Page 1

B7FY-2001-01

内蔵 LTO3 ユニット 取扱説明書

Tape Drv LTO3 Ultrium3/Ultrium2 400GB User’s Guide

(PG-LT302)

J

E

Page 2

はじめに

このたびは、弊社の内蔵 LTO 3 ユニット(PG-LT302/PGBLT302/PGBLT302C)をお買い上

げいただき、誠にありがとうございます。

本書は、内蔵 LTO 3 ユニット(以降、本製品)の取り扱いの基本的なことがらについて説

明しています。ご使用になる前に、本書をよくお読みになり、正しい取り扱いをされます

ようお願いいたします。

2007 年 4 月

安全にお使いいただくために

本書には、本製品を安全に正しくお使いいただくための重要な情報が記載されています。

本製品をお使いになる前に、本書を熟読してください。特に、本書の「安全上のご注意」をよくお読みにな

り、理解されたうえで本製品をお使いください。

また本書は、本製品の使用中にいつでもご覧になれるよう大切に保管してください。

本製品のハイセイフティ用途での使用について

本製品は、一般事務用、パーソナル用、家庭用、通常の産業用等の一般的用途を想定して設計・製造されて

いるものであり、原子力施設における核反応制御、航空機自動飛行制御、航空交通管制、大量輸送システム

における運行制御、生命維持のための医療器具、兵器システムにおけるミサイル発射制御など、極めて高度

な安全性が要求され、仮に当該安全性が確保されない場合、直接生命・身体に対する重大な危険性を伴う用

途(以下「ハイセイフティ用途」という)に使用されるよう設計・製造されたものではございません。お客

様は、当該ハイセイフティ用途に要する安全性を確保する措置を施すことなく、本製品を使用しないでくだ

さい。ハイセイフティ用途に使用される場合は、弊社の担当営業までご相談ください。

当社のドキュメントには「外国為替および外国貿易管理法」に基づく特定技術が含まれていることがありま

す。特定技術が含まれている場合は、当該ドキュメントを輸出または非居住者に提供するとき、同法に基づ

く許可が必要となります。

2

Page 3

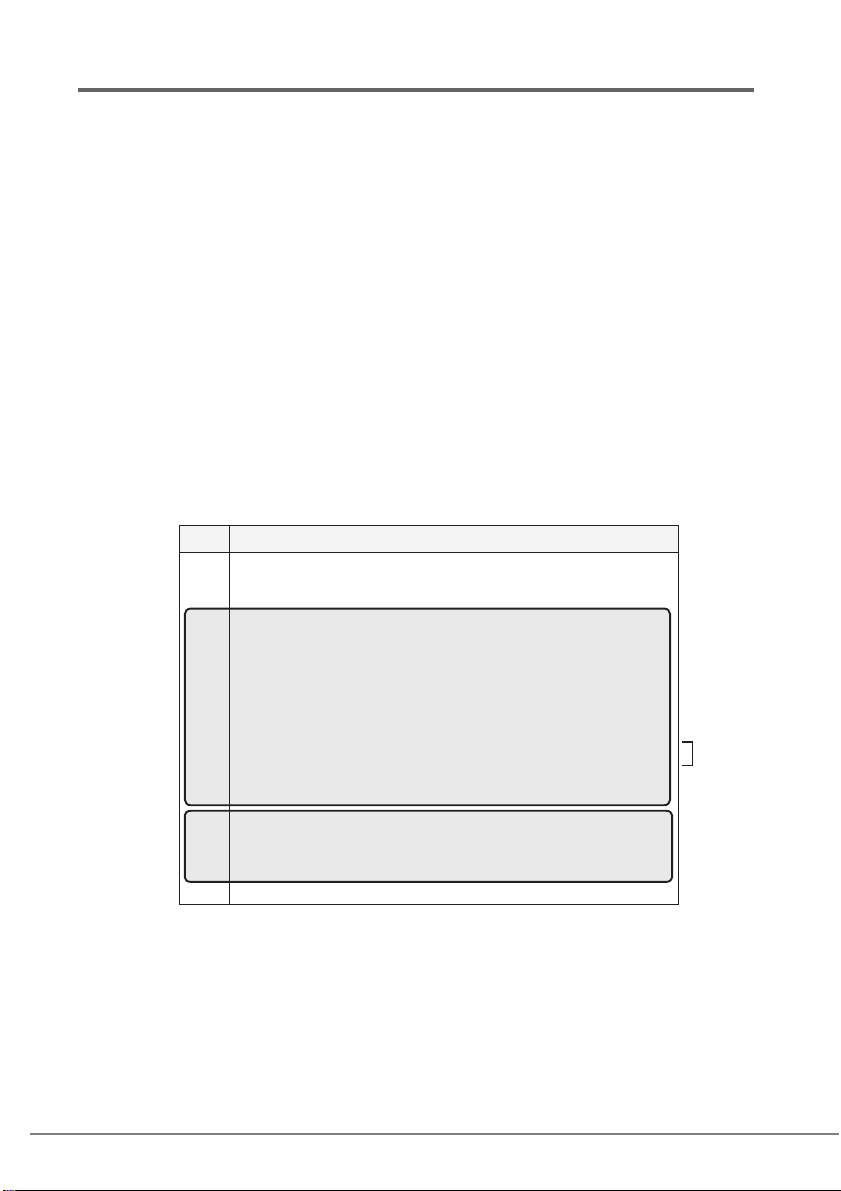

本書の表記

■ 警告表示

本書ではいろいろな絵表示を使っています。これは本製品を安全に正しくお使いいただ

き、あなたや他の人々に加えられるおそれのある危害や損害を未然に防止するための目印

となるものです。その表示と意味は次のようになっています。内容をよくご理解の上、お

読みください。

警告

注意

また、危害や損害の内容がどのようなものかを示すために、上記の絵表示と同時に次の記

号を使用しています。

この表示を無視して、誤った取り扱いをすると、人が死亡する可能性

または重傷を負う可能性があることを示しています。

この表示を無視して、誤った取り扱いをすると、人が損害を負う可能

性があること、および物的損害のみが発生する可能性があることを示

しています。

△で示した記号は、警告・注意を促す内容であることを告げるもので

す。記号の中やその脇には、具体的な警告内容が示されています。

で示した記号は、してはいけない行為(禁止行為)であることを告

げるものです。記号の中やその脇には、具体的な禁止内容が示されて

います。

●で示した記号は、必ず従っていただく内容であることを告げるもの

です。記号の中やその脇には、具体的な指示内容が示されています。

■ 本文中の記号

本文中に記載されている記号には、次のような意味があります。

記号 意味

お使いになる際の注意点や、してはいけないことを記述しています。

必ずお読みください。

ハードウェアやソフトウェアを正しく動作させるために必要なことが

書いてあります。必ずお読みください。

→ 参照ページや参照マニュアルを示しています。

■ ドライブ名の表記について

CD-ROM ドライブのドライブ名を、[CD-ROM ]で表記しています。

例:[CD-ROM]:\Setup.exe

J

3

Page 4

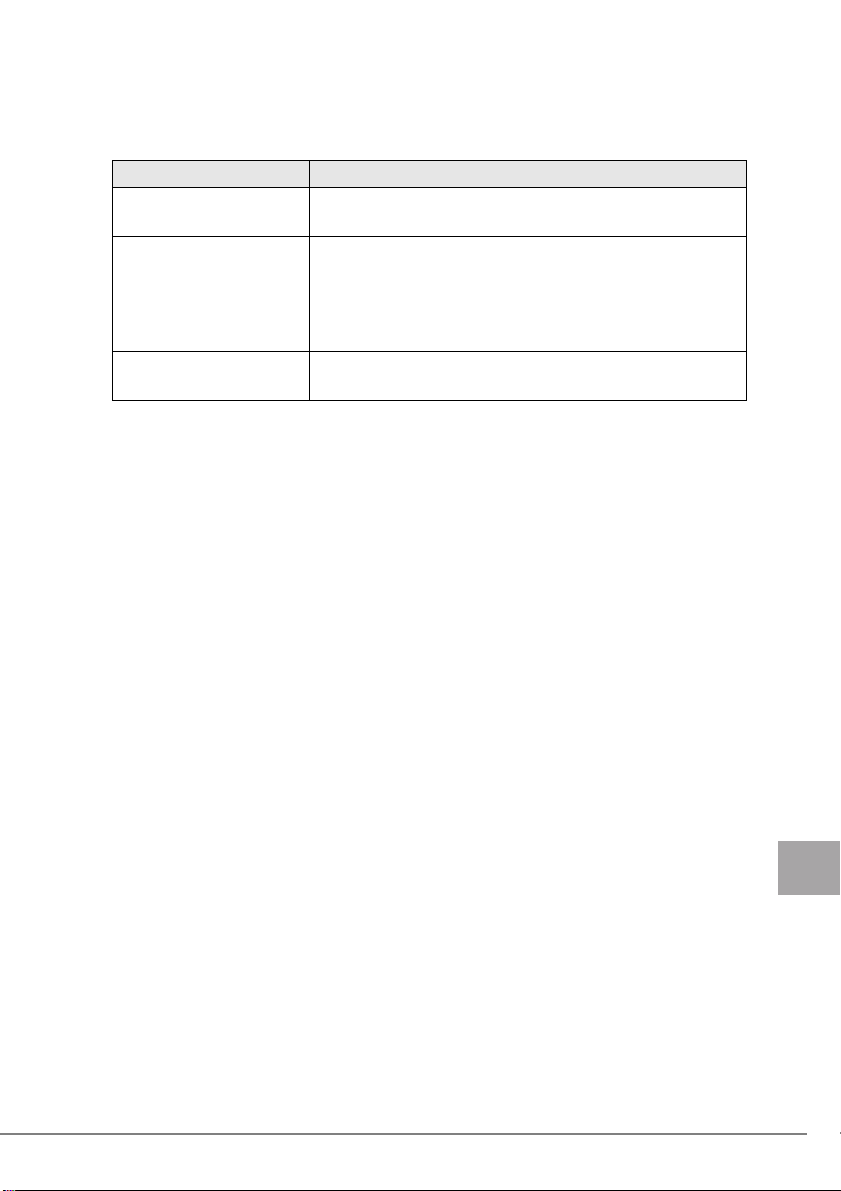

■ 製品の呼び方

本文中の製品名称を次のように略して表記します。

製品名称 本文中の表記

内蔵 LT O 3 ユニット

(PG-LT302/PGBLT302/PGBLT302C)

Microsoft

Microsoft

®

Windows Server® 2003, Standard Edition

®

Windows Server® 2003, Enterprise

Edition

Microsoft

®

Windows Server® 2003 R2, Standard

Edition

Microsoft

®

Windows Server® 2003 R2, Enterprise

Edition

®

Microsoft

Windows Server® 2003, Standard x64

Edition

Microsoft

®

Windows Server® 2003, Enterprise x64

Edition

Microsoft

®

Windows Server® 2003 R2, Standard x64

Edition

®

Microsoft

Windows Server® 2003 R2, Enterprise

x64 Edition

Microsoft

Red Hat

Red Hat

Red Hat

Red Hat

Red Hat

Red Hat

SUSE

®

Windows® 2000 Server Windows 2000 Server

®

Enterprise Linux® ES (v.3 for x86)

®

Enterprise Linux® AS (v.3 for x86)

®

Enterprise Linux® ES (v.4 for x86)

®

Enterprise Linux® AS (v.4 for x86)

®

Enterprise Linux® ES (v.4 for EM64T)

®

Enterprise Linux® AS (v.4 for EM64T)

™

Linux® Enterprise Server 9 for x86 SUSE Linux

BrightStor ARCserve Backup r11.5 for Windows BrightStor ARCserve Backup

NetVault 7 NetVault

Windows 用バックアップユーティリティ

本製品、またはテープ装置

Windows Server 2003

Windows Server 2003 x64

Linux v.3

Linux v.4

Linux v.4 for EM64T

Windows Backup

Windows

Linux

4

Page 5

安全上のご注意

警告

注意

本製品を安全にお使いいただくために、以降の記述内容を必ずお守りください。

■ 本製品の取り扱いについて

・ 梱包に使用しているビニール袋はお子様が口に入れたり、かぶって遊んだりし

ないよう、ご注意ください。窒息の原因となります。

・ 異物(水・金属片・液体など)が本製品の内部に入った場合は、ただちにサー

バ本体の電源スイッチを切り、電源プラグをコンセントから取り外してくださ

い。

その後、修理相談窓口にご連絡ください。

そのまま使用すると、感電・火災の原因となります。特にお子様のいるご家庭

ではご注意ください。

・ 開口部(通風孔など)から内部に金属類や燃えやすいものなどの異物を差し込

んだり、落としたりしないでください。感電・火災の原因となります。

・ 本製品をお客様自身で改造しないでください。感電・火災の原因となります。

・ 本製品を分解したり、解体したりしないでください。

・ 本製品は次の環境で動作させたり、保管したりしないでください。

- 極端な低温環境

- 極端な高温/多湿環境

- 温湿度変化の激しい環境

- 磁気の影響を受けやすい場所

- 衝撃や振動の加わる場所

- ゴミやほこり(煙草の煙、土埃、排気ガスなど)の多い環境

- 直射日光のあたる場所

- 発熱器具のそば

・ 寒い場所から暖かい場所に移動したり、室温を急に上げたりした直後は、内部

が結露する場合がありますので、使用しないでください。

結露したままお使いになると、本製品やデータカートリッジを損傷することが

あります。大きな温度変化があったときは、1 時間以上待ってから電源を入れ

てください。

・ サーバ本体の電源を切るときは、データカートリッジを取り出してください。

データカートリッジを本製品に挿入すると、磁気テープの記録面が露出します。

本状態が長く続くと、記録面へのほこりの付着やキズ発生の可能性があり、

データカートリッジが永久的に使用できなくなることがあります。

J

5

Page 6

注意

・ ご使用しない場合は、本製品からデータカートリッジを取り出してください。

・ データカートリッジを入れたまま本製品を持ち運ばないでください。

・ データカートリッジの挿入時、無理に押し込まないでください。

・ 内部に液体や金属など異物が入った状態で使用しないでください。

何か異物が入った場合は、修理相談窓口にご相談ください。

・ 本製品前面の汚れは、柔らかい布でからぶきするか、布に水または中性洗剤を

含ませて、軽くふいてください。ベンジンやシンナーなど揮発性のものは避け

てください。

■ リサイクルについて

本製品を廃棄する場合、担当営業員に相談してください。本製品は産業廃棄物として処理

する必要があります。

梱包物の確認

お使いになる前に、次のものが梱包されていることをお確かめください。

万一足りないものがございましたら、担当営業員にご連絡ください。

・内蔵 LTO3 ユニット(本製品)

・ 電源延長ケーブル

・ ネジ(4本)

( *1)

( *1)

・ クリーニングカートリッジ

・ ドライバフロッピーディスク「PRIMERGY LTO3 UNIT(PG-LT302) Device Driver for

Windows」

・保証書

( *2)

・ 取扱説明書(本書)

・「テープ装置 媒体の定期交換とクリーニングで安心バックアップ!」(小冊子)

・「内蔵 LTO3 ユニット運用チェックシート(設置・運用確認編)」

*1:カスタムメイドサービス(PGBLT302/PGBLT302C)の場合、サーバ本体に組み込ま

れています。

*2:一般製品(PG-LT302)のみ添付。

( *1)

6

Microsoft、Windows、Windows Server は、米国 Microsoft Corporation の米国およびその他の国におけ

る登録商標または商標です。

本取扱説明書に記載されている会社名、製品名は、各社の登録商標または商標です。

Linux は、Linus Torvalds 氏の米国およびその他の国における登録商標あるいは商標です。Red Hat お

よび Red Hat をベースとしたすべての商標とロゴは、米国およびその他の国における Red Hat, Inc. の

商標または登録商標です。

SUSE は、米国およびその他の国における Novell Inc. の商標です。

その他の各製品は、各社の著作物です。

All Rights Reserved, Copyright

©

FUJITSU LIMITED 2007

Page 7

目次

1 サーバ本体への搭載と導入方法 . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1 設置環境の確認 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 ジャンパの設定について . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 サーバ本体への搭載・接続 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4 デバイスドライバのインストール . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Tape Maintenance Advisor について . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.6 バックアップジョブの設定(自動排出の設定) . . . . . . . . . . . . . . . . . 18

1.7 運用の確認 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.8 デバイスドライバおよびバックアップソフトウェアの設定・注意事項 20

2 各部の名称と働き . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 フロントパネルおよびコネクタ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 データカートリッジの取り付け/取り外し . . . . . . . . . . . . . . . . . . . . 26

3 データカートリッジについて . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1 使用できるデータカートリッジ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2 データカートリッジの取り扱い . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 クリーニングについて . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 使用できるクリーニングカートリッジ . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 ヘッドクリーニングについて . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5 サプライ品 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 バックアップ運用上の注意 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 トラブルシューティング . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 仕様 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

付録 A 運用チェックシート(設置・運用確認編) . . . . . . . . . . . . . . . 40

付録 B Tape Maintenance Advisor について . . . . . . . . . . . . . . . . . 43

B.1 はじめに . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

B.2 Tape Maintenance Advisor 導入のメリット . . . . . . . . . . . . . . . . . . . . 43

B.3 製品概要 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

付録 C Windows 自動システム回復

(Automated System Recovery)について . . . . . . . . . . . . 47

C.1 Windows 自動システム回復ディスクについて . . . . . . . . . . . . . . . . . . 47

C.2 Windows 自動システム回復(ASR)の使用方法 . . . . . . . . . . . . . . . . 49

J

7

Page 8

1

サーバ本体への搭載と導入方法

この章では、本製品のサーバ本体への搭載と導入方法について説明しています。

本製品のサーバ本体への搭載と導入方法は、次の手順で行います。

カスタムメイドサービスの場合、手順 2 ~ 4 は必要ありません。

1 設置環境の確認

→「1.1 設置環境の確認」(P. 9)

2 ジャンパの設定

→「1.2 ジャンパの設定について」(P. 1 0)

3 サーバ本体への搭載・接続

→「1.3 サーバ本体への搭載・接続」(P. 11 )

4 デバイスドライバのインストール

→「1.4 デバイスドライバのインストール」(P. 12 )

5 Tape Maintenance Advisor のインストール

→「1.5 Tape Maintenance Advisor について」(P.1 6 )

6 バックアップジョブの設定(自動排出の設定)

→「1.6 バックアップジョブの設定(自動排出の設定)」(P. 1 8)

7 運用の確認

→「1.7 運用の確認」(P. 19 )

8 デバイスドライバおよびバックアップソフトウェアの設定・注意事項

→「1.8 デバイスドライバおよびバックアップソフトウェアの設定・注意事項」

(P. 20 )

8

Page 9

1.1 設置環境の確認

サーバの設置環境については、サーバ本体に添付の『安全上のご注意』および『はじめに

お読みください』を参照してください。

本製品は、データ記録面が内部で露出するため、設置環境(特に塵埃)の影響を受けやす

くなっています。一般的に、床面に近いほど塵埃濃度は高くなるので、机上など床面より

離れた場所への設置をお勧めします。次の「避けて頂きたい設置例」を参考に、よりほこ

りの少ない環境に設置するよう配慮をお願いいたします。

■ 避けていただきたい設置例

・ 本製品を床に直置き

・ 人通りの多い場所

・ 開放されるドアや窓の近く。特に土埃や車の排気ガス、などの外部の影響を受ける場所

・ 空気の取り込み口、吹き出し口の近く。(空調、エアコン、換気扇、などに注意)

・ タバコの煙の影響を受ける場所(本製品が設置された部屋での喫煙禁止)

・ プリンタの近くでトナーの影響を受ける場所

・ コピー機、シュレッダー、FAX 、など、紙を扱う装置の近くで、紙の粉の影響を受ける

場所

・ 設置後、数か月でデータカートリッジ投入口や周囲に塵埃が堆積するような場所

「 安全上のご注意」(→ P. 5 )も併せて参照してください。

1 サーバ本体への搭載と導入方法 9

J

Page 10

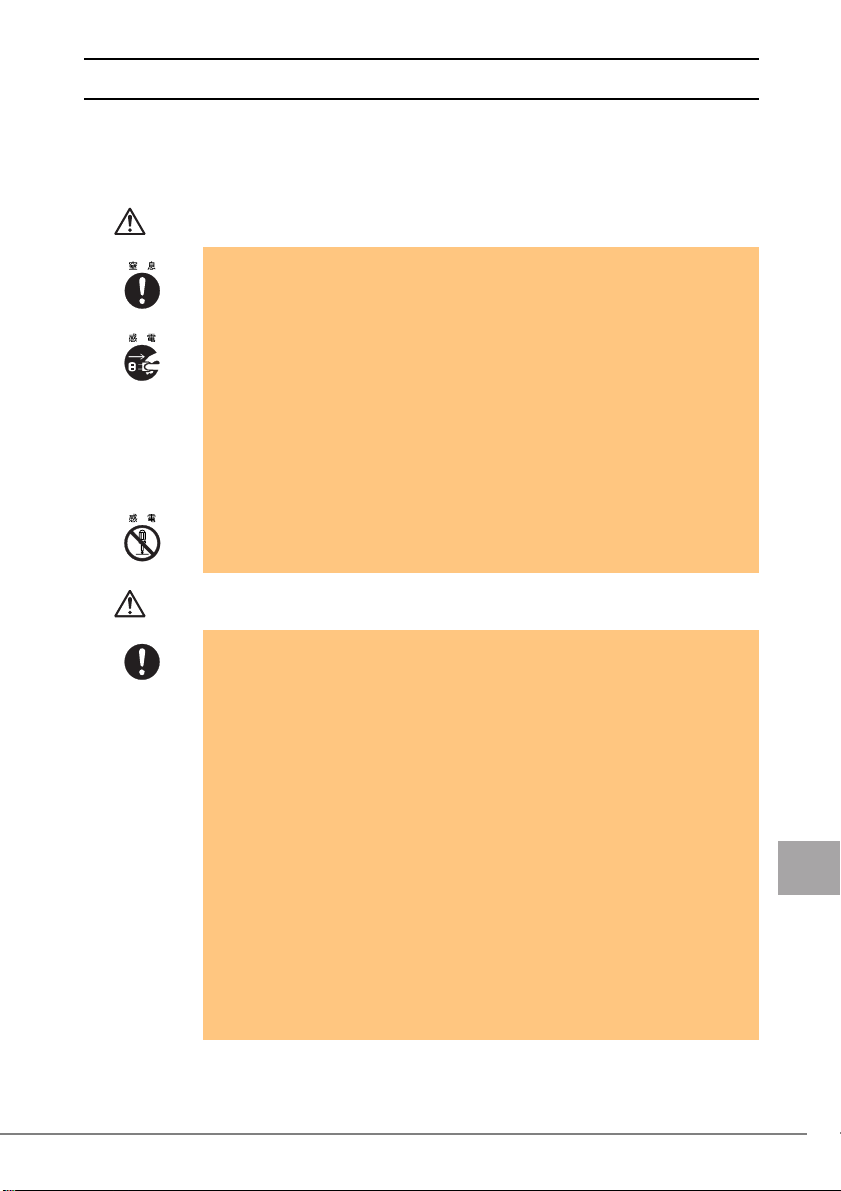

1.2 ジャンパの設定について

サーバ本体に本製品を搭載する場合、SCSI-ID 番号の設定が必要です。

SCSI-ID 番号は、本製品背面(下図)のショートジャンパで設定できます。

サーバ本体に添付の「PRIMERGY ドキュメント&ツール CD」内の『ユーザーズガイド』

の「内蔵オプションの取り付け」の章に従って、SCSI-ID 番号を設定してください。

[本製品背面]

2

0

1

3

変更禁止

*):ご購入時の設定

` SCSI-ID 以外の設定は変更しないでください。

` ジャンパを横向きに取り付けないでください。

次の表のように設定できます。

SCSI-ID 番号

0

1

2

3

4

(*)

5

6

7

8

9

10

11

12

13

14

15

0 1 2 3

オープン オープン オープン オープン

ショート オープン オープン オープン

オープン ショート オープン オープン

ショート ショート オープン オープン

オープン オープン ショート オープン

ショート オープン ショート オープン

オープン ショート ショート オープン

ショート ショート ショート ショート

オープン オープン オープン ショート

ショート オープン オープン ショート

オープン ショート オープン ショート

ショート ショート オープン ショート

オープン オープン ショート ショート

ショート オープン ショート ショート

オープン ショート ショート ショート

ショート ショート ショート ショート

SCSI ID

ショートジャンパ

10

Page 11

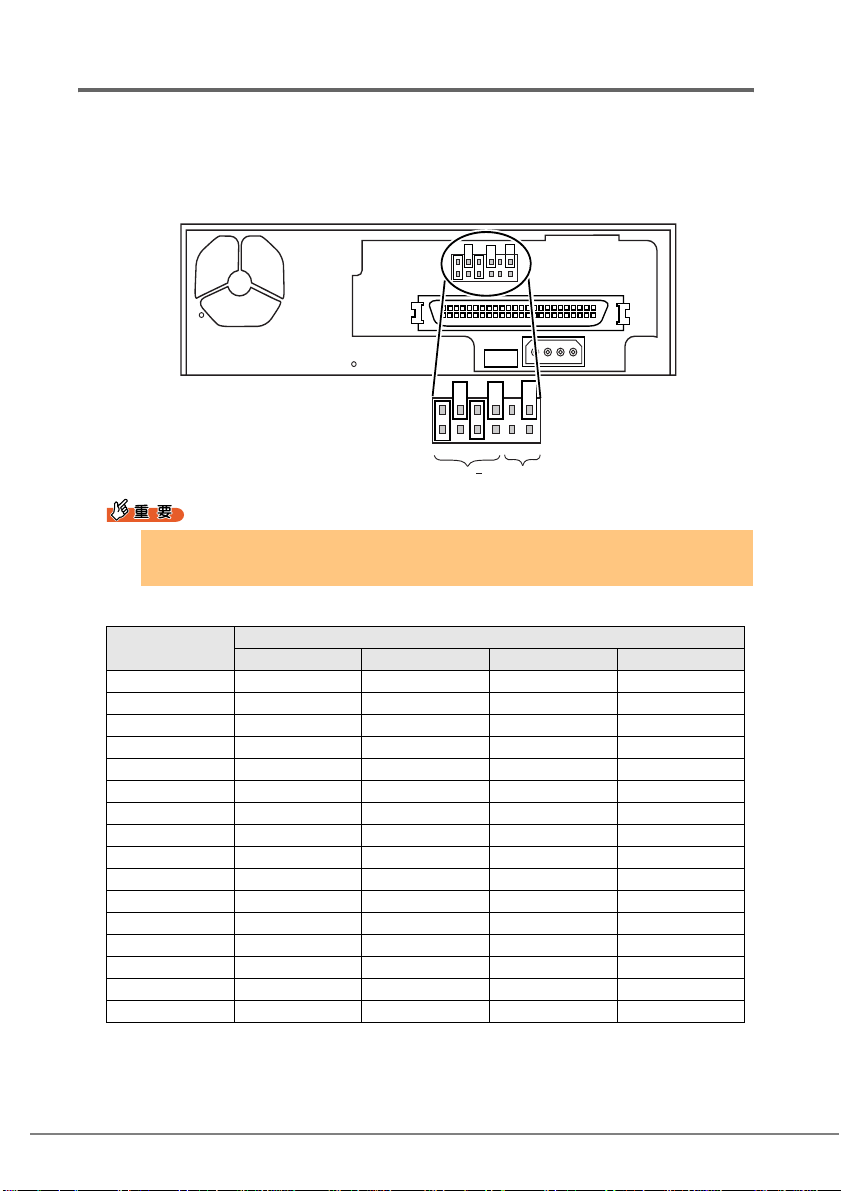

1.3 サーバ本体への搭載・接続

本製品のサーバ本体への搭載方法および接続方法については、サーバ本体に添付の「ド

キュメント&ツール CD」内の『ユーザーズガイド』を参照してください。『ユーザーズガ

イド』に本製品の記載がない場合は、内蔵 LT O2 ユニット(PG-LT201)の記載を参照して

ください。

本製品は LVD SCSI インタフェースに接続してください。また、本製品を接続した SCSI

ケーブル上に他の装置を接続しないでください。

` PRIMERGY TX200 S3、TX200FT S3、RX600 S2、RX600 S3、RX600 S3(SAS モデル)

に本製品を搭載する場合は、本製品に添付の電源延長ケーブルを使用して電源ケーブルに

接続してください。

なお、PRIMERGY TX200 S3 / TX200FT S3 に搭載する場合は 5 インチストレージベイの

一番上のベイに搭載してください。

SCSIࠤࡉ࡞ࠍធ⛯

ࠨࡃߩ㔚Ḯ

ࠤࡉ࡞ߦធ⛯

ᧄຠ㧔⢛㕙㧕

㔚Ḯᑧ㐳ࠤࡉ࡞

㧔ᧄຠߦઃ㧕

本製品を SCSI カード PG-128/PGB128 または PG-1281/PGB1281 に接続する場合は、LV D/

SE 用のコネクタを使用してください。また、本製品を接続した SCSI カードの外付デバイ

ス用コネクタを使用しないでください。

ᧄຠߦធ⛯

↪ߒߥߎߣ

↪ߒߥߎߣ

1 サーバ本体への搭載と導入方法 11

J

Page 12

1.4 デバイスドライバのインストール

Windows で本製品を使用する場合、本製品に添付のドライバフロッピーを使用し、次の手

順でデバイスドライバをインストールしてください。なお、Linux の場合はデバイスドラ

イバをインストールする必要はありません。

1.4.1 デバイスドライバのインストール(PRIMERGY FT モ

デル以外に搭載の場合)

■ Windows Server 2003 / Windows Server 2003 x64 の場合

1

Administrator 権限で Windows にログオンします。

2 「スタート」ボタン→「コントロールパネル」→「システム」の順にク

リックします。

3 「ハードウェア」タブを選択し、[デバイスマネージャ]をクリックしま

す。

4 「その他のデバイス」をダブルクリックし、「QUANTUM ULTRIUM 3

SCSI Sequential Device」をダブルクリックします。

5 「ドライバ」タブを選択し、[ドライバの更新]をクリックします。

「ハードウェアの更新ウィザードの開始」というメッセージが表示されます。

6 「ソフトウェア検索のため、Windows Update に接続しますか?」と表

示されるので、「いいえ、今回は接続しません」をクリックし、[次へ]を

クリックします。

12

7 「一覧または特定の場所からインストールする」をクリックし、[次へ]を

クリックします。

8 「次の場所で最適のドライバを検索する」をクリックします。

9 「次の場所を含める」にチェックを入れ、[参照]ボタンを押してコピー元

にデバイスドライバを復元したフォルダを指定します。

・ 添付のドライバフロッピーを使用する場合(またはダウンロードしたデバイスド

ライバをフロッピーに復元した場合)

A:\LTO3HH

・ ServerStart などの CD を使用する場合

[CD-ROM]:\DRIVERS\tape\LTO3HH

10 [次へ]をクリックします。

「ハードウェアの更新ウィザードの完了」とメッセージが表示されます。

11 [完了]をクリックし、[閉じる]をクリックします。

「テープドライブ」に「Quantum LTO 3 Tape Drive」と表示されます。

12 サーバを再起動します。

Page 13

■ Windows 2000 Server の場合

1

Administrator 権限で Windows 2000 Server にログオンします。

2 「スタート」ボタン→「設定」→「コントロールパネル」の順にクリック

します。

3 「システム」のアイコンをダブルクリックします。

4 「ハードウェア」タブを選択し、[デバイスマネージャ]をクリックしま

す。

5 「その他のデバイス」をダブルクリックし、「QUANTUM ULTRIUM 3

SCSI Sequential Device」をダブルクリックします。

6 「ドライバ」タブを選択し、[ドライバの更新]をクリックします。

「デバイスドライバのアップグレードウィザードの開始」とメッセージが表示され

ます。

7 [次へ]をクリックします。

8 「デバイスに最適なドライバを検索する」を選択し、[次へ]をクリックし

ます。

9 「場所を指定」を選択し、[次へ]をクリックし、コピー元を次のように設

定し、[OK]をクリックします。

・ 添付のドライバフロッピーを使用する場合(またはダウンロードしたデバイスド

ライバをフロッピーに復元した場合)

A:\LTO3HH

・ ServerStart などの CD を使用する場合

[CD-ROM]:\DRIVERS\tape\LTO3HH

「次のデバイスのドライバが検索されました」とメッセージが表示されます。

10 [次へ]をクリックします。

「デバイスドライバのアップグレードウィザードの完了」とメッセージが表示され

ます。

11 [完了]をクリックし、[閉じる]をクリックします。

「テープドライブ」に「Quantum LTO 3 Tape Drive」と表示されます。

12 サーバを再起動します。

1 サーバ本体への搭載と導入方法 13

J

Page 14

1.4.2 デバイスドライバのインストール(PRIMERGY FT モ

デルに搭載の場合)

■ 注意事項

・ 本製品は、FT1 にのみ搭載可能です。FT2 には搭載できません。

・ 本製品を同時に 2 つ搭載できません。

・本製品は FTvirtual Server(業務用 OS)からのみ使用可能です。CoServer(入出力 OS)

からは本製品を使用できません。

・ FT モデルでは、自動システム回復(ASR)セット、システム復旧ディスクを使用した

システムの復旧はできません。復旧には、サーバに添付のリカバリ CD を使用してくだ

さい。

・内蔵 5 インチオプションの取り付けについては、必ず FT モデルの『ユーザーズガイド』

を参照して作業をしてください。

■ Windows Server 2003 の場合

1

本製品を FT1 に搭載します。

2 FT1、FT2 の電源を入れ、CoServer を Online モードで起動します。

3 Administrator 権限で CoServer1 にログオンします。

サーバ本体が TX200FT S3 の場合、次の手順で一 度再起動してください。

1. 「スタート」ボタン→「すべてのプログラム」→「Marathon Endurance」→

「Management Tasks」→「Endurance Configuration」→「Restart」の順にク

リックします。

確認のメッセージが表示されます。

2. [OK]をクリックします。

再起動後は、手順 2 から行ってください。

再起動後は、上記手順を行う必要はありません。

14

4 「スタート」ボタン→「コントロールパネル」→「システム」の順にク

リックします。

5 「ハードウェア」タブを選択し、[デバイスマネージャ]をクリックしま

す。

デバイスマネージャが起動します。

6 「その他のデバイス」をダブルクリックし、「QUANTUM ULTRIUM 3

SCSI Sequential Device」をダブルクリックします。

7 「ドライバ」タブを選択し、[ドライバの更新]をクリックします。

セットアップウィザードが表示されます。

8 「ソフトウェア検索のため、Windows Update に接続しますか?」と表

示されるので、「いいえ、今回は接続しません」をクリックし、[次へ]を

クリックします。

ウィザードに従ってインストールを行ってください。

Page 15

9 インストール方法で「一覧または特定の場所からインストールする」をク

リックし、[次へ]をクリックします。

10 検索とインストールのオプションで、「次の場所で最適のドライバを検索

する」を選択して、次のオプションを設定します。

・「リムーバブルメディア(フロッピー、CD-ROM など)を検索」のチェックを外

します。

・「次の場所を含める」にチェックを入れ、デバイスドライバを復元したフォルダ

を指定します。

・ A ドライブのフロッピーに復元した場合

A:\LTO3HH

・ C ドライブの Te mp フォルダに復元した場合

C:\Temp\LTO3HH

11 [次へ]をクリックします。

「ハードウェアの更新ウィザードの完了」とメッセージが表示されます。

12 [完了]をクリックして、終了します。

「テープドライブ」配下に「Quantum LTO 3 Tape Drive」と表示されます。

13 FT モデルの『ユーザーズガイド』の「内蔵バックアップ装置取り付け後

の操作」の章に従い、FTvirtual Server へのリダイレクト作業を実施し

ます。

FTvirtual Server へのリダイレクト作業が完了すると、FTvirtual Server 上の「デバイ

スマネージャ」にその他のデバイスとして「QUANTUM ULTRIUM 3 SCSI

Sequential Device」が表示されます。

14 FTvirtual Server で手順 4 ~ 12 を繰り返してドライバをインストール

後、FTvirtual Server を再起動します。

1 サーバ本体への搭載と導入方法 15

J

Page 16

1.5 Tape Maintenance Advisor について

サーバ本体に「Tape Maintenance Advisor」をインストールすることにより、3 か月ごとの

磁気ヘッドのクリーニングの時期を通知することができます。定期的な磁気ヘッドのク

リーニングを行うために、「Tape Maintenance Advisor」を使用されることをお勧めします。

「Tape Maintenance Advisor」については、「付録 B Tape Maintenance Advisor について」(→

P. 43 )を参照してください。

1.5.1 インストールモジュールの準備

「Tape Maintenance Advisor」は、Windows 用と Linux 用でモジュールが異なります。使用す

る OS に応じたインストールモジュールを準備してください。

■ Windows Server 2003 / Windows Server 2003 x64 / Windows 2000

Server の場合

・ Tape Maintenance Advisor for Windows

サーバ本体に添付の ServerStart CD-ROM に格納されています。

- モジュール

[CD-ROM]:\PROGRAMS\Japanese\TmAdvisor

- 操作説明書(Fujitsu Tape Maintenance Advisor for Windows 操作説明書)

[CD-ROM]:\PROGRAMS\Japanese\TmAdvisor\TMAdoc

` 「Tape Maintenance Advisor」は、弊社のインターネット情報ページ

(http://primeserver.fujitsu.com/primergy/)内に最新版が登録されています。『ダウンロー

ド』→『ダウンロード検索』で、サーバの製品名および型名を選択し、カテゴリに「添付

ソフト」を指定して検索してください。

■ Linux v.3 / Linux v.4 / Linux v.4 for EM64T の場合

・ Tape Maintenance Advisor for Linux

「Tape Maintenance Advisor for Linux」は、弊社のインターネット情報ページ

(http://primeserver.fujitsu.com/primergy/)内の『ダウンロード』→『ダウンロード検索』

で、サーバの製品名および型名を選択し、カテゴリに「添付ソフト」を指定して検索

し、ダウンロードしてください。(例:Fujitsu Tape Maintenance Advisor for Linux V3.0)

本ソフトウェアをダウンロードしたときは、 tar.gz 形式になっています。次のコマンド

を実行すると復元できますので、あらかじめ適当なフォルダに復元してください(復

元作業は Linux で行ってください。Windows での復元は避けてください)。

tar xvfz ファイル名.tar.gz

復元すると次のようなフォルダ構成になっています。モジュールは、使用する Linux

のバージョンによって異なります。

- モジュール

・ Linux v.3 の場合

TmAdvisor/forv3/TmAdvisor/TMA

16

Page 17

・ Linux v.4 / Linux v.4 for EM64T の場合

TmAdvisor/forv4/TmAdvisor/TMA

- 操作説明書(Fujitsu Tape Maintenance Advisor for Linux 操作説明書)

TmAdvisor/TMAdoc

1.5.2 インストール方法

インストール方法は、各操作説明書を参照して行ってください。ここでは、インストール

する実行ファイルについて説明します。

■ Tape Maintenance Advisor for Windows

Administrator 権限で、サーバ本体に添付の ServerStart CD-ROM に格納されている次のファ

イルを実行してください。

[CD-ROM]:\PROGRAMS\Japanese\TmAdvisor\Setup.exe

ダウンロードした場合は、readme.txt の内容に従ってインストールしてください。

■ Tape Maintenance Advisor for Linux

使用する Linux のバージョンに応じて、管理者権限で、次のファイルを実行してください。

・ Linux v.3 の場合

TmAdvisor/forv3/TmAdvisor/TMA/Installer.bat

・Linux v.4

/ Linux v.4 for EM64T の場合

TmAdvisor/forv4/TmAdvisor/TMA/Installer.bat

1.5.3 設定方法

クリーニング時期や通知方法の設定を行います。設定方法の詳細は、各操作説明書を参照

して設定ください。

` 初期設定では、ポップアップメッセージを毎週月曜日の午前 9 時に表示し、イベントログ

通知を行うようになっています。

1.5.4 使用方法(概要)

・ 一般オペレータ(または管理者)は、メッセージを受け取ったら、テープ装置のクリー

ニング作業を行い、「Tape Maintenance Advisor」に作業を行った旨を伝えます。

・ 管理者は、イベントログなどを監視し、クリーニング作業を忘れていないかチェックし

てください。

使用方法の詳細は、各操作説明書を参照してください。

1 サーバ本体への搭載と導入方法 17

J

Page 18

1.6 バックアップジョブの設定(自動排出の設定)

バックアップを自動で行う場合は、次の手順に従ってバックアップ後にデータカートリッ

ジを自動的に排出するように設定してください(手動でバックアップを行う場合もバック

アップ後は、必ずデータカートリッジを取り出してください)。

■ BrightStor ARCserve Backup の場合

1

バックアップジョブのオプションのバックアップマネージャで[オプショ

ン]ボタンをクリックします。

2 「操作」タブの[バックアップ終了後のメディアのイジェクト]を「メ

ディアをイジェクトする」に設定します。

■ Windows Backup の場合

バッチファイルなどで、バックアップのコマンドの後に次のコマンドを実行する記述を

追加します。

例:rsm refresh /lf"Quantum LTO 3 Tape Drive"

rsm eject /lf"Quantum LTO 3 Tape Drive"/astart

*1:指定する名前は、「コンピュータの管理」の「記憶域→リムーバブル記憶域」の

「ライブラリ」(Windows Server 2003 / Windows Server 2003 x64 の場合)または

「物理的な場所」(Windows 2000 Server の場合)で確認してください。

[バッチファイルの例](Windows Server 2003 の場合)

ⴕ⇟ภ

@echo off

1:

cls

2:

setlocal

3:

rsm inventory /lf"Quantum LTO 3 Tape Drive" /aFULL

4:

timeout /t 60

5:

rsm refresh /lf"Quantum LTO 3 Tape Drive"

6:

timeout /t 60

7:

for /f "Tokens=1-4 Delims=/ " %%i in ('date /t') do set dt=%%i-%%j-%%k-%%l

8:

for /f "Tokens=1" %%i in ('time /t') do set tm=-%%i

9:

set tm=%tm::=-%

10:

set dtt=%dt%%tm%

11:

ntbackup backup @c:\test\test.bks /n "%computername%-%dtt%" /d "daily

12:

%dtt%" /j "daily %dtt%" /p "LTO Ultrium" V:no /R:no /L:f /M normal /RS:NO

/HC:ON /UM

timeout /t 60

13:

rsm refresh /lf"Quantum LTO 3 Tape Drive"

14:

timeout /t 60

15:

rsm eject /lf"Quantum LTO 3 Tape Drive"

16:

timeout /t 60

17:

endlocal

18:

䊋䉾䉼䊐䉜䉟䊦䈱ౝኈ

* 2:\test\test.bks は、Windows Backup を起動し、「バックアップ」タブでバック

アップする対象にチェックを入れ、「ジョブ」メニューから「選択したジョブの

保存」を選んで作成してください。

Windows Backup のバッチファイルでの使用例は、マイクロソフト技術情報 239892

(http://support.microsoft.com/default.aspx?scid=kb;ja;239892)などを参照してください。

ntbackup, rsm コマンドの使用法は、Windows のヘルプを参照してください(「スタート」

ボタン→「ヘルプとサポート」の順にクリックし、「ntbackup」または「rsm」を検索し

てください)。

(*1)

䊋䉾䉪䉝䉾䊒

䋨㪁㪉䋩

䊂䊷䉺

䉦䊷䊃䊥䉾䉳

䈱ឃ

18

Page 19

■ Linux のコマンドで使用する場合

シェルスクリプトなどで、バックアップコマンドの後に次のコマンドを実行する記述を

追加してください(/dev/st0 は、環境に合わせて変更してください)。

mt -f /dev/st0 eject

■ NetVault の場合

NetVault のデバイス管理で、デバイス名を確認します。

ここでは、本製品を「NetVaultSV:_1-0.3.0_(QUANTUM_ULTRIUM_3)」として説明しま

す。

確認したデバイス名を使用し、NetVault をインストールしたディレクトリ(/usr/

netvault)の scripts/users ディレクトリに、次の内容のシェルスクリプト(ここでは、

tapeeject.sh とします)を作成します(/usr/netvault/scripts/users/tapeeject.sh を作成しま

す)。

[tapeeject.sh の例]

/usr/netvault/util/nvdeviceeject -servername NetVaultSV

-devicename "NetVaultSV:_1-0.3.0_(QUANTUM_ULTRIUM_3)"

-servername:対象となるサーバ本体の名前を指定します(例 :NetVaultSV)

-devicename:対象となるドライブ(本製品)の名前を指定します

(例 : NetVaultSV:_1-0.3.0_(QUANTUM_ULTRIUM_3))

バックアップ実行時に、NetVault のバックアップウィンドウで、詳細設定(Advanced

Option)タブのポスト・スクリプト(Use Post Script)にチェックを入れ、「users/

tapeeject.sh」を指定してください。

1.7 運用の確認

日々のバックアップ運用上の注意事項を、「付録 A 運用チェックシート (設置・運用確認

編)」(→ P. 4 0)にまとめてあります。チェックシートを使用して、運用の確認を行ってく

ださい。また、テープ装置全般の注意事項について、本製品に添付の小冊子「テープ装

置、媒体の定期交換とクリーニングで安心バックアップ!」

併せてご確認ください。

*: インターネット情報ページ(http://primeserver.fujitsu.com/primergy/)内の「技術情報」

のシステム構築の手引きに最新版を掲載しています。

(*)

にまとめてありますので、

1 サーバ本体への搭載と導入方法 19

J

Page 20

1.8 デバイスドライバおよびバックアップソフト

ウェアの設定・注意事項

本章の情報は、2007 年 2 月現在のものです。内容が変わることがありますがご了承くださ

い。

■ Windows 用デバイスドライバについて

本製品の Windows 用のデバイスドライバの最新版は、インターネット情報ページ

(http://primeserver.fujitsu.com/primergy/)内の『ダウンロード』→『ダウンロード検索』で

サーバの製品名および型名を選択し、カテゴリに「バックアップ装置」を指定して検索

し、ダウンロードしてください。デバイスドライバは、最新版をご使用されることをお勧

めします。

■ バックアップソフトウェアについて

本製品は、次のバックアップソフトウェアで使用できます。

OS

Windows Server 2003

Windows Server 2003 x64

Windows 2000 Server

(SP4 以降)

Linux AS v.3

Linux AS v.4

Linux AS v.4 for EM64T

*:BrightStor ARCserve Backup および NetVault については、次の弊社ソフトウェアガ

イドをご参照ください。

・ BrightStor ARCserve Backup

Windows ソフトウェアガイド(http://software.fujitsu.com/jp/guide/windows/)で

「ARCserve」を検索してください

・ NetVault

Linux ソフトウェアガイド(http://software.fujitsu.com/jp/guide/linux/)で

「NetVault」を検索してください

BrightStor ARCserve Backup r11.5 + SP2(QO81201)

(*)

以降

BrightStor ARCserve Backup r11.5 + SP2(QO81201)

(*)

以降

NetVault7 7.4.2

NetVault7 7.4.2

NetVault7 for EM64T 7.4.2

バックアップソフトウェア

、Windows Backup

(*)

(*)

(*)

■ BrightStor ARCserve Backup の設定について

・ BrightStor ARCserve Backup を使用する場合は、デバイスドライバのインストール後に

BrightStor ARCserve Backup の「デバイス環境設定」で「デバイスの有効/無効(RSM

対応)」オプションを選択し、リムーバブル記憶域の管理を無効(チェックを付ける)

にしてください。

・ バックアップジョブの設定時に、本製品が割り当てられているデバイスグループ名を控

えておいてください。修理などで本製品を交換したあとの再設定時に必要です。

・ BrightStor ARCserve Backup をアンインストールする際は、事前に「デバイス環境設定」

-「デバイスの有効/無効(RSM 対応)」オプションを選択し、リムーバブル記憶域の

管理を有効(チェックを外す)にしてください。

20

Page 21

■ 修理などで本製品を交換したあとの BrightStor ARCserve Backup の

再設定について

BrightStor ARCserve Backup は、修理などで本製品が交換された場合、デバイスグループが

新規に作成される場合があります。本製品の交換後は、次の項目を確認してください。

確認項目 確認内容

デバイスの有効/無効

(RSM 対応)

デバイスグループ

Disaster Recovery Option

を使用している場合

リムーバブル記憶域の管理が無効(チェックが付いてい

る)か確認してください。

交換前のデバイスグループ名(ジョブの設定時のデバイス

グループ名)と同じデバイスグループ名に設定してくださ

い。

交換前のデバイスグループ名が分からない場合は、ジョブ

の再設定を行ってください。

交換後、復旧用フロッピーディスクを再作成してくださ

い。

■ ASR(Automated System Recovery)に関する注意事項

Windows Server 2003 / Windows Server 2003 x64 には、Windows 自動システム回復機能

(Automated System Recovery、以下 ASR)があります。

この機能には、次の注意事項があります。

・ ASR ディスクへのデバイスドライバの追加について

本製品を ASR で使用する場合、ASR ディスクに本製品のデバイスドライバを追加する

必要があります。作成方法については、「付録 C Windows 自動システム回復(Automated

System Recovery)について」(→ P. 4 7)を参照してください。

■ Windows 自動システム回復(ASR)使用時および

BrightStorARCserve Backup の Disaster Recovery Option 使用時

に、フロッピーディスクドライブ(USB)を使用する場合について

・ サーバ起動時のフロッピーディスクドライブ認識に関する注意事項

サーバ起動時にフロッピーディスクが挿入されたフロッピーディスクドライブ(USB)

が接続されていない場合は、BIOS がフロッピーディスクドライブ(USB)を認識でき

ません。Windows / Linux などのオペレーティングシステムインストール時、Windows の

自動システム回復(ASR)使用時および BrightStor ARCserve Backup の Disaster Recovery

Option 使用時は、必ずフロッピーディスクが挿入されたフロッピーディスクドライブ

(USB)を接続してからサーバを起動してください。

・ フロッピーディスク媒体交換認識に関する注意事項

次のソフトウェアにより、Windows のバックアップデータを使ってシステムリカバリを

使用する際、および Windows の手動インストールの際に、フロッピーディスクの媒体

交換を認識できないため、デバイスドライバなどを正しく読み込めず、システムリカバ

リ/インストールが正常に行えないことがあります。

- BrightStor ARCserve Backup r11.x for Windows Disaster Recovery Option. Japanese

- Windows Server 2003 自動システム回復機能

画面の手順に従い【Enter】キーを押してもフロッピーディスクドライブ(USB)のフ

ロッピーディスクアクセスランプが点灯せず、フロッピーディスクにアクセスできない

場合は、次の操作を行ってください。

J

1 サーバ本体への搭載と導入方法 21

Page 22

1. フロッピーディスクを取り出し、2 秒以上待ってから【Enter】キーを数回押しま

す。

2. フロッピーディスクを取り出し、2 秒以上待ってから【Enter】キーを押します。

フロッピーディスクにアクセスできない場合は、再度上記手順を行ってください。

22

Page 23

2

各部の名称と働き

この章では、本製品の各部の名称と働きについて説明しています。

2.1 フロントパネルおよびコネクタ

2.1.1 本製品前面

POWER

ACTIVITY

ERROR

CLEAN

EJECT

LED

䊐䊨䊮䊃䊄䉝

䉟䉳䉢䉪䊃䊗䉺䊮

■ イジェクトボタン

本製品に入っているデータカートリッジを取り出すときに押します。

→「2.2 データカートリッジの取り付け/取り外し」(P. 2 6 )

本製品が動作中の場合(ACTIVITY LED が点滅し、ロード/アンロードやデータの書き込

み/読み込みを行っている場合)、イジェクトボタンを押さないでください。動作が終わ

るまで待ってからイジェクトボタンを押してください。

■ フロントドア

データカートリッジを挿入するときは、フロントドアを上に引き上げてください。

→「2.2 データカートリッジの取り付け/取り外し」(P. 2 6 )

■ LED

本製品には、次の 4 つの LED があり、電源投入時の自己診断、使用中の状態やエラーな

どを示します。

・ POWER LED(緑色)

・ ACTIVITY LED(緑色)

・ ERROR LED (赤色)

・ CLEAN LED(橙色)

各 LED の状態の主な意味は次のとおりです。詳しくは、「7 トラブルシューティング」の

「■ LED の表示によるトラブルシューティング」(→ P. 3 5 )の表を参照してください。

点滅は 1 秒に 1 回、高速点滅は 1 秒に 4 回点滅します。

J

2 各部の名称と働き 23

Page 24

以下の表での記号は、次の状態を意味します。

●:消灯、○:点灯、◎:点滅(1 秒に 1 回)、☆:高速点滅(1 秒に 4 回)

・ POWER LED の表示について

POWER LED の表示 状態

● POWER : 消灯 本製品に電源が入っていません。

○ POWER : 点灯 本製品に電源が入っています。

・ ACTIVITY LED/ERROR LED/CLEAN LED の表示について

LED の表示 状態

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

:点灯

:消灯

:消灯

:消灯

:点灯

:点滅

:点滅または消灯

:点滅

:点灯

:点滅

:消灯

:消灯

:点灯

:消灯

:消灯

:点灯

本製品に電源が入っており使用可能な状態です。

電源投入時の自己診断テストおよび初期化動作を実行していま

す。

本製品が動作中です(データカートリッジのロード・アンロー

ド、巻き戻し、データの書き込み、データの読み出しなどを

行っています)。

クリーニングが必要です。

CLEAN LED が点灯するのは次の場合です。

・ 本製品自身がクリーニングを必要と判断した場合

・ データカートリッジの動作時間が 100 時間を越えた場

合。

クリーニングカートリッジを使用してクリーニングを行ってく

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

:点灯

:点灯

:消灯

:点灯

:点灯

:点灯

:消灯

:高速点滅

:点灯

:消灯

:高速点滅

:高速点滅

:点灯

:消灯

:高速点滅

:消灯

ださい。→「4 クリーニングについて」(P.3 1 )

クリーニング動作中です。

クリーニングカートリッジが寿命(50 回以上使用)です。新し

いクリーニングカートリッジを使用してください。

→「4 クリーニングについて」(P.31)

クリーニングに失敗した、またはデータカートリッジでメディ

アエラーが発生しました。データカートリッジが挿入されてい

ない場合は、前回使用したデータカートリッジでメディアエ

ラーが発生しています。→「7 トラブルシューティング」(P.35)

回復不可能なエラーが発生しました。

→「7 トラブルシューティング」(P. 35 )

24

Page 25

` CLEAN LED が点灯すると、正しくクリーニングが完了するまで消灯しません(電源をオ

ン/オフしても消灯しません)。CLEAN LED が点灯した場合は、クリーニングカート

リッジを使用してクリーニングを行ってください。

2.1.2 本装置背面

ࠫࡖࡦࡄ

SCSIࠦࡀࠢ࠲

㔚Ḯࠦࡀࠢ࠲

■ ジャンパ

SCSI-ID 番号を設定します。

→「1.2 ジャンパの設定について」(P. 1 0)

■ SCSI コネクタ

本製品用の SCSI ケーブルを接続してください。

→「1.3 サーバ本体への搭載・接続」(P. 11 )

■ 電源コネクタ

サーバ本体の内蔵オプション用の電源ケーブルを接続してください。

→「1.3 サーバ本体への搭載・接続」(P. 11 )

J

2 各部の名称と働き 25

Page 26

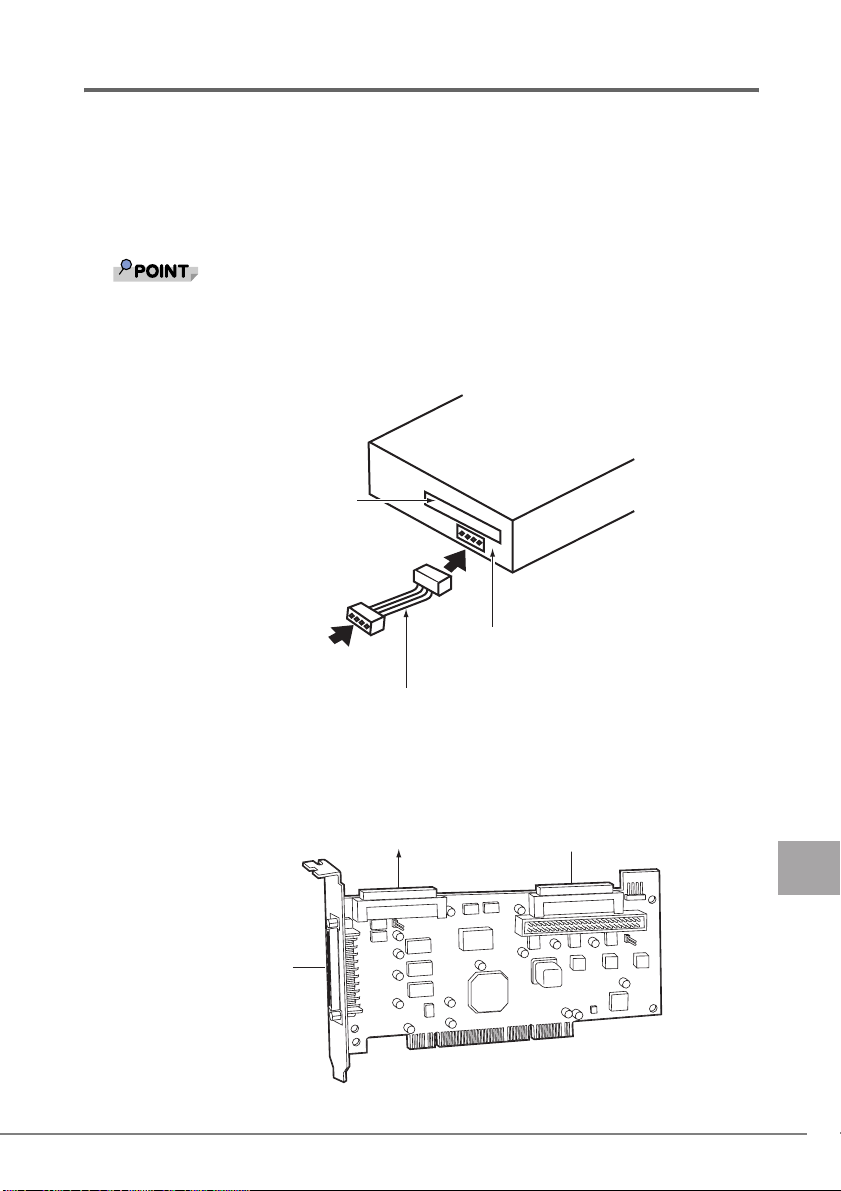

2.2 データカートリッジの取り付け/取り外し

面

データカートリッジは、「3 データカートリッジについて」(→ P. 2 8)を参照して正しく取

り扱ってください。

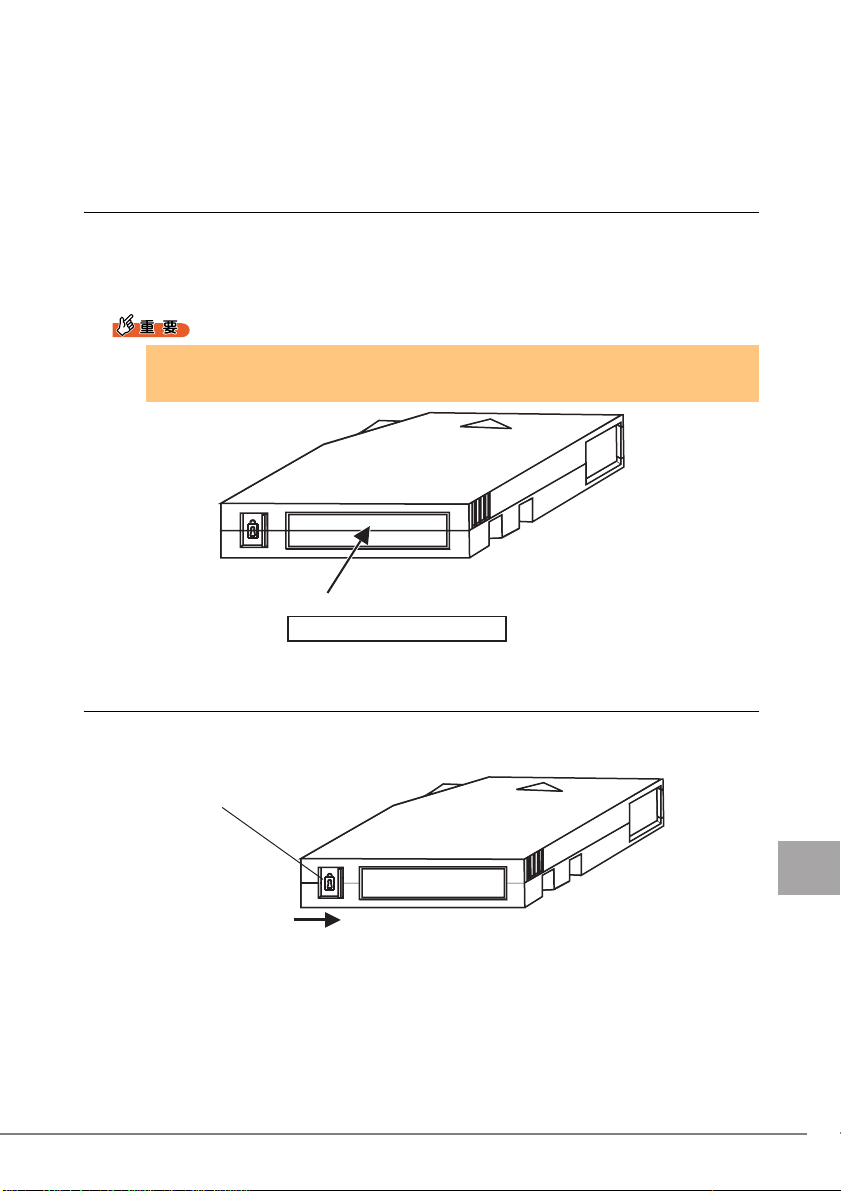

■ セット方法

データカートリッジは矢印が付いている面を上に向け、ラベル貼り付け面が手前になるよ

うにし、本製品のフロントドアを上に押し上げ、ゆっくりと挿入してください。止まるま

で挿入すると、自動的にロードが開始されます。

` 本製品およびデータカートリッジの損傷を避けるため、次のことに注意してくださ

い。

・力を加えすぎないでください。

・データカートリッジを正しい方向、正しい位置にまっすぐ挿入してください。

[本製品]

挿入方向を示す矢印

ラベル貼り付け

[データカートリッジ]

26

` データカートリッジをセットした直後にバックアップまたはリストアなどの操作を行う場

合、データカートリッジのロードが完了してから(ACTIVITY LED の点滅が終わり消灯し

てから)行ってください。

Page 27

■ 取り出し方法

ACTIVITY LED が消灯していることを確認し、イジェクトボタンを押します。

取り出したデータカートリッジは、ケースに入れて保管してください。

` データカートリッジが出てくるときに指で押さえたり、押し込んだりしないでくだ

さい。またデータカートリッジが完全にイジェクトされる前にデータカートリッジ

を引き抜いたりしないでください。本製品が故障する原因となります。

` 取り出しは、本製品がデータカートリッジを動かしていないとき(ACTIVITY LED が消え

ている状態)に行ってください。

` バックアップソフトウェアによっては、イジェクトボタンによるデータカートリッジの取

り出しをできないようにしていることがあります(NetVault など)。この場合、イジェク

トボタンを押してもデータカートリッジが排出されません。バックアップソフトウェアか

らの操作でデータカートリッジを取り出してください。

` 本製品の電源が入っていない状態で、データカートリッジのセット/取り出しはできませ

ん。

2 各部の名称と働き 27

J

Page 28

3

データカートリッジについて

この章では、本製品で使用できるデータカートリッジについて説明しています。

3.1 使用できるデータカートリッジ

本製品には、次の富士通純正品を使用されることをお勧めします。サプライ品について

は、「5 サプライ品」(→ P. 3 3 )を参照してください。

品名 商品番号 記憶容量

Ultrium2 データカートリッジ

Ultrium3 データカートリッジ

*:データ圧縮機能を使わない場合の値。記憶容量は、1GB=1000 × 1000 × 1000byte 換算です(な

お、本製品では Ultrium1 データカートリッジは読み込みのみ可能です)。

データカートリッジの消耗によるバックアップ失敗を防止するため、次のどちらか早い方

を目安にデータカートリッジを交換してください。

データカートリッジの交換周期(どちらか早いほう)

・ 使用期間で1年

・ 使用回数で 1000 回

データカートリッジの寿命は、本製品の設置環境(温度、湿度、塵埃など)や動作状況に

より大きく変化します。

` データカートリッジは消耗品です。消耗したデータカートリッジは、磁気テープ表

面の損傷、磁気ヘッド汚れの増加、メディアエラー多発など不具合の原因となりま

す。

0160310 200GB

0160320 400GB

(*)

出荷単位

5 巻

5 巻

3.2 データカートリッジの取り扱い

本製品で使用するデータカートリッジの取り扱い方法および注意事項について説明しま

す。

データカートリッジを取り扱うときは、次の事項をお守りください。

・ データカートリッジは、清潔に保ってください。

・ データカートリッジは、使用前に以下の確認を行ってください。

- データカートリッジの割れや破損のないこと

- ラベルが貼られている場合、正しい位置に貼られていること

→「3.2.1 データカートリッジラベルのセット」(P. 2 9 )

- リーダーピンが正しく固定されていること

→「3.2.4 データカートリッジのリーダーピンの状態確認」(P. 30 )

・ 壊れたデータカートリッジを、本製品に絶対に入れないでください。

・ データカートリッジを開いて磁気テープ部分を取り出したりしないでください。

・ 磁気テープ部分を直接手で触らないでください。

28

Page 29

・ データカートリッジを、直射日光の当たる場所や湿気のある場所に放置しないでくださ

い。

・ データカートリッジを磁界のある場所(ディスプレイやスピーカーの近くなど)に放置

しないでください。

・ 落下などにより強い衝撃が加わったデータカートリッジは、使わないでください。

3.2.1 データカートリッジラベルのセット

データカートリッジには、データカートリッジに貼り付けるためのラベルが添付されてい

ます。ラベルは、次の図に示す位置に貼ってください。ラベルには使用開始日を記入し、

使用期限が分かるようにしてください。

` 必ず添付のラベルを使用してください。

` ラベル貼り付け位置以外には、ラベルを貼らないでください。

ラベル貼り付け位置

使用開始日:2007年1月31日

ラベルの記入例

3.2.2 データの書き込み保護

データカートリッジを書き込み禁止にする場合は、ライトプロテクトスイッチを右側にス

ライドしてください。

ライトプロテクトスイッチ

書き込み禁止

3 データカートリッジについて 29

J

Page 30

3.2.3 データカートリッジの保管

注意

ア

データカートリッジを保管するときは、次の注意事項に従ってください。

・ 保管する場所は清潔にし、使用条件を守ってください。

・ データカートリッジは、24 時間以上使用環境に置いて、環境に慣らしてください。

・ データが記録されたデータカートリッジを長期保管する場合は、データカートリッジの

プラスチック容器に入れて、次に示す保管環境の温度、湿度条件を守って保管してくだ

さい。

温度 16 ~ 32 ℃

湿度 20 ~ 80%(ただし、結露しないこと)

最大湿球温度 26 ℃以下

3.2.4 データカートリッジのリーダーピンの状態確認

ご使用前に、データカートリッジのリーダーピン(磁気テープ先頭に取り付けられたピ

ン)の状態を確認してください。

・ リーダーピンが外れている、変形している、または衝撃が加わったなどの異常

なデータカートリッジを使用すると本製品が故障しますので、絶対に使用しな

いでください。

` カートリッジ・ドアをスライドして、リーダーピンが正しく固定されていることを

確認してください。

` リーダーピン、磁気テープには絶対に触らないでください。また、ほこりなどが

データカートリッジ内部に入らないように注意してください。

30

カートリッジ・ド

○リーダーピンが正しく固定されている ×リーダーピンが外れている

カートリッジ・ドアをスライドし、リーダーピンの状態を確認してください。

Page 31

4

クリーニングについて

この章では、本製品のクリーニングについて説明しています。

本製品にクリーニングカートリッジを挿入すると、自動的に磁気ヘッドのクリーニングが

行われます。クリーニングは、約 2 ~ 4 分かかります。クリーニング動作が完了すると、

クリーニングカートリッジは排出されます。

` 本製品は、データの書き込みや読み取りに磁気ヘッドを使用しています。磁気ヘッドがほ

こりやゴミで汚れていると、データの書き込みや読み取りが正常に行われません。

また、データカートリッジの寿命が短くなる、磁気テープ表面に傷が付き使用できなくな

るなどの不具合が発生します。このようなことを未然に防ぐために、クリーニングカート

リッジで清掃してください。

4.1 使用できるクリーニングカートリッジ

本製品には次のクリーニングカートリッジをお使いください。サプライ品については、

「5 サプライ品」(→ P. 3 3 )を参照してください。

品名 商品番号 購入単位 備考

Ultrium 1 クリーニングカートリッジ U

*:本製品では、Ultrium1 クリーニングカートリッジ(商品番号:0160290)は使用できません。

0160280

1 巻 ユニバーサルクリーニング

カートリッジ

(*)

` CLEAN LED が点灯している場合、クリーニングが必要です。クリーニングカートリッジ

を挿入し、クリーニングを行ってください。

` クリーニングカートリッジは、50 回まで使用できます。使用回数が 50 回に満たない場合で

も、購入後 5 年以上経過したクリーニングカートリッジは、新しいクリーニングカート

リッジと交換してください。

` クリーニングカートリッジをセットしても、自動的に排出されず、CLEAN LED が高速点

滅する場合は、新しいクリーニングカートリッジと交換してください。

4 クリーニングについて 31

J

Page 32

4.2 ヘッドクリーニングについて

例

)

■ クリーニングカートリッジの使用回数の管理

クリーニングカートリッジには寿命があり、使用可能回数は 50 回です。クリーニング媒

体に添付されているラベルなどを活用して、使用回数を管理してください。

寿命が過ぎたクリーニングカートリッジを使用した場合、CLEAN LED が高速点滅し、ク

リーニングカートリッジは排出されません。このときクリーニングは行われませんので、

新しいクリーニングカートリッジに交換して、再度磁気ヘッドのクリーニングを行ってく

ださい。

使用開始日:2007年1月31日

使用回数 :

クリーニングカートリッジラベル記入

■ 磁気ヘッドのクリーニングの実施時期

磁気ヘッドのクリーニングは、次の場合に行ってください。

・3ヵ月に一度(定期クリーニング)

および

・CLEAN LEDが点灯した場合(ヘッドクリーニング要求

・ 定期クリーニング

磁気ヘッドへの汚れの堆積の予防処置として定期的なヘッドクリーニング(3 か月に 1

回程度)をお勧めします。本製品をまったく使用していない場合でも、動作確認を兼ね

て定期的なクリーニングをお勧めします。

・ ヘッドクリーニング要求

本製品は、次の場合にヘッドクリーニング要求状態(CLEAN LED が点灯)となること

があります。

クリーニング要求状態になった場合、クリーニングカートリッジを挿入してクリーニン

グを行ってください。

- 突発的に磁気ヘッドにゴミが付いた場合

クリーニング実施後、設置環境の再確認をお願いします。

→「1.1 設置環境の確認」(P. 9 )

- データカートリッジ内の磁気テープが傷んでいる場合

クリーニング実施後、新しいデータカートリッジと交換してください。

- 一定時間(100 時間)、バックアップ/リストアなどの動作を行った場合

32

Page 33

5

サプライ品

本製品のサプライ品について説明します。

サプライ品には次のものがあり、富士通純正品を使用されることをお勧めします。

品名 商品番号 出荷単位 備考

Ultrium2 データカートリッジ

Ultrium3 データカートリッジ

Ultrium1 クリーニングカートリッジ U

*1:データ圧縮機能を使わない場合の値です。記憶容量は、1GB=1000 × 1000 × 1000byte 換算です。

*2:本製品では、Ultrium1 クリーニングカートリッジ(商品番号:0160290)は使用できません。

富士通サプライ品は、富士通コワーコ株式会社の取り扱い品です。

問い合せ先:富士通コワーコ株式会社

お客様総合センター:0120-505-279 月~金 9:00 ~ 17:30(土、日、祝日、年末年始除く)

http://jp.fujitsu.com/group/coworco

また、データカートリッジの取り扱いについては、上記ホームページ内の『サプライ商

品』→『データメディア』→『LT O テープ』の『LTO Ultrium カートリッジテープ説明書』

も参照してください。

0160310

0160320

0160280

5 巻容量200GB

5 巻容量400GB

1 巻 ユニバーサルクリーニング

カートリッジ

(*1)

(*1)

(*2)

5 サプライ品 33

J

Page 34

6

バックアップ運用上の注意

この章では、本製品のバックアップ運用上の注意事項について説明しています。

■ バックアップ後のデータカートリッジの排出について

データカートリッジを本製品内に入れたままにしないでください。データカートリッジは

使用する時間に応じて消耗しますので、寿命が短くなります。また、データカートリッジ

は本製品内では磁気記録面が露出しており、この状態が長く続くと浮遊塵埃の影響を受け

やすくなります。バックアップ運用直前にデータカートリッジを入れ、バックアップ運用

が終了したらすぐにデータカートリッジを取り出してください。

■ データの圧縮率について

本製品には、ハードウェアによるデータの圧縮機能があります。

データの圧縮率は、目安として 2 倍程度としておりますが、データの内容により圧縮率は

変化します。ソフトウェアにより圧縮処理されたデータでは、本製品による圧縮効果は期

待できません。

また、バックアップソフトウェアによってはデータ転送前にソフトウェアによりデータを

圧縮する機能がありますが、本製品のハードウェアによるデータ圧縮機能を有効にしてい

る場合は、ソフトウェアによるデータ圧縮を行わないでください。

■ バックアップ性能/容量について

次の要因により、バックアップ性能および 1 巻あたりに記録できるバックアップ容量が変

化します。

・ ご使用されるデータカートリッジの記録面の状態(消耗、汚れなど)

・ 本製品の磁気ヘッドの汚れ状態

・ データの圧縮率

・ サーバの負荷状況

■ システム構築時の留意事項

同一データカートリッジ 1 巻によるバックアップ運用では、バックアップに失敗した場

合、全データが失われる危険があります。また、バックアップしたデータカセットの磁気

テープが傷つくなどした場合にデータが復元できなくなります。複数のデータカートリッ

ジによるバックアップ運用を行うことにより、トラブル発生時の被害を最小限にできま

す。

例)曜日ごとのデータカートリッジを準備しバックアップ運用する。

34

Page 35

7

トラブルシューティング

■ LED の表示によるトラブルシューティング

LED の表示の意味と対処方法を次の表に示します。問題がある場合は次の表の対処方法

に従ってください。本対処方法で回復しない場合は、修理相談窓口にご連絡ください。

LED の表示は、●:消灯、○:点灯、◎:点滅(1 秒に 1 回)、☆:高速点滅(1 秒に 4

回)を意味します。

LED の表示 状態 対処方法

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

:消灯

:消灯

:消灯

:消灯

:点灯

:消灯

:消灯

:消灯

:点灯

:点滅

:点滅または消灯

:点滅

:点灯

:消灯

:高速点滅

:点灯

:点灯

:点滅

:消灯

:消灯

:点灯

:消灯

:消灯

:点灯

本製品に電源が入っていない。サーバ本体に電源が入っているのに本状

態となる場合は、サーバ本体と本製品が

正しく接続されていることを確認してく

ださい。回復しない場合は本製品が故障

している可能性があります。

本製品に電源が入っており

使用可能な状態です。

電源投入時の自己診断テス

トおよび初期化動作を実行

しています。

なし。

正常な状態です。

電源投入直後の場合、POWER LED のみ

が点灯になるまで待ってください。電源

投入直後以外で本状態となる場合は、

サーバ本体と本製品が正しく接続されて

いるか確認してください。回復しない場

合は本製品が故障している可能性があり

ます。

電源投入時の自己診断テス

トでエラーが発生しました。

サーバ本体をシャットダウンし再起動し

てください。回復しない場合は本製品が

故障している可能性があります。

本製品が動作中です(デー

タカートリッジのロード・

アンロード、巻き戻し、

データの書き込み、データ

の読み出しなどを行ってい

ます)。

クリーニングが必要です。

CLEAN LED が点灯するのは

次の場合です。

なし。

データカートリッジが挿入され動作して

いる場合は、正常な状態です。データ

カートリッジが挿入されていないのに本

状態となる場合は本製品が故障している

可能性があります。

クリーニングカートリッジを使用してク

リーニングを行ってください。

→「4 クリーニングについて」(P.31)

・ 本製品自身がクリーニン

グを必要と判断した場合

・ データカートリッジの動

作時間が 100 時間を越え

た場合。

J

7 トラブルシューティング 35

Page 36

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

POWER

ACTIVITY

ERROR

CLEAN

LED の表示 状態 対処方法

:点灯

:点灯

:消灯

:点灯

クリーニング動作中です。 クリーニングカートリッジが排出される

まで待ってください。クリーニングカー

トリッジが挿入され、ヘッドクリーニン

グが行われていると本状態となります。

ヘッドクリーニングが終わるとクリーニ

ングカートリッジは自動的に排出されま

す。

:点灯

:点灯

:消灯

クリーニングカートリッジ

が寿命(50 回以上使用)で

す。

新しいクリーニングカートリッジを使用

してください。

→「4 クリーニングについて」(P. 3 1)

:高速点滅

:点灯

:消灯

:高速点滅

:高速点滅

・ クリーニングカートリッ

ジ使用時

クリーニングに失敗しま

した。

・ データカートリッジ使用

時

メディアエラーが発生し

ました。データカート

リッジが挿入されていな

い場合は、前回使用した

データカートリッジでメ

ディアエラーが発生して

います。この表示は、別

のデータカートリッジを

・ クリーニングカートリッジ/データ

カートリッジに破損がないこと、本製

品で使用可能なことを確認してくださ

い

→「5 サプライ品」(P.33)

・ クリーニングカートリッジの場合、別

の新しいクリーニングカートリッジを

使用してください。

・ データカートリッジの場合、ライトプ

ロテクトスイッチが正しい位置にある

か確認してください。

・ データカートリッジの場合、ヘッドク

リーニングを実施し、別の新しいデー

タカートリッジを使用してください。

挿入するか本製品の電源

がオフになるまで継続し

ます。

:点灯

:消灯

:高速点滅

:消灯

:点灯

:消灯

:点灯

:消灯

:点灯

:高速点滅

:点滅

:高速点滅

:点灯

:高速点滅

:高速点滅

:高速点滅

回復不可能なエラーが発生

しました。

ファームウェアのエラーが

発生しました。

ファームウェアの更新中です。通常の動作時には発生しない状態です。

ファームウェアの更新が失

敗しました。

可能な場合、サーバをシャットダウンし

再起動してください。

回復しない場合は本製品が故障している

可能性があります。

可能な場合、サーバをシャットダウンし

再起動してください。

回復しない場合は本製品が故障している

可能性があります。

可能な場合、サーバをシャットダウンし

再起動してください。

回復しない場合は本製品が故障している

可能性があります。

通常の動作時には発生しない状態です。

可能な場合、サーバをシャットダウンし

再起動してください。

回復しない場合は本製品が故障している

可能性があります。

36

Page 37

■ 動作状況によるトラブルシューティング

本製品を使用していて、正常に動作しない場合の対処方法について説明します。

本対処方法で回復しない場合は、修理相談窓口にご連絡ください。

LED の状態については、「2.1 フロントパネルおよびコネクタ」(→ P. 2 3 )を参照してくだ

さい。

現象 対処方法

本製品が動作しない

(データカートリッジ

を挿入してもロードし

ない、サーバ本体の電

源を入れても本製品の

Power LED が点灯しな

い、など)。

本製品が OS、バック

アップソフトウェアで

認識されない。

カートリッジを挿入し

てもすぐに排出され

る。

電源ケーブル・SCSI ケーブルが正しく取り付けられているかを

確認してください。

→「1 サーバ本体への搭載と導入方法」(P. 8 )

・ 電源ケーブル、SCSI ケーブルが正しく取り付けられているこ

と、SCSI ケーブルに SCSI 終端抵抗が正しく取り付けられて

いることを確認してください。また、本製品の SCSI-ID が正

しく設定されているかを確認してください(同じバス上の他

の製品と同じ SCSI-ID に設定されていないこと)。

→「1 サーバ本体への搭載と導入方法」(P. 8 )

・ SCSI カード、SCSI ケーブル、SCSI 終端抵抗が本製品および

SCSI バスの種類と互換性があるかを確認してください。

・本製品が SCSI BIOS やオペレーティングシステムで認識され

ているかを確認してください(Windows のデバイスマネー

ジャなどで確認。"QUANTUM ULTRIUM 3" として認識され

ます)。

・ SCSI カードと本製品がバックアップソフトウェアでサポート

されているかを確認してください。また、デバイスドライバ

が必要な場合、正しいデバイスドライバがインストールされ

ているかを確認してください。

→「1.4 デバイスドライバのインストール」(P. 1 2 )

・ 使用可能なデータカートリッジかを確認してください。

→「3.1 使用できるデータカートリッジ」(P. 2 8)

→「4.1 使用できるクリーニングカートリッジ」(P. 3 1)

・ データカートリッジが正しい向きかを確認してください。

→「2.2 データカートリッジの取り付け/取り外し」(P. 2 6 )

・ データカートリッジに破損がないこと、リーダーピンが正し

く固定されていることを確認してください。

→「3.2.4 データカートリッジのリーダーピンの状態確認」

(P. 3 0)

・ 別の新しいデータカートリッジを使ってください。問題ない

場合は元のデータカートリッジを使わないでください。

J

7 トラブルシューティング 37

Page 38

現象 対処方法

データカートリッジが

排出されない。

・ イジェクトボタンを押してください。テープの巻き戻しに数

分かかることがあります。ACTIVITY LED が点滅している間

はそのまま待ってください。

・ バックアップソフトウェアからイジェクトを行ってくださ

い。バックアップソフトウェアによってはイジェクトボタン

による取り出しをできないようにしていることがあります。

・ サーバをシャットダウンし、再起動してください。その後、

イジェクトボタンを押してください(電源オフ/オンした場

合、データが正しく記録されていないことがあります)。再

度バックアップを実施してください。

38

Page 39

8

仕様

この章では、本製品の仕様と設置環境を示しています。

項目 機能・仕様

品名 内蔵 LT O3 ユニット

型名

データ記憶容量(非圧縮) 400GB

デ-タ転送速度(非圧縮) 64MB/s

データ・フォーマット Ultrium2、 Ultrium3 フォーマット(使用するデータ

インタフェース

外形寸法(単位:mm)横幅149.1 ×高さ 43.1 ×奥行き 222.6

質量

消費電力 最大 36W(スタンバイ時 12.5W)

発熱量 最大 129.6kJ/h

*1:1GB=1000 × 1000 × 1000byte 換算

*2:1MB=1024 × 1024byte 換算

設置環境条件を次に示します。

項目 設置条件

温度 動作時 10 ~ 35 ℃

休止時 -5 ~ 55 ℃

湿度 動作/休止時 20 ~ 80%RH(ただし、結露しないこと)

温度勾配 動作/休止時 15 ℃ /hr 以下(ただし、結露しないこと)

最高湿球温度 26 ℃

浮遊ほこり 0.15mg/m

設置環境については、「1.1 設置環境の確認」(→ P. 9 )も併せて参照してください。

PG-LT302/PGBLT302/PGBLT302C

(*1)

(Ultrium3 データカートリッジ使用時)

(*1)

200GB

カートリッジによる。Ultrium1 フォーマットは読み込

みのみ可能)。

Ultra 160 SCSI

1.7kg

(Ultrium2 データカートリッジ使用時)

(*2)

(Ultrium3 データカートリッジ使用時)

3

以下

J

8 仕様 39

Page 40

付録

A

運用チェックシート

(設置・運用確認編)

本製品は精密機器であり、日々の運用(クリーニング運用・データカートリッジ管理・設

置環境など)を誤るとバックアップ失敗などのトラブルが発生します。

トラブル防止のため、次の「運用チェックシート」を活用していただき、バックアップ運

用にお役立てください。各作業内容は、弊社の推奨運用になります。

No.

分類

ク

リ

|

ニ

ン

グ

運

用

チェック チェック項目 解説/作業内容(●)

1

□ 3 か月に一度の割

2

□ CLEAN LED が点

3

□ 交換用のクリーニ

合で、磁気ヘッド

のクリーニングを

行う運用になって

いますか?

灯したとき、ク

リーニングを行う

運用になっていま

すか?

ングカートリッジ

を用意しています

か?

本製品は、使用・未使用に関わらず磁気ヘッドが汚

れるため、定期クリーニングが必要です。磁気ヘッ

ドなどが汚れた状態では、テープ表面を傷つけ、

データカートリッジが短期間で使用できなくなる場

合があります。なお、メンテナンス時期を忘れない

ために、バックアップ環境支援ツール『Fujitsu Tape

Maintenance Advisor』をご使用していただき、メン

テナンス時期をオペレータの方へ自動通知すること

ができます。なお、本製品自体にもテープ走行 100

時間ごとに CLEAN LED を点灯して、クリーニング

を促す機能を持っています。

●本製品は、3 か月に一度クリーニングしてくださ

い。

本製品はテープ走行 100 時間ごとや、動作状態から

クリーニングが必要と判断した場合に CLEAN LED

を点灯して、クリーニングを促す機能を持っていま

す。CLEAN LED が点灯したままで使用を続けると、

データカートリッジやバックアップデータを損傷す

る場合があります。また、データカートリッジが消

耗し磁気ヘッドなどを汚していることが考えられま

す。

● CLEAN LED が点灯したときは、すぐにクリーニ

ングを実施してください。再発時はデータカート

リッジ交換を検討願います。

クリーニングカートリッジは、本製品では、使用回

数:50 回、使用期間:5 年のどちらか早い方を目安

に交換が必要です。

●運用に合わせて定期的に交換するようにしてくだ

さい。

●クリーニングカートリッジを使い切った場合のた

めに、交換時期が近づいたときは新しいクリーニン

グカートリッジを用意しておいてください。

40

Page 41

分類

ク

リ

|

ニ

ン

グ

運

用

デ

|

タ

カ

|

ト

リ

ッ

ジ

管

理

No.

チェック チェック項目 解説/作業内容(●)

4

□ クリーニングカー

5

□ データカートリッ

6

□

7

□ バックアップ直前

トリッジを使い

切った場合(ク

リーニングカート

リッジを入れたと

き、CLEAN LED

が高速点滅し排出

されない場合)

に、交換する運用

になっています

か?

ジに使用開始日を

書いていますか?

(交換目安:1年)

バックアップ時、

すぐに CLEAN

LED が点灯するよ

うな場合や、デー

タカートリッジ排

出遅延/ロード不

可の際は、データ

カートリッジを交

換する運用になっ

ていますか?

にデータカート

リッジをセット

し、バックアップ

直後にデータカー

トリッジを取り出

して専用ケースに

入れて保管する運

用ですか?

また、スケジュー

ルでのバックアッ

プ時は確実に自動

排出されるよう設

定していますか?

本製品にクリーニングカートリッジを入れたとき

に、自動的に排出されず、CLEAN LED が高速点滅

するときは、クリーニングカートリッジを使い切っ

ています。

●上記のような場合は新しいクリーニングカート

リッジに交換してください。

データカートリッジは消耗品です。消耗したデータ

カートリッジは磁気テープ表面が傷つき、磁気ヘッ

ド汚れの増加、媒体エラー多発などの不具合の原因

となります。データカートリッジの消耗によるバッ

クアップ失敗を防止するため、富士通純正品で、使

用期間:1 年、使用回数:1000 回のどちらか早い方

を目安に交換が必要です。

●上記に該当する場合は、新しいデータカートリッ

ジに交換してください。データカートリッジは富士

通純正品を使用されることをお勧めします。

データカートリッジが寿命に達している場合、バッ

クアップ中に磁気ヘッド汚れなどを検出し、

CLEAN LED が点灯しやすくなります。また、デー

タカートリッジの排出に時間がかかったり、データ

カートリッジがロードできなくなる場合がありま

す。

●このような現象の場合、使用回数/期間に関わら

ず、データカートリッジを新しいものに交換し様子

を見てください。その際、他のデータカートリッジ

の使用回数/期間をチェックし、交換周期に近づい

ているデータカートリッジは傷みが進行している場

合がありますのですべて交換することをお勧めしま

す。

データカートリッジのデータ記録面は、本製品内で

露出し、テンション(張力)により磁気ヘッドなど

と接触しています。この状態が長く続くと浮遊塵埃

やテンションの影響を受けやすく、データカート

リッジの寿命低下/バックアップ時のエラー発生/

本製品の故障などの原因となることがあります。

●データカートリッジは使用前に本製品にセット

し、使用後はただちに取り出して、ケースに入れて

保管してください。

●スケジュールでのバックアップなど、バックアッ

プを自動で行う場合は、「1.6 バックアップジョブの

設定(自動排出の設定)」(→ P.18)に従って自動的

に排出するように設定してください。

J

付録 A 運用チェックシート (設置・運用確認編) 41

Page 42

分類

設

置

環

境

そ

の

他

No.

チェック チェック項目 解説/作業内容(●)

8

□ 本製品が内蔵され

たサーバ本体の周

囲はほこりの少な

い環境ですか?

9

□ 本製品が内蔵され

たサーバ本体の電

源を切る場合や再

起動時には、デー

タカートリッジを

取り出す運用に

なっていますか?

10

□ バックアップ業務

には複数本のデー

タカートリッジを

用い、世代管理す

る運用になってい

ますか?(毎回同

じデータカート

リッジを使用する

運用になっていま

せんか?)

本製品は、データ記録面が内部で露出するため、設

置環境(特に塵埃)の影響を受けやすくなっていま

す。一般的に、床面に近いほど塵埃濃度は高くなる

ので、机上など床面より離れた場所への設置をお勧

めします。

● " 避けて頂きたい設置例 " を参考に、よりほこり

の少ない環境に設置するよう配慮をお願い致しま

す。

[避けていただきたい設置例]

・ 本製品を床に直置き

・ 人通りの多い場所

・ 開放されるドアや窓の近く。特に土埃や車の排気

ガス、などの外部の影響を受ける場所

・ 空気の取り込み口、吹き出し口の近く。(空調、

エアコン、換気扇、などに注意)

・ タバコの煙の影響を受ける場所(本製品が設置さ

れた部屋での喫煙禁止)

・ プリンタの近くでトナーの影響を受ける場所

・ コピー機、シュレッダー、FAX 、など、紙を扱う

装置の近くで、紙の粉の影響を受ける場所

設置後、数か月でデータカートリッジ投入口や周囲

に塵埃が堆積するような場合には設置場所を見直し

てください。

本製品は、データカートリッジ取り出し時にデータ

カートリッジに管理情報の書き込み処理を行いま

す。このため、本製品にデータカートリッジを入れ

たまま電源を切断すると管理情報が書き込まれない

異常なフォーマットのデータカートリッジが生成さ

れ、データリストア失敗などの問題に繋がります。

●サーバ本体の電源を切るときは、あらかじめ本製

品からデータカートリッジを取り出してから電源を

切断してください。

●スケジュールでのバックアップなど、バックアッ

プを自動で行う場合は、「1.6 バックアップジョブの

設定(自動排出の設定)」(→ P.18)に従って自動的

に排出するように設定してください。

1巻のデータカートリッジでバックアップを繰り返

すような運用では、バックアップ失敗時や、バック

アップデータを書き込んだデータカートリッジが破

損したときに、一時的に重要なバックアップデータ

が無くなる状態になります。

●バックアップ業務には複数本のデータカートリッ

ジを用い、世代管理する運用にしてください。

42

Page 43

付録

B

Tape Maintenance

Advisor について

B.1 はじめに

最近では、テープ装置をデータのバックアップのために使用されるお客様も非常に増えて

きています。テープ装置はハードディスクなどと異なり、定期的なメディアの交換やバッ

クアップ装置のクリーニングなどメンテナンスが必要な装置です。このことが認識されな

いまま使用され、「バックアップ作業が失敗する」「いざという時にデータが復元できな

い」といったトラブルが生じる事例が散見されます。

そこで、弊社では、このようなトラブルを起こさないために、サーバ本体に接続されてい

るテープ装置のメンテナンス時期をオペレータに通知する Fujitsu Tape Maintenance Advisor

(以降「Tape Maintenance Advisor」と表記します)

* :本ソフトウェアは、「Tape Maintenance Checker」の後継製品です。

B.2 Tape Maintenance Advisor 導入のメリット

B.2.1 提供する主な機能

・ PRIMERGY に接続しているテープ装置の決められたメンテナンス時期に、オペレータ

の端末(Windows)に Messenger 通知し、メンテナンス作業を促します。

・ オペレータがメンテナンス作業を実施しない場合には、翌日もメンテナンスを促す

Messenger が通知されます。

・ オペレータが一週間以上メンテナンス作業を実施しない場合には、Messenger 通知とと

もに、イベントログに「警告」のログを残します。

以上の機能により、システム管理者は当該サーバのイベントログ監視を行うだけで、テー

プ装置のクリーニング運用の実態を把握することができます(弊社ソフトウェア:System

Wal ke r などを併用すると効果的です)。

(*)

を提供いたします。

付録 B Tape Maintenance Advisor について 43

J

Page 44

B.2.2 メリット

本ソフトウェアを導入すると、次のような利点があります。

分類 導入前 導入後

現地のオペ

レータは?

システム管理

者は?

バックアップ

業務は?

・ テープ装置の定期的なクリーニ

ング作業を行っていない。

・ 週に一度、クリーニングをする

ことになっているが忘れてしま

い、クリーニングしなくなって

しまう。

・ 現地のオペレータがクリーニン

グ運用を実施しているかを把握

できない。

・ システム管理者が、定期的なク

リーニングの必要性を理解して

いない。

テープ装置の磁気ヘッド周囲に塵

埃が堆積

結果として

・ バックアップ業務がたびたび失

敗する。

・ バックアップしたデータカート

リッジを傷つけてしまい、デー

タの復元ができない事象も発

生。

・ あらかじめ設定された周期で、

クリーニングを促すメッセージ

がポップアップするので、ク

リーニング作業を忘れない。

・ クリーニング作業を怠ると翌日

もメッセージが通知される。

クリーニングしていないと当該

サーバのイベントログに残るの

で、イベントログを監視すれば、

現地オペレータのクリーニング作

業の実施具合が把握できる。

テープ装置はメンテナンスされた

状態

結果として

・ バックアップ業務の安定度が向

上する。

44

Page 45

B.3 製品概要

■ 製品名

使用する OS に応じて、2 つの製品があります。

・ Fujitsu Tape Maintenance Advisor for Windows

・ Fujitsu Tape Maintenance Advisor for Linux

■ 動作環境

・ OS

- Windows の場合

・ Windows 2000 Server(Service Pack 4 以降)

・ Windows Server 2003 / Windows Server 2003 x64

*:Windows Server 2003,Enterprise Edition for Itanium-Based Systems では動作しませ

ん。

-Linuxの場合

・ Linux v.3

・ Linux v.4 / Linux v.4 for EM64T

・ 動作ハードウェア

PRIMERGY シリーズ

・ 対応サーバ

Tape Maintenance Advisor が使用可能なサーバの場合、インターネット情報ページ

(http://primeserver.fujitsu.com/primergy/)内の『ダウンロード』→『ダウンロード検索』

で、サーバの製品名および型名を選択し、カテゴリに「添付ソフト」を指定して検索す

ると、Tape Maintenance Advisor が検索結果に出てきます。検索結果に出てこない場合

は、そのサーバ/ OS では Tape Maintenance Advisor の動作がサポートされていません。

・ メモリ使用量

5MB 以下

・ CPU 使用率

1%以下

(*)

` Windows では、本ソフトウェアはサービスを1つ使用します。

` Linux では、X-Window(GNOME)が導入され、ログインされている必要がありま

す。

■ 主な機能

・ メンテナンス時期の通知

- 接続されているテープ装置のメンテナンス時期を通知します。

- テープ装置が複数接続されている場合でも、それぞれの装置ごとに通知できます。

- テープ装置があらたに接続された場合も自動的に認識して通知します。

・ 通知方法の設定

テープ装置ごとにメンテナンスの通知周期と通知方法を設定できます。設定可能な通知

周期と通知方法は、次のとおりです。

- 通知周期

付録 B Tape Maintenance Advisor について 45

J

Page 46

・ 日単位

・ 週単位

・ 月単位(日付での設定と曜日での設定のいずれかを選択可)

- 通知方法

・ ポップアップメッセージ

・ アイコン(タスクトレイ)

・ イベントログ

・ 他の端末へのメッセージ

- ログの記録

Tape Maintenance Advisor の起動から終了までのイベント発生履歴を記録します。主な

記録イベントは、次の通りです。

・ テープ装置の検出

・ メンテナンス時期の通知

・ 通知に対する確認操作の実施操作

・ 発生したエラーの情報

- 特長

・ 本ソフトウェアはテープ装置に対してアクセスしないため、バックアップソフト

ウェアなど他のソフトウェアとの競合を気にする必要がありません。

・ Windows Messenger の機能を使用して、離れた端末へメッセージ送信が可能です。

■ 配付形式

サーバ本体に添付の ServerStart CD-ROM 内に収録されている場合があります。

最新版は、次の手順でダウンロードしてください。インターネット情報ページ

(http://primeserver.fujitsu.com/primergy/)内の『ダウンロード』→『ダウンロード検索』で

お使いのサーバの製品名を選択し、カテゴリに「添付ソフト」を指定して、検索してくだ

さい。

同時にダウンロードされるソフトウェアの操作説明書をよくご覧になり使用してくださ

い。

46

Page 47

付録

C

Windows 自動システム回復

(Automated System

Recovery)について

C.1 Windows 自動システム回復ディスクについて

Windows Server 2003 / Windows Server 2003 x64 において、Windows 自動システム回復機能

(Automated System Recovery、 以降 ASR)を使用するためには、Windows 自動システム回復

ディスク(Windows 自動システム回復機能用にシステムデータをバックアップした際に作

成したフロッピーディスク)に、本製品のデバイスドライバを追加しておく必要がありま

す。

ここでは、Windows 自動システム回復ディスク(以降、ASR フロッピーディスク)に本製

品のデバイスドライバを追加する方法を説明します。

` 以降の作業は隠しファイル・フォルダも含めたすべてのファイル・フォルダが表示されて

いる必要があります。また、ファイルの拡張子が表示される設定で行ってください。

1 本製品に添付のドライバフロッピーディスク(またはダウンロードしたデ

バイスドライバ)の全ファイルを作業用のフォルダ(ドライバ格納フォル

ダ)にコピーします。

2 各 OS に応じて、次の 3 つのファイルを ASR フロッピーディスクにコ

ピーします。

` フォルダはコピーしないでください。

・ Windows Server 2003 の場合

・ ドライバ格納フォルダ \LTO3HH\qltowin.inf

・ ドライバ格納フォルダ \LTO3HH\qltowin.cat

・ ドライバ格納フォルダ \LTO3HH\i386\qltowin.sys

・ Windows Server 2003 x64 の場合

・ ドライバ格納フォルダ \LTO3HH\qltowin.inf

・ ドライバ格納フォルダ \LTO3HH\qltowin.cat

・ ドライバ格納フォルダ \LTO3HH\amd64\qltowin.sys

付録 C Windows 自動システム回復(Automated System Recovery)について 47

J

Page 48

3 ASR フロッピーディスク内の asr.sif ファイルに次の記述を追加します。

ノートパッド(メモ帳)などで、次の 4 行([INSTALLFILES]を含む)を asr.sif

ファイル の "DISKS.GPT" セクションの下に追加してください。

=+056#..(+.'5?

#54(.122;SNVQYKPU[U6'/2>SNVQYKPU[U3WCPVWOZ

#54(.122;SNVQYKPKPH6'/2>SNVQYKPKPH3WCPVWOZ

#54(.122;SNVQYKPECV6'/2>SNVQYKPECV3WCPVWOZ

4 コマンドプロンプトから、ASR フロッピーディスクにラベルを付けます。

ラベルが書かれているかどうかは、プロパティで確認してください。

[例] C:\> label a: ASR

5 winnt.sif ファイルを作成し、次の記述を入力します。

ノートパッド(メモ帳)などで、winnt.sif ファイルを作成し、次の 9 行の記述を入

力して ASR フロッピーディスクに保存してください。

=&CVC?

#WVQ2CTVKVKQP

/U&QU+PKVKCVGF

7PCVVGPFGF+PUVCNN;GU

=7PCVVGPFGF?

1GO2TGKPUVCNN;'5

1GO(KNGU2CVJC>

1GO2P2&TKXGTU2CVJ6'/2

6 すべてのファイルを閉じて、次の 7 つのファイルが ASR フロッピーディ

スクに存在しているか確認します。

48

#>CUTUKH

#>CUTRPRUKH

#>SNVQYKPECV

#>SNVQYKPKPH

#>SNVQYKPU[U

#>UGVWRNQI

#>YKPPVUKH

以上で、ASR フロッピーディスクに本製品のデバイスドライバが追加されました。

システム復元の際には、このフロッピーディスクを使用してください。

Page 49

C.2 Windows 自動システム回復(ASR)の使用方

法

ASR の使用方法について説明します。

` Windows 標準ではないドライバ(例:RAID ドライバ、SCSI ドライバなど)が必要

な場合には、ASR を実施する前に次の準備を行ってください。

【事前準備】

1. Windows 標準ではないドライバのドライバフロッピーディスクを作成します

(手順 2 で使用)。作成方法は、サーバ本体の添付の『ユーザーズガイド』また

は RAID カードの『取扱説明書』を参照してください。

2. ASR 復元時の途中でドライバファイルを要求されたときに使用するドライバ

フロッピーディスクを作成します(手順 3 で使用)。

1. 【事前準備】の手順 1 で作成したドライバフロッピーディスクの空きス

ペースが 720KB 以上あるかどうかを確認します。ない場合は別途空きフ

ロッピーディスクを準備してください。

2. 各フロッピーディスクに「\$OEM$\TEXTMODE」のフォルダを作成してくだ

さい。

3. 【事前準備】の手順 1 で作成したドライバフロッピーディスクのルート以

下の全ファイルを【事前準備】の手順 2 で作成したフォルダにコピーし

てください。

` FDD ユニット(USB)を使用する場合の注意事項は、「1.8 デバイスドライバおよび

バックアップソフトウェアの設定・注意事項」の「■ Windows 自動システム回復

(ASR)使用時および BrightStorARCserve Backup の Disaster Recovery Option 使

用時に、フロッピーディスクドライブ(USB)を使用する場合について」(→ P. 2 1 )

を参照してください。

1 サーバの電源を入れます。

2 ASR フロッピーディスクおよび Windows Server 2003 インストール

CD をセットします。

Windows Server 2003 インストール CD からシステムが起動します。

` Windows 標準ではないドライバ(例:RAID ドライバなど)が必要な場合には、

画面の下部に「Press F6 if you need install a third party SCSI or RAID driver …」

とメッセージが表示されます。その場合は、【F6】キーを押してください。 この

メッセージは約 5 秒間しか表示されませんので注意してください。

画面の下部に「Press F2 to run Automated System Recovery (ASR) …」とメッセージが

表示されます。

3 【F2】キーを押します。

このメッセージは約 5 秒間しか表示されませんので注意してください。

手順 2 で【F6】キーを押した場合は、ドライバの読み込みを行います。

付録 C Windows 自動システム回復(Automated System Recovery)について 49

J

Page 50

1. 【事前準備】の手順 1 で作成したドライバフロッピーディスクをセットします。

2. 【S】キーを押して、ドライバの情報を読み込みます。

必要なだけ繰り返してください。

3. すべてのドライバの読み込みを完了したら【Enter】キーを押して、読み込み

を終了します。

4 以降、表示メッセージに従って、ドライバフロッピーディスク、ASR フ

ロッピーディスクのセットなど、操作を行います。

「ファイル nnn をコピーできません(nnn はファイル名)」と表示された場合は【事

前準備】の手順 2 で作成したドライバフロッピーディスクをセットし、対象ファイ

ルを読み込ませてください。

「Quantum LTO Tape Driver for Windows 2000/XP/2003/Vista 上のファイル "qltowin.sys"

が必要です。ファイルの格納場所へのパスを入力して、[OK]をクリックしてくだ

さい。」と表示された場合は、コピー元に "c:

してください。

\temp" を指定して[OK]をクリック

5 「自動システム回復ウィザードの開始」画面が表示されたら、ASR のバッ

クアップデータのデータカートリッジをセットします。

復元が開始されます。

6 復元が完了したら、システムを再起動し、正常に復元できているか確認し

ます。

50

Page 51

Before Reading This Manual

Thank you for purchasing the Fujitsu Tape Drv LTO3 Ultrium3/Ultrium2 400GB (PG-LT302/

PGBLT302/PGBLT302C).

This manual explains the basic usage of the Tape Drv LTO3 Ultrium3/Ultrium2 400GB (hereafter

referred to as "this product"). Before using this product, read this manual in order to ensure proper

use.

For Your Safety

This manual contains important information, required to operate this product safely.

Thoroughly review the information in this manual before using this product. Especially note the points under "Safety",

and only operate this product with a complete understanding of the material provided.

This manual should be kept in an easy-to-access location for quick reference when using this product.

High Safety

The Products are designed, developed and manufactured as contemplated or general use, including without limitation,

general office use, personal use, household use, and ordinary industrial use, but are not designed, developed and

manufactured as contemplated for use accompanying fatal risks or dangers that, unless extremely high safety is secured,

could lead directly to death, personal injury, severe physical damage, or other loss (hereinafter "High Safety Required

Use"), including without limitation, nuclear reaction control in nuclear facility, aircraft flight control, air traffic control,

mass transport control, medical life support system, missile launch control in weapon system. You shall not use this

Product without securing the sufficient safety required for the High Safety Required Use. If you wish to use this Product

for High Safety Required Use, please consult with our sales representatives in charge before such use.

April, 2007

51

E

Page 52

Remarks

Warning Descriptions

Various symbols are used throughout this manual. These are provided to emphasize important points

for your safety and that of others. The symbols and their meanings are as follows. Make sure to fully

understand these before reading this manual.

WARNING

CAUTION

The following symbols are used to indicate the type of warning or cautions being described.

Ignoring this symbol could be potentially lethal.

Ignoring this symbol may lead to injury and/or damage this product.

The triangle mark emphasizes the urgency of the WARNING and CAUTION.

Details are described next to the triangle.

A barred circle ( ) warns against certain actions (Do Not).

Details are described next to the circle.

A black circle indicates actions that must be taken.

Details are described next to the black circle.

Symbols

The following are symbols used throughout this manual.

Symbols Definition

These sections explain prohibited actions and points to note when using this

product. Make sure to read these sections.

These sections explain information needed to operate the hardware and

software properly. Make sure to read these sections.

→ This mark indicates reference pages or manuals.

CD-ROM Drive Description

CD-ROM drive names are shown as [CD-ROM].

Example: [CD-ROM]:\Setup.exe

52

Page 53

Abbreviations

The following expressions and abbreviations are used to describe the product names used in this

manual.

Product names Expressions and abbreviations

Tape Drv LTO3 Ultrium3/Ultrium2 400GB

(PG-LT302/PGBLT302/PGBLT302C)

Microsoft

®

Windows Server® 2003, Standard

Edition

®

Microsoft

Windows Server® 2003, Enterprise

Edition

Microsoft

®

Windows Server® 2003 R2, Standard

Edition

Microsoft

®

Windows Server® 2003 R2, Enterprise

Edition

®

Microsoft

Windows Server® 2003, Standard x64

Edition

®

Microsoft

Windows Server® 2003, Enterprise

x64 Edition

Microsoft

®

Windows Server® 2003 R2, Standard

x64 Edition

®

Microsoft

Windows Server® 2003 R2, Enterprise

x64 Edition

Microsoft

Red Hat

Red Hat

Red Hat

Red Hat

Red Hat

Red Hat

SUSE

®

Windows® 2000 Server Windows 2000 Server

®

Enterprise Linux® ES (v.3 for x86)

®

Enterprise Linux® AS (v.3 for x86)

®

Enterprise Linux® ES (v.4 for x86)

®

Enterprise Linux® AS (v.4 for x86)

®

Enterprise Linux® ES (v.4 for EM64T)

®

Enterprise Linux® AS (v.4 for EM64T)

™

Linux® Enterprise Server 9 for x86 SUSE Linux

BrightStor ARCserve Backup r11.5 for Windows BrightStor ARCserve Backup

NetVault 7 NetVault

Backup Utility for Windows Windows Backup

"This product"

Windows Server 2003

Windows Server 2003

x64

Linux v.3

Linux v.4

Linux v.4 for EM64T

Windows

Linux

53

E

Page 54

Safety

For safe use of this product, it is vital that the following warnings are heeded.

Handling this product

WARNING

• Keep the plastic bags used as packing, out of the reach of children.

They could cause suffocation.

• If a foreign object (water, pieces of metal, liquid) falls into this product,

immediately turn off the power and unplug it from the power source.

Contact an office listed in "Appendix C Contact Information" (Jpg.92).

Not doing so may cause electric shock and fire. Extreme care should be taken in

households with young children.

• Do not insert or drop foreign objects such as metals or inflammable objects into

openings in this product (ventilating holes, etc.). Doing so may cause electric

shock or fire.

• Do not remodel this product. Doing so may cause electric shock or fire.

54

Page 55

CAUTION

• Do not disassemble, or take this product apart.

• Do not operate or store this product in the following environments.

- Areas of extremely low temperature

- Areas of extremely high temperature or humidity

- Areas that experience extreme temperature changes

- Areas exposed to magnetic fields

- Areas exposed to shocks or vibration

- Dusty or dirty areas (cigarette smoke, emissions)

- Areas in direct sunlight

- Areas near radiators or other heat sources

• If this product is moved from cold areas to hot areas or if room temperature

suddenly rises, internal condensation may form.

If this product is used after condensation has formed, it may damage this product

or the data cartridge. After a large change in temperature, do not turn on the

power for 1 hour.

• Eject the data cartridge from this product whenever turning the server off. After

inserting the data cartridges into this product, the magnetic tape recording

surface is exposed. If this situation continues for a long time, dust may stick to the

recording surface or the magnetic tape may be damaged. This might destroy the

data cartridge permanently.

• Eject data cartridges when not using them.

• Do not carry this product with the data cartridge left in it.

• Do not forcibly insert the data cartridge.

• Do not use this product if foreign objects such as metals have fallen into this

product. If some foreign objects have fallen into this product, contact an office

listed in "Appendix C Contact Information" (Jpg.92).

• If the front surface of this product is stained, wipe with a soft, dry cloth or a cloth

wet with water or mild detergent. Do not use benzine, thinner or any volatile

compounds.

Recycle

When scrapping this product, contact an office listed in "Appendix C Contact Information" (Jpg.92).

This product must be disposed of as industrial waste.

E

55

Page 56

Checking the Items Supplied

Before using the product, check that no supplied or attached items are missing.

If any items are missing, contact an office listed in "Appendix C Contact Information" (

• Tape Drv LTO3 Ultrium3/Ultrium2 400GB (this product)

• Extension power cable

• Screws (x4)

(*1)

(*1)

(*1)

• Cleaning cartridge

• Driver floppy disk "PRIMERGY LTO3 UNIT (PG-LT302) Device Driver for Windows"

• User's Guide (this document)

*1: For custom made service (PGBLT302/PGBLT302C), items are supplied with the server.

Jpg.92).

56

Microsoft, Windows, and Windows Server are trademarks or registered trademarks of Microsoft

Corporation in the United States and other countries.

Linux is a trademark or registered trademark of Linus Torvalds in the United States and other countries.

Red Hat and all Red Hat-based trademarks and logos are trademarks or registered trademarks of Red

Hat, Inc. in the United States and other countries.

SUSE is a trademark of Novell Inc. in the United States and other countries.

All products are copyrights of their respective manufacturers.

All Rights Reserved, Copyright© FUJITSU LIMITED 2007

Page 57

Contents

1 How to Install and Introduce this product to a Server . . . . . 58

1.1 Checking the Installation Environment . . . . . . . . . . . . . . . . . . . . . . . 59

1.2 Setting Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1.3 Installing and Connecting to the Server . . . . . . . . . . . . . . . . . . . . . . . 61

1.4 Installing the Device Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1.5 Setting Backup Job (Setting Automatic Ejection) . . . . . . . . . . . . . . . 66

1.6 Checking Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1.7 Notes on Automated System Recovery . . . . . . . . . . . . . . . . . . . . . . 67

1.8 For using FDD Unit (USB) when Operating ASR and

BrightStor ARCserve Backup Disaster Recovery Option . . . . . . . . . 68

2 Componet Names and Functions . . . . . . . . . . . . . . . . . . . . . . 69

2.1 Front Panel and Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.2 Inserting/Ejecting the Data Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . 72

3 About the Data Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.1 Data Cartridges That can be Used . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.2 Handling the Data Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.1 Cleaning Cartridge That can be Used . . . . . . . . . . . . . . . . . . . . . . . . 77

4.2 Head Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5 Cautions Concerning Backup . . . . . . . . . . . . . . . . . . . . . . . . . 79

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix A Operation Checksheet

Appendix B Automated System Recovery (ASR) . . . . . . . . . 88

Appendix C Contact Information . . . . . . . . . . . . . . . . . . . . . . . 92

(Installation/Operation Check) . . . . . . . . . . . . . . 84

57

E

Page 58

1

How to Install and Introduce this product to a Server

This chapter explains installation and introduction of this product to a server.

This product is installed and introduced to a server according to the following

procedures.

Procedures 2 to 4 are not necessary for custom made service.

1 Checking the setting environment.

J"1.1 Checking the Installation Environment"(pg.59)

2 Setting jumpers.

J"1.2 Setting Jumpers"(pg.60)

3 Installing and connecting this product to the server.

J"1.3 Installing and Connecting to the Server"(pg.61)

4 Installing the device driver.

J"1.4 Installing the Device Driver"(pg.62)

5 Setting backup job (Setting automatic ejection).

J"1.5 Setting Backup Job (Setting Automatic Ejection)"(pg.66)

6 Checking operations.

J"1.6 Checking Operations"(pg.67)

58

Page 59

1.1 Checking the Installation Environment

For details about the server installation environment, refer to "Safety Precautions" and "Start Guide".

This product is susceptible to its installation environment (especially dust) because the data recording

surface is exposed inside this product. The closer to the floor, the higher the dust level is in general,

so it is recommended to install this product away from the floor, such as on a desk.

Install this product in environments that are not dusty, referring to the "Examples of installation

environments to avoid".

Examples of installation environments to avoid

•On the floor

• High-traffic areas

• Areas close to open doors/windows especially where affected by the external environment, such as

sandy dust, car exhaust emission, etc.

• Areas close to air ventilating ducts (Be careful of air conditioners, exhaust fans, etc.)

• Areas affected by cigarette smoke (Do not smoke in the room where this product is installed.)

• Areas close to printers and affected by a toner

• Areas close to paper-handling devices, such as copy machines, shredders, or fax machines, that are

affected by paper particles

• Reconsider the installation location if dust accumulates at the data cartridge slot and around the

product within a few months of installation.

Refer to " Safety" (

Jpg.54).

1 How to Install and Introduce this product to a Server 59

E

Page 60

1.2 Setting Jumpers

When installing the unit to the server, a SCSI-ID must be set.

A SCSI-ID can be set using the short jumpers on the rear of the unit (the following diagram). Follow

"Installing Internal Options" in "User's Guide" in "PRIMERGY Document & Tool CD" provided

with the server to set a SCSI-ID.

[Rear]

2

0

1

3

SCSI-ID

` Do not change any jumper settings other than the SCSI-ID locations.

` Do not install jumpers horizontally.

The SCSI-ID can be set as shown in the following table.

SCSI-ID

0 OpenOpenOpenOpen

1 Short Open Open Open

2 Open Short Open Open

3 Short Short Open Open

4 Open Open Short Open

[*]

5

6 Open Short Short Open

7 Short Short Short Short

8 Open Open Open Short

9 Short Open Open Short

10 Open Short Open Short

11 Short Short Open Short

12 Open Open Short Short

13 Short Open Short Short

14 Open Short Short Short

15 Short Short Short Short

0 1 2 3

Short Open Short Open

Short jumper

Not changeable

*: Settings at the time of purchase

60

Page 61

1.3 Installing and Connecting to the Server

For the procedures for installing and connecting this product to the server, refer to the "User's Guide"

in the "Document & Tool CD" provided with the server. If no description is found in the "User's

Guide", refer to the explanation in "Tape Drv LTO2 Ultrium2 200GB (PG-LT201)".

Connect this product to LVD SCSI Interface. Do not connect other devices on the SCSI cable that this

product is connected to.

` When connecting this product to PRIMERGY TX200 S3, RX600 S2, RX600 S3, RX600 S3

(SAS model) or use the extension power cable supplied with the product.

To install the product in PRIMERGY TX200 S3, install it in the bay placed in the top of the

five inch storage bay.

Connect the SCSI cable

Connect

the power cable

of the server

Extension power cable

(supplied with this product)

When connecting this product to SCSI Ctrl U160 (PG-128 / PGB128 or PG-1281 / PGB1281), use

the LVD/SE connector. Do not use the connector for the SCSI Ctrl U160 external device with which

this product is connected.

Connect to

this product

Do not use

1 How to Install and Introduce this product to a Server 61

This product (rear)

Do not use

E

Page 62

1.4 Installing the Device Driver

If using this product on Windows, install the device driver according to the following procedure using

the driver floppy disk provided with this product.

For Linux, installing the device driver is not required.

1.4.1 Device Driver Installation (For Any Model Other

than PRIMERGY FT)

For Windows Server 2003 / Windows Server 2003 x64

Log on to the Windows with administrator privileges.

1

2 Click the [Start] button → [Control Panel] → [System].

3 Select the [Hardware] tab and click [Device Manager].

4 Double click [Other devices], and then double click [QUANTUM

ULTRIUM 3 SCSI Sequential Device].

5 Select the [Driver] tab and click [Update Driver].

The "Welcome to the Hardware Update Wizard" message appears.

6 When the "Can Windows connect to Windows Update to search for

software?" message appears, click [No, not this time] and then

click [Next >].

62

7 Click [Install from a list or a specific location] and click [Next >].

8 Click [Search for the best driver in these locations].

9 Check [Include this location in the search], press the [Browse]

button to specify the folder which restored the device driver in the

copy source.

• When using the supplied driver floppy disk (or when the downloaded device driver was

restored in a floppy disk)

A:\LTO3HH

• When using CD-ROMs such as ServerStart

[CD-ROM]:\DRIVERS\tape\LTO3HH

10 Double click [QUANTUM ULTRIUM 3 SCSI Sequential Device].

The "Completing the Hardware Update Wizard" message appears.

11 Click [Finish], and click [Close].

The "Quantum LTO 3 Tape Drive" appears under "Tape Drive".

12 Restart the server.

Page 63

For Windows 2000 Server

Log on to the Windows 2000 Server with administrator privileges.

1

2 Click the [Start] button → [Settings] → [Control Panel].

3 Double click the [System] icon.

4 Select the [Hardware] tab and click [Device Manager].

5 Double click [Other devices], and then double click [QUANTUM

ULTRIUM 3 SCSI Sequential Device].

6 Select the [Driver] tab and click [Update Driver].

The "Welcome to the Device Driver Upgrade Wizard" message appears.

7 Click [Next].

8 Select [Find the best driver for the device], and click [Next].

9 Select [Specify the location], click [Next], set the folder which

restored the device driver in the copy source, and click [OK].

• When using the supplied driver floppy disk (or when the downloaded device driver was

restored in a floppy disk)

A:\LTO3HH

• When using CD-ROMs such as ServerStart

[CD-ROM]:\DRIVERS\tape\LTO3HH

The "The following device driver is found" message appears.

10 Click [Next].

The "Completing the Device Driver Upgrade Wizard" message appears.

11 Click [Complete], and click [Close].

The "Quantum LTO 3 Tape Drive" appears under "Tape Drive".

12 Restart the server.

1 How to Install and Introduce this product to a Server 63

E

Page 64

1.4.2 Device Driver Installation (For PRIMERGY FT)

Notes

• This product can be installed only to FT1. It cannot be installed to FT2.

• Two of this product cannot be installed at the same time.

• This product can only be used from a FTvirtual Server (professional-use OS). This product cannot

be used from a CoServer (input-output OS).

• FT model cannot restore the system using Automated System Recovery (ASR) set or system

recovery disk. For restoration, use the recovery CD supplied with the server.

• For installation of the internal 5-inch option, refer to the "User’s Guide" of the FT model.

For Windows Server 2003

Install this product to FT1.

1

2 Turn on the power of FT1 and FT2, and start the CoServer in online

mode.

3 Log on to the CoServer1 with administrator privileges.

4 Click the [Start] button → [Control Panel] → [System].

5 Select the [Hardware] tab and click [Device Manager].

The device manager starts.

6 Double click [Other devices], and then double click [QUANTUM

ULTRIUM 3 SCSI Sequential Device].

64