Page 1

Installation, Startup, Operation and Maintenance Manual

Price: $50.00 US

$75.00 Canadian

Webster Engineering & Manufacturing Co., L.L.C.

619 Industrial Road, Winfield, KS 67156

Cyclonetic JB Series

Forced Draft Burners

JB1 - JB2 - JB3

Gas - Oil - Gas/Oil

Manual Part No. 950063

www.webster-engineering.com

July, 2006

2006 All Rights Reserved

C

Page 2

SAFETY PRECAUTIONS

Good safety practices must be used when working on burner equipment. The potential energy in the electrical supply,

fuel and related equipment must be handled with extreme care to prevent equipment failures, injuries and potential

death.

Throughout this manual, the following symbols are used to identify potential problems.

WARNING

This indicates a potential hazardous situation, which if not avoided, could result in personal injury or death.

CAUTION

This indicates a potentially hazardous situation, which if not avoided, could result in damage to the equipment.

The following general safety precautions apply to all equipment work.

WARNING

IF YOU SMELL GAS, OPEN WINDOW, EXTINGUISH ANY OPEN FLAMES, STAY AWAY FROM ELECTRICAL

SWITCHES, EVACUATE THE BUILDING AND IMMEDIATELY CALL THE GAS COMPANY.

IN ACCORDANCE WITH OSHA STANDARDS, ALL EQUIPMENT, MACHINES AND PROCESSES SHALL BE

LOCKED OUT PRIOR TO SERVICING.

IF THIS EQUIPMENT IS NOT INSTALLED, OPERATED AND MAINTAINED IN ACCORDANCE WITH THE MAN

UFACTURERS INSTRUCTIONS, THIS PRODUCT COULD EXPOSE YOU TO SUBSTANCES IN FUEL OR FROM

FUEL COMBUSTION WHICH CAN CAUSE DEATH OR SERIOUS ILLNESS AND WHICH ARE KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

IMPROPER SERVICING OF THIS EQUIPMENT MAY CREATE A POTENTIAL HAZARD TO EQUIPMENT AND

OPERATORS.

SERVICING MUST BE DONE BY A FULLY TRAINED AND QUALIFIED PERSONNEL.

BEFORE DISCONNECTING OR OPENING UP A FUEL LINE AND BEFORE CLEANING OR REPLACING

PARTS OF ANY KIND,

• TURN OFF THE MAIN MANUAL FUEL SHUTOFF VALVES INCLUDING THE PILOT COCK, IF

APPLICABLE. IF A MULTIPLE FUEL BURNER, SHUT OFF ALL FUELS.

• TURN OFF ALL ELECTRICAL DISCONNECTS TO THE BURNER AND ANY OTHER EQUIPMENT OR

SYSTEMS ELECTRICALLY INTERLOCKED WITH THE BURNER.

Service Organization Information:

Date of Startup

-

Company Name

Address

Phone Number

Lead Technician

Page 2 Safety PrecautionsJB Manual

Page 3

TABLE OF CONTENTS

Safety Precautions ...............................................................................................................................

A. Introduction ..........................................................................................................................................

Burner Model Number .............................................................................................................

JB1 Specifications ...................................................................................................................

JB2 Specifications ...................................................................................................................

JB3 Specifications ...................................................................................................................

B. Component ldentification ......................................................................................................................

C. Installation ............................................................................................................................................

D. Special lnstructions For Canadian lnstallations .....................................................................................

E. Burner Mounting Criteria ......................................................................................................................

F. Fuel Systems ........................................................................................................................................

G. Initial Settings .......................................................................................................................................

H. Ignition Systems .................................................................................................................................

I. Start-up & Operating Adjustments .......................................................................................................

J. Trouble Shooting ..................................................................................................................................

K. General Maintenance and Care ...........................................................................................................

L. Care of The Burner During Extended Shutdown ..................................................................................

M. Replacement Parts ..............................................................................................................................

N. Warranty Validation & Field Start-up Report ........................................................................................

Start-Up Report .......................................................................................................................

A. INTRODUCTION

similar to the nameplates shown in Figure A-1. An

This manual covers the Models JB1, JB2 and JB3 CYCLONETIC burners offered by Webster Engineering & Manufacturing Co., LLC. These burners can be used in a wide

variety of Cast Iron, Firebox, Firetube, Flextube and other

applications. They can fire gas, oil and combination gas

and oil with several different operating systems.

“X” in the model number refers to a low NOx burner,

where FGR or a NOx cone is used to reduce the NOx

in the combustion gases. If the burner is not a low NOx

burner, there is no “X” in the model.

Figure A-1 Nameplate

2

3

5

6

8

10

12

17

18

19

20

28

30

32

42

45

48

48

48

49

READ AND SAVE THESE INSTRUCTIONS FOR REFER

ENCE

WARNING

DO NOT ATTEMPT TO START, ADJUST OR MAIN

TAIN THIS BURNER WITHOUT PROPER TRAINING

OR EXPERIENCE. FAILURE TO USE KNOWLEDGEABLE TECHNICIANS CAN RESULT IN EQUIPMENT

DAMAGE, PERSONAL INJURY OR DEATH.

The startup and maintenance of the JB burner requires the

skills of an experienced and properly trained burner technician. Inexperienced individuals should not attempt to start

or adjust this burner.

Every attempt has been made to accurately reflect the

burner construction, however, product upgrades and special order requirements may result in differences between

the content of this manual and the actual equipment.

These special components will be described in the information provided with the burner and should be used as the

controlling document.

NOTE: This manual must be readily available to all operators and maintained in legible condition.

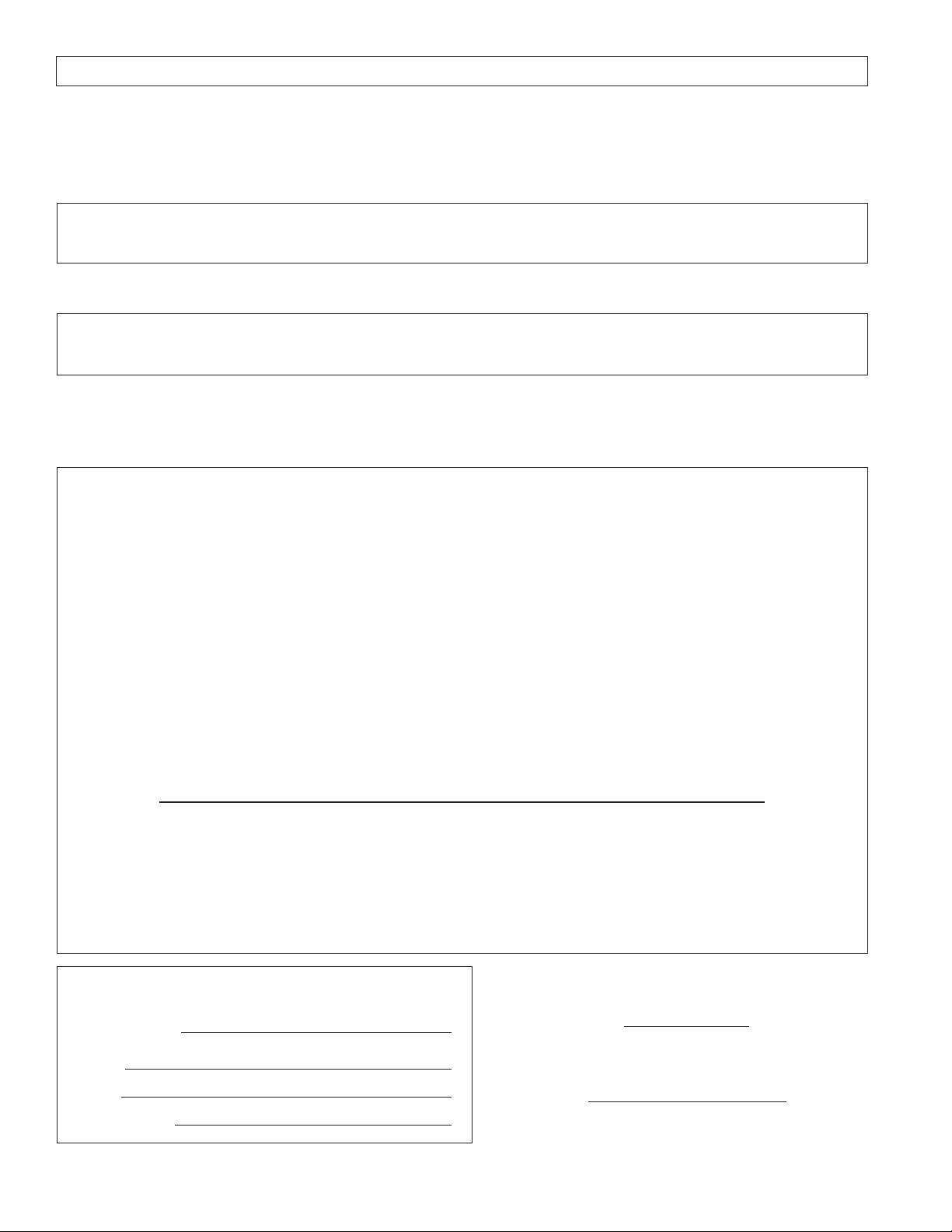

1. Nameplate Information

Each burner has a nameplate with important job details,

-

MAXIMUM

MINIMUM

FUEL

CONTROL CIRCUIT

BURNER MOTOR

OIL PUMP MOTOR

MODEL NUMBER

JB2C-15-RM7840L-UL-IRI

MBTU/HR IN.WC

2940 2.8

1680 1.0

NATURAL GAS

VOLTS AMPS HERTZ PHASE

115

208

208

5.0 60 1

5.9 60 3

4.3 60 3

SERIAL NUMBER

U81375A-018-06

OIL INPUT RATINGGAS INPUT RATING

GPH PSI

21 300

12 100

#2 FUEL OIL

HP

1.5

1/2

The serial number represents the unique number for that

burner and is a critical number that will be needed for any

communications with Webster Engineering.

The input rates define the maximum and minimum inputs

for that burner, given in MBH for gas and GPH for oil. Air

atomized burners show both the oil pressure and air pressure. Pressure atomized burners only list the oil pres-

Page 3 IntroductionJB Manual

Page 4

sure. For gas firing, the gas manifold pressure is given in

“in wc” which is inches of water column.

The electrical ratings of the burner are given, with the voltage, current load, frequency and phase (this will either be

single or 3-phase). For motors, the motor HP is listed.

2. Ratings

The ratings for each specific burner are given on the nameplate. The general burner ratings are given in Specification Sheets that follow this section. The maximun inputs

are given, based on the type of fuel. Other conditions, like

the supply gas pressure or the combination of fuels, emission requirements and control systems may prevent the

burner from reaching the lowest firing rate.

3. Product Offering

The JB burner can fire natural gas, propane and digester

gas as well as all grades of light and heavy oil (#2, #4, #5

and #6 oils as defined by ASTM D396).

DO NOT USE GASOLINE, CRANKCASE OIL OR ANY

OIL CONTAINING GASOLINE.

e. Catalog cuts of the major components. These provide

details on the installation, adjustment and maintenance of

the components used on the burner.

5. Service, Parts and other Information

Service and parts are available from your local Webster

Representative. For a list of Webster Representatives,

please visit the Webster web site at:

www.webster-engineering.com or call 620-221-7464.

This burner is also available as a low emission burner, and

will have model designation JBX. Several low NOx rates

are available for all gas and light oil burners, with the stan

dard offering of 60 ppm and 30 ppm when firing natural

gas. Heavy oil is not allowed in combination with low NOx,

as the high sulfur content can recirculate from the vessel

through the burner when switched from heavy oil to gas.

Low sulfur heavy oil can be used with gas FGR, when the

sulfur is under ½% (the FGR is closed during oil firing).

The burner can also be equipped with a NOx cone for low

NOx on gas, which does not require FGR. (See Addendum 950064).

Figure A-2 lists the common variations and options avail

able on this product. The minimum furnace conditions are

given in Section C.

4. Your Complete Manual

In addition to this manual, there are several other docu

ments that should be considered as part of the complete

manual for the burner. All of these documents are needed

to support the installation and startup of the unit. These

additional items include:

a. The wiring diagram, which shows the limits and interconnection of the burner and vessel controls.

b. The gas and oil piping schematics, which show the

components and their relative positions in the piping train.

c. The unit material list which provides an overview of

the burner requirements and a complete bill of material,

including the part numbers and description for each item.

d. The flame safeguard manual provides the operating sequence for the burner management system. This will be a

critical document for troubleshooting any future problems.

-

-

-

Page 4 IntroductionJB Manual

Page 5

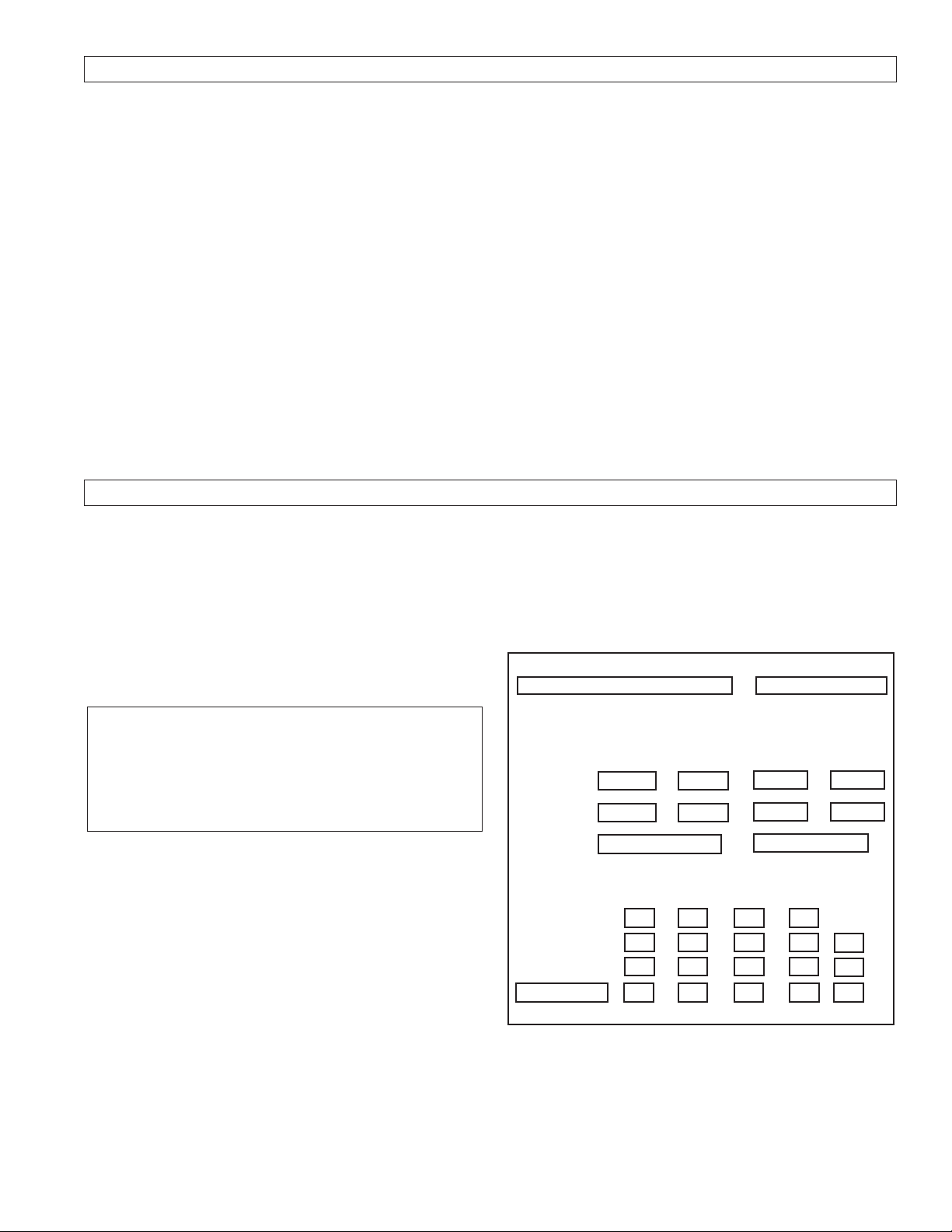

MODEL JB(X) BURNER MODEL CONFIGURATION

FIGURE A-2

JBX1G -05-RM7800L-M.25-M-A-UL/CSD-1

BURNER SERIES

JB JB SERIES

FGR or NOx CONE

USED X

NOT USED

HEAD SIZE (INCHES)

1 7 1/8 7 1/2

2 9 1/8 9 1/2

3 11 1/8 11 1/2

FUELS

G Gas

O Oil

C Gas / Oil

BLOWER MOTOR

HORSEPOWER

02 1/4

03 1/3

05 1/2

07 3/4

10 1

15 1 1/2

20 2

30 3

50 5

75 7 1/2

100 10

RM7800L Honeywell

M Mark AutoFlame - mini mark

E110/EP170

Nexus Fireye

LMV51 Siemens

LMV52 Siemens

BLANK

JB JBX

FLAME SAFEGUARD

VENDOR DESIGNATION

Fireye

CODES AND

LISTINGS

UL

ULc

CSD-1

FM

IRI

NFPA-85

OIL SYSTEMS

Pressure Atomizing

A On - Off

L Low Fire Start

H Low - Hi - Low

MP Modulation Simplex

MR Modulation By-Pass

Air or Steam Atomization

MA Air Atomization

MS Steam Atomization

GAS TRAIN VENDOR

VGD Siemens

VGG Siemens

M Maxon

Blank

.15 1 1/2 inches

.20 2 inches

.25 2 1/2 inches

.30 3 inches

.40 4 inches

GAS SYSTEM

A On-Off

L Low Fire Start

H Low-Hi-Low

M Modulation

All Others

(ASCO) - (std)

GAS TRAIN SIZE

The above represents the common model designations.

Contact the factory for other options and special applications.

Page 5 IdentificationJB Manual

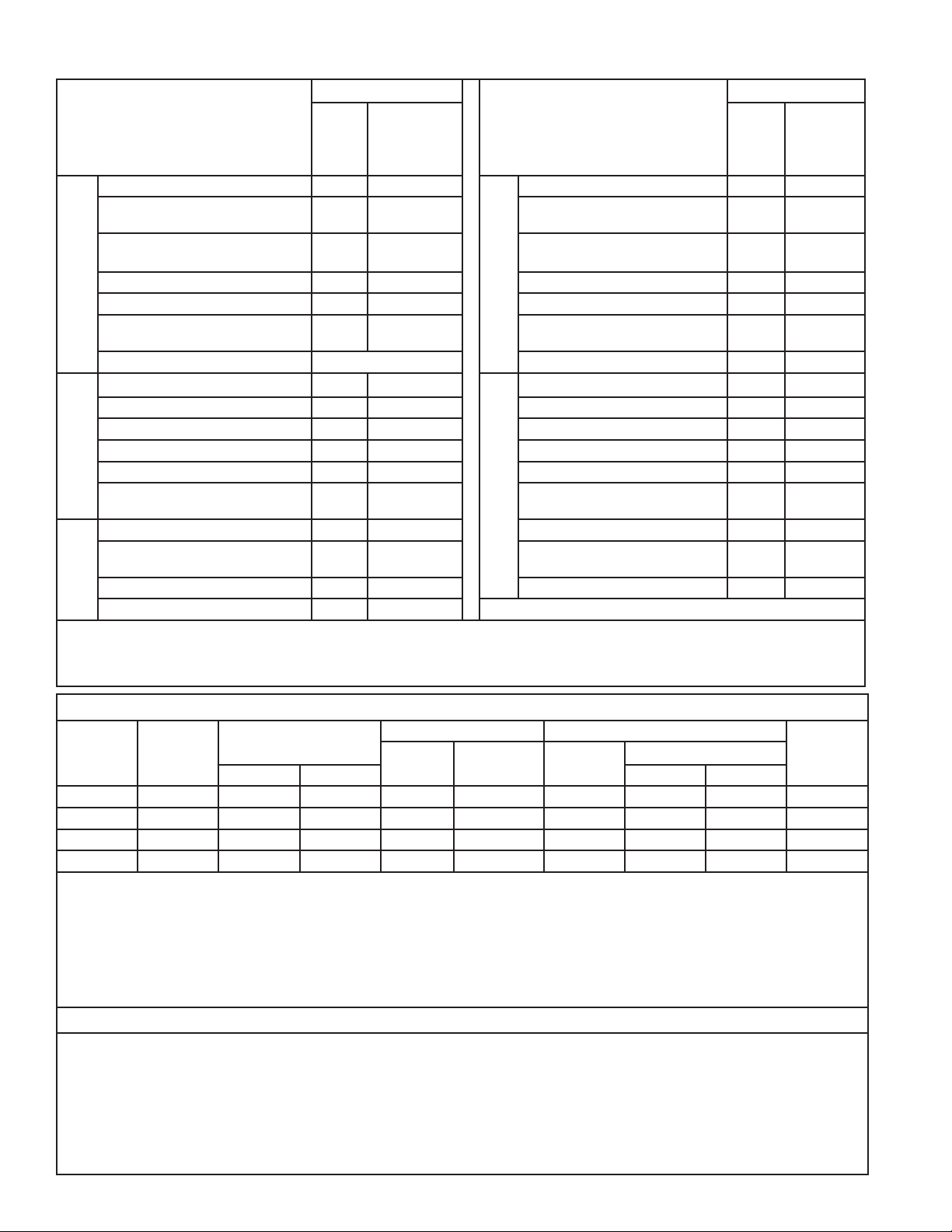

Page 6

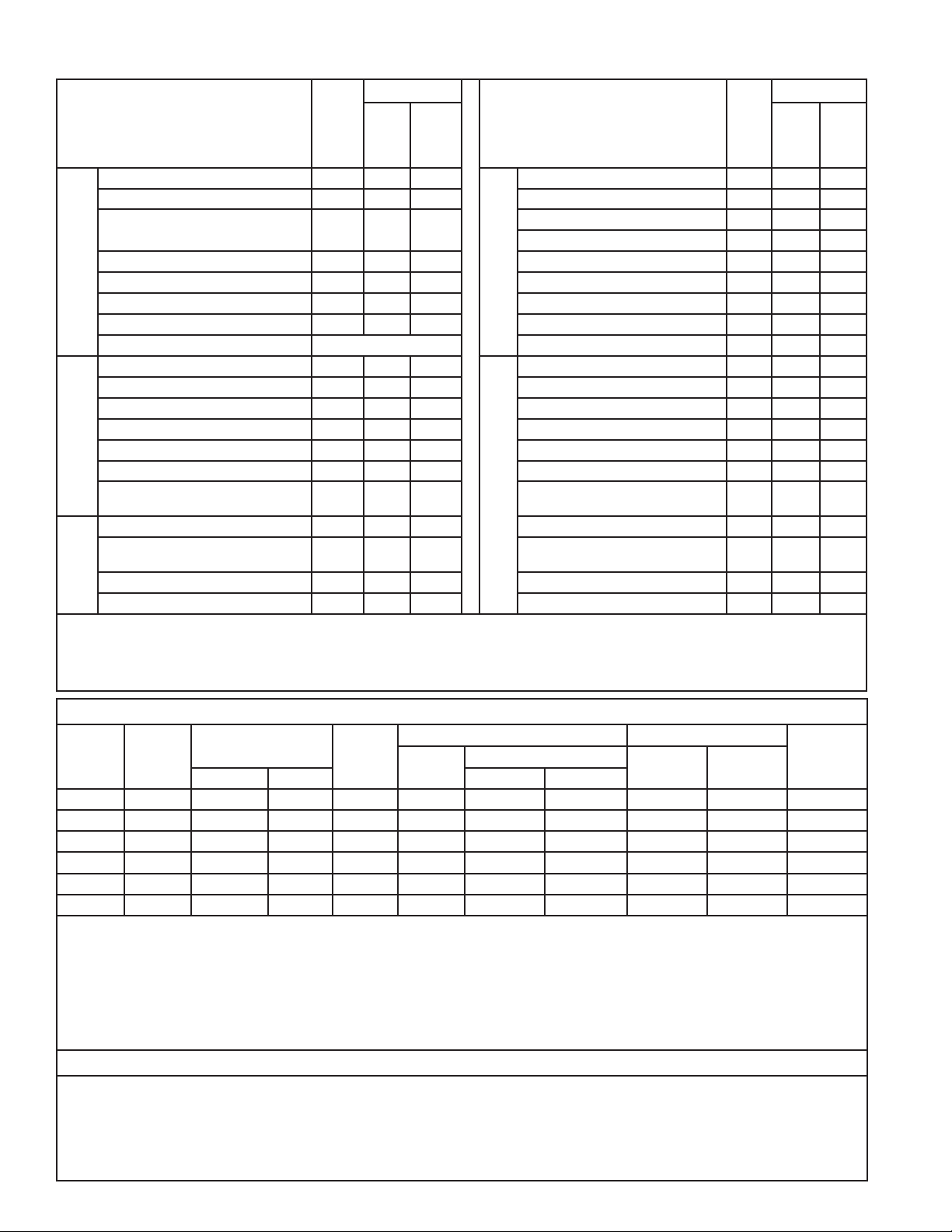

Model JB1 - Specification Data (400 - 2500 MBH Input)

Fuel Burned

Fuel Burned

(1) STANDARD UL EQUIPMENT

AND IMPORTANT OPTIONS

Motor, Fan and Air Inlet Control X X

Air Flow Switch (also with oil systems using remote pump)

(2) Burner Mounted Control Panel,

Switch and Indicator Lights

Flame Safety Control X X Main Gas Regulator X

General

Ultra Violet Scanner

Motor Controller (single phase

voltage)

Fuel Selector Switch Duel Fuel Burners Only Metering Valve (modulation only) X

Proven Gas Pilot Ignition

Pilot Solenoid Gas Valve X Oil Nozzle(s) X

Pilot Gas Regulator & Manual Valve

Pilot Gas Ignition Transformer

Ignition

Direct Spark Oil Ignition X Second Safety Shutoff Valve X

Direct Spark Oil Ignition

Transformer

Inverted Housing X X Oil Pressure Gauge X

Alternate Control Cabinet

Positioning

Remote Control Panel X X Future Gas Combustion Head-OPT Opt.

Optional

Fuel Metering CAM-NETIC II X X

1. The configuration of each unit will vary with specific job requirements such as input rating, electrical specification and special agency approval

codes. The above chart shows those items standard to a basic burner plus a few options that may be added.

2. Indicator lights are “Power On”, “Call for Heat”, ”Fuel On” and ”Flame Fail” for hard wired panels. “Alarm”, “Low Water”, “Power”, “Call for

Heat”, “Ignition On”, and “Fuel On” for circuit board light panels.

Gas

No. 2 Oil

pressure

atomized

X Main Safety Shutoff Valve X

X X Second Safety Shutoff Valve X

X X Gas Checking Valve X

X X

X

X Integral Oil Pump X

X Main Safety Shutoff Valve X

X

X X

STANDARD UL EQUIPMENT

AND IMPORTANT OPTIONS

Main Manual Shutoff Valve X

Gas Fuel

High and Low Gas Pressure

Switches (st’d over 2500 MBH)

Oil Drawer Assembly with Diffuser X

Low Oil Pressure Switch

Oil Fuel

(STD when using remote oil pump)

Oil Metering Valve (modulating

systems)

Gas

Opt.

No. 2 Oil

pressure

Opt.

X

atomized

Model JB1 - Sizing and Application Data (contact Webster for complete information)

Model

Number

JB1-02 1.25 400 / 1000 3.0 / 7.1 1/4 1/3 1” 6 / 14” 7 /14” Integral

JB1-03 1.25 600 / 1500 4.0 / 10.7 1/3 1/2 1 1/4” 8 / 14” 9 / 14” Integral

JB1-05 1.25 800 / 2100 6.0 / 14.8 1/2 1/2 1 1/2” 7 / 14” 8 / 14” Integral

JB1-07 1.25 900 / 2500 7.0 / 17.8 3/4 3/4 1 1/2” 9 / 14” 11 / 14” Integral

3. Larger motors may be required for single phase or 208 volts 4. Contact Webster for more complete details

The above maximum ratings are based on 0 furnace pressure, an altitude of 1000 feet, 90oF air temperature and 60 HZ electrical supply. Use

the following corrections for higher temperatures and altitude. Capacity decreases by 17% for 50 Hertz.

Capacity decreases by 4% for each 1000 feet above 1000 foot altitude.

Capacity decreases by 6% for each 1 inch of furnace pressure.

Capacity decreases by 2% for each 10oF increase in air temperature over 90oF.

Gas input ratings based on 1000 BTU/cu ft. and 0.64 specific gravity. Sizes and pressure will vary with gas.

Oil input ratings are based on 140,000 BTU/gal for ASTM #2 fuel oil.

Maximum

Furnace

Pressure

Burner Firing Capability

Range

Gas scfh #2 Oil gph On-Off, LFS Modulation

Burner Motor HP Gas Train Oil Pump

Gas Only

HP

(3) Oil or

Combination

Pipe Size

(4) Inlet Pressure

Motor HP

Essential Ordering Information and Data:

Power Supply - Confirm 120-60-1 for control circuit and electrical supply for burner motor(s) (voltage, frequency and phase).

Describe Boiler or Heater to be Fired - Including the manufacturer, model number, furnace pressure and furnace size.

Firing Rate - Define firing rates in MBH for gas and GPH for oil.

Fuel to be Burned - Type of gas and/or oil, including the BTU value.

Approval Agency - UL, FM, IRI (GE GAP), CSD-1, NFPA, Mil spec and local codes, if applicable.

Flame Safety Control Preferred - Honeywell or Fireye controls.

Gas Train Components Preferred - ASCO/ITT, Honeywell or Landis

Control System - ON-OFF, Low Fire Start, Low-High-Low, Modulation, Posi-Control

Required Options - Mounting plate, limit controls, etc.

Page 6 SpecificationJB Manual

Page 7

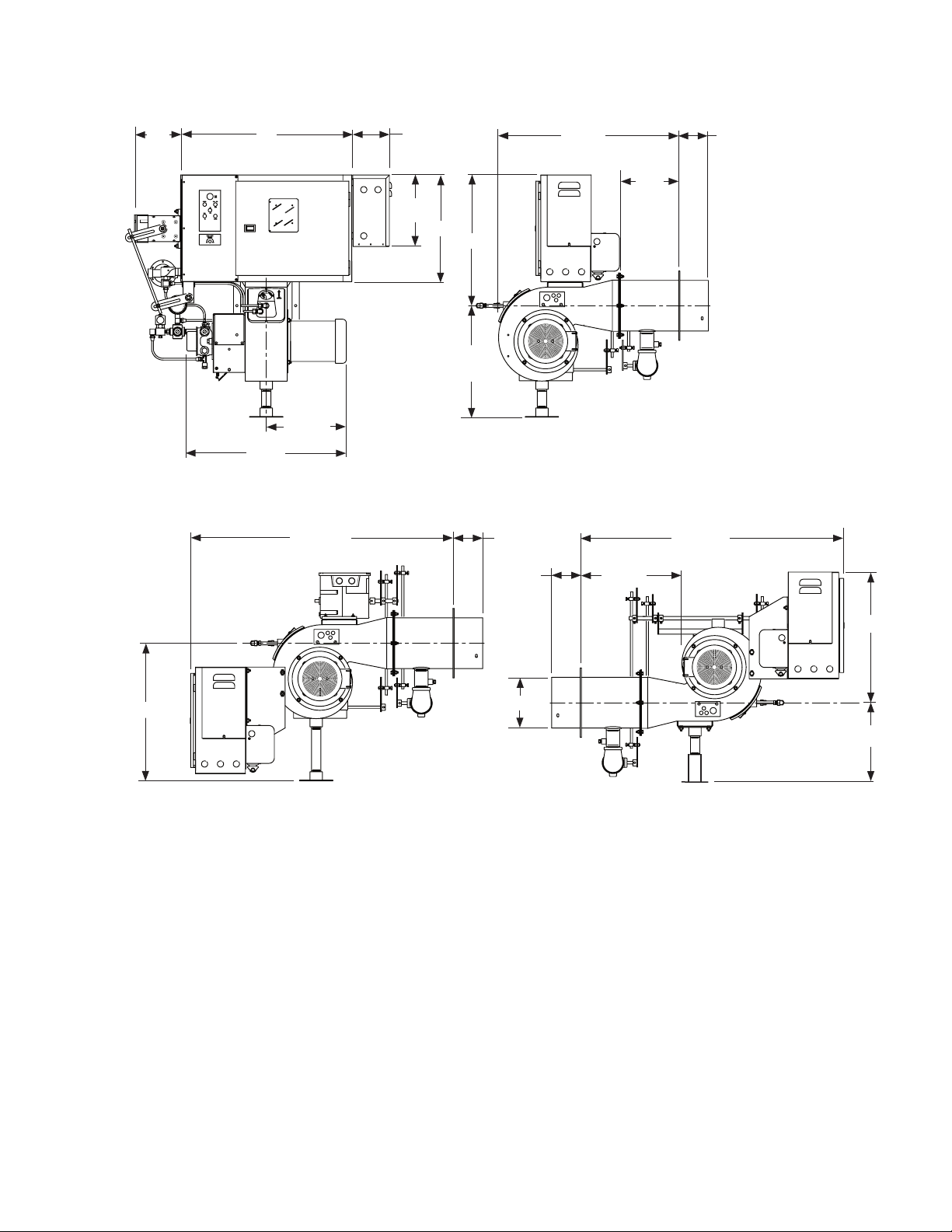

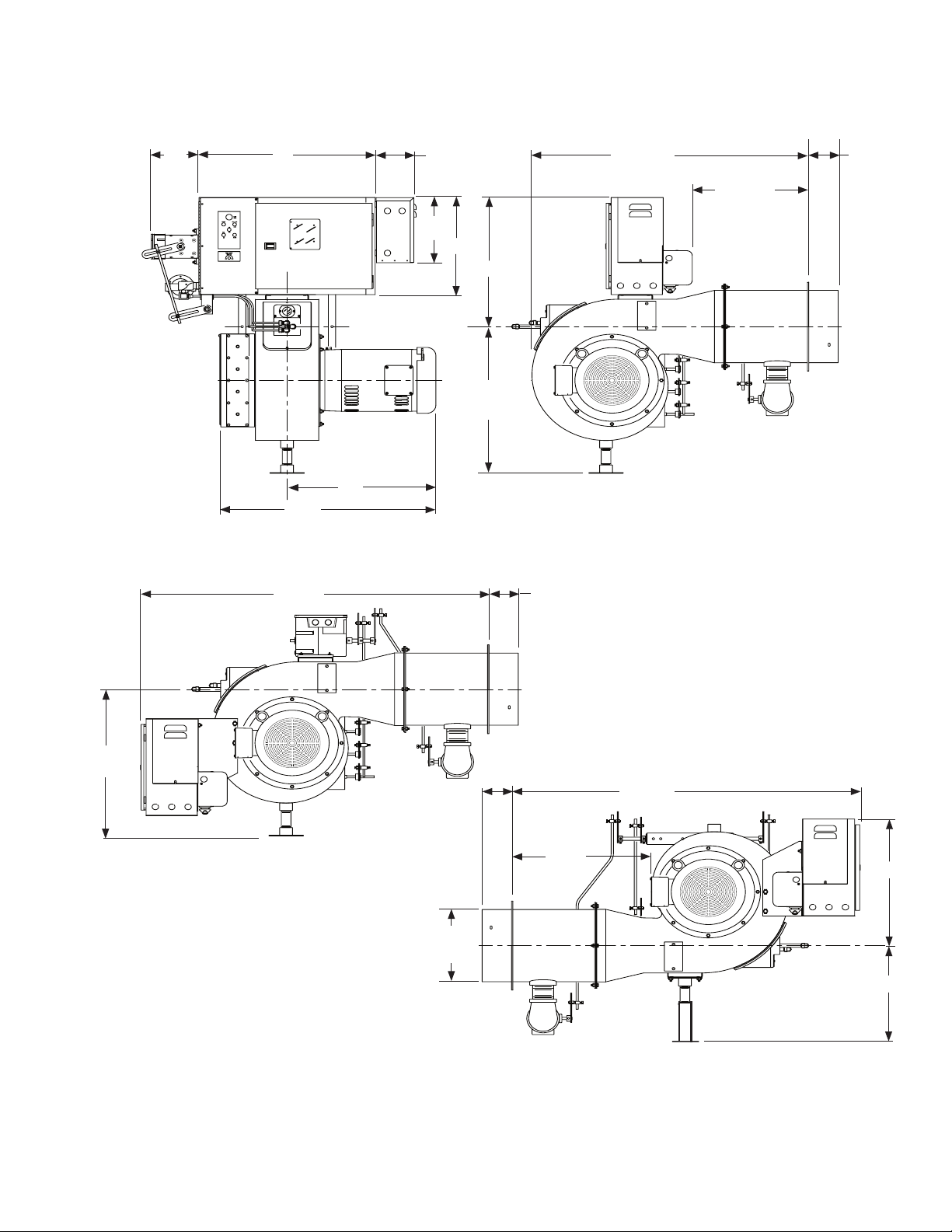

Model JB1 - Dimentional Data (400 - 2500 MBH Input)

(Dimensions are +/- 1/4 inch)

9 1/2

24

21 7/8

Standard Arrangement

End View

11 7/16

36 15/16

5 5/16

10

15

18 3/8

15 11/16

26 5/8

8 1/4

4

Standard Arrangement

Elevation

4

4

14 3/8

36 15/16

19 3/8

Standard Arrangement

7 1/4 O.D.

Inverted Arrangement

Elevation

W/ Optional Back Mount Control Cabinet

Fuels Burned and Control Systems

- Natural Gas, Propane, Digester or Mixed Gases

- Light #2 Oil, Mechanical Pressure

- On-Off, Low Fire Start, Low-High-Low, Modulating or Micro Modulation

- Control Circuit Requires 120 vac, 60 Hz, Single Phase Voltage Supply

18 3/8

11 3/8

Elevation

(Optional)

Model JB1 burners are listed by Underwriters Laboratories, Inc. (UL / ULC). Also by the State of Massachusetts

Fire Marshal, City of New York Board of Standards and Appeals, State of Minnesota and can be packaged to meet

specific requirements of IRI, FM, GE GAP, NFPA, MIL spec. or other special insurance or local code requirements.

Page 7 SpecificationJB Manual

Page 8

Model JB2 - Specification Data (6000 MBH Maximum Input)

No. 2 Oil

(1) STANDARD UL EQUIPMENT

AND IMPORTANT OPTIONS

Motor, Fan and Air Inlet Control X X X

Air Flow Switch X X X Main Safety Shutoff Valve X

(2) Burner Mounted Control Panel,

Switch and Indicator Lights

Flame Safety Control X X X Gas Checking Valve X

General

Ultra Violet Scanner

Motor Controller (single phase voltage) X X X Metering Valve (modulating systems) X

Motor Starter w/Overloads (3 PH volt) X X X Normally Open Vent Valve Opt.

Fuel Selector Switch Duel Fuel Burners Only

Proven Gas Pilot Ignition X X

JB2-30 and JB2-50 X X X Oil Nozzles X X

Pilot Solenoid Gas Valve

Pilot Gas Regulator & Manual Valve

Pilot Gas Ignition Transformer

Ignition

Direct Spark Oil Ignition (3) Low Air Atomizing Switch X

Direct Spark Oil Ignition

Transformer

Inverted Housing X X X Oil Pressure Gauge X X

Alternate Control Cabinet

Positioning

Options

Remote Control Panel X X X Future Gas Combustion Head Opt. Opt.

Fuel Metering CAM-NETIC II X X X Air Compressor X

1. The configuration of each unit will vary with specific job requirements such as input rating, electrical specification and special agency approval codes.

The above chart shows those items standard to a basic burner plus a few options that may be added.

2. Indicator lights are “Power On”, “Call for Heat”, ”Fuel On” and ”Flame Fail” for hard wired panels. “Alarm”, “Low Water”, “Power”, “Call for Heat”, “Ignition

On”, and “Fuel On” for circuit board panels.

3. Maximum rate for direct spark is 20 GPH at low fire or 35 GPH at high fire. (standard on straight oil burners, pressure atomized)

Gas

Pressure

X X X

X X X High and Low Gas Pressure Switches X

X X Integral Oil Pump (JB2-07 to JB2-20) X

X X Remote Oil Pump (JB2-30 to JB2-50) X Opt.

X X Two Safety Shutoff Valves X X

(3)

X X X

Air

Atomized

Atomized

STANDARD UL EQUIPMENT

AND IMPORTANT OPTIONS

Main Manual Shutoff Valve X

Second Safety Shutoff Valve

Main Gas Regulator X

Gas Fuel

Oil Drawer Assembly with Diffuser X X

Low Oil Pressure Switch (STD when

Oil Fuel

using remote oil pump)

Oil Metering Valve (modulating

system)

X

Gas

No. 2 Oil

Pressure

Atomized

X X

X X

Air

Atomized

Model JB2 - Sizing and Application Data (contact Webster for complete information)

Model

Number

JB2-07 2 900 / 2800 10 / 20 3/4 1 1/2” 10 / 14” 13” Integral N/A N/A

JB2-10 2 900 / 3500 10 / 25 1 2” 8 / 14” 9 / 14” Integral Optional 2

JB2-15 2 900 / 3500 10 / 25 1 1/2 2” 8 / 14” 9 / 14” Integral Optional 2

JB2-20 2 1200 / 4200 12 / 30 2 2”

JB2-30 2.5 1200 / 5300 12 / 37.8 3 2 1/2” N/A 13 / 14” 3/4 Optional 2

JB2-50 2.5 1200 / 6000 12 / 42.8 5 2 1/2” N/A 2-5 psi 3/4 Optional 2

3. Lower pressures may apply to reduced inputs. 4. 11-14” with IRI and LFS or LHL. 12-14” with IRI and modulation.

The above maximum ratings are based on 0 furnace pressure, an altitude of 1000 feet, 90

ing corrections for higher temperatures and altitude. Capacity decreases by 17% for 50 Hertz.

Capacity decreases by 4% for each 1000 feet above 1000 foot altitude.

Capacity decreases by 6% for each 1 inch of furnace pressure.

Capacity decreases by 2% for each 10oF increase in air temperature over 90

Gas input ratings based on 1000 BTU/cu ft. and 0.64 specific gravity. Sizes and pressure will vary with different gas properties.

Oil input ratings are based on 140,000 BTU/gal. for ASTM #2 fuel oil.

The vessel draft must be between -0.1 and +0.1 wc.

Maximum

Furnace

Pressure

Burner Firing

Capability Range

Gas scfh

#2 Oil gph

Burner

Motor

HP

Gas Train

Oil Pump Motor HP Air

Pipe Size (3) Inlet Press (in wc) Pressure

LFS, LHL Modulation

(4) 12 / 14” (3) 13 / 14”

o

F air temperature and 60 HZ electrical supply. Use the follow

o

F.

Atomizing

Integral Optional 2

Air

Atomizing

Compressor

Motor HP

Essential Ordering Information and Data:

Power Supply - Confirm 120-60-1 for control circuit and electrical supply for burner motor(s) (voltage, frequency and phase).

Describe Boiler or Heater to be Fired - Including the manufacturer, model number, furnace pressure and furnace size.

Firing Rate - Define firing rates in MBH for gas and GPH for oil.

Fuel to be Burned - Type of gas and/or oil, including the BTU value.

Approval Agency - UL, FM, IRI (GE GAP), CSD-1, NFPA, Mil spec and local codes, if applicable.

Flame Safety Control Preferred - Honeywell or Fireye controls. Gas Train Components Preferred - ASCO/ITT, Honeywell or Landis

Control System - ON-OFF, Low Fire Start, Low High Low, Modulation, Posi-Control. Required Options - Mounting plate, limit controls, etc.

JB Manual

Page 8

Specification

-

Page 9

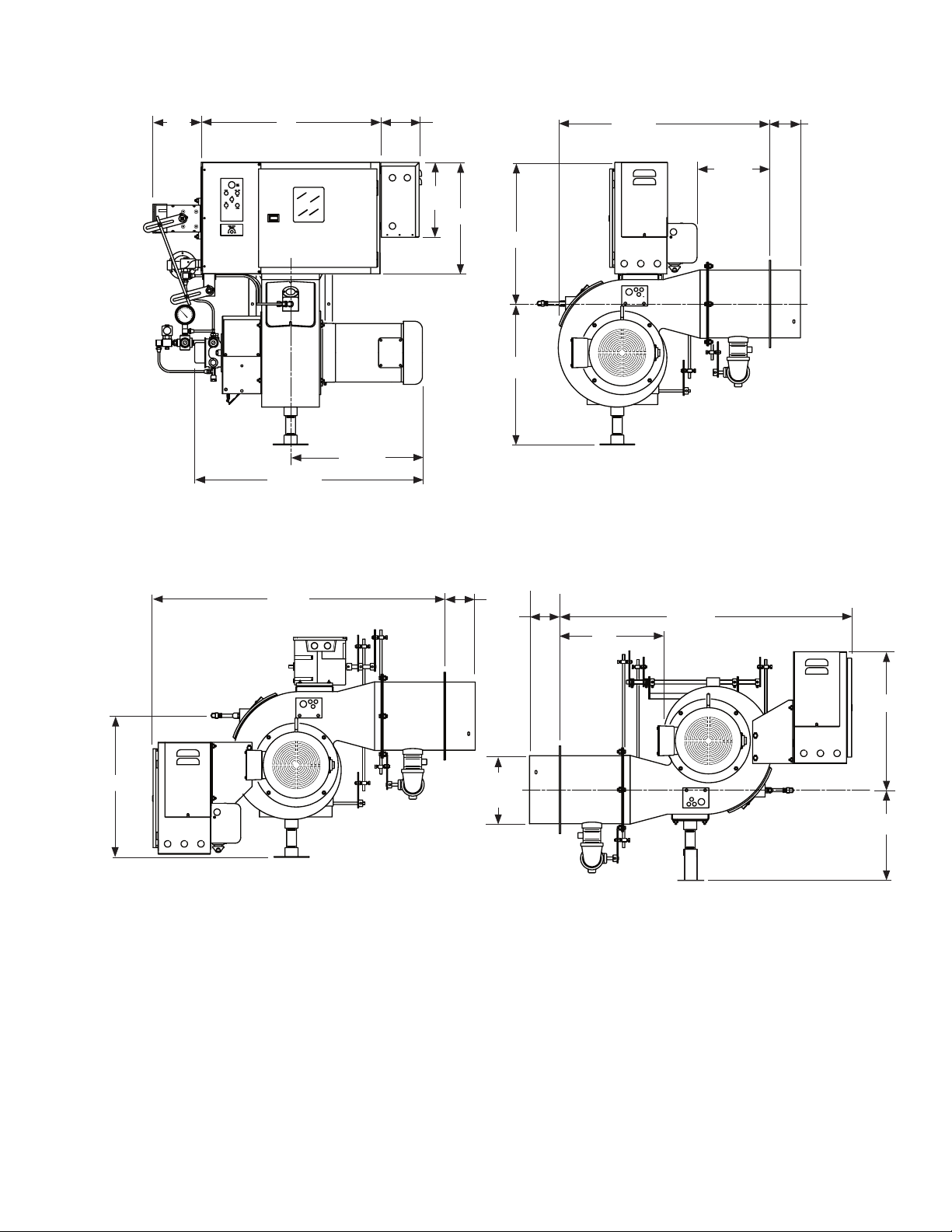

Model JB2 - Dimensional Data (6000 MBH Maximum Input)

(Dimensions are +/- 1/4 inch)

6 1/2

24

17 3/4

30 11/16

Standard Arrangement

End View

10

5 5/16

15

19 1/16

19

28 5/8

9 1/2

Standard Arrangement

Elevation

4

39 1/4

19 1/2

Standard Arrangement

Elevation

4

4

14

9 1/8

O.D.

Inverted Arrangement

W/ Optional Back Mount Control Cabinet

Fuels Burned and Control Systems

- Natural Gas, Propane, Digester or Mixed Gases

- Light #2 through Heavy #6 Fuel Oil

- Low Fire Start, Low-High-Low, Modulating or Micro Modulation

- Control Circuit Requires 120 vac, 60 Hz, Single Phase Voltage Supply

39 1/4

18 1/2

12 1/8

Elevation

Model JB1 burners are listed by Underwriters Laboratories, Inc. (UL/ULC). Also by the State of Massachusetts Fire

Marshal, City of New York Board of Standards and Appeals, State of Minnesota and can be packaged to meet spe

-

cific requirements of IRI, FM, GE GAP, NFPA, MIL spec. or other special insurance or local code requirements.

Page 9 SpecificationJB Manual

Page 10

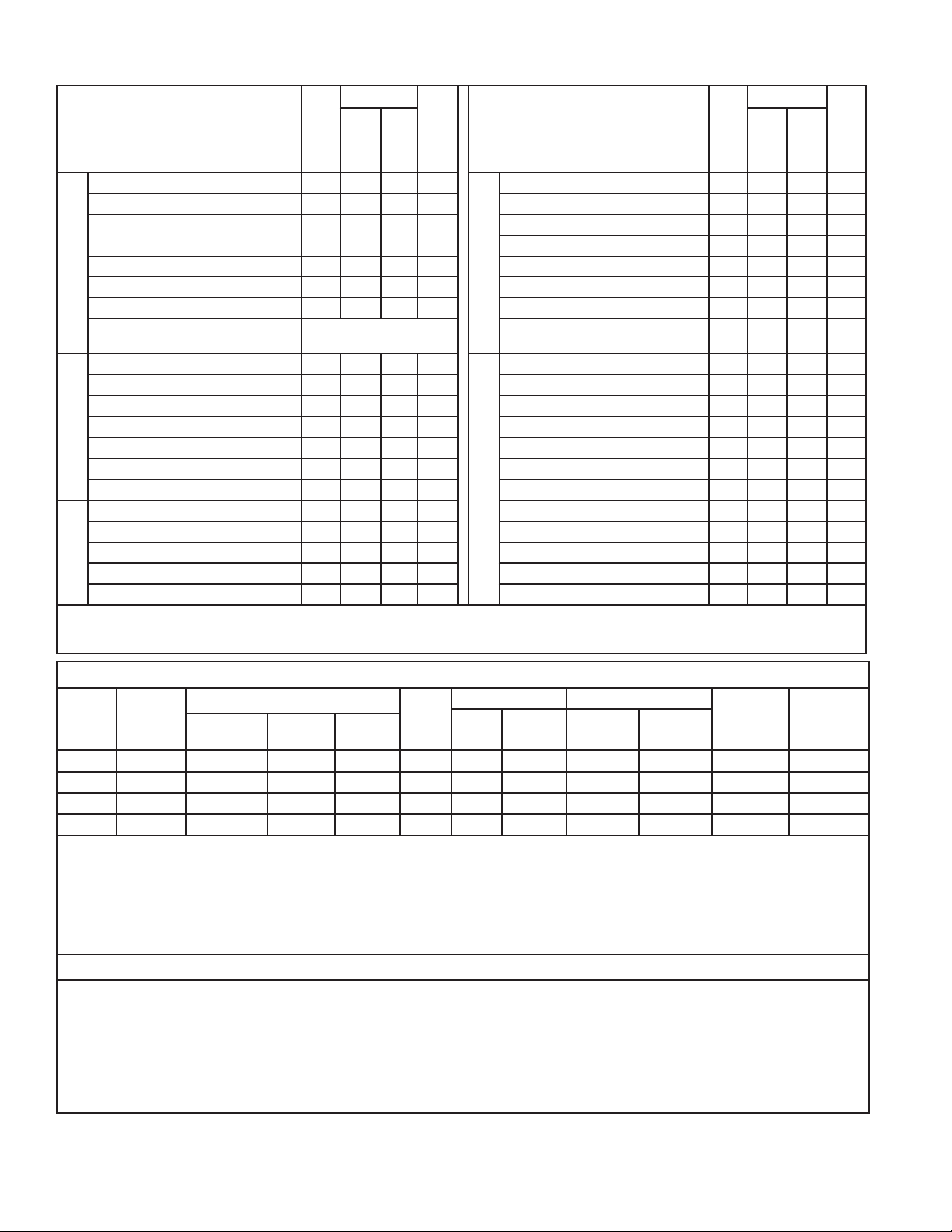

Model JB3 - Specification Data (12,600 MBH Maximum Input)

(1) STANDARD UL

EQUIPMENT

AND IMPORTANT OPTIONS

Motor, Fan and Air Inlet Control X X X X

Air Flow Switch X X X X Main Safety Shutoff Valve X

(2) Burner Mounted Control Panel,

Switch and Four Indicator Lights

Flame Safety Control X X X X Gas Checking Valve X

General

Ultra Violet Scanner

Motor Starter with Overloads X X X X Metering Valve (modulating systems) X

Fuel Selector Switch Duel Fuel Burners Only Normal Open Vent Valve (above

Proven Gas Pilot Ignition X X X

Pilot Solenoid Gas Valve

Pilot Gas Regulator & Manual Valve

Pilot Gas Ignition Transformer

Ignition

Inverted Housing X X X X Low Oil Pressure Switch X X X

Alternate Control Cabinet Positioning X X X X Oil Pressure Gauge X X X

Remote Control Panel X X X X Oil Metering Valve X X X

Options

Fuel Metering CAM-NETIC II X X X X Future Gas Combustion Head Opt. Opt. Opt.

Posi-Control X X X X Air Compressor X X

1. The configuration of each unit will vary with specific job requirements such as input rating, electrical specification and special agency approval codes.

The above chart shows those items standard to a basic burner plus a few options that may be added.

2. Indicator lights are “Power On”, “Call for Heat”, ”Fuel On” and ”Flame Fail”.

Gas

X X X X

X X X X High and Low Gas Pressure Switches X

X X X Oil Nozzles X X X

X X X Oil Heater with Integral Thermostat X

X X X Remote Oil Pump X Opt. Opt.

Air

Pressure

Atomized

No. 4 - 6 Oil

Atomized

STANDARD UL EQUIPMENT

AND IMPORTANT OPTIONS

Air Atomized

Main Manual Shutoff Valve X

Second Safety Shutoff Valve

Main Gas Regulator X

Gas Fuel

12,500 MBH)

Oil Drawer Assembly with Diffuser X X X

Two Safety Shutoff Valves

High Oil Temperature Switch

Low Air Atomizing Switch

Oil Fuel

No. 2 Oil

No. 2 Oil

Gas

X

X

Air

Pressure

Atomized

Atomized

X X X

N0. 4 - 6 Oil

Air Atomized

X

X

Model JB3 - Sizing and Application Data (contact Webster for complete information)

Model

Number

JB3-30 3.5 1400 / 6300 10.2 / 45 10 / 42 3 2 1/2” 12 / 27” 1 Optional Optional 2

JB3-50 3.5 1400 / 8300 11 / 59.2 10 / 55.3 5 3” 15 / 27” 1 1/2 Optional Optional 2

JB3-75 3.5 1600 / 10500 12.3 / 75 11 / 70 7 1/2 3” 23 / 27” 1 Optional Optional 2

JB3-100 3.5 1800 / 12600 20.3 / 90 12 / 84 10 3” 2-5 psi 1 Optional Optional 2

The above maximum ratings are based on 0 furnace pressure, an altitude of 1000 feet, 90

ing corrections for higher temperatures and altitude. Capacity by 17% for 50 Hertz.

Capacity decreases by 4% for each 1000 feet above 1000 foot altitude.

Capacity decreases by 6% for each 1 inch of furnace pressure.

Capacity decreases by 2% for each 10oF increase in air temperature over 90

Gas input ratings based on 1000 BTU/cu ft. and 0.64 specific gravity. Sizes and pressure will vary with gas.

Oil input ratings are based on 140,000 BTU/gal. for ASTM #2 fuel oil and 150,000 BTU/gal for ASTM #4-6 fuel oil.

The vessel draft must be between -0.1 and +0.1 wc.

Maximum

Furnace

Pressure

Burner Firing Capability Range Burner

Gas scfh #2 Oil

gph

#4-6

Oil gph

Motor

HP

Gas Train

Pipe

Size

#2 Oil Pump Motor HP #4 - 6

Pump

Motor HP

o

F.

Inlet

Press

o

Pressure

Atomizing

F air temperature and 60 HZ electrical supply. Use the follow

Air

Atomizing

Compressor

Motor HP

Essential Ordering Information and Data:

Power Supply - Confirm 120-60-1 for control circuit and electrical supply for burner motor(s) (voltage, frequency and phase).

Describe Boiler or Heater to be Fired - Including the manufacturer, model number, furnace pressure and furnace size.

Firing Rate - Define firing rates in MBH for gas and GPH for oil.

Fuel to be Burned - Type of gas and/or oil, including the BTU value.

Approval Agency - UL, FM, IRI (GE GAP), CSD-1, NFPA, Mil spec and local codes, if applicable.

Flame Safety Control Preferred - Honeywell or Fireye controls.

Gas Train Components Preferred - ASCO/ITT, Honeywell or Landis

Control System - ON-OFF, Low Fire Start, Low High Low, Modulation, Posi-Control

Required Options - Mounting plate, operating controls, limit controls, etc.

Air

-

JB Manual

Page 10

Specification

Page 11

Model JB3 - Dimensional Data (12,600 MBH Maximum Input)

(Dimensions are +/- 1/4 inch)

6 1/2

24

16

27

Standard Arrangement

End View

48

5 5/16

10

15

19 15/16

22 1/2

38 1/4

15 15/16

4

Standard Arrangement

Elevation

4

22 1/2

4

19 1/4

48

19 9/16

Standard Arrangement

Elevation

W/ Optional Back Mount Control Cabinet

11 1/4

O.D.

14 3/4

Fuels Burned and Control Systems

- Natural Gas, Propane, Digester or Mixed Gases

- Light #2 through Heavy #6 Fuel Oil

- Modulating Control System - Micro Modulation or Linkage

Inverted Arrangement

Elevation

- Control Circuit Requires 120 vac, 60 Hz, Single Phase Voltage Supply

Model JB3 burners are listed by Underwriters Laboratories, Inc. (UL/ULC). Also by the State of Massachusetts Fire

Marshal, City of New York Board of Standards and Appeals, State of Minnesota and can be packaged to meet specific requirements of IRI, FM, GE GAP, NFPA, MIL spec. or other special insurance or local code requirements.

Page 11 SpecificationJB Manual

Page 12

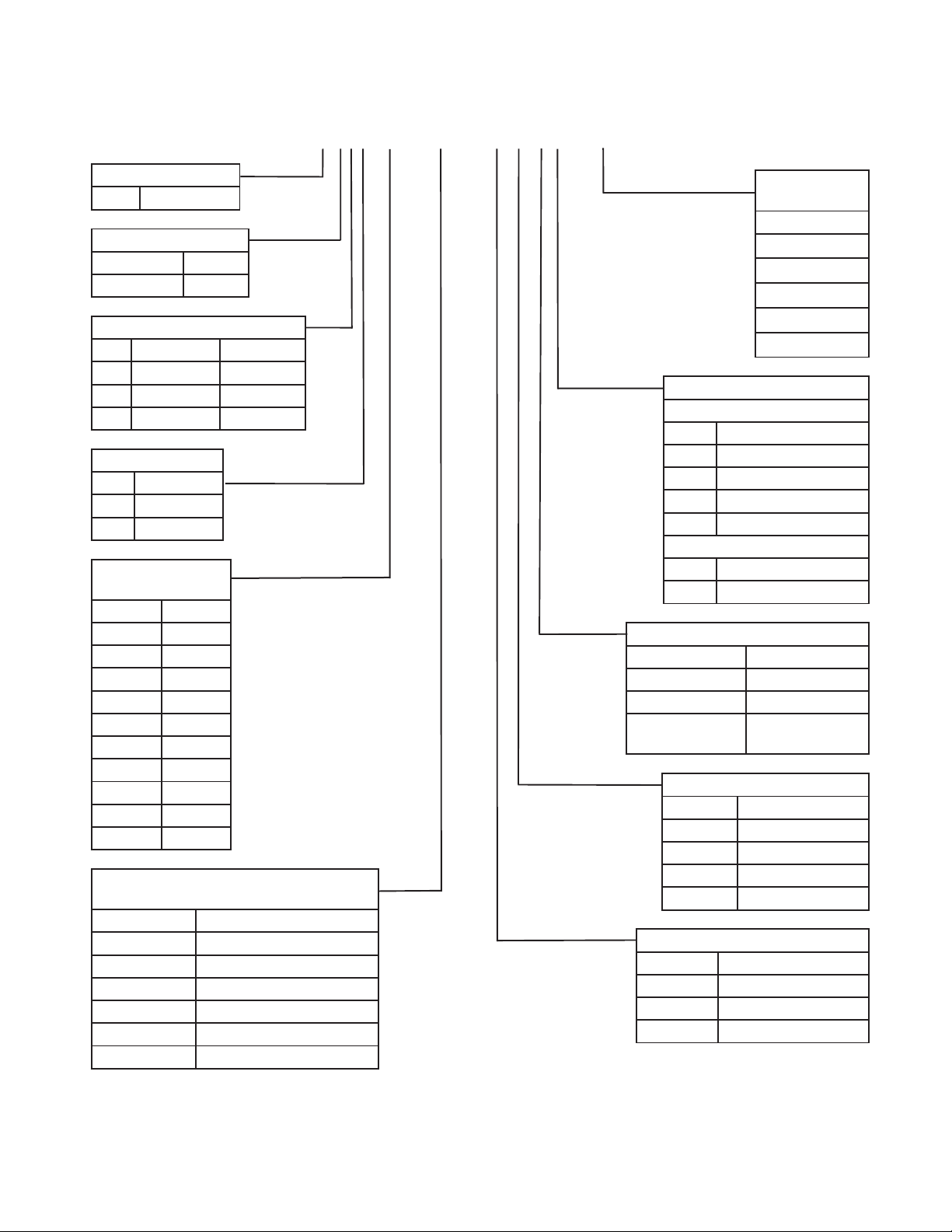

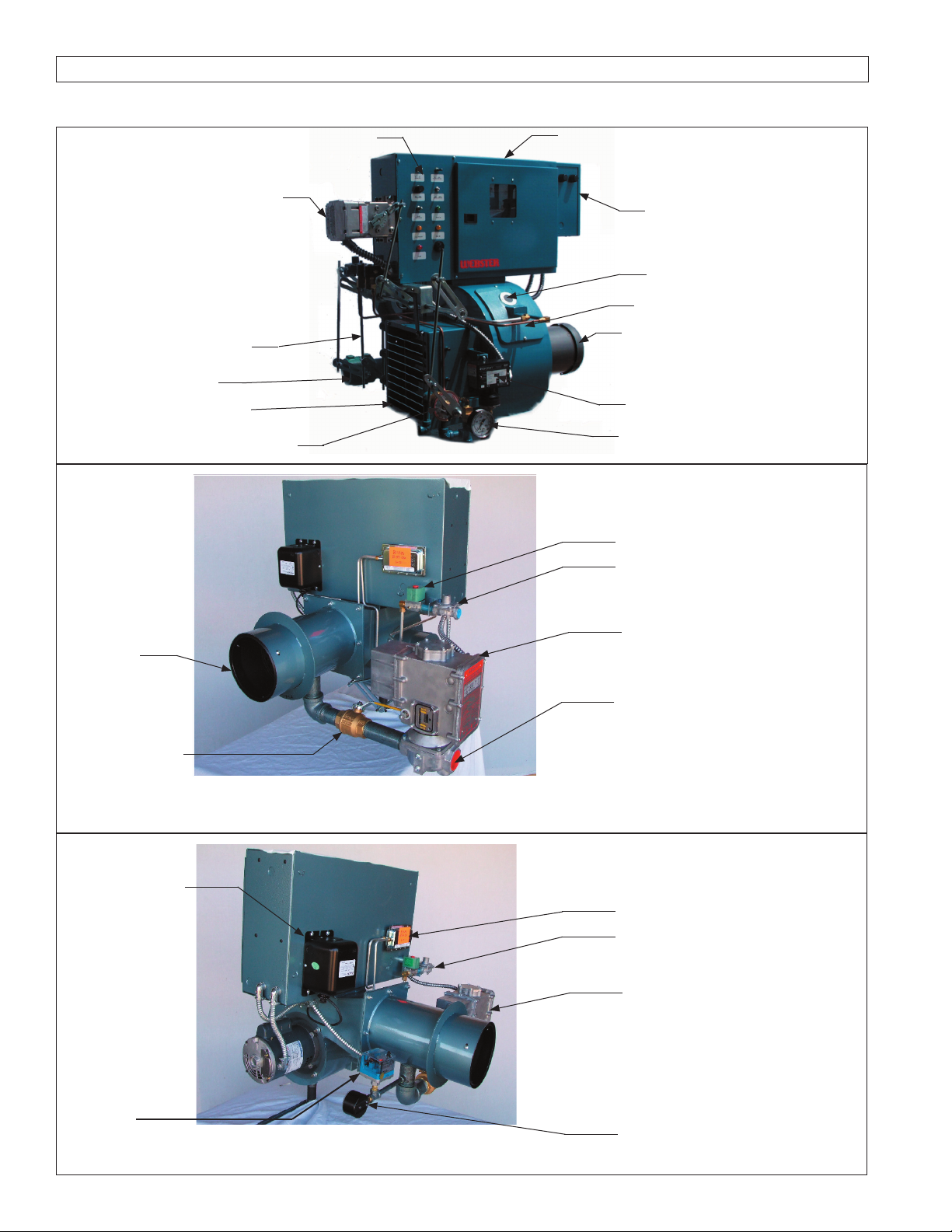

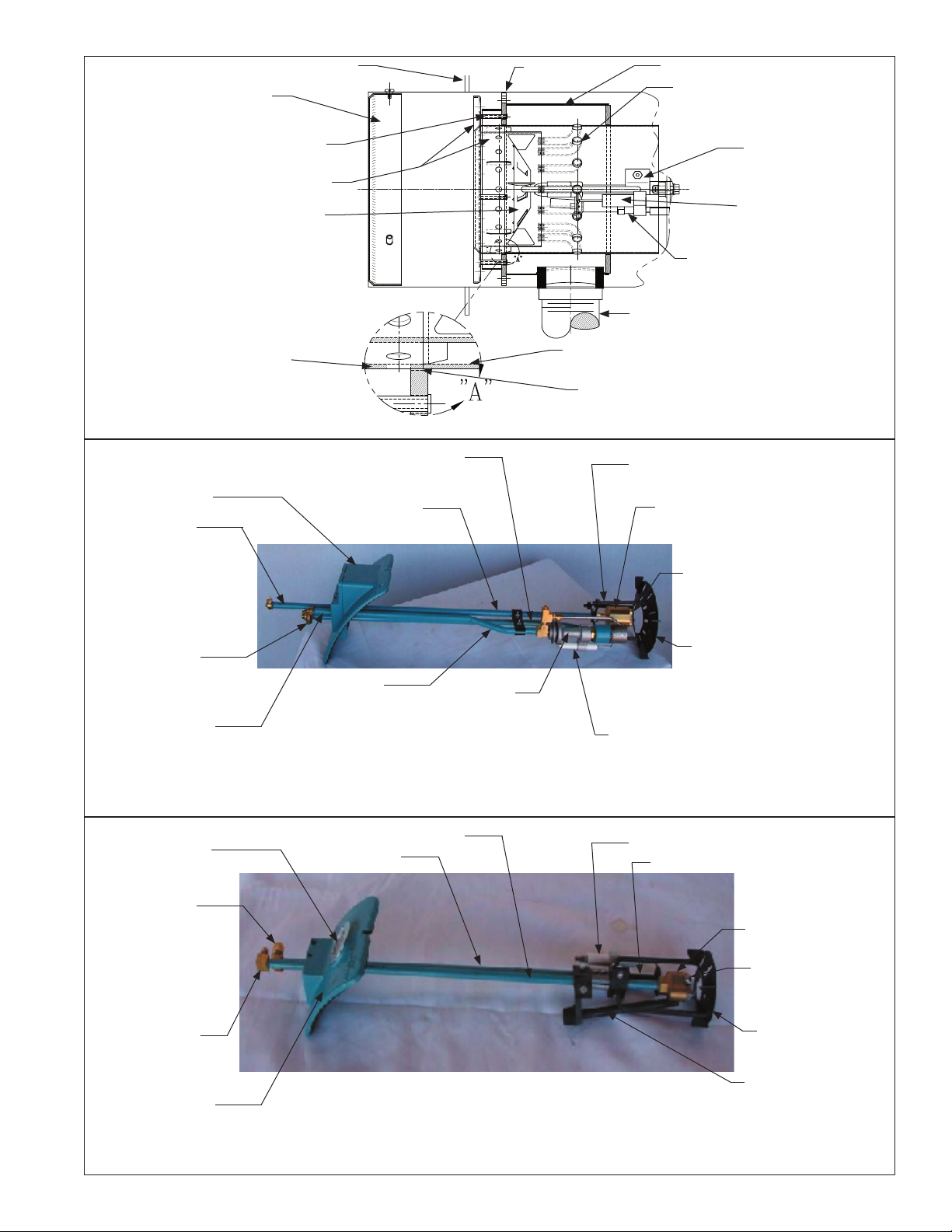

B. COMPONENT IDENTIFICATION

This secion shows the different common components used in the JB burner line and should be helpful to identify parts

described elsewhere in this manual.

Light & Switch Panel

Mod Motor

Figure B-1

JB2 Burner

Oil Fuel

Control Cabinet

Control Transformer

Sight Glass

Drawer Assembly

Gas Valve

Combustion

Head

Manual Ball Valve

Linkage

Louver Box

Oil Valve

Blower Motor

Oil Pressure Switch

Oil Pressure Gauge

Pilot Solenoid

Pilot Gas Regulator

Gas Actuator

Gas Valve

Ignition

Transformer

High Gas

Pressure Switch

Figure B-2

JB1G Left Side View

Figure B-3

JB1G Right Side View

Page 12 IdentificationJB Manual

Air Flow Switch

Pilot Gas Regulator

Gas Actuator

Gas Pressure Gauge

Page 13

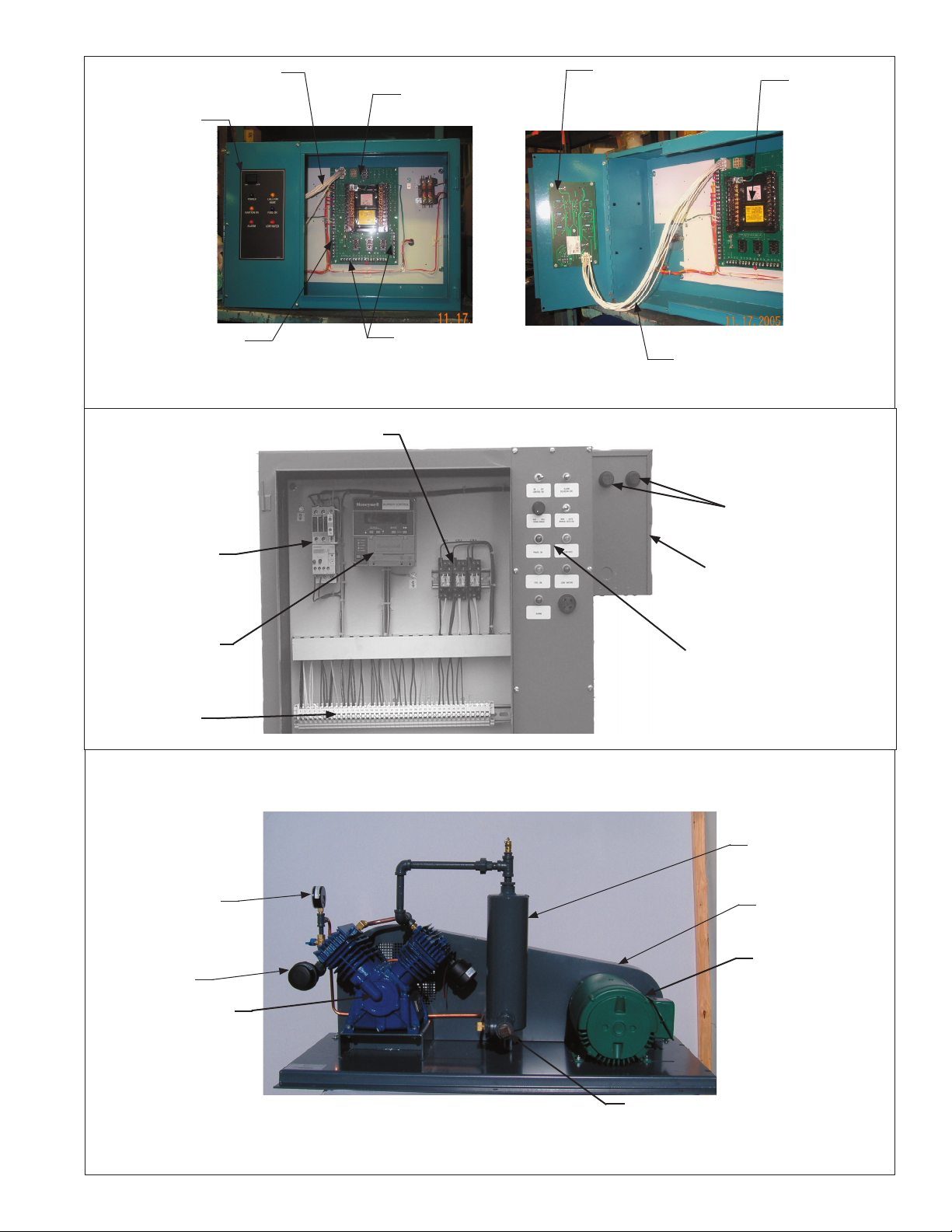

Switch / Light

Panel

Figure B-4

Control Panel

Circuit Board

Design

Board to Light

Panel Cable

Combination Flame

SafeGuard Base

and Circuit Board

Light Panel

Circuit Board

Flame SafeGuard

Base

Panel Wiring

Terminal Strip

Electrical Panel Identification: The above pictures show the flame safeguard base mounted on a circuit board. Connections are wired via cable to

light / switch circuit board. Picture below shows the flame safeguard (base) mounted directly to the panel back plate.

Figure B-5

Control Relays

Field Wiring

Terminal Strips

Board to Light

Panel Cable

Control Panel

Hard Wired

Design

Transformer Fuses

Burner Motor

Starter

Flame Safeguard

Terminal Strip

Control Transformer

Switch / Light Panel

Pressure

Gauge

Air Filter

Compressor

Figure B-6

Air Compressor

Page 13 IdentificationJB Manual

Air Chamber

Belt Guard

Electric Motor

Air Discharge

Connection

Page 14

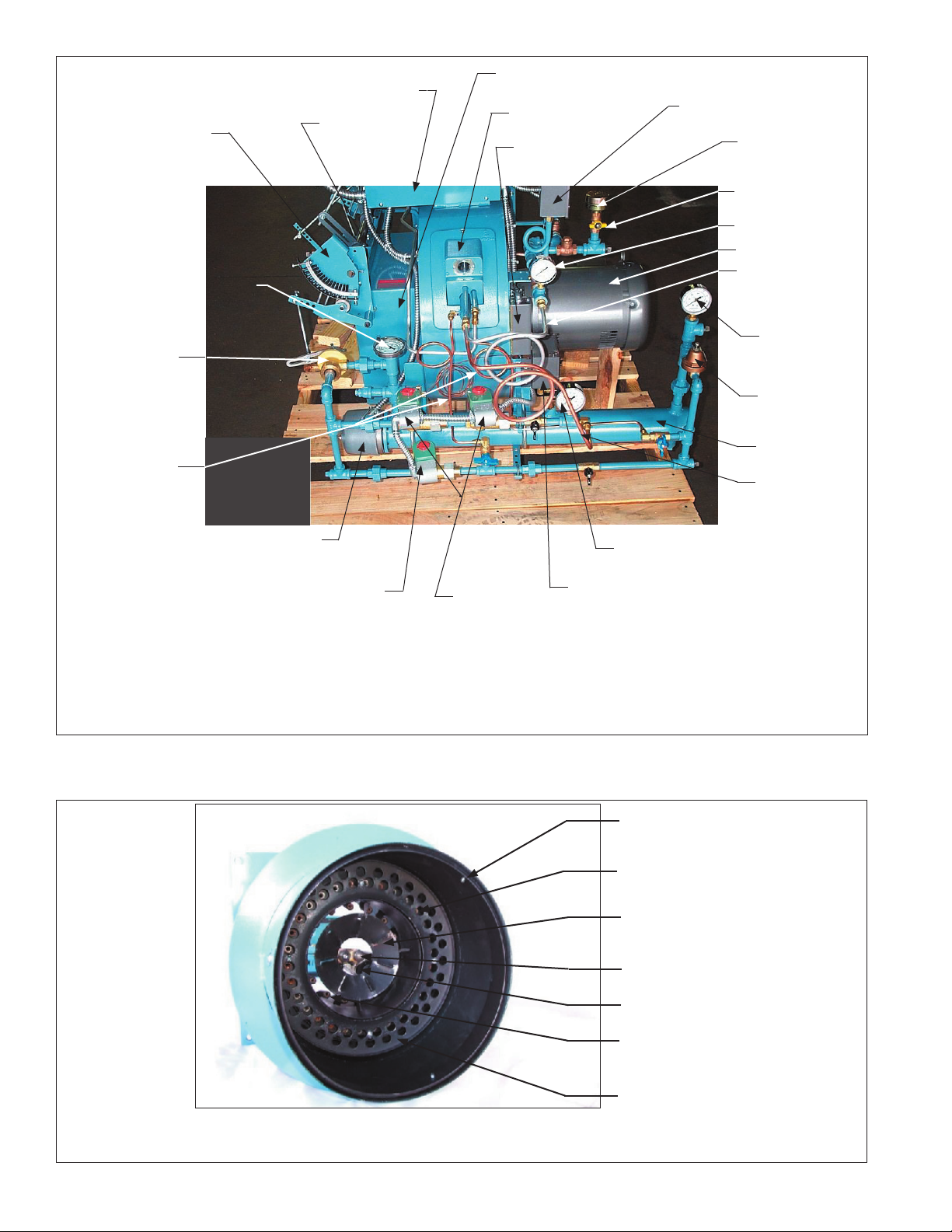

Oil Cam

Oil Metering

Valve

Drawer Assm.

Pre-heat Oil

Lines

Oil Temp.

Gauge

Electrical Junction Box

Jack Shaft

Air Inlet

Louver Box

Drawer Assembly

High Oil Temp.

Switch

Low Atomizing

Air Press. Sw.

Atomizing Air

Bleed Muffler

Air Bleed Valve

Atomizing Air

Press. Gauge

Blower Motor

Atomizing Line

to Nozzle

Supply Oil

Press. Gauge

Trim Heater

Safety Relief

Valve

Trim Heater

Oil Supply To

Nozzle

Thermostat Control

Switch & Cold Oil

Interlock Switch

N.O. Return

Oil Valve

Safety Oil

Valves

Figure B-7

JB Burner

#4 - 6 Fuel Oil

Nozzle Oil

Press. Gauge

Low Oil Press.

Switch

Choke Cone

JB1 & JB2 Only

Primary Gas Orifices

(Behind Retention Plate)

Diffuser Assembly

Oil Nozzle(s)

Figure B-8

JB Combustion Head - Dual Fuel

Page 14 IdentificationJB Manual

Gas Pilot

Secondary Gas Orifices

Retention Plate

Page 15

Nose Choke Cone

Mounting Flange

Orifice Plate

Gas Manifold

Secondary Gas Orifices

Primary Gas Orifice

Retention plate Assembly

Diffuser

Figure B-9

Standard Head Arrangement

Section View

Retention Plate

Assembly

Back Mounting

Plate w/View Port

To Oil System

Return

Oil Supply Line

Oil Return Line

Drawer Assembly

Ignition Electrode

Pilot Assembly

Gas Inlet

Gas Manifold (inner cylinder)

This connection between the retention plate assembly and the gas manifold inner cylinder must

be properly made for proper performance.

Diffuser Mounting Bracket

Oil Nozzle(s)

Adapter

Oil Nozzle(s)

Oil Supply Line

(lower pipe)

Pilot Gas Supply

View Port

Pilot Gas Inlet

Oil Supply Line

Backplate

Pilot Gas

Supply Line

Gas Pilot

Ignition Electrode

Figure B-10

JB3 Combination or Straight Oil Drawer Assembly

with Proven Gas Pilot

Oil Supply Line

Pilot Gas Line

Figure B-11

JB1 & 2 Combination Drawer Assembly

with Proven Gas Pilot Ignition

Diffuser

Ignition Electrode

Gas Pilot

Oil Nozzle(s)

Adapter

Oil Nozzle(s)

Diffuser

Sight Tube

Page 15 IdentificationJB Manual

Page 16

View Port

Oil Supply Line

Oil Supply Line

Oil Ignition Electrodes

Diffuser

Oil Nozzle(s)

Diffuser Clamp

Sight Tube

Oil Nozzle(s)

Adapter

Back Plate

Figure B-12

JB1 & 2 Straight #2 Oil Drawer Assembly

with Direct Spark Ignition

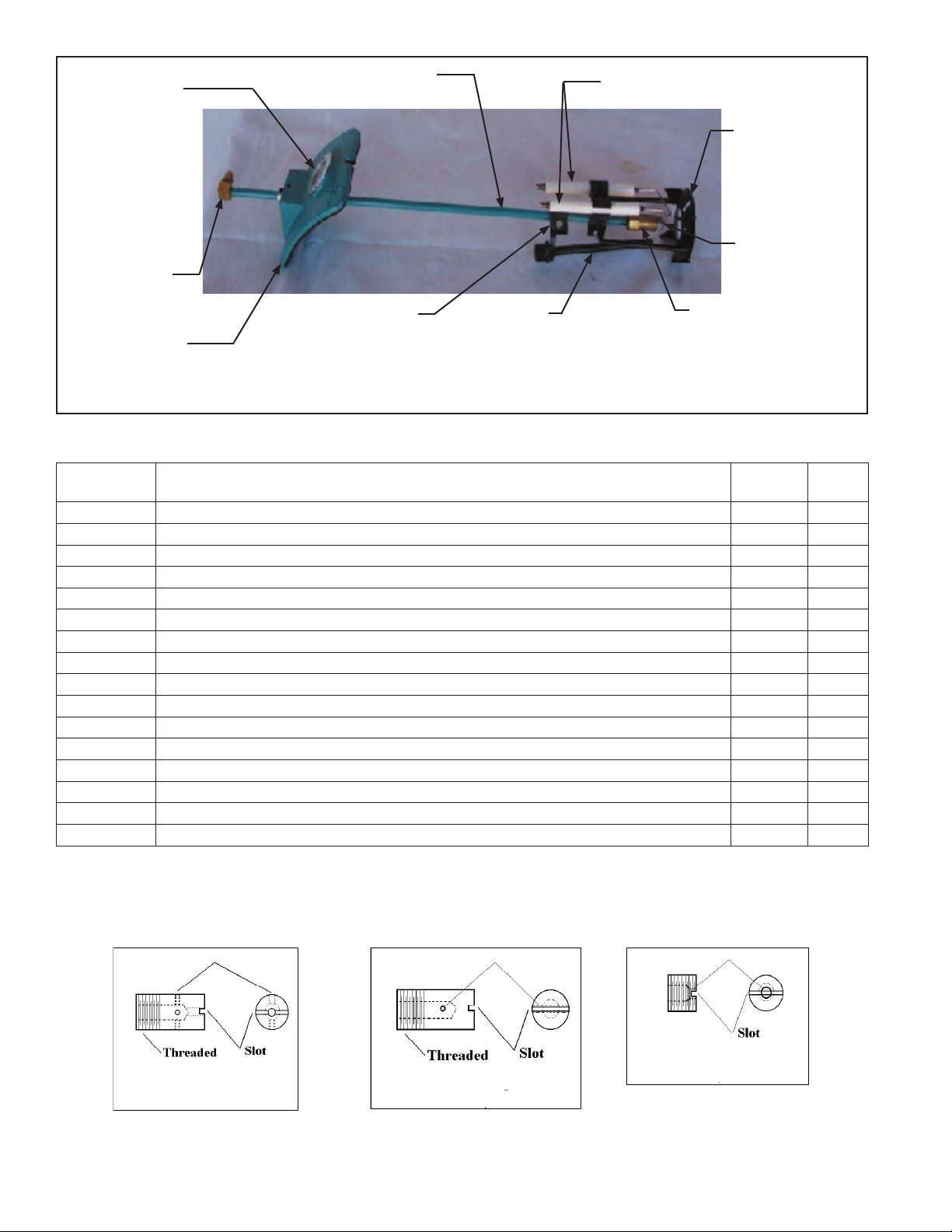

Gas Orifice Part Number and Description

Part No. Description Sketch

Example

090002 Gas orifice, 5/16” brass blank, no holes

090002-076 Gas orifice, 5/16” brass, (2) radial #48 holes, no axial hole (48 x 2) B FB

090002-098 Gas orifice, 5/16” brass, (2) radial #40 holes, no axial hole (40 x 2) B FB

090054-xxx Gas orifice, 5/16” brass, no radial holes, (1) axial hole (xxx = hole dia.) E FB, SF

090055-xxx Gas orifice, 5/16” steel, no radial holes, (1) axial hole (xxx = hole dia.) E

090069-xxx Gas orifice, 5/16” brass, (4) #40 radial holes, (1) axial hole (xxx = hole dia.) (40 x 4 x __ ) A FB, SF

090184-xxx Gas orifice, 5/16” steel, (4) #40 radial holes, (1) axial hole (xxx = hole dia.) (40 x 4 x __ ) A

090185-000 Gas orifice, 5/16” steel blank, no radial or axial holes

090185-098 Gas orifice, 5/16” steel, (2) radial #40 holes, no axial hole (40 x 2) B

090227-xxx Gas orifice, 5/16” brass, (4) #48 radial holes, (1) axial hole (xxx = hole dia.) (48 x 4 x __ ) A

090284-xxx Gas orifice, 1/4” steel, no radial holes, (1) axial hole (xxx = hole dia.) E

090287 Orifice extention, 5/16” OD steel tube, 1.188” long D

090288 Orifice extention, 5/16” OD steel tube, 2.75” long D

090318 Orifice extention, 5/16” OD brass tube, 1.188” long D SF

090319 Orifice extention, 5/16” OD brass tube, 2.75” long D

OT (open tube) No orifice used (If no orifice part number given in BOM, asume OP)

Vessel

Note: 1. Part numbers ending in “-xxx” use the drilled hole diameter as the last three digits, or

the “-xxx”. A number 40 drill would be “-098”.

2. Part numbers ending in “000” indicate no drilled hole.

3. Sketches show general appearance only, not number or type of holes.

4. Secondary orifices are closest to the burner center. primary orifices are on the outside.

4 Radial Holes

2 Radial Holes

Orifice Example “E”

Orifice Example “A”

4 Radial Holes, Axial Hole -xxx

If the radial drill size is a # 40 drill, this

would be called a “40 by 4” orifice,

which is common in the JB burner line.

JB Manual

Orifice Example “B”

2 Radial Holes, No Axial Holes

If the radial drill size is a # 40 drill, this

would be called a “40 by 2” orifice,

which is common in the JB burner line.

Page 16

No Radial Holes, 1 Axial Hole

The threads run the full length

of the orifice. This orifice cannot

have radial holes.

FB = Firebox

SF = Scotch Firetube

1 Axial Hole

Identification

Page 17

C. INSTALLATION

Prior to installing the burner, the site conditions and utilities need to be evalulated. This section provides some

general questions that can help the review process. Inspect the burner for any undetected damage that may

have occurred during shipment or by job-site handling.

Special attention should be given to the control panel

and protruding parts such as linkages. Check linkages,

air louver stops, wiring connections and fasteners for

tightness.

Verify that all ship loose (or separately shipped) items

are on hand. This normally will be: gas train components,

mounting lugs and insulating rope. Also, front mounting

plate and remote oil pump set, if supplied. The burner

material list included with the instruction manual serves

as a good checklist for this purpose.

1. Is there adequate outside ventilation to supply the

needed air for safe combustion as required by your local

regulatory agency?

2. If a burner mounting plate is required, is it available

and does it meet specifications? (See Section E)

3. Is 120-60-1 voltage available for the control circuit

and is the correct voltage available for the blower motor

as well for the remote oil pump set and air compressor,

if used?

4. Will the burner properly fit the boiler or heater with

ample clearance on top, bottom and sides?

5. If a gas burner, will there be adequate gas pressure to

assure the specified firing rate?

6. If a straight oil burner with gas pilot, is gas available at

the burner location?

7. If an oil burner, what is the age and condition of the

oil tank(s) and will there be special piping arrangements

needed to deliver the oil to the burner?

Important Note: The JB series burners must be operated with a two-pipe system.

8. If an oil burner, what grade of fuel oil is in the tank(s) or

on order? If a retrofit installation, has the same oil grade

always been used? Does it meet the grade specified on

the burner’s UL rating plate?

CAUTION

The oil burner shall only burn that grade of oil shown

on the UL rating plate. DO NOT USE GASOLINE,

CRANKCASE OIL, OR ANY OIL CONTAINING GASOLINE OR TOXIC CONTAMINANTS.

regulator and/or sensing line.

15. Oil piping to be flushed (cleaned) prior to use.

16. Check pump suction pressure (max 10” Hg) or max

press (3 psig) if transfer pump is used or tank elevation is

higher than the pump.

17. Strainer before oil pump, sized for max pump suction

capacity.

18. If FGR is used, does it follow Webster guidelines. (see

addendum 950064)

19. If multiple vessels connect to a single stack, are they

sized and designed to maintain +/- 0.1” wc draft at the vessel outlet under all operating conditions.

20. Is stack designed to maintain +/- 0.1” wc at outlet during

all operating conditions.

WARNING

DO NOT USE TEFLON TAPE OR COMPOUNDS

CONTAINING TEFLON. THIS COULD DAMAGE THE

VALVES CREATING AN UNSAFE OPERATION

21. Is the burner mounting plate and burner head sealed

with rope gasket? (See Figure E-2)

22. Has the new gas and oil piping been purged to remove

debris?

23. Is there a drop leg in the gas supply to capture foreign

material? (See Figure C-1)

24. Is the piping between the gas train and burner done in

a manner that will minimize the pressure drop?

25. Has all of the piping been pressure checked for leaks?

26. Is the combustion chamber of proper size and is the

center-line height of the burner head adequate? (See

charts C-2 & C-3.)

9. Is there adequate flue provisions to assure SAFE and

proper venting of the burner?

10. All manuals should be reviewed and understood and

stored in a convenient place.

11. Teflon tape should not be used on any field piping.

12. Rope gaskets should be used between vessel and

mounting plate, and between mounting plate and burner.

13. Gas piping should be flushed (cleaned) prior to use.

14. Check minimum straight lengths for gas pressure

Page 17 InstallationJB Manual

Page 18

Normally

open vent

valve

Pilot

Shutoff

Valve

Pilot Gas

Pressure

Regulator

Pilot Solenoid

Valve

Gas Supply

Gas Pressure

Regulator

Manual Gas

Shutoff Valve

If applicable, Webster

supplied gas train

Drip Leg

Low Gas

Pressure

Switch

Typical Gas Piping

Chart C-2 Chart C-3

TYPICAL COMBUSTION CHAMBER SIZE

FOR FIREBOX BOILERS, WATERTUBE &

CAST IRON SECTIONAL TYPES

Length

Shutoff

Valve

Figure C-1

FOR SCOTCH MARINE FIRETUBE BOILERS

High Gas

Pressure

Switch

Burner

Shutoff

Valve

Leak Test

Valve

TYPICAL COMBUSTION CHAMBER SIZE

Width

Height - Floor to Center of Burner

D. SPECIAL INSTRUCTIONS FOR CANADIAN INSTALLATIONS

1. The installation of a burner shall be in accordance with

the regulations of the provincial installation requirements,

or in their absence, the following shall govern:

Gas Burners--CGAB149.1 and CGAB149.2

Oil Burners--CSA Standard B139

Authorities having jurisdiction should be consulted before

installations are made.

2. All electrical wiring shall be done in accordance with

Page 18 Installation / Canadian InstallationsJB Manual

Length

Diameter

FURNACE DIAMETER - INCHES

the Canadian Electrical Code, Part I.

3. The installer shall identify (label) the main electrical

power disconnect and the manual shut-off valve on the

gas and/or oil supply drop-line to the burner.

4. Oil and gas burning equipment shall be connected to

flues having sufficient draft at all times, to assure safe

and proper operation of the burner.

Page 19

E. BURNER MOUNTING CRITERIA

It is of vital importance that the burner be properly mounted to the boiler or appliance being fired. Improper mounting

can cause leakage of the hot gases back around the burner head resulting in warpage and deterioration. The following

illustrations show the proper way the burner must be installed to validate warranty conditions.

TYPICAL JB1, 2, 3 BURNER REFRACTORY FRONTPLATE

B - Bolt Circle

Use minimum

of four (4) 1/2”

studs with lugs.

Minimum 7 gauge

A

4”

A - Opening

Minimum of six (6) holes for

boiler mtg. studs, 1/2” or larger

Minimum 14 Gauge

Figure E-1

Refractory Dimension

This surface must be

sealed against the vessel.

Check vessel mounting

requirements

Tighten clamp bolts

uniformly - check after

firing for several hours

MODEL DIM. A DIM. B

2” Minimum

2” Minimum

See Note 3

A

30o to 45o taper,

see note 4

Refractory OD is sized to fit

vessel opening with 1/4” to

1/2” gap, Refractory must

extend 2” beyond tube

sheet for scotch boilers.

Dimensions - Inches

JB1 7 5/8 10 3/4

JB2 9 5/8 12 3/4

JB3 11 5/8 14 3/4

Note: For JB burners equipped

with a low NOx cone, refer to addendum number 950064

Contact Webster for more detailed

refractory drawings

Fill voids between front plate

and vessel with

ceramic blanket

4” deep or as

defined by vessel

manufacturer.

The burner must

be level

Pipe support required

Flange secured to floor

Figure E-2

Burner Mounting Instruction

Page 19 Burner Mounting CriteriaJB Manual

If gap is over 3/16”,

wrap burner nose

with high temperature ceramic insulat-

Fiberglas rope

gasket must be

Refractory

Front Plate

Attachment to vessel varies with manufacturer (follow vessel manufacturers

recommendation.

The gas piping from the burner to the

train should have as few elbows as possible to reduce presure drop.

coiled to cover

the full mounting

flange surface

ing rope.

Page 20

F. FUEL SYSTEMS

The JB burner can be equipped with a wide range of fuel and operating systems to control the fuel, air, modulation

and pilots. This section describes how these systems operate. Burner start-up is expected to be done by service personnel who are qualified in the basics of mechanical know-how. The following illustrations and information is supplied

to identify the various fuel; air and ignition devices that have Adjustment Features. All adjustments can be done with

common place tools normally carried by burner and boiler service personnel.

NOTE

Refer to the bulletins included in the manufacturer’s data section of the burner instructions manual for items shown

below.

1. Pressure atomized oil systems

“A” - On - Off

Return to Tank

(No Manual Valves

in this line)

Suction

Supply Line

Field Piped

Check Valve

By Others

Shutoff Valve

Check

Valve

By Others

Unless Specified on Order

“L” - Low Fire Start or “H” - Low - Hi - Low

N.O. Low Fire

Bypass Oil Valve

Low Fire Bypass Regulator

(Adjustment for Low Fire

Approx. 100 - 125 PSI)

1

1

Strainer

Solenoid Valve

Gauge Port

Adjustment

Oil Pump

2

Low Oil

Press. Sw

Main Oil

Main Oil

Solenoid

.

Solenoid Valve

1

Valve

Safety Oil

Oil Nozzle

Notes & Options

These Lines are Field

Piped if a Remote

Pump is Used

Safety Oil

Solenoid Valve

2 or 3 1 (IN)

(out)

High Fire Cylinder

Louver Actuator

Field Piped

Return to Tank

(No Manual Valves

in this line)

Suction

Supply Line

Field Piped

Check Valve

By Others

Shutoff Valve

Page 20 Fuel SystemsJB Manual

1

1

Check

Valve

By Others

Unless Specified on Order

Strainer

Gauge Port

Adjustment

Oil Pump

ININ

Notes & Options

These Lines are Field

1

Piped if a Remote Pump

is Used

Required Above 20 GPH

2

if a Remote Pump is Used

Oil Nozzle

Page 21

“MP” - Modulating Simplex Nozzle

Oil Metering

Valve

2

Low Oil

Pressure Switch

Main Oil

Solenoid Valve

Safety Oil

Solenoid Valve

Return to Tank,

(No Manual

Valves in this

Line)

Suction

Supply Line

Field Piped

1

Check

Valve

By Others

Shutoff

Valve

Check

Valve

By Others

(Unless Specified on Order)

1

1

Strainer

Gauge Port

Adjustment

Oil Pump

Notes & Options

These Lines are Field

1

Piped if a Remote Pump

is Used

Usage Requirement

2

Varies with Code

Oil Nozzle

“MR” - Modulating Return Flow Nozzles

Back Pressure

Reg. Valve

1

Check

Valve

Check

Valve

Strainer

1

Suction

Supply Line

By Others

(Unless Specified in Order)

Return to Tank

(No Manual

Valves in this Line

Field Piped

Shutoff

Valve

2

Low Oil

Press. Sw

1

Check

Valve

Pressure

Gauge

.

Gauge Port

Oil Pump

Main Oil

Solenoid Valve

Oil Metering

Valve

Safety Oil

Solenoid Valve

Inline

Check

Valve

Pressure

Gauge

Oil Nozzle

(Bypassing)

Notes & Options

These Lines are

Field Piped if a

1

Remote Pump is

Used

Required Above 20

2

GPH if a Remote

Pump is Used

Page 21 Fuel SystemsJB Manual

Page 22

2. Air Atomized Oil Systems

Air Filter

Ball Valve

(man. set to adjust air

volume & high fire air

pressure)

Pressure

Gauge

Oil

Metering

Valve

Low Oil

Pressure

(man. set to adjust

air volume & high

fire air pressure)

Gauge

Air Filter

Ball Valve

Pressure

Gauge

Compressor

Relief Valve

Compressor

Oil

Metering

Valve

Safety

Valve

N.C.

Main Oil

Valve

Ball or

Gate

Valve

Air

Chamber

Air

Chamber

Air pipe same as

discharge open-

ing in air chamber

N.C. Main

Oil Valve

Air pipe same size

as discharge open-

ing in air chamber

(field Piped)

Safety

Oil

Valve

(field piped)

Safety

Oil Valve

Gauge

Low Air

Press Sw

“MA” - Modulating #2 Oil

Low

Atomizing

Pressure

Ball

Valve

Relief

Valve

Oil Pump

Check

Valve

Compound

Gauge

Gauge

Oil

Gauge

Flexible Metal Hoses or

Copper Tubing

Check

Valve

Check

Strainer

Valve

Field Piped

Field Piped

“MA” - Modulating #4 - 6 Oil

Air

Check

Valve

Ball

Valve

Gauge

Oil

Gauge

Oil Preheat Housing

Gate

Valve

Nozzle

Return

to Tank

Oil

Suction

Nozzle

N.O. Return

1 1

High Oil

Thermometer

Temp. Sw.

1

High Oil

Temp. Sw.

Electric oil heater w/integral low

oil temp. switch

Low Oil

Temp. Sw.

Relief

Valve

1

Low Oil

Temp. Sw.

Gauge

Drain

Oil Valve

Ball

Valve

Plug

Opening

Gate Valve

Back

Valve

Ball or

Gate Valve

Pressure

3 valve bypass optional for

back pressure valve.

Note: For a single burner

with the pump set close to

the burner the back pressure

valve can be furnished piped

with the oil pump set.

Ball or

Supply

Heating

System

Oil Supply for

Preheat Housing

Oil

Check

Valve

Ball or

Gate Valve

“MA” or “MS” - Modulating House Air or Steam

300 lb.

Gauge

Steam

Strainer

Drip Leg

Pressure

Reducing

Valve

Ball or Gate

Valve

Field Piped

125 PSIG

Max.

Atomizing

Steam

Condensate

Return

Steam

Syphon

Ball or Gate

Valve

Steam

Trap

Flexible Metal Hoses

or Copper Tubing

1/4” Ball

Valve

Relief

Valve

Gauge

Oil Pump

1/4” Ball

Valve

Compound

Gauge

Oil Return from

Preheat Housing

Strainer

Check

Valve

Check

Valve

Field Piped

Gate

Valve

Return

to Tank

Low Atomizing

Pressure Switch

Metering Lever

Ball Valve Linked

to Mod. Motor

N.C

Atomizing

Valve

Steam

Syphon

Check

Valve

Steam

Syphon

NOTE: House air does not use steam Syphon or Steam Trap

Oil

Suction

Gauge

Page 22 Fuel SystemsJB Manual

Page 23

3. Gas Systems

Illustrated Gas Trains by Capacity and Code: The following illustrations show the Webster configuration for UL,

FM and IRI as grouped by UL capacity ratings. Refer to the legend below for component part identification. These

illustrations are not to be used for field erection and/or system design purposes.

UL Capacity Range

BTU/Hr.

Operation Mode Webster

Designation

Code Illustration

UL / GE

FM

GAP

On-Off

A X X 722091

Low Fire Start L X X 722001

To 2,500,000

Low Hi Low H X X 722022

Modulating M X X 722003

Low Fire Start L X 722002

Low Fire Start L X 722009

2,500,001

to

5,000,000

Low Hi Low H X 722023

Low Hi Low H X 722024

Modulating M X 722004

Modulation M X 722010

5,000,001

to 12,500,000

12,500,001

and Up

Modulating M X 722005

Modulating M X 722011

Modulating M X 722082

Modulating M X 722084

NOTE: Pressure Drops; Pressure drop through a given gas train will vary somewhat in relation to the individual items

used, the specific gravity of the gas to be burned and the overall length.

722091

Gas

Supply

Field Piped

Manual Ball

Valve

Pilot Manual

Ball Valve

Vent To Outside

Atmosphere

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Main Solenoid

Pilot Solenoid

Gas Valve

S

Valve

S

Manual

Test Valve

Main Diaphragm

Gas Valve

D

Manual Test

Valve

Manual Ball

Valve

Field Piped

Test

Connection

UL-FM On-Off Gas Piping Diagram - Up to 2,500 MBH Firing Rate 1/2 PSI Max

Page 23 Fuel SystemsJB Manual

Gas Pilot

Ignitor

Gas Burner

Manifold

722091

Page 24

722001

Gas

Supply

Field Piped

Manual Ball

Valve

Gas Pressure

Regulator

Pilot Manual

Ball Valve

Vent To Outside

Atmosphere

Pilot Gas

Pressure

Regulator

Manual

Test Valve

Pilot Solenoid

Valve

Main Solenoid

Gas Valve

S

S

Field

Piped

Main Motorized

Gas Valve

26 Sec.

M

Manual Ball

Valve

Manual Test Valve

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

UL-FM Low Fire Start Gas Piping Diagram - Up to 2,500 MBH Firing Rate

722022

Gas

Supply

Field Piped

Manual Ball

Valve

Pilot Manual

Ball Valve

Vent To Outside

Atmosphere

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Pilot Solenoid

Main Solenoid

Gas Valve

S

Test Valve

Valve

S

Manual

Field

Piped

Main Motorized

Gas Valve

26 Sec.

M

Manual Test

Valve

Manual Ball

Valve

UL-FM Low-Hi-Low Gas Piping Diagram - Up to 2,500 MBH Firing Rate

722003

Gas

Supply

Field Piped

Manual Ball

Valve

Pilot Manual

Ball Valve

Vent To Outside

Atmosphere

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Main Solenoid

Pilot Solenoid

Gas Valve

S

Valve

S

Main Motorized

Gas Valve

26 Sec.

M

Manual Test

Valve

Manual

Test Valve

Manual

Ball Valve

Field Piped

UL-FM Modulation Gas Piping Diagram - Up to 2,500 MBH Firing Rate

722001

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

722022

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

Fuel Flow

Control Valve

722003

722002

Gas

Supply

Field Piped

Pilot Manual

Ball Valve

Manual Ball

Valve

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L

Pilot Solenoid

Valve

S

Main Reset Low

Gas Pressure

Switch

Main Solenoid

S

Gas Valve

Field Piped

Manual Test Valve

Main Motorized

Gas Valve

26 Sec.

M

Manual

Test

Valve

Vent

Field-Piped

H

Main Reset High

Gas Pressure

Switch

UL Low Fire Start Gas Piping Diagram - 2,501 to 5,000 MBH Firing Rate

Page 24 Fuel SystemsJB Manual

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

Manual Ball

Valve

722002

Page 25

722009

Gas

Supply

Field Piped

Manual Ball

Valve

Pilot Manual

Ball Valve

Vent To Outside

Atmosphere

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

L H

Manual Test

Valve

Pilot Solenoid

Valve

Man Reset Low

Gas Pressure

Switch

M

S

Main Motorized

Gas Valve

14 Sec.

Field Piped

Main Motorized

Gas Valve

26 Sec.

M

Manual

Test Valve

Man Reset High

Vent

Gas Pressure

Switch

Field

Piped

Manual Ball

Valve

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

FM Low Fire Start Gas Piping Diagram - 2,501 to 5,000 MBH Firing Rate

722023

Gas

Supply

Field Piped

Gas Pressure

Regulator

Manual Ball

Valve

Pilot Manual

Ball Valve

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L

Man Reset

Low Gas

Pressure

Switch

Pilot Solenoid

Main Solenoid

Gas Valve

S

Valve

S

Manual

Test Valve

Field

Piped

Main Motorized

Gas Valve

26 Sec.

M

Vent

H

Manual Test

Valve

Man Reset

High Gas

Pressure

Switch

Field

Piped

Manual Ball

Valve

UL Low-Hi-Low Gas Piping Diagram - 2,501 to 5,000 MBH Firing Rate

722024

Gas

Supply

Field Piped

Gas Pressure

Regulator

Manual Ball

Valve

Pilot Manual

Ball Valve

Vent To Outside

Pilot Gas

Pressure

Regulator

Atmosphere

Man Reset

Low Gas

Pressure

Switch

Main Motorized

Gas Valve

14 sec.

L

Pilot Solenoid

Valve

M

Manual

Test Valve

S

Man Reset

High Gas

Vent

Pressure

H

Switch

Field

Piped

Manual Ball

Valve

Field

Piped

Main Motorized

Gas Valve

26 Sec.

M

Manual Test

Valve

FM Low-Hi-Low Gas Piping Diagram - 2,501 to 5,000 MBH Firing Rate

722009

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

722023

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

7722024

722004

Gas

Supply

Field Piped

Pilot Manual

Ball Valve

Manual Ball

Valve

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L

Main Solenoid

Gas Valve

Pilot Solenoid

Valve

Man Reset Low

Gas Pressure

Switch

S

S

Main Motorized

Gas Valve

26 Sec.

M

Manual Test

Valve

Vent

H

Manual

Test Valve

Man Reset High

Gas Pressure

Switch

Manual

Ball Valve

Field Piped

Control Valve

UL Modulation Gas Piping Diagram - 2,501 to 5,000 MBH Firing Rate

Page 25 Fuel SystemsJB Manual

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

Fuel Flow

722004

Page 26

722010

Gas

Supply

Field Piped

Manual Ball

Valve

Pilot Manual

Ball Valve

Vent To Outside

Atmosphere

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

L

Manual Test

Valve

Pilot Solenoid

Man Reset Low

Gas Pressure

Switch

Main Mortorized

Gas Valve

14 Sec.

M

Valve

S

Main Motorized

Manual Test

Valve

Gas Valve

26 Sec.

M

Vent

High Pressure

H

Manual Ball Valve

Man Reset

Switch

Field Piped

Fuel Flow

Control Valve

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

FM Modulation Gas Piping Diagram - 2,501 to 5,000 MBH Firing Rate

722005

Gas

Supply

Field Piped

Pilot Manual

Ball Valve

Manual Ball

Valve

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L H

Main Solenoid

Gas Valve

Pilot Solenoid

Man Reset Low

Gas Pressure

Switch

S

Valve

S

Main Motorized

Gas Valve

W/POC

26 Sec.

Manual Test

POC

Valve

Man Reset High

Vent

Gas Pressure

Switch

M

Manual

Test Valve

Manual

Ball Valve

Field Piped

Fuel Flow

Control Valve

UL Modulation Gas Piping Diagram - 5,001 to 12,500 MBH Firing Rate

722011

Gas

Supply

Field Piped

Pilot Manual

Ball Valve

Manual Ball

Valve

Gas Pressure

Regulator

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L

Pilot Solenoid

Man Reset Low

Gas Pressure

Switch

Main Motorized

Gas Valve

14 Sec.

M

Valve

S

Main Motorized

Manual Test

Valve

Gas Valve

W/ POC

26 Sec.

M

POC

Vent

H

Manual Test

Valve

Man Reset

High Pressure

Switch

Manual Ball Valve

Field Piped

Fuel Flow

Control Valve

722010

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

722005

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

FM Modulation Gas Piping Diagram - 5,001 to 12,500 MBH Firing Rate

722082

Gas

Supply

Field Piped

Gas Pressure

Regulator

Manual Ball

Valve

Pilot Manual

Ball Valve

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L

Man Reset Low Gas

Pressure Switch

Pilot Solenoid

Normally Open

Vent Valve

Main Solenoid

Gas Valve

S

Valve

S

Vent

Manual

Test Valve

Main Motorized

Gas Valve

W/POC

14 sec.

S

M

POC

Vent

H

Manual Test

Valve

Man Reset High

Gas Pressure

Switch

Manual Ball

Valve

Field Piped

Fuel Flow

Control

Valve

UL Modulation Gas Piping Diagram - Over 12,500 MBH Firing Rate

Page 26 Fuel SystemsJB Manual

722011

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

722082

Page 27

722084

Gas

Supply

Field Piped

Gas Pressure

Regulator

Manual Ball

Valve

Pilot Manual

Ball Valve

Pilot Gas

Pressure

Regulator

Vent To Outside

Atmosphere

L

Man Reset Low Gas

Pressure Switch

Pilot Solenoid

Normally Open

Vent Valve

Main Motorized

Gas Valve

W/POC - 14 sec.

M

POC

Valve

S

Vent

S

Manual

Test Valve

Main Motorized

Gas Valve

W/POC

14 sec.

M

POC

Vent

H

Manual Test

Valve

Man Reset High

Gas Pressure

Switch

Manual Ball

Valve

Field Piped

Fuel Flow

FM Modulation Gas Piping Diagram - Over 12,500 MBH Firing Rate

Control

Valve

Gas Pilot

Ignitor

Test

Connection

Gas Burner

Manifold

722084

Page 27 Fuel SystemsJB Manual

Page 28

G. INITIAL SETTINGS

The burner will be set at the factory for normal initial settings. These are only rough settings that

must be adjusted at startup to match the furnace,

fuel pressure and environment of the specific application. These general settings are covered in

this chapter as a means of checking the burner

(linkage and settings can move in shipment) or

readjusting the burner if the settings are lost.

1. Oil nozzle position

The oil nozzle initial position is shown in Figure

G-2. The oil nozzle will be adjusted at start-up

and may be moved in or out from this initial setting. In some cases, the oil nozzle may be inside

the diffuser

B

Figure G-1

Oil Nozzle Position,

Gas Pilot

Flexible Strip

Chart G-2

PRESSURE ATOMIZED NOZZLE AIR ATOMIZED NOZZLE

Model Diffuser

I.D.

JB1

JB2

JB3

1 1/2”

1 3/4” 2

2 1/2” 3 60 5/8 2 1/2

2 7/8” 3 60 5/8 2 7/8

High Fire

Position

Qty. Spray

Angle

2

30 3/8

45 1/4

1

30 7/8

45 3/4

30 3/4

60 1/2

Cam

Low Fire Position

INNER FIRE CYLINDER

Dimension

Inches

Cam Set Screws

Adjusting Screws

Diffuser

I.D.

Nozzle

Type

Spray

Angle

Dim. ADim.

B

NA NA NA NA NA

2”

Single

Port

Multi

Port

60

80

o

o

1/4” NA45 5/8

NA 3/8

Return

Springs

Jack

Shaft

Retention

Plate

Aluminum Strip

End Screws

Spring

End Screw

Adjusting Nut

Cam Follower

Roller Washers

Figure G-3

Fuel Cam Adjustment

Page 28 Initial Settings JB Manual

Roller

Cam Follower

Page 29

COMBUSTION AIR CONTROL

Panel

Adjusting

Screw

Air Proving

Switch

AIR FLOW INTERLOCKING SWITCH

3. TYPICAL AIR AND FUEL ADJUSTMENT LOCATIONS

2. AIR PROVING SWITCH

The air proving switch has been adjusted at the factory

for an initial setting. If the switch trips during initial startup, turn the adjustment screw ccw two full turns to reduce the trip pressure setting.

4. Fuel Cam Adjustments (if applicable)

The fuel cam needs to be checked for correct travel

and alignment. Positions can change during shipment

and installation and they must be reviewed prior to

startup. The fuel cams are mounted to the ends of the

jackshaft assembly. A cam follower link follows the profile

established by the adjusting screws and drives the fuel

valve. A thin metal band is used between the screw and

cam follower to provide a smooth profile. The adjusting

screws are backed by compressed nylon inserts, which

provide a resistance to turning.

The cam (Figure G-3) should be checked for the following

conditions:

a. At the low fire position, the roller should be between

the first two adjusting screws. If not, adjust the position

of the cam accordingly, making sure to maintain the same

low fire fuel valve position.

b. When the linkage is modulated from low to high fire,

the roller must stay in the center of the adjusting screws

within 1/8”. If needed, the two cam set screws can be

loosened and the cam moved to center it on the roller.

JB Manual

Page 29 Initial Settings

c. At high fire, the roller should be between the last two

adjusting screws.

d. The adjusting screws should form a smooth contour

with no jumps between the screws.

e. In preparation of startup, the retention plate can

be removed temporarily to make it easier to adjust the

screws.

THE RETENTION PLATE MUST BE REPLACED WHEN

SETUP IS COMPLETE.

If the unit is equipped with a parallel positioning system

(linkageless), the control valves can be positioned and

operated in a similar manner, but accomplished through

the controller. Refer to the instruction manual for details.

CAUTION

LINKAGE AND ACTUATOR MOUNTINGS CAN BE BENT

OR MOVED DURING SHIPMENT AND INSTALLATION.

THEY MUST BE CHECKED PRIOR TO OPERATION AND

ANY FAULTS CORRECTED. FAILURE TO CORRECT A

MISALIGNED CONTROL WILL RESULT IN PREMATURE

FAILURE.

Page 30

H. IGNITION SYSTEMS

Electrode

Spark

Gap = 1/16”

Electrode Clamp

Pilot

Figure H-1

JB1 & JB2 Gas Pilot

Figure H-2 JB3 PILOT ASSEMBLY

Note: Required 2 1/2” - 3” wc

pressure for natural gas ans 1/2”

- 2” for LP, as measured at the

last solenoid in the pilot train.

Natural Gas Pressure;

4 - 6” wc

LP Gas Pressure;

1.5 - 2.5” wc

1. Gas Pilot Assembly

A crucial part of reliable burner operation is a dependable

pilot, which must be properly adjusted and kept clean. A gas

pilot is standard for all models except JB1 through JB2-20

straight oil pressure atomizing burners which have direct

spark ignition as standard. The following illustrations show

the typical configuration and nominal adjustment parameters of each pilot.

Figure H-1 showns the JB1 & JB2 gas pilot. Figure H-2

shows the JB3 gas pilot. Figure H-3 shows how the pilots

are positioned in the burner drawer.

Pilot gas pressure should be measured at the 1/8” port located on the downstream side of the last pilot solenoid valve.

2. Oil Nozzle Positiion, Direct Spark Oil.

Figures H-5 and H-6 show the position of direct spark ignition and nozzle positions. These are initial settings and will

be adjusted at start-up.

3. Air Damper Position

On a straight gas burner, the air damper should be open

about 1/4” at low fire and close to full open at high fire. In

Page 30 Ignition SystemsJB Manual

some applications, the pilot requires an orifice in the pilot

gas supply line. With the exception of the JB3, this orifice is located external of the blower housing.

The pilot to diffuser dimension is the distance of the face

of the pilot to the outer diameter of the diffuser.

For an oil or combination burner, the air damper should

be open about 3/8” at low fire and close to full open at

high fire.

4. Gas Modualting Control Valve Position

The gas valve should be open about 10% at low fire and

stroked to abput 60% open at high fire.

5. Oil Modulatining Control Valve Position.

For pressure atomizing, the low fire position should be

adjusted to get the correct low fire presure, as stated

on the rating label. Typically, this would be 100 psi for

simplex systems and 65 psi for return flow nozzles. The

high fire position should be about 45

low fire.

For air atomizing, the low fire should be on about #2 position and the high fire should be about the #8 position.

o

to 60o travel from

Page 31

Figure H-3

7/8”

Figure H-4

(2 1/2”)

(3 1/2”)

FIGURE H-5 DIRECT SPARK PRESSURE ATOMIZING OIL IGNITION (SEE TABLE BELOW)

Diffuser

ID

Note: These represent initial nozzle settings. The final

position will be determined in the start-up process.

FIGURE H-6

Page 31

Ignition SystemsJB Manual

Page 32

I. STARTUP AND OPERATING ADJUSTMENTS

1. Pre-start Checkout

2. Linkage Adjustments

3. Fuel Cam Adjustments

4. FGR Adjustment

5. Burner Drawer Adjustments

6. Single Fuel Setups

7. Combination Gas and Pressure Atomized Oil

8. Combination Gas and Air Atomized #2 Oil

9. Combination Gas and Heavy Oil

10. Gas Setup

11. Pressure Atomized Oil Setup

12. Air Atomized #2 Oil Setup

13. Heavy Oil Setup

14. Operating Control Adjustments

15. Limit Tests

16. Pilot Test

17. Burner Shutdown

18. Restart After Extended Shutdown

This section covers the startup and operating adjustments

of the Webster Models JB and JBX burners.

WARNING

BURNER STARTUP, COMBUSTION ADJUSTMENTS

AND LIMIT CONTROLS ADJUSTMENTS SHOULD

ONLY BE PERFORMED BY TRAINED AND EXPE

RIENCED SERVICE TECHNICIANS. ATTEMPTING

TO PERFORM THESE FUNCTIONS WITHOUT THE

PROPER TRAINING AND EXPERIENCE CAN RESULT IN EQUIPMENT DAMAGE, PERSONAL INJURY

OR DEATH.

Before proceeding with the startup and adjustment, be

sure that the overall installation is complete. Review the

boiler operating and installation manual, as well as all control manuals to verify that all equipment is ready for operation. These manuals must be read and understood prior

to starting the equipment.

If you are not qualified to service this equipment, DO NOT

TAMPER WITH THE UNIT OR CONTROLS - CALL YOUR

SERVICEMAN.

At the conclusion of the startup, document valve and

linkage positions, pressures and settings for future refer

ence.

READ AND SAVE THESE INSTRUCTIONS FOR FU

TURE REFERENCE.

-

______All fuel lines are connected and tight.

______Pilot gas is connected.

______Burner is mounted to vessel and floor, with all bolts

secured.

______The linkage is correct (in low fire position) and

tight.

______The stack is connected and routed to the outside.

Draft controls are installed and operational.

______Gas vent lines are connected and routed to the

outside.

______Do not start the unit unless all cleanout doors are

in place and secured.

______The vessel is completely installed, filled with water

and operating controls checked.

______Support equipment is in place and ready (feed

pumps, draft controls, steam/hot water systems, boiler

limits and controls and feedwater systems).