Page 1

CHAPTER 4 Installation Requirements

4.1 Mounting Requirements

4.2 Power Supply Requirements

4.3 Connection Requirements

This chapter describes the environmental, mounting, power supply, and connection requirements.

4.1 Mounting Requirements

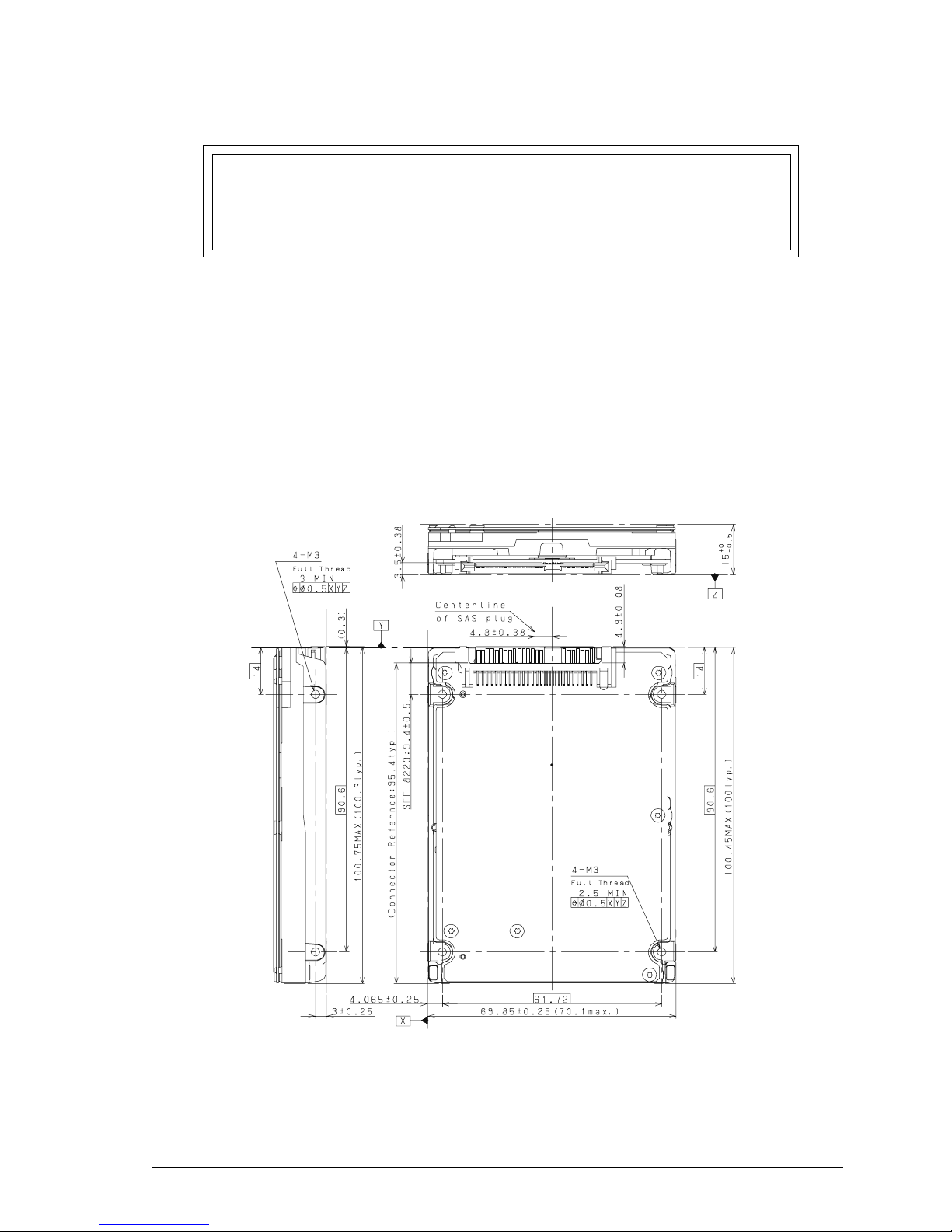

4.1.1 Dimensions

Figures 4.1 show the dimensions of the HDD and the location of the mounting screw holes.

C141-E219 4-1

[Units: mm]

Figure 4.1 Dimensions

Page 2

Installation Requirements

4.1.2 Mounting orientations

The permissible orientations of the HDD are shown in Figure 4.2, and the tolerance of the angle is

±5° from the horizontal plane.

As show in Figure 4.2, the drive can be installed flat on any of its six sides. Inclination from a

vertical or horizontal plane should not exceed 5°.

(a) Horizontal –1 (b) Horizontal –2

(c) Vertical –1 (d) Vertical –2

(e) Upright mounting –1 (f) Upright mounting –2

4-2 C141-E219

Direction of gravity

Figure 4.2 HDD orientations

Page 3

4.1.3 Notes on mounting

Damage

Never remove any labels from the drive or deface them in any way.

(1) The mounting screws must use M3 × 0.5 metric

(2) Examples of mounting frame structure

Special attention must be given to mount the HDD as follows.

a) As shown in Figure 4.3, use the frame with an embossed structure, or the like. Mount the

HDD with making a gap of 2.5 mm or more between the HDD and the frame of the system.

4.1 Mounting Requirements

b) The inward projection of the screw from the HDD frame wall at the corner must be 2.5 mm

±0.5 mm.

c) Tightening torque of screw must be secured with 0.49N·m (5kgf·cm) ±12%.

d) Impact caused by the electric screwdriver must be within the drive specifications.

e) Must be handled on an anti-static mat.

(3) Limitation of side-mounting

Use all 4 mounting holds on the both sides.

(4) Limitation of bottom-mounting

Use all 4 mounting holds on the bottom face.

C141-E219 4-3

Page 4

Installation Requirements

Figure 4.3 Mounting frame structure

(5) Never cover the vent hole as shown in Figure 4.4.

Vent hole

Figure 4.4 Breathing hole location

Label

4-4 C141-E219

Page 5

4.3 Connection Requirements

(6) Environmental temperature

Temperature condition at installed in a cabinet is indicated with ambient temperature measured

30 mm from the disk drive. At designing the system cabinet, consider following points.

• Make a suitable air flow so that the DE surface temperature never exceed 60°C.

• Cool the PCA side especially with air circulation inside the cabinet. Confirm the cooling effect

by measuring the surface temperature of specific ICs and the DE. These measurement results

must satisfy the temperature condition listed in Table 4.1.

• Keeping the DE surface temperature at 50°C or below at ambient temperature 30°C, which is a

condition for assuring an MTBF of 1,400,000 hours, requires an air flow of 0.5 m/s or more.

Table 4.1 Surface temperature check point and maximum temperature

No. Measurement point Maximum temperature

1 DE Surface 60°C

2 Read channel LSI 80°C

3 VCM/SPM Driver 93°C

4 HDC 92°C

5 MPU 90°C

Figure 4.5 Surface temperature measurement points

C141-E219 4-5

Page 6

Installation Requirements

(7) Service clearance area

The service clearance area, or the sides which must allow access to the HDD for installation or

maintenance, is shown in Figure 4.6.

[Surface X]

•

Holes for mounting screw

[Surface Y]

• Interface connection

(Both Side)

(8) Environmental magnetic field

Do not install the HDD in the vicinity of equipment giving off strong magnetic fields, such as

monitors, televisions, or loudspeakers.

(9) Leakage magnetic flux

Do not mount the HDD near the devices that the leakage magnetic flux influence easily.

[Surface Z]

• Holes for mounting screw

Figure 4.6 Service clearance area

4-6 C141-E219

Page 7

4.2 Power Supply Requirements

4.2 Power Supply Requirements

(1) Allowable input voltage and current

The power supply input voltage measured at the power supply connector pin of the HDD (receiving

end) must satisfy the requirement given in Subsection 2.1.3. (For other requirements, see Items (4)

below.)

(2) Current waveform (reference)

Figure 4.7 shows the waveform of +12V DC.

MAV2073RC

MAV2036RC

Current (500mA/div)

Current (500mA/div)

(3) Power on/off sequence

The order of the power on/off sequence of +5V DC and +12V DC, supplied to the HDD, does not

matter.

(4) Sequential starting of spindle motors

After power is turned on to the HDD, a large amount of current flows in the +12V DC line when the

spindle motor rotation starts. Therefore, if more than one HDD is used, the spindle motors should be

started sequentially using one of the following procedures to prevent overload of the power supply

unit.

a) Control the sending of the NOTIFY (ENABLE SPINUP) primitive so that the spindle motors of

individual disk drives are started in intervals of 12 seconds or more.

b) Turn on the +12V DC power in the power supply unit at more than 12-second intervals to start

the spindle motors sequentially.

Time (2 sec/div)

Figure 4.7 Current waveform (+12V DC)

Time (2 sec/div)

C141-E219 4-7

Page 8

Installation Requirements

(5) Noise filter

To eliminate AC line noise, a noise filter should be installed at the AC input terminal on the HDD

power supply unit. The specification of this noise filter is as follows:

• Attenuation: 40 dB or more at 10 MHz

• Circuit construction: T-configuration as shown in Figure 4.8 is recommended.

Figure 4.8 AC noise filter (recommended)

4.3 Connection Requirements

4.3.1 Connector

Figure 4.9 shows the locations of interface connector.

Interface connector (CN1)

(power lines included)

Figure 4.9 Connector location

4-8 C141-E219

Page 9

4.3 Connection Requirements

4.3.2 Interface connector

Figure 4.10 shows the SAS type interface connector (SAS plug) overview.

Table 4.2 lists the signal allocation of the SAS plug on the HDD.

S1

S7

P1

P15

S14

S8

Figure 4.10 SAS plug connector overview

C141-E219 4-9

Page 10

Installation Requirements

Table 4.2 Interface connector (SAS plug) signal allocation:CN1

Pin No. Signal Description

S1 GND GND for SAS Primary Port

S2 RP+ SAS Primary Port Receive(positive) signal

S3 RP- SAS Primary Port Receive(negative) signal

S4 GND GND for SAS Primary Port

S5 TP- SAS Primary Port Transmit(negative) signal

S6 TP+ SAS Primary Port Transmit(positive) signal

S7 GND GND for SAS Primary Port

Note1

S8

GND GND for SAS Secondary Port

Note1

S9

Reserved (not used) Not used

Note1

S10

S11

S12

S13

S14

P1

P2

P3

Note 1) S8 - S14 are SAS Secondary Port signals, and not used on MAV2073RC and MAV2036RC.

Reserved (not used) Not used

Note1

GND GND for SAS Secondary Port

Note1

Reserved (not used) Not used

Note1

Reserved (not used) Not used

Note1

GND GND for SAS Secondary Port

Note2

Reserved (not used) Not used

Note2

Reserved (not used) Not used

Note2

Reserved (not used) Not used

P4 GND GROUND

P5 GND GROUND

P6 GND GROUND

P7 +5V-Charge Pre-charge pin for +5V

P8 +5V +5V power supply input

P9 +5V +5V power supply input

P10 GND GROUND

P11 READY LED READY LED output

P12 GND GROUND

P13 +12V-Charge Pre-charge pin for +12V

P14 +12V +12V power supply input

P15 +12V +12V power supply input

Note 2) P1 to P3 are 3.3V power supply input and pre-charge signals, and not used on MAV2073RC and

MAV2036RC.

4-10 C141-E219

Loading...

Loading...