Fukuda FL-296 Series, FL-286 Installation Instructions Manual

10527-T-800E-00

http://www.fukuda-jp.com

COMPACT AIR LEAK TESTER

DESIGN DOCUMENT

FL-296 SERIES

Contents

MODEL ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 7

DO YOU HAVE EVERYTHING? ・・・・・・・・・・・・・・・・・・・・・・・ 8

OPTION ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

INSTALLATION INSTRUCTIONS ・・・・・・・・・・・・・・・・・・・・ 14-15

AIR PIPE CONFIGURATIONS ・・・・・・・・・・・・・・・・・・・・・・ 16-17

ELECTRIC WIRING CONFIGURATIONS ・・・・・・・・・・・・・・・・・ 18-19

LINE CONNECTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 20-35

RS-232C CONNECTION ・・・・・・・・・・・・・・・・・・・・・・・・・・ 60-63

PRINTER CONNECTIONS ・・・・・・・・・・・・・・・・・・・・・・・・ 65

EXTERNAL DIMENSIONS ・・・・・・・・・・・・・・・・・・・・・・・・ 72-74

■ Declaration

・This design documents is outline specification for system design which is extracted from operation manual

(10527-T-001E-05).

The above contents page numbers is mentioned the page numbers of operation manual.

For about details of operation and testing procedure, please refer to operation manual.

・The contents of this manual may be modified without notice due to function and performance improvements.

・This manual has been written with care to provide the user with helpful and useful information. Please

contact your local FUKUDA distributor if there are any inaccuracies or questions of concern.

・Do not use this tester for any purpose other than testing air leaks.

・For best operating results and optimum efficiency, read this instruction manual thoroughly

to understand the tester’s many functions prior to operation.

・Reprinting or duplicating this manual partially or completely is prohibited unless permitted by

FUKUDA CO., LTD.

■ Trademark

Company names and product names being used in this manual are the registered trademarks of

their respective holders.

6

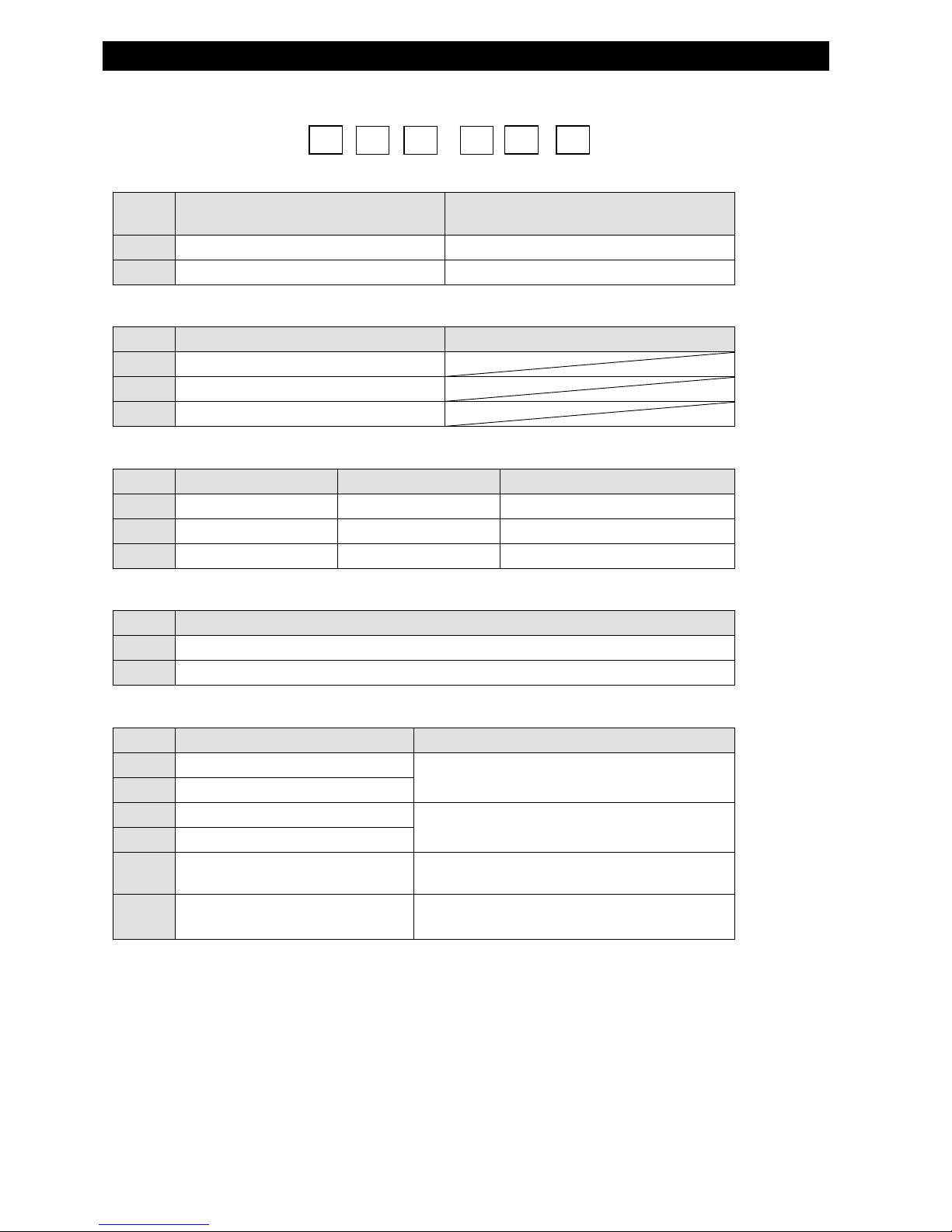

OUT LINE TESTER MODEL

■ OUT LINE TESTER MODEL

MODEL

FL-

2

① MODEL

Symbol Permissive Leak rangeApplication Application

8

±0.01~9.99 kPa

Middle Leak Detection

9

±1~999 Pa

Small Leak Detection

② CALIBRATOR (BUILT IN)

Symbol With/Without Calibrator Remarks

6 Without Calibrator

6A 1.0ml Calibrator

6B 0.1ml Calibrator

③ SET PRESSURE RANGE

Symbol

TEST PRESSURE RANGE SET PRESSURE RANGE DISPLAY PRESSURE RANGE

UL

-10.0~10.0kPa -10.0~10.0kPa -10.0~10.0kPa

L

-100~200kPa -100~200kPa -100~200kPa

H

-100~900kPa -100~900kPa -100~900kPa

④ POWER SUPPLY

Symbol POWER SUPPLY

0

AC100V ±10% 50/60Hz

2

AC90~110V AC200~240V 50/60Hz

⑤ INTERNAL OPTIONS

Symbol OPTION REMARKS

R RS-232C Output

Select either RS-232C output (R) or printer

output (P).

P Printer Output

B1 Special Buzzer Sounding

Select either a “Beep” (B1) or a pulsed tone (B2)

for notification.

B2 Special Buzzer Sounding

E

Piping modification to correspond with

the external exhaust unit

Only for use with a vacuum

V

Manual valve position indication

switch

Only at work side

⑥ EXTERNAL OPTIONS see page 9.

① ② ③-④ ⑤ ⑥

7

TESTER SPECIFICATIONS

■ PERFORMANCE SPECIFICATIONS

◆ Testing Method: Differential Pressure Comparison

◆ Leak Pressure Range・Measurement Accuracy

MODEL

Leak Pressure Measurement

Range

Measurement Sensor Accurac

y

(Including hysteresis)

FL-286

±0.01~9.99kPa ±5%F.S.(10.00kPa)

FL-296

±1~999Pa ±5%F.S.(1000Pa)

Direct Pressure Sensor Accuracy

MODEL Pressure Measurement Range

Measurement Sensor Accurac

y

(Including hysteresis)

UL

-10.0~10.0kPa ±5%F.S.(-10.0kPa、10.0kPa)

L

-100~200kPa ±5%F.S.(-100kPa、200kPa)

H

-100~900kPa ±5%F.S.(-100kPa、900kPa)

■ FUNCTION SPECIFICATIONS

Timer Setting Range

DLY

CHG

BAL

DET

EXH

(Delay)

(Charge)

(Balance)

(Detection)

(Exhaust)

0.0 ~ 999.9sec

0.1 ~ 999.9sec

0.1 ~ 999.9sec

0.1 ~ 999.9sec

0.2 ~ 999.9sec

Group Setting Function

4ch(DLY time, CHG time, BAL time, DET time, EXH time, -NG set,

+NG set, -NG set(leak amount), +NG set(leak amout), P.NG value,

Volume value, -NG unit (leak amount), +NG unit(leak amount),

Volume unit, Leak amout indication unit)

Supplemental Functions

BUBL(Bubble),CAL(Calibration), Cylinder Control

Test circuit internal volume

8 ml(when rear panel stop valve is closed)

Display Digital indication in four digi

t

External Input/Output

1. Contact input/output for control 38

P

2. Option input/output

・Output for printer(Centronics-compliant output system)

・RS-232C input/output with PC

■GENERAL SPECIFICATIONS

Operation Temperature Range

0~40℃

Operation Humidity Range

35~85%RH(without condensation)

Power Source

A

C100V±10% 50/60Hz

AC90~110V AC200~240V 50/60Hz

Power Consumption 150VA

Voltage enduranc

e

A

C1000V 1 minut

e

Insulating Resistance More than 50MΩ at DC500V

Leak Current Less than 1mA at AC100V

Pressure enduranc

e

UL Range:-50~+50kPa、L Range:-100~+600kPa、H Range:-0.1~+1.5MPa

Dimensions Function

W172.9 mm×H272.8 mm×D386 mm(Without external option)

Weight

Power Source100V:About 9.5 kg

Power Source 200V:About 10.5 kg

Air Specifications

Please supply clean , stable , and dry air

Recommended Condition: Based on JISB8392-1:2000

Compressed Air Quality Class1,3,1

Class

A

rticle Referenc

e

1 Maximum Particle Diameter

0.1μm

3

Minimum Pressure Dew-point

-20℃

1 Maximum Oil Conten

t

0.01mg/

m

3

8

OUTLINE DO YOU HAVE EVERYTHING ?

■ DO YOU HAVE EVERYTHING?

Confirm the following points prior to operating the tester. If there are any problems such as incorrect

specifications, missing accessory parts or damages with the delivered items, please contact your FUKUDA agent.

Please compare the model numbers described below with the number indicated on the tester’s nameplate.

Please specify the SER (serial number) when contacting your FUKUDA agent.

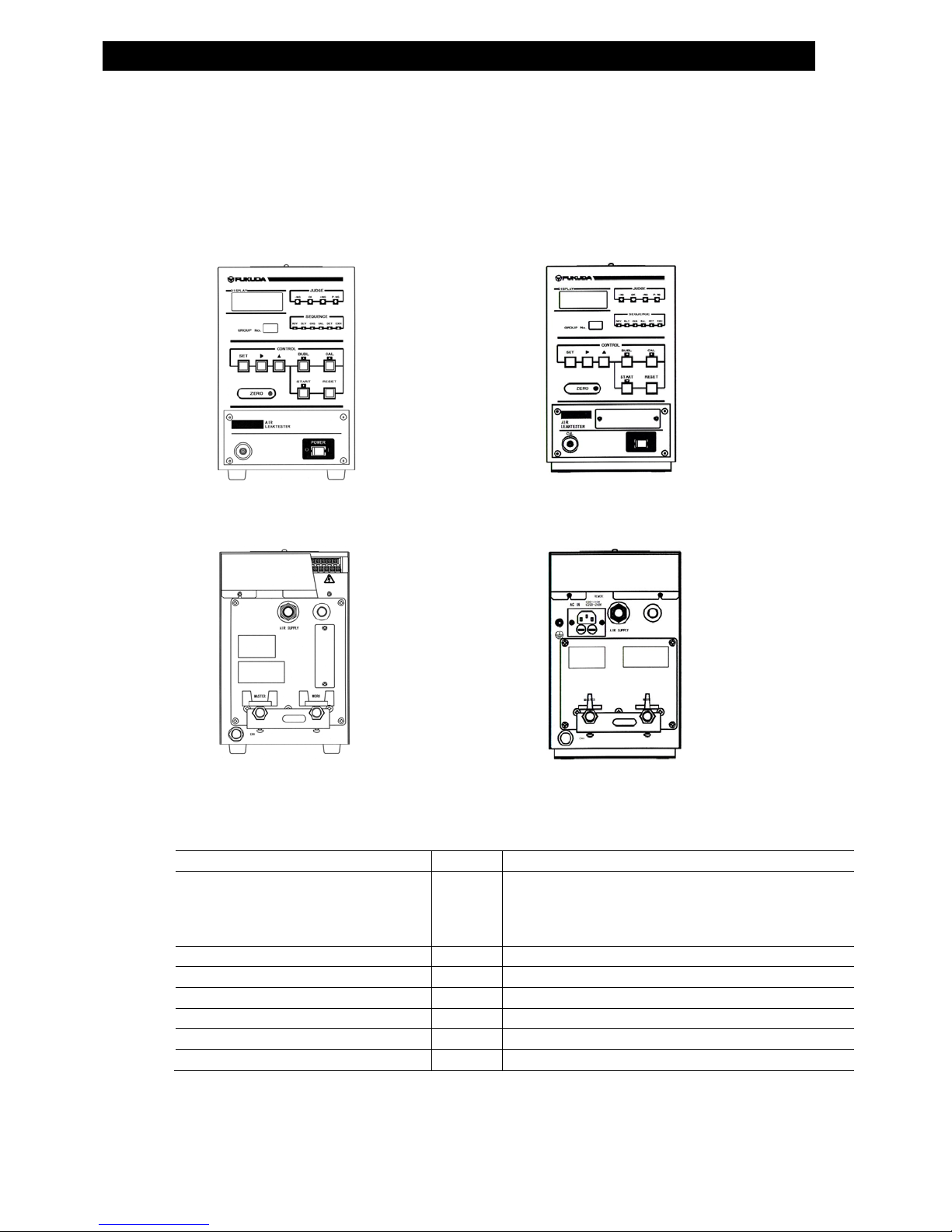

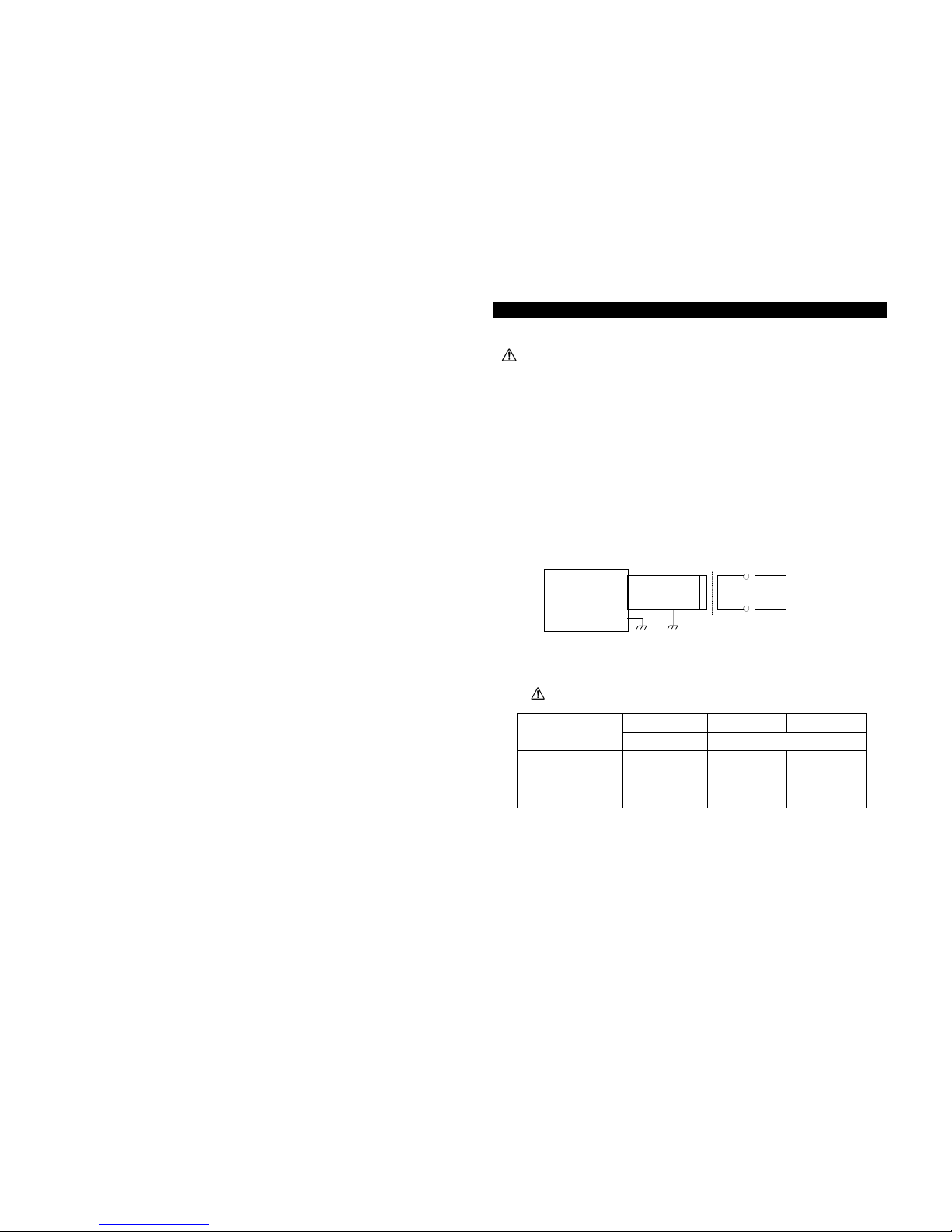

○ TESTER STRUCTURE

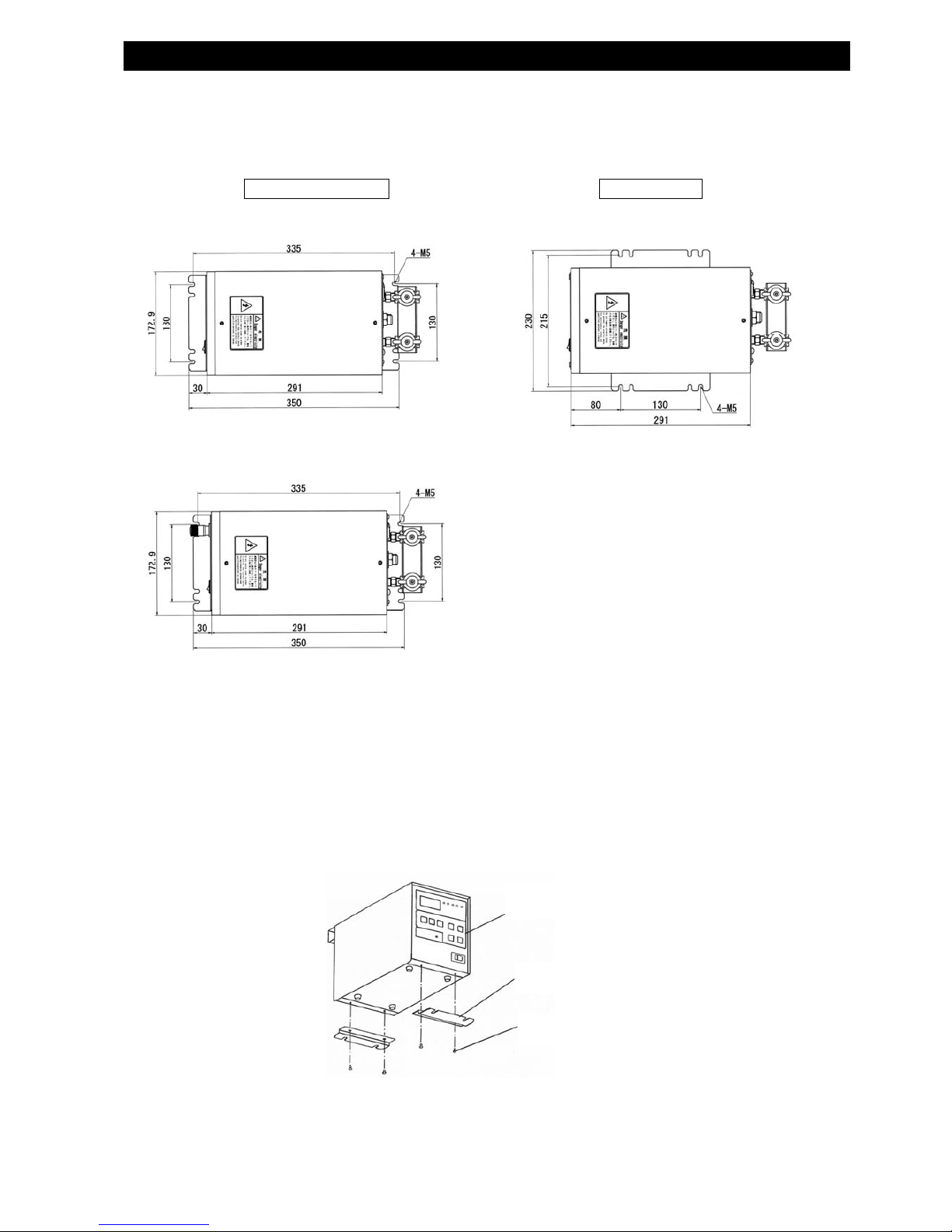

【FL-2□□□-0 FRONT】 【FL-2□□□-2 FRONT】

【FL-2□□□-0 REAR】 【FL-2□□□-2 REAR】

○ STANDARD ACCESSORIES

A

CCESSORIES

NUMBER

REMARKS

AC POWER CODE 1.5m 1

A

s the attached AC power cord is of Japanese

domestic specification (rating 125V), if it does not fit to

the specifications of the using area or place, kindly

please prepare the suitable one by yourself.

A

DJUSTMENT SCREW DRIVER

1

MOUNTING BRACKET

1

FIXING SCREW M4×8L 4

OPERATION MANUAL

1

TEST DATA SHEET

1

Unit Stickers

1

9

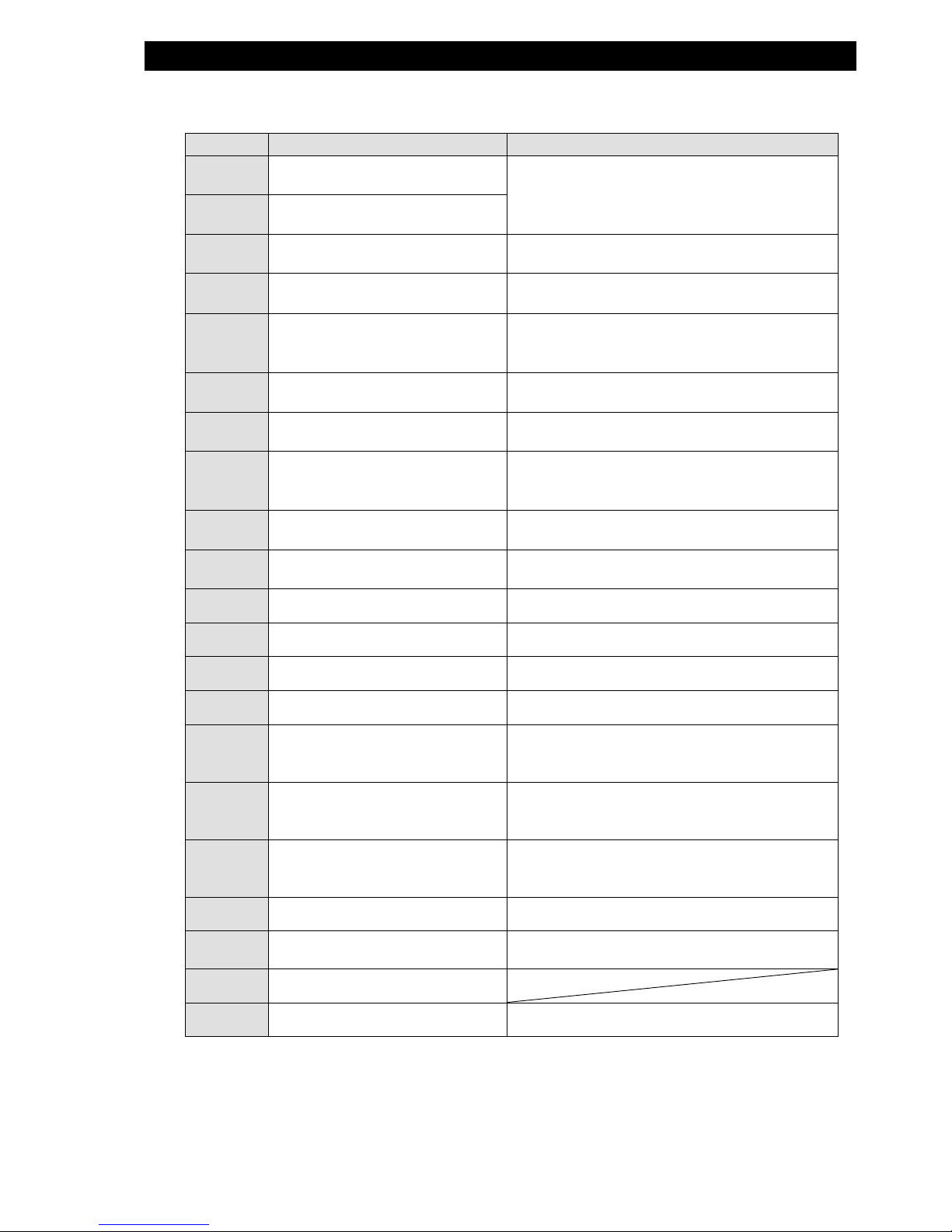

OUTLINE OPTIONS

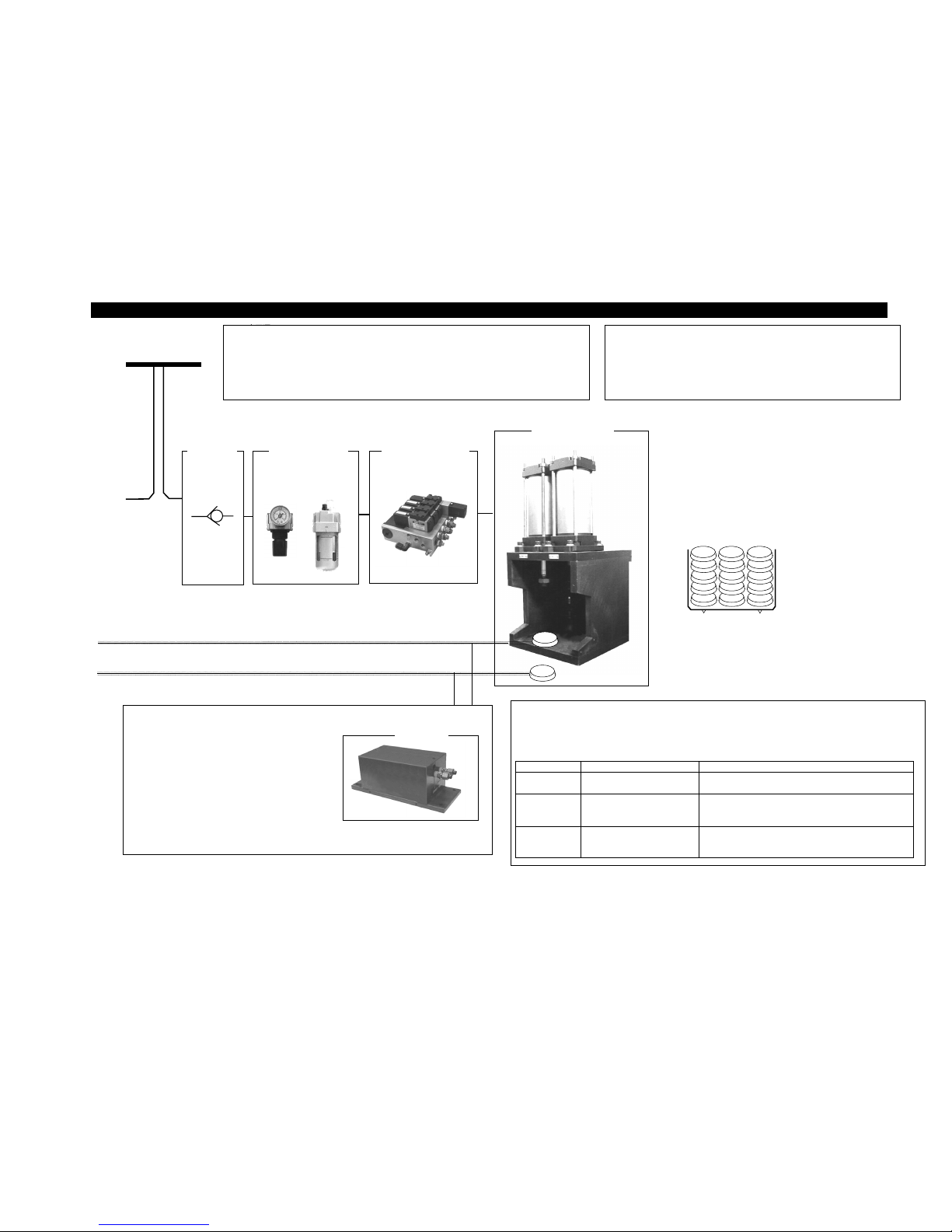

○ OPTION

⑥ EXTERNAL OPTIONS

MODEL COMMON OPTION REMARKS

C1

Manual Calibrator0.1mlF.S.

(Externa)

Mounted in the rear of the work port manual valve.

One of C1 or C3 is chosen.

C3

Manual Calibrator1.0mlF.S.

(External)

FR53 Filter/Regulator Unit

Positive Pressure Standard Spec.

Pressure Setting Range:0.02 ~ 0.2MPa

FR54 Filter/Regulator Unit

Positive Pressure Precision Spec。

Pressure Setting Range:0.005 ~ 0.2MPa

FR55 Filter/Regulator Unit

Positive Pressure Precision Spec.

+ High Performance Filter

Pressure Setting Range:0.005 ~ 0.2MPa

FR56 Filter/Regulator Unit

Positive Pressure Standard Spec.

Pressure Setting Range:0.05 ~ 0.85MPa

FR57 Filter/Regulator Unit

Positive Pressure Precision Spec.

Pressure Setting Range:0.005 ~ 0.8MPa

FR58 Filter/Regulator Unit

Positive Pressure Precision Spec.

+ High Performance Filter

Pressure Setting Range:0.005 ~ 0.8MPa

FR59 Filter/Regulator Unit

Positive Pressure Standard Spec.

Pressure Setting Range:0.1 ~ 1.6MPa

FR61 Filter/Regulator Unit

Negative Pressure Standard Spec.

Pressure Setting Range:-100 ~ -1.3kPa

FR62 Filter/Regulator Unit Negative Precision Spec. P-200

FE-20 External Exhaust Unit For Positive Pressure

FE-20C External Exhaust Unit For Positive Pressure with Drain

FE-20V External Exhaust Unit For Negative Pressure

PS-01 Pressure Switch

Small pressure switch for negative pressure,

Accuracy: ±3% F.S.

Pressure Setting Range:-101 ~ 0kPa (5~40℃)

PS-02 Pressure Switch

Small (low) pressure switch for positive pressure,

Accuracy: ±3% F.S.

Pressure Setting Range:0 ~ 100kPa (5~40℃)

PS-03 Pressure Switch

Small pressure switch for positive pressure,

Accuracy: ±3% F.S.

Pressure Setting Range:0 ~ 970kPa (5~40℃)

FP-100 Thermal Printer Print out measured data

CB-14 Manual Operation Box

One Circuit each for start and reset switch 4-group

switching function.

P-200 Pilot Regulator

R5 Regulator for small pressure

Pressure Setting Range:0.5 ~ 10kPa

※The high-performance filter consumes air at a rate of 0.3 m3/h.

INSTALLATION INSTRUCTIONS

■ INSTALLATION INSTRUCTIONS

Air leak testers detect leaks by reading out precise pressure (air condition) alterations.

Thus, it requires different handling instructions from other standard precision equipment.

WARNING

Tester must be in a stable position.

・ Be sure to install the tester on a level surface.

Vibrations or earthquakes may cause the tester to fall and cause injury to operators.

Do notplace anything on top of the tester.

・Do not place anything on top of the tester. Falling objects may

result in injury.

CAUTION

Do not install the tester in the following locations:

・ High moisture or dusty areas.

・ Areas in which oil and water can cause contamination.

・ Areas directly exposed to sunlight.

・ Outdoors

May result in fire or electric shock.

・ Areas with obstructions or places in which the testers fanning

system may be blocked.

The tester may overheat and may cause for fires.

Moving the Tester:

・ Be sure to shut off the power, unplug cords, cut off the

pneumatic source and remove piping.

・ Be sure to carry the tester in a stable manner.

(Do not carry the tester by the manual valve handle.)

May cause damage to the tester or to its casing and may result in

injury

.

○ OPERATION ENVIRONMENT

FL-286,296

14

FL-286,296

• To keep the stable measurement condition, install the air

leak tester where it will not receive any influences from

temperature or humidity changes, such as at the center of

the facility. Do not in stall the te ster n ear wi ndows or

an area that is directly exposed to the sunlight. The

operation temperature and humidity is as follows.

Ambient Temperature: 0~40℃

Ambient Humidity: 35~85%RH with no condensation.

• In order to attain best results and accuracy, it is re commended that the operation

temperature and environment humidity condition is 23 ±5℃, 55±10%RH.

• Rapid temperature change adds the noise on the measurement and specified

performance cannot be obtained.

• Transferring the tester rapidly from high to low temperature locations and/or

humidity points may cause condensation. When such cases cannot be avoided,

leave the tester in the environment for at least an hour in order for it to adjust to

the surrounding temperature.

• Environment

Temperature change is the enemy of leak test. Avoid

the direct sun shine or the wind from outside on

work, master and measurement piping. Also be

careful against the wind from air conditioner

(heating/cooling) duct or the entrance.

Warning

FL-286,29

6

1

5

INSTALLATION INSTRUCTIONS

● INSTALLATION LAYOUT

z Use a pair of brackets and the supplied screws.

※Dimensions in front & in the rear differ in case Manual Calibrator is mounted, or not.

●

INSTALLATION MEASURMENT

Follow the remarks listed below for installation.

Leave a sufficient amount of space in the rear for the work connection cables and

pressurized air piping.

See page 72 and page 74 for external dimensions.

● Fixing the Brackets

Example of Front/Rear Fixing

Fix the brackets using the screws into the tapped holes on the bottom of the unit.

Front/Rear Mounting Side Mounting

・Without calibrator

・With calibrator

・Both with and without calibrator

Main body

Supplied Screw

Mounting bracket

1

6

AIR PIPE CONFIGURATIONS

☆ Air leak testers are designed to detect a leak by sensing a small change in pressure.

For that reason, you must ensure that the air leak tester’s piping differs from normal piping.

Please keep this in mind to help obtain accurate and reliable leak testing.

☆

TEST CIRCUIT PIPES

For the test circuit piping, it is necessary to use rigid, leakless pipes that will not change in size and

configuration under applied pressure.

For connection, use a high-pressure type coupler.

Arrange them to minimize thermal effect.

Keep them away from heat generating elements such as solenoid valves.

Keep the piping arrangement as short as possible.

Wrap them with thermal insulation material.

(e.g. Spiral Tubes)

Others

Stabilize the piping to avoid unnecessary movements during measurement.

Allow “MASTER” and “WORK” piping to provide the same conditions.

Do not connect inappropriate items to the testing piping.

Make sure you always use the optional pressure switch which checks the internal

pressure of the work, if the equipment is used with a pressure of 10 kPa or lower.

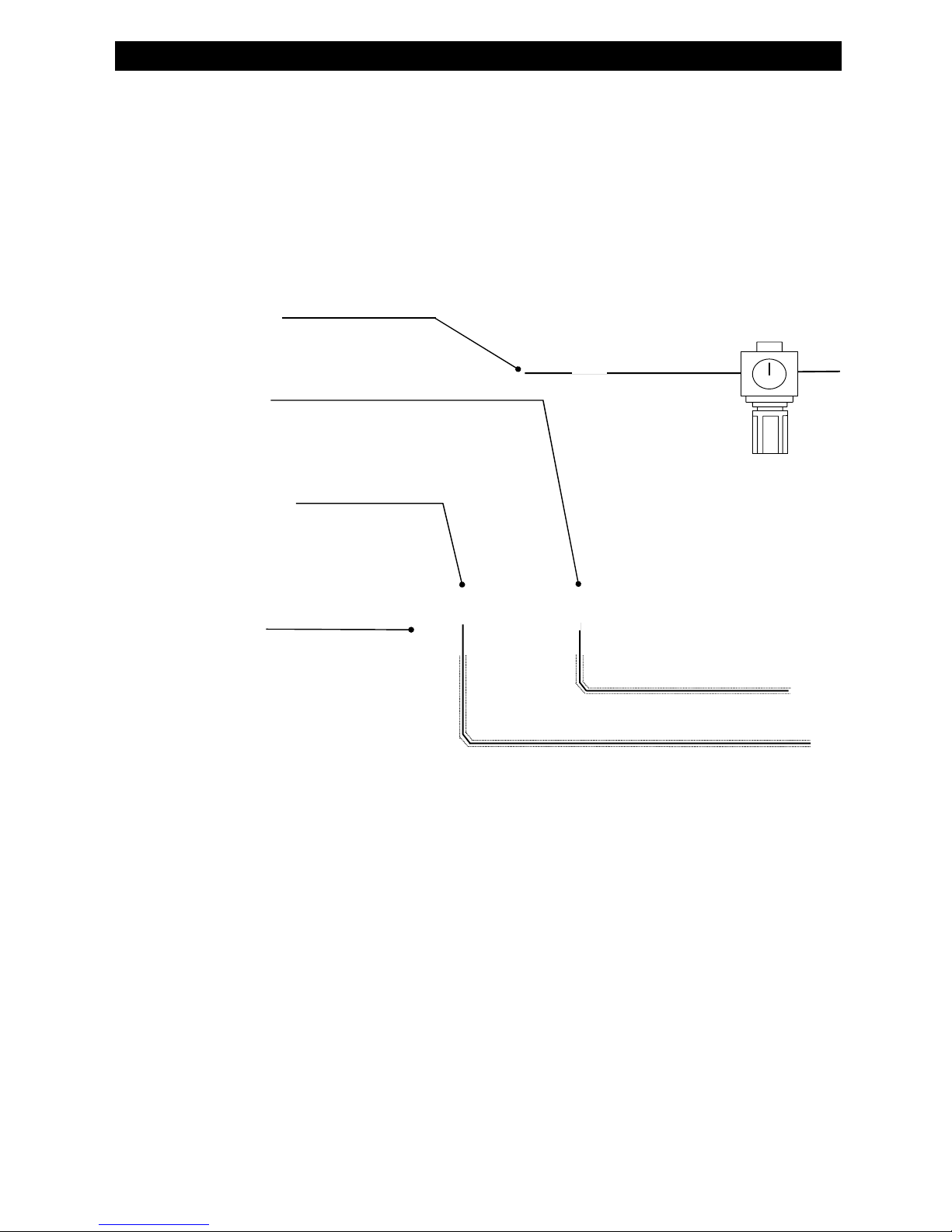

PRIMARY PRESSURE

REGULATOR

Adjust to: (approx.)

Test pressur

e

+100kPa

Pressure Supply Port

(AIR SUPPLY)

Rc 1/4

Work Port

(WORK)

Rc 1/4

Connect to a work (WORK)

This is a measurement pipe.

Master Port(MASTER)

Rc 1/4

Connect to a master.

This is a measurement pipe.

Exhaust Port

(EXH)

Rc 1/4

AIR PIPING CONFIGURATION

17

IN CASE OF WATER/OIL INTRUSION IN WORK

Oil, water or chippings may intrude in works

because of the previous process.

The tester may draw in unwanted objects

during the exhausting process, and may cause

possible break down.

Install the external exhaust unit (optional) within

the testing air circuit.

While the FE-20 optional external exhaust unit

is in use, close the exhaust port of the air leak tester

with the attached plug.

FE-20

FE-20C

FE-20

V

空圧源

供給エアーにはクリーンなものを御使用下さい。

エアリークテスターのセンサーにとって、油分・水分は大敵です。

エアフィルターはもちろん、必要に応じエアドライヤなどの空気清浄器を設備して

下さい。

またルブリケータを使用する時は、エアリークテスターへの供給配管と主配管から

クランプ装置

シリンダー駆動圧力を調整する減圧弁は、個別に設けて下さい。

シリンダーが動作する時の圧力変動が、エアリークテスターへの圧力供給を変動

させたり、他軸のシリンダーのクランプ力を変動させ、測定を不安定にする事が

あります。

漏れ測定部(ワーク、マスター)の内容積は、

測定感度を上げる為、配管を短くしたり、中子

等を利用して出来るだけ小さくして下さい。

Position close to the

Work parts.

主配管

マスターを御用意下さい。

漏れ測定を行う時は、マスターを取り付けて下さい。マスターの容積・形状・接続方法によ

り、漏れ測定の精度が変化します。マスターは、ワークと同一形状・同材質・同一の配管・

同一取付が望ましいのですが、実際の設備では全てを満たす事はなかなか出来ません。

マスター設置の際のポイントを以下に示します。

項 目 上 策 次 善 策

マスター

漏れの無いワーク

(ワーク側と同じ条件にする)

ワーク側より小さめの剛体タンク

(早く安定になるようにする)

取付位置

ワークの近くで同じ高さにする ワーク側と高さを同じにして周囲を囲う

(同じ温度で変動が無いようにする)

配管

ワーク配管と一緒にして平面に這わ

せる

ワーク側と長さを同じにする

(温度影響があるときは短くする)

手待ちワークの温度が変化

しないように、リークテス

ト装置の近くで同じ高さの

場所に保管して下さい。

クランプシリンダー

Master

COMPRESSED AIR SOURCE:

Water and oil intrusion often cause the pressure sensor in the air leak tester to malfunction. Be

sure to provide an air filter, and if necessary, equip an air purifier such as an air dryer.

Furthermore, it is important to contrive a bypass air piping system when using lubricator so that

lubricating oil will not intrude the tester

CLAMPING EQUIPMENT

Regulators to adjust the cylinder driving pressure must be provided separately

for each cylinder. This minimizes the possibility of cylinder movement, which

destabilizes the pressure supply to the air leak tester. Supplied air pressure

fluctuation may interfere with the clamping powers of the other cylinders

Main air source

制御用電磁弁

逆止め弁

Check Valve

Regulator

Lubricator

Sol. Valve for control

Clamp Cylinder

KEEPING THE INTERNAL VOLUME AS SMALL AS

POSSIBLE

In order to increase test sensitivity, keep the internal volume of

the work and master parts as small as possible. Shortening

pipes or using a core is ways to decrease internal capacity.

AVOID TEMPERATURE CHANGE

In order to avoid temperature

interference to work parts waiting to

be tested, keep them close to leak

tester and at about the same level.

PREPARE THE MASTER PARTS

It is recommended to use master (criterion) parts for air leak testing. Leak testing accuracy will change according

to the status of the applied master parts, so it would be ideal to use master parts equivalent to the work parts in

shape, material, piping and mounting. Maintaining these conditions can be difficult in actual settings. Please

refer to the following chart when choosing a master part.

Best Method

A

lternative

Master

・Test Parts with no leak

(same conditions as the work)

・A rigid tank that has a slightly smaller volume than that

of the work (to stabilize quickly)

Mounting

Position

・Same height from the ground

as the work

・Near the work

・Same height as the work and surround the peripheral

・Environment with the same temperature interference

conditions as the work parts

Piping

Arrangement

・Same conditions and

arrangement as the work piping

and arrange piping in plane .

・Same piping length as the work port (shorter when there is

temperature interference)

ELECTRIC WIRING CONFIGURATION

● ELECTRIC WIRING PRECAUTIONS

EXAMPLE

(AC 200V/100V step-down transformer is used for an air leak tester with AC 100V spec)

Air Leak Tester

MODEL

AC100V AC110V AC200V

FL-2□□□-0 FL-2□□□-2

POWER LINEVOLTAGE

AC100V±10%

50/60 Hz

AC90~110V

50/60 Hz

AC200~240V

50/60 Hz

※ Power consumption increases if valves and other parts are driven by an external control.

18

AC100V

BEFORE WIRING AIR LEAK TESTER, BE SURE TO TURN OFF THE MAIN POWER

SWITCH. (Unplu

g

the tester from the AC power source)

Insulated Transformer

AIR LEAK TESTER with AC100V

Supply line voltage suitable to the power line voltage of the tester.

● Select appropriate wires and material according to use, considering voltage and current

requirements for each of the terminal outlets located on the rear panel of the tester.

● To avoid noise interference, run the input signal lines separately (pins #1 to #12 of the Terminal Board)

from the output signal lines.

● To avoid noise interference, run the input signal lines separately from other power supply lines.

● To avoid noise interference, it is recommended to use a shield wired for input signal lines.

● Be sure to ground the frame grounding (pins #37 and #38 of Terminal Board).

● Use an insulated transformer when the power for the tester is supplied through a step-down

transformer.

AC200V

AC100V L

AC100V N

F.G.

○

○

ELECTRIC WIRING CONFIGURATION

Control testing and bubble testing procedures

・ START Start of air leak test.

Applies a pulse signal of 0.5 sec or longer during DLY sequence.

・BUBL Start of bubble test

Performs a bubble test while a signal is being applied.

・RESET Stop the tester in case of an emergency.

Apply a break signal to open the air circuit. The RDY sequence

is established after EXH sequence.

Test result output

・OK -NG set range < leak reange < +NG set range

・+NG leak reange ≧ +NG set range

・-NG -NG set range ≧ leak reange

・P.NG Test pressure is lower than the set value at the end of

PRES sequence.

・P.NG Test pressure is lower than the set value set up with

P.SW at time of BAL sequence.

Current status output

・RDY Standby (Ready Status)

・ERR Error has transpired.

When the power is OFF, ERR can be used to confirm

ON/OFF status.

・END Testing has ended.

*1 The air leak tester’s internal output status: power off.

*2 The names, indicated with line(***)imply that the signal is effective when it is open. 19

Controlling clamping cylinders

・LMT 1 Input of unclamp signals

・LMT 2 Input of clamp signals

・SOL 1 Cylinder Driving valve control signals

※

In the Internal Operation Mode, the tester cannot operate.

Specifies the Group # (0~3)

・ CH1

・ CH2

Group # selection

0 1 2 3

CH1 ○ ● ○ ●

CH2 ○ ○ ● ●

○:Open ●:Short

Controls the exhaust bypass unit

SUPPLIES POWER TO THE AIR LEAK TESTER

Apply power voltage specified by the manufacture

・F.G Be sure to ground this terminal.

EXHAUST BYPASS UNIT CONTROL SIGNALS

POWER SUPPLY

GROUP SWITCHING SIGNALS

CYLINDER CONTROL SIGNALS

Pressure Error (P.NG) Verification Signal Input

・P.SW Pressure switch signal input.

If pressure verification function is not used,

keep the P.SW pin connected to the COM- pin.

PRESSURE VERIFICATION SIGNALS

AIR LEAK TESTER CONTROL SIGNAL

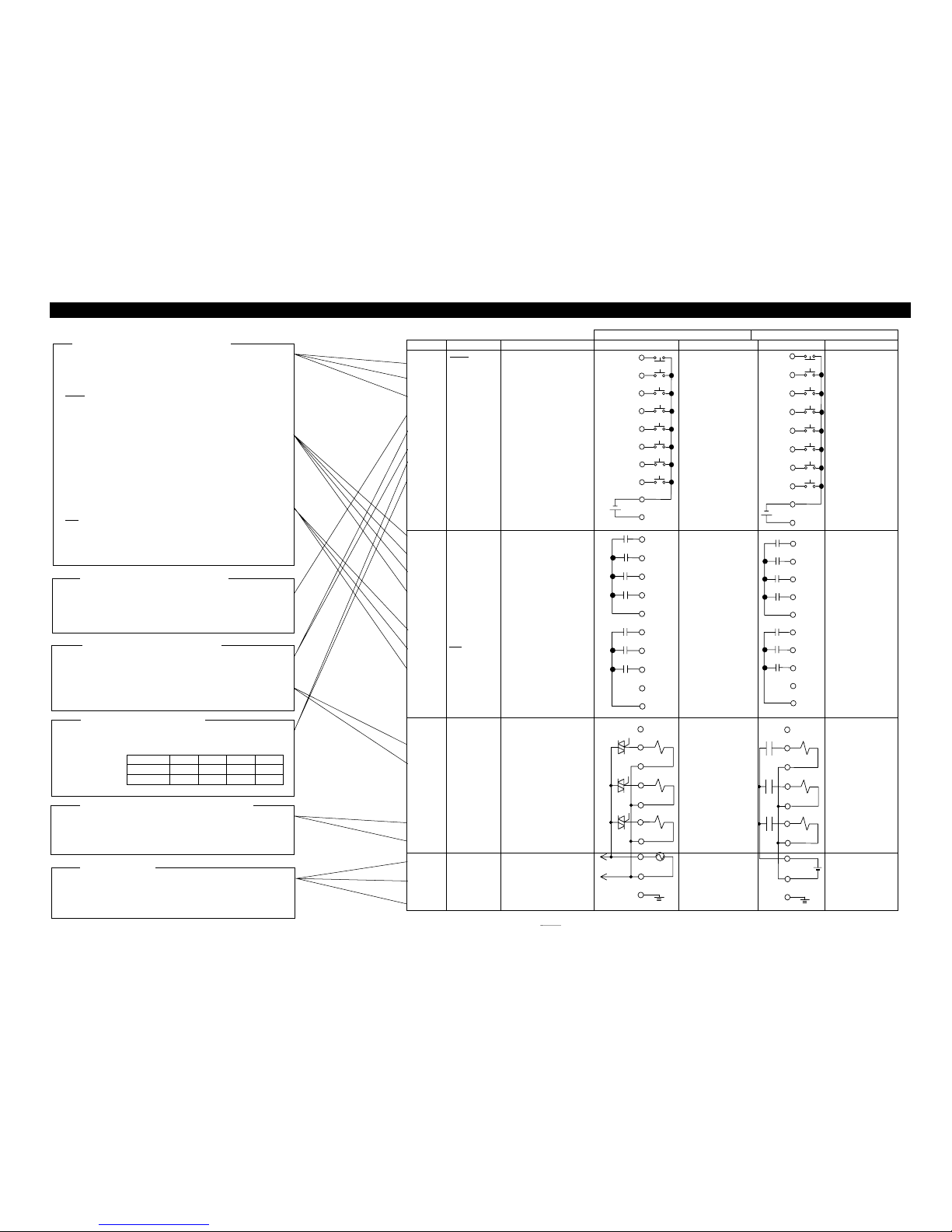

z REMOTE TERMINAL BOARD

FL-

2

□□□-0 FL-2□□□-

2No

Cod

e

Meanin

g

Connection *1 Specification Connection *1 Specification

1

2

3

4

5

6

7

8

9・10

11・12

RESET

START

BUBL

P.SW

LMT1

LMT2

CH1

CH2

COMCOM+

Reset signal

Measurement start signal

Bubble test

Pressure verification

Unclamp verification

Clamp verification

Group # switch

Group # switch

Input signal common

Power sup. for pres. switch

Input signal

(Photo coupler)

・Voltage when open

DC 12V type

・ Voltage when

shorted

5 mA type

COM+Power

Supply

・Output voltage

DC 12V type

・Output current

50 mA min

Input signal

(Photo coupler)

・ Voltage when

open

DC 12V type

・ Voltage when

shorted

5 mA type

COM+Power

Supply

・Output voltage

DC 12V type

・Output current

50 mA min

13

14

15

16

17・18

19

20

21

22

23・24

OK

+NG

-NG

P.NG

COM O

1

RDY

ERR

END

-

COM O

2

OK results output

+NG result output

-NG result output

Pressure malfunction. Output

Output signal common 1

Stand by (Ready) output

Error output

End output

Unconnected

Output signal common2

Output signal

(Relay contact)

・Rated load

AC 250V 0.4A

DC 30V 0.4A

Output signal

(Relay contact)

・Rated load

AC 250V 0.4A

DC 30V 0.4A

25・26

27

28

29

30

31

32

-

SOL1

SOL1

SOL2

SOL2

SOL3

SOL3

Unconnected

Cylinder drive valve output

Pressure valve output

Optional valve output

Output signal

(SSR)

・Output Voltage

Power source

supply

・Actual ON current

1.0 Arms

・Leak current

3 mA max

Output si

g

nal

(Relay contact)

・Rated load

AC 250V 1A

DC 30V 1A

To accord with

external supply

power source specs.

33・34

35・36

37・38

AC

AC

F.G.

AC power input

AC power input

Frame Ground

Power source for

tester

AC100V±10%

50/60Hz

(Used also as external

valve power source)

Power source for

external valve

AC100V

DC24V

(Power source for

tester is inlet.)

Loading...

Loading...