Page 1

SERVICE MANUAL

Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

I Exploded views

I Parts List

When servicing the deck

mechanism, refer to MK14 Deck

Mechanism Section.

Deck Mechanism Part No.:

N25E1FL

DVD/Video Cassette Recorder with HDD

T3A-A8182DB/

T3A-D8182DB/

T3D-D8182DB

PAL

Page 2

MAIN SECTION

DVD/Video Cassette Recorder

with HDD

T3A-A8182DB/

T3A-D8182DB/

T3D-D8182DB

Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

I Exploded Views

I Parts List

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Handling Precautions for HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

Preparation for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

Cabinet Disassembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

How to Self-Check and Initialize the DVD/VCR with HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Function Indicator Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Schematic Diagrams / CBA’s and Test Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

IC Pin Function Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16-1

Lead Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20-1

Page 3

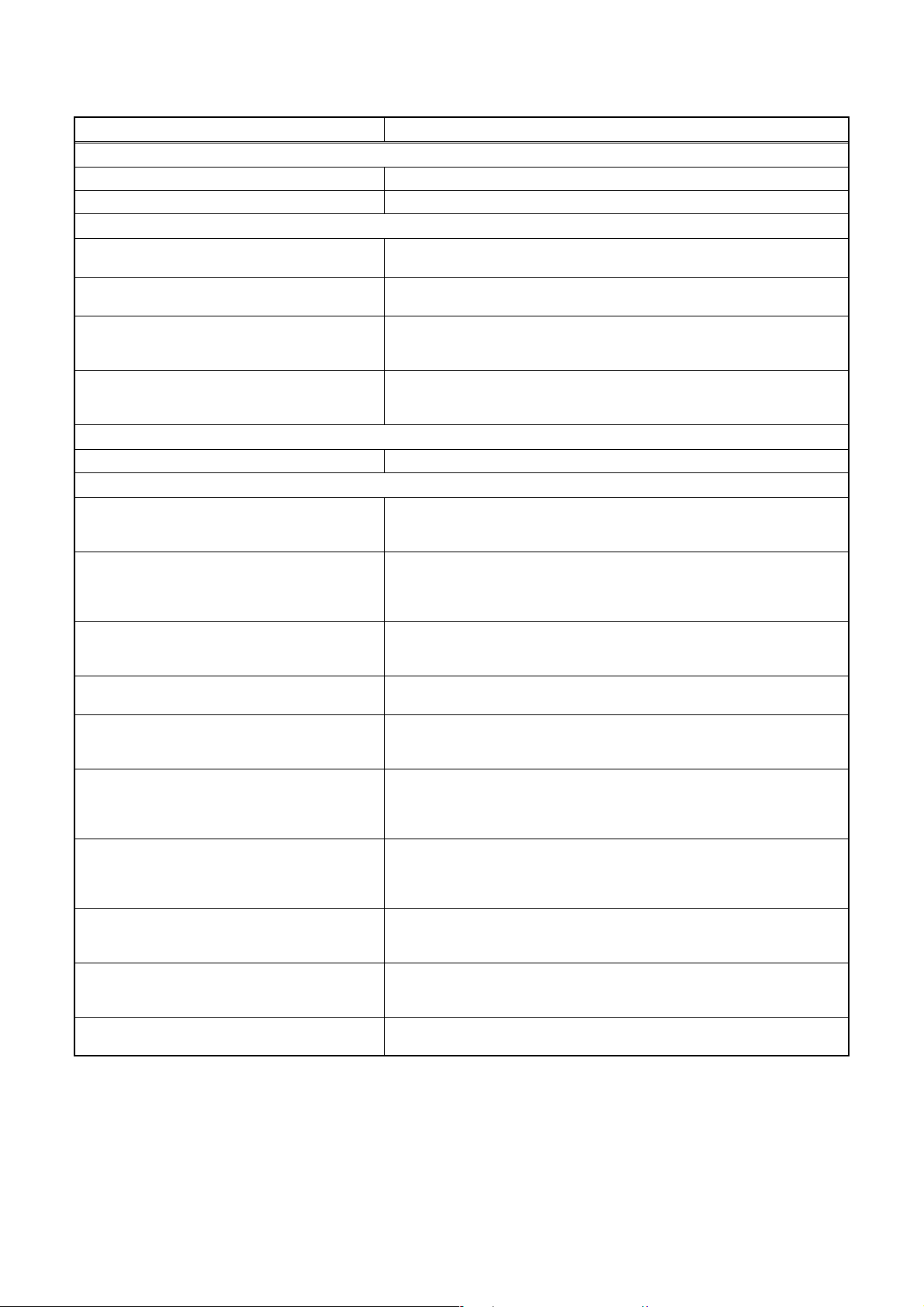

SPECIFICATIONS

ITEM Specifications

General

HDD Internal 3.5 inch HDD 250 GB

Power consumption 60W (standby: 8.0W)

Recording

Recording format Video Recording format (DVD-RW only)

Video format (DVD-RW, DVD-R)

Recordable discs DVD-ReWritable

Video recording format

Sampling frequency

Compression format

Audio recording format

Sampling frequency

Compression format

Tuner

Receivable channels E2-E69

Input/Output

Video input

Input level

Jacks

S-Video input

Y (Iuminance) - Input level

C (color) - Input level

Jacks

Audio input

During audio input

Jacks

Audio input/output

Jacks 21 pin scar t jack

Video input/output

Input/Output level

Jacks

S-Video output

Y (Iuminance) - Input/Output level

C (color) - Input/Output level

Jack

Component Video output

Y (Iuminance) - Output level

Pb/Cb, Pr/Cr (color difference) - Output level

Jacks

Audio output

During audio output

Jacks

Digital audio output

Output level

Jack

VHF/UHF antenna

input/output terminal VHF/UHF set 75Ω

DVD-Recordable

13.5MHz

MPEG

48kHz

Dolby Digital

AV3 (front)

1 Vp-p (75Ω)

RCA jack

AV3 (front)

1 Vp-p (75Ω)

300 mVp-p (75Ω)

4 pin mini DIN

AV3 (front) L/R

2V rms (10kΩ)

RCA jacks

1 Vp-p (75Ω)

21 pin scart jack

1 Vp-p (75Ω)

300 mVp-p (75Ω)

4 pin mini DIN

1 Vp-p (75Ω)

0.7 Vp-p (75Ω)

RCA jacks

2V rms (680Ω)

RCA jacks

500 mVp-p (75Ω)

Coaxial pin jack

NOTES:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply : 220 - 240 V ~ 50 Hz

3. Ambient temperature : 5

°C ~ 40 °C

1-1-1 E3B40SP

Page 4

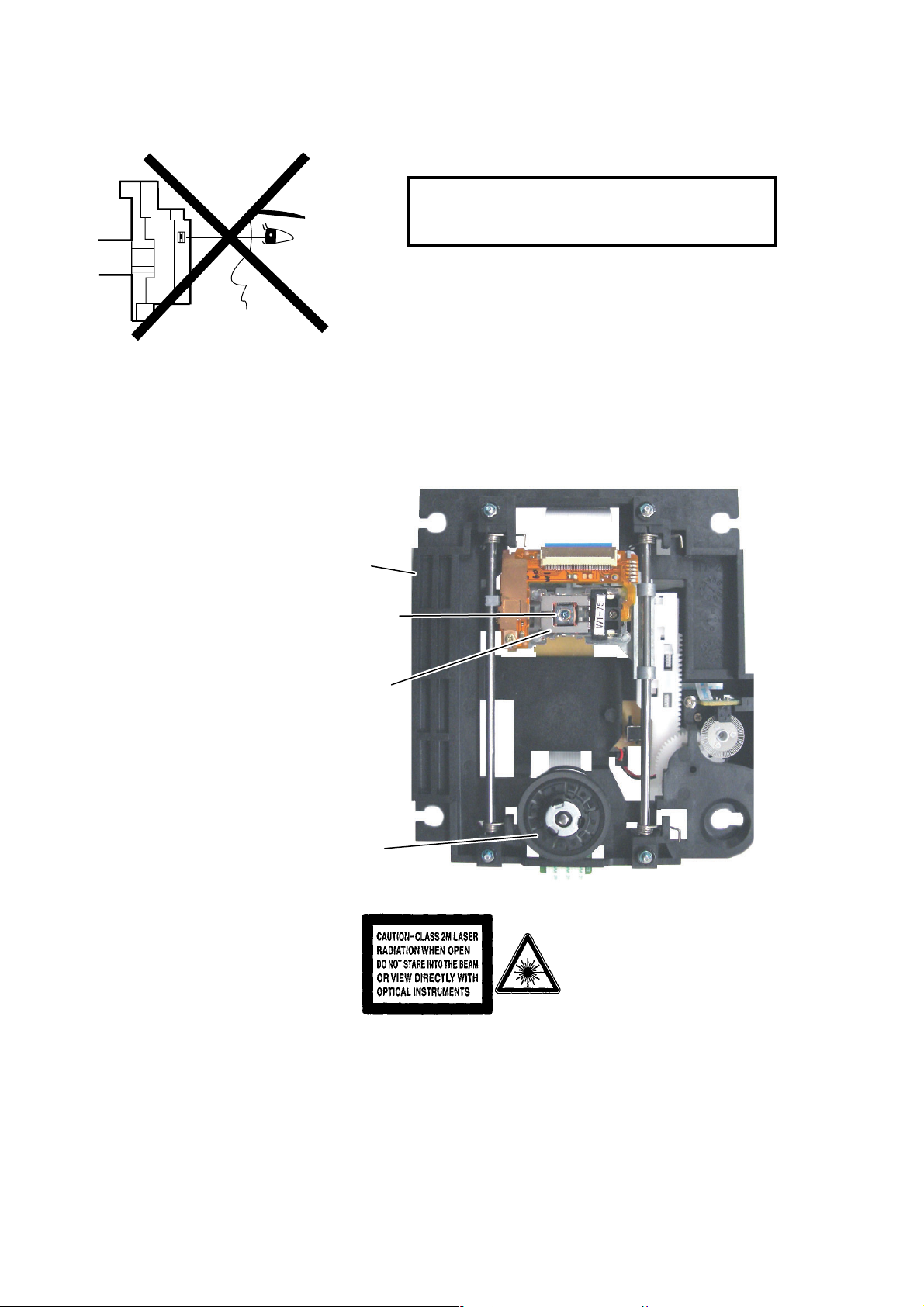

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of DVD mechanism.

1-2-1 R3PLSP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a ! on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review continuously and new instructions are issued whenever

appropriate. Prior to shipment from the factory, our

products are carefully inspected to confirm with the

recognized product safety and electrical codes of the

countries in which they are to be sold. However, in

order to maintain such compliance, it is equally important to implement the following precautions when a set

is being serviced.

Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

1-3-1 DVD_SFNP

Page 6

Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts, and wires have been returned to their original

positions. Afterwards, do the following tests and confirm the specified values to verify compliance with

safety standards.

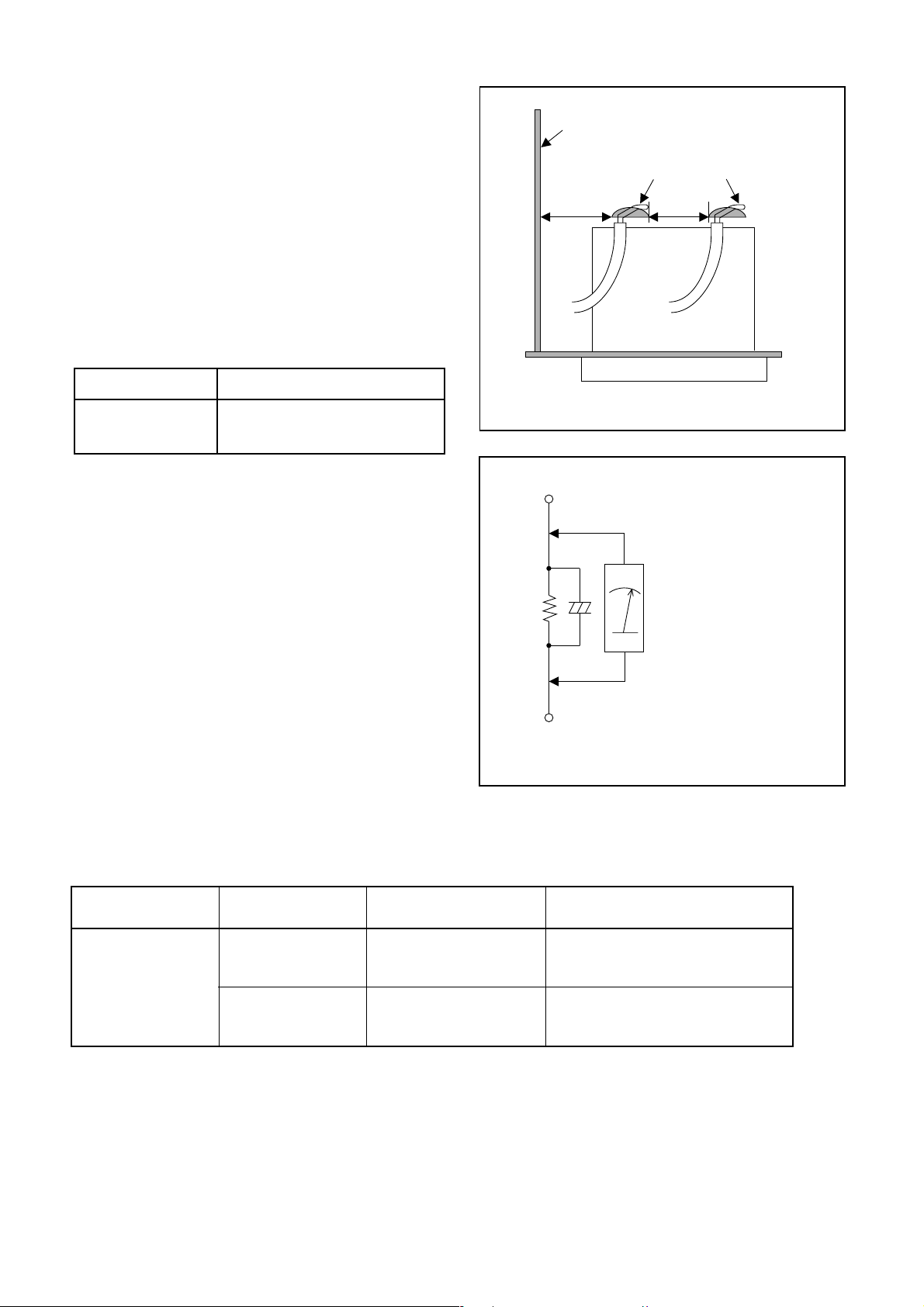

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

220 to 240 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

≥ 3 mm(d)

≥ 6 mm(d’)

Chassis or Secondary Conductor

Primary Circuit

d' d

Fig. 1

Exposed Accessible Part

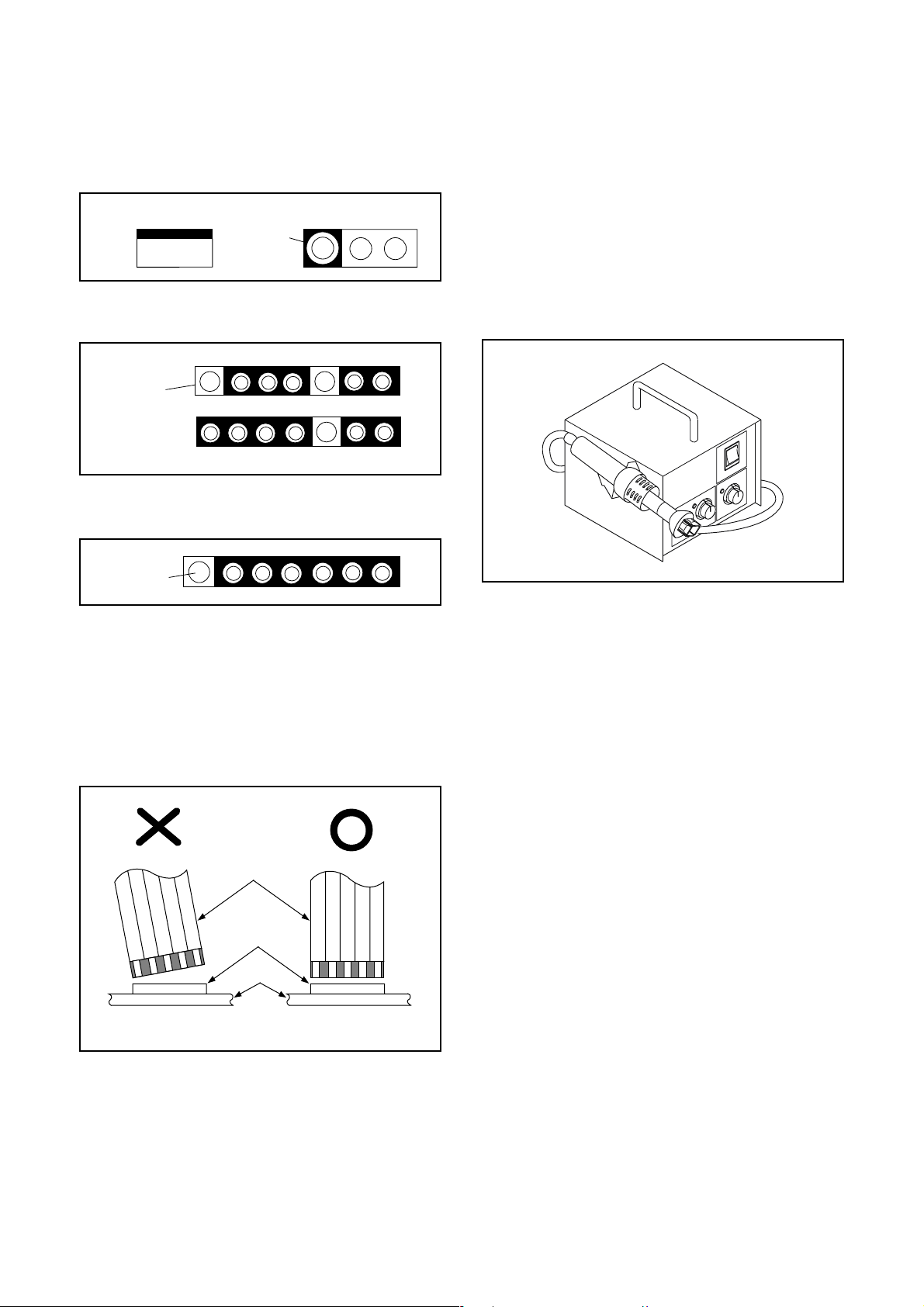

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across the terminals of load

Z. See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

220 to 240 V

2kΩ RES.

Connected in

parallel

50kΩ RES.

Connected in

parallel

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

Z

One side of

B

Power Cord Plug Prongs

One side of power cord plug

AC Voltmeter

(High Impedance)

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

1-3-2 DVD_SFNP

Page 7

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

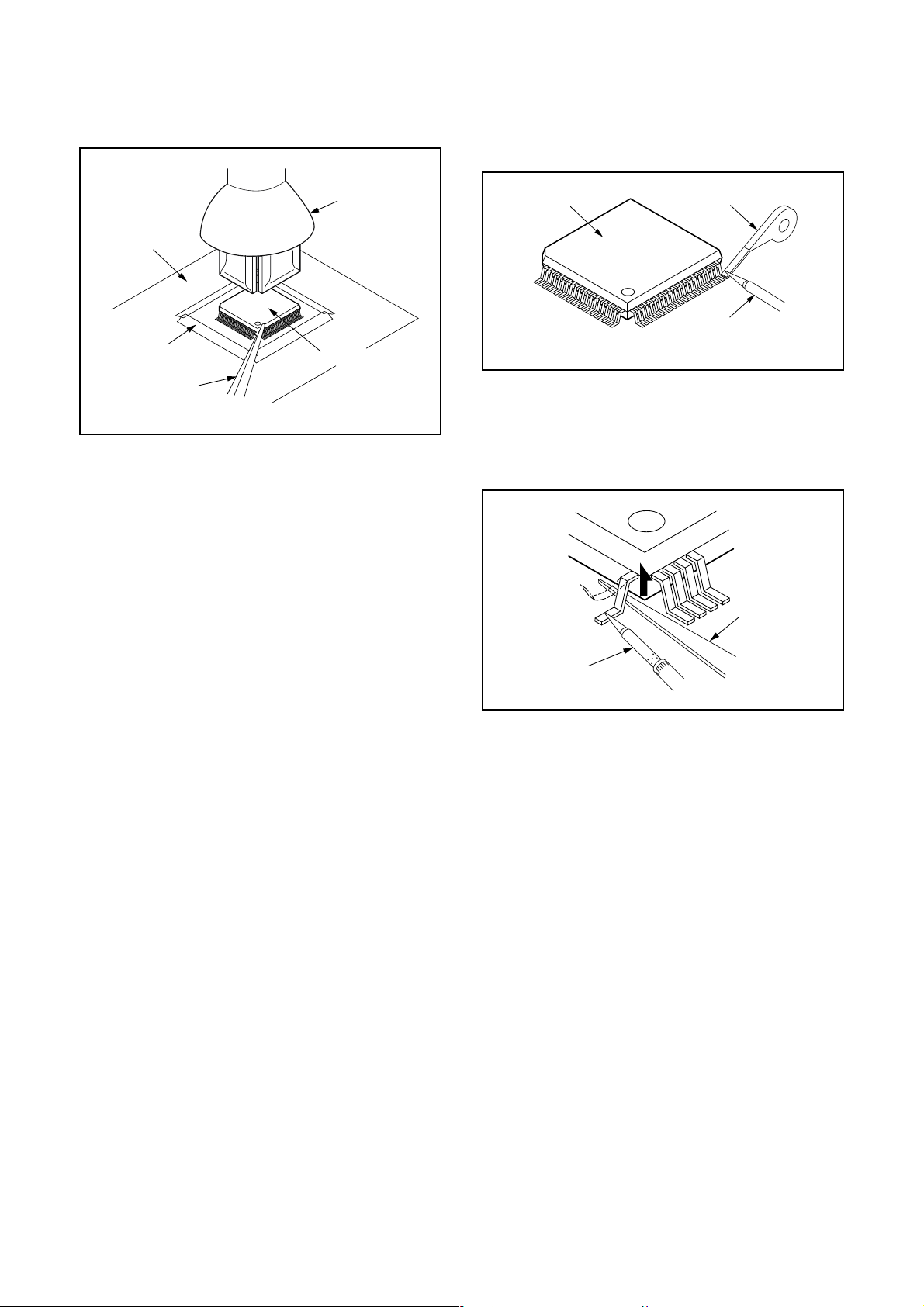

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 DVDP_SN

Page 8

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 DVDP_SN

Page 9

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-4-3 DVDP_SN

Page 10

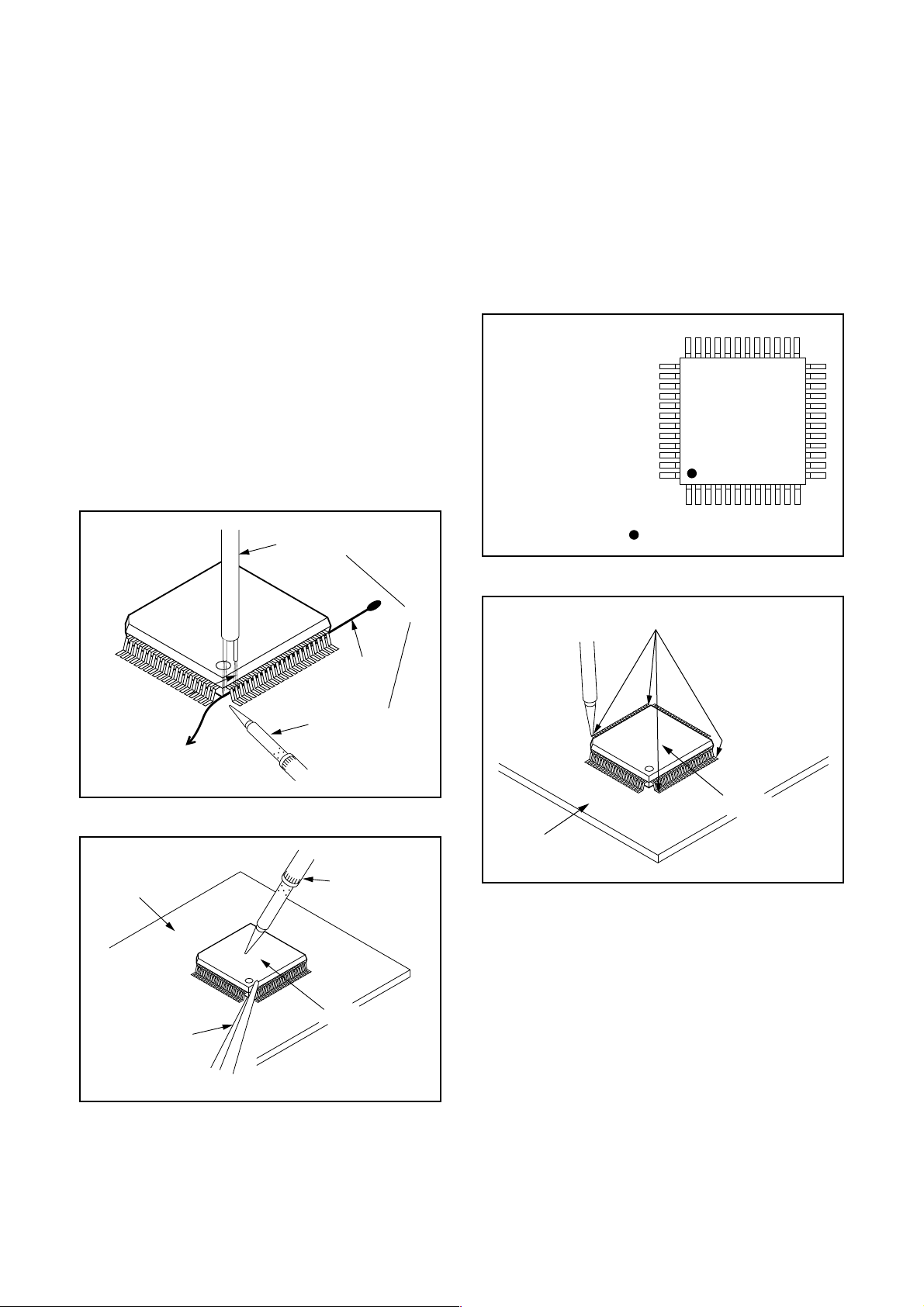

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

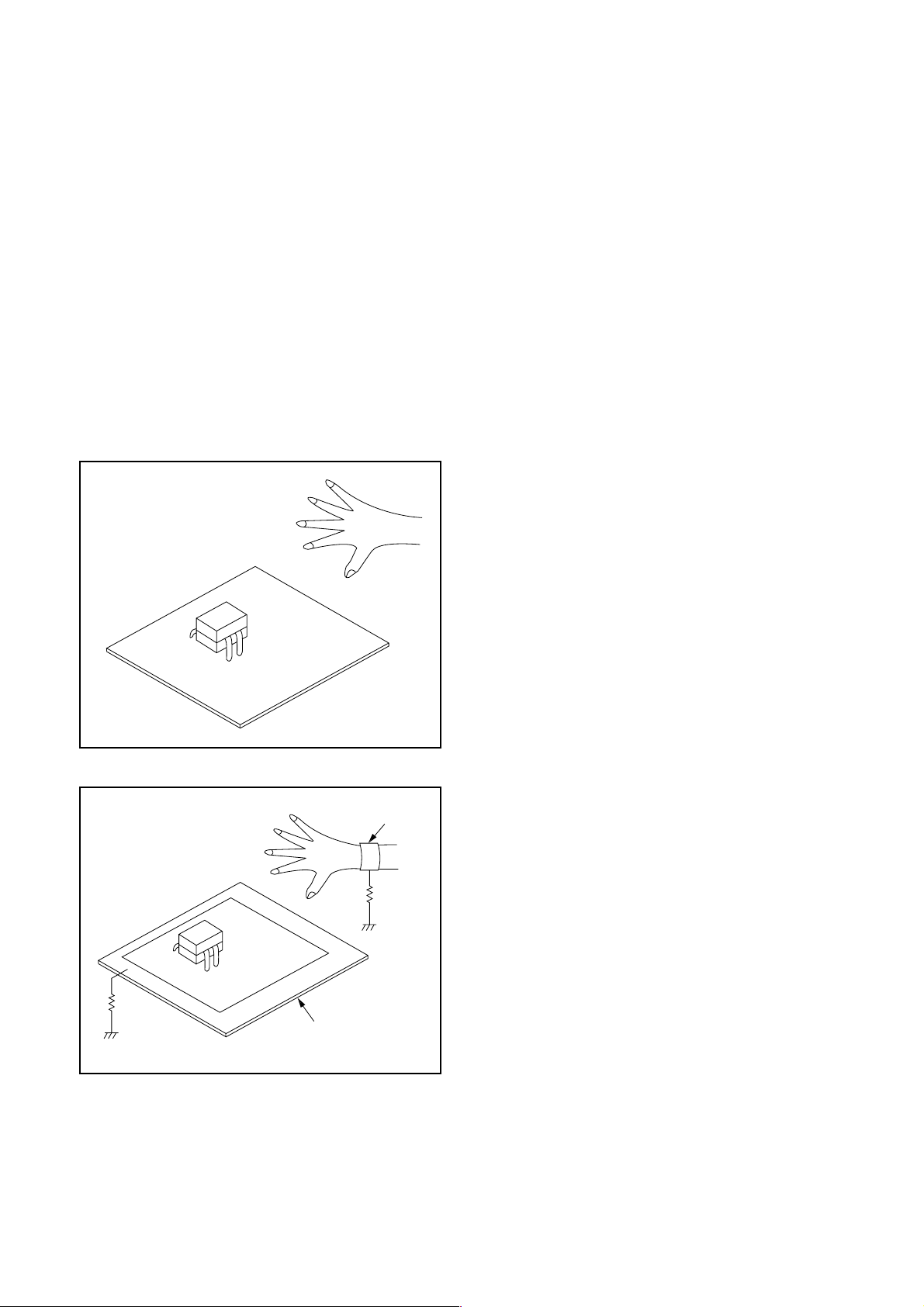

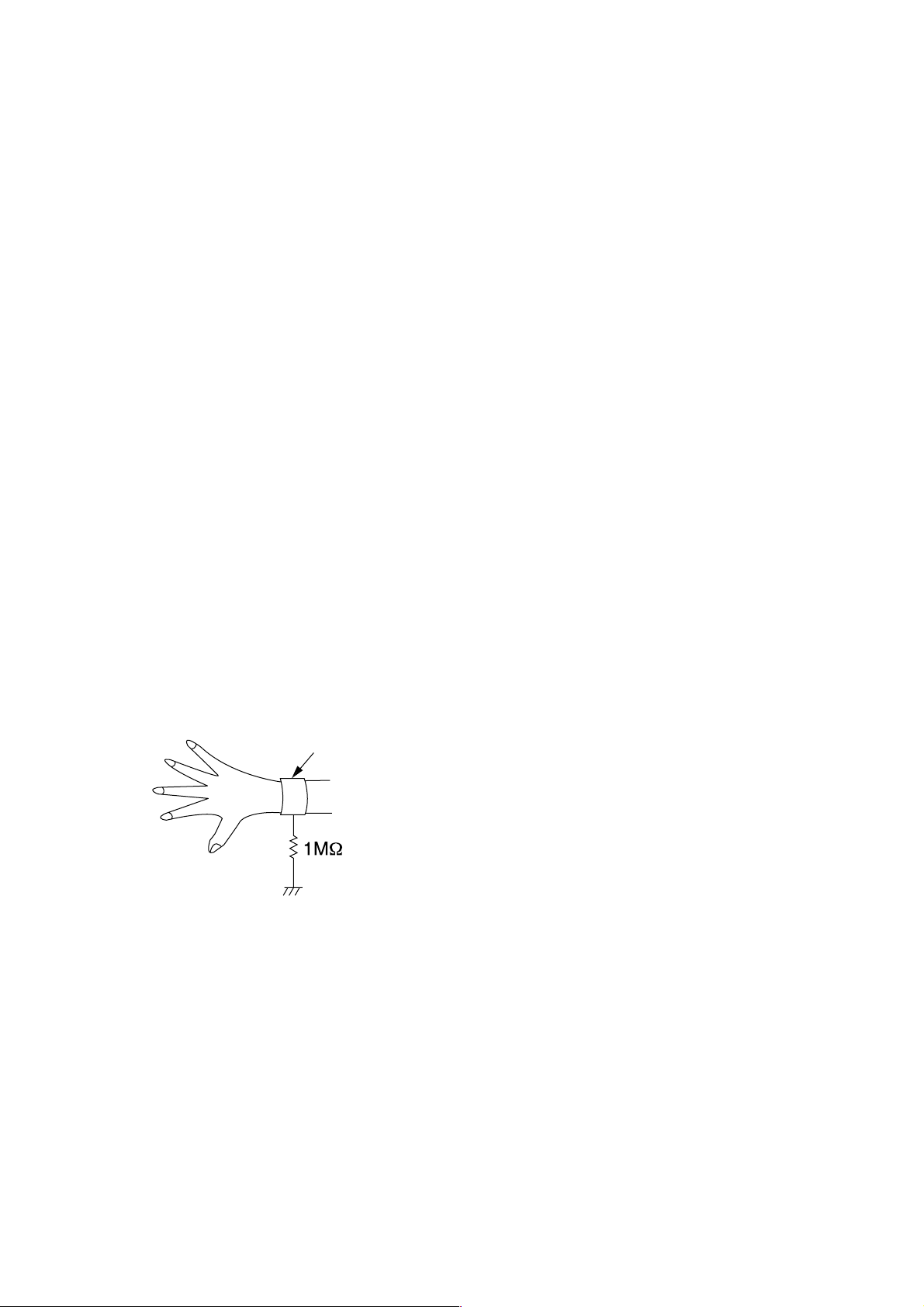

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 DVDP_SN

Page 11

HANDLING PRECAUTIONS FOR HDD

CAUTION:

1. SHOCK

a. Exposing HDD to shock may be the biggest

damaging factor. Please note that HDD is easily

damaged even if dropped from any height. Be sure

to place HDD on a shock-absorbent mat. Also, be

careful when transporting HDD.

b. Be careful not to subject HDD to any shock when

tightening screws for HDD replacement.

(Tighten screws manually, not with an electric

driver.)

2. MOISTURE

a. Moisture may also be a damaging factor. HDD is

semiclosed style. Sudden changes in ambient

temperature may cause moisture to form. Monitor

temperature and do not allow moisture to form on

the media surface. Also, when opening HDD

package, do so only after package is at ambient

temperature.

b. After replacing HDD, leave it to reach room

temperature (about 2 hours) for preventing dew

internal condensation, and then work necessary

task such as operation check.

4. OTHERS

a. Be careful so as not to do the followings.

Otherwise, HDD might be damaged.

- DO NOT disassemble HDD.

- When handling HDD, be sure to hold both sides

securely.

b. HDD should be stored, packed in the protective

bag, in suitable surroundings (i.e., no extreme

changes in temperature to avoid condensation).

c. When transporting HDD, be sure to use the

exclusive packing case (the replacement HDD

carton).

d. Do not stack HDDs.

e. Do not place vertically because HDD is unstable

and easy to fall.

3. STATIC ELECTRICITY

a. After removing HDD or taking replacement HDD

out of the protective bag (the replacement HDD is

packed in a protective bag), place HDD on a

conductive surface. A grounding band should be

worn when handling.

Grounding Band

Both the conductive surface and grounding band

should be grounded.

b. Make sure that HDD is placed on main unit

completely and then let go of it, when assembling.

c. Do not put HDD on a packing bag. (for preventing

electrostatic damage)

1-5-1 DHD_SN

Page 12

PREPARATION FOR SERVICING

How to Enter the Service Mode

About Optical Sensors

Caution:

An optical sensor system is used for the Tape Start

and End Sensors on this equipment. Carefully read

and follow the instructions below. Otherwise the unit

may operate erratically.

What to do for preparation

Insert a tape into the Deck Mechanism Assembly and

press [VCR PLAY] button. The tape will be loaded into

the Deck Mechanism Assembly. Make sure the power

is on, connect J78 to GND. This will stop the function

of Tape Start Sensor, Tape End Sensor and Reel Sensors. (If these TPs are connected before plugging in

the unit, the function of the sensors will stay valid.)

See Fig. 1.

Q503

J78

Note: Because the Tape End Sensors are inactive, do

not run a tape all the way to the start or the end of the

tape to avoid tape damage.

Q504

Fig. 1

1-6-1 E3B90PFS

Page 13

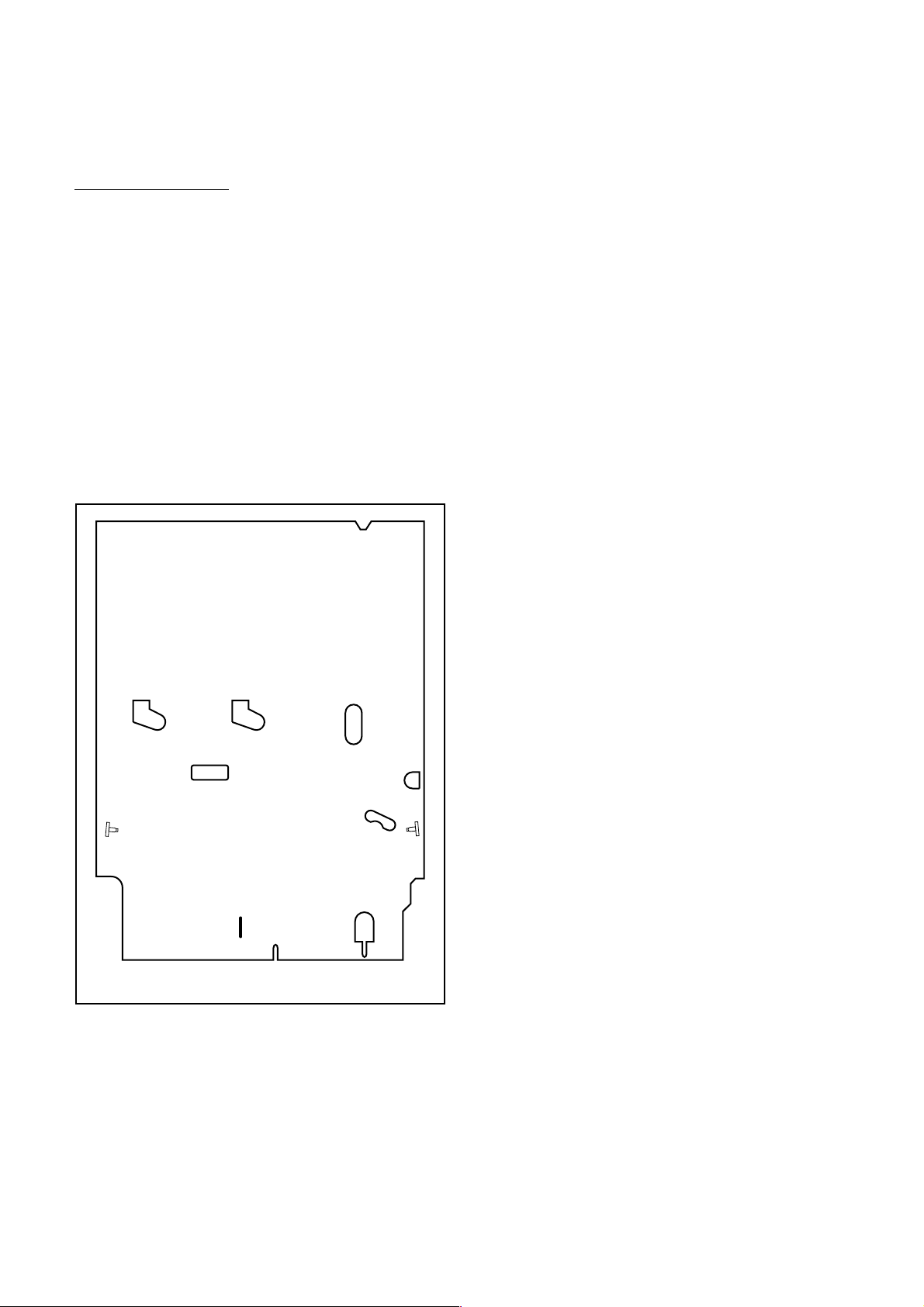

CABINET DISASSEMBLY INSTRUCTIONS

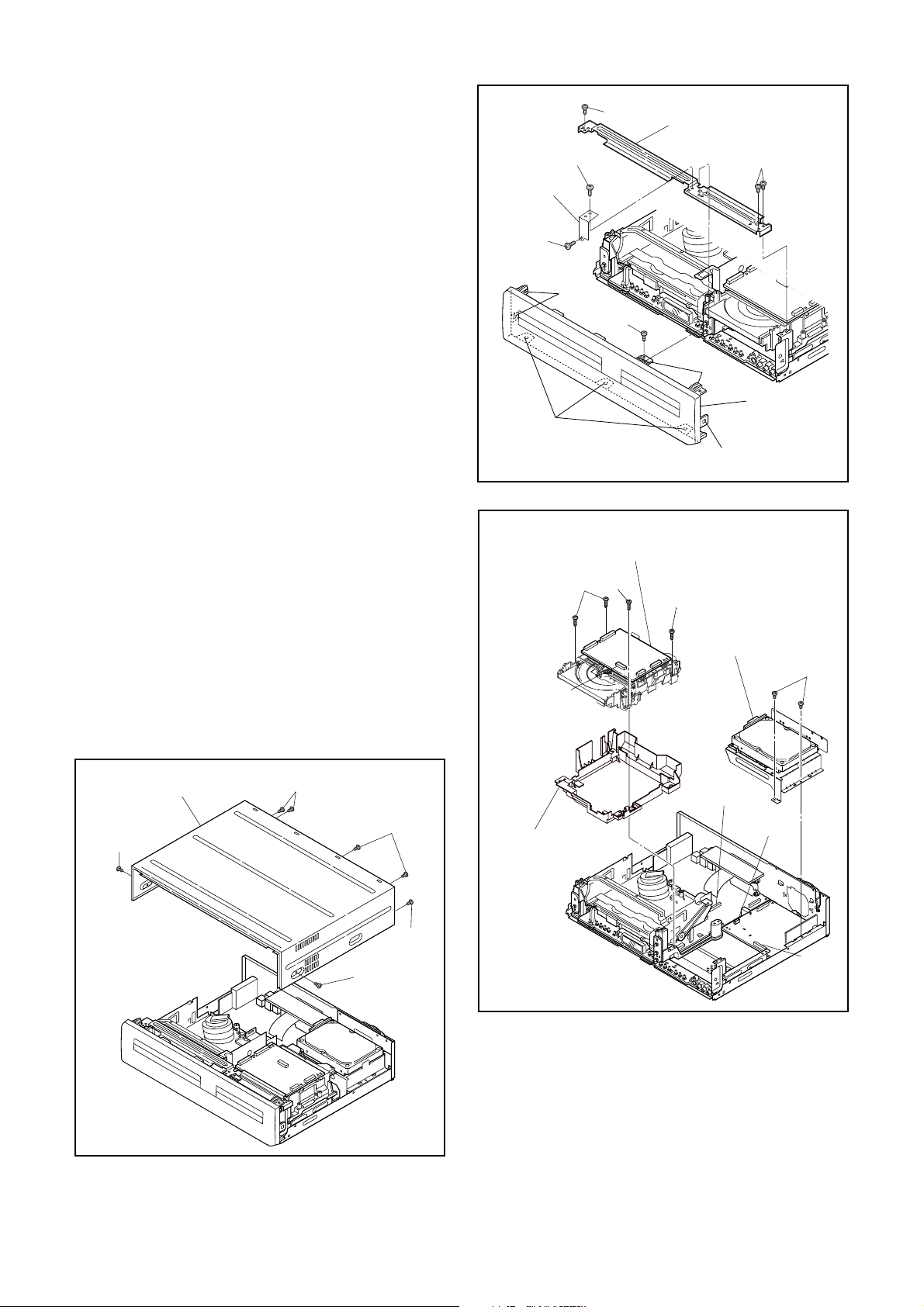

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] Top Cover

[2] Front

Assembly

[21] Front

Bracket R

[22] Bracket R

[13] Power

Supply CBA

[14] SW CBA

[15] Front

Jack CBA

[3] Front

Bracket

[4] HDD

Assembly

[5] DVD

Mechanism &

DVD/HDD Main

CBA Assembly

[10] Fan

Holder

[11] Brushless

Cooling Fan

[6] HDD

Bracket

[7] HDD Unit

[8] HDD

Support

[9] ATA CBA

ID/

LOC.

No.

[6]

PAR T

HDD

Bracket

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

4(S-7A), (S-7B), Earth

D4

Plate

Note

[7] HDD Unit D4 4(S-8), HDD Rubber 2

REMOVAL

HDD

[8]

Support

D4 Insulation Sheet ---

[9] ATA CBA D4 *CN3001, *CN3002 ---

[10] Fan Holder D5

3(S-9A), 2(S-9B),

*CN1002

Brushless

[11]

Cooling

D5 ---------- ---

Fan

[12] Rear Panel D5

Power

[13]

Supply

CBA

4(S-10A), 2(S-10B),

2(S-11)

D6 *CL1001, 4(S-12) ---

[14] SW CBA D6 (S-13), Desolder ---

---

---

---

[12] Rear

Panel

[16] VCR

Chassis Unit

[17] Deck

Assembly

[18] AV CBA,

AFV CBA

[20] Deck

Pedestal

[19] Power

SW CBA

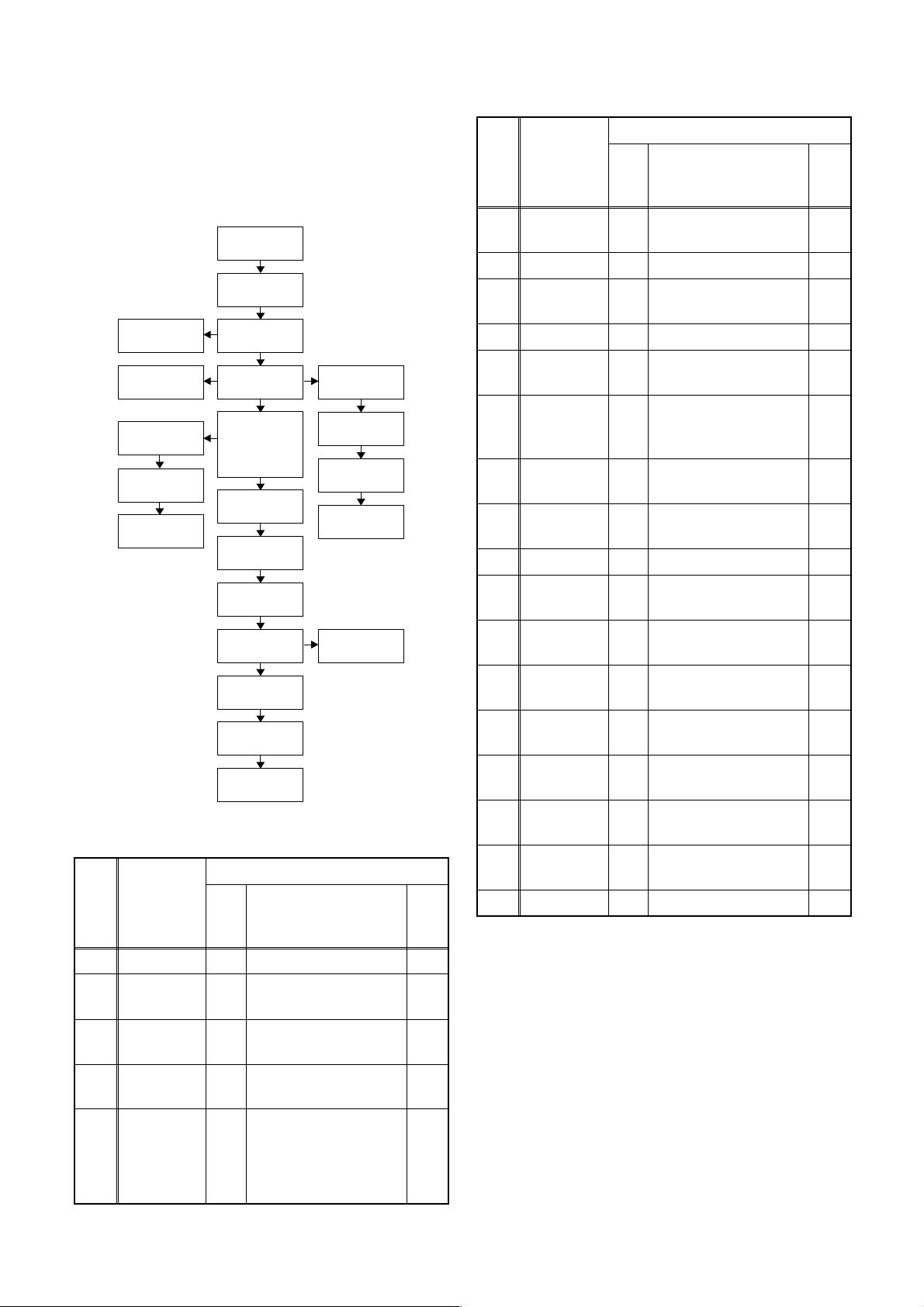

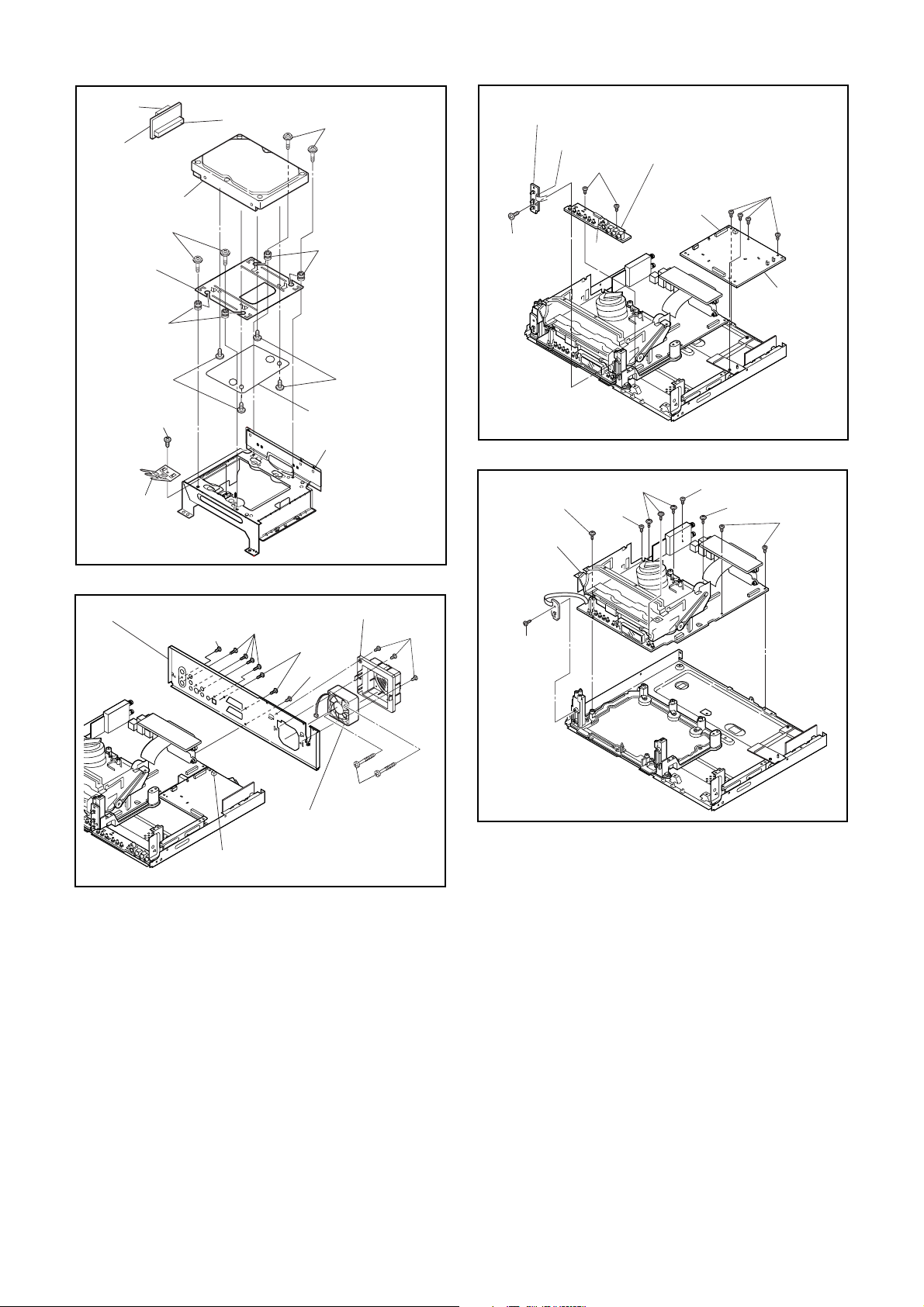

2. Disassembly Method

ID/

LOC.

No.

PART

Fig.

No.

[1] Top Cover D1 7(S-1) ---

Front

[2]

[3]

[4]

Assembly

Front

Bracket

HDD

Assembly

DVD

D2 (S-2), *5(L-1), *3(L-2) 1

D2

D3

Mechanism

[5]

&

DVD/HDD

D3

Main CBA

Assembly

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

2(S-3A), 3(S-3B),

Front Support

2(S-4), *CN901,

*CN1003

2(S-5), 2(S-6),

*CN1001, *CN1502,

Dust Cover

Note

---

---

2

Front Jack

[15]

[16]

[17]

[18]

[19]

[20]

[21]

CBA

VCR

Chassis Unit

Deck

Assembly

AV CB A ,

AFV CBA

Power SW

CBA

Deck

Pedestal

Front

Bracket R

D6 *CN3001, 2(S-14) ---

5(S-15), 4(S-16),

D7

(S-17)

(S-18), (S-19)

D8

Desolder

D8 ---------- ---

D8 Desolder ---

D9 8(S-20) ---

D9 (S-21) ---

---

[22] Bracket R D9 2(S-22) ---

↓

(1)

↓

(2)

↓

(3)

↓

(4)

(5)

Note:

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3): Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 6(S-1) = six Screws (S-1),

5(L-1) = five Locking Tabs (L-1)

(5): Refer to “Reference Notes.”

3

4

↓

1-7-1 E3B40DC

Page 14

Reference Notes

1. Locking Tabs (L-1) and (L-2) are fragile. Be careful

not to break them.

1-1. Remove Screw (S-2).

1-2. Release five Locking Tabs (L-1).

1-3. Release three Locking Tabs (L-2) and

remove the Front Assembly.

2. Do not replace the DVD Mechanism or the DVD/

HDD Main CBA Assembly separately, when

replacing the DVD Mechanism & DVD/HDD Main

CBA Assembly. Order the new DVD Mechanism &

DVD/HDD Main CBA Assembly.

2-1. Whenever you have replaced the HDD unit,

initialize the HDD unit. To initialize the HDD

unit, perform the following.To put the DVD/

VCR with HDD recorder into the HDD mode,

press the [HDD] button on the remote control

unit.

2-2. To put the DVD/VCR with HDD recorder into

the self-check mode, after pressing

[VARIABLE SKIP] button, press the [3], [6],

and [9] buttons on the remote control in that

order within three seconds.

2-3. Press [ENTER] button. The DVD/VCR with

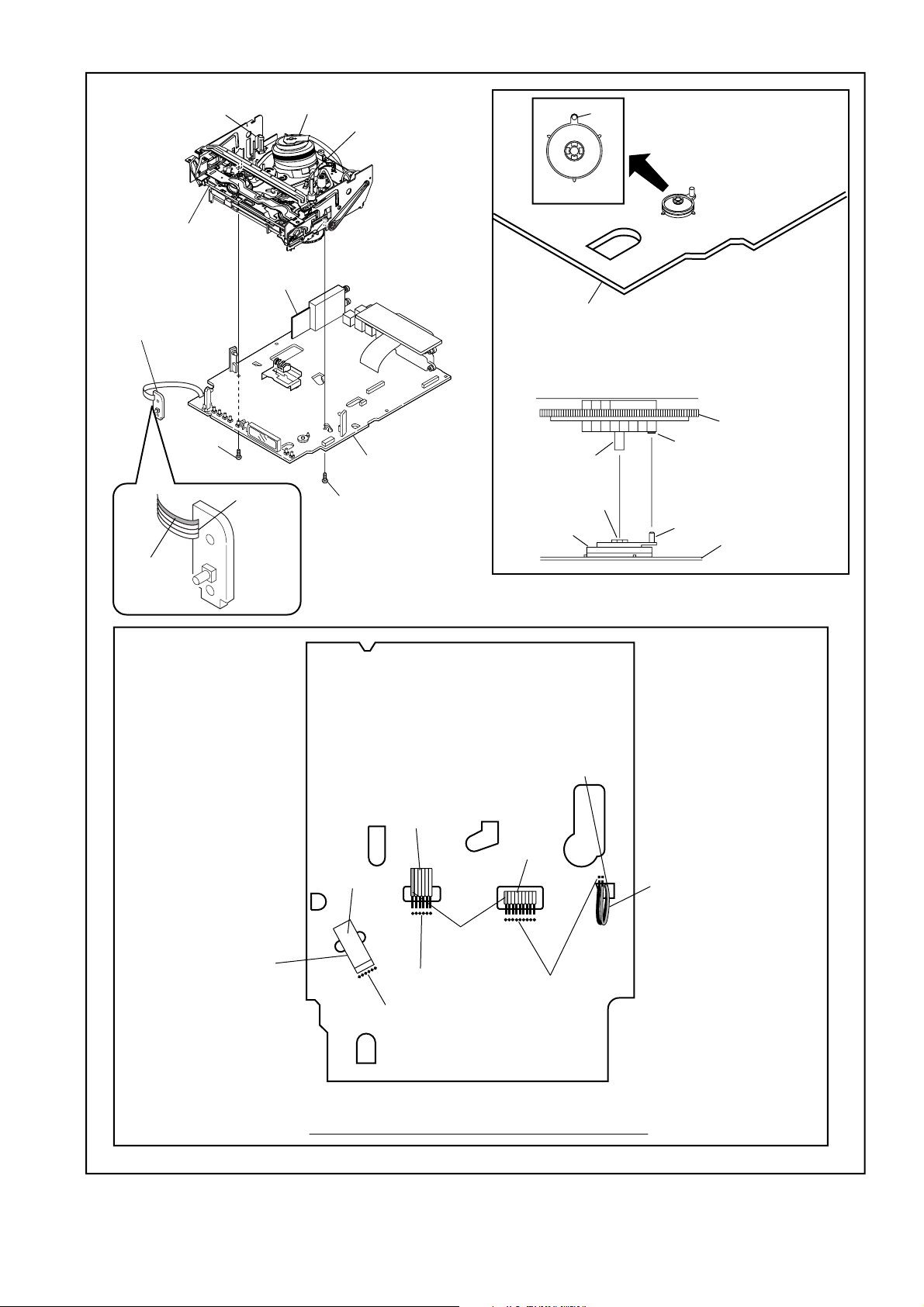

HDD recorder is initialized and the power is

turned off automatically after two seconds.

3. When reassembling, solder wire jumpers as

shown in Fig. D8.

4. Before installing the Deck Assembly, be sure to

place the pin of LD-SW on the AV CBA as shown

in Fig. D8. Then, install the Deck Assembly while

aligning the hole of Cam Gear with the pin of LDSW, the shaft of Cam Gear with the hole of LD-SW

as shown in Fig. D8.

(S-3B)

(S-3B)

Front

Support

(S-3B)

(L-1)

(S-2)

(L-2)

[5] DVD Mechanism &

DVD/HDD Main CBA

Assembly

(S-6)

(S-5)

CN901

[3] Front Bracket

(S-3A)

(L-1)

[2] Front

Assembly

(L-1)

Fig. D2

(S-5)

[4] HDD Assembly

(S-4)

[1] Top Cover

(S-1)

(S-1)

(S-1)

(S-1)

(S-1)

Fig. D1

Dust Cover

CN1502

CN1003

CN1001

Fig. D3

1-7-2 E3B40DC

Page 15

CN3002

[9] ATA CBA

[7] HDD Unit

(S-7A)

[8] HDD

Support

HDD Rubber

CN3001

(S-7A)

HDD Rubber

[14] SW CBA

(S-13)

Desolder

(S-14)

CN3001

[15] Front Jack CBA

(S-12)

CL1001

[13] Power

Supply

CBA

(S-8)

(S-7B)

Earth Plate

[12] Rear Panel

(S-11)

(S-10A)

CN1002

(S-8)

Insulation Sheet

[6] HDD Bracket

[10] Fan Holder

(S-10B)

(S-11)

(S-9B)

[11] Brushless

Cooling Fan

Fig. D4

(S-9A)

Fig. D5

(S-15)

[16] VCR

Chassis

Unit

(S-17)

(S-15)

(S-16)

Fig. D6

(S-16)

(S-15)

(S-16)

Fig. D7

1-7-3 E3B40DC

Page 16

FE Head

[17] Deck

Assembly

Cylinder

Assembly

[18]

AFV CBA

ACE Head

Assembly

Pin

Pin

SW507

LD-SW

[19] Power SW

CBA

(S-18)

Lead with

blue stripe

Desolder

[18] AV CBA

(S-19)

From

ACE Head

Assembly

[18] AV CBA

[17] Deck Assembly

Shaft

Hole

LD-SW

From

FE Head

From

Cylinder

Assembly

Cam Gear

Hole

Pin

[18] AV CBA

From

Capstan

Motor

Assembly

Printing side

Lead with

blue stripe

Desolder

Desolder

Desolder

BOTTOM VIEW

Lead connections of Deck Assembly and AV CBA

1-7-4 E3B40DC

Lead with

gray stripe

Fig. D8

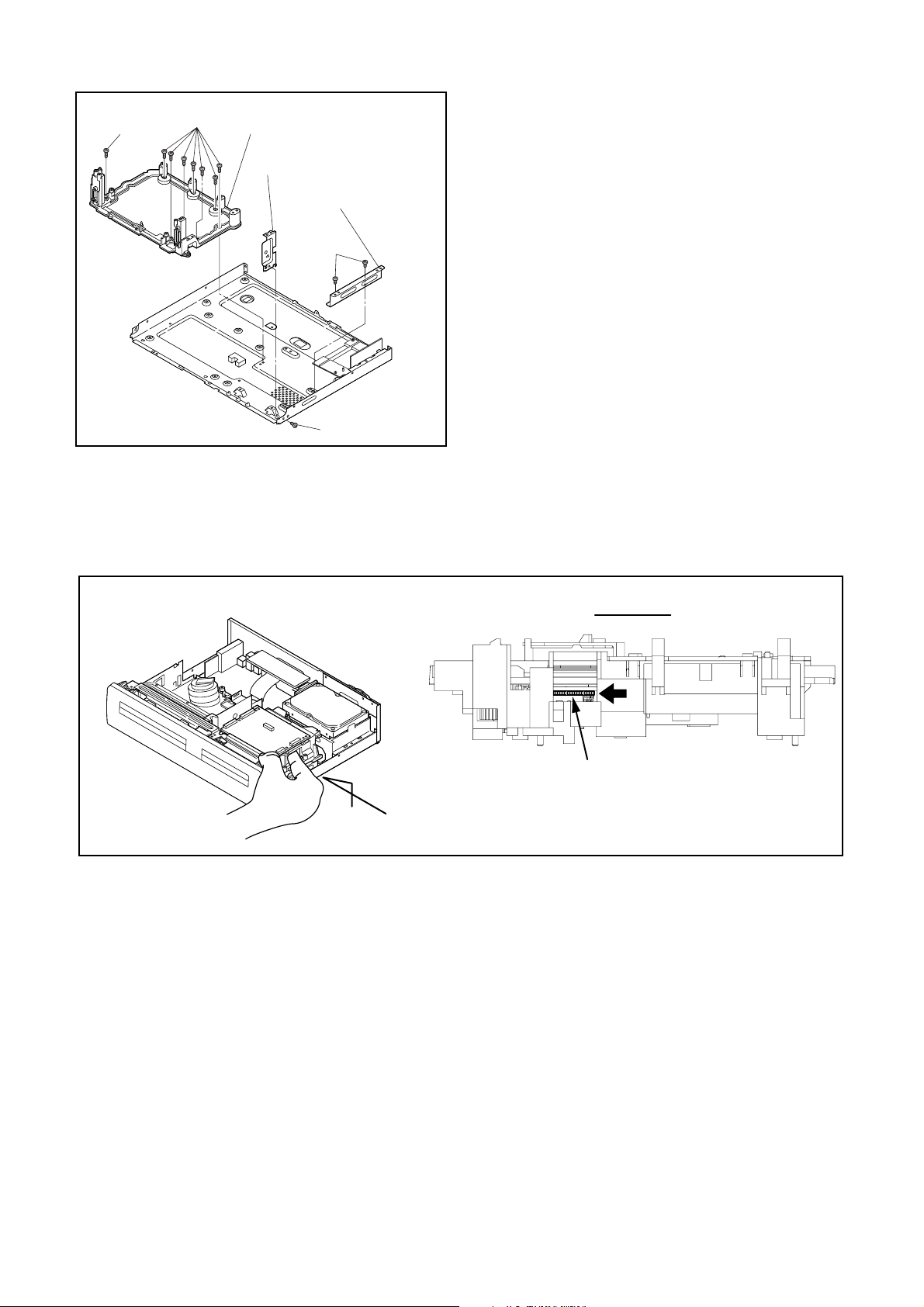

Page 17

(S-20)

(S-20)

[20] Deck Pedestal

[21] Front Bracket R

[22] Bracket R

(S-22)

(S-21)

Fig. D9

3. How to Eject Manually

Note: When rotating the gear, be careful not to damage the gear.

1. Remove the Top Cover.

2. Rotate the gear in the direction of the arrow manually as shown below.

Rotate this gear in

the direction of the arrow

A

View for A

1-7-5 E3B40DC

Page 18

ELECTRICAL ADJUSTMENT INSTRUCTIONS

y

General Note: "CBA" is an abbreviation for

"Circuit Board Assembly."

NOTE:

1.Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to do these adjustments only after

all repairs and replacements have been completed. Also, do not attempt these adjustments

unless the proper equipment is available.

2.To perform these alignment / confirmation procedures, make sure that the tracking control is set in

the center position: Press either [PROG. L5??] or

[PROG. K] button on the front panel first, then the

[VCR PLAY] button on the front panel.

Test Equipment Required

1.Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div.,

F-Range: DC~AC-20MHz

2.Alignment Tape (FL6A)

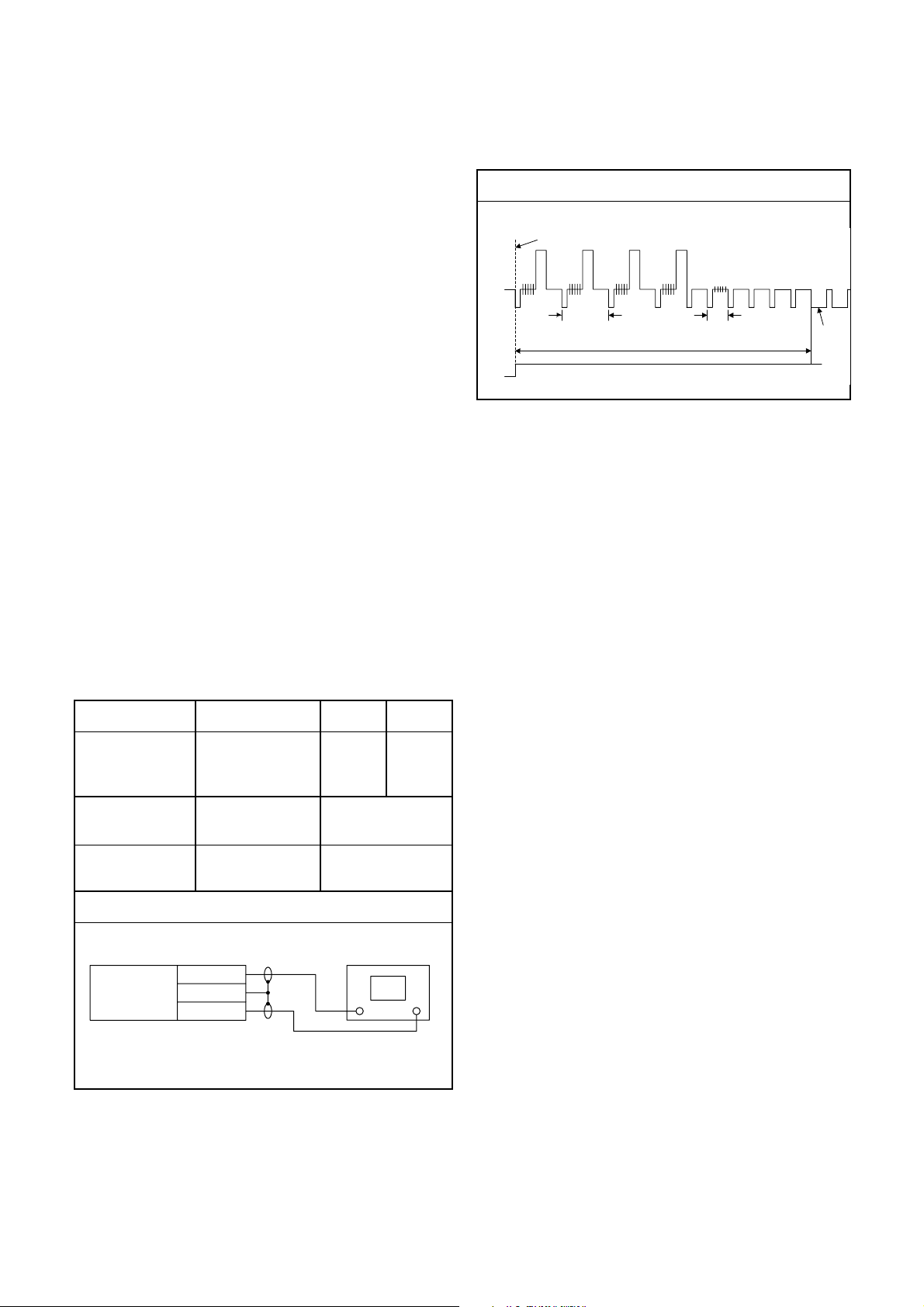

Head Switching Position Adjustment

Figure 1

EXT. Syncronize Trigger Point

CH1

CH2

Reference Notes:

Playback the Alignment tape and adjust VR501 so that

the V-sync front edge of the CH1 video output waveform is at the 6.5H±1H (416µs±64µs) delayed position

from the rising edge of the CH2 head switching pulse

waveform.

1.0H

6.5H±1H (416 µs ± 64 µs)

Switching Pulse

0.5H

V-S

Purpose:

To determine the Head Switching position during

playback.

Symptom of Misadjustment:

May cause Head Switching noise or vertical jitter

in the picture.

Test point Adj.Point Mode Input

J308(JK1-V-OUT)

TP504(RF-SW)

GND

Tape

FL6A Oscilloscope

Connections of Measurement Equipment

Main CBA

TP504

VR501

(Switching Point)

(AV CBA)

Measurement

Equipment

J308

GND

PLAY

(SP)

Spec.

6.5H±1H

(416µs±64µs)

Oscilloscope

-----

CH1 CH2

Trig. (+)

1-8-1 E3B40EA

Page 19

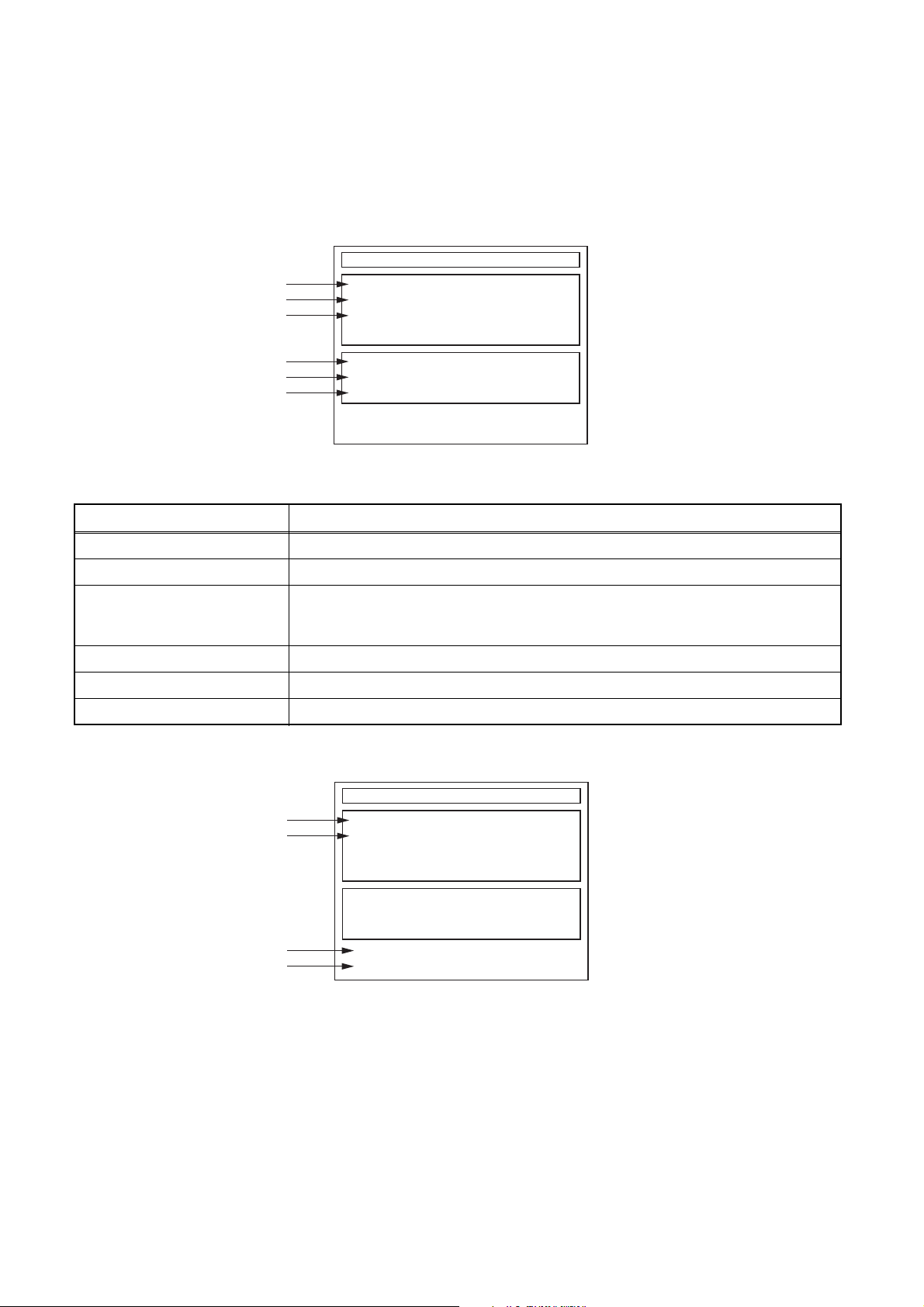

HOW TO SELF-CHECK AND INITIALIZE THE DVD/VCR WITH HDD

1. Turn on the DVD/VCR with HDD recorder.

2. To put the DVD/VCR with HDD recorder into the HDD mode, press [HDD] on the remote control unit.

3. To put the DVD/VCR with HDD recorder into the self-check mode, after pressing [VARIABLE SKIP] button,

press the [3], [6], and [9] buttons on the remote control in that order within three seconds.

Fig. a appears on the screen and all LEDs light.

"

" differs depending on the models.

*******

Self-Analysys and Report

*1

*2

*3

DVD CONNECT STATUS :

HDD CONNECT STATUS :

HDD POWER ON HOURS :

*4

*5

*6

BE Ver. :

FE Ver. :

Sub Micon Ver. :

T3*****B2S-****

R35_028_000

T3***TTP

Fig. a: Self-Check Mode Screen

Table 1: Description of Fig. a

INDICATION DESCRIPTION

DVD CONNECT STATUS (*1) Connecting Condition of DVD(F/E)

HDD CONNECT STATUS (*2) Connecting Condition of HDD

Value of HDD power on hours obtained from S.M.A.R.T. command. (If not obtainable,

HDD POWER ON HOURS (*3)

value of HDD power on hours is “0”.)

Value in parentheses is the factory setting value. (If no setting, the value is “0”.)

BE Ver. (*4) B/E version

FE Ver. (*5) F/E version

Sub Micon Ver. (*6) Sub micro controller version

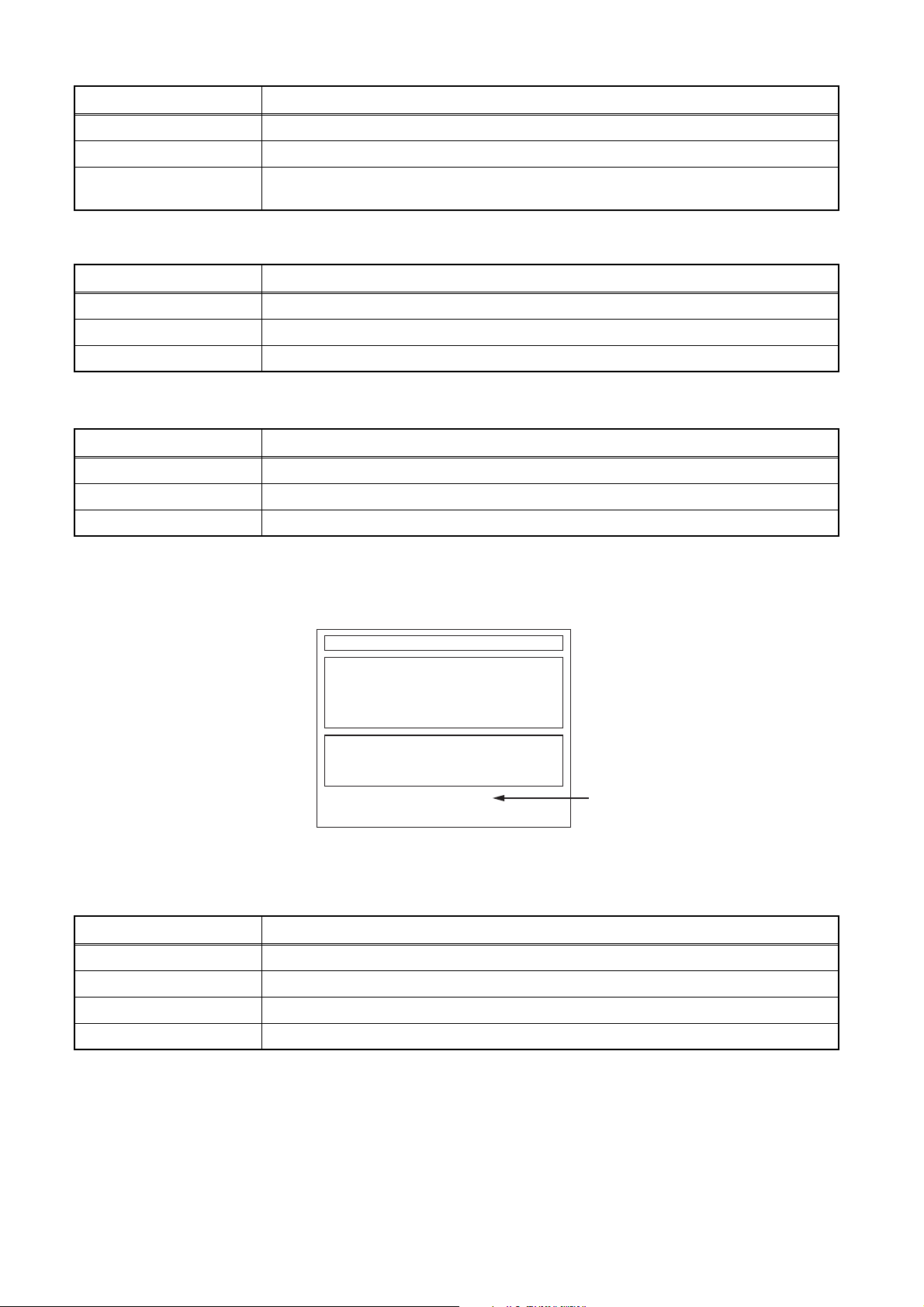

4. Upon the self-check completion, Fig. b appears on the screen.

"

" differs depending on the models.

*******

Self-Analysys and Report

*7

*8

DVD CONNECT STATUS : OK

HDD CONNECT STATUS : OK

HDD POWER ON HOURS : 100(40)

*10

BE Ver. :

FE Ver. :

Sub Micon Ver. :

*9

FACTORY DEFAULT :

POWER OFF :

T3*****B2S-****

R35_028_000

T3***TTP

ENTER

POWER

Fig. b: Screen of Finishing Self-Check Mode

1-9-1 E3B40INT

Page 20

Table 2: Indication of DVD self-check (*7)

INDICATION DESCRIPTION

OK Connection of DVD is normal.

NOT FOUND DVD drive cannot be found.

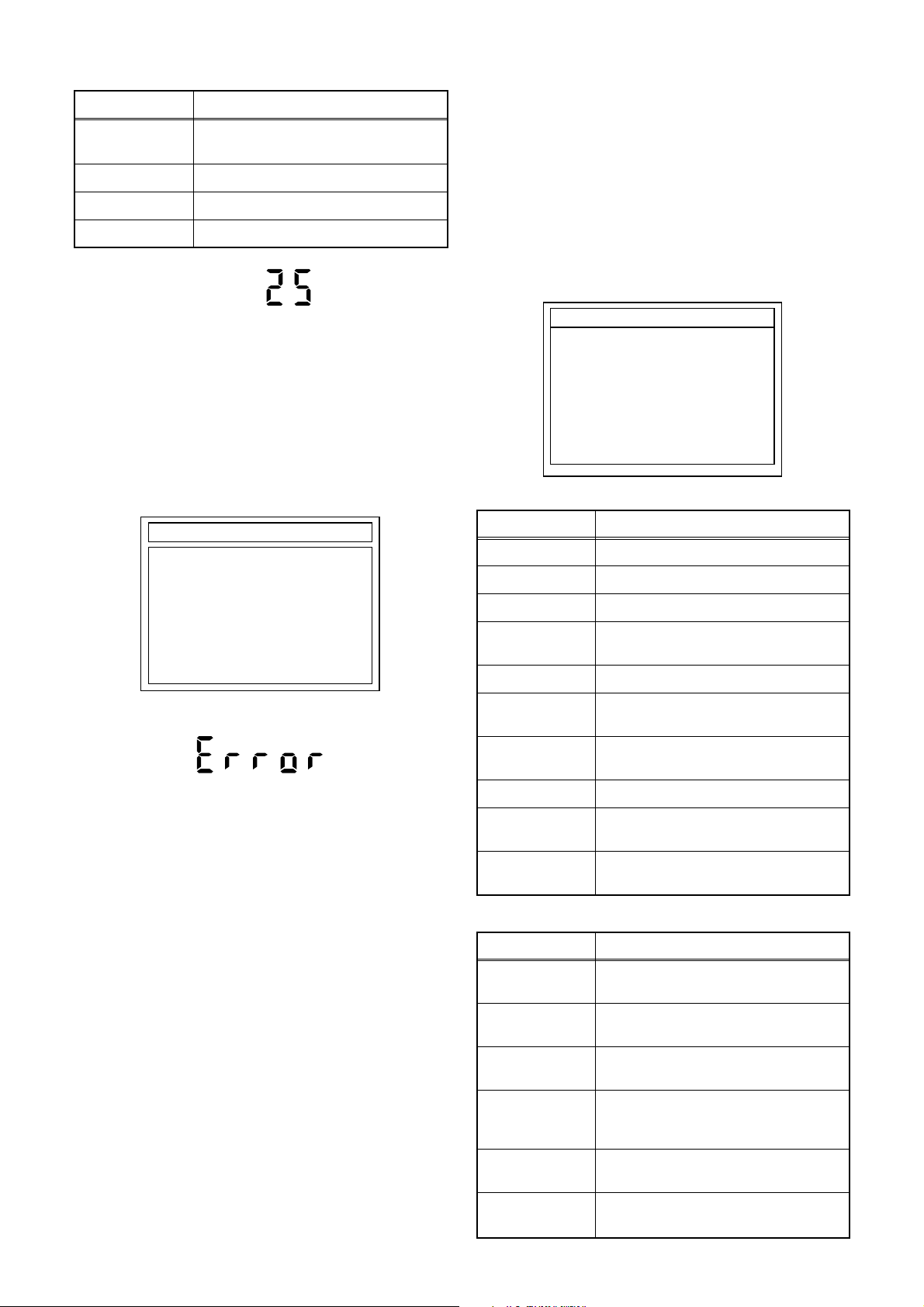

CABLE ERROR

FFC cable (connecting to CN401) between the DVD drive and the DVD/HDD Main CBA is

not connected correctly.

Table 3: Indication of HDD self-check (*8)

INDICATION DESCRIPTION

OK Connection of HDD is normal.

NOT FOUND HDD drive cannot be found.

CABLE ERROR FFC cable between the ATA CBA and the HDD drive is not connected correctly.

Table 4: Available button in self-check mode

BUTTON DESCRIPTION

ENTER (*9) Initialize (only when the self-check mode is complete)

STANDBY-ON (*10) Turn the power off (when the self-check mode is complete)

OTHER Not available

5. When the self-check mode is complete, press [STANDBY-ON] button to turn the power off.

When initializing the DVD/VCR with HDD recorder, press [ENTER] button. Fig. c appears on the screen. After

two seconds, the power is turned off automatically.

"

" differs depending on the models.

*******

SELF CHECK

DVD CONNECT STATUS : OK

HDD CONNECT STATUS : OK

HDD POWER ON HOURS : 100(40)

BE Ver. :

FE Ver. :

Sub Micon Ver. :

HDD FORMAT : *11WRITING

T3*****B2S-****

R35_028_000

T3***TTP

Fig. c: Initialize Mode Screen

Table 5: Description of *11 in Fig. c

INDICATION DESCRIPTION

ENTER Initialization preparation is complete.

WRITING Initializing

OK Initializing is finished normally.

NG Initializing is not finished normally.

NOTE: When initializing, “Current Clock”, “Setup Changing Item”, “Channel Setup”, “Area Setup”, “Program” and

“HDD Contents” are initialized.

1-9-2 E3B40INT

Page 21

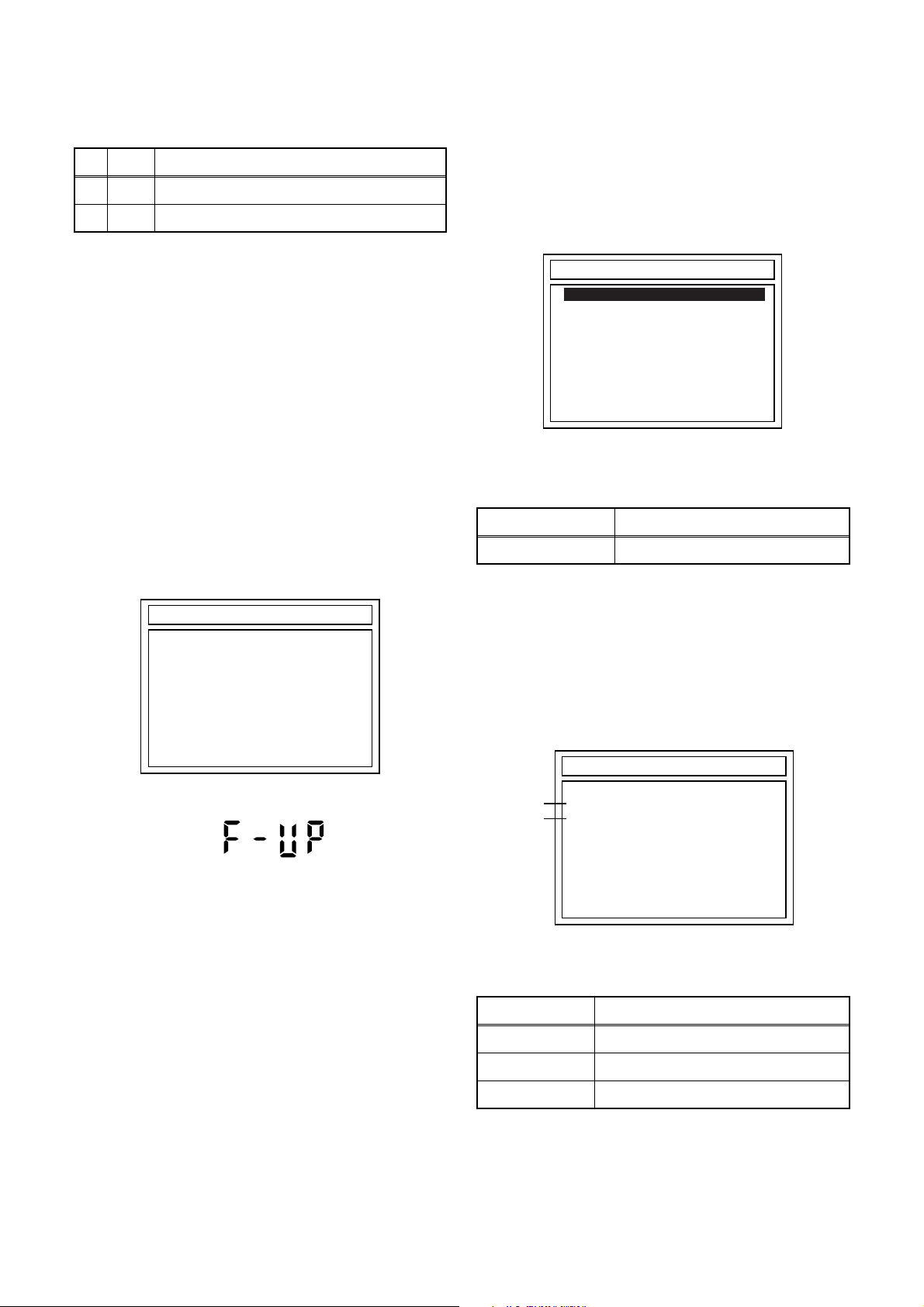

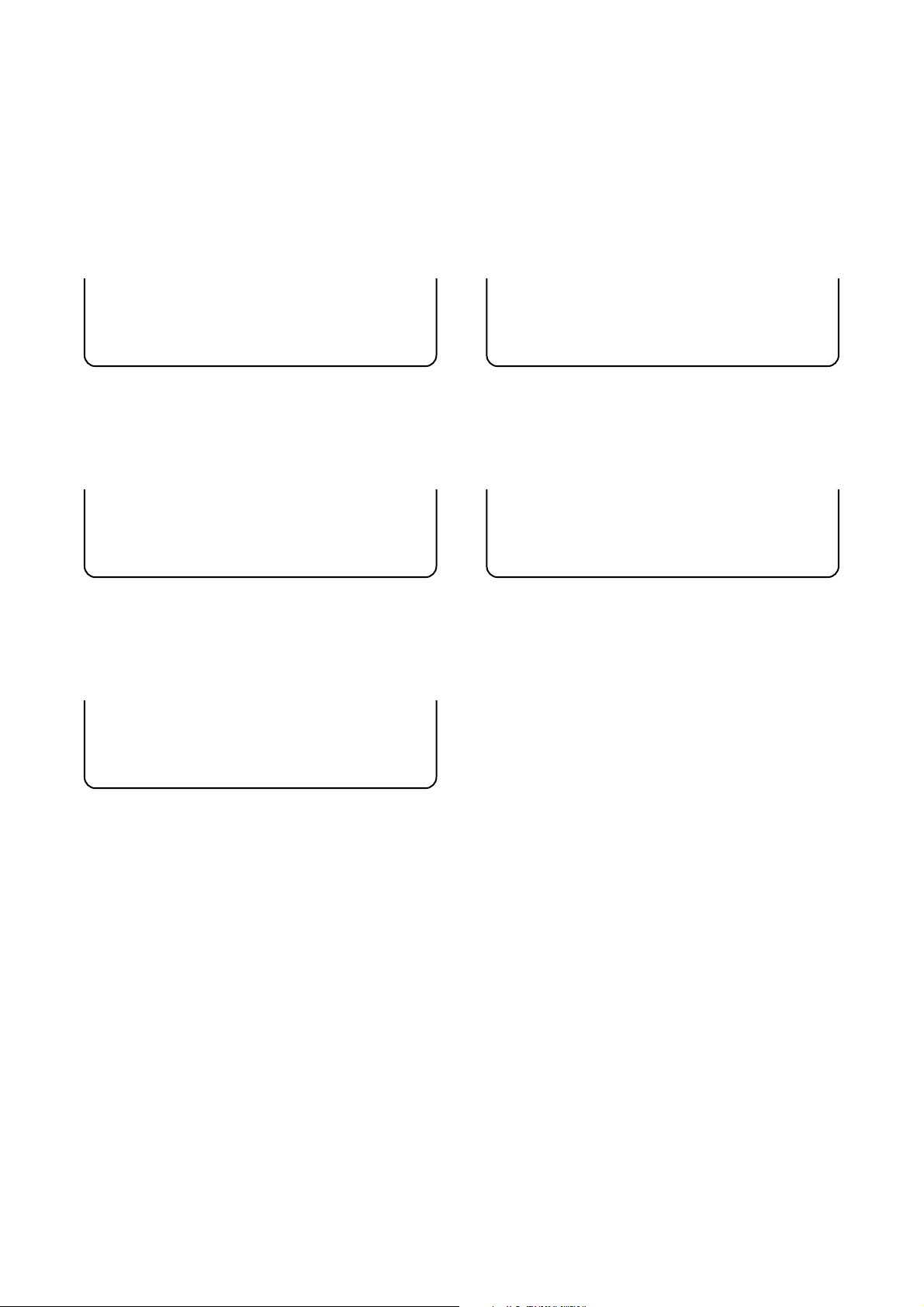

FIRMWARE RENEWAL MODE

1. Update Contents

Item Status

1 B/E Update B/E FIRMWARE

2 F/E Update F/E FIRMWARE

2. Update

Note: Update does not interrupt power during

firmware update process!

The unit will power off automatically when the

update is finished.

1. Turn the power on and remove the disc in the tray.

2. To switch the HDD & DVD into the HDD mode,

press [HDD] on the remote control unit.

3. To put the HDD & DVD into version up mode,

press [VARIABLE SKIP] and [6], [5], [4] buttons on

the remote control unit in that order within 3

seconds. The tray will open automatically.

Fig. a appears on the TV screen and Fig. b

appears on the VFD.

*FIRMWARE version will differ depending on the

model. Fig. a is an example.

DISC UPDATE

Please Insert F/W Disc

4. Load the update disc.

The TV screen will display Fig. c.

- If the update disc contains only a single file, the

update will initiate automatically when the disc is

inserted.

*FIRMWARE version will differ depending on the

model. Fig. c is an example.

DISC UPDATE

T3T00361B2S.MOT

<DIR> BE

<DIR> FE

Fig. c: Update Disc TV Screen

Effective FIRMWARE update files will have the file

extensions shown below.

File extension Status

MOT F/E FIRMWARE file

5. Select the desired FIRMWARE to be updated with

the arrow button and press the [ENTER] or [PLAY]

button.

The tray will open automatically; close the tray by

pressing [OPEN/CLOSE] button or by hand.

6. Fig. d appears on the TV screen and Fig. e

appears on the VFD, and the update will start.

*FIRMWARE version will differ depending on the

model. Fig. d is an example.

Fig. a: Update Mode TV Screen

Fig. b: VFD Display in Update Mode

DISC UPDATE

*1

TARGET: B/E

*2

STATUS: EXECUTING

DISC UPDATING

Fig. d: TV Display during update

The status displayed in *1 is as shown below.

Display Status

B/E FIRMWARE B/E

F/E FIRMWARE F/E

UNKNOWN Not FIRMWARE B/E or F/E

1-10-1 E3B40FW

Page 22

The status displayed in *2 is as shown below.

Display Status

EXECUTING

Loading F/W from Update Disc or

writing to Flash memory

ERROR Error during Flash memory writing

FILE ERROR Check SAM error in F/W file

READ ERROR Error during F/W file reading

3. How to Verify the Firmware

Version

1. Turn the power on and remove the disc in the tray.

2. To switch the HDD & DVD into HDD mode, press

[HDD] on the remote control unit.

3. To put the HDD & DVD into version display mode,

press [VARIABLE SKIP] and [1], [2], [3] buttons on

the remote control unit in that order within 3

seconds. Fig. i appears on the TV screen.

******* part will differ depending on the model.

Fig. i is an example.

Fig. e: VFD Display during update

When the TV screen displays "Firmware

Updating... XX% Complete," the VFD will indicate

"XX"%.

7. When update is complete, the unit will shut off

automatically.

8. If an error occurred during updating, the TV screen

will display Fig. f.

*FIRMWARE version will differ depending on the

model. Fig. f is an example.

DISC UPDATE

TARGET: B/E

STATUS: ERROR

PLEASE PUSH POWER BUTTON

Fig. f: TV Display when completing update with error

Fig. h: VFD Display when completing update with error

VERSION INFORMATION

Model Name :

BE Ver. :

FE Ver :

Sub Micon Ver. :

REGION:

CPRM KEY NO:

HDD MODEL:

DivX Ver.:

LD ADJUSTMENT:

DISC ADJUSTMENT:

E3B40ED

T3*****B2S-****

R35_***_***

T3***TTP

2

(0x***)

***********(***GByte)

***

OK

OK

Fig. i: Firmware version display

Display Contents

MODEL NAME Product number

BE Ver. Firmware B/E version

FE Ver. Application F/E version

Sub Micon Ver.

Sub Microcontroller firmware

version

REGION Region code of playable DVD disc

CPRM KEY

NO.

HDD MODEL

DivX Ver.

CPRM key number

HDD serial number and capacity

(GByte)

Version number of DivX file systems

In this case, all button operations will be invalid

except [STANDBY-ON] button.

9. Press [STANDBY-ON] button to turn the power off

and press [STANDBY-ON] button again to turn the

power back on and finish updating.

LD

ADJUSTMENT

DISC

ADJUSTMENT

LD adjustment progress (done: OK/

not done: --)

Factory adjustment progress (done:

OK/not done: --)

Effective buttons in this mode are the following...

Buttons Operations

POWER

SETUP

TOP MENU

Power off to release from this

mode.

Version display disappears and

SETUP screen appears.

Version display disappears and

TOP MENU screen appears.

Version display disappears and

TIMER PROG.

TIMER PROGRAMMING screen

appears.

DUBBING

MENU

Others

Version display disappears and

DUBBING screen appears.

While displaying version and

normal operation.

1-10-2 E3B40FW

Page 23

FUNCTION INDICATOR SYMBOLS

< VCR Section >

Note:

When the power comes on again after that by pressing [STANDBY-ON] button, an error message is displayed on

the TV screen as follows.

When reel or capstan mechanism is not functioning

correctly

A

R

SP 0:00:00

Fig. 1

When tape loading mechanism is not functioning

correctly

A

T

SP 0:00:00

Fig. 2

When cassette loading mechanism is not functioning

correctly

When the drum is not working properly

A

D

SP 0:00:00

P-ON+5V Power safety detection

A

P

SP 0:00:00

Fig. 4

Fig. 5

A

C

SP 0:00:00

Fig. 3

1-11-1 E3B40FIS

Page 24

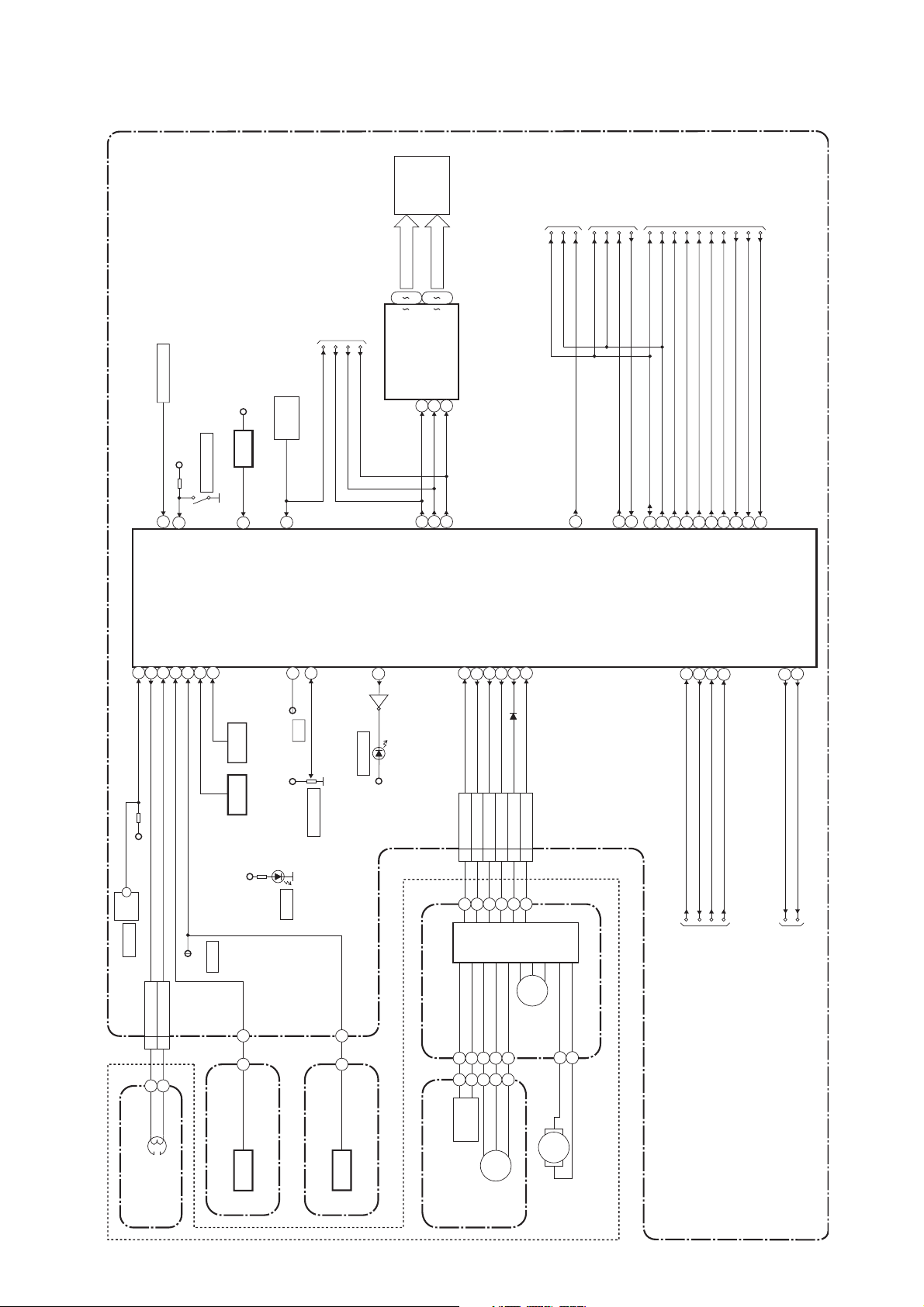

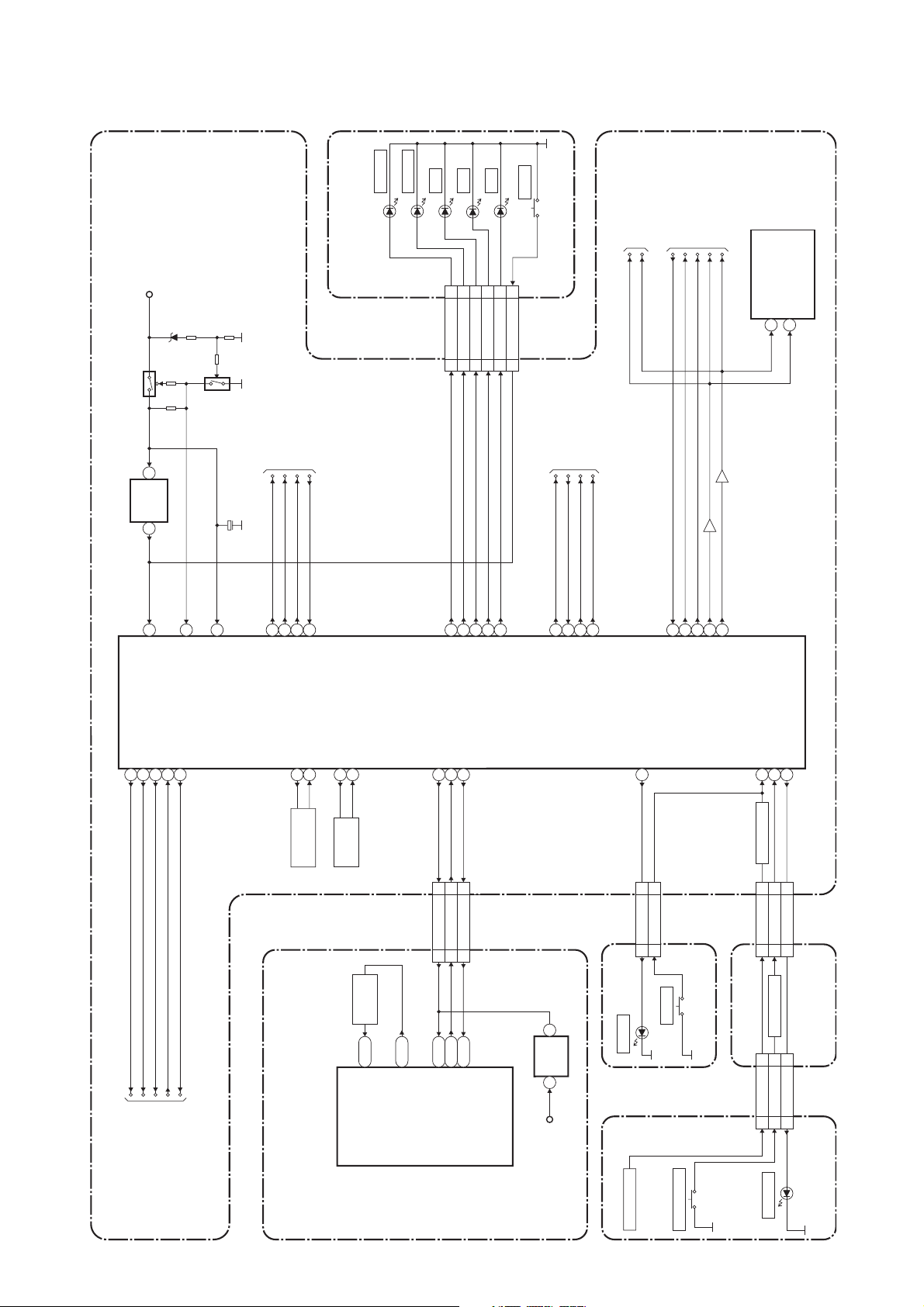

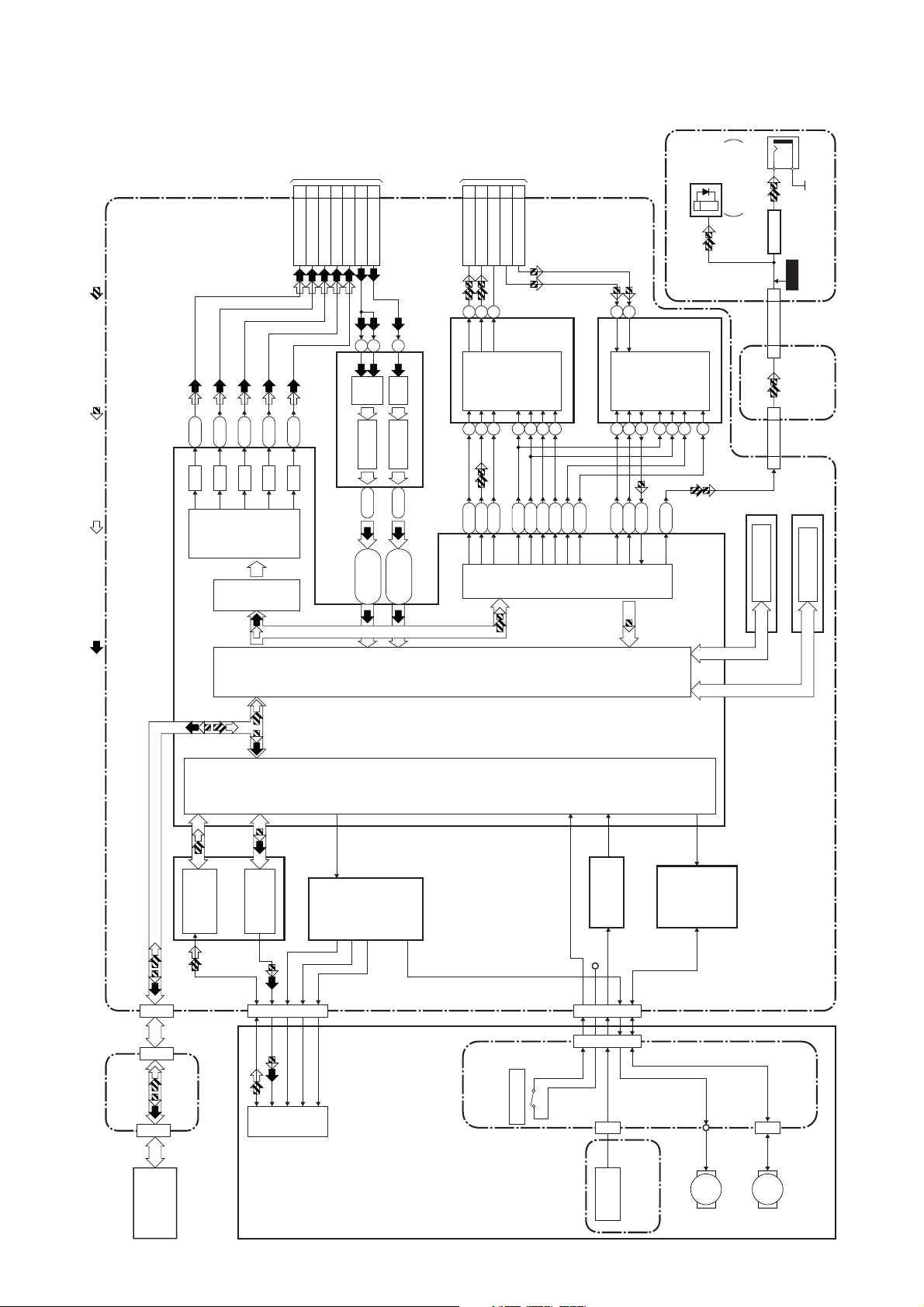

BLOCK DIAGRAMS

Servo/System Control Block Diagram

VFD

FL601

TO AUDIO

BLOCK DIAGRAM

TO Hi-Fi AUDIO

BLOCK DIAGRAM

TO VIDEO

BLOCK DIAGRAM

AV CBA

KEY SWITCH

AL+5V(2)

REC-SAFETY

SW506

7

31

KEY- 1

REC-SAF-SW

S-REEL79

ST-S

T-REEL

END-S

CTL(+)

CTL(-)

LD-SW9

IC501

(SERVO/SYSTEM CONTROL)

949510480

Q515

Q514,

AL+5V

RESET

34

RESET

REMOTE

SENSOR

RS1501

14

REMOCON-IN

CTL

97

TO SUB SYSTEM

CONTROL

FL-DIN

FL-CLK

REMOTE

PG-DELAY

2

GRID

23

1G

BLOCK DIAGRAM

(VFD DRIVER)

FL-STB

IC612

REC-LED

26

SEGMENT

7

17

a

7G

DIN

CLK

1

28

68

DRV-CLK70DRV-STB

DRV-DATA

16

i

STB

2

69

C-FG

87

C-F/R

78

C-CONT

LM-F/B/R

76

81

D-CONT77

IIC-BUS SDA

D-PFG

90

IIC-BUS SCL

IIC-BUS SCL

IIC-BUS SDA

VCR-AUDIO-MUTE

83

VCR-AUDIO-MUTE

A-MODE

Hi-Fi-H-SW

IIC-BUS SDA

32

19

A-MODE

Hi-Fi-H-SW

RF-SW

D-REC-H

IIC-BUS SCL

18

33

71

72

RF-SW

D-REC-H

IIC-BUS SCL

IIC-BUS SDA

S-CS

64

H-A-SW

C-ROTA

D-V-SYNC

16

13

15

H-A-SW

C-ROTA

D-V-SYNC

S-DATA-OUT

S-DATA-IN

S-CLOCK

65

66

67

V-ENV

C-SYNC

H-A-COMP

6

58

17

V-ENV

C-SYNC

H-A-COMP

75 P-ON-H

60 C-POW-SW

AL+5V(2)

LD-SW

SW507

CN504

5 CTL(+)

6 CTL(-)

CONTROL

HEAD

ACE HEAD ASSEMBLY

(DECK ASSEMBLY)

TP502

PS502

Q506

END-S

S-REEL

T-REEL

AL+5V

Q504

SENSOR CBA

ST-S

D555

TP503

AL+5V

S-LED

CTL

VR501

SW-POINT

END-S

Q503

Q520

VCR-REC

D520

AL+5V

SENSOR CBA

C-F/R5C-CONT7LM-F/B/R8D-CONT9D-PFG

CN502

3 C-FG

4

MOTOR

DRIVE

CIRCUIT

CAPSTAN MOTOR

CAPSTAN

PG

SENSOR

M

CYLINDER ASSEMBLY

DRUM

MOTOR

M

MOTOR

M

LOADING

MOTOR

S-DATA-OUT

S-CS

S-DATA-IN

S-CLOCK

TO SUB SYSTEM

CONTROL

BLOCK DIAGRAM

P-ON-H

C-POW-SW

TO SUB

POWER SUPPLY

BLOCK DIAGRAM

1-12-1

E3B40BLS

Page 25

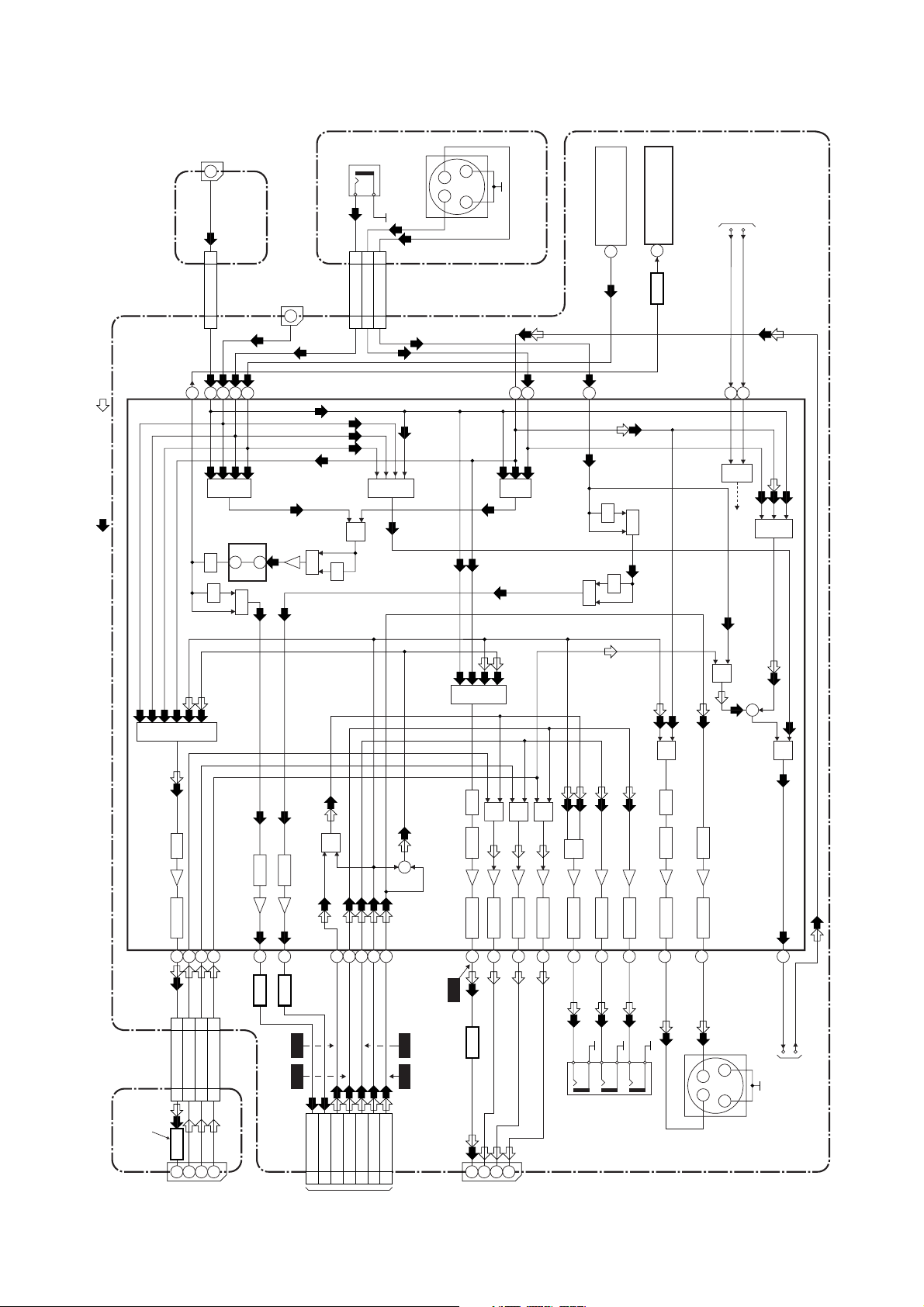

Sub System Control Block Diagram

VCR

HDD-REC

DVD-REC

D3002

D3005

CN3001

CN1504

TIMER+5V

Q1527

Q1528

D3001

FRONT JACK CBA

TO SERVO/

SYSTEM CONTROL

BLOCK DIAGRAM

DVD

D3003

874

VCR-LED

DVD-REC-LED

HDD-REC-LED

874

HDD

D3004

6

5

DVD-LED

HDD-LED

6

5

RESET

SW3001

11

RESET

11

TO VIDEO SELECTOR

BLOCK DIAGRAM

SCL

SDA

TO SERVO/

SYSTEM CONTROL

BLOCK DIAGRAM

TO AUDIO SELECTOR

BLOCK DIAGRAM

SDA

AUDIO-MUTE

SC-AUDIO-MUTE

DVD/HDD-AUDIO-MUTE

SCL

TU1501(TUNER UNIT)

SCL

9

SDA

10

IC1501

(SUB MICRO CONTROLLER)

RESET

IC1502

1 2

12

RESET

PW-SW

REG-CONT

22

77

LOW-POW

80

74

P-DOWN

FAN-LOCK

FAN-CONT1

87

78

C1511

62

BUP+5V

(BACKUP CAPACITOR)

FL-DIN

FL-CLK

1

FL-DIN

FL-STB

2

100

FL-CLK

FL-STB

X OUT

13

10MHz

X1502

S-CS

REMOTE

3

REMOTE

X IN

15

RESONATOR

X OUT

11

X1501

X IN

10

32KHz

X'TAL

60

DVD-REC-LED

SUB-RXD

SYS-RESET

233635

CN1502

4SYS-RESET

1SUB-RXD

413

CN701

61

58

68

69

DVD-LED

VCR-LED

HDD-LED

HDD-REC-LED

SUB-TXD

3SUB-TXD

S-DATA-IN

S-DATA-OUT

5

6

VCR-TXD

VCR-RXD

S-CLOCK

7

57

VCR-CS

VCR-CLK

POWER-LED

70

CN1505

1

POWER-LED

1

CN1601

2

POWER-SW

2

Q1529

21

202625

29

AUDIO-MUTE

SCART-AUDIO-MUTE

DVD/HDD-AUDIO-MUTE

Q1530

I2C-SDA

I2C-SCL

KEY-1

KEY-2

82

83

KEY SWITCH

CN1504

1

10

KEY-1

KEY-2

1

10

CN3001

AV CBA

DUBBING-LED

59

2

DUBBING-LED

2

REG-CONT

LOW-POW

PWR -SW

TO SUB

POWER SUPPLY

FAN-LOCK

FAN-CONT1

BLOCK DIAGRAM

27MHz

X'TAL

X552

N2

CLK 27 IN

N1

CLK 27 OUT

J25

N23

N24

SUB-TXD

SUB-RXD

SYS-RESET

IC107

12

D1602

RESET

DVD/HDD MAIN CBA

IC101

(MAIN MICRO CONTROLLER)

AL+2.8V

POWER

POWER

SW1601

CN3002

3

KEY-1

3

CN3003

KEY SWITCH

1

KEY-2

DUBBING-LED

144

FRONT JACK CBA

POWER SW CBA

SW CBA

DUBBING

D3006

E3B40BLSS

1-12-2

KEY SWITCH

SW3009

OPEN/CLOSE

Page 26

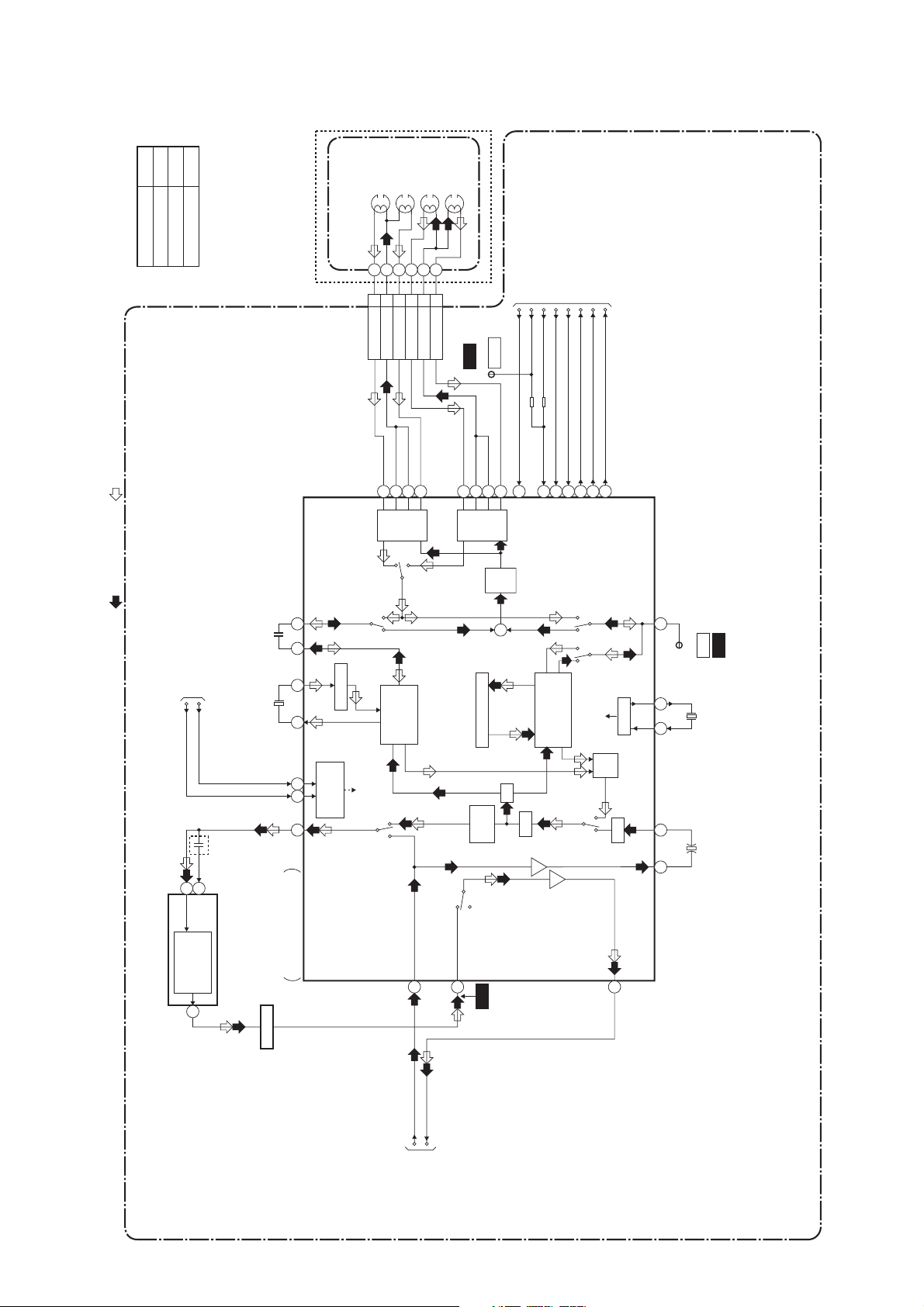

Digital Signal Process Block Diagram

TO VIDEO

SELECTOR

BLOCK

DIAGRAM

(CN1502)

24

30

28

26

10

G4

D/A

M4

D/A

L4

D/A

K1

D/A

CN701

G3

D/A

VIDEO-Y(I/P)-OUT

VIDEO-Y(I)-OUT

VIDEO-C-OUT22VIDEO-C-IN 8

VIDEO-Pb/Cb-OUT

VIDEO-Pr/Cr-OUT

IC701 (VIDEO DECODER)

VIDEO-Y/CVBS-IN

8

10

13

A/D

DECODER

DECODER A/D39-44

IC801

CN701

(AUDIO D/A CONVERTER)

TO AUDIO

SELECTOR

BLOCK

14

16

12

AUDIO(L)-OUT

AUDIO(R)-OUT

DVD/HDD-AUDIO-MUTE

151416

L-CH

R-CH

MUTE

768

DIAGRAM

(CN1502)

18

AUDIO(L)-IN20AUDIO(R)-IN

AUDIO D/A

CONVERTER

4

3

2

JK1502

(OPTICAL)

FIBER OPTIC

TRANS MODULE

(REAR)

Q1535

CN1503

CL1001

CN1001

CN101

DIGITAL

AUDIO OUT

JK1501

(REAR)

13

14

R-CH

L-CH

AUDIO A/D

IC802

(AUDIO A/D CONVERTER)

5

789

CONVERTER

101112

6

BUFFER

28 28SPDIF

28 28SPDIF

WF10

POWER

DIGITAL

AUDIO OUT

(COAXIAL)

AV CBA

SUPPLY

CBA

REC VIDEO SIGNAL PB VIDEO SIGNAL REC AUDIO SIGNAL PB AUDIO SIGNAL

IC101

IC201

RF/

ERROR AMP

VIDEO

ENCODER

VIDEO

LPC

45-50

AB1-AB4

Y2, AA4,

V3, Y3, W1,

I/F

Y4, W2, AA3

BACK-END

DIGITAL

SIGNAL

FRONT-END

DIGITAL

SIGNAL

U1R3U2

PROCESS

PROCESS

P26

N26

M26

T3

R26

AUDIO

I/F

P2R1P3

R2

T2

FLASH MEMORY

IC104,IC105 (FLASH MEMORY)

DDR SDRAM

IC102,IC103 (DDR SDRAM)

DVD/HDD MAIN CBA

IC301

MOTOR

DRIVER

OP AMP

IC202

+3.3V

IC302

MOTOR

DRIVER

CN3002CN3001 CN901

HARD DISK

DRIVE

ATA CBA

CN201

TILT

PICK

-UP

DVD MECHANISM

TRACKING

FOCUS

1-12-3

TRAY OPEN

CN301

CN1001

CN1003

FE

ENCODER

ENCODER

CN1002

M

SLED

MOTOR

CBA

SPINDLE

MOTOR

RELAY CBA

M

E3B40BLD

Page 27

Video Selector Block Diagram

VIDEO

JK2001

20

10

IN2

REAR JACK

CBA

JK3001

(FRONT)

VIDEO

16

-IN1

12

S-VIDEO

IN1

JK3004

(FRONT)

GG

C

Y

FRONT JACK CBA

TU1501

(TUNER UNIT)

(VPS)

VIDEO OUT

IC1501

17

VPS-V

89

TO SUB SYSTEM

CONTROL

BLOCK DIAGRAM

SCL

SDA

AV CBA

REC VIDEO SIGNAL PB VIDEO SIGNAL

SW

VIDEO-IN2

10

CN1506 CN2001

1262161420

GCL

LPF

SW

LPF

SW

BUFFER

Q1504

SW

SW

42

43

I/F

IIC

SW

+

SW

VIDEO IN1

JK1504

20

65

64

SW

SW

CN1504 CN3001

AGC

S-VIDEO-C-IN-F

VIDEO-IN1

S-VIDEO-Y-IN-F

S-VIDEO-Y-IN-F

141412

16

SW

SW

SW

100

SW

7

9

AGC

SW

(VIDEO SELECTOR)IC1509

REAR JACK

CBA

Q2001

JK2001

DRIVER FBC

224850

8

13

VIDEO-OUT2

VIDEO-G-IN

8

13

CN2001 CN1506

BUFFER

19

11

VIDEO-G

VIDEO OUT2

49

12

14

VIDEO-B-IN

VIDEO-R-IN

12

14

7

15

VIDEO-B

VIDEO-R

MUTE

61

BUFFER

Q1515

MUTE

59

BUFFER

Q1514

SW

5152535557

WF4

WF8

VIDEO-Y/CVBS-IN

VIDEO-Y(I/P)-OUT

CN1502

8 VIDEO-C-IN

10

24

TO DIGITAL

SIGNAL

VIDEO-Pr/Cr-OUT

VIDEO-Pb/Cb-OUT

VIDEO-Y(I)-OUT

VIDEO-C-OUT

26

28

30

22

PROCESS

BLOCK

DIAGRAM

(CN701)

+

WF7WF5

MUTE FBC

DRIVER

30

WF6

BUFFER

Q1541

JK1504

19

VIDEO OUT1

SW

DRIVER

46

11715

VIDEO-B

VIDEO-R

VIDEO-G

SW

SW

SW

DRIVER

DRIVER40DRIVER38DRIVER39DRIVER

44

45

(REAR)

JK1505

VIDEO-Y

-OUT

VIDEO-Pb/Cb

-OUT

VIDEO-Pr/Cr

-OUT

MUTE

DRIVER FBC

36

MUTE

DRIVER

34

C

Y

JK1510

(REAR)

GG

S-VIDEO

OUT

24

VCR-VIDEO-IN

VCR-VIDEO-OUT

TO VIDEO

BLOCK

DIAGRAM

1-12-4

E3B40BLVS

Page 28

Video Block Diagram

A

B

C

Model Mark

T3A-A8182DB

T3A-D8182DB

Comparison Chart of

Models & Marks

T3D-D8182DB

VIDEO (R)-1

HEAD

CYLINDER ASSEMBLY

(DECK ASSEMBLY)

123

VIDEO (L)-1

HEAD

VIDEO (L)-2

HEAD

456

VIDEO (R)-2

HEAD

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

MODE: SP/RECPB-VIDEO SIGNAL

REC-VIDEO SIGNAL

TO SERVO/SYSTEM

IIC-BUS SCL

50

CONTROL BLOCK

DIAGRAM

IIC-BUS SDA

C

55

CN251

VIDEO(L)-2

VIDEO(L)-1

VIDEO(R)-1

VIDEO-COM

969594

7978

Y. DELAY

46 43

6968

SERIAL

DECORDER

65

P

R

VIDEO-COM

93

SP

HEAD

AMP

SP

EP

LUMINANCE

SIGNAL

PROCESS

AGC

BYPASS

VIDEO(R)-2

908988

WF2

EP

CHARA.

RF-SW

D-REC-H

RF-SW

TP504

87

80

HEAD

AMP

D-REC-H

REC FMAGC

+

Y

C

CCD 1H DELAY

1/2

FBC

INS.

C-ROTA

V-ENV

H-A-SW

D-V-SYNC

H-A-COMP

84

83

71

62

70

V-ENV

H-A-SW

D-V-SYNC

H-A-COMP

RF-SW/C-ROTA

RPRP

CHROMINANCE

SIGNAL

PROCESS

PR

C-SYNC

67

C-SYNC

Y/C

MIX

AGC

VXO

21

WF3

C-PB

TP301

2928

X301

4.43MHz

AV CBA

58 59

IC501 (OSD)

COLOR

-IN

OSD

CHARACTER

MIX

52

VIDEO SIGNAL PROCESS

/HEAD AMP

IC301

BUFFER

Q402

PB/EE

48

56

VCR-VIDEO-OUT

VCR-VIDEO-IN

TO VIDEO

SELECTOR

BLOCK DIAGRAM

1-12-5

MUTE

61

WF1

E3B40BLV

Page 29

Audio Selector Block Diagram

IF SINAL

AUDIO(R)-IN2

AUDIO(L)-OUT2

AUDIO(R)-OUT2

AUDIO(L)-IN2

2

613

JK2001

MUTE-ON

Q2002

REAR JACK CBA

CN2001

AUDIO(L)-IN2

66

CN1506

MUTE-ON

Q2003

2

AUDIO-MUTE

AUDIO(R)-IN2

AUDIO(L)-OUT2

AUDIO(R)-OUT2

2

55

11

33

AUDIO(L)-IN1

613

JK1504

AUDIO(R)-IN1

AUDIO(L)-OUT1

AUDIO(R)-OUT1

2

Q1538

Q1537

AFV CBA

MUTE-ON

MUTE-ON

PROCESS

CN1

1

TU-AUDIO

SIF

TU-AUDIO(L)

1

22

55

CN1507

Q1534

DRIVE

AUDIO(L)

-OUT

(REAR)

JK1503

TU-AUDIO(R)

44

SIF OUT

AUDIO OUT

TU1501 (TUNER UNIT)

7

6

Q1540

MUTE-ON

AUDIO(R)

-OUT

Q1539

MUTE-ON

DRIVE

Q1536

AUDIO(L)

(FRONT)

JK3002

CN3001

18

AUDIO(L)-IN-F

AUDIO(R)-IN-F

18

20 20

CN1504

-IN

AUDIO(R)

(FRONT)

JK3003

-IN

FRONT JACK CBA

TO Hi-Fi AUDIO

BLOCK DIAGRAM

VCR-AUDIO-IN(L)

VCR-AUDIO-IN(R)

TO SUB

SYSTEM CONTROL

BLOCK DIAGRAM

AUDIO-MUTE

SC-AUDIO-MUTE

DVD/HDD-AUDIO-MUTE

REC AUDIO SIGNAL PB AUDIO SIGNAL

I/F

IIC

IC1509(AUDIO SELECTOR)

42

43

SDA

SCL

SW

90

)

OP AMP

(

IC1506

948592

82

(VCR DVD/HDD DUBBING)

SW

80

2

OP

AMP

1

8993849181

(DVD/HDD VCR DUBBING)

OP

SW

79

6

AMP

7

SW

70

SW

69

VCR-AUDIO-OUT(L)

VCR-AUDIO-OUT(R)

67

SW

68

SW

SW

SW

72

SW

(OP AMP)

IC1508

OP

77

1

2

71

SW

AMP

OP

76

7

6

74

AMP

73

SW

AV CBA

TO SUB SYSTEM

CONTROL

BLOCK DIAGRAM

WF9

CN1502

AUDIO(L)-OUT

AUDIO(R)-OUT

DVD/HDD-AUDIO-MUTE

AUDIO(L)-IN18AUDIO(R)-IN

14

16

12

20

TO DIGITAL

SIGNAL

PROCESS

BLOCK

1-12-6

DIAGRAM

(CN701)

TO Hi-Fi

AUDIO

BLOCK

DIAGRAM

E3B40BLAS

Page 30

Audio Block Diagram

Mode : SP/REC

ALC

12

DET

11

MUTE

LINE

ALC

AMP

REC-ON

SERIAL

DECODER

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

IIC-BUS SCL

IIC-BUS SDA

VCR-AUDIO-MUTE

71

68 69

PB-AUDIO SIGNAL REC-AUDIO SIGNAL

AV CBA

13

IC301

(AUDIO SIGNAL PROCESS)

INV

PB-ON

P

R

ATT

98

7

EQ

AMP

SP/LP-ON

5

6

P-ON+5V

Q404

Q403

BIAS

OSC

REC

AUTO

1

AMP

100

3

BIAS

2

Q406

16

AUDIO HD-SW

CONTROL

SWITCHING

D-REC-OFF

Q405

P-ON+5V

Q401

SWITCHING

PB-ON

N-A-PB

N-A-REC

TO Hi-Fi AUDIO

BLOCK DIGRAM

1-12-7

CN504

ACE HEAD ASSEMBLY

(DECK ASSEMBLY)

AUDIO-PB/REC

4

3 A-COM

1 AE-H

2 FE-H

AUDI O

HEAD

AUDI O

ERASE

HEAD

CN501

2 FE-H

FE HEAD

FULL

ERASE

1 FE-H-GND

HEAD

E3B40BLA

Page 31

Hi-Fi Audio Selector Block Diagram

TO AUDIO

SELECTOR

BLOCK DIAGRAM

TO

SERVO/ SYSTEM

CONTROL BLOCK

DIAGRAM

Hi-Fi

AUDIO(R)

HEAD

Hi-Fi

AUDIO(L)

HEAD

CYLINDER ASSEMBLY

REC-AUDIO SIGNALPB-AUDIO SIGNAL Mode : SP/REC

AV CBA

VCR-AUDIO-IN(L)

VCR-AUDIO-IN(R)

IIC-BUS SCL

IIC-BUS SDA

37

38

SERIAL

DATA

DECODER

R-CH

BPF

COMP

SW

NOISE

P

A-MODE

Hi-Fi-H-SW

767774

MUTE-ON

LPF

VCO

LIM DEV

R

OUTPUT

MUTE-ON

SELECT

73

39

HOLD

(DECK ASSEMBLY)

75

26

COMP

MIX

PULSE

NOISE

DET

Q451

21

ENV

LPF

VCO

LIM DEV

DET

R

DO

7

CN251

AUDIO(R)

Hi-Fi-

24

R

DET

P

Hi-Fi-COM 8

34 33

LIM

L-CH

COMP

SW

9

AUDIO(L)

Hi-Fi-

27

L

BPF

NOISE

IC451 ( Hi-Fi AUDIO PROCESS)

R-CH

PNR

47

1-12-8

48

R-CH

INSEL

50

VCR-AUDIO-OUT(R)

VCR-AUDIO-OUT(L)

TO AUDIO

SELECTOR

BLOCK DIAGRAM

14

L-CH

4

INSEL

L-CH

PNR

15

NOR

SW

78

80

N-A-REC

N-A-PB

TO AUDIO

BLOCK DIAGRAM

E3B40BLH

Page 32

Power Supply Block Diagram

TO SUB

POWER SUPPLY

BLOCK DIAGRAM

(CN1503)

AL+5V(3)

1 AL-30V

2 AL+44V

CL1001

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

14 P-ON+9V

7,8 AL+12V

3,4 AL+16.3V

Q1106

P-ON+5V

15,16

17,18

SW+5V

23 F1

22 AL+5V

24 F2

IC1105

+5V REG.

25 REG-CONT

26 LOW-POW

27 PWR-SW

12 FAN-CONT1

13 FAN-LOCK

Q1105

+9V REG.

FAN

1 FAN+12V

CN1002

Q1114

2 FAN-LOCK

Q1115

HARD

4 HDD+12V

CN1003

DISC

DRIVE

1 HDD+5V

4-6 P-ON+10.5V

CN1001

TO

DVD/HDD

MAIN CBA

AL+2.8V

P-ON+5V

9-11

19-21

(CN101)

P-ON+3.3V

P-ON+2.5V(1)

24,25

14-16

+2.5V REG.

IC1103

IC1104

+3.3V REG.

Q1107

18

17

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

T1001

3

BRIDGE

RECTIFIER

D1001 - D1004

16

5

Q1108

+8.5V REG.

15

Q1001

14

Q1100

Q1003

SW+12V

Q1101

13

SW-CTL

IC1102

POWER SUPPLY CBA

IC1001

ERROR

VOLTAGE DET

Q1102

Q1103

1

3

2

REG.

1

4

2

3

SHUNT

IC1101

Q1104

12

11

10

7

8

HOT COLD

LINE

FILTER

L1003

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

HOT CIRCUIT. BE CAREFUL.

F1001

T2.0A L 250V

AC1001

1-12-9

E3B40BLP

Page 33

Sub Power Supply Block Diagram

-FL

AL+44V

P-ON+15V

AL+16V/+12V

P-ON+9V(2)

AL+12V(2)

AL+12V

P-ON+5V(DECK)

P-ON+9V

AUDIO+5V

P-ON+5V(2)

AL+5V

P-ON+5V

TIMER+5VF1F2

P-ON+5V(A)

AL+3.3V

AL+9V

TO SERVO/SYSTEM

AL+5V(2)

CONTROL

BLOCK DIAGRAM

TO SUB SYSTEM

CONTROL

BLOCK DIAGRAM

J902

Q1511

Q1512

Q1508

Q1509

Q1513

Q1516

Q1518

+5V REG.

Q1502

Q1517

Q1519

SW+3.3V

Q1521

+9V REG.

Q1520

+5V REG.

SW-CTL

IC1507

P-ON-H

C-POW-SW

PWR-SW

LOW-POW

REG-CONT

FAN-LOCK

FAN-CONT1

AV CBA

CN1503

1 AL-30V

2 AL+44V

3,4 AL+16.3V

14 P-ON+9V

7,8 AL+12V

AL+5V(3)

P-ON+5V

15,16

17,18

TO

POWER SUPPLY

REG-CONT

23F122 AL+5V

24F225

26 LOW-POW

27 PWR-SW

BLOCK DIAGRAM

(CL1001)

FAN-CONT1

FAN-LOCK

12

13

1-12-10

E3B40BLSP

Page 34

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark " ! "

in the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly different

or amended since these drawings were prepared.

2. All resistance values are indicated in ohms

3

(K=10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in µF

(P=10

5. All voltages are DC voltages unless otherwise

specified.

6. Electrical parts such as capacitors, connectors,

diodes, IC’s, transistors, resistors, switches, and

fuses are identified by four digits. The first two

digits are not shown for each component. In each

block of the diagram, there is a note such as shown

below to indicate these abbreviated two digits.

, M=106).

-6

µF).

1-13-1 T3P_SC

Page 35

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications for PLAY and REC modes on the schematics are as shown below:

< DVD/HDD Section >

231

5.0

The same voltage for

both PLAY & STOP modes

5.0

(2.5)

Indicates that the voltage

is not consistent here.

5. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line number

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

PLAY mode

STOP mode

< VCR Section >

5.0

The same voltage for

both PLAY, REC &

DVD/HDD modes

5.0

(2.5)

< >

PLAY mode

REC mode

DVD/HDD mode

231

Indicates that the voltage

is not consistent here.

3

AREA D3

2

1

AREA B1

1-D3

ABCD

Unit: Volts

1-B1

: Used to indicate a test point with a test pin.

1-13-2 T3P_SC

Page 36

AV 1/9 Schematic Diagram < VCR Section >

Comparison Chart of

Models and Marks

MODEL MARK

T3A-A8182DB A

T3A-D8182DB B

T3D-D8182DB C

1-13-3

E3B40SCAV1

Page 37

AV 2/9 & Sensor Schematic Diagram < VCR Section >

C

G7(GR7) G6(GR6) G5(GR5) G4(GR4) G3(GR3) G2(GR2) G1(GR1)

P1

(SG1)

P2

(SG2)

P3

(SG3)

P4

(SG4)

P5

(SG5)

P6

(SG6)

P7

(SG7)

c

d

e

ff

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

P8

(SG8)

-

--

p

(S3)

(S2)

(S1)

P9

(SG9)

a

b

c

d

e

g

a

b

abababa

b

FL601 MATRIX CHART

CD

P-SCAN

DVD

HDD

VCRDB

R

W

G7

G6

G5 G4 G3 G2 G1

PM

TIME

SHIFT

P-SCAN

DB

VCR

S1

C

a

HDD

S2

b

f

g

p

DVD

S3

ce

d

CD

R

W

1-13-4

E3B40SCAV2

Page 38

AV 3/9 Schematic Diagram < VCR Section >

Comparison Chart of

Models and Marks

MODEL MARK

T3A-A8182DB A

T3A-D8182DB B

T3D-D8182DB C

1-13-5

E3B40SCAV3

Page 39

AV 4/9 Schematic Diagram < VCR Section >

1-13-6

E3B40SCAV4

Page 40

AV 5/9 & Power SW Schematic Diagram < VCR Section >

*1 NOTE

IC1502

IC1502

R3112N211A-TR-F

PST3621NR

Group A Group B

C1505

C1505 0.015

0.15

These components (IC1502, C1505) can be used

in any models.

However, you cannot mix components under

Group A with the ones under Group B.

You can choose either Group. The difference

between Group A and Group B is shown below.

----------

----------

----------

----------

1-13-7

E3B40SCAV5

Page 41

AV 6/9 Schematic Diagram < VCR Section >

1-13-8

E3B40SCAV6

Page 42

AV 7/9 Schematic Diagram < VCR Section >

1-13-9

E3B40SCAV7

Page 43

AV 8/9 Schematic Diagram < VCR Section >

1-13-10

E3B40SCAV8

Page 44

AV 9/9 Schematic Diagram < VCR Section >

1-13-11

E3B40SCAV9

Page 45

Power Supply Schematic Diagram < VCR Section >

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

1-13-12

E3B40SCP

Page 46

Front Jack & SW Schematic Diagram < VCR Section >

1-13-13

E3B40SCFJ

Page 47

Rear Jack Schematic Diagram < VCR Section >

1-13-14

E3B40SCRJ

Page 48

AFV Schematic Diagram < VCR Section >

ATA Schematic Diagram < DVD/HDD Section >

Comparison Chart of

Models and Marks

MODEL MARK

T3A-A8182DB A

T3A-D8182DB B

T3D-D8182DB C

1-13-15

E3B40SCAFV

E3B40SCAT

Page 49

DVD/HDD MAIN 1/5 Schematic Diagram < DVD/HDD Section >

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC101.

IC101 is divided into five and shown as IC101 (1/5) ~ IC101 (5/5) in this DVD/HDD Main Schematic Diagram Section.

1-13-16

E3B40SCD1

Page 50

DVD/HDD MAIN 2/5 Schematic Diagram < DVD/HDD Section >

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC101.

IC101 is divided into five and shown as IC101 (1/5) ~ IC101 (5/5) in this DVD/HDD Main Schematic Diagram Section.

1-13-17

E3B40SCD2

Page 51

DVD/HDD MAIN 3/5 Schematic Diagram < DVD/HDD Section >

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC101.

IC101 is divided into five and shown as IC101 (1/5) ~ IC101 (5/5) in this DVD/HDD Main Schematic Diagram Section.

1-13-18

E3B40SCD3

Page 52

DVD/HDD MAIN 4/5 Schematic Diagram < DVD/HDD Section >

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC101.

IC101 is divided into five and shown as IC101 (1/5) ~ IC101 (5/5) in this DVD/HDD Main Schematic Diagram Section.

1-13-19

E3B40SCD4

Page 53

DVD/HDD MAIN 5/5 Schematic Diagram < DVD/HDD Section >

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC101.

IC101 is divided into five and shown as IC101 (1/5) ~ IC101 (5/5) in this DVD/HDD Main Schematic Diagram Section.

1-13-20

E3B40SCD5

Page 54

AV CBA Top View

Sensor CBA Top View

VR501

SW-POINT

TP503

CTL

WF2

TP504

RF-SW

WF3

TP301

C-PB

TO SENSOR CBA

(END-SENSOR)

BHF300F01012A

BHF300F01012B

J308

AV1-V-OUT

TO SENSOR CBA (START-SENSOR)

1-13-21

BE3B00F01011A

Page 55

AV CBA Bottom View

WF1

PIN 56 OF

IC301

WF6

PIN 30 OF

IC1509

WF7

PIN 28 OF

CN1502

WF8

PIN 26 OF

CN1502

WF4

PIN 24 OF

CN1502

WF5

PIN 22 OF

CN1502

WF9

PIN 14 OF

CN1502

WF10

PIN 28OF

CN1503

1-13-22

BE3B00F01011A

Page 56

Power Supply CBA Top View

Because a hot chassis ground is present in the power

supply circut, an isolation transformer must be used.

Also, in order to have the ability to increase the input

slowly, when troubleshooting this type power supply

circuit, a variable isolation transformer is required.

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

1-13-23

BE3B00F01021A

Page 57

Power Supply CBA Bottom View

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

Because a hot chassis ground is present in the power

supply circut, an isolation transformer must be used.

Also, in order to have the ability to increase the input

slowly, when troubleshooting this type power supply

circuit, a variable isolation transformer is required.

1-13-24

BE3B00F01021A

Page 58

Front Jack CBA Top View

SW CBA Top View SW CBA Bottom View

Front Jack CBA Bottom View

BE3B00F01021B

BE3B00F01021C

1-13-25

Page 59

Rear Jack CBA Top View Rear Jack CBA Bottom View

Power SW CBA Top View Power SW CBA Bottom View

BE3B00F01021D

ATA CBA Top View ATA CBA Bottom View

BE3B00F01011B BE4340F01032

1-13-26

Page 60

AFV CBA Top View AFV CBA Bottom View

1-13-27

BE6800F01091

Page 61

WAVEFORMS

NOTE:

Input: COLOR BAR SIGNAL (WITH 1KHz AUDIO SIGNAL)

WF1

Pin 56 of IC301

V-OUT E-E 0.2V 20

WF1

WF2

UPPER

LOWER

Pin 56 of IC301

TP504

V-OUT 0.5V

RF-SW 5V

WF9

WF5

Pin 22 of CN1502

µs

50

µs

VIDEO-C 0.2V 20µs

WF6

Pin 30 of IC1509

VIDEO-CVBS 0.5V 20µs

Pin 14 of CN1502

AUDIO(L)-OUT

WF10

Pin 28 of CN1503

SPDIF 1V 0.1µs

1V 0.5ms

WF3

UPPER

WF2

LOWER

C-PB

RF-SW 5V 5m

WF4

Pin 24 of CN1502

TP301

TP504

0.2V

WF7

Pin 28 of CN1502

s

VIDEO-Cb

WF8

Pin 26 of CN1502

0.2V 20µs

VIDEO-Y 0.2V 20µs

VIDEO-Cr

0.2V 20µs

1-14-1

T3PWF

Page 62

Wiring 1/2 Diagram

TO

POWER

1

2

4

6

8

10

11

12

13

GND5GND

AL-30V

CN1503

AL+44V

AL+16.3V3AL+16.3V

GND9GND

AL+12V7AL+12V

1V2CONT

FAN-LOCK

FAN-CONT1

SUPPLY

CBA

CL1001

(W3)

16

AL+5V(3)17AL+5V(3)

P-ON+9V14P-ON+5V15P-ON+5V

WIRING DIAGRAMS

CONTINUE

WIRING

DIAGRAM 2/2

18

19

GND

21

GND20GND

22F123F224

AL+5V

26

27

25

PWR-SW

LOW-POW

REG-CONT

28

29NU30

SPDIF

SAFETY1

28

30

GND 29

CN1502

VIDEO-Y(I)-OUT

VIDEO-Pb/Cb-OUT

26

24

GND 27

GND 25

VIDEO-Pr/Cr-OUT

VIDEO-Y(I/P)-OUT

TO

DVD/HDD

MAIN CBA

CN701

(W1)

12

10

AUDIO+5V 11

VIDEO-Y/CVBS-IN

DVD/HDD-AUDIO-MUTE

GND 9

8

-IN

VIDEO-C

16

14

GND 15

GND 19

GND 17

GND 21

GND 23

AUDIO(L)-IN 20

VIDEO-C-OUT 22

AUDIO(R)-IN 18

GND 13

AUDIO(L)-OUT

AUDIO(R)-OUT

3NU2

1

NU 6

NU 5

GND 7

RESET 4

SUB-TXD

SUB-RXD

SYS-

DIGITAL

REAR

ANT-IN ANT-OUT

OPTICAL

AUDIO OUT

COAXIAL

AUDIO(R)

-OUT

AUDIO(L)

-OUT

S-VIDEO