MARINE RADAR MODEL1823C-BB

Back

MARINE RADAR MODEL1833C-BB

MARINE RADAR MODEL1933C-BB

MARINE RADAR MODEL1943C-BB

MARINE RADAR MODEL1953C-BB

COLOR VIDEO PLOTTER GD-1900C-BB

PRINTED IN JAPAN

Thepaperusedinthismanual

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*

0

*

0

*

0

*

0

A

*

I

*

I

*

I

*

I

Nishinomiya 662-8580, JAPANNishinomiya 662-8580, JAPAN

Telephone :Telephone : 0798-65-21110798-65-2111

FaxFax 0798-65-42000798-65-4200

::

iselementalchlorinefree.

Your Local Agent/Dealer Your Local Agent/Dealer

ll rights reserved.

ll rights reserved.

Pub. No.Pub. No. IME-35320-DIME-35320-D

((AKMU

KMU ))

M1803C-BB_GD1900C-BBM1803C-BB_GD1900C-BB

Printed in JapanPrinted in Japan

FIRST EDITION :FIRST EDITION :DEC.DEC. 20032003

DD ::MAY.MAY. 20, 200520, 2005

0014791603*

0014791603*

0014791603*

0014791603*

* 0 0 0 1 4 7 9 1 6 0 3 ** 0 0 0 1 4 7 9 1 6 0 3 *

ME35320D00*

ME35320D00*

ME35320D00*

ME35320D00*

* I M E 3 5 3 2 0 D 0 0 ** I M E 3 5 3 2 0 D 0 0 *

SAFETY INSTRUCTIONS

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service platform

from which to install the antenna unit.

Serious injury or death can result if someone falls from the radar mast.

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Only qualified personnel

should work inside the

equipment.

Wear a safety belt and hard

hat when working on the

antenna unit.

Serious injury or death can

result if someone falls from

the radar mast.

WARNING

Radio Frequency

Radiation Hazard

The radar antenna emits electromagnetic

radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never

look directly into the antenna aperture from

a close distance while the radar is in

operation or expose yourself to the transmitting antenna at a close distance.

Distances at which RF radiation levels of

100 and 10 W/m

table below.

Note: If the antenna unit is installed at a

close distance in front of the wheel house,

your administration may require halt of

transmission within a certain sector of

antenna revolution. This is possible - Ask

your FURUNO representative or dealer to

provide this feature.

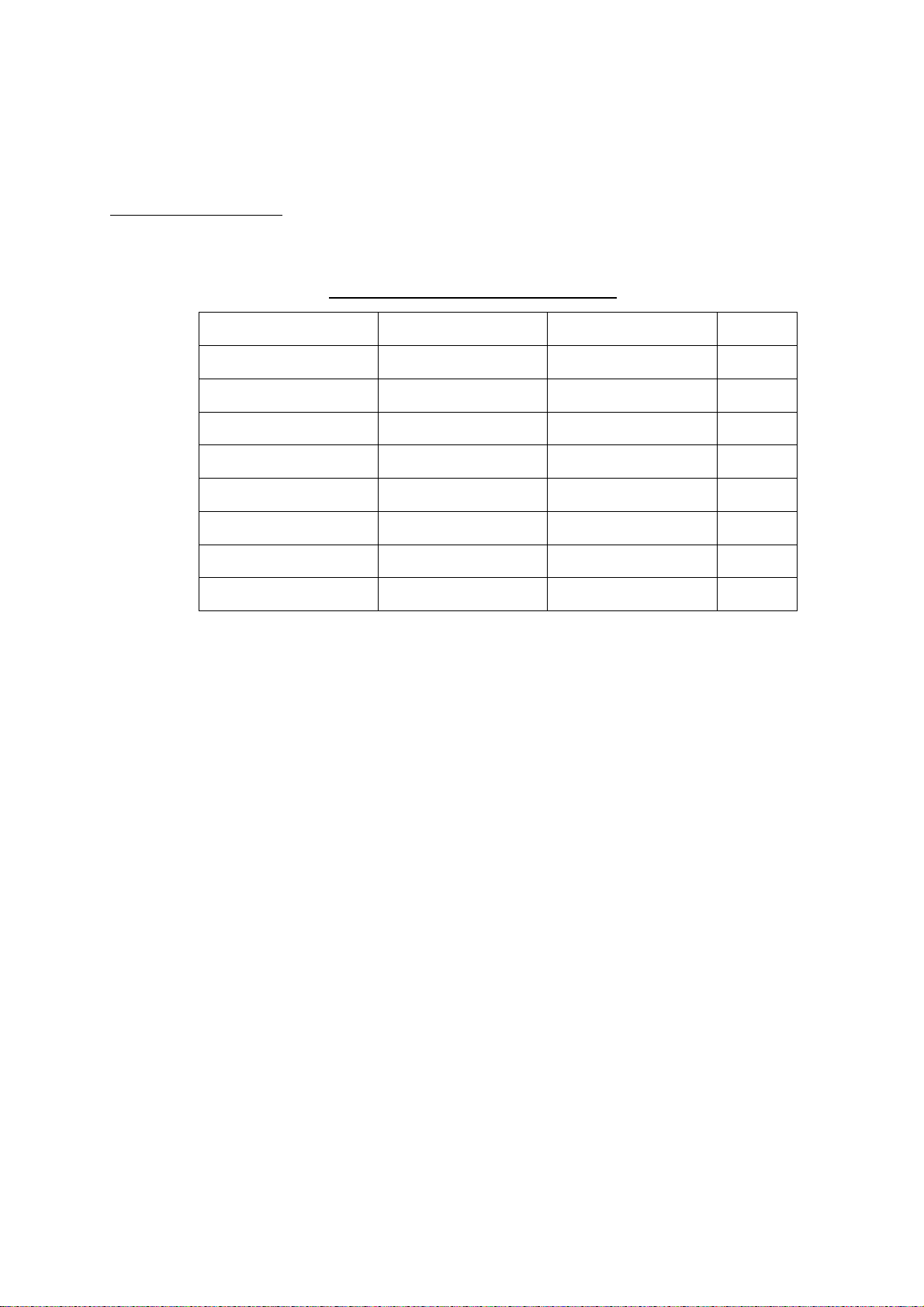

MODEL

MODEL

1823C-BB

2

exist are given in the

Distance to

100 W/m

point

Nil

Distance to

2

10 W/m

point

0.5 m

2

CAUTION

Observe the following compass safe

distances to prevent deviation of a

magnetic compass.

Steering

1.10 m

0.30 m

0.70 m

0.80 m

0.80 m

0.75 m

0.95 m

0.60 m

Processor unit

Control unit

MODEL1823C-BB antenna unit

MODEL1833C-BB antenna unit

MODEL1933C-BB antenna unit

MODEL1943C-BB antenna unit

MODEL1953C-BB antenna unit

Power supply unit (1953C-BB)

Memory card I/F unit

Standard

1.75 m

0.45 m

1.25 m 0.85 m

0.90 m

1.00 m

1.00 m

1.00 m

1.40 m

0.90 m

MODEL

1833C-BB

MODEL

1933C-BB

MODEL

1943C-BB

MODEL

1953CBB

Nil

Nil

Nil

XN12A

Nil

XN13A

1.8 m

2.7 m

1.9 m

2.5 m

2.3 m

i

TABLE OF CONTENTS

EQUIPMENT LISTS.................................................................................................iii

SYSTEM CONFIGURATIONS..................................................................................v

1. MOUNTING..........................................................................................................1-1

1.1 Mounting the Cont rol Unit...........................................................................................................1-1

1.2 Mounting the Pr ocessor Unit......................................................................................................1-4

1.3 Mounting the Antenna Unit of MODEL1823C-BB........................................................................1-5

1.4 Mounting the Antenna Unit of MODEL1833C-BB........................................................................1-13

1.5 Mounting the Antenna Unit of MODEL1933C-BB/ 1943C- B B /1953C-BB...................................... 1-18

1.6 Mounting the Power Supply Unit of MODEL1953C-BB ...............................................................1-27

1.7 Mounting the Mem ory Car d Int erface Unit ..................................................................................1-28

2. WIRING ................................................................................................................ 2-1

2.1 Standard Wiring .........................................................................................................................2-1

2.2 Wiring of Power Supply Unit (MODEL1953C-BB only)................................................................2-4

2.3 Connection of CU-200................................................................................................................2-6

3. ADJUSTMENT ..................................................................................................... 3-1

3.1 How to Access the Installation Menu..........................................................................................3-1

3.2 NETWORK SETUP Menu..........................................................................................................3-2

3.3 RADAR SETUP Menu................................................................................................................ 3-4

3.4 Checking Magnetron Heater Voltage..........................................................................................3-11

3.5 Navigation Data Source.............................................................................................................3-11

3.6 Setting up Data Ports.................................................................................................................3-16

3.7 Remote System Setting..............................................................................................................3-18

4. OPTIONS..............................................................................................................4-1

4.1 External Buzzer Connec tion....................................................................................................... 4-1

4.2 ARP Kit ARP- 11..........................................................................................................................4-2

PACKING LISTS ......................................................................................................A-1

OUTLINE DRAWINGS ............................................................................................. D-1

INTERCONNECTION DIAGRAMS...........................................................................S-1

ii

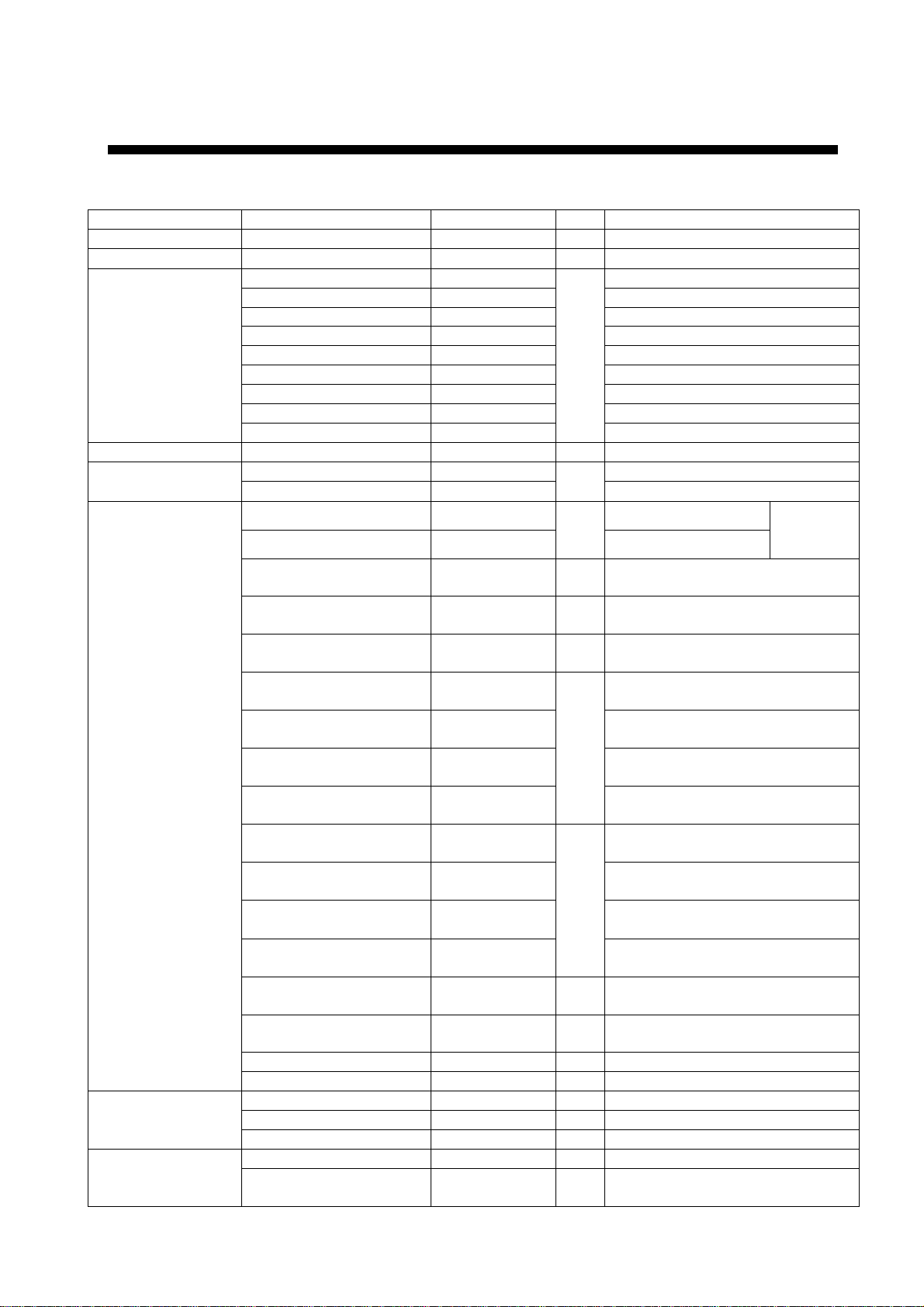

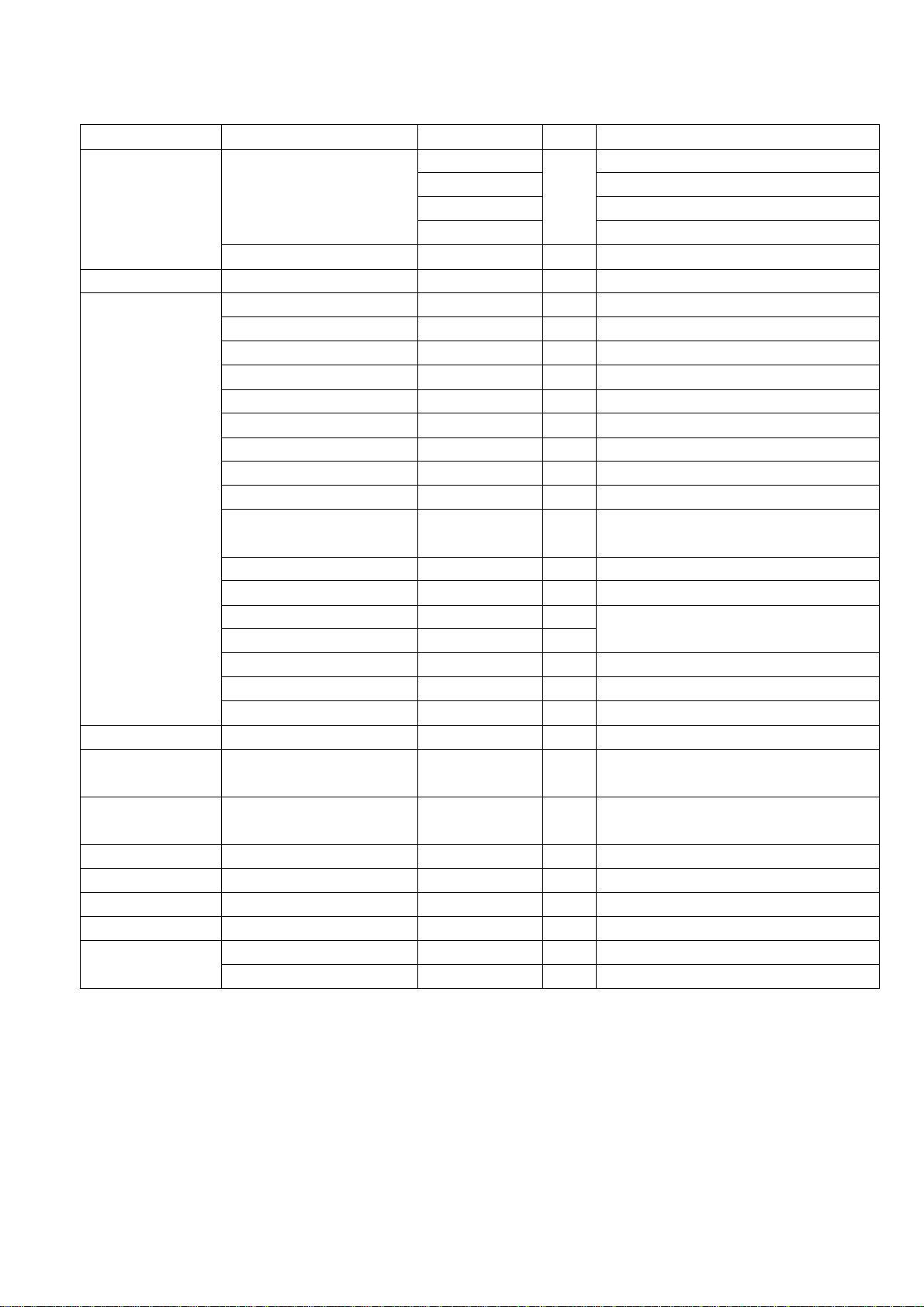

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Control unit RCU-017 - 1

Processor unit RPU-014 - 1

RSB-0094-0075 - MODEL1823C-BB

RSB-0071-057 - MODEL1833C-BB

XN10A-RSB-0070-064 - MODEL1933C-BB, 24 rpm

XN10A-RSB-0073-064 - MODEL1933C-BB, 48 rpm

Antenna unit

Power supply unit PSU-005 - 1 For MODEL 1953C-BB

interfac e unit

Installation

materials

Accessories

Spare parts

XN12A-RSB-0070-059 - MODEL1943C-BB, 24 rpm

XN12A-RSB-0073-059 - MODEL1943C-BB, 48 rpm

XN12A-RSB-0072-060 - MODEL1953C-BB, 4ft, 24 rpm

XN12A-RSB-0073-060 - MODEL1953C-BB, 4ft, 48 rpm

XN13A-RSB-0072-060 -

CU-200-NAVBB-5 - W/5m cables Memory card

CU-200-NAVBB-10 - 1 W/10m cables

CP03-26000 000-080-049 MJ-A7SPF0006-050

CP03-26100 000-080-536

CP03-25900 000-080-542 1

CP03-25401 008-443-160 1set

CP03-16901 008-478-750 1set

CP03-21800 000-080-014

CP03-21810 000-080-015

CP03-21820 000-080-016

CP03-21830 000-080-017

CP03-22000 000-080-021

CP03-22010 000-080-022

CP03-22020 000-080-023

CP03-22030 000-080-024

CP03-18401 008-503-360 1

CP03-22901 008-523-690 1

CP03-24500 000-080-191 1 For 1953C-BB, power supply unit

CP03-27401 008-539-520 1 For CU-200 flush mount

FP03-09301 008-522-970 1set Card remover

FP03-10001 008-537-530 1 For RCU-017

06-021-2121 100-320-101 1 Hard cover

SP03-14501 008-444- 420 1set Fuses, for processor unit

SP03-14001 000-080-018 1set

1

MODEL1953C-BB, 6ft, 24 rpm

1set

MJ-A7SPF0006-100

For Processor unit

MJ-A3SPF0018-050Z, CP03-25901

For MODEL1823C-BB

antenna unit

For MODEL1833C-BB

antenna unit

For MODEL1823C-BB/1833C-BB

10 m signal cable

For MODEL1823C-BB/1833C-BB

15 m signal cable

1

For MODEL1823C-BB/1833C-BB

20 m signal cable

For MODEL1823C-BB/1833C-BB

30 m signal cable

For 1933C-BB/1943C-BB/1953C-BB

10 m signal cable

For 1933C-BB/1943C-BB/1953C-BB

15 m signal cable

1

For 1933C-BB/1943C-BB/1953C-BB

20 m signal cable

For 1933C-BB/1943C-BB/1953C-BB

30 m signal cable

For 1933C-BB/1943C-BB/1953C-BB

antenna unit

For 1933C-BB/1943C-BB/1953C-BB

antenna radiator XN10A/XN12A

Fuses, for power supply unit

(1953C-BB only)

For control

unit

iii

Optional supply

Name Type Code No. Qty Remarks

000-013-484 For GD-1900C-BB, 100 VAC

Rectifier

PR-62

RU-3423 000-030-443 1 For MODEL series

External buzzer XH3-BZ-L970 000-146-422 1

MJ-A6SPF0014-010 000-144-421 1 For NavNet, 1 m

MJ-A6SPF0014-050 000-144-422 1 For NavNet, 5 m

MJ-A6SPF0014-100 000-144-423 1 For NavNet, 10 m

MJ-A6SPF0014-200 000-144-424 1 For NavNet, 20 m

MJ-A6SPF0014-300 000-144-425 1 For NavNet, 30 m

MJ-A6SPF0012-050 000-134-424 1 For navaid, 5 m, 6P-6P cross

MJ-A6SPF0012-100 000-133-817 1 For navaid, 10 m, 6P-6P cross

MJ-A6SPF0003-050 000-117-603 1 w/6P connector, 5 m

Cable assy.

MJ-A6SPF0009-100 000-125-236 1 w/6P connector, 10 m

MJ-A6SPF0007-100 000-125-237 1

MJ-A7SPF0007-050 000-144-418 1 w/7P connector, 5 m

MJ-A6SRMD/TM11AP8-005

3COX-2P-6C 5M 000-146-500 1

3COX-2P-6C 10M 000-146-501 1

MJ-B24LPF0010-100 000-147-880 1 For remote display, 10 m

MJ-B24LPF0010-200 000-147-881 1 For remote display, 20 m

MJ-B24LPF0010-300 000-147-882 1 For remote display, 30 m

ARP kit ARP-11 008-523-050 1 ARP Board, for radar only

Mounting

bracket (1)

Mounting

bracket (2)

OP03-92 008-445-070 1 For MODEL1833C-BB

OP03-93 008-445-080 1 For MODEL1823C-BB

Chart card - - Specified when ordering.

RAM card 00RAM08MC-0015 004-376-740 1 8 MB

EMI core CP03-24801 008-481-410 1

Ring unit MU3721 000-144-645 1

Desktop mount

kit

FP03-09901 008-443-540 1

FP03-10201 008-539-530 1

000-013-485 For GD-1900C-BB, 110 VAC

1

000-013-486 For GD-1900C-BB, 220 VAC

000-013-487

For GD-1900C-BB, 230 VAC

For compass, 10 m,

6P-6P straight

000-144-463 1 Adapter cable for HUB

For monitor D-sub 15

For remote display cable connection

For trackball of control unit

For control unit RCU-017

For memory card IF CU-200

iv

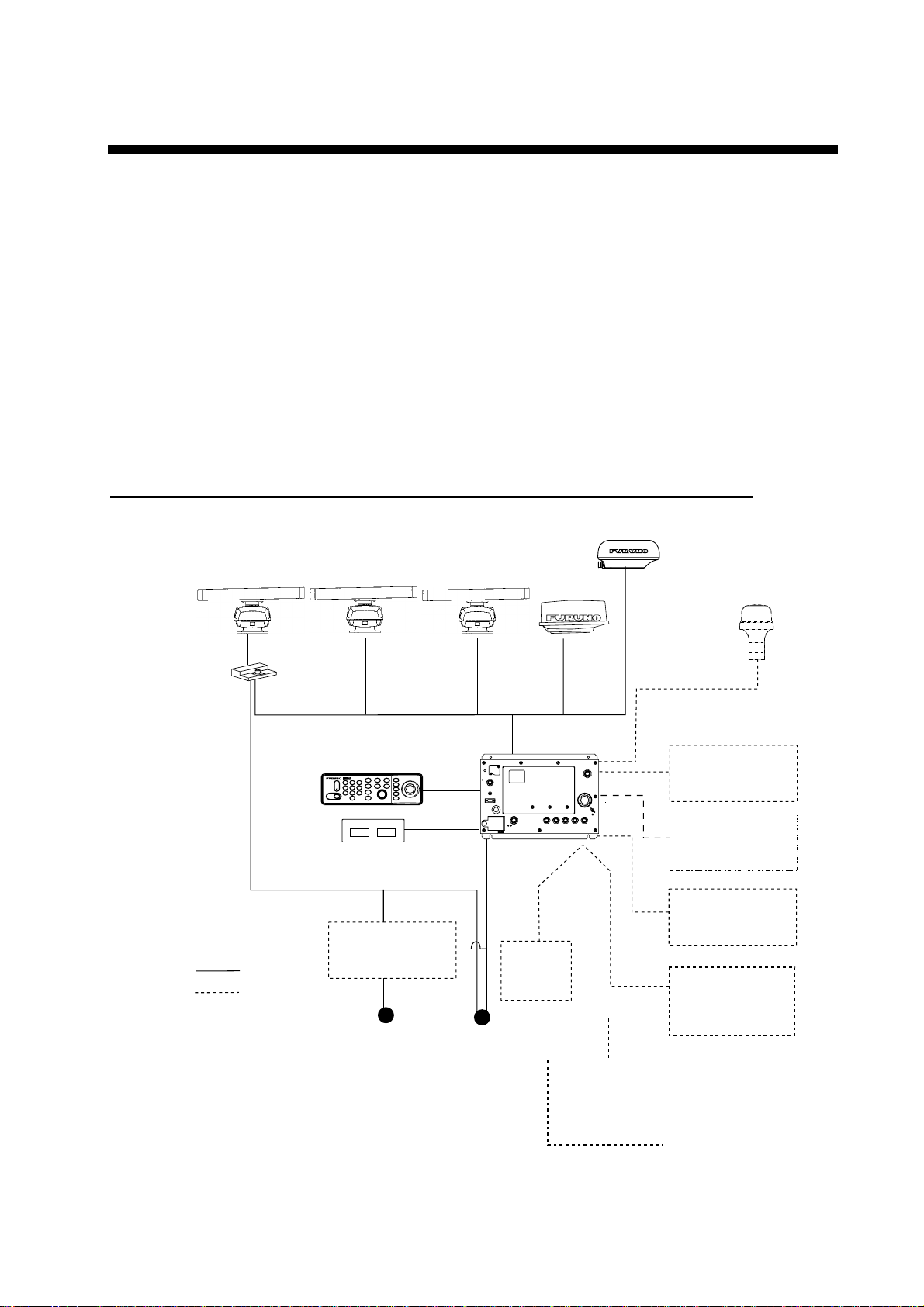

SYSTEM CONFIGURATIONS

All NavNet products incorporate a "network circuit board" to integrate each NavNet product

on board through an optional LAN cable (Ethernet 10BASE-T). Each NavNet product is

assigned an IP address to enable transfer of images between other NavNet products. For

example, video plotter pictures can be transferred to a radar and vice versa. Pictures

received via the NavNet may be adjusted at the receiving end.

The number of processor units which may be installed depends on the number of network

sounder connected. For a system incorporating three or more products, a "hub" is required

to process data.

For one network sounder: one radar and three plotters, or four plotters

For two network sounder: one radar and two plotters, or four plotters

NavNet system (Model 1823C-BB/1833C-BB/ 1933C-BB/1943C-BB/1953C-B B)

Power Supply

Unit PSU-005

MODEL

1953C-BB

:Standard

: Option

Antenna Unit

MODEL

1933C-BB

MODEL

1943C-BB

Control unit

RCU-017

SAVESAVE

CLEARCLEAR

MOBMOB

GHIGHI

DEFDEF

ABCABC

33

2211

RANGERANGE

ALARMALARM

DISPDISPEEMENUMENU

PQRPQR

MNOMNO

JKLJKL

66

55

44

GAINGAIN

VWXVWX

YZ&YZ&

STUSTU

99

88

77

POWERPOWER

TXTX

EBLEBL

_'#_'#

00

VRMVRM

PUSH TO ENTERPUSH TO ENTER

HIDEHIDE

AA

SHOWSHOW

BB

CC

DD

POWER

F.G.

321

GND

OUTPUT

12 VDC

NTSC/PAL

RGB OUT

OPTION

CARD SLOT

Memory card

interface unit CU-200

Rectifier

RU-3423

100/110/115/220/230 VAC

12 - 24 VDC*

1φ, 50/60 Hz*

*: The power for the power supply unit

and display unit must be drawn from

the same power source.

MODEL1823C-BB

MODEL

1833C-BB

Processor unit

RPU-014

DATA 3

NETWORK

CONT DATA 1DATA 2

INPUT

2

1

12-24 VDC

3

GND

Facsimile

Receiver

FAX-30

ETR-6/10N

SLAVE DISPLAY

DJ-1

Network

Sounder

ETR-30N

GPS receiver

GP-310B/320B

Plotter, etc.

monitor

(Owner supply)

(See next page)

Heading

sensor

Other NavNet

system

(GD-1900C-BB etc.)

NavNet system (M odel 1823C-BB/1833C-BB/1933C-BB/1943C-BB/1953C-BB)

v

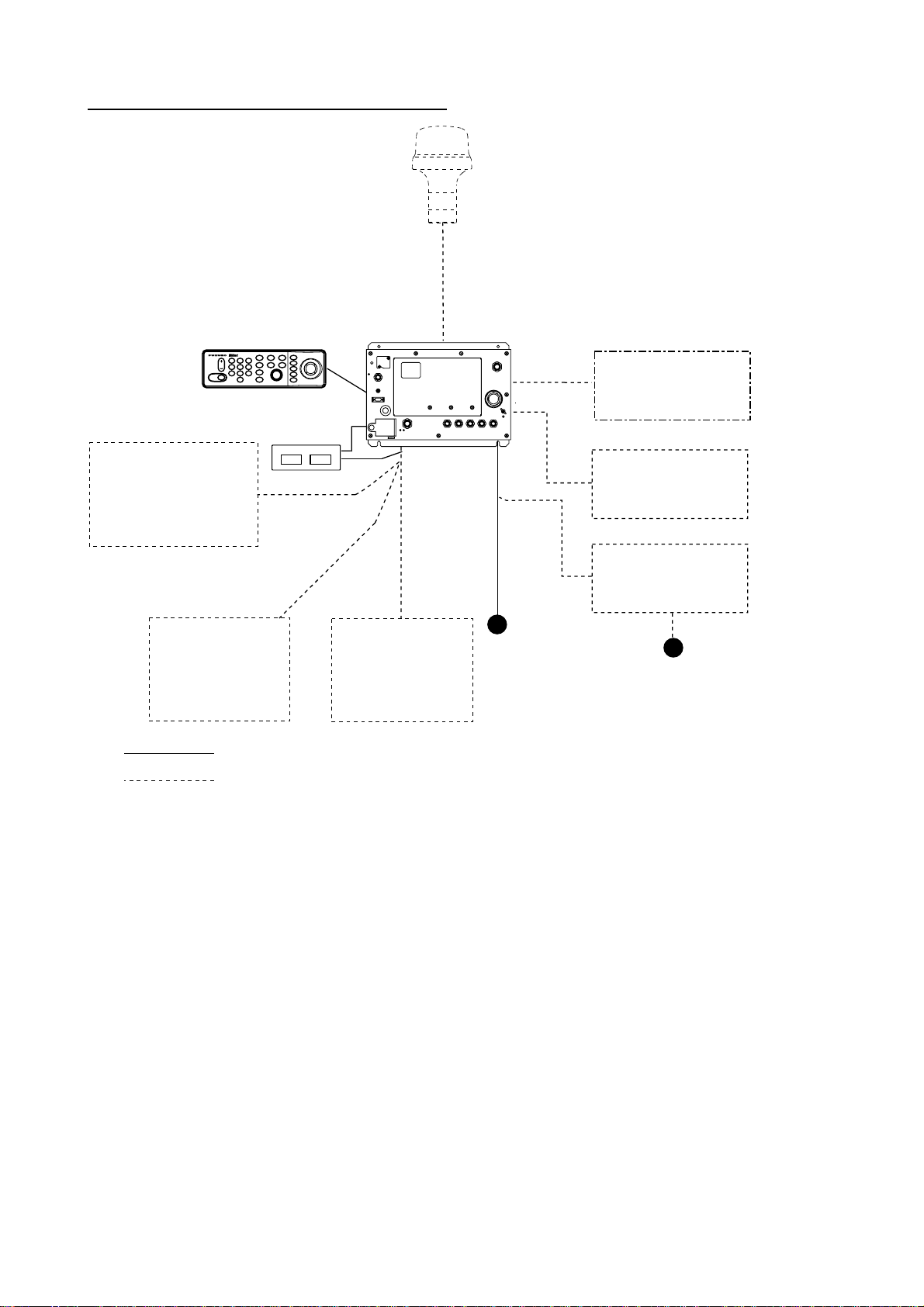

Singl e- unit NavNet system (GD-1900C-BB)

GPS receiver

GP-310B/320B

Control unit

RCU-017

Memory card

interface unit CU-200

Other NavNet

system

SAVESAVE

CLEARCLEAR

MOBMOB

GHIGHI

DEFDEF

ABCABC

33

2211

RANGERANGE

ALARMALARM

DISPDISPEEMENUMENU

PQRPQR

MNOMNO

JKLJKL

66

55

44

GAINGAIN

VWXVWX

YZ&YZ&

STUSTU

99

88

77

POWERPOWER

TXTX

EBLEBL

_'#_'#

00

VRMVRM

PUSH TO ENTERPUSH TO ENTER

Processor unit

HIDEHIDE

AA

SHOWSHOW

BB

CC

DD

RPU-014

POWER

F.G.

321

GND

OUTPUT

12 VDC

NTSC/PAL

RGB OUT

OPTION

CARD SLOT

SLAVE DISPLAY

DJ-1

DATA 3

NETWORK

INPUT

2

1

12-24 VDC

3

GND

CONT DATA 1DATA 2

Monitor

(Owner supply)

Plotter, etc.

(Model 1833C-BB, etc.)

Rectifier

PR-62

Facsimile

Receiver

FAX-30

Network

Sounder

ETR-6/10N

ETR-30N

12 - 24 VDC

100/110/115/220/230 VAC

1φ, 50/60 Hz

: Standard

: Option

Single-unit NavNet system (GD-1900C-B B)

Note: The output signal from the processor unit for a monitor is as follows.

RGB signal: Analog 0.7 Vpp, Output impedance 75 Ω

Synchro signal: H 31.5 kHz, V 60Hz (Separate), TLL level

(VGA signal)

Choose a monitor whose aspect ratio is 4:3, for example, VGA, SVGA, XGA, SXGAX,

VXGA, QXGA, etc

vi

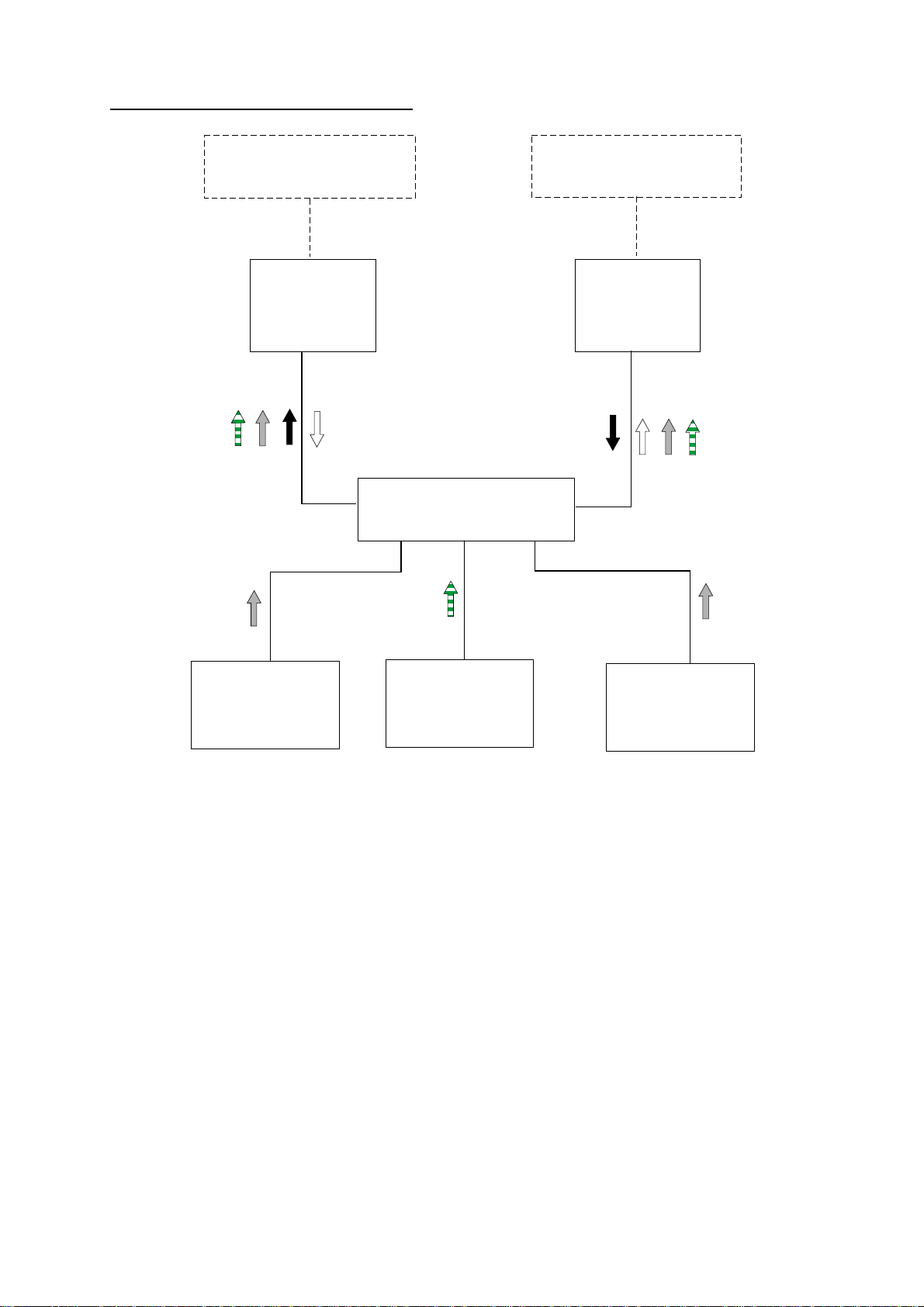

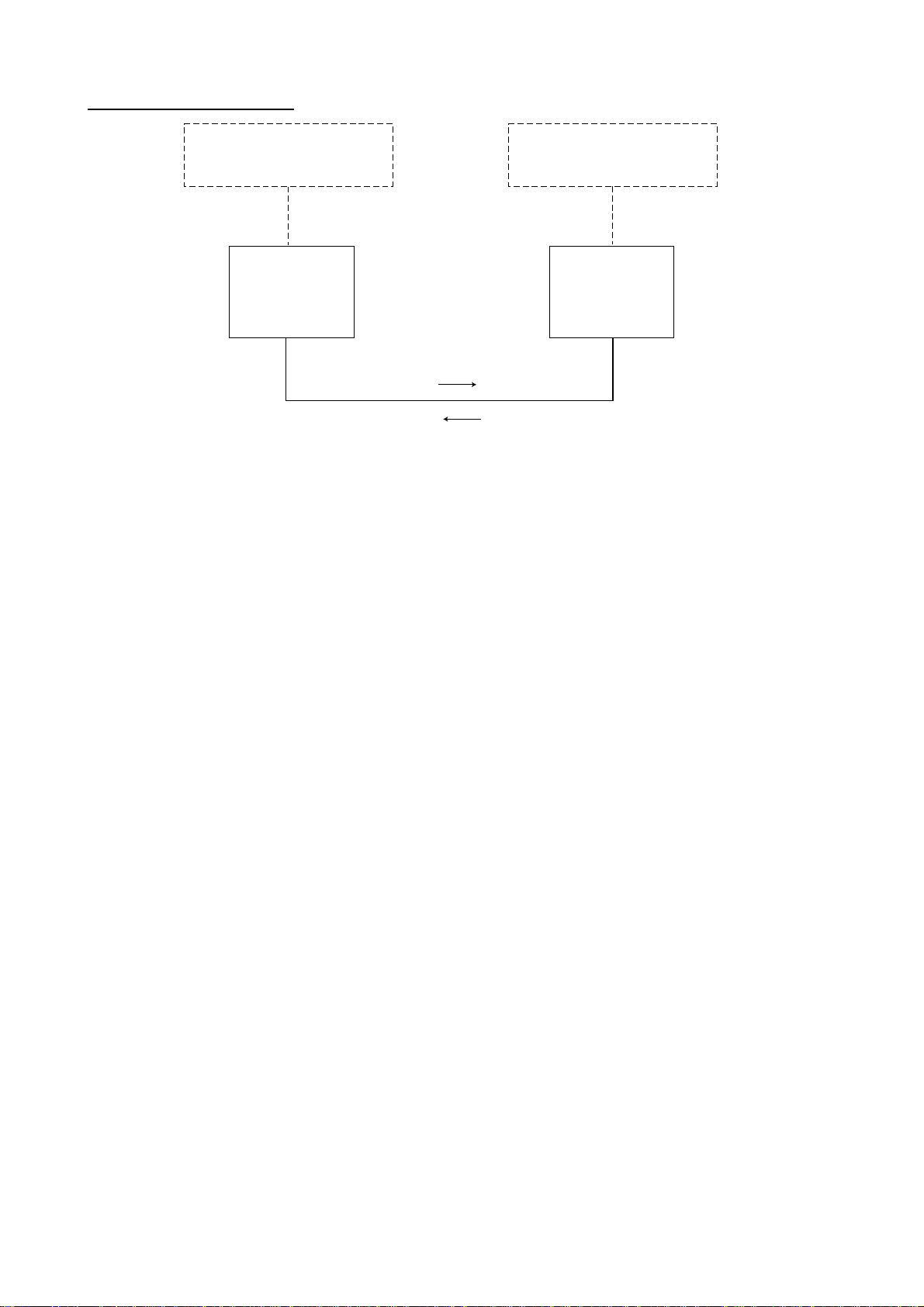

Three-or-mo re-uni t NavNet system

Radar Antenna Unit

OR

GPS Receiver GP-310B/320B

RADAR

or

PLOTTER

Radar data

Sounder data

Radar Antenna Unit

OR

GPS Receiver GP-310B/320B

RADAR

or

PLOTTER

Plotter data

HUB

Sounder data

Network Sounder

ETR-6/10N

ETR-30N

(option)

Facsimile data

Facsimile

Receiver

FAX-30

(option)

Three-or-more-unit NavNet system

Network Sounder

ETR-6/10N

ETR-30N

(option)

vii

Two-unit NavNet system

Radar Antenna Unit

OR

GPS Receiver GP-310B/320B

RADAR

or

PLOTTER

Radar, plotter data

Radar, plotter data

Radar Antenna Unit

OR

GPS Receiver GP-310B/320B

RADAR

or

PLOTTER

Two-unit NavNet system

viii

1. MOUNTING

1.1 Mounting the Control Unit

The control unit can be installed on a desktop or flush mounted in a console or panel. For

flush mounting, the optional flush mount kit is required.

When selecting a mounting location for the control unit keep the following in mind:

Keep the control unit out of direct sunlight.

•

The temperature and humidity of the mounting location should be moderate and stable.

•

Locate the unit away from exhaust pipes and vents.

•

The mounting location should be well ventilated.

•

Mount the unit where shock and vibration are minimal.

•

Keep the unit away from electromagnetic field generating equipment such as motor,

•

generator.

For maintenance and checking purposes, leave sufficient space at the sides and rear of

•

the unit and leave slack in cables.

A magnetic compass will be affected if the control unit is placed too close to the magnetic

•

compass. Observe the following compass safe distances to prevent disturbance to the

magnetic compass.

Standard compass: 0.45 m

Steering compass: 0.30 m

1-1

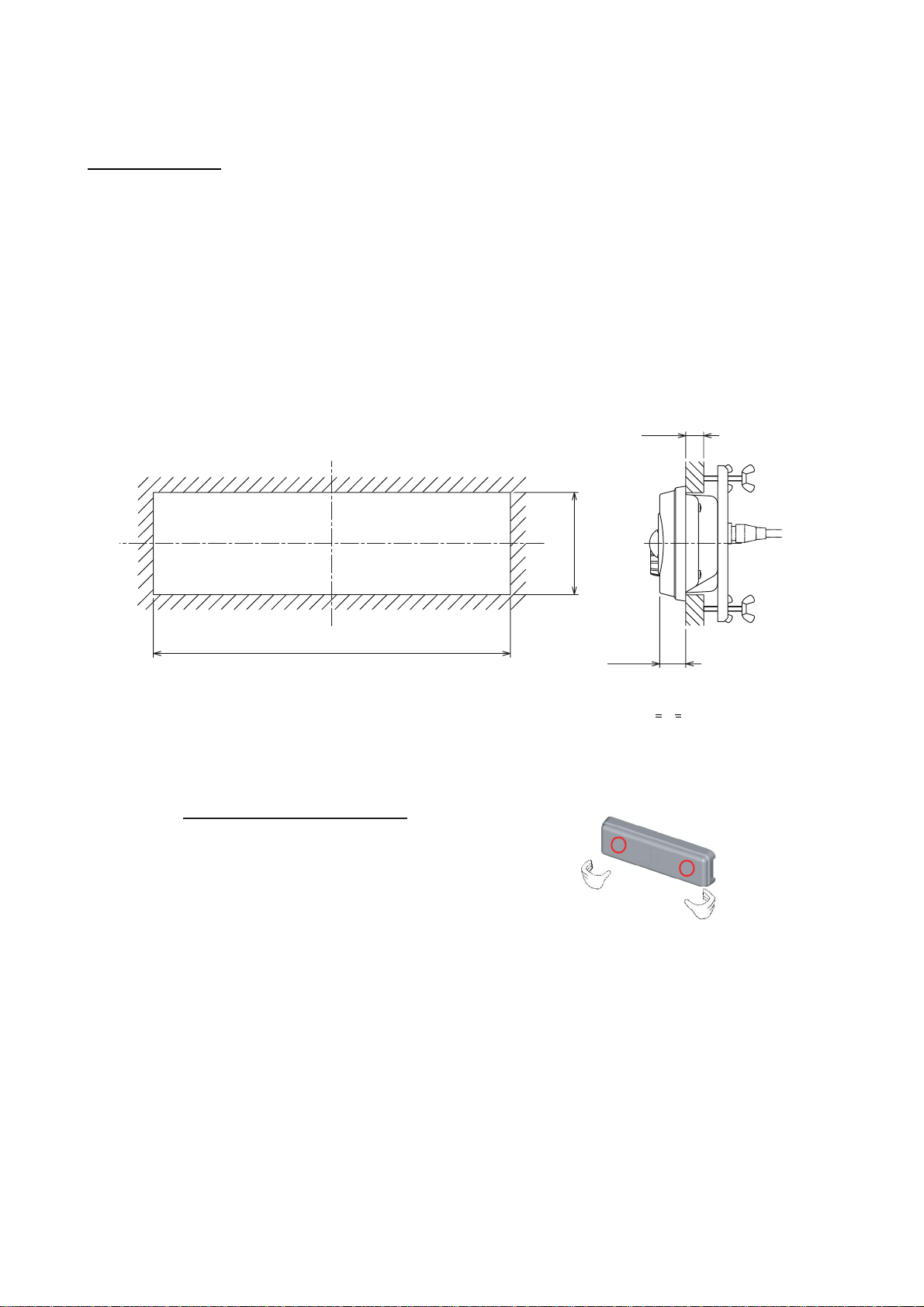

Mounting procedure

Flush mounting

Follow the procedure bel ow to mount the control uni t on a panel w ith accessories

FP03-10001.

1. Prepare a cutout in the mounting locat ion, referr ing to the outline drawing at the end of

this manual.

2. Set the control unit to the c utout.

3. Attach t he mounting plat e to the control unit wit h four sc r ews M4 x 10 from the r ear s ide.

4. Screw four wing bolts into wing nuts.

5. Fasten the control unit t o the mounting l oc ation with four wing bolts and wing nuts

assembled at step 4.

(A)

80±1

280±1

Flush mount ing of display unit

6. Attach hard cover to protect the control unit.

How to remove the hard cover

Place your thumbs at the locations shown with

circles in the illustration at right, and then lift the

cover while pressing it with your thumbs.

20.5

A: Thickness of panel

10<A<20 mm

1-2

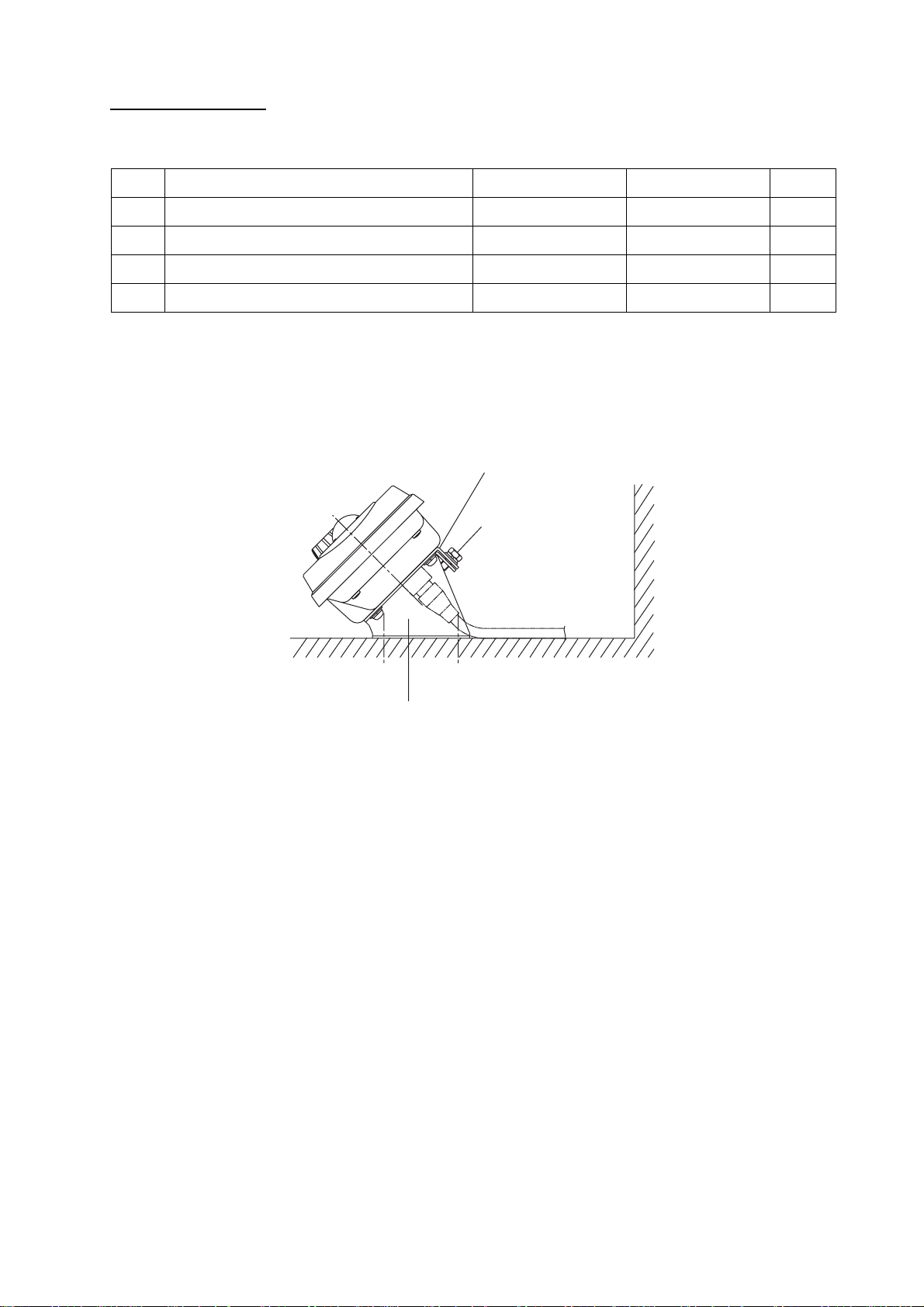

Desktop mounting

Use the optional desktop m ount kit FP03-09901 (Code number 008-443-54 0).

No. Name Type Code No. Qty

1 Hanger fixture 19-023-1061 100-307-941 1

2 Hanger fixture 19-023-1062 100-307-951 1

3 Tapping screw 5 x 20 000-802-081 4

4 Hex bolt M5 x 10 000-802-288 2

1. Fix the hanger fixture 19-023-1062 on a desk top wit h four tappi ng s c r ews (5x20).

2. Fix the hanger fixture 19-023-1061 to the r ear panel of the control uni t with four M 4x 10

(supplied as acc es sories).

3. Set the control unit to the hanger fixture 19-023-1062 fixed at step 1 and fit it wi th two

hex bolt s .

Hanger fixture

19-023-1061

Hex bolt

Hanger fixture 19-023-1062

Desktop mounting of dis play unit

4. Attach hard cover to protect the control unit.

1-3

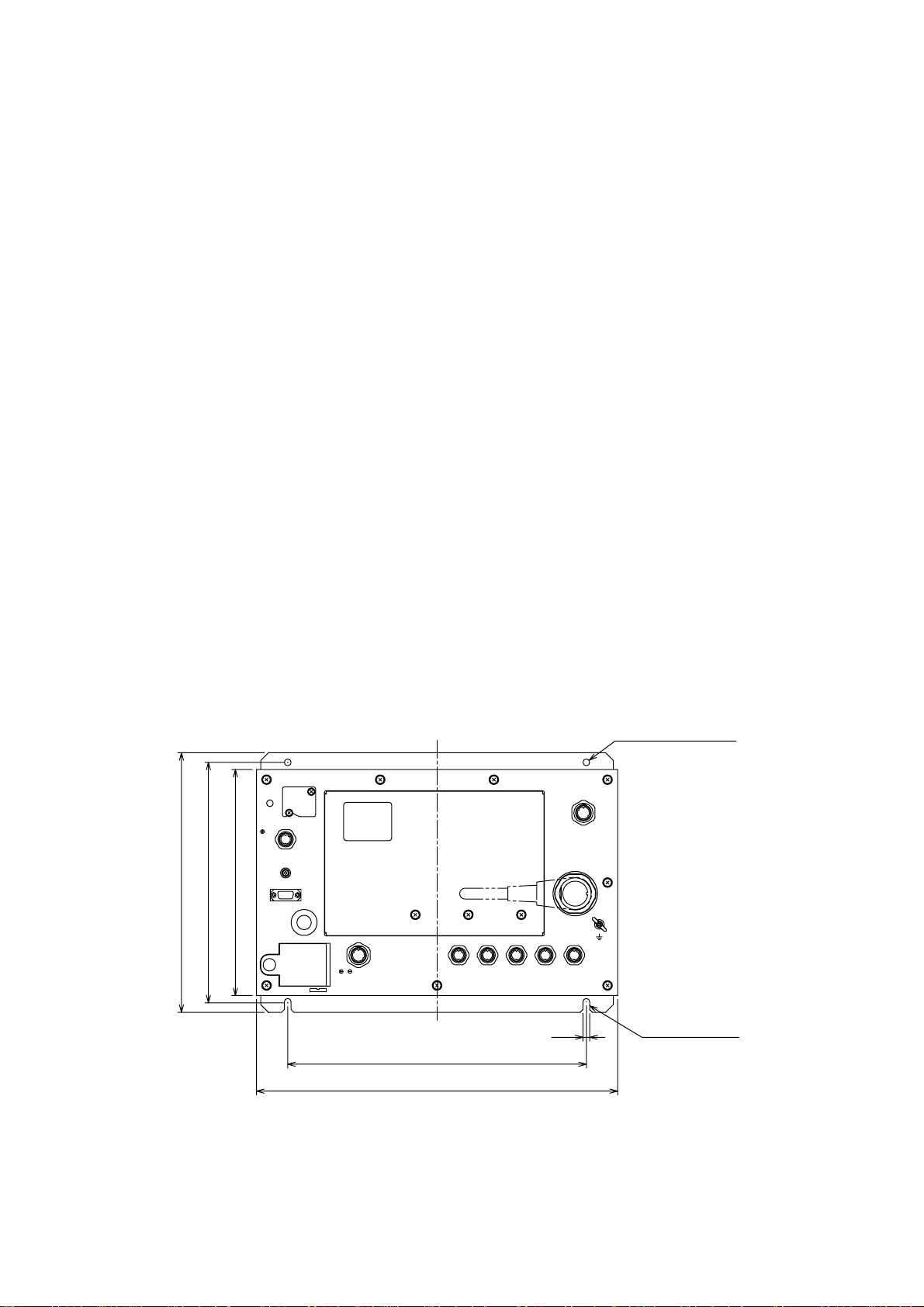

1.2 Mounting the Processor Unit

The unit can be mounted on th e dec k , a desktop or on a bulkhead. Select a mounting

locati on c ons idering the points below.

• Locate the unit out of direct s unlight.

• Select a location where temper ature and humidity are moderate and stabl e.

• Consider the length of the cable c onnected am ong the proces s or unit, antenna unit (or

power supply unit) and c ontrol unit.

• For mounting on a bulkhead, be sure the mounting locati on is strong enough to support

the unit (4.1kg) under the pitching and r olling norm ally encounter ed on the vessel.

• Leave sufficient space ar ound the unit for maintenance and servic ing. Recomme nded

maintenance space app ears in the outl ine drawing at t he bac k of this manual.

• A magnetic compass will be affected i f t he pr oc es s or unit is placed too clos e to the

magneti c c ompas s . Observe the follow ing compass saf e distances to pr event dis t ur bance

to the magnetic compass.

Standard compass: 1.75 m

Steering compass: 1.10 m

Tableto p or deck mounting: Fasten wit h four tapping screws.

Bulkhead mounting: Mark four fixing hol e pos itions on the bulkhead. S c r ew in two tappi ng

screw s at l ower fixing positions, leavi ng 5 m m protruding. Set the proces sor unit to the

screw s and s cr ew in two tappi ng s c rews at upper positions. Tighten all screws .

2-φ7 fixing holes

POWER

270

235

250±0.5

F.G.

321

0.3 A MAX

GND

OUTPUT

12 VDC

NTSC/PAL

RGB OUT

OPTION

CARD SLOT

INPUT

2

1

12-24 VDC

3

GND

NETWORK

DATA 3

CONT DATA 1DATA 2

310±0.5

REMOTE FMD DISPLAY

DJ-1

7

2 fixing holes

375

Processor u nit, mounting dim ens ions

1-4

1.3 Mounting the Antenna Unit of MODEL1823C-BB

Mounting considerations

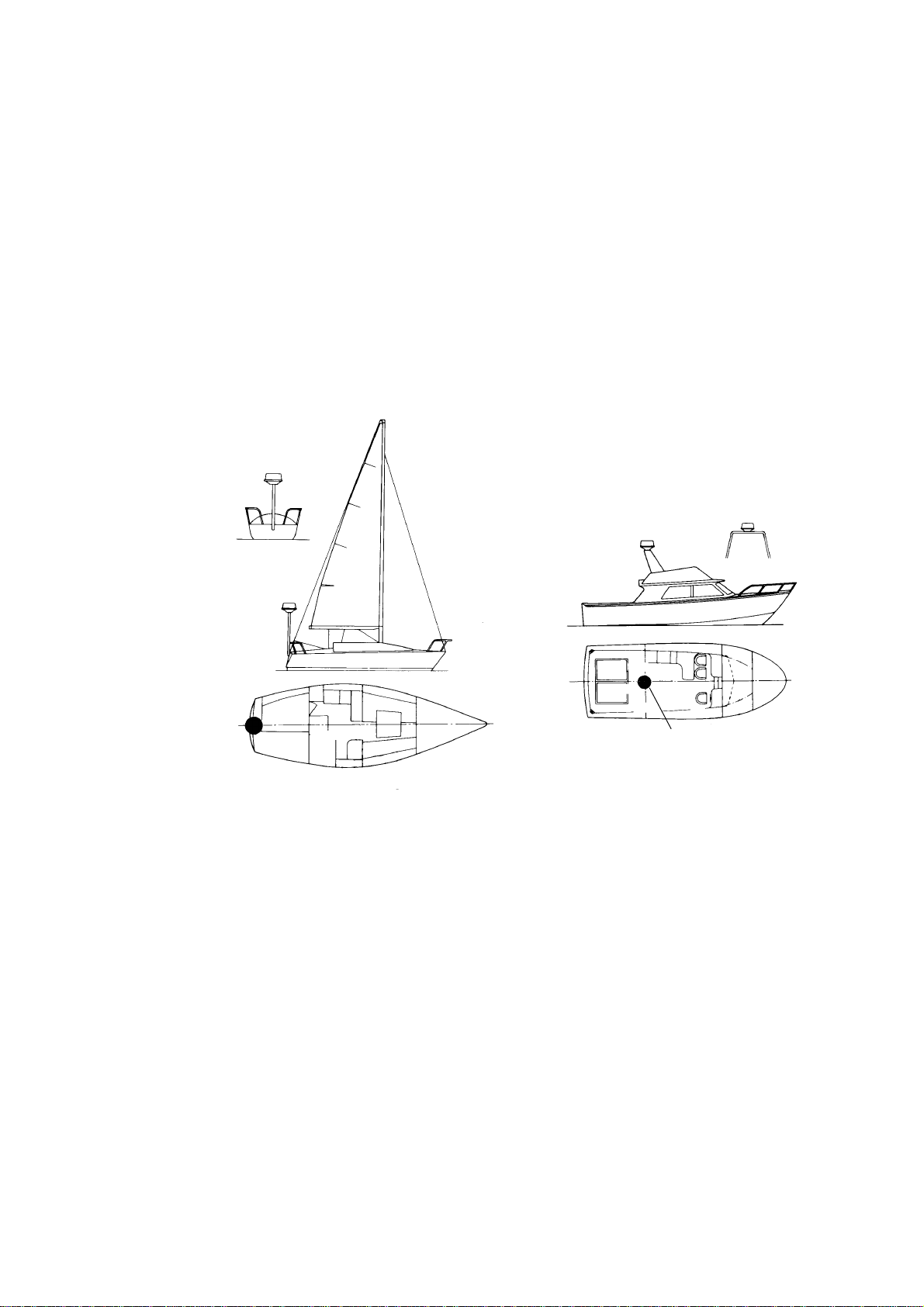

When selecting a mounting location for the antenna unit keep in mind the following points.

Install the antenna unit on the hardtop, radar arch or on a mast on an appropriate

•

platform. (F or sailboats, a mounting bracket is optionally available.) It should be placed

where there is a good all-round view with, as far as possible, no part of t he ship’s

superstructure or rigging intercepting the scanning beam. Any obstruction will cause

shadow and blind sectors. A mast, for instance, with a diameter considerably less than

the width of the antenna unit, will cause only a small blind sector. However, a horizontal

spreader or crosstrees in the same horizontal plane would be a much m ore serious

obstruction; place the antenna unit well above or below it.

Antenna unit

Antenna unit

Antenna unit

Typical antenna unit placement on sailboat and powerboat

In order to minim ize the chance of picking up electrical interference, avoid where possible

•

routing the antenna cable near other electrical equipm ent onboard. Also avoid running

the cable in parallel with power cables.

The compass safe distance of 1.25 meters (standard compass) and 0.85 meters (steering

•

compass) should be observed to prevent deviation of the magnetic compass.

Antenna unit

1-5

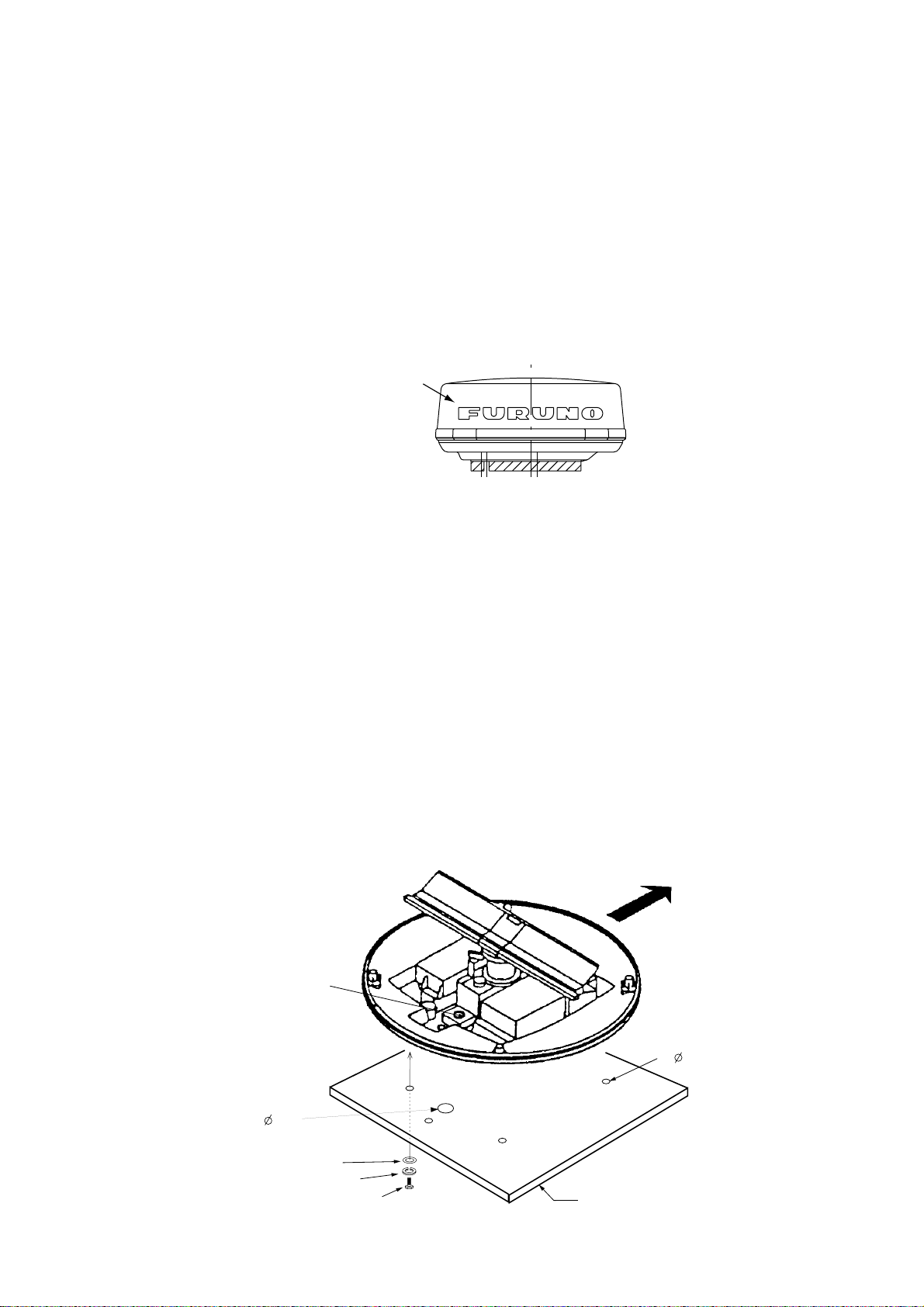

Mounting the antenna unit of MODEL1823C-BB

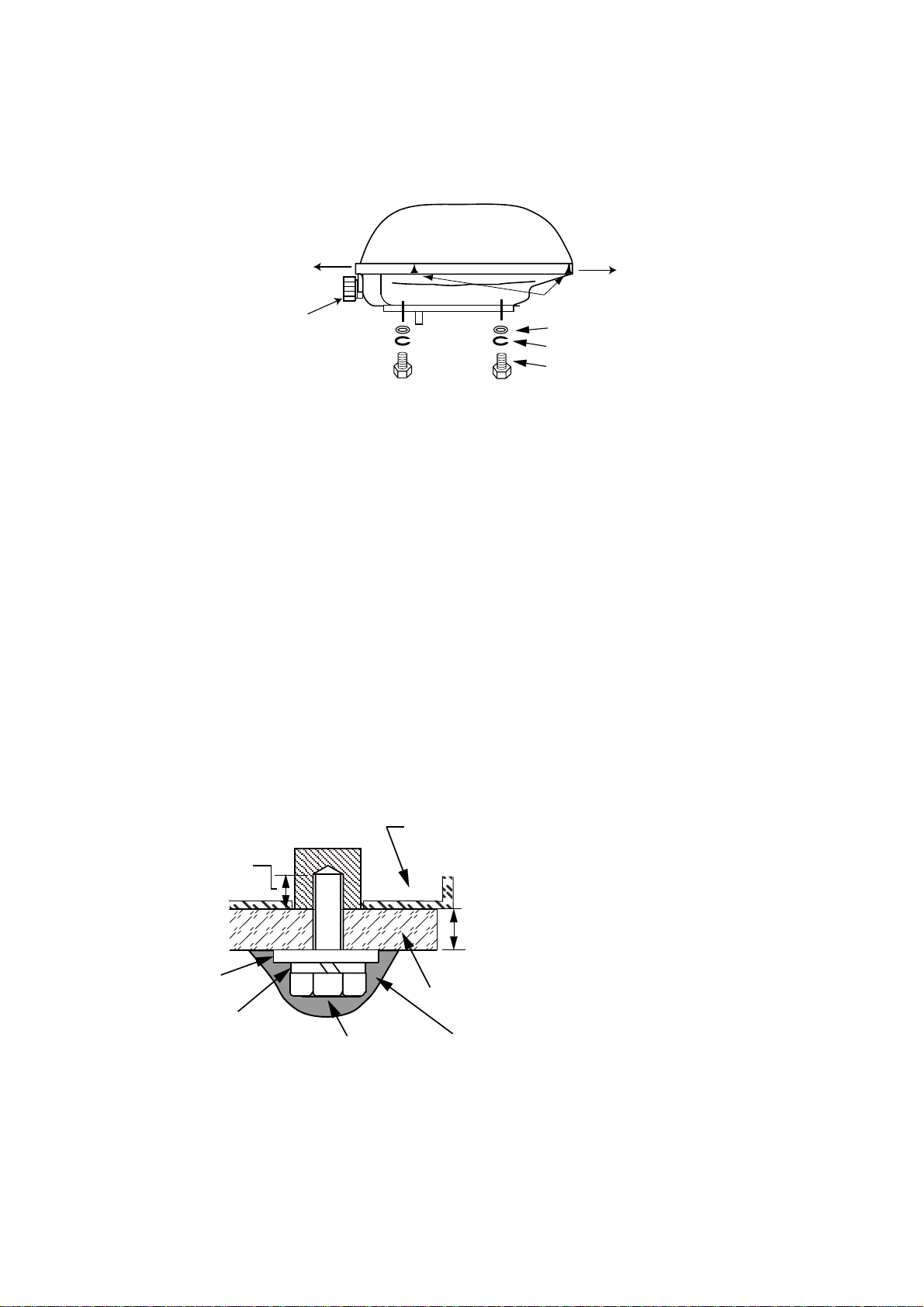

1. Remove mounting hardware at the bottom of the antenna unit; four each of hex. bolts

(M10X20), spring washers and flat washers. Save mounting hardware to use it to fix the

antenna unit to the mounting platform later on.

Stern

Cable entry

Bow

Screws

two screws on other side

Flat washer

Spring washer

Hex bolt (M10 x 20)

Antenna unit, showing location of mounting hardware

2. Construct a platform (wood, steel*, or aluminum) of 5-10 mm (recommended dim ension)

in thickness referring to the outline drawing at back of this manual. A mounting bracket

for mounting the ant enna unit on a sailboat mast is optionally available. (Refer to page

1-11.) Fasten the platform to the mounting location. Next, position the mounting base on

the platform so the cable entrance faces the stern direction.

*: For steel platform take appropriate measures to prevent corrosion.

Note: When drilling holes in the platform, be sure they are parallel with the fore and aft

line.

3. Using the hex bolts, flat washers and spring washers removed at step 1, fasten the

mounting base to the platform. The torque should be between 19.6-24.5 N•m.

Note: Longer hex bolts (M10X25) are supplied with the installation materials. Use them

instead of the hex bolts removed earlier if the mounting platform thickness is

5–10 mm.

Effective

thread

length:

12 mm

Antenna base

assy.

5 mm or under :M10x20

5-10 mm: M10x25

over 10 mm: locally supplied bolts

Flat

washer

Spring

washer

Hex bolt

(M10 x 25

or M10 x 20)

Platform

Apply silicone sealant.

How to fasten the mounting base to platform

1-6

Snap holder

Remove and discard

the packing material.

Antenna unit, inside view

4. The mounting base is fitted with a snap holder, which may be used to hang the cover

after removal. Use the hole next to screw hole inside the cover to hang it.

a) Unfasten the snap assy. with the st r ing attached at the holder in the mounting base.

b) Unwind the string.

c) Attach the snap to a screw hole on the inside of t he cover.

Note: Do not hang any other objects with the snap.

1-7

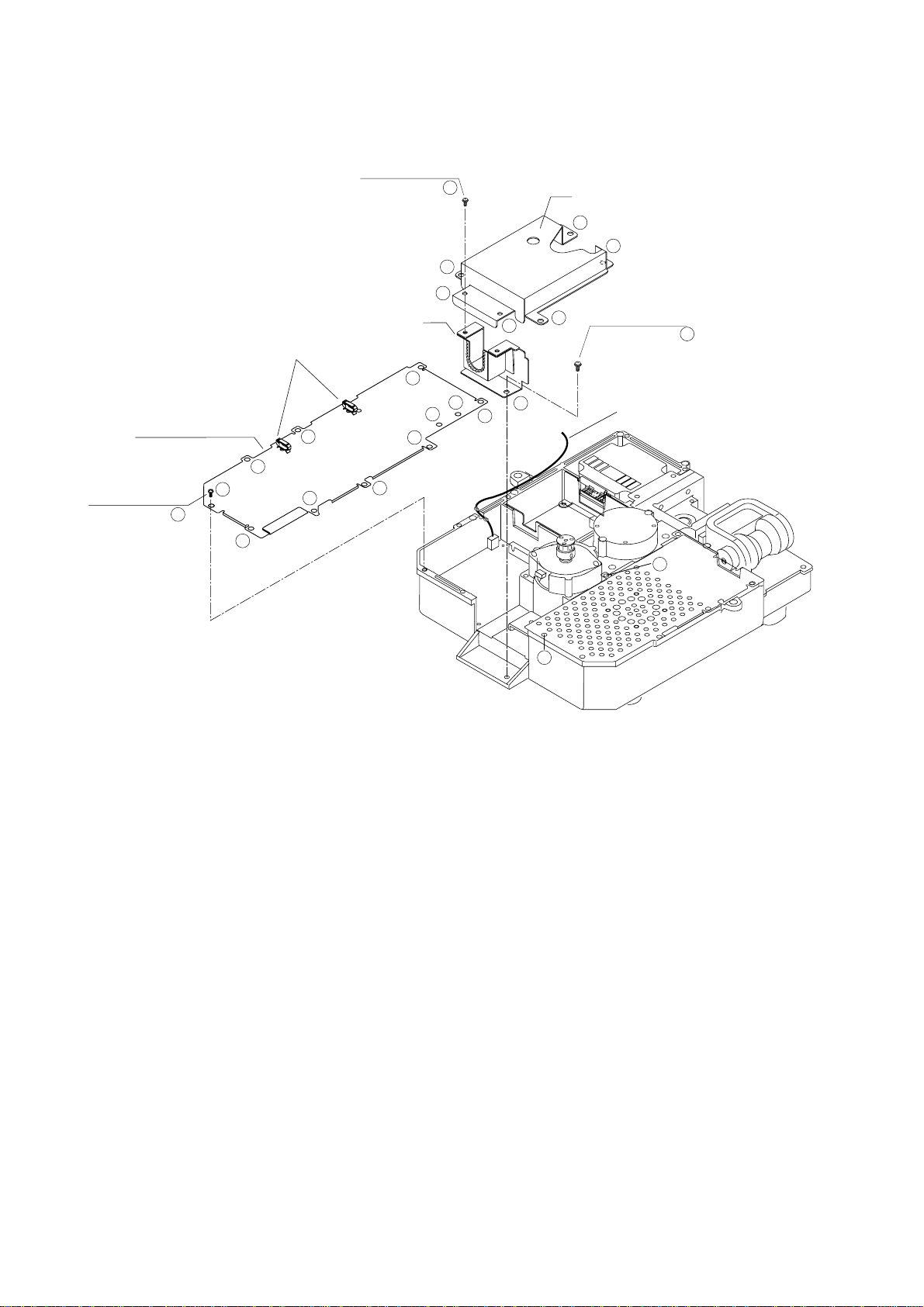

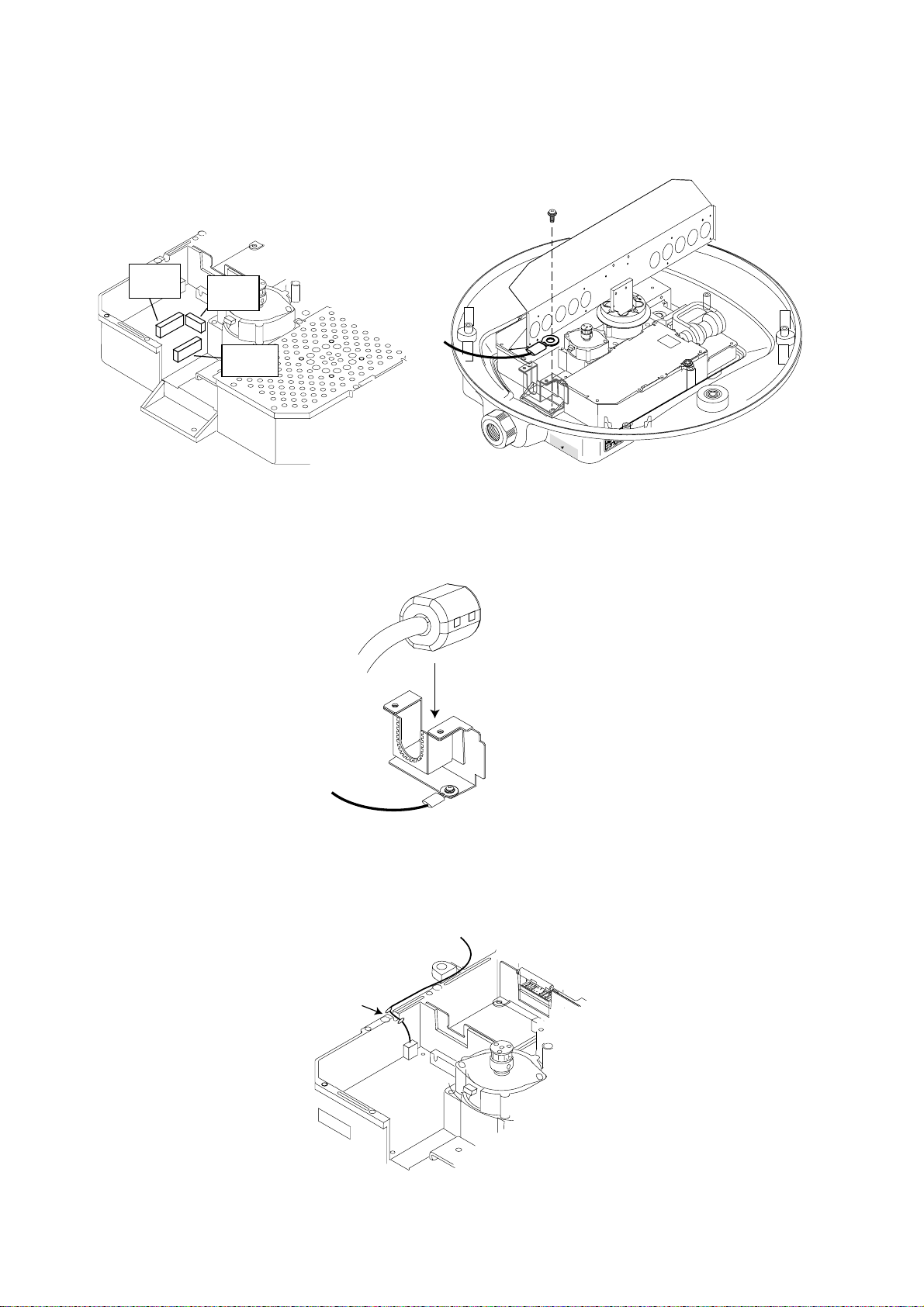

5. Unfasten the rot at ion detector cable from the cable clamps.

6. Unf asten 16 screws (

!

,

2

!

and

3

in the following figure) to dismount the shield plate,

!

1

core case and core case cover.

Pan head screws

M3x10 2 pcs. 2

3

2

3

3

Shield plate

Pan head screws

M4x8 9 pcs.

1

1

3

Cable clamps

1

1

1

Core case

3

2

1

1

1

1

1

Core case cover

3

3

Pan head screws

M4x10 5 pcs.

Rotation detector cable

GND

Vt

-V

OP

GND

+V

IF

OP

GND

3

3

3

Caution: Be careful not to pinch the rotation detector cable when remounting the shield

plate.

1-8

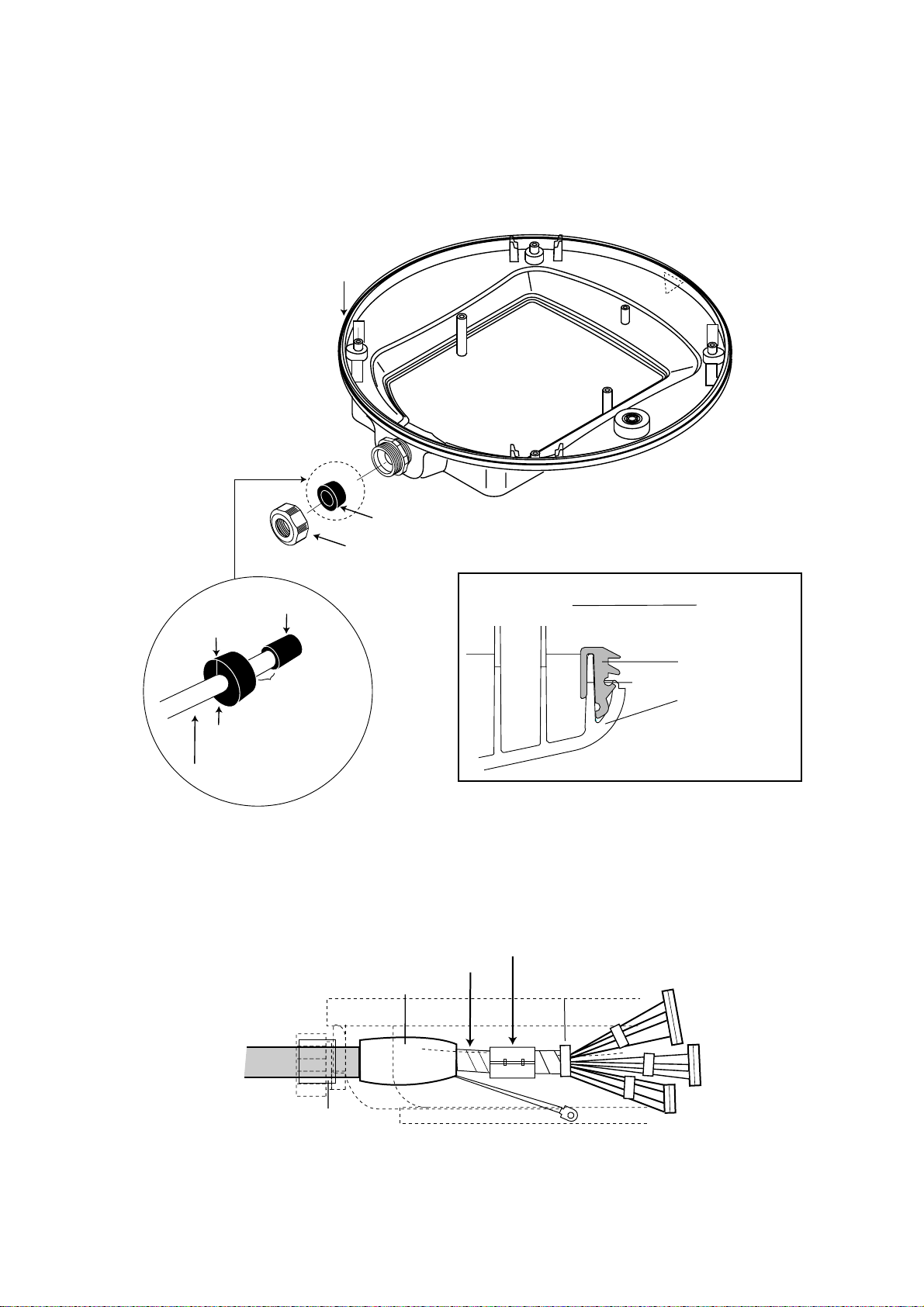

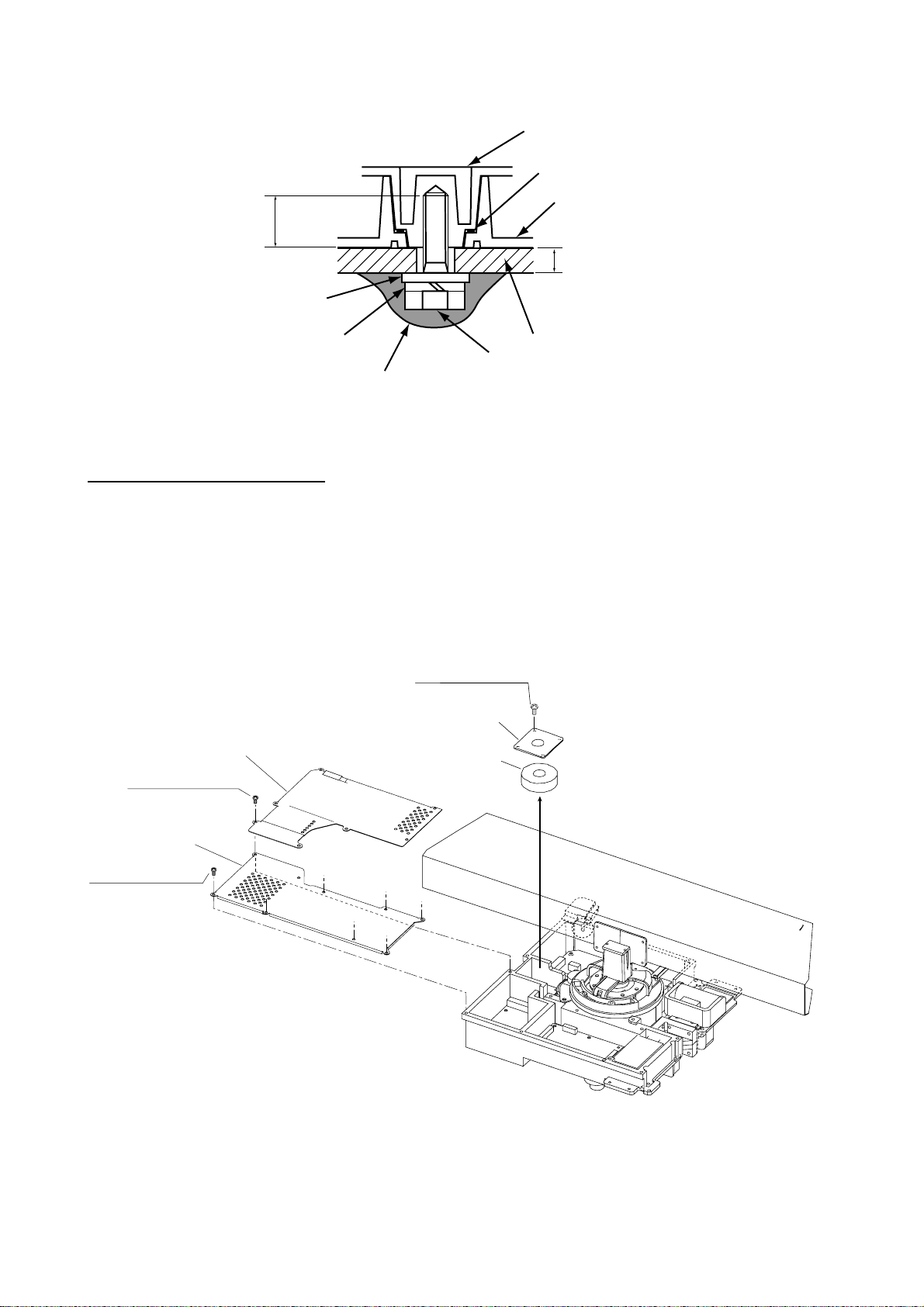

7. Pass the antenna cable with connector through t he cable gland, gasket and cable

entrance of the antenna unit, and t hen tighten cable gland.

Note 1: Be sure the shrink tube on the antenna cable does not contact the gasket.

Note 2: Pinch the gasket tightly and insert it into the cable entrance. Confirm that the slit

in the gasket is completely closed after inserting it into the cable entrance.

Rubber gasket

Gasket

Cable Gland

Shrink tube

Pinch the gasket

tightly.

Do not allow

the shrink tube to

Gasket

Antenna cable

contact the

gasket.

Sectional view

Rubber gasket

Mounting base

Antenna unit, inside view

8. Twist antenna connector cables at the position between the shrink tube and the cable tie,

and then attach EMI core (supplied) to cables as follows. After attachment, shift EMI

core slightly to confirm that it does not pinch cables.

Attach EMI core.

Twist cables here.

Shrink tube

Cable tie

Gasket

Mounting base

Location of EMI core

1-9

9. Att ach connect ors of the antenna cable to the locations shown in the figure below, and

then fasten a pan head screw M4x10 to fix shield cable and core case (removed at step

6.)

Pan head screws

M4x10 9 pcs.

J810

(13 pin)

J809

(4 pin)

J801

(9 pin)

Antenna unit, connector location and fixing the shield cable w/core case

10. Put t he EMI core on the antenna cable into the core case attached at step 9.

The flat side of the core should face downward.

EMI core

Core case

EMI core, putting into core case

11. Refasten the shield plate and core case cover with 15 screws. Be sure that the cable

from the rotation detector passes through the notch between the two cable ties.

To rotation detector

Notch

Mounting base

How to pass the rotation detector cable

1-10

12. Pass the cable from the rotation detect or through two cable clamps.

Rotate detector

Cable clamps

Cable tie

(Another should

be inside.)

Antenna unit, clamping the rotation detector cable

13. Follow the instructions on the label inside the mounting base to secure the snap assy.

14. Confirm that the rubber gasket is properly positioned and that the triangle mark on the

radome cover is aligned with the triangle mark on the mounting base, then tighten the

fixing screws for the cover. Refer to the figure of sectional view on the previous page for

positioning of rubber gasket.

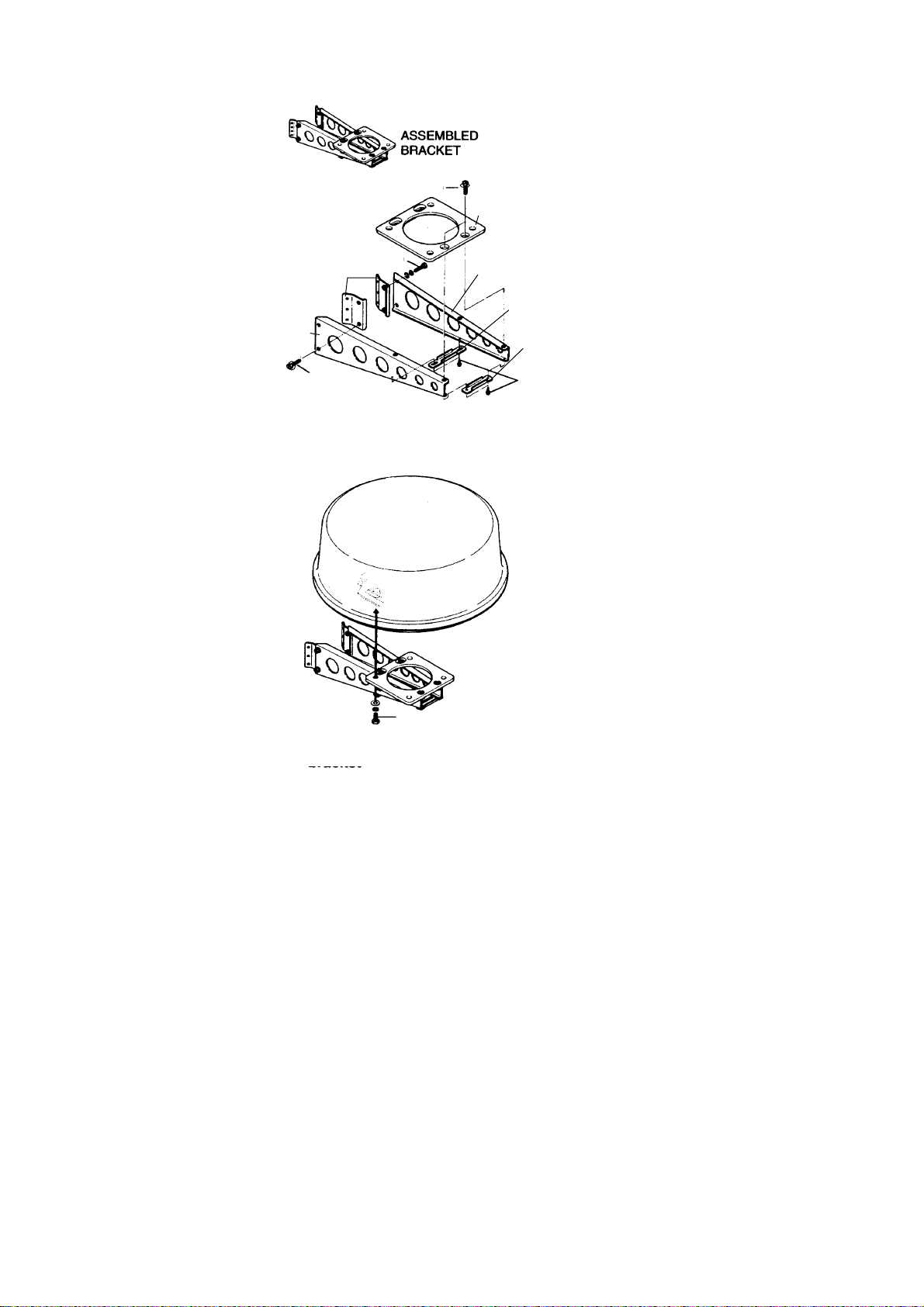

Mounting the optional mounting bracket

A mounting bracket for fastening the antenna unit to a mast on a sailboat is optionally

available.

Mounting bracket 2

Type: OP03-93

Code No.: 008-445-080

Type Code No. Qty

Hex. bolt M4x12 000-804-725 4

Hex. bolt M8x20 000-805-707 8

Mounting plate 03-018-9001-0 100-206-740 1

Support plate (1) 03-018-9005-0 100-206-780 1

Support plate (2) 03-018-9006-0 100-206-790 1

Bracket (1) 03-028-9101-0 100-206-810 1

Bracket (2) 03-028-9102-0 100-206-820 1

Fixing plate 03-028-9103-0 100-206-830 2

Assemble the mount ing bracket and fasten it to a mast . Fasten the antenna unit to the

bracket. For details, see the figure on t he next page.

1-11

M8 x 20

Mounting plate

M8 x 20

Fixing plate

Bracket (2)

M8 x 20

(A) Assembling the mounting bracket

Bracket (1)

Support plate (2)

Support plate (1)

M4 x 12

M10 x 25 (supplied with antenna unit)

(B) Fastening antenna to mounting

bracket

How to assemble and mount the optional mounting bracket

1-12

1.4 Mounting the Antenna Unit of MODEL1833C-BB

Mounting considerations

See the mount ing considerations f or the MODEL1823C- B B on page 1-5.

The compass s af e distance of 0.90 meters (st andard compass) and 0. 70 meters (s teering

compass) sh ould be obser v ed to prevent deviation of the magnetic compass.

Mounti ng the an te nn a un it of MODEL18 33C -B B

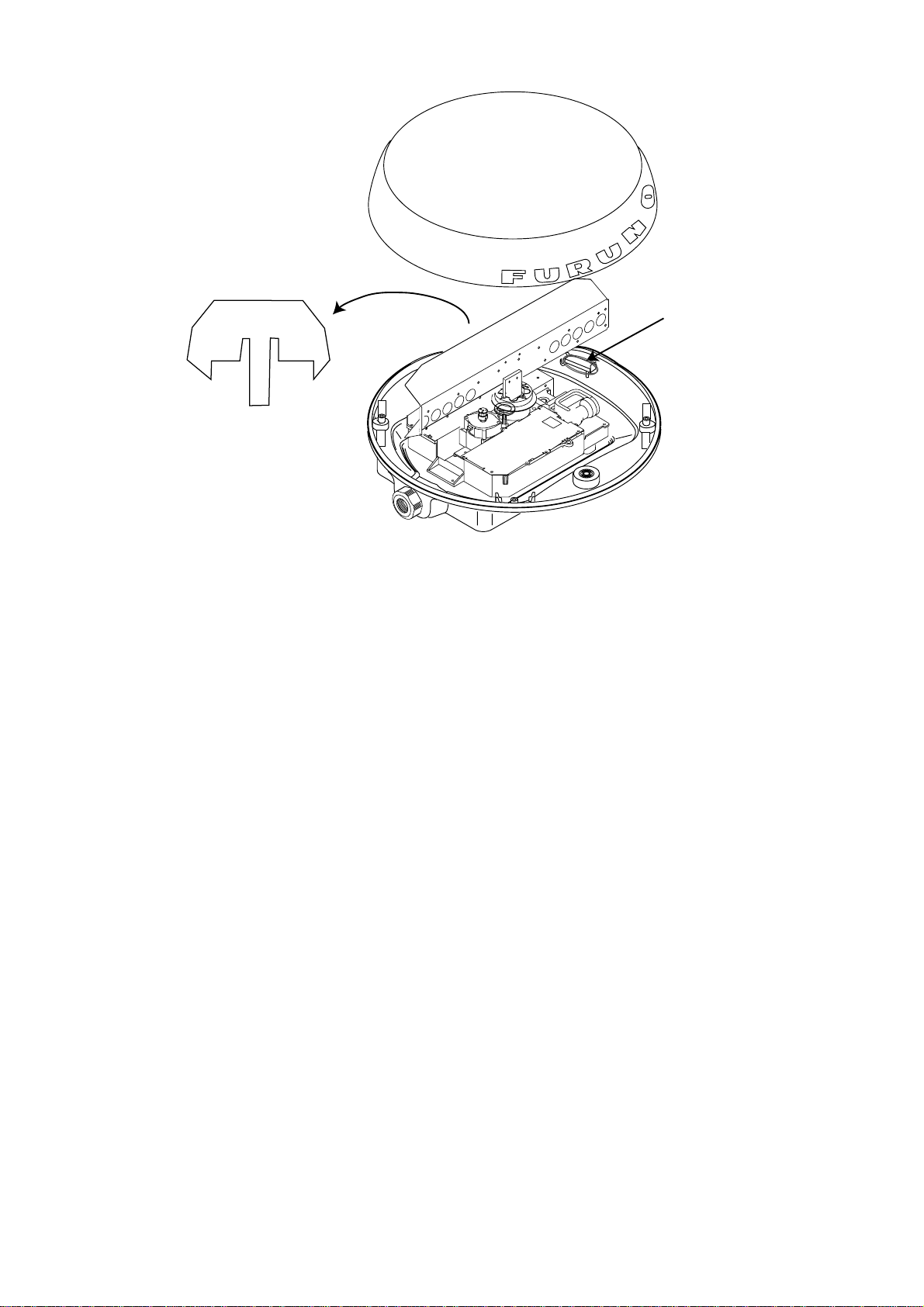

1. Open the antenna unit packing box careful ly.

2. Unbolt the four bolts at the bas e of the radome cover to remove it.

Radome cover

Antenna uni t

The mounting surface must be parallel with the waterline and provided with five holes (four

fixing holes and one cable entry) whose dimensions are shown in the outline drawing

attached at back of this manual.

The unit is adjusted so a target echo returned from the bow direction will be shown on the

zero degr ee (heading line) position on the screen. When drilling holes, be s ure they are

parallel wit h th e for e an d a ft line.

3. Prepare a plat form (wood, s teel*, or aluminum) of 5 to 10 millim et er s in thick nes s for the

antenna unit.

A mounting brac ket for mounting the antenna unit on a s ailboat mas t is optional ly

available. (Refer to page 1-17.) Find the cable ent r y on the radome base. Next, pos ition

the radome base so the cable entry fac es the stern direc tion. This alignment m us t be as

accurate as p os sible.

*: For steel platform, take appropriate measures to prevent corrosion.

Ship's bow

Cable

entry

Cable entry hole

(approx. 20)

Flat washer

Spring washer

M10 x 25 Hex bolt

Platform

4- 10 Holes

1-13

Antenna uni t, cover removed

Antenna base plate

Effective

thread length

25 mm

Flat

washer

Spring

washer

Apply silicone sealant.

M10 x 25

Hex bolt

Gasket

Radome

5 - 10 mm

Platform

How to fasten the radome base to the mount ing platform

Wiring and final preparation

4. Drill a hole of appr ox . 20 mm diamet er through the deck or bulkhead to run t he s ignal

cable between the antenna unit and the processor unit. (To prevent el ec trical

interfer enc e avoid runni ng the signal c able near other electri cal equipment and in

parallel with power c ables.) Pass the cable through the hole. T hen, seal the hole with

sealing com pound for waterproofing.

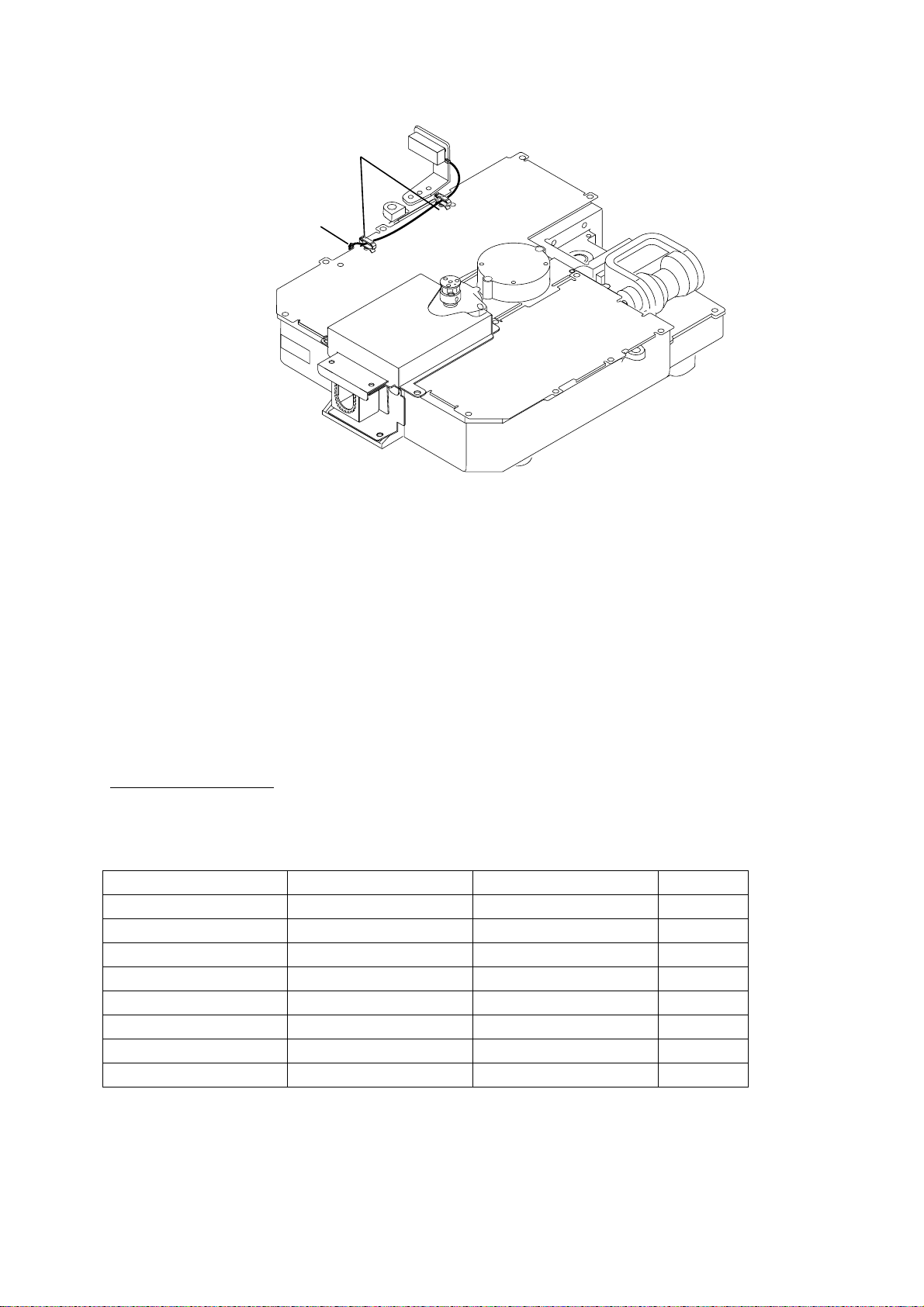

5. Remove two s hield covers in the radome.

6. Remove the cabl e clamping pl ate by unfastening four scr ews and removing a gasket.

Pan head screws

M4x8 4 pcs.

Cable clamping plate

Shield cover

Pan head screws

M4x8 7 pcs.

Shield cover

Pan head screws

M4x8 7 pcs.

Gasket

Antenna uni t, insi de vi ew

7. Pass the cable t hrough the hole at the bottom of the radome bas e.

8. Secure the cable with the cable clamping plate and gas k et. Ground the s hield wire by

1-14

one of the screws of the c able clamping plate.

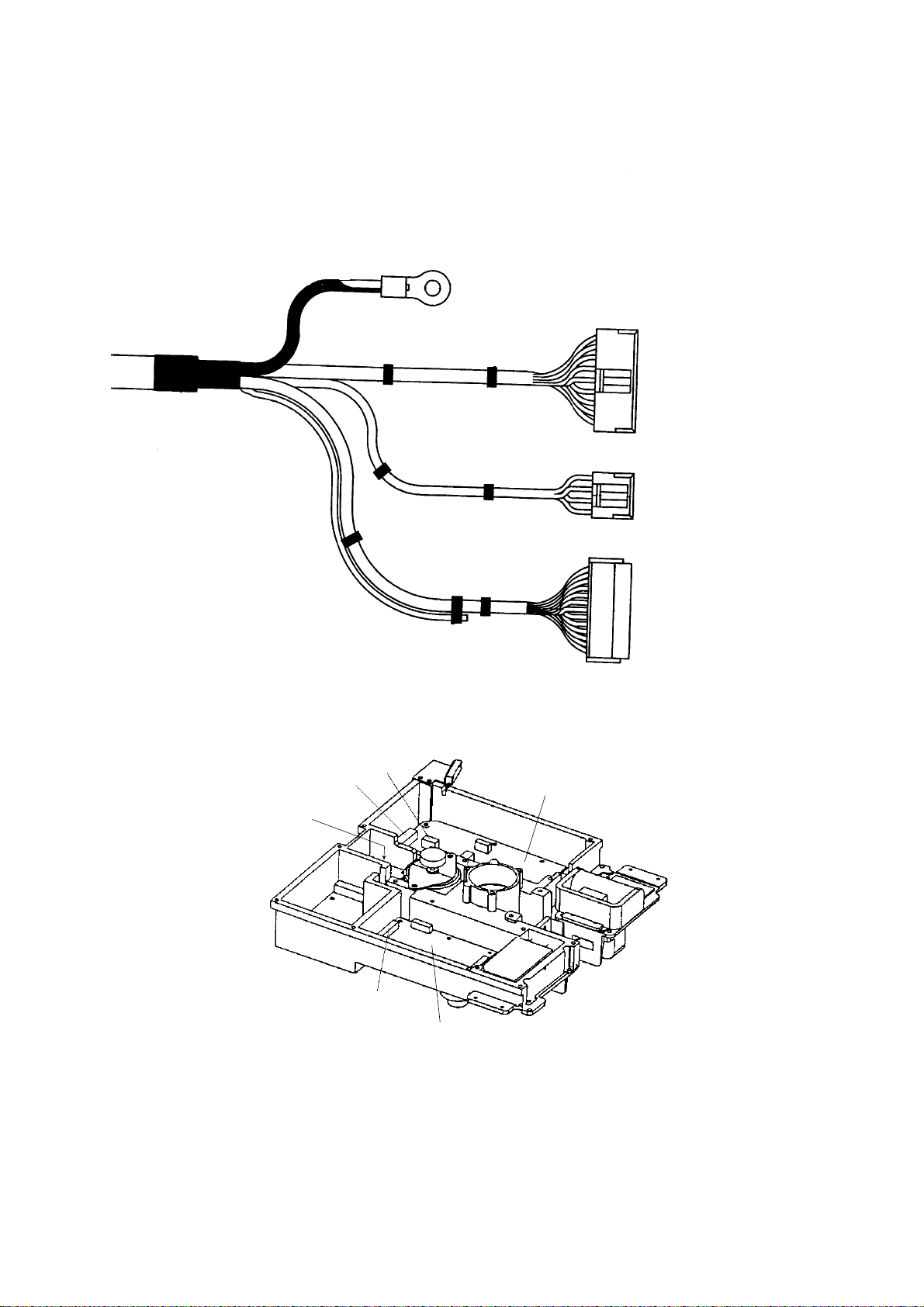

9. Attach three connectors of the signal c able to respective receptacles as shown below.

to one of the screws

of the cable clamping plate

9-pin connector:

to J801 on MD-9208

4-pin connector:

to J802 on MD-9208

13-pin connector:

to J611 on IF-9214A

Signal cable, antenna u nit side

J802

J801

Cable

entry

J611

IF-9214A

RF unit

MD-9208

1-15

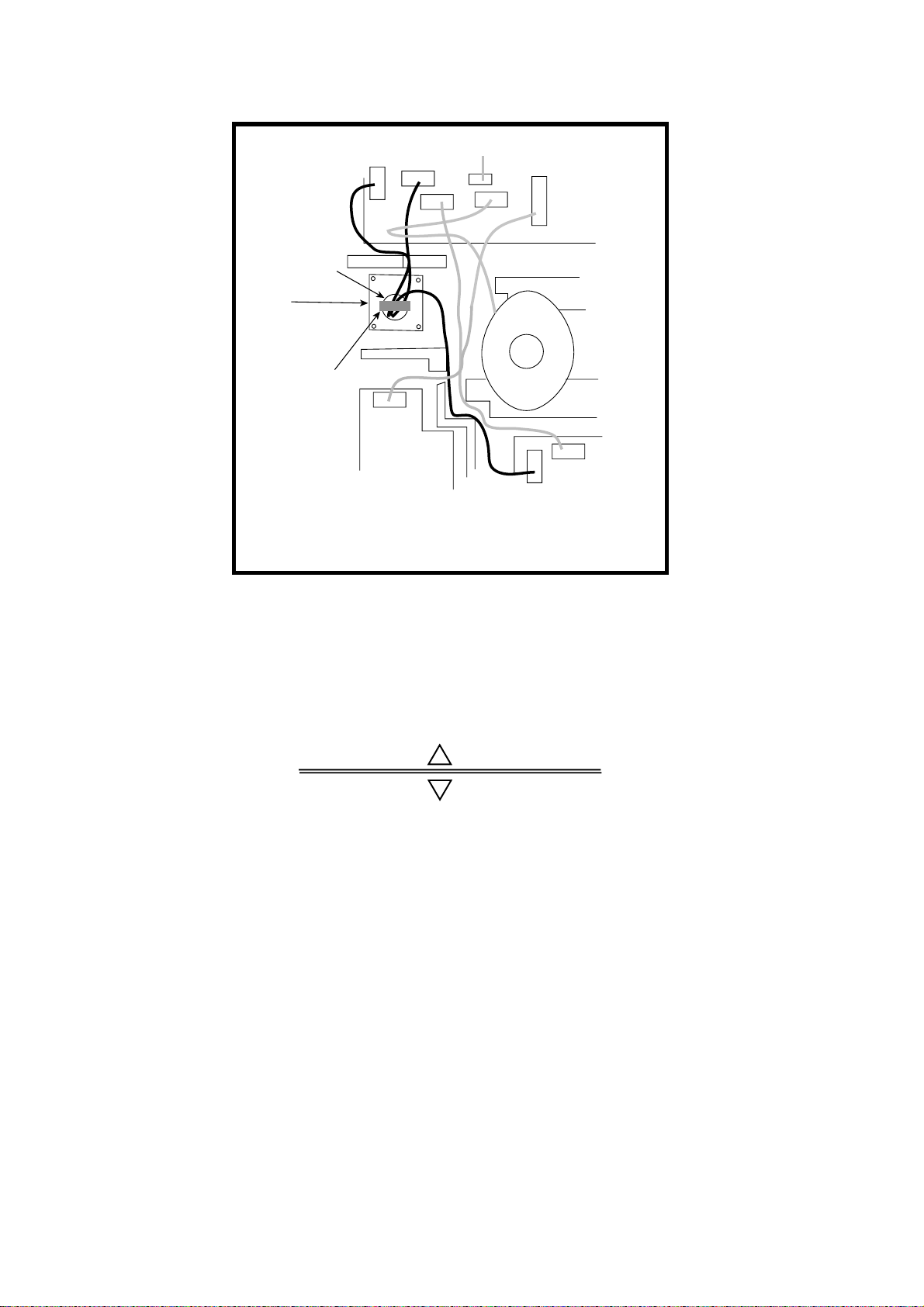

10. Attach the EMI core supplied as shown below.

J801

Cable

entrance

Cable

clamping plate

EMI core

E04SS251512

(Above cable

clamping

plate)

PTU-9335

J1

J802

J804

J805

J803

Motor

J611

MD-9208

J806

J613

IF9214IF9214A

How to attach EMI core

11. Fix the shield cover. Do not pinch the cable.

12. Attach the radome cover, aligning triangle mark on radome cover with that on radome

base.

Radome cover

Radome base

How to position the radome cover

13. Loosely fasten the radome fixing bolts. You will tighten them after confirming magnet ron

heater voltage.

1-16

Mounting the optional mounting bracket

A mounting bracket for fastening the antenna unit for the MODEL1833C-BB to a mast on a

sailboat is optionally available.

Mounting bracket 1

Type: OP03-92

Code No.: 008-445-070

Type Code No. Qty

Hex. bolt M4X12 000-804-725 4

Hex. bolt M8X20 000-805-707 8

Mounting plate 03-018-9001-0 100-206-740 1

Support plate (1) 03-018-9005-0 100-206-780 1

Support plate (2) 03-018-9006-0 100-206-790 1

Bracket (1) 03-018-9002-1 100-206-751 1

Table 1-1 Mounting bracket contents

Bracket (2) 03-018-9003-1 100-206-761 1

Fixing plate 03-018-9004-1 100-206-771 2

Assemble the mount ing bracket and fasten it to a mast . Fasten the antenna unit to the

bracket. For details, see the figure on page 1-12.

1-17

1.5 Mounting the Antenna Unit of

MODEL1933C-BB/1943C-BB/1953C-BB

Mounting considerations

• The antenna unit is generally install ed either on top of the wheelhouse or on the radar

mast on a suitable pl atform. Locate the antenna unit where there is a good all-round vi ew.

Any obstruction will cause shadow and blind sectors . A mast for instanc e, with a diameter

considerabl y less t han the width of the radiator, will cause only a small blind sector, but a

horizontal spreader or cr os s trees in the sam e hor izontal plane as the ant enna unit would

be a much more serious obs truction; you would need to pl ac e the antenna unit well

above or below it.

• It is rarely possible to pl ac e the antenna unit where a completely clear view in all

directions is avail able. Thus, y ou s hould determi ne the angular widt h and r elative bearing

of any shadow sectors for their influence on t he r adar at the firs t opportunit y after fitting.

• To lessen the chance of pick ing up electr ical interference, avoid where possible routing

the signal c able near other onboard el ec trical equipment. Also avoid running the cable in

parallel with power cables.

• A magnetic compass will be affected if the antenna unit is placed too close to the

magnetic com pass. Obser ve the following compass safe distances to prevent deviation of

a magnetic com pass: Standar d c om pass, 1.00 m, Steering compass, 0.80 m (1953C- B B :

0.75 m).

• Do not paint the radiator aperture, to ensure proper emission of the radar waves.

a) When this radar is to be installed on larger vessels, consider the following points:

The signal cable run between the antenna and the processor units comes in lengths of

10 m, 15 m, 20 m and 30 m.

b) Deposits and fumes from a funnel or other exhaust vent can adversely affect the aerial

performance and hot gases may distort the radiator portion. The antenna unit must not

be mounted where the temperature is more than 70°C.

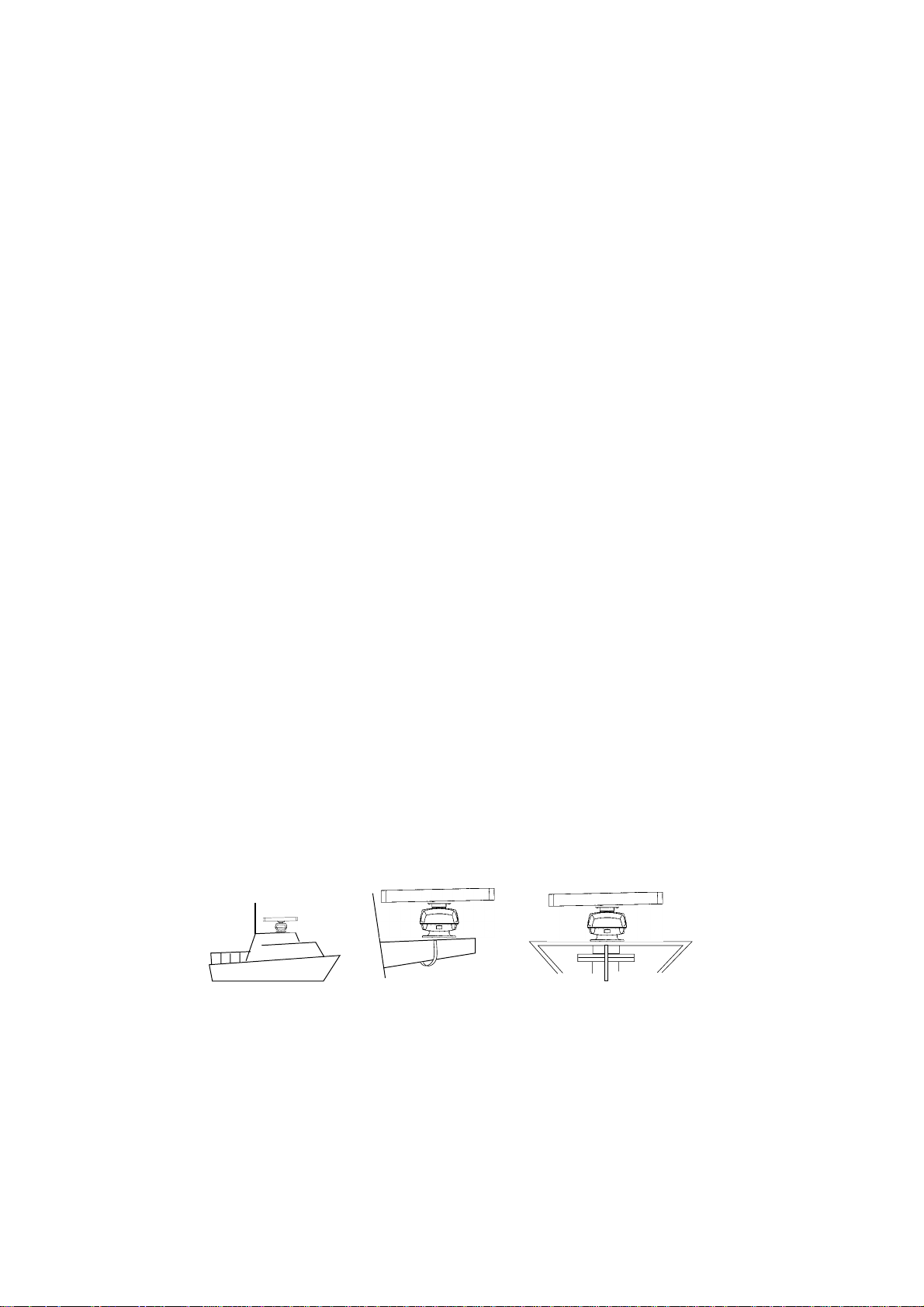

As show n in the figur e below, the antenna unit may be installed on the bridge, on a comm on

mast or on the radar m as t.

(a) On bridge

(b) Common mast

(c) Radar mast

1-18

Loading...

Loading...