Page 1

SERVICE MANUAL

Serial No. Label

MANUFACTURED:MAY2013PP10210001‒A33T1EP

※

"A33T1EP"

39˝ COLOR LCD TELEVISION

39FL753P/10

– EXTERNAL VOLUME –

This Service Manual is for the 39FL753P/10 (A33T1EP) model.

For the 39FL753P/10 (A33T1EP) model, the letter (A33T1EP) is printed on

the Serial Number Label on the back of the unit. Refer to the Serial

Number Label below.

Page 2

39˝ COLOR LCD TELEVISION

The LCD panel is manufactured to provide many years of useful life.

Occasionally a few non active pixels may appear as a tiny spec of color.

This is not to be considered a defect in the LCD screen.

39FL753P/10

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

How to Initialize the LCD Television. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Schematic Diagrams / CBA and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Electrical Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Page 3

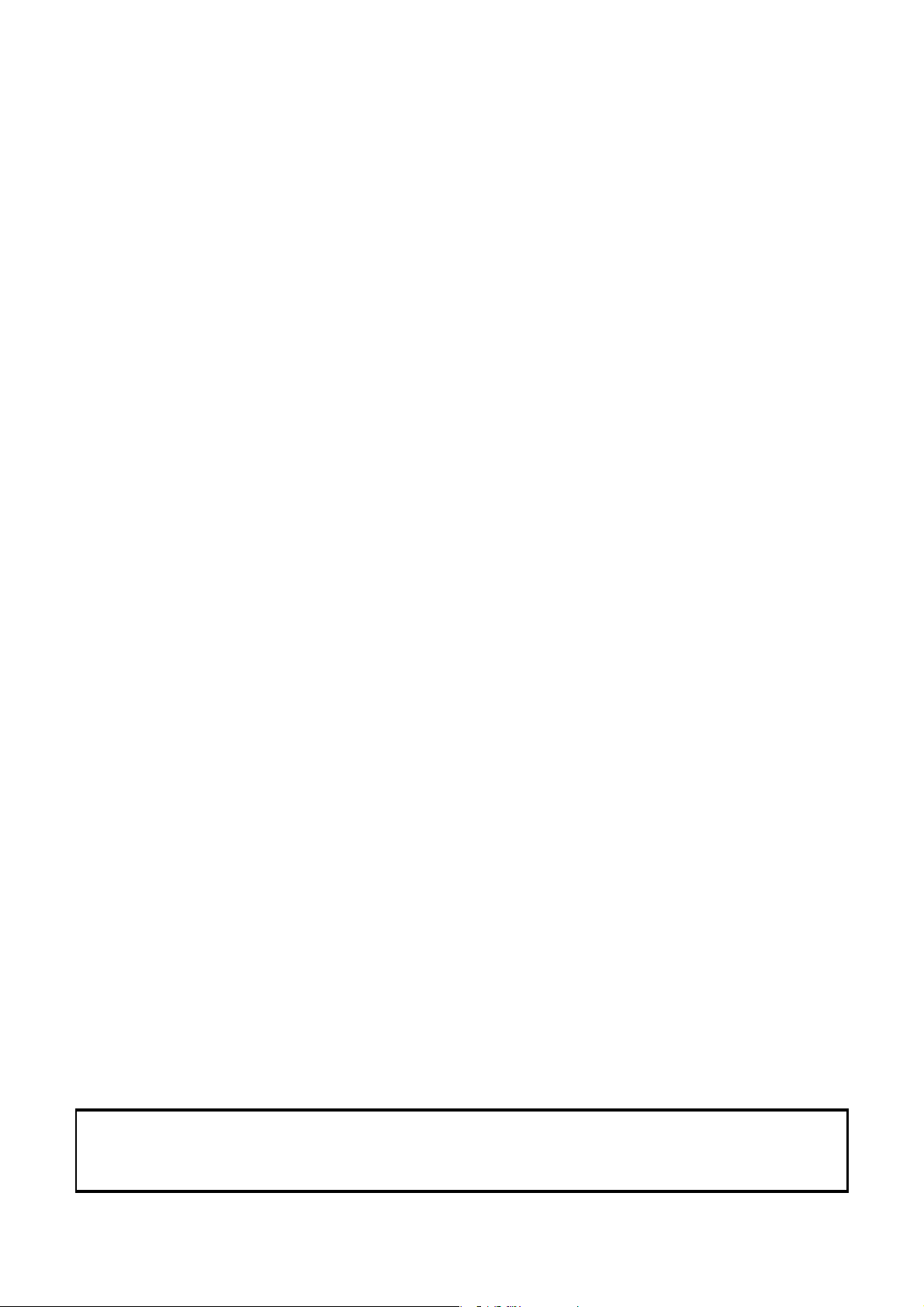

SPECIFICATIONS

< TUNER >

VHS/UHF Input ----------- 75 unbal., IEC Connector

Center IF ------------------- SECAM-L 38.9MHz, SECAM-L’ 33.9MHz

Description Condition Unit Nominal Limit

1. Video S/N 80 dB --- 40

2. Audio S/N --- dB --- 40/40

< LCD PANEL >

Description Condition Unit Nominal Limit

1. Number of Pixels

2. Viewing Angle

<DVB-T>

Description Condition Unit Nominal Limit

1.

RECEIVED FREQ.RANGE

(-60dBm, 45ch.) *1, *2

2. INPUT DYNAMIC

RANGE (mix./max)

3. C/N PERFORMANCE

(-50dBm)

4. MULTIPATH (-50dBm)

a. Performance with

short delay echoes

b. Performance with

long delay echoes

Horizontal

Ver t i cal

Horizontal

Ver t i cal

+

-

1):*1 VHF HIGH 8ch.

UHF 45ch.

2):*2 VHF HIGH 8ch.

UHF 45ch.

1):*1 VHF HIGH 8ch.

UHF 45ch.

2):*2 VHF HIGH 8ch.

UHF 45ch.

UHF 45ch.

1):*3

2):*4

1):*3

2):*4

pixels

pixels

kHz

kHz

dBuV

dBuV

dBuV

dBuV

dB

dB

dB

dB

dB

dB

dB

dB

1920

1080

°

°

-85 to 85

-80 to 80

1000

900

25/101

25/101

18/101

18/101

15

15

11

11

18.7

14.0

19.1

13.0

---

---

-75 to 75

-70 to 70

500

167

28/98

29/98

21/98

21/98

≦18

≦18

≦14

≦14

≦23

≦20

≦23

≦18

*1: modulation parameters = [8k 64QAM CR=2/3 GI=1/32]

*2: modulation parameters = [8k 16QAM CR=3/4 GI=1/8]

*3: modulation parameters = [2k 64QAM CR=2/3 GI=1/32]

*4: modulation parameters = [2k 16QAM CR=3/4 GI=1/32]

< VIDEO >

Description Condition Unit Nominal Limit

1. Over Scan

2. Color Temperature

3. Resolution

4. Brightness

AT 100% WHITE FIELD

Horizontal

Ver t i cal

AT 70% WHITE FIELD

x

y

Horizontal

Ver t i cal

(AT RETAIL MODE)

1-1 A33F0_F1 SP

%

%

°K 12000

0.272

0.278

line

line

2

cd/m

5

5

400

350

250 ---

---

---

--±0.015

±0.015

---

---

Page 4

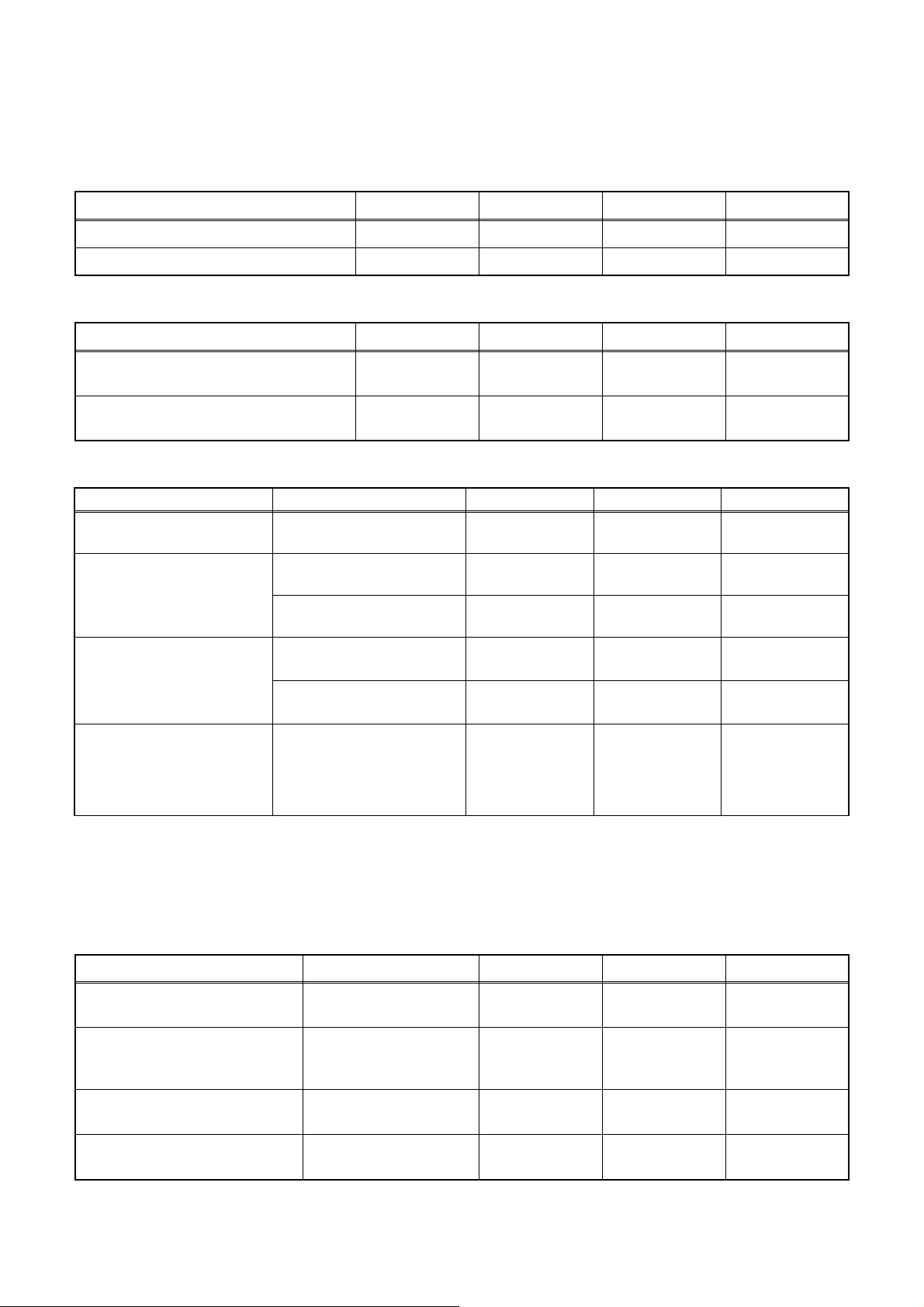

< AUDIO >

All items are measured across 8 load at speaker output terminal.

Description Condition Unit Nominal Limit

1. Audio Output Power

2. Audio Distortion 500mW: Lch/Rch % 1.5/1.5 3.0/3.0

3. Audio Freq. Response

4. Audio S/N Lch/Rch dB ---

Note: Nominal specifications represent the design specifications. All units should be able to approximate these.

Some will exceed and some may drop slightly below these specifications. Limit specifications represent

the absolute worst condition that still might be considered acceptable. In no case should a unit fail to meet

limit specifications.

2V rms input Lch/Rch

Vol:MAX

-

6dB: Lch

-

6dB: Rch

W8/87/7

Hz

Hz

---

---

---

---

≧45/45

1-2 A33F0_F1 SP

Page 5

IMPORTANT SAFETY PRECAUTIONS

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

TEST ALL EXPOSED

METAL SURFACES

READING SHOULD

NOT BE ABOVE 0.5 mA

EARTH

GROUND

_

DEVICE

LEAKAGE

CURRENT

TESTER

+

BEING

TESTED

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for LCD TV

Circuit

1. Before returning an instrument to the

customer, always make a safety check of the

entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are

defective and have been defeated during

servicing. (1) Protective shields are provided

on this chassis to protect both the technician

and the customer. Correctly replace all missing

protective shields, including any removed for

servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the

cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating

fishpapers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or

permit it to be operated without all

protective devices correctly installed and

functioning. Servicers who defeat safety

features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous

voltage. Such openings include, but are not

limited to, (1) spacing between the LCD module

and the cabinet mask, (2) excessively wide

cabinet ventilation slots, and (3) an improperly

fitted and/or incorrectly secured cabinet back

cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug

prongs. Place the instrument AC switch in the

on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch

the other ohmmeter lead in turn to each tuner

antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohm

or greater than 5.2 megohm, an abnormality

exists that must be corrected before the

instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off

position.

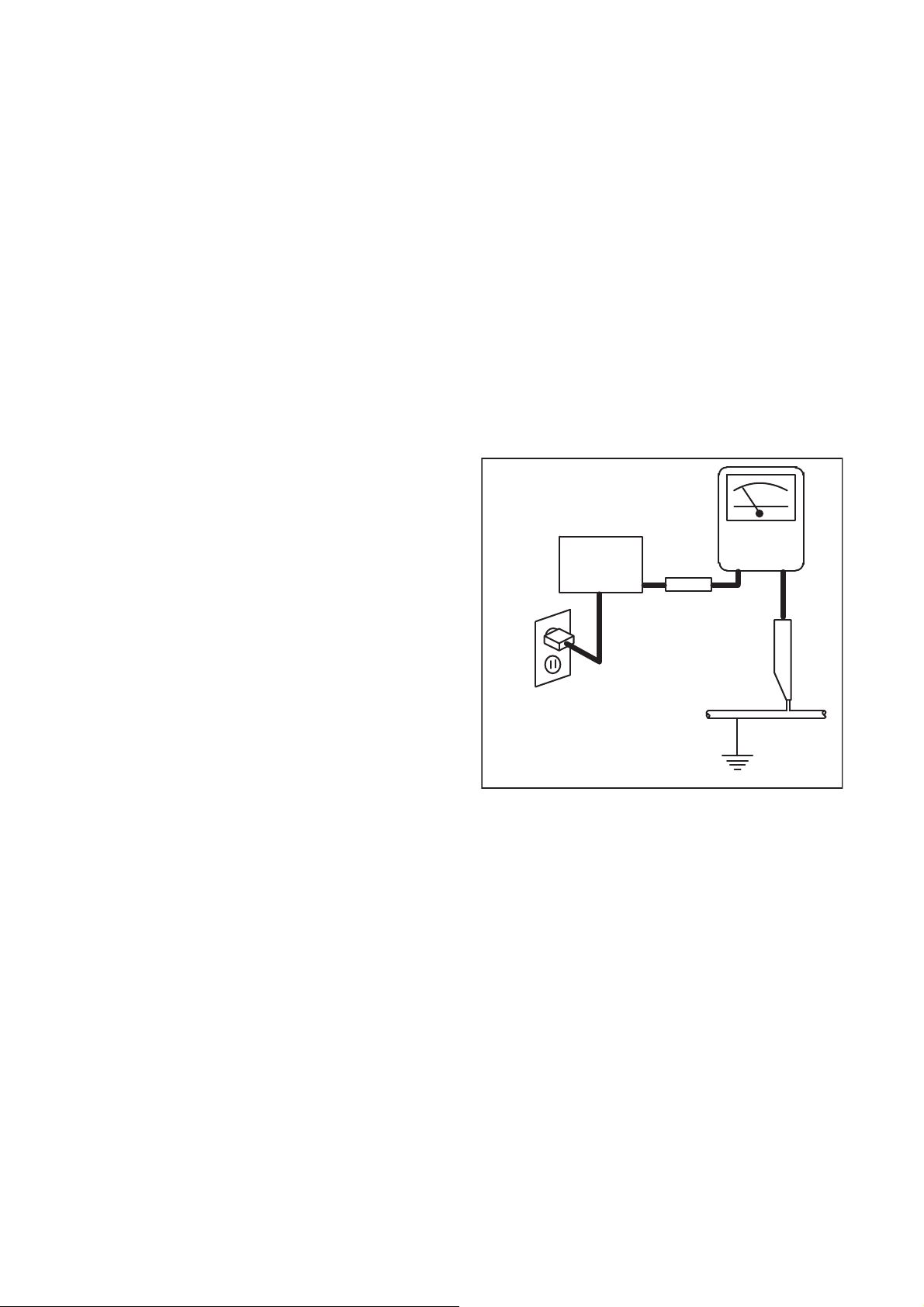

d. Leakage Current Hot Check - With the

instrument completely reassembled, plug the

AC line cord directly into a 230 V AC outlet. (Do

not use an isolation transformer during this

test.) Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI) C101.1

Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on

position and then in the off position, measure

from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the

chassis. Any current measured must not

exceed 0.5 milli-ampere. Reverse the

instrument power cord plug in the outlet and

repeat the test.

ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR

BEFORE CONNECTING THE ANTENNA OR

ACCESSORIES.

2. Read and comply with all caution and safety-

related notes on or inside the receiver cabinet, on

the receiver chassis, or on the LCD module.

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this LCD

TV receiver. Design alterations and additions,

including, but not limited to circuit modifications

and the addition of items such as auxiliary audio

2-1 LTVP_ISP

and/or video output connections, might alter the

safety characteristics of this receiver and create a

hazard to the user. Any design alterations or

additions will void the manufacturer's warranty and

may make you, the servicer, responsible for

personal injury or property damage resulting

therefrom.

Page 6

4. Hot Chassis Warning -

a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord and maybe safety-serviced without

an isolation transformer only if the AC power

plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is

inserted correctly, with an AC voltmeter,

measure between the chassis and a known

earth ground. If a voltage reading in excess of

1.0 V is obtained, remove and reinsert the AC

power plug in the opposite polarity and again

measure the voltage potential between the

chassis and a known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground

regardless of the AC plug polarity. This chassis

can be safety-serviced only with an isolation

transformer inserted in the power line between

the receiver and the AC power source, for both

personnel and test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulation material that must not be defeated or

altered.

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high

voltage, and, e. antenna wiring. Always inspect in

all areas for pinched, out of place, or frayed wiring.

Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

7. Product Safety Notice - Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc..

Parts that have special safety characteristics are

identified by a ! on schematics and in parts lists.

Use of a substitute replacement that does not

have the same safety characteristics as the

recommended replacement part might create

shock, fire, and/or other hazards. The product's

safety is under review continuously and new

instructions are issued whenever appropriate.

Prior to shipment from the factory, our products

are strictly inspected to confirm they comply with

the recognized product safety and electrical codes

of the countries in which they are to be sold.

However, in order to maintain such compliance, it

is equally important to implement the following

precautions when a set is being serviced.

2-2 LTVP_ISP

Page 7

Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC supply outlet.

L. When installing parts or assembling the cabinet

parts, be sure to use the proper screws and

tighten certainly.

2-3 LTVP_ISP

Page 8

Safety Check after Servicing

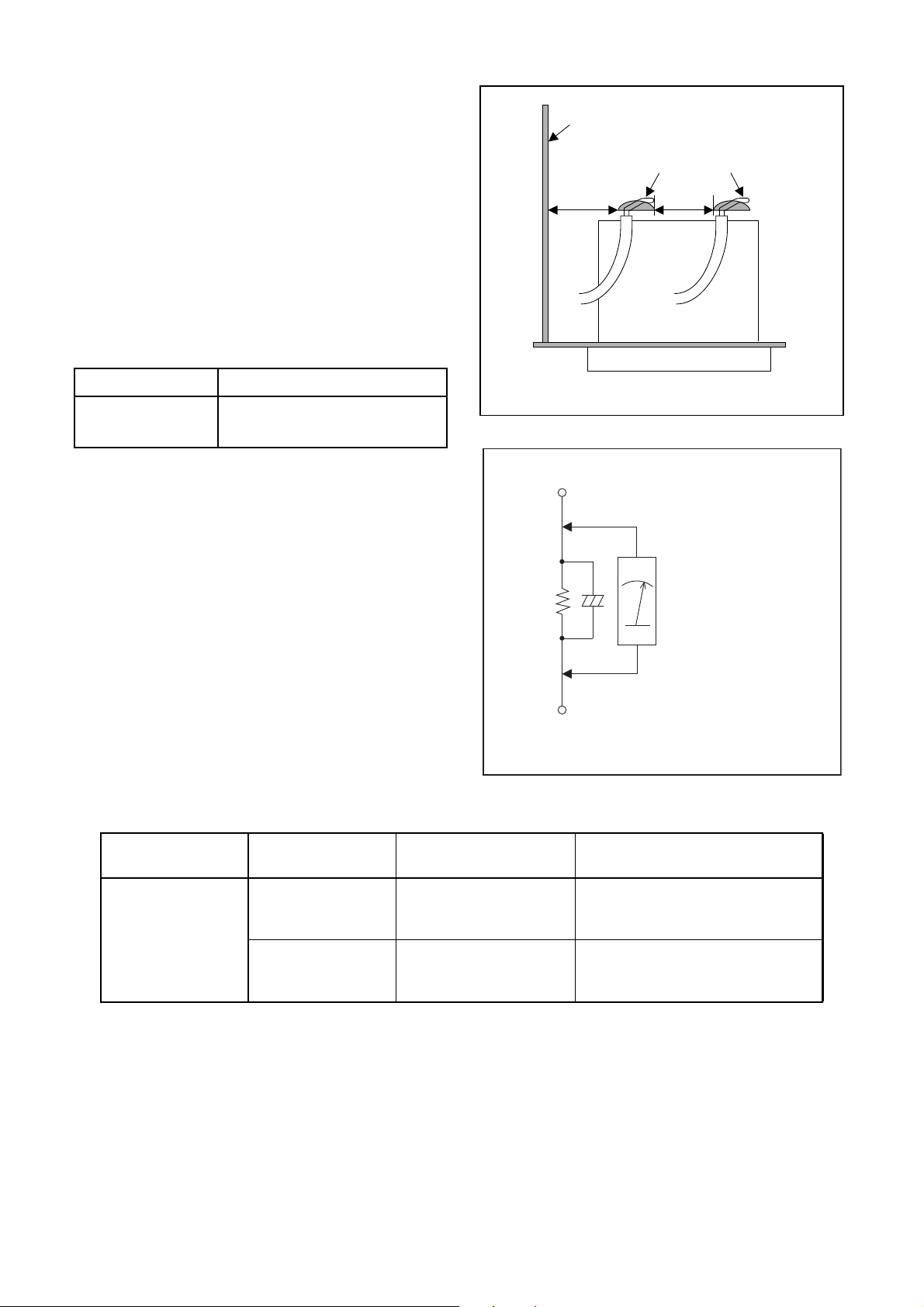

Fig. 1

Chassis or Secondary Conductor

Primary Circuit

d' d

Fig. 2

AC Voltmeter

(High Impedance)

Exposed Accessible Part

B

One side of

Power Cord Plug Prongs

Z

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts and wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order to verify compliance

with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

220 to 240 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

3mm(d)

8mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of load

Z. See Fig. 2 and following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

One side of power cord plug

prongs (B) to:

2kRES.

Connected in

220 to 240 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

parallel

50k RES.

Connected in

parallel

i0.7mA AC Peak

i2mA DC

i0.7mA AC Peak

i2mA DC

2-4 LTVP_ISP

Antenna terminals

A/V Input, Output

RF or

Page 9

STANDARD NOTES FOR SERVICING

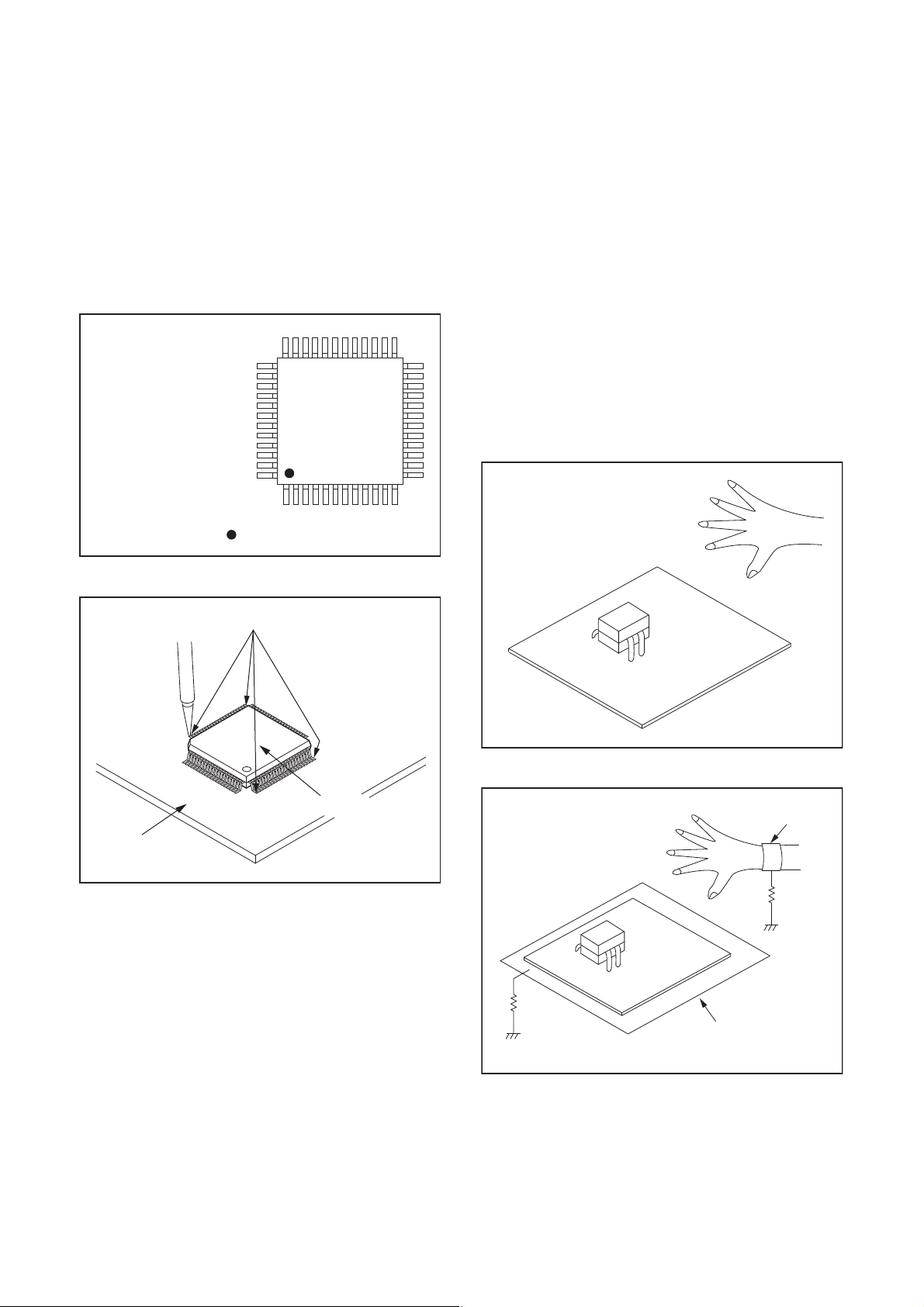

Top View

Out

In

Bottom View

Input

5

10

Pin 1

Pin 1

Fig. S-1-1

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

3. The 1st pin of every male connector is indicated as

shown.

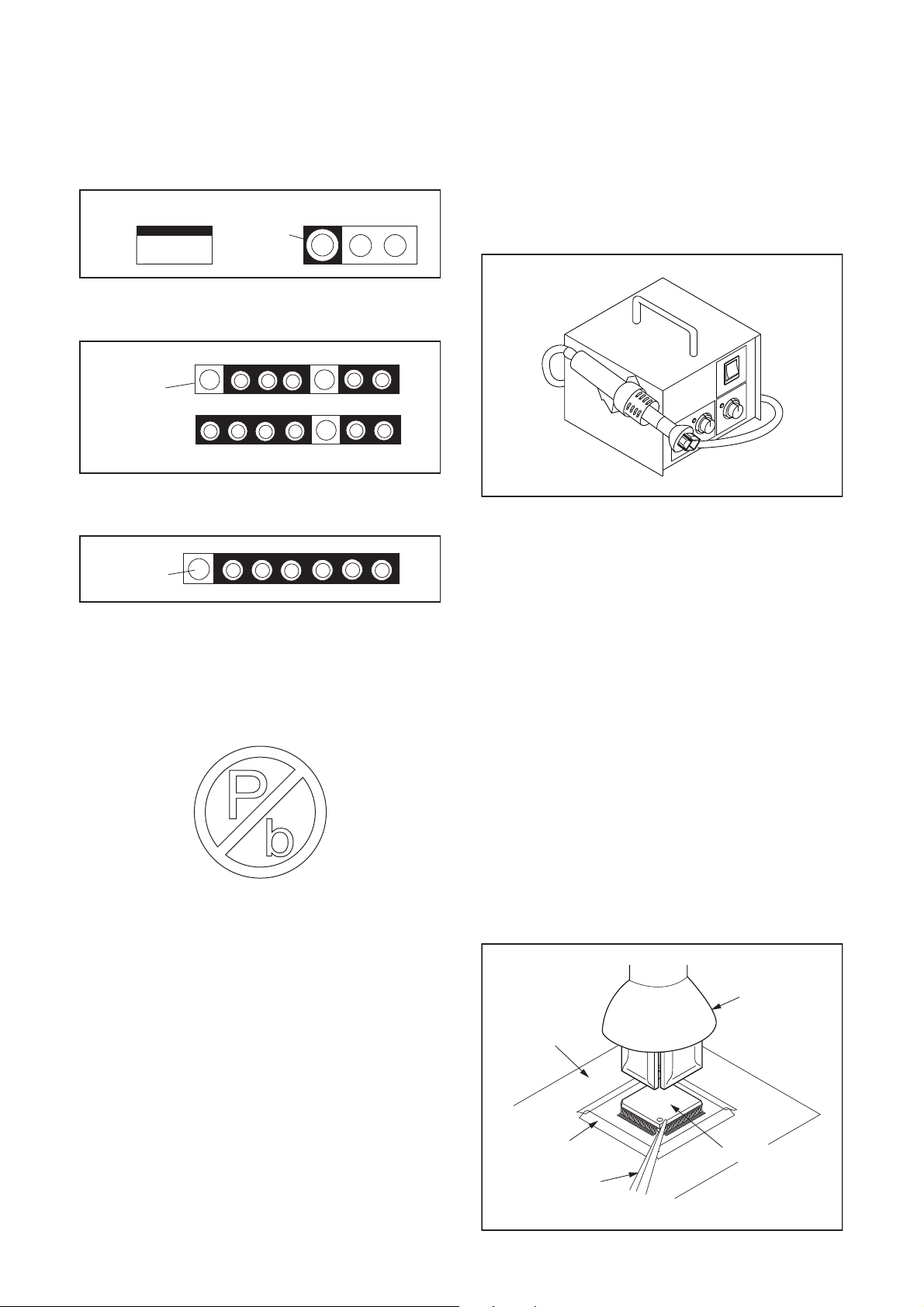

Pb (Lead) Free Solder

Pb free mark will be found on PCBs which use Pb

free solder. (Refer to figure.) For PCBs with Pb free

mark, be sure to use Pb free solder. For PCBs

without Pb free mark, use standard solder.

Pb free mark

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

3-1 TVP_SN

Machine

Flat Pack-IC

Fig. S-1-2

Page 10

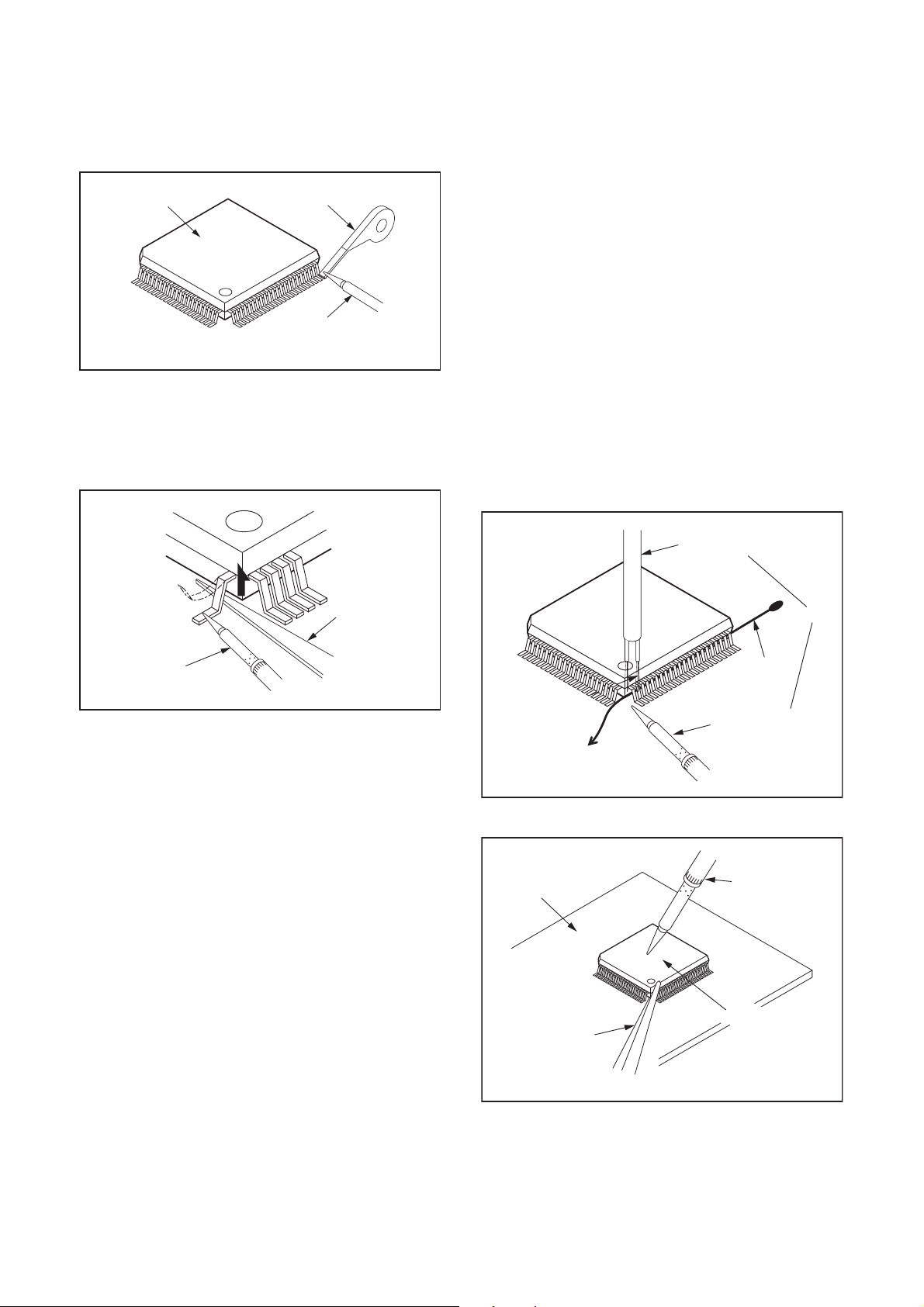

With Soldering Iron:

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

Fine Tip

Soldering Iron

Sharp

Pin

Fig. S-1-4

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

To Solid

Mounting Point

CBA

Hot Air Blower

or

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

Tweezers

Fig. S-1-6

3-2 TVP_SN

Page 11

2. Installation

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Presolder

CBA

Flat Pack-IC

Fig. S-1-8

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

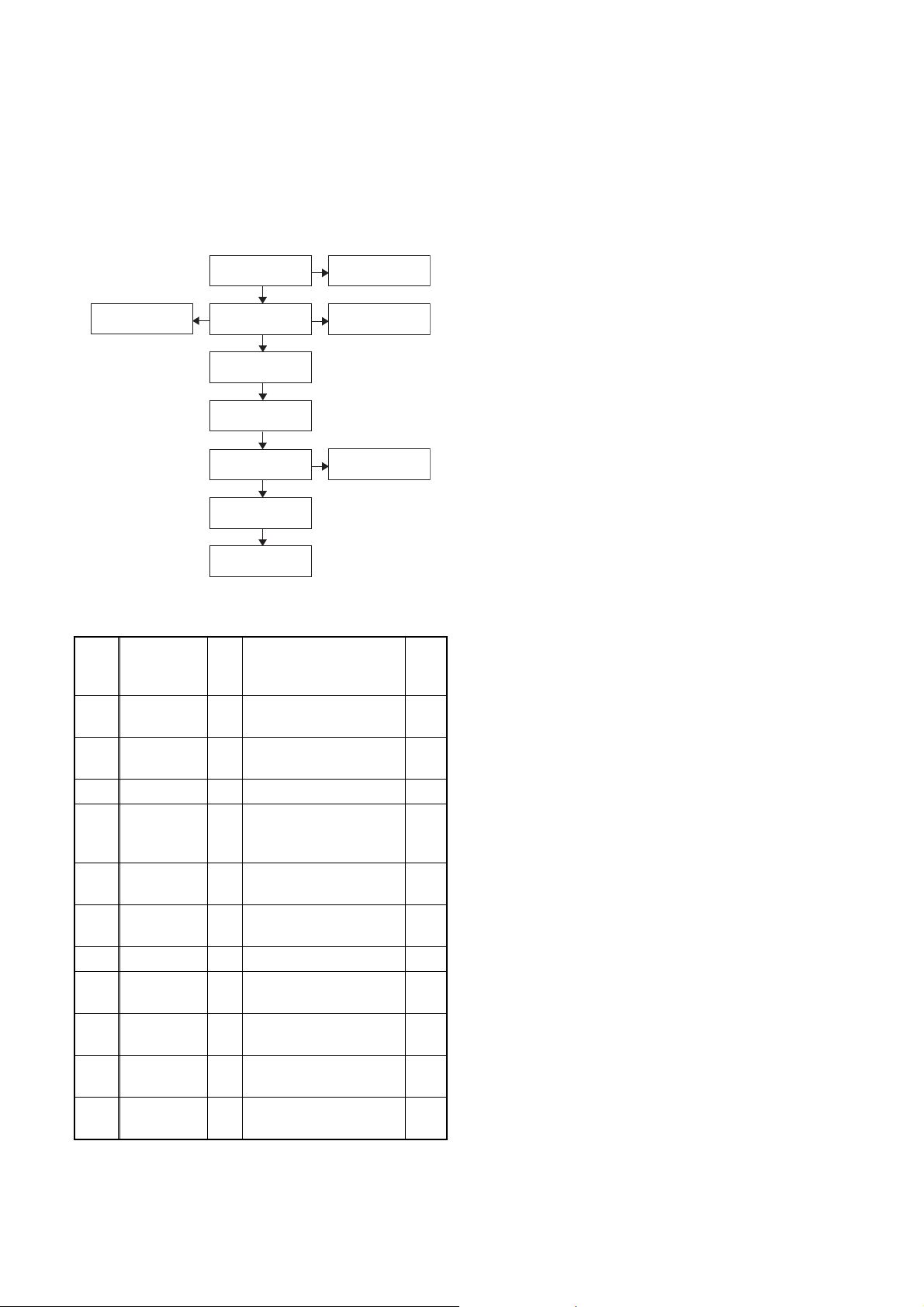

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 M) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 M) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

3-3 TVP_SN

Page 12

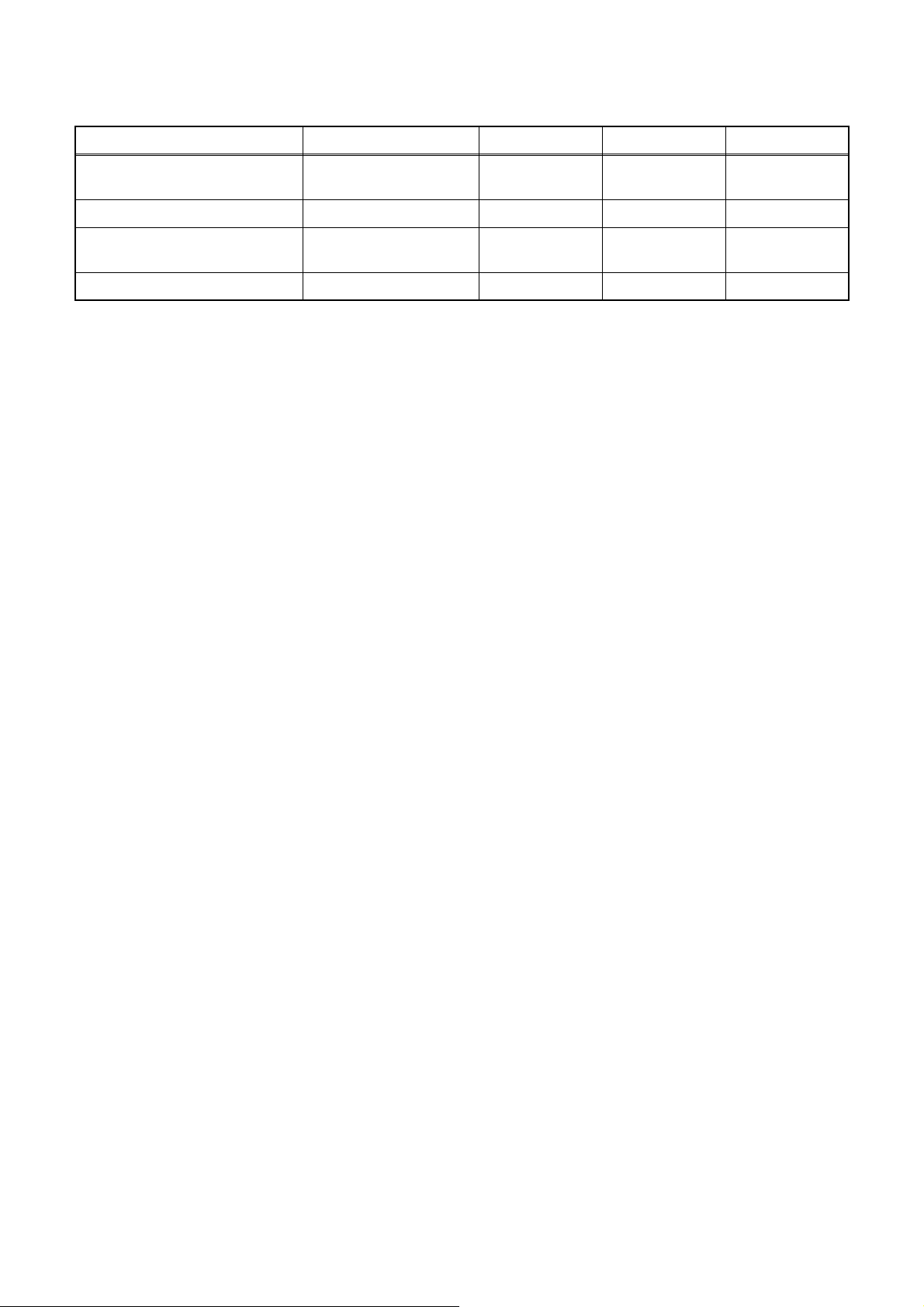

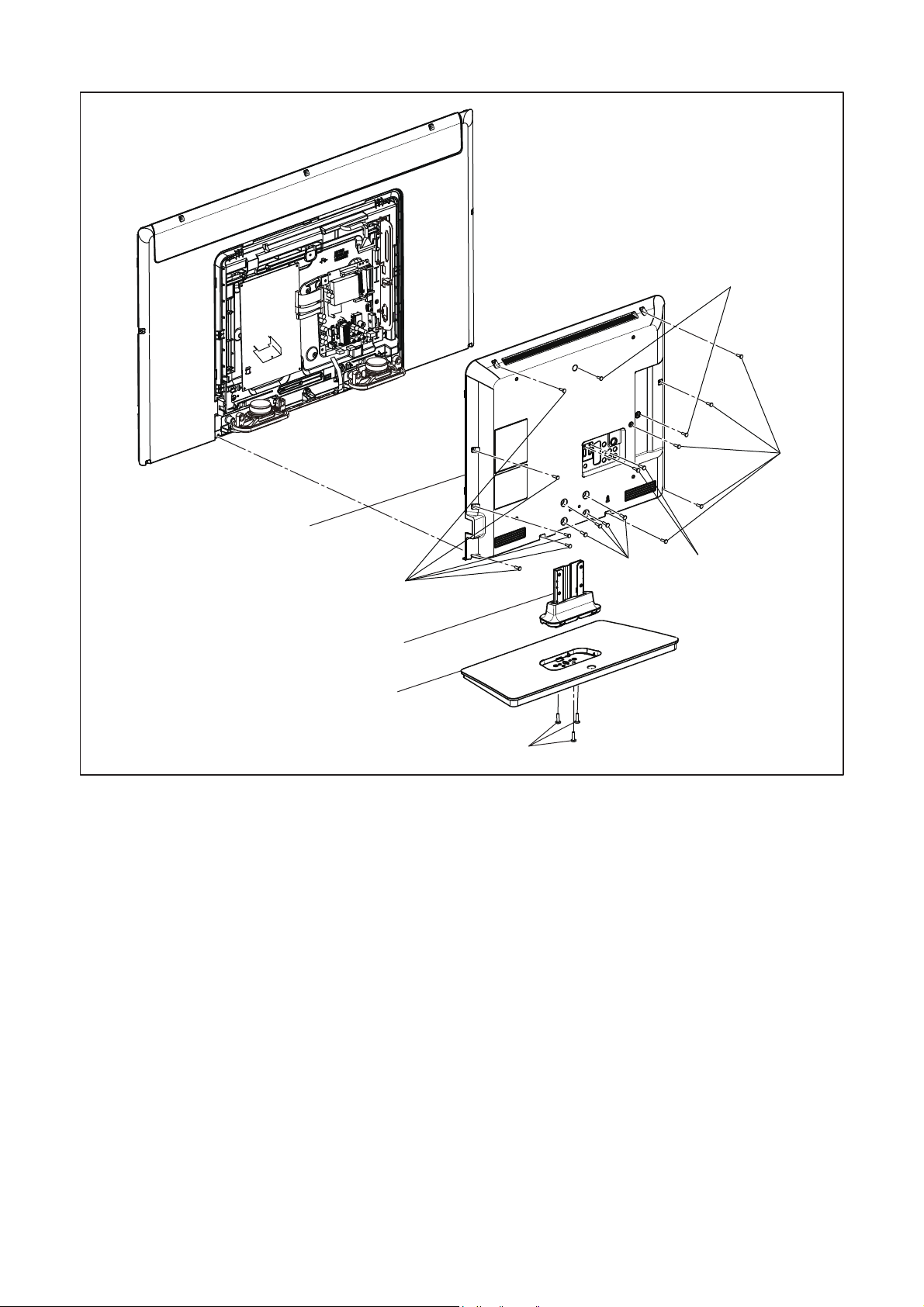

CABINET DISASSEMBLY INSTRUCTIONS

[2] Stand Base

Assembly

[3] Rear Cover

[4] Power Supply

CBA

[6] Stand Bracket

[7] Speaker

[5] Digital Main

CBA Unit

[8] LCD Panel

Assembly

[9] X-PCB Cover

[1] Stand Neck

Assembly

[10] Front Cabinet

[11] Function

CBA Unit

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts and the CBA in order to gain access to

items to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

2. Disassembly Method

Step/

Loc.

No.

[1]

[2]

[3] Rear Cover D1 4(S-3), 10(S-4) ---

[4]

[5]

[6]

[7] Speaker D3 --------------- ---

[8]

[9]

[10]

[11]

(1)

Part

Stand Neck

Assembly

Stand Base

Assembly

Power

Supply

CBA

Digital Main

CBA UnitD2D5

Stand

Bracket

LCD Panel

Assembly

X-PCB

Cover

Front

Cabinet

Function

CBA Unit

(2)

Fig.

No.

Removal Note

D1 4(S-1), 3(S-2) ---

D1 --------------- ---

5(S-5), CN101,

D2

CN102, CN103,

D5

CN104, CN105

4(S-6), CN7, CN12,

CN18, Jack Holder

D3 2(S-7) ---

D3 --------------- ---

D4 3(S-8) 1

D4 4(S-9) 2

Sensor Lens, Shield

D4

Plate, Control Plate

(3)

(4)

---

---

2

(5)

Note:

(1) Order of steps in procedure. When reassembling,

follow the steps in reverse order. These numbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

H = Hex Screw, CN = Connector

e.g. 2(S-2) = two Screws of (S-2),

2(L-2) = two Locking Tabs of (L-2)

(5) Refer to the following "Reference Notes in the

Ta bl e ."

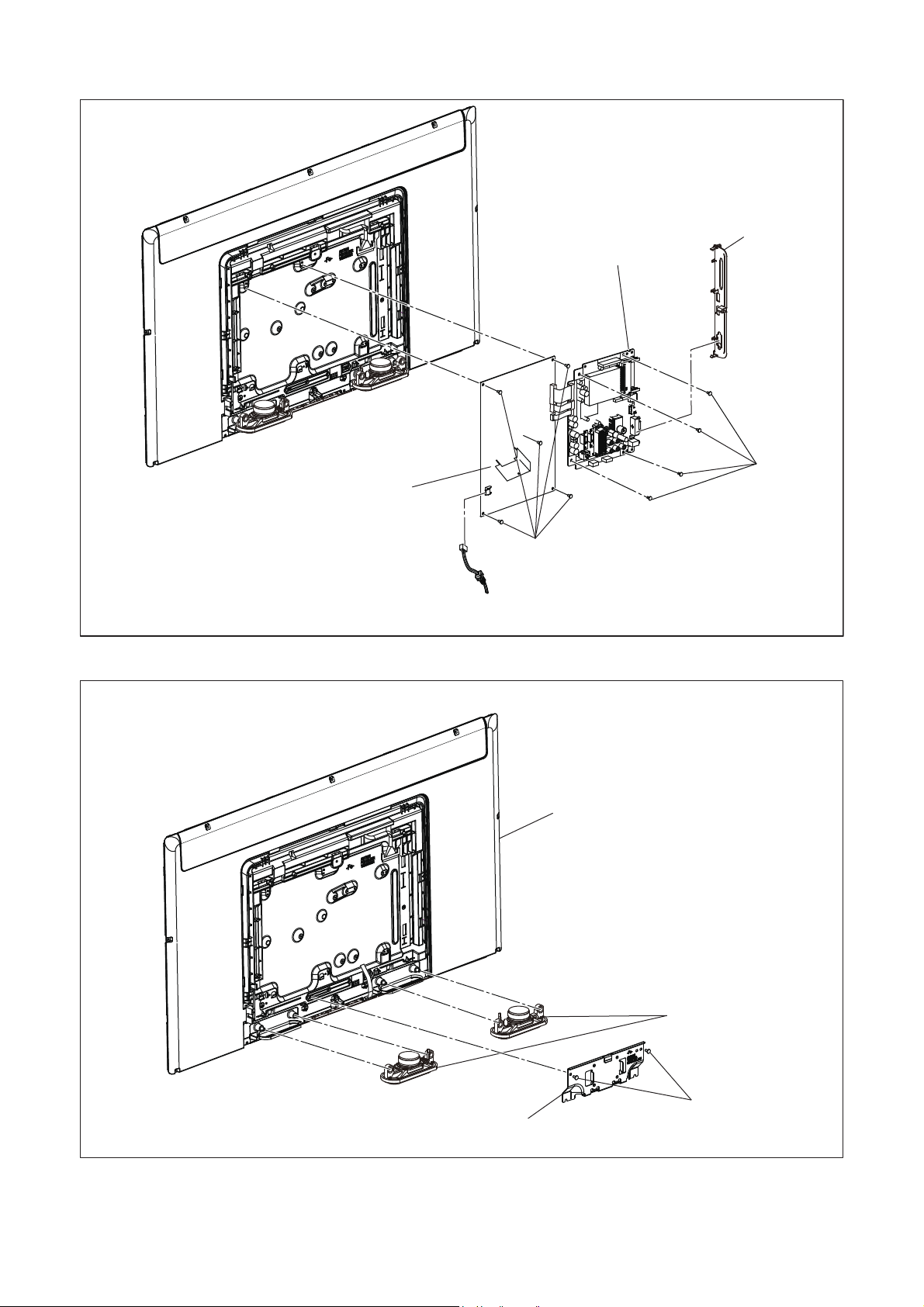

Important precautions concerning the

LCD Panel Assembly:

1. When you disassemble/re-assemble the X-PCB

Cover

• Be careful not to break the hooks. If you pull with too

much force, the hooks may be damaged.

• When disassembling, first hold the top and bottom of

the X-PCB Cover on both ends and then moving

toward the center, lift up the top side to detach the

hooks.

• When assembling, be careful not to damage the

X-PCB Board or the COF(Chip On Film).

• Make sure the hooks are securely in place when

re-assembling.

• The screw tightening torque must be 5.2lb·in

(6kgf·cm).

2. When you disassemble/re-assemble the Front

Cabinet or Function CBA Unit

• Be careful not to break the hooks. If you pull with too

much force, the hooks may be damaged.

• When disassembling, first detach the hooks on each

end on the bottom side, then detach the remaining

hooks moving toward the center.

• Make sure the hooks are securely in place when

assembling.

• Be careful not to scratch the display panel when

assembling.

• The Function CBA Unit and Sensor Lens are fixed in

place by the hooks. Make sure these hooks are not

damaged. Make sure the Function CBA Unit and

Sensor Lens are securely in place when

re-assembling.

• The screw tightening torque must be 5.2lb·in

(6kgf·cm).

• After replacing the Front Cabinet or Function CBA

Unit, make sure the tact switches operate normally.

• Make sure to replace the Control Plate to a new one

when replacing the Front Cabinet.

4-1 A33T1 DC

Page 13

(S-2)

[2] Stand Base Assembly

(S-3)

(S-4)

(S-3)

[1] Stand Neck Assembly

(S-4)

(S-1)

[3] Rear Cover

Fig. D1

4-2 A33T1 DC

Page 14

[4] Power Supply CBA

[7] Speaker

[8] LCD Panel Assembly

[6] Stand Bracket

(S-7)

Fig. D3

Jack Holder

[5] Digital Main CBA Unit

(S-6)

(S-5)

Fig. D2

4-3 A33T1 DC

Page 15

[11] Function CBA Unit

*

2

(S-9)

Sensor Lens

Control Plate

*

2

[10] Front Cabinet

*

2

Shield Plate

Hook

*

2

Hook

*

2

Hook

*

2

Hook

*

2

[9] X-PCB Cover

*

1

(S-8)

Hook

*

1

Fig. D4

*1: Make sure to read all the precautions on page 4-1 when you disassemble/re-assemble the

X-PCB Cover.

*

2

: Make sure to read all the precautions on page 4-1 when you disassemble/re-assemble the Front

Cabinet or Function CBA Unit.

4-4 A33T1 DC

Page 16

TV Cable Wiring Diagram

Power Supply CBA

Function CBA Unit

To LCD Panel

Assembly

To LCD Panel

Assembly

To AC Cord

To Speaker

Digital Main

CBA Unit

CN7CN18

CN12

CN3

CN105

CN101

CN104

CN103

CN102

CN4

CN5

CN17

Fig. D5

4-5 A33T1 DC

Page 17

ELECTRICAL ADJUSTMENT INSTRUCTIONS

0

1

2

3

4

5

6

7

8

9

10

11

12

White Balance

Aging Mode

Picture

Sound

General

Debug

EMC

System Info

Upgrade

Init fac channel tbl

Init TV

ADC Adjust

Factory Reset

>>>

>>>

->

->

->

->

->

->

->

>>>

>>>

->

>>>

T.MSD309.B95X

0xAE1E

2013-01-30 16:02:15

Main board

Checksum

Build Time

Factory Settings

General Note: “CBA” is abbreviation for

“Circuit Board Assembly.”

Note: Electrical adjustments are required after

replacing circuit components and certain

mechanical parts. It is important to perform

these adjustments only after all repairs and

replacements have been completed.

Also, do not attempt these adjustments unless

the proper equipment is available.

Test Equipment Required

1. Remote control unit

2. Color Analyzer,

CA-310 (KONICA MINOLTA Luminance meter) or

measuring instrument as good as CA-310.

How to set up the service mode:

Service mode:

1. Turn the power on.

2. Press [SOURCE], [2], [5], [8] and [0] buttons on

the remote control unit in this order to enter the

service mode. The Factory Setting menu appears

in the screen.

Example:

5-1 LC11P(A33M1_M0EP)EA

Page 18

The White Balance Adjustment should be

INPUT SIGNAL

Color Analyzer

Perpendicularity

To avoid interference from ambient

light, this adjustment should be

performed in a dark room.

INPUT: WHITE 70%, 40%

L = 1 cm

performed when replacing the LCD Panel

or Digital Main CBA.

1. White Balance Adjustment

Purpose: To mix red and blue beams correctly for

pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

1. Operate the unit for more than 60 minutes.

2. Input the White Raster of composite video signal

to AV (70%=70IRE, 40%=40IRE).

3. Enter the service mode.

4. Press [0] button on the remote control unit to

display the “White Balance” menu.

Additional step:

A1. Press [2] button on the remote control unit to

select the “Colour Temp” menu.

A2. Press [s] or [B] button to select the "Normal".

5. Select a color mode (“3 R-GAIN”, “5 B-GAIN”,

“6 R-OFFSET” or “8 B-OFFSET”).

6. Set the color analyzer at the CHROMA mode and

zero point calibration. Bring the optical receptor

pointing at the center of the LCD-Panel.

Note: The optical receptor must be set

perpendicularly to the LCD Panel surface.

7. In each color mode, press [s] or [B] button to

adjust the color temperature becomes 12000°K

=

0.272 / y= 0.278 ±0.015).

(x

8. To cancel or to exit from the White Balance

Adjustment, press [BACK] button.

5-2 LC11P(A33M1_M0EP)EA

Page 19

HOW TO INITIALIZE THE LCD TELEVISION

1. Turn the power on.

2. Enter the service mode. (Refer to page 5-1.)

- To cancel the service mode, press [BACK]

button on the remote control unit.

3. Select “Factory Reset” and [OK] button on the

remote control unit.

The TV set will go off and turn back on

automatically when initialization completes.

6-1 LC11P_INT

Page 20

FIRMWARE RENEWAL MODE

Equipment Required

a. USB storage device

b. Remote Control Unit

Firmware Update Procedure

[Preparation]

1. Prepare USB storage device.

2. Copy F/W-file to USB storage device.

Note: Make sure to use the blank USB Storage.

3. Make sure that the F/W-file’s name is

“LC11_308B_FUNAI.bin”.

[Update procedure]

1. Turn the power on.

2. Insert USB storage device with F/W to TV set.

3. Press the [MENU] button on the remote control

unit to display Menu.

4. Select “SETUP”.

5. Select “Software Update (USB)” and press [OK]

button.

The message “Are you sure?” will appear in the

screen.

6. Press [LEFT] button to select “YES”.

7. Updating starts.

Note: Do not turn off the TV set and do not

remove the USB storage device while this

procedure.

8. The TV set will go off and turn back on

automatically when update completes.

Additional step:

A1. Enter the service mode.

A2. Select "Init TV" and press [OK] button.

The TV set will go off and go back on

automaticaly.

A3. Adjust the white balance.

[Confirmation of update]

1. Enter the service mode. (Refer to page 5-1.)

2. Check the “Checksum” section.

7-1 LC11P_FW

Page 21

[Power Supply Section]

FLOW CHART NO.1

The power cannot be turned on.

TROUBLESHOOTING

Is the fuse (F602) normal?

Ye s

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

Ye s

Is the P-ON+21V line voltage normal?

Ye s

Check each rectifying circuit of the secondary

circuit and repair it if defective.

FLOW CHART NO.2

The fuse blows out.

Check if there is any leak or short-circuit on the

primary circuit component and repair it if defective.

Make sure to repair the primary circuit component before replacing the fuse (F602).

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuit on the

primary circuit component and repair it if defective.

(C608, D601, D602, D603, D604, D605, D608,

D609, D612, D615, D618, D622, D623, IC601,

IC602, Q601, Q602, Q603, R603, R604, T601)

Check if there is any leak or short-circuit on the

each rectifying circuit component of secondary side

and repair it if defective.

FLOW CHART NO.3

When the output voltage fluctuates.

Does the photocoupler circuit on the

secondary side operate normally?

Ye s

Check D608, D609, D612, D618, D622, D623, IC601,

IC602, Q601, Q602, Q603 and their periphery circuit.

Repair it if defective.

FLOW CHART NO.4

When buzz sound can be heard in the periphery of power circuit.

Check if there is any short-circuit on the rectifying diode and the circ

Repair it if defective. (D401, D402, D403, D501, D502, D503, D509, D510, IC501, Q403, Q701)

No

Check D504, IC301, IC601 and their periphery

circuit. Repair it if defective.

uit in each rectifying circuit of the secondary side.

8-1 A33T1TR

Page 22

FLOW CHART NO.5

P-ON+21V is not output.

Is approximately +21V voltage supplied to the cathode

of D501(D502, D503, D509, D510)?

Ye s

Check if there is any leak or short-circuit on the load

circuit. Repair it if defective.

FLOW CHART NO.6

AMP+13V is not output.

Is approximately +14V voltage supplied to the cathode

of D401(D402, D403)?

Ye s

Check if there is any leak or short-circuit on the load

circuit. Repair it if defective.

FLOW CHART NO.7

P-ON+13V is not output.

Is approximately +14V voltage supplied to the drain of

Q701?

Ye s

Is approximately +16V voltage supplied to the gate of

Q701?

Ye s

No

No

No

No

Check C502, C503, C504, C513, D501, D502, D503,

D504, D509, D510 and their periphery circuit.

Repair it if defective.

Check C402, C403, C407, C408, D401, D402, D403

and their periphery circuit. Repair it if defective.

Check C402, C403, C407, C408, D401, D402, D403

and their periphery circuit. Repair it if defective.

Check IC701, Q702, Q703, PS-ON line and their

periphery circuit. Repair it if defective.

Replace Q701.

FLOW CHART NO.8

PANEL+5V(+5V) is not output.

Is approximately +21V voltage supplied to Pin(8) of

IC501?

Ye s

Is approximately +2V voltage supplied to Pin(7) of

IC501?

Ye s

Replace IC501.

FLOW CHART NO.9

STB+5V is not output.

Is approximately +11V voltage supplied to the drain of

Q403?

Ye s

Is approximately +8V voltage supplied to the gate of

Q403?

Ye s

No

No

No

No

Check C502, C503, C504, C513, D501, D502, D503,

D504, D509, D510 and their periphery circuit.

Repair it if defective.

Check D507 and their periphery circuit.

Repair it if defective.

Check C402, C403, C407, C408, D401, D402, D403

and their periphery circuit. Repair it if def

Check IC402, R404, R407, R409 and their periphery

circuit. Repair it if defective.

ective.

Replace Q403.

8-2 A33T1TR

Page 23

[Video Signal Section]

FLOW CHART NO.1

The key operation is not functioning.

When pressing each buttons, does the Pin(6) voltage

of CN7 decrease?

Ye s

Replace the Digital Main CBA Unit.

FLOW CHART NO.2

No operation is possible from the remote control unit. (Operation is possible from the unit.)

Is approximately +5V voltage supplied to Pin(1) of

CN7?

Ye s

Is the "L" pulse supplied to Pin(4) of CN7 when the

infrared remote control is activated?

Ye s

Replace the Digital Main CBA Unit.

No

No

No

Replace the Function CBA Unit.

Check STB+5V line and repair it if defective.

Replace the Function CBA Unit or the remote control

unit.

FLOW CHART NO.3

Picture does not appear normally.

Is approximately +5V voltage supplied to Pin(1) of

CN104?

Ye s

Is

approximately +

CN103?

approximately +

Is

of CN104?

Digital Main CBA Unit or LCD Panel Assembly may

be defective.

Check and replace these parts.

13V voltage supplied to Pin(1, 2) of

Ye s

5V voltage supplied to Pin(5, 6, 7, 8)

Ye s

No

No

No

See FLOW CHART NO.9 <STB+5V is not output.

[Power Supply Section]>

See FLOW CHART NO.7 <P-ON+13V is not output.

[Power Supply Section]>

See FLOW CHART NO.8 <PANEL+5V(+5V) is not

output. [Power Supply Section]>

8-3 A33T1TR

Page 24

[Audio Signal Section]

FLOW CHART NO.1

Audio is not output normally.

Is approximately +5V voltage supplied to Pin(1) of

CN104?

Ye s

Is approximately +14V voltage supplied to Pin(1, 2) of

CN102?

Ye s

approximately +

Is

of CN104?

Are the audio signals output to Pin(1, 2, 3, 4) of CN18?

SP3801, SP3802 or CL18 may be defective.

Check and replace these parts.

5V voltage supplied to Pin(5, 6, 7, 8)

Ye s

Ye s

No

No

No

No

See FLOW CHART NO.9 <STB+5V is not output.

[Power Supply Section]>

See FLOW CHART NO.6 <AMP+13V is not output.

[Power Supply Section]>

See FLOW CHART NO.8 <PANEL+5V(+5V) is not

output. [Power Supply Section]>

Replace the Digital Main CBA Unit.

8-4 A33T1TR

Page 25

BLOCK DIAGRAMS

1. System Control Block Diagram

POWER SOURCE

MENU

TO LED BACKLIGHT DRIVE

TO POWER SUPPLY

BLOCK DIAGRAM

BLOCK DIAGRAM

RE1

SENSOR

REMOTE

CH + CH - VOL+

KEY-SW

VOL-

POWER

D15

LED-R 22

IR-KEY 66

REMOTE 44

CN7 CN3

SCL

SDA

T1 (TUNER UNIT)

4

3

FUNCTION CBA UNIT

STB+5V

QE22

QE21

PS-ON

CN104

PS-ON

22

CN4

M+5V

STB+3.3V

BACKLIGHT-SW

BACKLIGHT-ADJ

POWER SUPPLY CBA

CN103

BACKLIGHT-SW

BACKLIGHT-ADJ

3 3

4 4

CN5

QB1

QB12

QB11

U1

(MAIN MICRO CONTROLLER)

J5

REMOTE

T8

J14

KEYA

LED-R

AMP-MUTE

L20

AMP-MUTE

TO AUDIO

BLOCK DIAGRAM

W4

TUNER-SCL

9-1

W5

TUNER-SDA

(MEMORY)

UF11

SPI-SDO

SPI-SCK

SPI-SDI

A3

B3

B4

6 5 2

SI

SO

SCK

L5

POW-EN

SPI-CSN

L6

1

CS#

QF31

Y1

RESET

H6

RESET

XTAL-IN

XTAL-OUT

Y4

AA4

24MHz

OSC

K6

BL-EN

V17

PWM1

V16

PWM2

DIGITAL MAIN CBA UNIT

A33T1BLS

Page 26

2. Video Block Diagram

AUDIO SIGNAL

TO DIGITAL SIGNAL

PROCESS

BLOCK DIAGRAM

IF_P

IF_N

IF-AGC

VIDEO SIGNAL

VIDEO-B

VIDEO-R

VIDEO-G

RGB-VIDEO-IN

RGB-VIDEO-OUT

TO DIGITAL SIGNAL

PROCESS

BLOCK DIAGRAM

VIDEO-IN

COM-Y-IN

COM-Pb-IN

COM-Pr-IN

(TUNER UNIT)

T1

8

IF_P

7

IF_N

DIGITAL MAIN CBA UNIT

BUFFER

QS1, QS2

7

15

20

11

VIDEO-B

VIDEO-G

19

RGB-VIDEO-OUT

AV11

VIDEO-IN

CN8

COMPONENT

-Y IN

COMPONENT

-Pr-IN

COMPONENT

-Pb-IN

AV8

SCART JACK

IF-AGC 9

VIDEO-R

RGB-VIDEO-IN

9-2

A33T1BLV

Page 27

3. Audio Block Diagram

AUDIO SIGNAL

TO DIGITALSIGNAL

PROCESS

BLOCK DIAGRAM

SPDIF

AUDIO(L)

AUDIO(R)

PC-AUDIO(L)

PC-AUDIO(R)

RGB-AUDIO(L)-OUT

AMP(L)-OUT

RGB-AUDIO(L)-IN

RGB-AUDIO(R)-IN

RGB-AUDIO(R)-OUT

AMP(R)-OUT

TO SYSTEM

CONTROL

BLOCK DIAGRAM

AMP-MUTE

AMP+13V

QA31

DIGITAL MAIN CBA UNIT

BUFFER

QS3, QS4

BUFFER

QS5, QS6

3

PWM

(AUDIO AMP)

L+DRIVE

UA31

25,26

12

PWM

L-DRIVE

R+DRIVE

17,18

22,23

QA32

1,2

MUTE

R-DRIVE

20,21

CN18

3

4

2

1

AV27

DIGITAL

AV11

AUDIO-OUT

(COAXIAL)

AUDIO(L)-IN

AUDIO(R)-IN

AV7

PC-AUDIO-IN

AV8

SCART JACK

6RGB-AUDIO(L)-IN

2

RGB-AUDIO(R)-IN

1

3

RGB-AUDIO(L)-OUT

RGB-AUDIO(R)-OUT

9-3

JACK

AV30

HEADPHONE

SP(L)+

SP3801

SPEAKER

SP(L)-

L-CH

SP(R)-

SP(R)+

SP3802

SPEAKER

A33T1BLA

R-CH

Page 28

4. Digital Signal Process Block Diagram

LCD PANEL

ASSEMBLY

RXO0(-)

RXO0(+)

RXO1(-)

RXO1(+)

RXO2(-)

RXO2(+)

RXOC(-)

RXOC(+)

RXO3(-)

RXO3(+)

RXE0(-)

RXE0(+)

RXE1(-)

RXE1(+)

RXE2(-)

RXE2(+)

RXEC(-)

RXEC(+)

RXE3(-)

RXE3(+)

RXO4(-)

RXO4(+)

RXE4(-)

RXE4(+)

8

7

CN12

9

11

10

18

20

21

22

17

16

15

12

23

19

30

37

38

28

27

24

29

40

39

7 9 4 6 1

TMDS-D0(-)

TMDS-D1(-)

TMDS-D0(+)

TMDS-D1(+)

35

34

37

AV3

HDMI-IN3

3

TMDS-D2(-)

TMDS-D2(+)

TMDS-CLOCK(+)

36

39

38

10

12

16

15

SCL

SDA

TMDS-CLOCK(-)

7

8

33

32

AUDIO SIGNAL

VIDEO SIGNAL

P19

P20

R21

R20

T21

R19

A/D

T19

SW

CONVERTER

T20

U19

U20

W21

LVDS

V19

TX

Y21

W20

Y20

W19

Y19

AA20

W18

SIGNAL

DIGITAL

CI CONTROL

AA19

V20

V21

PROCESS

DESCRAMBLER

/TS INTERFACE

Y18

AA18

TO VIDEO

RGB-VIDEO-OUT

U3

DAC

DEMODULATOR

/MPEG DECODER

BLOCK DIAGRAM

(SDRAM)

DQU(0-7)

DQL (0-7)

U2

A-MDQU(0-7)

A-MDQL (0-7)

AUDIO I/F

A(0-13)

MA-A(0-13)

H20

I2C_SDA

Sil1292

U18

H19

I2C_SCL

AUDIO

MHL/

HDMI-to-HDMI

25

24

27

Y6

AA7

AA6

VIDEO

DECODER

DECODER

Bridge

26

29

W7

W6

28

23

Y7

AA5

HDMI I/F

22

Y5

MHL_SCL

MHL_SDA

18

17

U8

V8

DIGITAL MAIN CBA UNIT

HDMI SW

U1 (DIGITAL SIGNAL PROCESS)

T2

L1

R2

VIDEO-IN

COM-Y-IN

L2

L3

M1

COM-Pb-IN

COM-Pr-IN

TO VIDEO

BLOCK

DIAGRAM

J2

K2

VIDEO-G

VIDEO-R

J3

T3

P3

VIDEO-B

RGB-VIDEO-IN

RED

GREEN

PC-RGB-IN

AV6

1

N3

2

M2

BLUE

3

PC-HS

PC-VS

P2

P1

VSYNC

HSYNC

14

13

DATA

VGA-SDA

VGA-SCL

V7

U7

CLOCK

12

15

CI-D(0-7)

AV20

CI

CARD

CI-A(0-14)

SLOT

W2

IF_P

TO VIDEO

W1

IF_N

IF-AGC

DIAGRAM

BLOCK

IF-AGC

V2

U4

AUDIO(L)

AUDIO(R)

9-4

U5

U1

PC-AUDIO(L)

U6

AA2

PC-AUDIO(R)

RGB-AUDIO(L)-OUT

RGB-AUDIO(R)-OUT

TO AUDIO

BLOCK

T6

T7

Y2

RGB-AUDIO(L)-IN

RGB-AUDIO(R)-IN

DIAGRAM

Y3

H15

AA3

AMP(R)-OUT

AMP(L)-OUT

SPDIF

H3

G3

F2

TMDS-D1(-)

TMDS-D0(-)

TMDS-D0(+)

TMDS-D1(+)

7

9

4 6 1

H1

H2

G2

TMDS-D2(+)

TMDS-D2(-)

TMDS-CLOCK(+)

3

HDMI-IN1

AV1

F3

F1

C5

D5

SCL

SDA

TMDS-CLOCK(-)

10

12

16

15

E3

D3

C2

TMDS-D1(-)

TMDS-D0(-)

TMDS-D0(+)

TMDS-D1(+)

7

9

4 6 1

E1

E2

E2

C1

TMDS-D2(+)

TMDS-D2(-)

TMDS-CLOCK(+)

TMDS-CLOCK(-)

3

10

HDMI-IN2

AV2

A33T1BLD

C3

C4

D4

SCL

SDA

12

16

15

Page 29

5. LED Backlight Drive Block Diagram

LCD PANEL

ASSEMBLY

VLED11

ILED13

ILED24

ILED35

ILED47

ILED58

ILED69

CN105

VLED211

OVP

IC1001

(LED BACKLIGHT DRIVER)

10

Q1001

2

3

DRIVE

DRIVE

CONTROL

161413

LOGIC

1

5

DRIVE

IC1002

(LED BACKLIGHT DRIVER)

Q1002

2

3

5

DRIVE

DRIVE

DRIVE

CONTROL

LOGIC

OVP

10

161413

1

POWER SUPPLY CBA

P-ON+21V

BACKLIGHT-SW

TO

BACKLIGHT-ADJ

SYSTEM CONTROL

BLOCK DIAGRAM

9-5

A33T1BLLD

Page 30

6. Power Supply Block Diagram

AMP+13V

P-ON+13V

M+5V

STB+5V

PANEL+5V

P-ON+21V

TO SYSTEM CONTROL

BLOCK DIAGRAM

DIGITAL MAIN CBA UNIT

CN17

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

CN102

Q701

7

1,2 AMP+13V 1,2

SW+13V

IC701

SW

Q702

8

1,2 P-ON+13V 1,2

CN5

CN103

SHUNT

9

10

REG.

PS-ON

1 STB+5V 1

5-8 +5V 5-8

CN104 CN4

DLOC TOH

SW+5V

IC501

SW+5V

Q403

11

12

IC402

REG.

SHUNT

Q703

Q301

REG.

SHUNT

IC301

1 4

T601

6

5

BRIDGE

RECTIFIER

D601-D604

LINE

FILTER

L603

LINE

FILTER

L601

F602

T3.15A H/250V

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F602) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

HOT CIRCUIT. BE CAREFUL.

CN101

AC601

AC CORD

B

W

2

4

IC602

(SWITCHING CONTROL)

1

Q601

VH

IC601

SWITCHING

5 8 3

IS

OUT

(FEED BACK)

3 2

SWITCHING

Q602

2

6

FB

VCC

POWER SUPPLY CBA

9-6

A33T1BLP

Page 31

SCHEMATIC DIAGRAMS / CBA AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “!” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in F

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

6. Electrical parts such as capacitors, connectors,

diodes, IC’s, transistors, resistors, switches, and

fuses are identified by four digits. The first two

digits are not shown for each component. In each

block of the diagram, there is a note such as

shown below to indicate these abbreviated two

digits.

3

, M = 106).

-6

F).

10-1 LCDP_SC

Page 32

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

2

3

1

5.0 5.0

Voltage

Indicates that the voltage

is not consistent here.

Power on mode

(Unit: Volt)

3

2

1

ABCD

1-B1

1-D3

AREA D3

AREA B1

1-D3

Distinction Area

Line

Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line number

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE

FUSE.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F602) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications on the schematics are as shown below:

Plug the TV power cord into a standard AC outlet.:

5. How to read converged lines

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

The reference number of parts on Schematic Diagrams/CBA can be retrieved by

application search function.

10-2 LCDP_SC

Page 33

Power Supply 1 Schematic Diagram

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F602) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

4

3

2

1

HOT CIRCUIT. BE CAREFUL.

AC601

CN101

AC CORD

W

B

R623

1M

R624

1M

R625

1M

R626

620K

F602

T3.15A L/250V

D622

TFZGTR39B

D623

TFZGTR39B

324.0

D

C609

150P

/2KV

R613

0.12

/1/3W

R611

0.15

/1/3W

BC602

BEAD

BC605

BEAD

BC606

BEAD

BC607

BEAD

0.1

S

G

4.8

D612

1ZB36BB

SA601

VARISTOR

C601

0.47/250V

L601

LINE FILTER

C602

0.47/250V

L603

LINE FILTER

D616

1N4007

16.9

R628

C622

1.5M

0.1

Q601

TK5A65D

(SWITCHING)

D609

TFZGTR27B

C611

1

C612

1000P

R617

3.3K

R610

0.12

/1/3W

R612

0.15

/1/3W

G

C613

150P

D606

1N4007

R627

100/2W

35.5

D

S

19.9

D601

1N5408BH

D602

1N5408BH

R629

0

Q603

2SK3471

(SWITCHING)

R605

270

R606

D610

47

RS1GJTB

IC602

FA8A00N

SWITCHIG

CONTROL

1.2

ZCD

0.8

2

FB

0.1

3

IS

0

4

GND OUT

C614

D613

0.1

TFZGTR27B

C606

100

/450V

BC601

BEAD

VCC

D604

1N5408BH

D603

1N5408BH

R615

6.8K

C607

100

/450V

263.0

81

VH

7

NU

16.9

6

5.4

5

Q602

TK3P50D

(SWITCHING)

5.4 304.0

C617

10

R602

1.2/5W

R616

1.2/5W

R604

R603

20K

20K

/2W

/2W

D605

RS1JJTB

D615

RS1JJTB

C624

150P/2KV

DS

G

R621

0

10K

R622

10K

D618

EDZTE6120B

C621

470P/250V

C618

470P/250V

C605

470P/250V

C604

470P/250V

T601

POWER TRANS

6

C608

2200P

/1KV

5

4

2

1

D608

RS1GJTB

IC601

TLP781F

ERROR

VOLTAGE DET

0.8 20.4

4

0

32

C615

1000P/1KV

HOT

7

8

9

10

11

12

1

19.3

COLD

19.3

0

R303

2.2K

D401

SB3A0BH

D402

SB3A0BH

D403

SB3A0BH

D501

SB3150BH

D502

SB3150BH

D503

SB3150BH

D509

SB3150BH

D510

SB3150BH

C501

2200P

R511

/1KV

20

R512

20

R302

240

C303

0.1

2.5

IC301

SN431A-AT

ERROR

VOLTAGE DET

R301

240

R305

10K

POWER SUPPLY CBA

C403

C402

470/25V

C502

470/25V

R306

10K

R307

10K

R308

2.7K

470/25V

C503

470/25V

C407

470/25V

C504

470/25V

C408

470/25V

C513

470/25V 1ZB27BB

D504

D301

HSC119

BC501

BEAD

0

Q301

KTC3875S

-Y-RTK/P

(SWITCHING)

0

F501

0

R311

22K

R312

2.7K

0.7

C51510C516

10

R410

22/2W

R404

1K

R701

10K

Q703

KTC3875S

-Y-RTK/P

(SWITCHING)

R313

2.7K

R413

22/2W

20.6 20.9

Q702

19.9

KTA1504S

-Y-RTK/P

(SWITCHING)

R703

10K

0

0.7

0

R314

10K

D507

MM5Z18B

R504

100K

R503

100K

Q403

FDD5612

(SW+5V)

R710

0.47/2W

R702

1.8K

R704

2.7K

C507

0.22

R505

51

C508

0.01

11.3 5.0

DS

G

7.8

C404

0.1

7.8

2.5

IC402

0

SN431A-AT

SHUNT

REG.

14.4

DS

Q701

G

FDD5612

(SW+12V)

15.8

R711

22K

0

R705

10K

D508

CMS03

C506

0.1

0.3

0.1

C517

1

R426

0

12.9

15.8

C703

0.1

2.5

IC701

SN431A-AT

SHUNT

REG.

C701

0.1

R510

D505

16

CMS03

C518

150P

IC501

MP2482DN-LF-Z

(+5V REG.)

IN

SW

81

EN

BST

2

3

4

VCC

GND FB

R407

10K

R409

10K

R706

0

PG

R708

39K

R709

3K

R707

10K

7

6

5

20.6

1.9

5.0

0.80

L501

33uH

C405

100/10V

R513

100K

C511

10

C512

330/10V

R506

1.5K

R507

39K

R508

3K

R509

4.7K

D506

1ZB11BB

P-ON+21V

BACKLIGHT-ADJ

BACKLIGHT-SW

TO DIGITAL MAIN

CN102

CBA UNIT CN17

14.4

1 AMP+13V

14.4

2 AMP+13V

0

3 GND

0

4 GND

TO DIGITAL MAIN

CN103

CBA UNIT CN5

12.8

1 P-ON+13V

12.8

2 P-ON+13V

5.0

3 BACKLIGHT-SW

5.0

4 BACKLIGHT-ADJ

0

5 GND

0

6 GND

TO DIGITAL MAIN

CN104

CBA UNIT CN4

5.0

1 STB+5V

5.0

2 PS-ON

0

3 GND

0

4 GND

5.0

5 +5V

5.0

6 +5V

5.0

7 +5V

5.0

8 +5V

0

9 GND

10 NU

CONTINUE

POWER 2

A

10-3

FBCDE

G

A33T1SCP1

Page 34

Power Supply 2 Schematic Diagram

4

3

TO LCD PANEL

ASSEMBLY

CN105

51.0

1VLED1

2NU

0.6

3ILED1

0.5

4ILED2

0.6

5ILED3

6NU

0.7

7ILED4

0.5

8ILED5

0.7

9ILED6

10NU

51.0

11VLED2

R1016

0

R1017

0

R1018

0

C1038

1000P

R1019

330

R1020

13K

R1013

510K

R1014

430K

R1015

27K

R1021

100K

IC1001

HA7209PC

LED BACKLIGHT

DRIVER

4.5

1

0.6

2

0.5

3

0

4

0.6

5

0

6

GND

0

7

0

8

0

9

1.4

10

OVP

1.3

11

ISET

1.0

12

RT

C1007

47/100V

DRIVE

DRIVE

DRIVE

DRIVE

DRIVE

DRIVE

DRIVE

C1008

47/100V

DRIVE

CONTROL

LOGIC

C1010

1/100V

NU

COMP

MCP

SEL

VIN

GND

LDO

D1001

SK210TD

C1011

1/100V

R1005

R1008

200

100K

D1002

HSC119

R1035

1K

0

24

23

22

21

20

19

18

17

16

15

14

13

1.6

0

4.9

17.6

0

4.9

0

0.1

4.4

R1010

100

R1012

0

C1019

4.7

C1020

1

R1042

240

C1018

0.1

R1006

240

R1009

10

C1022

1000P

C1017

1000P

L1001

22uH

R1045

10

C1041

220P/100V

D

Q1001

AP18T10AGH-HFG

(SWITCHING)

S

0.2

R1007

0.18/1W

10KR1003

C1001

330

/25V

C1002

330

/25V

C10031C1004

1

C1006

1

R1004

100K

R1002

10K

CONTINUE

POWER 1

P-ON+21V

BACKLIGHT-ADJ

BACKLIGHT-SW

2

1

R1022

0

R1023

0

R1024

0

C1031

1000P

R1029

330

R1030

13K

R1025

510K

R1026

430K

R1027

27K

R1031

100K

IC1002

HA7209PC

LED BACKLIGHT

DRIVER

4.4

1

0.7

2

0.5

3

0

4

0.7

5

0

6

GND

0

7

0

8

0

9

1.4

10

OVP

1.3

11

ISET

1.1

12

RT

C1015

47/100V

DRIVE

DRIVE

DRIVE

DRIVE

DRIVE

DRIVE

DRIVE

C1016

47/100V

DRIVE

CONTROL

LOGIC

C1012

1/100V

NU

COMP

MCP

SEL

VIN

GND

LDO

D1003

SK210TD

C1013

1/100V

R1028

0

R1047

1K

0

24

23

22

21

20

19

18

17

16

15

14

13

1.5

0

4.9

17.6

0

4.9

0

0.1

4.4

R1036

100

R1033

0

C1029

4.7

C1027

1

R1040

240

C1028

0.1

R1032

0

R1041

240

D1004

HSC119

R1037

10

C1024

1000P

C1025

1000P

R1038

200

L1002

22uH

R1046

10

C1040

220P/100V

D

Q1002

AP18T10AGH-HFG

(SWITCHING)

S

0.2

R1039

0.18/1W

C1023

1

POWER SUPPLY CBA

HLKJIM

10-4

A33T1SCP2

Page 35

Power Supply CBA Top View

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

Because a hot chassis ground is present in the power supply

circuit, an isolation transformer must be used when repairing.

Also, in order to have the ability to increase the input slowly,

when troubleshooting this type of power supply circuit,

a variable isolation transformer is required.

GP1005

J601

T3.15AL/250V

F602

C601

BC606

BOND

BC607

BOND

D601

C604

C605

TOOL NO

1

2

JS604

JS602

D606

JS603

D604

JS601

J606

CN101

SA601

R608

L601

C602

L603

D616

D603

34

GP1004

1

J604

BC605

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F602) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

C624

IC602

B19

BC602

J602

Q601

C608

J603

BC601

HOT

D612

R627

R603

R604

C609

C615

IC601

C618

J605

COLD

IC301

J301

D403

D402

T601

C504

D401

BA33T1F01021

GP1003

C607

R710

C408

C402

J702

J703

J701

C701

3

D602

2

R616

JS607

JS606

C621 C623

C606

HOT

R602

COLD

CN102

123

+13V AMP

+13V AMP

GND

4

GND

D502

J302

CN103

D501

J610

C513

C502

C401

C503

IC701

D503

C407

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

J1007

J1013

BC501

R410

R413

IC402

J1008

L1002

J1012

L1001

J1009

C405

CN104

R1007

J1010

J1011

J501

C512

D506

D509

C403

J401

12345

BL-SW

+13V

+13V

C1001

J403

BL-ADJ

GND

D510

J1004

6

GND

J115

J304

J1003

C501

C1043

C1042

J1006

J1005

C1002

R1039

J402

D504

J404

C1007

IC1001

J1022

C1015

IC1002

J1014

D512

D513

IC501

123456789

+5VSb

GND

+5V

PS-ON

GND

4

C1008

J1023

+5V

+5V

L501

+5V

J1001

10

GND

NC

J1020

J1018

J1017

J1016

J1024

J1021

J1015

GP1002

GP1001

CN105

10

11

J1019

C1016

D

1

VLED1

2

NC

3

ILED1

4

ILED2

ILED3

5

6

NC

7

ILED4

8

ILED5

9

ILED6

NC

VLED2

C

10-5

BA33T1F01021

Page 36

Power Supply CBA Bottom View

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

Because a hot chassis ground is present in the power supply

circuit, an isolation transformer must be used when repairing.

Also, in order to have the ability to increase the input slowly,

when troubleshooting this type of power supply circuit,

a variable isolation transformer is required.

L1001

VLED1

NC

ILED1

ILED2

ILED3

NC

ILED4

ILED5

ILED6

NC

VLED2

C

D

C1033

C1032

R1027

C1031

R1029

R1031

1

2

3

4

5

6

7

8

9

10

11

J1015

R1025

C517

CN105

R1017

C1035

R1018

R1013

J1019

C1014

C1016

R1023

R1024

GP1001

J1021

R1014

R1020

J1018

J1017

J1016

R1026

R1030

J1024

D505

D508

C514

J1020

R1016

C1013

R510

R505

C506

R507

L501

J1001

10

NC

GP1002

C1010

C1011

C1009

C1012

R1022

9

GND

C518

+5V

D512

+5V

C1008

C1041

C1036

C1037

C1038

J1023

R1015

R1019

R1021

D513

+5V

+5V

C1007

Q1001

C1015

R1046

C1034

R1028

R1047

IC1002

J1014

C507

C511

GND

GND

IC1001

R1035

J1022

Q1002

R509

2345678

PS-ON

R1045

R1009

D1002

D1003

C1040

C515

C516

D507

R504

IC501

R508

C512

1

+5VSb

D1001

J1010

C1018

C1019

C1039

R1004

J1011

C1028

F501

C1021

R1044

D1004

R1037

C1026

R1034

C1029

C1025

R1032

C508

R513

R506

D506

R1040

J501

R503

CN104

R1007

R1010

R1008

C1017

C1024

R1036

R1033

R1038

C1030

C405

C1006

C1022

J1009

R1012

BC501

R410

R413

IC402

R407

C1020

J1008

L1002

C1023

C1027

R1041

J1012

C406

C704

R1042

4

J1003

J1007

R1006

C1004

J1006

C1003

J1013

J115

C501

J1005

C1002

R1039

J402

J304

C1043

R409

R426

R512

R511

C1042

J404

J1004

C1005

C1001

D504

R404

C404

Q403

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F602) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

COLD

R307

D510

6

GND

GND

D509

J403

J401

R703

R705

BL-SW

BL-ADJ

C305

R313

+13V

C403

R701

C702

R704

R706

R709

R707

12345

+13V

R314

R502

R501

C407

IC701

R1005

R1003

R1002

D503

Q703

C503

Q702

J610

C513

C502

C401

R401

R711

CN103

R311

R312

Q301

J302

D501

R411

R702

C703

R708

D502

D401

J703

D301

R308

R301

C302

R302

C504

J701

C701

Q701

T601

R305

C304

R306

D402

C402

J702

C408

R304

C303

IC301

R303

D403

R710

J301

Q602

R621

IC601

D608

C618

C609

R627

R603

R604

J605

GP1003

HOT

BA33T1F01021

R602

COLD

234

1

GND

GND

CN102

+13V AMP

+13V AMP

3

HOT

R622

C615

D611

D615

D605

D612

BC601

C606

R623

R616

C611

C612

D621

J603

C608

JS607

R617

C613

C620

D618

JS606

J602

Q601

R607

R606

C621C623

D614

B19

R605

BC602

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

C624

IC602

C614

R613

R610

R624

C607

D602

C617

D623

2

D610

D609

C610

Q603

C622

R628

R625

BC605

R615

D613

J601

J604

R626

R619

D622

R611

R612

D601

R629

BC607

BC606

F602

CN101

C601

D616

D603

SA601

R608

L601

J606

C602

JS601

L603

D604

1

JS603

D606

JS602

JS604

GP1005

GP1004

1

2

3

4

C604

C605

TOOL NO

10-6

BA33T1F01021

Page 37

WIRING DIAGRAM

DIGITAL MAIN CBA UNIT

CN12

3

5

VCC-Panel

ILED1

4

GND

GND

ILED2

ILED3NUILED4

6

GND

2

1

CL12

VCC-Panel

VCC-Panel

VLED1

NU

123456789

CN105

8

7

RXO0(+)

RXO0(-)

ILED5

9

101513

RXO1(+)

RXO1(-)

ILED6

NU

10

12

11

RXO2(+)

RXO2(-)

VLED2

11

GND

14

GND

16

RXOC(+)

RXOC(-)

17

18

RXO3(+)

RXO3(-)

19

20

RXE0(+)

RXE0(-)

CN101

21

23

2425262728293031323334353637383940

22

RXE2(+)

RXE1(-)

W

B

RXE2(-)

RXE1(+)

GND

GND

AC601

AC CORD

RXEC(-)

RXEC(+)

RXE3(-)

RXE3(+)

GND

GND

CON1

DISPLAY

VSEL1

VSEL2

RXO4(+)

RXO4(-)

RXE4(+)

RXE4(-)

LCD PANEL ASSEMBLY

TUNER UNIT

COMPONENT

123456789

CN104

CL4

STB+5V

PS-ON

12345

CN4

-Y-IN

COMPONENT

-Pb-IN

GND

GND

PANEL+5V

PANEL+5V

6

COMPONENT

-Pr-IN

+5V

+5VNUGND

7

8

9

VIDEO-IN

POWER SUPPLY CBA

CN103

1

10

CL5

P-ON+13V

1

10

CN5

AUDIO(L)-IN

AUDIO(R)-IN

REAR

234

5

P-ON+13V

BACKLIGHT-SW

BACKLIGHT-ADJ

GND

23456

DIGITAL

AUDIO-OUT

(COAXIAL)

6

GND

1

CN102

CL17

AMP+13V

1

CN17

HDMI-IN1

234

AMP+13V

GND

GND

234

HDMI-IN2

SP3801

SPEAKER

CN18

SCART JACK

HEADPHONE

JACK

L-CH

CL18

1

SP(L)+

3

2

SP(L)-

SP(R)-

SP3802

4

SP(R)+

SPEAKER

R-CH

PC-RGB-IN

+5V

LED-R

CN3

2

1

CL7

2

1

CN7

+5V

LED-R

USB JACK

PC-AUDIO-IN

SIDE