Page 1

Fujitsu Microelectronics Europe

User Guide

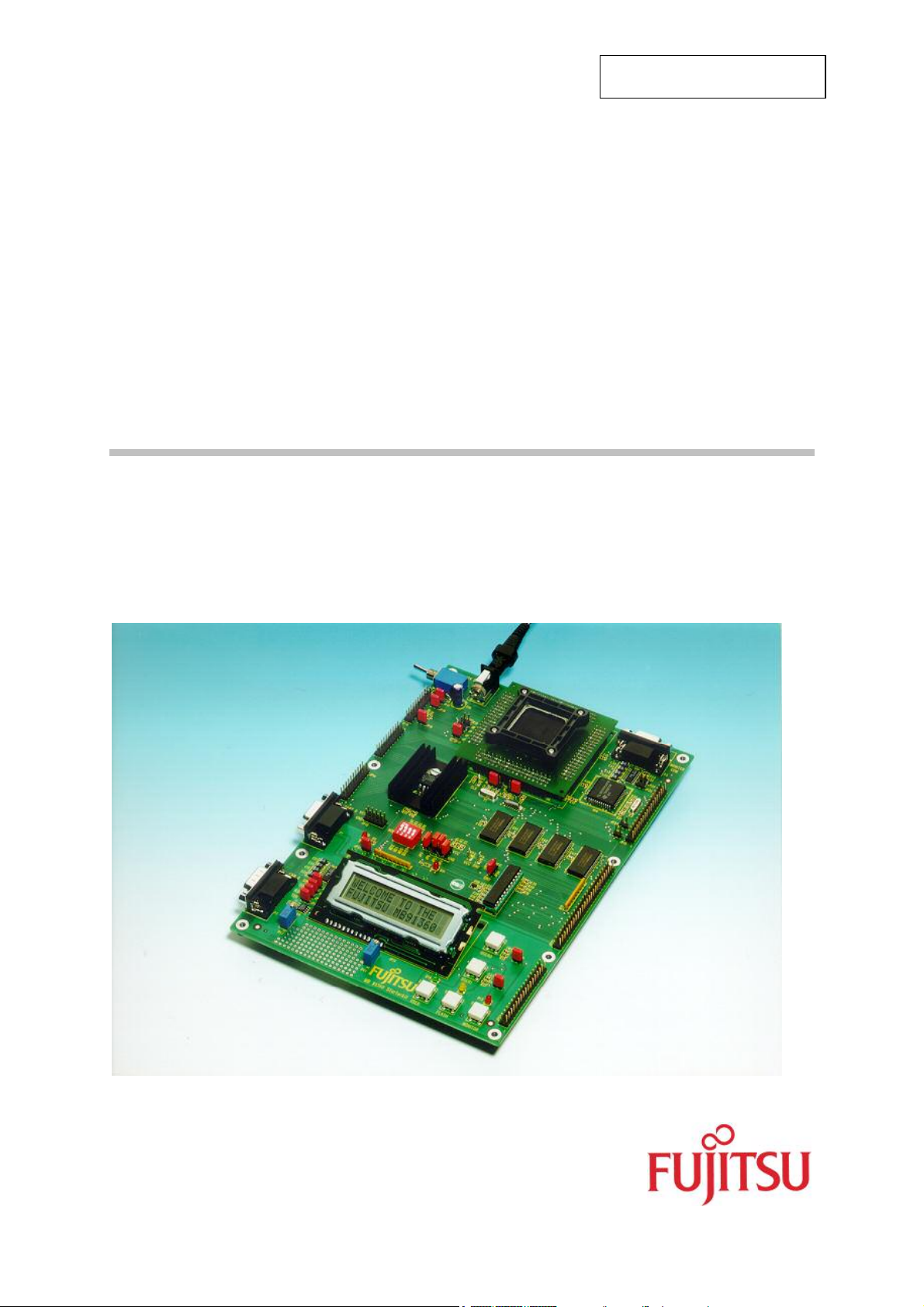

STARTERKIT MB91360

FMEMCU- UG-910006-13

MB91360 SERIES

EVALUATION BOARD

USER GUIDE

Page 2

Revision History

STARTERKIT MB91360

Revision History

ate

D

1999 1.0 MM

First draft

2001 1.2 MM

09 July 2003 V1.3, MSt

new format, Info about MB91F361 removed

This document contains 43 pages.

ssue

I

UG-910006-13 - 2 - © Fujitsu Microelectronics Europe GmbH

Page 3

STARTERKIT MB91360

Warranty and Disclaimer

Warranty and Disclaimer

To the maximum extent permitted by applicable law, Fujitsu Microelectronics Europe GmbH restricts

its warranties and its liability for STARTERKIT MB91360 and all its deliverables (eg. software

include or header files, application examples, target boards, evaluation boards, engineering samples

of IC’s etc.), its performance and any consequential damages, on the use of the Product in

accordance with (i) the terms of the License Agreement and the Sale and Purchase Agreement under

which agreements the Product has been delivered, (ii) the technical descriptions and (iii) all

accompanying written materials. In addition, to the maximum extent permitted by applicable law,

ujitsu Microelectronics Europe GmbH disclaims all warranties and liabilities for the performance of

F

the Product and any consequential damages in cases of unauthorised decompiling and/or reverse

engineering and/or disassembling. Note, the STARTERKIT MB91360 and all its deliverables are

intended and must only be used in an evaluation laboratory environment.

1. Fujitsu Microelectronics Europe GmbH warrants that the Product will perform substantially in

accordance with the accompanying written materials for a period of 90 days form the date of

receipt by the customer. Concerning the hardware components of the Product, Fujitsu

Microelectronics Europe GmbH warrants that the Product will be free from defects in material

and workmanship under use and service as specified in the accompanying written materials

for a duration of 1 year from the date of receipt by the customer.

2. Should a Product turn out to be defect, Fujitsu Microelectronics Europe GmbH´s entire liability

and the customer´s exclusive remedy shall be, at Fujitsu Microelectronics Europe GmbH´s

sole discretion, either return of the purchase price and the license fee, or replacement of the

Product or parts thereof, if the Product is returned to Fujitsu Microelectronics Europe GmbH in

original packing and without further defects resulting from the customer´s use or the transport.

However, this warranty is excluded if the defect has resulted from an accident not attributable

to Fujitsu Microelectronics Europe GmbH, or abuse or misapplication attributable to the

customer or any other third party not relating to Fujitsu Microelectronics Europe GmbH.

3. To the maximum extent permitted by applicable law Fujitsu Microelectronics Europe GmbH

disclaims all other warranties, whether expressed or implied, in particular, but not limited to,

warranties of merchantability and fitness for a particular purpose for which the Product is not

designated.

4. To the maximum extent permitted by applicable law, Fujitsu Microelectronics Europe GmbH´s

and its suppliers´ liability is restricted to intention and gross negligence.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES

To the maximum extent permitted by applicable law, in no event shall Fujitsu

Microelectronics Europe GmbH and its suppliers be liable for any damages whatsoever

(including but without limitation, consequential and/or indirect damages for personal

injury, assets of substantial value, loss of profits, interruption of business operation,

loss of information, or any other monetary or pecuniary loss) arising from the use of

the Product.

Should one of the above stipulations be or become invalid and/or unenforceable, the remaining

stipulations shall stay in full effect

© Fujitsu Microelectronics Europe GmbH - 3 - UG-910006-13

Page 4

STARTERKIT MB91360

Contents

Contents

REVISION HISTORY............................................................................................................ 2

WARRANTY AND DISCLAIMER ......................................................................................... 3

CONTENTS .......................................................................................................................... 4

1 INTRODUCTION.............................................................................................................. 6

1.1 Abstract................................................................................................................... 6

1.2 Key Features........................................................................................................... 6

1.3 General Board Usage.............................................................................................. 7

1.4 Mode Selection ....................................................................................................... 8

2 INSTALLATION ............................................................................................................... 9

2.1 Hardware Installation............................................................................................... 9

2.2 Software Installation.............................................................................................. 10

3 GETTING STARTED...................................................................................................... 11

3.1 Softune Workbench Development Introduction...................................................... 11

3.2 Softune Workbench Debugging Introduction ......................................................... 13

4 DETAILS OF THE INCLUDED MONITOR-DEBUGGER................................................ 15

4.1 Basic debugger features........................................................................................ 15

4.2 Advanced debugger features................................................................................. 17

5 FLASH PROGRAMMING............................................................................................... 20

5.1 Generic Flash Programmer ................................................................................... 20

6 EVALUATION BOARD HARDWARE ............................................................................ 22

6.1 Board Components ............................................................................................... 22

6.2 Overview of Jumpers............................................................................................. 23

6.3 Connectors for resources and IO-signals............................................................... 25

7 APPENDIX..................................................................................................................... 29

7.1 Memory Mappings MB91F362............................................................................... 29

7.1.1 MODE 000 (Single-Chip / Monitor Mode)................................................. 29

7.1.2 MODE 001 (External Bus / User Mode) ................................................... 30

7.2 Tool options for own projects................................................................................. 31

7.3 Starterkit limitations............................................................................................... 32

7.4 Board Schematics ................................................................................................. 33

7.5 Silk Screen............................................................................................................ 36

7.6 PAL Listing .......................................................................................................... 37

UG-910006-13 - 4 - © Fujitsu Microelectronics Europe GmbH

Page 5

STARTERKIT MB91360

Contents

7.7 Development tools and accessories.................................................................. 39

.8

7

elated Documents............................................................................................. 40

R

7.9 Trouble Shooting................................................................................................. 41

7.10 Figures 43

7.11 Tables 43

© Fujitsu Microelectronics Europe GmbH - 5 - UG-910006-13

Page 6

STARTERKIT MB91360

Chapter 1 Introduction

1 Introduction

1.1 Abstract

The Fujitsu MB91360 evaluation board is a stand-alone application board that makes it easy

to evaluate and demonstrate almost all features of the MB91360 microcontroller series.

Along with the supplied Windows-based development tools, it can be used as a system for

user program developments.

The board can be configured as a target for the MB91360 emulation-system or as a standalone evaluation unit. When using the system in stand-alone mode, a monitor debugger is

available to allow high-level debugging using Softune Workbench.

All peripheral functions are available on external pin-headers in order to design and test user

applications cost- and time-effectively. For some resource functions, additional hardware is

already present on the board (e.g. CAN- and UART-transceivers, LEDs, Buttons, etc).

The included Windows-based Software “Softune Workbench” is an integrated front-end for

development and debugging. It allows fast development of “ANSI C”-based applications for

the evaluationboard. To get started quickly, a number of example projects and templates are

available.

Related documents such as “MB91360 Hardware Manual” are available and should always

be used in addition to this manual (see appendix).

1.2 Key Features

< Footprint QFP208 (0.5mm pitch) + socket for MB91F362 (or emulation socket),

surrounded by headers for test-pins etc.

< 4MHz and 32kHz crystal

< DC Power-supply circuit (incl. testpins for Vcc, GND, LED and switch)

< 512kB external SRAM available for user code and data

< External 16550 UART (supports transfer-rates up to 115.2 kBaud)

< 22V10-PAL for various control functions

< Resets (“Monitor”=Start monitor mode, “User”=exec user program from external

RAM, “Flash”=exec user program from flash-ROM)

< MAX232 + DB9 (female) connectors for monitor and internal UART

< CAN tranceiver and DB9 (male) for internal CAN0

< External Interrupt 0 and 1 connected to buttons for user interaction

< Various jumpers for individual configuration

< 2x16 char LCD (on Port G)

< 8 LEDs (on Port J)

< External bus and all resources logically grouped on pin-headers

UG-910006-13 - 6 - © Fujitsu Microelectronics Europe GmbH

Page 7

STARTERKIT MB91360

Chapter 1 Introduction

< Area for extensions (2.54mm grid)

< Standard Euro-format (16x20 cm)

< Built-in monitor debugger (in Flash)

< Software includes Softune Workbench, a set of tools (e.g. flashloader) and example

projects.

1.3 General Board Usage

The MB91360 Starterkit can be used as stand-alone evaluation board or as a target system

for the MB2197-01 In-Circuit-Emulator.

To use the board as stand-alone evaluation board, a pre-programmed flash device

(MB91F362 with monitor software) must be present inside the QFP-208 socket. The chip will

use the built-in monitor to handle communication with the PC and makes use of the 512k

SRAM onboard as program-memory for user’s application. This manual explains how to use

the MB91360 Starterkit as a stand-alone evaluation board.

To use the board as target for the In-Circuit-Emulator, unscrew the socket and remove the

MB91F362 from the socket. Be careful not to bend any pins of the chip! Using a vacuum

chip-handler is highly recommended.

Then mount the emulator probe-cable on top of the QFP-socket. Use the provided screws

and make sure the cable has the right orientation. Follow the emulator set-up manual on the

CD-ROM for any further steps.

Figure 1: Using the Starterkit as target board for the ICE

© Fujitsu Microelectronics Europe GmbH - 7 - UG-910006-13

Page 8

STARTERKIT MB91360

Chapter 1 Introduction

1.4 Mode Selection

The board has three different “modes”, which are represented by the three reset-buttons

“USER”, “FLASH” and “MONITOR”.

By default, the board will startup in the “MONITOR”-mode, which automatically invokes the

debugger kernel. The board now can communicate with Softune Workbench. This means,

any application can be downloaded and debugged with all provided features such as

breakpoints, watches, single step etc. (see chapter “Softune Debugging Features”).

Once any code has been downloaded to SRAM, the application can also be executed

directly from a “USER” reset. The application will run without any intervention from the host

(e.g. breakpoints). This mode should mainly be used to test the application before

programming the entire contents to flash.

If finally the application has been transferred to flash-ROM, execution can start from the

flash-ROM using the “FLASH”-reset. This is the stand-alone mode for any user application.

As a last step, the board can be configured to start directly in the “FLASH”-mode after

power-on (by jumper JP34). This allows creating of a “real” stand-alone application.

UG-910006-13 - 8 - © Fujitsu Microelectronics Europe GmbH

Page 9

STARTERKIT MB91360

Chapter 2 Installation

2 Installation

2.1 Hardware Installation

What you’ll need :

< Host : IBM(-comp) PC with Windows 9x or Windows NT ; 1 COM-port

< Power Requirements: A power supply, capable of supporting 9-12V DC at about 500

mA. Note that the power connector must be + at the shield and - in the centre. Power

supplies are available from Fujitsu.

< RS232 : An ‘extension’ (1:1) RS232 cable with DB9 m+f connectors

Connect the power-supply (9-12V DC-input) and the RS232-cable

and switch on the Starterkit.

LED D10 should light up (power-indicator)

and LED D11 flashing (reset indicator).

During the initialization phase

the red monitor LED is on.

After that, a start message from the monitor

(“91360-STARTERKIT MONITOR VxLx”)

will be displayed on the LCD and the green user LED will light up.

The board is now ready to use.

© Fujitsu Microelectronics Europe GmbH - 9 - UG-910006-13

Page 10

STARTERKIT MB91360

Chapter 2 Installation

2.2 Software Installation

Insert the provided CD-ROM, browse to the installation page and select the Installation

option for Softune Workbench. Follow the instructions to unpack and install Softune

Workbench for FR ,as well as some example projects and additional tools for the MB91360

Starterkit. It is recommended to use the default installation path C:\Softune.

After the installation, you will find all language tools, the IDE and other system files within the

directory Softune\Bin. Samples for the Starterkit can be found in the \smplFR directory. The

\tools directory contains additional software tools (flashloader etc.).

Execute “FR Family Softune Workbench” from your Start-Menu.

If any errors occur during installation, remove any previous versions of Softune Workbench

from your PC and retry. Make sure you have enough disk space available and you have a

supported Windows OS installed. For more information see the provided installation

information and last-minute information.

Refer to the getting started session (next chapter) for more details on how to use Softune

Workbench for developing and debugging.

UG-910006-13 - 10 - © Fujitsu Microelectronics Europe GmbH

Page 11

STARTERKIT MB91360

Chapter 3 Getting Started

3 Getting Started

Make sure you have Softune Workbench for FR installed on your PC and the evaluation

board is ready to use. For details refer to the Hardware and Software Installation chapters.

This chapter uses the available examples to illustrate some features of Softune Workbench.

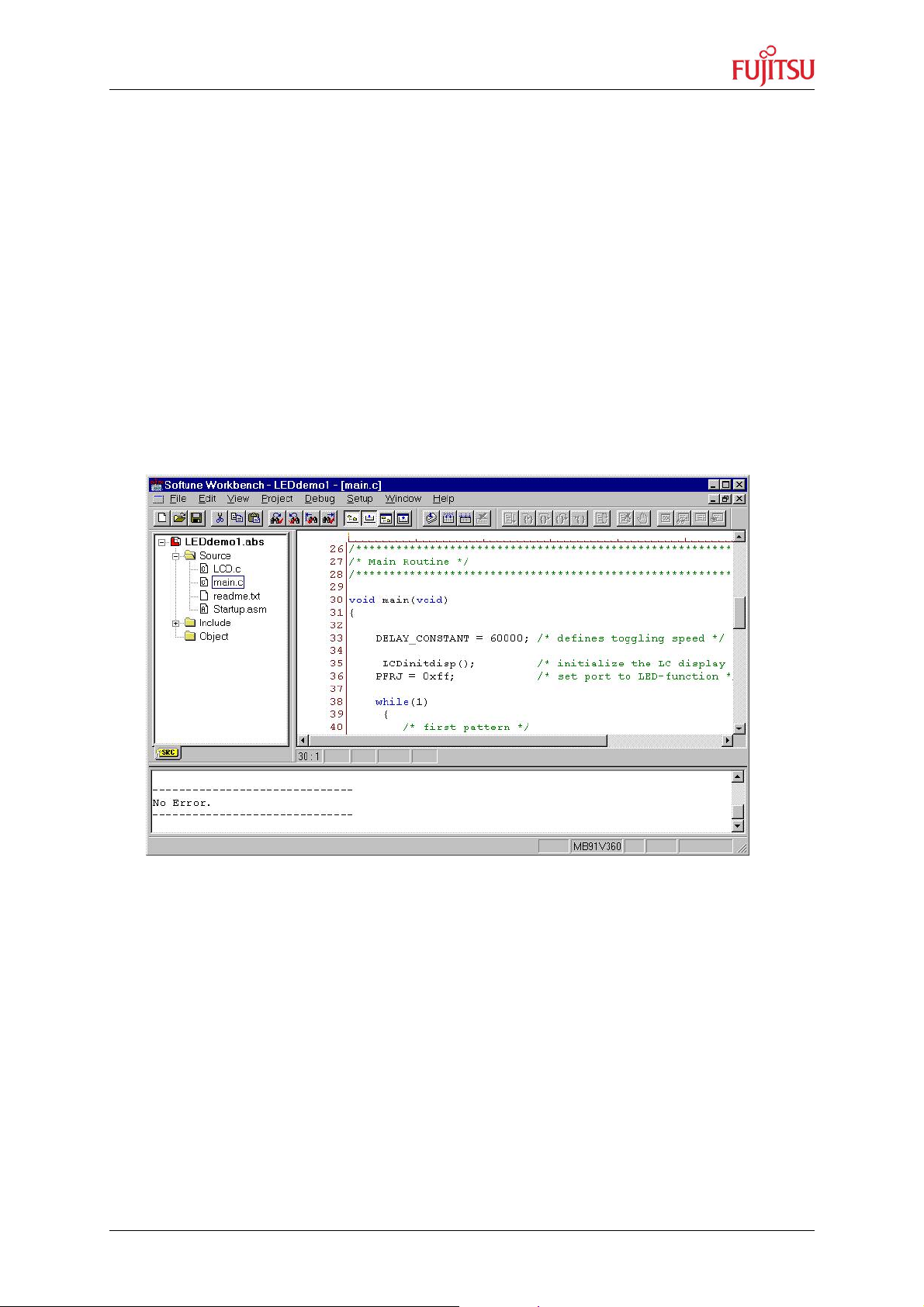

3.1 Softune Workbench Development Introduction

Start Softune Workbench. Select “File – Open Project” to load the first example

“LEDdemo1.Prj”. In the project tree on the left side, you can open the “source”-folder which

contains the source-files registered to this project. A double-click on one of the files will

invoke the built-in editor, which supports syntax-highlighting, tags and various other

functions.

Figure 2: Softune Workbench Editor

You may customize the editor by a right-click on the editor window.

Whenever you make changes to your source-files, you have to re-compile and link the

related files to produce a valid loadmodule (ABS-file). This is done using the MAKE-function.

MAKE invokes the assembler, C-compiler and linker for FR whenever necessary (only the

changed files will be re-compiled).

If you wish to re-compile the entire project regardless of any changes, you can use the

BUILD-function. To check for syntax-errors on a specific source-file, use the

COMPILE/ASSEMBLE function.

© Fujitsu Microelectronics Europe GmbH - 11 - UG-910006-13

Page 12

STARTERKIT MB91360

Chapter 3 Getting Started

These three functions are available on the button-bar or from the main menu (Project –

Compile / Make / Build / Abort).

Click on MAKE or BUILD. Messages from the individual language tools will be fed into the

output window at the bottom of the main screen. If the tool chain (C-compiler R Assembler

R Linker) was completed successfully, the message “No Error” will appear.

If you get any errors during compilation, an appropriate message will be generated. Try this

with a simple syntax-error (e.g. delete a semicolon “;” from the end of a C-line) and click on

MAKE again. You will now see a message like this:

Now Making...

main.c

*** c:\softune\sample\..\leddemo1\src\main.c(43) E4062C: syntax error near `for'

------------------------------

Error detected.

------------------------------

To locate the position in the source-file, where the error has occurred, double-click on the

message. The editor will open the appropriate source-file, indicating the error highlighted in

red, depending on the customise settings of the editor. Correct the error and re-compile the

project as explained above.

If more errors occurred, you can go through the error list step by step using the menu “Edit –

Top/Previous/Next/Bottom Error” or using the appropriate buttons which have the same

functions:

To get on-line help about a specific error, select the error message and press F1. In many

cases, you can get some useful hints how to solve the problem. Of cource, you can also

use the HELP-menu anytime during development or debugging.

UG-910006-13 - 12 - © Fujitsu Microelectronics Europe GmbH

Page 13

STARTERKIT MB91360

Chapter 3 Getting Started

3.2 Softune Workbench Debugging Introduction

Whenever you have successfully created a valid load module, you may switch from the

development mode to the debugging mode of Softune Workbench.

Basically, there are 3 types of debugging systems supported :

1. The software simulator: This type of debugger is always present and does not

require any special hardware extensions. The simulator will cover the FR-core

features, but no peripheral functions. Therefore, you can use the simulator to

verify program flow, check for dynamic errors, look at the generated assembler

code and so on.

2. The monitor debugger: This debugger type requires an evaluation board like the

MB91360 Starterkit connected to one of the COM-ports of your PC. Therefore,

make sure you have the evaluation board connected and powered-up as

described before. Explanations in this manual refer to the monitor debugger only.

3. The emulator debugger: The in-circuit-emulator (ICE) is a system, which allows a

connection to any target system using a probe-cable. The appropriate system for

the MB91360 series is the MB2197-01 system. More information about this

system can be found on the Fujitsu Micros CD-ROM or on our website.

Which debugger is used for the actual project can be configured in the “Project – Setup –

Debug” menu:

Always verify the settings before you start debugging a new project ! The current “setup” is

indicated by the selected item in the “Available Setup Name” dropdown-box. The provided

examples contain 3 setups (simulate, emulate and monitor). Ensure “monitor” is selected.

Click on “monitor” in the “Setup Name List” and click “Change”. A debug setup wizard will

appear to guide you through the possible settings.

Make sure you are using the right COM-port number and Baudrate !

The default-settings for the monitor-debugger are fixed to :

COM-Port1 and 38400 Baud. Change the settings if necessary.

© Fujitsu Microelectronics Europe GmbH - 13 - UG-910006-13

Page 14

STARTERKIT MB91360

Chapter 3 Getting Started

If these settings are correct, start the debugger using “Debug – Start Debug”. You should

see a progress bar indicating the download process.

If nothing happens, there will be an error message after some time (“Invalid communication

status”). Double-check the settings again as explained above. Also make sure the

evaluation-board is powered on, ready to use and the RS232-cable is connected properly.

Also see the trouble-shooting section in the appendix.

After starting the debugger, additional windows will appear which contain

locate-arrows for each (possible) source-line, the original source-code,

Figure 3: SWB Debugging window

breakpoint-indicators and the assembler code (in “mixed view”). The actual program position

will be indicated by a yellow line.

You can choose “mixed view” from the context menu (right-click) to display source

and assembly code at the same time. To easily locate the actual line, use “go to current” !

UG-910006-13 - 14 - © Fujitsu Microelectronics Europe GmbH

Page 15

STARTERKIT MB91360

Chapter 4 Details of the included Monitor-Debugger

4 Details of the included Monitor-Debugger

4.1 Basic debugger features

GO: Executes the program continuously from the memory location pointed to by the

current program counter (PC) until a termination factor occurs.

STEP IN: Executes the program stepwise according to the listing in the source

window (steps in C- or ASM). Note that Interrupts are disabled during step execution !

STEP OVER: Executes the program stepwise except call-instructions (which will be

executed until return). Interrupts are not disabled during a continuous CALL...RETURN

execution.

STEP OUT: Executes the program continuously to the parent function (until

RETURN). Interrupts are enabled. Note, that debug information is required for this function.

EXECUTE UNTIL CURSOR: Automatically sets a breakpoint at the actual cursor

position and executes continuously until this breakpoint, which will be deleted

afterwards.

Each valid code line in a debugger window automatically has a locator (blue arrow) and a

breakpoint-option (circle). Note that some C-lines may not be displayed with locators and

breakpoints, because the compiler has created “optimized” assembler-code. Select “mixed

view” in order to check the compiler output.

Instead of single-steps, you may also use the arrows to directly execute your program until a

certain line of your source-code :

© Fujitsu Microelectronics Europe GmbH - 15 - UG-910006-13

Page 16

STARTERKIT MB91360

Chapter 4 Details of the included Monitor-Debugger

ABORT: Forcibly terminates execution.

CAUTION: This function can be used in single code line operations only

(example: for(k=DELAY_CONSTANT; k>0; k--); ) !!

To abort continous execution on the Starterkit, you have to use an external

interrupt. All examples provided use the „USER0“-button for this purpose. If you

wish to use the „USER0“-button for Abort, make sure you have the ABORT-option in

STARTUP.ASM enabled :

#define ABORT 1

The USER0-button is an external interrupt source which will be initialized at the highest

priority. In the interrupt service routine (located in STARTUP.ASM) you will find a software

trap (INTE), which will force the debugger to stop at this specific point. You may use traps

also to intentionally stop in your code for debugging purposes.

UG-910006-13 - 16 - © Fujitsu Microelectronics Europe GmbH

Page 17

STARTERKIT MB91360

Chapter 4 Details of the included Monitor-Debugger

4.2 Advanced debugger features

TOGGLE BREAKPOINT: Sets or deletes breakpoint at the current source line or :

To set or delete a breakpoint, click the circles at the beginning of a source-line. A

indicates an active breakpoint. Hit “go” to execute until this line. A list of all breakpoints

can be found under the “Debug – Breakpoint” menu. 255 Software-Breakpoints (using TRAP

replacement) are possible.

To set breakpoints at positions which are currently not visible (e.g. because the source-

window of that module is not open), you can also enter a symbolic label directly in the

“Breakpoint” menu. Example: Enter “main” in the address-field and confirm. The new

breakpoint will automatically be assigned to the address of the “main()”-function.

REGISTER WINDOW: Displays the CPU-register window. Updated registers appear

in red. Setup in context menu defines which Registers should be displayed.

WATCH WINDOW: Displays the current variables to „watch“. Double-click on any

variable in your code then specify watch in context menu to add to watch window. All listed

variables in a watch window can be displayed in any number format. Use Edit to directly

change the contents.

Example: Open the Leddemo1-Project and execute until you see the first LED-pattern. Then

double-click on PDRJ in the debugger-window and select „watch“ in the context-menu. The

watch-window will appear and PDRJ will be added to any existing variables. Select PDRJ in

the watch window and choose „Edit“. Enter any value and confirm. You will now see the (8Bit) value displayed on the LEDs directly as binary code. This is because PDRJ is the output

latch of the LED-port (J).

MEMORY WINDOW: Displays memory areas in various formats defined by Setup

(context menu). Changing of address/data is possible when debugger is not executing.

Note : If you make changes to the ROM-area (080000..0FFFFF) it can affect the currently

loaded program !

DISASSEMBLER: Disassembles the contents of the code memory beginning from

actual PC position and displays the result in a separate window. Individual

assembler-lines can be changed using the „inline assemble“-function.

© Fujitsu Microelectronics Europe GmbH - 17 - UG-910006-13

Page 18

STARTERKIT MB91360

Chapter 4 Details of the included Monitor-Debugger

DEBUG - STACK: Displays the current stack contents in terms of function calls.

Parameters, if any, are given in brackets.

DEBUG - VECTOR: Reads out and displays the actual interrupt-vector table. Use the „jump“

function to display any code areas pointed to by an interrupt vector (e.g. interrupt service

routines used in your program).

DEBUG - CALL: This function can be used to „call“ any routine defined in your code when

the debugger is halted.

Example: Enter „LCDprinthex(0x1234,4)“ from any example project. The number 1234 will

appear on the LCD. The function-call will be terminated by showing the result (here : none).

You may restore the debugging context by „Clear call“ if execution was stopped during the

function-call. Note that this example assumes that „LCDinitdisp“ was executed before.

DEBUG – LOAD TARGET FILE: Starts a new download of the current load module (ABS

file). Usually this function will be executed automatically after starting the debugger (defined

in debug settings ; see „Project-Setup-Debug“). However, this function can be useful to reinitialize the debugger for the current debug session.

VIEW - SYMBOL: This function displays all (global) symbols of the current project.

Information about the type (char, integer etc.) and the location (address in RAM or register)

can be shown using „detail“.

VIEW - LOCAL: Similar to View-Symbol, but only local variables of the current function are

shown.

VIEW - COMMAND: From this window, the debugger can be controlled using a command

line input. All GUI functions are available as individual commands.

Examples :

go

step

examine PDRJ

set break main

Dump/Halfword 100000..1000ff

Shortcuts to complex commands can be defined (“alias”) and parameter strings can be

substituted by variables.

Example: candump = Dump/Halfword 100000..1000ff

A set of commands can be combined to a “macro”. Aliases and macros can be defined

using the command window context menu.

UG-910006-13 - 18 - © Fujitsu Microelectronics Europe GmbH

Page 19

STARTERKIT MB91360

Chapter 4 Details of the included Monitor-Debugger

Example: restart: set register PC=1f4000

set break main

go

In order to document or save debugging details such as memory contents, all outputs fed to

the command console can be written to a file (“logging”).

A whole “program” of commands (incl. flow control) can be written to a PRC-file and

executed. Procedure-files are simple text-files with the extension “.PRC” and can be created

by the Softune Workbench editor or any other text editor. To execute a procedure-file, use

the command window menu or the “file-open” menu during debugging.

Procedure-files can be very helpful to automatically configure the debug-environment,

perform automated tests (e.g. when a new C-module has to be tested) or to enhance

basic emulator functions such as breakpoints. Using a procedure file, breakpoints can be

dynamically defined depending on program conditions. See the “Command Reference

Manual” (on-line help) for detailed information about the available command and

parameter syntax.

© Fujitsu Microelectronics Europe GmbH - 19 - UG-910006-13

Page 20

STARTERKIT MB91360

Chapter 5 Flash Programming

5 Flash Programming

Whenever your application has been developed, debugged and tested as explained in the

last chapter, it can be programmed to the internal flash ROM using the „MB91360 Flash

Programmer“. This tool is a general flash programming utility, which allows programming the

internal flash ROM without any restrictions given by the starterkit.

5.1 Generic Flash Programmer

The tool „MB91360 Flash Programmer“ is a general flash programming tool which does not

take care of the special features of this Starterkit. Therefore, it should be used to re-program

the monitor-kernel. On the CD-ROM, you will find some kernel files (MHX-format) which are

fixed for various baud rates. Make sure, you have the latest version available!

The tool can also be used to program any applications directly (without the possibility to

have any debugging functions later on). In this case, the evaluation board will act as a target

system only.

CAUTION: Take special care not to write anything to location 0FFEF4, the „security vector“.

If you do, you will not be able to re-program the device ever again! See the hardware manual

for details!

Make sure you have installed the Flash Programmer from your CD-ROM. The package

includes the executable (Flashprg.exe) as well as some binary files (Brloadxx.bin) and a

user’s guide (Flashprg.pdf).

Figure 4: MB91360 Flash Programmer

UG-910006-13 - 20 - © Fujitsu Microelectronics Europe GmbH

Page 21

STARTERKIT MB91360

Chapter 5 Flash Programming

Follow these steps to use the MB91360 Flash Programmer :

1. Be sure to have the starterkit in Monitor (single-chip) mode. Check the position of the

jumpers and dip-switches onboard according to table1.

2. Connect the RS232-cable from any PC-COM-port to “UART0” (female UART

connector on the left side of the Starterkit - do NOT use the monitor COM

connector!).

3. Specify a (hex-)file in the “file to program”-field (use the browse-button to select).

This file must be a converted linker output file from Softune in the Motorola HexFormat “*.MHX” (for programming your own applications, be sure to have the load

module converter started in Softune Workbench to generate MHX-files !). For kernel

updates, select a MONxxx.MHX-file (xxx is the Starterkit-baudrate. E.g. :

MON115.MHX is the kernel for 115200 Baud).

4. Specify the COM-port and the desired baud rate for programming.

5. Click on Automatic Mode and press monitor reset on the Starterkit. The programming

sequence will be executed automatically.

CAUTION : DO NOT INTERRUPT THE FLASH PROGRAMMING OR CUT OFF THE

POWER DURING PROGRAMMING !

IT CAN DAMAGE THE FLASH ROM PERMANTENTLY !!!

6. After a successful programming procedure, hit monitor reset to re-initialize the

Starterkit and close the program. Do not forget to plug the RS232-cable back to

„Monitor COM“ if you want to use the monitor debugger again.

The Flash Programmer uses the internal Boot-ROM functions instead of the monitor

kernel for flash programming.

For more information and trouble shooting, see the „MB91360 Serial flash programmer

user’s guide“ (Flashprg.pdf) which is included in the installation.

© Fujitsu Microelectronics Europe GmbH - 21 - UG-910006-13

Page 22

STARTERKIT MB91360

Socket QFP208 for

Monitor UART and

tranceiver and

LEDs on

Port J

JP15 : PWM and

JP24 : Databus

JP16 : Analog

Reset Circuit and

Reset

-

LED

Chapter 6 Evaluation Board Hardware

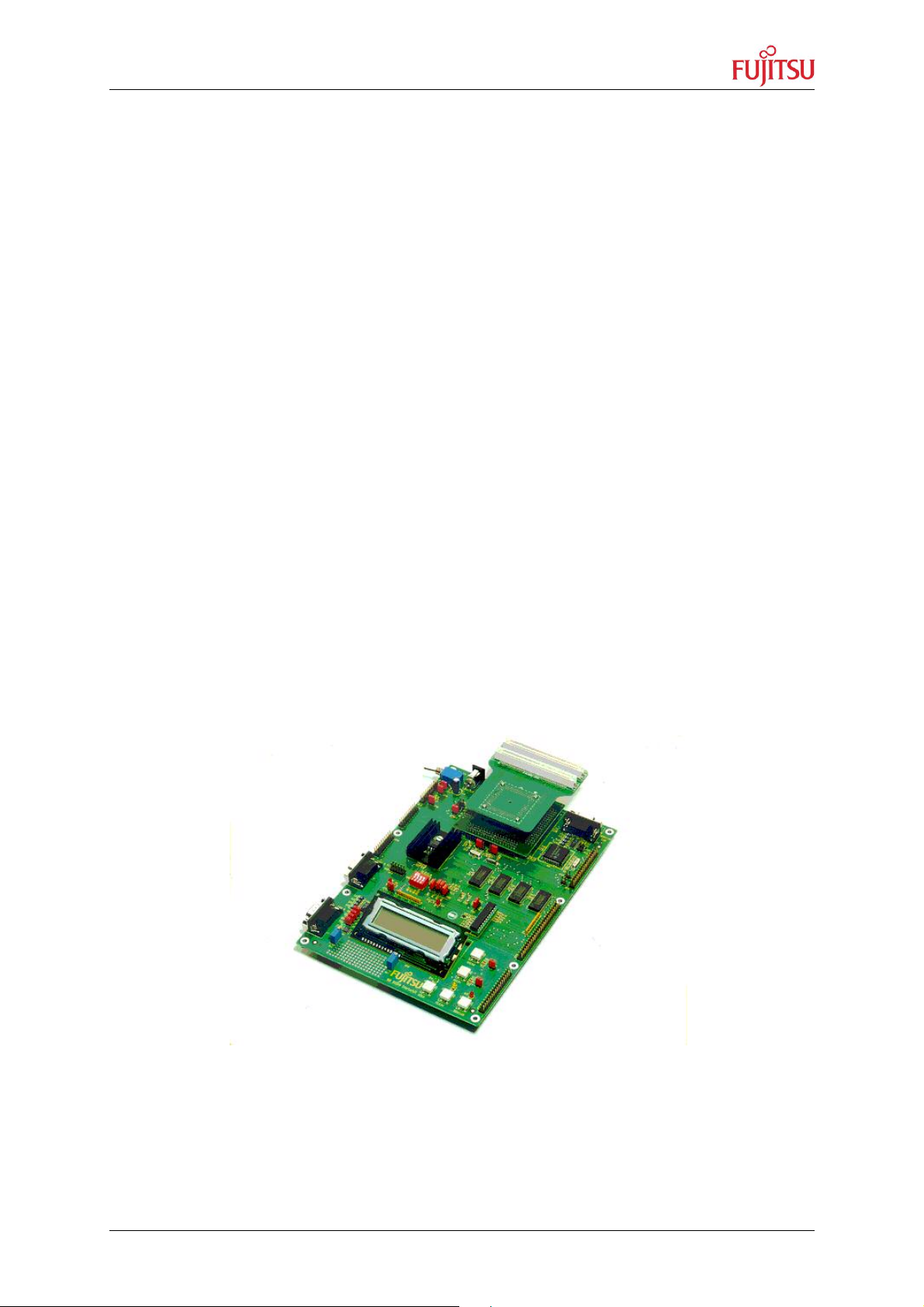

6 Evaluation Board Hardware

6.1 Board Components

Microcontroller

On/Off

Ports (AD/DA)

DC input

MB91F361/2

RS232-connector

Pulsgen. outputs

JP20 : INTs,

ICU and

5V Regulator

JP14 : Serial

Interfaces

MCU

Power-on LED

User-

RS232 driver

and connector

CAN

Oscillators

512k SRAM

JP25 :

Addressbus and

PAL

User buttons on

external Ints 0,1

LCD on Port

Mode LCD Prototyping CAN line slew rate

UG-910006-13 - 22 - © Fujitsu Microelectronics Europe GmbH

Page 23

STARTERKIT MB91360

Chapter 6 Evaluation Board Hardware

The evaluation board provides various IO-signals, which can be connected to external

devices. The controller resource functions are available on the connectors JP14, JP15, JP16

and JP20.

External peripheral devices can be connected via the address/data bus on JP24 and JP25.

For more information please refer to the following pin assignments and the schematics in the

appendix.

6.2 Overview of Jumpers

Jumper Description Standard Setting Jumper Position

JP1 Main Vcc Net for MCU Closed (Vcc supplied) Closed

JP2 32kHz-Oscillator GND (X0A disabled) (2-3 closed) Right

JP3 4 MHz-Oscillator X0 (Active) (1-2 closed) Left

JP4 LPF for 32kHz-Oscillator Vcc (Enabled) (2-3 closed) Up

JP5 Clock Select Pin Vcc (4 MHz) (2-3 closed) Up

JP6 Hardware Standby Pin Vcc (Disabled) (2-3 closed) Up

JP7 Select Source MD0 Vcc (PAL) (2-3 closed) Up

JP8-10 Test Mode Enable Open (no test mode) Open

JP13 LED enable Closed (LEDs active) Closed

JP17-19 Analog Supply Voltage Closed (A/D active) Closed

JP22-23 Driver Supply Voltage Closed (Driver active) Closed

JP26 Serial Output 0 enable Closed (enabled) Closed

JP27 Serial Input 0 enable Closed (enable) Closed

JP28-29 CAN0 driver enable Closed (enable) Closed

JP30,31 USER-buttons enable Closed (enable) Closed

JP32 Ext. UART int. enable Open (disable) Open

JP33 DTR reset enable Open (disable) Open

JP34 Power-up mode GND (Monitor mode) (1-2 closed) Down

MD2 Mode-Pin 2 GND On (Upper Dip Pos)

MD1 Mode-Pin 1 GND On

MD0 Mode-Pin 0 GND On

BOOT Boot-Pin GND On

Table 1: Selection jumpers on MB91360 Starterkit

© Fujitsu Microelectronics Europe GmbH - 23 - UG-910006-13

Page 24

STARTERKIT MB91360

Chapter 6 Evaluation Board Hardware

Jumper Description

JP12 Vcc/Gnd array for testpurposes

JP14 Serial communication pins (UART0-3 , CAN0-2)

JP15 Puls generator outputs 0-7, Stepper motor (PWM) outputs 0-4

JP16 A/D inputs 0-7, Alarm comp. Input, Sound gen. Output, D/A outputs 0-1

JP20 External Interrupts 0-7, Input Capture 0-3, Output Compare 0-3, I2C

JP25 Adressbus A0-A20 and Bus-control signals

JP24 Databus D0-D31

Table 2: Grouped jumpers on MB91360 Starterkit

UG-910006-13 - 24 - © Fujitsu Microelectronics Europe GmbH

Page 25

STARTERKIT MB91360

Chapter 6 Evaluation Board Hardware

6.3 Connectors for resources and IO-signals

MCU-pins are grouped according to their logical functions. See the hardware manual for

details on the resource functions.

JP16 :

Analog Inputs (ADC)

Analog Outputs (DAC)

Sound Generator

Alarm Comparator

JP20 :

External Interrupts,

Input Capture Units

Output Compare Units

I²C Interface

JP14 :

UARTs

Sync. serial interfaces

CANs

JP15 :

Stepper Motor Drivers

PWMs

Puls Generators

The available resource pins can also be used as general purpose IO-ports (using the Portfunction registers PFRx). See table below for details.

© Fujitsu Microelectronics Europe GmbH - 25 - UG-910006-13

Page 26

STARTERKIT MB91360

Chapter 6 Evaluation Board Hardware

Note: Address bus and data bus pins (JP24,25) cannot be used as IO-ports.

Jumper Pin-No. Pin Name IO-Port Resource Function

JP16

064 AVCC - Analog Vcc

065 AVRH - Analog Reference High

066 AN0 PH0 ADC Input Channel 0

067 AN1 PH1 ADC Input Channel 1

068 AN2 PH2 ADC Input Channel 2

069 AN3 PH3 ADC Input Channel 3

070 AN4 PH4 ADC Input Channel 4

071 AN5 PH5 ADC Input Channel 5

072 AN6 PH6 ADC Input Channel 6

073 AN7 PH7 ADC Input Channel 7

074 AVSS - Analog Reference Low

077 ALARM - Alarm Comparator Input

080 ATGX PI3 ADC Trigger Input

126 SGO PM0 Sound Generator Output

127 SGA PM1 Sound Generator Amplitude

JP20

075 DA0 - DAC Output Channel 0

076 DA1 - DAC Output Channel 1

094 INT0 PK0 Ext. Interrupt 0

095 INT1 PK1 Ext. Interrupt 1

096 INT2 PK2 Ext. Interrupt 2

097 INT3 PK3 Ext. Interrupt 3

098 INT4 PK4 Ext. Interrupt 4

099 INT5 PK5 Ext. Interrupt 5

100 INT6 PK6 Ext. Interrupt 6

101 INT7 PK7 Ext. Interrupt 7

102 IN0 PL0 ICU Input 0

103 IN1 PL1 ICU Input 1

104 IN2 PL2 ICU Input 2

105 IN3 PL3 ICU Input 3

106 OUT0 PL4 OCU Output 0

UG-910006-13 - 26 - © Fujitsu Microelectronics Europe GmbH

Page 27

STARTERKIT MB91360

Chapter 6 Evaluation Board Hardware

Jumper Pin-No. Pin Name IO-Port Resource Function

107 OUT1 PL5 OCU Output 1

108 OUT2 PL6 OCU Output 2

109 OUT3 PL7 OCU Output 3

128 SDA PM2 I2C-Interface SDA

129 SCL PM3 I2C-Interface SCL

JP14 146 TX0 PP0 CAN 0 TX

147 RX0 PP1 CAN 0 RX

148 TX1 PP2 CAN 1 TX

149 RX1 PP3 CAN 1 RX

150 TX2 PP4 CAN 2 TX

151 RX2 PP5 CAN 2 RX

152 SIN0 PQ0 UART 0 Input

153 SOT0 PQ1 UART 0 Output

154 SIN1 PQ2 UART 1 Input

155 SOT1 PQ3 UART 1 Output

156 SIN2 PQ4 UART 2 Input

157 SOT2 PQ5 UART 2 Output

130 SOT4 PN0 SIO Output

131 SIN4 PN1 SIO Input

132 SCK4 PN2 SIO Clock

133 SIN3 PN3 SIO Input

134 SOT3 PN4 SIO Output

135 SCK3 PN5 SIO Clock

JP15 136 OCPA0 PO0 PPG Output 0

137 OCPA1 PO1 PPG Output 1

138 OCPA2 PO2 PPG Output 2

139 OCPA3 PO3 PPG Output 3

140 OCPA4 PO4 PPG Output 4

141 OCPA5 PO5 PPG Output 5

142 OCPA6 PO6 PPG Output 6

143 OCPA7 PO7 PPG Output 7

© Fujitsu Microelectronics Europe GmbH - 27 - UG-910006-13

Page 28

STARTERKIT MB91360

Chapter 6 Evaluation Board Hardware

Jumper Pin-No. Pin Name IO-Port Resource Function

162 PWM1P0 PR0 SMC 0

163 PWM1M0 PR1 SMC 0

164 PWM2P0 PR2 SMC 0

165 PWM2M0 PR3 SMC 0

166 HVDD - SMC Driver Vdd

167 PWM1P1 PR4 SMC 1

168 PWM1M1 PR5 SMC 1

169 PWM2P1 PR6 SMC 1

170 PWM2M1 PR7 SMC 1

171 HVSS - SMC Driver Vss

172 PWM1P2 PS0 SMC 2

173 PWM1M2 PS1 SMC 2

174 PWM2P2 PS2 SMC 2

175 PWM2M2 PS3 SMC 2

177 PWM1P3 PS4 SMC 3

178 PWM1M3 PS5 SMC 3

179 PWM2P3 PS6 SMC 3

180 PWM2M3 PS7 SMC 3

Table 3: Overview of available resource-functions and IO-ports on jumpers

UG-910006-13 - 28 - © Fujitsu Microelectronics Europe GmbH

Page 29

STARTERKIT MB91360

Chapter 7 Appendix

7 Appendix

7.1 Memory Mappings MB91F362

7.1.1 MODE 000 (Single-Chip / Monitor Mode)

MB91F362 Memory Map Recommended Mappings

Figure 5: Memory Mapping Single Chip Mode / Monitor Mode

© Fujitsu Microelectronics Europe GmbH - 29 - UG-910006-13

Page 30

STARTERKIT MB91360

Chapter 7 Appendix

7.1.2 MODE 001 (External Bus / User Mode)

MB91F362 Memory Map Recommended Mappings

Figure 6: Memory Mapping External Mode / User Mode

UG-910006-13 - 30 - © Fujitsu Microelectronics Europe GmbH

Page 31

STARTERKIT MB91360

Chapter 7 Appendix

7.2 Tool options for own projects

Valid load module files for MB91360 devices can only be achieved if the language tool

configuration is appropriate. If you use the provided samples or templates, you do not have

to worry about these settings.

The most convenient way to create own projects is to copy the provided Template-Project

from the sample-directory and use it as “blank sheet”. However, if you intend to create

projects “from scratch” without the template, the following settings are important.

Target MCU (“Project – Setup” menu) : make sure “MB91FV360” or “MB91F362” is selected

as the target MCU device.

Linker Settings (“Project – Setup tool options – Linker – Disposition”) : MB91360 devices

use a fixed memory map for code stored in Flash-ROM or data assigned to the internal

RAM. In addition, certain Flash-sectors have special meanings, such as the boot-sector

(application always starts from 0F4000) or the kernel of the debugger stored from 0F0000.

Therefore, make sure the following memory map is applied:

Memory Type Used for Area Sections

Data RAM Stack 3D000..3DFFF STACK

Data RAM Variables 3E000..3FFFF DATA, INIT

Flash ROM User Code 080000..0EFFFF CODE

FlashROM Kernel 0F0000..0F3FFF

1.1.1.1.1 Reserved !

FlashROM Boot-Sector,

constants and

0F4000..0FFFFF START, CONST,

@INIT, VECTORS

vectors

Table 4: Memory Map

Your linker settings should look like this:

-ro CODE_AREA=0x00080000/0x000EFFFF

-ro ROM_AREA=0x000F4000/0x000FFFFF

-ra STACK_AREA=0x0003D000/0x0003DFFF

-ra RAM_AREA=0x0003E000/0x0003FFFF

-sc STACK/Stack=STACK_AREA

-sc DATA/Data+INIT=RAM_AREA

-sc CODE/Code=CODE_AREA

-sc START+CONST+@INIT=ROM_AREA

Also refer to the detailed memory maps in the appendix.

Always check the “map”-file (use the context menu in the project-view and select “open

list file”) to see the used sections and addresses !

© Fujitsu Microelectronics Europe GmbH - 31 - UG-910006-13

Page 32

STARTERKIT MB91360

Chapter 7 Appendix

7.3 Starterkit limitations

If creating new projects, be sure not to use the following functions, which are reserved for

the MB91360 Starterkit:

< Flash-ROM area 0F0000..0F3FFF (reserved for Monitor kernel)

< Port G / upper ADC inputs (used for LCD and mode input)

< Security-Vector (used to call the kernel in Monitor mode)

< External Interrupt 0 (used for Abort function)

< Chip selects 0,2 and 7 (used for MCU and board hardware)

< External memory space 200000..3FFFFF (used for board hardware)

UG-910006-13 - 32 - © Fujitsu Microelectronics Europe GmbH

Page 33

7.4 Board Schematics

STARTERKIT MB91360

Chapter 7 Appendix

© Fujitsu Microelectronics Europe GmbH - 33 - UG-910006-13

Page 34

STARTERKIT MB91360

Chapter 7 Appendix

UG-910006-13 - 34 - © Fujitsu Microelectronics Europe GmbH

Page 35

STARTERKIT MB91360

Chapter 7 Appendix

© Fujitsu Microelectronics Europe GmbH - 35 - UG-910006-13

Page 36

7.5 Silk Screen

STARTERKIT MB91360

Chapter 7 Appendix

UG-910006-13 - 36 - © Fujitsu Microelectronics Europe GmbH

Page 37

STARTERKIT MB91360

Chapter 7 Appendix

7.6 PAL Listing

;PALASM Design Description

;---------------------------------- Declaration Segment ------------

TITLE STK360_1.PDS

PATTERN A

REVISION 1.3

AUTHOR M.MIERSE

COMPANY FUJITSU MIKROELEKTRONIK GMBH

DATE 20/09/99

CHIP STK360 PAL22V10

; -------------------------------- Revision History ----------------

;

; 20.11.98 V1.0 First Version

; 17.02.99 V1.1 Rem-Req and ext. UART Mapping changed

; 16.03.99 V1.2 UART-Reset changed to high-active

; 20.09.99 V1.3 UART-CS changed for ext.bus mode

;

;---------------------------------- PIN Declarations ---------------

PIN 1 RESETIN COMBINATORIAL ; INPUT

PIN 2 DEFAULT COMBINATORIAL ; INPUT

PIN 3 AUXIN COMBINATORIAL ; INPUT

PIN 4 A19 COMBINATORIAL ; INPUT

PIN 5 A20 COMBINATORIAL ; INPUT

PIN 6 CS0 COMBINATORIAL ; INPUT

PIN 7 CS2 COMBINATORIAL ; INPUT

PIN 8 MONRES COMBINATORIAL ; INPUT

PIN 9 FLASHRES COMBINATORIAL ; INPUT

PIN 10 USERRES COMBINATORIAL ; INPUT

PIN 11 DTR COMBINATORIAL ; INPUT

PIN 13 UNUSED1 COMBINATORIAL ;

PIN 12 GND

PIN 14 UARTRES COMBINATORIAL ; OUTPUT

PIN 15 MASTRES COMBINATORIAL ; OUTPUT

PIN 16 CSRAM COMBINATORIAL ; OUTPUT

PIN 17 CSUART COMBINATORIAL ; OUTPUT

PIN 18 MODE COMBINATORIAL ; OUTPUT

PIN 19 PG5 COMBINATORIAL ; OUTPUT

PIN 20 PONFLAG REGISTERED ; INT. FLAG

PIN 21 LEDGRN COMBINATORIAL ; OUTPUT

PIN 22 LEDYEL COMBINATORIAL ; OUTPUT

PIN 23 LEDRED COMBINATORIAL ; OUTPUT

PIN 24 VCC

; -----------------------------------------------------------------------

; --------------------- OUTPUT EQUATIONS ------------------------------

; -----------------------------------------------------------------------

© Fujitsu Microelectronics Europe GmbH - 37 - UG-910006-13

Page 38

STARTERKIT MB91360

Chapter 7 Appendix

EQUATIONS

; -----------------------------------------------------------------------

; Power-on Indicator (Flip-Flop) :

; -----------------------------------------------------------------------

PONFLAG.CLKF = RESETIN ; Power-on-Flag ist 0 at Pon ; otherwise 1

PONFLAG := 1

; -----------------------------------------------------------------------

; Equations for Modes (Reset-States) :

; -----------------------------------------------------------------------

; --------------------> LEDRED is indicating the Monitor-Reset state, if

LEDRED = USERRES * FLASHRES * /MONRES ; Mon-reset button pressed

+ /DTR ; or uart-reset (DTR line low)

+ (/PONFLAG * /DEFAULT) ; or Power-on (Default-Mode=Mon)

+ /LEDGRN * /LEDYEL ; (hold-condition)

; --------------------> LEDGRN is indicating the User-Reset state, if

LEDGRN = /USERRES * FLASHRES * MONRES ; User-Reset button pressed

+ (A20 * /A19 * /CS2) ; or Remote-User-reset request

+ /LEDYEL * /LEDRED ; (hold-condition)

; --------------------> LEDYEL is indicating the Flash-Reset state, if

LEDYEL = USERRES * /FLASHRES * MONRES ; Flash-Reset button pressed

+ (/PONFLAG * DEFAULT) ; or Power-on (Default-Mode=Flash)

+ /LEDGRN * /LEDRED ; (hold-condition)

MODE = LEDGRN ; Mode-Pin (MD0) is 1, if User-Reset state, otherwise 0

PG5 = LEDYEL ; Flash-Ind-Pin is 1, if Flash-Reset state, otherwise 0

UARTRES = /RESETIN * LEDRED ; UART-reset only if Monitor-Reset

; -----------------------------------------------------------------------

; Reset-Request : Toggles the Masterreset-input (MAX811), if

; -----------------------------------------------------------------------

/MASTRES = ((/MONRES + /USERRES + /FLASHRES) * RESETIN) ; Buttons pressed

+ (( LEDGRN * /A19 * A20 ) * RESETIN) ; or Rem-Request

+ ((/DTR ) * RESETIN) ; or DTR low

; -----------------------------------------------------------------------

; Memory-Mapping Equations :

; -----------------------------------------------------------------------

UG-910006-13 - 38 - © Fujitsu Microelectronics Europe GmbH

Page 39

STARTERKIT MB91360

Chapter 7 Appendix

; SRAMS active in areas :

/CSRAM = (/A20 * A19 * /CS0) ; 08:0000...0F:FFFF (CS0)

+ ( A20 * A19 * /CS0) ; 18:0000...1F:FFFF (CS0)

+ ( A20 * A19 * /CS2) ; 38:0000...3F:FFFF (CS2)

; UART-Area = 20:0000...27:FFFF (CS0 in Monitor-mode or CS2 in USER mode)

/CSUART = (LEDRED * /A20 * /A19 * /CS0) ; CS0 in Mon-Mode

+ (LEDGRN * /A20 * /A19 * /CS2) ; CS2 in User-Mode

7.7 Development tools and accessories

In-Circuit Emulation Tools for MB91360 Series:

Emulation Main Unit MB2197-01

Emulation Board MB2197-120

Emulation Header (Probe) MB2197-127

Evaluation Device MB91FV360GCR

Evaluation Board StarterkitMB91360

In-Circuit Emulation Tools for MB91100 Series:

Emulation Main Unit MB2197-01

RAM Stack FR-RAM-STACK1-100P-M06

Header MB2197-111

Header MB2197-112

Header MB2197-115

Evaluation Device MB91V10x(A)CR

Evaluation Board StarterkitMB91100

Accessories:

Serial Cable Extension type

QFP208 Socket NQ-PACK208SD

Socket IC Lid HQ-PACK208SD

ICE-socket adapter YQ-PACK208SD

Test-PCB for Starterkit QFP208 footprint to 2.54mm pin rows

Power supply 9-12V DC (0.5A)

© Fujitsu Microelectronics Europe GmbH - 39 - UG-910006-13

Page 40

STARTERKIT MB91360

Chapter 7 Appendix

7.8 Related Documents

Available manuals for MB91360 series :

1. MB91360 Hardware Manual

2. MB91F36X Datasheet (General Specification)

3. FR Family C-Compiler Manual

4. FR Family Instruction Manual

5. FR Family Assembler Manual

6. FR Family Simulator Manual

7. FR Family Emulator Manual

8. FR Family Linkage Kit Manual

9. FR Family Softune Workbench Manual

Note : All documents are available from the provided CD-ROM, Fujitsu’s Microcontroller CDROMs or from our web-site.

UG-910006-13 - 40 - © Fujitsu Microelectronics Europe GmbH

Page 41

STARTERKIT MB91360

Chapter 7 Appendix

7.9 Trouble Shooting

Problem Solution

Evaluationboard does not

initialize after power-on.

LED D10 (Power indicator) does

not light up and the LC-display

remains empty.

Check voltage supply and jumpers :

The voltage on DC-Power plug

☛

should be in the range of 9-12V. The

plug should have + on shield and – on

the center. LED D10 should light up

after switching on the board. Use a

multimeter to see whether 5V are

present on the Vcc/Gnd terminals (TP2

and TP3).

Check jumper positions according to

☛

table 1 (Esp. : JP1 – JP7) !

Remove all user extensions on the

☛

board to avoid shorts !

Evaluationboard stays in reset.

LED D11 (Reset indicator) ligths

up permanently.

LED D11 (Reset) should flash. If D11

☛

lights up permantantly, the voltage is too

low (below 4.25V) - Increase the voltage

to solve the problem.

JP33 (DTR reset) should be left

☛

open. This option allows to reset the

board from a connected PC using the

DTR line (not used by Softune WB).

Remove all user extensions on the

☛

board to avoid shorts or leakage

currents !

After power-on, the initial

monitor-message is not shown

on the LCD.

Check JP34 (default-mode) : This

☛

jumper should be in the lower position

(Monitor mode). In the upper position,

the board will call the user program in

Flash-ROM directly and will not show

the message.

Maybe the monitor-kernel has been

☛

destroyed. Try to re-program the kernel

as desribed in the „flash programming“-

section.

Check all jumper positions (table 1).

☛

Adjust the LCD contrast using

☛

potentiometer RV1.

The communication from

Softune Workbench to the

Make sure your COM-port number

☛

and the baudrate settings are correct

© Fujitsu Microelectronics Europe GmbH - 41 - UG-910006-13

Page 42

STARTERKIT MB91360

Chapter 7 Appendix

Problem Solution

evaluation board fails

(Communication errors)

(see debugger introduction).

Make sure no other programs are

☛

using the same COM-port on your PC.

Close all other applications (e.g. Flash

programmer utilities, terminals etc.)

Use the provided RS232-cable (1:1

☛

extension type) to connect from your PC

to the „Monitor COM“ connector.

If you are using a PC without a fast

☛

UART (16550 type), you have to switch

to a lower baudrate (e.g. 38400 Baud)

and re-program the kernel according to

this baudrate (see „flash programming“

section).

The program stops at the label

„uninitialized interrupt !“

Before downloading a new project to

☛

the evaluation board, re-initialize using

the Monitor-Reset. This will erase all

valid interrupt definitions from previous

programs executed on the starterkit.

Make sure you haven’t enabled any

☛

interrupts that have no interrupt handler

(see the INTVECT.INC file) !

Note : Since the „Abort“-function uses

the external interrupt 0, interrupts are

usually enabled !

Hardware units such as LEDs,

user buttons, UART0 or CAN are

not working.

Make sure you have enabled these

☛

units on the evaluation board using the

appropriate jumpers (e.g. JP13 for

LEDs). See the provided examples and

the hardware manual for information on

how to control the peripherals.

CAN devices do not respond

Adjust the potentiometer RV2 (slew

☛

rate) according to the line.

Table 5: Trouble Shooting

For more information see the Softune Workbench on-line help, the provided manuals, last

minute information and additional or updated documentation on our web-site.

UG-910006-13 - 42 - © Fujitsu Microelectronics Europe GmbH

Page 43

7.10 Figures

STARTERKIT MB91360

Chapter 7 Appendix

Figure 1: Using the Starterkit as target board for the ICE....................................................... 7

Figure 2: Softune Workbench Editor .................................................................................... 11

Figure 3: SWB Debugging window....................................................................................... 14

Figure 4: MB91360 Flash Programmer ................................................................................ 20

Figure 5: Memory Mapping Single Chip Mode / Monitor Mode............................................. 29

Figure 6: Memory Mapping External Mode / User Mode ...................................................... 30

7.11 Tables

Table 1: Selection jumpers on MB91360 Starterkit...............................................................23

Table 2: Grouped jumpers on MB91360 Starterkit ............................................................... 24

Table 3: Overview of available resource-functions and IO-ports on jumpers ........................ 28

Table 4: Memory Map .......................................................................................................... 31

Table 5: Trouble Shooting....................................................................................................42

-- END --

© Fujitsu Microelectronics Europe GmbH - 43 - UG-910006-13

Loading...

Loading...