Page 1

FUJITSU SEMICONDUCTOR

HARDWARE MANUAL

MB87J2120 & MB87P2020 -A

Lavender & Jasmine

Colour LCD/CRT/TV Controller

Fujitsu Microelectronics Europe GmbH

European MCU Design Centre (EMDC)

Am Siebenstein 6-10

D-63303 Dreieich-Buchschlag

Germany

Version: 1.8

File: MB87P2020.fm

Specification

Page 2

MB87J2120, MB87P2020-A Hardware Manual

Revision History

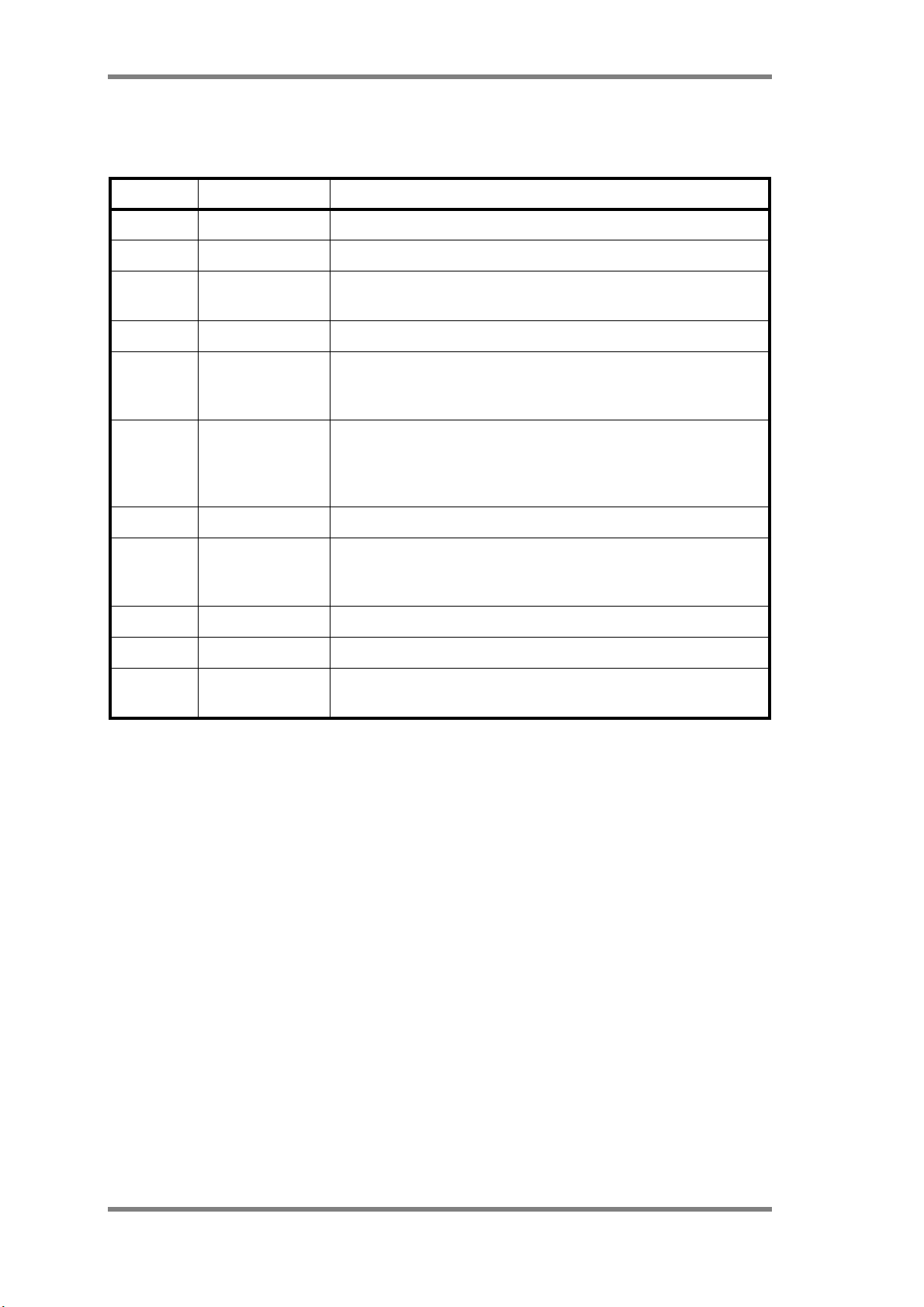

Version Date Remark

0.8 05. Apr. 2001 First Release

0.9 27. Apr. 2001 Preliminary Release

1.0 29. Jun. 2001 Overview Section and Register List reviewed

SDC, PP, AAF, DIPA and ULB descriptions reviewed

1.1 20. Jul. 2001 Register List improved, Lavender pinning added, overall review

1.2 02. Aug. 2001 APLL spec included (CU)

Review: overview, functional descriptions, register/command lists

Preliminary AC Spec for Jasmine

1.3 05. Oct. 2001 AC Spec for both devices, Lavender added/Jasmine reviewed

Two pinning lists - sorted by name/pin number

ULB DMA limit description (DMA FIFO limits vs. IPA block size)

SDC Register description reviewed

1.4 11. Oct 2001 Clarified AC Spec output characteristics (20/50pF conditions)

1.5 27. Mar 2002 Pinning and additional registers for MB87P2020-A added

Design description for changes in MB87P2020-A added

AC Spec updated for MB87P2020-A

1.6 05. Apr 2002 AC Spec for MB87J2120 updated

1.7 22. Jul 2002 Description changed to MB87P2020-A

1.8 18. Sep 2003 Display restriction description for physical colors added (1bpp,

4bpp, RGB111 colour formats only)

File: /usr/home/msed/gdc_dram/doc/manual/MB87P2020.fm

Copyright

© 2001 by Fujitsu Microelectronics Europe GmbH

European MCU Design Centre (EMDC)

Am Siebenstein 6-10

D-63303 Dreieich-Buchschlag

Germany

This document contains information considered proprietary by the publisher. No part of

this document may be copied, or reproduced in any form or by any means, or transferred

to anythird party without the prior written consent of the publisher. The document is subject to change without prior notice.

Page 12

Page 3

Table of Contents

Table of Contents

PART A - Lavender and Jasmine Overview

1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Application overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Jasmine/Lavender Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Clock supply and generation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Register and Command Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Register Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Command Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PART B - Functional Descriptions

B-1 Clock Unit (CU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.2 Reset Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.3 Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2 APLL Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.1.1 Phase Skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.1.2 Duty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.1.3 Lock Up Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1.4 Jitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.1.5 Variation in Output Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1.6 Maximum Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2 Usage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3 Clock Setup and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.1 Configurable Circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2 Clock Unit Programming Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3 Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

B-2 User Logic Bus Controller (ULB) . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table of Contents Page 1

Page 4

MB87J2120, MB87P2020-A Hardware Manual

1 Functional description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

1.1 ULB functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.2 ULB overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1.3 Signal synchronisation between MCU and display controller . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.3.1 Write synchronization for Lavender and Jasmine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.3.2 Read synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

1.3.3 DMA and interrupt signal synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1.3.4 Output signal configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.4 Address decoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.4.2 Register space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1.4.3 SDRAM space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.4.4 Display controller bus access types (word, halfword, byte). . . . . . . . . . . . . . . . . . . . . . . 51

1.4.5 Display controller data modes (32/16 Bit interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.5 Command decoding and execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.5.1 Command and data interface to MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.5.2 Command execution and programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.5.3 Structure of command controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1.5.4 Display controller commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.5.5 Registers and flags regarding command execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1.6 Flag and interrupt handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1.6.1 Flag and interrupt registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

1.6.2 Interrupt controller configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1.6.3 Interrupt generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1.6.4 Interrupt configuration example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.6.5 Display controller flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.7 DMA handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.7.1 DMA interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.7.2 DMA modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.7.3 DMA settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1.7.4 DMA programming examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2 ULB register set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.2 ULB initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

B-3 SDRAM Controller (SDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

1 Function Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Page 2

Page 5

Table of Contents

1.2 Arbitration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1.3 SDRAM Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1.4 Sequencer for Refresh and Power Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

1.5 Address Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1.5.1 Elucidations regarding Address Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2 SDRAM Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.1 External SDRAM I-/O-Pads with configurable sampling Time (Lavender). . . . . . . . . . . . . . 92

2.2 Integrated SDRAM Implementation (Jasmine). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.1 Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.2 Core clock dependent Timing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.2.1 General Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.2.2 Refresh Configuration for integrated DRAM (Jasmine). . . . . . . . . . . . . . . . . . . . . . . . . . 95

B-4 Pixel Processor (PP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

1.1.1 PP Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

1.1.2 Function of submodules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

1.2 Configuration Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.3 Special Command Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1.3.1 Bitmap Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1.3.2 Bitmap Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

2 Format Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2.1 Legend of symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2.2 Data Formats at ULB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

2.3 Data Formats for Video RAM / SDC Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

B-5 Antialiasing Filter (AAF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1.1 AAF Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1.1.1 Top Level Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1.1.2 AAU Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

1.2 Configuration Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1.3 Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

1.3.1 Restrictions due to Usage of AAF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table of Contents Page 3

Page 6

MB87J2120, MB87P2020-A Hardware Manual

1.3.2 Supported Colour Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

1.3.3 Related SDC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B-6 Direct and Indirect Physical Memory Access Unit (DIPA) . . . . .117

1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

2 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

2.1 Register List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

2.2 Recommended Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

2.3 Related Settings and Informations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B-7 Video Interface Controller (VIC). . . . . . . . . . . . . . . . . . . . . . . . . . 123

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

1.1 Video Interface Controller functions and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

1.2 Video data handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

2 VIC Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

2.1 Data Input Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

2.2 Data format in Video RAM (SDRAM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.3 Data Input Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

2.3.1 Videoscaler-Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

2.3.2 CCIR-Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

2.3.3 External-Timing-mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

3 VIC settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

3.1 Register list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.2 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

B-8 Graphic Processing Unit (GPU). . . . . . . . . . . . . . . . . . . . . . . . . . .149

1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

1.1 GPU Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

1.2 GPU Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.2.1 Top Level Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.2.2 DFU Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.2.3 CCU Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1.2.4 LSA Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

1.2.5 BSF Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

2 Color Space Concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Page 4

Page 7

Table of Contents

2.1 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

2.2 Data Flow for Color Space Conversion within GPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

2.3 Mapping from Logical to Intermediate Color Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

2.4 Mapping from Intermediate to Physical Color Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3 GPU Control Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.1 Layer Description Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.2 Merging Description Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

3.3 Display Interface Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

3.4 Supported Physical Color Space / Bit Stream Format Combinations . . . . . . . . . . . . . . . . . . 167

3.5 Twin Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

3.6 Scan Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

3.7 YUV to RGB conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

3.7.1 YUV422 Demultiplexing and Chrominance Interpolation. . . . . . . . . . . . . . . . . . . . . . . 171

3.7.2 Matrix Multiplication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

3.7.3 Inverse Gamma Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

3.8 Duty Ratio Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

3.8.1 Working Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

3.8.2 Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.9 Master Timing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

3.10 Generation of Sync Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.10.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.10.2 Position Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.10.3 Sequence Matching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

3.10.4 Combining First-Stage Sync Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

3.10.5 Sync Signal Delay Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

3.11 Pixel Clock Gating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

3.12 Numerical Mnemonic Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

3.12.1 Color Space Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

3.12.2 Bit Stream Format Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

3.12.3 Scan Mode Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

3.13 Bit to Color Channel Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

3.14 GPU Signal to GDC Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

3.14.1 Multi-Purpose Digital Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

3.14.2 Analog Pixel Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

3.14.3 Dedicated Sync Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

3.14.4 Sync Mixer connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

3.14.5 Color Key Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

4 GPU Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Table of Contents Page 5

Page 8

MB87J2120, MB87P2020-A Hardware Manual

4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

4.2 Determination of Register Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.2.1 Values Derived from Display Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.2.2 Values Determined by Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

4.2.3 User preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

4.3 GPU Initialization Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

5 Bandwidth Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

5.1 Processing Bandwidth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5.1.1 Average Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5.1.2 Peak Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5.2 Memory Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

5.2.1 Average Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

5.2.2 Peak Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

5.3 Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

6 Functional Peculiarities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

6.1 Configuration Constraints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6.2 Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6.3 Image Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

6.4 Data Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

6.5 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

7 Supported Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

7.1 Passive Matrix LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

7.2 Active Matrix (TFT) Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

7.3 Electroluminescent Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

7.4 Field Emission Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

7.5 Limitations for support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

7.5.1 No Support due to VCOM Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

7.5.2 Problems due to 5V CMOS Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

B-9 Cold Cathode Fluorescence Light Driver (CCFL). . . . . . . . . . . .215

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

2 Signal Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

2.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

2.2 Duration of the Phases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

2.3 Pulse shape of FET1 and FET2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

3 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Page 6

Page 9

Table of Contents

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

3.2 Control Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

4 Application Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.1 CCFL Setup Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.2 CCFL Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

PART C - Pinning and Electrical Specification

1 Pinning and Buffer Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

1.1 Pinning for MB87P2020-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

1.1.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

1.1.2 Buffer types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

1.2 Pinning for MB87P2020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

1.2.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

1.2.2 Buffer types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

1.3 Pinning for MB87J2120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

1.3.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

1.3.2 Buffer Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

2 Electrical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

2.1 Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

2.1.1 Power-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

2.1.2 External Signal Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

2.1.3 APLL Power Supply Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

2.1.4 DAC supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

2.1.5 SDRAM Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

2.2 Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

2.3 DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

2.4 Mounting / Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

2.5 AC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

2.5.1 Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

2.5.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

2.5.3 Clock inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

2.5.4 MCU User Logic Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

2.5.5 Interrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

2.5.6 DMA Control Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

2.5.7 Display Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

2.5.8 Video Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

2.5.9 CCFL FET Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Table of Contents Page 7

Page 10

MB87J2120, MB87P2020-A Hardware Manual

2.5.10 Serial Peripheral Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

2.5.11 Special and Mode Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

2.5.12 SDRAM Ports (Lavender) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

PART D - Appendix

D-1 Jasmine Command and Register Description. . . . . . . . . . . . . . . . 291

1 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .293

2 Flag Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .321

3 Command Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .325

3.1 Command List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

3.2 Command and I/O Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

D-2 Hints and restrictions for Lavender and Jasmine . . . . . . . . . . . . 333

1 Special hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

1.1 IPA resistance against wrong settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

1.2 ULB_DREQ pin timing to host MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

1.3 CLKPDR master reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

1.4 MAU (Memory Access Unit) commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

1.5 Pixel Processor (PP) double buffering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

1.6 Robustness of ULB_RDY signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

1.7 Robustness of command pipeline against software errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

1.8 DMA resistance against wrong settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

2 Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .341

2.1 ESD characteristics for I/O buffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

2.2 Command FSM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

2.3 GPU mastertiming synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

2.4 Read limitation for 16 Bit data interface to MCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

2.5 SDC sequencer readback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

2.6 Direct SDRAM access with 16bit and 8bit data mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

2.7 Input FIFO read in 16bit mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

2.8 ULB_DSTP pin function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

2.9 Software Reset for command execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

2.10 AAF settings double buffering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

2.11 Pixel Engine (PE) Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

2.12 Pixel read back commands (GetPixel, XChPixel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Page 8

Page 11

Table of Contents

2.13 Display Interface Re-configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

2.14 Display Limitation for physical color depths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

D-3 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Table of Contents Page 9

Page 12

MB87J2120, MB87P2020-A Hardware Manual

Page 10

Page 13

PART A - Lavender and Jasmine

Overview

Page 13

Page 14

MB87J2120, MB87P2020-A Hardware Manual

Page 14

Page 15

Graphic Controller Overview

1 Overview

1.1 Application overview

The MB87J2120 "Lavender" and MB87P2020-A “Jasmine” are colour LCD/CRT graphic display control-

1

lers (GDCs)

The architecture is designed to meet the low cost, low power requirements in embedded and especially in

automotive

Lavender and Jasmine support almost all LCD panel types and CRTs or other progressive scanned3moni-

tors/displays which can be connected via the digital or analog RGB output. Products requiring video/camera

input can take advantage of the supported digital video interface. The graphic instruction set is optimized

for minimal traffic at the MCU interface because it’s the most important performance issue of co-processing

graphic acceleration systems. Lavender uses external connected SDRAM, Jasmine is a compatible GDC

version with integrated SDRAM (1MByte) and comes with additional features.

Lavender and Jasmine support a set of 2D drawing functions with built in Pixel Processor, a video scaler

interface, units for physical and direct video memory access and a powerful video output stream formatter

for the greatest variety of connectable displays.

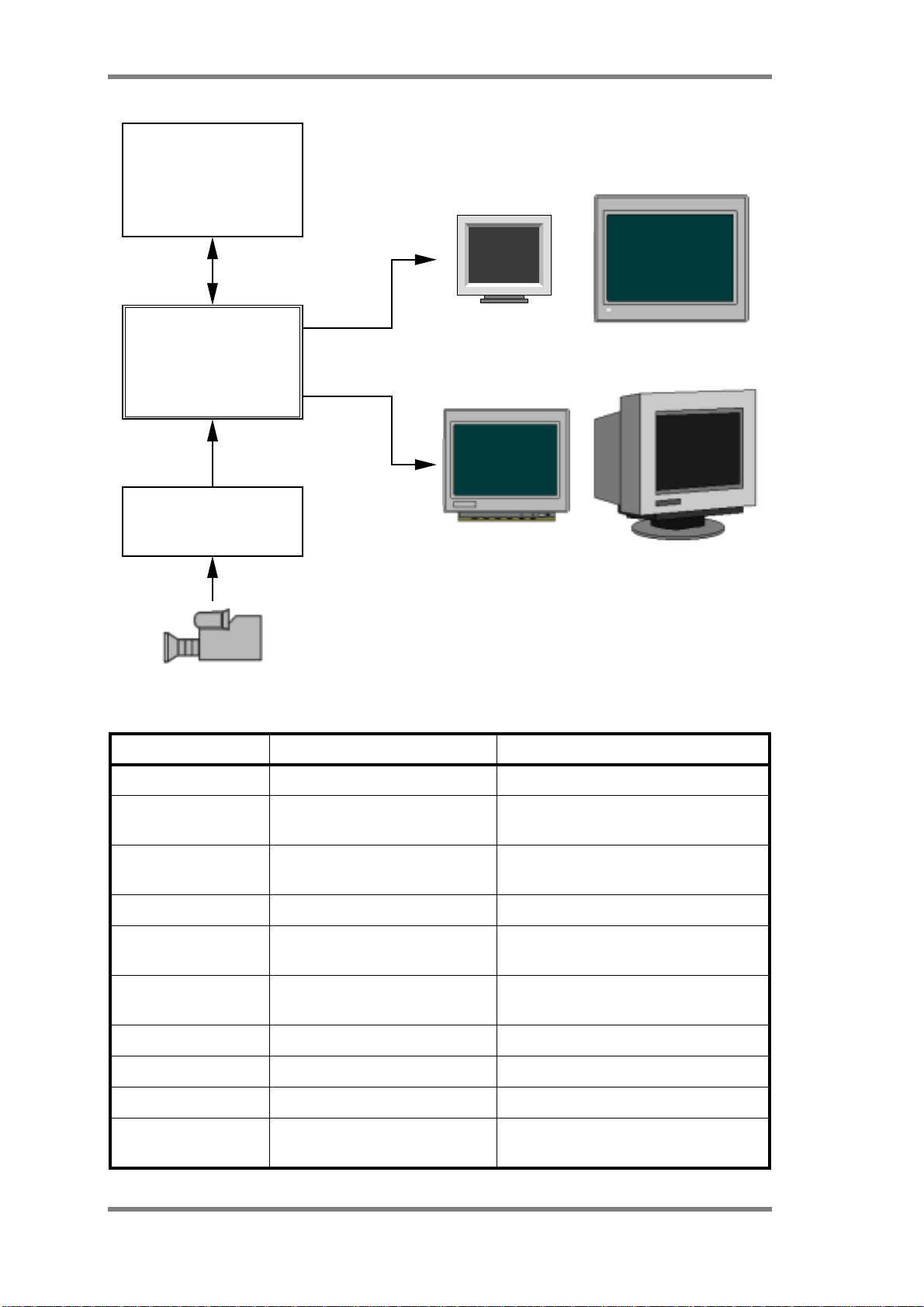

Figure 1-1 displays an application block diagram in order to show the connection possibilities of Jasmine.

For Lavender external SDRAM connection is required in addition.

interfacing to MB91xxxx micro controller family and support a wide range of display devices.

2

applications.

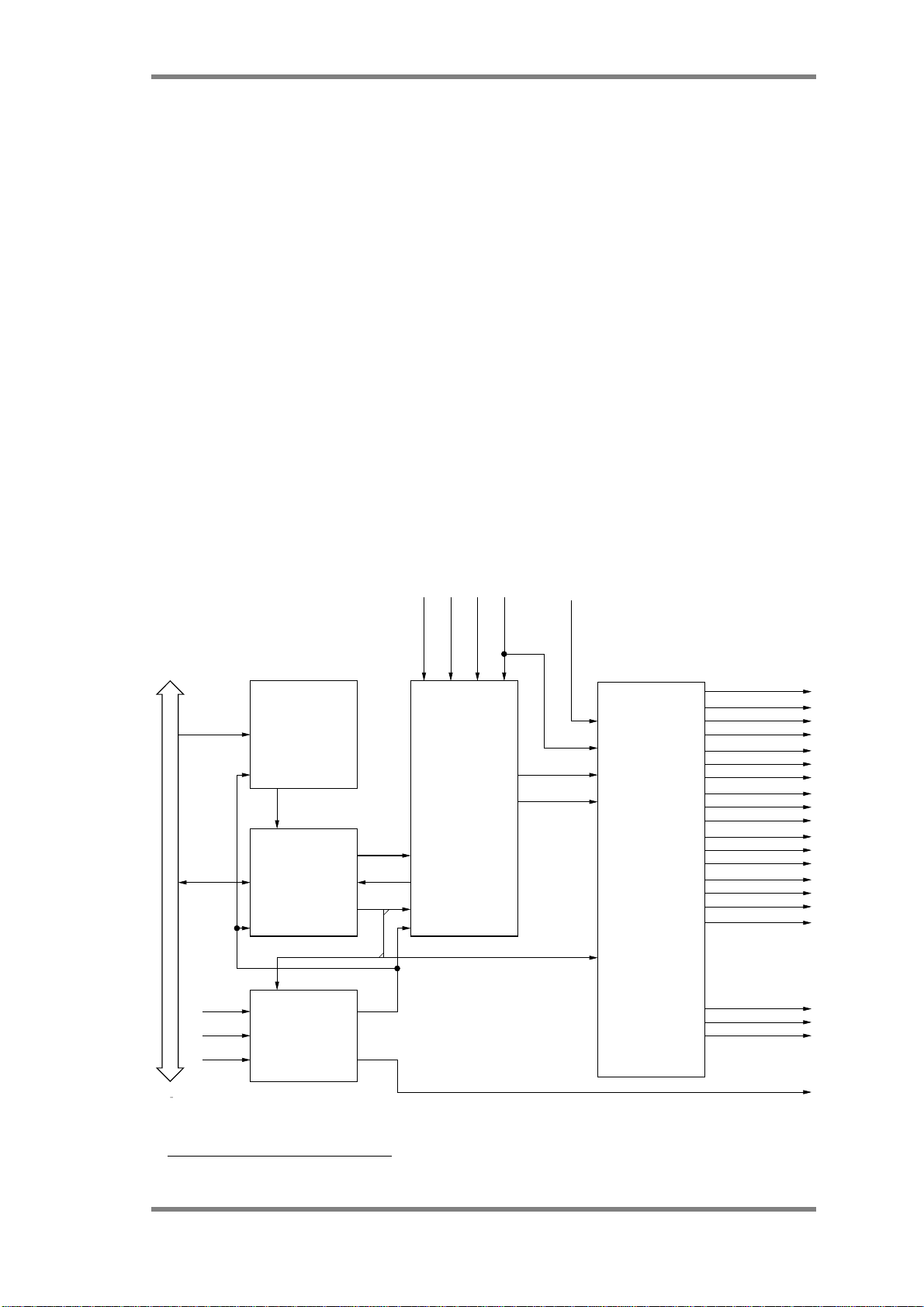

1.2 Jasmine/Lavender Block Diagram

Figure 1-2 shows all main components of Jasmine/Lavender graphic controllers. The User Logic Bus controller (ULB), Clock Unit (CU) and Serial Peripheral Bus (SPB) are connected to the User Logic Bus interface of 32 bit Fujitsu RISC microprocessors. 32 and 16 bit access modes are supported.

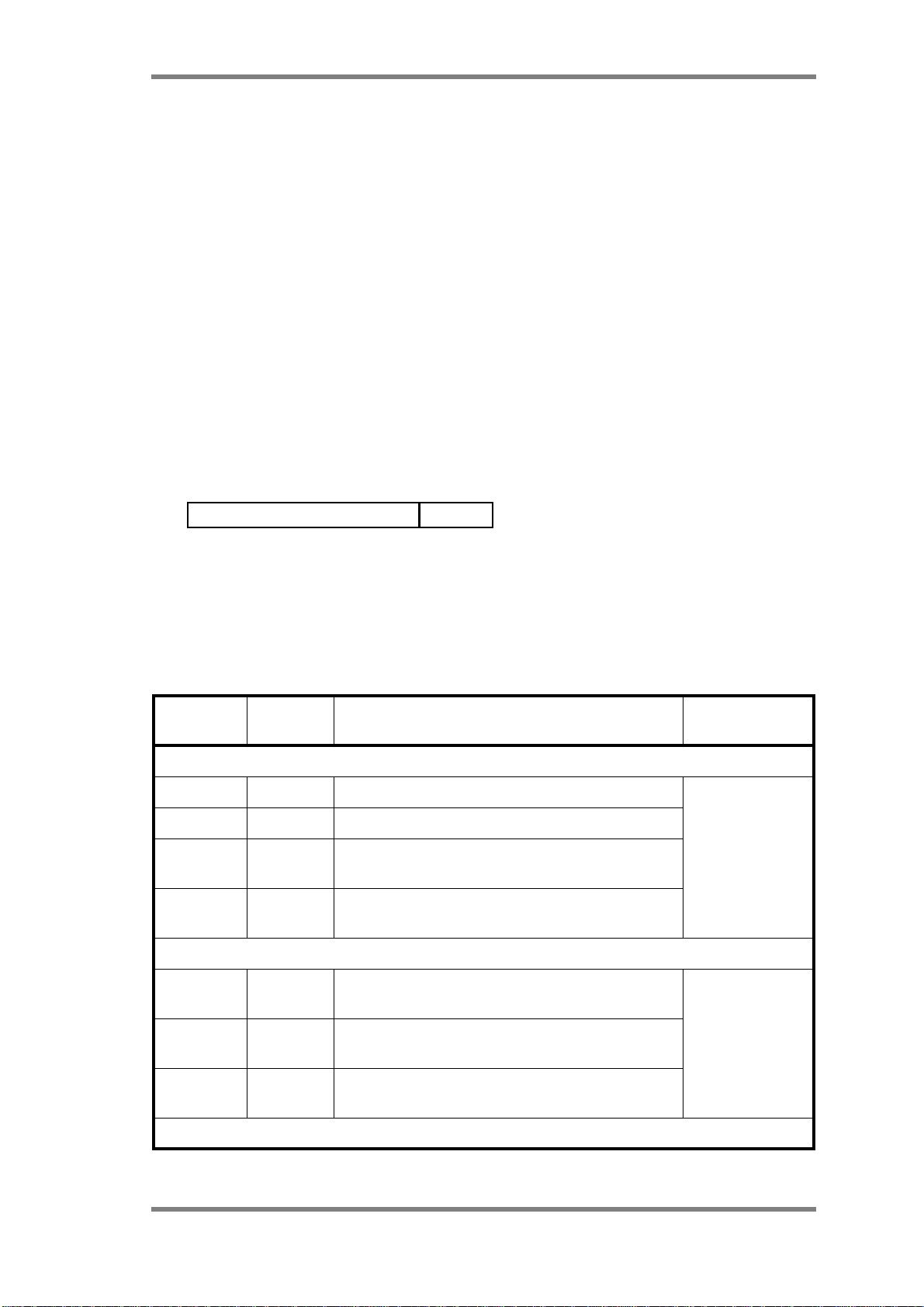

Table 1-1: GDC components

Shortcut Meaning Main Function

CCFL Cold Cathode Fluorescence

Lamp

CU Clock Unit Clock gearing and supply, Power save

DAC Digital Analog Converter Digital to analog conversion for analog

DPA (part of DIPA) Direct Physical memory Access Memory mapped SDRAM access with

GPU Graphics Processing Unit Frame buffer reader which converts to

DFU (part of GPU) Data Fetch Unit Graphic/video data acquisition

CCU (part of GPU) Colour Conversion Unit Colour format conversion to common

Cold cathode driver for display backlight

display

address decoding

video data format required by display

intermediate overlay format

1. The general term ’graphic display controller’ or its abbreviation ’GDC’ is used in this manual to identify both

devices. Mainly this is used to emphasize its common features.

2. Both display controllers have an enhanced temperature range of -40 to 85oC.

3. TV conform output (interlaced) is also possible with half the vertical resolution (line doubling).

Overview Page 15

Page 16

MB87J2120, MB87P2020-A Hardware Manual

Host MCU

MB91xxxx

Digital Video

MB87P2020 or MB87J2120

(Jasmine or Lavender)

RGB Analog

Video Scaler

e.g. VPX3220A, SAA7111A

Figure 1-1: Application overview

Table 1-1: GDC components

Shortcut Meaning Main Function

LSA (part of GPU) Line Segment Accumulator Layer overlay

BSF (part of GPU) BitStream Formatter Intermediate format to physical display

Format converter, Sync generation

IPA (part of DIPA) Indirect Physical memory Access SDRAM access with command register

and FIFO

MAU (part of PP) Memory Access Unit Pixel access to video RAM

MCP (part of PP) Memory CoPy Memory to memory copying of rectan-

gular areas

PE (part of PP) Pixel Engine Drawing of geometrical figures and bit-

maps

PP Pixel Processor Graphic oriented functions

SDC SDRAM Controller SDRAM access and arbitration

SPB Serial Peripheral Bus Serial interface (master)

ULB User Logic Bus (see MB91360

series specification)

Address decoding, command control,

flag, interrupt and DMA handling

Page 16

Page 17

Embedded DRAM (1MByte) or external SDRAM (8MByte)

Graphic Controller Overview

MB87P2020 (Jasmine)

MB87J2120 (Lavender)

SDRAM Controller (SDC)

Anti Aliasing Filter (AAF)

Pixel Processor (PP)

Pixel

Engine

(PE)

User Logic Bus Interface (ULB)

Command Control

User Logic Bus

XTAL

PIX

BUS

Video Scaler Interface

Graphic Processing Unit (GPU)

CCUMAU MCP DIPA VIC DFU LSA BSF

Clock

Unit

(CU)

Figure 1-2: Component overview for Lavender and Jasmine graphic controllers

CCFL

Video

DACs

SPB

Back

Light

Analog

Video

Digital

Video

Serial

Table 1-1: GDC components

Shortcut Meaning Main Function

VIC Video Interface Controller YUV-/RGB-Interface to video grabber

The ULB provides an interface to host MCU (MB91360 series). The main functions are MCU (User Logic

Bus) control inclusive wait state handling, address decoding and device controls, data buffering / synchronisation between clock domains and command decoding. Beside normal data and command read and write

operation it supports DMA flow control for full automatic data transfer from MCU to GDC and vice versa.

Also an interrupt controlled data flow is possible and various interrupt sources inside the graphics controller

can be programmed.

The Clock Unit (CU) provides all necessary clocks to module blocks of GDC and a FR compliant (ULB)

interface to host MCU. Main functions are clock source select (XTAL, ULB clock, display clock or special

pin), programmable clock multiplier/divider with APLL, power management for all GDC devices and the

generation of synchronous RESET signal.

For Fujitsu internal purposes one independent macro is build in the GDC ASIC, the Serial Peripheral Bus

(SPB). It’s a single line serial interface. There is no interaction with other GDC components.

All drawing functions are executed in Pixel Processor (PP). It consists of three main components Pixel Engine (PE), Memory Access Unit (MAU) and Memory Copy (MCP). All functions provided by these blocks

are related to operations with pixel addresses {X, Y} possibly enhanced with layer information. GDC supports 16 layers by hardware, four of them can be visible at the same time. Each layer is capable of storing

Overview Page 17

Page 18

MB87J2120, MB87P2020-A Hardware Manual

any data type (graphic or video data with various colour depths) only restricted by the bandwidth limitation

of video memory at a given operating frequency.

Drawing functions are executed in the PE by writing commands and their dedicated parameter sets. All

commands can be taken from the command list in section 4.2. Writing of uncompressed and compressed

bitmaps/textures, drawing of lines, poly-lines and rectangles are supported by the PE. There are many special modes such as duplicating data with a mirroring function.

Writing and reading of pixels in various modes is handled by MAU. Single transfers and block or burst

transfers are possible. Also an exchange pixel function is supported.

With the MCP unit it is possible to transfer graphic blocks between layers of the same colour representation

very fast. Only size, source and destination points have to be given to duplicate some picture data. So it offers an easy and fast way to program moving objects or graphic libraries.

All PP image manipulation functions can be fed through an Antialiasing Filter (AAF). This is as much faster

than a software realisation. Due to the algorithm which shrinks the graphic size by two this has to be compensated by doubling the drawing parameters i.e. the co-ordinates of line endpoints.

DIPA stands for Direct/Indirect Physical Access. This unit handles rough video data memory access without pixel interpretation (frame buffer access). Depending on the colour depth (bpp, bit per pixel) one or

more pixel are stored in one data word. DPA (Direct PA) is a memory-mapped method of physical access.

It is possible in word (32 bit), half word (16 bit) or byte mode. The whole video memory or partial window

(page) can be accessed in a user definable address area of GDC. IPA (Indirect PA) is controlled per ULB

command interface and IPA access is buffered through the FIFOs to gain high access performance. It uses

the command GetPA and PutPA, which are supporting burst accesses, possibly handled with interrupt and

DMA control.

For displaying real-time video within the graphic environment both display controllers have a video interface for connection of video-scaler chips, e.g Intermetall’s IC VPX32xx series or Phillips SAA711x. Additionally the video input of Jasmine can handle CCIR standard conform digital video streams.

Several synchronisation modes are implemented in both controllers and work with frame buffering of one

up to three pictures. With line doubling and frame repetition there exist a large amount of possibilities for

frame rate synchronisation and interlaced to progressive conversion as well. Due to the strict timing of most

graphic displays the input video rate has to be independent from the output format. So video data is stored

as same principles as for graphic data using up to three of the sixteen layers.

The SDC is a memory controller, which arbitrates the internal modules and generates the required access

timings for SDRAM devices. With a special address mapping and an optimized algorithm for generating

control commands the controller can derive full benefit from internal SDRAM. This increases performance

respective at random (non-linear) memory access.

The most complex part of GDC is its graphic data processing unit (GPU). It reads the graphic/video data

from up to four layers from video memory and converts it to the required video output streams for a great

variety of connectable display types. It consists of Data Fetch Unit (DFU), Colour Conversion Unit (CCU)

which comes with 512 words by 24-bit colour look up table, Line Segment Accumulator (LSA) which does

the layer overlay and finally the Bitstream Formatter (BSF). The GPU has such flexibility for generating

the data streams, video timings and sync signals to be capable of driving the greatest variety of known display types.

Additional to the digital outputs video DACs provide the ability to connect analog video destinations. A

driver for the displays Cold Cathode Fluorescence Lamp (CCFL) makes the back light dimmable. It can be

synchronized with the vertical frequency of the video output to avoid visible artefacts during modulating

the lamp.

Page 18

Page 19

Graphic Controller Overview

2 Features and Functions

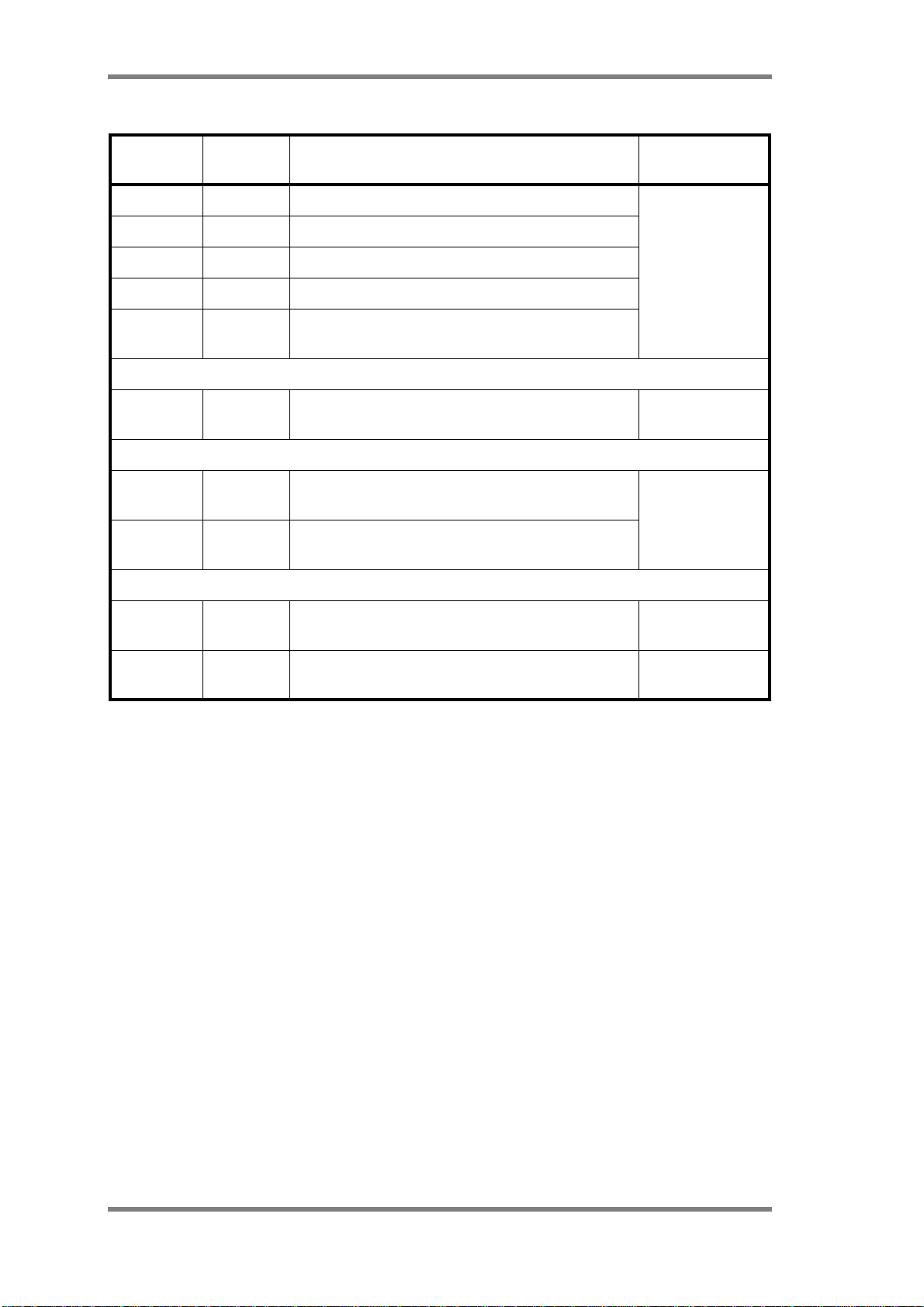

Table 2-1: Lavender and Jasmine features in comparison

MB87J2120 (Lavender) MB87P2020-A (Jasmine)

General features

• 2M words x 32 Bit external SDRAM

(64 Mbit)

•nointernal SDRAM

• Package: BGA-256P-M01 • Package: FPT-208P-M06

• Chip select sharing for up to four GDC devices

• synchronized reset (needs applied clock) • immediate asynchronous reset, synchronized

Pixel manipulation functions

• 2D Drawing and Bitmap Functions

- Lines and Polygons

- Rectangular Area

- Uncompressed Bitmap/1bit pixelmask

- Compressed Bitmap (TGA format)/1bit pixelmask

• Pixel Memory Access Functions

- Put Pixel

- Put Pixel FC (fixed colour)

- Put Pixel Word (packed)

- Exchange Pixel

- Get Pixel

• 256k words x 32 Bit internal SDRAM

(8 Mbit)

reset release

• Layer Register for text and bitmap functions • Layer Register enhancement for drawing functions (simplifies pixel addressing)

• Copy rectangular areas between layers

• Anti Aliasing Filter (AAF)

- resolution increase by factor 2 for each dimension (2x2 filter operator size)

• Free programmable Bitstream Formatter for a

great variety of supported displays (single/

dual/alternate scan):

- Passive Matrix LCD (single/dual scan)

- Active Matrix (TFT) Displays

- Electroluminescent Displays

- Field Emission Displays

- TV compatible output

- CRTs...

• 24 bit digital video output (RGB)

• Additional 4x4 AAF operator size

Display

• Additional Twin Display Mode feature (simultaneous digital and analog output without limitation of DIS_D[23:16] that carry special sync

signals).

Features and Functions Page 19

Page 20

MB87J2120, MB87P2020-A Hardware Manual

Table 2-1: Lavender and Jasmine features in comparison

MB87J2120 (Lavender) MB87P2020-A (Jasmine)

• On-Chip Video DAC, 50M Samples/s (dot clock)

• Flexible three-stage sync signal programming (trigger position/sequence, combining and delay) for

up to 8 signal outputs

• Colour keying between two limits

• Brightness modulation for displays with a Cold Cathode Fluorescence Lamp back-light

• Display resolution/drawing planes up to 16383 pixels for each dimension

• 4 layer + background colour simultaneous display and graphic overlay, programmable Z-order

• Blinking, transparency and background attributes

• Free programmable display section of a layer

• Separable Colour LUT with

256 entries x 24 Bit

• Duty Ratio Modulation (DRM) for pseudo hue/grey levels

• Hardware support for 16 layers, usable for graphic/video without restrictions

• Performance sharing with adjustable priorities and configurable block sizes for memory transfers enable maximal throughput for a wide range of applications

• Variable and display independent colour space

concept: Layers with 1, 2, 4, 8, 16, 24 bit per

pixel can be mixed and converted to one display specific format (logical-intermediatephysical format mapping)

Physical SDRAM access

• Memory mapped direct physical access for storage of non-graphics data or direct image access

• Indirect physical memory access for high bandwidth multipurpose data/video memory access

MCU interface

• 32/16 Bit MCU interface, designed for direct connection of MB91xxxx family (8/16/32Bit access)

• DMA support (all MB91xxxx modes)

• Interrupt support

• Colour LUT expansion to 512 entries

• Additional GPU a YUV to RGB converter in

order to allow YUV coded layers

• Additional Gamma correction RAMs are included (3x256x8Bit)

Video interface

• Video interface VPX32xx series by Micronas

Intermetall, Phillips SAA711x and others

• Video synchronization with up to 3 frame buffers

Clock generation

• Flexible clocking concept with on-chip PLL and up to 4 external clock sources:

- XTAL

- ULB bus clock

- Pixel clock

- Additional external clock pin (MODE[3]/RCLK)

• Separate power saving for each sub-module

• Additional CCIR conform input mode

Page 20

Page 21

Graphic Controller Overview

3 Clock supply and generation

GDC has a flexible clocking concept where four input clocks (OSC_IN/OUT, DIS_PIXCLK, ULB_CLK,

RCLK) can be used as clock source for Core clock (CLKK) and Display clock (CLKD).

The user can choose by software whether to take the direct clock input or the output of an APLL independent for Core- and Display clock. Both output clocks have different dividers programmable by software

(DIV x for CLKD and DIV z for CLKK). The clock gearing facilities offer the possibility to scale system

performance and power consumption as needed.

OSC_IN/OUT

DIS_PIXCLK

ULB_CLK

RCLK

VSC_CLKV

PLL Clock

Direct Clock

APLL

MUL y

System Clock Prescaler

DIV z

Pixel Clock Prescaler

DIV x

invert option

invert option

(Jasmine only)

INV INV

CLKK

CLKD

CLKM

CLKV

Figure 3-1: Clock gearing and distribution

Beside these two configurable clocks (CLKK and CLKD) GDC needs two additional internal clocks:

CLKM and CLKV (see also figure 3-1). CLKV is exclusively for video interface and is connected to input

clock pin VSC_CLKV. CLKM is used for User Logic Bus (ULB) interface and is connected to input clock

ULB_CLK. As already mentioned ULB_CLK can also be used to build CLKK and/or CLKD.

Table 3-1 shows all clocks used by GDC with their requirements.

Table 3-1: Clock supply

Clock Type Symbol Requirements Unit

Min Typ Max

XTAL clock input OSC_IN, OSC_OUT

Reserve clock input RCLK

a

12

ULB_CLK

-64MHz

b

-64MHz

ULB clock input ULB_CLK - - 64 MHz

Pixel clock input DIS_PIXCLK - - 54 MHz

Video clock input VSC_CLKV - -

54

c

MHz

Core clock internal CLKK ULB_CLK - 64 MHz

Display clock internal CLKD - - 54 MHz

Video clock internal CLKV - -

54

c

MHz

ULB clock internal CLKM - - 64 MHz

Clock supply and generation Page 21

Page 22

MB87J2120, MB87P2020-A Hardware Manual

a. If used as PLL input. APLL input frequency has to be at minimum 12 MHz, regardless which clock is routed

to APLL.

b. If used as direct clock source bypassing the APLL, the user should take care that resulting core clock fre-

quency is above or equal to MCU bus interface clock.Be aware of tolerances!

c. The video interface is designed to achieve 54 MHz but there is a side condition that video clock should be

smaller than half of core clock.

Page 22

Page 23

Graphic Controller Overview

4 Register and Command Overview

4.1 Register Overview

The GDC device is mainly configurable by registers. These configuration registers are mapped in a

64 kByte large address range from 0x0000 to 0xffff. It is possible to shift this register space in steps of

64 kByte by the Mode[1:0] pins in order to connect multiple GDC devices.

Above this 4*64 kByte = 256 kByte address range the SDRAM video memory could be made visible for

direct physical access.

At byte address 0x1f:ffff GDC memory map ends with a total size of 2 MByte.

4.2 Command Overview

The command register width is 32 Bit. It is divided into command code and parameters:

31

parameters

Partial writing (halfword and byte) of command register is supported. Command execution is triggered by

writing byte 3 (code, bits [7:0]). Thus parameters should be written before command code.

Not all commands need parameters. In these cases parameter section is ignored.

In table 4-1 all commands are listed with mnemonic, command code and command parameters (if neces-

sary. This is only a short command overview, a more detailed command list can be found in appendix.

Table 4-1: Command List

Mnemonic Code Function Addressed

Bitmap and Texture Functions

PutBM 01H Store bitmap into Video RAM Pixel Processor

PutCP 02H Store compressed bitmap into Video RAM

PutTxtBM 05H

PutTxtCP 06H

Draw uncompressed texture with fixed foreground

and background colour

Draw compressed texture with fixed foreground and

background colour

07

code

device

Drawing Functions (2D)

DwLine 03H

DwPoly 0FH

DwRect 04H

"Draw a line" - calculate pixel position and store

LINECOL into Video RAM

"Draw a polygon" - draws multiple lines between

defined points, see DwLine

"Draw an rectangle" - calculate pixel addresses and

store RECTCOL into Video RAM

Pixel Operations

Pixel Processor

Register and Command Overview Page 23

Page 24

MB87J2120, MB87P2020-A Hardware Manual

Table 4-1: Command List

Mnemonic Code Function Addressed

device

PutPixel 07H Store single pixel data into Video RAM Pixel Processor

PutPxWd 08H Store word of packed pixels into Video RAM

PutPxFC 09H Store fixed colour pixel data in Video RAM

GetPixel 0AH Load pixel data from Video RAM

XChPixel 0BH

MemCopy 0CH

PutPA 0DH

GetPA <n>,0EH

SwReset 00H

NoOp FFH

Load old pixel in Output FIFO and store pixel from

Input FIFO into Video RAM

Memory to Memory Operations

Memory Copy of rectangular area. Transfer of bitmaps from one layer to another or within one layer.

Physical Framebuffer Access

Store data in physical format into Video RAM, with

physical address auto-increment

Load data in physical format from Video RAM with

address auto-increment, stop after n words

System Control Commands

Stop current command immediately, reset command

controller and FIFOs

No drawing or otherwise operation, finish current

command and flush buffers

Pixel Processor

DIPA

All drawing and

access devices

Command Control (ULB)

Page 24

Page 25

PART B - Functional Descriptions

Page 25

Page 26

MB87J2120, MB87P2020-A Hardware Manual

Page 26

Page 27

B-1 Clock Unit (CU)

Page 27

Page 28

MB87J2120, MB87P2020-A Hardware Manual

Page 28

Page 29

Clock Unit

1 Functional Description

1.1 Overview

The clock unit (CU) provides all necessary clocks to GDC modules and an own interface to host MCU

(MB91360 series) in order to have durable access even if ULB clocks switched off.

The main functions of CU are:

• Clock source select (Oscillator, MCU Bus clock, Display clock and a reserve clock input)

• Programmable clock muliplier with APLL

• Separate dividers for master (core) clock and pixel clock

• Power management for all GDC modules

• Generation of synchronized RESET signal

• MB91360 series compliant (ULB) Bus interface for clock setup

Figure 1-1 shows the overview of the Clock Unit. OSC_IN, DIS_PIXCLK, ULB_CLK and RCLK1are possible to use as input sources. Both clock outputs of the main unit (MASTERCLK and PIXELCLK) and two

directly used clock inputs (ULB_CLK and VSC_CLKV) driving the clock gates unit which distributes to

all connected GDC sub-modules.

RCLK

DIS_PIXCLK

Main Unit

ULB_CLK

MASTERCLK

PIXELCLK

VSC_CLKV

Clock Gates

PE_CLKK_OUT

MAU_CLKK_OUT

MCP_CLK_OUT

PP_CLKK_OUT

AAF_CLKK_OUT

DIPA_CLKK_OUT

VIS_CLKK_OUT

VIS_CLKV_OUT

SDC_CLKK_OUT

CCFL_CLKK_OUT

SPB_CLKM_OUT

ULB_CLK_OUT

ULB_CLKM_OUT

GPUF_CLKK_OUT

GPUM_CLKK_OUT

GPUB_CLKK_OUT

PIX_CLKD_OUT

SPB_CLKMX_OUT

ULB_CLKKX_OUT

ULB_CLKMX_OUT

inverted clock outputs not inverted clock outputs

K

ULB

_A

_RDX

_WRX

_CSX

_CLK

ULB

_D

_A

_WRX

User Logic Bus

_CLK

OSC_IN

ULB_CLK

RESETX

Address Decoder

RSTX

Clk[Con|Pd]R_[rd|wr]

Register Set

RSTX

SW_RST

Reset Generator

ClkConR

LOCK

ClkPdR

[11]

[15]

OSC_IN

RSTX

SYNC_RSTX_CU

SYNC_RSTX

Figure 1-1: Block diagram of Clock Unit

1. MODE[3] pin is used for RCLK at Lavender

Functional Description Page 29

Page 30

MB87J2120, MB87P2020-A Hardware Manual

The GDC device has four different clock domains, that means clocks derived from four different sources.

The largest part of the design runs at core clock which operates at the highest frequency driven by the MASTERCLK output. Thus normally the APLL is used to provide a higher internal operation frequency. The

next domain is the display output interface which operates at pixel clock frequency. For most applications

it is recommended that this is the clock from OSC_IN pin, divided by two1. So the crystal oscillator has to

be choosen to have a whole-numbered multiple of the display clock frequency. Preferred routing is the DIRECT clock source channel since some displays require a small clock jitter which is not able to provide by

the APLL. The other clocks for MCU interface (ULB_CLK) and video interface (VSC_CLKV) are not derived by the clock routing and generating part and used directly from the appropriate input pin.

Finally the generated source clocks of the for domains go to the clock gating/distribution module. There are

gated clock buffers and inverters for each GDC module implemented. Each module has it’s own clock enable flag which can be programmed for modules needed by the application only. This method saves power

of not used functional blocks of GDC (refere to table 3-1).

The configuration of CU is stored in two registers, ClkConR and ClkPdR, which are connected to User Logic Bus for writing and reading. The bus interface consists of an address decoder and circuitry for different

access types (word, halfword and byte access over a 16 or 32 bit bus connection).

1.2 Reset Generation

GDC works with an internally synchronized, low active reset signal. The global chip reset can be triggered

by an external asynchronous reset or internally by software reset (configuration bit in ClkPdR). The external

triggered RESETX results in resetting all GDC components including the Clock Unit, however software

reset has no influence on CU internal registers.

Lavender synchronizes its external reset (RSTX pin). Reset is delayed until 4 clock cycles of each

ULB_CLK and OSC_IN are executed. This gives stability against spikes on the RSTX line but has the disadvantage of delayed reset response of Lavender.

For Jasmine internal reset is active immediately after tying RESETX low plus a small spike filter delay. Due

to the synchronization of RESETX the internal reset state ends after 4 clock periods of OSC_IN and 4 clock

periods of ULB_CLK after releasing RESETX pin. Reset output RSTX_SYNC for all internal GDC register

states are synchronized with OSC_IN, however internal Clock Unit registers are synchronized with

ULB_CLK in addition. Thus a minimum recovery time of 4 clock cycles of OSC_IN plus 4 cycles of

ULB_CLK is needed before writing to Clock Unit configuration registers is possible after RESETX becomes inactive.

The reset generator of Jasmine has a spike filter implemented, which suppresses short low pulses, typical

smaller than 9 ns. Under best case operating conditions (-40 deg. C; 2.7V; fast) maximum suppressed spike

width is specified to 5.5ns. This is the maximum reset pulse width which did not result in resetting the GDC

device. Minimum pulse width for guaranteed reset is specified to 1 clock cycle of OSC_IN (80 ns typical).

1.3 Register Set

Table 1-1 listst the clock setup registers. ClkConR (Clock Configuration Register) is mainly for generation

of the base clocks and the routing/selection from one of the four input sources. It controls the clock dividers

and the use of the APLL. The possibility to use a second clock path, called direct clock source, gives a high

flexibility for using the APLL either for MASTERCLK or PIXELCLK generation or both. Also the pin

function of DIS_PIXCLK can be defined in this register. If DIS_PIXCLK is selected as clock source the

pin should be configured as an input.

Upper 8 bits of ClkConR are used as identification of the different GDC types. Lavender is identified with

reading back a ’0x00’, Jasmine with a ’0x01’.

Use of DIS_PIXCLK as pixel clock output and selection of DIS_PIXCLK for the clock source can result in

unintentional feedbacks and has to be avoided.

1. Preferred is an even divider value to achive 50% clock duty

Page 30

Page 31

Clock Unit

ClkPdR (Clock Power Down Register) is a set of enable bits for the clocks provided to the dedicated GDC

modules. A bit set to ’1’ means the clock is enabled. If a module requires multiple clocks (inverted ones or

different domains) the enable bit switches all these lines.

Additional ClkPdR controls the work of the PLL and gives status information about it’s lock-state. Also a

global GDC reset function can be executed by setting a configuration bit of this register.

Table 1-1: CU registers

Register Bit Function Description Reset

Value

ClkConR [31:30] Direct Clock Source 00 Crystal oszillator (reset default)

01 Pixel clock

10 MCU Bus clock

11 reserved clock input (RCLKa)

[29:24] System clock prescaler

(DIV z)

[23:22] PLL Clock Source 00 Crystal oszillator (reset default)

[21:16] PLL Feedback divider

(DIV y)

[15] System Clock Select 0 Direct

[14] Pixel Clock Select 0 Direct

[13] Inverted Pixel Clock 0 not inverted

[12] Output disable

DIS_PIXCLK

[5:0] system clock prescaler value 0

01 Pixel clock

10 MCU Bus clock

11 reserved clock input (RCLK)

[5:0] pll multiplier value 0

1 PLL output

1 PLL output

1 inverted

0 internal pixelclock (output)

1 external pixelclock (input), high-Z

output

"00"

"00"

’0’

’0’

’0’

’1’

[11]

[10:0] Pixel clock prescaler

reserved test operation

(DIV x)

b

0 normal operation

1 core clock output on pin SPB_TST

[10:0] pixelclock prescaler value 0

’0’

Functional Description Page 31

Page 32

MB87J2120, MB87P2020-A Hardware Manual

Table 1-1: CU registers

Register Bit Function Description Reset

Value

ClkPdR 0 PP/PE Pixelengine clock

enable

1 PP/MAU clock enable 0 = disable, 1 = enable ’0’

2 PP/MCP clock enable 0 = disable, 1 = enable ’0’

3 AAF clock enable 0 = disable, 1 = enable ’0’

4 DIPA clock enable 0 = disable, 1 = enable ’0’

5 VIS clock enable 0 = disable, 1 = enable ’0’

6 SDC clock enable 0 = disable, 1 = enable ’0’

7 CCFL clock enable 0 = disable, 1 = enable ’0’

8 SPB clock enable 0 = disable, 1 = enable ’0’

9 ULB clock enable 0 = disable, 1 = enable ’0’

10 GPU clock enable 0 = disable, 1 = enable ’0’

11 PLL enable 0 = power down , 1 = run mode ’0’

12 VIC clock invert

(Jasmine)

PLL Lock (Lavender)

0 = disable, 1 = enable ’0’

0 = not inverted, 1 = inverted ’0’

0 = unlocked, 1 = locked (read only)

c

13 reserved - ’0’

14 PLL Lock (Jasmine)

15 Global HW Reset

0 = unlocked, 1 = locked (read only)

0 = run mode, 1 = reset (write only)

b

’0’

d

’0’

[31:24] Chip Id 0 = Lavender, 1 = Jasmine (read only) -

a.RCLK is mapped on MODE[3] at Lavender.

b.Only applicable for Jasmine

c.Normally all register bits are read-write. As the PLL lock bit is status information only, no write

access is possible to it. The lock bit is for test operation only and should not be used.

d.Read access results always in a value of ’0’. Writing ’1’ starts global HW Reset function, writing ’0’ releases reset.

Page 32

Page 33

Clock Unit

2 APLL Specification

This informations are for implemented APLL - U1PN741A. Output range is given for APLL output directly, not for the divider outputs.

The APLL macro has an operating supply voltage (VDD) of 2.5 0.25V. The oscillation guaranteed frequency range, maximum output frequency range and operating junction temperature range of the APLL are

shown in the table below.

Table 2-1: APLL Specifications

Operating Junction Temperature (Tj) -40 to 125 deg. C

Voltage supply (VDDI) 2.5 V +/- 0.25 V

Oscillation guaranteed frequency range 120 to 208.4 MHz

Maximum output frequency range

a

Input Frequency range 12 to 160 MHz

a.Range in which oscillation may be possible.

Table 2-2: APLL Characteristics for guaranteed design range

Input

[MHz]FBdivider

Out-

put

[MHz]

Phase

Skew

[ps]

25 8 200 444

-448

20

a

8 160 540

-520

13.217

b

10 132.17 1200

-1360

12

b

10 120 1334

-1466

40

b

4 160 640

-700

Duty

[%]

100.5

87.9

102.6

94

104.4

99.33

111.1

100.7

105.9

101.5

5.77 to 598.1 MHz

Lock Up

Time [us]

Jitter

[ps]

70 176

-142

100 232

-168

500 420

-246

25 760

-560

20 350

-190

Variations

in output

cycle [ps]

+130

-134

+64

-170

+234

-278

480

-560

238

-304

Power con-

sumption

[mW]

2.45

1.9

1.88

1.793

1.147

23.5

33

160

50

20

b

b

b

b

b

8 188 740

-940

6 198 560

-540

1 160 240

-150

4 200 340

-280

10 200 3600

-4200

110.6

97.2

100.4

88

101.2

98.9

98.5

87.7

109.5

87.5

65 208

-162

165 172

-140

12 190

-140

26 148

-140

88 560

-360

160

-182

148

-180

110

-140

96

-120

420

-480

2.387

2.397

1.147

2.45

2.45

a.Operating temperature -20 ... 90 deg. C, operating voltage 2.5 V +/- 0.15 V.

b.Operating temperature -40 ... 125 deg. C.

APLL Specification Page 33

Page 34

MB87J2120, MB87P2020-A Hardware Manual

2.1 Definitions

2.1.1 Phase Skew

Maximum phase differences between reference clock and feed back clock measured by the CK pin of the

PLL and the feedback clock measured by the FB pin.

CK

FB

2.1.2 Duty

Duty is the maximum and minimum values indicated by the ratio of a high pulse width to a low pulse with

(T

low

to T

) in one cycle of the output clock measured by the X pin of the PLL.

high

X

TT

high low

2.1.3 Lock Up Time

Lock up time is the time period that starts when the S pin of the PLL changes from 0 to 1 and ends when

the PLL is locked.

S

L

lock up time

2.1.4 Jitter

Jitter is the maximum and minimum values for cycle variations (T2-T1,T3-T2and T4-T3) in two continuous

cycles measured by the X pin of the PLL.

X

T1 T2 T3 T4

2.1.5 Variation in Output Cycle

The max./min. time periods from the rising edge of the output clock to thenext rising edge measured by the

X pin of the PLL. Observation points: 1400. The max./min values in T1, T2, T3 and T4 in above figure.

Page 34

Page 35

Clock Unit

2.1.6 Maximum Power Consumption

This is the maximum power consumption of the PLL when PLL is in locked state. The power dissipated by

extrenal dividers is not included into this amount.

2.2 Usage Instructions

•

Input the clock of crystal oscillator level into the CK pin of the PLL. Variations in the input clock

directly affects the PLL output, leading to unconformity to the specifications.

• In addition to the normal power supply, the PLL has a power supply for VC0 (pin name:

APLL_AVDD, APLL_AVSS). The VC0 power supply should be separate from other power supplies.

APLL Specification Page 35

Page 36

MB87J2120, MB87P2020-A Hardware Manual

3 Clock Setup and Configuration

3.1 Configurable Circuitry

Clock configuration can be easily done by setting up both registers ClkConR (Clock Configuration Register) and ClkPdR (Clock Power Down Register). ClkConR mainly controls the setup of multiplexers and

clock dividers in the main part of CU, which is shown in figure 3-1.

OSC_IN

DIS_PIXCLK

ULB_CLK

RCLK

Default Path

ClkConR

ClkPdR

[23:22]

[31:30]

[ bits ]

{ bits }

{11} [15]

lock {12}

L

S

A

CK

FB

[21:16]

APLL

DIV y

PLL CLOCK

X

DIRECT

[14]

[29:24]

DIV z

[10:0]

DIV x

[13]

XOR

tst

TST_MAS_CLKTST_PIX_CLK

tst

[12]

MASTERCLK

PIXELCLK

XZ_CU_PIXCK

(tristate)

Figure 3-1: Clock routing and configuration bits

ClkPdR decides which clocks should be enabled and distributed to the appropriate modules, listed in table

2-1. During change of ClkConR all enable bits in ClkPdR[10:0] have to be turned off to attain spike protection.

Table 3-1: Mapping of clock sources, outputs and their enable bits

ClkPdR Control Bit Clock Source Clock Output

0|1|2|3

Master

a

Pixel Processor (PP)

0 Master PP: Pixel Engine

1 Master PP: Memory Access Unit

2 Master PP: Memory Copy

3 Master Anti Aliasing Filter

4 Master Direct/Indirect Physical Access

5 Master Video Interface

5 Video Scaler (VSC_CLKV) Video Interface

6 Master SDRAM Controller

7 Master Cold Cathode Fluorescence Light

8 MCU Bus (ULB_CLK) Serial Peripheral Bus

9 Master User Logic Bus Interface and Com-

mand Controller

9 MCU Bus (ULB_CLK) User Logic Bus Interface

Page 36

Page 37

Table 3-1: Mapping of clock sources, outputs and their enable bits

ClkPdR Control Bit Clock Source Clock Output

10 Master Graphic Processing Unit

Clock Unit

10

a.Master and Pixel clock could be derived from one of four possible clock inputs (OSC_IN,

DIS_PIXCLK, ULB_CLK, RCLK/MODE[3]) with or without use of the PLL.

All clocks except VSC_CLKV can be used as Master or Pixel clock source. VSC_CLKV is for video interface dedicated use only.

There are no special requirements for the quartz crystal parameters. At the case of overtone oscillation additional external inductance L’=5-10uH and capacitor C’=10pF are needed. Two capacitors C=22pF have

to be connected from the OSC pins to ground in any case. Figure 3-2 shows recommendet circuit.

Pixel Clock

a

Graphic Processing Unit

OSC_IN OSC_OUT

XQ

L’

CC C’

Figure 3-2: Crystal connection between pins OSC_IN and OSC_OUT

Without a crystal oscillator connected (e.g. extrnal oscillator) the clock has to fed in the OSC_IN pin.