Page 1

C US

15 AMP

MINIPORT

120 VAC, 50/60 Hz

MAX LOAD 15A

POWER

EXTREME VOLTAGE

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SECONDARY

LINK

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

PRIMARY

LINK

BYPASS

120 VAC

/60/HZ

A MAX.

15 AMPS

PUSH TO RESET

C US

CN-15MP

120 VAC

/60/HZ

A MAX.

120 VAC

/60/HZ

A MAX.

C US

20 AMP

MINIPORT

120 VAC, 50/60 Hz

MAX LOAD 20A

POWER

EXTREME VOLTAGE

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SECONDARY

LINK

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

PRIMARY

LINK

BYPASS

C US

CN-20MP

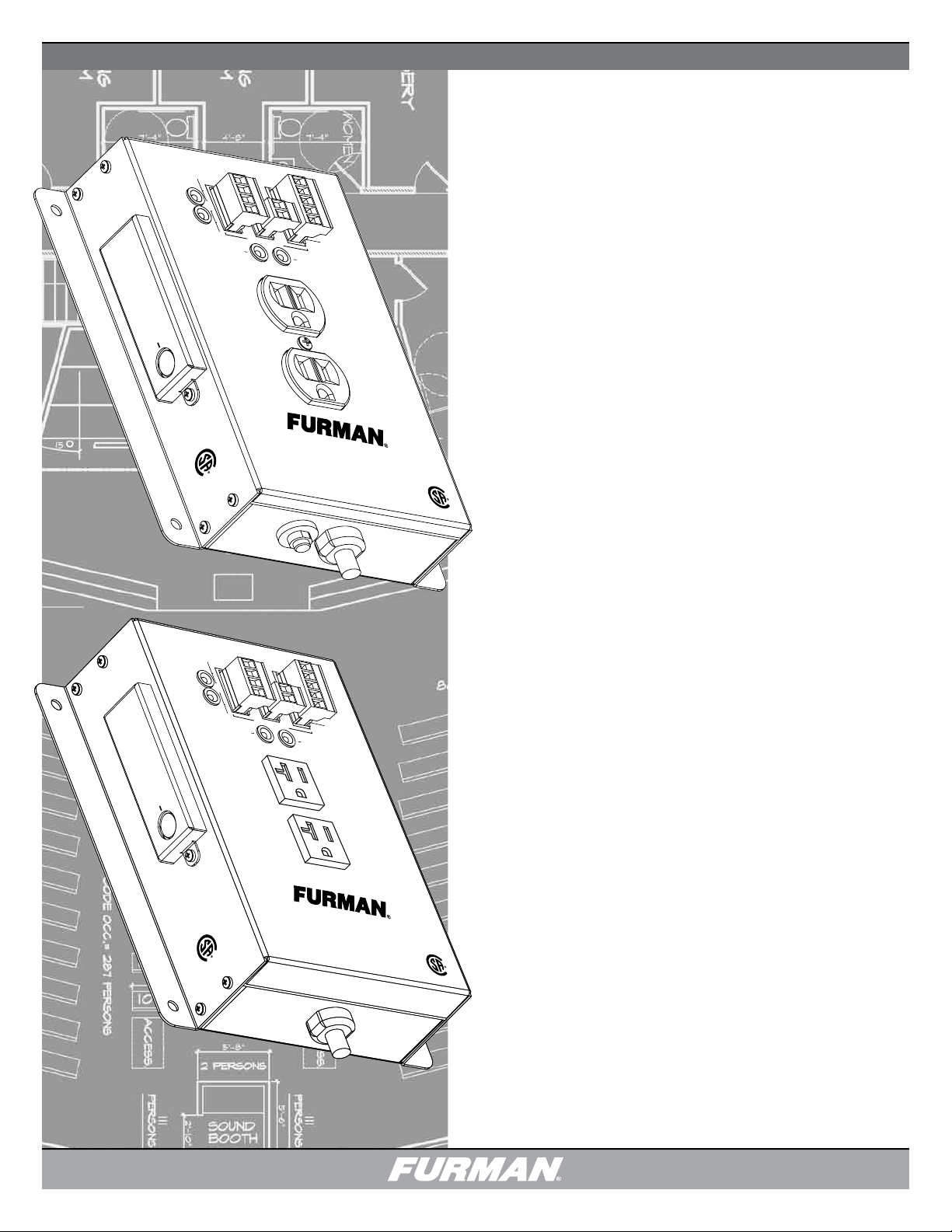

CONTRACTOR SERIES SmartSequencer™

MINIPORT CN-15MP

and CN-20MP

Instructions

Contractor Grade Power Management with

SmartSequencing™ Technology

Features:

SmartSequencing™ technology allows large complex A/V systems to

be safely power cycled on and off sequentially, with the press of a button.

Extreme Voltage Shutdown (EVS) with safeguards against operation

during under and over voltage conditions.

CN-15MP

Security features include cover shield to prevent tampering with switch

settings.

Forced Off immediate shutdown: for safety and fire ordinance compliance.

Multi-Color LED Indicators for status functions.

2 Power Outlets on 1 bank providing 1800 Watts of AC power (CN-15MP)

and 2400 Watts of AC power (CN-20MP).

CN-15MP – 10 ft. Power Cord 14AWG

CN-20MP - 10 ft. Power Cord 12AWG

15 Year Limited Product Warranty

CN-20MP

CN-15-20MP-DIN-00020-A

Page 2

C US

15 AMP

MINIPORT

120 VAC, 50/60 Hz

MAX LOAD 15A

POWER

EXTREME VOLTAGE

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SECONDARY

LINK

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

PRIMARY

LINK

BYPASS

120 VAC

/60/HZ

A MAX.

15 AMPS

PUSH TO RESET

C US

CN-15MP

120 VAC

/60/HZ

A MAX.

120 VAC

/60/HZ

A MAX.

C US

20 AMP

MINIPORT

120 VAC, 50/60 Hz

MAX LOAD 20A

POWER

EXTREME VOLTAGE

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SECONDARY

LINK

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

PRIMARY

LINK

BYPASS

C US

CN-20MP

Introduction

Before You Begin Inspect Upon Receipt

Congratulations and thank you for choosing the Furman CN-15MP or CN20MP Miniport. We assure you that your Miniport will provide many years

of trouble free operation. The Miniport Power Sequencer is equipped with

Furman’s exclusive SmartSequencing™ technology. SmartSequencing™ defines a whole new level of power management and control while

streamlining installations from start to finish.

Why choose Furman?

At Furman Sound, we have spent the last 30 years quietly obsessing

about professional audio and how to best separate your equipment from

the noise and damage often associated with AC power. Over the years we

have developed a multitude of technologies that have spared countless

devices from damage and earned the trust and respect of the Professional A/V industry. The Contractor series represents the culmination of our

engineering expertise and leverages more than 30 years of experience.

Why choose AC power sequencing?

Many pro audio/video installations need audio power amplifiers to activate

last. Our solution is the AC power sequencer. The power sequencer provides AC power to outlet groups one at a time, thus allowing equipment to

be powered up and down in an orderly fashion by first providing power to

signal processing equipment and then providing power to the amplifiers.

When shutting down the A/V system, a sequencer will turn off the system

in the reverse order, hence the amps will be turned off first, and then the

signal processing equipment will be turned off last.

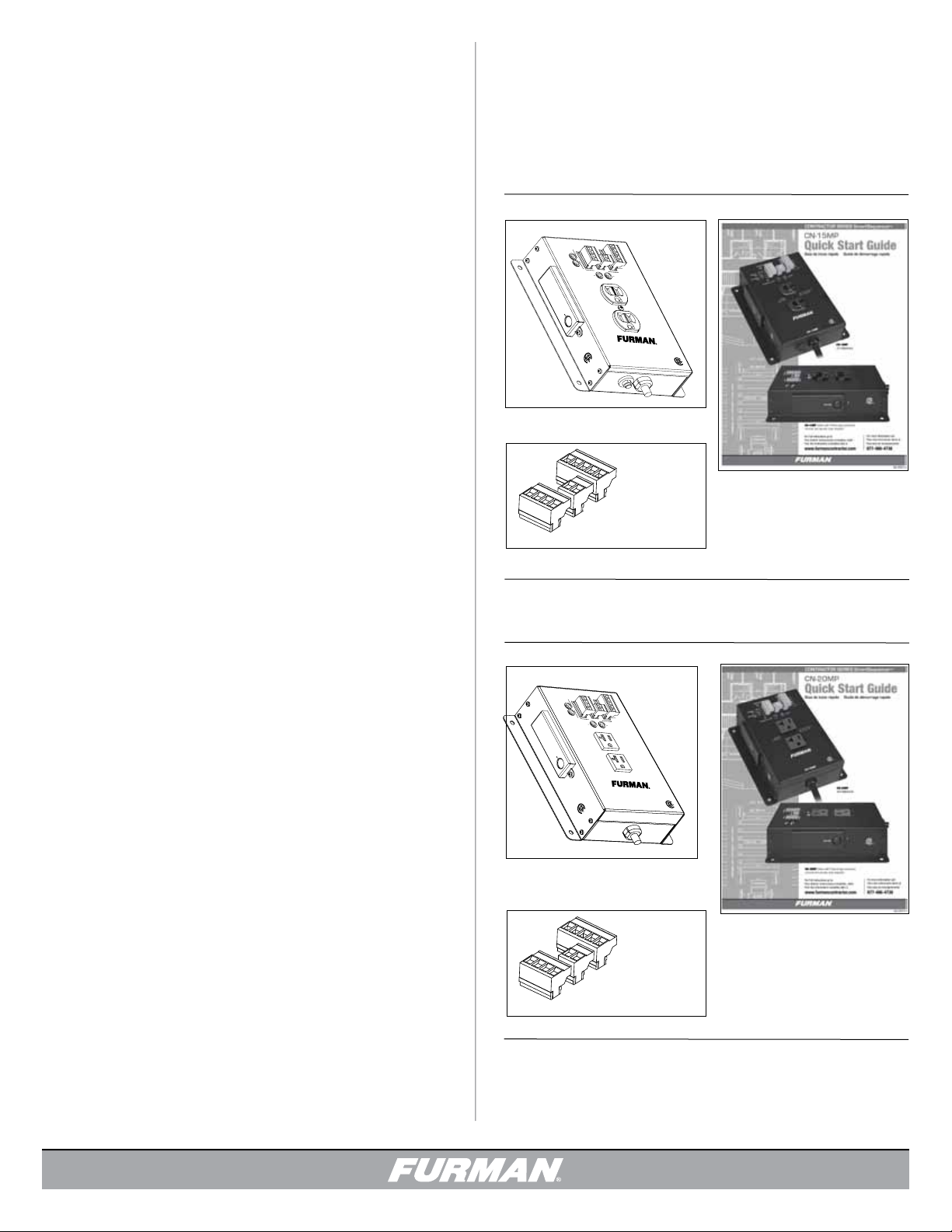

The box should contain the following items:

1) Miniport CN-15MP or CN-20MP

2) Quick Start Guide

3) Phoenix –Type Connectors

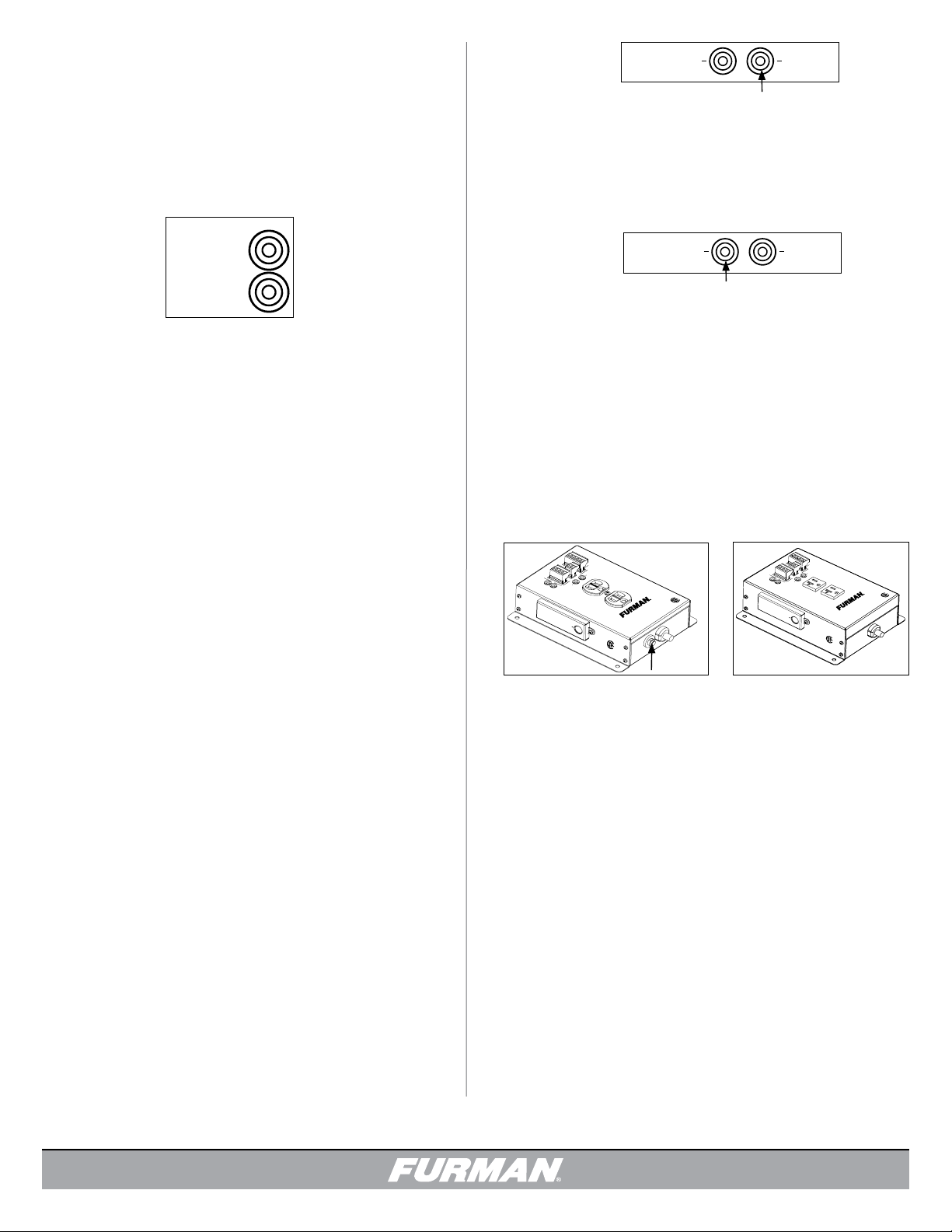

CN-15MP

CN-15MP

FORCE

OFF

3. FIVE PIN CONNECTOR

2. TWO PIN CONNECTOR

1. FOUR PIN CONNECTOR

3 Phoenix Type Connectors

CN-15MP Quick Start Guide

This is necessary because, as most sound reinforcement professionals

know, the majority of equipment damage occurs when devices are either

being powered up or powered down. Power sequencing allows equipment to power up in sequence which prevents the dreaded speaker “pop”

associated with on off switching of signal processing equipment while

the audio power amplifiers are energized. If the signal processing “pop”

is amplified sufficiently, the result can damage amplifiers and speaker

components. Because it prevents this unwanted, and often costly, circumstance, AC power sequencing is extremely valuable.

Furman Contractor Series equipment allows sound reinforcement equipment to be remotely powered up or powered down over a large distance,

not just in the immediate vicinity of the operator. A remotely mounted

switch or control pad can be used to sequence equipment on or off. In

addition, Furman Contractor Series remote functions can be initiated

across a room, on-site, or off-site with our BlueBOLT technology.

The Miniport SmartSequencer fulfills many power sequencing requirements that have very difficult to achieve in the past. Furman SmartSequencing™ delivers an end-to-end solution right out of the box! Please

review this manual to discover how the Miniport with SmartSequencing™

can deliver professional results for you.

CN-20MP

CN-20MP

FORCE

OFF

1. FOUR PIN CONNECTOR

3 Phoenix Type Connectors

3. FIVE PIN CONNECTOR

2. TWO PIN CONNECTOR

CN-20MP Quick Start Guide

1

Page 3

Table of Contents

Remote Access (and BlueBOLT

®)

Feature Descriptions_____________________________________ 2

Important Safety Instructions________________________________ 3

Abbreviated Product Features_______________________________3

Set Up Diagrams____________________________________4 & 5

SmartSequencing™101__________________________________ 6

Side Panel Overview _______________________________7, 8 & 9

Front Panel Overview_______________________________10 & 11

Setup and Troubleshooting________________________________ 11

Single Unit Set Up_____________________________________ 11

Multiple Unit Set Up______________________________________11

Breaker Overload______________________________________11

Re-syncing Multiple Sequencers____________________________12

Specifications ________________________________________12

15 Year Limited Warranty_________________________________12

SmartSequencing™

Furman SmartSequencing™ is a contractor-friendly technology that

makes AC power sequencing easy to employ by non-technical personnel. Using SmartSequencing technology, multiple Furman Contactor

Series units can be linked together over distances up to 1000 feet using

inexpensive two conductor wire. These same two wires not only control

the sequencers, but also form the backbone of an amazingly robust

and reliable communication system through which information about

status, voltage, current, and power can be queried from any device in the

SmartSequencing network.

Generally, high-priced automation systems are used for large, innovative

installs, yet these control systems seldom combine AC power distribution

and bidirectional sequencing. SmartSequencing™ provides the answer

right out of the box by offering a simple approach to AC power management and control. Furman’s newest power sequencing technology is

an end-to-end solution that is operational up to 1000 feet via a nonpolarized, isolated current loop. In situations where power sequencing is

critical, or more than one AC electrical circuit is utilized, wiring Furman

SmartSequencing™ products in series is simple, fast and reliable.

EVS (EXTREME VOLTAGE SHUTDOWN)

Furman’s trusted (EVS) over-voltage detection protects against prolonged

over-voltage conditions, such as accidental connections to 208 or 240

VAC or an intermittent loss of neutral. It does so by continuously monitoring the incoming AC voltage and when an unsafe condition is detected,

a relay shuts off the power to the outlets until the overvoltage condition

has subsided. The Miniport also allows the EVS shut-down feature to be

overridden. The Extreme Voltage Shutdown technology is a tremendous

asset.

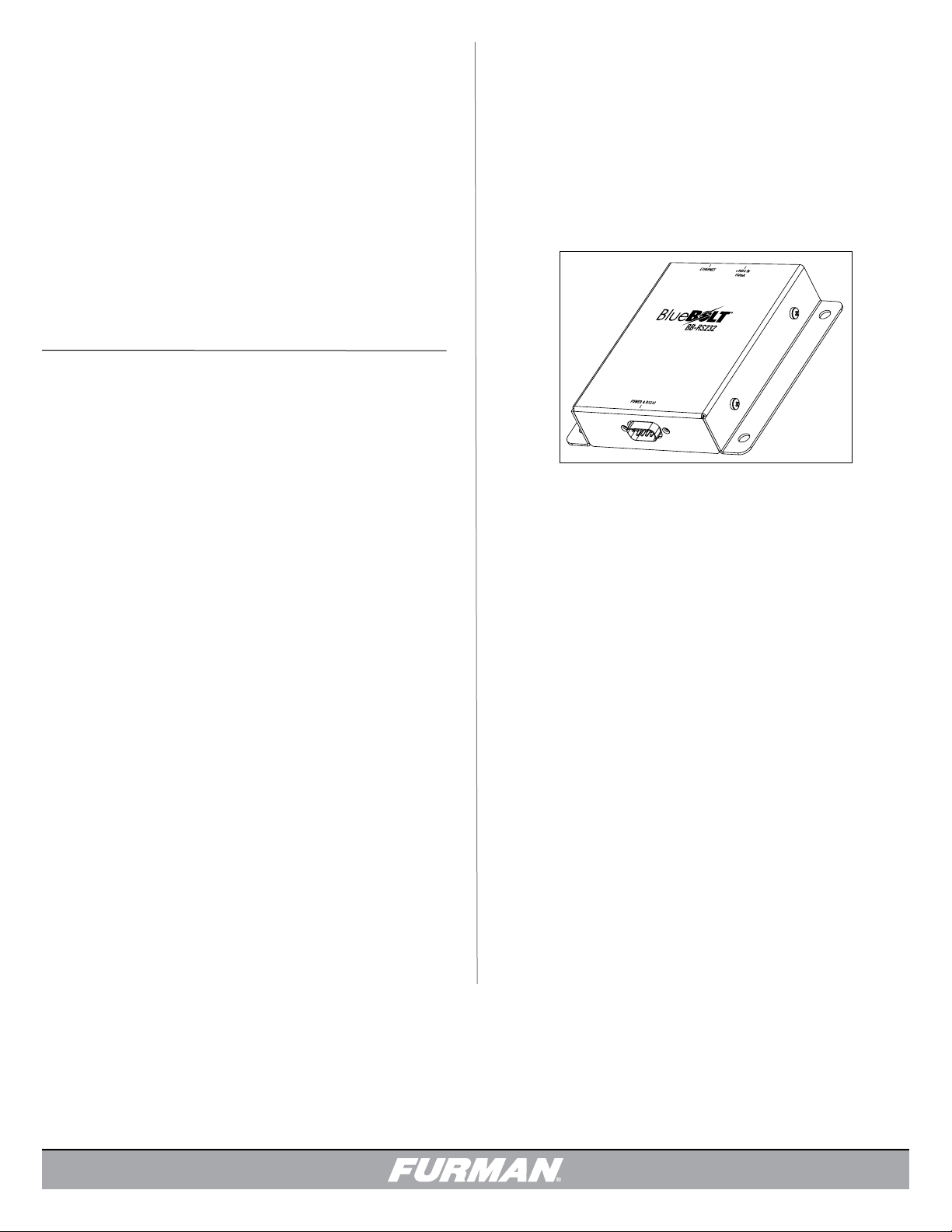

The Miniport is a member of Furman’s Contractor series of devices. All

members of the Contractor series can be controlled remotely using an

integral data-link and command API. The remote access feature delivers

integration with various control systems. The API provides a rich set of

commands and queries that allow remote control and situational awareness over large distances. Furman’s optional BlueBOLT® RS-232-toEthernet adaptor provides additional control programming and monitoring

from any Web-enabled device via Telnet, direct HTTP connection, or www.

mybluebolt.com

BB-RS232

Security and Safety

The Miniport is readily adaptable to a wide range of installation requests

and requirements. It was designed from the ground up to be out-ofbox compatible with Furman legacy and third party equipment. Forced

Off inputs and selectable DIP switch settings are provided to allow easy

interface to devices, such as alarm systems.

Additional Features

The Miniport is equipped with LED indicators to provide visual aid in

tracking conditions such as power, protection, sequencing and communication. The Miniport CN-15MP is supplied by a 14 AWG, 10 foot AC cord.

And the Miniport CN-20MP is supplied with a 12 AWG, 10 foot AC cord.

All Contractor Series units are backed by our exclusive 15 year Limited

Warranty

2

Page 4

C US

15 AMP

MINIPORT

120 VAC, 50/60 Hz

MAX LOAD 15A

POWER

EXTREME VOLTAGE

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SECONDARY

LINK

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

PRIMARY

LINK

BYPASS

120 VAC

/60/HZ

A MAX.

15 AMPS

PUSH TO RESET

C US

CN-15MP

Important Safety Instructions

CLASS 2 WIRING

FORCE

OFF

POWER

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

1. Please read and follow all instructions.

2. Please keep these instructions.

3. Please heed all warnings.

4. WARNING: This device is intended for indoor use only. Do not use this device

near water. To reduce the risk of fire or electric shock, do not expose this device

to rain or moisture.

5. CAUTION: To reduce risk of shock, please disconnect the CN-15MP / CN20MP Sequencer from AC power before servicing any equipment connected to

the CN-15MP / CN-20MP Sequencer.

6. Clean only with dry cloth.

7. CAUTION: Do not install near any heat sources such as radiators, heat regis-

ters, stoves, or other equipment that may produce heat.

8. Protect the power cord from being walked on or pinched, particularly at plugs

and the point where they exit the device.

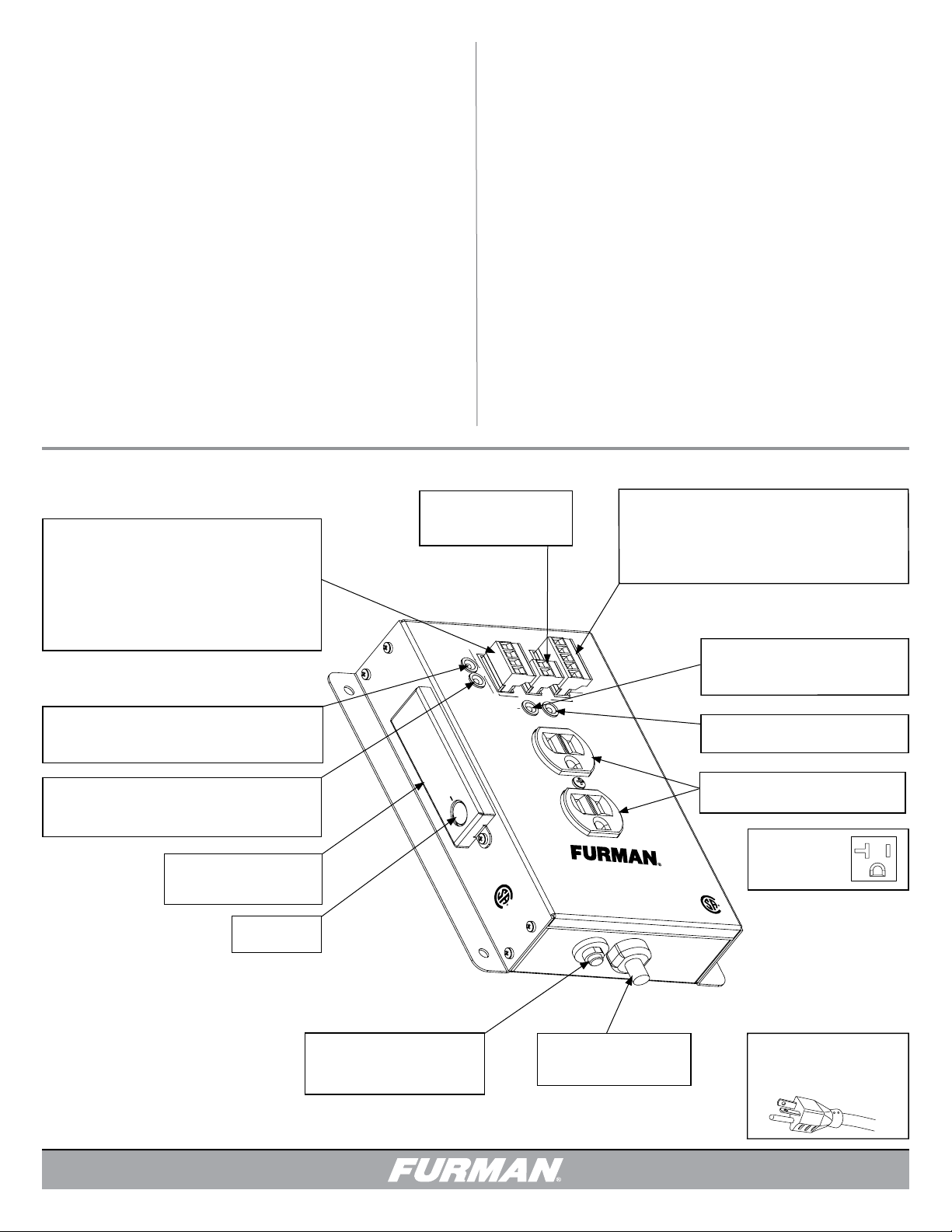

ABBREVIATED PRODUCT FEATURES

PHOENIX TYPE CONNECTORS

SmartSequencing Barrier Strip (1)

Primary terminals connect OUT to Secondary terminals

of next SmartSequencing device.

Secondary terminals connect IN from Primary terminals

of previous SmartSequencing device.

NOTE: Chain units in series.

CONNECTION STATUS LIGHTS

PRIMARY LINK – Multi-color LED indicates the condition

of communication between the Secondary Link and the

Primary Link of the preceding unit.

SECONDARY LINK – Multi-color LED indicates the condition

of communication between the Secondary Link and the

Primary Link of the following unit.

SECURITY PLATE Protects DIP

Switches and Delay Adjustment

Settings

BYPASS SWITCH

For force on

Force Off Barrier Strip (2)

FORCE OFF Provides immediate

shutdown by fire alarm

9. Please, only use accessories specified by the manufacturer.

10. Refer all servicing to qualified personnel.

Servicing is required when the unit has been damaged in any way or fails to

operate.

11. WARNING: Do not use power cord as the main power disconnect. The device

is intended for AC power sequencing.

12. Do not defeat the safety purpose of the polarized plug. A polarized plug has

two blades, with one wider than the other. The wide blade is provided for your

safety. If the provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet. (*See below for 20A plug)

13. Do not defeat the safety purpose of the grounding prong. A ground type plug

has two blades and a third grounding prong. The third prong is provided for your

safety. If the provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

14. WARNING: This device must be connected to an AC outlet with a protective

earth ground connection.

Remote Barrier Strip (3)

+12V - Main DC terminal output for remote triggering

STAT - DC terminal output for a remote LED indicator (ANODE)

REM - Main terminal input for remote triggering

GND -

Terminal for remote LED status and/or triggering (CATHODE)

DLY OUT - Legacy Miniport compatible Delay On function

POWER PROTECTION INDICATORS

EXTREME VOLTAGE Illuminated RED when

an extreme voltage condition is present

(consequently, all outlets are powered off).

POWER Illuminated GREEN indicates when

the AC duplex is powered.

CN-15MP

TWO NEMA 5-15R AC RECEPTACLES

CN-20MP

TWO NEMA 5-20R

AC RECEPTACLES

3

CIRCUIT BREAKER 15A Press to

reset in the event of current overload.

No circuit breaker on CN-20MP

CN-15MP

10 FT. AC POWER CORD

3/14 AWG, NEMA 5-15P PLUG

CN-20MP

10 FT. AC POWER CORD

3/12 AWG, NEMA 5-20P PLUG

Page 5

SmartSequencer

™

DIAGRAM 1

-

SMALL SMARTSEQUENCING SET-UP

CLASS 2 WIRING

24 AWG RECOMMENDED

Fire ordinances sometime require immediate shut

down, no matter how large or small a sound system.

SmartSequencing provides the solution.

RS-2 Momentary

Remote Switch

CN-1800S

+12

STAT

REM

GND

+12

STAT

REM

GND

P

S

FIRE ALARM (2 POLE)

V S R G D

P S

FORCE OFF

V S R G D

P S

FRONT PANEL DIP SWITCH SET

POWERED ARRAYS

MONITOR SYSTEM

BACK PANEL TERMINALS

CN-20 MP

CN-20 MP

FORCE

OFF

NO

NC

C

FORCE OFF

DELAY

ADJUST

IMMEDIATE FORCED OFF WITH SHORT

V = VOLTAGE

S = STATUS

R = REMOTE

G = GROUND

D = DELAY

ON

1 2 3 4 5 6 7 8 9

ON

1 2 3 4 5 6 7 8 9

DIP SWITCH SET

DIP SWITCH SET

ON

1 2 3 4 5 6 7 8 9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

ON

FOR REFERENCE

ONLY

ABBREVIATED

DESCRIPTIONS

AS SHOWN ON

THE PRODUCT.

NOT FOR

SETTING(S)

INSTRUCTIONS.

CN-15MP PRIMARY

CN-1800 replaces Legacy product for

purposes of immediate shutdown.

RS-1 Maintained

Key Switch

+12

STAT

REM

GND

SmartSequencer

™

DIAGRAM 2

-

SMARTSEQUENCING SET-UP - BUDGET

CLASS 2 WIRING

24 AWG RECOMMENDED

CN-15 MP

V S R G D

V S R G D

MP-20 (Old)

V S R G D

V S R G D

P S

FORCE OFF

ON

1 2 3 4 5 6 7 8 9

DIP SWITCH SET

MP-20 (Old)

FOR REFERENCE

ONLY

ABBREVIATED

DESCRIPTIONS

AS SHOWN ON

THE PRODUCT.

NOT FOR

SETTING(S)

INSTRUCTIONS.

GND

ON

MOM

MNT

PRI

SEC

EVS ON

EVS OFF

6

7

8

9

1M

2M

4M

N.O.

N.C.

12V ON

12V OFF

1

2

3 4

5

1 2 3 4 5 6 7 8 9

ON

EXAMPLE 1 DIAGRAM - SMALL SmartSequencing SET-UP

EXAMPLE 2 DIAGRAM - SMARTSEQUENCING SET-UP - SAMLL LEGACY UPGRADE

When using Legacy Port,

Dip Switch #8 must be in

the up position.

4

Page 6

This upgrade is based upon scenario number 3 in

the ASD-120 manual. The new example substitutes

CN-2400S units at the old miniport locations.

PRIMARY CONTROL AMP RACK

P

S

+12

STAT

START

REM

FORCE ON

FORCE OFF

REM COMM

GND

RLY COMM

F

ASD-120

A

B

C

D

E

CN-2400S

+12

STAT

REM

GND

STAT

REM

GND

(LOCATION ORIGINALLY WAS A MP-20Q)

STAGE MONITOR CIRCUITS

WAS MP-20

CN-2400S

P

S

+12

STAT

REM

GND

STAT

REM

GND

#1 B

WAS MP-20

CN-2400S

P

S

+12

STAT

REM

GND

STAT

REM

GND

#2

SmartSequencer

™

DIAGRAM 3

-

LARGE LEGACY UPGRADE

BACK PANEL TERMINALS

BACK PANEL TERMINALS

ON

1 2 3 4 5 6 7 8 9

DIP SWITCH SET #2

FORCE OFF

FORCE OFF

FORCE OFF

FORCE OFF

ON

1 2 3 4 5 6 7 8 9

DIP SWITCH SET #1

ON

1 2 3 4 5 6 7 8 9

DIP SWITCH SET

FORCE OFF

FORCE OFF

RS-1 Maintained

Key Switch

+12

STAT

REM

GND

CLASS 2 WIRING

24 AWG RECOMMENDED

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

ON

FOR REFERENCE

ONLY

ABBREVIATED

DESCRIPTIONS

AS SHOWN ON

THE PRODUCT.

NOT FOR

SETTING(S)

INSTRUCTIONS.

#1 A

P

P

S

S

CN-1800S

+12

STAT

REM

GND

UNIT 3

SECONDARY INTERFACE

NO

NC

C

FORCE OFF

FORCE OFF

P

P

S

S

CN-1800S

+12

STAT

REM

GND

UNIT 2

SECONDARY INTERFACE

NO

NC

C

FORCE OFF

FORCE OFF

FORCE OFF

FORCE OFF

NO

NC

C

ON

1 2 3 4 5 6 7 8 9

SECONDARY DIP SWITCH SET

SYSTEM CONTROLLER

RS-232 PROTOCOL

CN-1800S

+12

STAT

REM

GND

System controllers can interface

with the CN Series sequencers

locally or from the cloud. Yet also

be interrupted by fire alarms.

SmartSequencer

™

DIAGRAM 4

-

LARGE SMART SET-UP PRIMARY INDEPENDENT MULTI-ROOM

COMMON SETTING FOR UNITS (2, 3, 4, 5)

SECONDARY INTERFACE UNITS ABOVE

UNIT 1

PRIMARY INTERFACE

SEPARATE ROOM

P

P

S

S

FIRE ALARM

3 POLE

ON

1 2 3 4 5 6 7 8 9

PRIMARY DIP SWITCH SET

COMMON SETTING FOR UNIT 1

PRIMARY INTERFACE UNIT ABOVE

CLASS 2 WIRING

24 AWG RECOMMENDED

V S R G D

P S

FORCE OFF

CN-15MP

V S R G D

P S

FORCE OFF

UNIT 5

UNIT 4

CN-15MP

SECONDARY

INTERFACE

SECONDARY

INTERFACE

FOR REFERENCE ONLY

ABBREVIATED

DESCRIPTIONS

AS SHOWN ON

THE PRODUCT.

NOT FOR

SETTING(S)

INSTRUCTIONS.

GND

ON

MOM

MNT

PRI

SEC

EVS ON

EVS OFF

6

7

8

9

1M

2M

4M

N.O.

N.C.

12V ON

12V OFF

1

2

3 4

5

1 2 3 4 5 6 7 8 9

ON

EXAMPLE 3 DIAGRAM - LARGE LEGACY UPGRADE

EXAMPLE 4 DIAGRAM - LARGE SET-UP PRIMARY CONTROLLED VIA RS-232

5

Page 7

SmartSequencing™ 101

SMARTSEQUENCING

SECONDARY

SmartSequencing requires that a pair of wires be connected between the

Primary OUT terminals of one sequencer to the Secondary IN terminals of

a second sequencer. SmartSequencing is polarity independent, so it does

not matter which terminals are used at the IN port or the OUT port. Two

wire runs connecting two or more units create a SmartSequencing chain.

OUT

P

P

S

S

IN

PRIMARY

OUT

P

P

S

S

IN

OUT

P

P

S

S

IN

SECONDARY

Furman SmartSequencing™ products can be connected end-to-end to

form a chain of sequencers. Each Contractor Series unit has two communication ports (OUT and IN) divided into 4 terminals, responsible for

half-duplex transmissions via two bi-directional current loops. The messages between connected devices are communicated in the form of ASCII

character strings utilizing a proprietary data link protocol.

A Furman SmartSequencing™ chain communicates using a bucket

brigade technique. A Primary Unit communicates to the first Secondary

Unit downstream by sending commands out of its Primary OUT terminals

to the Secondary IN terminals of the first downstream Secondary Unit. If

there is an additional Secondary Unit in the chain, the first Secondary Unit

will communicate to the additional Secondary Unit using its Primary OUT

terminals to the second Secondary Unit’s Secondary IN terminals. This

continues down the sequence chain until the last Secondary Unit. The

last Secondary Unit will receive commands into its Secondary IN terminal

port but will not use its Primary OUT terminal port (because there are no

Secondary Units after it). Please see figure above:

SmartSequencing™ commands between units are always accepted

when continuity exists, however SmartSequencing commands that control

the outlets are not always honored. This may occur if the Miniports

switch settings of conditions conflict with the requested SmartSequencing

command. For example: BYPASS switch, REMOTE Input, EVS, or FORCE

OFF may have priority over the SmartSequencing command.

Additional SmartSequencing™ information is available throughout this

manual and also on the website www.furmancontractor.com. Details

such as connection diagrams and a Quick Start Guide, etc., can also be

found at the website.

The first SmartSequencer within a chain is referred to as the “Primary”

or “Primary Unit”. The Primary unit controls the other sequencers in

the chain. The other sequencers are termed “Secondary” or “Secondary

Units”. The Primary Unit only has one active current loop because the

Primary Unit only has one Secondary sequencer attached to it. Secondary units have two active current loops because they are inserted

between two sequencers. A chain of sequencers is created by connecting the PRIMARY OUT terminals of one sequencer to the Secondary IN

of the next downstream sequencer.

6

Page 8

1 2 3 4 5 6 7 8 9

C US

Side Panel Overview

6 7 8 9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

DIP Switches

1M

1

2

2M

4M

3 4

DLY

ADJ

6

1 2 3 4 5 6 7 8 9

7

MOM

MNT

GND

ON

Potentiometer

FACTORY DEFAULT SETTING

Bypass Switch

The BYPASS push button switch is located on the side panel to the right

of the DIP Switch. A hole in the security cover provides access to the

BYPASS switch even when the security cover is installed.

The BYPASS switch has a dual purpose:

The BYPASS switch is provided to allow a layperson to activate the outlets

if the external control system is either inaccessible or commanding the

outputs to an OFF state. It should be noted that the FORCE OFF and EVS

conditions have priority over the BYPASS switch and if either of these

conditions are true, the outlets will be deactivated regardless of the position of the BYPASS switch. The BYPASS switch operates in a push on/

push off mode and latches either on or off. If the switch is pushed on,

the outlet will remain powered until the switch is pressed a second time

and latches in the off state.

The BYPASS switch is also used to clear the FORCE OFF error. If the unit

is in FORCE OFF mode, and the conditions at the FORCE OFF inputs that

spawned the FORCE OFF error have been removed, the user can use

the BYPASS switch to clear the FORCE OFF error by quickly toggling the

BYPASS switch ON/OFF.

12V ON

5

12V OFF

Bypass Switch

N.O.

N.C.

BYPASS

PRI

8

SEC

EVS ON

9

EVS OFF

1 2 3 4 5

N.O.

N.C.

12V ON

12V OFF

EVS AUTO

MANUAL

4M

2M

1M

1 2 3 4 5 6 7 8 9

GND

Default DIP Switch Settings

ON

MOM

MNT

PRI

SEC

DIP 1, 2, & 3 and the Delay Adjustment

DIP Switch positions 1, 2 and 3 are used to define the time delay or

“dwell” time that is imposed between activating/deactivating consecutive devices within a chain of sequencers. Miniports will activate their

outlet as soon as an activation message or signal has been received, but

impose a delay (defined by the settings of DIP 1, 2 & 3) when forwarding

the activation message to the next downstream device. When activating,

the delay countdown starts after the outlet has been activated. When

deactivating, the delay occurs prior to deactivating the outlet.

DIP Switch and Delay Adjustment

The DIP Switch is found near the center of the side panel, under the

Security Cover. You can access the DIP switch by removing the security

cover screw using a small Philips screwdriver. The DIP Switch is used to

set various options. It is also used in combination with the DLY ADJ pot to

the ON/OFF delay.

ON

ON

OFF

NOTE: The DIP switch

ON / OFF settings are

indicated as shown

below throughout

this manual.

7

DIP SWITCH DEFAULT SETTING Switches are factory pre-set as shown

below. Switches 1, 4, 8, and 9 are up

(ON) position.

DIP 1 = ON adds 1 to the minute maximum time delay

DIP 2 = ON adds 2 minutes

DIP 3 = ON adds 4 minutes.

Note: The DIP switch settings are cumulative, thus if all three DIP

switches are in the ON position, the maximum allowable time delay will

be 7 minutes, i.e. 1min+2min+4min=7min. The factory default setting

is DIP 1 ON or UP, and DIP 2 and 3 are OFF or DOWN. You can set these

switches in any position you like to achieve your preferred time delay

DIP 1 DIP 2 DIP 3 Maximum Time Delay

OFF OFF OFF 10 Seconds

ON OFF OFF 1 Minute

OFF ON ON 2 Minute

ON ON OFF 3 Minute

OFF OFF ON 4 Minute

ON OFF ON 5 Minute

OFF ON ON 6 Minute

ON ON ON 7 Minute

Page 9

Delay Adjustment

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

6 7 8 9

8

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

1 2 3 4 5

N.O.

12V ON

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

6 7 8 9

8

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

The Delay Adjustment (DLY ADJ) pot is used in conjunction with DIP 1,

2, and 3 to precisely dial in your preferred delay time. The DLY ADJ is

located to the left of the DIP Switch. If this potentiometer is turned to its

100% value (fully clockwise), the time delay will be equal to the maximum

time delay defined by DIP switches 1, 2, and 3. If the potentiometer is in

the 12:00 o’clock position (50%), then the time delay will be 50% of the

maximum time delay interval defined by the setting of DIP Switch positions 1, 2 & 3. If all three DIP switches are off, and the potentiometer is

turned completely counter-clockwise, the time delay is 100 milliseconds,

which is the minimum time setting. The Delay Adjustment potentiometer

comes factory-set at 50%, the 12 o’clock position.

Example: If the DIP Switches are set to a 6 minute maximum delay

and the potentiometer is set to its 50% setting, then the delay interval

between sequenced banks will be 3 minutes. (DIP 1 OFF or DOWN, DIP 2

and DIP 3 ON or UP) x .50 = 6 minutes x .50 = 3 minutes.

1 2 3 4 5

2M

1M

4M

N.O.

N.C.

12V ON

12V OFF

Once FORCE OFF has been cleared, normal operation will resume. Force

off (DIP 4) has priority over all other DIP switch settings, including DIP 5,

DIP 6, and DIP 7 settings. Further information on DIP 5, DIP 6, and DIP

7 can be found in the sections that follow. The use of DIP 4 may or may

not be a consideration for every install, yet it may be a vital feature for

safety compliance. The Force Off feature is always working, despite the

fact sometimes it is in a forgotten state.

1 2 3 4 5

N.O.

N.C.

12V ON

12V OFF

EVS AUTO

MANUAL

REMOTE

PORT

Remote Port

+12V

STAT

REM

GND

DLY OUT

4M

2M

1M

1 2 3 4 5 6 7 8 9

GND

ON

Default DIP Switch Settings

MOM

MNT

PRI

SEC

DIP 5 and 6 Remote input setting

1 2 3 4 5 6 7 8 9

GND

MOM

PRI

ON

MNT

SEC

EVS AUTO

MANUAL

Default DIP Switch

Settings

DIP 4 FORCE OFF setting

DIP Switch position 4 is used to define how the Miniport will implement

its FORCE OFF feature. FORCE OFF is a safety feature that is designed

to cut AC power to all outlets instantaneously. Some municipalities may

require this feature as a means of disabling equipment in the presence of

fire or an alarm. The FORCE OFF inputs can be used with a momentary

or maintained dry contact in either a Normally Open or Normally Closed

state. The factory default position for DIP 4 ON or UP, or (NO) Normally

Open. In this configuration, the FORCE OFF will be triggered when the

FORCE OFF pins are shorted together. If DIP Switch position #4 is off (DIP

4 DOWN) the FORCE OFF pins must remain shorted for normal operation.

In this configuration, the FORCE OFF will be triggered when the short

between the two FORCE OFF pins is removed.

If a FORCE OFF is triggered, the FORCE OFF message will be propagated

to all SmartLink connected devices. The power to all of the outlets will

be disabled and the POWER LEDs will begin to blink. To clear the FORCE

OFF, the FORCE OFF pins must first be cleared of the condition that

originally triggered the FORCE OFF event. After this has been done you

can reset the FORCE OFF in three ways:

1) Cycle the BYPASS switch on/off.

2) Cycle the power to the unit on/off

3) If you are using a rack-mounted Contractor device (CN-1800S,

CN-2400S, CN-3600S) as a Primary unit, you can clear the

FORCE OFF from all SmartLink connected units by turning the

key to the OFF position and then back to the ON or REMOTE

position.

DIP Switch positions 5 and 6 are used to define what happens when

either 12VDC or GND are applied to the remote (REM) signal input. All of

the signals discussed in this section appear on the REMOTE PORT connector on the top right side of the CN-15MP.

The factory default settings for DIP 5 and DIP 6 are OFF

With DIP 5 and DIP 6 OFF (factory default) connecting the 12VDC signal

to the REM terminal will cause the outlet power to turn OFF. With DIP 5

ON and DIP 6 OFF, connecting the 12VDC signal to the REM terminal will

cause the outlet power to turn ON. With DIP 6 ON connecting GND to

the REM terminal will cause the outlet power to turn on regardless of the

setting of DIP switch 5.

The table below summarizes the power outlet behavior as a function of

DIP 5 and DIP 6

DIP 5 DIP 6 Outlet behavior as a function of the REM signal input

OFF OFF Outlet is deactivated when REM is connected to 12VDC

ON OFF Outlet is activated when REM is connected to 12VDC

OFF ON Outlet is activated when REM is connected to GND

ON ON Outlet is activated when REM is connected to GND

Note that the setting of DIP switch 6 overrides DIP switch 5.

If DIP Switch 6 is ON the setting of DIP switch 5 is ignored.

The settings for DIP 5 and DIP 6 may be useful in situations where

the existing remote key switch operates different from that which was

anticipated by the factory default settings, or Furman standard wall

switch products (RS-1 and RS-2). Please feel free to contact Furman tech

support if further assistance is necessary.

8

Page 10

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

1M

1 2 3 4 5

6 7 8 9

8

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

6 7 8 9

1M

1 2 3 4 5

2M

4M

N.O.

N.C.

12V ON

12V OFF

GND

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

6 7 8 9

1 2 3 4 5 6 7 8 9

6 7 8 9

2M

4M

N.O.

N.C.

12V ON

12V OFF

1 2 3 4 5

N.O.

1M

2M

4M

N.C.

12V ON

12V OFF

1 2 3 4 5 6 7 8 9

GND

ON

Default DIP Switch Settings

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

DIP Switch position 7 is used to define the switching preference for

switches or devices connected to the remote (REM) signal input. The

Miniport can be set to operate in a Maintained Mode (DIP 7 OFF or

DOWN) or a Momentary Mode (DIP 7 ON or UP) dependent upon the

preferred method of remote switching. The factory default for DIP 7 is

OFF (Maintained Mode)

When operating in Maintained Mode, the REM input assumes that an

external switch or device will behave like a toggle switch wherein the

switch contacts remain in a given position (open or closed) until the state

of the switch has been changed. Maintained switching is considered

more stable because control signals must be continuously asserted to

“maintain” a system in operation.

When operating in Momentary Mode, the REM Input assumes that an

external switch will behave like a momentary contact (push button)

switch where the switch contacts are shorted only as long as the button

is pressed. The output will toggle ON or OFF each time the REM input is

activated. Momentary Mode is considered more flexible than Maintained

mode as multiple push button switches, such as the Furman RS-2 can be

wired in parallel and used to toggle a Miniport ON or OFF from multiple

locations.

1 2 3 4 5

N.O.

1M

4M

2M

1 2 3 4 5 6 7 8 9

N.C.

12V ON

12V OFF

GND

Default DIP Switch Settings

DIP 8 Primary / Secondary setting

DIP Switch position 8 is used to define the Miniports role in the SmartSequencing™ system. In an array of sequencers connected via SmartLink, there can be only one Primary Sequencer, and multiple (up to 99)

Secondary Sequencers. A Primary Sequencer sends commands to all

ON

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

REMOTE

PORT

Remote Port

Secondary sequencers over the SmartLink interface. If DIP Switch 8 is

ON, the Miniport is set as Primary Sequencer. If DIP Switch 8 is OFF the

Miniport will operate as a Secondary Sequencer.

DIP 9 EVS ON or EVS OFF setting

DIP Switch position 9 is used to define how the Miniport will behave in

the presence of Extreme voltage. If DIP 9 is ON (EVS = ON) the Miniport

will automatically turn off power to its outlet if the incoming power ever

goes above or below tolerable conditions. If DIP 9 is OFF (EVS = OFF) the

Miniport will register, but not turn off power to its outlet if the incoming

power ever goes above or below tolerable conditions.

For the Miniport the over-voltage EVS triggers at 145 VAC +/- 5% and the

under-voltage EVS is triggered at 77 VAC +/- 5%.

If DIP 9 is set to ON and an EVS event occurs, the Miniport will not automatically turn on after the EVS event has subsided unless the BYPASS

switch is on, or the remote port has been configured to enable the outlet.

To reactivate a Miniport operating in a Smartlink, all units must be

sequenced off and then back on. This can be done by sequencing the

Primary unit OFF/ON.

Please note, if there is an underlying wiring fault, such as an intermittent

+12V

STAT

REM

GND

DLY OUT

loss of Neutral, the EVS event may continue to be encountered. If this is

the case, an operator should avoid resetting the unit without first checking the source of the problem and perhaps changing the AC source.

1 2 3 4 5 6 7 8 9

GND

ON

Default DIP Switch Settings

MOM

MNT

PRI

SEC

EVS AUTO

MANUAL

9

Page 11

Connection Status Lights

FORCE

OFF

P

P

S

S

SMARTSEQUENCING

OUT

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

CLASS 2 WIRING

FORCE

OFF

P

P

S

S

SMARTSEQUENCING

OUT

IN

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

Each multi-color Connection Status Light provides information on the

Miniports’ communication links. There are two LEDs, labeled PRIMARY

LINK and SECONDARY LINK that are associated with the SmartSequencer

link communications system. Each of these LEDs can illuminate Red,

Green, or amber. When a number of Miniports are connected together

via their SmartSequencer link ports, the LEDs will illuminate Green and

occasionally blink as messages are passed between units.

Power Indicator

EXTREME VOLTAGE

POWER

One POWER LED is provided to indicate the ON or OFF state of the power

outlet. If power is provided to the outlet, the LED will illuminate green. If

the Miniport is operating under safe power conditions and no utility fault

conditions exist the POWER LED will remain steadily lit. Once triggered to

power-down the POWER LED will go off as the power outlet is deactivated.

PRIMARY

LINK

SECONDARY

LINK

SmartSequencing Note: When there are two or more SmartSequencer

units linked in series, a slowly blinking Green Primary Link LED identifies the Primary Unit. Similarly, a SmartSequencer displaying a solid

Green Primary Link LED would indicate the unit is the last Secondary in

the chain of sequencers. Secondary Units in the middle of the chain will

display both a solid Green Primary Link LED and a solid Green Secondary Link LED. The Connection Status Link Indicators will flash accordingly

during power up and power down as SmartSequencer messages are sent

between units.

Green LED status is a sign of good communications. If a Contractor Series

unit is used independently (no connections) and the unit is configured as

a Primary Unit (DIP 8, ON or UP), the Primary Link LED will slowly blink

Green at 1 second intervals. If there is a SmartSequencer link connecting

a Primary Unit to a Secondary Unit, the Primary unit will send messages

to the Secondary Unit and the Secondary Link LED will illuminate Green

on the Primary Unit, indicating there is an established communication

link with a the Secondary Unit. On Secondary units (DIP Switch 8, OFF or

DOWN), the Primary Link LED will be Green, indicating there is communication to a Primary.

The Red Connection status LED can sometimes illuminate briefly if a

message is lost corrupted on the SmartSequencing link. Unless the Red

LED is illuminated continuously, this should be no cause for concern. The

SmartSequencing protocol is robust and redundant. As long as a physical

link is in place, the message will eventually get through.

A continuous Red Connection Status LED indicates that a unit has no

SmartSequencing link connection where the unit has been configured to

expect link communications. This occurs when a Secondary Unit cannot

communicate with surrounding units in a SmartSequencing chain. The

result is that the Secondary Units Primary Link LED may be Red because

the link is broken to a Primary Unit or the Secondary Link LED may be

Red because the link is broken to a Secondary Unit. This could also

mean that the Secondary Unit sees the Primary Unit, but the Primary Unit

does not see its Secondary.

The Amber LED may be seen upon start up initialization or as communication ensues between Smart Sequencers. This Amber LED state should

resolve to a Red or Green state. If the amber indication does not resolve,

please contact Furman Support.

EVS LED

EXTREME VOLTAGE

POWER

The EXTREME VOLTAGE LED indicator is normally OFF. The EVS function

is tied to this LED and monitors the incoming voltage for out of tolerance

conditions. If enabled, the EVS will disable the AC power before damage

can occur. The EXTREME VOLTAGE LED will be illuminated Red anytime

the voltage is found to be below 77 volts or more than 145 volts. The

EVS LED will remain illuminated, and the outlets will be disabled as long

as an out of tolerance condition exists.

Circuit Breaker

The CN-15MP is equipped with a 15 Amp thermal circuit breaker button

which will pop outward if the amount of current distributed to all loads

exceeds 15 Amperes. The CN-20MP does not have a circuit breaker.

SMARTSEQUENCING

OUT

P

LINK

PRIMARY

LINK

SECONDARY

+12V

STAT

REM

REMOTE

PORT

GND

DLY OUT

FORCE

OFF

POWER

P

CLASS 2 WIRING

S

S

IN

120 VAC, 50/60 Hz

EXTREME VOLTAGE

BYPASS

MAX LOAD 20A

20 AMP

MINIPORT

C US

CN-20MP

C US

120 VAC

120 VAC

/60/HZ

/60/HZ

A MAX.

A MAX.

+12V

STAT

REM

REMOTE

PORT

GND

DLY OUT

FORCE

OFF

SMARTSEQUENCING

PRIMARY

POWER

OUT

P

P

CLASS 2 WIRING

S

S

LINK

IN

LINK

SECONDARY

EXTREME VOLTAGE

BYPASS

15 AMP

MINIPORT

C US

120 VAC, 50/60 Hz

MAX LOAD 15A

CN-15MP Circuit Breaker

PUSH TO RESET

C US

CN-15MP

120 VAC

/60/HZ

A MAX.

15 AMPS

CN-20MP No Circuit Breaker

CN-15MP

If the combined current, drawn by all devices plugged into the CN-15MP

exceeds 15 Amps at any time, the circuit breaker will “trip’, cutting off

power to all connected devices. If this occurs; the operator must reduce

the load by unplugging one or more devices from the CN-15MP, and reset

it. The operator can reset the circuit breaker by pressing in the circuit

breaker button. However, because the safety feature is a thermal breaker,

it is suggested that you wait one minute after the “trip” occurs to allow

the breaker to cool down before resetting.

CN-20MP

The CN-20MP does not have an integral circuit breaker and relies on

the branch circuit breaker to limit the current to the loads. The CN-20MP

must be connected to a branch circuit equipped with a 20 Amp breaker,

and capable of sustained 20 Amp service. If the branch circuit breaker

trips, the operator must reduce the load by unplugging one or more

devices from the CN-20MP.

10

Page 12

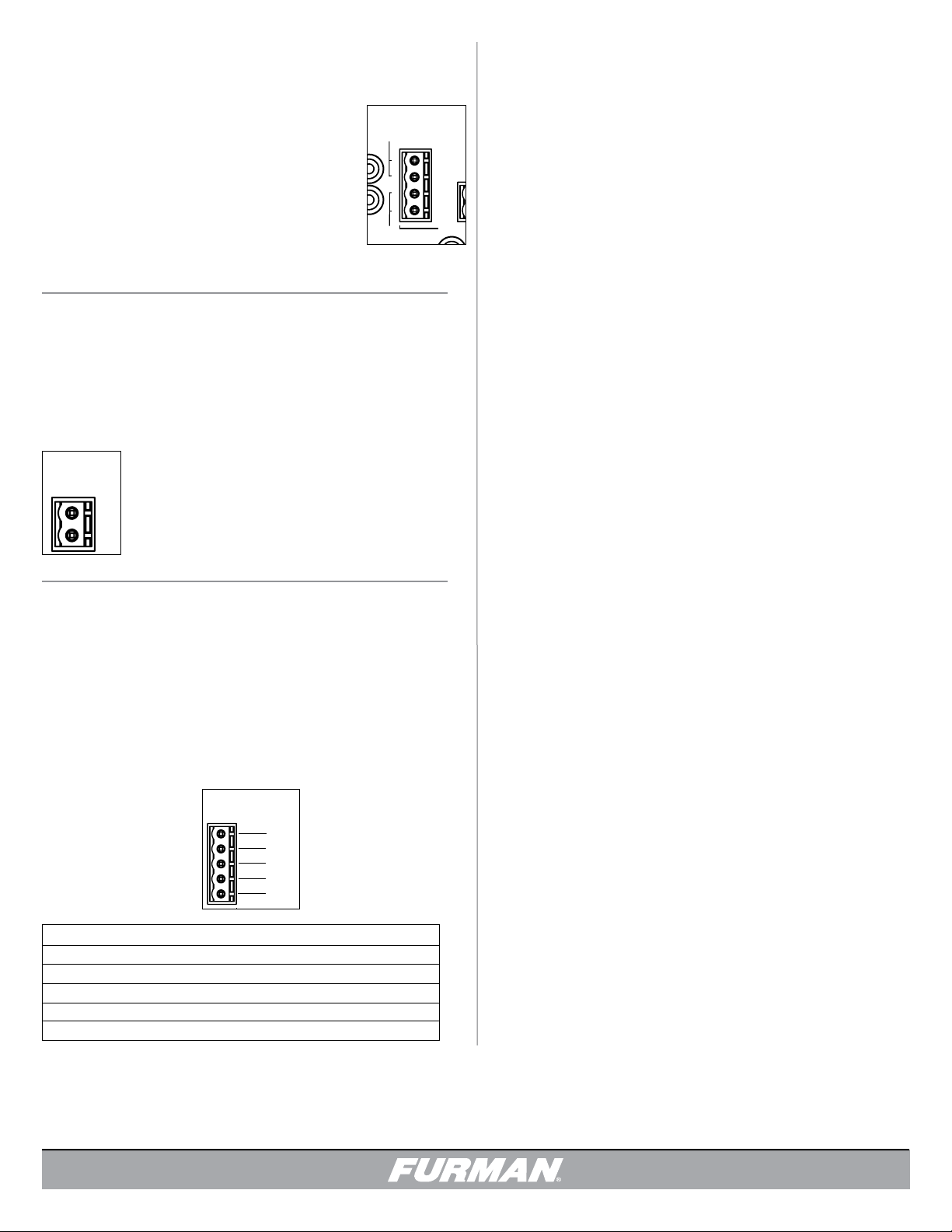

Terminal Barrier Strips

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

CLASS 2 WIRING

FORCE

OFF

SMARTSEQUENCING

+12V

STAT

REM

GND

DLY OUT

REMOTE

PORT

Setup and Troubleshooting

SMART SEQUENCING– 4 Pin Phoenix-Type

The SmartSequencing Barrier Strip is used to connect

and daisy-chain other SmartSequencing units together.

SmartSequencing requires that a pair of wires be

connected between the Primary OUT terminals of one

sequencer to the Secondary IN terminals of a second

sequencer. The recommended wire is 22AWG but

SmartSequencing is extremely tolerant of wire gauge.

OUT

P

P

S

S

IN

FORCE OFF (2) – 2 Pin Phoenix-Type

The FORCE OFF input provides terminals for initiating an immediate

shutdown of all SmartLink devices in a SmartLink chain. Fire alarms and

other safety devices can be connected to the FORCE OFF input. When

activated, the system will begin an immediate, but orderly shutdown

starting with the last sequencer in the chain first.

FORCE

OFF

Pin # Description

1 FORCE OFF Input – dry contact active state

defined by DIP #4

2 FORCE OFF Input common

As discussed at the introduction, in order to prevent expensive repairs to

speaker enclosures, a power sequencer or multiple power sequencers

are employed to coordinate the activation of power within an A/V system.

The amplifiers receive AC power last when a system is turned on and

amplifiers have the AC power cut before the signal processing is turned

off. There are many applications besides those pro audio applications

discussed here and SmartSequencing opens up many possibilities. We

cover the basics within our documentation, yet this does not mean that

other applications cannot garner the benefits of SmartSequencing.

Security and IT professionals can also benefit from remote power

management and power sequencing. Please feel free to consult a

Furman professional to answer any questions or to address the needs

for any particular installation.

Single Unit Set Up

Basic installation of the Miniport is ready right out of the box. The default

DIP Switch settings should be appropriate for a single stand-alone installation.

Multiple Unit Set Up

If you plan to use the Miniport as a Secondary device within a chain of

sequencers, the Miniport will need to be changed from Primary to Secondary status. This is done by changing the setting of DIP switch #8 from

ON to OFF and then cycling power.

Remote Port – 5 Pin Phoenix-Type

The Remote Port Barrier strip is provided to allow Furman Legacy devices

to be interoperable with the Miniport. One or more remote location

switches can be connected to the Miniport. The switch or switches used

may be either a momentary or maintained-contact type. In the most basic

configuration, only two wires and an SPST switch are needed to initiate

a remote ON or OFF sequence. If a four-conductor cable is used, an LED

may be installed between the STAT and GND pins to indicate when the

power outlets are on.

REMOTE

PORT

+12V

STAT

REM

GND

DLY OUT

Pin # Label Description

1 +12VDC General purpose output 10mA Max

2 STAT Status output, intended to drive anode of LED

3 REM Remote control input, behavior defined by DIP 5,6,7

4 GND General purpose ground 10mA Max

5 DLY OUT Delayed output, for connecting downstream devices

If you are using several Miniports to control an AV system it is recommended that you connect the signal processing equipment to the Miniports near the beginning of the chain, and the Amplifiers to the sequencers nearest the end of the chain. This will ensure that the power to the

signal processing equipment will be active and have had the opportunity

to stabilize before power to the amplifiers is activated.

Breaker Overload

The overall current capacity is 15Amps for the CN-15MP and 20Amps

for the CN-20MP. This refers to the combined steady-state current drawn

by all devices plugged into the power outlets. If the combined current

level exceeds the current capacity at any time, the circuit breaker will trip,

cutting off power to the connected equipment. If this occurs, the operator

must reduce the load by unplugging one or more devices.

Although 15 Amps is an absolute limit, the CN-15MP will allow the

operator to come as close as possible to using the full 15 Amps. Power

sequencing greatly reduces the risk of tripping the breaker because

power sequencing offsets large but temporary inrush currents by activating equipment in stages, rather than simultaneously. This allows each

stage to settle to its steady-state current draw before the next stage

is powered. If for any reason, reasonable efforts are made to resolve

breaker trips and trips continue, please to do not hesitate to contact

Furman technical support.

11

Page 13

Re-syncing Multiple Sequencers

SPECIFICATIONS

There can be unique situations where multiple sequencers fall out of

sync. For example, loss of sync can occur when a branch circuit experiences an overload or high voltage and triggers an EVS shutdown of one

or more units. If you are using a rack mounted Contractor unit equipped

with SmartSequencing, you can re-establish sync by pressing and holding

the Start Sequence pushbutton on the Primary Unit for several seconds.

Sync can also be re-established by rotating the key on the primary unit

from the REMOTE to the OFF position and then back to REMOTE. When

pressing and holding the pushbutton on dedicated SmartSequencing

units, the Primary Unit commands the Secondary Units to “Go Home”

and all units will sequence down in reverse order. Once the chain of

sequencers has cycled off, the sequencers can be sequenced on again

by pressing the START SEQUENCE button or turning the key switch to the

ON position.

Legacy connected sequencers can also be re-synced if the sequencers

are operating Momentary Mode. The units will resync can be accomplished by pressing and holding the Start Sequence pushbutton. Unlike

the SmartSequencing chains, units will cycle down, yet may not cycle

down in hierarchical order. It is advised that all sound sources be muted

before a re-sync action is initiated. Once the re-sync is initiated, unit will

cycle down and return to an off state. A sequence can now be “ramped

up” in order.

Maximum AC Current Rating:

• CN-15MP - 15 Amps, 120 VAC (Thermal circuit breaker)

• CN-20MP - 20 Amps, 120 VAC (No circuit breaker))

AC Cord:

• 3/14 AWG, 10 feet, black, fixed, NEMA 5-15P plug

AC Receptacles:

• AC Outlets: 2 Switched NEMA 5-15R (1 duplex)

Surge/Under-Overvoltage Protection:

• AC Undervoltage Protection: EVS, 77VAC+/-3VAC

• AC Overvoltage Protection: EVS, 145VAC+/-5VAC

• AC EVS Protection Activate/Deactivate Modes: ON or OFF DIP 9 (configurable)

Operating Temperature Range:

• 5C (40F) to 40C (105F) degrees

Humidity Range:

• <90% rH (Relative Humidity)

User Interface:

• Thermal Circuit Breaker: Bottom panel, pushbutton (CN-15MP only)

• Front panel diagnostic indicators: Primary link, Secondary link, Power, Extreme Voltage

• Side Panel DIP Switches: Hidden by security cover, 1 Minute Delay,

2 Minute Delay, 4 Minute Delay, Force Off NO/NC, 12V Mode ON/OFF, GND Mode On,

Momentary/Maintained, Primary/Secondary, EVS ON/OFF

• Potentiometer: Side panel, time calibration hidden by security cover, fine tune delay

adjust

15 YEAR LIMITED PRODUCT WARRANTY*

Furman warrants to the original purchaser of this product for a

period of fifteen (15) years from the date of purchase, that the

unit shall be free of defects in design, material or workmanship, and Furman will repair or replace any defective unit.

Full Warranty and Policy information available at

www.furmancontractor.com

Control/Status/Triggering (Front Panel):

• Remote Terminal: +5-30VDC IN, 12VDC (12mA) OUT

• SmartSequencing: Phoenix type 4-Pin Connector, with Screw Terminals, Primary &

Secondary Links (Current Loop - 1000’ maximum)

• Remote Terminal: Phoenix type 5-Pin Connector with Screw Terminals;

+12V, STAT, REM, GND, DLY OUT (Class 2 Wiring)

• Force Off: Phoenix type 2-Pin Connector with Screw Terminals, (Class 2 Wiring)

Power Consumption (No Load): 10 Watts

Safety Agency: NRTL-C CSA/NRTL Compliant:

Specifications subject to change due to product upgrades and improvements.

CAUTION! WARRANTY LIMITATION FOR INTERNET PURCHASERS

Furman products purchased through the Internet do not carry a valid

Product Warranty unless purchased from an Authorized Furman

Internet Dealer and the original factory serial numbers are intact

(they must not have been removed, defaced or replaced in any way).

Purchasing from an Authorized Furman Internet Dealer insures that

the product was intended for consumer use, has passed all quality

inspections and is safe. Buying through auction sites or unauthorized

dealers may result in the purchase of salvaged, failed and/or products

not intended for use in the US. In addition, Authorized Furman Internet

dealers have demonstrated sufficient expertise to insure warranty

compliant installations.

For a list of Authorized Furman Internet Dealers

go to www.furmansound.com

12

Loading...

Loading...