Page 1

INSTALLATION AND

OPERATION MANUAL

Reliance (RLN)

High E ciency Hydronic Boilers

500,000 - 3,000,000 BTU/HR

Serial/ National

Board Number

Model

Fulton Order

Sold To

Job Name

Date

RLN-IOM-2012-1205

Page 2

Page 3

RLN-IOM-2012-1205 TABLE OF CONTENTS

Introduction 1-1

Overview .............................................................................................................. 1-2

Warnings & Cautions ............................................................................................1-2

Disclaimers and Local Codes ................................................................................1-2

Installation 2-1

Product Overview ................................................................................................. 2-2

Placement & Rigging ........................................................................................... 2-3

Clearances and Serviceability ..............................................................................2-3

Install Boiler Trim .................................................................................................2-5

Install Water Piping .............................................................................................. 2-6

LOW WATER CUT OFF .................................................................................................................210

Meet Water Chemistry Requirements ................................................................2-10

PREVENT FREEZING ...................................................................................................................211

PREVENT OXYGEN CONTAMINATION ........................................................................................211

ELIMINATE SYSTEM AIR ............................................................................................................212

Fill the Boiler With Water ...................................................................................2-12

Install Gas Piping ................................................................................................2-12

Install Condensate Drain (Optional) ................................................................... 2-13

Venting ............................................................................................................... 2-15

COMBUSTION AIR SUPPLY FROM THE BOILER ROOM ..............................................................216

COMBUSTION AIR PIPED FROM OUTSIDE BUILDING WITHOUT SEALED COMBUSTION ........216

Exhaust Venting .................................................................................................2-17

STANDARD VENTING CONFIGURATION, CATEGORY IV .............................................................217

OPTIONAL VENTING CONFIGURATION, CATEGORY I ................................................................217

FOR BOTH VENTING CONFIGURATION OPTIONS ......................................................................218

COMMON AIR INTAKE AND EXHAUST VENTING OF MULTIPLE BOILERS .................................218

Venting Terminations ......................................................................................... 2-19

WALL THIMBLE INSTALLATION .................................................................................................220

HORIZONTAL VENT TERMINATION ............................................................................................220

Electrical Connections ....................................................................................... 2-21

AIR PIPED FROM OUTSIDE BOILER ROOM ................................................................................222

INTAKE DUCT SIZING ................................................................................................................222

Operation 3-1

Test of High Back Pressure Switch ........................................................................3-5

Normal Operation of the Boiler ............................................................................ 3-5

CHANGING THE OPERATING SET POINT .....................................................................................36

SETTING COMBUSTION ................................................................................................................36

Shut Down Procedures .........................................................................................3-7

NORMAL SHUT OFF PROCEDURES .............................................................................................37

EMERGENCY SHUT OFF PROCEDURES .......................................................................................37

SHUTTING THE BOILER DOWN FOR AN EXTENDED PERIOD OF TIME ........................................37

STARTING BOILER AFTER PROLONGED SHUTDOWN ..................................................................37

SOLA Control Features .......................................................................................... 3-7

FLAME DETECTION ......................................................................................................................37

CYCLE AND RUN HOURS MONITORING .......................................................................................38

SETPOINT CONFIGURATION.........................................................................................................38

SETTING THE CENTRAL HEAT SETPOINT .....................................................................................38

REVIEWING STATUS DETAIL ........................................................................................................38

LEAD/LAG OUTDOOR RESET FOR SINGLE BOILER APPLIC ATIONS ...........................................310

Maintenance 4-1

General ................................................................................................................. 4-2

Daily Maintenance and Inspection Schedule ......................................................4-2

Weekly Maintenance and Inspection Schedule .................................................. 4-2

Monthly Maintenance and Inspection Schedule .................................................4-2

Procedure for Cleaning the Air Inlet Filter ..........................................................4-3

Relief Valve Testing ............................................................................................... 4-3

Annual Maintenance and Inspection Schedule ................................................... 4-3

EXAMINE THE VENTING SYSTEM ................................................................................................44

INSPECT HEATING SYSTEM FOR OTHER PROBLEMS ..................................................................45

Procedure for Removing/Cleaning The Burner .................................................... 4-5

After All Repairs and Maintenance ...................................................................... 4-6

Troubleshooting ...................................................................................................4-6

Warranty & Parts 5-1

Standard Warranty for Fulton Reliance Boilers .................................................... 5-2

Parts ..................................................................................................................... 5-3

PARTS LISTING .............................................................................................................................54

Perform Pre-Start-Up Inspection .........................................................................3-2

Fill and Purge the System..................................................................................... 3-2

SOLA Control Program Presets .............................................................................3-3

Commission The Boiler ......................................................................................... 3-3

TEST OF IGNITION SAFETY SYSTEM ............................................................................................34

Perform Test of Low Water Cut O ....................................................................... 3-4

Perform Test of Limit Controls ............................................................................. 3-4

Perform Test of Low Gas Pressure Switch ............................................................ 3-5

Perform Test of High Gas Pressure Switch ............................................................ 3-5

Perform Test of Air Switch .................................................................................... 3-5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

0-1

Page 4

TABLE OF CONTENTS RLN-IOM-2012-1205

0-2

© The Fulton Companies 2012

Page 5

INTRODUCTION

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

1-1

Page 6

INTRODUCTION RLN-IOM-2012-1205 SECTION 1

Overview

Prior to shipment, the following inspections and tests are

made to ensure the highest standards of manufacturing for

our customers:

§ Material inspections

§ Manufacturing process inspections

§ American Society of Mechanical Engineers (ASME)

welding inspection

§ ASME hydrostatic test inspection

§ Electrical components inspection

§ Operating test

§ Final engineering inspection

§ Crating inspection

This manual is provided as a guide to the correct operation

and maintenance of your Fulton equipment, and should be

read in its entirety and be made permanently available to the

sta responsible for the operation of the boiler. It should not,

however, be considered as a complete code of practice, nor

should it replace existing codes or standards which may be

applicable. Fulton reserves the right to change any part of

this installation, operation and maintenance manual.

Installation, start-up, and maintenance of this equipment

can be hazardous and requires trained, quali ed installers

and service personnel. Trained personnel are responsible

for the installation, operation, and maintenance of this

product, and for the safety assurance of installation,

operation, and maintenance processes. Do not install,

operate, service or repair any component of this

equipment unless you are quali ed and fully understand

all requirements and procedures. Trained personnel

refers to those who have completed Fulton Service School

training speci c to this product.

Warnings & Cautions

WARNINGS and CAUTIONS appear in various chapters of this

manual. It is critical that all personnel read and adhere to all

information contained in WARNINGS and CAUTIONS.

§ WARNINGS must be observed to prevent serious injury

or death to personnel.

§ CAUTIONS must be observed to prevent damage

or destruction of equipment or loss of operating

e ectiveness.

All Warnings and Cautions are for reference and guidance

purposes, and do not substitute for required professional

training, conduct, and strict adherence to applicable

jurisdictional/professional codes or regulations.

Disclaimers and Local Codes

Installation of the equipment shall conform to all the

requirements or all national, state and local codes established

by the authorities having jurisdiction or, in the absence

of such requirements, in the US to the National Fuel Gas

Code ANSI Z223.1/NFPA 54 latest edition, and the speci c

instructions in this manual. Authorities having jurisdiction

should be consulted prior to installation.

When required by local codes, the installation must conform

to the American Society of Mechanical Engineers Safety Code

for Controls and Safety Devices for Automatically Fired Boilers

(ASME CSD-1).

The boiler heat exchanger is manufactured and stamped

in accordance with ASME Boiler and Pressure Vessel Code,

Section IV for a maximum allowable working pressure

and operating temperature of 160 psig and 210 F (121 C)

respectively.

When working on this equipment, observe all warnings,

cautions, and notes in literature, on stickers and labels, and

any additional safety precautions that apply. Follow all safety

codes and wear appropriate safety protection. Follow all

jurisdictional codes and consult any jurisdictional authorities

prior to installation.

1-2

© The Fulton Companies 2012

Page 7

INSTALLATION

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-1

Page 8

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Crystalline silica may be present

in components of this equipment.

Exposure to crystalline silica may

pose signi cant health hazards,

including but not limited to eye and

respiratory system damage. Per

the Centers for Disease Control and

Prevention (CDC) and Occupational

Safety and Health Administration

(OSHA), appropriate personal

protective equipment must be worn

to minimize exposure to hazardous

substances. Refer to most current

guidelines o ered by the CDC and

OSHA for more information, including

personal protective equipment

recommendations.

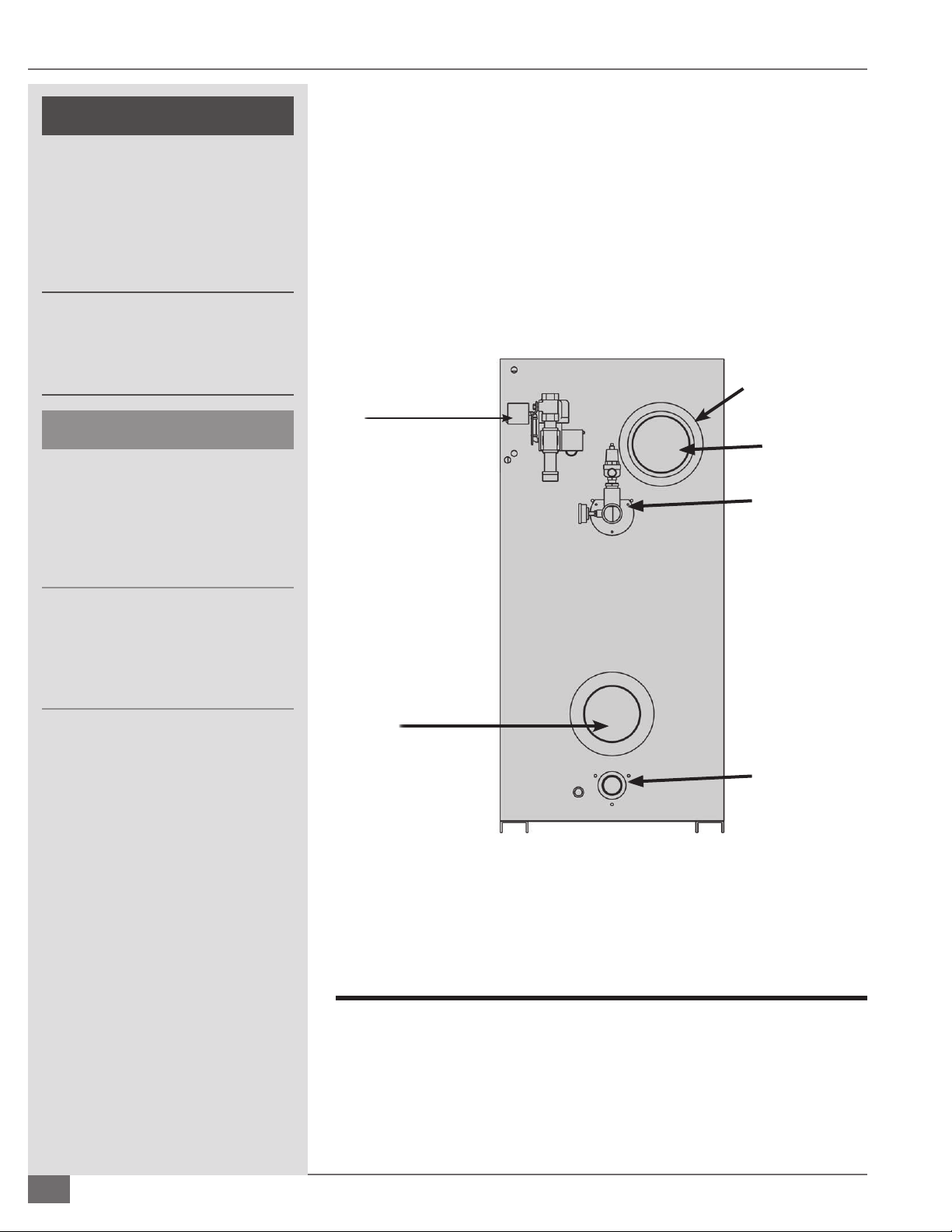

Product Overview

Prior to the performance of installation, operation, or maintenance procedures,

personnel should become familiar with the equipment (Table 1 and Figure 1) and

its components.

The Fulton Reliance hot water boiler is an automatic, fuel- red, high-e ciency

boiler. The boiler can either be of the sealed combustion/direct vent type or

utilize conventional combustion air intake and ue methods.

The boiler is capable of sidewall venting when the appropriate venting materials

are used, and when permitted by local code requirements. It features low

emission pre-mix combustion with pulse width modulation and fully automatic

safety controls.

The Fulton Reliance boiler is constructed to ASME Section IV and certi ed to

Underwriters Laboratories (UL) 795 Issue 2006/10/27 Edition 6 Standard for

Safety Commercial-Industrial Gas Heating Equipment. All Reliance boilers are

hydrostatically tested, test red and shipped as a complete packaged unit.

This boiler is to be installed as part of a hydronic heating system. A quali ed

engineer must be consulted for the selection of the equipment and components

of the heating system. Various system conditions can result in incorrect heat

distribution to users of the heating system.

Each Reliance Boiler is supplied with the following:

4 CAUTION

This boiler is certi ed for indoor

installation only.

This boiler is not designed for use in

systems where water is continuously

replenished. The warranty is valid for

closed loop systems only.

Fulton cannot be held responsible for

the selection, engineering, installation,

or sizing of any additional equipment

or components of the hydronic heating

system.

A quali ed engineer must be consulted

for equipment selection and heating

system components.

§ Outer cabinet utilizing an air gap as insulation

§ Integrated combustion supervision and temperature operating control

§ Operating and high temperature dual temperature probe

§ Low water ow switch

§ Fully matched modulating premix combustion system including burner,

blower and fuel train controls.

§ ASME pressure relief valve

§ Instruction manual

§ Wiring diagram

§ Combustion Air Adapter

§ Temperature and pressure (T&P) gauge

The customer should examine the equipment for any damage. It is the

responsibility of the installer to ensure all parts supplied with the equipment are

tted in a correct and safe manner.

2-2

© The Fulton Companies 2012

Page 9

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

Placement & Rigging

Proper placement of your Fulton product is essential. Attention paid to

the following points will save a great deal of di culty in the future. Correct

placement is the rst step to trouble-free installation, operation, and

maintenance.

Adhere to the following for placement and rigging:

1. Check building speci cations for permissible oor loading. Use Table 1 for

unit reference.

2. Conform to all the requirements of all national, state and local codes

established by the authorities having jurisdiction and/or the U.S. to the

National Fuel Gas Code, latest edition. Authorities having jurisdiction

should be consulted before installations are made. Where required by local

codes, the installation must conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for Automatically

Fired Boilers (ASME CSD-1).

3. Since an external electrical source is utilized, the boiler, when installed,

must be electrically ground in accordance with the National Electric Code,

American National Standards Institute (ANSI) National Fire Protection

Association (NFPA) 70, latest edition.

4. This boiler is certi ed for indoor installation only. National Electrical

Manufacturers Association (NEMA) 3R Con guration is available as an

option from the factory, but an existing boiler cannot be retro tted for

outdoor installation.

5. Install so that all system components are protected from water (dripping,

spraying, rain, etc.) during boiler operation and service.

6. Install on a level, non-combustible surface in the vertical position. Concrete

is strongly recommended.

7. Provide combustion and ventilation air in accordance with applicable

provisions of local building codes or: USA – NFPA 54/ANSI Z223.1, Section

5.3, Air for Combustion and Ventilation.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

Competent personnel in accordance

with all applicable local codes should

carry out the installation of the Fulton

equipment. All state and jurisdictional

codes beyond the scope of the applicable

ASME Boiler and Pressure Vessel Codes,

for its corresponding classi cation, should

be followed in all cases. Jurisdictional

authorities must be consulted prior to

installation.

A competent rigger experienced in

handling heavy equipment should handle

rigging your equipment into position.

The equipment must be installed on a

non-combustible surface.

Failure to provide required and safe

access to the equipment could impede

commissioning and maintenance.

Service technicians are instructed not to

commence commissioning if hazardous

conditions exist.

Failure to provide proper minimum

clearances between equipment and

combustible materials may result in re.

8. Locate the boiler so that the air supply and exhaust piping between the

boiler and outside wall/roof are within the maximum lengths for horizontal

or vertical venting if sealed combustion will be used. See Clearances and

Serviceability section of this manual.

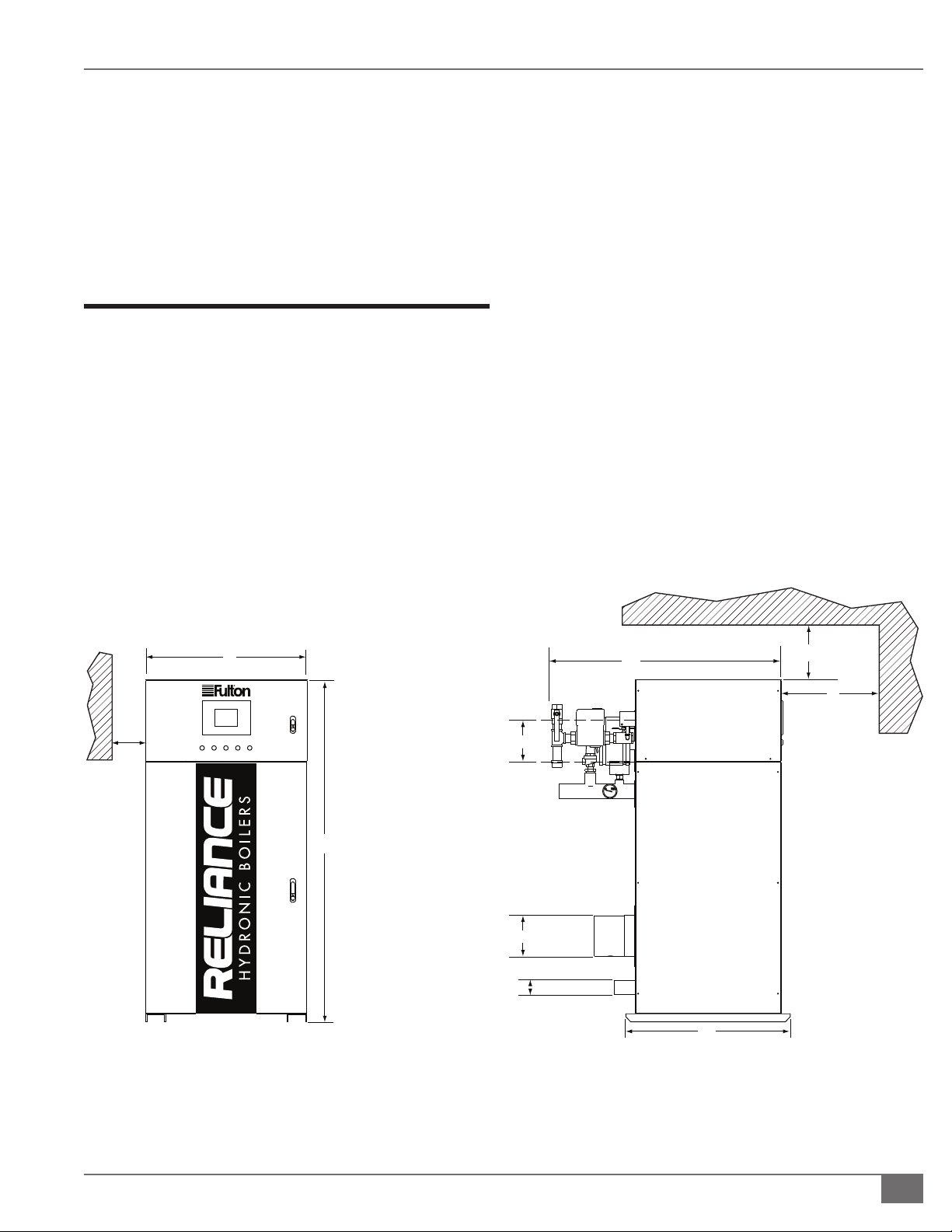

Clearances and Serviceability

Adhere to the following for clearances and serviceability:

1. All local and national codes (NFPA, ANSI, UL, CSA, ASME) must be

followed for proper clearances and serviceability for your boiler or heater.

Authorities having jurisdiction should be consulted before installations are

made.

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

4 CAUTION

Do not allow weight to bear on equipment

components to prevent damage.

Boiler must be installed in such a way as

to protect from water (including dripping,

misting, etc.) during boiler operation.

2-3

Page 10

INSTALLATION RLN-IOM-2012-1205 SECTION 2

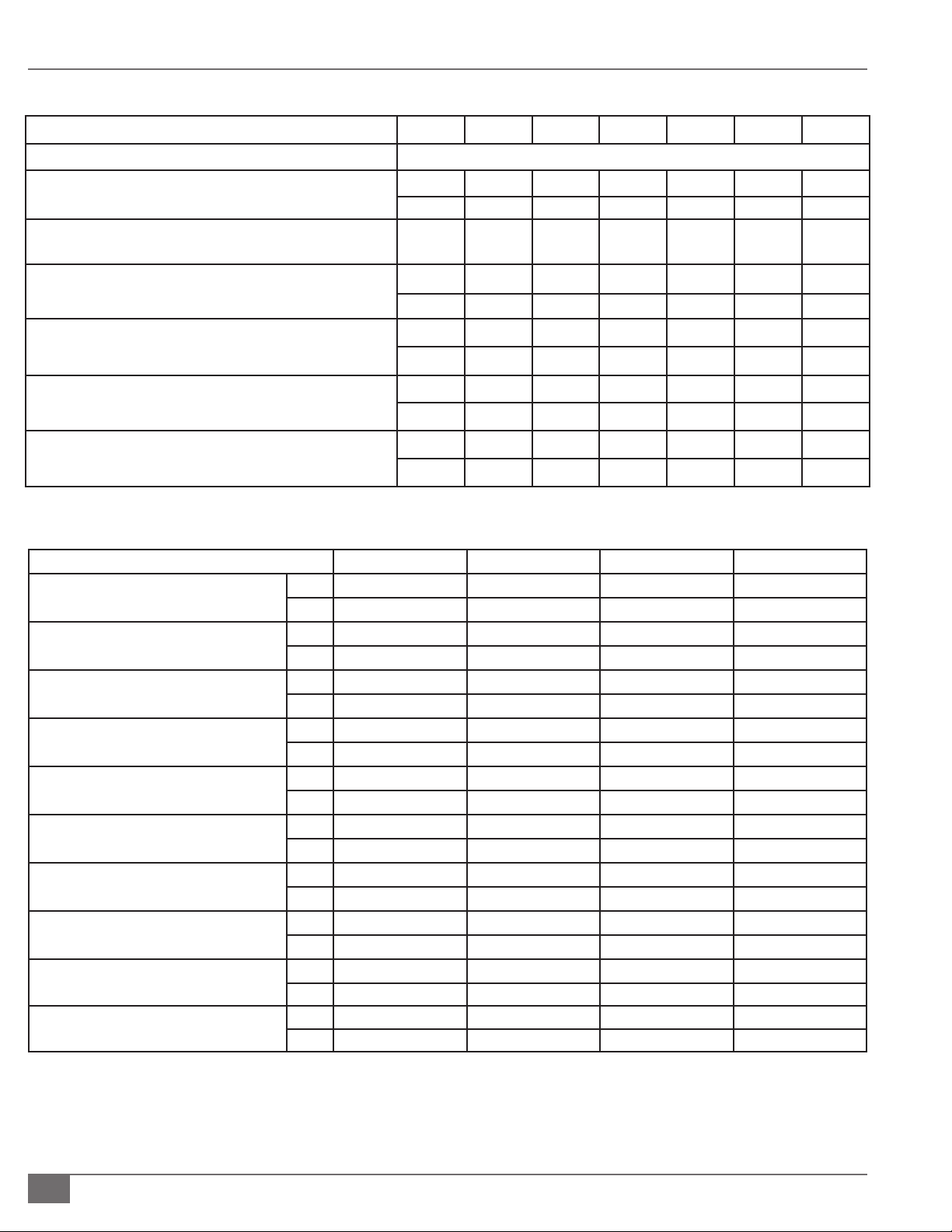

TABLE 1A OPERATING REQUIREMENTS

Reliance Model Size

Fuel Type Natural Gas or Propane*

Input BTU/Hr Max

Min

Electrical Requirements (Amps) (120V/60/1)

(240V/60/3)

Water Content Gal

Liter

Dry Weight LB

KG

500 750 1000 1500 2000 2500 3000

500,000 750,000 1,000,000 1,500,000 2,000,000 2,500,000 3,000,000

100,000 150,000 200,000 300,000 400,000 500,000 600,000

<3

NA

2.7 3 3 7.3 7.3 11 11

10.2 11.4 11.4 27.6 27.6 41.6 41.6

675 700 700 1000 1000 1400 1400

306 318 318 454 454 635 635

<3

NA

<3

NA

<6

NA

<6

NA

NA

<10

NA

<10

Operating Weight LB

KG

Anchor Bolt Size IN

MM

Dimensions • Reliance Hydronic Boiler

TABLE 1B BOILER DIMENSIONS REFER TO FIGURE 1

700 725 725 1060 1060 1492 1492

317.5 329 329 481 481 676.75 676.75

.75 .75 .75 .75 .75 .75 .75

19 19 19 19 19 19 19

Reliance Model Size 500 750 & 1000 1500 & 2000 2500 & 3000

A. Boiler Width IN

MM

B. Boiler Height IN

MM

C. Boiler Depth IN

MM

D. Boiler Depth with Trim IN

MM

E. Air Inlet Diameter IN

MM

F. Flue Outlet Diameter IN

MM

G. Water Inlet/Outlet Size IN

MM

H. Min Clearance to Walls IN

MM

I. Min Clearance to Front and Rear IN

MM 914.4 914.4 914.4 914.4

J. Min Clearance to Ceiling

Notes:

Speci cations and dimensions are approximate. We reserve the right to change speci cations and dimensions without notice.

*The use of propane is allowable with concentration of up to 5% propylene, commonly referred to as HD5. The use of o -standard grades of propane,

such as propane HD10 (10% propylene) is not permitted unless a system is in place to reduce propylene concentration to less than 5% prior to

reaching any fuel delivery piping. This is the responsibility of the customer. Verify propylene concentration with supplier prior to commissioning and

operation of equipment.

IN 24 24 24 24

MM 609.6 609.6 609.6 609.6

24 24 32.125 34

610 609.6 815.9 863.6

45 50.7 67.9 72

1143 1287.8 1724.6 1828.8

29.3 29.3 34.3 42.2

744.2 744.2 871.2 1071.8

43.9 43.9 49.3 55.9

1115 1115 1115 1419.8

4 6 8 10

101.6 152.4 203.2 254

4 6 8 10

101.6 152.4 203.2 254

2 2 2.5 3

50.8 50.8 63.5 76.2

1 1 1 1

25.4 25.4 25.4 25.4

36 36 36 36

2-4

© The Fulton Companies 2012

Page 11

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

A

B

D

J

H

I

C

Front View

Right Side View

F

E

G

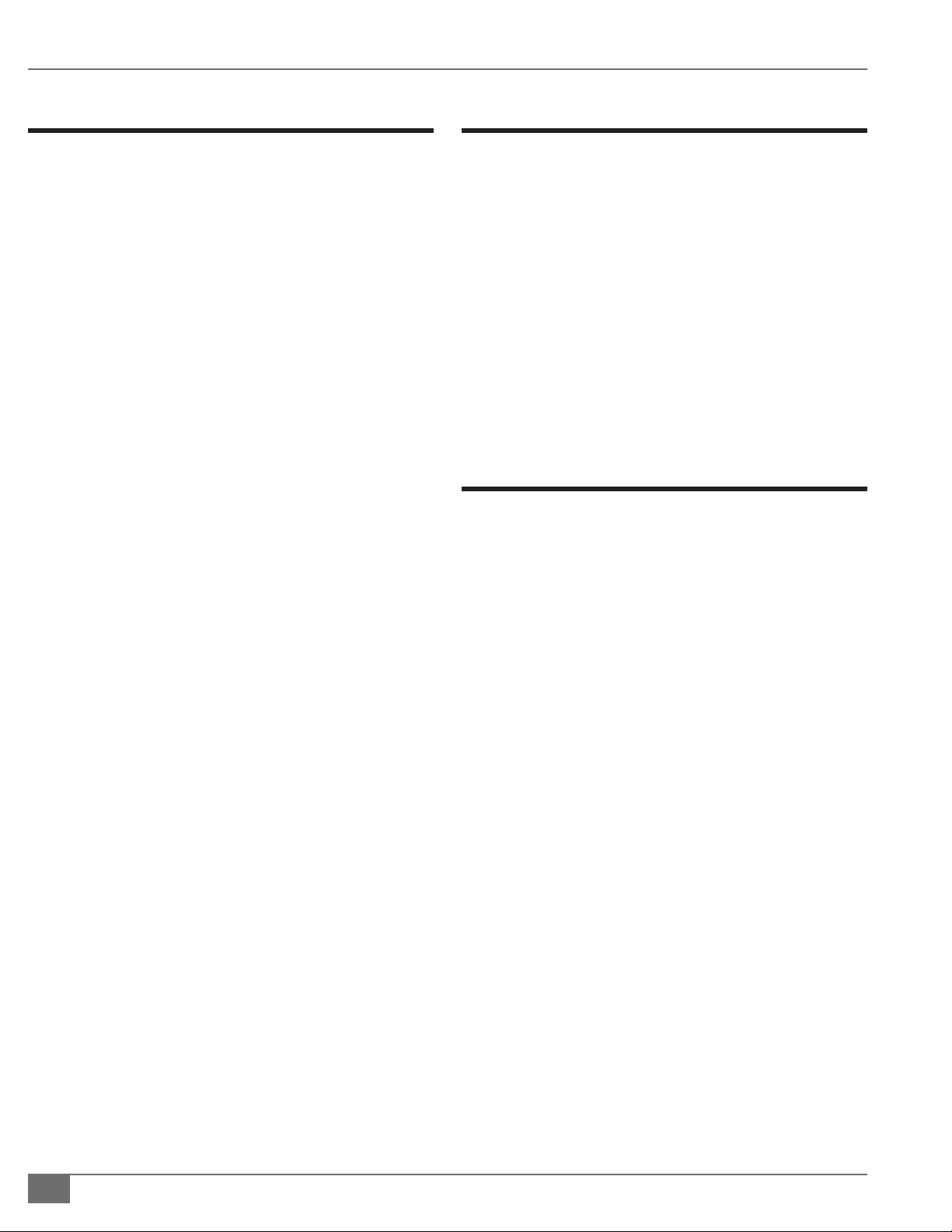

2. Appropriate front, back, side and top clearances must

be maintained (Figure 1). This will allow access around

the equipment to facilitate maintenance and a safe

work environment. An 1 inch (25.4 mm) side clearance

is acceptable between boilers.

3. Ensure all labels on the boiler will be fully visible for

maintenance and inspection.

Install Boiler Trim

Each Reliance boiler is supplied with a safety relief valve

sized in accordance with ASME requirements. Adhere to the

following installation requirements:

1. The safety relief valve (Figure 2) must:

» Be connected to the coupling located in the

top rear outlet section of the boiler.

» Be installed in the vertical position.

» Be installed with a 4 inch (101.6 mm) nipple

between the boiler and the safety valve.

NOTE: ´ Safety relief valve size is determined by trim pressure

and is supplied in the trim kit along with appropriate bushing,

inlet and outlet sizes.

The discharge pipe must:

» Not have a diameter less than the full area of the

valve outlet.

» Be as short and straight as possible and so

arranged as to avoid undue stress on the valve.

» Be supported by means other than the safety

valve itself.

» Be piped to avoid danger of scalding personnel.

NOTE: ´ Each boiler is equipped with a pressure-temperature

gauge to be installed in the outlet piping section of the boiler.

FIGURE 1 RELIANCE HYDRONIC BOILER CLEARANCES REFER TO TABLE 1B

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-5

Page 12

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

Ensure tank return line is not clogged.

Obstructions in the line could cause

damage to the pump seal.

The discharge from the safety relief valve

must be arranged to ensure no danger

of scalding personnel, or equipment

damage.

Provisions must be made to properly pipe

the safety relief discharge away from the

boiler to the point of discharge.

No shuto of any kind shall be placed

between the safety relief valve and

the boiler, or in the discharge pipe

between the valve and the atmosphere.

Doing so may cause an explosion from

overpressure.

The hydronic system should never be

ushed while the boiler is attached to the

system since the debris could accumulate

in the boiler and block water from passing

through the heat exchanger.

Ensure all labels on the boiler are legible.

All connections and safety devices, both

mechanical and electrical, must be kept

clean, with ease of access for inspection,

use and maintenance.

Install Water Piping

All water supplies contain some solids, dissolved gases or dissolved minerals.

These may promote corrosion, deposition and/or fouling of equipment. To

prevent these contaminants from impacting boiler performance, valve operation

and general pipe longevity, each location must be analyzed and treated

accordingly.

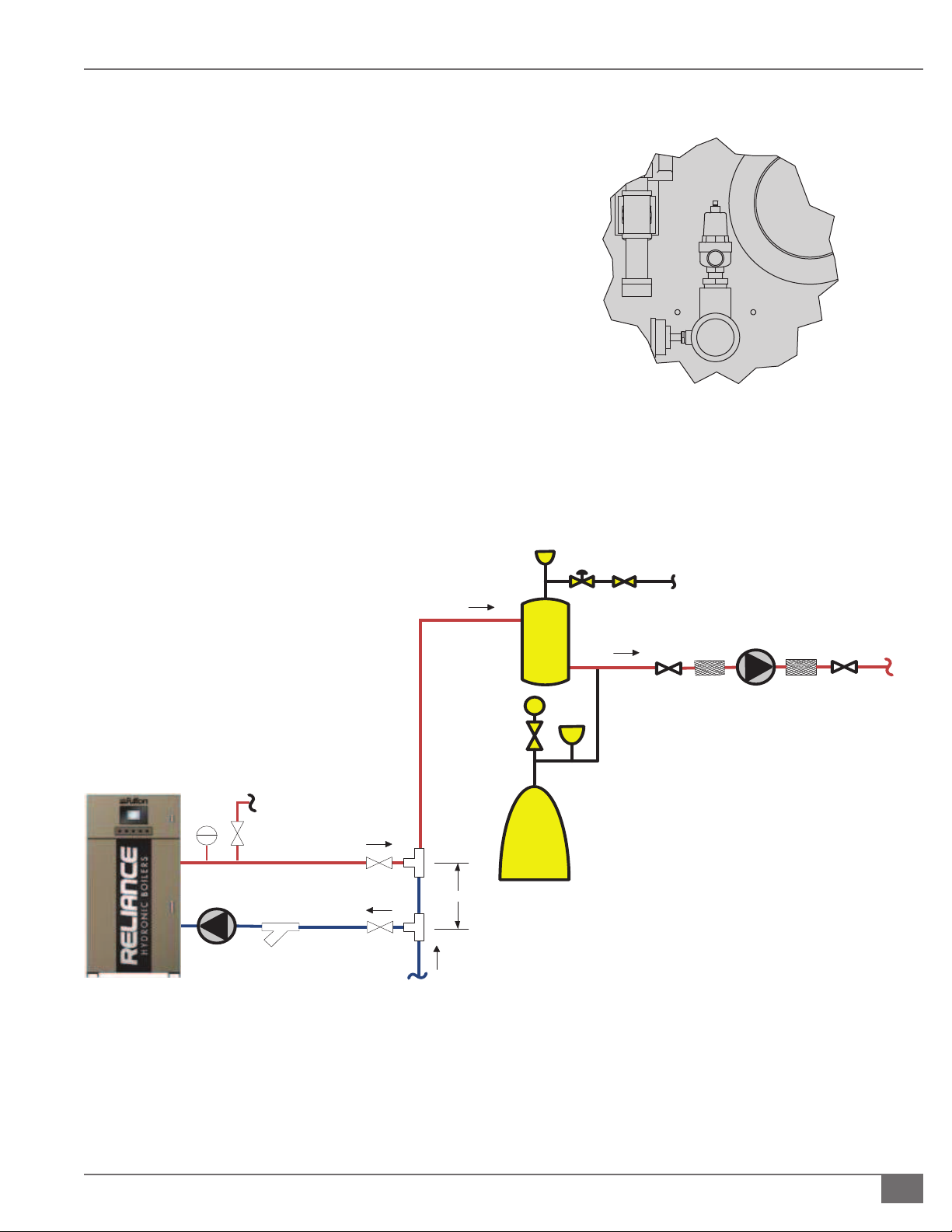

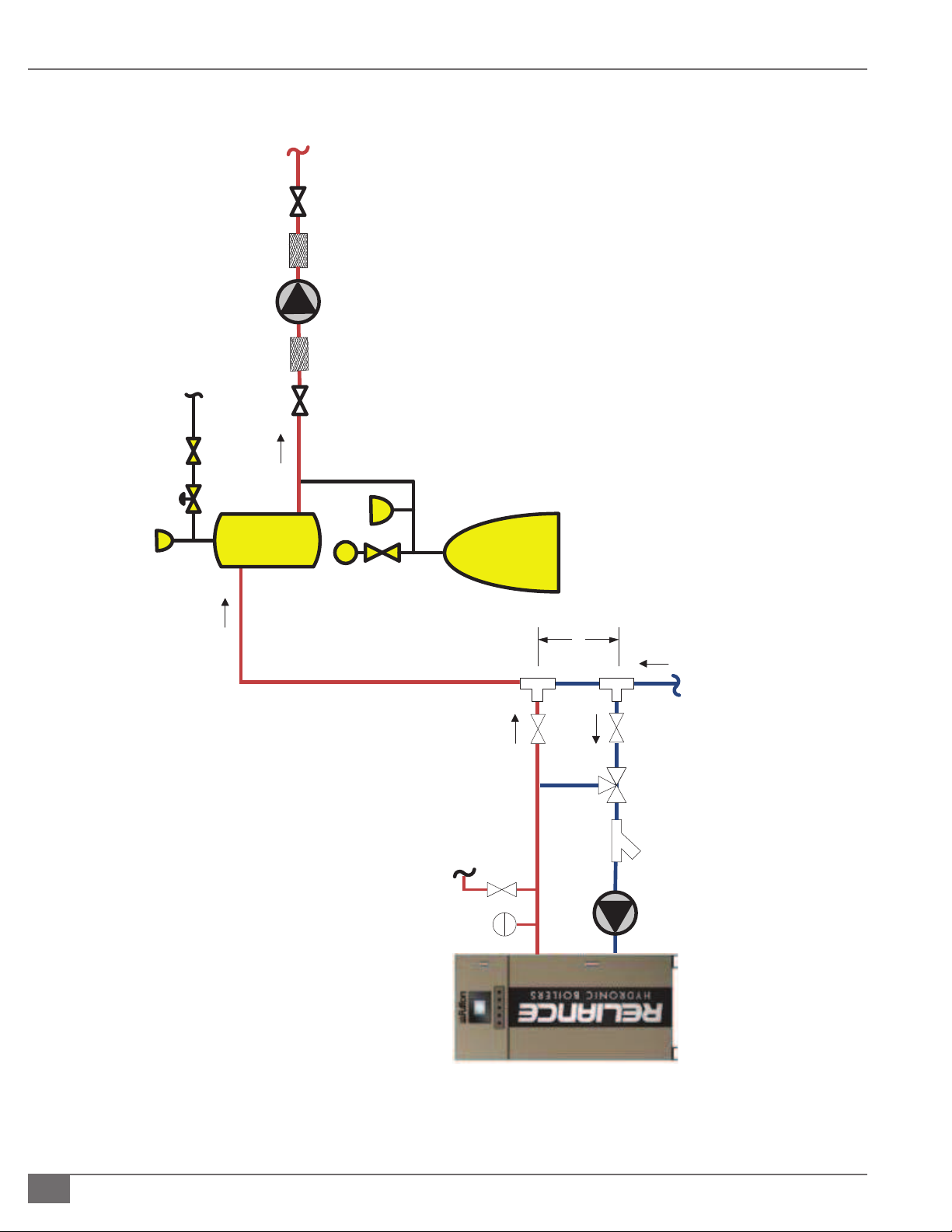

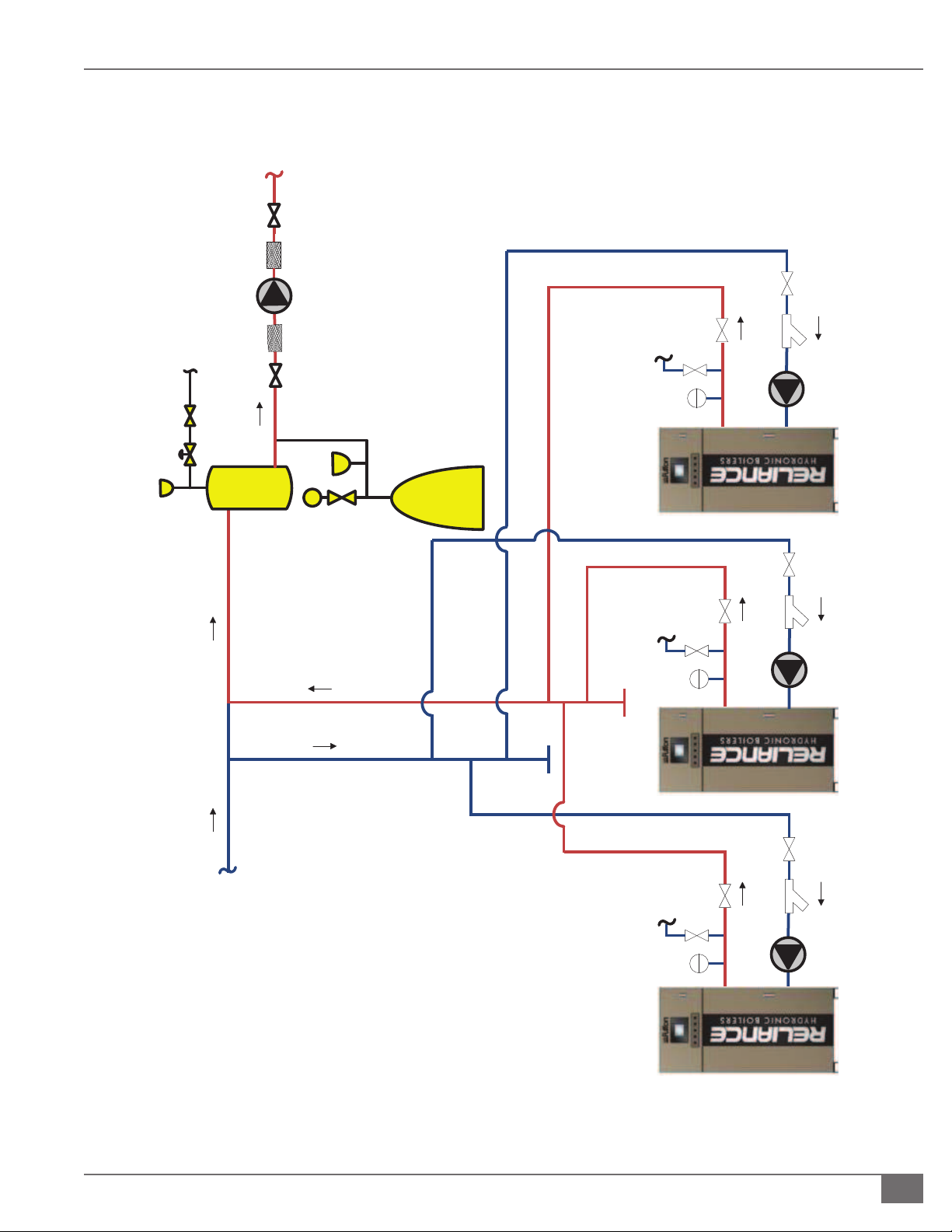

Adhere to the following for water piping installation (See Figure 3-5):

1. Boiler requires a minimum temperature di erential across the heat

exchanger at high re, and has a minimum ow requirement. Use Table 2

to identify ideal ow rates for the Reliance boiler.

TABLE 2 IDEAL FLOW RATES/GALLONS PER MINUTE*

RLN

Model

Min.

GPM

Max.

GPM

*The boiler warranty does not cover heat exchanger failure related to water ow rates outside

of these parameters. The minimum return water temperature must be greater than 140 F

(60 C) at all times to avoid condensation in the heat exchanger. Warranty does not cover heat

exchanger failure due to condensation of products of combustion.

2. Ensure piping arrangements allow for heat-up times at or below

500 750 1000 1500 2000 2500 3000

23 45 45 75 90 130 140

43 63 83 130 150 200 210

30 seconds; this will reduce condensation which may contribute to

equipment failure.

Do not store or use gasoline or other

ammable vapors and liquids or corrosive

materials in the vicinity of this or any other

appliances.

4 CAUTION

Low ow conditions will cause excessive

cycling, damage and failure of equipment.

Ensure water piping arrangements allow

for heat-up times at or below 30 seconds;

this will reduce condensation which may

contribute to equipment failure.

2-6

3. Pipe unions and isolation valves are recommended on both water

connections for ease of service.

4. Install piping so that the boiler is not supporting any additional piping.

5. The top water connection on the back of the boiler is the hot water

outlet and must be connected as the supply to the system. The bottom

connection is the return/boiler inlet. See Figure 6.

6. Install a hot water circulator, remote mounted from boiler. Do not attach

directly to the boiler. Refer to Figures 3 - 5 for proper location of circulators.

7. Install manual purging valves in all loops and zones. Install a pressure

reducing (automatic ll) valve in the cold water ll line to the boiler system.

Check that the proposed operation of zone valves, zone circulator(s) and

diverting valves will not isolate air separator(s) and/ or expansion tank(s)

from the boiler. Clearance from hot water pipes to combustibles must be at

least 6 inch (152.4 mm).

8. The boiler, when used in conjunction with a refrigeration system, must

© The Fulton Companies 2012

Page 13

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

Dedicated

Pump

T

Safety

Relief

Valve

Heating

Loop

Return

12"

Strainer

Cold Water

Supply

Air

Separator

PRV

P

Expansion

Tank

Hot Water

Heating

Loop Supply

System

Pump

Air

Sep.

be installed so the chilled medium is piped in parallel

with the boiler with appropriate valves to prevent the

chilled medium from entering the boiler. If the boilers

are connected to heating coils, located in air handling

units where they may be exposed to refrigerated

air circulation, such boiler piping systems shall be

equipped with ow control valves or other automatic

means to prevent gravity circulation of the boiler water

during the cooling cycle.

9. The boiler is not provided with a drain valve directly on

the boiler. A drain valve should be installed near the

system return (water inlet) connection to the boiler and

piped to a drain.

10. Before installing a Reliance boiler into a hydronic

loop, be sure that the system piping and any other

components of the system are clean and free of debris

and any foreign matter. The hydronic system should be

completely ushed prior to installing the boiler itself.

FIGURE 2 SAFETY VALVE

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

FIGURE 3 SAMPLE PIPING LAYOUT: SINGLE BOILER WITH RETURN WATER TEMPERATURE >140 F 60 C

2-7

Page 14

INSTALLATION RLN-IOM-2012-1205 SECTION 2

Dedicated

Pump

T

Safety

Relief

Valve

Heating

Loop

Return

12"

3-Way

Mixing

Valve

Strainer

Cold Water

Supply

Air

Separator

PRV

P

Expansion

Tank

Hot Water

Heating

Loop Supply

System

Pump

Air

Sep.

2-8

FIGURE 4 SAMPLE PIPING LAYOUT: SINGLE BOILER APPLICATION, WITH MIXING VALVE

© The Fulton Companies 2012

Page 15

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

Dedicated

Pump

T

Safety

Relief

Valve

T

Safety

Relief

Valve

Dedicated

Pump

T

Safety

Relief

Valve

Dedicated

Pump

Cold Water

Supply

Air

Separator

PRV

P

Expansion

Tank

Hot Water

Heating

Loop Supply

Heating

Loop

Return

System

Pump

Strainer

Strainer

Strainer

FIGURE 5 SAMPLE PIPING LAYOUT: MULTIPLE BOILERS IN A COMMON HYDRONIC LOOP, RETURN TEMPERATURE >140 F 60 C

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-9

Page 16

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

The boiler must be disconnected at

the boiler shut o valve from the

gas supply piping system during any

pressure testing of the system.

4 CAUTION

Small levels of chlorides and/or sulfur

presence in the combustion air or

fuel will negatively impact the heat

exchanger components. Any presence

of these contaminants will void the

warranty.

Install a strainer upstream of each boiler to ensure that no foreign matter

will have the opportunity to get inside the heat exchanger.

¡ Low Water Cut Off

The Reliance boiler comes with an installed ow-switch type low water cut-o

(LWCO). The LWCO does not require eld piping or wiring. If the ow switch

does not sense ow, the boiler will shut down and an alarm condition will be

annunciated on the SOLA color screen display.

Customer Electrical

Connection

Rubber Air Inlet

Coupling

Air Inlet

Water Outlet

Connection

(system

supply)

Some soaps used for leak testing are

corrosive to certain types of metals.

Rinse all piping thoroughly with

clean water after leak check has been

completed.

Exhaust Outlet

Connection

Water Inlet

Connection (system

supply)

FIGURE 6 WATER INLET AND OUTLET CONNECTIONS

Meet Water Chemistry Requirements

System water chemistry requirements are as follows:

§ Maximum hardness of 8.5 grains (150 ppm)

2-10

§ Acceptable pH range of 7.5-10

§ Solids less than 2500 ppm

§ Alkalinity less than 500 ppm

© The Fulton Companies 2012

Page 17

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

§ Foreign matter: Oils, fats, grease, and other matter should be limited to 10

ppm.

Adhere to the following:

1. Refer to your water conditioning or chemical treatment supplier for

analysis and recommendations for proper system conditions.

2. Follow a program with appropriate monitoring and maintenance of system

water conditions as provided by your water conditioning or chemical

treatment supplier.

3. Appropriate ow rates and return water temperature may be achieved

through primary and secondary ow loops. Please refer back to Figures

3 - 5 for example systems. Multiple pumps, valves and heating zones

operating at a variety of conditions will cause system ow to vary. System

design professionals should consider the variety of conditions the heating

system will experience.

4. Operate the boiler in a closed-loop system using water or water/glycol

(not requiring a make-up water supply). A large amount of improperly

treated make-up water can cause premature failure of the heat exchanger

resulting from scale build up. Scale build up will reduce the e ciency and

useful life of the boiler.

! WARNING

If the water supply must be

temporarily disconnected, the

boilers must be turned o to prevent

accidental ue gas emission into the

boiler room.

4 CAUTION

Care needs to be taken to eliminate

oxygen from the water system, as

excess oxygen in the system will

reduce the life of any boiler. The

boiler warranty does not cover heat

exchanger replacement due to oxygen

contamination of boiler water.

Heat exchanger failure due to

inappropriate water quality, foreign

matter or debris damage is not covered

under the warranty.

¡ Prevent Freezing

It is imperative to prevent freezing; adhere to the following:

§ If water/glycol is to be used in the system, a hazard analysis should be

performed to determine proper use and disposal. No greater than 40%

glycol should be used.

§ Precautions for freeze protection are recommended for boiler installations

where freezing potential exists and for installations that will use sealed

combustion with potential for outdoor air to fall below freezing point.

¡ Prevent Oxygen Contamination

There are several ways to prevent boiler water oxygen contamination:

§ Minimize system leaks to minimize make up water requirement

§ Do not use open tanks or ttings

§ Do not use oxygen permeable materials anywhere in the water system

§ Repair leaks in the system quickly

§ Eliminate ttings wherever possible

If the piping system attached to this

unit will be chemically cleaned, the

boiler must be disconnected from the

system and a bypass installed so that

the chemical cleaning solution does

not circulate through the boiler.

The hydronic system should never be

ushed while the boiler is attached

to the system since the debris could

accumulate in the boiler and block

water from passing through the heat

exchanger. This will lead to premature

boiler failure.

§ Use air elimination devices in system piping

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-11

Page 18

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

Do not use matches, candles, ame or

other sources of ignition to check for gas

leaks.

DO NOT USE GASOLINE, CRANKCASE OIL

OR ANY OIL CONTAINING GASOLINE. If in

doubt, contact your Fulton representative

prior to operation.

4 CAUTION

Some soap used for leak testing is corrosive

to certain types of metals. Clean all piping

thoroughly after completing the leak check.

¡ Eliminate System Air

NOTE: ´ There are no built-in boiler air eliminating features.

Adhere to the following for air elimination:

1. The installation of an air separator and air eliminator (air vent) is required.

2. To prevent scale corrosion in boiler and associated piping, make up water

must be kept to a minimum. This is best achieved by ensuring immediate

repair of all leaks and that system pressure is maintained.

3. If a sealed diaphragm-type expansion tank is used, install an air eliminator

in the hot water piping at the air separator.

4. If an air cushion type expansion tank is used, pipe tank directly into boiler

supply.

5. On multi-zoned systems (or a system with both space and domestic water

heating), air elimination must be provided either in the common piping or

on every loop.

6. When the boiler is installed at a higher level than baseboard radiation (if

used), air elimination must be provided directly above the unit.

Fill the Boiler With Water

To be sure that the boiler is not air-bound, open the pressure-relief valve located

at the rear of the boiler. Leave the relief valve open until a steady ow of water is

observed. Close the valve and nish lling the system.

Install Gas Piping

The Reliance boiler is factory test red and combustion is adjusted per the boiler

data plate and test re sheet.

The gas train (Figure 7) components are UL-795 certi ed to operate at speci c

gas pressure requirements. If available gas pressure is greater than 14” W.C., a

lock up style gas pressure regulator must be provided to reduce the provided

pressure to the acceptable range of 3.5” W.C. to 14” W.C. for natural gas, and 7”

W.C to 14” W.C. for propane.

Adhere to the following for gas piping installation:

1. See Table 3 for required natural gas pipe size, based on overall length of

pipe from the meter plus equivalent length of all ttings. Approximate

sizing may be based on 1,020 BTU for 1 cubic foot of natural gas.

2-12

2. Piping must be installed such that no piping stresses are transmitted to the

boiler. The boiler cannot be used as a pipe anchor.

3. The boiler and all gas piping connections must be pressure-tested and

checked for leaks before being placed into service. Test with compressed

air or inert gas if possible.

© The Fulton Companies 2012

Page 19

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

Ball Valve

Ball Valve

Gas Valve

Gas Inlet

installed upstream of the gas safety shut o valves.

8. Connect gas supply line to the open end of the tee on

which the drip leg is installed.

9. When making gas-piping joints, use a sealing

compound resistant to lique ed petroleum gases. Do

not use Te on tape on gas line threads.

10. After gas piping is completed and before wiring

installation is started, carefully check all piping

connections, (factory and eld), for gas leaks. Use a soap

and water solution.

Install Condensate Drain (Optional)

A condensate drain kit (Figure 8) is intended for use with the

Fulton Reliance boiler.

FIGURE 7 TYPICAL GAS TRAIN

The Condensate Drain is Fulton Model Part Number 4-57-

000440. Its recommended Operating Temp. is 175 F max;

4. The boiler must be disconnected at the boiler manual

shuto valve (located at the end of the supplied gas

train) from the gas supply piping system during any

pressure testing of the system at pressures in excess of

capacity is 4 QT; Inlet Size is 1inch; Outlet Size is 1 ½ inch;

Water Supply is 100 psi max.; and Max. Btu’s input per drain

kit is 12 MMBtu.

PH neutralization kits are available from the factory, if desired.

1/2 psig (14 inch W.C.).

Adhere to the following for installation:

5. Gas piping must be installed in accordance with

National Fuel Gas Code, ANSI Z223.1 1991 or latest

addenda and any other local codes, which may apply.

1. The 3/4” condensate drain on the Reliance unit must

be connected to the drain of the “Boot Tee” that must

be installed on the exhaust outlet of the boiler and

6. The pipe and the ttings used must be new and free of

dirt or other deposits.

7. Piping must be of the proper size to ensure adequate

gas supply. A drip leg and union connection must be

TABLE 3 NOMINAL PIPE SIZE

Nominal

Pipe Size

(“) (“) 90 Elb

1-1/4 1.380 3.45 6.9 950 ----- ----- ----- ----- ----- -----

1-1/2 1.610 4.02 8.04 1460 990 810 ----- ----- ----- -----

2 2.067 5.17 10.3 2750 1900 1520 1300 1150 950 800

2-1/2 2.469 6.16 12.3 4350 3000 2400 2050 1850 1500 1280

3 3.068 7.67 15.3 7700 5300 4300 3700 3250 2650 2280

4 4.026 10.1 20.2 15800 10900 8800 7500 6700 5500 4600

ID Equivalent Pipe

Length

(Feet)

Tee

(Feet)

Max Capacity in ft3 of natural gas per hour. Pressure drop of

0.5”wc/Equivalent length of pipe (feet)

20 40 60 80 100 150 200

then tied together to the 1” inlet on the drain kit. One

or more drain lines may be connected to this inlet

(maximum of 12 MBH total per drain kit) through a

common header.

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-13

Page 20

INSTALLATION RLN-IOM-2012-1205 SECTION 2

Detail A

(Condensate Drain Kit)

BACK VIEW

For multiple boiler installation, maintain a

minimum pipe size of 1” for the header piping.

(8boilers maximum per drain kit)

5 1/2”

Minimum

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Do not store or use gasoline or other

ammable vapors and liquids or

corrosive materials in the vicinity of

this or any other appliances. Cements

for plastic pipe should be kept away

from all sources of ignition. Proper

ventilation should be maintained to

reduce the hazard and to minimize

breathing of cement vapors.

An uninterruptible water supply is

required and shall be connected to

the ¼” compression tting on the

condensate drain. The water supply

maintains a water level in the drain

kit to prevent accidental ue gas

emission into the boiler room.

FIGURE 8 OPTIONAL CONDENSATE DRAIN KIT

2. An uninterruptible water supply is required and shall be connected to the

1/4” compression tting on the drain oat. The water supply maintains a

water level in the drain kit to prevent the ue gas from entering the boiler

room through the condensate connection.

3. The 1 1/2” connection shall be piped to an appropriate drain for disposal. If

the water supply must be temporarily disconnected, the boiler(s) must be

turned o to prevent accidental ue gas emission into the boiler room.

4. The cover should be kept on at all times, except during maintenance of

the drain. This drain should be monitored and checked regularly in your

Reliance maintenance schedule.

5. If the water supply must be temporarily disconnected, the boilers must be

turned o to prevent accidental ue gas emission into the boiler room.

6. The condensate drain cover must be kept on at all times, except during

maintenance of the drain. This drain should be checked regularly in your

boiler maintenance schedule.

2-14

7. A condensate collecting tank and condensate pump will be required if a

oor drain is not available to collect condensate (collecting tank and pump

are not supplied with the boiler).

8. All piping (Figure 9) must be galvanized, or stainless steel and should

be free of leaks. Copper, carbon steel/iron pipe, PVC or CPVC are not

acceptable.

9. Connect 3/4” condensate drain(s) to the 1” header connected in a manifold

as shown in Figure 10. The header must be at least 5 1/2” below the

© The Fulton Companies 2012

Page 21

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

Reliance

Boiler

AL294C

Exhaust Pipe

4” Loop

4” Loop

Piped/Pitched to

Appropriate Drain

Condensate

Connection

on Boiler

FIGURE 9 CONDENSATE DRAIN PIPING FOR RELIANCE BOILERS

condensate outlet of the individual boiler and must

remain ooded by being at least 5 ½” below the outlet

of the condensate drain trap.

10. Connect 1 1/2” drain outlet to an appropriate waste line

following applicable codes. The 11/2” drain connection

on the condensate drain must be the highest point

prior to going to the drain. Failure to keep drain

piping lower than this point will result in over ow of

the condensate drain. Slope the drain pipe away at a

minimum pitch of 1 inch (25.4 mm) for every 12 feet

(3.65 m).

11. Attach a 1/4” water supply to the compression tting

on the oat. The water line must be connected to an

uninterruptible supply. Fulton recommends connecting

it before the “Fast-Fill” valve to the boiler supply but

after the back ow preventer to avoid contamination

of a potable water supply. Maximum allowable water

pressure to the compression tting is 100 PSI.

Venting

Adhere to the following venting requirements:

1. The boiler can be installed with either sealed

combustion or a conventional venting arrangement.

With either venting con guration, the di erence in

pressure readings at the boiler exhaust connection

and air intake connection cannot exceed +2.0” W.C.

This equates to 70 feet (21.3 m) and 8 elbows when

combining the distances on the air intake and exhaust

with the piping diameters matching the standard

connections.

2. The pressure at the boiler exhaust connection must not

exceed 0.04” W.C. negative. This pressure must remain

relatively constant throughout the operation of the

boiler.

3. The boiler should not be operated with a negative

pressure in the boiler room (unless there is sealed

combustion [intake piped outside]). Pay particular

attention to other equipment installed in the boiler

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-15

Page 22

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

Do not use the boiler as support for

ducted air piping. Ducted piping

must be supported independently of

the boiler.

Cements for plastic pipe are

ammable liquids and should

be kept away from all sources of

ignition. Proper ventilation should

be maintained to reduce the hazard

and to minimize breathing of cement

vapors. Avoid contact of cement with

skin and eyes.

room such as compressors and air handling units.

4. Consult your venting pipe supplier for assistance with sizing of vent

materials and other potentially required accessories.

NOTE: ´ The installation of an air intake lter is recommended for any Reliance

installation where particulate matter >50 microns could enter the boiler. An air

intake lter is available as an option from Fulton if required. The air intake lter

must be inspected and, if required, cleaned and/or replaced on a monthly basis at

a minimum.

¡ Combustion Air Supply From the Boiler Room

Adhere to the following for installation:

1. Adequate combustion air and ventilation must be supplied to the boiler

room in accordance with local codes and NFPA54/ANSI Z233.1, Section 5.3,

Air for combustion and ventilation.

2. The boiler room must meet the NFPA criteria for a non-con ned space.

3. It is important to provide free access of air to the boiler. To burn fuel

properly, it requires 0.4 square inch opening of fresh air for every 1,000 BTU

input of fuel (2.58 cm2 for every 252Kcal).

4. Consistent proper ventilation of the boiler room is essential for good

combustion. Install two fresh air openings, one at a low level, within 12

inches (305 mm) from the oor but not less than 3 inches (76 mm), and

one at a higher level within 12 inches (305 mm) of the ceiling but not less

than 3” in the boiler room wall. This will provide a ow of air to exhaust the

hot air from the boiler room. Each opening must have a minimum of 1in2

per 1000 Btu/hr and be no less than 100in2.

5. Consider the blocking e ect of louvers and grills.

6. A combustion air supply damper (which can be shipped mounted to

the boiler from the factory) is recommended for sealed combustion

installations with high draft ow. This is typical of installations with a total

of 70 ft linear distance or greater of the combined distance of air intake

and exhaust piping. In cold ambient conditions, high natural draft through

an idle boiler can cause the water inside the heat exchanger to freeze.

¡ Combustion Air Piped From Outside Building Without Sealed

Combustion

Adhere to the following for installation:

1. If the boiler room is deemed a con ned space two permanent ducts

connected to the outdoors must be installed.

2-16

NOTE: ´ Assembly should be completed within 20 seconds after last application of

cement. Do not use a hammer to insert pipe.

© The Fulton Companies 2012

Page 23

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

2. After assembly, wipe excess cement from pipe at end of tting socket.

A properly made joint will show a bead around its entire perimeter. Any

gaps may indicate a defective assembly due to insu cient cement. Handle

joints carefully until completely set. Galvanized steel joints should be

sealed with adhesive aluminum tape.

Exhaust Venting

The Reliance boiler is equipped with a round vent connection (Figure 6) at the

lower rear of the boiler.

¡ Standard Venting Confi guration, Category IV

The Reliance boiler is standardly con gured as a Category IV appliance. The vent

connection sizes are adequate for a Category IV arrangement. Venting material

must be appropriate for condensing, positive pressure applications (condensing

occurs in the stack).

Adhere to the following:

1. Venting material supplied for the Reliance boiler con gured as Category IV

must be AL29-4C or 316L SS, listed and labeled to UL 1738, and guaranteed

appropriate for the application by the manufacturer and supplier of the

venting.

2. Do not utilize automatic vent dampers or barometric dampers with the

Reliance boiler. Because the exhaust system operates at a positive pressure,

utilizing dampers could result in ue gases leaking into the boiler room.

3. The exhaust line must be sloped down toward a drain with a pitch of

at least ¼” per foot. Failure to do so can result in a condensate pocket,

which can result in an inoperative boiler. This must be no low spots in the

exhaust pipe, as this can also result in a condensate pocket. A high spot is

acceptable, provided the pitch from the high spot is maintained back to

the drain.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Do not use the boiler/burner as

support for ducted air piping.

Ducted piping must be supported

independently of the boiler.

Do not terminate venting into an

enclosed area.

Never use open ame or smoke from

a cigarette, cigar, or pipe as a testing

method during boiler installation,

operation, or maintenance.

Foreign substances, such as

combustible volatiles in the

combustion system can create

hazardous conditions. If foreign

substances can enter the air stream,

the boiler combustion air inlet must

be piped to an outside location.

Regular maintenance of the

lter is required (as per the lter

manufacturer’s recommendations) to

maintain the warranty.

¡ Optional Venting Confi guration, Category I

The Reliance boiler can be con gured as a Category I appliance. The boiler must

be ordered this way from the factory. The operating controls will be con gured

to limit the minimum modulation point to 50% of full input, thus preventing

condensing from occurring in the stack.

Adhere to the following:

1. Shipped loose with the boiler will be a stack increaser tting and a

barometric draft regulator. These components must be used when venting

the Reliance as a Category I appliance. The stack material must be 4”

diameter larger than the stack connection on the boiler.

2. Venting material must be appropriate for non-condensing, negative

pressure applications and should be B-Vent style material. This must be

guaranteed appropriate for the application by the manufacturer and

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

Particulate matter or chemicals in

the combustion air supply to the

boiler will cause damage or failure to

the burner and is not covered under

warranty.

2-17

Page 24

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Use of automatic vent dampers

or barometric dampers with the

Reliance boiler in positive pressure

systems may result in exhaust leaking

into the boiler room.

4 CAUTION

Failure to slope the exhaust line

toward the drain with a pitch of at

least 1/4” per foot may result in a

condensate pocket, which can result

in an inoperative boiler.

supplier of the venting.

3. Category I Installations, individual piping for each boiler: The pressure

drop of the exhaust piping (not including the air intake piping) should be

a negative during all possible operating conditions, between -0.02 and

-0.04”wc. Vertical rise in the exhaust pipe is typically required to achieve

the desired negative pressure.

¡ For Both Venting Confi guration Options

Adhere to the following:

1. The exhaust vent installer should be familiar with and adhere to the

National Fuel Gas Code, ANSI A233.1, Part 10 or any other applicable

provisions of local building codes.

2. The exhaust vent installer should follow the vent manufacturer’s

instructions for proper installation procedures.

3. A tee/boot tee with a drain must be installed at the rst elbow from the

boiler ue outlet. There must be a minimum of 4” of water within a loop

style trap (loop diameter 4”). The loop style trap can be high temperature

silicone rated for 500 F (see Figure 9) and must be piped/pitched to drain

freely.

4. The loop style trap must be lled with water before connecting it to the

exhaust pipe. It is important that this trap is periodically checked and

veri ed that it remains ooded during regular operation of the equipment.

Failure to do this could result in ue gases leaking into the boiler room.

5. The condensate connection on the boiler should be piped into the stack

drain piping (see Figure 9). The pipe from the boiler directed to the drain

should be installed at a slope of ¼” per foot.

6. Ensure that condensate drain piping will not be exposed to temperatures

where water condensate will freeze in the lines.

¡ Common Air Intake and Exhaust Venting of Multiple Boilers

Combining multiple Reliance boilers into a common pipe for combustion air

supply, exhaust, or both is only permitted on a case by case basis and must be

accomplished with an engineered solution.

Adhere to the following:

1. The engineered solution must guarantee the prevention of ue gases

moving backwards through idle boilers. This is important to prevent

ue gases from entering the mechanical room (if sealed combustion is

not being used) and also to prevent ue gases from corroding the heat

exchanger and/or other components in the upper cabinet of the boiler.

2-18

2. Reliance boilers should not be common vented with other types of

equipment.

3. Fulton requires the use of a combustion air supply damper (which can be

provided shipped mounted on the boiler by Fulton and incorporated into

© The Fulton Companies 2012

Page 25

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

control logic) for any common air intake/exhaust applications.

4. The pressure drop across an exhaust pipe shared by multiple boilers

must have a negative pressure at all operating conditions up to -0.05” wc.

A mechanical draft assist system, such as a variable speed fan, may be

required to accomplish this.

5. Combustion air dampers and/or a variable speed exhaust fan may be

required. Please contact your venting manufacturer for proper vent size

and arrangement.

Venting Terminations

Adhere to the following for installation (see Figure 10):

1. All vent pipes and ttings must be installed with appropriate air space

clearances to combustibles. These air space clearances apply to indoor or

outdoor vents—whether they are open, enclosed, horizontal or vertical or

pass through oors, walls, roofs, or framed spaces. The air space clearances

should be observed to joists, studs, sub oors, plywood, drywall or plaster

enclosures, insulating sheathing, rafters, roo ng, and any other material

classed as combustible.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Fulton cannot assume responsibility

for an air intake or exhaust

arrangement where Reliance boilers

are common vented with any other

type of equipment.

2. The required minimum air space clearances also apply to electrical wires

and any kind of building insulation.

3. Adequate provision must be made to support the weight of the exhaust

venting. It cannot be supported by the boiler exhaust connection.

4. Listed termination parts must be used.

5. Select the air intake point of penetration where a minimum of 1/4” per foot

upward pitch can be maintained.

6. When penetrating a non-combustible wall, the hole through the wall must

be large enough to maintain the pitch of the vent and provide sealing. Use

adhesive material to seal around the vent on both sides of the wall. When

penetrating a combustible wall, a wall thimble must be used. See Figure 11

for installation instructions. Minimum wall thickness through which vent

system may be installed is 3.25 inches (82.5 mm). Maximum wall thickness

through which vent system may be installed is 20 inches (508 mm).

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-19

Page 26

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

The exhaust vent installer should be

familiar with Federal Codes as well

as local codes and regulations.

Fulton cannot assume responsibility

for an air intake or exhaust

arrangement where Reliance boilers

are common vented with any other

type of equipment.

4 CAUTION

To prevent the possible re-circulation

of ue gases, the vent designer must

take into consideration such things

as prevailing winds, eddy zones,

building con gurations, etc. It is the

responsibility of the installer to locate

the exhaust duct in such a way that it

does not become blocked due to snow,

ice, and other natural or man-made

obstructions.

¡ Wall Thimble Installation

FIGURE 10 VENTING TERMINATIONS

Do not locate the vent termination too

close to shrubbery as ue products may

stunt their growth or kill them.

Adhere to the following for installation (see Figure 11):

1. The thimble is inserted through the wall from the outside. Secure the

outside ange to the wall with nails or screws, and seal with adhesive

material.

2. Install the inside ange to the inside wall, secure with nails or screws, and

seal with adhesive material.

3. Pass the vent pipe through the thimble from the outside and join to the

rest of the vent system.

4. Seal the pipe to the thimble ange with adhesive material.

5. Install two pipe retaining clamps around the intake as well as vent pipes

on both ends of the wall thimble (on the inside and outside of the wall)

through which intake and vent pipes are passed. They will prevent the

intake and vent pipes from being pushed or pulled.

¡ Horizontal Vent Termination

Adhere to the following for installation:

1. The vent termination is joined to the vent pipe outside the wall. Use the

same joining procedures for vent pipe and ttings. The termination of the

vent system must be at least 12 inches (304.8 mm) above the nished

grade, or at least 12 inches (304.8 mm) above normal snow accumulation

2-20

© The Fulton Companies 2012

Page 27

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

level (for applicable geographical areas). The termination of the vent

system shall not be located in tra c areas such as walk ways, adjacent

buildings, operable windows and building openings unless the venting

system is at least 7 ft (21.3 m) above nished grade, (National Fuel Gas

Code, ANSI Z223.1). The vent terminations must be at least 4 feet (1.22

m) horizontally from electric meters, gas meters, regulators, and relief

equipment. See Figure 12.

2. When installing inlet and exhaust terminations on the same wall, the

exhaust outlet must be installed 3 ft (.914 m) minimum above and

downwind from air supply inlet to prevent exhaust recirculation. Under

certain wind conditions, some building materials may be a ected by ue

products expelled in close proximity to unprotected surfaces. Sealing

or shielding of the exposed surfaces with a corrosion resistant material

(such as an aluminum sheet) may be required to prevent staining or

deterioration.

3. Do not locate the vent termination too close to shrubbery as ue products

may stunt their growth or kill them.

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Cements for plastic pipe are

ammable liquids and should

be kept away from all sources of

ignition. Proper ventilation should

be maintained to reduce the hazard

and to minimize breathing of cement

vapors. Avoid contact of cement with

skin and eyes.

4. The minimum vent height should extend at least 3 ft (.914 m) above the

roof, or at least 2 ft (.609 m) above the highest part of any structure within

10 ft (3.04 m) of the vent.

5. If the exhaust vent terminates within 10 ft (3.04 m) horizontally of the

air inlet, the exhaust vent must be at least 4 ft (1.22 m) above the inlet.

Dimensions listed above and those illustrated are minimum, and may or

may not be su cient for conditions at a speci c job site.

6. To prevent the possible re-circulation of ue gases, the vent designer

must take into consideration such things as prevailing winds, eddy zones,

building con gurations, etc. Fulton cannot be responsible for the e ects

such adverse conditions may have on the operation of the boilers. It is

important to locate the exhaust duct in such a way that it does not become

blocked due to snow, ice, and other natural or man-made obstructions.

Electrical Connections

Adhere to the following when installing electrical connections:

1. Install wiring and ground boiler in accordance with authority having

jurisdiction, or in absence of such requirements utilize National Electrical

Code, ANSI/NFPA 70.

Assure all electrical connections are

powered down prior to attempting

replacement or service of electrical

components or connections of the

boiler.

2. This boiler requires an independent 120V 60Hz single phase connection.

Connect power to the terminal strip as supplied on the inside cover of the

panel box.

NOTE: ´ Connect a ground wire to green colored ground lug in electrical control

box.

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-21

Page 28

INSTALLATION RLN-IOM-2012-1205 SECTION 2

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Do not use any dangerous source of

re or smoke (e.g., lighter, candle) to

test equipment at any time.

Assure all electrical connections are

powered down prior to attempting

replacement or service of electrical

components or connections of the

boiler.

4 CAUTION

Never install a barometric damper on

ue systems designed with positive

pressure.

¡ Air Piped From Outside Boiler Room

Adhere to the following:

1. The combustion air supply can be piped directly to the air inlet of the

boiler.

2. A rubber air intake coupling is recommended with boilers speci ed for

installation with ducted air supply. It must be used to connect the intake

piping to the boiler air inlet. This rubber air inlet coupling is available from

Fulton as an option. See Figure 6.

3. The air intake must be piped out of the building if the boiler room contains

contaminated air.

¡ Intake Duct Sizing

1. Air intake ducting must be sized in conjunction with the exhaust venting

to provide no greater than a +2.0” W.C. combined pressure drop. This

equates to 70 feet and 8 elbows when combining the distances on the

air intake and exhaust with the piping diameters matching the standard

connections.

2. The installation of a recognized termination screen is required. Contact

your local venting supplier for assistance in venting sizing.

3. Air Intake pipes and ttings shall be Schedule 40 PVC pipe or galvanized

steel. All Schedule 40 PVC pipe, ttings, primer and cement must conform

with American National Standard Institute and the American Society for

Testing and Materials (ANSI/ASTM standards.)

4. Intake PVC piping must be assembled using cement. This will ensure that

the intake is airtight and will not allow contaminates from the boiler room

into the boiler. The cement shall be free owing and contain no lumps,

un-dissolved particles or any foreign matter that adversely a ects the joint

strength or chemical resistance of the cement. The cement shall not show

gelation, strati cation, or separation that cannot be removed by stirring.

} CEMENTING JOINTS

The following procedure for cementing joints (per ASTM D2855) should be

adhered to:

1. Measure and cut PVC pipe to desired length.

2. Chamfer end of pipe, removing any ridges or rough edges. If end is not

chamfered, the edge of the pipe may remove cement from the tting

socket and result in a leaking joint.

3. Clean and dry the surfaces to be joined.

4. Test t joint and mark depth of tting on pipe outside.

5. Uniformly apply a liberal coat of primer to inside socket surface of tting

and male end of pipe to depth of tting socket.

2-22

© The Fulton Companies 2012

Page 29

SECTION 2 RLN-IOM-2012-1205 INSTALLATION

DIAMETER "C"

STAINLESS

3 1/2 IN. OR

4.35 CM

AIR GAP

ALL AROUND

THRU PIPE

VARIABLE

(3 1/4 IN. MIN.) - (20 IN. MAX.)

(8.255 CM MIN. - 50.8 CM MAX.)

DIAMETER "B"

ADJUSTABLE

WALL THUMBLE

WIDTH TO VARY WITH

WALL THICKNESS

DIAMETER "A"

COLLAR

END VIEW

SCREW OR BOLT EACH THUMBLE COLLAR

TO WALL (TYPICAL 4 PLACES) ORIENT

COLLAR AND CLAMPS AS REQUIRED

PIPE RETAINING

CLAMP, TYPICAL

EACH SIDE

6. Promptly apply solvent cement to end of pipe and

inside socket surface of tting. Cement should be

applied lightly—but uniformly—to inside of socket.

Take care to keep excess cement out of socket. Apply

second coat to pipe end

NOTE: ´ Time is critical at this stage. Do not allow primer to

dry before applying the cement.

7. Immediately after applying last coat of cement to pipe,

while inside socket surface and end of pipe are wet with

cement, insert end of pipe into socket, turn pipe 1/4

turn to distribute cement evenly, continue to insert pipe

until it bottoms out.

FIGURE 11 WALL THIMBLE INSTALLATION

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-23

Page 30

INSTALLATION RLN-IOM-2012-1205 SECTION 2

ROOF

SUPPORT

WIRES AND INSULATION

TO COMBUSTABLES,

AIR SPACE CLEARANCES

MAINTAIN MIN 9" / 22.86 CM

NOTE:

AIR INTAKE AND EXHAUST TERMINATION

SHOULD BE SEPARATED AS FAR AS POSSIBLE

TO PREVENT FLUE GAS RECIRCULATION

DURING DIFFERENT WIND CONDITIONS.

4FT / 122 CM

FLASHING

ADJUSTABLE

4" PVC PIPE

FLASHING

ADJUSTABLE

ADHESIVE SEAL

STORM COLLAR

EXHAUST STACK IS DOWNWIND

OF AIR INTAKE OPENING

SCREENED INLET

MIN 4FT / 122 CM

ABOVE AIR INTAKE

PIPING

METAL PLATE

FIRE STOP

DO N OT PLACE

INSULATION

IN REQUIRED AIR

SPACE CLEARANCE

TYPICAL ROOF PENETRATIONS

( SUGGESTED TERMINATION CONFIGURATIONS )

IF SNOW ACCUMULATION

IS APPLICABLE, OPENING

TO BE 1 FT. / 30 CM ( MIN. )

ABOVE THIS NORMALLY

EXPECTED LEVEL.

FIGURE 12 ROOF PENETRATION DETAILS

2-24

© The Fulton Companies 2012

Page 31

OPERATION

INTRODUCTION

INSTALLATION

1

2

OPERATION

MAINTENANCE

WARRANTY & PARTS

3

4

5

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

3-1

Page 32

OPERATION RLN-IOM-2012-1205 SECTION 3

! WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes and regulations.

Failure to follow instructions may result

in a re or explosion, causing property

damage, personal injury, or loss of life.

Crystalline silica may be present in

components of this equipment. Exposure

to crystalline silica may pose signi cant

health hazards, including but not limited

to eye and respiratory system damage.

Per the Centers for Disease Control and

Prevention (CDC) and Occupational

Safety and Health Administration

(OSHA), appropriate personal protective

equipment must be worn to minimize

exposure to hazardous substances. Refer

to most current guidelines o ered by the

CDC and OSHA for more information,

including personal protective equipment

recommendations.

This boiler is equipped with an ignition

device, which automatically lights the

burner. Do not try to light the burner by

hand.

Perform Pre-Start-Up Inspection

Prior to start-up, perform the following:

1. Smell all around the boiler area for gas. Be sure to smell next to the oor, as

some gas is heavier than air and will settle. If you smell gas:

§ Do not try to light any appliance.

§ Do not touch any electrical switch; do not use any phone in your building.

§ Immediately call your gas supplier from a neighbor’s phone.

2. Ensure the boiler is located with the proper clearances as shown in the

Clearances and Serviceability section of this manual.

3. Ensure that relief valves have been properly piped to oor drains.

4. Ensure ue gas from the boiler is properly vented.

5. Ensure the water system has been ushed and is free of debris.

6. Ensure combustion air openings are not obstructed in any way and have

adequate capacity.

7. Ensure there are no ammable liquids, materials or hazardous fumes

present in the environment.

8. Ensure nothing was damaged or knocked loose during installation and/or

shipment.

9. Inspect the main gas train and trim assembly to be sure they were not

damaged during shipment and/or installation.

Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliances.

Use only your hand to turn the valve

handle. Never use tools. If the knob will

not turn by hand, don’t try to repair it. Call

a quali ed service technician. FORCE OR

ATTEMPTED REPAIR MAY RESULT IN A FIRE

OR EXPLOSION.

WHAT TO DO IF YOU SMELL GAS • Do not

try to light any appliance. • Do not touch

any electrical switch; do not use any phone

in your building. • Immediately call your

gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions. • If

you cannot reach your gas supplier, call

the re department. -A quali ed installer,

service agency or the gas supplier, must

perform installation and service.

3-2

Fill and Purge the System

Completely ll and purge the heating system as follows:

1. Close combination shuto /purge valve in supply, all drain cocks, the

shuto valve for the pressure reducing ( ll) valve, and all manual air vents.

2. Open all other system shuto valves and one of the zone valves, the vent

on the combination shuto / purge valve and the shuto valve to the

pressure-reducing ( ll) valve.