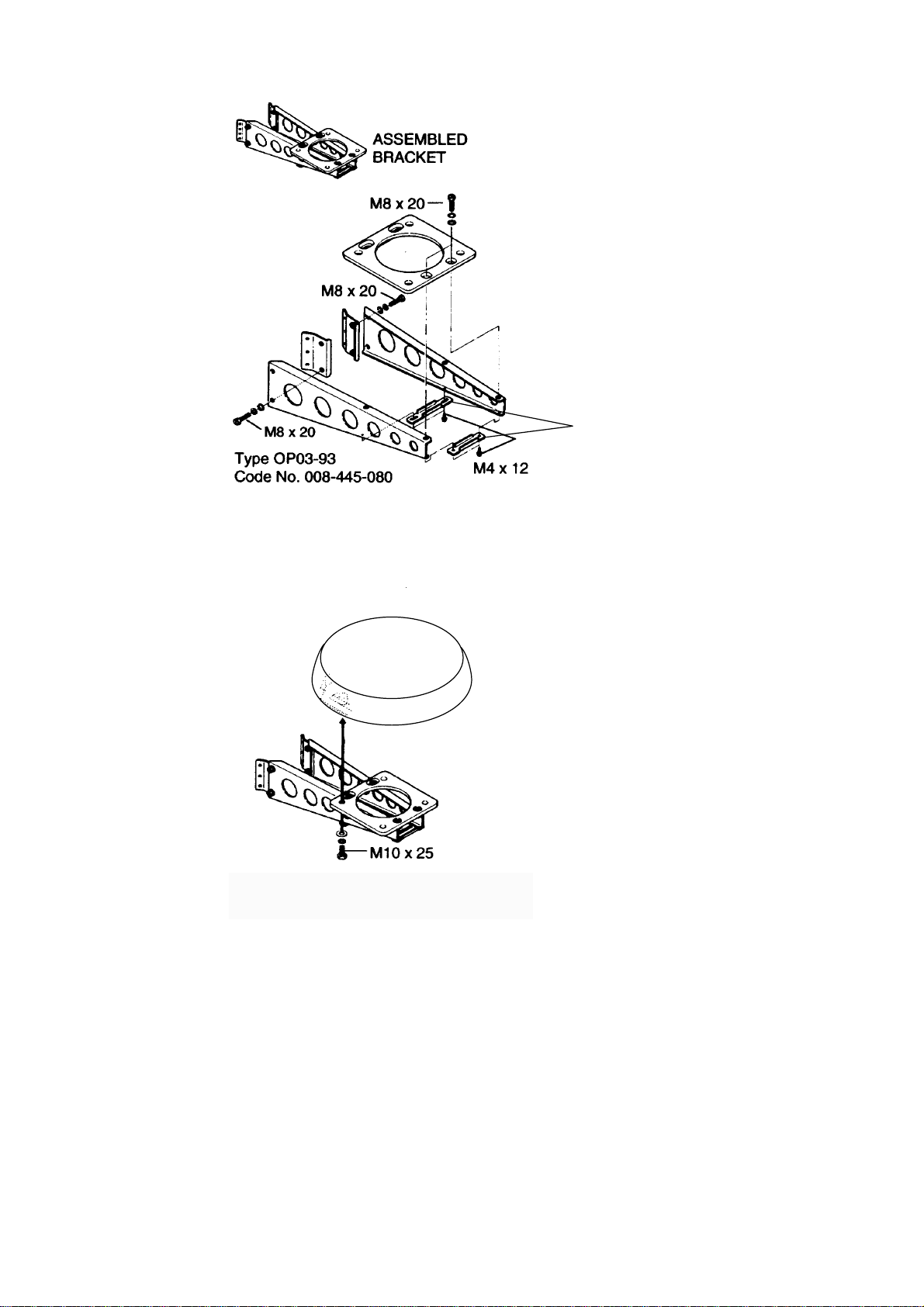

1.2.3 Mounting the optional mounting bracket

A mounting bracket for fastening the antenna unit for MODEL1833 to a mast on a sailboat

is optionally available.

Mounting bracket 1

Type: OP03-92

Code No.: 008-445-070

Type Code No. Qty

Hex. bolt M4X12 000-804-725 4

Hex. bolt M8X20 000-805-707 8

Mounting plate 03-018-9001-0 100-206-740 1

Support plate (1) 03-018-9005-0 100-206-780 1

Support plate (2) 03-018-9006-0 100-206-790 1

Bracket (1) 03-018-9002-1 100-206-751 1

Table 1-1 Mounting bracket contents

Bracket (2) 03-018-9003-1 100-206-761 1

Fixing plate 03-018-9004-1 100-206-771 2

Assemble the mount ing bracket and fasten it to a mast. Fasten the antenna unit to the

bracket.

1-9

Page 18

(A) Assembling the mounting bracket

Support plate

(B) Fastening antenna to mounting

bracket

How to assemble and mount the optional mounting bracket

1-10

Page 19

1.3 Mounting of Antenna Unit for MODEL1933/1943

1.3.1 Mounting considerations

The antenna unit is generally installed either on top of the wheelhouse or on the radar

•

mast on a suitable platf orm. Locate the antenna unit where there is a good all-round view.

Any obstruction will cause shadow and blind sectors.

A mast for instance, with a diameter considerably less than the width of the radiator, will

cause only a small blind sector, but a horizontal spreader or crosstrees in the same

horizontal plane as the antenna unit would be a much more serious obstruction; you

would need to place the antenna unit well above or below it.

It is rarely possible to place the antenna unit where a completely clear view in all

•

directions is available. Thus, you should determine the angular width and relative bearing

of any shadow sectors for their influence on the radar at the first opportunity after fitting.

If you have a radio direction finder on your boat, locate its antenna clear of the antenna

•

unit to prevent interference to the direction finder. A separation of more than two meters

is recommended.

To lessen the chance of picking up electrical interference, avoid where possible routing

•

the signal cable near other onboard electrical equipment. Also avoid running the cable in

parallel with power cables.

A magnetic compass will be affected if the antenna unit is placed too close to the antenna

•

unit. Observe the following compass safe distances to prevent deviation of a magnetic

compass: Standard com pass, 1.00 m, Steering compass, 0.80 m.

Do not paint the radiator aperture, to ensure proper emission of the radar waves.

•

When this radar is t o be inst alled on larger vessels, consider the following points:

•

The signal cable run between the antenna and the display comes in lengths of 10 m, 15

•

m, 20 m and 30 m. Whatever length is used it must be unbroken; namely, no splicing

allowed.

Deposits and fumes from a funnel or other exhaust vent can adversely affect the aerial

•

performance and hot gases may distort the radiator portion. The antenna unit must not be

mounted where the temperature is more than 70°C.

As shown in the figure below, the antenna unit may be installed on t he bridge, on a common

mast or on the radar mast.

(a) On bridge

(b) Common mast

(c) Radar mast

1-11

Page 20

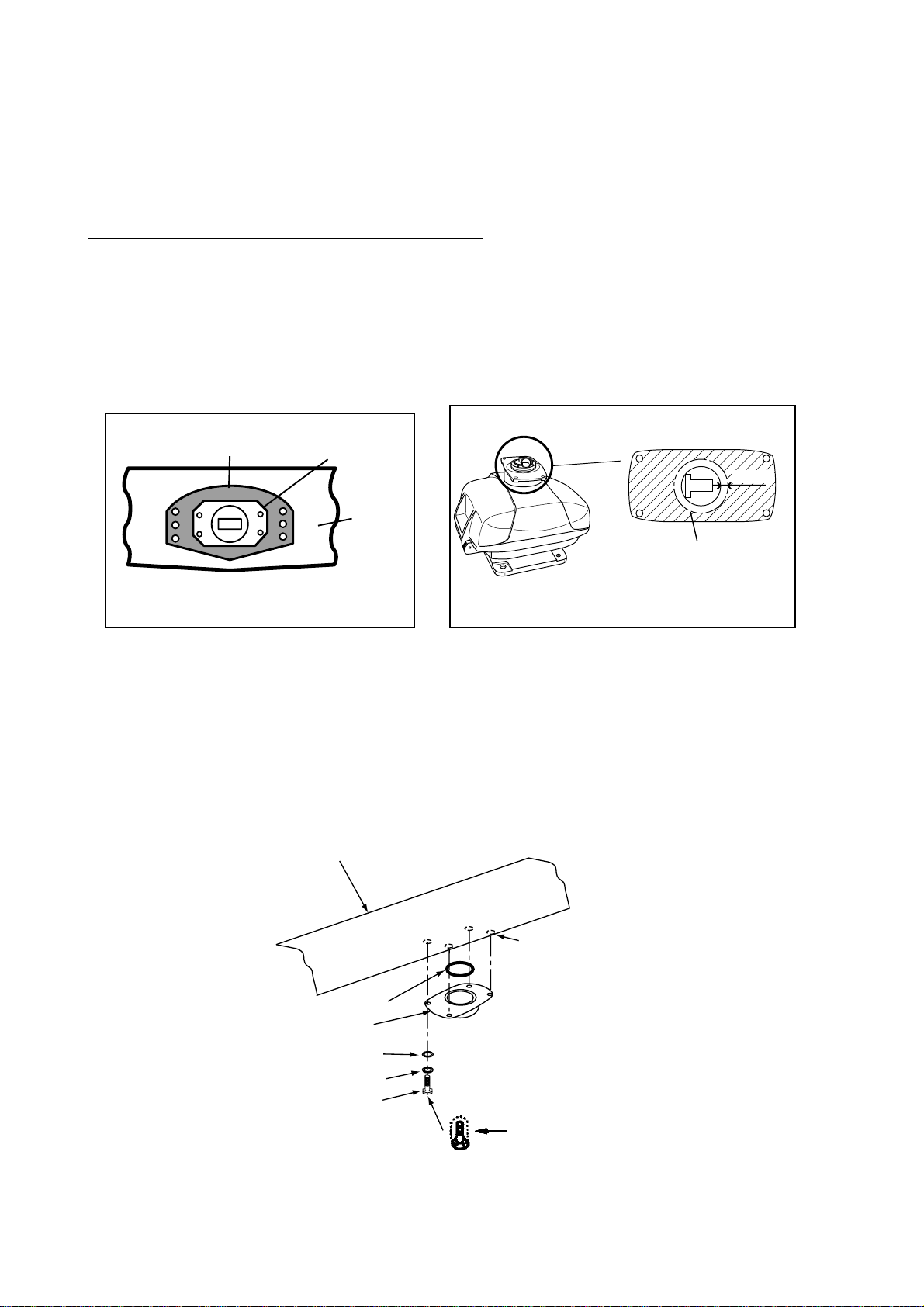

1.3.2 Mounting antenna unit of MODEL 1933/1943

Referring to the outline drawing at the back of this manual, drill five holes in the mount ing

platform: four holes of 15 mm diameter for fixing the antenna unit and one hole of 25-30 mm

diameter for the signal cable.

Fastening the Radiator to the Radiator Bracket

For your reference, antenna installation m aterials list appears in the packing lists at the

back of this manual (see page A-4 to A-6).

1. Remove the radiator cap from the radiator bracket.

2. Coat contacting surface between antenna radiator and radiator bracket with silicone

sealant as shown in figure below.

ANTENNA RADIATOR

(bottom view)

Coat hatched area with

silicone sealant.

(MODEL 1933)

Groove

Radiator

(MODEL 1943)

RADIATOR BRACKET

(top view)

10mm

Coat hatched area with

anticorrosive sealant.

Coating the bottom of antenna radiator with silicone sealant

3. Coat threaded holes on the antenna radiator with silicone sealant.

4. Grease t he O-ring and set it to the radiator bracket.

5. Lay the antenna radiator on the radiator bracket.

6. Coat the radiator fixing bolts (4 pcs.) with silicone sealant. Fasten the antenna radiator to

the radiator bracket with the radiator fixing bolts, flat washers and spring washers.

Antenna

radiator

1-12

Coat threaded

holes with silicone

sealant.

O-ring

Radiator bracket

Flat washer

Spring washer

Hex head bolt

(M8 x 30)

Coat bolts with

silicone sealant.

Fastening the radiator bracket to the antenna unit chassis

Page 21

Mounting of antenna unit

The antenna unit can be mounted using t he fixing holes on the outside (200 x 200 mm) or

inside (140 x 150 mm) the ant enna unit.

Outside fixing holes

Use the hex head bolt (supplied) to mount the ant enna unit as below.

1. Lay the corrosion-proof rubber mat (supplied) on the mounting platform.

Ground

terminal

Rubber

mat

Bow mark

Location of rubber mat

2. Lay the antenna unit on the mounting platform, orienting it as shown in below.

BOW

STERN

Antenna unit

CAUTION

Do not lift the Antenna unit by the

radiator; lift it by the housing.

The radiator may be damaged.

3. Insert four hex bolts (M12x60, supplied) and seal washers (Ф30, supplied) from the top

of the antenna housing. Insert the seal washers with the larger diameter next t o the bolt

heads. Be sure the seal washer, not other washers, is next to bolt head.

1-13

Page 22

Hex bolt

Seal washer

Flat washer

Spring washer

Nut

Fixing the antenna unit chassis

4. Pass f lat washers (M12, supplied), spring washers (M12, supplied) and nuts (M12,

supplied) onto hex bolts. Fasten by tightening nuts. Do not fasten by tightening the hex

bolts; seal washers may be damaged.

Seal washer

Antenna

Rubber mat

unit

Mounting

platform

Flat washer

Silicone

sealant

How to fasten antenna unit to mounting platform

5. Coat flat washers, spring washers, nuts and exposed parts of bolts with silicone sealant.

6. Prepare ground point in mounting platform (within 300 mm of ground terminal on

antenna unit) using M6 x 25 bolt, nut and flat washer (supplied).

7. Run the ground wire (RW - 4747, 340 mm, supplied) between the ground terminal and

ground point.

8. Coat ground terminal and ground point with silicone sealant as shown on the next page.

1-14

Page 23

Hex bolt

Flat washer

Ground

terminal

Silicone

sealant

Ground

wire

GROUND

TERMINAL

OR

Weld here.

Flat washer

Spring washer

Hex nut

GROUND

POINT

Hex nut

Spring washer

Flat washer

Hex nut

Silicone

sealant

Ground

wire

antenna

unit

How to coat ground point and ground terminal with silicone sealant

1-15

Page 24

Fixing holes inside antenna unit

This method requires rem oval of the RF unit in the antenna unit to access inside fixing

holes. Use hex head bolts, flat washers, spring washers and nuts (local supply) to mount

the antenna unit, confirming length of bolts.

1. Loose four scanner bolts to open the antenna unit. Refer to figure in below for location.

Antenna unit chassis, upper chassis separated

2. Unplug connector connected bet ween upper and lower chassis.

3. Separate upper chassis from lower chassis by removing two hex head bolts (M8x25).

4. Remove cover by unfastening four pan head screws.

5. Remove connector from RF unit.

6. Remove RF unit by unfastening four hex head bolts.

7. Lay the corrosion-proof rubber mat (supplied) on the mounting platform.

8. Fasten the lower chassis to the mounting platform with hex head bolts, spring washers,

flat washers and nuts (local supply), and then coat flat washers, nuts and exposed parts

of bolts with silicone sealant. Cut a slit in rubber bushing and insert bolt into bushing. Do

not use seal washers.

9. Reassemble RF unit, cover and chassis.

10. Set four knob caps (supplied) into outside fixing holes.

11. Do steps 6-8 in “Outside fixing holes”.

1-16

Page 25

2. WIRING

2.1 Standard Wiring

All wiring are terminated at the rear of the display unit.

Optional cable

(Remote display

and external monitor)

Drain hole

(Allows moisture

to escape.)

Power cable

connector

Connect power

cable here.

Signal cable

(to antenna unit)

Ground terminal

Connect ground wire between

here and ship's ground.

CAUTION

CAUTION

Replace fuse to 7 A

when the ship's battery

is 24 VDC, and attach

a label to the fuse cover

on power cable.

The unit is shipped

with 15 A fuse.

Use of wrong fuse can

result in damage to the

equipment.

NETWORK

NavNet

equipment

(GD-1900C,

ETR-6/10N,

HUB etc.)

(6P)

DATA3

Ext. buzzer/

PC (7P)

Display unit, rear view

Ground the

equipment to

prevent

interference.

DATA2

Heading

sensor (6P)

(AD or

NMEA)

DATA1

GPS sensor

GPS-310B,

320B/NMEA

equipment

(7P)

2-1

Page 26

Power cable

Connect the power cable to the POWER connector.

Signal cable connection (from the antenna unit)

Connect the signal cable to SIGNAL connector.

Ground terminal

Connect the ground wire (local supply, IV-2sq) between the ground term inal and ship’s

ground.

DATA1 to DATA3

Other equipments can be connected here as shown below.

DATA1 (7P) DATA2 (6P) DATA3 (7P)

NMEA (IN/OUT)

GPS sensor GPS-310B/320B,

Navaid, sounder etc.

Heading sensor

(ex. SC-60/120)

NMEA IN, NMEA OUT for PC

External buzzer

PC

This equipment can receive the following NMEA 0183 format sentence from an other

equipment.

• Own ship’s position: GGA>RMC>RMA> G LL

• Ship’s speed: RMC>RMA>VTG> VHW

• External waypoint: RMB>WPL>BWR>BWC

• Heading (True): HDT>HDG>HDM

• Course: RMC>RMA>VTG

• Depth: DPT>DBT

• Temperature: MTW

• Time: ZDA

• Other ship’s information: TTM

• Insight satellite information: GSV

• Target L/L TLL

You will need the optional NMEA cable to connect with other equipment.

2-2

Page 27

NETWORK port

Other NavNet equipment should be connect ed to this port with the optional NavNet cable.

Available equipment are shown below.

Radar Plotter Transducer Other

MODEL1722/1732/

1742/1762/1722C/

1732C/1742C/1762C/1752C

1833/1933/1943/

1833C/1933C/1943C/1953C

GD1700/1700C/1900C ETR-6/10N

HUB (used when more

than two NavNet unit s

are connected.)

2.2 External Buzzer (OP03-136, option) Co nnection

The optional external buzzer provides a louder alert when the guard alarm is violated.

External buzzer

Type: OP03-136

Code no.: 000-096-443

Further, you need the optional cable assy MJ-A7SPF0007-050 (w/7P connector, 5 m, code

no. 000-144-418).

1. Attach the MJ-A7SPF0007-050 cable assy (option) to the DATA 3 port at the rear of the

display unit.

2. Cut the XH connector at the end of the external buzzer cable with appropriate length.

3. Solder the cables made at step 2 with MJ-A7SPF0007-050 cable as shown below.

Red

Soldering

External buzzer

Black

Cut other cables off, and wrap here with tape.

MJ-A7SPF0007-050

Connection of external buzzer and display unit

using cable assy type MJ-A7SPF0007-050 cable

4. Fasten the buzzer with the double-sided tape or t wo tapping screws (3x15 or 3x20, local

supply).

2-3

Page 28

2.3 How to Connect with PC

When connecting with the personal computer, prepare the optional cable assy

MJ-A7SPF0007-050 and D-sub 9 pins plug (local supply), and connect them as follows.

SHIELD

BLUE

WHITE

5

1

69

D-SUB 9PIN

RI

1

2

3

4

5

6

7

8

9

CD

RD

TD

DTR

GND

DSR

RTS

CTS

WHITE

BLUE

SHIELD

short

MJ-A7SPF0007-050

1

TD

2

RD

3

RD_A

4

RD_B

5

+12V

6

EXT BUZZ

7

GND

MJ-A7SPF0007-050 cable connection for PC

2-4

Page 29

3. ADJUSTMENT

3.1 How to Access to Installation Menu

You should do the set up for the equipment t hrough the installation menu when installation

has been finished. To access to the installation menu, follow the steps in below.

1. Press the [P OWER/BRILL] key with touch-and-release action while pressing the [MENU]

key down. You hear a beep sound.

2. Releas e t he [MENU] key when the message of “STARTING INSTALLATION MODE”

appears.

3. After the radar display appears, press the [MENU] key followed by SYSTEM

CONFIGURATION soft key to display the SYSTEM CONFIG menu.

4. Press the INSTALLATION SETUP soft key to display the INSTALL SETUP menu.

RADAR

MENU

RADAR DISPLAY SETUP

RADAR RANGE SETUP

ARP SETUP

FUNCTION KEY SETUP

SYSTEM CONFIGURATION

Start up display

GENERAL SETUP

NAV OPTION

SYSTEM SETUP

INSTALLATION SETUP

System configuration menu

SYSTEM

CONFIG

NETWORK SETUP

RADAR SETUP

NETWORK SOUNDER SETUP*

RETURN

*: Do not change settings in this menu.

Install setup menu

How to access the Installation menu

Note: The very first time the system is powered you are asked if you want to start the

simulation mode, which provides simulated operation of the equipment. Press the

[CLEAR] key to start normal operation for radar adjustment. For further details about

the simulation mode, see the operator’s manual.

INSTALL

SETUP

RETURN

START

SIMULATION MODE?

YES ... PUSH ENTER KNOB

NO ... PUSH CLEAR KEY

TO SKIP.

Simulation mode window

3-1

Page 30

3.2 NETWORK SETUP Menu

To communicate with other NavNet equipment, this setting should be done.

1. Open t he INSTALL SETUP menu.

2. Press the NETWORK SETUP soft key.

▲

IP ADDRESS

172.031.003.002

HOST NAME

RADAR________

RADAR SOURCE

NETWORK

SETUP

EDIT

RADAR________

CHART SOURCE

______________

______________

______________

SOUNDER SOURCE

SOUNDER_____

SUBNET MASK

255.255.000.000

GATEWAY ADDRESS

RETURN

000.000.000.000

OFFSET PORT NUMBER

10000

NavNet SETUP menu

3. Select menu option and press the [ENTER] knob or EDIT soft key. For example, select

HOST NAME.

HOST NAME

R A D A R _ _ _

Host name window

4. Use the tr ackball or [ENTER] knob to select location and rotate the [ENTER] knob to set

character (or value).

5. Press the [E NTER] knob or ENTER soft key to finish.

6. Repeat steps 3-5 f or other items.

7. Press the [MENU] key to finish.

8. Continue next setup.

3-2

Page 31

Contents of Network setup menu

Item Description Default Setting

IP ADDRESS This address is assigned at the factory. Change

the address (last three digits; 001 t o 254) when

like models are connected directly or through the

hub. Do this change before connecting the

equipment to the other eq uipment or hub to

distinguish. Do not set the same IP address in the

network.

HOST NAME Set the name for your display unit to distinguish it

from others in the NavNet system. Confirm that

two equipment don’t hav e same host names. The

host name has been preset depending on the

series of NavNet. See the table in below. This host

name is used for RADAR SOURCE and CHART

SOURCE.

RADAR SOURCE Enter the host name “RADAR (preset)” or the new

name set at HOST NAME item setting if the unit

has been changed of the networ k radar to use for

the radar display.

172.031.003.002

RADAR

RADAR

CHART SO URCE Enter a host name (set at HOST NAME) of

network display unit to select equipment which has

chart card in its slot (Max. three un its, excluding

own) to use.

SOUNDER

SOURCE

SUBNET MASK 255.255.000.000

GATEWAY

ADDRESS

OFFSET POR T

NUMBER

The host name of the network sounder ETR-6/10N

is preset (SOUNDER) to use for the video sounder

display. Clear the host name when no network

sounder is connected.

Not used. Reserved for future use.

None

SOUNDER

000.000.000.000

10000

NavNet equipment default sett i ngs

Model IP ADDRESS HOST NAME

MODEL1722/1732/1742/1762 172.031.003.004 RADAR

MODEL1722C/1732C/1742C/1762C/1752C 172.031.003.001 RADAR

MODEL1833/1933/1943 172.031.003.002 RADAR

MODEL1833C/1933C/1943C/1953C 172.031.003.003 RADAR

GD-1700/1700C 172.031.014.001 PLOTTER

GD-1900C 172.031.003.003 PLOTTER

3-3

Page 32

3.3 RADAR SETUP Menu

After the network setup, do the following in order to adjust the radar.

Open the INSTALL SETUP menu, and then press the RADAR SETUP soft key to display

the RADAR SETUP menu. When the message of “RADAR DOES NOT TRANSMIT.

TRANSMIT RADAR?” appears, press the [ENTER] knob to transmit or [CLEAR] key to

cancel transmitting.

▲

ANTENNA TYPE

B

HEADING DATA

MAGNETIC

ANTENNA ROTATION*

ROTATE

TUNING

OFF

TIMING ADJUST

OFF

VIDEO ADJUST

OFF

M.B. SUPPRESSION

OFF

RADAR ANTENN HEIGHT

MEDIUM

STC CURVE

NORMAL

*: Do not change this item setting.

Page 1

RADAR

SETUP

EDIT

NEXT

PAGE

RETURN

Radar setup menu

▲

HEADING ADJUST

OFF

TOTAL ON TIME

000000.0 h

TO TAL TX TIME

000000.0 h

GUARD EXTERNAL BUZZER

OFF

Page 2

RADAR

SETUP

EDIT

PREV.

PAGE

3.3.1 ANTENNA TYPE

Select the antenna type connecting with your di splay unit. Default setting is B.

If necessary, reselect the antenna type referring to the table shown below.

After selection, press the [ENTER] knob or ENTER soft key.

Your unit Setting

MODEL1833 B

MODEL1933 F

MODEL1943 G

3-4

Page 33

3.3.2 TUNING

Initialize the tuning as follows.

1. Transmit the radar

2. Open t he RADAR SETUP menu, and then select TUNING by the trackball or [ENTER]

knob.

3. Press the EDIT soft key or [ENTER] knob to show the setting window.

TUNING

ON

OFF

Tuning setup menu

4. Select ON.

5. Press the [ ENTER] knob or ENTER soft key to start the auto tuning.

6. After the adjustment is completed, the message of “NOW TUNING” disappears.

7. The equipment returns to the menu display automatically.

3.3.3 TIMING ADJUST

This adjustment ensures proper radar performance, especially on short ranges. The radar

measures the time required for a transmitted echo to travel to the target and return to the

source. The received echo appears on the display based on this time. Thus, at the instant

the transmitter is fired, the s weep should start from the center of the display (sometimes

called sweep origin.)

A trigger pulse generated in the display unit goes to the antenna unit through the signal

cable to trigger the transmitter (magnetron). The time taken by the signal to travel up to the

antenna unit varies, depending largely on the length of signal cable. During this period the

display unit should wait before starting the sweep. When the display unit is not adjusted

correctly, the echoes from a straight local object (for example, a harbor wall or straight pier)

will not appear with straight edges – namely, they will be seen as “pushed out” or “pulled in”

near the picture center. The range of objects will also be incorrectly shown.

(1) Target

pulled

(2) Correct

(3) T arget pushed

outward

Examples of improper and correct sweep timing

1. Transmit on the shortest range and confirm that gain and A/C SEA are properly

adjusted.

2. Visually select a target which form s straight line (harbor wall, straight piers).

3. Open the RADAR SETUP menu and select TIMING ADJUST.

3-5

Page 34

4. Press the EDIT key or [ENTER] key to show the setting window.

TIMING ADJUST

ON

OFF

Timing adjust setting menu

5. Select ON and press the [ENT ER] knob or ENTER soft key t o show the radar display.

RETURN

PUSH ENTER KNOB AFTER

ADJUSTING SWEEP TIMING.

Timing adjustment setting display

6. Rotate the [ENTER] knob to straighten the target selected at step 2, and t hen press the

RETURN soft key to finish.

3.3.4 VIDEO ADJUSTMENT

Adjusts video amplifier input level.

1. Open the RADAR SETUP menu and select VIDEO ADJUST by the trackball or [ENTER]

knob.

2. Press the EDIT soft key or [ENTER] knob to show the setting window.

VIDEO ADJUST

ON

OFF

Video adjustment setting window

3. Select ON.

4. Press the [E NTER] key or ENTER soft key to start video adjustment.

5. When adjustment is completed, the message of “NOW ADJUSTING VIDEO” disappears,

and return to the menu display autom atically.

3-6

Page 35

3.3.5 HEADING ADJUST

You have mounted the antenna unit facing st raight ahead in the direction of the bow.

Therefore, a small but conspicuous target dead ahead visually should appear on the

heading line (zero degrees).

In practice, you will probably observe some small error on the display because of the

difficulty in achieving accurate initial positioning of the antenna unit. The follo wing

adjustment will compensate for this error.

1. Set ship’s heading to ward a suitable target (for example, ship or buoy) at a range

between 0.125 and 0.25 nautical mile.

2. Open the RADAR SETUP menu, and press the NEXT PAGE soft key.

3. Select HEADING ADJUST and press the EDIT soft key or [ENTER] knob to show the

HEADING ADJUST window .

4. Select ON followed by [ENTER] key or ENTER soft key to show the radar display.

SET

RETURN

PUSH SOFTKEY 'SET' AFTER

ADJUSTING HEADING LINE.

Heading adjustment setting display

5. Rotate the [ENTER] knob to bisect the target with the EBL.

6. Press the SET soft key.

7. As a final test, move the boat towards a small buoy and confirm that t he buoy shows up

dead ahead on the radar when it is visually dead ahead.

3-7

Page 36

3.3.6 M. B. (Main Bang) SUPPRESSION

Main bang (black hole), which appears at the display center on short ranges, can

suppressed as follows.

1. Open the RADAR SETUP menu and select M.B. SUPPRESSION by trackball.

2. Press the EDIT soft key or [ENTER] knob to show the setting window.

3. Select ON.

4. Press the [ E NTER] knob or ENTER soft key to start video adjustment.

RETURN

M.B. SUPPRESSION

0

Main bung suppression setting window

5. Rotate the [ENTER] knob to suppress main bang (between 0 and 25).

6. Press the RETURN soft key.

3.3.7 RADAR ANTENNA HEIGHT

The A/C SEA function is affected by the antenna height above the waterline. Enter antenna

height above the waterline to optimize the A/C SEA function.

1. Open t he RADAR SETUP menu and select RADAR ANTENNA HEIGHT.

2. Press the EDIT soft key or [ENTER] knob to show the setting window.

RADAR ANT. HEIGHT

HIGH

MEDIUM

LOW

Radar antenna height setting windo w

3. Select ant enna height above the waterline; HIGH (6-10 m ) , MIDIUM (3-6 m) or LOW

(0-3 m). The default setting is MEDIUM.

4. Press the [ENTER] key or ENTER soft key to finish.

3-8

Page 37

3.3.8 STC CURVE

The default STC curve can be maintained in most cases. If necessary the STC curve can

be changed as follows:

1. Open the RADAR SETUP menu and select STC CURVE.

2. Press the EDIT soft key or [ENTER] knob to show the setting window.

RETURN

STC CURVE

NARROW

NORMAL

WIDE

STC curve setting window

3. Select STC curve;

NARROW: The effective range of the [ A/ C S EA] adjustment is relatively short.

NORMAL: Between NARRO W and WIDE.

WIDE: The effective range of the [A/ C S EA] adjustment is relativ ely long.

4. Press the RETURN soft key to finish.

3-9

Page 38

3.3.9 HEADING DATA

Select the heading reference, MAGNETI C or TRUE. Select MAGNETIC when connecting

with the magnetic compass, select TRUE when connecting with the gyrocompass. For your

reference, when connecting with Satellite Compass SC-60/120 or Integrated Hading Sensor

PG-1000 which Furuno makes, set the heading data as the table shown below.

Model Setting of HEADING DATA

PG-1000

SC-60/120 TRUE

1. Open the RADAR SETUP menu and select HEADING DATA.

2. Press the EDIT soft key or [ENTER] knob to show the setting window.

3. Select MAGNETIC or TRUE.

4. Press the [E NTER] knob or ENTER soft key.

with L/L data TRUE

w/o L/L data MAGNETIC

HEADING DATA

MAGNETIC

TRUE

Heading data setting window

3.4 Checking Magnetron Heater Voltage

Magnetron heater voltage is formed on t he PTU (1833)/MD (1933/ 1943) Board of the

antenna unit, and preadjusted at the factory. Therefore no adjustment is required. However,

check magnetron heater voltage for confirmation as follows:

1. Open t he antenna unit.

2. Turn on the power. Do not transmit the radar.

3. Connect a multimeter, set to 10VDC range, appropriate position on the PTU (1833) or

RTB (1933/1943) Board in the antenna unit. Refer to the table in below.

4. Confirm that the multimeter indication is appropriate.

MODEL1833 MODEL1933 MODEL1943

Check point

Multimeter indication 7.4 to 7.6 V 7.4 to 7.6 V 7.4 to 7.6 V

Adjustment point R106 on PTU Board VR801 on MD Board VR801 on MD Board

TP802#4 (+) and #6 (-)

on PTU Board

J825#4 and #6 (GND)

on RTB Board

J825#4 and #6 (GND)

on RTB Board

3-10

Page 39

3.5 Navigation Data Source

The NAV SOURCE SETTINGS menu mainly selects the source of nav data. For navigator

other than the FURUNO GP-310B/320B, speed averaging and local time offset (to use local

time instead of UTC time) are also available from this menu.

1. Press the [MENU] key followed b y SYSTEM CONF IGURATION, NAV OPTION and NAV

SOURCE SETTINGS soft keys to show the NAV SETUP menu.

POSITION SOURCE

ALL

SPEED AVERAGING*

0000

LOCAL TIME OFFSET*

+00:00

TEMP CALIBRATION

+00 F

DEPTH CALIBRATION

+00 ft

NAV

SETUP

EDIT

* For GPS receiver other

than GP-310B/320B.

RETURN

Nav setup menu

2. Select POSITION SOURCE and press the [EDIT] key or [ENTER] knob to show the

position source window.

3. Select FURUNO BB GPS, GP, LC or ALL as appropriate and press the [ENTER] knob or

ENTER soft key.

FURUNO BB GPS: GPS Receiver GP-310B/320B

GP: GPS navigator (via NETWORK or DATA 1 connector)

LC: Loran C (via NETWORK or DATA 1)

ALL: Multiple navaid connection (via NETWORK or DATA 1 connector )

4. Fo r GPS receiver other than the GP-310B/320B, you m ay adj ust speed averaging and

use local time.

a) Choose desired item and press the EDIT soft key.

b) Use the trackball to select location and rotate the [ENTER] knob t o set value. For time, use

the +< - -> - soft key to switch from plus to minus and vice versa.

c) Press the RETURN sof t key.

Speed A veraging : Calculat ion of ETA is ba sed on average ship’s speed ov er a given period. If

the period is too long or too short calculation error will result. Change this setting if calculation

error occurs. The default sett ing, 60 seconds, is suitable for most conditions. The range o f

adjustment is 0-9999 (sec).

Local Time Offset: GPS uses UTC time. If you would rather use local time enter the time

difference between it and UTC. The range of offset is –13:30 to + 13:30 and t he default setting is

zero (no offset).

T emp Calibration: Offsets NMEA w at er t emperat ure (-40ºF to +40ºF)

Depth Calibratio n : Offsets NMEA depth data (-15 ft to +90 ft)

3-11

Page 40

5. For GP-310B/320B, press the RETURN soft key twice to show SYSTEM CONFIG

menu.

6. Press the SYSTEM SETUP soft key followed by PORT SETUP and GPS/NMEA PORT

soft keys.

7. Select FURUNO GPS SENSOR, and press the [ENTER] knob or EDIT soft key to show

FURUNO GPS SENSOR window.

8. Select YES and press the [ENTER] knob or ENTER soft key.

9. Press the RETURN soft key three times followed by NAV OPTIONS, GPS SENSOR

SETTINGS soft keys to show the GPS SETUP menu.

LOCAL TIME OFFSET

GEODETIC DATUM

POSITION SMOOTHING

SPD/CSE SMOOTHING

GPS SPEED AVERAGE

LATITUDE OFFSET

LONGITUDE OFFSET

DISABLE SATELLITE

LATITUDE

LONGITUDE

ANTENNA HEIGHT

GPS FIX MODE

COLD START

+00:00

WGS-84

000 second(s)

005 second(s)

060 second(s)

0.000’N

0.000’E

_ _ _ _ _ _

45 35.000’ N

125 00.000’ W

005m

2D/3D

NO

GPS

SETUP

EDIT

GPS

STATUS

RETURN

GPS SETUP menu

10. Select LOCAL TIME OFFSET and press the EDIT soft key.

11. Enter time difference between local time and UTC time. Use the + <- - > - soft key to

switch from plus to minus and vice versa. And then press the [ENTER] knob or ENTER

soft key.

12. Select ANTENNA HEIGHT and press the EDIT soft key.

ANTENNA HEIGHT

005 m

Antenna height window

13. Enter the height of the GP-310B/320B antenna unit above sea surface. Use the trackball

to select digit and rotate the [ENTER] knob t o set value. The default height is 5 m.

14. Press the [ENTER] knob or ENTER soft key.

15. Choose and set other items as appropriate, referring to the table on the next page.

3-12

Page 41

Contents of GPS sensor settings menu

Item Description Settings Default Setting

Local Time Offse t

Geodetic Datum

Position Smoothing

Allows the user to use local time (instead

of UTC time). Enter time difference

between local time and UTC time. Use

the + < - - > - soft key to switch from plus

to minus and vice versa.

Your equipment is preprogrammed with

most of the major chart systems of the

world. Although the WGS-84 system, the

GPS standard, is now widely used other

categories of charts still exist. Select the

chart system used, not the area where

your boat is sailing.

When the DOP or receiving condition is

unfavorable, the GPS fix may change,

even if the vessel is dead in water. This

change can be reduced by smoothing the

raw GPS fixes. A setting between 000 to

999 is available. The higher setting the

more smoothed the raw data, however

too high a setting shows response time to

change in latitude and longitude. This is

especially noticeable at high ship’

speeds. Increase the setting if the GPS

fix changes.

-13:30 to +13:30 hr 0 hr (no offset)

Use the trackball or

[ENTER] knob to

select appropriate

chart.

0-999 sec

WGS-84

0 sec (no position

smoothing)

Spd/Cse

Smoothing

GPS Speed

Average

Latitude Offset

During position fixing, ship’s velocity

(speed and course) is directly measured

by receiving GPS satellite signals. The

raw velocity data may change randomly

depending on receiving conditions and

other factors. You can reduce this

random variation by increasing the

smoothing. Like with latitude and

longitude smoothing, the higher the

speed and course smoothing the more

smoothed the raw data. If the setting is

too high, however, the response to speed

and course change slows. For no

smoothing, enter all zeros.

Calculation of ETA is based on average

ship’s speed over a given period. If the

period is too long or too short calculation

error will result. Change this setting if

calculation error occurs. The default

setting is 60 seconds, which is suitable

for most conditions.

Offsets latitude position to further refine

position accuracy. Use the N <- - > S soft

key to switch coordinate.

0-9999 sec 5 sec

0-9999 sec 60 sec

9.999’S – 9.999’N 0.0’ (no offset)

(Continued on next page)

3-13

Page 42

Contents of GPS sensor settings menu (con’t.)

Description Settings Default Setting

Item

Longitude Offset

Disable Satellite

Latitude

Longitude

As above but for longitude. Use the W < -

- > E soft key to switch coordinate.

Every GPS satellite is broadcasting

abnormal satellite number (s) in its

Almanac, which contains general orbital

data about all GPS satellites, including

those which are malfunctioning. Using

this information, the GPS receiver

automatically eliminates any

malfunctioning satellite from the GPS

satellite schedule. However, the Almanac

sometimes may not contain this

information. If you hear about a

malfunctioning satellite from another

source, you can disable it manually. Enter

satellite number (max. 3 satellites) in two

digits and press the ENTER soft key.

Set initial latitude position after cold start.

Use the N < - -> S soft key to switch

coordinate.

Set initial longitude position after cold

start. Use the W <- - > E soft key to

switch coordinate.

9.999’E – 9.999’W 0.0’ (no offset)

None

90°S - 90°N 45°35.000’N

180°E – 180°W 125°00.000’’W

Fix Mode

Antenna Height

Cold Start

GPS STA T US

(soft key)

Choose position fixing method: 2D (three

satellites in view), 2 D/3D (three or four

satellites in view whichever is greate r).

Enter the height of the GPS antenna unit

above sea surface.

Clears the Almanac to receive the latest

Almanac.

Displays GPS satellite status display.

2D, 2D/3D 2D/3D

0-99 m 5 m

No, Y es No

3-14

Page 43

3.6 Setting up Data Ports

Setup the data ports according to the equipment connect ed to them as follows.

1. Press the [ MENU] key to open t he menu.

2. Press the SYSTEM CONFIGURATION, SYSTEM SETUP and PORT SETUP soft keys.

3. Press the GPS/NMEA PORT for DATA1 port or PC/NMEA EXT, BUZZ PORT for DATA3

port soft key as appropriate. One of the following displays ap pear depending on your

selection.

FURUNO GPS SENSOR

NO

OUTPUT FORMAT

LAT/LON FORMAT

OUTPUT DESTINATION

WIRING INFORMATION

TD-A >1>---WHITE

TD-B >2>---BLUE

RD-A >3>---YELLOW

RD-B >4>---GREEN

+12V >5>---RED

GND >6>---BLACK

FG >7>---SHIELD

NMEA0183 2.0

DD˚ MM.MMM'

NO

GPS

PORT

EDIT

SELECT

SNTNC

RETURN

▲

NMEA OUTPUT FORMAT

NMEA 0183 VER2.0

BAUD RATE

BIT LENGTH

STOP BIT

PARITY

(CONTROL: Xon/Xoff)

WIRING INFORMATION

TxD >1>---WHITE

RxD >2>---BLUE

RD-A >3>---YELLOW

RD-B >4>---GREEN

+12V >5>---RED

EXT BUZZ >6>---BLACK

GND >7>---SHIELD

4800bps

8bits

1bit

NONE

NMEA

PORT

EDIT

SELECT

SNTNC

RETURN

DATA 1 port

DATA 3 port

3. Select item and press the EDIT soft key.

4. Set opt ion referring to the tables on the next page.

5. To select NMEA data sentences to output, press the SELECT SNTNC soft key.

OUTPUT THROUGH NETWORK port for DATA4 port, select the sentence to output t o

the network equipment.

AAM

APB

BOD

BWR

DPT

GGA

GLL

GTD

MTW

RMA

RMB

RMC

VHW

VTG

WPL

XTE

ZDA

HDT

HDG

MWV

TTM

--

--

--

--

ON

--

ON

--

ON

-ON

ON

ON

ON

--

-ON

--

--

--

--

SELECT

SNTNC

ON/OFF

RETURN

AAM

APB

BOD

BWC

DBT

GGA

GLL

GTD

MTW

RMA

RMB

RMC

VHW

VTG

WPL

XTE

ZDA

HDT

HDG

MWV

TTM

--

--

--

--

ON

--

ON

--

--

-ON

ON

-ON

--

-ON

--

--

--

--

SELECT

SNTNC

ON/OFF

RETURN

NMEA Version 2.0

Range and bearing mode: Rhumb line

NMEA Version 1.5 (w/ARP)

Range and bearing mode: Great circle

3-15

Page 44

7. Select sentence and press the ON/OFF soft key to show ON (output) or OFF (no output)

as appropriate.

8. Press the RETURN soft key.

9. Press the [MENU] key to quit.

Item Description Settings Default Setting

FURUNO GPS

Sensor

Output Format

Lat/Lon Format

Output Destination

SELECT SNTNC

(soft key)

Contents of DATA 1 PORT menus

Selects whether the GPS Receiver

GP-310B/320B is connected to the

DA TA1 port or not.

Selects NMEA output version of the

equipment connected.

Selects latitude/longitude format to

output.

Selects whether to output route (data

sentence RTE) and waypoint data (data

sentence WPL) when destination is set.

Selects data sentence(s) to output. Select sentence with the trackball and press the

ON/OFF soft key to show ON or “- -“ (OFF) as appropriate. See the figure above for

sentence and default settings.

Contents of DATA 3 PORT menu

Yes, No No

NMEA0183 Ve r.

1.5, NMEA0183

Ver. 2.0

DD°MM.MM’,

DD°MM.MMM,

DD°MM.MMMM’

Yes, No No

NMEA0183 Ve r. 2.0

DD°MM.MMM’

Item Description Settings Default Setting

NMEA Output

Format

Baud Rate Sets baud rate. 4800, 9600, 19200 (bps) 4800(bps)

Bit Length Sets character length. 8 bit, 7 bit 8 bit

Stop Bit Sets number of stop bits. 1 bit, 2 bit 1 bit

Parity Sets parity bit. Even, Odd, None None

SELECT

SNTNC

(soft key)

Selects NMEA output format.

Chooses data sentences to output. For further details see the illustration “NMEA data

sentences” on page 3-15.

NMEA Ver. 1.5, NMEA

Ver. 2.0

NMEA Ver. 2.0

3-16

Page 45

3.7 Remote Controller Setting

A remote controller can be set exclusivel y for use with a specific display unit, in the case of

multiple NavNet display units. Set the remote controller mode desired on the menu and

attach appropriate label (supplied with accessories) to the remote controller and display

unit.

1. Press the [MENU] key, SYSTEM CONFIGURATION soft key, GENERAL SETUP soft

key in order to show the GENERAL SETUP menu.

KEY BEEP

LANGUAGE

RANGE UNIT

TEMPERATURE UNIT

DEPTH UNIT

TEMPERATURE SOURCE

DEPTH SOURCE

RESET TRIP LOG

ON

ENGLISH

nm, kt

°

F

ft

NMEA

NMEA

NO

Page 1

GENERAL

SETUP 1

EDIT

NEXT

PAGE

RETURN

LAT/LON DISPLAY

DD° MM.MMM'

TD DISPLAY

LORAN C

SPEED

SOG

POSITION DISPLAY

LAT/LON

TIME DISPLAY

24 HOURS

INFRARED REMOTE MODE

A

RANGE & BEARING MODE

RHUMB LINE

BEARING READOUT

MAGNETIC

MAGNETIC VARIATION

AUTO 7.0° W

VIDEO BOOST TIME

3 minutes

Page 2

GENERAL

SETUP 2

EDIT

PREV.

PAGE

GENERAL SETUP menu

2. Press the NEXT PAGE soft key to show Page 2.

3. Select INFRARED REMOTE MODE, and press the EDIT soft key.

The SELECT I/R R EMOTE window appears.

4. Point the remote controller toward the display unit, and press any key (except [ENTER]

key) on the remote controller. The remote controller mode window appears.

SELECT I/R REMOTE

A

B

C

D

MODE

A

Remote controller

mode window

PRESS '0' AND '2' KEY

TOGETHER TO CHANGE MODE.

Select I/R REMOTE window

5. After confirm ing the remote controller mode on the window, press the [0] and [2] key

together on the remote controller to change the controller mode setting among A, B, C

and D.

6. Operat e the trackball or [ENTER] knob so that the display m ode should be the same as

the controller mode setting.

7. Press the [MENU] key to close t he menu.

3-17

Page 46

This page is intentionally left blank .

Page 47

4. OPTIONS

4.1 ARP Kit ARP-11

Necessary parts

Name: ARP kit

Type: ARP-11

Code no.: 008-523-050

Table 4-1 ARP-11 contents

Name Type Code No. Qty

ARP Board 18P9013 008-521-830 1

Pan head screw M3x6 C2700W 000-881-403 4

Spacer

Spring washer M3 C5191W 000-864-204 3

SQ9 000-801-850 1

SQ15 000-801-779 3

1. Unscrew six connecter nuts at the rear of t he display unit.

2. Unf asten 16 binding screws (M3x10) to remove the display cover.

3. Remove the pan head screw (M3x8) on the SPU Board shown in the figure below.

24P Connector Nut

Connector Nuts

5 pcs.

(Large) 1 pc.

(Small) 4 pcs.

Display cover

Unfasten this screw.

Binding Screws

M3x10 (w/nylon washer)16 pcs.

Display unit, cover removed

4-1

Page 48

4. Fasten four spacers and washers (supplied with option kit) to the locations shown below.

5. Mate P109 on the ARP Board (option) t o J109 on the SPU Board.

6. Fix the ARP Board and SPU Board with four pan head screws and spring washers

(supplied with option kit).

Spring washer (M3)

4 pcs.

Spacer SQ9 (short)

J109

1 pc.

P109

Spacer SQ15 (long)

3 pcs.

7. Reassemble the display unit.

ARP Board attachment

Pan head screws

(M3x6) 4 pcs.

4-2

Page 49

4.2 Connection of External Monitor/Remote Display

The above units can be connected to the MODEL1833/1933/1943 by using the hole at t he

rear of the display unit. Remove the connector cover to use this hole. After connecting,

cover the hole with soft putty to seal the hole.

VGA monitor

CAUTION

Even though the display

unit meets waterproof

standard IPX-5,

Remote display (ex. FMD-811)

Connection of External monitor/remote display

4.2.1 Connecting external monitor

this modification can

affect waterproofness.

Watertight integrity

cannot be guaranteed.

You can display the MODEL1833/1933/1943 screen on the external monitor, which accepts

industrial standard VGA input by using the optional RGB output cable kit OP03-176. Supply

monitor and interconnection cable (with HD-15P connectors of male, three rows of 15 pins)

locally.

Necessary parts for connecting of external monitor

Name: RGB output cable kit

Type: OP03-176

Code No.: 008-526-360

Name Type Code No. Qty

Cable assy. 15SDS/XHP10-005 000-144-511 1

Grommet MG-4 000-871-378 1

1. Unscrew six connecter nuts at the rear of t he display unit.

2. Unf asten 16 binding screws (M3x10) to remove the display cover.

3. Remove the connector cover at the rear of the display cover.

4. Cut a “x” in the rubber grommet to pass the cable.

5. Pass the RGB output cable through the rubber gromm et (supplied with option) hole and

then connect the XH connector (10P) of the RGB out put cable to J106 on the SPU

Board.

Put the ground wire of the RGB output cable outside of the display cover.

4-3

Page 50

Connector Nut

5 pcs.

(Large) 1 pc.

24P Connector Nut

(Small) 4 pcs.

Rubber grommet

Cut a "X" in the

rubber grommet.

Use this pan head

screw to fix the

ground wire of the

RGB output cable.

Remove

connector cover.

SPU Board

J106

Cable tie

How to connect the RGB output cable

5. Attach the cable tie supplied as installation material to the posit ion shown above, and

then tie the cable with it.

6. Reassemble the display unit. Fix the ground wire of the RGB output cable with the pan

head screw shown above.

7 Attach the rubber grommet to the hole at the rear of the display unit.

4-4

Page 51

4.2.2 Connecting remote display

The FURUNO Display unit FMD-811, MODEL1832 or GD-280/380, etc. can be connected

to the NavNet display as remote display. To interconnect them, use a cable attached with or

set as option for the remote display.

1. Unscrew six connecter nuts at the rear of t he display unit.

2. Unf asten 16 binding screws (M3x10) to remove the display cover.

3. Remove the connector cover at the rear of the display cover.

4. Pass the signal cable for remote displaying through the hole, and then connect the XH

connector (8P) of the signal cable to J105 on the SPU Board. If your remote signal cable

has the ground wire, put it outside of the display cover and fix it with the pan head screw

shown below.

24P Connector Nut

(Small) 4 pcs.

Connector Nut

5 pcs.

(Large) 1 pc.

Use this pan head screw

to fix the ground wire of

the remote signal cable.

Remove

connector cover.

SPU Board

Cable tie

J105

How to connect remote signal cable

5. Attach the cable tie supplied as installation material to the posit ion shown above, and

then tie the cable with it.

6. Reassemble the display unit.

7. Apply soft putty to seal the hole at the rear of the display unit.

4-5

Page 52

This page is intentionally left blank .

Page 53

1/2

C3502‑Z01‑D

A-1

Q'TY

3

3

1

FP03‑09301FP03‑09301

FP03‑09301

1

FP03‑09202FP03‑09202

FP03‑09202

1

FP03‑09203FP03‑09203

FP03‑09203

2

FP03‑09204FP03‑09204

FP03‑09204

1

CP03‑21901CP03‑21901

CP03‑21901

19AL‑X‑9851 ‑4

DESCRIPTION/CODE№

FGBO7AAC125V

OUTLINE

NAME

ヒューズ

000‑549‑013

FGBO15AAC125V

FUSE

ヒューズ

000‑549‑014

FUSE

03‑153‑1311‑0

ACCESSORIESACCESSORIES

ACCESSORIES FP03‑09301

付属品

付属品付属品

付属品 ACCESSORIES

カード用ピン

100‑292‑130

CARDREMOVER

03‑156‑1053‑1

ACCESSORIESACCESSORIES

ACCESSORIES FP03‑09202

付属品

付属品付属品

付属品 ACCESSORIES

フード

100‑291‑991

HOOD

FP03‑09203

ACCESSORIESACCESSORIES

ACCESSORIES FP03‑09203

付属品

付属品付属品

付属品 ACCESSORIES

ハンガー組品

008‑523‑640

HANGERASSY.

FP03‑09204

ACCESSORIESACCESSORIES

ACCESSORIES FP03‑09204

付属品

付属品付属品

付属品 ACCESSORIES

ノブ組品

008‑523‑650

KNOBASSY.

SG‑130

INSTALLATIONMATERIALSINSTALLATIONMATERIALS

INSTALLATIONMATERIALS CP03‑21901

工事材料

工事材料工事材料

工事材料 INSTALLATIONMATERIALS

スナップバンド

000‑809‑171

CABLETIE

RDP‑127

RDP‑127RDP‑127

RDP‑127

1

RDP‑127‑E‑N

UNITUNIT

UNIT

1

**

000‑080‑012

RMC‑100

REMOTECONTROLLERSETREMOTECONTROLLERSET

REMOTECONTROLLERSET

000‑144‑471

14‑034‑2075‑1

1

1

100‑292‑801

R6PKRCP‑2

1

000‑142‑527

03‑153‑1314‑2

1

100‑292‑792

03‑153‑1315‑2

1

100‑292‑822

03‑153‑1316‑2

1

100‑292‑832

03‑153‑1317‑2

SP03‑14001SP03‑14001

SP03‑14001

100‑292‑842

SPAREPARTSSPAREPARTS

SPAREPARTS SP03‑14001

PACKING LIST

PACKING LISTPACKING LIST

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE№

ユニット

ユニットユニット

ユニット UNIT

指示部

DISPLAYUNIT

リモコンセット

リモコンセットリモコンセット

リモコンセット REMOTECONTROLLERSET

リモコンキーユニット

REMOTECONTROLLER

リモコンビニールケース

VINYLCASEFORREMOTE

CONTROLLER

BATT(MN)

SIZEAABATTERY

リモコンシール(1)

LABELFORREMOTE

CONTROLLER

リモコンシール(2)

LABELFORREMOTE

CONTROLLER

リモコンシール(3)

LABELFORREMOTE

CONTROLLER

リモコンシール(4)

LABELFORREMOTE

CONTROLLER

注記) コード末尾に[**]の付いたユニットは代表の型式/コードを表示しています。

DOUBLE ASTERISK DENOTES COMMONLY USED EQUIPMENT.

予備品

予備品予備品

予備品 SPAREPARTS

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 54

2/2

C3502‑Z03‑D

A-2

Q'TY

19AL‑X‑9851 ‑4

DESCRIPTION/CODE№

OUTLINE

NAME

RDP‑127

RDP‑127RDP‑127

RDP‑127

1

03‑153‑1312‑0

100‑292‑140

5X20SUS3041シュ

4

4

000‑802‑081

M4X20SUS304

1

000‑804‑742

03‑156‑1055‑0

1

100‑292‑760

MJ‑A3SPF0018‑050Z*5M*

OTHERINSTALLATIONMATERIALSOTHERINSTALLATIONMATERIALS

OTHERINSTALLATIONMATERIALS

000‑139‑872

PACKING LIST

PACKING LISTPACKING LIST

PACKING LIST

NAME OUTLINE Q'TYDESCRIPTION/CODE№

ヒューズハリマーク

FUSELABEL

+トラスタッピンネジ

+TAPPINGSCREW

+ナベセムスネジB

WASHERHEADSCREW

型紙

TEMPLATESHEET

その他工材

その他工材その他工材

その他工材 OTHERINSTALLATIONMATERIALS

ケーブル組品MJ

CABLEASSY.

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

注記) コード末尾に[**]の付いたユニットは代表の型式/コードを表示しています。

DOUBLE ASTERISK DENOTES COMMONLY USED EQUIPMENT.

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

3421

MJ-A3SPF0018

(03S9368-0),5m,φ10

12-24 VDC

100/110/220/230VAC

A

1φ,50/60Hz

DPYC-1.5 *1

(VV-S 2.0x2C)

5612

(+)(-)

整流器

RECTIFIER

RU-3423

VGAモニター

VGA MONITOR

*1

VGA MONITOR CABLE

D-SUB 15P

副指示器

SLAVE DISPLAY

GPS受信機

GPS RECEIVER

10m

GP-310B/320B

GYRO

ADコンバータ

A-D CONVERTER

MJ-A6SPF0009,10m,φ6

MJ-A6SPF0003,5m,φ6

AD-100

選択

B

SELECT

ヘディングセンサ

HEADING SENSOR

PG-1000

魚群探知機・PC

ECHO SOUNDER

MJ-A6SPF0007,10m,φ6

MJ-A7SPF0007,5m,φ7

PC(RS232C)

アカ RED

クロ BLK

MJ-A3SRMD

FUSE 1A

MJ-A15A3F0003-030

3m,φ6.8

外部ブザー

EXT. BUZZER

OP03-136

メモリカードI/F

+12V

1

GND

2

MEMORY CARD I/F

FG

3

CU-200

外部装置

EXT. EQUIP.

GP-1700/C

1m

MJ-A6SPF/TM11AP8-C050,5m,φ5.1

*5

MJ-A6SPF0014,φ6

MAX.30m

ETR-6/10N

12 VDC

注記

C

*1)造船所手配

*2)コネクタは工場にて取付済み。

*3)シールドは両ユニット側で完全に接地すること。

*4)レーダーモニターとして使用する場合は、指示器の内部設定を変更する。

*5)輸出仕様のみ。

NOTE

*1. SHIPYARD SUPPLY

*2. CONNECTOR PLUG FITTED AT FACTORY.

*3. SHIELD SHOULD BE EFFECTIVELY GROUNDED AT BOTH UNIT ENDS.

*4. CHANGE SETTING IN THE DISPLAY UNIT FOR USING AS A RADAR MONITOR.

*5. OVERSEAS SPECIFICATION ONLY.

HUB

*1

MJ-A6SRMD/TM11AP8

(19S1005),0.5m

MJ-A6SPF0014,φ6

MAX.30m

FUSE

7A:24V

15A:12V

*2

MJ-A3SRMD

シロ WHT

クロ BLK

19S1004,0.5m

OP03-174,MAX.30m

*2

MJ-A7SRMD

*2

MJ-A6SRMD

シロ

WHT

クロ

BLK

キ

YEL

ミド

GRN

*2

MJ-A7SRMD

シロ

WHT

アオ BLU

キ

YEL

ミド

GRN

アカ RED

クロ BLK

*2

MJ-A6SRMD

指 示 部 DISPLAY UNIT

RDP-127

J106(XH10P)

SIG-R

J1351

(+)

1

(-)

2

GND

3

DATA1

J1352

1

TD1-A

2

TD1-B

3

RD1-A

4

RD1-B

5

+12V

GND

6

7

SHIELD

DATA2

J1353

DATA-H/HDG-H

1

DATA-C/HDG-C

2

CLK-H

3

CLK-C

4

5

NC

6

SHIELD

DATA3

J1354

TD_DT

1

RD_DT

2

RD3-A

3

RD3-B

4

+12V

5

EXT.BUZZ

6

SHIELD/GND

7

NETWORK

J1355

E_TD_P

1

E_TD_N

2

E_RD_P

3

E_RD_N

4

NC

5

SHIELD

6

GND

IV-2SQ.

*1

(RS-232C)

NMEA0183

DRAWN

CHECKED

APPROVED

SCALE MASS

DWG.No.

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

Apr. 1 '04

TAKAHASHI.T

C3504-C01- D

GND

SIG-G

GND

SIG-B

GND

E_HSYNC_N

GND

E_VSYNC_N

GND

J105(XH8P)

GND

TRU_HD

GND

OP_BP

GND

PR_TRIG

GND

OP_VIDEO

K.MIYAZAWA

03P9288

DJ1

+12V

+12V

GND

-12V

-12V

TX_TRIG

P/L A

P/L B

BEARING

MOTOR(+)

HD SIG.

MOTOR(-)

TUNE_IND.

MBS_L 3

GND

GND

VIDEO

TUNE_CONT

SPARE

SPARE

kg

*2

10

11

20

14

15

2

8

7

9

1

17

5

18

24

21

16

6

13

12

4

NC

NC

19

NC

23

*3

03-155-6002-2

MJ-B24LPF0005,10/15/20/30m,φ11

(17C+2C2V,MAX.30m)

キ(太) YEL[B]

クロ(太) BLK[B]

アカ(太) RED[B]

シロ(太) WHT[B]

チャ(太) BRN[B]

チャ BRN

アオ BLU

ミドリ GRN

シロ WHT

アオ(太) BLU[B]

クロ BLK

ムラサキ(太) PPL[B]

シロ/チャ WHT/BRN

アカ RED

シロ/ダイ WHT/ORG

ドウジク 2C-2V COAX

キ YEL

ミドリ(太) GRN[B]

ダイ(太) ORG[B]

*4

*2

DJ1

MJ-B24LPF0008,10m,φ11(OPTION)

17

20

9

24

23

21

16

TYPE

MODEL 1933/1943

名称

船舶用レーダー

相互結線図

NAME

MARINE RADAR

INTERCONNECTION DIAGRAM

空中線部 ANTENNA UNIT

RSB-0070/0073

*2

J8211(VH9P)

1

2

3

4

5

6

7

8

9

J823(VH4P)

1

2

3

4

J824(NH13P)

1

2

3

4

5

6

7

8

9

10

11

12

13

J822(NH13P)