Fukuda Denshi FCP-7101 ECG Service manual

F

F

C

C

P--

P

7

7

1

1

0

0

1//

1

F

F

X--

X

7

7

1

1

0

0

2

2

●

Service Manual

●

FCP-7101

M

O

D

E

LEAD

O

Main

Power

N

/O

(stby)

FF

Charge

PO

O

F

W

1

F

m

:H

ER

V

O

L

D

2

s

ec

.

CONTRAST

START/STOP

C

A

N

C

E

L

ID

RESET

ENTER

SENSE

・ Before setting up/maintenance, please read this service manual carefully.

・ Keep this manual where it can be always referred to.

Copyright © 2004 by Fukuda Denshi Co., Ltd.

No part of this document may be copied or transmitted in any form without the prior written

permission of Fukuda Denshi Co., Ltd.

Printed in China

Notice

This manual contains technical information on the FCP-7101/FX-7102 aimed

at Fukuda Denshi service representatives and professional engineers.

Before performing maintenance the unit, read the manual carefully and use it

to help you work correctly and safely.

When you have finished using the manual, store it carefully in a designated

location.

Strictly follow the instructions of this manual whenever you perform

maintenance or make adjustments to the unit. Failure to do so may lead to a

serious accident.

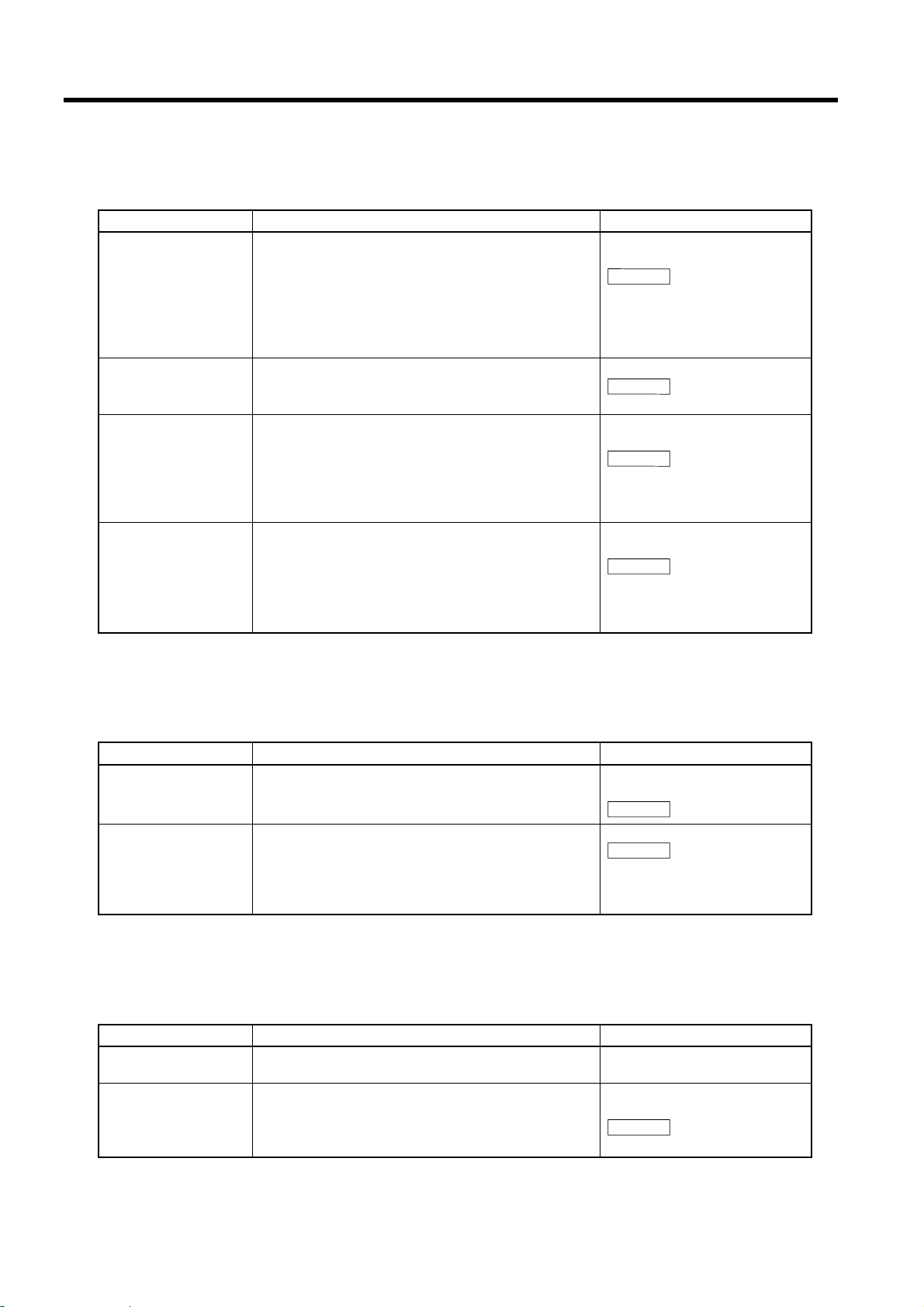

●Safety

This manual utilizes the graphic symbols shown below. Make sure that you

understand the meaning represented by these symbols, carefully read the

instructions given in the text, and work safely.

DANGER

Failure to follow this message may result in death or serious injury to the

patient or operator, damage to the equipment, or create a fire hazard.

WARNING

Failure to follow this message may result in death or serious injury to the

patient or operator.

CAUTION

Failure to follow this message may cause injury to the patient, or may

cause damage to the equipment.

Symbol Description

A note is not related to product safety. A note provides

NOTE

information about the proper use and operating method

to prevent incorrect operation and trouble with the

unit.

Indicates an action that must not be performed.

REFERENCE

Indicates an action that must be performed.

Indicates the reference page for the operation method.

i

●Servicing Precautions

In servicing the FCP-7101/FX-7102, observe the following.

DANGER

Never remodel the medical electronic equipment.

If remodelled, the equipment may not ensure safe operation,

thereby causing accidental hazards to the patient and

operator.

CAUTION

y The service manual is intended for the service engineers

of Fukuda representatives and the technical staff

concerned with medical electronic equipment. Servicing,

reassembling, and adjustment shall be performed by

autorized service engineers.

y Prepare proper facilities and tools when servicing.

y Be sure to follow the instructions of operation manual

when operating the instrument. For operating precautions,

refer to the operation manual.

ii

CAUTION

Disassembling/Reassembling Precautions

y Be sure to turn the power off and disconnect the power supply cord

from the wall outlet. Then start disassembling the instrument.

y When removing the main PC board, remove the battery in advance.

y Take care not to disconnect and connect the key panel and sensor

board from/to the connector too frequently. Too frequent disconnection

and connection of these units may cause poor contact.

y Use proper screwdrivers to loosen screws.

y When reassembling, make sure all screws are tightened to original

positions and all disconnected connectors are reconnected properly.

PC Board Handling Precautions

y PC boards are equipped with extremely sensitive devices to static

electricity.

y PC boards are sensitive electronic assemblies. Take proper measures

for removed PC boards, e.g. put them in a conductive bag.

y Handle PC boards carefully. Giving an impact to them may damage

devices mounted onto them.

y Never remove a PC board or connect the connector to it when it is

supplied with power.

CAUTION

If you find a value which exceeds the allowable level, be sure to let the

user avoid using the instrument. If the user operates the instrument as it

is, he/she may receive an hazardous accident.

●Equipment Classification

The FCP-7101/FX-7102 is classified into the following equipment:

1. Protection against electrical shock

Class Ⅱ, Internally powered

2. Type against electrical shock

Applied part: Type CF

3. Degree of protection against harmful water invasion

Ordinary equipment

4. Degree of safety in using under air-inflammable anesthetic gases or

oxygen/nitrous

oxide-anesthetic gases

Equipment used under an environment containing no inflammable

anesthetic gases or no inflammable cleaning agent.

5. Running mode

Continuous running mode

iii

Overview of the Manual

This manual consists of the following 9 chapters.

Contents of each chapter are briefly explained below.

Chapter 1 Component Names and Functions

The locations and functions of the unit's operation panel, switches, connectors,

and other components. A list of specifications is also given.

Chapter 2 Troubleshooting

How to resolve problems that occur, using flowcharts for each symptom.

Chapter 3 Maintenance

Cleaning, test menu, program version updating, periodical inspection items,

and methods.

Chapter 4 Disassembly

How to disassemble the unit in order to replace defective parts.

Chapter 5 Electric Circuit Diagrams

Electric circuit diagrams and diagrams of the connections between printed

circuit boards.

Chapter 6 Spare Parts List

A list of components supplied as spare parts.

Chapter 7 Board Component Diagrams

The layout of the connectors and other mounted parts for each of the unit's

printed circuit boards.

Chapter 8 Assembly Diagrams

The illustrations of the parts in three dimensional exploded views.

A list of the parts is also given.

iv

Chapter 9 Technical Instructions Related to EMC

Technical instructions required by IEC60601-1-2 Ed.2 are described in this

chapter.

Contents

Notice ···································································································································· ⅰ

Safety······················································································································ ⅰ

Servicing Precautions ····························································································· ⅱ

Equipment Classification························································································· ⅲ

Overview of the Manual···································································································· ⅳ

Chapter 1 Component Names and Functions ······························································· 1-1

Unit (top face) ··················································································································· 1-1

Unit (side, rear, and bottom faces) ················································································· 1-2

Operation panel ················································································································ 1-3

Specifications list·············································································································1-5

Chapter 2 Troubleshooting ····························································································· 2-1

On power supply in equipment (ECG AMP not included)········································ 2‐1

On ECG AMP supply voltage·················································································· 2‐2

Problem conditions and corrective action································································ 2‐3

Unit doesn't start up when main power is switched ON.·········································· 2‐4

Battery operations are not executed. ······································································ 2‐4

Troubleshooting related to supply voltages ····························································· 2‐5

Failures related to charging operations ··································································· 2‐6

Charge error LED is lit····························································································· 2‐6

Charging operation ended normally, but the battery is

nearly uncharged. ··································································································· 2‐6

LCD does not display or display is abnormal. ························································· 2‐7

Cannot perform key operations.·············································································· 2‐8

Does not detect mark on z-fold paper. Does not detect end

of paper. Always displays "No recording paper" warning. ······································· 2‐8

Date/time changes. ································································································· 2‐9

Buzzer would not sound·························································································· 2‐9

Recording paper is fed, but printing and waveform recording

are not performed.··································································································· 2‐10

Recording paper is not fed ······················································································ 2‐10

A certain lead record appears as a baseline. ·························································· 2‐10

All 12-lead patient records appear as baselines.····················································· 2‐11

Detection of electrode misposition cannot be led. ··················································· 2‐11

Some leads do not detect electrode misposition. ···················································· 2‐11

Chapter 3 Maintenance ···································································································· 3-1

Cleaning ···························································································································· 3‐1

Cleaning the unit ····································································································· 3‐1

Replacing the battery······································································································· 3‐2

Update of the software····································································································· 3‐4

Self-diagnostics test ········································································································ 3‐5

User self-diagnostics test ························································································ 3‐6

ECG Test Pattern ······························································································ 3‐7

Recording Test ·································································································· 3‐8

Key Test ············································································································ 3‐9

LCD Test ··········································································································· 3‐10

Buzzer Test ······································································································· 3‐11

Manufacturer self-diagnostics test··········································································· 3‐12

Status Test ········································································································ 3‐14

ECG A/D DATA ································································································· 3‐15

LAN Test ··········································································································· 3‐16

Memory Test······································································································ 3‐17

ROM WRITE Test······························································································ 3‐18

Recorder Test···································································································· 3‐19

v

Memory initialize ································································································ 3‐21

UPDATE············································································································· 3‐22

Periodical inspections······································································································3-23

Periodical inspection intervals and precautions ·······················································3-23

List of periodical inspection items ············································································3-23

Safety inspections (4 items)····················································································· 3-24

Before checking the leakage current··································································3-24

Checking the enclosure leakage current

(current that flows from the enclosure to

the earth terminal of the power outlet)······························································3-25

Checking the patient leakage current I·······························································3-25

Checking the patient leakage current III·····························································3-25

Checking the patient measurement current························································3-25

Inspection of electrical performance/characteristics ················································3-26

Hardware inspections (10 items) ·············································································3-28

Periodical inspection (2) record ······················································································3-30

Chapter 4 Disassembly ···································································································· 4-1

Removing the LCD············································································································4‐1

Removing the enclosure cover························································································4‐2

Removing the recorder unit ·····························································································4‐3

Removing the main board ································································································ 4‐4

Chapter 5 Electric Circuit Diagrams ··············································································· 5-1

Overall block diagram of unit (AC adapter not included)··············································5‐1

MAIN BOARD block diagram ··················································································5‐3

MAIN BOARD (PCB-6950) circuit ···········································································5‐5

1.Digital logic block ··································································································5‐5

CPU section·········································································································5‐5

FPGA section·······································································································5‐5

Memory section ···································································································5‐6

KEY I/F section ···································································································· 5‐8

Thermal head control section··············································································· 5‐9

Real time clock ····································································································5‐10

Reset circuit section····························································································· 5‐11

Sensor control section ·························································································5‐12

Motor control section····························································································5‐13

LCD voltage generating section···········································································5‐14

2.ECG AMP block····································································································5‐15

3.Power supply block·······························································································5‐16

Power voltage generating section ········································································ 5‐17

Battery charging section ······················································································5‐20

Power control section···························································································5‐21

KEY BOARD (PCB-6949) circuit··············································································5‐22

SENSOR BOARD (PCB-6948) circuit······································································ 5‐23

MAG UP BOARD (PCB-6951) circuit·······································································5‐23

AC adaptor block diagram ·······························································································5‐24

MAIN BOARD Circuit Diagrams (PCB-6950) ···································································5‐25

Power connection table No.1 ··················································································· 5‐25

Power connection table No.2 ··················································································· 5‐26

POWER /CAPACITOR/RESET IC/CLOCK

LCD POWER block·································································································· 5‐27

CPU block················································································································5‐28

FPGA block··············································································································5‐29

MEMORY block ·······································································································5‐30

LAN CONTROL block ······························································································ 5‐31

LCD I/F / RTC / LED block······················································································· 5‐32

THERMAL I/F block ·································································································5‐33

SENSOR I/F /MAGAZIN UP SENSOR I/F

MOTOR I/F /JTAG I/F block·····················································································5‐34

ECG AMP block

(Differential amplification, multiplexer section)·························································5‐35

ECG AMP block (ADC,CPLD and POWER section)················································ 5‐36

vi

MAIN POWER SUPPLY +24V block······································································· 5‐37

CHARGE block ······································································································· 5‐38

+5V /+3.3V /+1.8V Power generation block ···························································· 5‐39

POWER STATUS block ·························································································· 5‐40

POWER / CHARGE ERROR block ········································································· 5‐41

+3.3VSTB / POWER ON RESET block··································································· 5‐42

BATTERY ON CONTROL / THERMAL POWER

GENERATION BLOCK ··························································································· 5‐43

POWER-MAIN I / F block························································································ 5‐44

POWER ON / OFF CONTROL block ······································································ 5‐45

KEY BOARD (PCB-6949)·································································································· 5‐46

SENSOR BOARD (PCB-6948) ·························································································· 5‐47

MAG UP BOARD (PCB-6951)··························································································· 5‐48

Chapter 6 Spare Parts List ······························································································ 6-1

MAIN BOARD (PCB-6950) ································································································ 6‐1

KEY BOARD (PCB-6949)·································································································· 6‐8

SENSOR BOARD (PCB-6948) ·························································································· 6‐9

MAG UP BOARD (PCB-6951)··························································································· 6‐10

Other spare parts list ······································································································ 6‐11

Chapter 7 Board Component Diagram··········································································· 7-1

MAIN BOARD (PCB-6950 component side)···································································· 7‐1

MAIN BOARD (PCB-6950 soldering side)······································································· 7‐2

KEY BOARD (PCB-6949 component side) ····································································· 7‐3

KEY BOARD (PCB-6949 soldering side)········································································· 7‐4

SENSOR BOARD (PCB-6948 component side)······························································ 7‐5

MAG UP BOARD (PCB-6951 component side) ······························································ 7‐6

Chapter 8 Assembly Diagrams ······················································································· 8-1

Magazine ··························································································································· 8‐1

Paper shaft························································································································ 8‐2

Recorder···························································································································· 8‐3

Upper case (FCP-7101) ···································································································· 8‐4

Upper case (FX-7102) ······································································································· 8‐5

Lower case ······················································································································ 8‐6

General assembly diagram (FCP-7101) ·········································································· 8‐7

General assembly diagram (FX-7102)············································································· 8‐8

Outline view (FCP-7101)··································································································· 8‐9

Outline view (FX-7102) ····································································································· 8‐10

Paper guide······················································································································· 8‐11

50mm Magazine adapter (option)···················································································· 8‐12

50mm Paper adapter (option)·························································································· 8‐13

Chapter 9 Technical Instructions Related to EMC ························································ 9-1

Emission information CISPR11······················································································· 9‐2

Immunity information (to other than radiation/conduction)········································· 9‐3

Immunity information (to radiation/conduction)···························································· 9‐4

Recommended distance of separation from

portable telephone, etc ···································································································· 9‐5

vii

viii

Chapter

1

Component Names and Functions

Unit (top face) ......................................................................................1-1

Unit (side, rear, and bottom faces) ....................................................1-2

Operation panel................................................................................... 1-3

Specifications list................................................................................ 1-5

Chapter 1

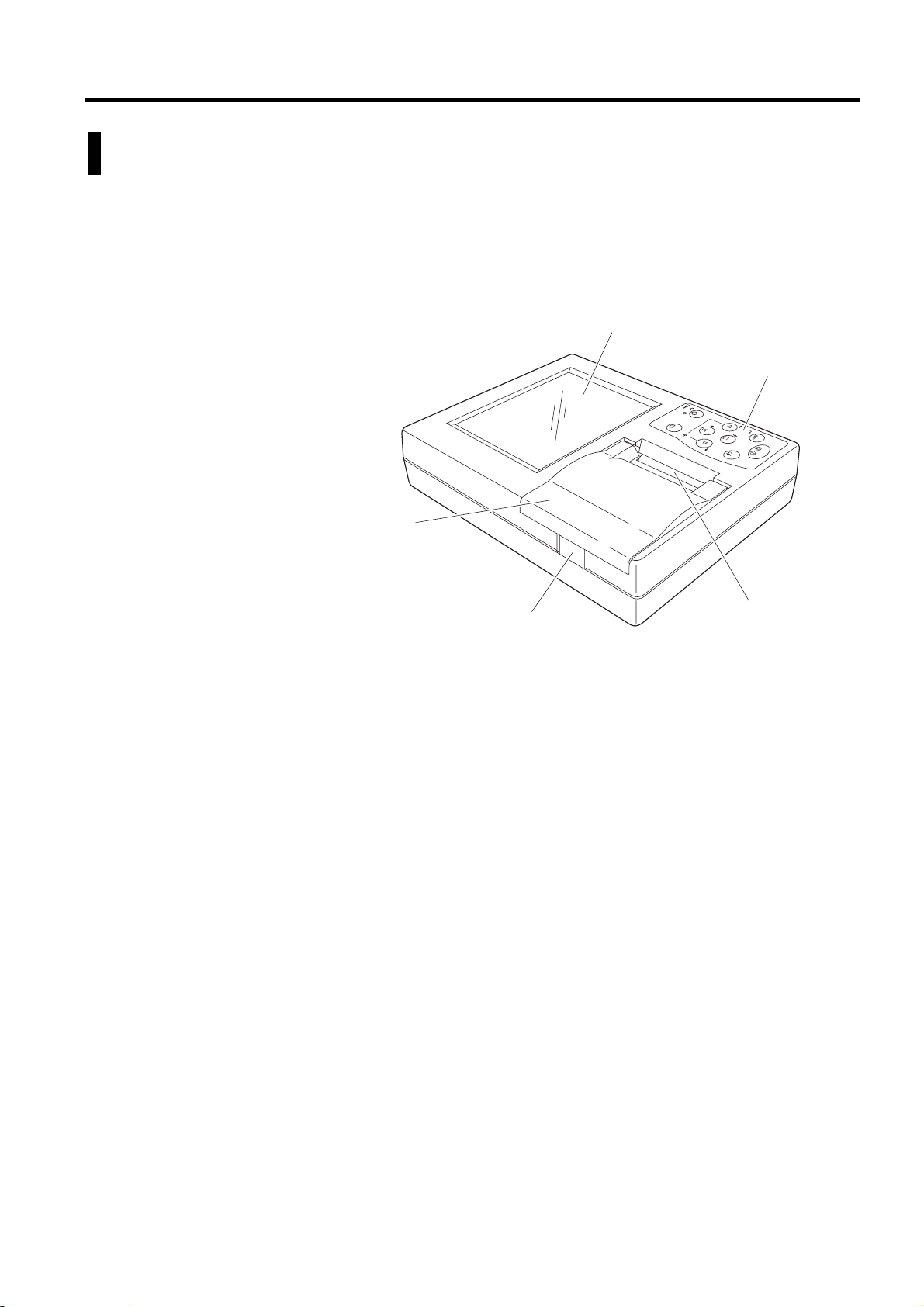

Unit (top face)

(4) Paper magazine

Component Names and Functions

Liquid crystal display, operation panel, and paper magazine are provided on

the top face of the unit.

(1) Liquid crystal display(LCD)

(2) Operation panel

Charge

Main

R

Power

.

E

ec

W

s

O

2

P

D

L

O

:H

F

(stby)

F

O

ON/OFF

FCP-7101

E

D

O

M

1mV

D

LEA

ENTER

SENSE

RESET

CANCEL

ID

START/STOP

(3) Magazine open button

(5) Thermal print head

(1) Liquid crystal display (LCD)

Displays electrocardiogram (ECG) waveforms, patient data, unit status, etc.

(2) Operation panel

Push the key switches on the panel to operate the electrocardiograph.

Provided with the LED that indicates the operation status.

(3) Magazine open button

Push to open the magazine cover.

(4) Paper magazine

Load the recording paper here.

(5) Thermal print head

Records (prints) ECG waveforms and measured values.

1 - 1

Chapter 1

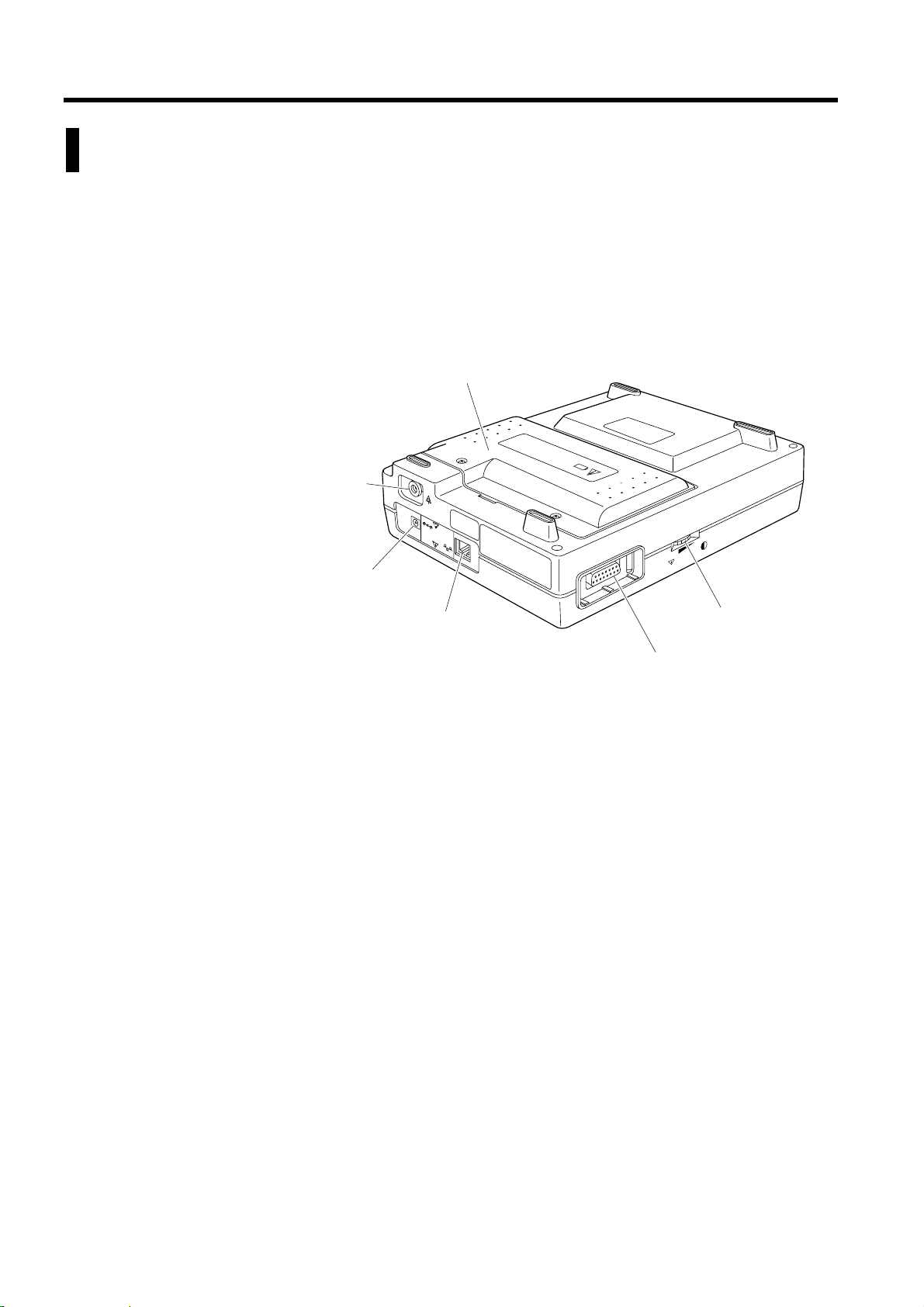

Unit (side, rear, and bottom faces)

PATIENT connector and CONTRAST volume are provided on the side of

the unit.

AC adapter jack, LAN port, and potential equalization terminal are

provided on the rear face of the unit.

BATTERY PACK compartment is located on the underside of the unit.

(11) BATTERY PACK compartment

(10) Potential equalization

terminal

Ni-MH BATTERY PACK

DCIN18V

LAM

CONTRAST

(8) AC adapter jack

(9) LAN port

(6) PATIENT connector

(7) CONTRAST volume

(6) PATIENT connector

Plug in the patient cable here.

(7) CONTRAST volume

Use the volume to adjust the contrast of the LCD.

(8) AC adapter jack

Plug in the DC plug here.

(9) LAN port

Plug in the LAN cable here to communicate with a PC.

(10) Potential equalization terminal

Plug in the ground cable here.

1 - 2

(11) BATTERY PACK compartment

Install the optional battery pack (8PH-4/3A3700-H-J18) in this

compartment.

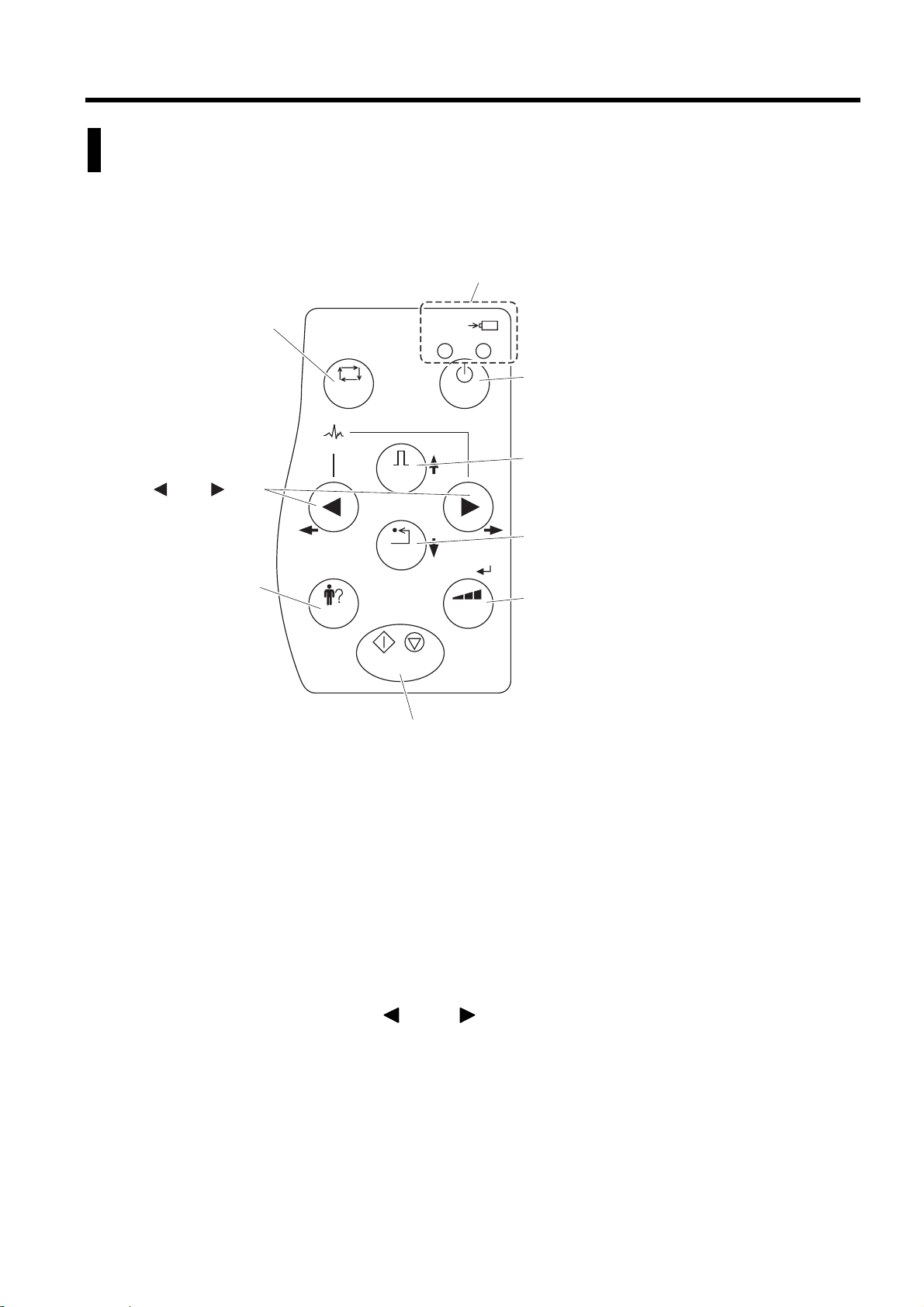

Operation panel

Component Names and Functions

The electrocardiograph can be operated on the operation panel. The LED

that indicates the operation status is at the upper right-hand corner of the

operation panel.

(9) LED

(2) [MODE] key

(4) LEAD [ ] and [ ] keys

(6) [ID] key

ON/OFF

(stby)

1mV

Main

Power

Charge

POWER

OFF:HOLD 2Sec.

ENTERCANCEL

SENSE

FCP-7101

MODE

LEAD

RESET

ID

START/STOP

(8) [START/STOP] key

(1) [POWER ON/OFF] key

(1) [POWER ON/OFF] key

(3) [1mV] key

(5) [RESET] key

(7) [SENSE] key

Turns ON/OFF the power.

If AC power is set to OFF, charging of the battery, if provided, is started.

(2) [MODE] key

Press this key to select diagnosis mode and setting.

(3) [1mV] key

Press this key to display and record waves calibrated in 1mV.

The key moves the cursor upward on the setting screen.

(4) LEAD [ ] and [ ] keys

Press these keys to change the leads to be monitored.

The key moves the cursor horizontally on the setting screen.

(5) [RESET] key

Press this key to reset the ECG waveform to baseline state.

The key moves the cursor downward on the setting screen.

1 - 3

Chapter 1

(6) [ID] key

Press this key to enter ID. The key serves as the CANCEL key on the

setting screen.

(7) [SENSE] key

Press this key to change the sensitivity of the ECG. The key serves as the

ENTER key on the setting screen.

(8) [START/STOP] key

Press this key to start/stop the recording, etc. of various data.

(9) LED

Displays the following operation status.

Status of LED Operation of ECG

Main Power LED lit in blue. Stays on while DC plug is

connected to the equipment.

Charge LED lit in blue. Battery charging underway.

Charge LED lit in yellow. Charging abnormally terminated.

1 - 4

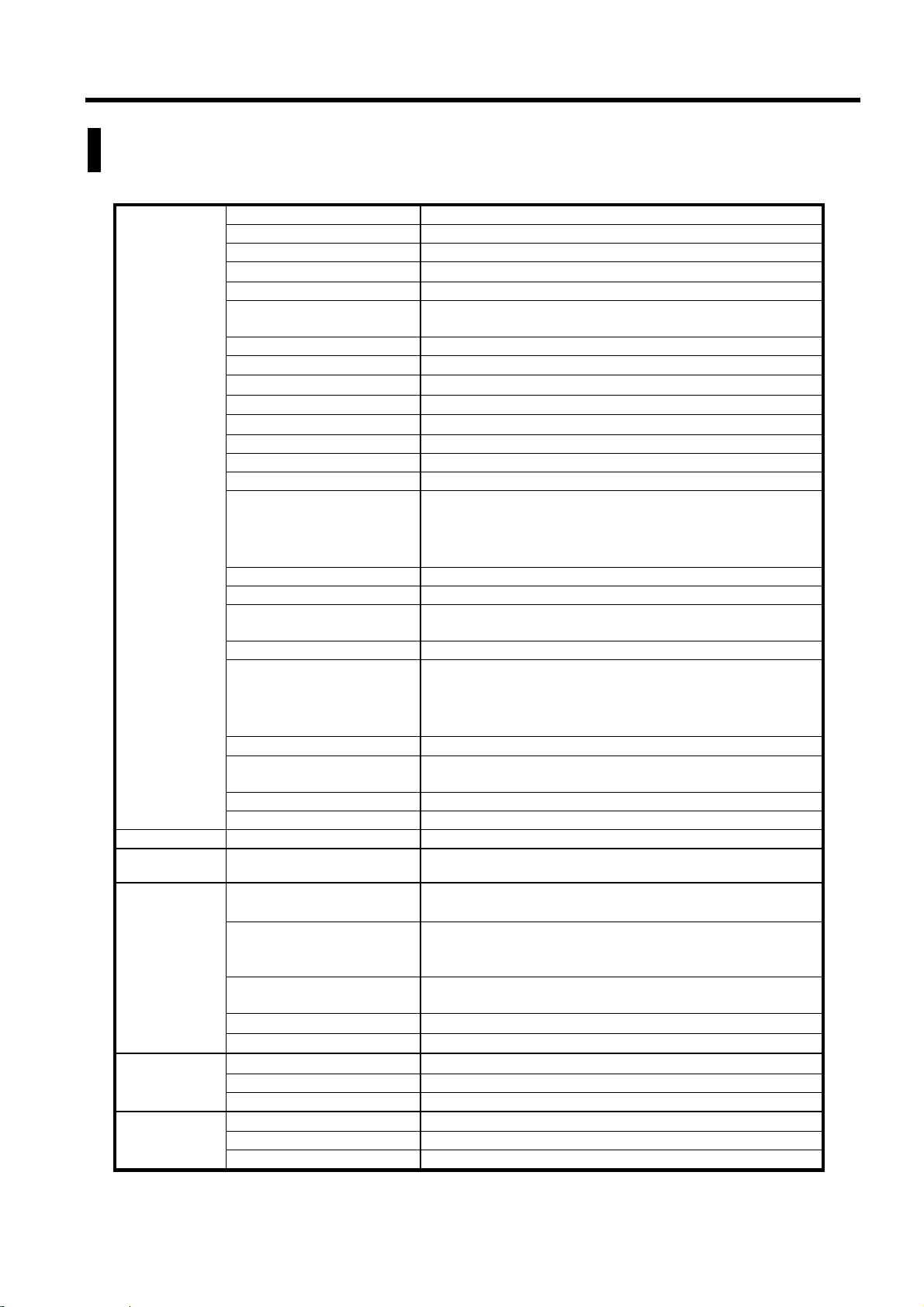

Specifications list

Lead Standard 12 leads

Standard sensitivity 10mm/mV

Sensitivity selection 1/4, 1/2, 1, 2, Auto

Polarization voltage

Frequency response 0.05 to 150Hz

Transient characteristics

(Time constant)

Common mode rejection 103dB or more (Standard sensitivity 22mmp-p or lower)

Input impedance

Input circuit current

Internal noise

Calibrated voltage

Amplifier composition 8ch (II, III, V1 to V6) Amplifier system

A/D conversion 13 bits

Sampling rate 1000/sec/ch

Electrocardiography

Filter

Recording system Thermal array head

Recording speed 5, 10, 12.5, 25, 50mm/sec.

Recording resolution

Recording channels 1ch, 3ch

Recording paper

Display

Display contents

Patient data ID number, age, sex.

Key panel 9 keys

Signal I/O LAN port 10BASE-T compliant

Measurement

operation

Basic measurement value

Safety

Power supply

General

Power consumption

(Max.)

Dimensions (W×D×H) 180×225×50mm (Projection not included)

Weight

Operating

environment

Storage

environment

Temperature

Humidity 25 to 95% (Condensation not allowed)

Atmospheric pressure 70 to 106kPa (700 to 1060mbar)

Temperature

Humidity 10 to 95% (Condensation not allowed)

Atmospheric pressure 70 to 106kPa (700 to 1060mbar)

±550mV or higher

3.2 sec.

50MΩ or greater

8

−

5×10

A or lower

20µVp-p or lower

1mV±2% or lower

HUM filter: 50 or 60Hz (−20dB or less)

Muscle filter: 25 or 35Hz (−6dB/Oct)

Drift filter: 0.25 or 0.5Hz (−6dB/Oct)

High cut filter: 75Hz, 100Hz or 150Hz (−6dB/Oct)

Deflection axis: 8 dots/mm

Time axis: 1msec.

Rolled paper: OP-119TE (63mm×30M)

Rolled paper: OP-18TE (50mm×30M)

Z-fold paper: OP-122TE (63mm×20M)

Z-fold paper: OP-123TE (50mm×20M)

FSTN LCD (320×240 dots)

Cardiograms, patient data, analysis and observation,

error message

Heart rate, R-R time, etc.

Class Ⅱ type CF and internally powered equipment,

type CF

AC power supply: AC adaptor, 100 to 240V AC (±10%),

DC power supply: 9.6V DC (Battery pack)

At AC operation: 70 VA

At DC operation: 40 W

1.2kg±0.5kg (Battery included)

10 to 40°C

−10 to +50°C

Component Names and Functions

50/60Hz

1 - 5

Chapter 1

1 - 6

Chapter

2

Troubleshooting

On power supply in equipment (ECG AMP not included)................ 2-1

On ECG AMP supply voltage.............................................................. 2-2

Problem conditions and corrective action........................................ 2-3

Unit doesn't start up when main power is switched ON...........2-4

Battery operations are not executed. ......................................2-4

Troubleshooting related to supply voltages .............................2-5

Failures related to charging operations ...................................2-6

Charge error LED is lit............................................................. 2-6

Charging operation ended normally, but the battery is

nearly uncharged. ...................................................................2-6

LCD does not display or display is abnormal. ......................... 2-7

Cannot perform key operations............................................... 2-8

Does not detect mark on z-fold paper. Does not detect end

of paper. Always displays "No recording paper" warning. .......2-8

Date/time changes. ................................................................. 2-9

Buzzer would not sound.......................................................... 2-9

Recording paper is fed, but printing and waveform recording

are not performed..................................................................2-10

Recording paper is not fed .................................................... 2-10

A certain lead record appears as a baseline. ........................2-10

All 12-lead patient records appear as baselines. .................. 2-11

Detection of electrode misposition cannot be led.................. 2-11

Some leads do not detect electrode misposition................... 2-11

Chapter 2 Troubleshooting

On power supply in equipment (ECG AMP not included)

The following concerns the supply voltages in the equipment.

This equipment generates various DC power supply voltages (+24, +5,

+5VSTB, +3.3V, +3.3VSTB, +1.8V and −24V) inside using the DC power

supply, +18V, output by the attached AC adaptor or the DC power supply

of the battery.

If the following power is not supplied, the intended functions by that power

do not work.

If +3.3V, is not supplied, the CPU and FPGA do not operate, whereby all

functions are inoperable.

DC power +18V from AC adaptor or battery pack voltage

+24V: Supplied to the thermal head and the motor driver.

Generates +3.3VSTB.

+3.3VSTB: Standby power used when DC plug is

inserted or the Battery is set.

+5V: Used as LCD logic drive voltage or mark sensor drive

voltage. Generates +1.8V.

+1.8V: Used as the core power for CPU and FPGA.

+5VSTB: Standby power used when DC plug is inserted.

+3.3V: Supplied to the CPU, FPGA, memory, control/logic IC,

crystal oscillator, sensor, etc. Generates −24V.

−24V: Used as LC voltage VEE of LCD.

2 - 1

Chapter 2

On ECG AMP supply voltage

Since the ECG AMP is insulated, power is supplied through the push-pull

circuit with a pulse transformer (FT-2155).

+5V

VTRF: Main power supply of the ECG AMP. Generated

through the pulse transformer (FT-2155). Generates

+5VDF (+2.5VF) and +3.3VDF.

+5VDF (+2.5VF): Used mainly as the power supply for

the differential amplifier or photocoupler.

+3.3VDF: Used as the power supply to drive the CPLD

for the ECG AMP.

2 - 2

Problem conditions and corrective action

CAUTION

If any part mounted on the MAIN BOARD (PCB-6950) or other circuit boards

seems to be faulty, replacing not the part itself only but the entire circuit

board is recommended.

CAUTION

When checking the circuit voltage and signals to correct a problem, be

careful not to cause a short circuit.

Maintenance

2 - 3

Chapter 2

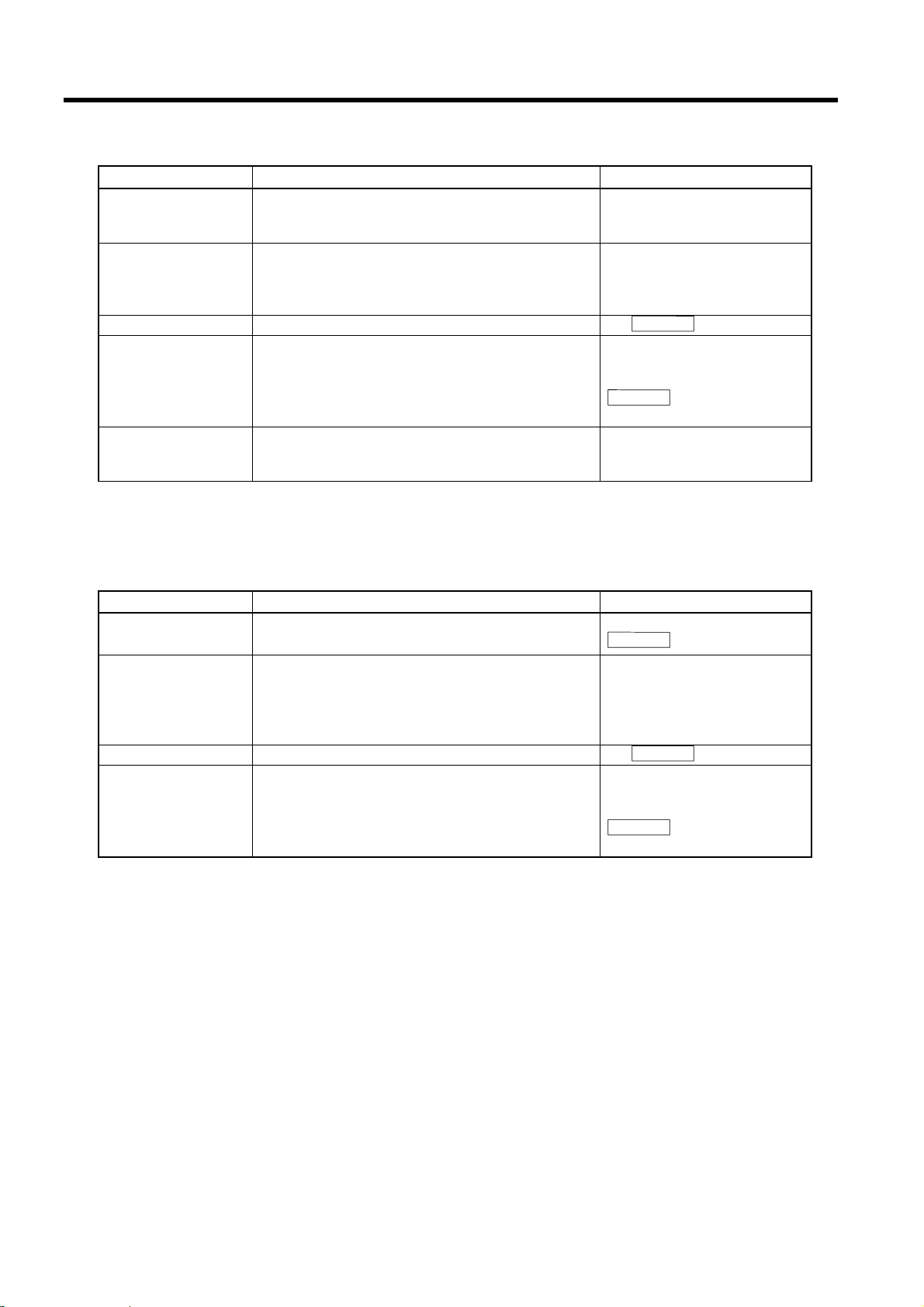

●Unit doesn't start up when main power is switched ON.

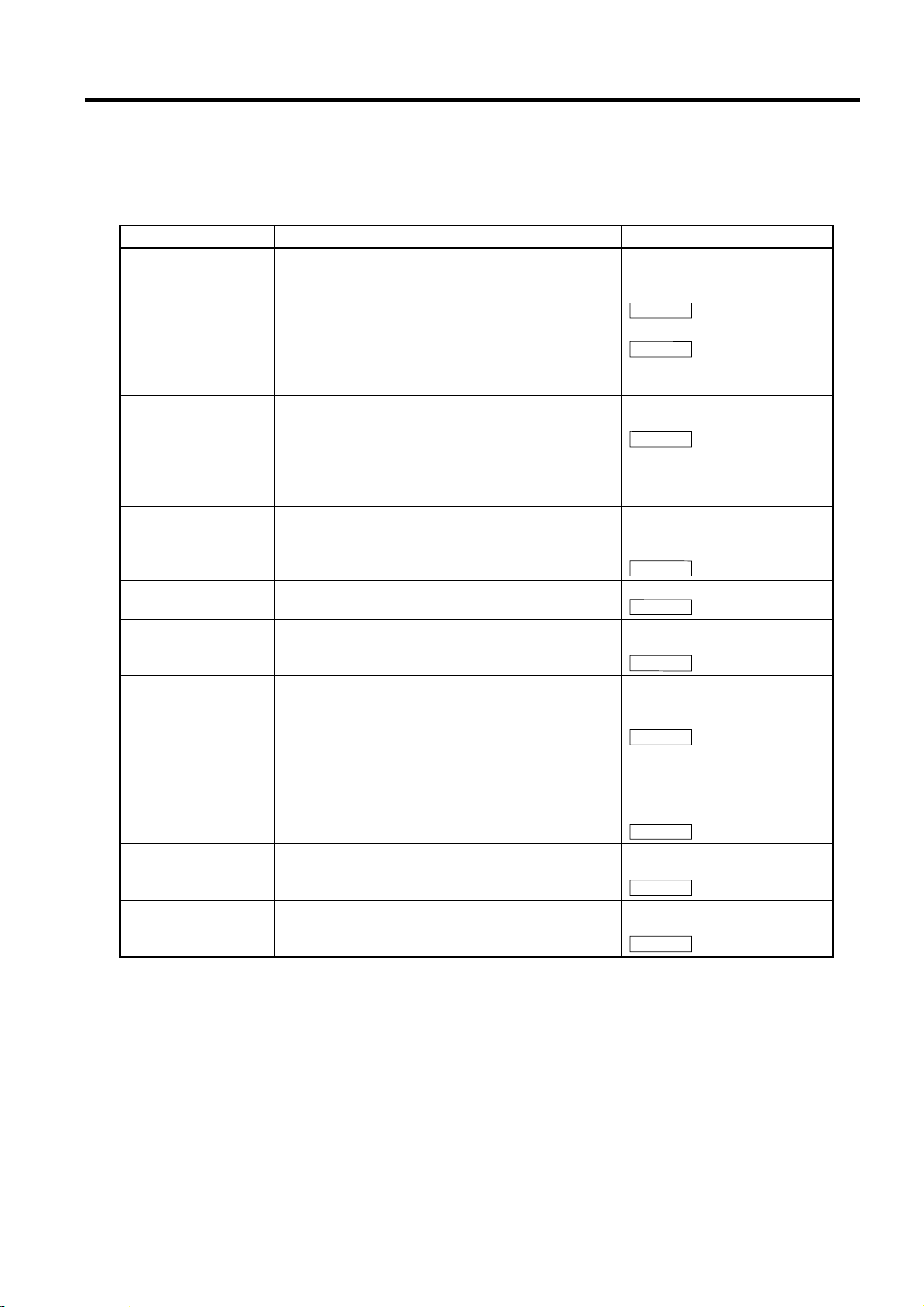

Item to Check Method of Checking and Corrective Action Place to Check

Power cable Check that the power cable is plugged into the power

outlet and the AC adaptor. Check that the DC plug

is connected to the equipment.

LED on the operation

panel

Cable

Fuse

Checking the voltage

on MAIN BOARD

AC adaptor Check that the LED of the AC adaptor is lit.

Connect the DC plug and check that the [Main

Power] LED on the operation panel is kept ON. If

not, check the KEY cables connecting the operation

panel and the MAIN BOARD for a break, etc.

Using a voltmeter, check that F6 fuse is not blown.

Using a voltmeter, check that +18V, +5V, +3.3V,

+1.8V, +3.3VSTB, and +5VSTB are present at

C100, C311, C312, C317, C314, and C310 terminals

of the MAIN BOARD. When +5V or +3.3V is

present, LED4 or LED5 is lit.

Using a voltmeter, check that +18V is present at DC

plug terminal.

Power cable

DC plug

[Main Power] LED on the

operation panel

KEY cable

F6

REFERENCE

P5-37

C100, C310, C311, C312,

C314, C317

LED4, LED5

REFERENCE

P5-37,39

LED of AC adaptor

DC plug

●Battery operations are not executed.

Item to Check Method of Checking and Corrective Action Place to Check

Battery connection Open the battery compartment cover, and verify that

the battery pack is securely connected

Checking the charge After the end of charging the battery, start the

operation using the battery.

If the operation is impossible or soon fails, the

battery is deteriorated. Replace the battery with a

new one.

Fuse

Checking the voltage

on MAIN BOARD

Using a voltmeter, check that F3 fuse is not blown.

Using a voltmeter, check that the battery pack

voltage, +5V, +3.3V, +1.8V, and +3.3VSTB are

present at C100, C311, C312, C317, and C314

terminals of the MAIN BOARD. When +5V or

+3.3V is present, LED4 or LED5 is lit.

Battery compartment

REFERENCE

P3-2

Starting after charging.

F3

REFERENCE

P5-37

C100, C311, C312, C314,

C317

LED4, LED5

REFERENCE

P5-37,39

2 - 4

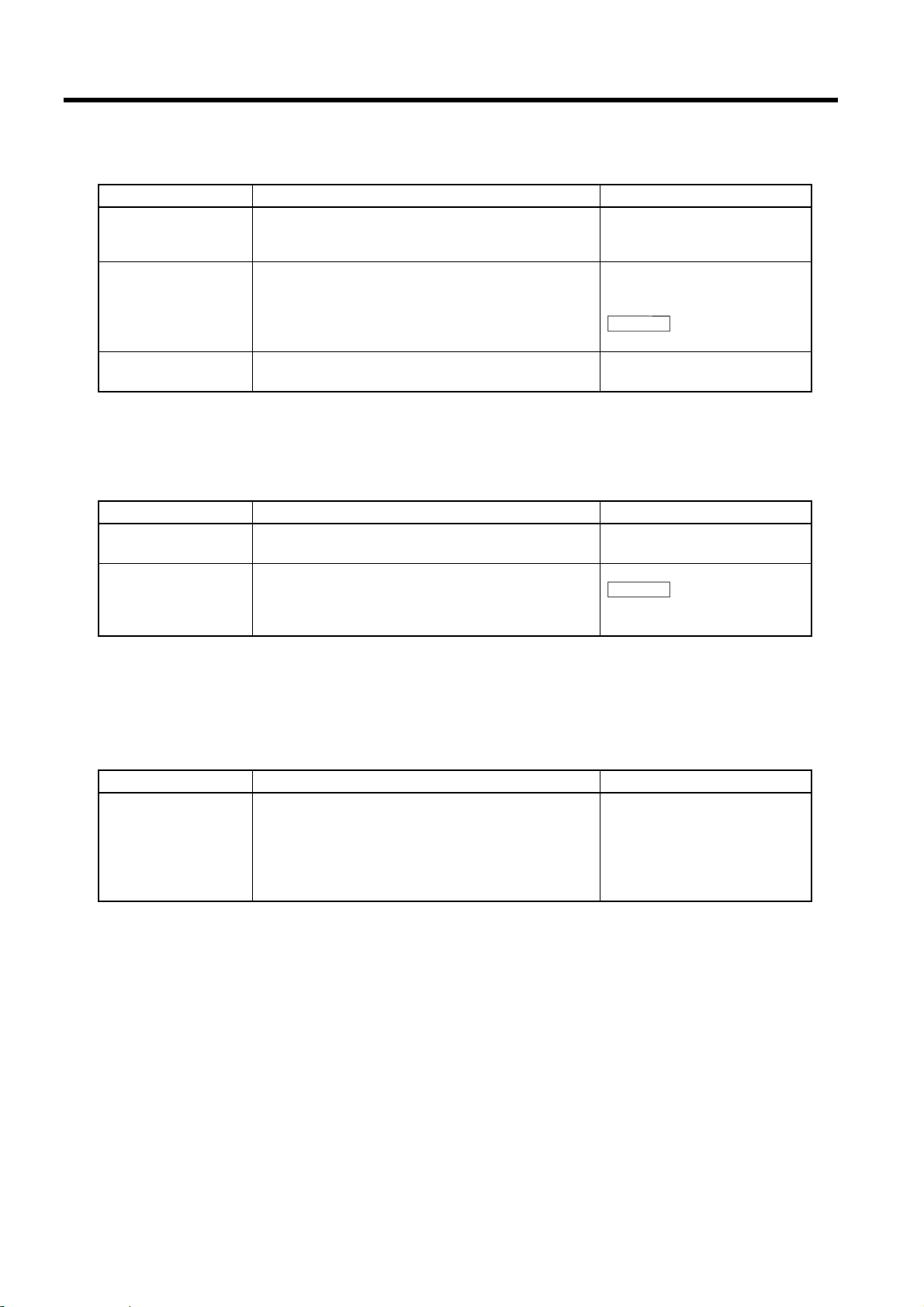

● Troubleshooting related to supply voltages

* The following troubleshooting assumes that the fuses F6 and F3 are not

blown. Check fuses first when you have a trouble with the supply voltage.

Item to Check Method of Checking and Corrective Action Place to Check

+3.3V

Check that +3.3V is applied to terminal C312 on the

MAIN BOARD. Check also that LED5 is kept ON.

If voltage is not applied, +24V may not be supplied

or IC46 may be faulty.

+3.3STB Connect the DC plug without starting the equipment,

and check that +3.3V is applied to terminal C314 on

the MAIN BOARD. If not, +18V may not be

supplied or IC62 may be faulty.

+1.8V

Check whether or not +1.8V is applied at terminal

C317 on the MAIN BOARD.

If not applied, check whether or not +5V is applied at

IC45 pin 8.

If not applied, refer to the remedy for absence

of+5V. If voltage is applied, IC45 may be faulty.

+5V

Check that +5V is applied to terminal C311 of the

MAIN BOARD. Check also that LED4 is lit.

If voltage is not applied, +24V may not be supplied,

or IC47 may be faulty.

+5V STB

Check that +5V is applied to IC43 pin 1 of the

MAIN BOARD. If not, IC43 may be faulty.

+24V

Check that +24V is applied to C101 terminal of the

MAIN BOARD.

If not, IC42 or Q25 may be faulty.

-24V(VEE)

Check that −24V is applied to P1 pin 12.

Check also that +3.3V is applied to IC1 pin 6.

If not, see troubleshooting for absence of +3.3V.

If +3.3V is applied, IC1 or IC7 (CPU) may be faulty.

VTRF

Check that +6.2V is applied to C274 terminal. If not,

T1 (FT2155) may be faulty.

Check that 125kHz rectangular waves are input to

IC20 pins 13 and 15. If not, IC8 (FPGA) may be

faulty.

+5VDF(+2.5VF)

Check that +5V is applied to C275 terminal. If not,

VTRF may not be generated, or IC40 may be faulty.

+3.3VDF

Check that +3.3V is applied to C276 terminal. If not,

IC39 may be faulty, or VTRF (about +6.2V) may not

be applied to IC39 pin 6.

C312

LED5

IC46

REFERENCE

IC62

REFERENCE

C317

IC45 pin 8

REFERENCE

C311

LED4

IC47

REFERENCE

IC43 pin 1

REFERENCE

C101

IC42,Q25

REFERENCE

P1 pin 12

IC1 pin 6

IC7 pin 13

REFERENCE

C274

T1

IC20

IC8

REFERENCE

C275

IC40

REFERENCE

C276

IC39

REFERENCE

P5-37,39

P5-42

P5-39

P5-39

P5-38

P5-37

P5-32,27,28

P5-36,29

P5-36

P5-36

Maintenance

2 - 5

Chapter 2

●Failures related to charging operations

Item to Check Method of Checking and Corrective Action Place to Check

Power cable Check that the power cable is plugged into the power

outlet and the AC adaptor. Check that the DC plug is

connected to the equipment.

Battery Open the battery compartment cover on the botton of

the unit. Verify that the battery is present and that the

battery and unit are securely connected.

Verify also that the connecting cable is not

disconnected/broken.

Battery voltage Check whether or not the battery voltage is +8.0 V or

higher.

●Charge error LED is lit

Item to Check Method of Checking and Corrective Action Place to Check

Battery voltage

Battery temperature Detach the battery from the equipment, and check

Check whether or not the battery voltage is +14.4 V

or higher

whether the battery is excessively hot or not. The

charge error LED comes on if the battery

temperature exceeds 70°C.

Power cable

DC plug

Connection between the

battery and unit

Cable

REFERENCE

Battery voltage

Battery voltage

Battery temperature

REFERENCE

P3-2

P3-2

●Charging operation ended normally, but the battery is nearly

uncharged.

Item to Check Method of Checking and Corrective Action Place to Check

Battery The number of charge and discharge cycles of

battery is about 300 although it depends on the

particular operating environment. The duration in

hours after charging shortens as the number of

discharges increases. If the battery cannot hardly be

charged, replace it.

Battery

2 - 6

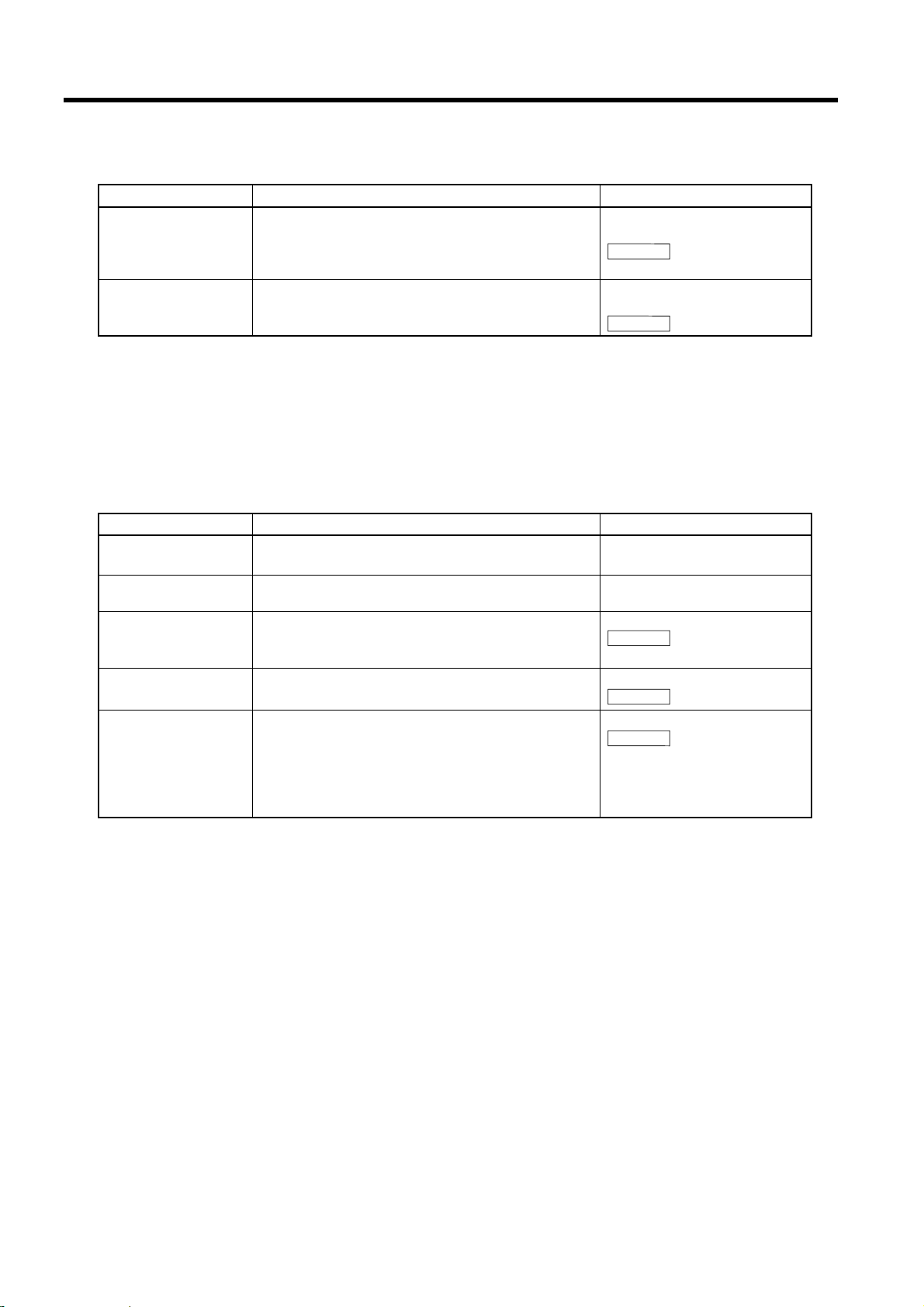

●LCD does not display or display is abnormal.

Item to Check Method of Checking and Corrective Action Place to Check

Contrast

Operate the contrast control knob to adjust the LCD

brightness.

Connector Verify that the flat cable of the LCD unit and P1 on

the KEY

• LCD I/F board is securely connected.

Verify also that the flat cable is inserted in the

correct direction and is free of cuts and separation.

Power supply Check the voltage for the main board.

・ V

: P1 (11 and 14 pins) GND level

SS

・ V

: P1 (10 pins) +5V

DD

or VDD is abnormal, refer to the section of +5

If V

SS

V in "Troubleshooting related to supply voltages".

Control signals Verify that LCD control signals FLM,CL1,CL2 and

D0-3 are not at the H or L fixed levels.

Verify also that the DISPOFF* signal is at the H

level.

The LCD module is controlled by IC7(CPU); thus, if

the control signal is abnormal, IC7 is likely to be

defective.

Liquid crystal voltage

V

EE

Check the voltage on P1 pins 12.

・ V

P9 (pins A24, A25) VEE.

EE

is a liquid crystal drive voltage. The LCD

V

EE

contrast is controlled in terms of this voltage. The

voltage depends on the operation circumstances.

Operate the contrast adjusting knob to see if the

voltage is between +21 and +24 V.

If V

is abnormal, refer to the section of VEE in

EE

"Troubleshooting related to supply voltages". Also

check the action of Q1 area.

Contrast adjusting knob

REFERENCE

P1-2

Flat cable of LCD unit and P1

REFERENCE

P5-32

P1 pins 11,14

P1 pins 10

REFERENCE

P2-4, P5-32

P1 Pins 1 to 4 and pins 6, 8, 9

IC7

REFERENCE

P5-28, 32

P1 pins 12

Q1

REFERENCE

P2-4, P5-32

P5-27

Maintenance

2 - 7

Chapter 2

●Cannot perform key operations.

Item to Check Method of Checking and Corrective Action Place to Check

Cable Check that the KEY cable is connected to P2 and the

KEY BOARD.

Check that the parts around P2 are properly

mounted.

Key signal

Check that the signal corresponding to the key

pressed is at “L” level.

●Does not detect mark on z-fold paper. Does not detect end of paper.

Always displays "No recording paper" warning.

Item to Check Method of Checking and Corrective Action Place to Check

Program setting

Sensor Verify that the mark sensor area is free of foreign

Connector Verify that the sensor cable is securely connected

Mark drive signal Check that 2kHz rectangular waves are input to P6

Detection signal At a status where the magazine is closed and other

Check whether the recording paper is set at roll

paper or not.

matter and that the sensor is securely attached.

and not broken. Verify also that the soldering of the

connector P6 on the MAIN BOARD is free of defect.

pin 4. If not, IC8 or IC20 may be faulty.

than a mark on the recording paper is aligned with

the sensor, check whether or not the waveform

coming from IC16 pin 7 is 2 kHz.

If the above signal is not detected, check the mark

sensor and mark drive signals.

P2

Key cable

REFERENCE

P2 pins 3 to 10.

Key scan signal

REFERENCE

Program setting (recording

paper)

Mark sensor

P6

REFERENCE

P6 pin 4, IC8,IC20

REFERENCE

IC16 pin 7,Mark sensor

REFERENCE

P5-32

P5-32

P5-34

P5-29,34

P5-34

2 - 8

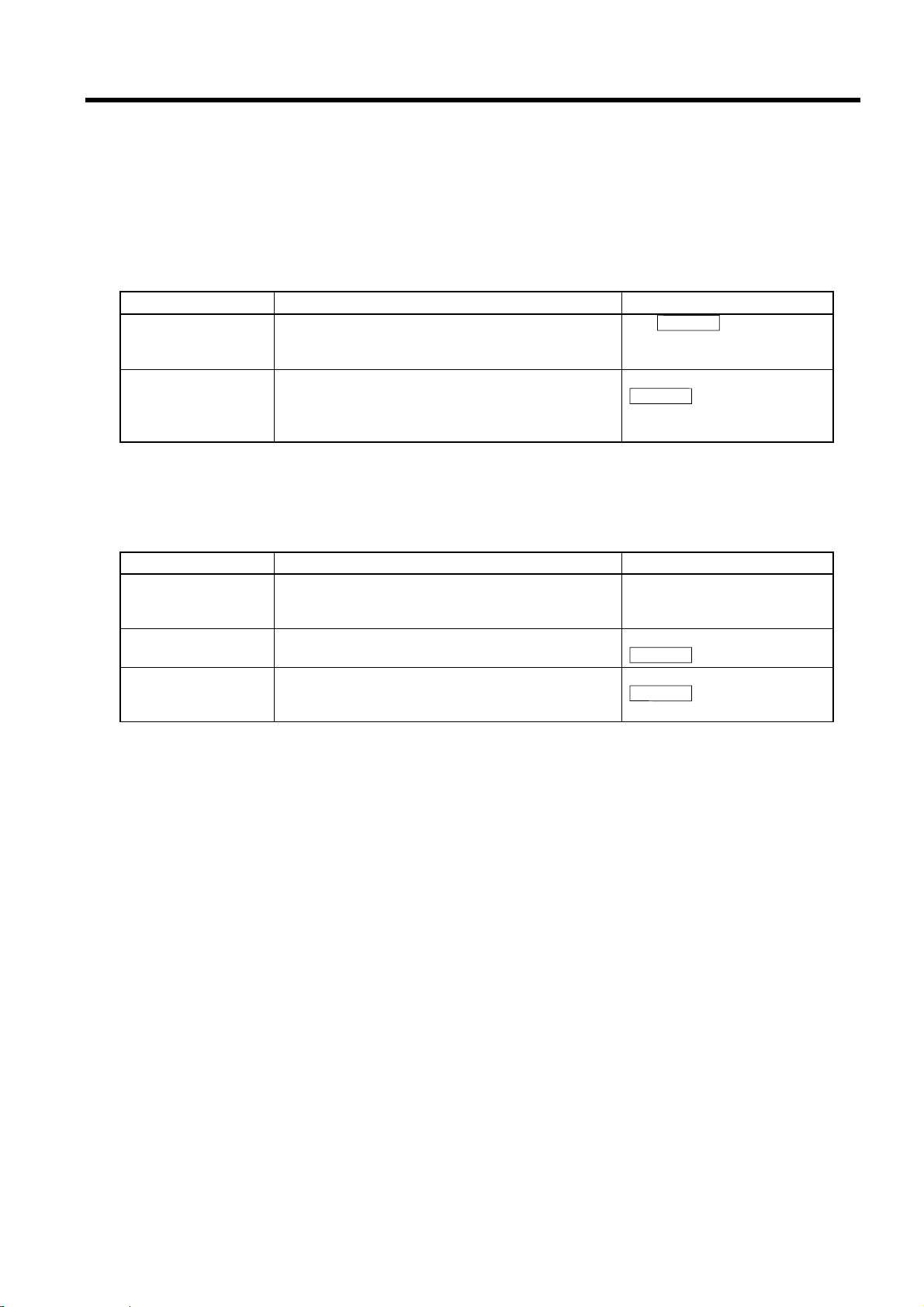

●Date/time changes.

The clock function is performed by lithium battery (BT1) at all times. The

setting of the equipment is backed up for about 5 years, on condition that it

is stored at the room temperature.

Item to Check Method of Checking and Corrective Action Place to Check

Lithium battery

voltage

Control signal Verify that RTCCE, RTCDATA, and RTCCLK

Check that the voltage of the lithium battery (BT1) is

+2V or higher. Check also that the battery is properly

mounted to the MAIN BOARD.

signals on the IC13 do not become fixed at H or L

each time the date/time is changed in the program

settings.

REFERENCE

RT1

IC13 pin 11,12,13

REFERENCE

P5-32

P5-32

●Buzzer would not sound

Maintenance

Item to Check Method of Checking and Corrective Action Place to Check

Program setting Check the program setting to make sure that the

buzzer is not set to OFF, or the volume is set to

extremely low setting.

Buzzer

Buzzer signal With an oscilloscope, observe the potential at IC8

Check that the buzzer (Y1) is properly mounted to

the MAIBN BOARD.

pin 103 while the buzzer is sounding, and make

sure it is not a fixed potential.

Program setting of the buzzer

Y1

REFERENCE

IC8 pin 103

REFERENCE

P5-29

P5-29

2 - 9

Chapter 2

●Recording paper is fed, but printing and waveform recording are not

performed.

Item to Check Method of Checking and Corrective Action Place to Check

Connector Verify that the thermal print head cable is securely

attached to connector P3 on the MAIN BOARD.

Verify also that the soldering of connectors P3 is free

of defect.

Verify that the thermal print head and thermal print

head cable are securely connected and that the

thermal print head cable is not broken.

Power supply

Control signal When recording, verify that the signals of

Overheat Printing is not performed if the temperature of the

Verify that pins No. 1,2,13 and 14 of P3 on the

POWER BOARD are supplied with +24 volts during

recording.

[LATCH*] (pin No. 10), [CLOCK] (pin No. 9), and

[STROBE1*-4*] (pins No. 7and8) of P3 on the

MAIN BOARD are not fixed at "H" or "L."

If the above is abnormal, check the signals for IC7B

to IC8, 56-59.

thermal head is 60°C or higher.

Check that IC15 pin 7 is not at “L” level.

Check the maker maintenance status to make sure

that the temperature of the thermal head is not set to

60°C or higher.

P3

Thermal print head cable

REFERENCE

P3 pins 1,2,13and 14

REFERENCE

P3 pins 7 to 10

IC8pins 56 to59

REFERENCE

IC15 pin 7

Maker maintenance status

REFERENCE

P5-33

P5-33

P5-29,33

P5-33, P3-14

●Recording paper is not fed

Item to Check Method of Checking and Corrective Action Place to Check

Connector

Control signal While recording, check that a signal is present at P5

Check that the motor cable is securely connected and

that it is not broken.

pins 1 through 4 on the MAIN BOARD.

Also check that the level is not "L" at Q6 and Q7

pins 3.

If a signal is present, the motor may be faulty.

P5

Motor cable

REFERENCE

P5

REFERENCE

P5-34

P5-34

●A certain lead record appears as a baseline.

Item to Check Method of Checking and Corrective Action Place to Check

Patient cable Check the patient cable. for a break and check the

connection staus.

OP Amp of ECG

AMP, A/D converter

and limiter

Check that the operation of the OP Amp, IC23 to

IC27, and A/D converter IC37 (which are related to

the baseline lead) and the transistors Q13 to Q21 for

the protection against excess input are not shorted.

Patient cable

IC23 to IC27, IC37,Q13 to

Q21

REFERENCE

P5-35,36

2 - 10

Loading...

Loading...