Page 1

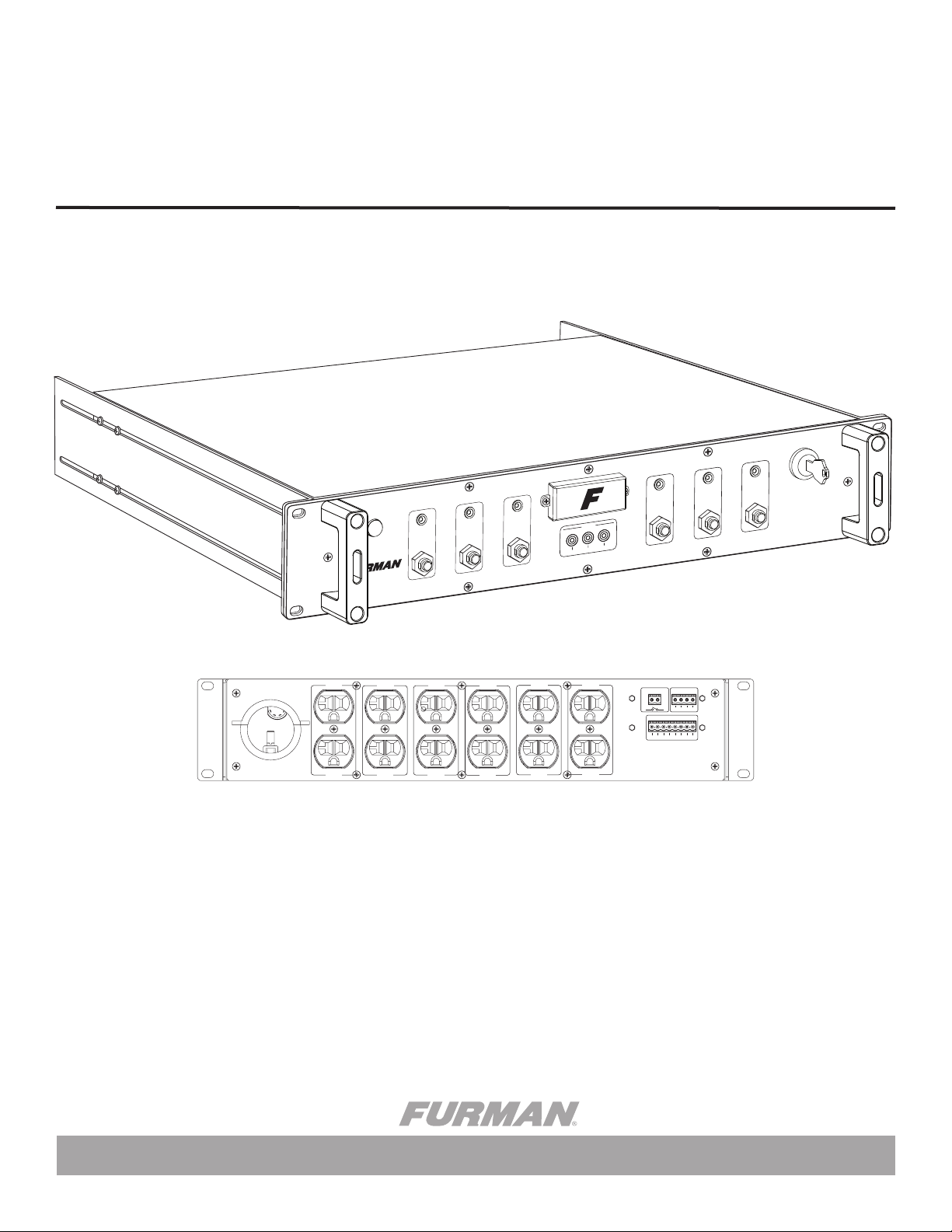

ASD-120 2.0

OWNER’S MANUAL

SIX CHANNEL SEQUENCING POWER DISTRIBUTION

START

SEQUENCE

DELAY A DELAY B DELAY C

(SEE COVER PLATE)

DLY

1 2 3 4 5 6 7

ADJ

X Y Z

PHASE

ALWAYS ON

ALWAYS OFF

REMOTE

OFF ON

DELAY D DELAY E DELAY F

WARNING! ELECTRIC SHOCK HAZARD. CONNECTION OF A POWER

INPUT CABLE TO THIS DEVICE AND TO A POWER SOURCE MUST BE

DONE BY QUALIFIED PERSONNEL ONLY.

DANGER: MANIPULER SEL ON LES INSTRUCTIONS DU

FABRICANT ET CONFIER LA MAINTENANCE A UN T

ECHNICIEN QUALIFIE

INPUT 120 / 3Ø, 208 / 240 VAC

14400 WATTS – 120 AMPS MAX

DELAY A

20A MAX

ASD-120 2.0

120 AMP POWER SEQUENCER

DELAY B

20A MAX

DELAY C

20A MAX

DELAY D

20A MAX

DELAY E

20A MAX

DELAY F

20A MAX

FORCE OFF

12V STAT REM GND

DELAY OUTPUTS

NC A B C D E F NO

DRY RELAY CONTACTS - RATING 48V / 1 AMP

REMOTE

10007825 REV. B ASD-120 2.0 INST. 10-15

Page 2

INTRODUCTION

Thank you for choosing a Furman product and congratulations on your choice

of the ASD-120 2.0. The ASD-120 2.0 is a six channel power sequencing

device intended for use in installations where multiple electrical loads must be

powered on and off in a delayed and orderly sequence. Typical applications for

the ASD-120 2.0 include: touring PA or sound reinforcement systems, musical or

theatrical acts, mobile recording facilities, and on-location film or video shoots.

Essentially, any situation where AC power must be distributed to multiple circuits

and activated or deactivated in discrete stages would benefit from the use of an

ASD-120 2.0.

• All settings, options, and controls are now easily accessible from the front panel

• The output capacity of the 12V remote interface has been increased to 250mA

• Maximum sequencing delay has been increased to 7 minutes per stage

• The operation of the Remote interface has been harmonized with other Furman

products

• The Force Off warning is now highly visible

• The sequencing bypass switches are now low profile to prevent inadvertent

operation

• A security cover has been added to prevent unauthorized access.

• Rear rack mounting ears have been added to enhance road worthiness

Please read this manual completely and carefully and review the installation man-

• Phoenix-type connectors have been used to simplify installation

ual before installing or applying power to your ASD-120 2.0. Those familiar with

the ASD-120 will recognize that the ASD-120 2.0 provides the same functionality

Please note:

as the preceding version but adds a number of features that the user might

appreciate. These new features include the following:

Because the ASD-120 2.0 switches hazardous voltages and high currents, we

recommend that installation be performed by a qualified electrician. For safe

operation, the ASD-120 2.0 must be installed in accordance with local/municipal

and National Electrical Codes. Please feel free to contact Furman Technical Services if you have any questions or concerns regarding the installation, operation,

or service of your ASD-120 2.0.

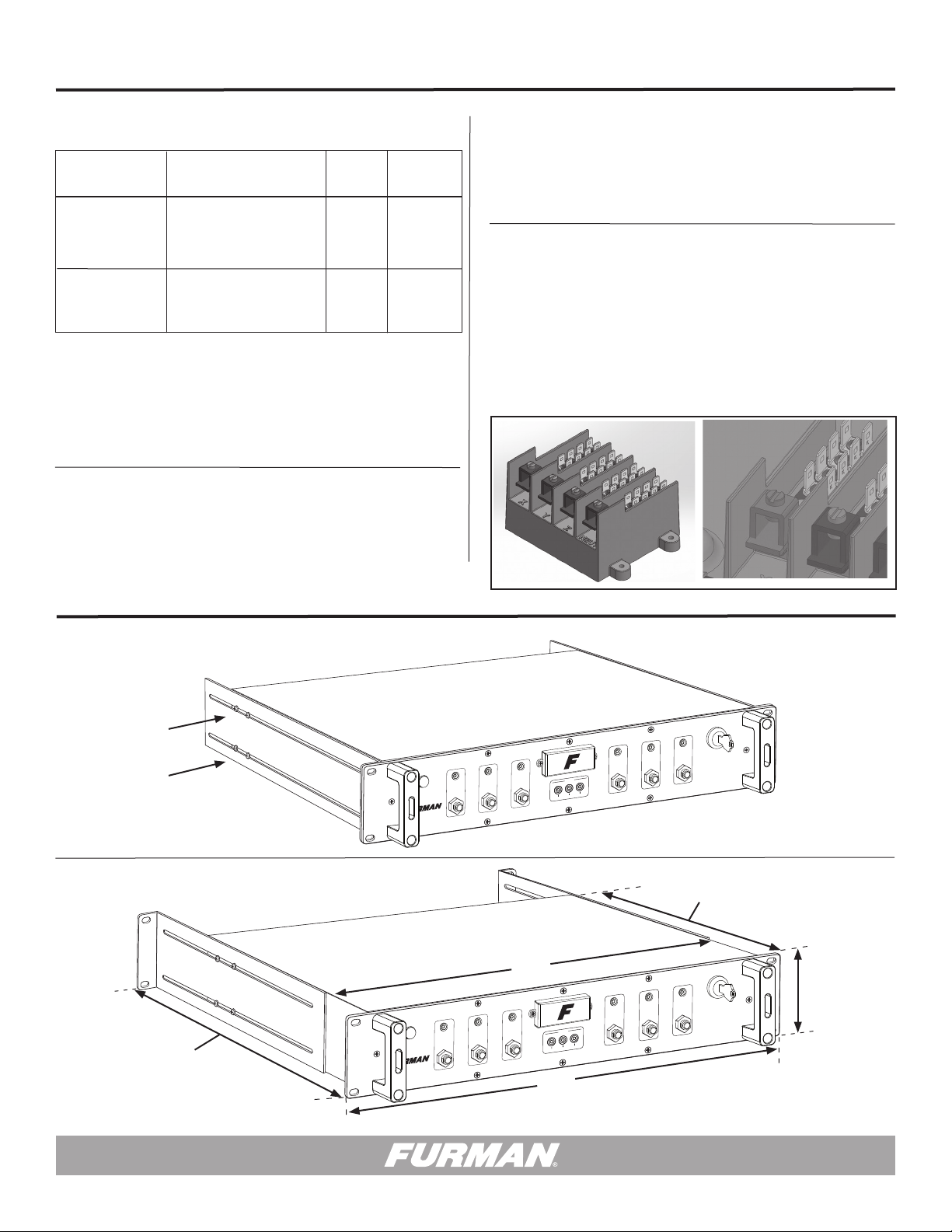

BEFORE YOU BEGIN, PLEASE INSPECT UPON RECEIPT

This box should include the following items:

1. Model ASD-120 2.0

2

2. Two adjustable rear rack mounting ears

3. Security cover with Two 6-32 3/8”

Screws

4. One pair of security keys

5. Removable Rack Handles

6. 1.5 in. Cable Clamp (Please see wiring

instructions)

WARNING! ELECTRIC SHOCK HAZARD. CONNECTION OF A POWER

INPUT CABLE TO THIS DEVICE AND TO A POWER SOURCE MUST BE

DONE BY QUALIFIED PERSONNEL ONLY.

DANGER: MANIPULER SEL ON LES INSTRUCTIONS DU

7. Two pin Phoenix-type connector

8. Four pin Phoenix-type connector

9. Eight pin Phoenix-type connector

6

FABRICANT ET CONFIER LA MAINTENANCE A UN T

ECHNICIEN QUALIFIE

INPUT 120 / 3Ø, 208 / 240 VAC

14400 WATTS – 120 AMPS MAX

IMPORTANT SAFETY NOTE:

While the subject of attaching a power cable to the ASD-120 2.0 is covered in

the Wiring Instructions, the connection to utility power or generator power is

not. We strongly recommended that the ASD-120 2.0 be installed by a qualified

electrician. Please refer to the “Wiring Instructions” section in this manual.

DELAY A

20A MAX

START

SEQUENCE

ASD-120 2.0

120 AMP POWER SEQUENCER

DELAY B

20A MAX

1

DELAY A DELAY B DELAY C

DELAY C

20A MAX

DELAY D

20A MAX

DLY

ADJ

(SEE COVER PLATE)

1 2 3 4 5 6 7

PHASE

X Y Z

3

ALWAYS ON

ALWAYS OFF

5

DELAY E

20A MAX

DELAY D DELAY E DELAY F

DELAY F

20A MAX

REMOTE

OFF ON

7

FORCE OFF

DELAY OUTPUTS

NC A B C D E F NO

DRY RELAY CONTACTS - RATING 48V / 1 AMP

4

8

REMOTE

12V STAT REM GND

9

1

Page 3

TABLE OF CONTENTS

Introduction, Before You Begin, and Important Safety Note__________________________________________________________________ 1

Important Safety Instructions _____________________________________________________________________________________ 2

Wiring Instructions ___________________________________________________________________________________________ 3, 4

Rear Rack Mounting Ears _________________________________________________________________________________________ 4

Product Features _____________________________________________________________________________________________ 5

Product Overview ___________________________________________________________________________________________ 6, 7

Front Panel Configurations and Features_______________________________________________________________________ 7, 8, 9, 10

ASD-120 2.0 Programming Summary_______________________________________________________________________11, Back Cover

Rear Panel Control Terminal Interface ________________________________________________________________________________12

Advanced Installation Topics___________________________________________________________________________________13, 14

Local Operating Modes____________________________________________________________________________________15, 16, 17

Product Installation Examples_______________________________________________________________________________ 18, 19, 20

Specifications _______________________________________________________________________________________________ 21

Warranty Information __________________________________________________________________________________________ 22

IMPORTANT SAFETY INSTRUCTIONS

WARNING

• With the exception of input wire connections, there are no user serviceable

parts inside the ASD-120 2.0. The top panel should never be removed while

power is applied to the unit.

• Input power must be connected by a qualified electrician. The unit must be

properly grounded through a protective earth ground connection.

• Refer all servicing to qualified personnel. Servicing is required when the unit

has been damaged in any way or fails to operate as designed.

• The ASD-120 2.0 is intended for use in a dry environment. Do not use this

product in or near water. To reduce the risk of fire or electric shock, do not

expose this device to rain or moisture.

• The device is intended for AC power sequencing. All output circuits should be

sequenced OFF prior to removing power to the unit.

• Do not install this product near heat sources or other equipment that generates

excessive heat.

CAUTION

• The ASD-120 2.0 remote interface differs from the original ASD-120. While

the original ASD-120 REM terminal input was compatible with AC voltages, the

ASD-120 2.0 is not. For example, if an original ASD-120 is to be controlled by

the ASD-120 2.0, please use the Direct Current 12V and REM terminals of the

ASD-120 2.0 to provide the DC control signal to the REM input of the older ASD120 product.

• Ground loops at the control terminals and remote interface should be avoided.

The ASD-120 2.0 remote interface is designed to provide the flexibility of being

connected to multiple pieces of equipment within the same power distribution

system. To avoid ground loops, do not connect the remote interface to more than

one non-isolated ground referenced interface.

• A building’s AC Power Distribution System is grounded at the Utility Service

Entrance or Service Point. The ASD-120 2.0 Remote interface control is not intended for applications between multiple buildings or where connected equipment

has multiple AC grounds or earth paths. If the ASD-120 2.0 Remote interfaces are

connected to equipment grounded elsewhere, catastrophic voltage irregularities

can damage the remote interface. All control equipment interfacing the ASD120 2.0 power distribution network must be properly grounded through a single

protective earth ground connection. Please consult a qualified electrician if there

are questions concerning equipment grounding.

2

Page 4

20A MAX

DELAY A

20A MAX

DELAY B

20A MAX

DELAY C

20A MAX

DELAY D

20A MAX

DELAY E

20A MAX

DELAY F

FORCE OFF

DELAY OUTPUTS

REMOTE

NC A B C D E F NO

12V STAT REM GND

DRY RELAY CONTACTS - RATING 48V / 1 AMP

WIRING INSTRUCTIONS

WARNING! ELECTRIC SHOCK HAZARD. CONNECTION OF A POWER

INPUT CABLE TO THIS DEVICE AND TO A POWER SOURCE MUST BE

DONE BY QUALIFIED PERSONNEL ONLY.

DANGER: MANIPULER SEL ON LES INSTRUCTIONS DU

FABRICANT ET CONFIER LA MAINTENANCE A UN T

ECHNICIEN QUALIFIE

INPUT 120 / 3Ø, 208 / 240 VAC

14400 WATTS – 120 AMPS MAX

Prior to use, an appropriately sized power cable must be installed on the ASD120 2.0. A qualified electrician should be employed for selection of cabling and

installation. Bus bars for the connection of AC input power are accessible when

the top panel is removed. One safety ground terminal is also provided. The ASD120 2.0 is configured for 120/208 three phase power at time of shipment, but a

120/240V single phase source can be supported. Heavily loaded circuits can be

re-distributed between phases to balance the load as necessary.

The following instructions are provided as a guide for powering the ASD-120 2.0.

All steps should be performed while the unit is disconnected from power and

before it is installed in an equipment rack.

1. Determine the power source to be used with the ASD-120.

In North America, there are two possibilities: 120/208V three phase, and

120/240V single phase (sometimes called “Single Split”). Three Phase requires

an additional conductor, but it provides better copper utilization. A three phase

source will require five conductors; X (L1), Y (L2), Z (L3), N, and Safety GROUND.

The source must be a “Y” or “Wye” configuration and must include a star point

neutral. A 120/240V single phase source is connected with four conductors;

X (L1), Y (L2), N, and Safety GROUND. If the loads are balanced, the neutral current will be zero, but if the load is predominately on one phase, the neutral must

support the entire load current. Since phases are distributed to different circuits

a neutral conductor of the same gauge is the minimum recommendation,

a licensed electrician may recommend a thicker gauge neutral based on other

technical considerations.

120/208 3 Phase

5 Conductor

3 Conductors at 40A

Loss/ft (W) vs. % Load

120/240 Single Phase

4 Conductor

2 Conductors at 60A

Loss/ft (W) vs. % Load

AWG 100% Load 50% Load 100% Load 50% Load

6 3.8 W/ft 0.9 W/ft NA NA

4 2.4 W/ft 0.6 W/ft 3.6 W/ft 0.9 W/ft

2 1.5 W/ft 0.4 W/ft 2.3 W/ft 0.6 W/ft

Table 1 – Cable Loss Comparison

If the equipment is to be portable, a common connection method is to permanently attach a short cable whip to the Furman and terminate it with a high-current

connector. A long feeder cable with a mating connector would then be prepared

which could easily be disconnected for storage.

3. Prepare and connect the AC supply:

The AC supply cable will be connected to the internal bus bars via terminals that

secure the individual conductors with set screws. These terminals can accept

wires as large as 2 AWG. Strip one end of the cable to expose the wires. When

removing the outer jacket, be careful not to nick or cut into the insulation of the

individual conductors. When stripping the individual conductors, be careful not

to cut through any of the copper strands. All of the individual conductors should

be stripped one-half inch. After threading the cable end through the strain relief

clamp, connect the stripped conductors to the bus bar blocks. Be sure to put

each wire in the lower part of its terminal, so that it is compressed above and be-

low by copper rather than by the set screw itself. Tighten the set screws securely.

2. Select a cable and determine its length.

If the ASD-120 2.0 is installed in a permanent or semi-permanent location, it is

possible to connect it with flexible metal-jacketed conduit. A flexible type SOW

or SOOW supply cable known as a “whip” is recommended for portable use. In

three phase applications, the whip must carry a rating of 40 Amps minimum in

each of three out of five conductors; and for a single phase 120/240 source, a 60

Amp rated minimum for load current in two out of four conductors. The minimum

recommended conductor gauge is 6AWG for a 120/208 three phase source and

4AWG for a 120/240 single phase source.

Cable efficiency losses per foot are listed in Table 1. Losses are dramatically

reduced at lower currents since the losses are a function of the square of the

current. A larger cable size should be considered for critical loads that have high

peak currents, such as power amplifiers. Cable lengths can be longer if the load

current is significantly below the rated maximum, and if large transient peaks are

not expected.

3

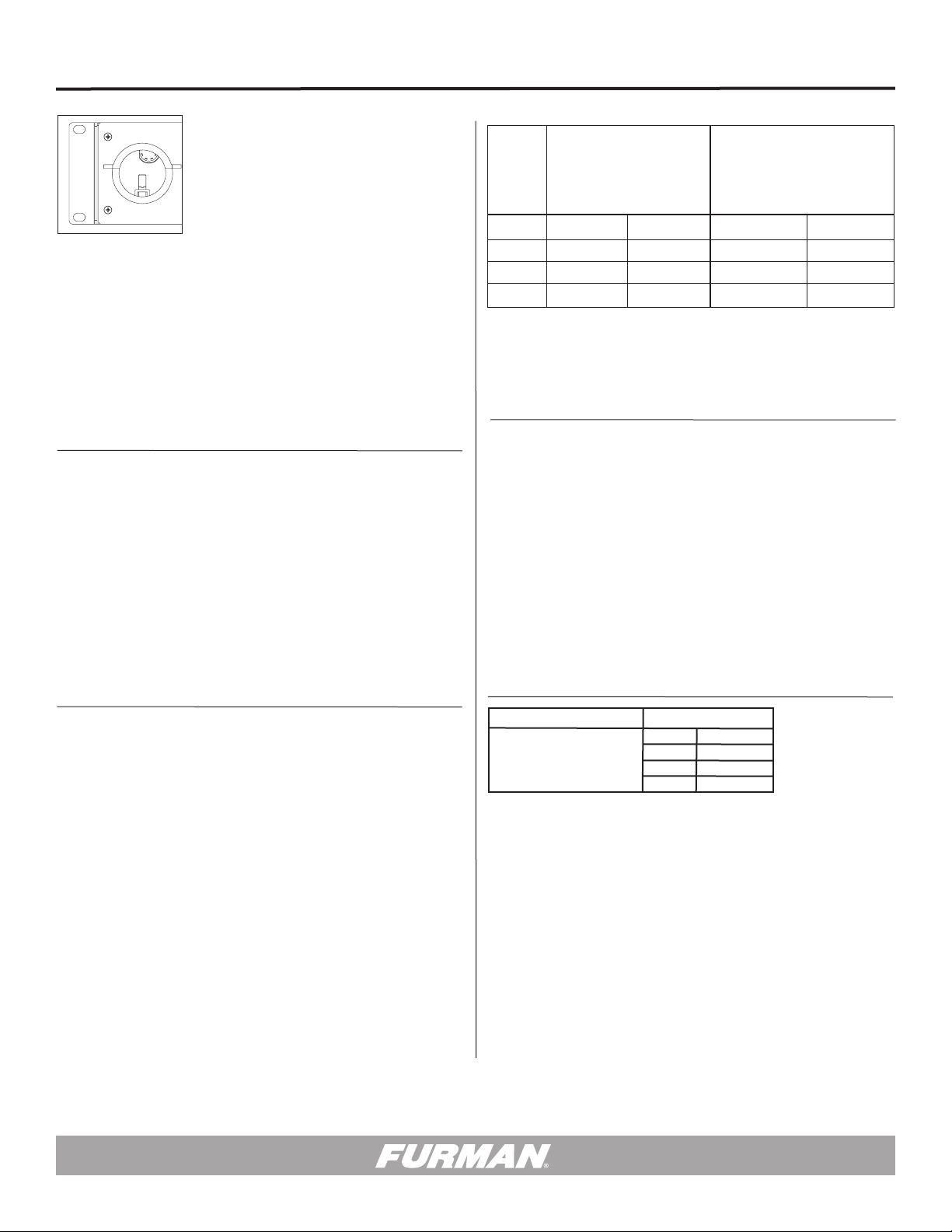

POWER DISTRIBUTION BLOCK

MAX VOLTS: 240 VAC

MAX AMPS:

60A / PHASE

120A TOTAL

TORQUE SPECIFICATIONS

AWG lb-in (N-m)

2 45 (5.1)

3 50 (5.6)

4 - 6 50 (5.6)

4. Load Balancing:

The load should be balanced between phases. As shipped, the load circuits are

evenly divided among the X, Y, and Z bus bars in support of a balanced 120/208V

three phase input. If a 120/240 source is connected to the ASD-120 2.0, the Z

bus bar is not used and the load conductors connected to this bus bar must be

moved to the appropriate X and Y bus bars. (Please see Table 2.)

By default, there are two 12 AWG black conductors connected by Fast-On terminals to each bus bar. The black wires are labeled with a letter (A, B, C, D, E, or F)

corresponding to the circuit to which it is connected. Since the load is applied in

a sequence, the loads should be alternately applied to each phase as determined

by the position of the load phase conductors.

An example of how the loads should be connected is shown in Table 2.

Page 5

An example of how the loads should be connected is shown in Table 2.

6. Next, terminate the source end of the cable:

Source

120/208

Three Phase

120/240

Single Phase

Blue, Brown, or Orange

Cable

Color

Black

Red

Black

Red

Buss

Bar

X

Y

Z

X

Y

Circuits

A,D

B,E

C,F

A,C,E

B,D,F

Table 2. Load Balancing Example

To move a wire, grasp it by the terminal and pull straight up. Then re-position it

over an unused Fast-On male terminal on the appropriate bus bar and push down

firmly. Do not pull on the wires as this may compromise the integrity of the wire

crimp. If it is necessary to move load conductors, it will not be necessary to move

the smaller Phase LED indicator wires.

5. Tighten the cable strain relief clamp firmly:

At least one half inch of the outer jacket must extend beyond the clamp into the

interior of the unit. Replace the top cover. This completes the internal wiring of

the ASD-120 2.0.

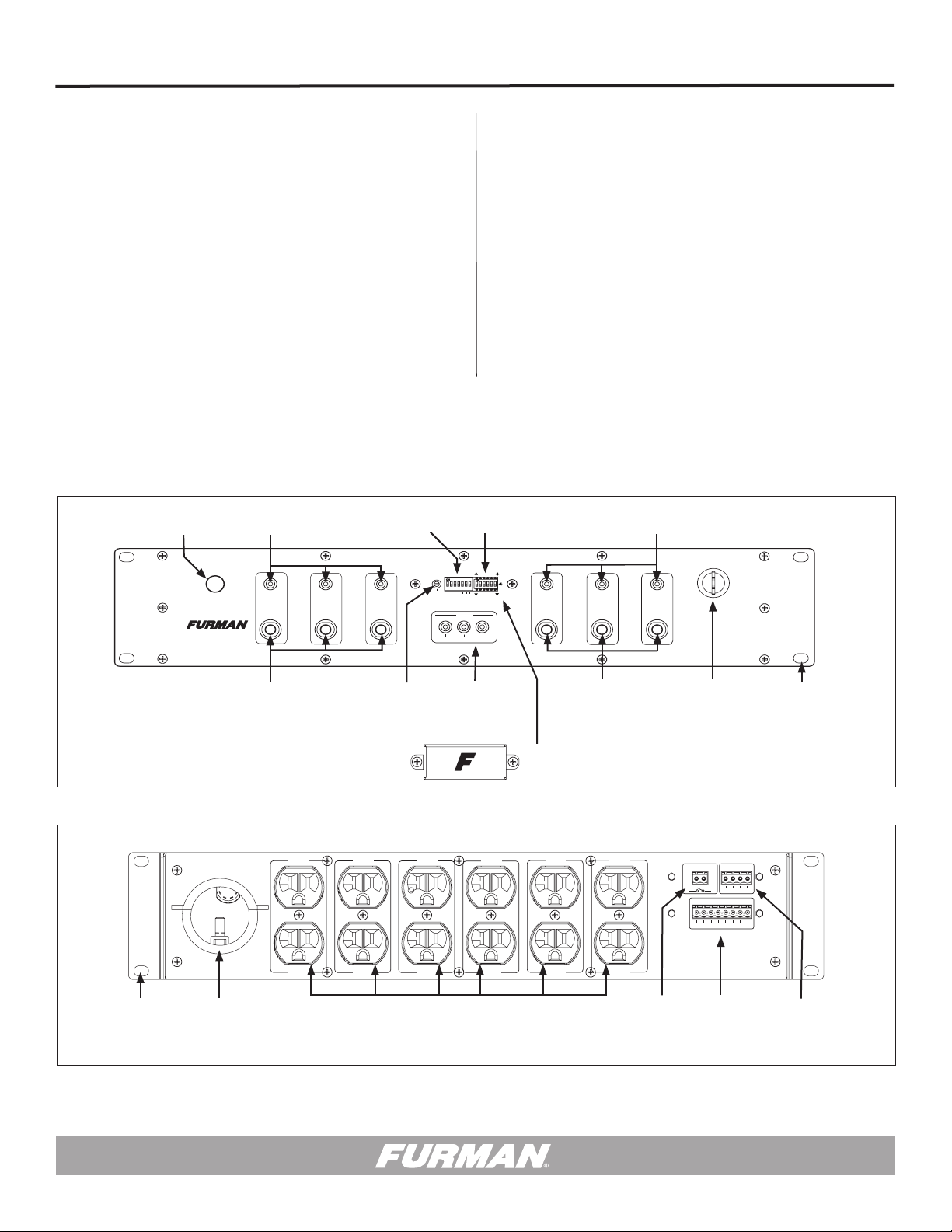

REAR RACK EAR MOUNTING

The source end of the cable must be terminated by a qualified electrician

in accordance with national, local and municipal safety standards.

7. Optional 120V single phase source:

The ASD-120 2.0 can be powered from a 120VAC source, with the AC source

connected between the X and NEUT bus bar inputs, but the source current must

not exceed 60 amps and the maximum load must not exceed the source current.

The number of output circuits connected to the X bus bar must not exceed the

source current divided by 20A. For example, a 120 Volt 60 Amp feed will limit the

Furman ASD-120 2.0 to a capability of only (3) 20A breaker circuits, and therefore, only 3 internal load conductors are recommended. (Only three 20A circuits

will be operational and the other three 20A circuits must be defeated.)

Internal power distribution block terminals (See torque specs on page 3).

1. Remove the screws from the side of the ASD-120 2.0 adjustable rear rack ear.

START

DELAY A DELAY B DELAY C

SEQUENCE

ASD-120 2.0

120 AMP POWER SEQUENCER

2. Reverse the rack ears and reattach the rack ears to the chassis (as shown here).

3. Adjust length to

connect to back side of

equipment rack. (Maximum

reach from the front to the rear

is 20.75 inches).

START

SEQUENCE

ASD-120 2.0

120 AMP POWER SEQUENCER

DELAY A DELAY B DELAY C

17 in.

DLY

ADJ

X Y Z

(SEE COVER PLATE)

DLY

1 2 3 4 5 6 7

ADJ

X Y Z

19 in.

(SEE COVER PLATE)

1 2 3 4 5 6 7

PHASE

ALWAYS ON

ALWAYS OFF

PHASE

ALWAYS ON

ALWAYS OFF

DELAY D DELAY E DELAY F

DELAY D DELAY E DELAY F

REMOTE

OFF ON

10 in. (allow an extra inch

for connectors, buttons, etc.)

REMOTE

OFF ON

3.5 in.

4

Page 6

START

SEQUENCE

REMOTE

DLY

ADJ

DELAY A DELAY B DELAY C

PHASE

X Y Z

DELAY D DELAY E DELAY F

OFF ON

1 2 3 4 5 6 7

ASD-120 2.0

120 AMP POWER SEQUENCER

(SEE COVER PLATE)

ALWAYS ON

ALWAYS OFF

S

E

Q

REMOTE

OFF ON

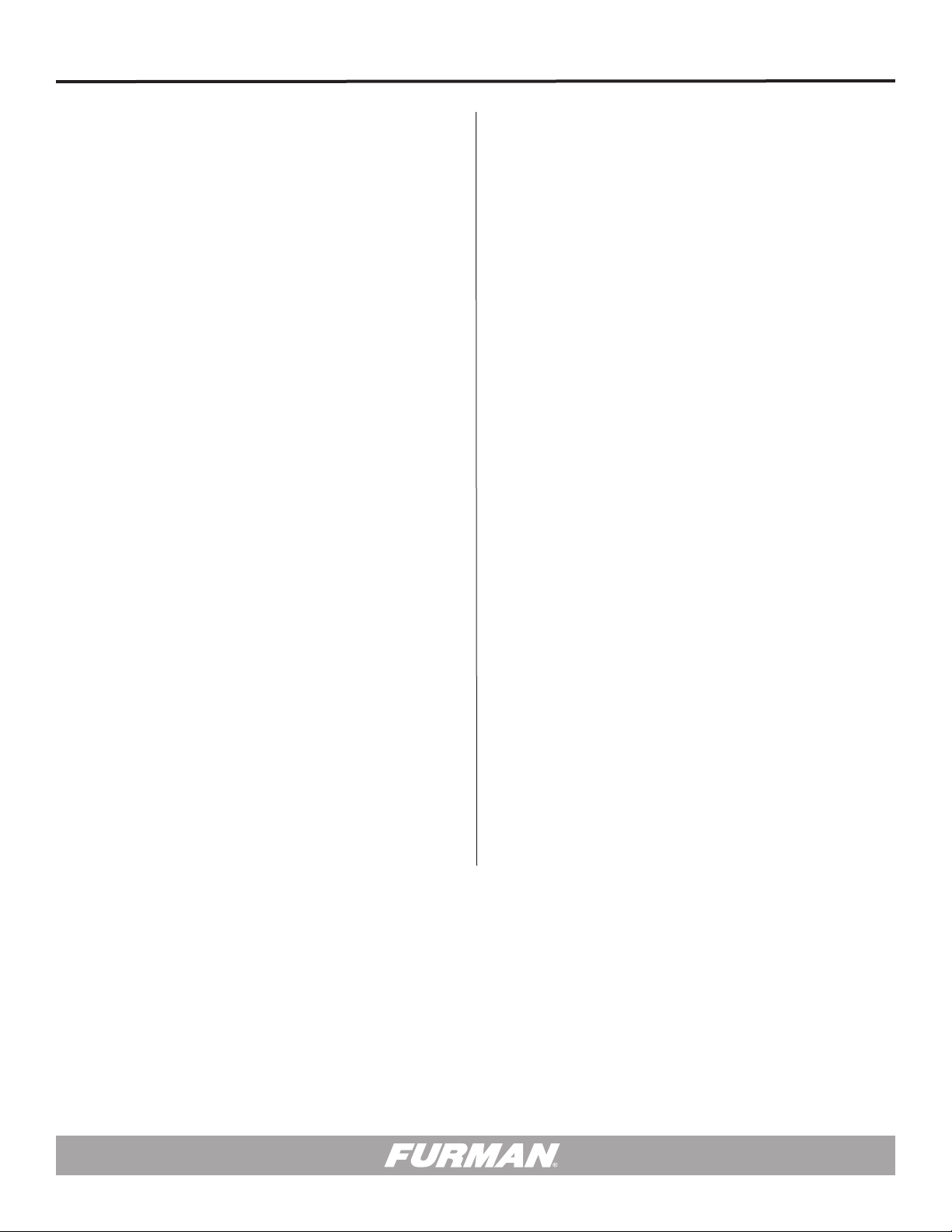

PRODUCT FEATURES

• 120 Amp 120 Volt AC Sequenced Distro and Controller

• Six Independent 20 Amp Circuits @ 120Volts - 120 Amp Total Load Capacity

• Rear panel NEMA 5-20R duplex outlet and optically isolated DC relay outputs

on each of six Delay Banks.

• Front panel Status Power LED, Bypass Switch and Circuit Breaker for each

Delay Bank

• 120A power distribution block accommodates 120V/240V single phase, or

120/208-Y three phase power

• X Y Z Status LED confidence indicators for each Input Phase

• Sequence unit ON or OFF from front panel or by remote switch

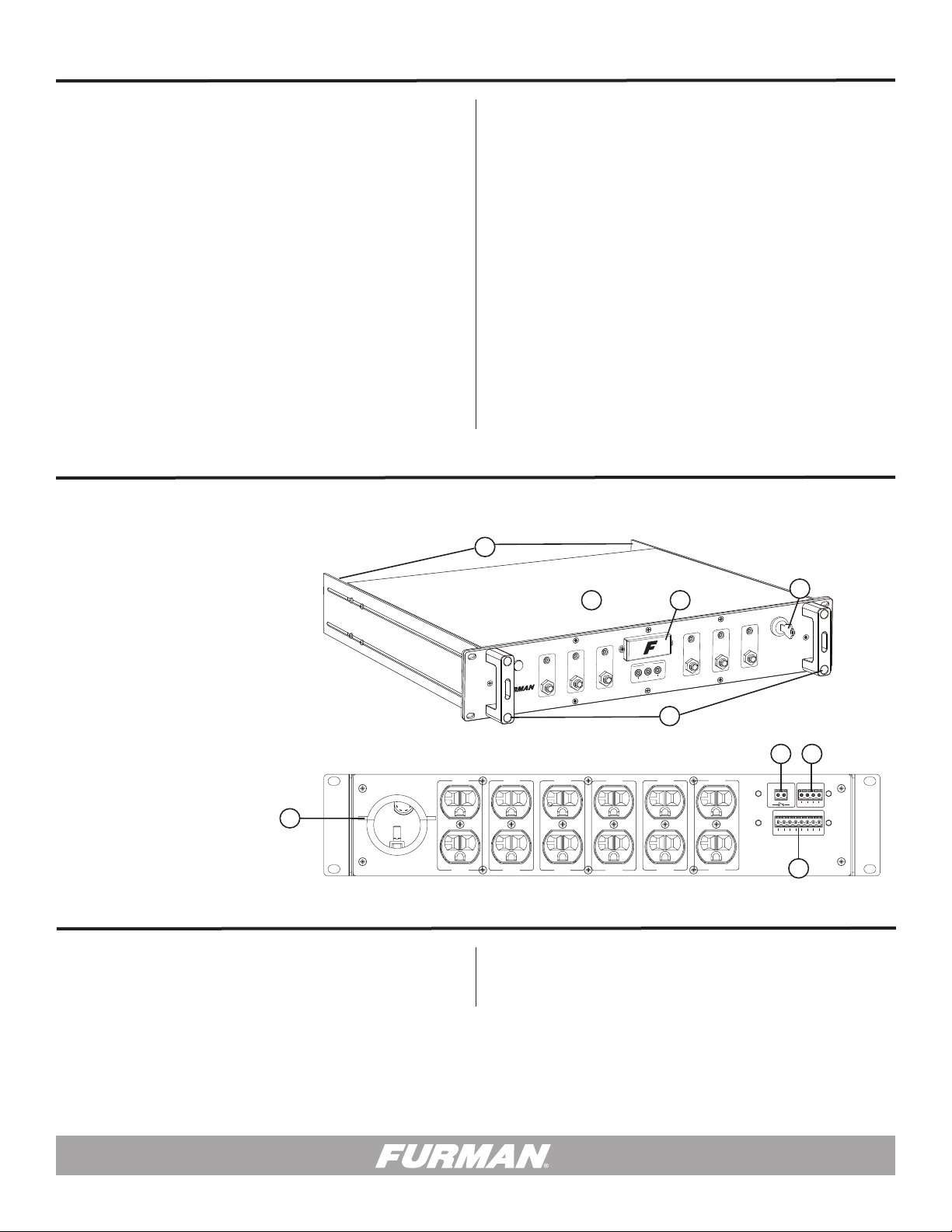

FRONT PANEL FEATURES

Front Panel Start

Sequence Switch

Indicator LEDs for

Delay A, B and C

Multi-function DIP Switch

7 Position ON/OFF

• Independent three position switches to power sequence (SEQ) or Bypassed ON

or OFF each Bank

• Adjustable Delay with up to 7 Minute Interval between Banks, Total maximum

Sequence Time 35 minutes

• Remote interface with an isolated 12VDC, 250mA power source for external

secondary applications.

• Signal level relay contacts (NO or NC) used to control and sequence other units.

• Front panel key switch and Anti-tamper DIP cover for added security

• Force Off emergency shutdown

• Rugged two rack space (2RU) chassis

Sequence Bypass Switch

6 Position ON/SEQUENCE/OFF

Indicator LEDs for

Delay D, E and F

REAR PANEL FEATURES

WARNING! ELECTRIC SHOCK HAZARD. CONNECTION OF A POWER

INPUT CABLE TO THIS DEVICE AND TO A POWER SOURCE MUST BE

DANGER: MANIPULER SEL ON LES INSTRUCTIONS DU

FABRICANT ET CONFIER LA MAINTENANCE A UN T

5

Adjustable

Rear Mount

Rack Ears

1.5” Cable Clamp

Input 120V/Phase

DONE BY QUALIFIED PERSONNEL ONLY.

ECHNICIEN QUALIFIE

INPUT 120 / 3Ø, 208 / 240 VAC

14400 WATTS – 120 AMPS MAX

Circuit Breakers 20A

for Delay A, B and C

DELAY A

20A MAX

DELAY B

20A MAX

Delay

Adjustment

Indicator LEDs for

Phases X, Y and Z

Circuit Breakers 20A

for Delay D, E and F

Security Cover to Protect

Program Settings

DELAY C

20A MAX

DELAY D

20A MAX

DELAY E

20A MAX

Six 20A duplex outlets Force Off, 2 Pin

Phoenix-type

Connector

Front Panel Key Switch

for Remote Security

DELAY F

20A MAX

FORCE OFF

REMOTE

12V STAT REM GND

DELAY OUTPUTS

NC A B C D E F NO

DRY RELAY CONTACTS - RATING 48V / 1 AMP

Delay Outputs, 8 Pin

Phoenix-type

connector

Integrated Front Panel

Rack Ears

Remote, 4 pin

Phoenix-type

connector

Page 7

PRODUCT OVERVIEW

The ASD-120 2.0 can be used as a stand-alone unit or in combination with other

Furman power distribution devices. The ASD-120 2.0 provides six sequenced

120V, 20A circuits for a total load power of 14.4kW. Higher levels of power

can be achieved by connecting additional Furman sequencers or other power

conditioning products, including additional ASD-120 2.0 units. Furman products

provide a practical means of centralized control over an extensive network of

power distribution and conditioning equipment.

As most sound reinforcement professionals know, AC power sequencing is necessary because the majority of equipment damage occurs when devices are either

powered up or powered down. In addition, power sequencing is needed whenever

various kinds of equipment must be powered up or down in discrete groups,

rather than simultaneously. Power sequencing allows equipment to be powered

up and powered down in an orderly and time-delayed sequence.

In professional audio, power sequencing is used to prevent speaker “pop” in

speaker cabinets, enclosures and line arrays. The “pop” is generated when audio

sources are switched on or off while an amplifier is still “live” or energized. The

activation of source (signal processing) equipment often creates a small spike of

transient voltage. When this voltage is amplified by the amplifiers, the resulting

“pop” can be deafening and can easily damage speaker voice-coils. The reverse

or “power down” of signal processing equipment can create a similar effect as

during power down many devices emit uncontrolled transients. Power down

transients can result in speaker “pop” and damage speaker components as well.

Because AC power sequencing prevents this universally unwanted and often

costly circumstance, AC power sequencing is prudent.

Power sequencing has the added benefit of preventing nuisance breaker trips by

offsetting the in-rush current demands of connected equipment over time. It is

not difficult to imagine the extreme current demand that would be placed upon a

breaker if all connected loads were to be activated at the same time. Power sequencing allows equipment to be sequenced on in discrete stages - which allows

each device to power up and current demands to stabilize individually. Although

each device will undergo its own in-rush current at power up, because these

events occur over time, the stress placed upon the breaker is greatly reduced.

For this reason, AC power sequencing is a reliable strategy for protecting event

productions and electrical infrastructure.

Years ago Furman introduced the original ASD-120, along with a full line of power

sequencers, to address the concerns outlined above. Furman power sequencing

products have been used by professional audio experts in a multitude of applications for decades. When conceiving the ASD-120 2.0, we listened intently to the

voice of our customers and industry experts. We appreciate all of the feedback

and believe that the ASD-120 2.0 delivers the power switching needs and wishes

of all of our customers.

The ASD-120 2.0 has a host of features and options that will be highlighted in

this manual.

Here is a quick overview:

The ASD-120 2.0 can be thought of as an array of six high current relays that operate under the control of a microprocessor. The six relays (referred to as DELAY

A through DELAY F) control the ON/OFF state of the power to six receptacles (also

referred to as DELAY A through DELAY F) located on the rear panel. The ON or

OFF state of each of the six receptacles is indicated by a series of six green status

LEDs on the front panel. There are a series of six circuit breakers located on the

front panel (underneath the status LEDs) that protect the loads connected to each

of the receptacles, DELAY A through DELAY F. Finally, there are a series of six low

power relays that operate in unison with the power switching relays. The contacts

of these low power relays are available on the right side of the rear panel and

allow the user to connect low voltage and low power devices to the ASD-120 2.0.

The ASD-120 2.0 has a rectangular security cover on the front panel. This cover

can be removed to provide access to an array of switches that are used to configure the operation of the ASD-120 2.0. Details of these switches can be found

later in this manual.

The basic operation of the ASD-120 2.0 can be described as follows:

Six individual Delay Banks feature a 120 Volt 20 Ampere AC circuit, and each AC

circuit can be sequenced on or off with a programmable delay at set intervals.

On/Off sequences can be initiated with ASD-120 2.0 front panel switches or a

wired connection to the ASD-120 2.0 rear panel Remote interface. Each Delay

Bank has one NEMA 5-20R duplex provided on the rear panel. In addition, any

Delay Bank can be configured as Always On or Always Off independent from the

sequence. The Delay Banks also have their own independent DC relay terminal

for triggering other devices, including another ASD-120 2.0 or any Furman

sequencing product.

The ASD-120 2.0 should be configured at time of installation. X Y Z Status LED

indicators confirm the input phase of AC power. The configuration DIP switches

are located behind a cover plate in the center of the front panel. A potentiometer

is used to set delay timing intervals. After the ASD-120 2.0 is configured, the

cover plate prevents inadvertent changes and tampering. A locking switch with a

removable key is provided for added security.

6

Page 8

START

SEQUENCE

REMOTE

DLY

ADJ

DELAY A DELAY B DELAY C

PHASE

X Y Z

DELAY D DELAY E DELAY F

OFF ON

1 2 3 4 5 6 7

ASD-120 2.0

120 AMP POWER SEQUENCER

(SEE COVER PLATE)

ALWAYS ON

ALWAYS OFF

S

E

Q

REMOTE

DLY

ADJ

DELAY A DELAY B DELAY C

DELAY D DELAY E DELAY F

OFF ON

1 2 3 4 5 6 7

(SEE COVER PLATE)

ALWAYS ON

ALWAYS OFF

S

E

Q

REMOTE

DELAY D DELAY E DELAY F

OFF ON

The ASD-120 2.0 Remote interface located at the rear panel provides a great

deal of flexibility. The ASD-120 2.0 can be configured to command or respond

to other controller-type equipment via low voltage DC impulses. If configured

as a remotely controlled power source, the ASD-120 2.0 can respond to

continuous maintained or momentary contact closures, open contacts, or the

presence or absence of external DC voltage. At the same time, maintained

control signals can be generated by the ASD-120 2.0 triggering connected

equipment into or out of operation. Low level DC relay contacts A through

F on each Delay Bank provide the means for external control of equipment

associated with each AC circuit Delay Bank.

Other Furman products which have remote interfaces compatible with the

ASD-120 2.0 are listed below. All of these products can be used with the

new ASD-120 2.0 through low voltage DC control.

• Furman Contractor Series CN-1800S, CN-2400S, CN-15MP & CN-20MP

• PowerPort & Legacy MiniPorts MP-15, MP-20, MP-15Q & MP-20Q

• M-8S & Legacy Sequencers PS-8R, PS-PRO, PS-8R II & PS-PRO II

• Original Furman ASD-120 & Powerlink

• RS-1 & RS-2 Remote System Control Panels

• The Furman PS-REL AC Relay Accessory

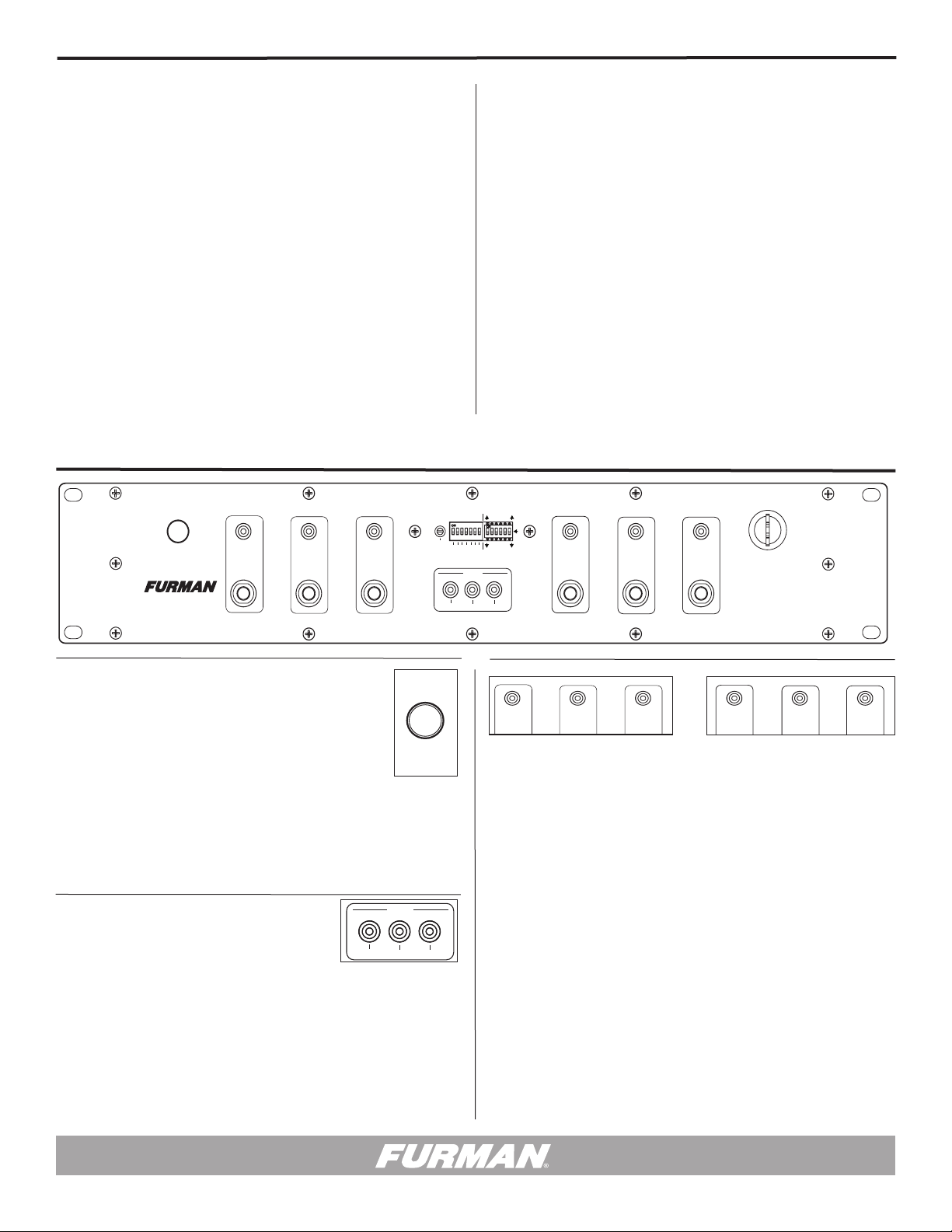

FRONT PANEL CONFIGURATION & FEATURES

Installation is simplified by the unit’s 19 inch rack-mount design and hidden

rear rack-mount ears. This feature is found alongside an industry standard 2RU

chassis. The hidden rear mounts are adjustable.

Once installed and configured, you may expect years of trouble-free operation

from the ASD-120 2.0. If during the service life of the product a question or

issue may arise, please welcome our assistance and contact Furman. The unit

is backed by a three year manufacturer’s warranty detailed on page 22 of this

manual.

Note: The ASD-120 2.0 has no line cord or master breaker, and is designed to

be wired to a single phase 120/240V source with 60 amps per phase capacity, or

to a three phase 208 WYE source with at least 40 amps capacity per phase.

Start Sequence Button Switch

The Start Sequence button located on the left side of the front

panel can be used for sequencing power up or power down.

The “START SEQUENCE” button is only activated when the key

switch is set to the “Remote” mode. The function of this switch

depends on the position of DIP Switch 7 and the duration of time

that the button is depressed. Please note, setting the key switch

to ON defeats operation of the START SEQUENCE push button.

Both the key switch and the START SEQUENCE button operate in

either Maintained or Momentary mode.

Phase Indicators:

The ASD-120 2.0 features a set of three phase indicators; X, Y, and Z that will

illuminate green when the corresponding phase (X, Y, and Z) is receiving power.

These are sometimes referred to as “confidence indicators” because when these

lamps are illuminated, you can be confident that the ASD-120 2.0 is receiving

power. Although three indicators are provided, all three indicators will only be

illuminated when the unit is connected to 3-phase 208-WYE power. When using

240 split phase, only two of the only phase indicators (X and Y) will illuminate

Note: X Y Z Status LED indicators confirm AC power on each Input Phase.

7

START

SEQUENCE

PHASE

X Y Z

Delay Bank Indicators:

The ASD-120 2.0 has six Delay Bank LED indicators that will illuminate green

when the corresponding Delay Bank (A through F) has been activated. When a

Delay Bank LED is OFF, the corresponding rear panel receptacle has not been

activated. When all Delay Banks have sequenced ON, all of the Delay Bank LEDs

should illuminate green. When all Delay Banks have sequenced OFF, all of the

Delay Bank LEDs should be off.

Note that the Delay Bank LED indicators only indicate when a bank has been

activated. The indicators do not guarantee that power is being delivered to the

corresponding Delay Bank. If a Delay Bank breaker has been tripped, the Delay

Bank LED indicator may still illuminate green even though power is not being

delivered to the Delay Bank with an open breaker.

The Delay Bank LED indicators are also used to indicate when the ASD-120 2.0

has been disabled due to a FORCE OFF condition. When the ASD-120 2.0 is in

FORCE OFF mode the Delay Bank LED indicators will flash on and off. More on

FORCE OFF mode later…

Note: A front panel Delay Bank LED indicator confirms the active state of the AC

duplex and its associated DC relay.

Page 9

20 Amp Thermal Circuit Breakers

REMOTE

DLY

ADJ

DELAY A DELAY B DELAY C

PHASE

X Y Z

DELAY D DELAY E DELAY F

OFF ON

1 2 3 4 5 6 7

(SEE COVER PLATE)

ALWAYS ON

ALWAYS OFF

S

E

Q

REMOTE

DELAY D DELAY E DELAY F

OFF ON

START

SEQUENCE

REMOTE

DLY

ADJ

DELAY A DELAY B DELAY C

PHASE

X Y Z

DELAY D DELAY E DELAY F

OFF ON

1 2 3 4 5 6 7

ASD-120 2.0

120 AMP POWER SEQUENCER

(SEE COVER PLATE)

ALWAYS ON

ALWAYS OFF

S

E

Q

1M 2M

DELAY

Security Cover Shield and DIP Switch Program Interface

The ASD-120 2.0 has six, 20 Amp thermal circuit breakers that protect each of

the six individual Delay Banks (A through F). The circuit breakers are located on

the front panel immediately below the Bank Status LEDs. Each of the six circuit

breakers (A through F) correspond to a Delay Bank (A through F)

If the combined current level plugged into a Delay Bank exceeds 20 Amps at any

time, the circuit breaker will “trip”, the circuit breaker button will pop outward, and

power will be cut to the devices connected to that particular Delay Bank.

If a breaker “trips” the user should review the load that is connected to the

offending Delay Bank and make adjustments as necessary to reduce load to

below 20A. To reset the breaker simply press the button in. Please note that

the breakers are thermally activated. It is best to wait a few minutes to allow the

breaker to cool before attempting to reset it.

Key Switch - 3 position ON/OFF Security Switch

The ASD-120 2.0 has a three position key switch that functions as a Local ON

Local OFF, and Remote interface selection switch. When the key is in the ON position, the ASD-120 2.0 will sequence all Delay Banks on and remain on. When

the key is in the OFF position, the ASD-120 2.0 will sequence all Delay Banks OFF

and remain off. When the key is in the REMOTE position the ASD-120 2.0 will

operate according to the signal presented at the remote interface and the action

of the front panel START SEQUENCE button.

If the key switch is in the REMOTE position and no signal is presented on the

rear panel Remote interface, the ASD-120 2.0 will operate according to the front

panel START SEQUENCE button. If the DELAY BANKS are off, pressing the START

SEQUENCE button will cause the DELAY BANKS to sequence on. If the DELAY

BANKS are on, pressing the START SEQUENCE button will cause the DELAY

BANKS to squence off. If the key switch is rotated from REMOTE to the ON or

OFF position, the ASD-120 2.0 will sequence ON or OFF according to the final

position of the key switch.

When the key switch is in the REMOTE position, the ASD-120 2.0 can accept on/

off commands from the rear panel 4-Pin Remote interface. The operation of the

remote interface is explained elsewhere in this manual. Please note that the ON

or OFF key switch positions defeat the rear panel remote interface.

REMOTE

ON: ON: Banks sequence ON and remain ON except

those configured as “ALWAYS OFF” with the bypass

OFF ON

switch.

OFF: Banks sequence OFF and remain OFF except those

configured as “ALWAYS ON” with the bypass switch.

The ASD-120 2.0 had two configuration DIP switches that are located underneath

a security cover near the center of the front panel. The two DIP switches are used

to set various sequencer options. You will need a small Philips screwdriver to

3

remove two 6-32

/8” Philips screws to gain access to these switches.

The ASD-120 2.0 comes with the security cover pre-installed to protect against

unauthorized configuration changes. The security cover is intended to discourage

unauthorized personnel from tampering with or adjusting set programming once

the unit has been installed. The security cover is attached to the front panel using

two 6-32 3/8” Philips head screws. Please use only the two screws provided for

attaching the security cover.

Note: Other types of tamper-resistant screws may be preferable depending on

the desired level of security. Please do not exeed the 3/8” length restriction.

ALWAYS ON

SET TO

S

MIDDLE

E

POSITION

Q

The Sequence Bypass DIP Switches

ALWAYS OFF

The ASD-120 2.0 has a six-position, three-state DIP switch located under the

security cover on the front panel to the right of the multi – function DIP switch.

The sequence bypass switch is used to bypass the sequencing on any or all of the

DELAY BANKS. The sequence bypass switch is an array of six tri-state switches,

and each tri-state switch has three possible positions (ON. OFF, and SEQUENCE).

When the switch is set to the ON (“Always On”) position, the corresponding

DELAY BANK will be ON regardless of the state of the sequencer. When the switch

is set to the OFF (Always Off”) position, the corresponding DELAY BANK will be

OFF regardless of the state of the sequencer. When the switch is set to SEQ

(“Sequence”), the corresponding DELAY BANK will follow the state of the

sequencer.

Note that FORCE OFF mode has priority over the sequence bypass DIP switches.

When the ASD-120 2.0 is in FORCE OFF mode, all banks will be disabled regardless of the state of the sequence bypass DIP switches.

DIP position ON (A thru F) = Delay Bank and Relay is ALWAYS ON

DIP position SEQ (A thru F) = Delay Bank and Relay activates in Sequence

DIP position OFF (A thru F) = Delay Bank and Relay is ALWAYS OFF

REMOTE: Accepts On/Off signals through the rear

panel REMOTE connector and the front panel START

SEQUENCE push-button switch.

Note: Except for a Force Off condition, the Sequence Bypass DIP Switch

overrides any local or remote switch function.

8

Page 10

ON

ALWAYS ON

ALWAYS OFF

S

E

Q

SET TO

MIDDLE

POSITION

ON

DIP SETTINGS

1 2 3 4 5 6 7

ALWAYS ON

ALWAYS OFF

S

E

Q

SET TO

MIDDLE

POSITION

The Multi-Function DIP Switch

1 2 3 4 5 6 7

The ASD-120 2.0 has a seven-position Multi-Function DIP switch array located

under the security cover on the front panel to the left of the bypass DIP switch.

The Multi-Function DIP switches are designated 1 through 7 from left to right and

a label for programming can be found on the inside of security cover plate.

This DIP switch is used to set the sequence delay time, active state of the FORCE

OFF feature, and program the behavior of the remote interface. The sequence

delay time is controlled by DIP positions 1, 2, and 3, FORCE OFF is controlled by

DIP position 4, and the remote interface behavior is controlled by DIP positions 5,

6 and 7. The DIP switch settings are ON when in the UP position and OFF when in

the DOWN position.

Note: The function of each switch is shown on a label located inside the F logo

cover plate.

Front Back

DELAY

1M 2M

N.O.

4M

N.C.

ON

1 2 3 4 5 6 7

12V ON

12V OFF

MOM

GND

MNT

ON

DIP 4,

FORCE OFF Settings

DIP Switch position 4 is used to define how the ASD-120 2.0 will implement its

FORCE OFF feature. FORCE OFF is a safety feature that is designed to cut AC

power to all outlets instantaneously. Many municipalities require this feature as a

means of disabling equipment in the presence of fire or alarm. The FORCE OFF

inputs can be used with a momentary or maintained dry contact in either a Normally Open or Normally Closed state. The factory default position is DIP 4 ON or

UP, or (NO) Normally Open. In this configuration, the FORCE OFF will be triggered

when the FORCE OFF pins are shorted. If DIP Switch position #4 is on (DIP 4 OFF

or DOWN) the FORCE OFF pins must remain shorted for normal operation. In

this configuration, the FORCE OFF will be triggered when the short between the

FORCE OFF pins is removed.

If a FORCE OFF occurs, the power to all outputs will be immediately disabled and

the Delay Bank LEDs will blink together. To recover from a FORCE OFF condition,

the ASD-120 2.0 must be sequenced off locally, by turning the key swich to the

OFF position. Once reset, normal operations will resume. DIP 4 has priority over

DIP 5, DIP 6, and DIP 7 settings. Information on DIP 5, DIP 6, and DIP 7 can be

found in the following section.

The use of DIP 4 may or may not be a consideration for every install. By default,

DIP 4 is set to the ON (UP) position or (NO) Normally Open; meaning that the

ASD-120 will operate normally with an open circuit applied to the FORCE OFF input. In this default setting, shorting the FORCE OFF pins will cause the ASD-120

2.0 to go into FORCE OFF mode.

DIP 1, DIP 2, and DIP 3: DIP Time Adjustment

DIP switch positions 1, 2 and 3 and the position of the DLY ADJ (Delay Adjustment) pot control the time delay interval or “dwell time” between consecutive

stages when sequencing ON or OFF. The maximum time for each DIP switch is

shown inside the cover plate label and represents the delay time when the DLY

ADJ potentiometer is fully clockwise. DIP 1 adds 1 minute maximum time delay,

DIP 2 adds 2 minutes and DIP 3 adds 4 minutes. Please note these time delays

are cumulative. If all three DIP switches are in the UP position, the maximum

allowable time delay will be 7minutes, i.e. 1min+2min+4min=7min. The factory

default setting is DIP 1 ON or UP, and DIP 2 and 3 are OFF or DOWN. You can set

these switches in any position you like to achieve your preferred time delay.

Delay Adjustment (potentiometer)

DLY

ADJ

In order to precisely dial in your preferred sequence delay time, it is necessary

to set the Time Delay Adjustment (DLY ADJ) located left of the multi-function DIP

Switch. If this potentiometer is turned to its 100% value (fully clockwise), then the

time delay will be equal to the maximum time delay defined by DIP switches 1, 2,

and 3. If the potentiometer is in the 12 o’clock position (50%), then the time delay

will be 50% of the maximum time delay interval defined by the setting of DIP

Switch positions 1, 2 & 3. If all three DIP switches are off, and the potentiometer

is turned completely counter-clockwise, the time delay is minimal. The Time Delay

Adjustment potentiometer comes factory-set at 50%, the 12 o’clock position.

Example: If the DIP Switches are set to a 6 minute maximum delay and the potentiometer is set to its 50% setting, then the delay interval between sequenced

banks will be 3 minutes. (DIP 1 OFF or DOWN, DIP 2 and DIP 3 ON or UP = 6

minutes) x .50 = 3 minutes.

DIP 5, DIP 6 & DIP 7

Remote Mode Trigger Settings

DIP 5 (+12V, ON OFF) and DIP 6 (GND ON) are used in special situations, where

the factory-set remote options are not preferred. For instance, a newly remodeled

location has an existing remote key switch different from a Furman remote key

switch design, and it would be advantageous to use the existing key switch, since

many personnel already have keys. DIP 5 (+12V, ON OFF) and DIP 6 (GND ON)

could possibly address such situations. Please feel free to contact Furman, if

further assistance is necessary.

DIP 7 is used to set the remote switching preference. The ASD-120 2.0 can be

set to a Maintained Mode (DIP 7 OFF or DOWN) or a Momentary Mode (DIP 7

ON or UP) dependent upon the chosen method of remote switching. A Maintained switch method stays open until switched, and then remains closed until

switched again (such as toggle switches, e.g. Furman RS-1 key lock switch).The

Momentary switch method is normally open and stays closed only as long as the

button is depressed (such as pushbutton switches, similar to the Furman RS-2

security switch).

Momentary Mode does offer an advantage over Maintained Mode when multiple

remote switching locations are desired. Due to technical flexibility, Momentary

switching easily adapts when implemented with more than one remote switch.

However, maintained switching can be more stable, truly shunting control

voltages when actuated. DIP 5 and DIP 6 offer additional methods of applying

Maintained switching. Regardless of which switching method is chosen, when

changing DIP 4, DIP 5, DIP 6, or DIP 7, it is required to reset the Key Switch to

the OFF position before continuing the programming and installation.

9

Page 11

The ASD-120 2.0 has one Momentary Mode of operation (DIP 7 ON or UP),

which is also compatible with Furman Legacy products. As suggested, when

more than one remote switching location is required, momentary switches offer

an advantage. In addition to this benefit, multiple Primary units set to Momentary

Mode can be interfaced together using the Remote Pole contacts +12V, REM and

GND, wired in parallel pole to pole. No one unit is considered the Primary Unit, yet

any unit can act as one. The multiple units’ delay cycle would initiate at the same

time, in combination with each other; in other words, the units would all start at

once and all initiate a cycle down at once, once any Momentary switch (button) is

pushed (including Remote Momentary switches). As mentioned, multiple momentary remote contacts should be used if more than one remote power up location

is desired. If units should drop out of sync, simply press and hold down the Start

Sequence button for several seconds to re-sync.

A front panel position DIP switch is used to set the sequence mode (+12V

ON, +12V OFF, GND ON, Mom/ Maint) which defines how the ASD-120 2.0 will

react to the signal presented on its REM input. The table below summarizes the

behavior which is described in further detail below. Note that DIP switch position

6 overrides the setting of DIP switch 5, and DIP switch 7 overrides switches 5

and 6.

DIP Switch position #5 (Factory default is OFF)

DIP Switch position #6 (Factory default is OFF)

DIP Switch position 6 defines how the ASD-120 2.0 will behave when GND is applied to the REM pin on the Remote interface. If this switch is in the ON position,

the ASD-120 2.0 will sequence ON when GND is applied to the REM input. If this

switch is in the OFF position the ASD-120 2.0will follow the behavior defined by

DIP Switch #5. DIP switch 7 must be in the OFF position (Maintained mode).

DIP Switch position #7 (Factory default is OFF)

DIP Switch position 7 defines the switching preference for switches or devices

connected to the REM pin on the Remote Interface. If this switch is in the ON

position, the ASD-120 2.0 will operate in Momentary mode. If this switch is in the

OFF position the product will operate in Maintained mode.

Maintained switches, for example toggle switches or push-ON / push-OFF push

button latching switches maintain their contact position until the switch is actuated a second time. Thus a switch that is closed will remain closed until the switch

position is changed (such as the Furman RS-1).

DIP Switch position 5 defines how the ASD-120 2.0 will behave when +12VDC is

applied to the REM pin on the Remote interface. If this switch is in the ON position, the ASD-120 2.0 will sequence ON when +12V is applied to the REM input.

If this switch is in the OFF position (+12V OFF) the ASD-120 2.0 will sequence

OFF when +12V is applied to the REM input. DIP switches 6 and 7 must be in

the OFF position (Maintained mode).

DIP #s

5 6 7

DIP 5

12V ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

DIP 6

GND ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

DIP 7

MOM/MNT

OFF

OFF

OFF

OFF

ON

ON

ON

ON

MODE

+12V OFF

+12V ON

GND ON

GND ON

Momentary

Momentary

Momentary

Momentary

Note: The front panel START SEQUENCE switch is only active when the Key Switch is in the

REMOTE Position

Sequences the ASD-120 2.0 ON when REM = Open Circuit

Sequences the ASD-120 2.0 OFF when REM = 12VDC

Sequences the ASD-120 2.0 ON when REM = 12VDC

Sequences the ASD-120 2.0 OFF when REM = Open Circuit

Sequences the ASD-120 2.0 ON when REM is connected to GND terminal

Sequences the ASD-120 2.0 OFF when REM = Open Circuit

Sequences the ASD-120 2.0 from ON to OFF or OFF to ON each time +12V is applied to the REM input.

FACTORY DEFAULT SETTING

10

Page 12

ASD-120 2.0 PROGRAMMING SUMMARY

Note: When programming a new configuration it is recommended to start with

the front panel Key Switch in the OFF position.

Multi-Function DIP Switch

• DIP 1 1M = 1 Minute Delay

• DIP 2 2M = 2 Minute Delay

• DIP 3 4M = 4 Minute Delay

Note: DIP 1, 2 and 3 sum together for a total sequence time of 35 minutes.

• DIP 4 N.O. / N.C. sets the active state of the FORCED OFF input

The factory default setting for FORCED OFF is “ON” or “normally open”. In this

mode, FORCE OFF is triggered when the FORCE OFF pins are shorted.

Note: If FORCED OFF mode is triggered ASD-120 2.0 will be disabled until

FORCE OFF state is cleared by resetting Key Switch to OFF.

Note: Force Off overrides the Sequence Bypass DIP Switch and all Delay Bank

LED indicators will flash.

• DIP 5 12VDC ON sets +12V Remote Mode

The factory default setting for 12VDC ON is “OFF” or disabled. If 12VDC ON is set

to ON, the ASD-120 2.0 will sequence ON if 12VDC is applied to the remote pin

on the remote interface.

12V OFF = 12VDC to REM deactivates

12V ON = 12VDC to REM activates

Note: Factory Default is MAINTAINED ON Mode with DIP 5 set down to 12V OFF.

• DIP 6 GROUND ON

The factory default setting for GND ON is “OFF”. If this switch is changed to the

“ON” position, the ASD-120 2.0 will sequence ON when GND is applied to the

remote pin on the remote interface.

REM to GND = ON

Note: To disable the front panel button completely, the GND ON Maintained Mode

should be used.

Note: GROUND ON mode overrides DIP 5.

• DIP 7 MOM / MNT - Momentary / Maintained

Sets local mode and remote contact closure preference for either Momentary or

Maintained switches.

Note: Momentary mode overrides DIP 5 and 6.

Sequence Bypass DIP Switch

• DIP position ON

(A thru F) = Delay Bank and Relay is ALWAYS ON

• DIP position SEQ

(A thru F) = Delay Bank and Relay activates in Sequence

• DIP position OFF

(A thru F) = Delay Bank and Relay is ALWAYS OFF

Note: Except for a Force Off condition, the Sequence Bypass DIP Switch

overrides any local or remote switch function.

Key Switch

• OFF = Banks sequence OFF except those configured as “ALWAYS ON” in the

sequence bypass DIP switch.

• REMOTE = Accepts On/Off signals through the rear panel REMOTE connector

and the Start Sequence button.

• ON = Banks sequence ON except those configured as “ALWAYS OFF” in the

sequence bypass DIP switch.

Note: The Start Sequence Button is disabled when DIP 6 is in GND ON mode

(Position UP).

Note: Loss of AC Power or utility interruption in Maintained Mode will result in all

Banks returning to the previous state when the utility service is restored. Maintained On, Banks will return to ON. Maintained OFF, Banks will return to OFF.

Note: Loss of AC Power or utility interruption in Momentary Mode will result in all

Banks returning to an OFF state when the utility service is restored.

Note: If switch #4 on the Multi-Function DIP switch is set to OFF (NC Mode) the

FORCE OFF pins on the rear panel must be shorted for normal operation.

In NC Mode, a FORCE OFF condition will be triggered if the FORCE OFF pins are

open circuit. The factory default is ON (NO Mode). In NO Mode, the ASD-120

2.0 functions normally with the FORCE OFF pins open circuit and FORCE OFF is

triggered when FORCE OFF pins are shorted.

11

Page 13

REAR PANEL CONTROL TERMINAL INTERFACE

WARNING! ELECTRIC SHOCK HAZARD. CONNECTION OF A POWER

INPUT CABLE TO THIS DEVICE AND TO A POWER SOURCE MUST BE

DONE BY QUALIFIED PERSONNEL ONLY.

DANGER: MANIPULER SEL ON LES INSTRUCTIONS DU

FABRICANT ET CONFIER LA MAINTENANCE A UN T

ECHNICIEN QUALIFIE

INPUT 120 / 3Ø, 208 / 240 VAC

14400 WATTS – 120 AMPS MAX

DELAY A

20A MAX

DELAY B

20A MAX

DELAY C

20A MAX

REMOTE INTERFACE

The ASD-120 2.0 has a remote interface which can be used to control the ASD120 2.0 remotely using a Furman RS-1 (Maintained) or RS-2 (Momentary) wall

switches. In the most basic, single unit configuration, only two wires and a switch

are required to initiate a remote ON or OFF sequence. The switch may be either

a momentary or maintained-contact type. If a third & fourth wire are available, an

LED “Status Light” can be installed at the remote switching location to indicate

the status of the ASD-120 2.0. The pins on the remote interface are described

below:

Remote Interface

Pin Label Description

REMOTE

1 12V 12VDC @250mA General

Purpose Output

2 STAT Output for driving an

12V STAT REM GND

1 2 3 4

external status LED

3 REM Input for controlling the

sequencer remotely

4 GND Ground (12VDC Power and

Signal Common)

PIN 1 +12VDC (12VDC Voltage Source)

The +12VDC terminal pin is a general purpose, 12VDC voltage source relative to

the GND (#4) pin. It is provided to allow the user to control the operation of the

sequencer by feeding the +12VDC signal back into the REM terminal input; which

is pin #3 on the same barrier strip.

PIN 2 STATUS (Output)

The STAT (status) terminal is an output that may be used to activate an LED to

indicate the status of the ASD-120 2.0. If the STAT terminal is high, the ASD-120

2.0 Delay outlets are either ON, or are in the process of sequencing ON. If the

STAT terminal is low, the ASD-120 2.0 Delay outlets are OFF. To use the STAT

terminal output simply connect an LED between the STAT and GND with the

Cathode (flat) side of the LED oriented toward the GND pin (Pin #4). Do not use a

series current limiting resistor. If the LED does not light when the remote switch

is ON, check the polarity of the LED and reverse the leads if necessary.

• If the LED is OFF, the DELAY outputs are OFF

• If the LED is ON, the DELAY outputs are ON

• If the LED is blinking, the DELAY 1, 2 or 3 outputs are in transition either from

ON to OFF or OFF to ON

PIN 3 REMOTE (Input)

The REM (remote) terminal is provided to allow remotely connected devices to sequence the ASD-120 2.0 ON or OFF. The ASD-120 2.0s’ REM terminal has been

designed to work with voltages from 5 to 30VDC. Filtering has been added to this

input to prevent false-triggering. The behavior of the ASD-120 2.0 is controlled

by the combination of the signal presented at the REM terminal input, and the

arrangement of the rear panel DIP switches. Please refer to FRONT PANEL DIP

SWITCH section (page 9) for more details.

DELAY D

20A MAX

DELAY E

20A MAX

DELAY F

20A MAX

FORCE OFF

REMOTE

12V STAT REM GND

DELAY OUTPUTS

NC A B C D E F NO

DRY RELAY CONTACTS - RATING 48V / 1 AMP

PIN 4 GND (Power)

The GND (ground) terminal operate in unison with Delay A through F. GND can

also be fed back into the REM pin (Pin #3) to activate the sequence when the

ASD-120 2.0 has been configured for GND ON mode. Please note that the GND

terminal on the Remote Interface is not the same as chassis ground and should

never be connected to chassis ground.

Note: The ASD-120 2.0 Remote interface is also compatible with other relay

contact and low voltage DC control interfaces often used by other equipment

brands and manufacturers.

DELAY OUTPUTS TERMINAL

DELAY OUTPUTS

The Delay Outputs are related to the activation

of 6 relay contact. Each DC relay A thru F

is activated when the corresponding Delay

Bank and is switched ON. All outputs share a

common connection at the left or right ends of

NC A B C D E F NO

DRY RELAY CONTACTS - RATING 48V / 1 AMP

this connector that will allow selection between

normally closed (NC) or

normally open (NO).

The Delays outputs terminal conssist of a series of six relays, internal to the ASD-120 2.0.

These relays mirror the state of Delay Banks A

through F. The diagram to the right shows how

the relays are wired inside the ASD-120 2.0

FORCE OFF

RELAY A

RELAY B

RELAY C

RELAY D

RELAY E

RELAY F

FORCE OFF TERMINAL

The optically isolated FORCE OFF inputs are to be connected to a pair of dry

switch contacts provided by an alarm or emergency kill switch. The ASD-120 2.0

will respond to NC or NO contacts based on the setting of DIP 4. All Delay Banks,

including those configured as “Always On” will be powered off immediately when

FORCE OFF is triggered. When triggered, all the Delay Bank LEDS will blink in

unison while FORCE OFF state is active. The FORCE OFF input is designed with a

12VDC 10mA source for this purpose. To reset FORCE OFF, turn the Key Switch

to the OFF position to clear the condition.

NC

A

B

C

D

E

F

NG

12

Page 14

ADVANCED INSTALLATION TOPICS

The beginning of the manual provides basic information for those who are familiar

with Furman equipment. A more complete description of ASD-120 2.0 operations

and configuration options are provided in the following sections.

Sequence Timing

Please note all Banks participate in the programmed time interval. The programmed delay time will cycle through all Banks A thru F, regardless of a Bank’s

assignment on the Bypass Switch. Banks that have been programmed as

ALWAYS ON, or ALWAYS OFF experience no effect in the program timing, since

bypassed Banks are independent of the ASD-120 2.0 control circuitry.

Note: The ASD-120 2.0 sequences each Delay Bank in order from A to F when

sequencing ON, and turn Banks F to A OFF in the reverse order when sequencing OFF. Triggers to initiate an ON or OFF sequence can occur at any time even

during a programmed sequence. If triggered to do so, a unit’s programmed

sequence will be and can be reversed at any time.

Sequence Initialization

Factory default mode for the ASD-120 2.0 is Maintained On. A sequence can occur at any time, reverse at any time, and/or FORCED OFF at any time, even while

a sequence is in progress. If Maintained Mode is configured and an SEQUENCE

ON trigger is received while the Banks are On, nothing will happen. The same is

true if all Delay Banks are OFF and a trigger to SEQUENCE OFF is received. Therefore if two or more remote switch locations are desired and the user would like

to sequence ON or OFF from both locations. Momentary Mode and Momentary

Switches must be employed. For example, if two Maintained switches are used

and the Multi-Function Set is configured in Maintained On mode, the ASD-120

2.0 will remain ON until both remote locations are set to OFF.

A time-delayed On or Off sequence can be initiated at the front panel Key Switch,

the START SEQUENCE button, or using the 4-Pin Remote Interface. The configuration Multi-Function DIP switches can program a sequence response utilizing

either Closed or Open Contacts, or the presence or absence of an external DC

voltage (5 to 30VDC max). The following basic examples of remote integration

are provided:

DIP SETTINGS

1. Key Switch and Start Sequence Button Control

(Local and Remote Activation MAINTAINED ON).

ON

A sequence is initiated by turning the key switch

past the REMOTE position to initiate a sequence

ON or OFF.

1 2 3 4 5 6 7

A. DIP 7 set to (MNT) mode – DOWN Position Maintained Mode.

B. Set DIP 5, DIP 6, and DIP 7 switches DOWN reserving DIP 1, DIP 2,

and DIP 3 for delay timing.

C. Turn Key Switch to the ON position for Local operation – Remove key

if and when desired.

D. Or turn Key Switch to REMOTE position – Use Start Sequence button

or a remote switch to initiate sequence.

E. Connect Maintained switch between REM and 12V at the REMOTE 4

Pin Connector (e.g. Furman RS-1).

Note: Start Sequence button on front panel is inoperative when the key switch is

in the ON or OFF positions.

2. Start Sequence Button Control or Remote Push Button (Local and Remote

MOMENTARY Operation)

When the front panel Key Switch is in the REMOTE

position, the START SEQUENCING buttons can be

used to toggle the sequence On or Off. A remote

DIP SETTINGS

ON

pushbutton such as the RS-2 momentary contact

switch can be added to provide remote control as

well:

1 2 3 4 5 6 7

A. Set Key Switch to the Remote position - Remove key if desired.

B. DIP 7 (MOM) in the UP position - Momentary operation is selected.

C. Set DIP 5 and DIP 6 switches DOWN reserving DIP 1, DIP 2, and DIP 3

for delay timing.

D. Connect Push Button Momentary Switch between REM and 12V at

the REMOTE 4 Pin Connector.

Note: Multiple Push Button Momentary Switches can be employed from multiple

locations (e.g. Furman RS-2).

13

Page 15

3. Control by Remote Contact Closure (Remote Activation MAINTAINED OFF) Any

external dry switch CONTACT CLOSURE can be used to activate the sequence ON.

An Open Contact will result in a sequence OFF.

5. SEQUENCE OFF using external 5 to 30VDC power supply. In this mode an

external power supply will prevent the ASD-120 2.0 from sequencing ON. The

ASD-120 2.0 will automatically sequence ON when the DC power is removed.

A. Turn Key Switch to the REMOTE position – Remove key if desired.

B. DIP 6 is in the up position - GND ON mode.

C. DIP 7 in the down position - MNT (Maintained) operation is now

selected.

D. Set Multi-Function DIP 5 DOWN reserving DIP 1, DIP 2, and DIP 3 for delay

timing.

E. Connected external contacts between the REM and GND connections at the

REMOTE 4-Pin Connector.

Note: The Front Panel Start Sequence Button is disabled when DIP 6 is in the

GND ON mode (UP).

4. SEQUENCE ON using external 5 to 30VDC power supply. In this mode, an

external power supply will cause the ASD-120 2.0 to sequence ON. When the

power supply is removed, the ASD-120 2.0 will automatically sequence OFF.

A. Turn Key Switch to the REMOTE position – Remove key if desired.

B. DIP 5 in the up position.

C. DIP 6 is in the down position.

D. DIP 7 in the down position - MNT (Maintained) operation is now

selected.

A. Turn Key Switch to the REMOTE position – Remove key if desired.

B. DIP 5 in the down position - 12V OFF mode.

C. DIP 6 is in the down position.

D. DIP 7 in the down position - MNT (Maintained) operation is now

selected.

E. Reserve DIP 1, DIP 2, and DIP 3 for delay timing.

F. Connected external DC supply (+) to REM pin and (-) to GND pin at

the REMOTE 4-Pin Connector will cause the unit to SEQUENCE OFF.

Note: The ASD-120 2.0 is disabled when DIP 4 is set for (N.C.) mode. Factory

DIP 4 (N.O.) mode is recommended. Only a short across the Forced Off terminals

will activate the ASD-120 2.0 when DIP 4 is in (N.C.) mode. This DIP setting is

reserved for alarm systems. Factory default for DIP 4 is (N.O) mode position UP.

Note: The Front Panel Start Sequence Button is disabled when DIP 6 is in GND

ON mode (Position UP).

Note: When programming a new configuration it is recommended to start with

the front panel Key Switch in the OFF position.

Note: Loss of AC Power or utility interruption in Maintained Mode will result in all

Banks returning to the previous state when the utility service is restored. Maintained On, Banks will return to ON. Maintained OFF, Banks will return to OFF.

E. Reserve DIP 1, DIP 2, and DIP 3 for delay timing.

F. Connected external DC supply (+) to REM pin and (-) to GND pin at the

REMOTE 4-Pin Connector.

Note: The Front Panel Start Sequence Button is disabled when DIP 6 is in the

GND ON mode (UP).

Note: Loss of AC Power or utility interruption in Momentary Mode will result in all

Banks returning to an OFF state when the utility service is restored.

14

Page 16

LOCAL AND REMOTE OPERATING MODES

Other configuration options are possible with an understanding of the REMOTE interface and configuration features of the ASD-120 2.0 discussed in the following

sections.

Key Switch Control

Secured local control of the ASD-120 2.0 is best accomplished by using the

front panel Key Switch. When in the ON position, all Delay Banks will sequence

ON, except those configured with the Bypass Set as Always OFF. All Banks not

configured as Always ON will be switched OFF once the Key Switch is returned to

the OFF position. If the Key Switch is intended to be the primary control method,

no external control connection to the rear panel REMOTE interface REM terminal

is recommended, and DIP 6 should be set to the GND ON position (DIP 6 UP). In

the absence of any external control signal, once the key switch has initially been

rotated to the ON position and returned to the REMOTE position, the ASD-120 2.0

defaults to ON in either Maintained Mode or Momentary Mode.

Note:: The front panel Key Switch must be in the REMOTE position for ASD-120

2.0 to accept remote commands. Furthermore, an ON or an OFF key position setting functions in either DIP 7 Maintained or Momentary mode effectively bypasses

all other command functions except the Bypass Set or a FORCE OFF condition.

Note: The Start Sequence Button is disabled when DIP 6 is in GND ON mode

(Position UP).

Note: Loss of AC Power or utility interruption in Maintained Mode will result in

all Banks returning to the previous programmed state when the utility service is

restored. Maintained On, Banks will return to ON. Maintained OFF, Banks will

return to OFF.

Note: Loss of AC Power or utility interruption in Momentary Mode will result in all

Banks returning to an OFF state when the utility service is restored.

Front Panel Start Sequence Button Control

The ASD-120 2.0 front panel Start Sequence button can be used as the primary

control to initiate a sequence. If the unit is programmed for Momentary Mode

(DIP 7 = ON), each time Start Sequence is depressed, the ASD-120 2.0 will toggle between ON and OFF sequences. If the button is pressed and held for more

than six seconds, the ASD-120 2.0 will sequence to the OFF state.

The front Start Sequence button should only be used when the Key Switch is in

the REMOTE position with DIP 7 the MOM/MNT dip switch set to MOM (DIP 7 in

the UP position).

Push buttons in multiple locations can be used to initiate ON/OFF sequences.

Remote control options are discussed in the Momentary Mode Section.

Note: The Start Sequence Button is disabled when DIP 6 is in GND ON mode

(Position UP).

Note: Loss of AC Power in Momentary Mode will result in all Banks returning to

an OFF state when the utility service is restored.

Remote Operating Modes

When the Key Switch is in the REMOTE position, the ASD-120 2.0 will respond as

configured by the switches behind the front panel cover plate. The ASD-120 2.0

can be programmed to respond to remote Momentary and sustained (Maintained)

trigger conditions. The unit can be triggered by the presence or absence of

contact closures or a DC voltage. The ASD-120 2.0 can also be used to trigger

remote equipment using the same type of trigger conditions.

The ASD-120 2.0 and similar equipment (available from FURMAN and other

sources) can be controlled in parallel with a control signal wired from a single

switch. Also, control connections can be made in series with various units triggered from an event occurring at another piece of equipment. An infinite variety

of connection schemes using any combination of these two methods is possible.

The momentary mode is only used with trigger signals that are of a short duration

such as a push button. Equipment compatible with this type of trigger can be

connected in a way that permits the initialization of a sequence from push buttons

in multiple locations.

Signal level relay contacts A thru F are provided at the rear panel of the ASD-120

2.0 which can be used for the purpose of triggering external equipment. The

contacts can be configured as a group as normally open (NO) or normally

closed (NC).

When the key switch is in either the ON or OFF position, the ASD-120’s sequencing circuits will not respond to the rear panel remote control inputs. If the key

switch is returned to the REMOTE position, the signals supplied to the rear panel

remote inputs will again control the unit.

15

Page 17

Configuration for Remote Operation

Maintained switches are generally most convenient when there is only one remote

control location. The ASD-120 2.0 is shipped factory-set for Maintained On

operation. The alternate method of controlling the ASD-120 2.0 through the use

of a momentary push button switches can be used when more than one remote

switch location is required.

Note: The front panel Key Switch must be in the REMOTE position for ASD-120

2.0 to accept commands. Furthermore, an ON or an OFF key position functions

in either DIP 7 Maintained or Momentary mode bypassing all other program

functions except the Bypass Set or a Force Off condition.

Maintained On - 12V ON/OFF

When the Key Switch is in REMOTE mode, +12V present at the REM input with

respect to GND will initiate an ON or OFF sequence depending on the position

of DIP 5 (12V ON/12V OFF). After the sequence is complete, the output circuits

will remain in the configured state as long as +12V is present. The source of the

+12V can be from the remote interface itself, through remote relay contacts, or

can be supplied by a +12V source from connected equipment. The absence of

12V will cause the ASD-120 2.0 to toggle, and remain in the opposite state.

The ASD-120 2.0 cannot operate in the 12V ON/OFF Maintained Mode when DIP

6 is set to the GND ON mode. The GND ON switch will take priority. In 12V ON/

OFF Maintained Mode, one cannot use the START ON/OFF SEQUENCE button.

If someone does press the button, the ASD-120 2.0, if ON, will start an OFF

sequence that will last until you release the button.

Note: To disable the front panel button Start Sequence completely, the GND ON

Maintained Mode should be used.

Maintained On - GND ON

A simple connection from the REM terminal to the GND will initiate an ON sequence when DIP 6 is in the up position. After the sequence is complete,

the output circuits will remain in the configured state as long as the ground connection to REM is present. Opening this connection initiates the OFF sequence.

When DIP 6 is set for GND ON, the position of DIP 5 12V ON/OFF is ignored.

DIP #7 switch is set in the down position (MNT) for operation in Maintained

Mode. And when utilizing the REM and GND terminals, an ON response can be

programmed by setting DIP switches #5 and #6 accordingly. And when utilizing

the 12V and REM terminals, the same is true. The connection to the REMOTE

interface must exist, whether it be a presence or absence of 12V or open/closed

contacts. This mode is not typically used.

Note: The Start Sequence Button is disabled when DIP 6 is in GND ON mode

(Position UP).

Momentary Mode

In the Momentary Mode, a momentary switch such as the one located on the

front panel of the ASD-120 2.0, or the Furman RS-2 remote switch panel, can

be used to initiate an ON or OFF sequence. The Momentary Mode is selected

when DIP #7 (MOM/MNT) is in the up (MOM) position and DIP #6 (GND ON) is

in the down position. The position of DIP #5 (12V ON/12V OFF) is ignored. In

Momentary Mode, the ASD-120 2.0 will toggle between ON and OFF sequences

every time a trigger is received from the front panel button or at the REM terminal

with respect to GND. Multiple Furman devices with a REMOTE interface can be

synchronized by connecting the REM and GND terminals together.

When the ASD-120 2.0 has been configured for momentary mode, the REM

connection at the rear panel can act as an input or output depending on which

button is pressed. If the ASD-120 2.0 button has been pushed, the REM

connection provides a +12V output for as long as the button is depressed. Any

connected Furman products with REM and GND terminals will also cycle on or off.

To synchronize all equipment connected together in this way, press the START

SEQUENCE button for at least 6 seconds. The outputs of all connected products

will be shut off. If the connected product is a sequencer, the Sequence OFF will

be triggered. If remotely triggered, the sequence starts on the rising edge of the

signal at the REM terminal.

All Furman products connected in this way must be configured for Momentary

Mode. When first plugged in (or after power is lost and reapplied for any reason),

the ASD-120 2.0 outputs will remain off until a momentary trigger is received at

the REM input or the START SEQUENCE button is pressed. Pressing the START

SEQUENCE button while an ON or OFF sequence is in progress will result in an

immediate change in direction of the sequence.

Note: The Start Sequence button has no effect when thw ASD-120 2.0 is in

GND ON mode.

Maintained Off Mode

In the Maintained Off Mode, the ASD-120 2.0 will sequence ON or OFF with the

Key Switch or a remote activation trigger. In this mode the ASD-120 2.0 will

always remain in an OFF state until a connection is present between the REM

and GND terminals or between the 12V and REM terminals.

Note: Loss of AC Power in Momentary Mode will result in all Banks returning to

an OFF state when the utility service is restored.

16

Page 18

STATUS Output

SIGNAL WIRE CONSIDERATIONS

The STATUS terminal is an output that may be used to illuminate an LED at

remote locations to indicate the ASD-120 2.0 has active Delay Banks. If it is high

(+12V), the unit is on (or at least in the process of sequencing on); if low, the unit

is off (or sequencing off). Simply connect the indicator LED between STATUS and

GND (a series resistor is not required). If the LED does not light when the switch

is in the ON position, check the polarity and reverse the LED leads. The STATUS

output is a 12V source, current limited to 10 mA. If you wish to generate a STATUS output voltage to a confidence monitor or an indicator, please use a 1k Ohm

1/4-watt resistor in series with the LED.

REMOTE Interface – Rear Panel 4 pin Connector

The four pin Remote Interface terminal strip on the back of the ASD-120 2.0

allows a switch (or parallel switches) to be connected to turn the unit on and off

from a distance. In the most basic configuration, only two Class 2 wires and an

SPST switch or relay contacts are needed to initiate an on or off sequence. The

switch may be either a momentary or maintained-contact type. An LED may also

be installed at the remote end to indicate when power is on, but this will require

a third wire.

DELAY OUTPUTS – Rear Panel 8 pin Connector