Page 1

MAW3300NC/NP, MAW3147NC/NP,

MAW3073NC/NP

DISK DRIVES INSTALLATION GUIDE

CARE OF YOUR FUJITSU DRIVE

Careful handling and installation of your disk drive is paramount to the longevity of the unit. Serious damage can occur to the internal

mechanisms if forces outside the environmental specifications are exerted to the casing. In transportation, always use the original packing

in which the drive was supplied and avoid sharp changes in temperature to minimise the risk of condensation.

Handling

1. Never drop. Handle with care.

2. Never move the disk drive while the disks are spinning. This is when the drive is powered on and also immediately after power off.

Refer to the Start/Stop specification for your drive.

3. Always turn off the power before connecting or disconnecting the interface cable. The same applies to changing any of the switches or

terminal settings except Write protect switch on NP model drives.

4. Never place the drive in the vicinity of strong magnetic fields such as monitors, televisions, or loudspeakers.

5. Never use any cleaning agents or liquids on the drive.

6. Always use an antistatic mat and wrist strap when handling the drive. Hold the drive by the Base casting and never touch the components

on printed circuit board.

7. Never remove any labels from the drive and do not deface them in any way; these labels are part of the disk drive design.

8. Never open the disk enclosure for any reason. Doing so voids any warranty.

9. Always pay close attention to the mounting specifications such as sway space and cooling. If the temperature difference between storage

location and installation locations is more than 10°C, leave the drive in the new location for at least two hours for Temperature acclimation.

This minimises any risk of condensation forming on the drive.

INSTALLATION

1. ORIENTATION–The drive can be installed in each six surface down orientations. Inclination from vertical or horizontal should not

exceed 5

2. MOUNTING SCREW INSTALLATION–When the mounting screw holes on the side of the drive are used, be sure to use the two pairs

of outer holes. Do not use the center hole in conjunction with only one of the outer holes. The screws must not penetrate the drive by more

than 5.0 millimeters. Impact caused by the electric driver must be within the device specifications.

3. COOLING–Allow space above and below the drive to provide an adequate air flow. Fan cooling is recommended. The disk enclosure

temperature measured at center of base cover (label side) should never exceed 60°C. See Table 1.

4. TERMINATION–A terminator should be installed externally at both ends of the SCSI bus.

5. TERMINATOR POWER–Terminator power must be supplied to terminator for correct operation. This can be supplied from either the

drive, except for NC model or the SCSI bus. If only NC model drives are connected to the SCCI bus, terminator power should be supplied

externally.

6. ATTACHING THE CABLES–To avoid possible damage to the drive, make sure the direction of the connector matches.

CAUTION: Warranty may be avoided if damage to the connector is caused by wrong insertion.

The Drive needs NO preventative or periodic maintenance during its life time if properly used in the correct environment.

°.

Table 1. Reference value of airflow

Environmental temperature Required velocity of airflow

35

°C > 0.2m/s

40

°C > 0.5 m/s

45°C > 0.9 m/s

50°C > 1.5 m/s

FUJITSU LIMITED

Storage Products Group

4-1-1 Kamikodanaka, Nakahara-ku, Kawasaki 211-8588, Kanagawa-ken, Japan

Copyright © 2005 FUJITSU LIMITED

Corporate http://www.jp.fujitsu.com/

USA http://www.fcpa.com/

EUROPE http://www.fujitsu-europe.com/

C141-E227-01EN

Page 2

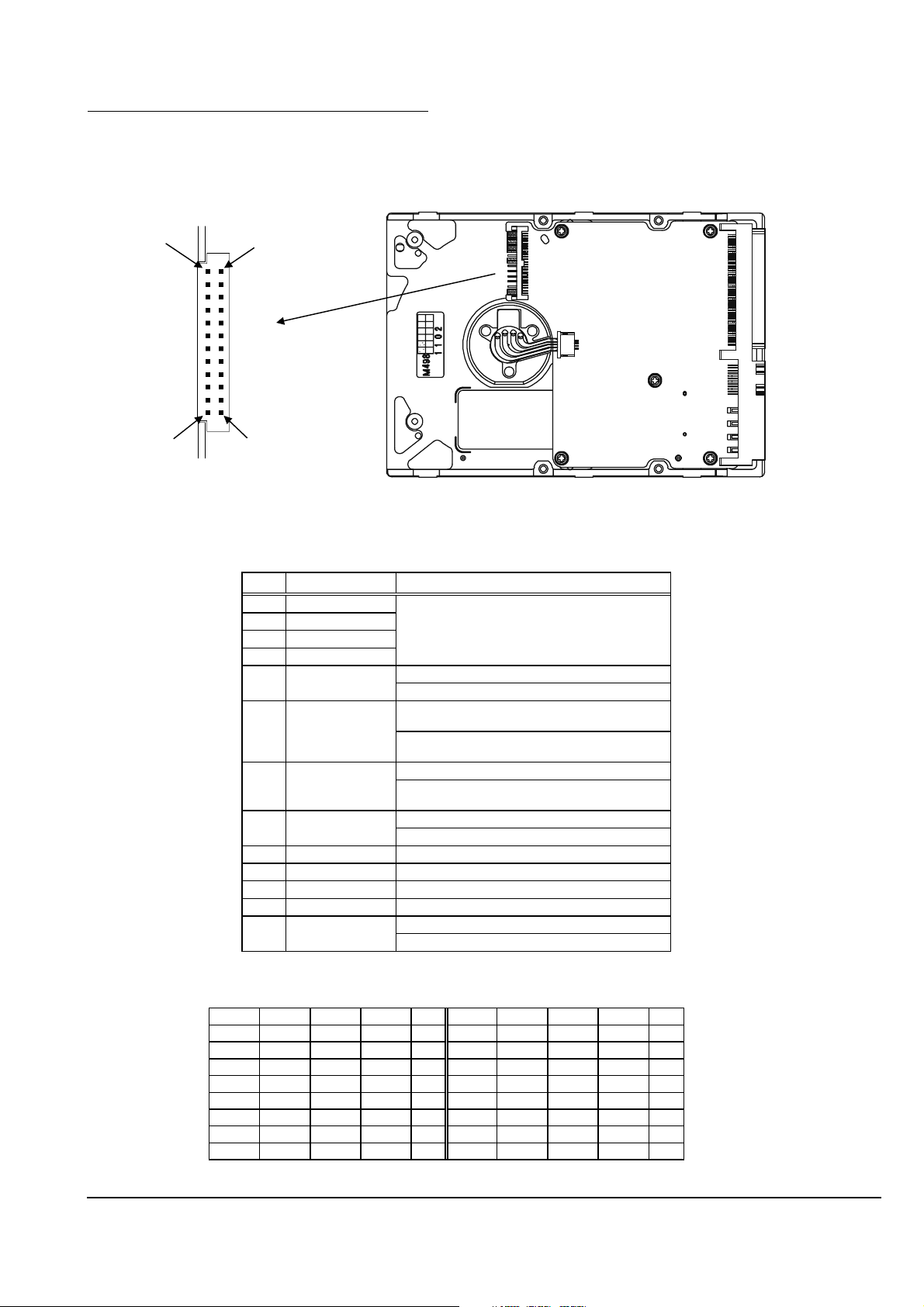

Diagram and user-selectable options (on NP models only)

Below is a diagram of the main board of SCSI disk drives and also a summary of the user-selectable options including guidelines for

installation of the drives.

This setting applies only for NP model drives.

Pin 1

Pin 2

CN2

Pin 23

Pin 24

Figure 1. Option select terminal

Pin #

1-2 SCSI ID 0 See Table 3.

3-4 SCSI ID 1

5-6 SCSI ID 2

7-8 SCSI ID 3

9-10 Write protect Open ……Write operation is enabled. (default)

11-12 Motor start mode Open ……Starting of motor is controlled with START/STOP

13-14 Force Narrow Open ……16-bit bus mode (default)

15-16 Force Single Ended Open ……Follows DIFFSNS signal level on SCSI bus. (default)

17 GND

18, 19 N.C

20 IDD Reset Input signal

21-22 Remote LED Output signal

23-24 Terminal power supply Open ……Drive does not supply terminator power to SCSI bus.

Table 2. CN2 Terminal Setting (on NP models only)

Setting Item

Short

Short

Short

Short ……Single-Ended mode

Short ……Drive supplies terminator power to SCSI bus. (default)

Table 3. SCSI ID Setting on CN2 (on NP models only)

Pin 1-2 Pin 3-4 Pin 5-6 Pin 7-8 ID Pin 1-2 Pin 3-4 Pin 5-6 Pin 7-8 ID

Open Open Open Open 0 Open Open Open Short 8

Short Open Open Open 1 Short Open Open Short 9

Open Short Open Open 2 Open Short Open Short 10

Short Short Open Open 3 Short Short Open Short 11

Open Open Short Open 4 Open Open Short Short 12

Short Open Short Open 5 Short Open Short Short 13

Open Short Short Open 6 Open Short Short Short 14

Short Short Short Open 7 Short Short Short Short 15 (default)

Function

……Write operation is disabled.

UNIT command.

……Motor is started immediately after power supply is

turned on or microcode is downloaded.

……Pull upper 8bits and parity internally when drive is

connected to Narrow SCSI bus.

(default)

Loading...

Loading...