Furman CN-3600SE Instruction Manual

CONTRACTOR SERIES SmartSequencer™

CN-3600SE

Instruction Manual

CN-3600SE

16 A Maximum

For additional information refer to the Quick Start

Guide, included with product packaging.

www.furmancontractor.com

For more information call:

Para más información llame al:

Pour plus de renseignements:

877-486-4738

DIN-00021-A 10-12

Introduction

Congratulations and thank you for choosing the

Furman CN-3600SE. We assure you that your

sequencer will provide many years of trouble

free operation. The CN-3600SE is a 230VAC 16

Why choose Furman?

At Furman Sound, we have spent the last 30 years

quietly obsessing about AC Power Quality and how

best to protect your professional equipment from

the noise and hazards of AC power. Over the years

we have developed a multitude of technologies

that have spared countless devices from damage

Why choose AC power sequencing?

AV equipment is most vulnerable and susceptible

to damage during those first few milliseconds after

the power is turned on or off.

Amp Contractor Grade Surge Protector and Power

Sequencer equipped with Furman’s exclusive

SmartSequencing™ technology. SmartSequencing™ defines a whole new level of power manage-

and earned the trust and respect of the Professional A/V industry. This manual will explain some

of the Furman technologies that have been incorporated into the design of the CN-3600SE. If you

are already a Furman customer you are probably

already familiar with our portfolio of protective

Powering down A/V is equally as perilous. Unlike

other A/V equipment, the large capacitors found

in amplifiers will store their charge. This means

if signal processing devices and amplifiers are

When audio amplifiers are powered, a large inrush

current occurs as the large capacitors in the power

supply charge. This inrush can be on the order of

several hundred amps for a number of AC cycles.

If more than one amplifier is connected to a single

branch circuit, the inrush current is multiplied and

switched off simultaneously, the amplifiers are still

operational as the signal processing equipment is

switched off. Just as with startup, the power down

phase can cause equipment to emit transients

which are amplified by the amplifier, then propa-

gated to the speakers and “pop”!

can cause the circuit breaker to trip, or the line voltage to sag. Additionally, if the amplifier is powered

either before or concurrent with signal processing

equipment, the result can be a dreaded speaker

“pop”. This all-too familiar noise occurs as transients from the signal processing equipment flow

uncontrolled to the inputs of the power amplifier.

The amplifier amplifies this signal and passes the

transient “pop” along to the speakers. The result

AC Power sequencing addresses these problems

by powering up your equipment in stages. The

signal processing equipment is powered up first

and allowed to stabilize, and then the amplifiers

are powered up. The first stage signal processing

equipment may still emit transient noise upon pow-

er up, but because the amplifiers have yet to power

on, the transient signal passes without incident.

can be catastrophic to both speaker and amplifier.

ment and control while streamlining installations

from start to finish.

technologies. If this is your first Furman Contractor

purchase, we appreciate your business. We have

spared no expense in making sure that your CN3600SE will perform admirably. Welcome Aboard!

Power sequencing stages the activation of heavy

loads, which prevents nuisance breaker trips and

equipment damage due to line sags and brownouts. This means that inrush currents are offset

in time, rather than occurring simultaneously. This

can also be advantageous to upstream equipment

if the sequencer is supplementing other power

management such as a UPS or voltage regulator.

The Furman Contractor CN-3600SE provides three

delay stages. Each stage is independently fused

and protected. If three stages of power sequencing

are not enough for your application, you can chain

together multiple (up to 99) sequencers using Furman’s exclusive SmartSequencing™ technology

for up to 297 independent stages! Please review

the reference materials for CN-3600SE thoroughly,

for a clear understanding of SmartSequencing

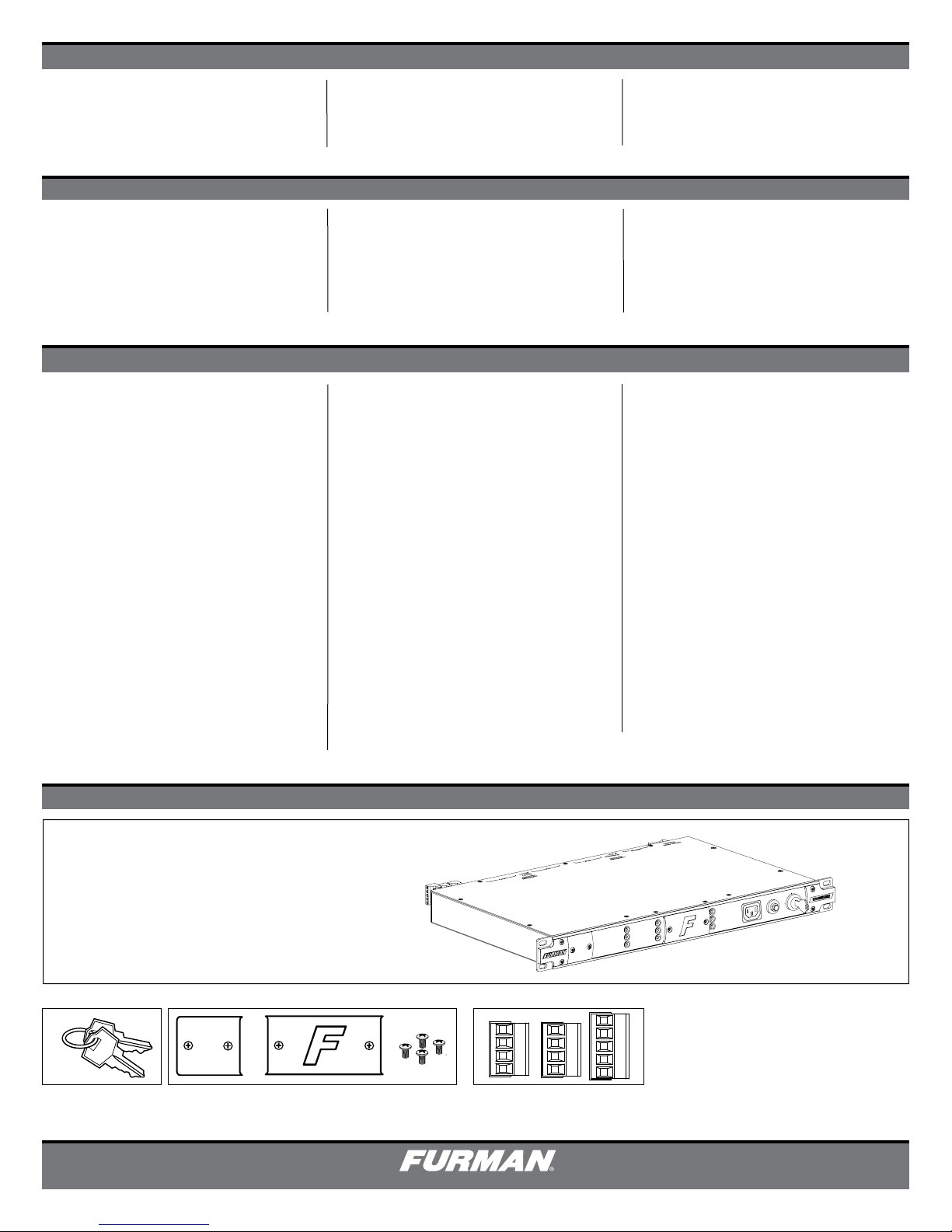

Before You Begin Inspect Upon Receipt

The box should contain the following items:

1) Contractor Series Quick Start Guide

2) Pair of Security Keys

3) Two removable Cover Shields and four screws

4) Three Phoenix –Type Connectors

Pair of Security Keys Two Removable Cover Shields and Four Screws

1

3 Phoenix Type Connectors

(2 four pin, 1 five pin)

PRIMARY LINK

SECONDARY LINK

REMOTE

16 AMPS

ON

UNSWITCHED ~ 220V-240V, 50/60Hz

MAX LOAD 10A, 2300 WATTS

PUSH TO RESET

OFF

SEQUENCE

POWER

PROTECTION OK

DELAY 1

DELAY 2

DELAY 3

ETHERNET

EXTREME VOLTAGE

CN-3600SE

EVSVOLTAGEPROTECTION

AUTOMATICEXTREME

SmartSequencing

AVOIDEXCESSIVEINRUSHCURRENTS

EVSVOLTAGEPROTECTION

AUTOMATICEXTREME

OVER-VOLTAGEPROTECTION

DIAGNOSTICLIGHTS

SmartSequencing

AVOIDEXCESSIVEINRUSHCURRENTS

SURGEPROTECTION

HIGHESTLEVELOF

PROTECTIONAVAILABLE

EVS

EXTREME VOLTAGE

SHU TD OW N

EVSVOLTAGEPROTECTION

AUTOMATICEXTREME

OVER-VOLTAGEPROTECTION

LINEARFILTERINGTECHNOLOGY

NOISEFILTRATIONFORUNEQUALED

AUDIOANDVIDEOCLARITY

DIAGNOSTICLIGHTS

INDICATESPOWERQUALITY

SmartSequencing

AVOIDEXCESSIVEINRUSHCURRENTS

SURGEPROTECTION

HIGHESTLEVELOF

PROTECTIONAVAILABLE

OK

EVS

EXTREME VOLTAGE

SHU TD OW N

SERI ES MUL TI-STA GE

PROTECTION

SMP

EVSVOLTAGEPROTECTION

AUTOMATICEXTREME

OVER-VOLTAGEPROTECTION

Table of Contents

Technologies..................................................................................................................................................................................................................2

Front and Back Panel Features.......................................................................................................................................................................................3

Security and Safety........................................................................................................................................................................................................4

SmartSequencing™101.............................................................................................................................................................................................4, 5

DIP Switch Settings................................................................................................................................................................................................5, 6, 7

SmartSequencing Link Status Lights..............................................................................................................................................................................7

Indicator Lights..............................................................................................................................................................................................................8

Circuit Breakers.............................................................................................................................................................................................................8

Rear Panel Terminal Barrier Strips............................................................................................................................................................................9, 10

CN-3600SE System Setup............................................................................................................................................................................................10

Example Setup Diagrams.............................................................................................................................................................................................11

Trouble Shooting Guide.................................................................................................................................................................................................12

Specifications...............................................................................................................................................................................................................13

Warranty Information....................................................................................................................................................................................................13

Technologies

LINE AR FIL TERING

TECHNOLOGY

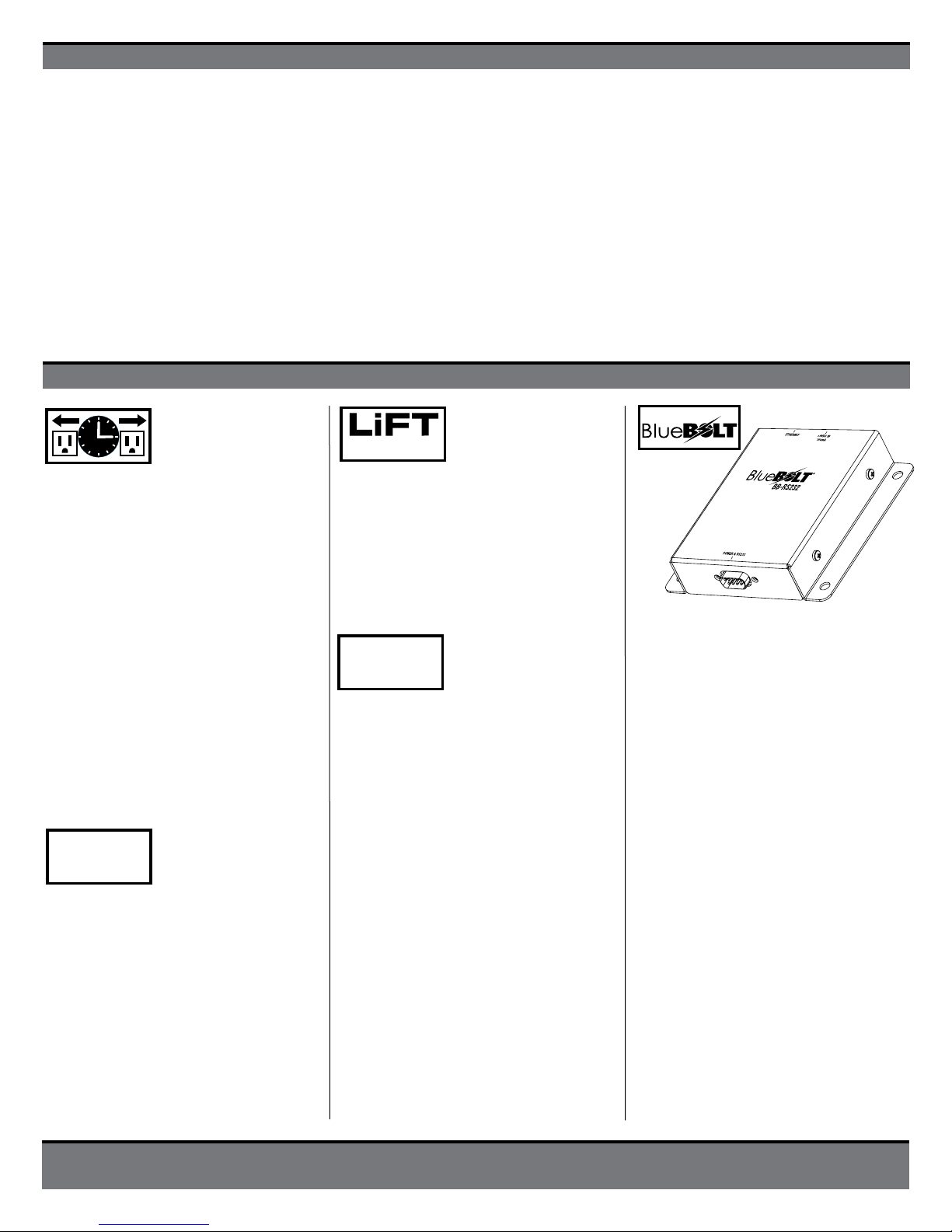

SmartSequencing™

Furman SmartSequencing™ is a communication technology that allows Furman contractor

devices to be linked together and controlled up

to distances of 300 Meters (about 1000 feet).

SmartSequencing devices can be chained together to form a network of sequencers. A maximum of 99 SmartSequencers can be linked together to form a SmartSequencing network that

spans a distance of 30 KM (18.2 Miles)!

SmartSequencing devices can be connected together without regard for polarity, wire type, and

environmental noise. It is an extremely forgiving technology. Although we recommend solid

twisted pair for best results, virtually any wire

size and type can be used over short distances

without concern for signal degradation.

SMP

SERI ES MUL TI-STA GE

PROTECTION

SMP Protection

Furman’s exclusive Series Multistage Protection

(SMP) Technology prevents equipment downtime by monitoring and quickly reacting to extreme line voltage conditions. SMP protection

is designed to withstand voltages of 6000 Volts

and 3000 Amps without sustaining damage. As

the name implies, there are multiple stages of

protection which are designed to shield connected equipment from line hazards.

Linear Filtering Technology

Linear Filtering Technology (LiFT) uses a finely

tuned low-pass filter to reduce differential AC

noise. LiFT is remarkable in its ability to linearly

filter AC noise such that the attenuation curve is

continuous over a wide bandwidth.

EVS

EXTREME VOLTAGE

SHU TD OW N

BB-RS232

Remote Access (and BlueBOLT®) The CN3600SE is a member of Furman’s Contractor

Extreme Voltage Shutdown

series of devices. All members of the Contractor

series can be controlled remotely using an inteFurman’s trusted (EVS) over-voltage detection

protects against prolonged over-voltage conditions, such as accidental connection to high

voltage or an intermittent loss of neutral. It does

so by continuously monitoring the incoming AC

gral data-link and command API. The remote ac-

cess feature allows for integration with various

control systems. In addition to remote control,

API queries provide situational awareness and

local power quality data.

voltage. When an unsafe condition is detected,

a relay shuts off the power to the outlets until

the EVS condition has subsided. The CN-3600SE

also allows the user to define how the unit will

recover from an EVS shut-down. The Extreme

Voltage Shutdown technology is a tremendous

Furman’s optional BlueBOLT® RS-232-to- Eth-

ernet adaptor (shown above) provides additional

control programming and monitoring from any

Web-enabled device via Telnet, direct HTTP con-

nection, or www.mybluebolt.com

asset.

www.furmancontractor.com • 877-486-4738

Optional BlueBolt to RS232 adapter

2

COMM/

POWER

DELAY 3

NO

NC

C

FO

FO

COMM/

POWER

FORCE OFF

DELAY 3

NO

NC

C

FO

FO

COMM/

POWER

COMM/

POWER

FORCE OFF

DELAY 3

NO

NC

C

FO

FO

P

P

S

S

OUT

IN

SMARTSEQUENCING

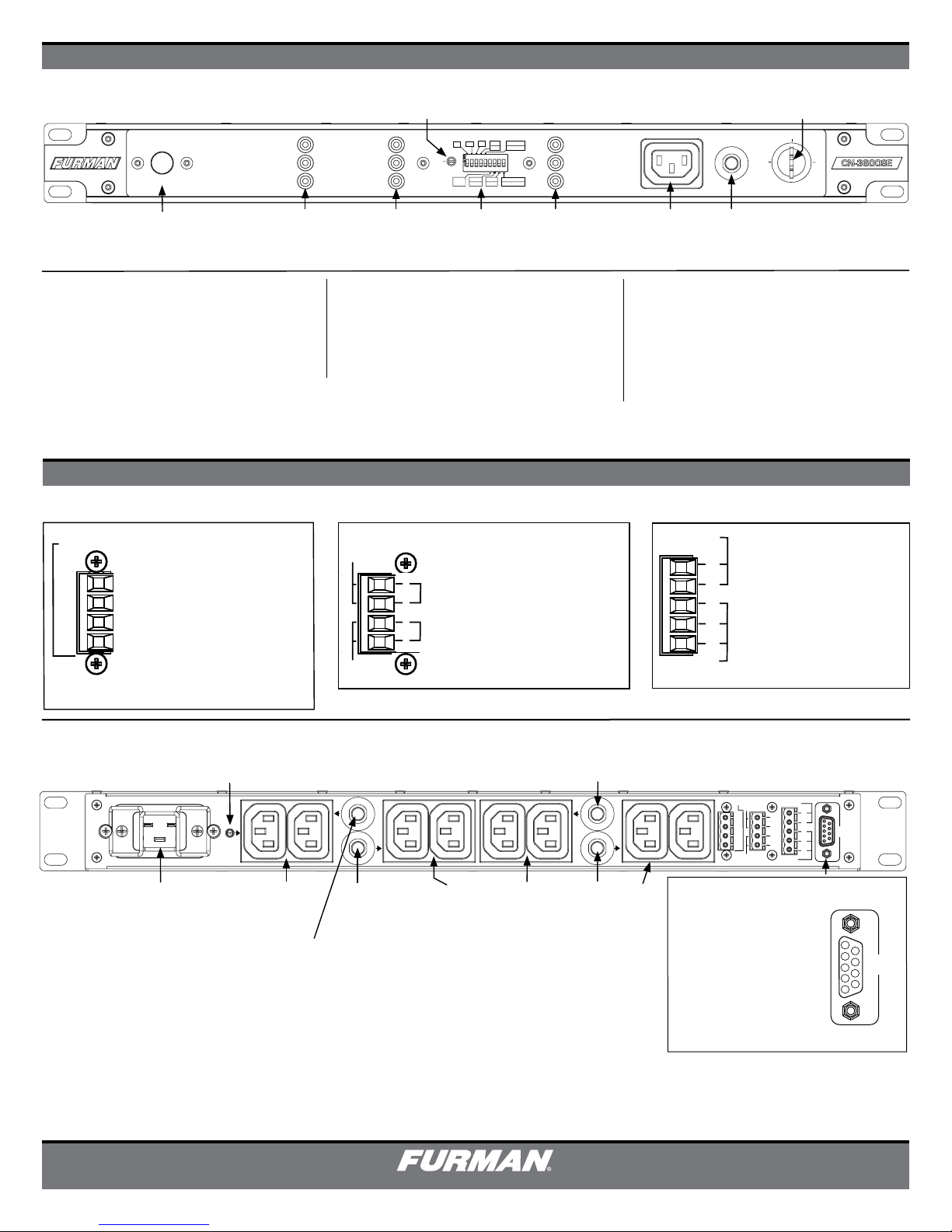

CN-3600SE Front Panel Features

COVER SHIELDS REMOVED

START

SEQUENCE

START SEQUENCE

PUSH BUTTON

START SEQUENCE PUSH BUTTON

Triggers sequence in remote mode.

• Activates or deactivates sequence

• Hold button to re-sync multiple sequencer

CN-3600SE Back Panel Features

PRIMARY LINK

SECONDARY LINK

ETHERNET

CONNECTION STATUS

LIGHTS

s

BASIC POWER MANAGEMENT

• UNSWITCHED OUTLET - 10A Courtesy Outlet

• CIRCUIT BREAKER- Press to reset in the event

PHOENIX TYPE CONNECTORS

REMOTE PORT

+12V

STAT

REM

GND

Remote Barrier Strip (1)

+12V - Main DC terminal output for

remote triggering

STAT - DC terminal output for a

remote LED indicator (ANODE)

REM - Main terminal input for remote

triggering

GND -

Terminal for remote LED status

and/or triggering (CATHODE)

DELAY ADJUSTMENT

DELAY 1

DELAY 2

DELAY 3

DELAY

INDICATOR

LIGHTS

of current overload.

SMARTSEQUENCING

OUT

P

P

S

S

IN

1 2 3 4 5

1M

DLY

ADJ

GND

ON

6 7 8 9

DIP SWITCH

12V ON

N.O.

4M

2M

12V OFF

N.C.

MOM

PRI

EVS AUTO

MNT

SEC

MANUAL

POWER

PROTECTION OK

EXTREME VOLTAGE

POWER

INDICATOR

LIGHTS

SmartSequencing Barrier Strip (2)

Primary poles connect OUT to Secondary

poles of next SmartSequencing device.

Secondary poles connect IN from Primary

poles of previous SmartSequencing device.

NOTE: Chain units in series.

KEY SWITCH

UNSWITCHED ~ 220V-240V, 50/60HZ

MAX LOAD 10A, 2300 WATTS

UNSWITCHED

OUTLET

16 AMPS

PUSH TO RESET

CIRCUIT

BREAKER

REMOTE

OFF

ON

SEQUENCE

KEY SWITCH SETTINGS

3 position ON/OFF Security Switch

• OFF = Bypasses remote sequenced outlets to OFF

• REMOTE = Engages and activates remote features

• ON = Bypasses remote sequenced outlets to ON

NOTE: Settings affect COMM port (see full manual)

FORCE OFF

DELAY 3

Delay 3 may be utilized with Furman PS-8REII and PS-PROEII

Relay Barrier Strip (3)

FORCE OFF Provides immediate

FO

shutdown by fire alarm

FO

Delay 3 - Provides dry contact

NO

closures for relays

NC

(max. 1A @ 24VDC)

C

Rear LED – Indicates unit is receiving AC

power and “Unswitched” outlets are active.

AC

POWER

UNSWITCHED

OUTLET BANK

ALWAYS ON

RESETTABLE CIRCUIT

BREAKER OUTLET

BANK US

DETACHBLE

2.5 METER

16 AMP

POWER CORD

3

U

S

D

1

CIRCUIT BREAKER

OUTLET BANK D1

CIRCUIT BREAKER

OUTLET BANK D2

D

2

D

3

DELAY 1

OUTLET

BANK

DELAY 2

OUTLET

BANK

CIRCUIT

BREAKER

OUTLET

BANK D3

DELAY 3

OUTLET

BANK

IMPORTANT, PLEASE READ

DE-9 Communications port can also provide

power. Pin 2, Pin 3, and Pin 5 can be used for

non-Furman RS-232 devices and protocols.

Please verify pin assignment and protocol

of another manufacturer’s device before

connecting to port.

REMOTE

+12V

FORCE OFF

PRIMARY

STAT

REM

GND

SECONDARY

FO

P

FO

P

S

S

DELAY 3

COMM/

NO

POWER

NC

C

DE-9 FEMALE CONNECTOR RS-232

PIN 1 - ACCESSORY POWER ONLY

(NEGATIVE 12VDC RETURN)

PIN 2 - TRANSMIT DATA

PIN 3 - RECEIVE DATA

PIN 4 - ACCESSORY POWER ONLY

PIN 5 - SIGNAL GROUND

PIN 6 - ACCESSORY POWER ONLY

PIN 7 - REQUEST TO SEND

PIN 8 - CLEAR TO SEND

PIN 9 - ACCESSORY POWER ONLY

(POSITIVE 12V)

1

9

2

8

3

7

4

6

5

COMM/

POWER

Security and Safety

COMM/

POWER

P

P

S

S

OUT

IN

SmartSequencing

PRIMARY

P

P

S

S

OUT

IN

P

P

S

S

OUT

IN

SECONDARY

SECONDARY

The CN-3600SE is readily adaptable to a wide

range of installation requests and requirements.

It was designed from the ground up to be compatible with Furman legacy and third party

equipment. Forced Off inputs and selectable DIP

switch settings are provided to allow easy interface to devices, such as alarm systems.

Additional Features

The CN-3600SE is equipped with LED indicators to provide visual aid in tracking conditions

such as power, protection, sequencing and

communication. The CN-3600SE is supplied by

a 1.5mm^2 AWG, 2.5 meter AC cord. All Contractor Series units are backed by our 15 year

Limited Warranty

Important Safety Instructions

1. Please read and follow all instructions.

2. Please keep these instructions.

3. Please heed all warnings.

4. WARNING: This device is intended for indoor

use only. Do not use this device in or near water.

To reduce the risk of fire or electric shock, do not

expose this device to rain or moisture.

5. CAUTION: Always On receptacles are present,

providing constant AC power. To reduce risk of

shock, please disconnect the CN-3600SE from

AC power before servicing any equipment connected to the CN-3600SE Sequencer.

6. Clean only with dry cloth.

7. CAUTION: Do not install near any heat sources

such as radiators, heat registers, stoves, or other

equipment that may produce heat.

8. Protect the power cord from being walked on

or pinched, particularly at plugs, convenience

receptacles, and the point where they exit the

device.

9. WARNING: The DE-9 RS-232 communications port provides power for Furman accessories (e.g. BB-RS232). Please verify pin assignment and protocol before connecting any other

manufacturer’s device to this port.

10. Please, only use accessories specified by the

manufacturer.

11. Refer all servicing to qualified personnel.

Servicing is required when the unit has been

damaged in anyway or fails to operate.

12. WARNING: Do not use power cord as the

main power disconnect. The device is intended

for AC power sequencing.

13. Do not defeat the safety purpose of the

Schuko plug. A Schuko plug has two pins and

a grounding contact or receptacle. If the Schuko

plug does not fit into your outlet, please consult

an electrician for assistance.

14. This device is supplied with a detachable

IEC-C19 to CEE-7/7 Schuko power cord. Any

prospective replacement cord must comply with

the minimum ratings of the line cord originally

supplied with this device and be HAR Certified

for use in the country in which the unit is de-

ployed.

15. WARNING: This device must be connected

to an AC outlet with a protective earth ground

connection.

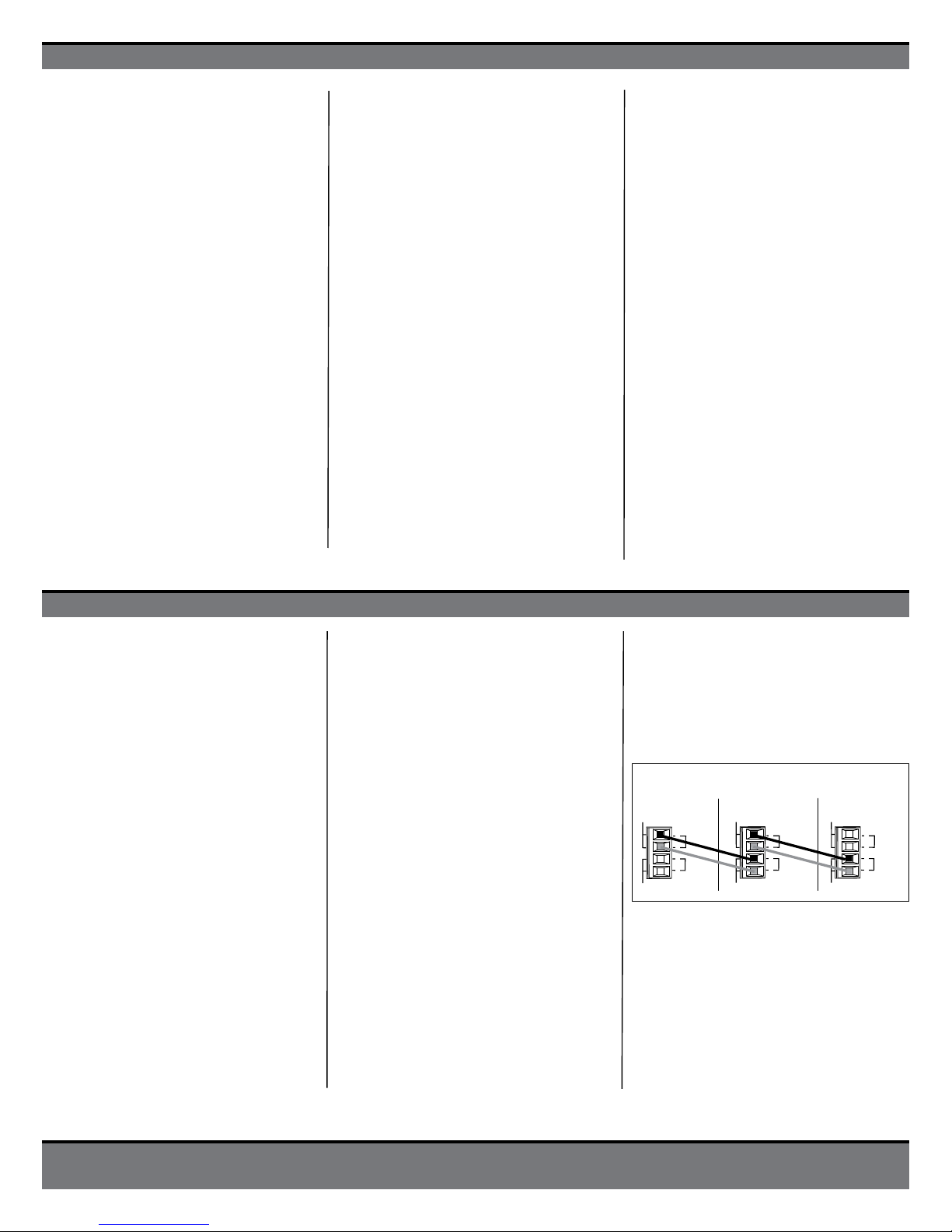

SmartSequencing™ 101

SmartSequencing™ technology provides a very

simple means of connecting together a group of

Furman Contractor devices to form a network or

“chain” of sequencers. SmartSequencing™ allows all devices within a chain to be controlled

and queried from a single Primary sequencer.

One of the defining characteristics of SmartSequencing™ technology is its ability to allow anyone to quickly achieve professional results.

SmartSequencing Hierarchy:

In a SmartSequencing™ network, there can only

be one Primary unit. Secondary units respond

to the commands from the Primary. The Primary unit manages the communications within

the SmartSequencing™ chain. (This includes

principal communication between the chain of

sequencers and the outside world, e.g. BlueBOLT®). Secondary units relay messages and/

or execute commands and queries that have

been routed to them by the Primary unit. The

CN-3600SE can serve as a Primary or Secondary sequencer depending on the setting of DIP

Switch #8 – more on this later.

SmartSequencing Communications:

A Furman SmartSequencing™ chain communicates using a bucket brigade technique. A

Primary sequencer communicates to the first

downstream Secondary sequencer by sending

commands out of its Primary (P) OUT terminals

to the Secondary (S) IN terminals of the next

downstream Secondary sequencer. If there are

additional Secondary sequencers within the

chain, the first Secondary sequencer will communicate to the next downstream Secondary

sequencer using its Primary (P) OUT terminals

to the second Secondary (S) Unit’s Secondary IN

terminals. This continues down the chain until

the last Secondary sequencer has received the

message. The last Secondary sequencer will

receive commands into its Secondary (S) IN

terminal port but will not forward the message

because there are no more units downstream.

Forming a chain of sequencers:

Create a SmartSequencing chain by linking the

Primary (P) OUT terminals of the Primary to the

Secondary (S) IN terminals of the first Secondary sequencer. To add more sequencers, simply

connect

connect this first upstream Secondary Primary

OUT (P) terminals to the Secondary (S) IN ter-

minals of the next Secondary sequencer down-

stream. This pattern continues until all sequenc-

ers have been linked together as is shown in the

figure below.

SmartSequencing

PRIMARY UNIT

PRIMARY (OUT)

P

P

S

S

SECONDARY

SECONDARY UNIT

PRIMARY (OUT)

P

P

S

S

SECONDARY (IN)

SECONDARY UNIT

PRIMARY

P

P

S

S

SECONDARY (IN)

Example of SmartLink connections

SmartSequencing is polarity independent, so it

does not matter which OUT (P) terminal is con-

nected to the IN (S) terminals on the next se-

quencer. All that matters is that the connections

proceed in the order in which you would like your

chain of sequencers to activate.

www.furmancontractor.com • 877-486-4738

4

Loading...

Loading...