Page 1

INSTALLATION AND

OPERATION MANUAL

Vertical Multi-Port

Hot Water Boilers

Model VMP-W

40 -150 HP

Serial/ National

Board Number

Model

Fulton Order

Sold To

Job Name

Date

VMPW-IOM-2012-1001

Page 2

Page 3

VMPW-IOM-2012-1001 TABLE OF CONTENTS

Introduction 1-1

Overview .............................................................................................................. 1-2

Warnings & Cautions ............................................................................................1-2

Disclaimers and Local Codes ................................................................................1-2

Installation 2-1

Placement & Rigging ........................................................................................... 2-2

Clearances & Serviceability .................................................................................. 2-4

Environment, Ventilation and Combustion Air Requirements ............................ 2-4

Utilities .................................................................................................................2-6

THE GAS SUPPLY ..........................................................................................................................26

THE OIL SUPPLY ...........................................................................................................................27

Electrical Supply ................................................................................................... 2-8

Water Supply ........................................................................................................2-8

INSTALL WATER PIPING ...............................................................................................................28

Water Chemistry Requirements ...........................................................................2-9

PREVENT OXYGEN CONTAMINATION ........................................................................................210

ELIMINATE SYSTEM AIR ............................................................................................................210

Piping Speci cations .......................................................................................... 2-11

Insulation ........................................................................................................... 2-12

System Interfaces ............................................................................................... 2-12

FILL CONNECTION ......................................................................................................................212

Assembly of Multi-Skid Systems ........................................................................ 2-12

Stack and Flue ....................................................................................................2-13

EXHAUST SIDE WALL VENTING ................................................................................................215

Testing ................................................................................................................ 2-16

Maintenance 4-1

Daily Maintenance Schedule ................................................................................ 4-2

Weekly Maintenance Schedule ............................................................................4-2

Monthly Maintenance Schedule .......................................................................... 4-2

Recommended Semi-Annual Maintenance Schedule ......................................... 4-3

Recommended Annual Maintenance Schedule ..................................................4-5

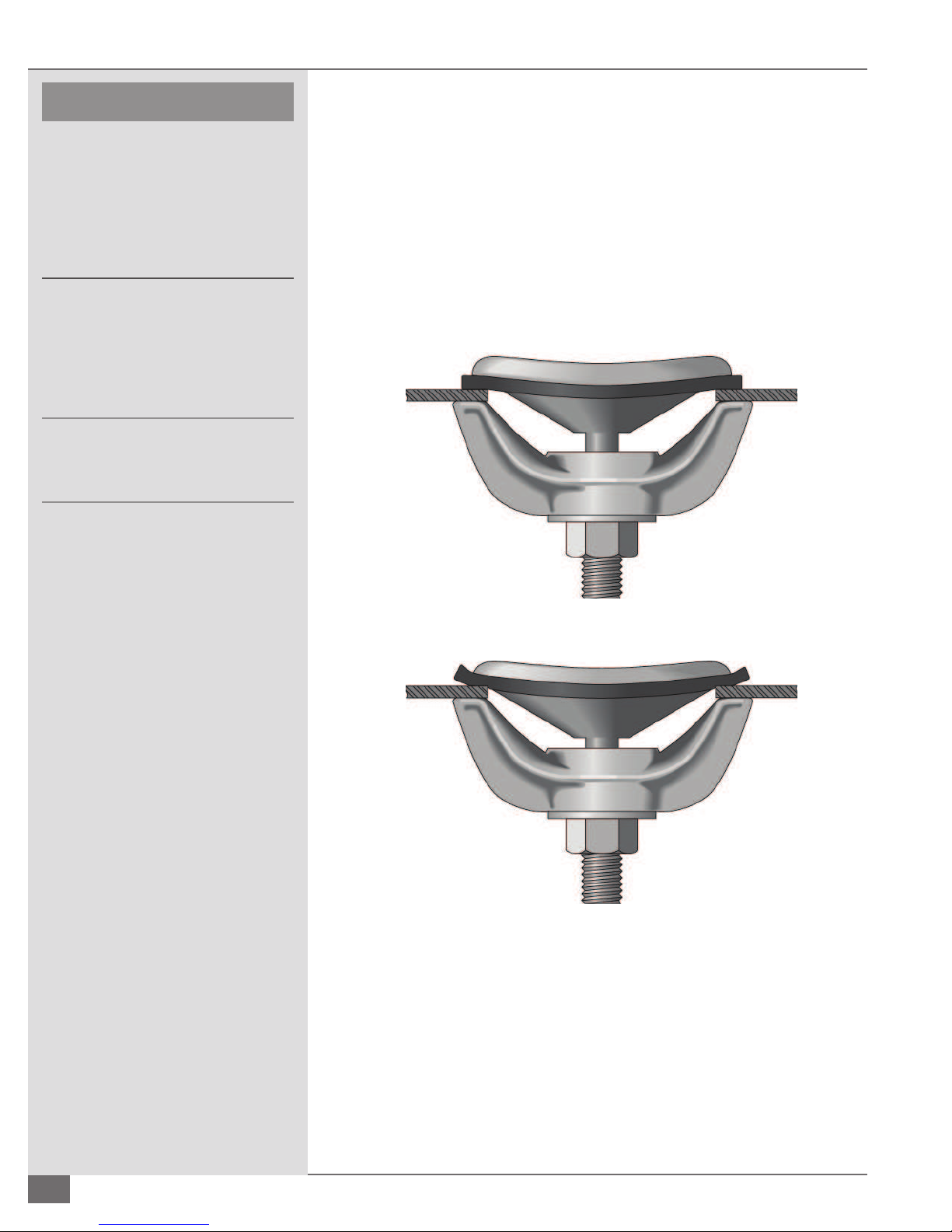

Procedure for Primary Air Adjustment/Inspection .............................................. 4-6

Procedure for Secondary Air Adjustment/Inspection ..........................................4-6

Procedure for Flame Scanner Adjustment ...........................................................4-7

GAS UNIT ......................................................................................................................................47

OIL UNIT ......................................................................................................................................47

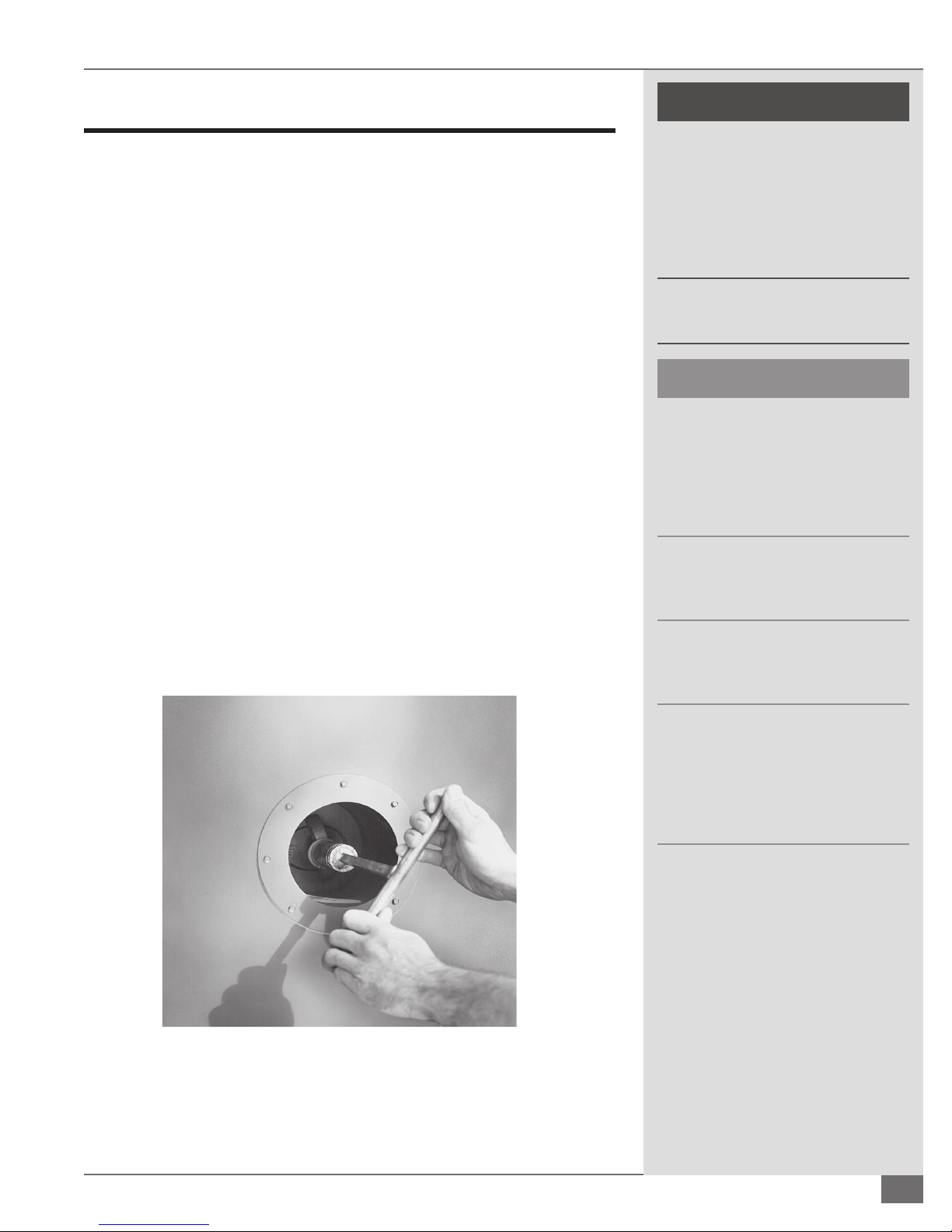

Procedure for Removing/Cleaning the Burner ....................................................4-8

Procedure for Soot Cleaning................................................................................. 4-8

After All Repairs or Maintenance .........................................................................4-9

Troubleshooting ...................................................................................................4-9

Warranty & Parts 5-1

Standard Warranty for Fulton Boilers................................................................... 5-3

Parts ..................................................................................................................... 5-4

Operation 3-1

Start-Up Preparation & Installation Review ........................................................ 3-2

Start-Up Service ................................................................................................... 3-3

Initial Start-Up ..................................................................................................... 3-4

COMBUSTION ...............................................................................................................................34

Flame Programmers ............................................................................................ 3-5

Operating Controls ............................................................................................... 3-5

WATER RELIEF VALVE ...................................................................................................................35

WATER OUTLET VALVE .................................................................................................................35

TEMPERATURE CONTROL ...........................................................................................................35

OPERATING TEMPERATURE AQUASTAT ......................................................................................35

HIGH LIMIT AQUASTAT/HIGH TEMPERATURE LIMIT ..................................................................36

AIR SAFETY SWITCH ....................................................................................................................36

PROBE TYPE LOW WATER CUTOFF .............................................................................................36

Optional Circulating Pump Switch .......................................................................3-6

Cycle Testing ......................................................................................................... 3-6

Before Leaving the Installation ............................................................................ 3-6

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

0-1

Page 4

TABLE OF CONTENTS VMPW-IOM-2012-1001

0-2

© The Fulton Companies 2012

Page 5

INTRODUCTION

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

1-1

Page 6

INTRODUCTION VMPW-IOM-2012-1001 SECTION 1

Overview

Prior to shipment, the following inspections and tests are

made to ensure the highest standards of manufacturing for

our customers:

§ Material inspections

§ Manufacturing process inspections

§ American Society of Mechanical Engineers (ASME)

welding inspection

§ ASME hydrostatic test inspection

§ Electrical components inspection

§ Operating test

§ Final engineering inspection

§ Crating inspection

This manual is provided as a guide to the correct operation

and maintenance of your Fulton equipment, and should be

read in its entirety and be made permanently available to the

sta responsible for the operation of the boiler. It should not,

however, be considered as a complete code of practice, nor

should it replace existing codes or standards which may be

applicable. Fulton reserves the right to change any part of

this installation, operation and maintenance manual.

Installation, start-up, and maintenance of this equipment

can be hazardous and requires trained, quali ed installers

and service personnel. Trained personnel are responsible

for the installation, operation, and maintenance of this

product, and for the safety assurance of installation,

operation, and maintenance processes. Do not install,

operate, service or repair any component of this

equipment unless you are quali ed and fully understand

all requirements and procedures. Trained personnel

refers to those who have completed Fulton Service School

training speci c to this product.

Warnings & Cautions

WARNINGS and CAUTIONS appear in various chapters of this

manual. It is critical that all personnel read and adhere to all

information contained in WARNINGS and CAUTIONS.

§ WARNINGS must be observed to prevent serious injury

or death to personnel.

§ CAUTIONS must be observed to prevent damage

or destruction of equipment or loss of operating

e ectiveness.

All Warnings and Cautions are for reference and guidance

purposes, and do not substitute for required professional

training, conduct, and strict adherence to applicable

jurisdictional/professional codes or regulations.

Disclaimers and Local Codes

Installation of the equipment shall conform to all the

requirements or all national, state and local codes established

by the authorities having jurisdiction or, in the absence

of such requirements, in the US to the National Fuel Gas

Code ANSI Z2231/NFPA 54 latest edition, and the speci c

instructions in this manual. Authorities having jurisdiction

should be consulted prior to installation.

When required by local codes, the installation must conform

to the American Society of Mechanical Engineers Safety Code

for Controls and Safety Devices for Automatically Fired Boilers

(ASME CSD-1).

When working on this equipment, observe all warnings,

cautions, and notes in literature, on stickers and labels, and

any additional safety precautions that apply. Follow all safety

codes and wear appropriate safety protection. Follow all

jurisdictional codes and consult any jursidictional authorities

prior to installation.

1-2

© The Fulton Companies 2012

Page 7

INSTALLATION

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-1

Page 8

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Crystalline silica may be present

in components of this equipment.

Exposure to crystalline silica may

pose signi cant health hazards,

including but not limited to eye and

respiratory system damage. Per

the Centers for Disease Control and

Prevention (CDC) and Occupational

Safety and Health Administration

(OSHA), appropriate Personal

Protective Equipment must be worn

to minimize exposure to hazardous

substances. Refer to most current

guidelines o ered by the CDC and

OSHA for more information, including

Personal Protective Equipment

recommendations.

This boiler is certi ed for indoor

installation only.

A competent rigger experienced in

handling heavy equipment should

handle rigging your equipment into

position.

The equipment must be installed on a

non-combustible surface.

Do not store or use gasoline or other

ammable vapors and liquids or

corrosive materials in the vicinity of

this or any other appliances.

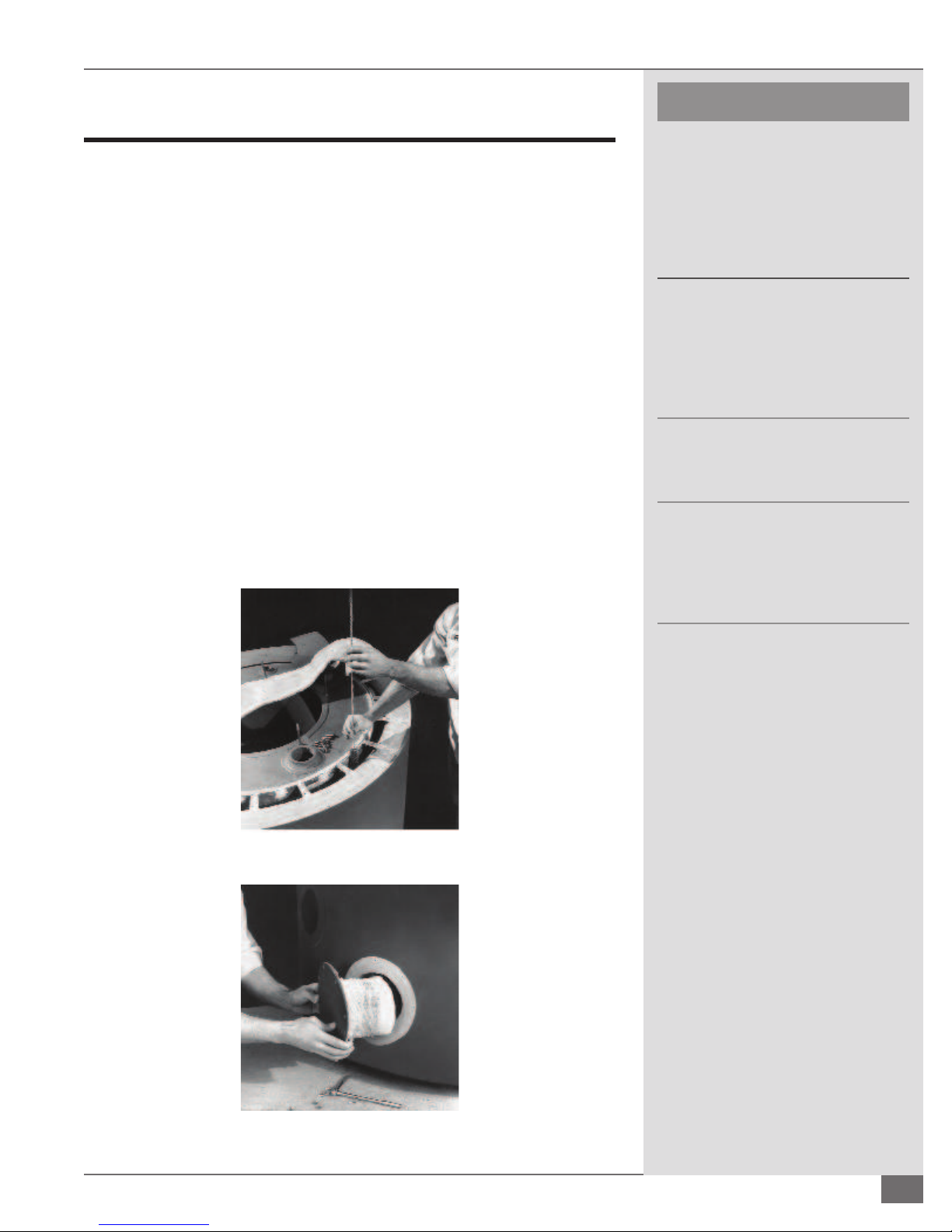

Placement & Rigging

Proper placement of your Fulton Product (see Figure 1, and Tables 1 and 2) is

essential. Attention paid to the following points will save a great deal of di culty

in the future. Correct placement is the rst step to trouble-free installation,

operation and maintenance.

Adhere to the following for equipment placement and rigging:

1. Consult authorities with jurisdiction over any national or local codes

(including but not limited to National Fire Protection Agency (NFPA),

American National Standards Institute (ANSI), Underwriters Laboratories

(UL), SCA, and ASME, which might be applicable to boiler applications

before beginning.

2. Make appropriate determinations for placement, based on the following:

§ Check building speci cations and Table 2 for unit weights.

§ Ensure the equipment is to be placed on a non-combustible level base

with adequate clearances from combustible materials. See Clearances &

Serviceability section.

§ Locate boiler as close as possible to the place where the heat will be used

in order to keep pipe work costs to a minimum.

§ Ensure that there is adequate clearance around the unit to provide

access for operators and maintenance personnel to all parts of the

equipment. Ensure also that clearance provides for component removal for

maintenance. See Clearances & Serviceability section. The equipment

should be placed in a suitable boiler house or well ventilated separate

room through which personnel do not normally pass. The layout should

eliminate tra c in potentially hazardous areas. For instance, the service

engineer or the operator should not have to pass exposed, hot pipe work

to make adjustments to the boiler controls.

§ Ensure the equipment is to be placed in such a way that the electrical

components are protected from exposure to water or excessive humidity.

§ Ensure the boiler is located a safe distance from the fuel oil tank (if

applicable).

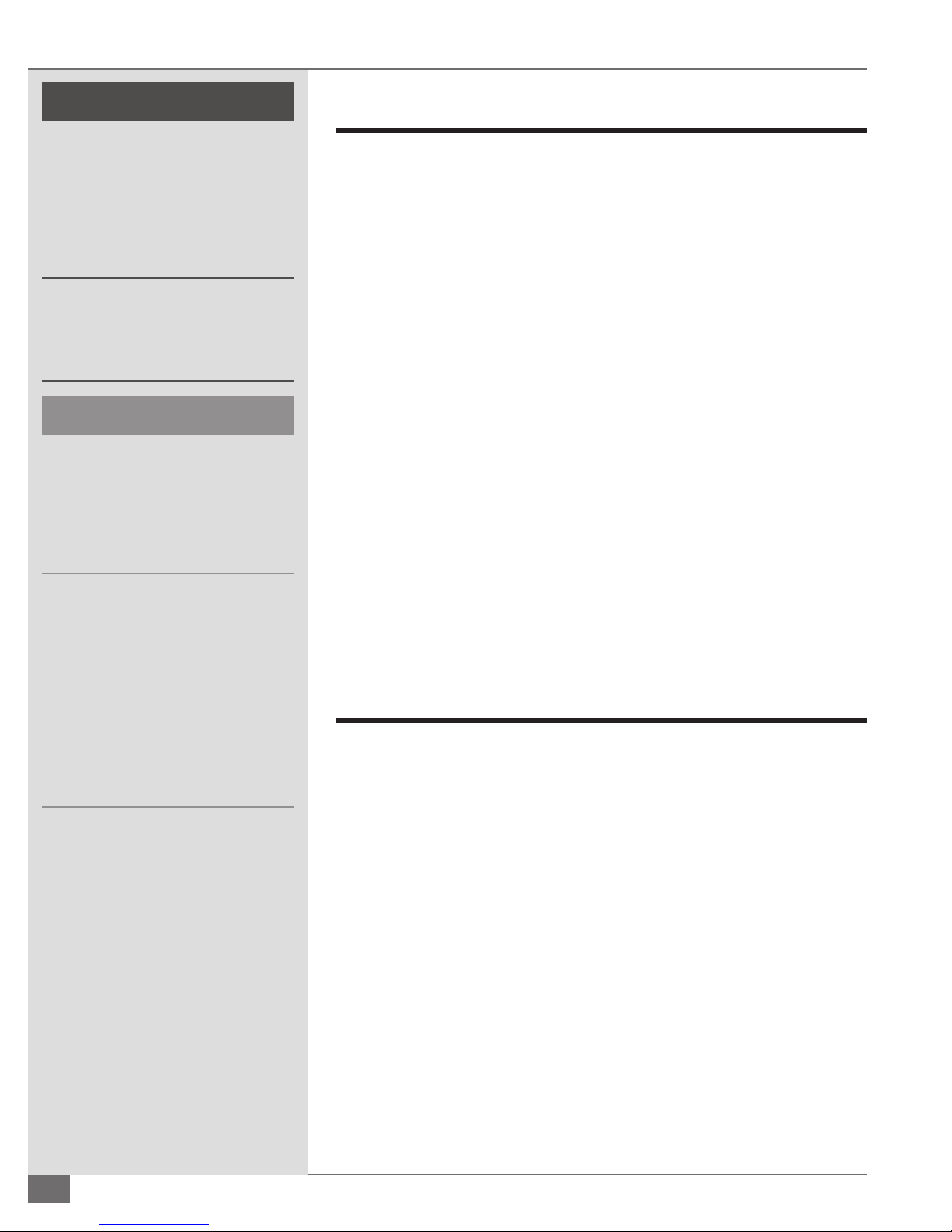

3. Determine rigging procedure, based on the following:

§ Units are shipped and crated for forklift transport. Once uncrated, all units

can be transported with a forklift and/or lifting lugs at the top of the boiler.

All skidded units can be moved with forklifts.

4 CAUTION

Do not allow weight to bear on

equipment components to prevent

damage.

2-2

§ If means of lifting are not available, place rollers beneath the frame of the

equipment for guidance to the position of where it is to be installed.

§ Under no circumstances allow weight to bear on the jacket, control panel,

burner, fuel train or fan housing of any Fulton boiler.

§ Tagged support legs on boiler are for shipping purposes only. These must be

removed at time of installation, and may not be used to mount or anchor

boilers.

© The Fulton Companies 2012

Page 9

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

F

E

C

G

K

D

B

J

A

H

H.H.

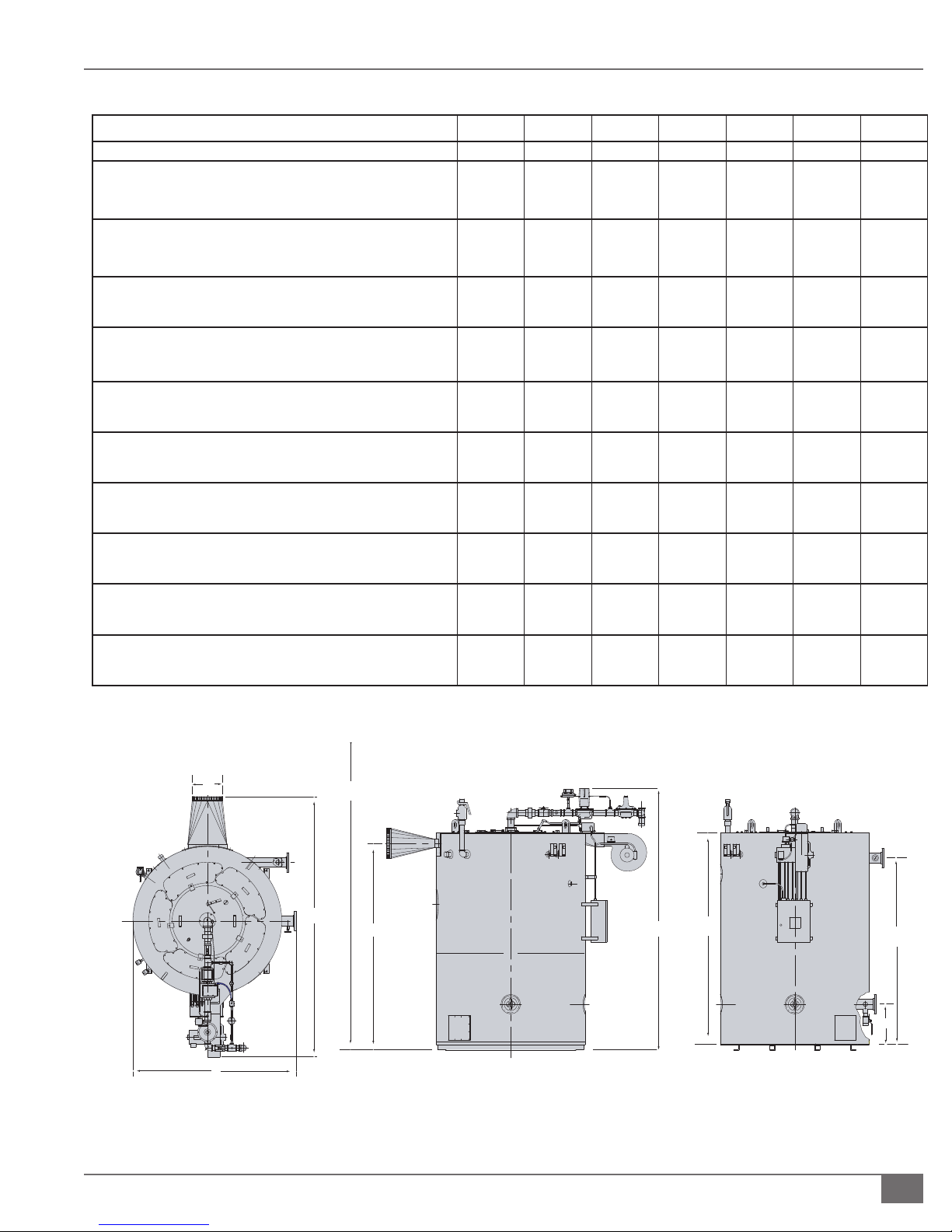

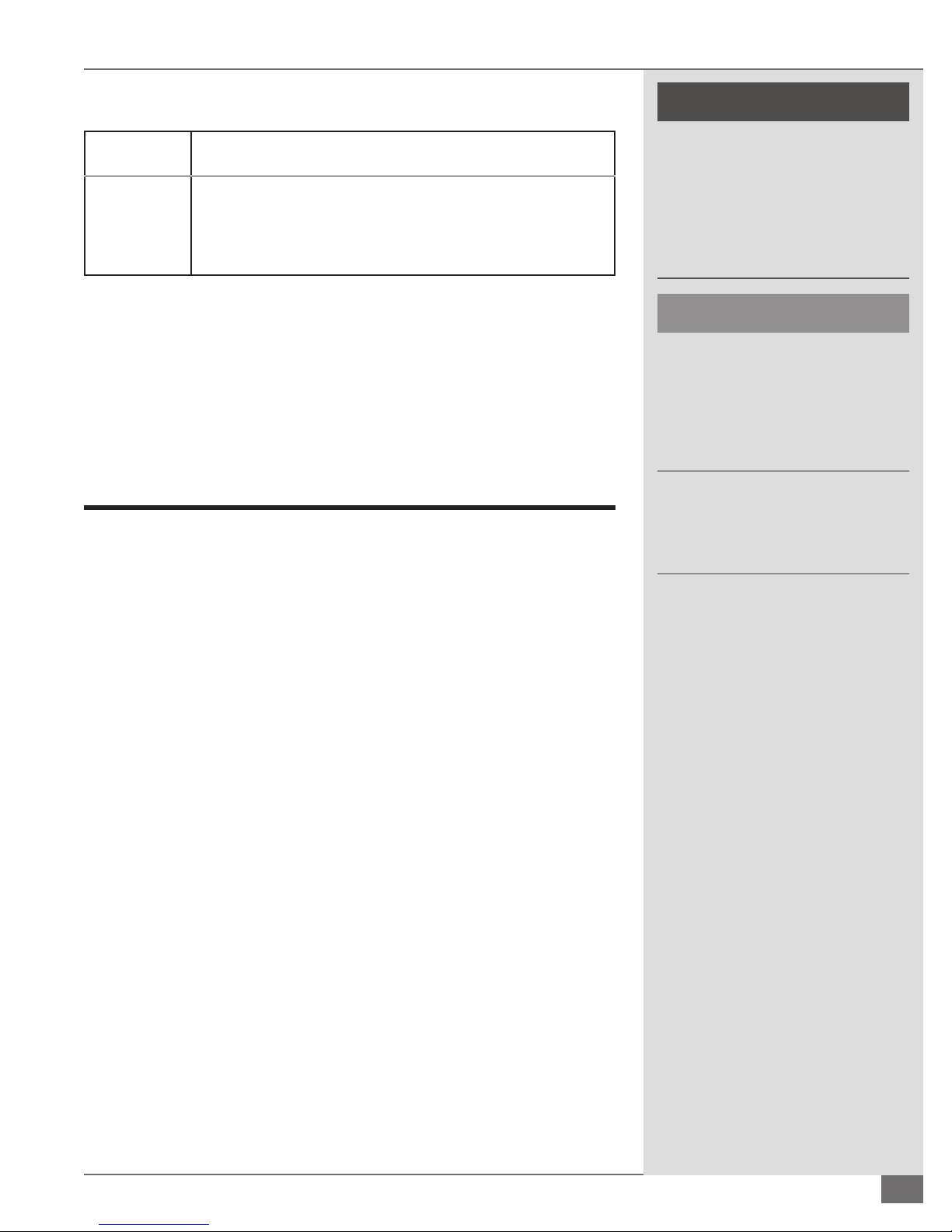

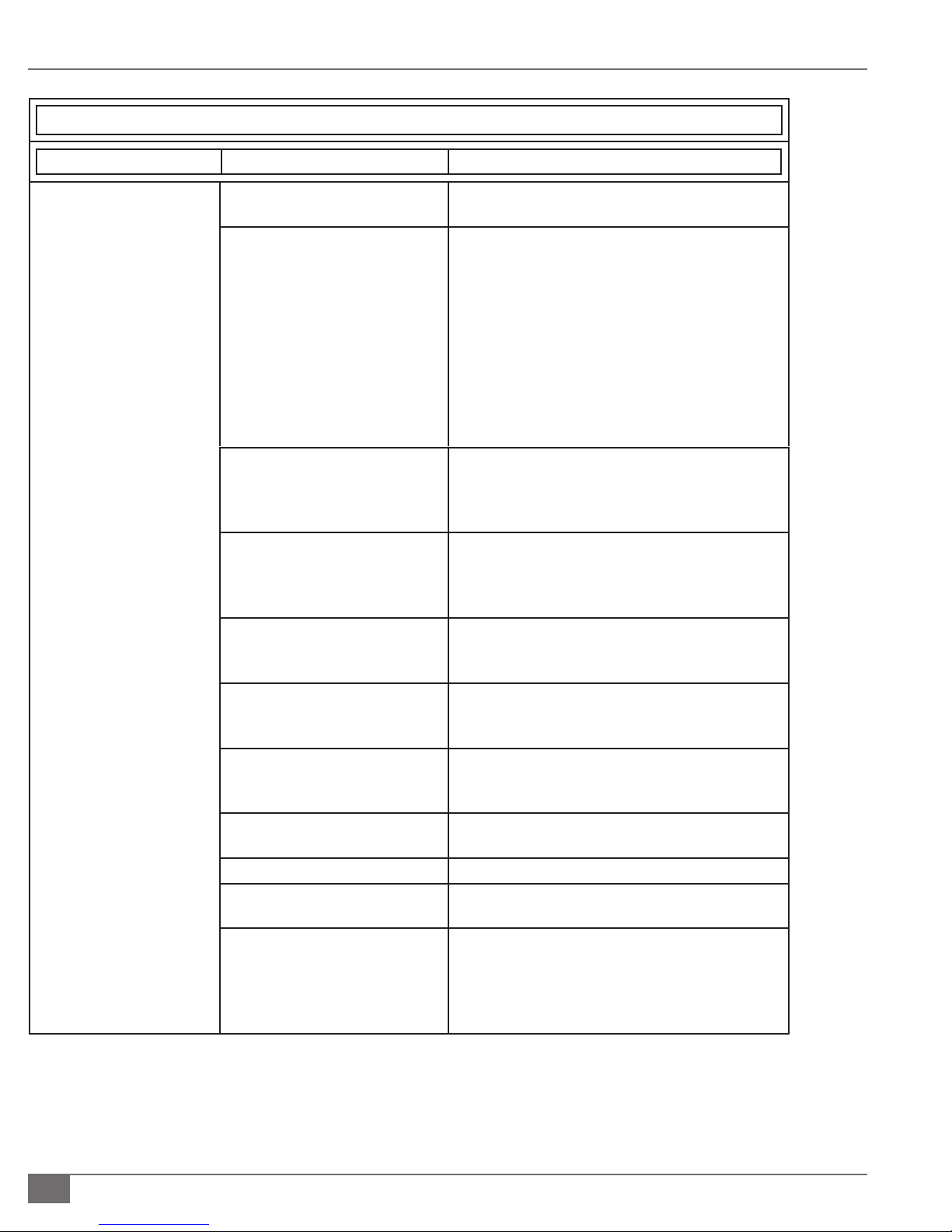

TABLE 1 DIMENSIONS REFER TO FIGURE 1

Model VMP-W 40 50 60 80 100 130 150

Unit Size BHP 40 50 60 80 100 130 150

A. Boiler Diameter

IN

MM

(B) Boiler Height

IN

MM

(C) Boiler Depth

IN

MM

(D) Boiler Height With Trim

IN

MM

(E) Overall Boiler Width

IN

MM

(F) Flue Outlet Diameter

IN

MM

(G) To Center of Flue Outlet

IN

MM

(H) Return Water Inlet Height

IN

MM

(J) Water Outlet

IN

MM

(K) Min. Clearance to Ceiling for Burner Removal

IN

MM

49

1245

84

2133

90

2286

107

2718

56

1422

12

305

79

2006

20.3

516

73.8

1870

123

3124

55

1397

91

2312

100

2540

113

2870

62

1575

12

305

83

2108

20.3

516

77.8

1980

135

3429

55

1397

97

2464

100

2540

119

3023

62

1575

12

305

89

2261

20.3

516

83.8

2130

144

3658

63

1600

100

2540

114

2896

125

3175

68

1727

14

356

95

2413

20.3

516

89.8

2280

147

3734

69

1753

100

2540

119

3022

125

3175

74

1880

14

356

95

2413

20.3

516

89.8

2280

147

3734

76.5

1943

115

2921

128

3251

149

3785

84.5

2146

14

356

107

2718

23.6

599

101.1

2570

155

3937

76.5

1943

115

2921

130

3302

149

3785

84.5

2146

14

356

107

2718

23.6

599

101.1

2570

155

3937

All data is approximate. Fulton reserves the right to change data without prior notice.

FIGURE 1 MODEL VMPW DIMENSIONS/SPECIFICATIONS REFER TO TABLES 1 AND 2

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-3

Page 10

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

Failure to provide required and safe

access to the equipment could impede

commissioning and maintenance.

Service technicians are instructed not to

commence commissioning if hazardous

conditions exist.

Failure to provide proper minimum

clearances between equipment and

combustible materials may result in re.

The installation of an exhaust fan in the

boiler room is not recommended. An

exhaust fan or similar equipment can

create a downdraft in the stack or restrict

the burner’s air supply and result in poor

combustion. It is essential only fresh

air be allowed to enter the combustion

air system. Foreign substances such as

combustible volatiles and lint may create

hazardous conditions.

NOTE: ´ When calculating ventilation requirements, heat losses from the Fulton

equipment (and other equipment) should be considered.

Clearances & Serviceability

Adhere to the following for equipment clearances and serviceability:

1. Ensure appropriate front, back, sides and top clearances are met. This

will allow access around the equipment to facilitate maintenance and a

safe work environment, and ensure technicians will commission the unit.

Technicians will not commence commissioning if hazardous conditions

exist.

2. Place boiler with clearances to unprotected combustible materials,

including plaster or combustible supports, not less than the following:

§ Heater Front: 36 in. (914 mm)

§ Heater Sides and Rear: 18 in. (457 mm)

§ Heater top: 24 in. (610 mm)

§ Allow for additional minimum clearances for personnel access and burner

removal, as necessary.

§ Verify that all clearances are acceptable with the local ordinances.

Environment, Ventilation and Combustion Air

Requirements

Ensure all labels on the boiler are legible.

All connections and safety devices, both

mechanical and electrical, must be kept

clean, with ease of access for inspection,

use and maintenance.

It is critical to provide free access of air to the boiler. To burn fuel properly, it

requires one square inch opening for every 3,000 BTU input of fuel (6.4 cm2 for

every 756 kCal).

Adhere to the following to meet ventilation and combustion air requirements:

1. Install two fresh air openings, one at a low level, 24” (610 mm) from the

oor, and one at a higher level on the equipment room wall. This will

provide a ow of air to exhaust the hot air from the equipment room.

2. Ensure the equipment room air supply openings are kept clear at all times.

2-4

© The Fulton Companies 2012

Page 11

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

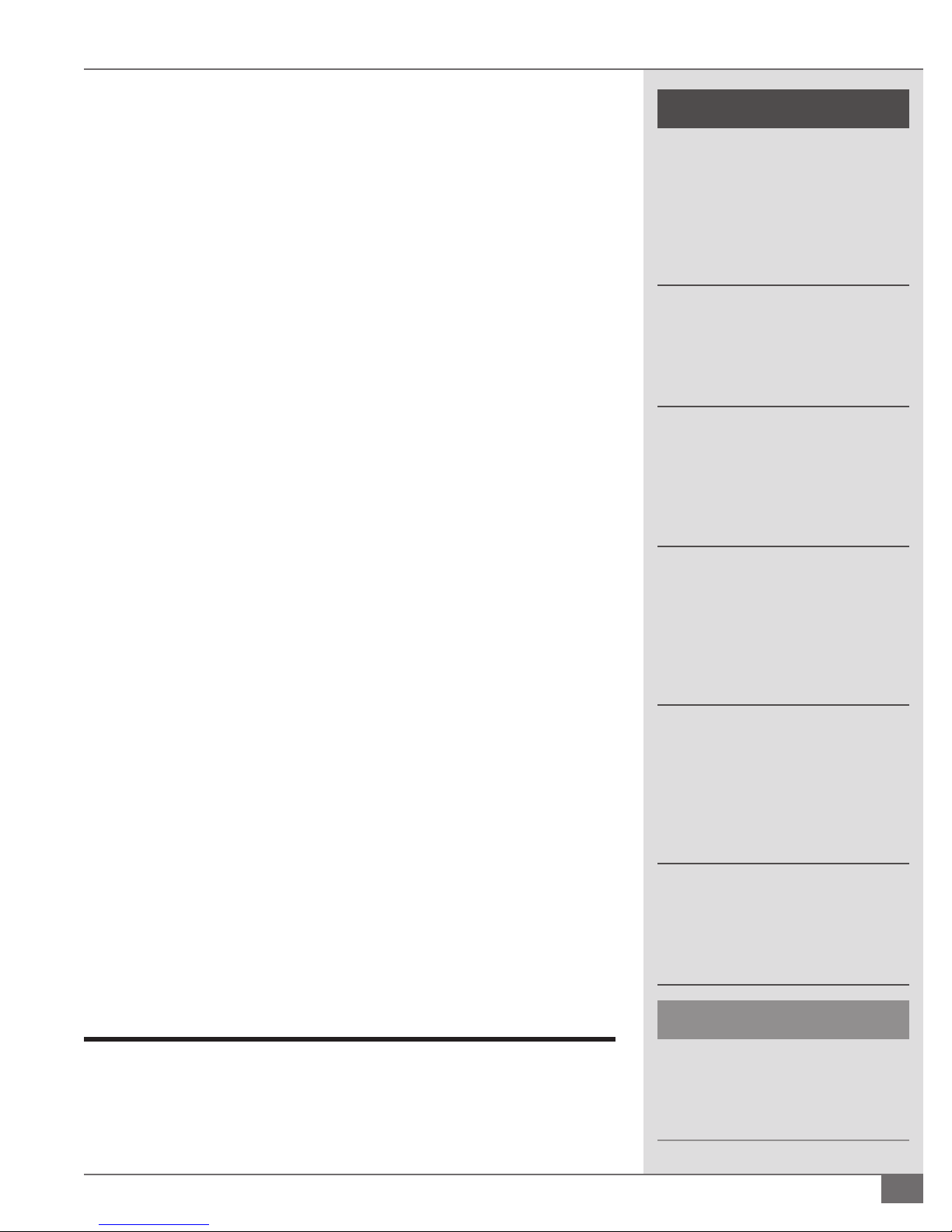

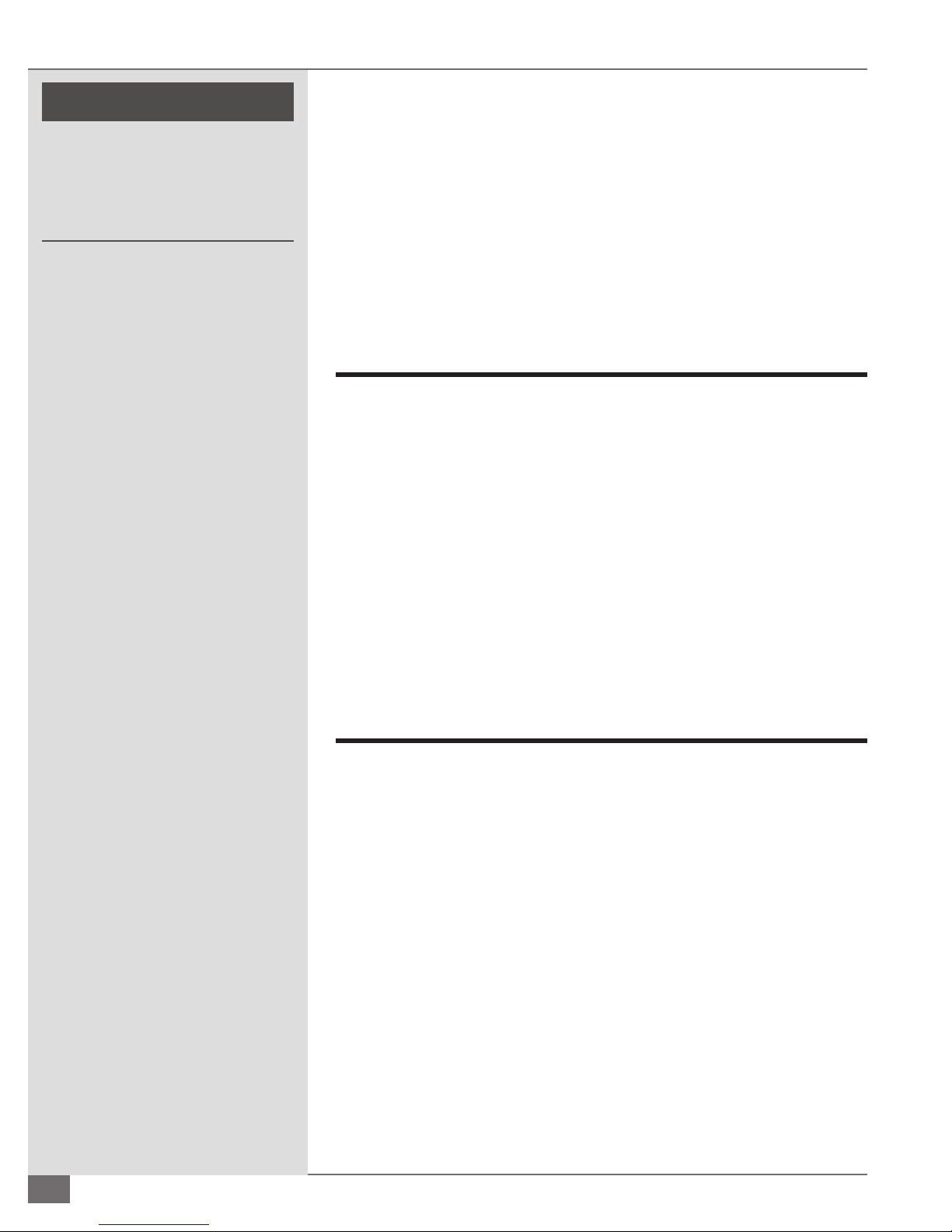

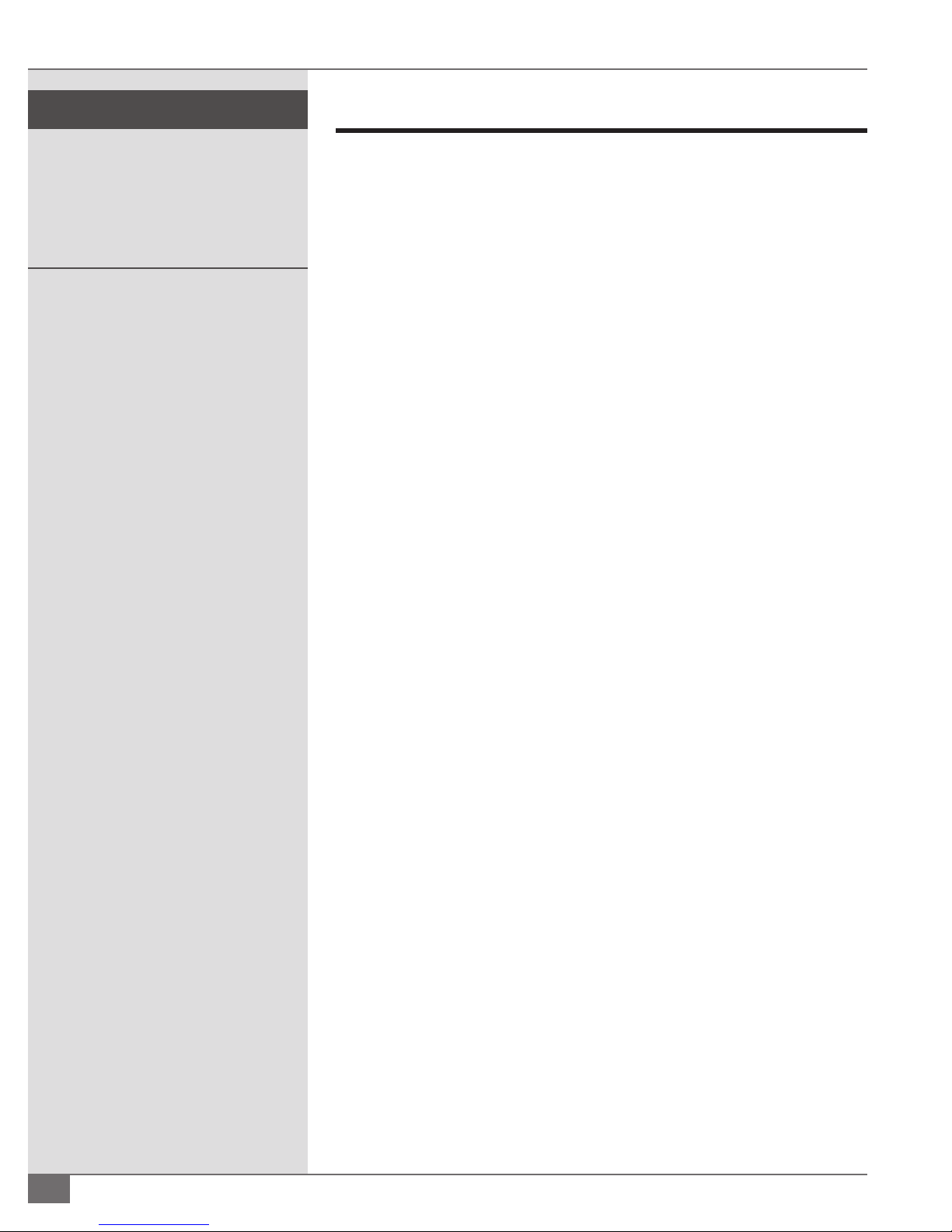

TABLE 2 SPECIFICATIONS REFER TO FIGURE 1

Model VMP-W 40 50 60 80 100 130 150

Boiler Connec ons

Safety Valve Outlet

IN

MM

Safety Valve Inlet

IN

MM

Natural Gas Connec on

IN

MM

Water Supply & Return Connec ons*

IN

MM

Ra ngs (sea level to 3000 /914 m) Output

1000 BTU/HR

1000 KCAL/HR

Water Content

GAL

Liters

Light Oil Connec on

IN

MM

Burner Motor

HP

Wa! s

Approximate Weights

Shipping Weight

LB

KG

Opera ng Weight

LB

KG

Approximate Fuel Consump on at Rated Capacity+

Natural Gas

3

FT

3

M

LP Gas

3

FT

3

M

Light Oil

GPH

LPH

Min. Gas Pressure Required; In. W.C. 7 7 7 9 9 40 40

Max Gas Pressure Required (Standard Gas Train) In. W.C. 13 13 13 27 27 10 psig 10 psig

Electric Power Requirements/Amps for Burner Motor

208V 50/60 CY 3 Phase (Gas/Oil) 6.6/7.5 6.6/7.5 6.6/7.5 10.6 10.6 30.8 30.8

230V 50/60 CY 3 Phase (Gas/Oil) 6.0/6.8 6.0/6.8 6.0/6.8 9.6 9.6 28 28

460V 50/60 CY 3 Phase (Gas/Oil) 3.0/3.4 3.0/3.4 3.0/3.4 4.8 4.8 14 14

1.5

38.1

1.25

31.8

1.5

38

4

102

1356

342

210

795

Model VMP-W STANDARD MOTOR

.25

6

1.5

1119

5775

2620

7526

3414

1595

45

638

18

11

41.6

1.5

38.1

1.25

31.8

1.5

38

4

102

1693

427

290

1098

.25

6

1.5

1119

6575

2980

8994

4080

1992

56

797

23

14

53

1.5

38.1

1.25

31.8

2

51

4

102

2033

512

315

1192

.25

6

1.5

1119

7370

3340

9997

4535

2392

68

957

27

17

64.3

2

50.8

1.5

38.1

2

51

4

102

2710

683

440

1665

.25

6

3

2237

8000

3636

11670

5294

3188

90

1275

36

23

87

2

50.8

1.5

38.1

2

51

4

102

3387

853

602

2278

.25

6

3

2237

9500

4318

14520

6587

3985

113

1594

45

28

106

2

50.8

1.5

38.1

2.5

63

4

102

4405

1110

920

3482

.375

9.5

10

7460

12,350

5601

20023

9083

5182

147

2080

59

37

140

2

50.8

1.5

38.1

2.5

63

4

102

5081

1280

920

3482

.375

9.5

10

7460

12,500

5675

20172

9150

5978

169

2381

68

42

159

* 150 pound fl anged.

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

CONTINUED ON NEXT PAGE

2-5

Page 12

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

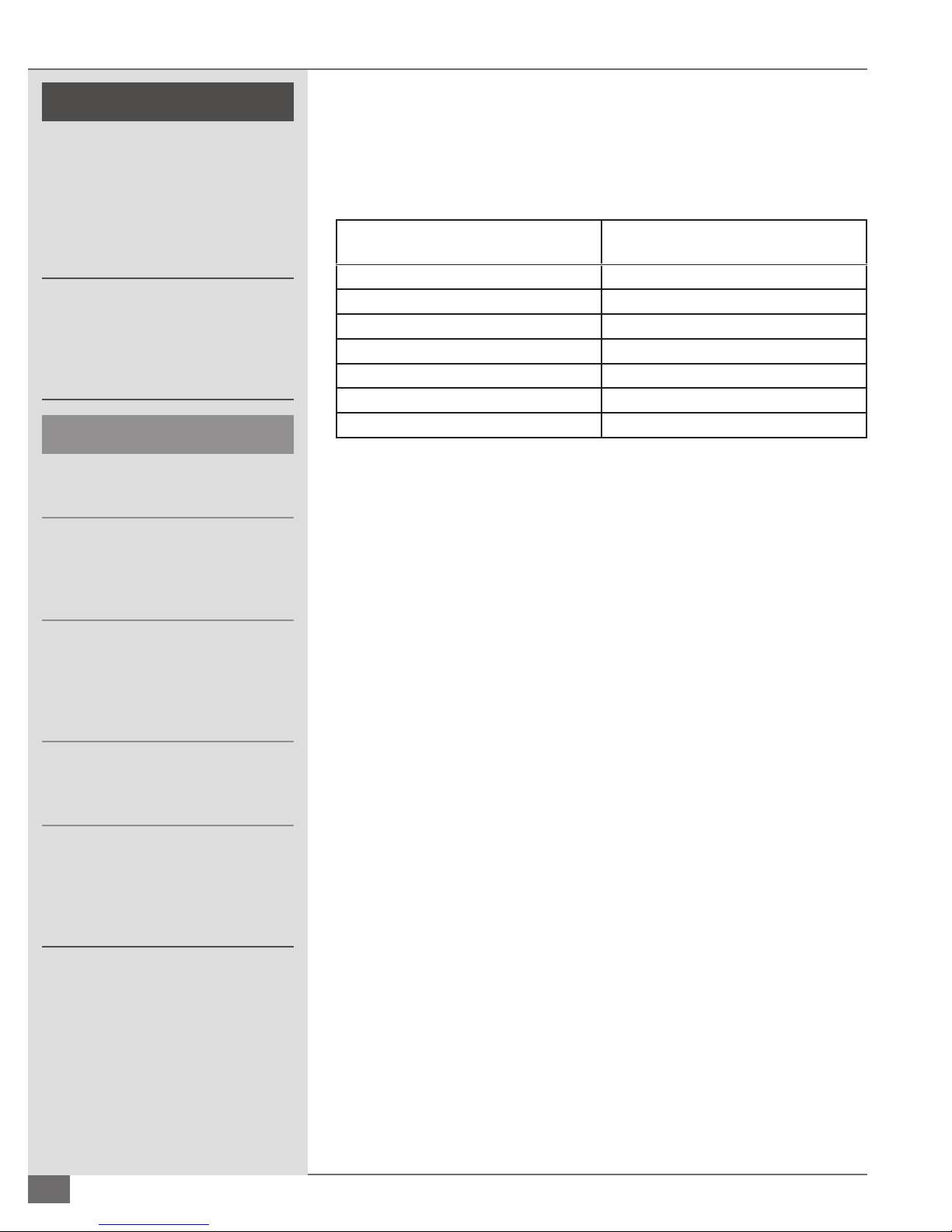

Model VMP-W Low Emissions (LE) MOTOR

Model VMP-WModel 40 50 60 80 100 130 150

Model VMP-W 40 50 60 80 100 130 150

Burner Motor **

HP

Wa! s

Approximate Weights

Shipping Weight

LB

KG

Opera" ng Weight

LB

KG

Approximate Fuel Consump! on at Rated Capacity+

Natural Gas

3

FT

3

M

Required Gas Pressure (IN. W.C./PSIG)

Minimum/Maximum 30/10 30/10 40/10 40/10 40/10 60/10 60/10

208V, 60 CY, 3 Phase 16.7 16.7 16.7 16.7 24.2 Consult Factory

230V 60 CY 3 Phase 15.2 15.2 15.2 15.2 22 Consult Factory

460V 60 CY 3 Phase 7.6 7.6 7.6 7.6 11 Consult Factory

Specifi ca" ons and dimensions are approximate. We reserve the right to change data without prior no" fi ca" on.

Design condi" ons based on 160 F return and 180 F supply.

+ Consump" on based on natural gas 1000 Btu/$ 3.

** Sub 20 ppm; for lower requirements, consult factory.

5

3730

6575

2982

8659

3928

1595

45

5

3730

7373

3345

9684

4393

1992

56

5

3730

8170

3706

10671

4840

2392

68

5

3730

8800

3992

12051

5466

3188

90

5

3730

10300

4672

14700

6668

3985

113

Consult

Factory

12800

5806

20585

9337

5182

147

Consult

Factory

12800

5806

20585

9337

5978

169

3. See Table 3 for minimum make up air openings required

for each model.

TABLE 3 MINIMUM MAKE UP AIR OPENING REQUIREMENTS

Model Fresh Air Opening FT2 (M2)

40 1 (.09)

50 1 (.09)

60 1.5 (.14)

80 4 (.37)

100 4 (.37)

130 5 (.46)

150 7.5 (.69)

4. If positive forced ventilation is adopted, ensure that

there will be no appreciable pressure variation in the

equipment room.

5. Avoid ventilation which creates a negative pressure

in the building as it will seriously a ect combustion

and proper operation of the burner. Please note that

exhaust fans or similar equipment can create a down

draft in the chimney or starve the burner’s air supply.

Either case may result in poor combustion or nuisance

failures. A properly designed make-up air system in the

equipment room will preclude these possibilities and is

required to maintain proper combustion.

6. Eliminate potential for high risk situations for particulate

matter to be in the combustion air supply (e.g., as a

result of construction and maintenance activities).

Utilities

¡ The Gas Supply

Adhere to the following for gas supply installation:

1. Install gas piping in accordance with all applicable

codes.

2. Ensure pipe and ttings used are new and free of dirt or

other deposits.

3. Ensure piping is of the proper size for adequate gas

supply to the gas head assembly. Consult your gas

company for speci c recommendations.

4. When making gas piping joints, use a sealing

compound resistant to the action of lique ed

petroleum gases. Do not use Te on tape on gas line

heads.

2-6

© The Fulton Companies 2012

Page 13

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

5. Ensure no piping stresses are transmitted to the equipment. The

equipment shall not be used as a pipe anchor.

6. Ensure all vent connections on diaphragms, gas valves, pressure

regulators, and pressure switches (gas- red units) are vented per local

code.

7. On gas- red units with NFPA 85 valve trains, ensure the vent valve is

piped to atmosphere per local code.

8. During any pressure testing of the system at pressures in excess of 1/2

psig (14 inch W.C.), isolate the boiler with the manual shuto valve

(located at the end of the supplied gas train) from the gas supply

piping system.

9. Ensure the supply pressure is regulated by a non-stacking, tight, shuto regulator.

10. Arrange gas piping so that it does not interfere with any cover or

burner, inhibit service or maintenance, or prevent access between

unit and walls or another unit.

11. After gas piping is completed and before wiring installation is started,

carefully check all piping connections, (factory and eld), for gas

leaks. Use an appropriate leak test solution.

¡ The Oil Supply

! WARNING

A quali ed installer, service agency or the

gas supplier must perform installation and

service on the fuel delivery system.

Do not use matches, candles, ame or

other sources of ignition to check for gas

leaks.

What to do if you smell gas:

Do not try to light the appliance.

Do not touch any electrical switch.

Do not use any phone in the building.

Leave building and contact gas supplier

from neighbor’s phone. If you cannot

reach gas supplier, phone the re

department.

When making gas piping joints, maintain

proper ventilation to reduce breathing

hazards.

An exhaust fan may draw products of

combustion into the work environment

creating a possible hazard to personnel.

Adhere to the following for installation:

1. Fuel pipes must be of approved materials and of a diameter suitable

for the quantity of oil being delivered to the burner. Vacuum must

not exceed 10 in. (254 mm) of mercury at the pump inlet. Maximum

inlet pressure to oil pump is 3 PSIG.

2. Make fuel connection in accordance with the details on the enclosed

fuel pump cut sheet.

3. Ensure fuel oil piping is in accordance with local/national

requirements.

4. Meet the maximum pressure allowed at the fuel oil pump inlet per

the National Fire Protection Association (NFPA).

5. Oil pumps are of a two-line design system, requiring a return line and

a supply line. The oil pump is factory set per Test Fire Sheet. Do not

alter the setting without consulting the factory.

6. A stop valve, a check valve, and an oil lter must be installed on the

oil supply line.

7. Ensure there are no loose ttings. Loose ttings in the fuel oil line will

permit air to enter the fuel line and cause improper ring.

4 CAUTION

It is essential that only fresh air be allowed

to enter the combustion air system. Foreign

substances, such as combustible volatiles

and lint in the combustion system can create

hazardous conditions. If foreign substances

can enter the air stream, the combustion air

inlet must be piped to an outside location.

Failure to do so will void the warranty.

To avoid failures due to poor combustion,

ensure make-up air system is properly

designed.

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-7

Page 14

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

4 CAUTION

Loose ttings in the fuel oil line will permit

air to enter the fuel line and cause improper

ring.

Electrical Supply

Adhere to the following for electrical supply installation:

1. Locate electrical schematic diagram, a copy of which is inside of the panel

box.

2. Ensure the information on the electrical drawing corresponds to your

voltage and frequency. Check the supply voltage and make sure that there

is no over- or under-voltage exceeding 10% of the nominal value.

3. Install a separate fuse switch for the contactor and a separate fuse switch

for the circulating pump. If pump motor is 3/4 HP or larger, install an

across-the-line starting switch ahead of the circulating pump motor.

4. Install wiring and ground in equipment in accordance with authority

having jurisdiction or in absence of such requirements the National

Electrical Code, ANSI/NFPA.

5. Provide a fused disconnect sized for the unit. Size fuses according to motor

name plates and local electrical codes.

6. Connect power to the terminal strip as supplied on the inside of the panel

box.

Water Supply

¡ Install Water Piping

All water supplies contain some solids, dissolved gases or dissolved minerals.

These may cause corrosion, deposition and/or fouling of equipment. To prevent

these contaminants from impacting boiler performance, valve operation and

general pipe longevity, each location must be analyzed and treated accordingly.

Adhere to the following for water piping installation:

1. Isolation valves and unions are recommended on both water connections

for ease of service.

2. Install piping so that the boiler is not supporting any additional piping.

3. Install manual purging valves in all loops and zones. Install a pressure-

reducing (automatic ll) valve in the cold water ll line to the boiler system.

Check that the proposed operation of zone valves, zone circulator(s) and

diverting valves will not isolate air separator(s) and/ or expansion tank(s)

from the boiler. Clearance from hot water pipes to combustibles must be at

least 6 inches (152 mm).

4. Pipe the water supply line to the lower opening on the back of the boiler.

Water stop valve should be in line between the boiler and the rst piece

of equipment. Hot water outlet should be piped to process/equipment

requiring hot water. Water makeup supply should be installed. Hot water

inlet should be piped to the make-up water supply.

2-8

© The Fulton Companies 2012

Page 15

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

5. Pipe the water safety valve carry piping from the outlet of the valve to a

safe blow-o point.

NOTE: ´ Do not alter water temperature/pressure gauge assembly in any way.

6. Drain valve is connected to the lowest opening at bottom rear of boiler.

Carry piping from the outlet of the valve to safe drain point. Provision

should be made for easy access to drain valve of boiler.

NOTE: ´ The water connection on the top of the boiler is the outlet connection. The

water connection on the rear of the boiler is the inlet connection.

7. Install ltration to remove particulates if appropriate.

8. Install bypass chemical feeder for corrosion inhibitor maintenance if

appropriate.

9. Install corrosion coupon holder to assess corrosion inhibitor performance if

appropriate.

NOTE: ´ The boiler is provided with a drain valve connection and a drain valve.

10. Heating system:

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

» An automatic pressure activated water make up valve with back

ow preventer. It must be set to maintain required Net Positive

Suction Head (NPSH) for re-circulating pumps, a positive system

pressure at the highest point of at least 5-10 PSIG, and make up

water valve should be designed to add water to the system at the

outlet of the boiler and should not be fed directly into the boiler.

» Air removal equipment, including an air separator and automatic

breather valves, along with a functioning expansion tank . Each

must be designed to system speci cations.

11. When used in conjunction with a refrigeration system, install the boiler

so that the chilled medium is piped in parallel with the boiler with

appropriate valves to prevent the chilled medium from entering the

boiler. If the boilers are connected to heating coils (located in air handling

units where they may be exposed to refrigerated air circulation) such

boiler piping systems must be equipped with ow control valves or other

automatic means to prevent gravity circulation of the boiler water during

the cooling cycle.

Water Chemistry Requirements

System water chemistry requirements are as follows:

§ pH: Range of 8.5 - 10.5

§ Oxygen: Less than 250 ppb (operating condition)

§ Total Iron/Copper: Less than 5 ppm

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-9

Page 16

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

4 CAUTION

A large amount of improperly treated makeup water can cause premature failure of the

heat exchanger resulting from scale build

up. Scale build up will reduce the e ciency

and useful life of the boiler and is not

covered under warranty.

§ Corrosion Inhibitor: Capable of maintaining iron corrosion rates <2

mpy. Due to changing environmental restrictions a non-heavy metal

ALL ORGANIC inhibitor is recommended which is designed for multi

metal systems including ferrous metals and yellow metals such as

copper and brass.

§ Chloride: Less than 250 ppm

Adhere to the following:

1. Refer to your water conditioning or chemical treatment supplier for

analysis and recommendations for proper system conditions.

2. Follow a program with appropriate monitoring and maintenance of

system water conditions as provided by your water conditioning or

chemical treatment supplier.

3. Operate the boiler in a closed-loop system using water or water/glycol

(not requiring a make-up water supply). A large amount of improperly

treated make-up water can cause premature failure of the heat

exchanger resulting from scale build up. Scale build up will reduce the

e ciency and useful life of the boiler and is not covered under warranty.

¡ Prevent Oxygen Contamination

There are several ways to prevent boiler water oxygen contamination:

§ Minimize system leaks to minimize make up water requirement

§ Do not use open tanks or ttings

§ Do not use oxygen permeable materials anywhere in the water

system

§ Repair leaks in the system quickly

§ Eliminate ttings wherever possible

§ Use air elimination devices in system piping

¡ Eliminate System Air

NOTE: ´ There are no built-in boiler air eliminating features.

Adhere to the following for air elimination:

1. The installation of an air separator and air eliminator (air vent) is required.

2. To prevent scale corrosion in boiler and associated piping, make up

water must be kept to a minimum. This is best achieved by ensuring

immediate repair of all leaks and that system pressure is maintained.

2-10

3. If a sealed diaphragm-type expansion tank is used, install an air

eliminator in the hot water piping at the air separator.

4. If an air cushion type expansion tank is used, pipe tank directly into

© The Fulton Companies 2012

Page 17

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

boiler supply.

5. On multi-zoned systems (or a system with both space and domestic water

heating), air elimination must be provided either in the common piping or

on every loop.

6. When the boiler is installed at a higher level than baseboard radiation (if

used), air elimination must be provided directly above the unit.

Piping Specifi cations

For piping, the basic considerations are: the design temperature, the pressure

retained by the pipe, the uid in the pipe, the load resulting from thermal

expansion or contraction, impact or shock loads imparted such as water hammer,

external loads, wind loads and vibration from equipment.

Adhere to the following for piping installation:

1. Ensure the arrangement of the piping and its appurtenances takes into

consideration the location of other structures and equipment adjacent to

the piping, which may result in freezing interference and/or damage as a

result of expansion, contraction, vibration, or other movements.

2. Consider the appropriate location and orientation of valves necessary

for safe operation and isolation of the piping. Valves are used in piping

systems to stop and start the ow of uids, to regulate ow, to prevent the

back ow, and to relieve excessive pressure build up in the piping.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

The vent line connection on the gas

pressure regulator must be piped to

outdoor air by the installer in accordance

with National Fuel Gas Code, ANSI Z2231-1991 or latest addenda. In Canada, gas

installations must be in accordance with

the current CAN/CGA B149.1 and 2 and/or

local codes.

4 CAUTION

Some soap used for leak testing is

corrosive to certain types of metals. Use

an appropriate leak test solution. Clean all

piping thoroughly after completing the leak

check.

3. Ensure all piping and piping components are suitable for the design

temperatures, pressure and uid used in the system.

4. Ensure all pipework is constructed from seamless mild steel pipe, Schedule

40 or Schedule 80 as required by code and/or application; or copper if

system parameters allow.

5. During construction of the installation, ensure that no dirt, water, or

residue from welding is left in the system.

6. Provide expansion joints or properly designed and sited loops to

accommodate thermal expansion. Thermal expansion should be calculated

using the maximum possible utilization uid temperature, regardless of

whether the pipe considered is in the feed or return circuit. Steel pipe will

expand approximately 1 “ per 100’ over a 100° F temperature rise (1 mm

per meter over 100 C rise).

7. Provide supports and anchors for all pipes where necessary to prevent

undue stresses from being placed on items of equipment, including

pumps, valves, and the boiler. Supports and anchors which will not

interfere with thermal expansion should be chosen.

8. Cut screw threads carefully and accurately. If possible, new tools should be

used. It is recommended that GR5 or higher tensile steel bolts be used for

all anged joints.

9. Use gaskets to make all anged connections. Gasketing material must be

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-11

Page 18

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Hot pipework and vessels must be

adequately insulated with material

suited to the temperature and

application to prevent both heat loss

and personnel injury.

suitable for use with the pressure, temperatures and uids in the system.

Ensure that all bolts are tightened evenly and to the torque recommended

values provided by the gasket manufacturer.

10. Install high point bleeds at all high points in the system piping. 1/2” x 12”

nipples welded in the top of the piping with ball valves and plugs attached

are to be used.

11. Install all pipes with a pitch to facilitate draining and venting.

Insulation

After the appropriate system tests have been satisfactorily completed (see

Testing section of this manual), all hot pipework and vessels must be adequately

insulated with material suited to the temperature and application to prevent

both heat loss and personnel injury. For inspection and maintenance purposes,

leave pumps, anges, valves and ttings uninsulated but suitably shielded for

safety. Removable insulation may also be used over these components.

System Interfaces

Proper selection and installation of the components in the system will ensure

proper and safe operation of the boiler. Consult Fulton representative or contact

Fulton at (315) 298-5121.

¡ Fill Connection

The system is usually lled from the lowest point, with the aid of a pump. On skidmounted units, a ll connection is provided in the inlet piping to the pump.

Pressure Gauges

The range in which readings are expected to fall should comprise mid-scale

on the pressure gauge chosen. Pressure gauges must be able to withstand

overpressure equal to the rating of the safety relief valves, normally 100 psig.

NOTE: ´ The Water temperature pressure gauge should not be altered in any way.

Assembly of Multi-Skid Systems

Adhere to the following for multi-skid engineered systems:

1. Refer to the Fulton mechanical/electrical drawings during assembly.

2. Ensure that equipment orientation allows for operation interface and

maintenance.

3. Align the skids as shown on the drawings ensuring that skid fasteners (skid

joint angles) are matched. The skid joint angles are a matched set and the

edges of the fasteners should be exactly aligned.

2-12

© The Fulton Companies 2012

Page 19

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

NOTE: ´ Do not bolt the skids to the housekeeping pad/ oor until all of the piping

has been reassembled and tightened.

4. Ensure the skids are level and at before fastening the skids together with

the supplied bolts. The skids should be leveled front to back, side to side

and corner to corner. Failure to properly level the skids will result in piping

misalignment. A level or laser level should be used to verify skid alignment

(when a standard level is used, the length should be appropriate for the

skid). If assembling multi-component support stands, attach sections

using the supplied bolts through the tank frame mounting plates. These

should be hand tight until all of the piping is assembled. Note: skids are

leveled at the factory using a laser level.

5. Connect the piping between the skids by matching the union connections

and/or ange stamps and tightening. Refer to the mechanical drawing

as necessary to con rm location of spool pieces etc. as the ange stamps

are shown on the drawing in hexagonal callouts. The ange stamps

should matched and aligned (the ange stamps should be directly across

from one another. Rotating a ange will result in piping misalignment).

Bolts should be hand tight until all of the piping is assembled. Refer to

the appropriate instructions to tighten the anges to the required torque

speci cations. Support pipe runs as required.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Assure all electrical connections are

powered down prior to attempting

replacement or service of electrical

components or connections of the

equipment.

Cements for plastic pipe should

be kept away from all sources of

ignition. Proper ventilation should

be maintained to reduce the hazard

and to minimize breathing of cement

vapors.

6. Ensure that a low point drain is installed in the piping.

7. Connect the conduit runs between the skids and tighten conduit

connectors.

8. Locate the supplied wiring for the equipment and pull wiring through

the appropriate conduit runs. Electrical wires are labeled for easy landing.

Connect all wiring per the Fulton supplied electrical drawings.

9. If a header is supplied, mount the header as shown in the mechanical

drawing.

NOTE: ´ For piping supplied in sections, make up and connect hand tight until all

sections are in place to ensure sections align properly. Sections are match marked

for reassembly.

10. Tighten all connections.

11. Pneumatically test the piping (at 15 psig maximum) prior to lling the

systems.

12. Check bolts and connections for tightness after the rst heat up cycle.

Retorquing may be required.

No shuto of any kind may be

placed between the safety relief

valve and the equipment, or in the

discharge pipe between such valve

and the atmosphere. Doing so may

cause accidental explosion from

overpressure.

Discharge from safety relief valve

must be con gured so that there

is no danger of scalding personnel

or causing equipment damage.

Provisions must be made to properly

drain safety relief valve discharge

piping.

For reasons of safety, the hot exhaust

gas duct and chimney must be

insulated or shielded within the

locality of the heater in compliance

with local codes and regulations.

Stack and Flue

An appropriately sized stack should be connected to the ue gas outlet at the

boiler. The proper ue size and draft control is most important for proper burner

operation. See Table 4.

Stack and chimney must be constructed from material that is rated for 1000 F

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

4 CAUTION

The stack arrangement and draft

conditions should be in accordance

with the information in this manual for

proper performance of the equipment.

2-13

Page 20

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Non-Fulton product information is for

reference purposes only. No Fulton

document may substitute for full

review of documentation available

from the component manufacturer.

4 CAUTION

Boilers damaged due to adverse water

conditions are not covered by warranty.

The weight of all piping must be

properly supported. Failure to support

piping may result in equipment

damage and/or system leakage.

Piping must take into consideration

potential for freezing interference and/

or damage as a result of expansion,

contraction, vibration, or other

movements.

Dirt, water, and/or other debris in the

piping system after welding may result

in equipment failure.

To maintain a reasonable

temperature in the equipment area

and ensure safety to personnel, the

section of the chimney duct within

the building should be insulated.

operating temperature. Check all local codes for requirements.

The ue must be as large or larger than the outlet on the vessel. Avoid ue

piping and elbows by placing the equipment as close as possible to the chimney.

TABLE 4 MINIMUM FLUE SIZES

Model Minimum Flue Size

inches (mm)

40 12 (305)

50 12 (305)

60 12 (305)

80 14 (356)

100 14 (356)

130 14 (356)

150 16 (406)

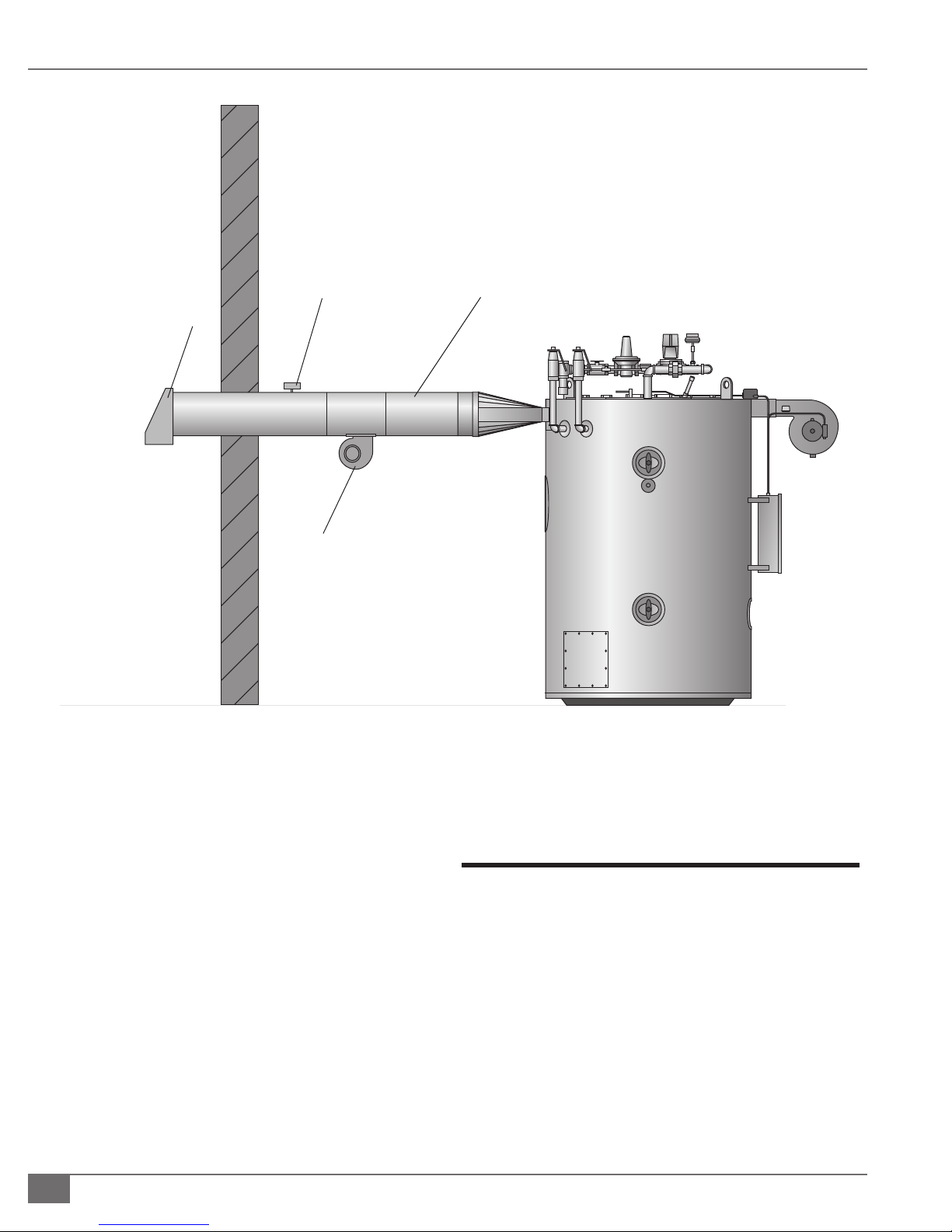

Adhere to the following for stack and ue installation (see Figure 2):

1. Ensure the stack rises continuously to the connection at the chimney and

contains no more than two bends at 45 degree angles or less. If required,

as a result of space limitations, one 90 degree elbow (or tee) can be tted

at the back of the vessel.

2. Ensure 2 feet (0.6 m) of straight, horizontal ue before any change in

direction, tting or draft regulator. This is to prevent potential pilot or

main ame failures due to back pressure build up during ignition. Any

alternative stack arrangement must supply negative 0.02 to 0.04”wc.

3. Ensure the run in the total distance of stack ducting, as measured in a

straight line from the outlet of the boiler to the outlet of the stack, does

not exceed 25% of the rise. With the exception of the duct run previously

described, horizontal sections of ducting must be avoided and should not

exceed 4 feet (1.2 m) total. See Figure 2.

4. Ensure the stack, chimney, and any components associated with the stack,

such as heat reclaimers or assist fans, are constructed from material that is

rated for a 1000 F (538 C) operating temperature.

5. Ensure the stack and chimney material complies with all applicable codes.

6. Make adequate provisions for the support of the weight of the chimney

and stack to avoid having a load imparted to the outlet connection of the

equipment.

2-14

7. Ensure the draft, when ring, is negative and constant. A reading of -0.02

to -0.04”wc (-0.508 to -1.016 mm) when the unit and stack are cold usually

indicates su cient draft. When the unit is running and the stack is hot, the

draft should read -0.04 to -0.08 “wc (-1.016 to -1.524 mm) negative.

8. The installation of a draft regulator by the client/contractor is

recommended at all installations. This will help to maintain the required

draft. The placement of the draft regulator should be as shown in Figure 3.

Insulate the section of the chimney duct within the building.

© The Fulton Companies 2012

Page 21

SECTION 2 VMPW-IOM-2012-1001 INSTALLATION

Roof

Minimum

6' Above

Any Structure

Within 30'

Support As

Necessary

Install

Appropriate

Weather

Cap

Horizontal

Run 2'

Draft Regulator

(If Necessary)

Draft Regulator

(If Necessary)

Expansion Joints

As Required

Horizontal

Run 2'

60¡

(45¡ Min.)

Cleanout

Door

Cleanout

Door

Cleanout

Door

This Distance

Must Not

Exceed 70%

Of Total Rise

Baffle

3'

3'

30¡

Max

Stagger

Entrances

A A

A-A

Total

Rise

9. Concentration levels of only a few ppm of chlorine

containing compounds in combustion air can produce

serious corrosion of the ue over long periods of time.

High chlorine containing compounds such as carbon

tetrachloride or perchloroethylene would be prime

suspects.

¡ Exhaust Side Wall Venting

Boilers for which sidewall venting (Figure 4) may be utilized

are propane, natural gas, or combination propane and natural

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

FIGURE 2 TYPICAL STACK ARRANGEMENT

gas sizes 10 to 30 HP.

Adhere to the following for installations requiring sidewall

venting:

1. Flue vent piping must be pitched upward at ¼ in (6.35

mm) per one foot (3.048 m) of length.

2. An UL-approved draft fan must be installed to provide

su cient draft (-0.02 to -0.04” wc) to safely vent

products of combustion.

2-15

Page 22

INSTALLATION VMPW-IOM-2012-1001 SECTION 2

Air Flow

Safety Switch

U.L. Approved

Induced Draft Fan

Side Wall

Vent

Termination

(By Others)

Side Wall Vent

(By Others)

FIGURE 3 TYPICAL SIDEWALL VENTING

3. The draft fan should be located as close to the ue

outlet as possible.

4. Draft regulation su cient to lower the draft to between

-0.02 to -0.04 “ wc may be required. The draft regulator

must be between the boiler and the fan.

5. The draft fan shall have an air ow proving switch wired

in series with the boiler air safety switch.

6. The sidewall vent total length from boiler exhaust to

termination shall not exceed 35 feet (10.6 m) with 4

elbows maximum.

Testing

Upon completion of the installation, perform the following

testing:

1. A pneumatic test of water piping not exceeding 15

psig.

2. Leak tests at all welds and joints to ensure that the

system is free from leaks.

2-16

© The Fulton Companies 2012

Page 23

OPERATION

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

3-1

Page 24

OPERATION VMPW-IOM-2012-1001 SECTION 3

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

Do not operate, or allow others to operate,

service or repair this equipment unless

you (they) fully understand all applicable

sections of this manual and are quali ed

to operate/maintain the equipment.

Defective or improperly installed

equipment is hazardous. Do not

operate equipment which is defective or

improperly installed.

Defective equipment can injure you

or others. Do not operate equipment

which is defective or has missing parts.

Make sure all repairs or maintenance

procedures are completed before using

the equipment. Do not attempt repairs or

any other maintenance work you do not

understand.

4 CAUTION

Installation in accordance with the

guidelines within the manual should be

fully completed before performing the initial

start-up; and start-up must be complete

prior to putting the unit into service. Starting

a unit without the proper piping, venting

or electrical systems can be dangerous and

may void the product warranty.

Start-Up Preparation & Installation Review

Review the installation section of this manual carefully. Con rm accordance with

the Installation guidelines, including:

1. You have read and followed all safety information.

2. The equipment area is in conformance with established boiler room

requirements. Review national and local codes.

3. There are no obstructions left in the uid circuit from pressure leak testing

such as blanking plates in anged joints.

4. Boiler is located with the proper clearances as shown in Installation

section of this manual.

5. Relief valves have been properly piped to oor drains.

6. Flue gas from the boiler is properly vented.

7. Combustion air openings are not obstructed in any way and have

adequate capacity.

8. There are no ammable liquids, materials or hazardous fumes present in

the environment.

9. Nothing was damaged or knocked loose during shipment and installation.

Inspect the main gas train and trim assembly to be sure they were not

damaged during shipment or installation.

10. Local authorities where approval for start-up is required have been

noti ed. In some localities, nal inspection of services may be required.

11. Installation checklist is complete.

} FILL AND AIR REMOVAL PROCEDURE

1. Close combination shuto /purge valve in supply, all drain cocks, the

shuto valve for the pressure reducing ( ll) valve, and all manual air vents.

2. Open all other system shuto valves and one of the zone valves, the vent

on the combination shuto / purge valve and the shuto valve to the

pressure-reducing ( ll) valve.

“Factory Trained Personnel” refers to

someone who has attended a Fulton Service

School speci cally for the equipment

covered in this manual.

3-2

3. Water will now begin to ll the system. Air will escape through the vent

on the combination shuto / purge valve. Continue lling until a constant

stream of water (no bubbling) is discharged from the vent.

4. Close the zone valve on the purged loop, and open the zone valve on

the next loop to be purged. When all air has escaped and only water is

discharged, close the zone valve. When all zones have been purged (one at

a time), close the vent on the combination shuto /purge valve.

5. At this point, the system has been initially lled. However, air pockets

may still remain at high points in the system and in heating loops above

the level of the combination shut/o purge valve. It is quite possible,

© The Fulton Companies 2012

Page 25

SECTION 3 VMPW-IOM-2012-1001 OPERATION

depending on the particular system that all piping above the combination

shuto /purge valve still contains air. If manual vents are installed on the

system high points, these should be opened to vent these locations. When

only water is discharged from all vents, the initial purging is complete.

6. Open the combination shuto / purge valve (keep the vent closed). With

the gas shuto valve closed, turn on power to the boiler and operate the

circulator. Circulate the system water for approximately 30 minutes to

move all air to the automatic air separation point.

7. Again, open manual air vents at high points of heating loop until a

constant stream of water is discharged from the vent. Close the vent and

make sure it’s watertight. Repeat procedure for all high points and for

every zone.

8. Check temperature/pressure indicator reading, which should equal the

pressure-reducing ( ll) valve set pressure. No more water should be

entering the system. Close the shuto valve on the cold-water ll line.

9. Visually inspect all pipe joints and equipment connections for leaks. If

necessary, drain system, repair leaks and re ll/purge the system. If no

pressure drop is detected for a period of two hours under pressure, the

system may be considered watertight.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

4 CAUTION

Do not use this equipment if any part

has been under water (or subjected to

heavy rains/water if the equipment

does not have NEMA 4 wiring, controls

and instrumentation). Immediately

call a quali ed service technician to

inspect the equipment and to replace

any part of the control system and/or

gas control(s) which have been under

water.

10. When purging is completed, make sure the following are open—

combination shut-o /purge valve, shuto valve to pressure reducing ( ll

valve), shuto valve in cold water ll line, and shuto valve in return line.

11. Make sure the following are closed - all drain cocks, the vent on the

combination shuto -purge valve, & all manual vents. Reset zone valves to

normal mode of operation and turn o power to boiler.

12. Open fuel shuto valve, allowing fuel to ow to the boiler.

Start-Up Service

If start-up service has been included in the order, the factory should be contacted

after the installation has been successfully completed and approved by the

client’s representative or engineers. Where possible, contact the factory at least

three weeks before a Fulton service engineer is required on site.

Consider the following in preparation for your on-site visit:

1. All procedures covered in manual sections Start-Up Preparation and

Fill the System, including installation review, air testing of piping, pump

alignment (where applicable), and lling the system must be completed

before the service person’s arrival.

Please read these instructions and

post in an appropriate place near the

equipment. Maintain in good legible

condition.

2. Depending on the size of the system and the amount of service time

contracted, start-up service includes ring the boiler, checking, verifying

and adjusting all safety settings.

3. Careful preparation can expedite the commissioning of your boiler. Most

delays can be avoided by following the instructions in this manual. Failure

to complete required procedures properly can result in the need for further

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

3-3

Page 26

OPERATION VMPW-IOM-2012-1001 SECTION 3

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Crystalline silica may be present

in components of this equipment.

Exposure to crystalline silica may

pose signi cant health hazards,

including but not limited to eye and

respiratory system damage. Per

the Centers for Disease Control and

Prevention (CDC) and Occupational

Safety and Health Administration

(OSHA), appropriate Personal

Protective Equipment must be worn

to minimize exposure to hazardous

substances. Refer to most current

guidelines o ered by the CDC and

OSHA for more information, including

Personal Protective Equipment

recommendations.

service time, at extra cost to the customer.

4. Service people will not commence start-up if there are obvious system

de ciencies. However, start-up service in no way constitutes a system

design check or approval of the installation.

5. In addition to commissioning the boiler, the service person will also

familiarize heater room personnel with the operation of all Fulton

equipment. Personnel must be quali ed to understand the basic operation

and function of controls.

Initial Start-Up

Adhere to the following:

1. Turn on the main power fuse switch.

2. Activate the boiler power ON switch, located on the side of the panel box.

NOTE: ´ The Low Water Control will also be activated when the boiler is powered

on. With the unit full of water, the Low Water Relay requires manual reset.

3. If for any reason the water leaves the unit the Low Water Control will

automatically turn the burner o , and if audible alarm is installed, alarm

will activate.

When opening any drains on the

equipment or piping system, steps

should be taken to avoid scalding/

burning of personnel due to hot

uids. Whenever possible, the system

should be cooled prior to opening any

drains.

Use only your hand to turn valve

handles. Never use tools. If the

handle will not turn by hand, don’t try

to repair. Forced or attempted repair

may result in re or explosion.

WHAT TO DO IF YOU SMELL GAS :

Do not use matches, candles, ame

or other sources of ignition to check

for gas leaks. Do not try to light the

appliance. Do not touch any electrical

switch; do not use any phone in your

building. Immediately call your gas

supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

If you cannot reach your gas supplier,

call the re department.

¡ Combustion

It is critical for all personnel to be familiar with start up, controls, and shutdown

procedures.

} STARTING THE BURNER GAS

1. Verify incoming gas pressure.

2. Open the manual gas cocks on the pilot and main lines on the gas head.

3. Switch on the main power to the burner. If the water level relay is equipped

with a manual reset. If the boiler was in a low water condition, the manual

reset button must be pressed.

4. Check motor rotation.

5. Start the burner by turning on the switch on the outside of the panel box.

The blower motor will begin to deliver air into the furnace.

6. When su cient air pressure has built up in the blower housing, the air

switch located on the top side of the blower housing will make contact

and after a seven-second delay, will allow the ignition transformer and

pilot valve to operate. This creates pilot re.

7. When the pilot ame is established, the ame rod or UV scanner senses

the electrical current (microamps). The signal is transmitted to the

protectorelay, which opens the main gas valve for full re.

3-4

© The Fulton Companies 2012

Page 27

SECTION 3 VMPW-IOM-2012-1001 OPERATION

NOTE: ´ For new installations/burner has been disassembled, the burner may not

re upon rst attempt because air must be cleared from gas lines. The burner

protectorelay may go into lockout mode; allow a period of one minute to elapse,

then repeat procedure for starting the burner.

} STARTING THE BURNER OIL

1. Open the oil line’s shut-o valves.

2. Verify oil is present at the oil pump.

3. Switch on main power to burner. If the boiler was in a low water condition,

the manual reset button must be pressed.

4. Start the burner by turning on the switch on the outside of the panel box.

The blower motor will begin to deliver air into the furnace.

5. As the blower starts, the magnetic oil valve is energized, allowing the oil

pump to deliver fuel for ignition.

6. If the protectorelay does not sense ame via the CAD cell or UV scanner

located on the top of the burner in approximately 15 seconds, it will shut

down the burner.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Do not attempt to start the

equipment for any testing prior

to lling and purging the vessel.

A dry re will seriously damage

the equipment and may result in

property damage or personnel injury

and is not covered by warranty. In

case of a dry ring event, shut o

the fuel supply and allow the vessel

to cool to room temperature before

uid is reintroduced to the pressure

vessel.

Flame Programmers

Refer to inserts provided.

Operating Controls

¡ Water Relief Valve

The Water Relief Valve releases extra pressure.

¡ Water Outlet Valve

The Water Outlet Valve serves as the isolation valve for the system.

¡ Temperature Control

The Temperature Control is a digital indicating control used to turn the boiler on

and o , and to control the ring rate when the boiler is modulated. The digital

display will show both the boiler process temperature and the boiler setpoint.

¡ Operating Temperature Aquastat

4 CAUTION

A quali ed installer, service agency

or the gas supplier must perform

installation and service on the fuel

delivery system.

Before commissioning the equipment,

verify with authorized personnel that

the gas lines have been purged.

Never attempt to operate equipment

that has failed to pass all the safety

checks.

After checking controls by manual

adjustment, make sure they are always

reset to their proper settings. Contact

your Fulton dealer before modifying the

equipment.

The Operating Temperature Aquastat controls the working temperature of the

boiler. This is an ASME CSD-1 code control which will turn the boiler o when the

water temperature exceeds its setpoint. It is an auto-reset control.

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

3-5

Page 28

OPERATION VMPW-IOM-2012-1001 SECTION 3

! WARNING

This boiler is equipped with an ignition

device which automatically lights the

burner. Do not try to light burner by hand.

Operating this equipment beyond its

design limits can damage the equipment

and can be dangerous. Do not operate the

equipment outside of its limits. Do not try

to upgrade the equipment performance

through unapproved modi cations.

Unapproved modi cations may cause

injury, equipment damage, and will void

the warranty.

Check daily that the equipment area

is free and clear of any combustible

materials, including ammable vapors

and liquids.

Do not tamper with safety features

provided by the operating controls.

Should overheating occur or the gas

supply fails to shut o , manually shut o

the gas supply external to the equipment .

¡ High Limit Aquastat/High Temperature Limit

The High Limit Aquastat/High Temperature Limit prevents over-temperature

conditions. This is an ASME CSD-1 code control which includes a manual

reset feature for over-temperature. Press the manual reset button when the

temperature drops to reset the control.

¡ Air Safety Switch

This switch is controlled by the pressure of air entering the burner. This

switch proves that the blower fan is delivering combustion air.

¡ Probe Type Low Water Cut-Off

The Low Water Cut-O shuts down the unit when the water level is too low, after

a three-second time delay to prevent nuisance shut downs. Fulton boilers are

equipped with ASME CSD-1 Code controls which include a manual reset feature

on the burner low water cut o relay. Press the low water reset button to reset

the control, and the boiler will start.

Optional Circulating Pump Switch

The fused switch that controls the circulating pump should be kept in the ON

position at all times during boiler operation and non-operating mode of the

boiler. It should be placed in the OFF position when repairs or adjustments must

be made.

4 CAUTION

Operation of the circulating pump for any

amount of time without rst bleeding will

result in equipment damage.

For all systems containing boilers or un red

steam generators, the water chemistry in

the boiler (generator) must be kept within

required limits. Failure to do so may cause

premature pressure vessel failure and poor

steam quality and will void the warranty.

If any “Manual Reset” limit device trips

DO NOT reset without determining and

correcting the cause. (Manual Reset Limits

may include: ame safeguard, high or low

gas pressure, high temperature limit, low

water).

Never tamper with low water (liquid level)

cuto sensors or circuitry.

Cycle Testing

The boiler should be cycled tested and automatically allowed to go through

its normal starting sequence several times to verify that all components are

functioning properly. This will also verify that combustion is set properly so that

boiler light o has a smooth transition from ignition to main ame.

A minimum of 10 cycles should be met without any ame failures, with

combustion readings comparable to the factory test re sheet and no interlocks

causing the boiler to shutdown.

Before Leaving the Installation

1. Check all controls to insure they are operating properly. Cycle the boiler

several times by raising and lowering operating temperature on the

thermostat.

2. Make sure the installation complies with all applicable codes.

3. Turn switch to OFF position.

3-6

© The Fulton Companies 2012

Page 29

SECTION 3 VMPW-IOM-2012-1001 OPERATION

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

3-7

Page 30

OPERATION VMPW-IOM-2012-1001 SECTION 3

3-8

© The Fulton Companies 2012

Page 31

MAINTENANCE

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

4-1

Page 32

MAINTENANCE VMPW-IOM-2012-1001 SECTION 4

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable