Page 1

Fujitsu Microelectronics Europe

User Guide

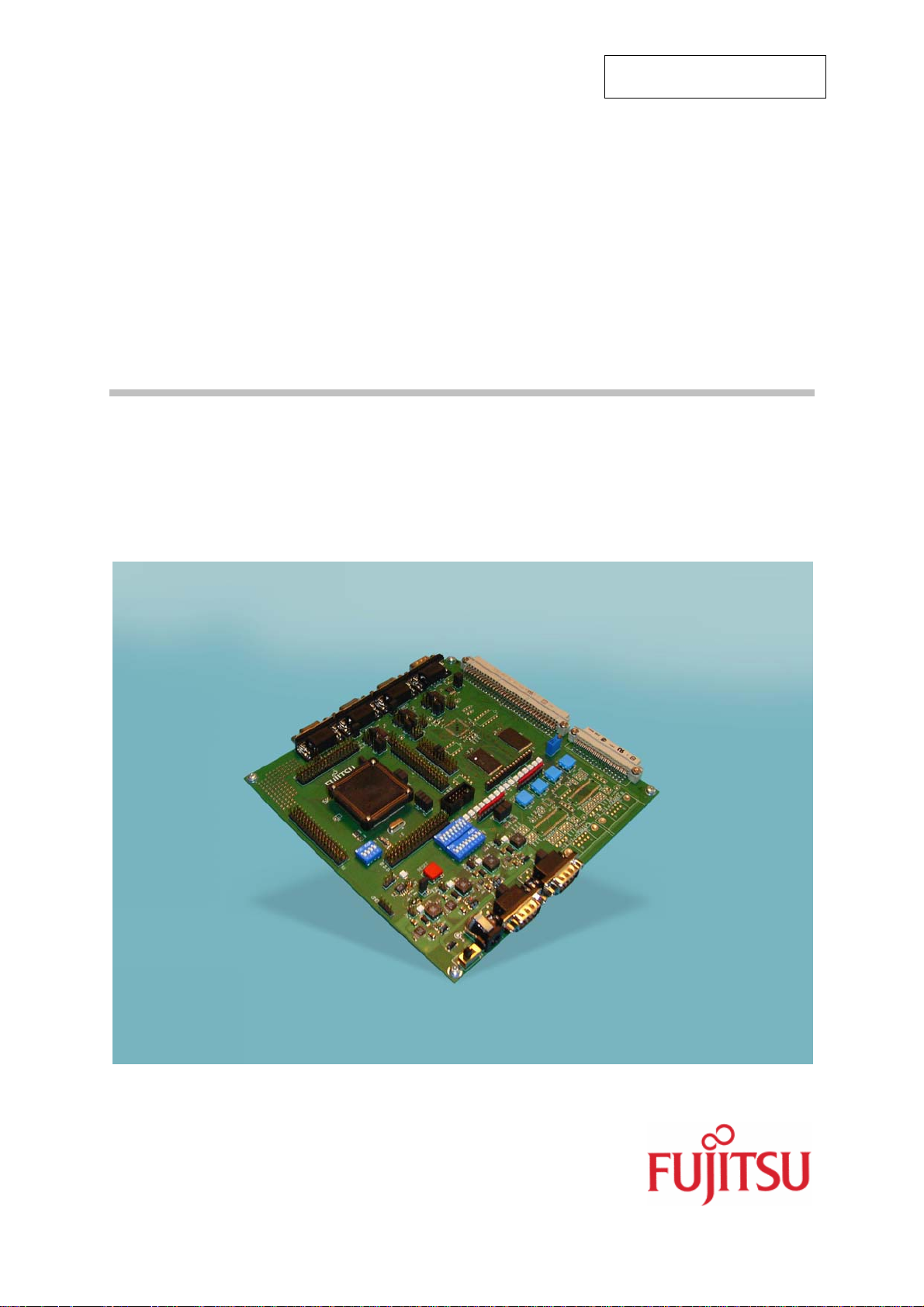

SK-91F467D-208PFV

FMEMCU-UG-910014-13

MB91460 SERIES

EVALUATION BOARD

USER GUIDE

Page 2

SK-91F467D-208PFV V1.1

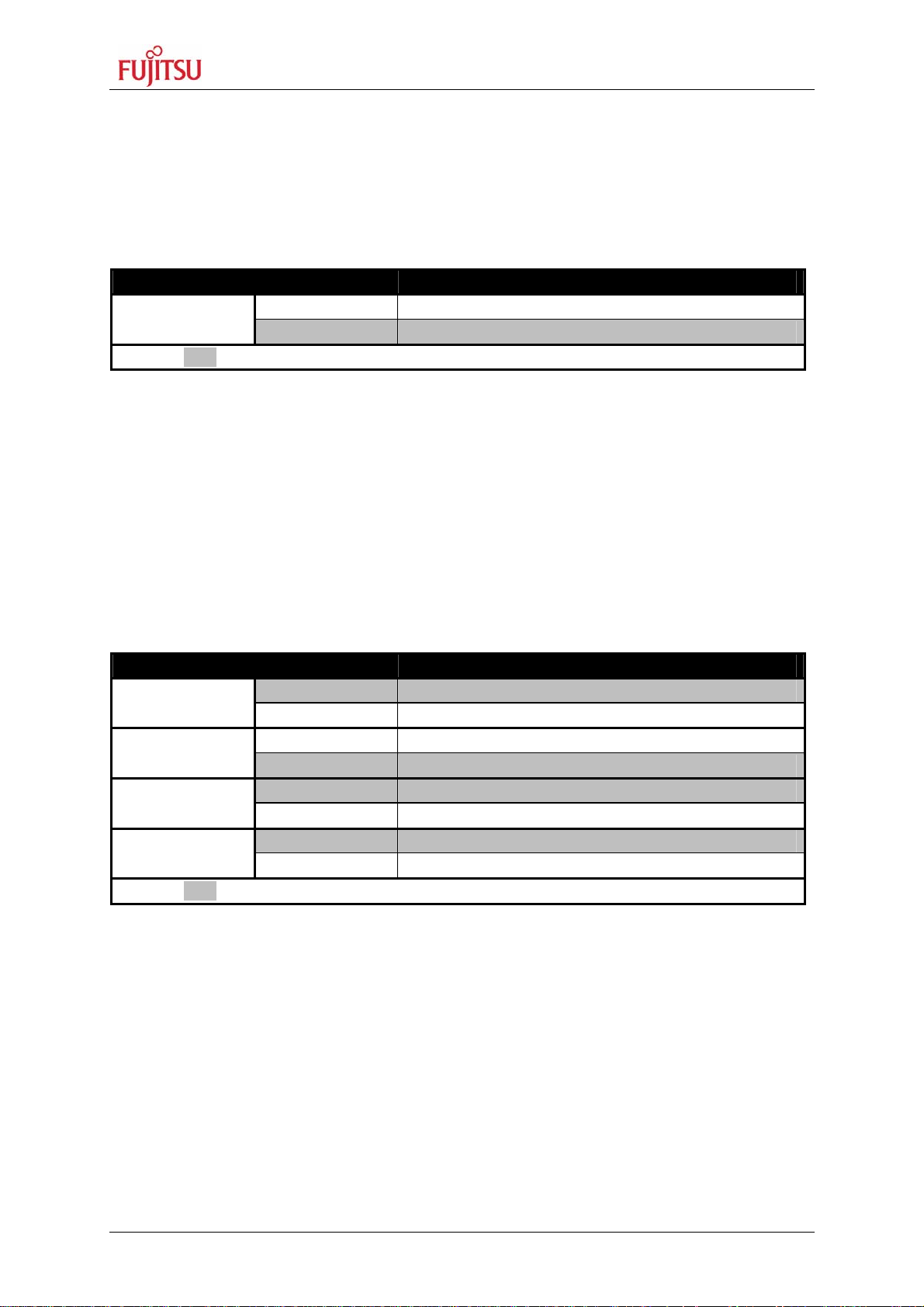

Revision History

Revision History

Date Issue

22.11.2005 V1.0, UMa,

first official version

28.03.2006 V1.1, UMa

Updated the description of the SWB Monitor Debugger, which is now

located in the external flash.

13.04.2006 V1.2, UMa

Added chapter “Internal Flash Programming”

04.06.2006 V1.3, UMa

Changed chapter “Programming the Monitor Debugger”.

This document contains 60 pages.

FMEMCU-UG-910014-13 - 2 - © Fujitsu Microelectronics Europe GmbH

Page 3

SK-91F467D-208PFV V1.1

Warranty and Disclaimer

Warranty and Disclaimer

To the maximum extent permitted by applicable law, Fujitsu Microelectronics Europe GmbH restricts

its warranties and its liability for the SK-91F467D-208PFV and all its deliverables (eg. software

include or header files, application examples, target boards, evaluation boards, engineering samples

of IC’s etc.), its performance and any consequential damages, on the use of the Product in

accordance with (i) the terms of the License Agreement and the Sale and Purchase Agreement under

which agreements the Product has been delivered, (ii) the technical descriptions and (iii) all

accompanying written materials. In addition, to the maximum extent permitted by applicable law,

Fujitsu Microelectronics Europe GmbH disclaims all warranties and liabilities for the performance of

the Product and any consequential damages in cases of unauthorised decompiling and/or reverse

engineering and/or disassembling. Note, the SK-91F467D-208PFV board and all its deliverables

are intended and must only be used in an evaluation laboratory environment.

1. Fujitsu Microelectronics Europe GmbH warrants that the Product will perform substantially in

accordance with the accompanying written materials for a period of 90 days form the date of

receipt by the customer. Concerning the hardware components of the Product, Fujitsu

Microelectronics Europe GmbH warrants that the Product will be free from defects in material

and workmanship under use and service as specified in the accompanying written materials

for a duration of 1 year from the date of receipt by the customer.

2. Should a Product turn out to be defect, Fujitsu Microelectronics Europe GmbH’s entire liability

and the customer’s exclusive remedy shall be, at Fujitsu Microelectronics Europe GmbH’s

sole discretion, either return of the purchase price and the license fee, or replacement of the

Product or parts thereof, if the Product is returned to Fujitsu Microelectronics Europe GmbH in

original packing and without further defects resulting from the customer’s use or the transport.

However, this warranty is excluded if the defect has resulted from an accident not attributable

to Fujitsu Microelectronics Europe GmbH, or abuse or misapplication attributable to the

customer or any other third party not relating to Fujitsu Microelectronics Europe GmbH.

3. To the maximum extent permitted by applicable law Fujitsu Microelectronics Europe GmbH

disclaims all other warranties, whether expressed or implied, in particular, but not limited to,

warranties of merchantability and fitness for a particular purpose for which the Product is not

designated.

4. To the maximum extent permitted by applicable law, Fujitsu Microelectronics Europe GmbH’s

and its suppliers´ liability is restricted to intention and gross negligence.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES

To the maximum extent permitted by applicable law, in no event shall Fujitsu

Microelectronics Europe GmbH and its suppliers be liable for any damages whatsoever

(including but without limitation, consequential and/or indirect damages for personal

injury, assets of substantial value, loss of profits, interruption of business operation,

loss of information, or any other monetary or pecuniary loss) arising from the use of

the Product.

Should one of the above stipulations be or become invalid and/or unenforceable, the remaining

stipulations shall stay in full effect.

© Fujitsu Microelectronics Europe GmbH - 3 - FMEMCU-UG-910014-13

Page 4

SK-91F467D-208PFV V1.1

Contents

Contents

REVISION HISTORY.............................................................................................................. 2

WARRANTY AND DISCLAIMER........................................................................................... 3

CONTENTS ............................................................................................................................4

1 INTRODUCTION................................................................................................................ 7

1.1 Abstract..................................................................................................................... 7

1.2 Features.................................................................................................................... 8

1.3 General Description .................................................................................................. 9

1.3.1 On Board Memory..................................................................................... 10

1.3.2 MCU Clocks .............................................................................................. 10

1.3.3 MCU Operating Mode ............................................................................... 10

1.3.4 External Bus interface Connectors............................................................ 10

1.3.5 CAN Bus ................................................................................................... 10

1.3.6 RS-232 and LIN ........................................................................................ 10

1.3.7 MCU Pins .................................................................................................. 10

1.3.8 User Buttons ............................................................................................. 10

1.3.9 User LEDs and Optional LCD ................................................................... 11

1.3.10 Power Supply ............................................................................................ 11

2 INSTALLATION............................................................................................................... 12

2.1 Jumper Settings ...................................................................................................... 14

2.2 Jumper Location ..................................................................................................... 15

2.3 Software Installation................................................................................................ 16

2.3.1 Installation of Softune Workbench ............................................................ 16

3 JUMPERS AND SWITCHES ........................................................................................... 17

3.1 MCU Operating-Mode (S5) ..................................................................................... 17

3.2 Power Supply.......................................................................................................... 18

3.2.1 MCU Power Supply Voltage...................................................................... 20

3.2.2 MCU Analogue Power Supply Voltage ..................................................... 20

3.3 CAN0 – CAN2......................................................................................................... 22

3.4 LIN / RS-232 UART................................................................................................. 22

3.4.1 UART 2 ..................................................................................................... 23

3.4.2 UART 4 (Flash Programming)................................................................... 24

3.4.3 UART 5 ..................................................................................................... 25

3.5 User Push Buttons INT0, INT1, INT2 and ICU0/TIN0............................................. 26

3.6 User DIP Switch 8 Bit (S4)...................................................................................... 26

FMEMCU-UG-910014-13 - 4 - © Fujitsu Microelectronics Europe GmbH

Page 5

SK-91F467D-208PFV V1.1

Contents

3.7 Reset Generation.................................................................................................... 27

4 CONNECTORS................................................................................................................ 29

4.1 Power Connector (X5)............................................................................................. 29

4.2 UART / LIN Connector (X1, X4, X8)........................................................................ 29

4.3 CAN Connector (X9, X10, X11) .............................................................................. 30

4.4 USER-LEDs and Optional LC-Display (D1-D16, J6)............................................... 31

4.5 In-Circuit-Programming Connector (X12)................................................................ 32

4.6 MCU Pin Connectors (J1-J4) .................................................................................. 32

4.7 External Bus Connectors (X13, X14) ...................................................................... 33

4.7.1 VG96ABC DIN 41612 (X13)...................................................................... 33

4.7.2 VG48ABC DIN 41612 (X14)...................................................................... 34

4.7.3 Distance between VG-Connectors............................................................ 34

5 GETTING STARTED ....................................................................................................... 35

5.1 Introduction to Softune Workbench......................................................................... 35

5.2 Project Start-up ....................................................................................................... 37

5.2.1 Create a New Project: ............................................................................... 37

5.3 Softune Workbench Monitor Debugger................................................................... 39

5.3.1 General Description .................................................................................. 39

5.3.2 Starting the SWB Monitor Debugger......................................................... 40

5.3.3 Basic Debugger Features ......................................................................... 42

5.4 Advanced Softune Workbench SWB Monitor Debugger Features ......................... 44

5.5 Memory Configuration............................................................................................. 46

6 PROGRAMMING THE INTERNAL FLASH..................................................................... 47

7 PROGRAMMING THE SWB MONITOR DEBUGGER.................................................... 51

8 TROUBLE SHOOTING.................................................................................................... 52

9 SILK-PLOT OF THE BOARD.......................................................................................... 53

9.1 Top Side.................................................................................................................. 53

9.2 Bottom Side ............................................................................................................ 54

10 PCB HISTORY................................................................................................................. 55

10.1 SK-91F467-208PFV V1.0 ....................................................................................... 55

© Fujitsu Microelectronics Europe GmbH - 5 - FMEMCU-UG-910014-13

Page 6

SK-91F467D-208PFV V1.1

Contents

11 APPENDIX....................................................................................................................... 56

11.1 Related Products..................................................................................................... 56

11.2 Information on the WWW........................................................................................ 57

11.3 Tables 58

11.4 Figures 59

11.5 Abbreviations .......................................................................................................... 60

FMEMCU-UG-910014-13 - 6 - © Fujitsu Microelectronics Europe GmbH

Page 7

SK-91F467D-208PFV V1.1

Introduction

1 Introduction

1.1 Abstract

The SK-91F467D-208PFV is a multifunctional development board for the FUJITSU 32-bit

flash microcontroller MB91460 series.

It can be used stand-alone for software development and testing or together with the Softune

Workbench Monitor Debugger.

The board allows the designer immediately to start with the software and system

development, before his own final target system is available.

© Fujitsu Microelectronics Europe GmbH - 7 - FMEMCU-UG-910014-13

Page 8

SK-91F467D-208PFV V1.1

Introduction

1.2 Features

• Supports 32-bit flash microcontroller MB91F467D

• 9-12 V (2000 mA) unregulated external DC power supply

• 5 V, 3.3 V, 2.5 V and 1.8 V on-board switching regulators with power status LEDs

• Triple supply monitor to watch 5 V, 3.3 V and selectable 2.5 V or 1.8 V

• On-board Memory:

o 32 Mbit (4 MByte) SRAM

o 128 Mbit (16 MByte) flash

• All microcontroller resources available for evaluation

• All microcontroller pins routed to pin header

• In-circuit serial flash programming

• Three selectable RS-232 or LIN UART-interfaces

• Three high-speed CAN interfaces

• 16 User LEDs

• optional: alphanumeric standard LC-Display connectable

• Reset button, reset LED

• 4 User buttons, one 8 bit MCU port can be connected to DIP switches

• External bus interface routed to 96pin and 48pin DIN 41612 (VG) connectors

This board must only be used for test applications

in an evaluation laboratory environment.

FMEMCU-UG-910014-13 - 8 - © Fujitsu Microelectronics Europe GmbH

Page 9

SK-91F467D-208PFV V1.1

Introduction

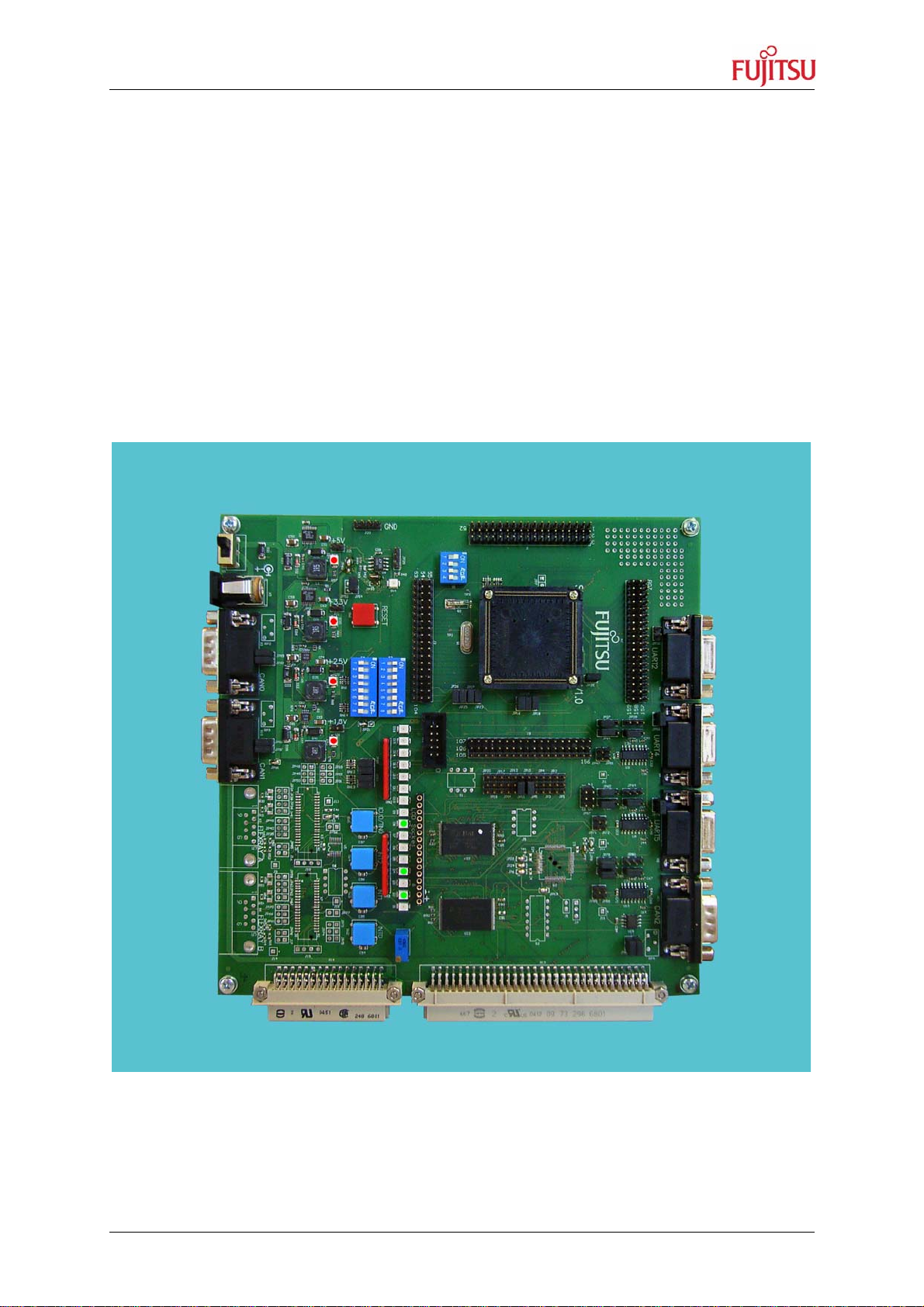

1.3 General Description

The SK-91F467-208PFV supports the FUJITSU 32-bit flash microcontroller MB91F467D.

The starter-kit can be used as a stand-alone development platform, or instead of the flash

MCU MB91F467D, with the emulation system MB2198-01 and the adapter board (MB2198-

300) and the 208 pin probe cable board (PB-91467D-208PFV or PB-91467D-LS-208PFV).

This User Guide is describing PCB version V1.1. The PCB version is printed at the TOP side

of the starter-kit close to MB91F467D MCU [U1].

© Fujitsu Microelectronics Europe GmbH - 9 - FMEMCU-UG-910014-13

Page 10

SK-91F467D-208PFV V1.1

Introduction

1.3.1 On Board Memory

SK-91F467D-208PFV: The starter-kit SK-91F467D-208PFV includes 32 Mbit (4 MByte)

SRAM memory and 128 Mbit (16 MByte) flash memory on board. The flash can be used with

3.3 V external bus supply voltage only (JP21: 2-3).

1.3.2 MCU Clocks

The board is supplied with a 4 MHz crystal as the main oscillation clock for the MCU. Using

the internal PLL of the MCU, internal clock rates up to 96 MHz can be achieved. The MCU

sub clock is connected to a 32.768 kHz crystal.

1.3.3 MCU Operating Mode

The operating mode of the microcontroller can be selected with the DIP-switch S5.

1.3.4 External Bus interface Connectors

Via DIN 41612 VG96ABC and VG48ABC connectors (external bus interface of the MCU), it

is possible to connect other devices e.g. user applications or Fujitsu graphic device sub

boards.

1.3.5 CAN Bus

Three high-speed CAN-transceivers (PCA82C250) are available to connect all available onchip CAN-controllers to 9-pin D-Sub connectors (X9, X10 and X11). The transceivers

provides differential transmit and receive capability between CAN-controller and CAN-bus.

1.3.6 RS-232 and LIN

Three separate RS-232 transceivers and three separate LIN transceivers are available to

connect the on-chip USARTs to the 9-pin D-Sub connectors.

The RS-232 transceivers generate the adequate RS-232 levels for receive (RXD) and

transmit (TXD) lines. The RTS signal can be shortcut to CTS using jumpers (some PC

software needs this connection).

Either the DTR line or the RTS line of X1, X4 or X8 connectors can be selected to generate

a system reset.

The LIN transceivers (TLE6259) generate the adequate levels to drive the bus line in LINsystems for automotive and industrial applications.

1.3.7 MCU Pins

All 208 pins of the microcontroller are connected to the edge connectors J1, J2, J3 and J4

and are directly available to the user.

1.3.8 User Buttons

There are four push buttons on board, which can be connected to input-ports of the

microcontroller. Some ports may support additional functions like external interrupts (INT0,

INT1 and INT2) and trigger for the Reload Timer or for the Input-Capture Unit (TIN0 / ICU0).

One additional button is reserved as system-reset-button to reset the MCU, but it is possible

to disconnect the RST-port with JP54.

It is possible to connect with DIP-switch S3 eight port input switches at S4 to the MCU port

P26. All eight ports can be switched separately to use e.g. only four ports as input.

FMEMCU-UG-910014-13 - 10 - © Fujitsu Microelectronics Europe GmbH

Page 11

SK-91F467D-208PFV V1.1

Introduction

1.3.9 User LEDs and Optional LCD

Sixteen user-LEDs are connected via two pull-down resistor networks to port P25 and to port

P16. Parallel to the LEDs on port P25, the connector J6 can be used to connect a standard

alphanumeric display. The resistor networks RN2 and RN3 can be removed to free the ports.

1.3.10 Power Supply

The four on-board step-down switching regulators allow the user to connect an unregulated

DC input voltage between +9 V to +12 V (max. 2000 mA) to the starter-kit. The switching

regulators provide the voltages of 5 V(3 A), 3.3 V(3 A), 2.5 V(1.5 A) and 1.8 V(1.5 A) on the

starter-kit. These voltages give also the possibility to connect an optional graphic-controller

starter-kit to the board. The switching regulators are short circuit protected and provide a

thermal shutdown.

© Fujitsu Microelectronics Europe GmbH - 11 - FMEMCU-UG-910014-13

Page 12

SK-91F467D-208PFV V1.1

Installation

2 Installation

Remove the board carefully from the shipping carton.

First check whether there are any damages before power on the starter-kit.

To supply the starter-kit use the delivered plug-in AC-DC Adapter (UPA 2000). Select the AC

plug adapter suitable for your country power sockets

Figure 2-1 AC plug adapter

and insert this adapter in the connection terminal on the AC-DC adapter.

Figure 2-2: AC plug adapter selection

Check the selected output DC voltage of the AC-DC plug-in adapter at the voltage selection

key. It should be 9 V! Change the output voltage only in a powered-down condition!

Figure 2-3: DC voltage selection

Select the low voltage adapter suitable to the power connector X5 at the SK-91F467D208PFV and plug it to the connecting socket in the right orientation (‘+’ connected to shield

and ‘GND’ connected to centre pin).

Figure 2-4: Low voltage adapter selection

Now connect the DC low voltage adapter to the starter-kit and plug in the plug-in power

supply to a power socket. The SK-91F467D-208PFV can be turned on with the on board

power switch S8 (or S9).

FMEMCU-UG-910014-13 - 12 - © Fujitsu Microelectronics Europe GmbH

Page 13

SK-91F467D-208PFV V1.1

Installation

For the power supply of the SK-91F467D-208PFV a DC input voltage of 9V – 12V is

recommended. The positive voltage (+) must be connected to the shield, and ground

(GND) must be connected to the centre of the connector X5!

After power-on of the SK-91F467D-208PFV, the four red power-on LEDs D24 (5 V), D30

(3.3 V), D34 (2.5 V) and D40 (1.8 V) should be light. The reset LED D18 should be off.

The starter-kit is delivered with programmed Softune Workbench (SWB) Monitor Debugger

in the external flash. The SWB Monitor Debugger checks also the external SRAM access at

CS1. In case of successful access to external SRAM the LED D1, D4 and D8 are on.

To use the SWB Monitor Debugger, the CPU mode selection must be set to the External

Reset Vector mode by setting DIP switch S5 to (On, Off, Off, Off), which is the delivery state.

To use the MCU with the internal flash, which is normally required for the final application,

the CPU mode selection must be set to the Internal Reset Vector mode by setting DIP switch

S5 to (Off, Off, Off, Off)

Figure 2-5: Starter-kit status after power on

© Fujitsu Microelectronics Europe GmbH - 13 - FMEMCU-UG-910014-13

Page 14

SK-91F467D-208PFV V1.1

Installation

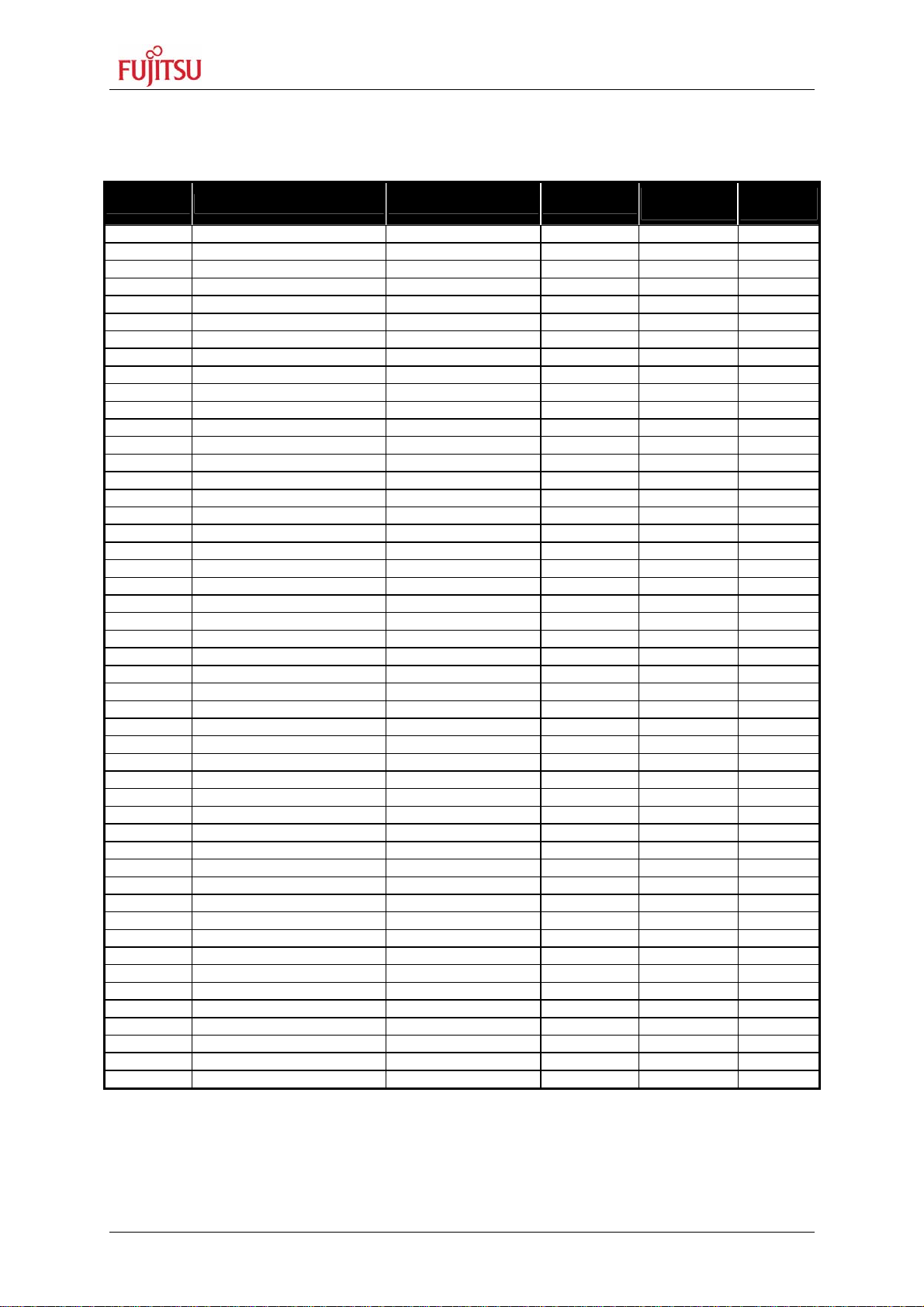

2.1 Jumper Settings

The following table lists all jumpers including its default setting and location on the starter-kit.

Jumper Description / Function Type Default

JP15 MCUVcc - AVcc Jumper 2 pin Closed E 9 1 / 3

JP16 AVcc - AVRH Jumper 2 pin Closed E 9 1 / 3

JP18 GND - AVss Jumper 2 pin Closed E 8 1 / 3

JP21 VDD35 MCUVcc / 3.3V Solder Jumper 3 pad 2-3 F 15 1 / 3

JP23 MCUVcc – HVDD5 Jumper 2 pin Closed E 10 1 / 3

JP25 MCUVcc – VDD5R Jumper 2 pin Closed E 11 1 / 3

JP26 Vcc - MCUVcc Jumper 2 pin Closed E 11 1 / 3

JP27 MCUVcc – VDD5 Jumper 2 pin Closed E 11 1 / 3

JP28 GND – HVSS5 Jumper 2 pin Closed E 6 1 / 3

JP29 DTR select DTR / /DTR Jumper 3 pin Open B 14 2 / 3

JP30 UART2 RTS - CTS Jumper 2 pin Open D 3 2 / 3

JP37 UART2 RxD RS232 / LIN Jumper 3 pin 2-3 F 5 2 / 3

JP39

JP42

JP43

JP44

JP46

JP47

JP51

JP54 RESET - MCU RST

JP57 UARTX RST Select

JP58

JP60 UART4 RxD RS232 / LIN

JP64 UART4 DTR / RTS

JP65 UART4 TxD RS232 / LIN

JP68 Vcc 5V / 3.3V

JP69 UART4 RS232 / LIN

JP71 UART4 LIN Enable

JP72 UART4 LIN Master Yes / No

JP78 UART5 RTS - CTS Jumper 2 pin Closed H 3 2 / 3

JP79 UART5 RxD RS232 / LIN Jumper 3 pin 1-2 J 5 2 / 3

JP80

JP81

JP82 CAN0 RxD Jumper 2 pin

JP83 CAN0 TxD Jumper 2 pin Closed D 19 2 / 3

JP84

JP85

JP86

JP87 CAN1 RxD Jumper 2 pin

JP88 CAN1 TxD Jumper 2 pin Closed F 19 2 / 3

JP89 CAN2 RxD Jumper 2 pin

JP90 CAN2 TxD Jumper 2 pin Closed M 4 2 / 3

JP91 Vin – Ext Voltage Solder Jumper 2 pad Closed G 18 3 / 3

JP92 INT0 Jumper 2 pin Closed G 15 3 / 3

JP93 INT1 Jumper 2 pin Closed G 15 3 / 3

JP94 INT2 Jumper 2 pin Closed G 15 3 / 3

JP95 ICU0/TIN0 Jumper 2 pin Closed G 15 3 / 3

JP96 Direct RESET Solder Jumper 3 pad 1-2 A 14 2 / 3

JP97 VCC1V8 to X14B2 Solder Jumper 2 pad Open H 16 3 / 3

UART2 DTR / RTS

Watch 1.8V

Watch 2.5V

UART2 TxD RS232 / LIN

UART2 RS232 / LIN

UART2 LIN Enable

UART2 LIN Master Yes / No

UART4 RTS - CTS Jumper 2 pin Closed

UART5 DTR / RTS

UART5 TxD RS232 / LIN

UART5 RS232 / LIN

UART5 LIN Enable

UART5 LIN Master Yes / No

Jumper 3 pin Open F 4 2 / 3

Solder Jumper 2 pad Open

Solder Jumper 2 pad Closed B 15 2 / 3

Jumper 3 pin 2-3 F 5 2 / 3

Jumper 3 pin 2-3 F 4 2 / 3

Jumper 2 pin Closed G 6 2 / 3

Jumper 2 pin Closed G 5 2 / 3

Jumper 2 pin Closed

Jumper 6 pin

Jumper 3 pin 1-2

Jumper 3 pin Open

Jumper 3 pin 1-2

Solder Jumper 3 pad 1-2

Jumper 3 pin 1-2

Jumper 2 pin Open

Jumper 2 pin Open

Jumper 3 pin Open J 4 2 / 3

Jumper 3 pin 1-2 K 5 2 / 3

Jumper 3 pin 1-2 K 4 2 / 3

Jumper 2 pin Open K 6 2 / 3

Jumper 2 pin Open K 6 2 / 3

Open H 6

Closed

Closed

Closed

Layout

Coordinates

B 15

B 15

F 3

H 5

H 4

H 5

B 16

H 4

H 6

H 6

D 19 2 / 3

G 19 2 / 3

M 4 2 / 3

Schematic

Page

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

Table 2-1: Jumper settings

FMEMCU-UG-910014-13 - 14 - © Fujitsu Microelectronics Europe GmbH

Page 15

SK-91F467D-208PFV V1.1

Installation

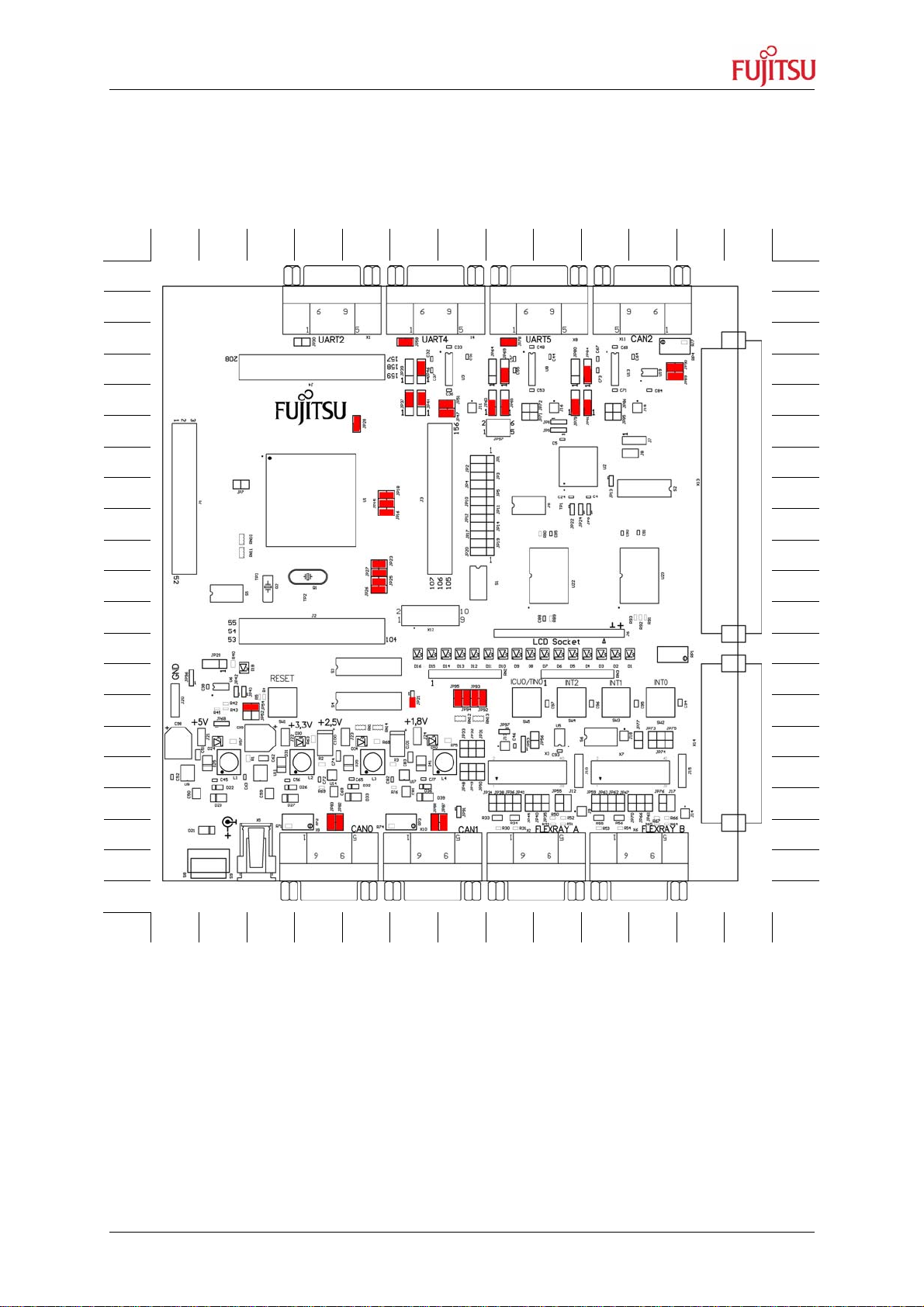

2.2 Jumper Location

The following picture shows the silk plot of the starter-kit with marked default jumper

settings.

A B C D E F G H J K L M N

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21

21

A B C D E F G H J K L M N

Figure 2-6: Default jumper settings

© Fujitsu Microelectronics Europe GmbH - 15 - FMEMCU-UG-910014-13

Page 16

SK-91F467D-208PFV V1.1

Installation

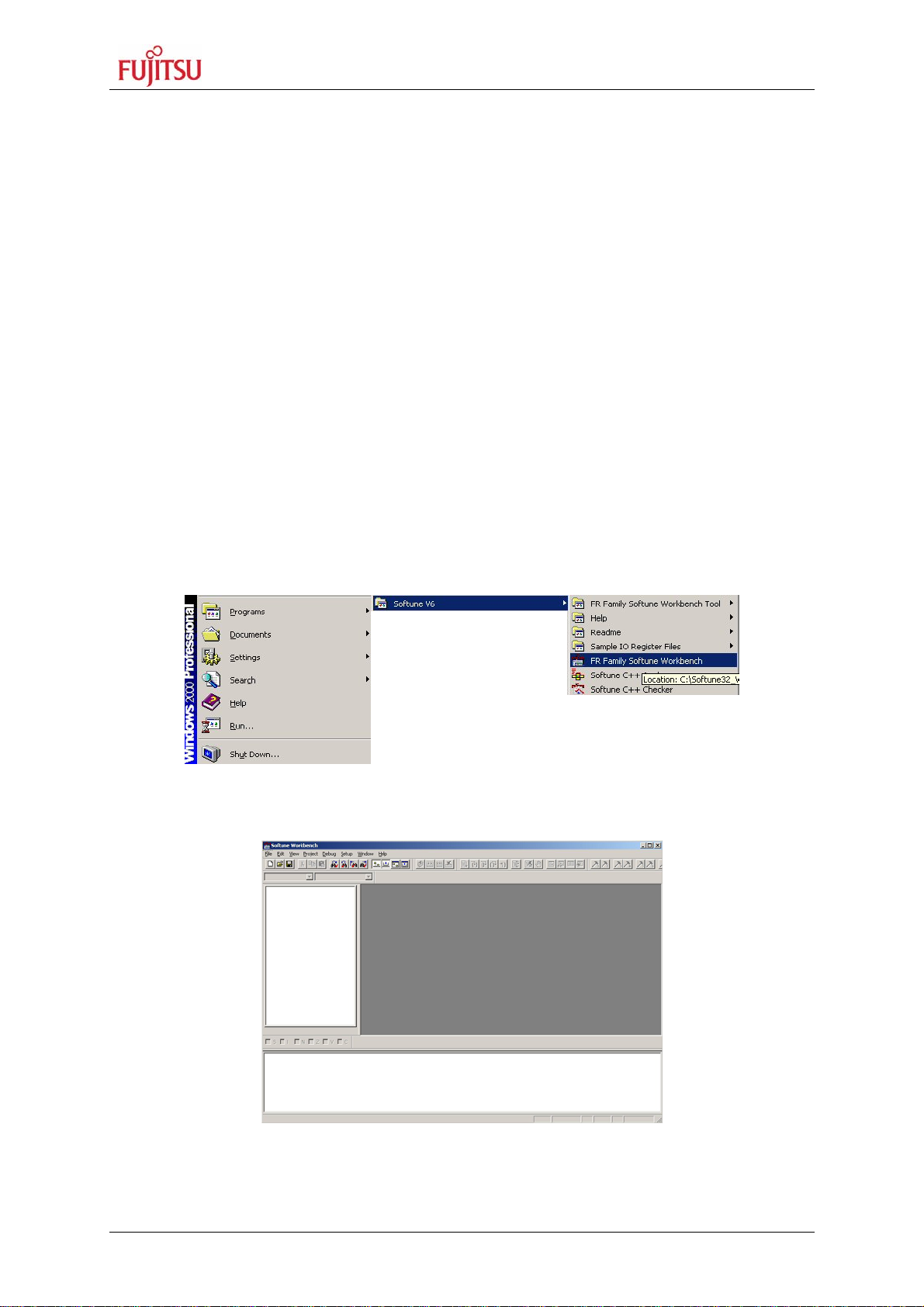

2.3 Software Installation

2.3.1 Installation of Softune Workbench

With the “SK-91F467D-208PFV” Fujitsu supplies a full working development environment

called Softune Workbench V6. The Softune Workbench also supports the SWB Monitor

Debugger which is pre-programmed into the external flash memory of the “SK-91F467D208PFV”. To develop own software and to work with the SWB Monitor Debugger of the “SK91F467D-208PFV” the Softune Workbench development environment must be installed first.

Follow the instructions for successful installation of the Softune Workbench.

1) Before starting the installation setup ensure that you are logged in with administrator

or poweruser permissions, otherwise the Softune Workbench installation will fail! Be

aware that Softune Workbench does not support multi-user support. Therefore

install- and user login must be the same.

2) Browse on the starter-kit CD-ROM into the directory Software\SWB_Install and start

the FRSTA*.exe.

3) Follow the installation instructions.

4) For the default installation path it is recommended to use c:\Softune32.

5) After the installation is finished. The FR Family Softune Workbench can be started

via the Windows “Start” menu.

Figure 2-7: Softune Workbench start menu location

6) When Softune Workbench was started the following window will be shown.

Figure 2-8: Softune Workbench V6 IDE

FMEMCU-UG-910014-13 - 16 - © Fujitsu Microelectronics Europe GmbH

Page 17

SK-91F467D-208PFV V1.1

Jumpers and Switches

3 Jumpers and Switches

This chapter describes all jumpers and switches that can be modified on the starter-kit. The

default setting is shown with a grey shaded area.

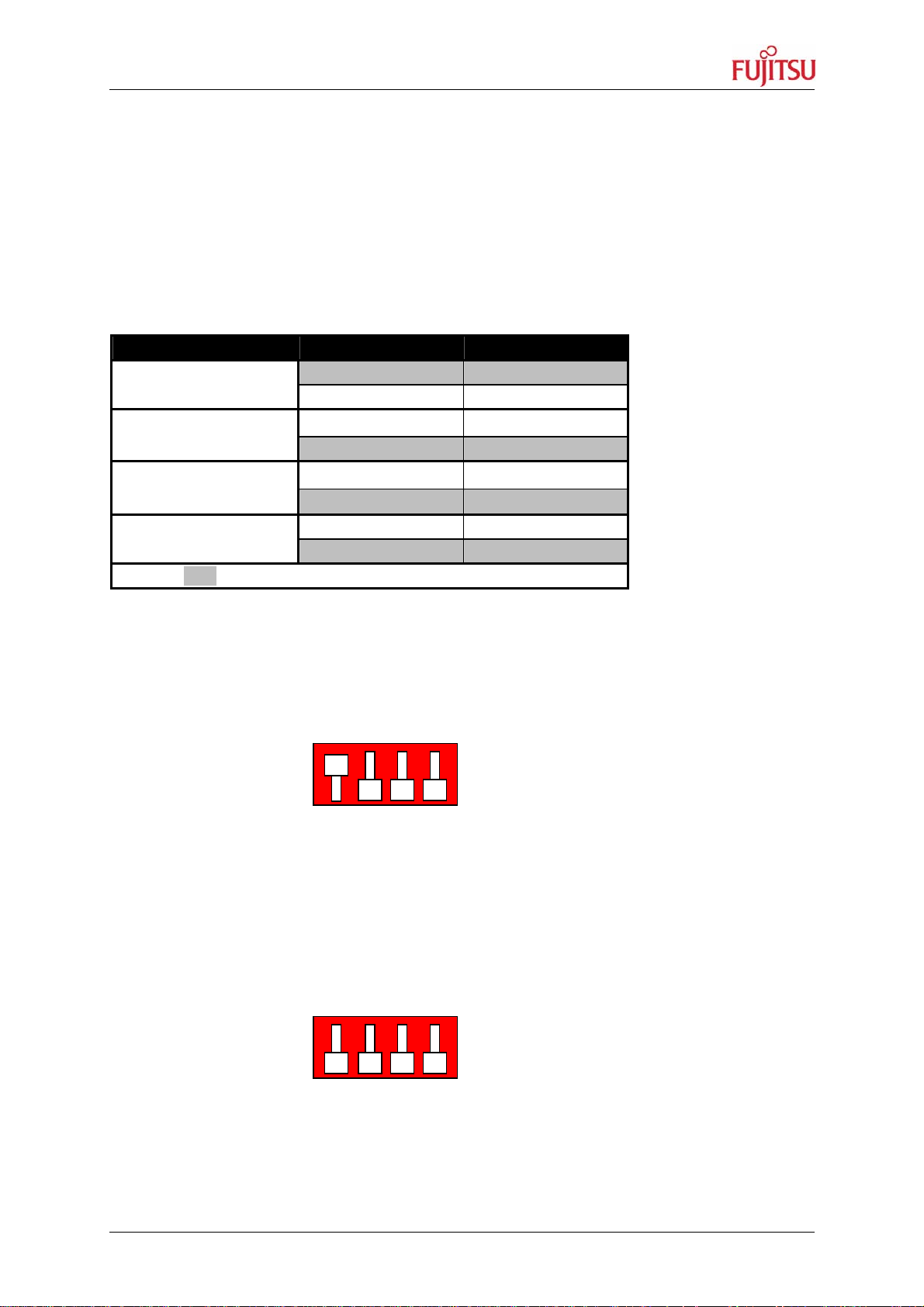

3.1 MCU Operating-Mode (S5)

The DIP-switch S5 is used to set the operating mode of the MCU. Ensure that the mode pin

settings correspond to the operation-mode of the application. For more detailed information

please check the hardware manual of the microcontroller.

DIP switch Setting Logical value

S5/1 (MD0)

ON (closed) 1 (high)

OFF (open) 0 (low)

S5/2 (MD1)

ON (closed) 1 (high)

OFF (open) 0 (low)

S5/3 (MD2)

ON (closed) 1 (high)

OFF (open) 0 (low)

S5/4 (Not used)

ON (closed) Not connected

OFF (open) Not connected

Default: grey

Table 3-1: MCU operating mode

By default, the “External ROM Mode Vector” is selected for the SWB Monitor Debugger,

which is pre-programmed into the external flash. In this mode the internal flash is

inaccessible.

DIP-Switch S5

(default setting)

MD0 MD1 MD2 nc

ON

OFF

1 2 3 4

Figure 3-1: MCU mode switch: External ROM Mode Vector

The “Internal ROM Mode Vector” of MB91F467D is normally required for the final

application, which should be stored in the internal flash. In this mode the internal flash is

accessible.

MD0 MD1 MD2 nc

DIP-Switch S5

(default setting)

1 2 3 4

ON

OFF

Figure 3-2: MCU mode switch: Internal ROM Mode Vector

© Fujitsu Microelectronics Europe GmbH - 17 - FMEMCU-UG-910014-13

Page 18

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.2 Power Supply

There are four on-board switching regulators to provide the voltages 5 V, 3.3 V, 2.5 V and

1.8 V on the starter-kit. With the power ON/OFF-switch S8 or S9 (S9 is a soldering option to

use a different switch), the main input voltage from DC-connector X5 will be connected to the

Vin voltage of the board. The Vin voltage supplies the switching regulators.

Switch Setting Description

S8 or S9

Default: grey

With JP91 the pins B14, B15 and B16 of the external bus interface connector X14 can be

connected to the Vin voltage, so that it is possible to supply the board from an external

connected board.

ON (1-2) Power ON

OFF (2-3) Power OFF

Table 3-2: Power switch

There is a triple supply monitor on-board, which monitors three of the four DC output

voltages and generates a system reset, in case with wrong levels of the on board voltages.

5 V and 3.3 V are always monitored and the third monitored voltage can be selected with the

solder jumpers JP42 and JP43.

With JP68 it is possible to select the whole board supply voltage Vcc to 5 V or 3.3 V

Jumper Setting Description

JP91

ON (closed) Vin is connected to X14 pins B14, B15 and B16

OFF (open) Vin is not connected to X14 pins B14, B15 and B16

JP42

ON (closed) Vcc1V8 is connected to supply monitor

OFF (open) Vcc1V8 is not connected to supply monitor

JP43

ON (closed) Vcc2V5 is connected to supply monitor

OFF (open) Vcc2V5 is not connected to supply monitor

JP68

1-2 Vcc is connected to 5 V

2-3 Vcc is connected to 3.3 V

Default: grey

Table 3-3: Power supply configurations

FMEMCU-UG-910014-13 - 18 - © Fujitsu Microelectronics Europe GmbH

Page 19

SK-91F467D-208PFV V1.1

Jumpers and Switches

Figure 3-3: Voltage Test Points

Regulator Test point Voltage

U9 J21 +5V

U11 J22 +3.3V

U14 J23 +2.5V

U17 J24 +1.8V

- J20 GND

Table 3-4: Voltage Test Points

© Fujitsu Microelectronics Europe GmbH - 19 - FMEMCU-UG-910014-13

Page 20

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.2.1 MCU Power Supply Voltage

JP21 With this jumper it is possible to connect the MCU external bus interface supply

VDD35 to 3.3 V. The MCU MB91460 series supports the function to supply the MCU

with 5 V so that the normal I/O ports work with 5 V and supply the external bus

interface with 3.3 V.

JP23 This jumper is used to connect the HVDD5 supply to MCUVcc. The HVDD5 is the

MCU supply voltage for the high current ports.

JP25 This jumper is used to connect the VDD5R MCU supply pins to MCUVcc.

JP26 This jumper is used to connect the Vcc voltage to MCUVcc.

JP27 This jumper is used to connect the VDD5 MCU supply pins to MCUVcc.

JP28 This jumper is used to connect the HVSS5 MCU pins to GND. HVSS5 are the GND

pins for the high current ports.

Note:

JP23, JP25, JP26, JP27 and JP28 can be used for

measurements of power consumption of the MCU.

Jumper Setting Description

JP21

1-2 VDD35 is connected to MCUVcc

2-3 VDD35 is connected to 3.3 V

JP23

ON (closed) HVDD5 is connected to MCUVcc

OFF (open) HVDD5 is not connected to MCUVcc

JP25

ON (closed) VDD5R is connected to MCUVcc

OFF (open) VDD5R is not connected to MCUVcc

JP26

ON (closed) MCUVcc is connected to Vcc

OFF (open) MCUVcc is not connected to Vcc

JP27

ON (closed) VDD5 is connected to MCUVcc

OFF (open) VDD5 is not connected to MCUVcc

JP28

ON (closed) HVSS5 is connected to GND

OFF (open) HVSS5 is not connected to GND

Default: grey

Table 3-5: MCU power supply SK-91F467D-208PFV

3.2.2 MCU Analogue Power Supply Voltage

The power supply as well as the reference voltage for the A/D-converter can be provided

internally or externally.

JP15 Connects power supply AVcc of the A/D converter to MCUVcc

JP16 Connects high reference voltage AVRH of the A/D converter to AVcc

JP18 Connects AVss of the A/D converter to GND

FMEMCU-UG-910014-13 - 20 - © Fujitsu Microelectronics Europe GmbH

Page 21

SK-91F467D-208PFV V1.1

Jumpers and Switches

Jumper Setting Description

JP15

ON (closed) AVcc is connected to MCUVcc

OFF (open) AVcc is disconnected

JP16

JP18

ON (closed) AVRH is connected to AVcc

OFF (open) AVRH defined by resistor network

ON (closed) AVss is connected to GND

*1

OFF (open) AVss is disconnected

Default: grey

*1

By default the resistor network (R10 and R13) is not assembled on the board

Table 3-6: MCU ADC Supply

Note:

If JP15 or JP18 are open, the user has to supply an adequate analogue voltage supply (AVcc

and AVss) to the A/D-converter.

If JP16 is open, the potential divider comprising resistors R10 and R13 define AVRH.

© Fujitsu Microelectronics Europe GmbH - 21 - FMEMCU-UG-910014-13

Page 22

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.3 CAN0 – CAN2

Three high-speed CAN-transceivers (PCA82C250) are on-board to connect all available onchip CANs to 9-pin D-Sub connectors (X9, X10 and X11).

JP82 Connects MCU RX0 to CAN transceiver U15

JP83 Connects MCU TX0 to CAN transceiver U15

JP87 Connects MCU RX1 to CAN transceiver U18

JP88 Connects MCU TX1 to CAN transceiver U18

JP89 Connects MCU RX2 to CAN transceiver U19

JP90 Connects MCU TX2 to CAN transceiver U19

Jumper Setting Description

JP82

JP83

JP87

JP88

JP89

JP90

Default: grey

ON (closed) CAN0 RxD connected to MCU

OFF (open) No connection to the microcontroller

ON (closed) CAN0 TxD connected to MCU

OFF (open) No connection to the microcontroller

ON (closed) CAN1 RxD connected to MCU

OFF (open) No connection to the microcontroller

ON (closed) CAN1 TxD connected to MCU

OFF (open) No connection to the microcontroller

ON (closed) CAN2 RxD connected to MCU

OFF (open) No connection to the microcontroller

ON (closed) CAN2 TxD connected to MCU

OFF (open) No connection to the microcontroller

Table 3-7: CAN-MCU connection

3.4 LIN / RS-232 UART

There are three UART connectors X1, X4 and X8 (9-pin D-Sub) on-board, which can be

used for RS-232 or LIN communication (to get information in detail about pin usage, please

refer to chapter 4.2 UART / LIN Connector (X1, X4, X8)). The LIN transceiver needs to be

configured as LIN-master or LIN-slave.

FMEMCU-UG-910014-13 - 22 - © Fujitsu Microelectronics Europe GmbH

Page 23

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.4.1 UART 2

UART2 (connector X1) is selected as LIN master at default setting.

JP37 Select, whether SIN2 is connected to RS-232- or LIN-transceiver

JP44 Select, whether SOT2 is connected to RS-232- or LIN-transceiver

JP46 Select, whether RS-232- or LIN-transceiver is connected to X1 pin2 (shared pin)

JP30 Some terminal programs needs a connection between CTS and RTS

JP39 Selects, whether DTR or RTS will be used for system reset generation

JP47 Enables the LIN transceiver

JP51 Selects, whether UART2 will be LIN master or LIN

slave

Jumper Setting Description

JP37

1-2 MCU SIN2 connected to RS-232 transceiver

2-3 MCU SIN2 connected to LIN transceiver

JP44

1-2 MCU SOT2 connected to RS-232 transceiver

2-3 MCU SOT2 connected to LIN transceiver

JP46

1-2 X1 pin2 is connected to RS-232 transceiver

2-3 X1 pin2 is connected to LIN transceiver

JP30

ON (closed) RTS and CTS is shortcut at connector X1

OFF (open) RTS and CTS is not shortcut at connector X1

JP39

1-2 DTR can be used for system reset

2-3 RTS can be used for system reset

JP47

ON (closed) LIN transceiver is enabled

OFF (open) LIN transceiver is not enabled

JP51

ON (closed) LIN master mode

OFF (open) LIN slave mode

Default: grey

Note:

UART2 has to be selected with

JP57 to generates a system reset

Table 3-8: UART2 settings

© Fujitsu Microelectronics Europe GmbH - 23 - FMEMCU-UG-910014-13

Page 24

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.4.2 UART 4 (Flash Programming)

UART4 (connector X4) is selected as RS-232 at default setting. UART4 is also used to write

user software into the flash of the MCU.

JP60 Select, whether SIN4 is connected to RS-232- or LIN-transceiver

JP65 Select, whether SOT4 is connected to RS-232- or LIN-transceiver

JP69 Select, whether RS-232- or LIN-transceiver is connected to X4 pin2 (shared pin)

JP58 Some terminal programs needs a connection between CTS and RTS

JP64 Selects, whether DTR or RTS will be used for system reset generation

JP71 Enables the LIN transceiver

JP72 Selects, whether UART4 will be LIN master or LIN

slave

Jumper Setting Description

JP60

1-2 MCU SIN4 connected to RS-232 transceiver

2-3 MCU SIN4 connected to LIN transceiver

JP65

1-2 MCU SOT4 connected to RS-232 transceiver

2-3 MCU SOT4 connected to LIN transceiver

JP69

1-2 X4 pin2 is connected to RS-232 transceiver

2-3 X4 pin2 is connected to LIN transceiver

JP58

ON (closed) RTS and CTS is shortcut at connector X4

OFF (open) RTS and CTS is not shortcut at connector X4

JP64

1-2 DTR can be used for system reset

2-3 RTS can be used for system reset

JP71

ON (closed) LIN transceiver is enabled

OFF (open) LIN transceiver is not enabled

JP72

ON (closed) LIN master mode

OFF (open) LIN slave mode

Default: grey

Note:

UART4 has to be selected with

JP57 to generates a system reset

Table 3-9: UART4 settings

FMEMCU-UG-910014-13 - 24 - © Fujitsu Microelectronics Europe GmbH

Note:

UART4 is used as serial interface

for Softune Workbench Monitor

Debugger. Jumper J58 must be

closed.

Page 25

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.4.3 UART 5

UART5 (connector X8) is selected as RS-232 at default setting.

JP79 Select, whether SIN5 is connected to RS-232- or LIN-transceiver

JP81 Select, whether SOT5 is connected to RS-232- or LIN-transceiver

JP84 Select, whether RS-232- or LIN-transceiver is connected to X8 pin2 (shared pin)

JP78 Some terminal programs needs a connection between CTS and RTS

JP80 Selects, whether DTR or RTS will be used for system

reset generation

JP85 Enables the LIN transceiver

JP86 Selects, whether UART5 will be LIN master or LIN

slave

Jumper Setting Description

JP79

1-2 MCU SIN4 connected to RS-232 transceiver

2-3 MCU SIN4 connected to LIN transceiver

JP81

1-2 MCU SOT4 connected to RS-232 transceiver

2-3 MCU SOT4 connected to LIN transceiver

JP84

1-2 X4 pin2 is connected to RS-232 transceiver

2-3 X4 pin2 is connected to LIN transceiver

JP78

ON (closed) RTS and CTS is shortcut at connector X4

OFF (open) RTS and CTS is not shortcut at connector X4

JP80

1-2 DTR can be used for system reset

2-3 RTS can be used for system reset

JP85

ON (closed) LIN transceiver is enabled

OFF (open) LIN transceiver is not enabled

JP86

ON (closed) LIN master mode

OFF (open) LIN slave mode

Default: grey

Note:

UART5 has to be selected with

JP57 to generates a system reset

Table 3-10: UART5 settings

© Fujitsu Microelectronics Europe GmbH - 25 - FMEMCU-UG-910014-13

Page 26

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.5 User Push Buttons INT0, INT1, INT2 and ICU0/TIN0

There are four user push buttons on the starter-kit, which can be connected to the

microcontroller.

JP92 – JP95 Connects the user push buttons (SW2 – SW5) to the microcontroller

Jumper Setting Description

JP92 (SW2)

JP93 (SW3)

JP94 (SW4)

JP95 (SW5)

Default: grey

ON (closed) Button INT0 is connected to the microcontroller

OFF (open) No connection to the microcontroller

ON (closed) Button INT1 is connected to the microcontroller

OFF (open) No connection to the microcontroller

ON (closed) Button INT2 is connected to the microcontroller

OFF (open) No connection to the microcontroller

ON (closed) Button ICU0/TIN0 is connected to the microcontroller

OFF (open) No connection to the microcontroller

Table 3-11: User push buttons

3.6 User DIP Switch 8 Bit (S4)

There is an 8 bit user-DIP-switch on-board, which can be connected to one MCU port (P26)

in order to set high- or lowlevel. S3, also an 8 bit DIP-switch, dis- / connects the eight

channels of S4 to the MCU pins. In case of other usage of these pins, open S3 switch

accordingly.

DIP switch Setting Logical value

S4/1 - 8

Default: grey

Table 3-12: S4 values

DIP switch Setting Description

S3/1 - 8

Default: grey

ON (closed) 0 (low)

OFF (open) 1 (high)

Note:

DIP-switch S3 is used to connect DIP-switch S4 to the MCU port

pins at port P26.

ON (closed) S4/1-8 connected to MCU port P26_0-7

OFF (open) No connection to the microcontroller

Table 3-13: S3 settings

FMEMCU-UG-910014-13 - 26 - © Fujitsu Microelectronics Europe GmbH

Page 27

SK-91F467D-208PFV V1.1

Jumpers and Switches

3.7 Reset Generation

A system reset can be generated in different ways. The first possibility is to press the user

reset push button (SW1). Secondly, the supply monitor will generate a reset if an unusual

voltage is detected and third, a reset is raised if the selected UART generates one.

An active system reset is indicated by the reset LED D18.

The system reset will do a simultaneous reset of the microcontroller. The MCU can be

disconnected from the system reset signal.

JP96 The Reset push button can be used in two modes:

• Immediate reset

• Secured Reset (2s)

The selection is done by solder jumper JP96.

JP54 Connects the MCU to the system reset signal

Jumper Setting Description

JP54

JP96

Default: grey

ON (closed) Reset is connected to MCU INITX

OFF (open) No connection to the MCU

1-2 Reset is generated immediately when SW1 is

pressed

2-3 Reset is generated after SW1 is pressed 2s

Table 3-14: Reset connections

The triple supply monitor on-board has the possibility to watch 5V, 3.3V and the third voltage

is user configurable 2.5V or 1.8V. If any voltage fails, a system reset will be done.

JP42 Monitoring of 1.8V supply voltage

JP43 Monitoring of 2.5V supply voltage

Jumper Setting Description

JP42

ON (closed) Vcc1V8 connected to supply monitor

OFF (open) Vcc1V8 not connected to supply monitor

JP43

ON (closed) Vcc2V5 connected to supply monitor

OFF (open) Vcc2V5 not connected to supply monitor

Default: grey

Table 3-15: Supply monitor settings

By default 2.5V supply will be monitored. Do not close both jumpers simultaneously.

The system reset also can be done via any UART. Therefore the user has the possibility to

select one of the three on-board UARTs.

JP57 Select which UART should generate the system reset

JP29 The polarity of the DTR/RTS signal can be inverted by this jumper. Remove the

jumper to disable the UART reset function

© Fujitsu Microelectronics Europe GmbH - 27 - FMEMCU-UG-910014-13

Page 28

SK-91F467D-208PFV V1.1

Jumpers and Switches

Jumper Setting Description

1-2 Reset will be done via UART2

JP57

3-4 Reset will be done via UART4

5-6 Reset will be done via UART5

JP29

1-2 No polarity inversion for the DTR/RTS signal

2-3 Polarity inversion for the DTR/RTS signal

Table 3-16: Reset UART selection

By default the UART reset is disabled.

Note:

During normal operation, the reset LED should be off!

If the reset LED is steadily on, check the power supply

voltages and the settings for the reset generation by UART.

FMEMCU-UG-910014-13 - 28 - © Fujitsu Microelectronics Europe GmbH

Page 29

SK-91F467D-208PFV V1.1

Connectors

4 Connectors

4.1 Power Connector (X5)

The following figure shows the power connection jack of the starter-kit. This connector is

used to connect an external unregulated DC power supply voltage (9 V-12 V DC

recommended 2000 mA).

Shield is connected to positive voltage supply (+)

Centre is connected to ground (GND)

Figure 4-1 Power connector

4.2 UART / LIN Connector (X1, X4, X8)

Three 9-pin D-Sub female connectors are used for the serial interfaces LIN/UART2,

LIN/UART4 and LIN/UART5.

Take care, that the RS232 as well as the LIN signals are shared at the connectors and have

to be selected by jumpers (see chapter 3.4).

Figure 4-2 UART connector

Pin Number Pin Signal Description

1 +VBat Power from LIN bus

2

3 RXD RS-232 receive input

4 DTR Connected to DSR (pin 6)

5 GND Ground normally used for RS232 connection

6 DSR Connected to DTR (pin 4)

7 RTS Can be connected with CTS by jumper

8 CTS Can be connected with RTS by jumper

9 LGND Ground normally used for LIN connection

Shield GND Ground

TXD RS-232 transmit output

LIN Bi-directional LIN-interface

Table 4-1: UART connector signals

© Fujitsu Microelectronics Europe GmbH - 29 - FMEMCU-UG-910014-13

Note:

Please use 1:1 cable for RS232 PC-connection.

Page 30

SK-91F467D-208PFV V1.1

Connectors

4.3 CAN Connector (X9, X10, X11)

Three 9-pin D-Sub male connectors are used for the CAN interfaces CAN0, CAN1 and

CAN2.

Figure 4-3: CAN connector

Pin Number Pin Signal Description

1 NC Not used

2 CANL LOW-level CAN voltage input/output

3 GND Ground

4 NC Not used

5 NC Not used

6 NC Not used

7 CANH HIGH-level CAN voltage input/output

8 NC Not used

9 NC Not used

Shield GND Ground

Table 4-2: CAN connector signals

FMEMCU-UG-910014-13 - 30 - © Fujitsu Microelectronics Europe GmbH

Page 31

SK-91F467D-208PFV V1.1

Connectors

4.4 USER-LEDs and Optional LC-Display (D1-D16, J6)

There are sixteen user LEDs on-board, D1-D8 connected to MCU port P25 and D9-D16

connected to MCU port P16. To disconnect the LEDs from the MCU, it is possible to remove

RN3 (D1-D8 at port P25) and RN2 (D9-D16 at port P16).

It is also possible to connect a standard LCD module with backlight to connector J6. With the

potentiometer RP1 the contrast of the LCD can be adjusted.

Pin 14 13 12 11 10 9 8 7 6 5 4 3 2 1 16 15

LCD DB7 DB6 DB5 DB4 - - - - E R/W RS VO Vcc GND LED- LED+

LED D8 D7 D6 D5 D4 D3 D2 D1

Port P25_7 P25_6 P25_5 P25_4 P25_3 P25_2 P25_1 P25_0

MCU 187 186 185 184 181 180 179 178

Table 4-3: LED/LCD Signals

LCD contrast

(Port: P16_7)

D16

D9

(Port: P16_0)

D8

(Port: P25_7)

Figure 4-4: User LEDs / LCD

D1

(Port: P25_0)

© Fujitsu Microelectronics Europe GmbH - 31 - FMEMCU-UG-910014-13

Page 32

SK-91F467D-208PFV V1.1

Connectors

4.5 In-Circuit-Programming Connector (X12)

There is a flash-programming socket on the starter-kit which makes it possible to program

the flash MCU with a special programming adapter. Mode pins and reset signal are also

available at this connector.

Figure 4-5: In-circuit programming connector

Pin Number Pin Signal Description

1 NC Not used

2 NC Not used

3 MD0 MCU mode-pin 0

4 MD2 MCU mode-pin 2

5 INITX MCU reset signal

6 SIN4 UART4 receive data

7 SOT4 UART4 transmit data

8 SCK4 UART4 clock

9 VCC Board supply voltage

10 GND Ground

Table 4-4: In-circuit programming connector

4.6 MCU Pin Connectors (J1-J4)

All MCU pins are directly connected to the four pin header around the MCU. The last two

pins of the pin header J1, J2, J3 and J4 are unused (see PCB silk plot).

Connector MCU Pins

J1 1-52

J2 53-104

J3 105-156

J4 157-208

Table 4-5: MCU pin connectors

The corresponding pin numbers of the MCU are written next to the connector pins on the

PCB.

FMEMCU-UG-910014-13 - 32 - © Fujitsu Microelectronics Europe GmbH

Page 33

SK-91F467D-208PFV V1.1

Connectors

4.7 External Bus Connectors (X13, X14)

4.7.1 VG96ABC DIN 41612 (X13)

Pin Name MCU-P. Pin Name MCU-P. Pin Name MCU-P.

A1 2.5 V - B1 2.5 V - C1 2.5 V -

A2 3.3 V - B2 3.3 V - C2 3.3 V -

A3 5.0 V - B3 5.0 V - C3 5.0 V -

A4 GND - B4 GND - C4 GND -

A5 D0 192 B5 D1 193 C5 D2 194

A6 D3 195 B6 D4 196 C6 D5 197

A7 D6 198 B7 D7 199 C7 D8 200

A8 D9 201 B8 D10 202 C8 D11 203

A9 D12 204 B9 D13 205 C9 D14 206

A10 D15 207 B10 D16 2 C10 D17 3

A11 D18 4 B11 D19 5 C11 D20 6

A12 D21 7 B12 D22 8 C12 D23 9

A13 D24 10 B13 D25 11 C13 D26 12

A14 D27 13 B14 D28 14 C14 D29 15

A15 D30 16 B15 D31 17 C15 GND -

A16 GND - B16 GND - C16 GND -

A17 A0 18 B17 A1 19 C17 A2 20

A18 A3 21 B18 A4 22 C18 A5 23

A19 A6 24 B19 A7 25 C19 A8 28

A20 A9 29 B20 A10 30 C20 A11 31

A21 A12 32 B21 A13 33 C21 A14 34

A22 A15 35 B22 A16 36 C22 A17 37

A23 A18 38 B23 A19 39 C23 A20 40

A24 A21 41 B24 A22 42 C24 A23 43

A25 A24 44 B25 A25 45 C25 NC -

A26 NC - B26 NC - C26 NC -

A27 NC - B27 NC - C27 GND -

A28 P27_0 158 B28 P27_1 159 C28 P27_2 160

A29 P27_3 161 B29 P27_4 164 C29 P27_5 165

A30 P27_6 166 B30 P27_7 167 C30 GND -

A31 2.5V - B31 2.5V - C31 NC

A32 GND - B32 GND - C32 GND

Table 4-6: VG96 (X13) signals

Note:

The pin numbers of the VG connectors refer to the male connectors, that plugs

into the starter-kit. Please see chapter 5 to find the right orientation.

© Fujitsu Microelectronics Europe GmbH - 33 - FMEMCU-UG-910014-13

Page 34

SK-91F467D-208PFV V1.1

Connectors

4.7.2 VG48ABC DIN 41612 (X14)

Pin Name MCU-P. Pin Name MCU-P. Pin Name MCU-P.

A1 CSX0 56 B1 GND - C1 CSX1 57

A2 CSX2 58 B2 1.8V - C2 CSX3 59

A3 NC - B3 GND - C3 NC -

A4 CSX6 60 B4 1.8V - C4 RDY 55

A5 BGRNTX 51 B5 GND - C5 BRQ 54

A6 RDX 50 B6 NC - C6 WRX0 46

A7 WRX1 47 B7 NC - C7 WRX2 48

A8 WRX3 49 B8 NC - C8 ASX 62

A9 NC - B9 NC - C9 MCLKO 65

A10 DREQ0 189 B10 NC - C10 DACKX0 190

A11 DEOP0 191 B11 NC - C11 NC -

A12 INT12 97 B12 NC - C12 SDA0 99

A13 INT13 98 B13 NC - C13 SCL0 100

A14 SIN5 109 B14 Vin - C14 SOT5 110

A15 GND - B15 Vin - C15 SCK5 111

A16 INITX 73 B16 Vin - C16 GND -

Table 4-7: VG48 (X14) signals

Note:

The pin numbers of the VG connectors refer to the male connectors, that plugs

into the starter-kit. Please see chapter 5 to find the right orientation.

4.7.3 Distance between VG-Connectors

To connect own applications to the starter-kit the following figure shows the distance

between the VG DIN 41612 connectors.

Figure 4-6: Layout of DIN VG connectors

8,89 mm/

350 mil

FMEMCU-UG-910014-13 - 34 - © Fujitsu Microelectronics Europe GmbH

Page 35

SK-91F467D-208PFV V1.1

Getting Started

5 Getting Started

Make sure that the FR Family Softune Workbench is installed on your PC and the “SK91F467D-208PFV” is ready to use (power-on (X5), serial connection (UART4) to COM port

of the PC).

5.1 Introduction to Softune Workbench

Start Softune Workbench. Select <File> <Open Workspace> to load the first example

“mb91460_io.wsp”. All examples can be found in the folder \Software\SWB_Samples on the

starter-kit CD-ROM. It is recommended to copy this folder to the local hard-drive. In the

project tree on the left side, you can open the “source”-folder which contains the source-files

registered to this project. A double-click on one of the files will invoke the built-in editor,

which supports syntax-highlighting, tags and various other functions.

Figure 5-1: Softune Workbench main window

Note:

You may customize the editor by a right-click on the editor

window.

© Fujitsu Microelectronics Europe GmbH - 35 - FMEMCU-UG-910014-13

Page 36

SK-91F467D-208PFV V1.1

Getting Started

Whenever you modify the source-files, you have to re-compile and link the related files to

produce a valid loadmodule (ABS-file). This is done using the MAKE-function. MAKE

invokes the assembler, C-compiler and linker for FR whenever necessary (only modified files

will be re-compiled).

If you wish to re-compile the entire project regardless of any changes, you can use the

BUILD-function. To check for syntax-errors on a specific source-file, use the

COMPILE/ASSEMBLE function.

These three functions are available on the button-bar or from the main menu (Project –

Compile / Make / Build / Abort).

Click on MAKE or BUILD. Messages from the individual language tools will be fed into the

output window at the bottom of the main screen. If the tool chain (C-compiler → Assembler

→ Linker) was completed successfully, the message “No Error” will appear.

If you get any errors during build, an appropriate message will be generated. Try this with a

simple syntax-error (e.g. delete a semicolon “;” from the end of a C-line) and click on MAKE

again. You will now see a message like this:

Now Making...

--------------------Configuration: 91460_io.prj - Debug-------------------main.c

*** C:\SK-91F467-208PFV\91460_io\Src\main.c(81) E4065B: expected a ";"

*** C:\SK-91F467-208PFV\91460_io\Src\main.c(104) W1012B: warning: parsing restarts here after

previous syntax error

1 error detected in the compilation of

"C:\ SK-91F467-208PFV\91460_io\Src\main.c".

-----------------------------Error detected.

------------------------------

To locate the position in the source-file, where the error occurred, double-click on the

message. The editor will open the appropriate source-file, indicating the error highlighted in

red, depending on the customise settings of the editor. Correct the error and re-compile the

project as explained above.

If more errors occurred, you can go through the error list step by step using the menu “Edit –

Top/Previous/Next/Bottom Error” or using the appropriate buttons which have the same

functions:

FMEMCU-UG-910014-13 - 36 - © Fujitsu Microelectronics Europe GmbH

Note:

To get on-line help about a specific error, select the error

message and press F1. In many cases, you can get some useful

hints how to solve the problem. Of course, you can also use the

HELP-menu anytime during development or debugging.

Page 37

SK-91F467D-208PFV V1.1

Getting Started

5.2 Project Start-up

In order to allow a quick and smooth project start-up Fujitsu Microelectronics Europe

supplies a template project as a reference. The easiest way to start a new project is to make

a copy of the template project and use this copy as a start-up. The template includes the

latest start91460.asm file, MCU header file, IRQ table, basic linker and C-Compiler settings.

Note:

In any case the settings done in the template must be checked and have to be

adjusted to the specific needs and settings of the final application. The template is

providing an example for building up a new project.

THIS SAMPLE CODE IS PROVIDED AS IS AND IS SUBJECT TO ALTERATIONS. FUJITSU

MICROELECTRONICS ACCEPTS NO RESPONSIBILITY OR LIABILITY FOR ANY ERRORS

OR/ELIGIBILITY FOR ANY PURPOSES. (C) Fujitsu Microelectronics Europe GmbH

5.2.1 Create a New Project:

1. In order to start a new user-project use the “91460_template_91467d” project

2. Copy the folder 91460_template_91467d and rename the folder to e.g.

my_application

3. Enter the folder “my_application”

Rename “91460_template_91467d.prj” into “my_application.prj”

Rename “91460_template_91467d” into “my_application.wsp”

4. Edit “my_application.prj”

Rename “91460_template_91467d” -> “my_application”

5. Edit “my_application.wsp”

Rename “91460_template_91467d” -> “my_application”

© Fujitsu Microelectronics Europe GmbH - 37 - FMEMCU-UG-910014-13

Page 38

SK-91F467D-208PFV V1.1

Getting Started

Rename “91460_template_91467d”

into “my_application”

6. Start Softune Workbench and open your project

Figure 5-2: Open Softune Workbench workspace (*.wsp)

FMEMCU-UG-910014-13 - 38 - © Fujitsu Microelectronics Europe GmbH

Page 39

SK-91F467D-208PFV V1.1

Getting Started

7. Select the active configuration STANDALONE. In this configuration the application is

linked for the available memory on flash-device, e.g. MB91F467D.

8. Use “Make”, or “Build” to compile and link the project for available memory on flash-

device. The generated output files can be found in the sub-folder STANDALONE of

the project folder. The *.mhx file (Motorola S-Record) is located in the ABS subfolder.

Note:

Always check the memory map of the linker settings and ensure

that this memory map is suitable for the application and target

system in use. Additionally the *.mp1 file should be checked to

ensure correct settings.

9. Now, the application can be debugged, therefore, please have a look at the next

chapter. Or the generated *.mhx file (Motorola S-Record) can be programmed with

the flash programming utility into the internal flash. Please keep in mind, that

therefore the mode pins have to be set to “Internal ROM Mode Vector”.

Note:

The starter-kit is delivered with the mode pin settings for the

“External ROM Mode Vector”, which allows to debug the

application with the pro-programmed SWB Monitor Debugger.

If the application should be programmed into the internal flash, the

mode pins have to be switched to the “Internal ROM Mode

Vector”.

5.3 Softune Workbench Monitor Debugger

5.3.1 General Description

Whenever you have created a valid load module successfully, you can switch from the

development mode to the debugging mode of Softune Workbench.

Basically, there are 3 types of debugging systems supported:

1. The software simulator: The simulator is part of the Softune Workbench and does

not require any target hardware. The simulator will cover the FR-core features,

but no peripheral functions. Therefore, you can use the simulator to verify

program flow, check for dynamic errors, look at the generated assembler code,

etc. .

2. The SWB Monitor Debugger: This debugger type requires an evaluation board

like the “SK-91F467-208PFV” connected to one of the COM-ports of your PC.

Explanations in this manual refer to the SWB Monitor Debugger only. For further

information please see also the application note “swb_monitor_debugger”

3. The emulator debugger: The in-circuit emulator (ICE) is a system, which allows a

connection to any target system using a probe-cable. The appropriate system for

the MB91460 series is the MB2198-01 system. More information about this

system can be found on the Fujitsu website.

Which debugger is used for the actual project can be configured in the project tree as shown

below or in the “Project – Setup Project – Debug” menu. The current selection is blue

marked (icon):

© Fujitsu Microelectronics Europe GmbH - 39 - FMEMCU-UG-910014-13

Page 40

SK-91F467D-208PFV V1.1

Getting Started

There are some little restrictions, when using the SWB Monitor Debugger:

1) Due to the fact that the application code is located in the external RAM, the execution

speed of the code is slower, because of the slower external bus access.

2) Depending on the used linkage option of the SWB Monitor Debugger, CS 0 and CS 1

are required for the external memory. The affected CS has to be switched off in the

start-up of the application. (#set CS0 OFF, #set CS1 OFF).

3) Since some settings for the SWB Monitor Debugger during start-up are required, the

start-up file cannot be debugged. After starting the SWB Monitor Debugger, the

program execution stops at main(). Furthermore, the clock settings of the application

start-up are omitted. For the desired clock settings the SWB Monitor Debugger has to

be adapted.

4) To indicate the current state of the SWB Monitor Debugger a certain port is used.

This feature can also be disabled to give the port free for the application.

To stop the execution of the program the external interrupt INT0 is used. This feature can

also be disabled to give the port free for the application. The “abort” button of the Softune

Workbench is not fully supported. A detailed explanation of the necessary changes of the

SWB Monitor Debugger can be found in the application note “mb91460_swb_monitor

_debugger”.

5.3.2 Starting the SWB Monitor Debugger

After software development the SWB Monitor Debugger can be used for debugging.

1) Please make sure, that SWB Monitor Debugger is programmed into the external

Flash. To use the Monitor Debugger, the CPU Mode selection must be set to

“External ROM Mode Vector” mode by setting DIP switch S5 to (On, Off, Off, Off).

The correct start-up of the SWB Monitor Debugger is indicated by D2, D4 and D8

Figure 5-3: Correct start-up of the SWB Monitor Debugger

FMEMCU-UG-910014-13 - 40 - © Fujitsu Microelectronics Europe GmbH

Page 41

SK-91F467D-208PFV V1.1

Getting Started

2) To start the SWB Monitor Debugger, double-click the entry

“Mondeb_57K6_com1.sup” for communication via COM1 (57K6 baud, 8N1) or

“Mondeb_57K6_com2.sup” for communication via COM2 (57K6 baud, 8N1).

Figure 5-4: Start SWB Monitor Debugger with external flash and SRAM

3) Since some settings for the SWB Monitor Debugger during start-up are required, the

start-up file can not be debugged. The settings are done with the help of procedure

files. After starting the SWB Monitor Debugger, the program execution stops at

main().

© Fujitsu Microelectronics Europe GmbH - 41 - FMEMCU-UG-910014-13

Page 42

SK-91F467D-208PFV V1.1

Getting Started

5.3.3 Basic Debugger Features

After starting the SWB Monitor Debugger, the source window will be opened which contains

locate-arrows for each (possible) source-line, the original source-code,

Figure 5-5: SWB debugging window

Breakpoint-indicators and the assembler code (in “mixed view”). The current program

position will be indicated by a yellow line. Use right-click in the source window to configure

the view (add/remove control characters, view mixed source code, breakpoint …)

Note:

You can choose “mixed view” from the context menu (right-click)

to display source and assembly code at the same time. The

command “go to current” will take you to the active code line!

FMEMCU-UG-910014-13 - 42 - © Fujitsu Microelectronics Europe GmbH

Page 43

SK-91F467D-208PFV V1.1

Getting Started

In the following the basic features of the SWB Monitor Debugger are described.

GO: Executes the program continuously from the memory location pointed to by the

current program counter (PC) until a termination factor occurs.

STEP IN: Executes the program stepwise according to the listing in the source

window (steps in C- or ASM). Note that interrupts are disabled during step execution!

STEP OVER: Executes the program stepwise except call-instructions (which will be

executed until return). Interrupts are not disabled during a continuous CALL...RETURN

execution.

STEP OUT: Executes the program continuously to the parent function (until

RETURN). Interrupts are enabled. Note, that debug information is required for this function.

EXECUTE UNTIL CURSOR: Automatically sets a breakpoint at the actual cursor

position and executes continuously until this breakpoint, which will be deleted

afterwards.

Each valid code line in a debugger window automatically has a locator (blue arrow) and a

breakpoint-option (circle). Note that some C-lines may not be displayed with locators and

breakpoints, because the compiler has created “optimized” assembler-code. Select “mixed

view” in order to check the compiler output.

Instead of single-steps, you may also use the arrows to directly execute your program until a

certain line of your source-code:

© Fujitsu Microelectronics Europe GmbH - 43 - FMEMCU-UG-910014-13

Page 44

SK-91F467D-208PFV V1.1

Getting Started

ABORT: Forcibly terminates execution. This button is not fully supported by the

SWB Monitor Debugger and may cause malfunction if used to abort “continuous

operation” of the MCU.

This command button can only be used to abort single code line operations

Example: for(k=DELAY_CONSTANT; k>0; k--);

Use the button INT0 on the “SK-91F467-208PFV” for ABORT function.

To ABORT continuous execution, you have to use the INT0 button on the starter-

kit.

5.4 Advanced Softune Workbench SWB Monitor Debugger Features

In the following advanced features of the SWB Monitor Debugger are described.

TOGGLE BREAKPOINT: Sets or deletes breakpoint at the current source line:

To set or delete a breakpoint, click the circles at the beginning of a source-line.

A indicates an active breakpoint. Hit “Run continuously” to execute code until

reaching this line. A list of all breakpoints can be found under the “Debug – Breakpoint”

menu. 255 Software-Breakpoints (using TRAP replacement) are possible.

Note:

To set breakpoints at positions which are currently not visible (e.g.

because the source window of that module is not open), you can

also enter a symbolic label directly in the “Breakpoint” menu.

Example: Enter “main” in the address-field and confirm. The new

breakpoint will automatically be assigned to the address of the

“main()”-function.

REGISTER WINDOW: Displays the CPU-register window. Updated registers appear

in red. Setup in context menu defines which Registers should be displayed.

WATCH WINDOW: Displays the current variables to „watch“. Double-click on any

variable in your code then specify watch in context menu to add to watch window. All listed

variables in a watch window can be displayed in any number format. Use Edit to directly

change the contents.

MEMORY WINDOW: Displays memory areas in various formats defined by Setup

(context menu). Changing of address/data is possible when debugger is not executing.

The memory window can be very helpful to check the registers or the frame memory of the

connected graphic controller!

FMEMCU-UG-910014-13 - 44 - © Fujitsu Microelectronics Europe GmbH

Page 45

SK-91F467D-208PFV V1.1

Getting Started

DISASSEMBLER: Disassembles the content of the code memory beginning from

actual PC position and displays the result in a separate window. Individual

assembler-lines can be changed using the „inline assemble“-function.

DEBUG - STACK: Displays the current stack contents in terms of function calls.

Parameters, if any, are displayed in brackets.

DEBUG - VECTOR: Reads out and displays the actual interrupt-vector table. Use the “jump”

function to display any code areas pointed to by an interrupt vector (e.g. interrupt service

routines used in your program).

DEBUG - CALL: This function can be used to “call” any routine defined in your code when

the debugger is on hold.

DEBUG – LOAD TARGET FILE: Starts a new download of the current load module (ABS

file). Usually this function will be executed automatically after starting the debugger (defined

in debug settings; see „Project-Setup-Debug“). However, this function can be useful to re-

initialize the debugger for the current debug session.

VIEW - SYMBOL: This function displays all (global) symbols of the current project.

Information about the type (char, integer etc.) and the location (address in RAM or register)

can be shown using „detail“.

VIEW - LOCAL: Similar to View-Symbol, but only local variables of the current function are

shown.

VIEW - COMMAND: From this window, the debugger can be controlled using a command

line input. All GUI functions are available as individual commands.

In order to document or save debugging details such as memory contents, all outputs fed to

the command console can be written to a file (“logging”).

A whole “program” of commands (incl. flow control) can be written to a PRC-file and

executed. Procedure-files are simple text-files with the extension “.PRC” and can be created

by the Softune Workbench editor or any other text editor. To execute a procedure-file, use

the command window menu or the “file-open” menu during debugging.

Note:

Procedure-files can be very helpful to configure the debugenvironment automatically, perform automated tests (e.g. when a

new C-module has to be tested) or to enhance basic emulator

functions such as breakpoints. Using a procedure file, breakpoints

can be defined dynamically depending on program conditions.

See the “Command Reference Manual” (on-line help) for detailed

information about the available command and parameter syntax.

Some procedure files exist already included in the example project

directory.

© Fujitsu Microelectronics Europe GmbH - 45 - FMEMCU-UG-910014-13

Page 46

SK-91F467D-208PFV V1.1

Getting Started

5.5 Memory Configuration

The following picture shows the linkage map and the memory organisation, if the SWB

Monitor Debugger is used with external flash and SRAM.

2:8000h

4:0000h

F:FC00h

F:FFFFh

14:FFFFh

(MB91467D)

Internal RAM/Flash External Flash

Appl. Data

Appl. Code

Appl. Vector Table

2:8000h

2:FFFFh2:FFFFh

4:0000h

Internal RAM External SRAM

Appl. Data

Not accessable

CS 1

Appl. Code

Appl. Vector Table

Free

MDE Data

4:0000h

F:FC00h

F:FFFFh

14:FFFFh (MB91467D)

3F:F000h

3F:FFFFh

100:0000h

10F:FC00h

10F:FFFFh

11F:FFFFh

17F:FFFFh

MDE Vector Table

CS 0

MDE Code

Free

Figure 5-6: Default linkage map for the SWB Monitor Debugger of the MB91467D

On the left hand site the memory organisation of the normal operation mode of the

microcontroller MB91F467D can be seen, the whole application is internal. For this operation

mode the mode pins have to be set to 0-0-0, hence DIP switch S5 has to be set to off, off,

off, off.

On the right hand site the microcontroller runs in the external reset-vector mode, which

requires the mode pins setting 1-0-0, hence DIP switch S5 has to be set to on, off, off, off. In

this mode the internal flash is not accessible any more. The external SRAM takes the place

of the internal flash. The kernel of the SWB Monitor Debugger is located in the external

flash.

FMEMCU-UG-910014-13 - 46 - © Fujitsu Microelectronics Europe GmbH

Page 47

SK-91F467D-208PFV V1.1

Programming the internal Flash

6 Programming the internal Flash

This chapter describes the serial asynchronous programming of the internal flash with the

help of the ‘FME-FR Programmer’ in automatic mode. For other programming possibilities,

please see the application note mcu-an-300012-e-mb91460_flash_programming.pdf.

1) For serial asynchronous programming SUB-D9 connector X4 which is connected to

UART4 has to be used. The following jumper setting is needed.

Jumper Setting Description

JP60 1-2 closed MCU SIN4 connected to RS-232 transceiver

JP65 1-2 closed MCU SOT4 connected to RS-232 transceiver

JP69 1-2 closed X4 pin2 is connected to RS-232 transceiver

Table 6-1: Jumper setting on starterkit SK-91F467D-208PFV

2) If the programming software should generate a reset signal on RTS or DTR line, refer

to the following jumper list.

Jumper Setting Description

closed RTS and CTS is shortcut at connector X4

JP58

open RTS and CTS is not shortcut at connector X4

1-2 closed DTR can be used for system reset

JP64

2-3 closed RTS can be used for system reset

JP57 3-4 closed Reset will be done via UART4

1-2 closed No polarity inversion for the DTR/RTS signal

JP29

2-3 closed Polarity inversion for the DTR/RTS signal

Table 6-2: Jumper settings for reset signal on starterkit SK-91F467D-208PFV

3) The CPU Mode selection must be set to internal reset vector mode by setting DIP

switch S5 to (Off, Off, Off, Off)

© Fujitsu Microelectronics Europe GmbH - 47 - FMEMCU-UG-910014-13

Page 48

SK-91F467D-208PFV V1.1

Programming the internal Flash

JP29

JP58

X4

JP60 JP64

JP57

JP65 JP69

Figure 6-1: Jumper setting on starterkit SK-91F467D-208PFV

4) Start the ‘FME-FR Programmer’ and connect the UART4 to your serial PC

communication port. A straight cable connection has to be used.

5) Choose the microcontroller device (“MB91F467D”) as device type and browse to the

mhx-file you want to program to the embedded flash memory of the microcontroller.

Press the button “Automatic Mode” to start programming.

6) After that, immediately reset the microcontroller.

FMEMCU-UG-910014-13 - 48 - © Fujitsu Microelectronics Europe GmbH

Page 49

SK-91F467D-208PFV V1.1

Programming the internal Flash

RESET MCU

Figure 6-2: Settings for Automatic Mode

7) If your hardware supports MCU reset via DTR or RTS signal lines of the PC’s COM

port, go to sheet “Signals” and select the appropriate reset signal line. The

programmer now resets the microcontroller automatically before starting the

programming sequence and you do not have to reset the MCU manually immediately

after pressing the button “Automatic Mode”.

Figure 6-3: Reset Signal Settings

© Fujitsu Microelectronics Europe GmbH - 49 - FMEMCU-UG-910014-13

Page 50

SK-91F467D-208PFV V1.1

Programming the internal Flash

The software now automatically writes a flash loader to the microcontroller, does a blank

check and erases the flash memory if necessary. After that the user application is

programmed to the embedded flash memory.

During this sequence the actual progress status can be seen by checked off steps on the

“Automatic” sheet and the messages below in the message box.

If the programming sequence is ended successfully, you will receive the output shown in

figure 7.

The Addresses 0x14:8000 to 0x14:800F cannot be written in automatic mode. This is a built

in security feature to prevent unintended writing to the Flash Security Vectors and Boot

Security Vectors. Otherwise it would be possible to secure flash content and to lock the

microcontroller for serial programming/reading/erasing by not being able to enter the internal

loader anymore. If you want to use these features explicitly, you have to program these

dedicated addresses by using the “Prog Word” Function of the step-by-step mode.

Figure 6-4: Successful Programming in Automatic Mode

FMEMCU-UG-910014-13 - 50 - © Fujitsu Microelectronics Europe GmbH

Page 51

SK-91F467D-208PFV V1.1

Programming the SWB Monitor Debugger

7 Programming the SWB Monitor Debugger

The following procedure describes the installation process for the SK-91F467D-208PFV and

the MB91F467D.

1) The CPU mode selection must be set to internal reset vector mode by setting DIP