Page 1

AR-15

AC LINE VOLTAGE REGULATOR

AND

POWER CONDITIONER

VOLTAGE

REGULATORS

Page 2

ACD-100 / AC POWER DISTRIBUTION

- 2 -

SAFETY WARNING

The instructions provided here

are insufficient for completing

a working ACD 100 installation.

While the subject of attaching a

supply cable to the ACD 100 is

covered, the connection of the far end (pigtail

end) of that cable to a power source is not.

Because of the many configurations that 100

amp or larger electrical services can take and

the numerous connector types that may be

used, it is not possible to adequately describe

every situation that may be encountered.

Therefore, it is strongly recommended that

the selection of the ACD 100 supply cable,

and the connections to both ends of it, be

done by a licensed electrician who is familiar

with the available electrical service.

GENERAL

INFORMATION

Congratulations on your purchase of a Furman

ACD 100 AC Power Distro. The ACD 100 is a

compact rack mount power distribution system

that is ideal for touring PA systems, touring

musical and theatrical acts, mobile recording

facilities, on location film and video shoots, etc.

any situation where AC power must be distributed

to multiple circuits and a hard wired, built in

system is missing, inadequate, or impractical.

Use of a Power Distro is cost effective, both

in terms of the convenience it offers and the

elimination of bulky and expensive parallel

feeds and related connectors.

incoming power, distributing it to five 20 amp,

120V circuits. Each circuit has a neon status

indicator that lights up when its breaker is

turned on, and a 20 amp duplex outlet on the

rear panel.

The circuit breakers used in the ACD 100 are

high inrush magnetic types designed specifically

for critical data processing and broadcast

applications where nuisance tripping cannot

be allowed. They have a pulse tolerance* of

10 times the rated current, or 200 amperes.

This makes them particularly suited for use

with power amps and other devices with high

reactance loads, since the high pulse tolerance

will keep them from tripping falsely at the instant

power is applied or on musical peaks. If a

breaker should trip, it can be reset as soon as the

overload is correctedthere is no cool down delay

time required. Temperature compensations

which aff ‘ ect fuses and inexpensive thermal

breakers are not a concern. The breakers are

of the highest industrial grade, UUCSA listed,

precise in operation and rugged in construction.

They may be used as on off switches for the five

circuits.

The ACD 100 provides basic spike and surge

suppression, with metal oxide varistors (MOV’s)

connected between the hot and neutral

conductors of each circuit. The MOV’s respond

to line derived spikes in less than a nanosecond,

clamping transient voltages to safe levels of

250V or less.

* Pulse tolerance is defined as the maximum peak current

amplitude of a single half sine wave pulse of 8 ms. duration

that will not trip the circuit breaker

The ACD 100 can handle up to 100 amps of

Page 3

AC POWER DISTRIBUTION / ACD-100

- 3 -

WIRING

INSTRUCTIONS

Prior to use, the ACD 100 must be fitted with

a proper supply cable, which must then be

connected to a 100 amp power source and

disconnect. The following instructions will

guide you through the selection and connection

process. All steps should be done while the unit

is disconnected from power and is not mounted

in a rack. Begin by removing the six screws that

hold the top cover in place and put the screws

and cover aside.

1. Determine the power source: In

North America, there are generally three

possibilities: 120V single phase, 240V

single phase, or 208V three phase. The first

alternative requires only three* conductors,

but they will need to be heavy to avoid

voltage drop in the cable, making the cable

stiffer and less flexible. The second voltage

configuration is 240V, available in most

residential and some commercial sites

and requiring a four* conductor cable. The

third alternative, 3 phase, will require five*

conductors which can be lighter gauge,

but 3 phase power may not be available in

every building.

cable) bundled together every foot or two

with plastic ties. The gauge and number of

conductors depends on the supply voltage

and cable or wire bundle length. Consult

Table 1 below to select the cable type best

suited for your application:

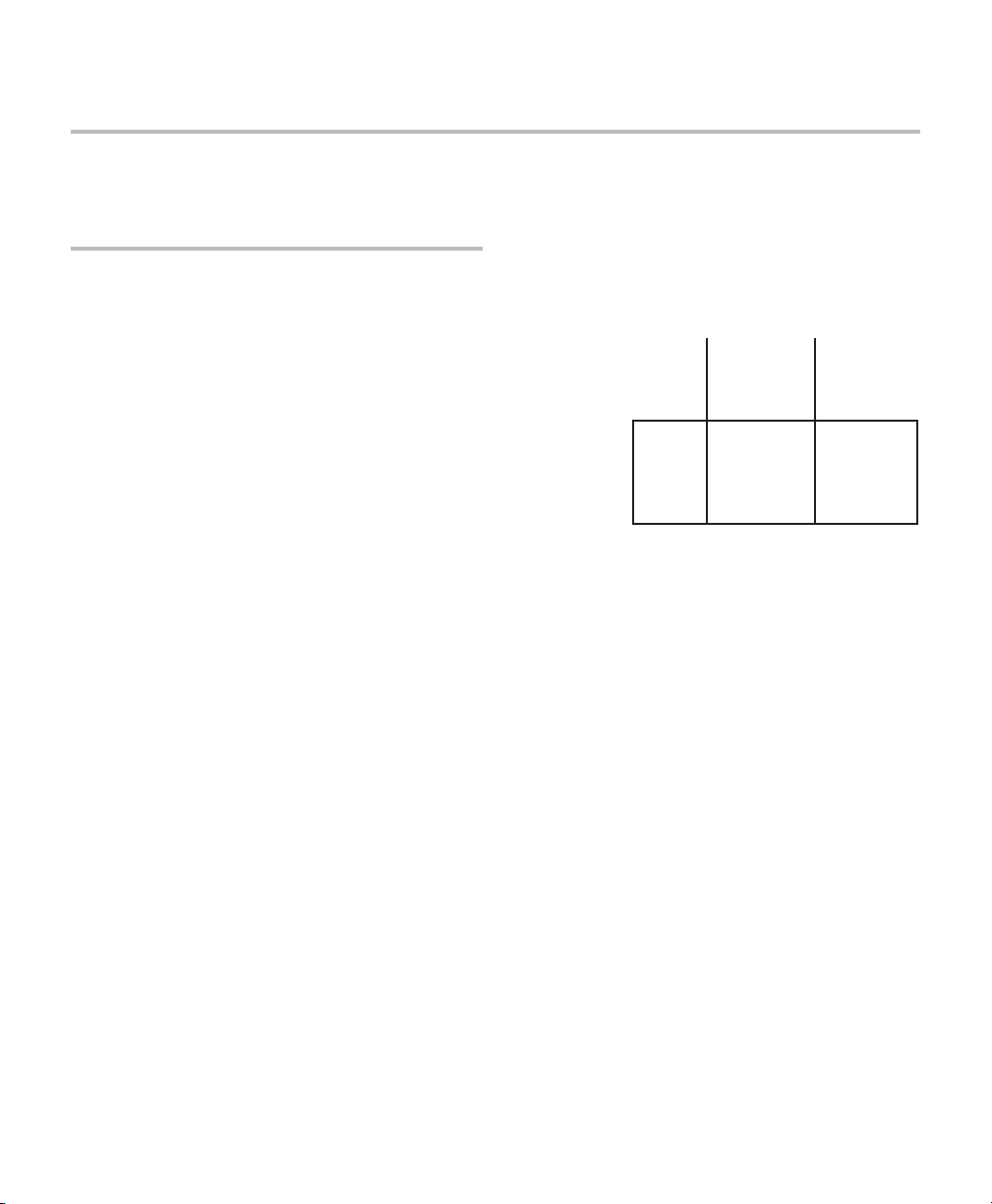

# Of

Conductors

Including

Ground

120V 3 4 AWG 8 AWG

240V ** 4 6 AWG 10 AWG

208V 3-ph *** 5 8 AWG 12 AWG

Current

Carrying

Conductors

Ground

Conductors

TABLE 1, REQUIRED WIRE GAUGES

The “Current Carrying Conductor” and

“Ground Conductor” columns give the

minimum recommended AWG size for

cable lengths of 100 feet or less. Note

that while it is acceptable for the ground

conductor to be a smaller gauge than the

current carrying conductors, many cables

have all conductors the same size. If they

are all the same size, it must be the size

specified in the table for the current carrying

conductors.

2. Select a cable and determine its

length: If the ACD 100 is installed in a

permanent or semi permanent location, it

is possible to connect it with flexible metal

jacketed conduit. However, rubber jacketed

(type S) or neoprene jacketed (type SO)

cable will usually be preferable in portable

use because of its flexibility and ease of

coiling for storage. Another possibility is

to use individual wires (such as welding

* Including ground, assuming the system neutral must

be kept separated from the safety (chassis) ground.

** Assumes three 20 amp loads on one conductor and

two 20 amp loads on the other conductor.

*** Assumes two 20 amp loads on each of the first

two conductors and one 20 amp load on the third

conductor.

Page 4

ACD-100 / AC POWER DISTRIBUTION

- 4 -

The ACD 1 00’s strain relief clamp can

accommodate a cable up to 1.5 inches in

diameter. For reference, a 4 conductor, 2

AWG type S or SO portable cord’s diameter

is 1.28 inches.

If the cable is to be moved from location

to location frequently, we suggest you

make it at least a few yards longer than the

length needed for the most distant location.

This is because the’vow source end will

typically be left as “pigtails” that is, with the

outer jacket stripped off a few feet and no

connectors attached. When the electrician

makes the connection to the power source,

he or she will often cut a few inches off each

conductor to expose clean copper to assure

a reliable connection. In this way, the cable

will become slightly shorter with each use.

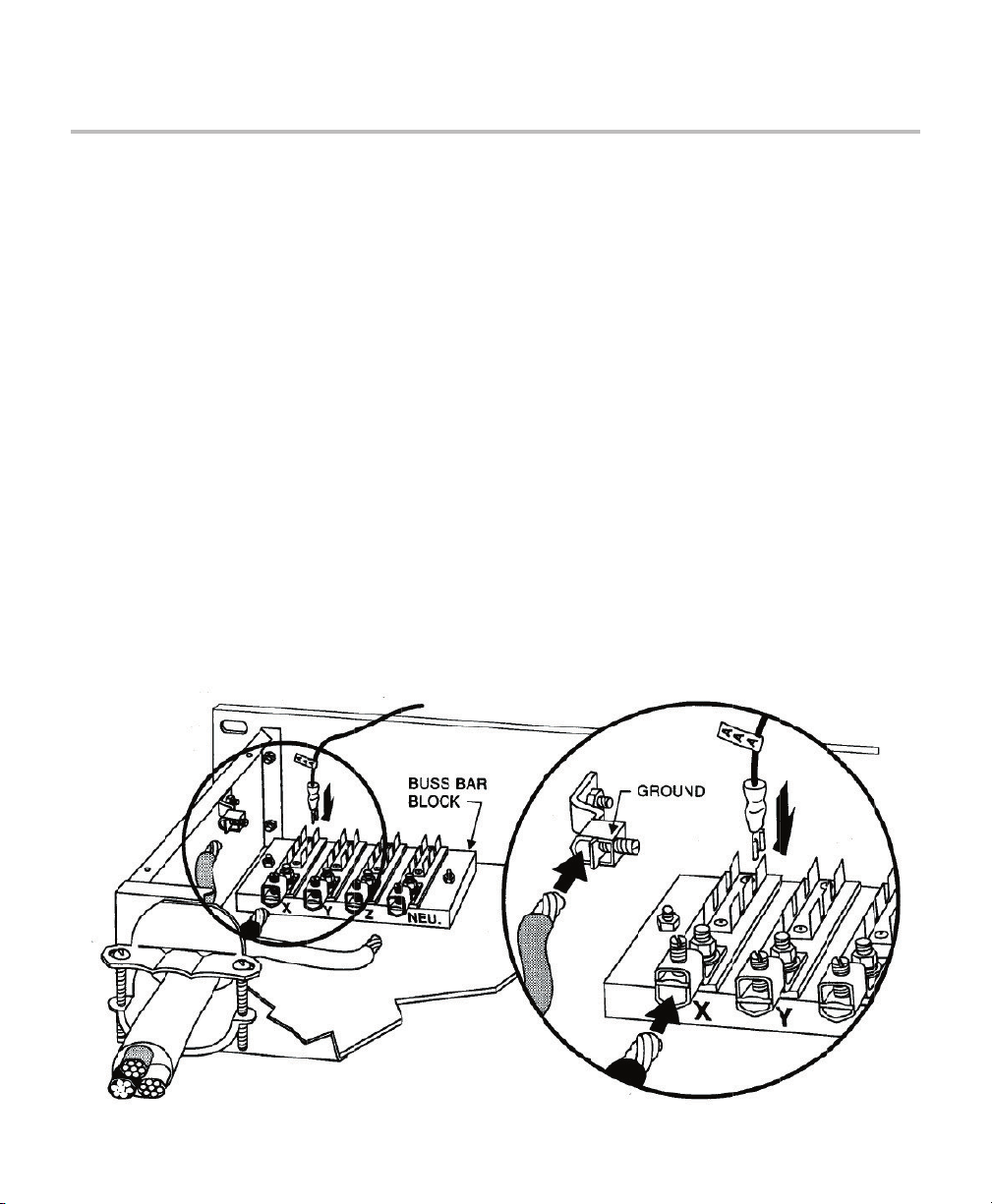

3. Prepare and connect the cable: The

supply cable will be connected to the ACD

100’s buss bars via terminals that secure

the individual conductors with set screws.

These can accept wires as large as 2 AWG.

Strip one end of the cable as shown in the

Strip Length drawing. When removing the

outer jacket, be careful not to nick or cut into

the insulation of the individual conductors.

When stripping the individual conductors,

be careful not, to cut through any of the

copper strands.

remaining two conductors are Red, hot no.

2 (labeled Y) and Blue (sometimes Orange),

hot no. 3 (labeled Z).

After threading the cable end through the

strain relief clamp, connect the stripped

conductors to the buss bar block. Be sure to

put each wire in the lower part of its terminal,

so that it is compressed above and below by

copper rather than by the set screw itself.

Tighten the set screws securely.

4. Divide the load: If there is more than

one hot wire, the five 20 amp loads must be

split among them and balanced as well as

possible. This is done by reconnecting the

wires from the buss bars to the five circuits.

There are two wires to each circuit, a hot

(black) and a neutral (white). Only the black

wires may be moved. All white wires must

connect to the NEU (neutral) buss bar. Each

black wire is labeled with a letter (A, B, C,

D, or E) corresponding to the circuit it goes

to. The connections are made by Fast On

terminals on the buss bars. To reconnect a

Input Cable

Color

120V Black X A,B,C,D,E

240V Black X A,B,C

Red Y D,E

Circuits

Buss Bar

The individual conductors should be color

coded as follows: Green, chassis ground;

White, neutral (labeled NEU on the bussbar

block); and Black, hot no. 1 (labeled X). If

a four or five conductor cable is used, the

208V 3-ph Black X A,B

Red Y C,D

Blue or Orange Z E

TABLE 2, DIVIDING THE LOAD

Page 5

AC POWER DISTRIBUTION / ACD-100

- 5 -

wire, grasp it by the terminal and pull straight

up. Then reposition it over an unused Fast

On male terminal on the appropriate buss

bar and push down firmly. Wire the loads in

accordance with Table 2.

5. Tighten clamp and close unit: Tighten

the cable strain relief clamp firmly. If you

are using a cable, make sure about a half

inch of the outer jacket extends beyond the

clamp into the unit. If you are using a wire

bundle, it is a good idea to wrap the bundle

with several layers of heat shrink tubing or

other sturdy material at the point where the

clamp tightens, to minimize the likelihood

that the clamp will cut into the insulation of

the individual wires. Replace the top cover.

This completes the internal wiring of the

ACD 100.

6. Terminate source end of cable or wire

bundle: As mentioned in Rem 2 above, the

most common cable termination is to break

the ends out as pigtails and leave its hookup

to the house electrician in each venue. In

some circumstances, a suitable connector

may be provided at the power source and

the cable can be terminated with a mating

connector. Often these will be Cam Lok ®

or similar connectors for each individual

conductor.

Page 6

ACD-100 / AC POWER DISTRIBUTION

- 6 -

LIMITED

If you want to provide a way to disconnect

the cable from the ACD 100 for separate

storage or shipment, one good way is to

permanently attach a very short cable to

the ACD 100 and terminate it with Cam

Lok connectors. A long cable with mating

CamLoks would then be prepared which

could easily be disconnected and stored.

ACCESSORIES

If you wish to monitor your ACD 100’s output

voltage, we recommend you use a Furman PM

PRO II or PL PRO II Power Conditioner on one

or more circuits. These rack mount products

are perfect complements to a power distribution

system. Each offers bar graph line voltage

meters to monitor the incoming line, and the

PM PRO II has an AC ammeter as well. Each

has nine outlets protected with comprehensive

spike and surge suppression and RFI filtering. If

rack illumination is needed, the PL PRO II has

twin slide out, swiveling lights with a dimmer

control.

Furman also makes a 20 amp Power Sequencer,

the PS PRO II, which can turn various units on

in a predetermined sequence, reversing the

sequence on power down. The PS PRO II also

provides comprehensive power conditioning

capability.

WARRANTY

Furman Sound, Inc., having its principal place

of business at 1997 South McDowell Blvd.,

Petaluma, CA 94954 (“Manufacturer”) warrants

its ACD-100 (the “Product”) as follows:

Manufacturer warrants to the original Purchaser

of the Product that the Product sold hereunder

will be free from defects in material and

workmanship for a period of three years from the

date of purchase. The Purchaser of the product

is allowed fifteen days from the date of purchase

to complete warranty registration by mail or online at the Furman website. If the Product does

not conform to this Limited Warranty during the

warranty period (as herein above specified),

Purchaser shall notify Manufacturer in writing of

the claimed defects. If the defects are of such

type and nature as to be covered by this warranty,

Manufacturer shall authorize Purchaser to

return the Product to the Furman factory or to

an authorized Furman repair location. Warranty

claims should be accompanied by a copy of the

original purchase invoice showing the purchase

date; this is not necessary if the Warranty

Registration was completed either via the mailed

in warranty card or on-line website registration.

Shipping charges to the Furman factory or to

an authorized repair location must be prepaid

by the Purchaser of the product. Manufacturer

shall, at its own expense, furnish a replacement

Product or, at Manufacturer’s option, repair the

defective Product. Return shipping charges back

to Purchaser will be paid by Manufacturer.

Page 7

AC POWER DISTRIBUTION / ACD-100

- 7 -

THE FOREGOING IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. Manufacturer does

not warrant against damages or defects arising

out of improper or abnormal use of handling of

the Product; against defects or damages arising

from improper installation, against defects in

products or components not manufactured by

Manufacturer, or against damages resulting

from such non-Manufacturer made products or

components. This warranty shall be cancelable

by Manufacturer at its sole discretion if the

product is modified in any way without written

authorization from Furman Sound. This

warranty also does not apply to Products upon

which repairs have been affected or attempted

by persons other than pursuant to written

authorization by Manufacturer.

THIS WARRANTY IS EXCLUSIVE. The sole

and exclusive obligation of Manufacturer shall

be to repair or replace the defective Product in

the manner and for the period provided above.

Manufacturer shall not have any other obligation

with respect to the Products or any part

thereof, whether based on contract, tort, strict

liability or otherwise. Under no circumstances,

whether based on this Limited Warranty or

otherwise, shall Manufacturer be liable for

incidental, special, or consequential damages.

Manufacturer’s employees or representatives’

ORAL OR OTHER WRITTEN STATEMENTS

DO NOT CONSTITUTE WARRANTIES, shall

not be relied upon by Purchaser, and are not

a part of the contract for sale or this limited

warranty. This Limited Warranty states the

entire obligation of Manufacturer with respect to

the Product. If any part of this Limited Warranty

is determined to be void or illegal, the remainder

shall remain in full force and effect.

Page 8

ACD 100 SPECIFICATIONS

VOLTAGE AND CURRENT

Input Current: 100 amps

Input Voltage: Either: 120V single phase, 240V single phase, or 208V 3 phase

Output: Five identical 20 amp, 120V circuits

CIRCUIT BREAKERS

Pulse Tolerance: 200 amps

(maximum peak current amplitude of a single half sine wave pulse of 8 ms. duration

that will not trip the breaker)

Overload vs. Trip Time: 100% overload: No trip. 125% overload: 0.7 12 sec. 200% overload: 0. 1 3 sec.

SPIKE/SURGE PROTECTION

Spike Protection Mode: Line to neutral on each circuit

Clamping Voltage: 200V peak

Response time: 1 nanosecond

Maximum surge current: 6,500 amps

Maximum spike energy: 80 joules per mode, 240 joules total

OTHER

Mechanical:

Dimensions: 3.5" H x 19" W x 8" D, rack mount.Weight: 12 lbs (5.5 kg).

Construction: Steel chassis, zinc chromate plating; .125" brushed

and black anodized aluminum front panel

Power Consumption: None

Safety Information: All current carrying components are TUV listed.

041905-A

Phone: 707-763-1010 • Fax: 707-763-1310 • Web: www.FurmanSound.com • E-mail: info@furmansound.com

Furman Sound, Inc. • 1997 South McDowell Blvd. • Petaluma, CA 94954-6919 USA

Made in China

Loading...

Loading...