Page 1

Page 2

(

C

9-52, Ashihara-cho,

Nishinomiya, Japan

Telephone: 0798-65-2111

Telefax: 0798-65-4200

All rights reserved.

Printed in Japan

Your Local Agent/Dealer

FIRST EDITION : AUG. 1998

D : SEP. 4, 2001

PUB. No. IME-34620-D

YOSH)

MODEL-1932/1942 MARK-2

Page 3

SAFETY INSTRUCTIONS

WARNING

Radio Frequency Radiation Hazard

The radar scanner emits electromagnetic radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never look directly into the scanner aperture from a

close distance while the radar is in operation or expose yourself to the transmitting

scanner at a close distance.

Distances at which RF radiation levels of 100 and 10 W/m

below.

Note: If the scanner unit is installed at a close distance in front of the wheel house,

your administration may require halt of transmission within a certain sector of scanner

revolution. This is possible Ask your FURUNO representative or dealer to provide

this feature.

MODEL

1932 MK-2

1942 MK-2

Radiator

type

XN10A

XN12A

Distance to

100 W/m

point

Worst case 0.2 m

Nil

2

exist are given in the table

2

Distance to

10 W/m

point

Worst case 3.0 m

Worst case 2.5 m

2

i

Page 4

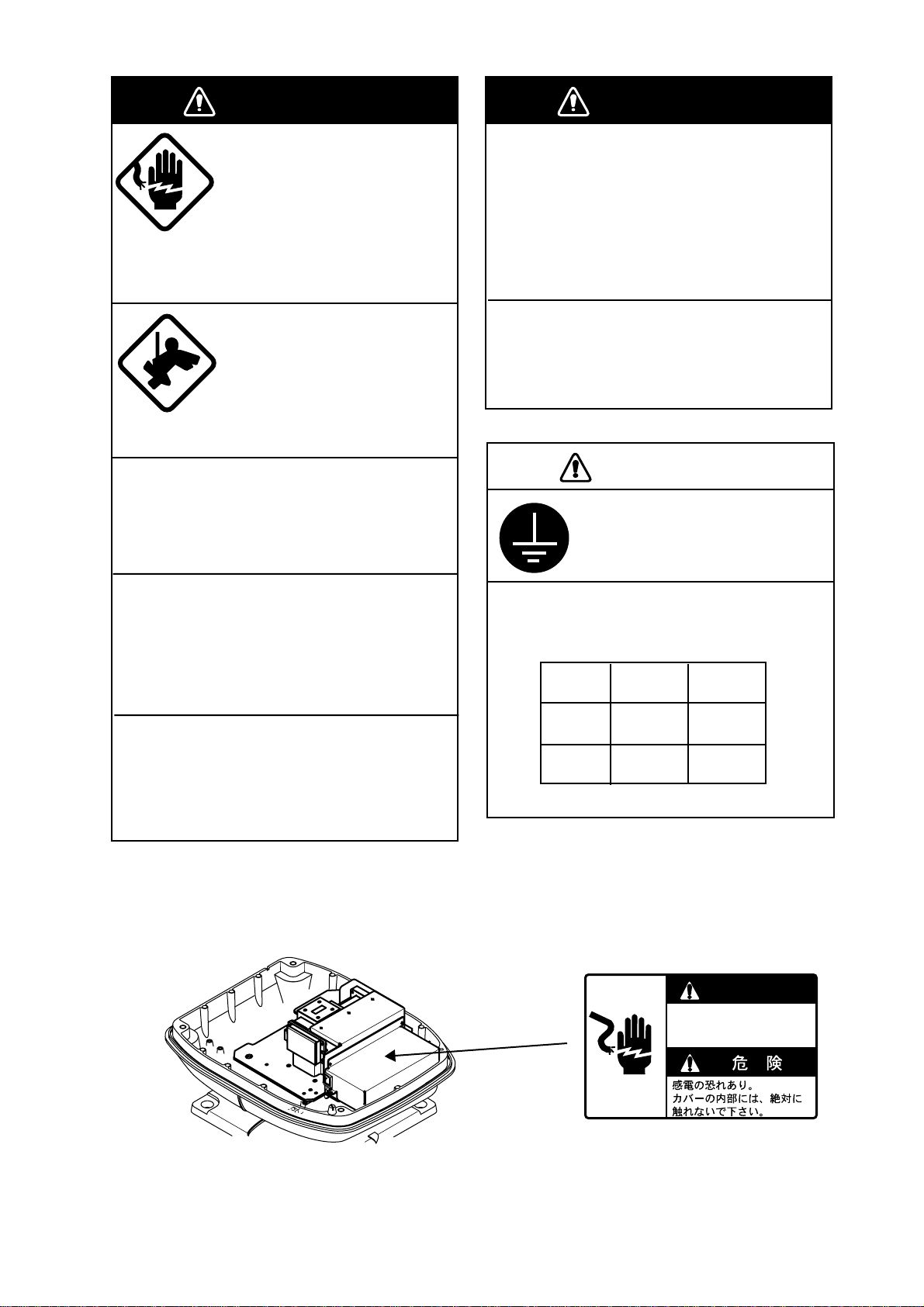

CAUTION

WARNING

WARNING

WARNING

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service platform

from which to install the scanner unit.

Serious injury or death can result if someone falls from the radar scanner mast.

Only qualified personnel

should work inside the

equipment.

Wear a safety belt and hard

hat when working on the

scanner unit.

Serious injury or death can

result if someone falls from

the radar scanner mast.

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Do not install the display unit where it

may get wet from rain or water splash.

Water in the display unit can result in fire,

electrical shock or equipment damage.

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

Use only the specified power cable.

Fire or equipment damage can result if a

different cable is used.

CAUTION

Ground the equipment to

prevent electrical shock and

mutual interference.

Observe the following compass safe

distances to prevent deviation of a

magnetic compass:

Standard Steering

compass compas

Display

unit

Scanner

unit

0.75 m 0.60 m

1.00 m 0.80 m

HIGH TENSION WARNING

DANGER

Electrical shock hazard.

Do not touch parts in side this cover.

Name: Danger Label

Type: 14-055-4202-0

Code No.: 100-245-220

ii

Page 5

TABLE OF CONTENTS

SYSTEM CONFIGURATION .............................................................iv

EQUIPMENTS LIST............................................................................v

1. MOUNTING

1.1 Mounting Methods for Scanner Unit..................................................................1-1

1.2 Fixing Holes in Mounting Platform ....................................................................1-1

1.3 Fastning the Radiator to the Radiator Bracket..................................................1-2

1.4 Mounting the Scanner Unit................................................................................1-2

1.5 Display Unit Mounting .......................................................................................1-4

2. CONNECTIONS

2.1 Connecting the Signal Cable.............................................................................2-1

2.2 Display Unit Connections..................................................................................2-2

2.3 Connection of External Equipment....................................................................2-3

2.4 Exchange of Fuse for 24/32V Power Supply.....................................................2-4

2.5 Checking the Installation...................................................................................2-4

3. ADJUSTMENTS

3.1 Preparation........................................................................................................3-1

3.2 Adjusting Tuning/V ideo......................................................................................3-1

3.3 Entering Antenna Height ...................................................................................3-1

3.4 Aligning Heading ...............................................................................................3-2

3.5 Adjusting Sweep T iming ....................................................................................3-2

3.6 Adjusting MBS...................................................................................................3-3

3.7 Selecting STC Curve.........................................................................................3-3

3.8 Setting Dead Sector ..........................................................................................3-3

3.9 Checking Magnetron Heater Voltage ................................................................3-4

4. INSTALLATION OF ARP-10 (OPTION)

4.1 Necessary Parts................................................................................................4-1

4.2 Mounting ...........................................................................................................4-1

4.3 Adjustments.......................................................................................................4-1

INSTALLATION MATERIALS, ACCESORIES, SPARE PARTS..... A-1

OUTLINE DRAWING ...................................................................... D-1

SCHEMATIC DIAGRAM ................................................................. S-1

iii

Page 6

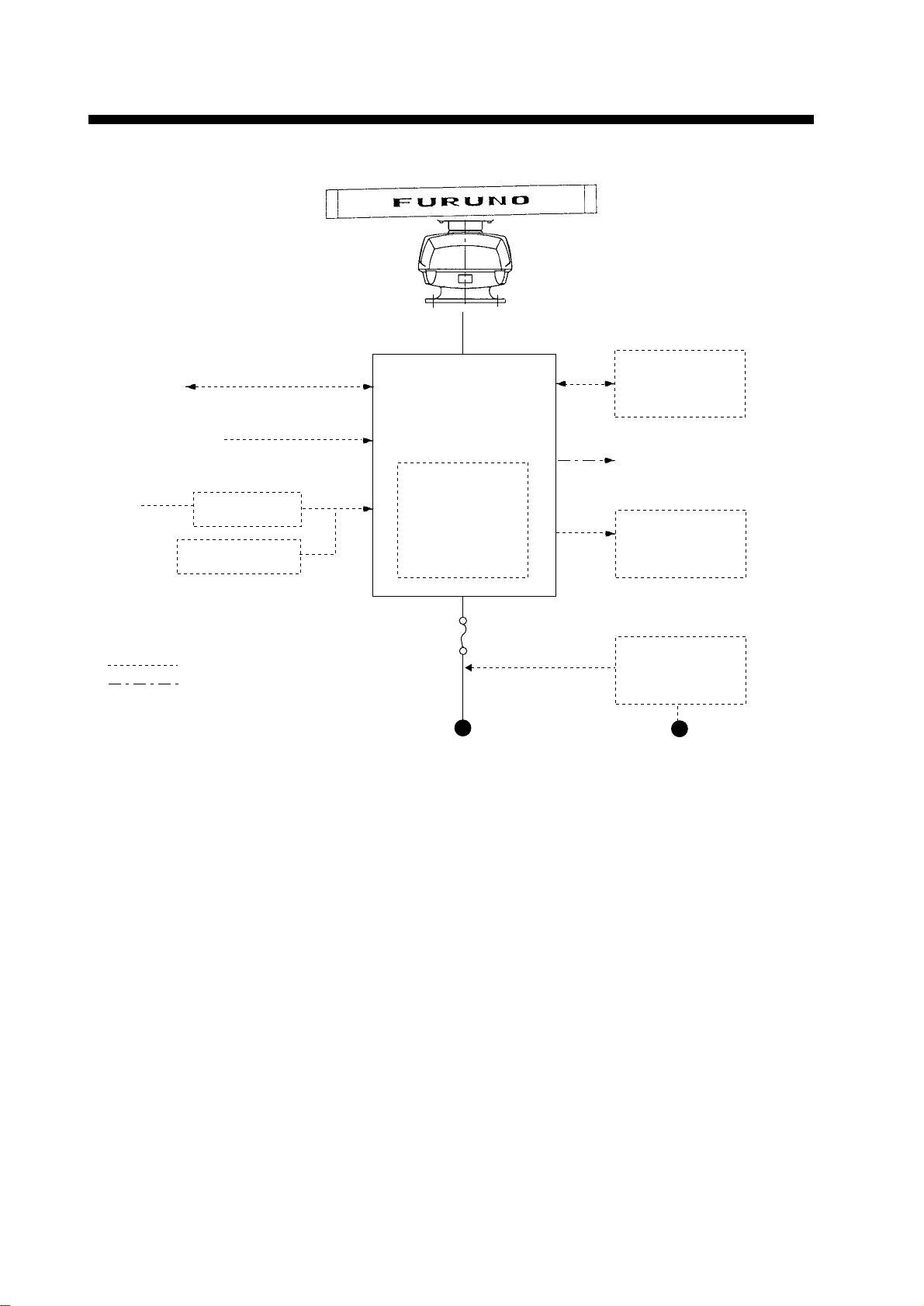

SYSTEM CONFIGURATION

Scanner Unit

MODEL 1932 MARK-2

XN10A-RSB-0070-064 (24 rpm)

XN10A-RSB-0073-064 (48 rpm)

MODEL 1942 MARK-2

XN12A-RSB-0070-059 (24 rpm)

XN12A-RSB-0073-059 (48 rpm)

Navigation

device

Video Sounder

IEC 61162* (In/Out)

IEC 61162* (In/Out)

Display Unit

RDP-118

Radar Plotter

RP-110

Remote Display

FMD-811/1800

Gyrocompass

*Equivalent to NMEA 0183

Gyro Converter

AD-100

Integrated Heading

Sensor PG-1000

: Option

: Local Supply

Auto Plotter

ARP-10

(24 rpm only)

12 VDC: 10A

24/32 VDC: 5A

12/24/32 VDC

External Alarm

Buzzer OP03-21

Rectifier

RU-3423

115/230 VAC

Note: Even though the display unit meets waterproof standard IPX-5, the connection of external buzzer, radar plotter and/or remote display can af fect waterproofness. W atertight integrity cannot be guaranteed. When these modification has been done, the display unit should

not be mounted where exposed.

Input data

Own ship’s position: GGA>RMC>RMA>GLL (GLL is available Ver.1.5 only)

Speed: RMC>RMA>VTG>VHW

Heading (True): HDT>HDG *1>HDM *1 >VHW>VHW

Heading (Magnetic): HDM>HDG *1>HDT *1>VHW>VHW

Course (True): RMC>RMA>VTG

Course (Magnetic): VTG>RMC>RMA

Waypoint (Range, Bearing): RMB>BWC>BWR

Loran time difference: RMA>GLC>GTD

Water depth: DPT>DBT>DBK>DBS

Water temperature: MTW>MDA

Time: ZDA

XTE: RMB>XTE>APB

*1

*1

*1: calculate by magnetic drift.

Output data

NMEA0183 (Ver.1.5/2.0), RS-422

TLL(target data) and RSD

iv

Page 7

Standard Supply

emaNepyT.oNedoCytQskrameR

EQUIPMENT LISTS

tinUrennacS

tinUyalpsiD811-PDR—1

noitallatsnI

slairetaM

seirosseccA00460-30PF278-680-000tes101840-30PF,01460-30PF

straPerapS00221-30PS569-680-000tes1

Optional Supply

emaNepyT.oNedoCskrameR

460-0700-BSR-A01NX—

460-3700-BSR-A01NX— mpr84,2M2391roF

950-0700-BSR-A21NX—

950-3700-BSR-A21NX— mpr84,2M2491roF

00391-30PC419-680-000

01391-30PC519-680-000

02391-30PC619-680-000

03391-30PC719-680-000

tceleS

eno

tceleS

eno

tceleS

eno

mpr42,2M2391roF

mpr42,2M2491roF

,elbacrewop,10481-30PC

elbaclangism01

,elbacrewop,10481-30PC

elbaclangism51

,elbacrewop,10481-30PC

elbaclangism02

,elbacrewop,10481-30PC

elbaclangism03

*rezzuBlanretxE12-30PO790-030-000

reifitceR3243-UR344-030-000

001-7000FPS6A-JM732-521-000

050-2100FPS6A-JM424-431-000

ssorc

.yssAelbaC

001-2100FPS6A-JM718-331-000

ssorc

001-9000FPS6A-JM632-521-000

elbaClangiS050-3000FPS6A-JM306-711-000dneenotarotcennocP6/w,m5

tiKtnuoMhsulF541-30PO060-674-800tinuyalpsidroF

rettolPotuA01-PRA258-680-000.rennacsmpr42htiwelbaliavA

*rettolPradaR011-PR-

.yssAelbaC500-6000FPL42B-JM834-041-000rotcennocretrevnocelbaC

.desopxeerehwdetnuom

P6/wm01,rosnesgnidaehroF

thgiarts,sdnehtobtarotcennoc

m5,rednuosoediv,diavanroF

,sdnehtobtarotcennocP6/w

m01,rednuosoediv,diavanroF

,sdnehtobtarotcennocP6/w

,rednuosoediv,diavanroF

P6/wm01,rosnesgnidaeh

edisenotarotcennoc

lanretxefonoitcennoceht,5-XPIdradnatsfoorpretawsteemtinuyalpsidehthguohtnevE:*

ytirgetnithgitretaW.ssenfoorpretawtceffanacyalpsidetomerro/dnarettolpradar,rezzub

ebtondluohstinuyalpsideht,enodneebsahnoitacifidomesehtnehW.deetnaraugebtonnac

v

Page 8

1. MOUNTING

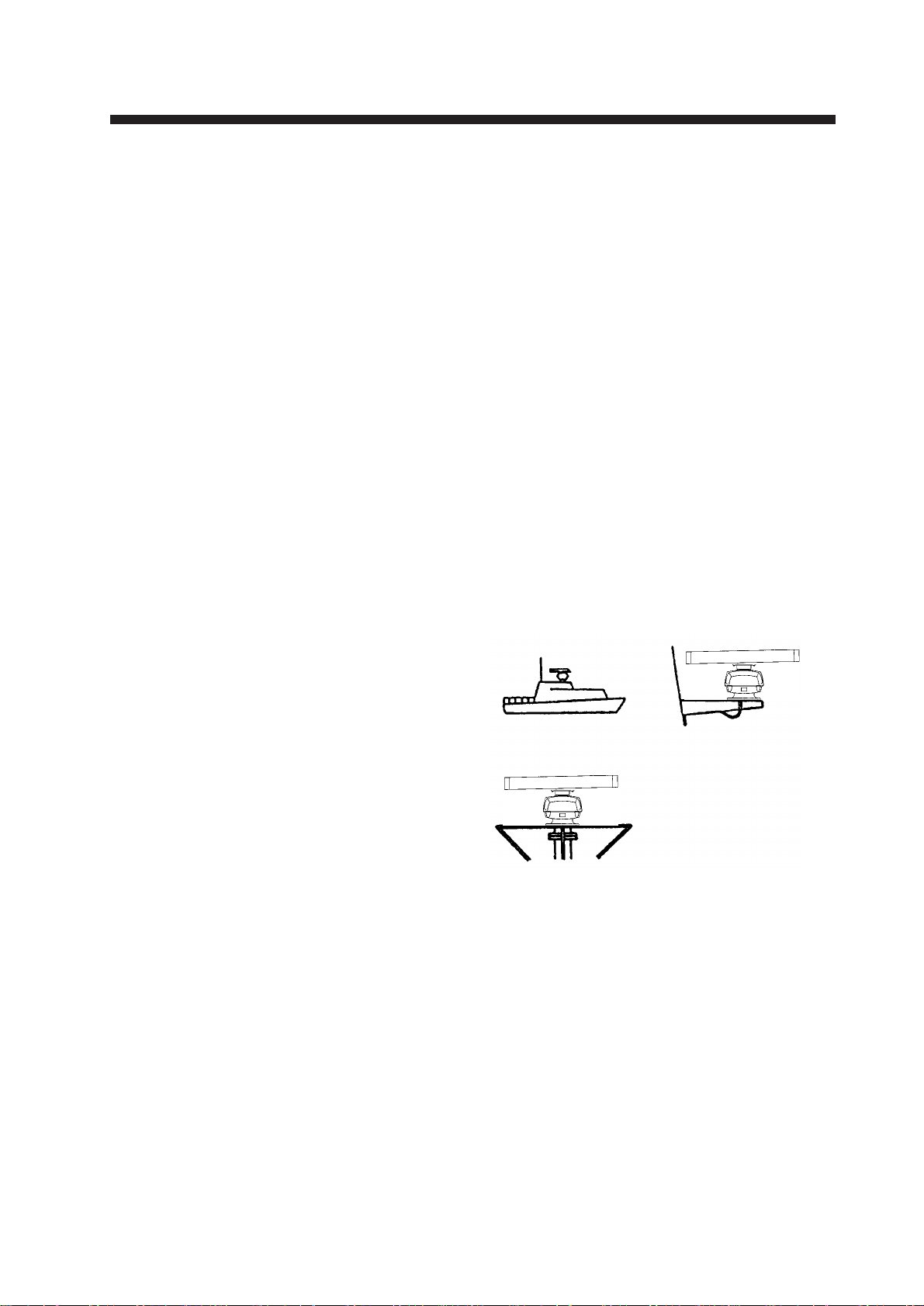

1.1 Mounting Methods for Scanner Unit

• The scanner unit is generally installed either on top of the wheelhouse or on the

radar mast on a suitable platform. Locate

the scanner unit where there is a good allround view. Any obstruction will cause

shadow and blind sectors. A mast for instance, with a diameter considerably less

than the width of the radiator, will cause

only a small blind sector, but a horizontal

spreader or crosstrees in the same horizontal plane as the scanner unit would be

a much more serious obstruction; you

would need to place the scanner unit well

above or below it.

• It is rarely possible to place the scanner

unit where a completely clear view in all

directions is available. Thus, you should

determine the angular width and relative

bearing of any shadow sectors for their influence on the radar at the first opportunity after fitting.

• Do not paint the radiator aperture, to ensure proper emission of the radar waves.

• When this radar is to be installed on larger

vessels, consider the following points:

• The signal cable run between the scanner and the display comes in lengths

of 10 m (standard), 15 m, 20 m and 30

m. Whatever length is used it must be

unbroken; namely , no splicing allowed.

• Deposits and fumes from a funnel or

other exhaust vent can adversely affect

the aerial performance and hot gases

may distort the radiator portion. The

scanner unit must not be mounted

where the temperature is more than

70 C.

As shown in the figure below, the scanner

unit may be installed on the bridge, on a common mast or on the radar mast.

• If you have a radio direction finder on your

boat, locate its antenna clear of the scanner unit to prevent interference to the direction finder. A separation of more than

two meters is recommended.

• To lessen the chance of picking up electrical interference, avoid where possible

routing the signal cable near other onboard

electrical equipment. Also avoid running

the cable in parallel with power cables.

• A magnetic compass will be affected if

placed too close to the scanner unit. Observe the following compass safe distances to prevent deviation of a magnetic

compass: Standard compass, 1.00 m,

Steering compass, 0.75 m.

(a) On bridgh

(c) Radar mast

Figure 1-1 Scanner unit mounting methods

(b) Common mast

1.2 Fixing Holes in Mounting Platform

Referring to the outline drawing on page D1, drill five holes in the mounting platform:

four holes of 15 mm diameter for fixing the

scanner unit and one hole of 25-30 mm diameter for the signal cable.

1-1

Page 9

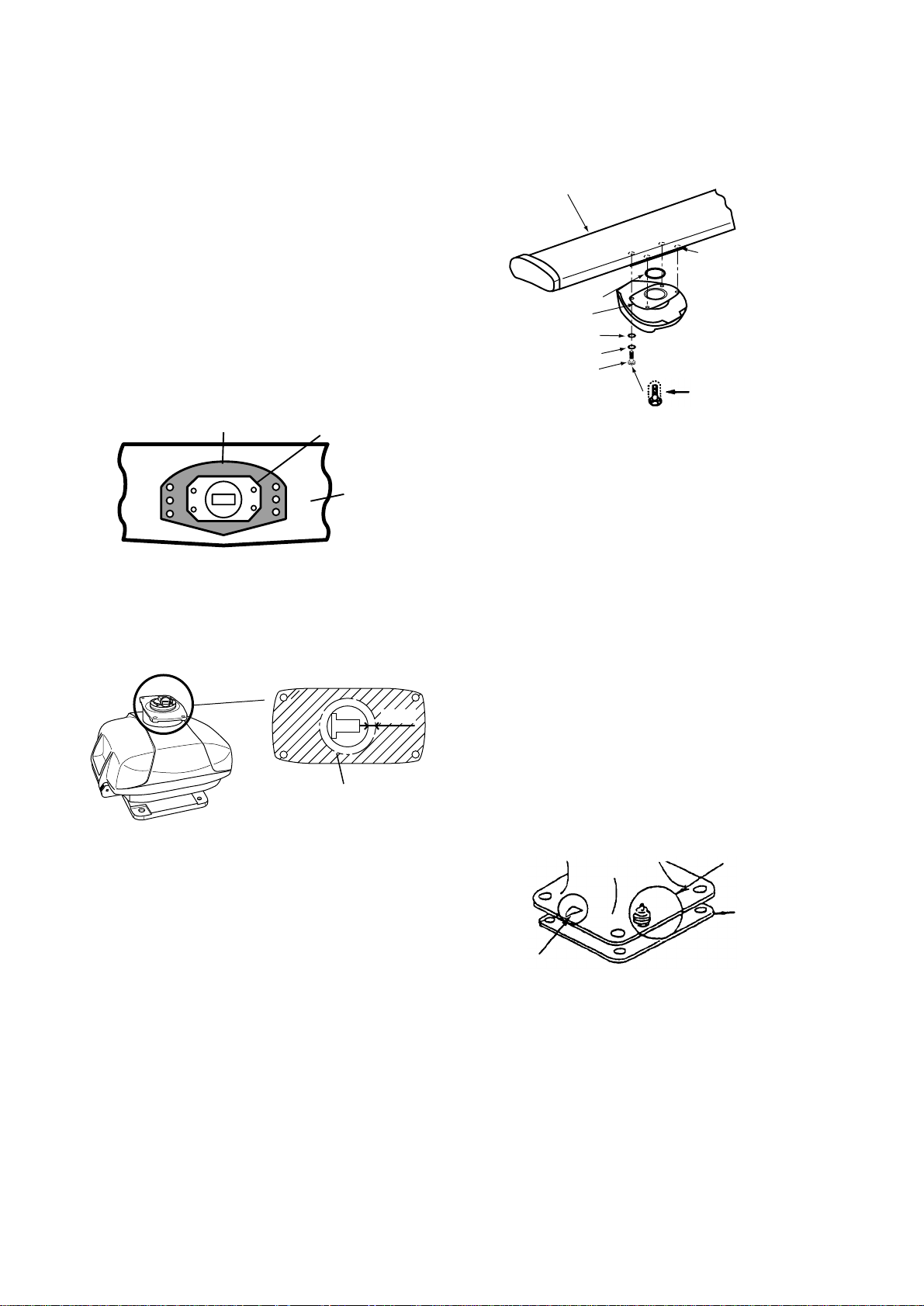

1.3 Fastening the Radiator to

the Radiator Bracket

For your reference, scanner installation materials list appears in the packing lists at the

back of this manual.

1. Remove the radiator cap from the radiator bracket.

2. Coat contacting surface between scanner radiator and radiator bracket with anticorrosive sealant as shown in Figure 1-2

(scanner unit XN10A) or Figure 1-3 (scanner unit XN12A).

Coat hatched area with

anticorrosive sealant.

Groove

Radiator

anticorrosive sealant. Fasten the scanner

radiator to the radiator bracket with the

radiator fixing bolts, flat washers and

spring washers.

Scanner

radiator

Coat threaded

holes with anti-

O-ring

Radiator bracket

Flat washer

Spring washer

Hex head bolt

(M8 x 30)

corrosive

sealant.

Coat bolts with

anticorrosive

sealant.

Figure 1-4 Fastening the radiator bracket to

the scanner unit chassis (shown: XN12A)

Figure 1-2 Coating the bottom of

scanner radiator for XN10A with

anticorrosive sealant

RADIATOR BRACKET

(top view)

10mm

Coat hatched area with

anticorrosive sealant.

Figure 1-3 Coating scanner bracket

for XN12A with anticorrosive sealant

3. Coat threaded holes on the scanner radiator with anticorrosive sealant.

4. Grease the O-ring and set it to the radiator bracket.

5. Lay the scanner radiator on the radiator

bracket.

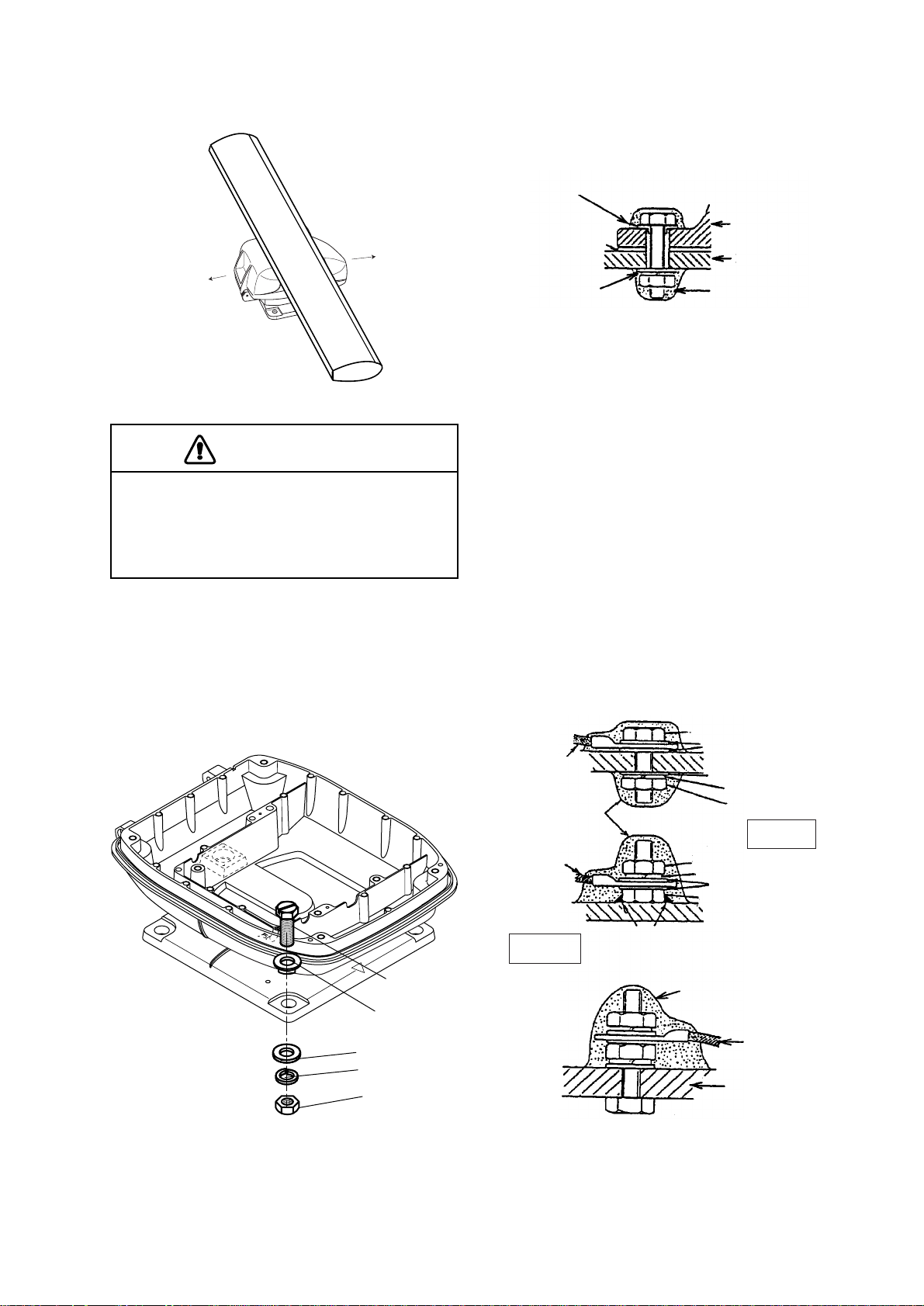

1.4 Mounting the Scanner Unit

The scanner unit can be mounted using the

fixing holes on the outside (240 x 240 nm) or

inside (140 x 150 nm) the scanner unit.

Outside fixing holes

Use the hex head bolt ( supplied ) to mount

the scanner unit as below.

1 . Lay the corrosion-proof rubber mat ( sup-

plied) on the mounting platform.

Ground

terminal

Rubber

mat

Bow mark

Figure 1-5 Location of rubber mat

6. Coat the radiator fixing bolts (4 pcs.) with

1-2

Page 10

2. Lay the scanner unit on the mounting platform, orienting it as shown in Figure 1-6.

BOW

STERN

4. Pass flat washers, spring washers and

nuts onto hex bolts. Fasten by tightening

nuts. Do not fasten by tightening the hex

bolts; seal washers may be damaged.

Seal washer

Scanner

Rubber mat

Flat washer

unit

Mounting

platform

Silicone

sealant

Figure 1-8 How to fasten scanner unit to

mounting platform

Figure 1-6 Scanner unit (Shown: XN12A)

CAUTION

Do not lift the scanner unit by the

radiator; lift it by the housing.

The radiator may be damaged.

3. Insert four hex bolts and seal washers

from the top of the scanner housing. Insert the seal washers with the larger diameter next to the bolt heads. Be sure

the seal washer , not other washers, is next

to bolt head.

5. Coat flat washers, spring washers, nuts

and exposed parts of bolts with anticorrosive sealant.

6. Prepare ground point in mounting platform

(within 300 mm of ground terminal on

scanner unit) using M6 x 25 bolt, nut and

flat washer.

7. Run the ground wire (RW-4747, 370 mm)

between the ground terminal and ground

point.

8. Coat ground terminal and ground point

with silicone sealant as shown in Figure

1-9.

Hex bolt

Flat washer

Ground

terminal

Ground

wire

Silicone

sealant

OR

Flat washer

Spring washer

Hex nut

GROUND

POINT

Hex nut

Spring washer

Flat washer

Hex nut

Hex bolt

Seal washer

Flat washer

Spring washer

Nut

Figure 1-7 Fixing the scanner unit chassis

GROUND

TERMINAL

Weld here.

Silicone

sealant

Ground

wire

Scanner

unit

Figure 1-9 How to coat ground point and

ground terminal with silicone sealant

1-3

Page 11

Fixing holes inside szcanner unit

1.5 Display Unit Mounting

This method requires removal of the RF unit

in the scanner unit to access inside fixing

holes. Use hex head bolts, flat washers,

spring washers and nuts (local supply) to

mount the scanner unit, confirming lengh of

bolts.

1. Loose four scanner bolts to open the scanner unit. Refer to Figure 11 for location.

Hex head bolt

M8X25

SUS 2pcs.

Hex head bolt

M10X20

SUS 4pcs.

Spring Washer

M10 SUS

4 pcs.

Upper chassis

RFunit

Cover

Square bushing

Lower chassis

Pan head screw

M3X8 4pcs.

Figure 10 Scanner unit chassis, upper

chassis separated

2. Unplug connector connected between upper and lower chassis.

3. Separate upper chassis from lower chassis by removing two hex head bolts.

4. Remove cover by unfastening four pan

head screws.

5. Remove connector from RF unit .

6. Remove RF unit by unfastening four hex

head bolts.

7. Lay the corrosion-proof rubber mat (supplied) on the mounting platform.

8. Fasten the lower chassis to the mounting

platform with hex head bolts, spring

washers, flat washers and nuts (local supply ), and then coat flat washers, nuts and

exposed parts of bolts with anticorrosive

sealant. Cut a slit in rubber bushing and

insert bolt into bushing. Do not use seal

washers.

9. Reassemble RF unit, cover and upper

chassis.

10. Set four knob caps (supplied) into

outside fixing holes.

11. Do steps 6-8 in “Outside fixing holes”.

1-4

Mounting considerations

When selecting a mounting location for the

display unit keep in mind the following points:

• Provide adequate space behind and

around the unit to permit circulation of air

and to provide convenient access to the

rear connection.

• Even though the picture is quite legible

even in bright sunlight, keep the display

unit out of direct sunlight or at least shaded

because of heat that can build up inside

the cabinet.

• Locate the display unit in a position where

you can view and operate it conveniently

but where there is no danger of salt or

fresh water spray or immersion.

• The orientation of the display unit should

be so the radar screen is viewed while the

operator is facing in the direction of the

bow. This makes determination of your

position much easier.

• Make sure you allow enough clearance

both to get to the connectors behind the

unit and to allow you to get your hands in

on both sides to loosen or tighten the

mounting knobs. Make sure you leave at

least a foot or so of “service loop” of cables

behind the unit so it can be pulled forward

for servicing or easy removal of the connectors.

• The compass safe distance of 0.75 meters

(standard compass) and 0.6 meters (steering compass) should be observed to prevent deviation of the magnetic compass.

• Even though the display unit meets waterproof standard IPX-5, the connection of

external buzzer, radar plotter and/or remote display can affect waterproofness.

W atertight integrity cannot be guaranteed.

When these modification has been done,

the display unit should not be mounted

where exposed.

Mounting

The display unit is designed to be mounted

on a tabletop or bulkhead.

1. Using the hanger as a template, mark

screw locations in the mounting location.

2. Fix the hanger to the mounting location

with five M6 tapping screws (supplied).

3. Fit the knob bolts to the display unit. In-

stall the display unit in the hanger. Tighten

the knob bolts securely.

Page 12

2. CONNECTIONS

2.1 Connecting the Signal Cable

Only the signal cable runs from the display

unit to the scanner unit. In order to minimize

the chance of picking up electrical interference, avoid where possible routing the signal cable near other onboard electrical

equipment. Also, avoid running the cable in

parallel with power cables. Pass the cable

through the hole and apply sealing compound

around the hole for waterproofing.

1. Open the scanner cover by loosening two

screws, and then fix the stay.

Stay

Cable gland

3. Unfasten the cable gland assembly (plate,

gasket, flat washer).

4. Pass the signal cable w/connector

through the bottom of the scanner unit

chassis. Pass the cable through the gland

assembly as shown below.

Figure 2-3 Passing the signal cable through

the cable gland assembly

5. Fasten the crimp-on lug on the shield to

one of the fixing bolts of the cable gland

assembly.

6. Position the signal cable so that no more

than 4 cm of the sheath is exposed as

shown in the figure below. Tighten fixing

bolts on the cable gland assembly .

Fixing screw

Figure 2-1 Scanner unit chassis,

cover opened

2. Fabricate the signal cable as shown below.

Figure 2-2 Fabrication of signal cable

Figure 2-4 How to fix signal

cable in cable gland

2-1

Page 13

7. Unfasten four screws shown in the figure

below.

Four screws

9. Connect the signal cable to the RTB

Board (03P9249), referring to the interconnection diagram and the figure below.

Note that connector VH2P is not used.

10.Attach three EMI cores to the signal cable

as shown below.

J821 VH9P

Figure 2-5 Scanner unit chassis,

cover opened

8. Pass the signal cable through the cable

protector.

Cable

protector

Figure 2-6 Scanner unit chassis,

cover opened

Lead in

cable here.

EMI core

RFC-13

Route cable along here.

J824 NH13P

J823 VH4P

Clamp

Figure 2-7 Scanner unit chassis,

cover opened

1 1.Fix the signal cable with the cable clamp.

12.Release the stay and close the cover.

Loosely fasten the cover fixing screws;

you will have to make some adjustments

inside after completion of wiring.

2.2 Display Unit Connections

Power cable connector

Signal cable connector

(DJ-1, waterproof)

Left: HDG connector

Middle: NMEA connector (for NAV)

Right: NMEA connector (for E/S)

Figure 2-8 Connection on the display unit

External equipment

connector

(For Remote Display,

External Alarm Buzzer

OP03-21 and Radar

Plotter, RP-110)

Ground terminal

CAUTION

Ground the equipment to prevent

mutual interference.

2-2

Page 14

Connection procedure

epyT.onedoCskrameR

001-7000FPS6A-JM732-521-000)m01(P6-P6

001-9000FPS6A-JM632-521-000)m01(rotcennoc/w

050-3000FPS6A-JM306-711-000)m5(rotcennoc/w

Heading sensor connection

1. Connect the power cable to the power

cable connector on the rear of the display

unit.

2. Connect the signal cable to connector DJ1 on the rear of the display unit.

3. Run a ground wire (local supply) between

the ground terminal on the rear of the display unit and the ship’s superstructure.

2.3 Connection of External

Equipment

Navigation aid, video sounder

connection

If your navigation aid can output data in IEC

61162 (NMEA 0183) format, your vessel’s

position in latitude and longitude, the range

and bearing to waypoint, speed and course

may be input to this radar, and be seen on

the screen.

Further if your video sounder can output

depth data in IEC61 162 (NMEA 0183) format,

depth can be displayed on the radar screen.

You will need an NMEA cable. The following

cables are optionally available.

epyT.onedoCskrameR

050-2100FPS6A-JM424-431-000)m5(P6-P6

001-2100FPS6A-JM718-331-000)m01(P6-P6

050-3000FPS6A-JM306-711-000)m5(rotcennoc/w

001-9000FPS6A-JM632-521-000)m01(rotcennoc/w

Heading signal can be connected to the

“HDG” connector. You will need a heading

sensor cable. The following cables are optionally available.

Input/Output Data List

ledoM

2M165VCF1J)5.1(3814tuO/nI

L185VCFAEMN)0.2/5.1(3816tuO/nI

L285VCFAEMN)0.2/5.1(3816tuO/nI

192VCFAEMN)0.2/5.1(3816tuO/nI

292VCFAEMN)0.2/5.1(3816tuO/nI

866VCFAEMN)5.1(3814tuO/nI

L006VCFAEMN)0.2/5.1(3816tuO/nI

0181PGTUO/NI)0.2/5.1(3816tuO/nI

2M0013PGTUO/NI)5.1(3816tuO/nI

2M0008PGAEMN)0.2/5.1(3814tuO/nI

2M0008SPAEMN)0.2/5.1(3814tuO/nI

08PG1ATAD)0.2/5.1(3816tuO/nI

08PG2ATAD)0.2/5.1(3816tuO/nI

C0161PGAEMN)0.2/5.1(3816tuO/nI

FC0161PGAEMN)0.2/5.1(3816tuO/nI

rotcennoC

emaN

ataDniPtuO/nI

Note: All plotters listed in the table above can

receive TLL data (radar target position).

This radar can output NA V data received from

a navaid to an echosounder.

J1352 (NMEA)

(TLL)

SPU9211

1932 MARK2/42 MARK2

INT9213

J1354

Figure 2-9 Data flow

Navaid

Echosounder

2-3

Page 15

2.4 Exchange of Fuse for 24/32V Power Supply

The power cable comes with a 10A fuse in

its the fuse its holder . This fuse is for use with

a 12V DC power supply. For 24V/32V DC

power supply, replace the fuse with the 5A

fuse (supplied) and attach 5A label (supplied)

to fuse holder .

CAUTION

Use the proper fuse.

Use of an improper fuse can damage the

equipment and void the warranty.

2.5 Checking the Installation

After completing the installation, it is a good

idea to recheck it to be sure all steps were

correctly done. Use the table below to check

the installation.

❑ The signal cable is securely retained

against the mast or mounting platform and

is free of interference from running rigging.

❑ The cable gland or entry on the deck, if

provided, is waterproofed.

❑ The power connections to the battery are

of correct polarity.

❑ The plugs at the rear of the display unit

are tightly fastened.

❑ The fuse in the power cable is 10A (12V)

or 5A (24V/32V DC).

2-4

Page 16

3. ADJUSTMENT

This section covers adjustment of the radar

after installation. You will need to

• adjust tune/video amplifier level

• enter antenna height

• align heading

• adjust sweep timing

• adjust main bang suppression

• select STC curve

• set a dead sector, and

• confirm magnetron heater voltage.

These adjustments are done through the in-

stallation setup menu.

3.1 Preparation

Most adjustments and initial settings may be

completed on the Installation Setup menu,

and you can display this menu as follows:

1. Turn off the radar. While pressing and

holding down the [GAIN] control (at least

three seconds), press the [POWER] key .

3.2 Adjusting Tuning/Video

Do the following to automatically adjust tuning and video amplifier level input.

1. Press the [STBY/TX] key to transmit.

WARNING

Before transmitting the radar make sure

no one is near the scanner unit, to prevent the potential risk of being struck

by the rotating scanner and exposure

to RF radiation hazard.

2. On the Installation Setup menu, select “8.

Tune/Video Adjustment” and press the

[ACQ/ENTER] key.

3. The unit automatically adjusts tuning and

video, displaying the following message.

[ Tune/Video Auto Adjustment ]

Now under correction.

Return to installation setup

menu after the correction.

2. Press the [MENU] key , select “OTHERS”

by using the omnipad, and press [ACQ/

ENTER] key.

3. Select “24. Installation Setup”.

4. Press the [ACQ/ENTER] key to open the

Installation Setup menu.

[ Installation Setup ]

Select item by omnipad

and press ENTER key.

1 . Nav Talker

2 . Depth Unit

3 . Temp Unit

4 . Hdg Sensor

5 . Key Beep

6 . Ant on Tx

7 . Dead Sector

8 . Tuning/Video Auto Adjustment

9 . Heading Alignment

10. Sweep Timing Adjustment

11. MBS Adjustment

12. Ant Height

13. STC Curve

14. Ope Mode

15. Hours in Use

16. Tx Hours

All

m

ßC

Magnet

Off

Rotate

180ß~180ß

Low

Sharp

Master

000001.5H

000000.0H

GPS

fa

ßF

Gyro

On

Stop

Mid

Std

Slave

LC

ft

High

Gntl

Figure 3-2 Tune/video auto

adjustment message

4. When adjustment is completed, the message disappears.

3.3 Entering Antenna Height

The STC curve changes with respect to antenna height above the waterline. Enter antenna height above the waterline to optimize

the STC curve.

1. Select “12. Ant Height” from the Installation Setup menu and press the [ACQ/ENTER] key.

2. Operate the omnipad to select antenna

height above the waterline; Low (3 m or

less), Mid (3 to 6 m) or High (6 to 10 m).

3. Press the [ACQ/ENTER] key.

Figure 3-1 Installation Setup menu

3-1

Page 17

3.4 Aligning Heading

3.5 Adjusting Sweep Timing

(Adjustment sector: 0~359.90)

You have mounted the scanner unit facing

straight ahead in the direction of the bow.

Therefore, a small but conspicuous target

dead ahead visually should appear on the

heading marker (zero degrees).

In practice, you will probably observe some

small bearing error on the display because

of the difficulty in achieving accurate initial

positioning of the scanner unit. The following

adjustment will compensate for this error.

1. Identify a suitable target (for example, ship

or buoy) at a range between 0.125 to 0.25

nautical miles, preferably near the heading marker. To lessen error, keep echoes

in the outer half of the picture by changing the range. Also, be sure the zoom and

off center functions are off.

2. Select “9. Heading Alignment” from the

Installation Setup menu and press the

[ACQ/ENTER] key. The following message appears:

[Heading Alignment]

Set EBL1 to center of target

dead ahead and press ENTER.

(Adjustment range: 0.000~4.266 nm)

This adjustment ensures proper radar performance, especially on short ranges. The

radar measures the time required for a transmitted echo to travel to the target and return

to the source. The received echo appears on

the display based on this time. Thus, at the

instant the transmitter is fired, the sweep

should start from the center of the display

(sometimes called sweep origin).

A trigger pulse generated in the display unit

goes to the scanner unit through the signal

cable to trigger the transmitter (magnetron).

The time taken by the signal to travel up to

the scanner unit varies, depending largely on

the length of the signal cable. During this period the display unit should wait before starting the sweep. When the display unit is not

adjusted correctly , the echoes from a straight

local object (for example, a harbor wall or

straight pier) will not appear with straight

edges – they will be seen as “pushed out” or

“pulled in” near the picture center. The range

of objects will also be incorrectly shown.

Correction 0.0°

<Press MENU for inst setup>

Figure 3-3 Heading alignment message

3. Operate the omnipad to bisect target selected at step 1 with the heading marker.

4. Press the [ACQ/ENTER] key.

5. As a final test, move the boat towards a

small buoy and confirm that the buoy

shows up dead ahead on the radar when

it is visually dead ahead.

(1) Correct

(2) Target pushed

inward

(3) Target pushed

outward

Figure 3-4 Examples of improper and

correct sweep timing

1. Transmit on the shortest range and confirm that the [GAIN] and [A/C SEA] controls are properly adjusted.

2. Visually select a target which forms a

straight line (for example, harbor wall,

straight pier).

3. Select “10. Sweep Timing Adjustment”

from the Installation Setup menu and

press the [ACQ/ENTER] key . The following message appears:

3-2

Page 18

[ Sweep Timing Adjustment ]

Use omnipad to straighten

target and press ENTER key.

1. Select “13. STC Curve” from the Installation Setup menu and press the [ACQ/ENTER] key.

Correction 0.000 nm

<Press MENU for inst setup>

Figure 3-5 Sweep timing adjustment

message

4. Operate the trackball to straighten the target selected at step 2, and then press the

[ACQ/ENTER] key.

3.6 Adjusting MBS

(Adjustment range: 0.00~0.25)

Main bang, a large filled circle which appears

at the display center on short ranges, can be

suppressed as follows:

1. Transmit on long range about 10 minutes.

2. Adjust the gain to show a small amount

of noise on the display.

2. Select STC curve desired;

Sharp: The effective range of the [A/C

SEA] control is relatively short.

Std: Between Sharp and Gentle.

Gntl (Gentle): The effective range of

the [A/C SEA] control is relatively long.

3. Press the [ACQ/ENTER] key.

3.8 Setting a Dead Sector

When the scanner is installed at a close distance in front of the wheelhouse, the radar

should be set not to transmit within that area,

to prevent microwave hazard. The dead sector area graphic can be turned on/off on the

OTHERS menu.

1. Select “7. Dead Sector” from the Installa-

tion Setup menu and press the [ACQ/ENTER] key.

3. Change to the 0.125 nautical mile range

and adjust the [A/C SEA] control.

4. Select “1 1. MBS Adjustment” from the Installation Setup menu and press the

[ACQ/ENTER] key. The following message appears:

[MBS Adjustment]

Set value by T-ball

and press ENTER key.

Correction 000

<Press MENU for inst setup>

Figure 3-6 MBS adjustment message

5. Operate the trackball to suppress main

bang (adjustment range: 000 to 025).

6. Press the [ACQ/ENTER] key.

3.7 Selecting STC Curve

The STC curve changes with respect to the

antenna height above the waterline. The default STC curve can be maintained in most

cases. If necessary the STC curve can be

changed as follows:

2. Operate the omnipad to enter starting

point of sector (in figures).

3. Press the [ACQ/ENTER] key.

4. Operate the omnipad to enter ending point

of sector (in figures, Max: 270°).

5. Press the [ACQ/ENTER] key.

Note: This setting should be done after other

adjustment are finished.

Dead

sector

Figure 3-7 Dead sector

3-3

Page 19

3.9 Checking Magnetron Heater

Unf

5. Confirm that the meter reads 7.5 V ±0.1 V .

Voltage

Magnetron heater voltage is formed on the

MD Board of the scanner unit, and is

preadjusted at the factory for use with any

length of signal cable. Therefore no adjustment is required. However , check magnetron

heater voltage as follows:

1. Turn on the radar and leave it in

by.

2. Open the scanner cover.

3. Unfasten two screws to remove the RF

section cover.

stand-

DANGER

ELECTRICAL SHOCK HAZARD

This check is done with the

power on — DO NOT touch

the magnetron.

6. Close the scanner cover and tighten the

cover fixing screws.

Magnetron

asten two

screws.

Figure 3-8 Scanner unit, cover opened

4. Connect a multimeter, set to 10 VDC

range, between test point J825#4 and

J825#6(GND) on the RTB Board

(03P9249).

Measure voltage

at this connector

(J825).

Figure 3-9 Scanner unit, cover removed

3-4

Page 20

4. INSTALLATION OF ARP-10 (OPTION)

NOTICE

This option is not available

with 48 rpm scanner unit.

4.1 Necessary Parts

emaNepyT.oNedoCytQ

draoB01-PRA7009P81039-674-8001

recapS02-QS056-108-0004

rehsaWgnirpSW1915C3M402-468-0004

wercSdaeHnaPW0072C8x3M404-188-0006

wercSdaeHnaP

*rehsaw/w

8x3M

01MRWS

477-508-0003

(3)Faster the ARP-10 Board to the chas-

sis with three pan head screws and

springs washers.

Front

Spring Washer

Spacer

SQ-20 3 pcs.

Pan Head

Screw

M3 x 8 3 pcs.

ARP-10 Board

18P9007

M3 3 pcs.

P107

J107

SPU Board

SPU9211

$

$

Note: Remaining hardware may be discarded.

*Not used.

4.2 Mounting

1. Turn off the power. Remove the cover

from the display unit as follows:

1 Unfasten four binding screws (M4 x 10).

2 Unfasten six binding screws (M3 x 10).

3 Remove three rubber covers to unfas-

ten three hex nuts.

4 Loosen two hex nuts.

1

2

4

1

3

Figure 4-1 Display unit, rear view

2. Fasten the ARP-10 Board to the righthand chassis of the display unit, using the

pan head spacers, screws, and washers

(supplied) as follows.

(1)Attach three spacers.

(2) Attach the P107 connector from the

ARP-10 Board to J107 connector on

the SPU Board.

1

2

1

Figure 4-2 How to mount the

ARP-10 Board

4.3 Adjustments

Input signal

1. Connect the gyrocompass. Turn on the

radar and transmit.

2. Press the [MENU] key and select the

OTHERS menu

3. Select “23. Self T est” and press the [ACQ/

ENTER] key . Confirm that the ARP-10 test

results show OK for SPEED, COURSE,

TRIGGER< BP and HP.

Video signal

Confirm the following on the ARP-10 test display:

• Video is “OK.”

• Adjust the GAIN, A/C and A/C RAIN controls so FE-DATA1 and FE-DATA2 indications on the ARP-10 TEST show less

than 1,000. Also, raise/lower the gain

while watching the FE-DATA1 and FEDATA2 indications. Confirm that the FEDATA1 and FE-DATA2 indications rise/

lower according to GAIN control adjustment.

4-1

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Loading...

Loading...